Page 1

Page 2

Page 3

English ..............................................

Fraqais ............................................

Espafiol .............................................

Italian0 ..............................................

Deutsh ...............................................

Svenska ............................................

Suomeksi ..........................................

Norsk

.................................................

Dansk ................................................

Netherland ........................................

Portugise

...........................................

Grekisk ..............................................

Page

1

page

10

pagina 14 .

pagina 18

seite 22

sidan

26

sivulla 29

side 32

side

35

blz.

38

Pag

42

page

46

Foreword

In order to ensure that your power cutter is the good Partner you have every right to expect,

we advise you to devote a few minutes to reading through this book which is intended to make

proper maintenance of the machine easier and also to show you how to carry out necessary

checks and service work.

The power cutter is a tool with high cutting capacity and is fitted with protective components

to make work as safe as possible. If these components are out of operation or if the machine’

is used carelessly or the wrong way, then it can cause injuries to the operator or people standing close to the machine.

For this reason you should read through the safety regulations very thoroughly.

Under no circumstances may a power cutter be modified from its original design unless the

manufacturer has granted permission for this in writing. Non-authorized modifications can

result in safety hazards.

Partner industrial

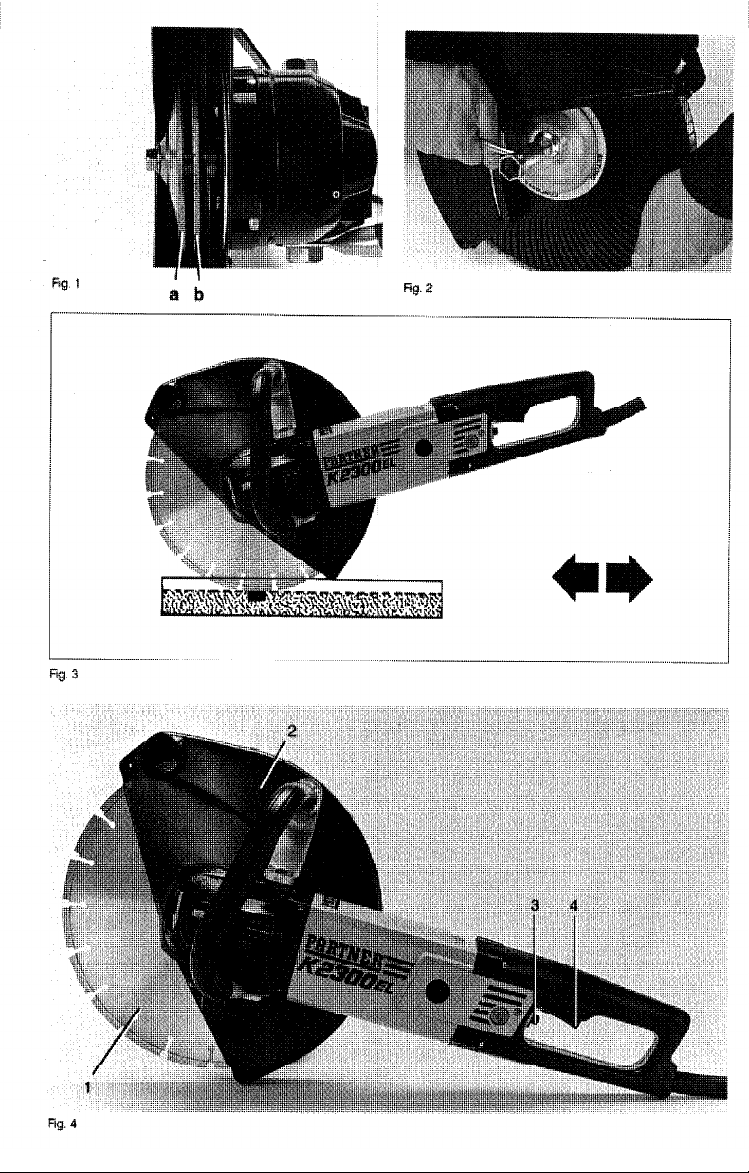

What is what? (Fig 4)

1. Cutter wheel

2. Guard

Technical data

3. Lock button for switch

4. Switch

Voltage

K2300 EL 23Ov

23Oow

K2300 EL 11ov

2cOow

K2800 EL 120v

15A-6OHz

K2300 EL 1OOv

14OOW

K2300 EL 115v

15A, 60 Hz-CSA

‘The machme IS not double tnsulated - must be grounded.

r.p.m.

4500

4500

4500

4500

4500

Class 1.

Europa

Class 1’

GB

Class l* USA

Class 1.

Japan

Class 1’

CSAlCanada

Disc diameter max. 300 mm (12’)

Weight 9.0 kg (20 Ibs)

Sound level A’ 95

B” 108

A’ = Swnd ~mssvre level al the ear of the user dB (A) max. speed act. to lSO/DlS 11201,,

B’ = Sound power level dB (A) ace. to IS0 3744.

Vibration level

Handle vibrations measured act. to ISOlCD 8662-4, m/s2

Front handle 3,7

Rear handle 4,2

1

Page 4

SAFETY

a

WARNING: highlights procedures especially important for human safety.

CAUTION: highlights procedures especially important to protect property.

General

1

a

WARNING: Improper use of any power tool may cause fatal injury. Read, understand and carefully follow all operating, maintenance and safety instructions n this Owner’s

Manual and tn the Owner’s Safety Manual before ustng the K2300 EL.

2. This cut-off saw must not be modrfred wrthout the permtssion of the manufacturer in writing.

Unauthorized modrfrcatron can lead to serious injury or death.

3 Use of accessories not specrfred rn this manual may be hazardous. Use of power boosters

that cause the tool to be driven at speeds greater than its rated speed constttutes misuse.

4. Since safety regulations vary rn drfferent countnes and states, contact local authorities and

carefully follow their regulations.

Operator

5. Never use a cut-off saw unless you are trained. If not handled properly and with care, a cut-off

saw can be a dangerous tool. Operation of a cut-off saw should be restricted to mature, properly instructed adults.

6. Stay alert, watch what you are doing and use common sense. Do not operate the tool when

tired, under stress or under the Influence of medicine, drugs or alcohol.

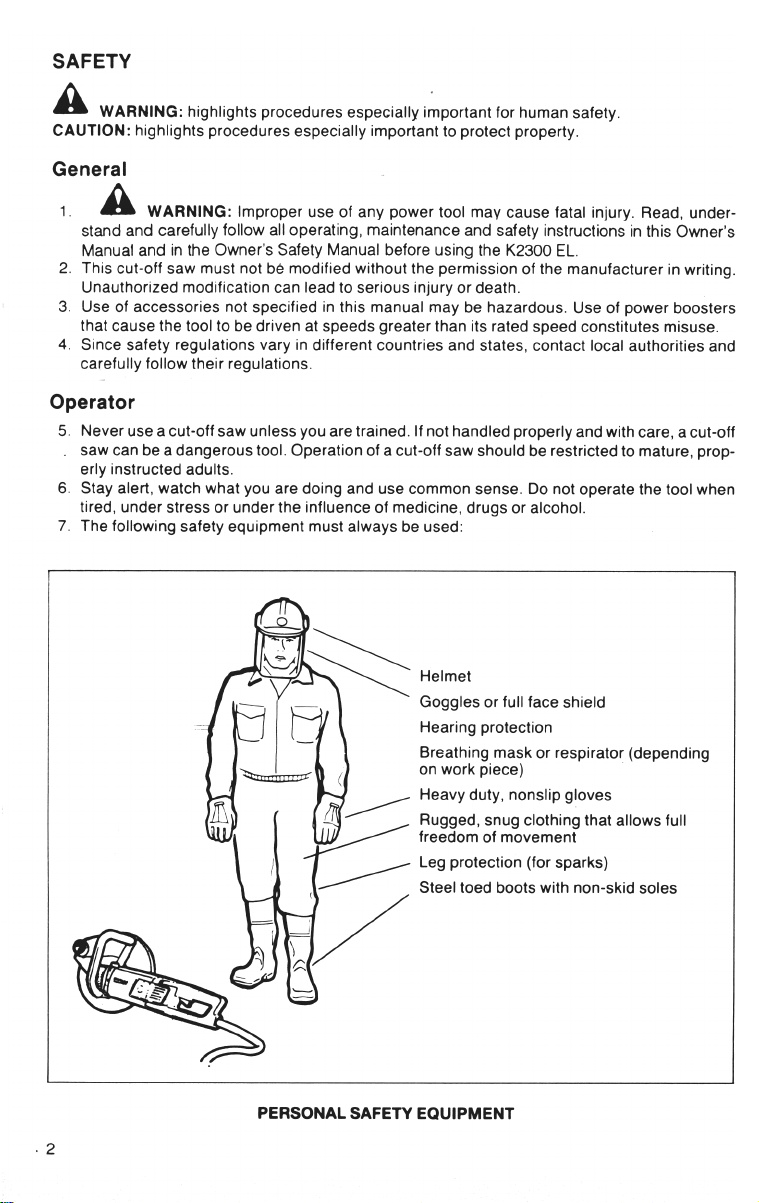

7. The following safety equipment must always be used:

.2

Helmet

Goggles or full face shield

Hearing protectron

Breathing mask or respirator (depending

on work piece)

Heavy duty, nonslip gloves

Rugged, snug clothing that allows full

freedom of movement

Leg protection (for sparks)

Steel toed boots with non-skid soles

PERSONAL SAFETY EQUIPMENT

:

Page 5

Work Site

8. Do not work alone. Make sure you can contact someone in the event of an accident.

9. Consider the work-area environment. Don’t expose the cut-off saw to water, rain or snow.

Don’t use the cut-off saw in damp or wet locations. Keep work area well lit.

10. Guard against electric shock. Prevent body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerator enclosures.

11. Do not permit anyone to stand close to the cut-off saw when it is running. Make sure spec-

tators and animals are kept away from the work site. Do not let bystanders contact tool or extension cord.

12. Do not operate your electric cut-off saw near explosive or flammable liquids, gases or material. Motors in electric tools normally spark and the sparks could cause explosion or fire.

3

Page 6

SAFETY (Continued)

Saw Preparation/Condition

.

13. Check out the cut-off saw before use. Never use a saw that is damaged, faultily adjusted, or

not completely and securely assembled. Guards and other parts must operate properly and

perform their intended function. Check for~misalignment or binding of moving parts, loose

mounting or any other condition that may affect operation. Any damaged part should be re-

paired or replaced by an authorized service center. Do not use tool if switch does not turn it

on and off. Have defective switches replaced by an authorized service center.

14. Form a habit of checking to see that keys and adjusting wrenches are removed from the saw

before turning it on.

15. Never use the saw without the guard. The guard must be adjusted so that its rear section is

close to the work piece.

16. Keep the handles dry, clean and free from oil and grease

CHECKING WHEEL

A DAMAGED WHEEL

17. Use only cutter wheels that have been approved for hand-held, portable, high speed cut-off

saws. Never exceed the maximum operating speed established for the wheel. Inspect all

wheels before mounting for possible damage in transit. Do not use a wheel that has been

dropped.

Always allow a newly mounted abrasive wheel to run at operating speed with guard in place

for at least 30 seconds before you start to use it. Never start the tool with a person, including

the operator, in line with the wheel.

19. Do not use carbide tipped wheels.

19. When tool is used outdoors, use only extension cords intended and marked for outdoor use.

4

Page 7

Operation

20. Always hold the cut-off saw with both hands whrle the motor IS running Use a firm gnp wrth

thumbs and fingers encrrclmg the handles. Keep all parts of your body away from the cut-off

wheel when the motor is running.

21.

Do not cock, jam or wedge the wheel in the cut.

22. Do not grind with the side of a cut-off wheel.

NEVER CUT WITH SIDE OF WHEEL

23. Secure work with clamps, or a vise. It is safer than using your hand and frees both hands to

operate the tool.

24.

Don’t force tool. Use the right tool for the job. Don’t overload. Keep the RPM high for best cut-

ting speed and cooling. Too low an RPM may result in overheating and burn out.

25.

A

WARNING: Do not water cool due to the risk of electrocution.

Handling and Service

26.

Don’t abuse the the cord. Never carry tool by the cord or yank on the cord. Keep cord away

from heat, oil and sharp edges.

27.

Disconnect tools before servicing, when changing wheels and when not in use.

28. Avoid unintentional starting. Don’t carry a tool that’s plugged-in with your finger on the switch.

Be sure the switch is off when plugging in saw.

29.

Remove the cutter wheel when transporting or storing the saw. Store tool in a high or locked

dry place out of reach of children.

30. All service, with the exception of service described in this owner’s manual, must be carried

out by an authorized service workshop.

F

s

Page 8

STARTING

Adjusting Guard

.

1.

A

WARNING: Disconnect tool from power supply and be sure switch is in off position

before adjusting guard. The guard should always be adjusted so that the rear section is in

contact with the work piece so that ground off particles and sparks are trapped by the

guard, and directed away from the operator

CHECKINGGUARDPOSITION

2.

A

WARNING: Grasp tool firmly with both hands, and with fingers encircling the handles,

before attempting to start.

3. Grasp switch ban-dFe firmly and squeeze to depress trigger. To stop tool, release trigger.

STARTING POSITION

6

Page 9

OPERATION

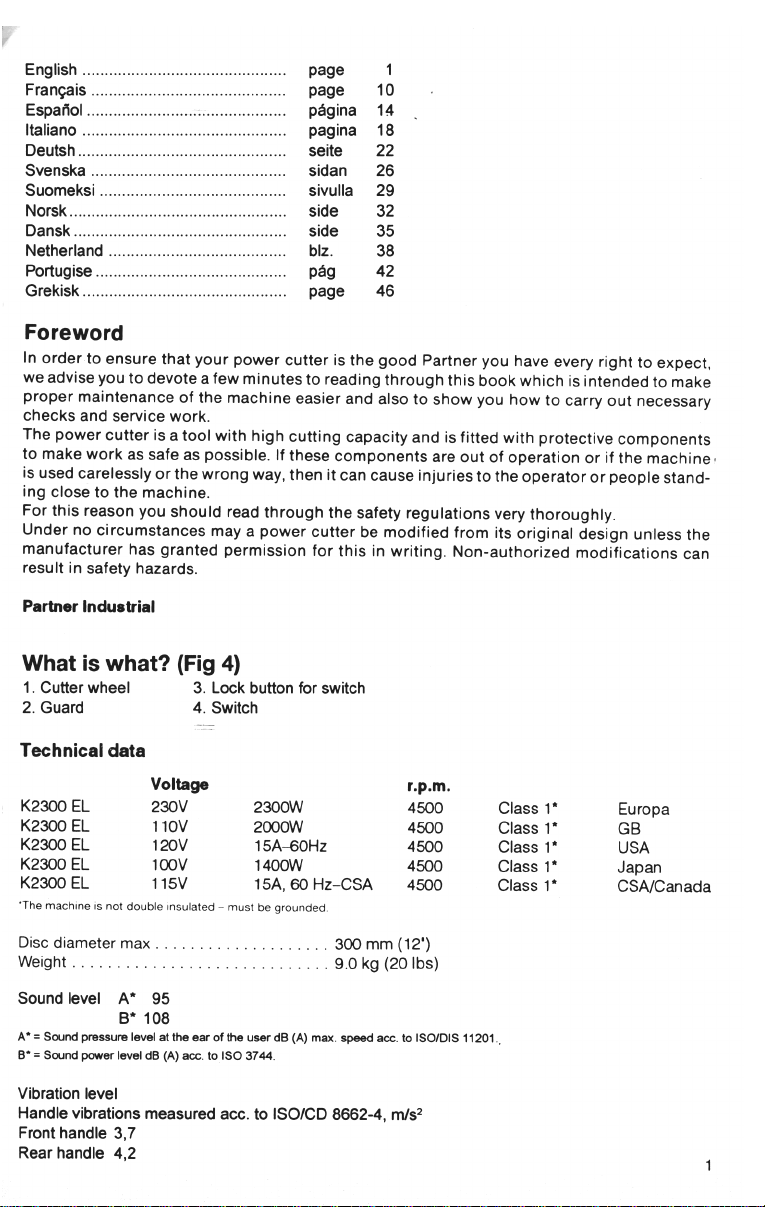

(See picture no. 3)

1. CAUTION: Your 12 inch Partner K23OO EL cut-off saw is furnished with a cord and a threepronged plug. Before plugging in the tool, make sure that the voltage markedon the tool is the

same as the power supply.

2. Before turning on the tool, grasp both handles firmly and pick up the tool. Make sure nothing

is near to or in contact with wheel. Line up wheel with material to be cut.

3. Turn on the cut-off saw, and feed wheel into work slowly. Use firm pressure and move the disc

slowly backward and forward in the cutting slot to oblain as small a contact surface as possi-

ble. This will give you good cutter disc economy and maximum cutting capacity.

CAUTION: Do not press so hard that RPM drops significantly. Thus will substantially decrease

your cutting efficiency, and overload the saw. Overloadmg causes faster drsc wear and poor cutting, and may cause burn out. Allow the saw to cool down, and back off slrghtly on the pressure

when you continue.

Cooling

The machine is fitted with an effective fan to cool the motor. Cooling air sucked through the grill

in the inspection cover passes over the stator and motor and then leaves the machine through the

front section of the motor housing.

CAUTION: To ensure that the machine always has satisfactory cooling, the cooling air opening

must be kept clear. Clean the machine regularly with compressed air. Clogged coolrng passages

will cause the saw to burn out.

MAINTENANCE

To ensure safety and reliability, repairs, maintenance and adjustments (excluding cleaning, brush

inspection, and brush replacement) should be performed by a Partner authorized service shop or

other qualified service organization, always using original Partner replacement parts.

Carbon brushes

(%e picture no. 5)

The electric plug must be taken out of the power outlet before any work is done on the machine.

The brushes and commutator in your Partner cut-off saw have been engineered and matched for

many hours of dependable service. Like any other tool with a universal motor, it is necessary to

replace the carbon brushes when they are worn.

When replacing the carbon brushes (always replace both at the same time) loosen the two screws

and remove the inspection covers. Clean the brush holders with a dry brush and blow out dust

carefullyCheck that the new carbon brushes slide easily in the brush holders. Allow the new carbon brushes to be run in for several minutes with the saw running half load.

For maintenance of abrasive wheels, please refer to your Operator’s Safety Manual

7

Page 10

Grounding

a

WARNING: This tool must be grounded properly while in use to protect the operator from

electnc shock.

The tool is equipped with an approved three-conductor cord and a three-pronged grounded type

plug to fit the proper grounding type receptacle. The green (or green and yellow) conductor in the

cord is the grounding wire. Never connect the green (or green and yellow) wire to a live terminal.

Never disassemble the tool, or try to do any rewiring in the electrical systems. Any such repair

should be performed only by an authorized Partner service center or other qualified service organization.

Voltage

A voltage decrease of more than 10 percent will cause loss of power and overheating. All Partner

tools are factory tested. If the tool does not operate, check the power supply.

CAUTION: When used on job sites, where arc or resistance welding is being performed, the cord

could be damaged by welding currents usmg the cord as a parall return path.

To maintatn the protectron the ground wire provides, the cord should be Inspected frequently and

replaced as necessary. Avoid unnecessary contact between the metallic exterior of the tool and

grounded conductive surfaces.

Extension cords

Tools that have three-wire cords requiring grounding must only be used with extensioncords that

have three-prong grounding type plugs and a three-pole receptacle. Only round-jacketed extension cords should be used, and we recommend that they be listed by Underwriter’s Laboratories

(U.L.) (CSA in Canada). If the extension cord will be used outside, it must be suitable for outdoor

use Any cord marked for outdoor use can also be used indoors. An extension cord must have

adequate size (AWG or American Wire Gauge) for safety, and to prevent loss of power or overheating.

Extension cord length 25 ft. -- Use 12 (A.W.G.)

Extension cord length 50 ft. - Use 10 (A.W.G.)

Do not use extension cords over 50 ft. to prevent loss of power and overheating.

Replace defecttve cords immediately.

Cleaning and changing grease

Dependrng on operating condrtrons, the grease in the gear housing must be changed after 4-6

months. Use good quality gear grease, Castro1 Spheerol EPL 1 or corresponding. The gear

housrng must contain a total of 90 grams of grease.

Too much grease can cause the machine to run warm.

In order to change the grease in the gear housrng, the following parts must be removed:

- The flange washers retaining the cutter disc

- The support flange for the protective quard (Fig. 6)

- The protective quard (Fig. 7)

- The mounhng plate together with crown wheel assembly are lifted out of the gear housing

after the four screws have been removed. (Fig. 8 & 9)

NOTE. Do not damage the gaskets since these act at the same time as spacers for gear

settings.

8

Page 11

WHEELS

Selecting Wheels-

.

Partner wheels and blades are specially manufactured for hand-held portable highspeed cut-off

saws. If another manufacturer’s wheel is used, you must make sure the wheel meets all regulations and standards relating to this kind of hand-held, portable high-speed equipment.

Diamond blades are preferred as they require less power for good cutting performance. Diamond

blades must not be used for cutting metal. Do not use diamond blades that require water cooling.

Due to the risk of electrocution, water cooling of blades must never be done. Use only approved

dry cuttinq wheels.

a

WARNING: Under no circumstances may the saw be used with carbide tipped blades.

This type of blade is more subject to kick-back than other wheels. The K23OO EL is not equipped

with a slip clutch. Should a kick-back inadvertently be encountered with the K2300 EL, the forces

are stronger and harder to control. For n-ore information about kick-back, please refer to your

Operator’s Safety Manual.

Installing wheels

(See picture no. 2)

CAUTION: Never use wheels rated lower than speed on name plate of unit. The arbor size must

correspond with the plate on the saw.

1. Be sure tool is disconnected from power supply and swatch IS in off posrtron. Remove screw

and outer washer using socket wrench furnrshed with unit.

2. Put wheel and washers in place. Tighten the screw with a socket wrench. Do not over ttghten.

3. Turn wheel by hand to make sure the wheel is properly centered and that the wheel does not

hit the guard.

APPLICATIONS

118” Max. gauge sheet metal.

Concrete, cinder block and bricks

Reinforcing rods: gene-Blly under 3/4” in diameter.

l/8” diameter concrete wire mesh.

Corrugated floor and ceiling form.

Electrical conduit l/8” wall thickness.

l/8” max structural form such as channel, angles, plate, etc.

CAUTION: The cutting of materials heavier than those listed above is not recommended due to

the possibility of electrical overloading. For heavier work, use Partner’s more powerful, gas powered models.

9

Loading...

Loading...