OPERATING INSTRUCTIONS

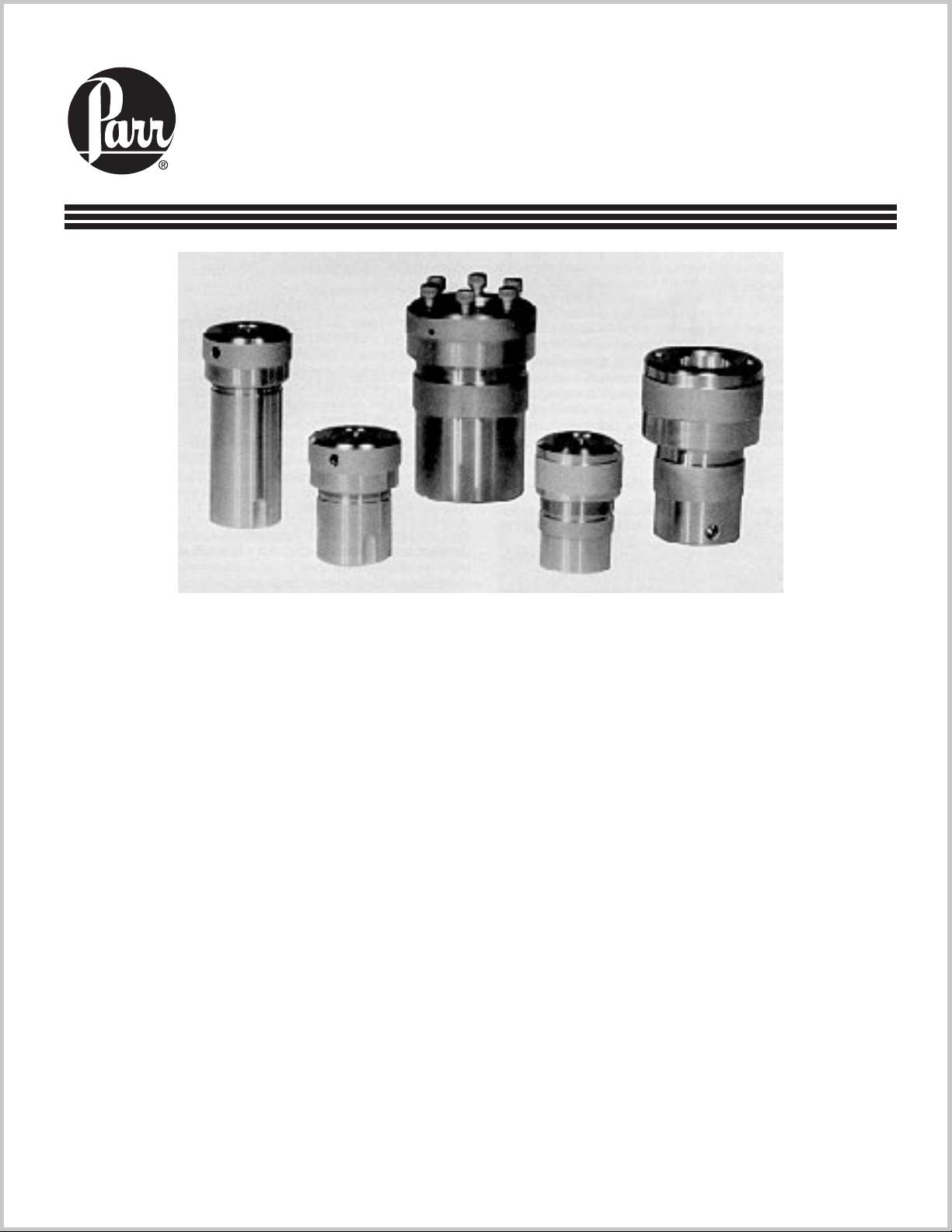

Parr Acid Digestion Bombs

No. 249M

Scope

These instructions are to acquaint the user with the procedures to be followed and the precautions to be taken

when using any ParrAcid Digestion Bomb, except those

designed specifically for microwave heating.(Microwave

bombs are covered by separate instructions, No. 243M.)

Parr PTFE-lined digestion bombs provide a convenient

means for dissolving analytical samples rapidly in strong

acids or alkalis,it is important that the user understand

the capabilities and limitations of the equipment and

will be well aware of the safety precautions to be observed in its operation. Pages 1 through 6 of these instructions apply equally to all Parr Acid Digestion

Bombs with metal bodies and removable PTFE liners.

The user should read these basic instructions carefully

before starting to use any of these bombs. Then turn to

pages 8 through 11 for the special instructions which

apply to each individual model. It must be understood

that the excellent mechanism for sample digestion and

dissolution provided by these bombs can be hazardous if

a bomb is misused. Therefore careful reading and full

compliance with these instructions must be observed in

all applications.

Contents

Scope ......................................................................... 1

Contents.................................................................... 1

Assumption of Risk .................................................. 2

The Nature of PTFE................................................. 2

Potential Hazards .................................................... 2

Sample Selection......................................................3

Loading Limits ......................................................... 3

Acid Selection........................................................... 4

Pressure and Temperature Limits.......................... 4

Heating and Cooling the Bomb ............................... 5

Pre-Treating PTFE Parts ........................................ 5

Liner Maintenance................................................... 5

Liner Lifetimes......................................................... 5

Bomb Maintenance .................................................. 6

References................................................................. 6

Vapor Pressure Tables............................................. 7

Operating Procedure

4745 General Purpose Bomb.................................8

4744 and 4749 General Purpose Bombs...............9

4746 and 4747 High Strength Bombs................. 10

4748 Large Capacity Bomb................................. 11

Assumption of Risk

Potential Hazards

The Parr Instrument Company offers its PTFE-lined

Acid Digestion Bombs to skilled analytical chemists as

an attractive means for digesting and dissolving analytical samples for analysis. Parr designed and manufactures these bombs to be as effective as possible when

used within the limitations prescribed for each individual model. But, since the pressures generated within

these bombs are solely dependent upon the nature of the

materials being treated, the filling level and the amount

of heat applied to promote the reaction, Parr will not be

responsible for personal injuries or damage to the bomb,

to the oven or to other equipment resulting from the use

of these bombs. As with all laboratory operations, the

user must assume responsibility for and institute safety

procedures to protect all personnel from any hazards associated with this equipment. Rigid controls must be established to guarantee that the operator does not

overcharge or overheat the bomb.

The Nature of PTFE

PTFE offers such unique inertness and high temperature usefulness that it is an obvious choice as the material of construction for lining these acid digestion bombs.

PTFE does, however,have two characteristics which

make it somewhat less than perfect for this application,

and the user who understands these deficiencies will be

able to minimize the effect upon his work.

First, PTFE has a tendency to creep or flow under pressure or load. This tendency is present even at room temperature and it is accentuated at higher temperatures.

At operating temperatures below 150ºC the creep effect

will become more pronounced, making it more difficult to

maintain tight seals and resulting in deformation and

shorter life for the PTFE components. The extent of the

creep effect will be roughly proportional to the maximum

operating temperature.

Secondly, PTFE is a porous material. Although the materials and designs used in Parr Acid Digestion Bombs

minimize the effects of this porosity,users of these

bombs can expect to see evidence of vapor migration

across the cover seal and through the wall of the liner itself. Parr is able to minimize these problems by machining these parts from virgin PTFE which has been

molded at an optimum pressure selected to reduce any

porosity to an absolute minimum. The thick walls and

long path seals used in Parr bomb liners also help to

overcome these undesirable properties. Experiments

have shown that the amount of solute lost in this manner during a normal digestion is negligible, but vapor

migration will occur and frequently it will be sufficient

to produce noticeable discoloration on the inner metal

wall of the bomb body and the screw cap.

While many thousands of these bombs have been used

safely and routinely for treating a great variety of samples with different digestion media under a broad range

of operating conditions,it is possible to create conditions

under which these bombs will explode. The bulk of the

reported incidents of this type have been caused by failure of the operator to recognize one or more of the

following potential hazards.

Excessive temperature. When a bomb is overheated,

two factors come into play: (1) the vapor pressure of the

materials in the bomb increases exponentially with temperature and (2) the strength of the materials from

which the bomb is made falls off (again exponentially)

if the bomb is heated above its maximum temperature

limit. Dangerous overheating can be produced by ovens

with defective temperature controls, by water baths boiling dry, or by operator inattention or carelessness.

Excessive pressure. Excessive pressure can be produced not only by overheating, as mentioned above, but

also from uncontrolled gaseous reactions and from high

vapor pressure or explosive materials, or from overloading the bomb as mentioned below.

Excessive loading. When organic materials are treated

in these bombs, they may liberate gases as well as heat.

Since the PTFE liner is an excellent thermal insulator,

this internal heat will be translated into higher internal

temperatures and pressures. The loading limits prescribed for these bombs are purposely conservative to

ensure that the energy released from the sample will not

over-stress the bomb.The user must also remember that

when a water-based solution is heated to 250ºC it expands to fill a space approximately 25 percent larger

than its volume at room temperature. If there is insufficient vapor space in the bomb to accommodate this expansion, the tremendous hydrostatic pressure which

will be generated will destroy the bomb.

Explosive materials. The nitro compounds produced

when nitric acid reacts with certain organic materials

may have explosive properties capable of destroying the

bomb, even when present in quantities well within the

normal recommended charging limits.Consider, for example, what might happen if nitroglycerin were produced by reactions in the bomb. For this reason, fats,

fatty acids, glycerin and similar materials must not be

treated with nitric acid in these bombs, and cellulosic

materials must not be treated with mixed nitric and

sulfuric acids. Similarly, because of its unpredictable

nature, perchloric acid must not be used in these

bombs.

2

Sample Selection

Inorganic materials. Most inorganic digestions proceed smoothly without unusual hazards, using not more

than 1.0 gram of sample in a 23 mL bomb, 2.0 grams in a

45 mL bomb and 5.0 grams in the larger,125 mL size. As

in all reactions, the bomb must never be completely filled

as there must always be vapor space above the surface of

the charge.To besure that there is adequate free space,

the total volume of the charge must never exceed twothirds (66%) of the capacity of the cup when working

with inorganic materials. By observing these limits and

taking precautions to prevent overheating, there should

be no unusual hazards in treating inorganic samples

with mineral acids.

Ores, rock samples, glass and other inorganic materials

can be dissolved in Parr acid digestion bombs using

strong mineral acids: HF, HCl, H2SO4, HNO3, Aqua Regia and others.Digestion times for these materials can

vary anywhere from 2 hours to several days. Ordinary

glass materials (SiO2) will mandate the use of HF,sometimes in combination with HCl, or aqua regia. Temperatures in the range of 100 to 150ºC are routinely used.

Alumina is routinely digested using 10% sulfuric acid.

Temperatures used for these samples are typically in excess of 200ºC.It is advantageous, from the standpoint of

minimizing the digestion time, to reduce the sample to

granular or powder form prior to digestion. The increase

in surface area of the sample has a significant impact on

the reaction with the digestion aid.

The following

used for glass and other silicate samples using the Parr

23 mL Acid Digestion Bomb. For the dissolution of glass,

sand and mineral silicate samples, weigh 0.4 g of the

powdered sample into the PTFE liner.Moisten the sample with water and cautiously and 4 mL of 40 to 50% HF

to the liner. Cover the liner and allow it to stand until

the initial reaction has taken place, then seal the bomb.

Place the bomb assembly into a preheated lab oven for 2

hours at 130-150ºC.Remove the bomb from the oven, and

after cooling the room temperature, the bomb may be

opened.

Elements that form insoluble fluorides, such as Al, Ba,

Ca, and Mg can be dealt with effectively by adding 1

gram of boric acid, after cooling, and re-heating again for

1 hour. A blank, used throughout the dissolution and

analysis procedure,should contain the same amount of

HF and boric acid. For example, it is important to have

the boric acid blank subtracted from the sample spectrum in ICPES analysis to account for the boron interferences with other elemental lines.

Organic materials. Many organic materials can be

treated satisfactorily in these digestion bombs but careful attention must be given to the nature of the sample

and to possible explosive reactions with the digestion me-

general digestion procedure can be

dia. In all cases the size of the sample and the amount of

oxidant used must be carefully controlled. For nitric

acid digestions (Carius decompositions) of organic compounds, the dry weight of organic matter must not exceed 0.1 gram in a 23 mL bomb, 0.2 gram in a 45 mL

bomb and 0.5 gram in the 125 mL size. The sample does

not have to be dried before it is placed in the bomb, but

the amount used must not exceed the above limits when

converted to a dry weight basis. The amount of concentrated nitric acid (sp. g 1.42) added to the above charges

must fall within the amounts shown in the table of loading limits. Notice that both minimum and maximum

amounts of acid are specified. If the sample contains less

than the specified maximum amount of dry organic matter, the amount of nitric acid must be reduced proportionately.

As stated above, fats, fatty acids,glycerin and similar materials which form explosive compounds in an intermediate stage must not be treated with nitric acid in these

bombs. Digestions involving other organic materials

must also be handled cautiously since it is impossible to

list all of the potentially dangerous combinations which

might arise. For best protection, the user and his supervisor should study each reaction carefully before proceeding to use the Parr digestion bomb or any other pressure

vessel, asking such questions as: Is the reaction exothermic? What intermediate and final products might be produced and what will be their behavior?

When working with new or unfamiliar materials it is always advisable to run preliminary experiments using

small samples and observing the behavior of the reactants carefully.This initial screening is best conducted in

the heavier 4746 bomb which has a safety rupture disc.

Organic samples are typically treated with concentrated

nitric acid. Nitric - sulfuric mixtures are not recommended for digesting organic samples due to the possibility of forming potentially unstable reaction products.

Digestion with perchloric acid can be dangerous,for the

same reason, and must not be used. Typical heating

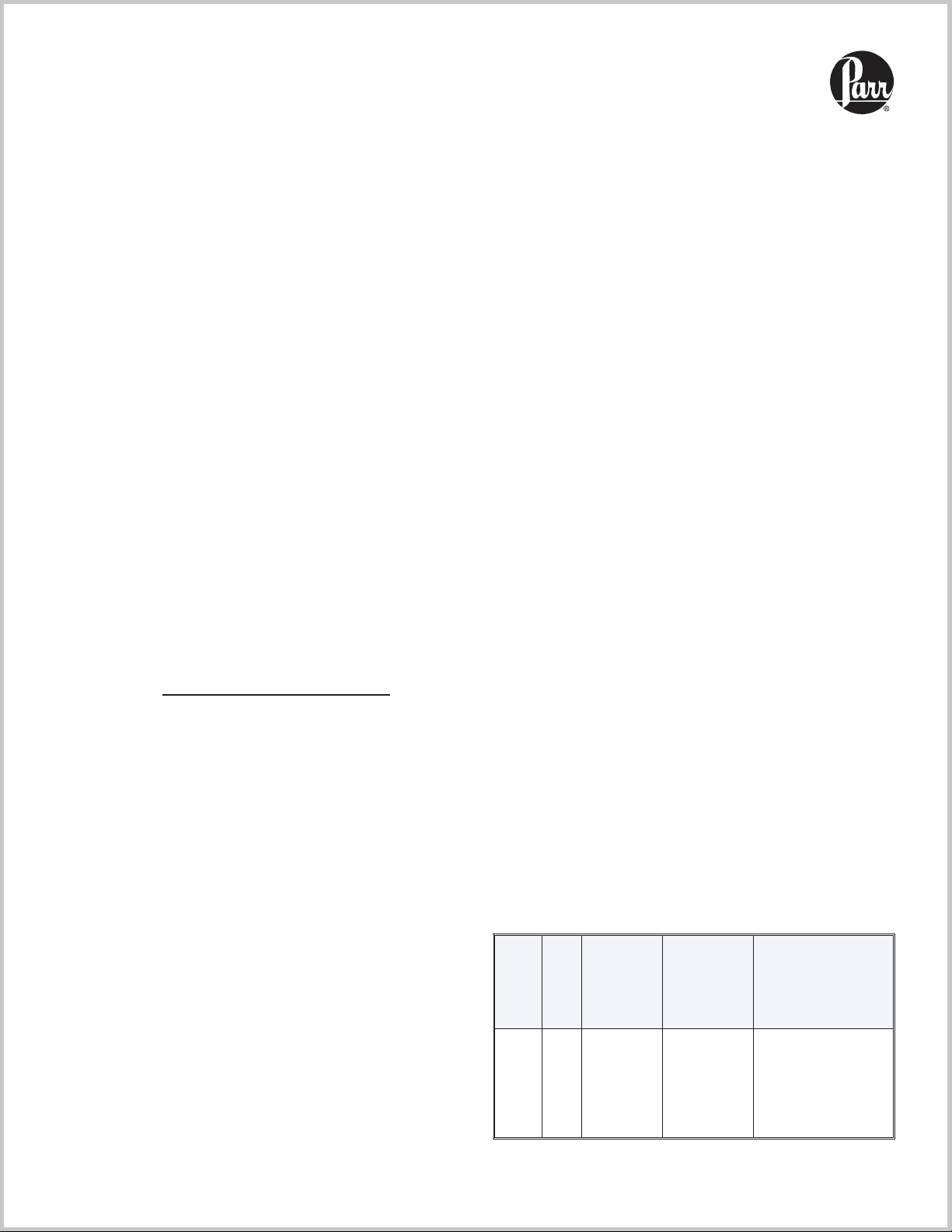

Loading Limits

Minimum and

Bomb

No.

4744

4745

4746

4747

4748

4749

Size

mL

45

23

23

23

125

23

Maximum

Inorganic

Sample

2.0 gram

1.0

1.0

1.0

5.0

1.0

Maximum

Organic

Sample

0.2 gram

0.1

0.1

0.1

0.5

0.1

Maximum Nitric

Acid to be used

with an

Organic Sample

5.0-6.0 mL

2.5-3.0

2.5-3.0

12-15

2.5-3.0

3

times range from 1 to 8 hours. Temperatures in the 150

to 200ºC range are generally quite effective.

The following

ganic samples using the Parr 23 mL Acid Digestion

Bomb. Weigh no more than 0.1 g of sample (dry weight

basis) into the PTFE digestion vessel. Add 2.5 mL hot

concentrated nitric acid and let stand open for 15 minutes. Add 0.2 mL of hydrofluoric acid to dissolve siliceous

materials contained in the sample. (In case that the sample does not contain siliceous material, this step can be

omitted.) Close the vessel and place into a preheated

oven (100-150ºC) for 1 to 4 hours,as required until the

solution is clear. If the solution is colloidal, heat until

clear. Remove the vessel from the oven and let cool to

room temperature (2 hours) before opening.Sample

sizes and amount of reagents used are proportional to

the free volume of the PTFE liner.

general digestion procedure for or-

Acid Selection

With the vigorous action that can be achieved in these

bombs at elevated temperatures and pressures, most

organic samples can be decomposed in nitric acid alone

without using mixed nitric and sulfuric acids as in oxidations at atmospheric pressure. Users should always try

nitric acid alone and resist the temptation to add sulfuric acid to the charge. Sulfuric acid may not be needed at

the higher temperature and it may tend to dehydrate the

system and promote the formation of unstable nitro

compounds.

Do not use perchloric acid. We repeat again the

warning that perchloric acid should not be used in these

bombs because of its unpredictable behavior when

heated in a closed vessel. Also, other reactions which are

highly exothermic or which might be expected to release

large volumes of gas should be avoided.

Pressure and Temperature Limits

Maximum working pressures for each acid digestion

bomb are shown in the individual listings on pages 8

through 11. Extreme care must be exercised to ensure

that pressures do not exceed these prescribed limits.The

user must understand that in acid systems the solubility

of gases such as NO

the temperature rises, having the effect of adding noncondensable gas to the vapor phase in a closed vessel. As

a result, the amount of acid present, the acid concentration and the free head space above the liquid will all

have a bearing on the pressure developed in a closed

bomb. Free head space must therefore be provided in

all procedures,and the volume and concentration of

the acid must be held to a minimum.

Maximum operating temperatures for each acid digestion bomb are shown in the individual listings. But these

limits must be used cautiously because, with certain

acids, pressures higher than the allowable limit will be

generated if the bomb is heated to the listed maximum

temperature. For example,Table I on page 6 shows the

heating only 3 mL of fuming nitric acid to 256ºC in a 23

mL bomb will generate a pressure of 1565 psi which is

well above the 1200 psi limit for the 4745 general purpose bomb. Table II shows that heating 10 mL of concentrated hydrochloric acid to 255ºC in a 23 mL bomb will

generate 2150 psi, which is well above the allowable

limit for the 4744, 4745 and 4749 bombs. But if the acid

is diluted, Table III shows that much lower pressures are

developed at temperatures to 250ºC.Diluting or reducing

the amount of acid in the charge will generally allow the

use of higher temperatures to develop a given pressure.

But in all operations the user must use good judgment in

selecting the operating temperature, and he must control

the heating medium carefully to be sure that both temperature and pressure are held within prescribed limits.

, HCl and SO3will be reduced as

2

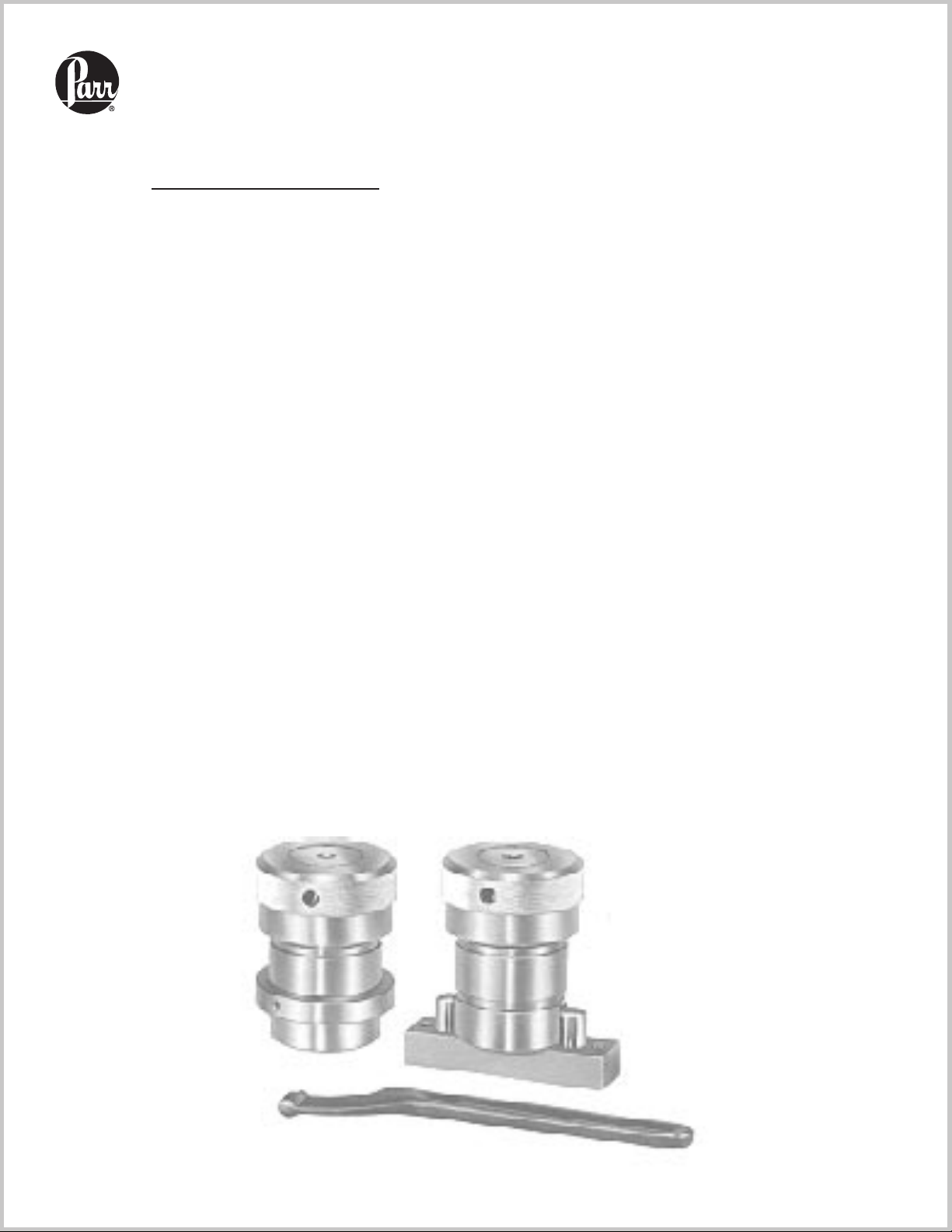

The 4744 and 4749

Bombs can be held

4749 Bomb

with A284AC

Tumbling Ring

4

firmly in an A285AC

Holding Fixture while

tightening the cap with a

264AC2 Hook Spanner

Heating and Cooling the Bomb

Parr metal-jacketed acid digestion bombs can be heated

in a variety of ways, including ovens, water baths, sand

baths, oil baths, mantles or block heaters. In all cases it

is critical to ensure that proper temperature control is

maintained to prevent the build-up of dangerous high

pressures. When working with organic materials the

bomb should be heated in a remote location or behind a

protective barricade to shield all personnel in the laboratory in case the bomb should unexpectedly explode.

At the end of a run the bomb must be cooled to the touch

before attempting to remove the PTFE cup. Cooling must

proceed slowly. Do not submerge the bomb in a sink on

an aluminum plate and run cold water over the plate but

not over the bomb. Cooling can be accelerated by placing

the bomb in the air flow from a small fan. If it is difficult

to remove the PTFE cup after a bomb has been cooled to

the touch, additional cooling in a refrigerator or freezer

may be necessary to shrink the cup sufficiently to remove it from the bomb body.

With use, these liners will absorb nitric and other acids

and become discolored. Generally this will not affect the

usefulness of the liner unless it represents unwanted contamination. Absorbed material can sometimes be driven

out by heating the liner, but care must be taken to prevent deformation as noted above. A 2 or 3 percent solution of the sodium salt of EDTA (ethylenediamine

tetracetic acid) has been found to be effective in removing heavy metal ions from these liners.

If the bomb has been used with nitric acid, the PTFE

liner should be removed, washed thoroughly and stored

outside of the bomb body to prevent possible corrosion of

the metal parts from any residual acid absorbed on the

liner. If there is a long storage period between uses, the

cup may not fit in the cylinder. To bring the cup back to

size, chill both the cup and cover in a refrigerator or

freezer at 0ºC for about an hour.Then slide the cup and

cover into the body and allow the assembly to come to

ambient temperature.

Liner Lifetimes

Pre-Treating PTFE Parts

Before using a new PTFE cup and cover,these parts

should be heated in a bomb with a charge of pure water.

This pre-treatment will help to develop the required

seals and it may prevent annoying leakage in subsequent procedures.The amount of water used in this

pre-treatment should not exceed 40 percent of the capacity of the cup. Thus:

For 23 mL cups...... use 9 mL of pure water

For 45 mL cups...... use 18 mL of pure water

For 125 mL cups ... use 50 mL of pure water

Assemble the bomb as directed in the individual instructions and heat the bomb in an oven at 150ºC for one hour.

Although some digestion procedures may require longer

heating periods,a one hour preliminary treatment

should be sufficient to prepare the PTFE parts for

effective use.

Liner Maintenance

Always handle PTFE liners with care to protect the sealing faces from mechanical damage which would make it

impossible to develop a reliable seal.

Never heat a PTFE liner without slipping it into a bomb

body. If heated outside of the bomb its dimensions will

change and it will no longer fit in the body. If this happens, cooling the liner in a refrigerator or freezer will

usually shrink it back to its original size. Then by alternately heating and cooling the liner in the bomb its dimensions should stabilize. Similarly, if a liner is stuck in

the metal body it usually can be removed by cooling the

bomb.

The lifetime of the PTFE liners used in Parr acid digestion bombs is governed by the unique characteristics of

PTFE as detailed on page 2. Cup lifetimes depend primarily upon the pressures and temperatures to which

they are exposed. Lifetimes as short as 10 to 30 runs, or

as many as 100 runs,have been reported. In general, exposure to high temperatures and/or pressures can be expected to shorten the lifetime of a cup.

A PTFE cup should be considered no longer usable and it

should be replaced if it loses one percent (1%) or more of

its contents when filled half-full with water and heated

for thirty minutes at the intended operating temperature. Continued use of a leaky cup will expose the outer

body to corrosive agents, resulting in loss of strength and

possible bomb failure. When replacing a cup, the cover

must be replaced also. Replacement cups and covers

are readily available.

The A263AC Spanner-Jack holds the 4746 Bomb firmly

during opening and closing operations and provides a

convenient tool for pressing the PTFE cup out of the

body.

5

Bomb Maintenance

References

These bombs have been designed to operate with little or

no maintenance other than careful inspection to ensure

that they have not been deformed by undetected high internal pressures.Individual replacement parts are available. The screw caps are made of either brass or a high

strength bronze to minimize the need for a lubricant on

the screw threads, but a thin film of an antisieze compound will be helpful if a bomb is to be used at temperatures above 200ºC.The several procedures and

precautions listed below should be observed in all

operations.

If the bottom plate is deformed by over pressure, replace

the plate.Then, before proceeding, review the chemistry

of the digestion which caused the over pressure.

If the inside of the metal body becomes discolored it

should be repolished to remove any metallic corrosion

products which might contaminate the liner.

Corrosion discs and rupture discs should be replaced

whenever they show signs of corrosion or wear.

If several acid digestion bombs of the same style are

used in the same laboratory, do not interchange the

cups or other parts of the assembly.

If the bomb or any of its parts should suffer any unusual

damage, contact the Technical Service Department of

Parr Instrument Company to determine the proper

corrective action or repairs which may be required.

1. J. Dolezal, P. Povondra, Z. Sulcek, “Decomposition

Techniques in Inorganic Analysis”, London Iliffe

Books Ltd., New York American Elsevier Publishing

Co., Czech Edition 1966, English Edition 1968, Library of Congress Catalog Card, No. 68-27170.

2. Zdenek Sulcek, Pavel Povondra, “Methods of Composition in Inorganic Analysis”, CRC Press, Boca Raton,

FL 33431, ISBN 0-8493-4963-X, QD75.3.S84 1989

543 88-10572

3. Wesley M. Johnson, John A. Maxwell, “Rock and Mineral Analysis Second Edition, 1981, Vol.27", John

Wiley & Sons, ISSN 0069-2883; v. 27, QE 438.J64

1981 552’.06 81-1659, ISBN 0-471-02743-X AACR2.

4. Jon C. Van Loon, “Selected Methods of Trace Metal

Analysis Biological and Environmental, Samples

Vol. 80", John Wiley & Sons 1981, ISSN 0069-2883;

v. 80, QD139.T7V35 1985 548-85-3279.

6

V aporPressureTab les

Table IV

Table I

Pressure developed at constant volume by 3 mL of fuming (91%) HNO3, Sp.gr. 1.48, in a 23 mL space.

Temperature Pressure

Deg. C psi

133 180

165 380

192 630

219 995

256 1565

285 2245

313 2945

326 3135

Data from: Journal of Research of the National Bureau of

Standards, Vol.30, February 1943, p. 110.

Table II

Pressure developed at constant volume by 10 mL of 36%

HCl in a 23 mL space.

Temperature Pressure

Deg. C psi

178 705

223 1430

255 2150

285 3095

298 3615

Data from: Journal of Research of the National Bureau of

Standards, Vol.33, December 1944, p. 468.

Table III

Pressure developed at constand volume by 10 mL of

aqua regia in a 23 mL space.

Temperature Pressure

Deg. C psi

106 305

155 705

162 765

202 1375

221 1670

236 1960

258 2505

Aqua regia made with 20 volumes, 36% HCl + 1 volume

fuming (91%) HNO3.

Data from: Journal of Research of the National Bureau of

Standards, Vol.33, December 1944, p. 469.

Table V

Saturation pressure of water.

Temperature Pressure

Deg. C psi

125 34

150 69

175 129

200 225

225 370

250 576

275 862

300 1245

325 1747

Data from: Harr, Gallagher and Kell, NBS/NRC Steam

Tables, McGraw-Hill, New York.

Pressure developed at constant volume by 10 mL of

22.9% HCl in a 23 mL space.

Temperature Pressure

Deg. C psi

132 70

159 125

191 265

220 510

250 920

285 1640

315 2250

338 3400

Data from: Journal of Research of the National Bureau of

Standards, Vol.33, December 1944, p. 468.

7

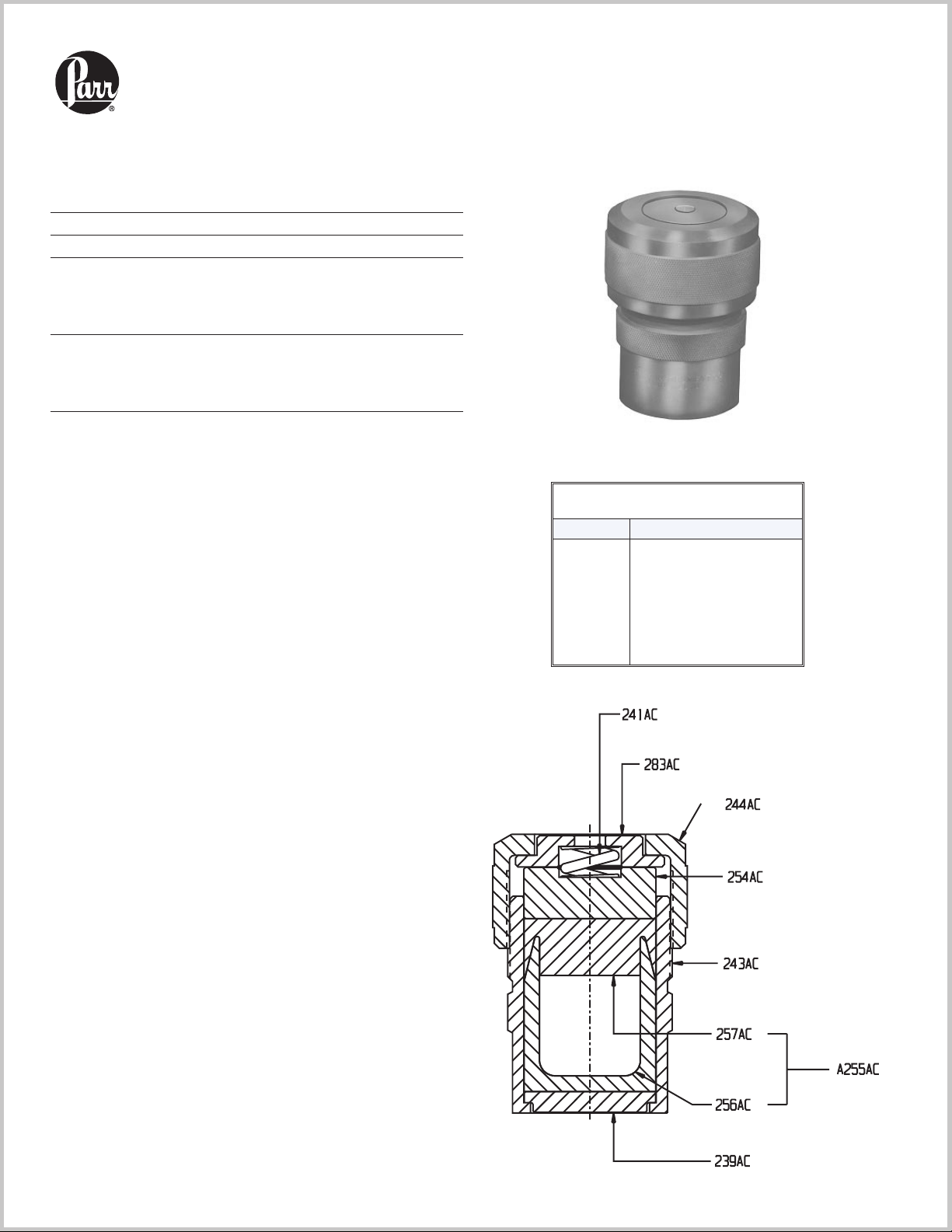

4745

General Purpose

Acid Digestion Bomb

Bomb Number 4745

Size, mL 23

Maximum charge, grams,

Inorganic sample 1.0

Organic sample 0.1

Recommended max. temperature, °C 150

Absolute max. temperature, °C 250

Absolute max. pressure, psig 1200

Operating Procedure

Always keep the bomb upright during assembly and closing operations.Check the 239AC Bottom Disc to be sure

that it is installed with the proper side facing upward to

provide full diameter support for the liner.

Place the sample and the digestion media in the PTFE

cup, attach the cover and push it down firmly with a

twisting motion. Slide the closed liner into the bomb

body and push it down as far as it will go. It may be helpful to push the bottom disc upward to meet the liner and

thereby prevent air binding between the liner and the

disc.

Set the 254AC Pressure Plate on top of the cup cover,

add the 241AC Spring and the 283AC Upper Plate, then

attach the screw cap and turn it down firmly by hand. A

firm twist by hand should be sufficient to develop and

maintain a tight seal. No wrench or spanner is required.

Place the bomb in a temperature controlled oven or

other heating medium and follow the heating and cooling procedures described in the general instructions.

If mixing is required, an optional tumbling ring

(A284AC) can be attached to the bomb body, the

same as offered for the 4744 and 4749 Bombs.

Parts List

Part No. Description

239AC

241AC

243AC

244AC

254AC

A255AC

283AC

Bottom disc

Sprint

Bomb body

Screw cap

Pressure plate, lower

PTFE cup with cover

Pressure plate, upper

8

4744 and 4749

45

23

General Purpose

Acid Digestion Bomb

Bomb Number 4744 4749

Size, mL 23 45

Maximum charge, grams,

Inorganic sample 1.0 2.0

Organic sample 0.1 0.2

Recommended maximum

temperature, °C 250 250

Absolute maximum

temperature, °C 250 250

Absolute maximum

pressure, psig 1800 1800

Operating Procedure

point where it is impossible to maintain a tight seal.

When this happens, the cup and cover must be replaced.

Any attempt to force a seal by over tightening the screw

cap might crack the cap.

4749

Always keep the bomb upright during assembly and closing operations.Check the 277AC Bottom Disc to be sure

that it is installed with the proper side facing upward to

provide full diameter support for the liner.Place sample

and digestion media in the PTFE cup, add the cover and

slide the liner into the bomb body. Push it down as far as

it will go. It may be helpful to push the bottom disc upward to meet the liner and thereby prevent air binding

between the liner and disc.

Place the 286AC Corrosion Disc and the 287AC Rupture

Disc on top of the liner.Notice that two discs are required, with the thinner (corrosion) disc next to the

PTFE cover and the thicker (rupture) disc on the outside

of the sandwich next to the blowout opening. Add the

241AC Spring with upper and lower pressure plates,

then attach the screw cap and turn it down firmly by

hand. Additional closing force applied with a hook spanner will be required to seal these bombs, but avoid over-

tightening. Set the bomb in the A285AC Holding

Fixture and tighten the cap not more than one-eight turn

with the 264AC2 Hook Spanner.Any further tightening

in excess of one-eighth turn will destroy the seal on the

liner and it may put an excessive load on the screw cap,

causing it to deform and possibly crack and fail.

Place the bomb in a temperature controlled oven or other

heating medium and follow the heating and cooling procedure described in the general instructions. If mixing is

required an optional tumbling ring (A284AC) can be attached to the bomb body.With this ring in place,the

bomb will roll smoothly when placed in a powered roller,

providing good agitation during long digestion procedures.

After extended use, the tapered rim on the PTFE cup

will become thin and the cover may be deformed to a

Parts List

Part No. Description

241AC

264AC2

276AC

276AC2

277AC

278AC

A280AC

A280AC2

282AC

283AC

A284AC

A285AC

286AC

287AC

Spring

Hook spanner

Bomb body (23 mL)

Bomb body (45 mL)

Bottom disc

Screw cap

PTFE cup with cover (23 mL)

PTFE cup with cover (45 mL)

Pressure plate, lower

Pressure plate, upper

Tumbling ring

Holding fixture

Corrosion disc, .002"

Rupture disc, .003"

4744

9

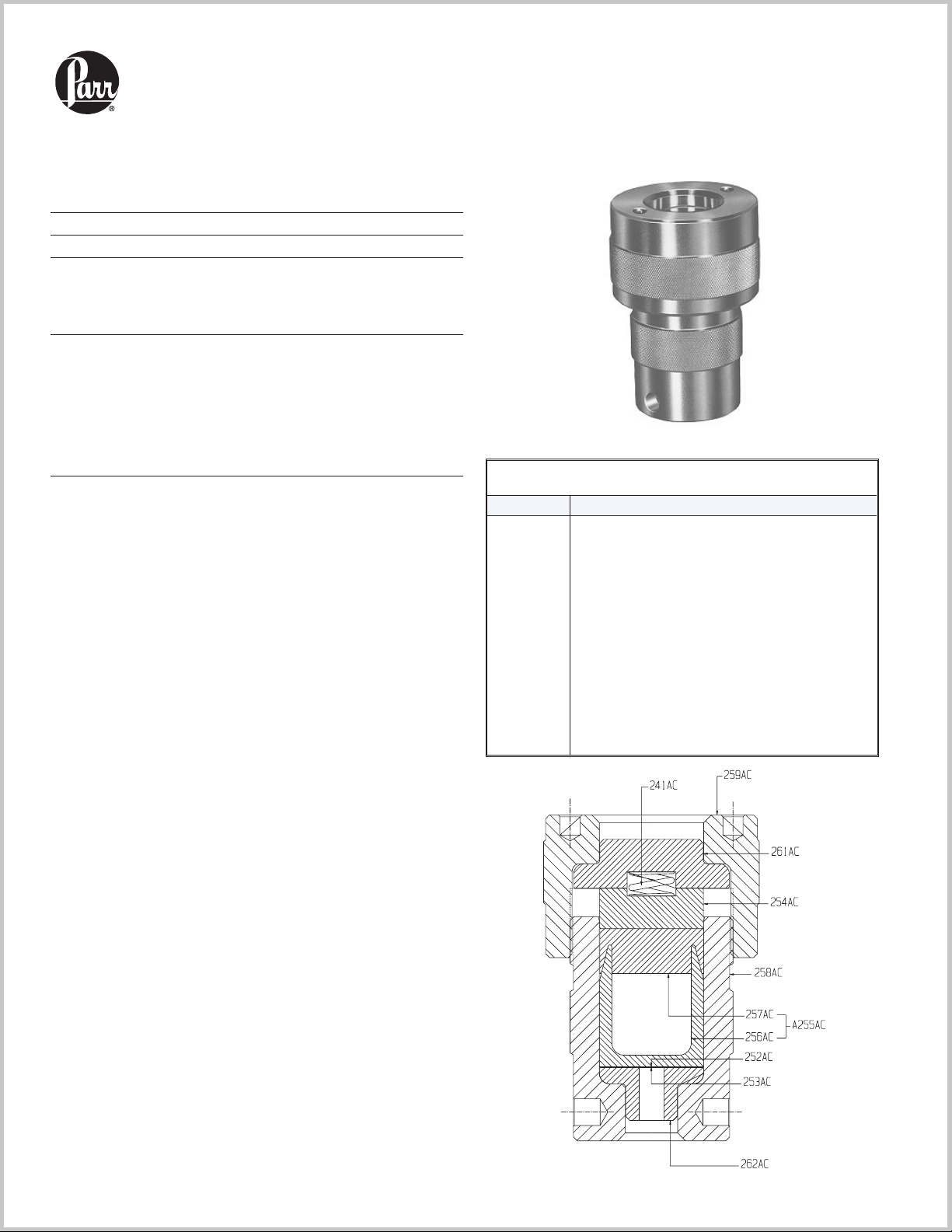

4746 and 4747

High Strength

Acid Digestion Bomb

Bomb Number 4746 4747

Size, mL 23 23

Maximum charge, grams,

Inorganic sample 1.0 1.0

Organic sample 0.1 0.1

Recommended maximum

temperature, °C 275 275

Absolute maximum

temperature, °C 275 275

Absolute maximum

pressure, psig 5000 3300

Operating Procedure

Always keep the bomb upright during assembly and closing operations.Check the 262AC Bottom Orifice in the

4746 Bomb, or the 262AC2 Solid Plug in the bottom of

the 4747 Nickel Bomb, to be sure that it is in place. Then

drop the 253AC Rupture Disc and the 252AC Corrosion

Disc into the body of the 4746 Bomb. When in place, the

thinner (corrosion) disc should be on top of the thicker

(rupture) disc in the bottom sandwich next to the blowout orifice. (No discs are used in the 4747 Nickel Bomb.)

Place the sample and the digestion media in the PTFE

cup, attach the cover and push it down firmly with a

twisting motion. Slide the closed liner into the bomb

body and push it down as far as it will go. It may be helpful to push the bottom plug upward to meet the liner and

thereby prevent air binding between the liner and disc.

Set the 254AC Pressure Plate on top of the PTFE cover,

add the 241AC Spring and the 261AC Top Cap, then attach the screw cap and turn it down firmly by hand. A

firm twist by hand should be sufficient to develop a tight

seal, but a slight additional force applied with a 264AC

Face Spanner will be helpful. However, do not tighten

the cap more than one-eight turn with the spanner.

Place the bomb in a temperature controlled oven or

other heating medium and follow the heating and cooling procedures described in the general instructions.After use at the maximum operating temperature the

PTFE liner may be deformed sufficiently to make it difficult to remove the liner from the bomb after cooling.To

overcome this problem an A263AC Spanner Jack Assembly can be used to push the liner out of the bomb with a

smooth, uniform pressure without damaging the cup.

This spanner jack will also be helpful for holding the

bomb when removing the screw cap with a 264AC Face

Spanner.

Parts List

Part No. Description

241AC

252AC

253AC

254AC

254ACCN

A255AC

258ACAB

258ACCN

259ACBC

261ACAB

262AC

262AC2

A263AC

264AC

Spring

Corrosion disc, .002"

Rupture disc, .010"

Pressure plate, stainless

Pressure plate, nickel

PTFE cup with cover

Bomb body, stainless

Bomb body, nickel

Screw cap, bronze, plated

Top cap, stainless

Bottom orifice, stainless

Bottom plug, nickel

Spanner jack assembly with 265AC spanner

Face spanner only

10

4748

Large Capacity

Acid Digestion Bomb

Bomb Number 4748

Size, mL 125

Maximum charge, grams,

Inorganic sample 5.0

Organic sample 0.5

Recommended max. temperature, °C 250

Absolute max. temperature, °C 250

Absolute max. pressure, psig 1900

Operating Procedure

There must always be adequate free space above the

charge in the 4748 Bomb. For inorganicsamples which

do not generate gases, leave at least 33% of the capacity

of the cup as free space, and increase the space to 50% or

more if the charge tends to liberate gases. For organic

samples, leave at lease 50% free space for non-oxidizing

reactions and 66% to 75% if an oxidizing medium is used.

For Carius and similar decompositions use not more

than 15 mL or less than 12 mL of 70% nitric acid with a

0.5 gram sample. For smaller samples, use 2.5 to 3.0 mL

of nitric acid for each 0.1 gram of dry organic matter.

Slide the filled cup into the bomb and raise the bottom

plate slightly to release any trapped air.Place the 310AC

(thinner) corrosion disc on top of the PTFE cover and the

311AC (thicker) rupture disc on top of the corrosion disc.

NOTE: the PTFE cover will rupture and digestion media

will be sprayed from the opening in the top plate if the

corrosion and rupture discs are not included in the assembly. Add the 306AC pressure plate and two 309AC

Bellville spring washers, topped by the 307AC compression ring.

Back all of the compression screws out of the screw cap

until they are slightly recessed, then advance one screw

until one full thread is observable on the underside. Attach the screw cap to the cylinder and turn it down by

hand as far as it will go.Then, using the TX31SK Allen

wrench furnished with the bomb, tighten the socket head

screws firmly in a criss-cross pattern, moving in sequence around the circle.Repeat the tightening sequence

four times for a final torque of approximately 5 ft-lbs on

each screw.

Place the bomb in a temperature controlled oven and follow the heating and cooling procedure described in the

general instructions.After digestion, allow the bomb to

cool to ambient temperature on an aluminum plate or a

metal table top. It is not good practice to cool the bomb in

cold water or in a freezer. The internal forces will some-

times distort the liner, making it difficult to remove the

liner from the bomb body. Usually the liner can be dislodged by pressing the uncovered bomb against a brass

or plastic projection about 3 cm in diameter and 5 cm

high. A firm tap against the projection may be required.

In extreme cases it may be necessary to cool the bomb in

a refrigerator or freezer to shrink the liner.

After extended use the tapered rim on the PTFE cup will

become thin and the cover may be deformed to a point

Parts List

Part No. Description

301AC

302AC

A305AC

306AC

307AC

A308AC

308ACF

309AC

310AC

311AC

Bottom plate

Bomb body

PTFE cup with cover

Pressure plate

Compression ring

Screw cap with cap screws

Cap screw, 3/8-24 x 3/4, soc. hd.

Bellville spring washer

Corrosion disc, .002", stainless

Rupture disc, .003", Inconel

11

Printed in USA

11/97

PARR INSTRUMENT COMP ANY

211 Fifty-Third Street

Moline, Illinois 61265 USA

309/762-7716 800/872-7720

Fax 309/762-9453

http://www.parrinst.com parr@parrinst.com

Loading...

Loading...