Parkside Performance PWSAP 20-Li B2 Operation And Safety Notes Translation Of The Original Instructions

CORDLESS ANGLE GRINDER 20 V

PWSAP 20‑Li B2

CORDLESS ANGLE

GRINDER 20 V

Operation and safety notes

Translation of the original instructions

AKU KUTNA BRUSILICA 20 V

Upute za posluživanje i za Vašu sigurnost

Prijevod originalnih uputa

АКУМУЛАТОРЕН

ЪГЛОШЛАЙФ 20 V

Инструкции за обслужване и безопасност

Превод на оригиналната инструкция

ΕΠΑΝΑΦΟΡΤΙΖΌΜΕΝΟΣ

ΓΩΝΙΑΚΌΣ ΤΡΟΧΌΣ 20 V

Υποδείξεις χειρισμού και ασφαλείας

Μετάφραση του πρωτοτύπου των οδηγιών χρήσης

AKU UGAONA BRUSILICA

20 V

Napomene o upotrebi i bezbednosti

Prevod originalnog uputstva

IAN 322689_1901

AKKU‑

WINKELSCHLEIFER 20 V

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

GB/CY Operation and safety notes Page 5

HR Upute za posluživanje i za Vašu sigurnost Stranica 29

RS Napomene o upotrebi i bezbednosti Strana 53

BG Инструкции за обслужване и безопасност

GR/CY Υποδείξεις χειρισμού και ασφαλείας Σελίδα

DE/AT/CH Bedienungs- und Sicherheitshinweise Seite

Страница

78

104

128

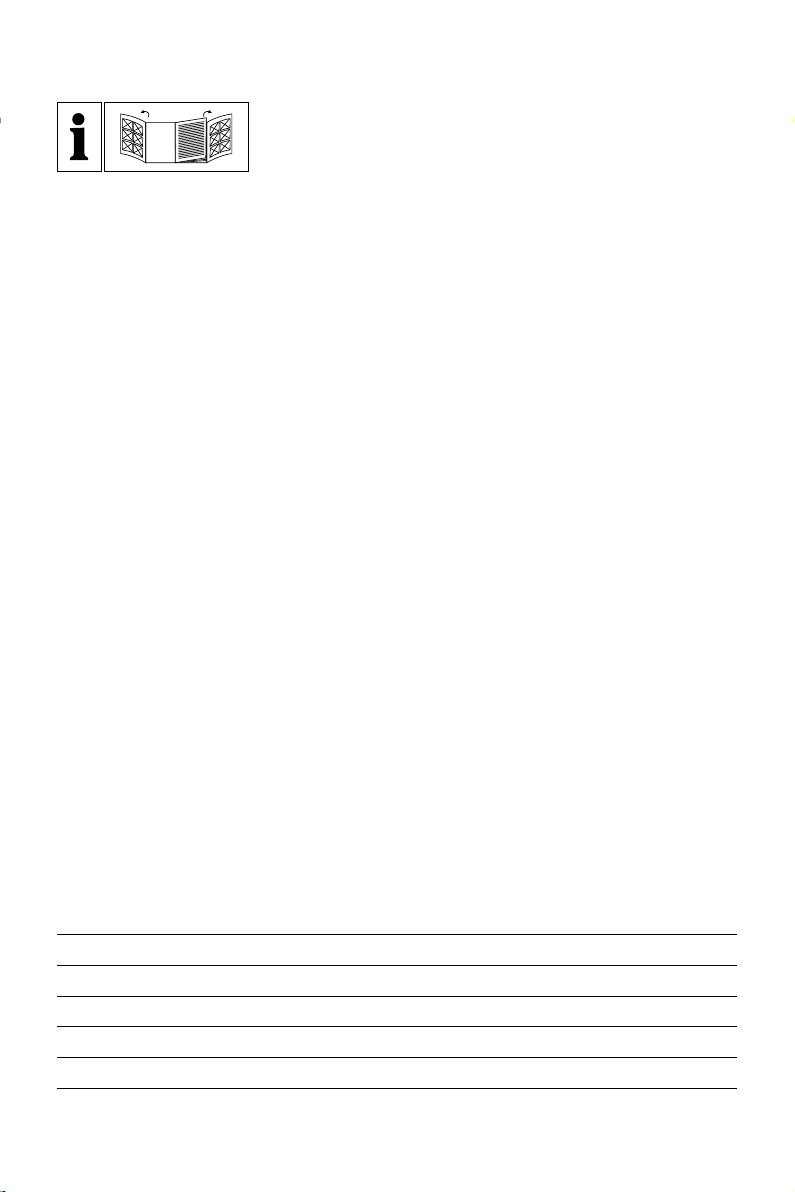

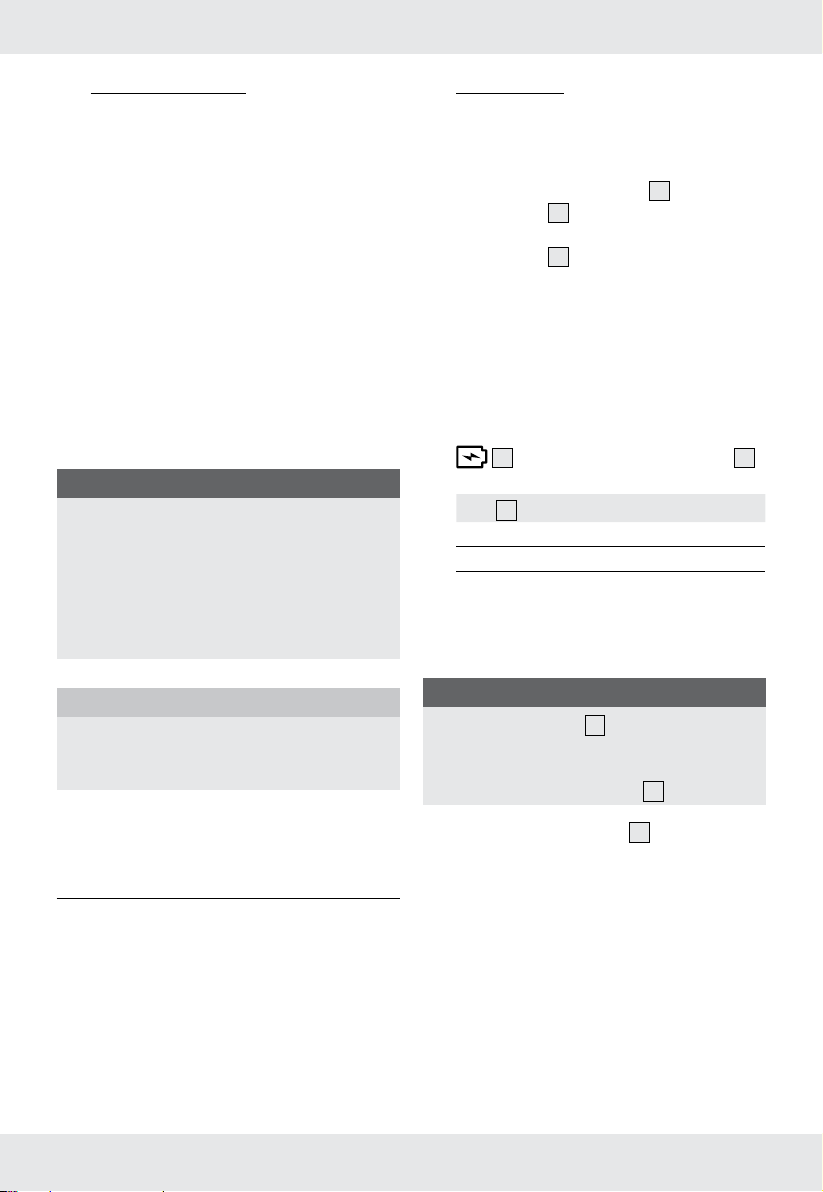

A

1 2

3 4

5

14

13

12

B

15

5

C

18

6

7

8

9

10

11

5

19

17

20

21

16

BATTERY COMPATIBLE WITH ALL DEVICES OF THE SERIES

“PARKSIDE X 20 V TEAM“

PUNJIVA BATERIJA KOMPATIBILNA JE SA SVIM UREĐAJIMA IZ SERIJE

„PARKSIDE X 20 V TEAM“

AKUMULATOR JE KOMPATIBILAN SA SVIM UREĐAJIMA SERIJE

„PARKSIDE X 20 V TEAM“

АКУМУЛАТОРНАТА БАТЕРИЯ Е СЪВМЕСТИМА С ВСИЧКИ УРЕДИ ОТ

СЕРИЯТА „PARKSIDE X 20 V TEAM“

ΜΠΑΤΑΡΙΑ ΣΥΜΒΑΤΗ ΜΕ ΟΛΕΣ ΤΙΣ ΣΥΣΚΕΥΕΣ ΤΗΣ ΣΕΙΡΑΣ

«PARKSIDE X 20 V TEAM»

AKKU KOMPATIBEL MIT ALLEN GERÄTEN DER SERIE

„PARKSIDE X 20 V TEAM“

20V max.

18V

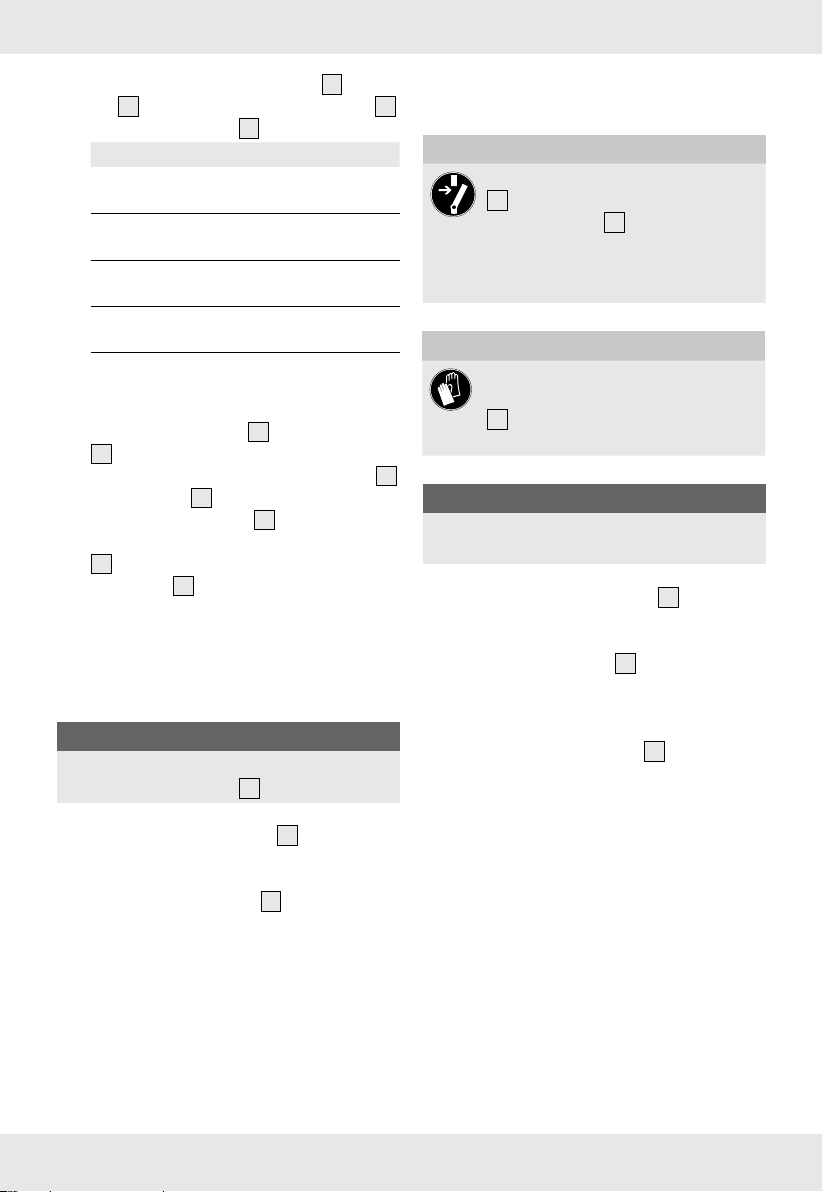

D E

F G

H I

c

b

a

J K

3.

2.

1.

Warnings and symbols used .......................................... Page 6

Introduction............................................................ Page 6

Intended use............................................................ Page 6

Scope of delivery........................................................ Page 7

Parts description......................................................... Page 7

Technical data .......................................................... Page 7

Safety instructions..................................................... Page 9

General power tool safety warnings ......................................... Page 9

Grinder safety warnings................................................... Page 12

Angle grinder warnings ................................................... Page 12

Vibration and noise reduction .............................................. Page 17

Behaviour in emergency situations........................................... Page 18

Residual risks ........................................................... Page 18

Battery charger safety warnings ............................................ Page 19

Before first use......................................................... Page 20

Accessories ............................................................ Page 20

Operation.............................................................. Page 20

Attaching/removing the battery pack ........................................ Page 20

Checking the battery pack charging level ..................................... Page 20

Charging the battery pack................................................. Page 20

Attaching/removing the auxiliary handle ..................................... Page 21

Adjusting the guard ...................................................... Page 21

Changing the guard...................................................... Page 22

Attaching/removing the accessory tool .......................................Page 22

Switching on and off ..................................................... Page 23

Trial run ............................................................... Page 24

Working instructions .................................................. Page 24

Grinding............................................................... Page 24

Wire brushing .......................................................... Page 24

Abrasive cutting ......................................................... Page 24

Cleaning and care ..................................................... Page 25

Cleaning............................................................... Page 25

Maintenance ........................................................... Page 25

Repair................................................................. Page 25

Storage ............................................................... Page 25

Transportation .......................................................... Page 26

Disposal................................................................ Page 26

Warranty .............................................................. Page 26

EC declaration of conformity .......................................... Page 28

5 GB/CY

Warnings and symbols used

The following warnings are used in this instruction manual, on the packaging and on the rating label:

Switch the product off and remove

Read the instruction manual.

Follow the warnings and safety notes!

Use in dry indoor rooms only.

Wear protective gloves! Protect the battery pack from fire.

Wear hearing protection! Protection class II (double insulation)

the battery pack before replacing

attachments, cleaning and when not

in use.

Protect the battery pack against heat

and continuous intense sunlight.

max. 45°C

Protect the battery pack against water

and moisture.

Alternating current

Wear eye protection!

CORDLESS ANGLE GRINDER

20 V PWSAP 20‑Li B2

Introduction

We congratulate you on the purchase of your

new product. You have chosen a high quality

product. The instructions for use are part of the

product. They contain important information

concerning safety, use and disposal. Before using

the product, please familiarise yourself with all

of the safety information and instructions for use.

Only use the product as described and for the

specified applications. If you pass the product on

to anyone else, please ensure that you also pass

on all the documentation with it.

Direct current

T3.15A

Fuse

Intended use

This cordless angle grinder (hereinafter “product”

or “power tool”) is designed for

¾ abrasive cutting-off,

¾ grinding metal/concrete/tiles without the use

of water, and

¾ wire brushing metal.

The product is not intended for any other types

of applications (e.g. grinding with unsuitable

grinding tools, grinding with a coolant solution,

grinding or cutting hazardous materials such as

asbestos).

6 GB/CY

The product is not intended for sanding and

polishing.

Cut-off grinding: A separate guard must

be installed for this task. The guard can

be ordered via our customer service

(article number HG03642).

Always use the correct accessory tools according

to the intended use! Observe the technical

requirements of this product (see “Technical

data“) when purchasing and using accessory

tools!

Any other use or modification of the product

are considered improper use and can result in

hazards such as death, life-threatening injuries

and damage. The manufacturer is not liable

for any damages caused by improper use. The

product is not intended for commercial use or for

any other use.

Scope of delivery

Parts description

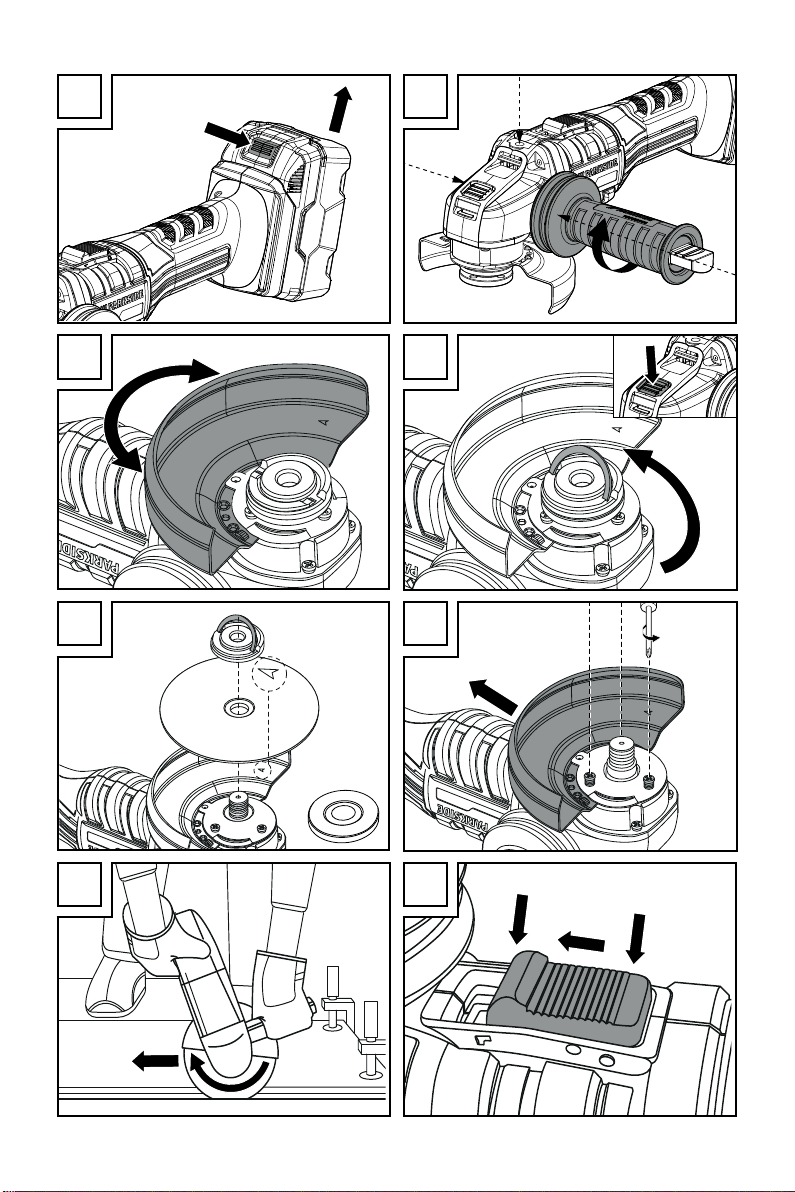

Figure A:

Spindle lock button

1

Auxiliary handle threads

2

On/off switch

3

Grip handle

4

Battery pack

5

Auxiliary handle (with chuck key storage)

6

Chuck key

7

Guard for grinding

8

Directional arrow (on the guard)

9

Spindle

10

Backing flange

11

Locking flange (with tightening tab)

12

Cover with clamp

13

Directional arrow (on the angle grinder)

14

Figure B:

Battery pack

5

Release button for battery pack

15

button (charging level)

16

Charging level LEDs (red/orange/green)

17

WARNING!

m

u The product and the packaging are not

children’s toys! Children must not play with

plastic bags, sheets and small parts! There

is a danger of choking and suffocation!

1 x Cordless angle grinder 20 V

PWSAP 20-Li B2

1 x Auxiliary handle

1 x Guard for grinding (pre-installed) *

1 x Chuck key (stored in the auxiliary handle)

1 x Battery pack PAP 20 A3

1 x Rapid battery charger PLG 20 B1

1 x Carrying case

1 x Instruction manual

* Guard for cutting is not supplied and can be

ordered via our customer service.

Figure C:

Battery charger (rapid battery charger)

18

Power cord with power plug

19

Charging control LED – Green

20

Charging control LED – Red

21

Not illustrated:

Carrying case

22

Technical data

Cordless angle grinder PWSAP 20‑Li B2

Rated voltage: 20 V

Rated speed n: 10000 min

Accessory tool diameter: Ø 125 mm

Wheel thickness: max. 8 mm

Spindle thread: M14

–1

7 GB/CY

Battery pack PAP 20 A3

Type: Lithium-Ion

Rated voltage: 20 V

max.

Capacity: 4 Ah

Energy value: 72 Wh

Number of cells: 10

Rapid battery charger PLG 20 B1

Input:

Rated voltage: 230–240 V∼

Rated frequency: 50 Hz

Rated power: 120 W

Output:

Rated voltage: 21.5 V

Charging current: 4.5 A

Protection class:

Fuse (internal):

II /

3.15 A /

Charging time:

¾ Battery type PAP 20 A3, 4.0 Ah (supplied):

60 minutes

¾ Battery type PAP 20 A1, 2.0 Ah

(available separately): 45 minutes

Recommended ambient temperature:

While charging: +4 to +40 °C

During operation: +4 to +40 °C

During storage: +20 to +26 °C

Noise emission value

The measured values have been determined in

accordance with EN 60745. The A-rated noise

level of the power tool is typically as follows:

Sound pressure level L

Uncertainty K

pA

Sound power level L

Uncertainty K

WA

: 81.6 dB(A)

pA

: 3 dB

: 92.6 dB(A)

WA

: 3 dB

Vibration emission value

Vibration total values (triaxial vector sum)

determined according to EN 60745:

Main handle:

Hand/arm vibration a

: 4.27 m/s²

h,AG

Uncertainty K: 1.5 m/s²

Auxiliary handle:

Hand/arm vibration a

: 5.31 m/s²

h,AG

Uncertainty K: 1.5 m/s²

The values apply for the work mode surface

grinding. Other applications may have different

vibration emission values.

WARNING!

m

Wear ear protection!

NOTE

u The declared vibration total value and

the declared noise emission value have

been measured in accordance with a

standard test method and may be used for

comparing one tool with another.

u The declared total vibration value and the

declared noise emission value may also

be used for a preliminary assessment of

exposure.

8 GB/CY

WARNING!

m

u The vibration and noise emissions during

actual use of the power tool can differ

from the declared values depending on

the manner in which the tool is used,

especially what kind of workpiece is

processed.

Try to minimise exposure to vibration and

noise. Examples of measures to reduce

vibration include wearing gloves when

using the tool and limiting working time. All

parts of the operating cycle must be taken

into account (e.g. times when the power

tool is switched off and when it is running

idle in addition to the trigger time).

Safety instructions

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

1) Keep work area clean and well

lit. Cluttered or dark areas invite accidents.

2) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3) Keep children and bystanders

away while operating a power

tool. Distractions can cause you to lose

control.

General power tool safety

warnings

WARNING!

m

u Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Electrical safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power

tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

9 GB/CY

2) Avoid body contact with earthed

or grounded surfaces, such as

pipes, radiators, ranges and

refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

3) Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of electric

shock.

4) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

5) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk

of electric shock.

6) If operating a power tool in a

damp location is unavoidable, use

a residual current device (RCD)

protected supply. Use of an RCD

reduces the risk of electric shock.

Personal safety

1) Stay alert, watch what you are

doing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the influence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

2) Use personal protective

equipment. Always wear eye

protection. Protective equipment such as

dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

3) Prevent unintentional starting.

Ensure the switch is in the off‑

position before connecting to power

source and/or battery pack, picking

up or carrying the tool. Carrying

power tools with your finger on the switch or

energising power tools that have the switch

on invites accidents.

4) Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left attached to

a rotating part of the power tool may result

in personal injury.

10 GB/CY

5) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

6) Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

7) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use

of dust collection can reduce dust-related

hazards.

Power tool use and care

1) Do not force the power tool. Use

the correct power tool for your

application. The correct power tool will

do the job better and safer at the rate for

which it was designed.

2) Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot be

controlled with the switch is dangerous and

must be repaired.

3) Disconnect the plug from the

power source and / or the battery

pack from the power tool before

making any adjustments, changing

accessories, or storing power

tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4) Store idle power tools out of the

reach of children and do not allow

persons unfamiliar with the power

tool or these instructions to operate

the power tool. Power tools are

dangerous in the hands of untrained users.

5) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect

the power tool’s operation. If

damaged, have the power tool

repaired before use. Many accidents

are caused by poorly maintained power

tools.

6) Keep cutting tools sharp and

clean. Properly maintained cutting tools

with sharp cutting edges are less likely to

bind and are easier to control.

11 GB/CY

7) Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking into

account the working conditions and

the work to be performed. Use of

the power tool for operations different from

those intended could result in a hazardous

situation.

Battery tool use and care

1) Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type of

battery pack may create a risk of fire when

used with another battery pack.

2) Use power tools only with

specifically designated battery

packs. Use of any other battery packs may

create a risk of injury and fire.

3) When battery pack is not in use,

keep it away from other metal

objects, like paper clips, coins,

keys, nails, screws or other small

metal objects, that can make a

connection from one terminal to

another. Shorting the battery terminals

together may cause burns or a fire.

4) Under abusive conditions, liquid

may be ejected from the battery;

avoid contact. If contact accidentally

occurs, flush with water. If liquid

contacts eyes, additionally seek

medical help. Liquid ejected from the

battery may cause irritation or burns.

Service

1) Have your power tool serviced by

a qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Grinder safety warnings

WARNING!

m

u Dust from materials such as lead paint,

some types of wood, and metal can be

harmful to your health.

u Contact with or inhaling this type of

dust can present a danger to the user or

persons nearby.

WARNING!

m

Wear safety glasses and a dust mask!

Angle grinder warnings

Safety warnings common for grinding,

wire brushing and abrasive cutting‑off

1) This power tool is intended for

use as a grinder, wire brush and

abrasive cutting machine. Follow all

safety instructions, instructions for

use, illustrations and data included

with the device. Failure to heed the

following instructions can result in electric

shock, fire and / or serious injury.

12 GB/CY

2) Operations such as sanding and

polishing are not recommended to

be performed with this power tool.

Operations for which the power tool was not

designed may create a hazard and cause

personal injury.

3) Do not use accessories which

are not specifically designed

and recommended by the tool

manufacturer. Just because the accessory

can be attached to your power tool, it does

not assure safe operation.

4) The rated speed of the accessory

must be at least equal to the

maximum speed marked on the

power tool. Accessories running faster

than their rated speed can break and fly

apart.

5) The outside diameter and the

thickness of your accessory must be

within the capacity rating of your

power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

6) Threaded mounting of accessories

must match the grinder spindle

thread. For accessories mounted

by flanges, the arbour size hole of

the accessory must fit the locating

diameter of the flange. Accessories that

do not match the mounting hardware of the

power tool will run out of balance, vibrate

excessively and may cause loss of control.

7) Do not use a damaged accessory.

Before each use inspect the

accessory such as abrasive wheels

for chips and cracks, backing pad

for cracks, tear or excess wear,

wire brush for loose or cracked

wires. If power tool or accessory

is dropped, inspect for damage or

install an undamaged accessory.

After inspecting and installing an

accessory, position yourself and

bystanders away from the plane

of the rotating accessory and run

the power tool at maximum no‑

load speed for 1 minute. Damaged

accessories will normally break apart during

this test time.

8) Wear personal protective

equipment. Depending on

application, use face shield, safety

goggles or safety glasses. As

appropriate, wear dust mask,

hearing protectors, gloves

and workshop apron capable

of stopping small abrasive or

workpiece fragments. The eye

protection must be capable of stopping flying

debris generated by various operations. The

dust mask or respirator must be capable

of filtrating particles generated by your

operation. Prolonged exposure to high

intensity noise may cause hearing loss.

13 GB/CY

9) Keep bystanders a safe distance

away from work area. Anyone

entering the work area must wear

personal protective equipment.

Fragments of workpiece or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

10) Hold the power tool by insulated

gripping surfaces only, when

performing an operation where

the cutting tool may contact hidden

wiring. Contact with a “live” wire will also

make exposed metal parts of the power tool

“live” and could give the operator an electric

shock.

11) Never lay the power tool down

until the accessory has come to a

complete stop. The spinning accessory

may grab the surface and pull the power

tool out of your control.

12) Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory could

snag your clothing, pulling the accessory into

your body.

13) Regularly clean the power tool’s

air vents. The motor’s fan will draw

the dust inside the housing and excessive

accumulation of powdered metal may cause

electrical hazards.

14) Do not operate the power tool near

flammable materials. Sparks could

ignite these materials.

15) Do not use accessories that require

liquid coolants. Using water or other

liquid coolants may result in electrocution or

shock.

Further safety instructions for all

operations – Kickback and related

warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in

turn causes the uncontrolled power tool to be

forced in the direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

14 GB/CY

1) Maintain a firm grip on the power

tool and position your body and

arm to allow you to resist kickback

forces. Always use auxiliary handle,

if provided, for maximum control

over kickback or torque reaction

during start‑up. The operator can control

torque reactions or kickback forces, if proper

precautions are taken.

2) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

3) Do not position your body in the

area where power tool will move

if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s

movement at the point of snagging.

4) Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the

accessory. Corners, sharp edges or

bouncing have a tendency to snag the

rotating accessory and cause loss of control

or kickback.

5) Do not attach a saw chain

woodcarving blade or toothed

saw blade. Such blades create frequent

kickback and loss of control.

Specific safety instructions for grinding

and abrasive cutting

1) Use only wheel types that are

recommended for your power tool

and the specific guard designed for

the selected wheel. Wheels for which

the power tool was not designed cannot be

adequately guarded and are unsafe.

2) The grinding surface of centre

depressed wheels must be mounted

below the plane of the guard lip.

An improperly mounted wheel that projects

through the plane of the guard lip cannot be

adequately protected.

3) The guard must be securely

attached to the power tool and

positioned for maximum safety,

so the least amount of wheel is

exposed towards the operator. The

guard helps to protect the operator from

broken wheel fragments, accidental contact

with wheel and sparks that could ignite

clothing.

4) Wheels must be used only for

recommended applications. For

example: do not grind with the side

of cut‑off wheel. Abrasive cut-off wheels

are intended for peripheral grinding, side

forces applied to these wheels may cause

them to shatter.

15 GB/CY

5) Always use undamaged wheel

flanges that are of correct size and

shape for your selected wheel.

Proper wheel flanges support the wheel thus

reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different

from grinding wheel flanges.

6) Do not use worn down wheels from

larger power tools. Wheel intended

for larger power tool is not suitable for the

higher speed of a smaller tool and may

burst.

Additional safety warnings specific for

abrasive cutting‑off operations

1) Do not “jam” the cut‑off wheel or

apply excessive pressure. Do not

attempt to make an excessive depth

of cut. Overstressing the wheel increases

the loading and susceptibility to twisting

or binding of the wheel in the cut and the

possibility of kickback or wheel breakage.

2) Do not position your body in line

with and behind the rotating wheel.

When the wheel, at the point of operation, is

moving away from your body, the possible

kickback may propel the spinning wheel and

the power tool directly at you.

3) When wheel is binding or when

interrupting a cut for any reason,

switch off the power tool and hold

the power tool motionless until the

wheel comes to a complete stop.

Never attempt to remove the cut‑off

wheel from the cut while the wheel

is in motion otherwise kickback

may occur. Investigate and take corrective

action to eliminate the cause of wheel

binding.

4) Do not restart the cutting operation

in the workpiece. Let the wheel

reach full speed and carefully re‑

enter the cut. The wheel may bind, walk

up or kickback if the power tool is restarted

in the workpiece.

5) Support panels or any oversized

workpiece to minimize the risk of

wheel pinching and kickback. Large

workpieces tend to sag under their own

weight. Supports must be placed under the

workpiece near the line of cut and near the

edge of the workpiece on both sides of the

wheel.

6) Use extra caution when making a

“pocket cut” into existing walls or

other blind areas. The protruding wheel

may cut gas or water pipes, electrical wiring

or objects that can cause kickback.

16 GB/CY

Additional safety instructions for wire

brushing operations – Safety warnings

specific for wire brushing operations

1) Be aware that wire bristles are

thrown by the brush even during

ordinary operation. Do not

overstress the wires by applying

excessive load to the brush. The wire

bristles can easily penetrate light clothing

and/or skin.

2) If the use of a guard is

recommended for wire brushing,

do not allow any interference of

the wire wheel or brush with the

guard. Wire wheel or brush may expand

in diameter due to work load and centrifugal

forces.

Additional angle grinder warnings

1) Only use grinding wheels where the

indicated rotational speed is at least as high

as what has been specified on the name

plate of the product.

2) Carry out a visual inspection of the grinding

wheel before use. Do not use any damaged

or deformed wheels. Replace any damaged

or worn wheels.

3) Make sure that the sparks produced by

grinding do not present a danger, e.g. reach

people or ignite flammable substances.

4) Always wear safety goggles, safety gloves,

respiratory protection and ear protection

when grinding.

5) Never keep the fingers between the wheel

and spark protection or in close proximity

to the protective hoods. There is a risk of

crushing.

6) The rotating parts of the product cannot be

covered due to functional reasons. Therefore,

proceed cautiously and hold the workpiece

firmly in order to avoid slipping which could

cause your hands to come into contact with

the wheel.

7) The workpiece gets hot during grinding. Do

not touch the machined area, allow it to cool

down. There is a risk of burning. Do not use

coolants or the like.

8) Do not work with the product, if you are tired

or have consumed alcohol or tablets. Always

have a break on time.

9) Turn off the product and, before doing any

servicing, remove the battery pack.

Vibration and noise reduction

To reduce the impact of noise and vibration

emission, limit the time of operation, use lowvibration and low-noise operating modes as well

as wear personal protective equipment.

Take the following points into account to minimise

the vibration and noise exposure risks:

¾ Only use the product as intended by its

design and these instructions.

¾ Ensure that the product is in good condition

and well maintained.

17 GB/CY

¾ Use correct accessory tools for the product

and ensure they are in good condition.

¾ Keep tight grip on the handles / grip surface.

¾ Maintain this product in accordance with

these instructions and keep it well lubricated

(where appropriate).

¾ Plan your work schedule to spread any high

vibration tool use across a longer period of

time.

Behaviour in emergency

situations

Familiarise yourself with the use of this product by

means of this instruction manual. Memorise the

safety warnings and follow them to the letter. This

will help to prevent risks and hazards.

¾ Always be alert when using this product,

so that you can recognise and handle risks

early. Fast intervention can prevent serious

injury and damage to property.

¾ Switch the product off and disconnect it from

the mains if there are malfunctions. Have the

product checked by a qualified professional

and repaired, if necessary, before you

operate it again.

Residual risks

Even if you are operating this product in

accordance with all the safety requirements,

potential risks of injury and damage remain. The

following dangers can arise in connection with the

structure and design of this product:

¾ Health defects resulting from vibration

emission if the product is being used over

long periods of time or not adequately

managed and properly maintained.

¾ Injuries and damage to property due to

broken accessory tools or the sudden impact

of hidden objects during use.

¾ Danger of injury and property damage

caused by flying objects.

NOTE

u This product produces an electromagnetic

field during operation! This field may

under some circumstances interfere with

active or passive medical implants! To

reduce the risk of serious or fatal injury, we

recommend persons with medical implants

to consult their doctor and the medical

implant manufacturer before operating this

product!

18 GB/CY

Battery charger safety

warnings

¾ This appliance can be used

by children aged from 8 years

and above and persons with

reduced physical, sensory

or mental capabilities or

lack of experience and

knowledge if they have

been given supervision or

instruction concerning use of

the appliance in a safe way

and understand the hazards

involved.

Children shall not play with the

appliance.

Cleaning and user

maintenance shall not be made

by children without supervision.

¾ Do not charge non-

rechargeable batteries.

Disregarding this instruction is

hazardous.

¾ If the supply cord is damaged,

it must be replaced by the

manufacturer, its service agent

or similarly qualified persons in

order to avoid a hazard.

¾ Protect the electrical parts

against moisture. Do not

immerse such parts in water

or other liquids to avoid

electrical shock. Never hold

the appliance under running

water. Pay attention to the

instructions provided for

cleaning, maintenance and

repair.

¾ The appliance is suitable for

indoor use only.

¾ ATTENTION! This charger is

only designed for charging the

battery pack types:

Parkside 20 V

battery pack

PAP 20 A1 2 Ah 5 cells

PAP 20 A2 3 Ah 10 cells

PAP 20 A3 4 Ah 10 cells

¾ An up-to-date list of battery

compatibility can be found at

www.lidl.de/akku.

19 GB/CY

Before first use

Accessories

To operate this product safely and correctly, the

following accessories, i.e. tools and accessory

tools, are necessary:

¾ Grinding wheel

¾ Abrasive cutting wheel

¾ Guard for cutting

¾ Cross tip screwdriver

¾ Wire brush

Accessories and accessory tools are available

through your authorised dealer. When buying

always consider the technical requirements of this

product (see “Technical data”).

If you are not certain, ask a qualified specialist

and get advice from your trusted dealer.

NOTE

u This instruction manual contains

information and suggestions for several

accessory tools and their uses. The

accessory tools depicted are not included

in the shipment (see “Scope of delivery”),

but are meant to indicate additional

possibilities for using this product.

Operation

Attaching/removing the

battery pack

¾ Removing the battery pack: Press the

battery pack release button

battery pack

¾ Attaching the battery pack: Align the

battery pack

into it. Ensure it clicks noticeably in place.

The battery pack can only be inserted into

the product in one direction.

(Fig. D).

5

to the handle and slide it

5

. Remove the

15

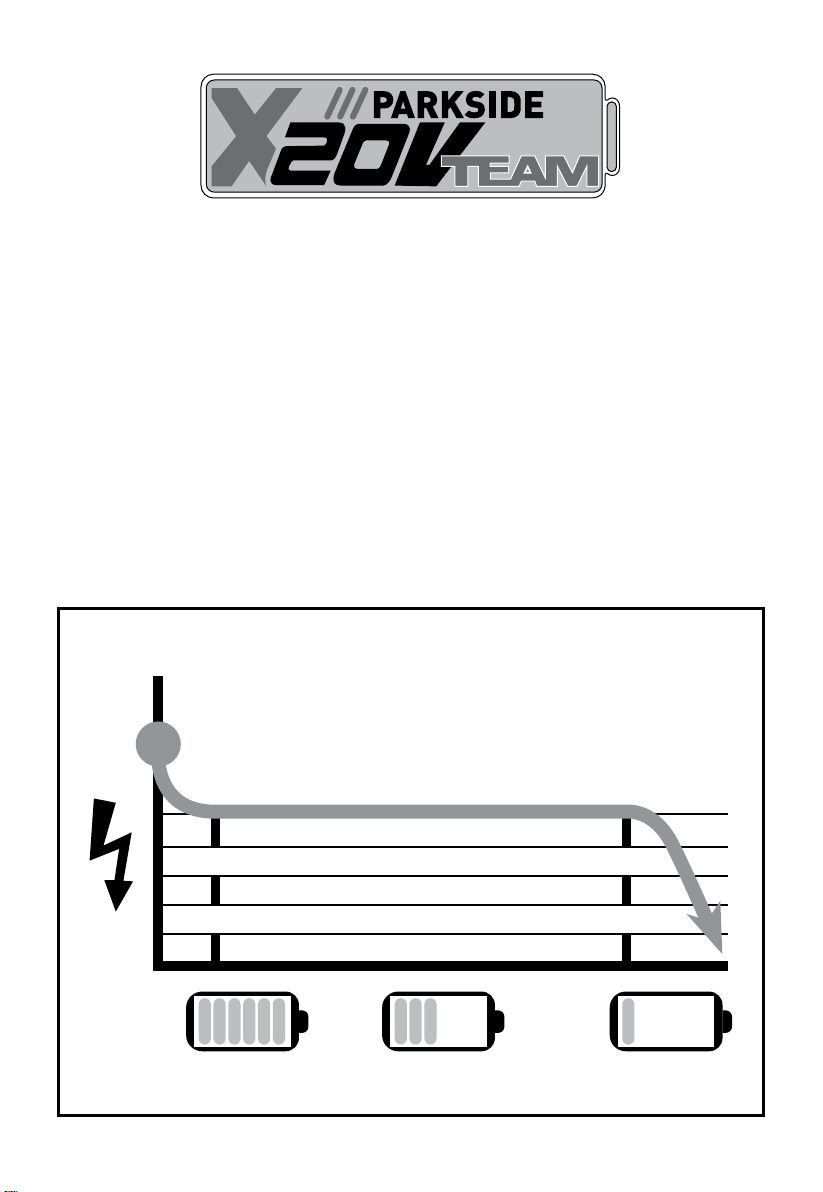

Checking the battery pack

charging level

(Fig. B)

¾ Check battery pack charge level: Press the

16 button. The charging level LEDs 17

light up:

LED

17

Red / orange / green Maximum

Red / orange Medium

Red Low

Charging level

Charging the battery pack

(Fig. C)

WARNING!

m

u Do not use accessories not recommended

by Parkside. This may result in electric

shock or fire.

Suitable battery packs and chargers

Battery

pack:

Charger:

20 GB/CY

Parkside 20 V battery pack

PAP 20 A1, PAP 20 A2, PAP 20 A3

Parkside 20 V charger PLG 20 A1,

PLG 20 A2, PLG 20 B1, PLG 20 A3

NOTE

u The battery pack

any time without reducing the life.

u Interrupting the charging process does not

damage the battery pack

¾ Charge the battery pack

operation when it is at medium or low

charging level.

may be charged at

5

.

5

before

5

¾ The charging control LEDs (green 20 and

red

) indicate the status of the charger 18

21

and the battery pack

LED Status

Red LED lights up Battery pack

Green LED lights up Battery pack fully

Green and red LED

flashing

Red LED flashing Battery pack too

Green LED lights up

(without battery pack)

¾ Insert the battery pack

.

18

¾ Connect the power cord with power plug

of the charger

¾ When the battery pack

Remove the battery pack from the charger

. Then disconnect the power cord with

18

power plug

socket.

18

of the charger from the

19

:

5

charges

charged

Battery pack

defective

cold or too warm

Charger ready

into the charger

5

to the socket.

is fully charged:

5

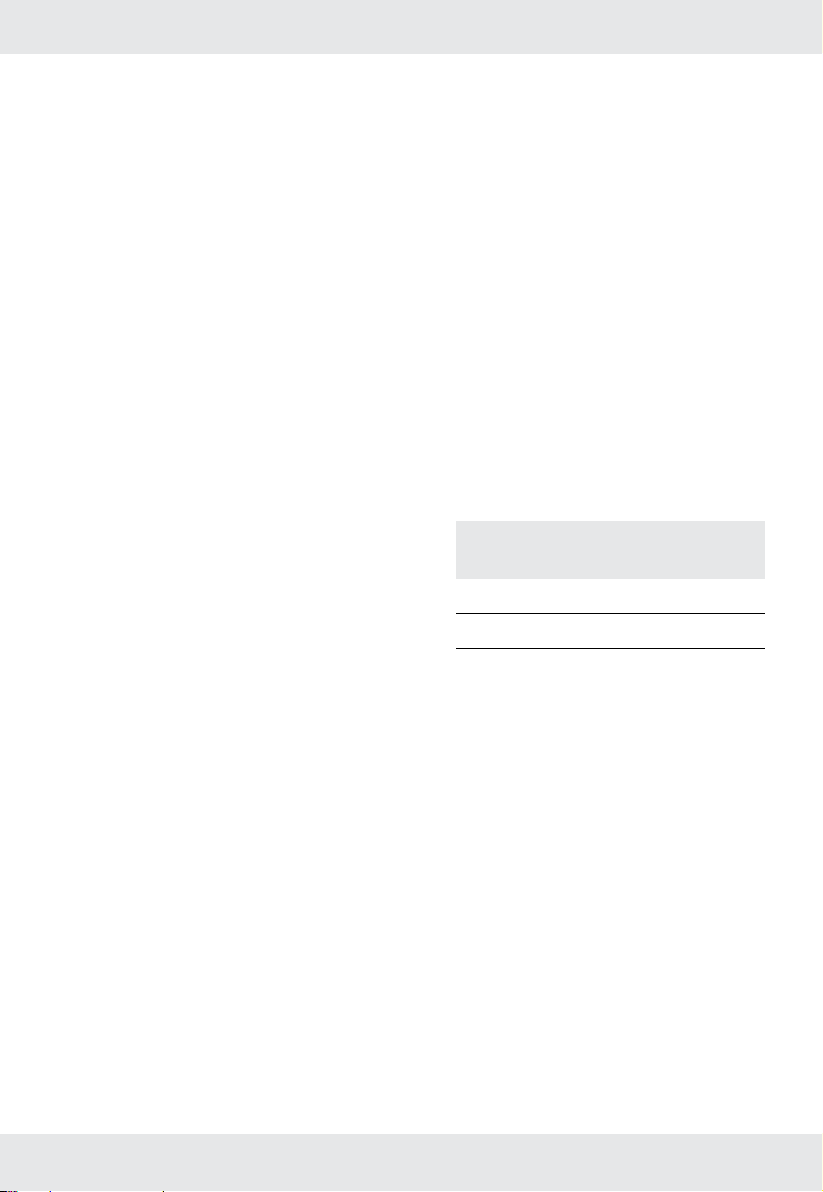

Attaching/removing the

auxiliary handle

(Fig. E)

NOTE

u The product may only be operated with

the auxiliary handle

6

fitted.

19

Adjusting the guard

(Fig. F)

WARNING!

m

Before adjusting the guard for grinding

: Switch the product off. Remove

8

the battery pack

to prevent the product from starting

unintentionally. Let the product cool

down before making any adjustments!

CAUTION! RISK OF INJURY!

m

Wear protective gloves. Be careful

when handling the guard for grinding

as there is a pinching hazard

8

between the guard and the wheel.

NOTE

u The product must only be operated with

the guard mounted.

¾ Adjust the guard for grinding

any sparks or detached parts cannot hit

either the user or any bystanders.

¾ The guard for grinding

positioned such that the sparks cannot ignite

combustible parts, including those in the

surroundings.

¾ Turn the guard for grinding

required position. The clamp must engage in

one of the guard’s notches.

5

8

from the product

such that

8

must also be

to the

8

¾ Screw the auxiliary handle

on the type of work, to the left (a), right (b)

or on the top (c) of the product using the

auxiliary handle threads

, depending

6

.

2

21 GB/CY

Changing the guard

NOTE

u For cut-off grinding, you must disassemble

the supplied guard for grinding

for grinding work and fit a separately

available guard for cutting-off work.

u This guard must be suitable for cutting-off

work and can be ordered via our customer

service (article number HG03642).

8

¾ Reinsert backing flange

and locking flange

order.

NOTE

u A chuck key

auxiliary handle

used (in addition to the tightening tab) to

loosen or tighten the locking flange

is stored inside the

7

, accessory tool

11

: Proceed in reverse

12

. The chuck key can be

6

12

.

WARNING!

m

Before changing the guard for grinding

: Switch the product off. Remove

8

the battery pack

to prevent the product from starting

unintentionally. Let the product cool

down before making any adjustments!

¾ Press and hold the spindle lock button

Lift up and rotate the tightening tab in a

counter-clockwise direction. Release the

spindle lock button (Fig. G).

¾ Remove the current accessory tool (if

applicable) and the backing flange

(Fig. H).

¾ Loosen the cover with clamp’s

until the guard for grinding

removed. It is not necessary to remove the

screws (Fig. I).

¾ Insert a new guard. The clamp must engage

in one of the guard’s notches. Retighten the

3 screws.

¾ Check whether the guard can be adjusted

(Fig. F).

from the product

5

3 screws

13

can be

8

11

.

1

.

Attaching/removing the

accessory tool

WARNING!

m

Always switch the product off, remove

the battery pack

product cool down before making any

adjustments!

CAUTION! RISK OF INJURY!

m

u Keep your hands away from the accessory

tool when the product is in operation.

CAUTION! RISK OF INJURY!

m

u After the product has been switched off,

the accessory tool continues moving for

some time. Do not touch the accessory tool

and do not attempt to brake it.

WARNING!

m

u Never press the spindle lock button

whilst the spindle

u The arrow direction on the accessory tool

must be aligned with the directional arrow

(

or 14).

9

and let the

5

is rotating!

10

1

22 GB/CY

CAUTION! RISK OF INJURY!

m

u Only use accessory tools recommended

by the manufacturer. Using other

accessory tools and other accessories can

represent a risk of injury for you.

u Only use accessory tools, which bear

information about the manufacturer, type

of binding, dimension and permitted

number of revolutions.

u Only use accessory tools where the

printed rotational speed is at least as high

as what has been specified on the product

marking.

u Do not use any broken, cracked, or

otherwise damaged accessories.

u Only use flawless accessory tools.

u Ensure that the accessory tool dimensions

match those of the product.

u Never re-drill a locating hole which is too

small to make it larger.

u Never use separate bushings or adaptors

in order to make wheels with a hole that is

too large fit the product.

u Support plates or workpieces to reduce

the risk of kickback from a jammed wheel.

Large workpieces may bend under their

own weight. The workpiece must be

supported on both sides of the wheel, near

the wheel as well as at the edge.

¾ Release the locking flange

hold the spindle lock button

and rotate the tightening tab in a counterclockwise direction. Release the spindle lock

button (Fig. G).

¾ If applicable, remove the current accessory

tool.

¾ Mount the desired accessory tool onto the

backing flange

¾ Press and hold the spindle lock button

Lift up the tightening tab. Thread the locking

flange

the tightening tab to tighten the accessory

tool securely. Push down the tightening tab.

Release the spindle lock button.

in a clockwise direction. Use

12

(Fig. H).

11

: Press and

12

. Lift up

1

1

Switching on and off

CAUTION! RISK OF INJURY!

m

Always wear protective gloves when

handling or working with the product.

CAUTION! RISK OF INJURY!

m

u Always hold the product with both hands

while working (Fig. J).

CAUTION! RISK OF INJURY!

m

u Keep your hands away from the accessory

tool when the product is in operation.

.

CAUTION! RISK OF INJURY!

m

u After the product has been switched off,

the accessory tool continues moving for

some time. Do not touch the accessory tool

and do not attempt to brake it.

23 GB/CY

CAUTION! HEALTH RISK!

m

u Never work on materials containing

asbestos. Asbestos is considered

carcinogenic.

¾ Switching on: Push the rear part of the

on/off switch

(Fig. K, 1&2).

Continuous operation: Tilt the front part

of the on/off switch

engages (Fig. K, 3).

¾ Switching off: Press the rear part of the

on/off switch

off position.

down and slide it forward.

3

downwards until it

3

so that it snaps back into its

3

Trial run

NOTE

u Always carry out a no-load trial run before

starting work and after every accessory

tool replacement. Switch the product off

immediately if the accessory tool is not

running smoothly, if considerable vibration

occurs or if you hear abnormal noises.

Working instructions

Grinding

WARNING!

m

u Never use a cutting wheel for grinding!

¾ Hold the product at a 10 to 15° angle for

easy handling and smooth grinding results.

¾ Apply the grinding wheel to the work surface

with a light, steady pressure for maximum

grinding efficiency. It should never be

necessary to force the product. The weight of

the product applies adequate pressure.

¾ Excessive pressure will overload the motor,

slow the grinding action, put dangerous

stress on the grinding wheel and causes

breakage.

¾ Move the product back and forth steadily.

Wire brushing

WARNING!

m

u Do not use a brush that is damaged,

or which is out of balance. Use of a

damaged brush could increase potential

for injury from contact with broken brush

wires.

¾ Avoid applying too much pressure which

causes over bending of wires, leading to

premature breakage.

¾ Work with moderate feed, suited to the

material being worked.

¾ Avoid bouncing and snagging the wire

brush, especially when working corners,

sharp edges etc. This can cause loss of

control and kick-back.

Abrasive cutting

WARNING!

m

u Never use grinding wheels for cutting!

When using a cutting wheel, the guard for

cutting must be used when operating the

power tool.

24 GB/CY

¾ Only use tested, fibre reinforced cutting or

grinding wheels.

¾ Always work at a low forward speed. Apply

only moderate pressure to the workpiece.

¾ Always use up (conventional) milling. This

will prevent loss of the product when it leaves

the cut.

Cleaning and care

WARNING!

m

Always switch the product off, remove

the battery pack

product cool down before performing

inspection, maintenance and cleaning

work!

and let the

5

Cleaning

¾ Never allow fluids to get into the product.

¾ The product must always be kept clean, dry

and free from oil or grease. Remove debris

from it after each use and before storage.

¾ Regular and proper cleaning will help ensure

safe use and prolong the life of the product.

¾ Clean the product with a dry cloth. Use a

soft brush for areas that are hard to reach.

¾ In particular clean the air vents after every

use with a cloth and soft brush.

¾ The vents must always be clear.

NOTE

u Do not use chemical, alkaline, abrasive

or other aggressive detergents or

disinfectants to clean this product as they

might be harmful to its surfaces.

Maintenance

¾ The product is maintenance-free.

¾ Before and after each use, check the product

and accessories (e.g. accessory tools) for

wear and damage. If required, exchange

them for new ones as described in this

instruction manual. Observe the technical

requirements (see “Technical data”).

Repair

This product does not contain any parts that can

be repaired by the user. Contact an authorised

service centre or a similarly qualified person to

have it checked and repaired.

Storage

¾ Switch the product off.

¾ Clean the product as described above.

¾ Store the product and its accessories in a

dark, dry, frost-free, well-ventilated place.

¾ Always store the product in a place that is

inaccessible to children. The ideal long term

storage (longer than 3 months) temperature

is between +20 and +26 °C.

¾ Store the product in its case

¾ Grinding wheels must be dry and stored

upright, and should never be stacked.

22

.

25 GB/CY

Battery pack advice

¾ Only store the battery pack

charged. The battery pack should be

charged to 40 to 60 % (red and orange LED

in the charge indicator

storing for extended periods.

¾ Check the battery pack

every 3 months when storing for extended

periods. Recharge as necessary.

partially

5

light up) before

17

charge about

5

Transportation

¾ Switch the product off.

¾ Transport the product in its carrying case

¾ Protect the product from any heavy impact

or strong vibrations which may occur during

transportation in vehicles.

¾ Secure the product to prevent it from slipping

or falling over.

Disposal

The packaging is made entirely of recyclable

materials, which you may dispose of at local

recycling facilities.

Observe the marking of the packaging

materials for waste separation, which

are marked with abbreviations (a) and

numbers (b) with following meaning:

1 – 7: plastics / 20 – 22: paper and

fibreboard / 80 – 98: composite

materials

The product and packaging materials

are recyclable, dispose of it separately

for better waste treatment.

The Triman logo is valid in France only.

Contact your local refuse disposal

authority for more details of how to

dispose of your worn-out product.

To help protect the environment, please

dispose of the product properly when

it has reached the end of its useful

life and not in the household waste.

Information on collection points and

their opening hours can be obtained

from your local authority.

Faulty or used batteries / rechargeable batteries

must be recycled in accordance with Directive

2006/66/EC and its amendments. Please return

the batteries / rechargeable batteries and / or

the product to the available collection points.

.

22

Environmental damage

through incorrect disposal of

the batteries / rechargeable

batteries!

Before disposal: Remove the battery pack from

the product.

Warranty

The product has been manufactured to strict

quality guidelines and meticulously examined

before delivery. In the event of product defects

you have legal rights against the retailer of this

product. Your legal rights are not limited in any

way by our warranty detailed below.

The warranty for this product is 5 years from the

date of purchase. Should this product show any

fault in materials or manufacture within 5 years

from the date of purchase, we will repair or

replace it – at our choice – free of charge to you.

The warranty period begins on the date of

purchase. Please keep the original sales receipt

in a safe location. This document is required as

your proof of purchase. This warranty becomes

void if the product has been damaged, or used or

maintained improperly.

26 GB/CY

The warranty applies to defects in material

or manufacture. This warranty does not cover

product parts subject to normal wear, thus

possibly considered consumables (e. g. batteries)

or for damage to fragile parts, e. g. switches,

rechargeable batteries or glass parts.

The warranty for the battery pack is 1 year from

the date of purchase.

Service

Service Great Britain

Tel.: 0800 404 7657

E-Mail: owim@lidl.co.uk

Service Cyprus

Tel.: 8009 4409

E-Mail: owim@lidl.com.cy

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

Please have the till receipt and the item number

(e.g. IAN 123456_7890) available as proof of

purchase.

You will find the item number on the type plate,

an engraving on the front page of the instructions

(bottom left), or as a sticker on the rear or bottom

of the appliance.

If functional or other defects occur, please contact

the service department listed either by telephone

or by e-mail.

You can return a defective product to us free

of charge to the service address that will be

provided to you. Ensure that you enclose the proof

of purchase (till receipt) and information about

what the defect is and when it occurred.

Serbian mark of conformity

27 GB/CY

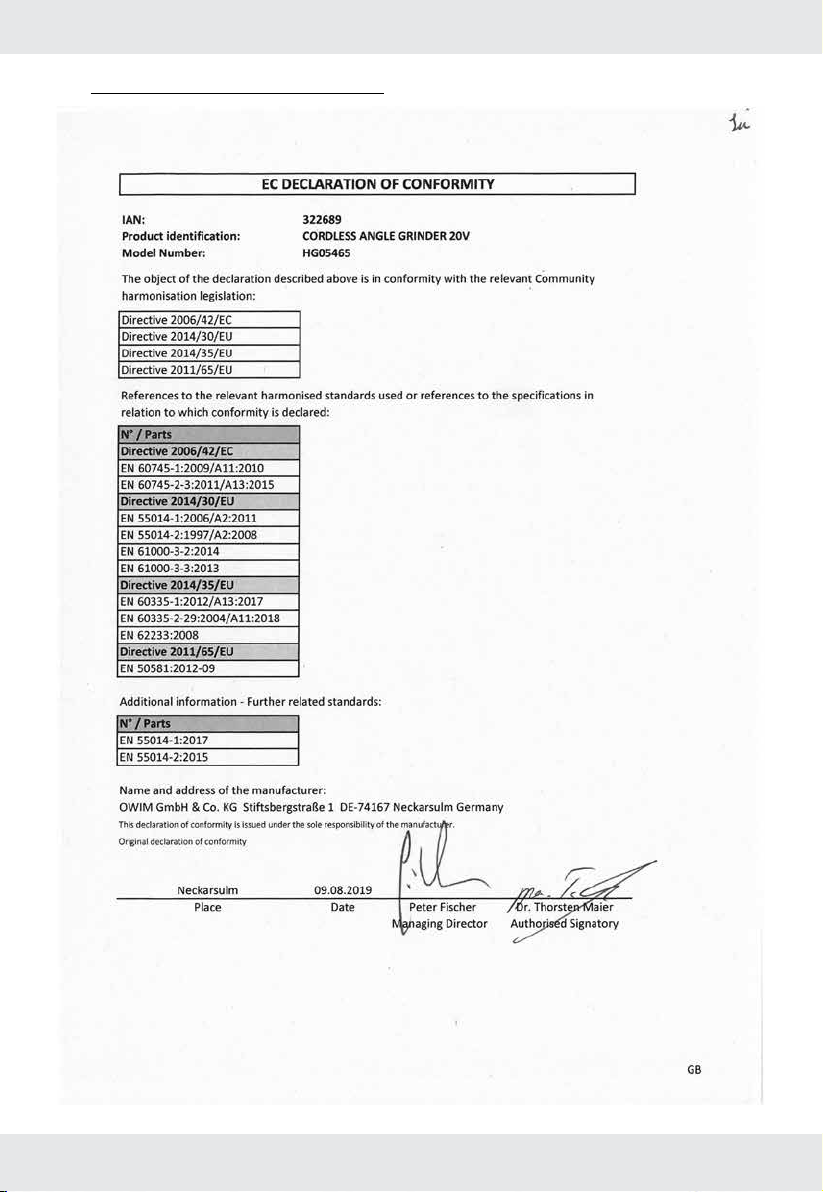

EC declaration of conformity

28 GB/CY

Korištene upozoravajuće napomene i simboli......................Stranica 30

Uvod .................................................................Stranica 30

Uvjeti korištenja .......................................................Stranica 30

Sadržaj isporuke ......................................................Stranica 31

Opis dijelova .........................................................Stranica 31

Tehnički podaci .......................................................Stranica 31

Sigurnosne upute ....................................................Stranica 33

Opće sigurnosne napomene za električne alate ..............................Stranica 33

Sigurnosne napomene za brusilice ........................................Stranica 36

Sigurnosne napomene za kutne brusilice....................................Stranica 36

Smanjenje vibracija i zvukova ............................................Stranica 41

Ponašanje u slučaju opasnosti ............................................Stranica 42

Ostali rizici...........................................................Stranica 42

Sigurnosne smjernice za punjače..........................................Stranica 43

Prije prve uporabe ..................................................Stranica 44

Dodatna oprema ......................................................Stranica 44

Korištenje ............................................................Stranica 44

Uklanjanje/umetanje baterijskog modula ...................................Stranica 44

Provjera stanja napunjenosti baterijskog modula..............................Stranica 44

Punjenje baterijskog modula .............................................Stranica 44

Stavljanje/skidanje dodatne ručke ........................................Stranica 45

Namještanje zaštitnog poklopca ..........................................Stranica 45

Zamjena zaštitne ploče .................................................Stranica 46

Umetanje/vađenje opreme ..............................................Stranica 46

Uključivanje i isključivanje ...............................................Stranica 47

Probni rad ...........................................................Stranica 48

Upute za rad.........................................................Stranica 48

Brušenje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stranica 48

Žičane četke..........................................................Stranica 48

Rezanje brušenjem.....................................................Stranica 48

Čišćenje i njega ......................................................Stranica 49

Čišćenje .............................................................Stranica 49

Održavanje ..........................................................Stranica 49

Popravak ............................................................Stranica 49

Skladištenje ..........................................................Stranica 49

Transport ............................................................Stranica 50

Zbrinjavanje .........................................................Stranica 50

Jamstvo ..............................................................Stranica 50

EC Izjava o sukladnosti ..............................................Stranica 52

29 HR

Korištene upozoravajuće napomene i simboli

U ovim uputama za uporabu, na pakiranju i na tipskoj pločici korištene su sljedeće upozoravajuće

napomene:

Prije zamjene pribora, čišćenja te ako ga

Pročitajte upute za uporabu.

ne upotrebljavate, isključite proizvod i

izvadite baterijski modul.

Pazite na upozorenja i sigurnosne

napomene!

Proizvod upotrebljavajte samo u suhim

prostorijama.

Nosite zaštitne rukavice! Zaštitite baterijski modul od vatre.

Nosite zaštitu sluha! Razred zaštite II (dvostruka izolacija)

Nosite zaštitne naočale!

AKU KUTNA BRUSILICA 20 V

PWSAP 20-Li B2

Uvod

Čestitamo vam na kupnji novog proizvoda.

Ovom kupnjom odlučili ste se za visokokvalitetan

proizvod. Uputa za uporabu je sastavni dio ovog

proizvoda. Ona sadrži važne upute o sigurnosti,

uporabi i uklanjanju otpada. Prije upotrebe

proizvoda upoznajte se sa svim njegovim

uputama za korištenje i sigurnosnim uputama.

Koristite ovaj proizvod u skladu s navedenim

uputama te u navedene svrhe. Ukoliko proizvod

dajete nekoj drugoj osobi, predajte toj osobi

također i sve upute.

Zaštitite baterijski modul od topline i

trajnog, jakog sunčevog svjetla.

maks. 45 °C

Zaštite baterijski modul od vode i vlage.

Izmjenična struja

Istosmjerna struja

T3.15A

Fini osigurač

Uvjeti korištenja

Ova baterijska kutna brusilica (u nastavku:

„proizvod“ ili „električni alat”) predviđena je za

¾ Rezanje brušenjem,

¾ suho brušenje metala/betona/keramike i

¾ žičano četkanje

metala.

Proizvod nije predviđen za druge primjene

(npr. Brušenje neprikladnim brusnim alatima,

brušenje s rashlađivačima, brušenje ili rezanje

opasnih materijala poput azbesta) koje nisu ovdje

navedene.

30 HR

Ovaj proizvod nije prikladan za brušenje brusnim

papirom ni poliranje.

Rezanje brušenjem: Za taj zadatak mora se

ugraditi poseban zaštitni poklopac. Zaštitni

poklopac može se naručiti preko naše Korisničke

službe (kataloški broj HG03642).

Opremu uvijek koristite u skladu s namjenom! Pri

kupnji i uporabi opreme uvijek obratite pažnju na

tehničke specifikacije proizvoda (vidi poglavlje

„Tehnički podatci“).

Druge uporabe ili izmjene proizvoda smatraju se

nenamjenskima i mogu uzrokovati rizike kao što su

opasnost po život, ozljede i oštećenja. Proizvođač

ne preuzima nikakvu odgovornost za štete nastale

od nenamjenske uporabe. Ovaj proizvod nije

namijenjen za komercijalnu ili drugu uporabu.

Opis dijelova

Slika A:

Tipka za blokadu vretena

1

Navoj dodatne ručke

2

Prekidač za uključivanje/isključivanje

3

Ručka

4

Baterijski modul

5

Dodatna ručka (s prostorom za držanje

6

steznog ključa)

Stezni ključ

7

Zaštitni poklopac za radove brušenja

8

Strelica smjera okretanja (na zaštitnom

9

poklopcu)

Vreteno

10

Potporna prirubnica

11

Stezna prirubnica (s pričvrsnim jezičkom)

12

Pokrov sa stezaljkom

13

Strelica smjera okretanja (na kutnoj brusilici)

14

Sadržaj isporuke

UPOZORENJE!

m

u Proizvod i ambalažni materijal nisu

igračke! Djeca se ne smiju igrati plastičnim

vrećicama, folijama ni sitnim dijelovima!

Postoji opasnost od gutanja i gušenja!

1 x Aku kutna brusilica 20 V PWSAP 20-Li B2

1 x Dodatna ručka

1 x Zaštitni poklopac za radove brušenja

(prethodno ugrađen) *

1 x Stezni ključ (nalazi se u dodatnoj ručki)

1 x Baterijski modul PAP 20 A3

1 x Punjač za brzo punjenje PLG 20 B1

1 x Kućište za prenošenje

1 x Upute za uporabu

* Zaštitni poklopac za brušenje i rezanje nije

isporučen i može se naručiti preko naše

Korisničke službe.

Slika B:

Baterijski modul

5

Tipka za deblokadu baterijskog modula

15

Tipka (razina punjenja)

16

LED lampice stanja napunjenosti (crvena/

17

narančasta/zelena)

Slika C:

Punjač (uređaj za brzo punjenje)

18

Priključni kabel s mrežnim utikačem

19

LED lampica za kontrolu punjenja – Zelena

20

LED lampica za kontrolu punjenja – Crvena

21

Nije na slici:

Kućište za prenošenje

22

Tehnički podaci

Baterijska kutna

brusilica

Nazivni napon: 20 V

Nazivni broj okretaja n: 10000 min

Promjer opreme: Ø 125 mm

Debljina ploče: maks. 8 mm

Navoj vretena: M14

PWSAP

20-Li B2

–1

31 HR

Baterijski modul PAP 20 A3

Tip: Litij-ion

Nazivni napon: 20 V

maks.

Kapacitet: 4 Ah

Energetska vrijednost: 72 Wh

Broj ćelija baterije: 10

Punjač za brzo punjenje PLG 20 B1

Ulaz:

Nazivni napon: 230–240 V∼

Nazivna frekvencija: 50 Hz

Nazivni napon: 120 W

Izlaz:

Nazivni napon: 21,5 V

Struja punjenja: 4,5 A

Razred zaštite:

Osigurač (interni):

II /

3,15 A /

Vrijeme punjenja:

¾ Baterijski tip PAP 20 A3, 4,0 Ah

(isporučeno): 60 minuta

¾ Baterijski tip PAP 20 A1, 2,0 Ah

(dostupno zasebno): 45 minuta

Preporučena okolna temperatura:

Tijekom punjenja: +4 do +40 °C

Tijekom rada: +4 do +40 °C

Tijekom skladištenja: +20 do +26 °C

Vrijednosti emisije buke

Izmjerene vrijednosti utvrđene su sukladno normi

EN 60745. Standardna procijenjena razina buke

A električnog alata:

Razina zvučnog tlaka L

Nesigurnost K

: 3 dB

pA

Razina zvučnog tlaka L

Nesigurnost K

WA

: 81,6 dB(A)

pA

: 92,6 dB(A)

WA

: 3 dB

Vrijednosti emisije vibracija

Ukupne vrijednosti vibracija (zbroj vektora triju

smjerova), utvrđeno prema normi EN 60745:

Glavna ručka:

Vibracija šake/ruke a

: 4,27 m/s²

h,AG

Nesigurnost K: 1,5 m/s²

Dodatna ručka:

Vibracija šake/ruke a

: 5,31 m/s²

h,AG

Nesigurnost K: 1,5 m/s²

Navedene vrijednosti odnose se na površinsko

brušenje. Druge primjene mogu dovesti do

drugačijih vrijednosti emisija vibracija.

UPOZORENJE!

m

Nosite zaštitu sluha!

NAPOMENA

u Navedena ukupna vrijednost vibracija i

navedena vrijednost emisije buke izmjereni

su prema normiranom postupku provjere

i mogu se koristiti za uspoređivanje

električnog alata s nekim drugim.

u Navedena ukupna vrijednost vibracija i

navedena vrijednost emisija buke mogu

se koristiti i za prethodnu procjenu

opterećenja.

32 HR

UPOZORENJE!

m

u Emisije vibracija i buke mogu tijekom

stvarne uporabe električnog alata

odstupati od navedenih vrijednosti, ovisno

o načinu uporabe električnog alata, a

posebice o vrsti obratka.

Opterećenje vibracijama i buku pokušajte

održati čim manjima. Primjer mjera

koje služe za smanjenje opterećenja

vibracijama jesu nošenje rukavica pri

uporabi alata i ograničenje vremena rada.

Pritom u obzir valja uzeti sve dijelove

radnog ciklusa (primjerice vremena

u kojima je električni alat isključen te

vremena u kojima je uključen, ali radi bez

opterećenja).

Sigurnosne upute

Opće sigurnosne napomene

za električne alate

UPOZORENJE!

m

u Pročitajte sve sigurnosne

napomene i upute. Propusti u

pridržavanju sigurnosnih napomena i

uputa mogu uzrokovati električni udar,

požar i/ili teške ozljede.

Sve sigurnosne savjete u i upute čuvajte

na sigurnom mjestu radi buduće

uporabe.

Pojam „električni alat“, koji se upotrebljava

u sigurnosnim napomenama, odnosi se na

električne alate koji rade na mrežni pogon (s

mrežnim kabelom) kao i na električne alate s

pogonom na punjive baterije (bez mrežnog

kabela).

Sigurnost na mjestu rada

1) Mjesto rada održavajte urednim

i dobro osvijetljenim. Nered ili

neosvijetljena područja rada mogu

uzrokovati nesreće.

2) Električnim alatom nemojte

raditi u prostorima ugroženima

eksplozivnom atmosferom u kojima

se nalaze zapaljive tekućine, plinovi

ili prašine. Električni alati stvaraju iskre

koje mogu zapaliti prašinu ili pare.

3) Djecu i ostale osobe držite podalje

tijekom uporabe električnog

alata. Ako se dekoncentrirate, možete

izgubiti kontrolu nad električnim alatom.

Električna sigurnost

1) Priključni utikač električnog

alata mora odgovarati u utičnicu.

Utikač se ne smije mijenjati ni na

koji način. Zajedno s električnim

alatima sa zaštitnim uzemljenjem

nemojte upotrebljavati adapterske

utikače. Nepromijenjeni utikači i

odgovarajuće utičnice smanjuju opasnost od

električnog udara.

33 HR

2) Izbjegavajte dodir tijela s

uzemljenim površinama kao što su

površine cijevi, grijanja, štednjaka

i hladnjaka. Ako vam je tijelo uzemljeno,

postoji povećana opasnost od električnog

udara.

3) Električne alate držite podalje od

kiše ili vlage. Prodiranje vode u električni

alat povećava opasnost od električnog

udara.

4) Kabel nemojte upotrebljavati za

nošenje i vješanje električnog alata

niti za povlačenje utikača iz utičnice.

Kabel držite podalje od vrućine,

ulja, oštrih bridova ili pokretljivih

dijelova uređaja. Oštećeni ili zapetljani

kabeli povećavaju opasnost od električnog

udara.

5) Ako s električnim alatom radite na

otvorenom, upotrebljavajte samo

produžne kabele koji su prikladni

za eksterijere. Uporaba produžnog

kabela prikladnog za eksterijere smanjuje

opasnost od električnog udara.

6) Ako nije moguće izbjeći rad

električnog alata u vlažnoj okolini,

upotrijebite zaštitnu sklopku od

struje kvara. Uporaba zaštitne sklopke

od struje kvara smanjuje opasnost od

električnog udara.

Sigurnost ljudi

1) Uvijek budite oprezni, pazite što

radite i budite razumni pri radu

električnim alatom. Električni alat

nemojte upotrebljavati ako niste

koncentrirani ili ste umorni odnosno

ako ste pod utjecajem droga,

alkohola ili lijekova. Već samo jedan

trenutak nepažnje pri uporabi električnog

alata može uzrokovati ozbiljne ozljede.

2) Nosite osobnu zaštitnu opremu te

uvijek i zaštitne naočale. Nošenje

osobne zaštitne opreme kao što su maska za

prašinu, protuklizne zaštitne cipele, zaštitna

kaciga ili zaštita sluha, ovisno o vrsti i

primjeni električnog alata, smanjuje opasnost

od ozljeda.

3) Izbjegavajte slučajno puštanje u

rad. Prije nego što električni alat

priključite na naponsko napajanje

i/ili punjivu bateriju, prije nego što

ga uzmete ili nosite, uvjerite se da

je isključen. Ako su vam pri nošenju

električnog alata prsti na sklopci ili ako je

uređaj već uključen kad ga priključujete na

naponsko napajanje, postoji opasnost od

nesreće.

4) Prije nego što uključite električni

alat, uklonite alat za namještanje

ili francuski ključ. Alat ili ključ, koji se

nalazi u rotirajućem dijelu uređaja, može

uzrokovati ozljede.

34 HR

5) Izbjegavajte neobično držanje

tijela. Pobrinite se za sigurno

stajanje i u svakom trenutku

održavajte ravnotežu. Tako

možete bolje kontrolirati električni alat u

neočekivanim situacijama.

6) Nosite prikladnu odjeću. Nemojte

nositi široku odjeću niti nakit. Kosu,

odjeću i rukavice držite podalje

od pokretljivih dijelova. Lepršava

odjeća, nakit ili duga kosa mogu se uhvatiti u

pokretljive dijelove.

7) Ako je moguće montirati naprave

za usisavanje i skupljanje prašine,

uvjerite se da su priključene i da se

ispravno upotrebljavaju. Uporaba

usisavača može smanjiti ugrozu od prašine.

Uporaba električnog alata i rukovanje

njime

1) Nemojte preopteretiti uređaj.

Upotrebljavajte električni alat koji

je namijenjen za vaše radove. S

odgovarajućim električnim alatom radit

ćete bolje i sigurnije u navedenom području

snage.

2) Nemojte upotrebljavati električni

alat s oštećenom sklopkom. Električni

alat koji se više ne može uključiti ili isključiti

opasan je i valja ga popraviti.

3) Prije nego što obavljate

namještanja na uređaju, mijenjate

dijelove pribora ili odlažete

uređaj, izvucite utikač iz utičnice i/

ili uklonite punjivu bateriju. Ova

mjera opreza sprečava slučajno pokretanje

električnog alata.

4) Električne alate čuvajte izvan

dohvata djece. Nemojte dopustiti

da električni alat upotrebljavaju

osobe koje nisu upoznate s njime ili

koje nisu pročitale upute. Električni su

alati opasni ako ih upotrebljavaju neiskusne

osobe.

5) Oprezno njegujte električne alate.

Provjerite rade li pokretljivi dijelovi

besprijekorno i da nisu prikliješteni,

jesu li dijelovi slomljeni ili oštećeni

tako da je ugrožena funkcija

električnog alata. Prije uporabe

uređaja organizirajte popravak

oštećenih dijelova. Loše održavanje

električnih alata uzrok je mnogih nesreća.

6) Alate za rezanje održavajte oštrima

i čistima. Pomno njegovani alati za

rezanje s oštrim reznim bridovima manje se

zaglavljuju i lakši su za vođenje.

35 HR

7) Električni alat, pribor, opremu itd.

upotrebljavajte u skladu s ovim

uputama. Pritom u obzir uzmite

radne uvjete i radnju koju valja

obaviti. Uporaba električnih alata za

primjene drukčije od predviđenih može

uzrokovati opasne situacije.

Servis

1) Popravljanje električnog alata

prepustite samo kvalificiranom

stručnom osoblju koje će to obaviti

samo s originalnim rezervnim

dijelovima. Tako ćete osigurati trajnu

sigurnost električnog alata.

Uporaba baterijskog alata i rukovanje

njime

1) Punjive baterije punite samo

punjačima koje preporučuje

proizvođač. Kod punjača koji je

prikladan za određenu vrstu punjivih baterija

postoji opasnost od požara ako se koristi s

drugim punjivim baterijama.

2) Za električne alate upotrijebite

samo predviđene punjive

baterije. Uporaba drugih punjivih baterija

može izazvati ozljede i opasnost od požara.

3) Punjivu bateriju koju ne koristite

držite dalje od uredskih spajalica,

kovanica, ključeva, čavala, vijaka ili

drugih sitnih metalnih predmeta koji

bi mogli prouzročiti premošćivanje

kontakata. Kratki spoj između kontakata

punjive baterije može izazvati opekline ili

požar.

4) Kod pogrešne uporabe može doći

do curenja tekućine iz punjive

baterije. Izbjegnite kontakt s njom.

U slučaju nehotičnog kontakta

isperite vodom. Ako tekućina

dospije u oči, potražite dodatnu

liječničku pomoć. Tekućina koja curi iz

punjive baterije može izazvati iritacije kože

ili opekline.

Sigurnosne napomene za

brusilice

UPOZORENJE!

m

u Prašine materijala poput olovnih premaza,

nekih vrsta drveta i metala mogu biti štetne

za zdravlje.

u Dodir ili udisanje tih prašina može ugroziti

osobu koja rukuje alatom ili osobe u

blizini.

UPOZORENJE!

m

Nosite zaštitne naočale i masku za

zaštitu od prašine!

Sigurnosne napomene za

kutne brusilice

Zajedničke sigurnosne napomene za

brušenje, radove sa žičanim četkama i

brušenje i rezanje

1) Ovaj električni alat treba koristiti

kao brusilicu, čeličnu četku i stroj

za odvajanje brušenjem. Uzmite u

obzir sve sigurnosne napomene,

upute, slike i podatke isporučene

s uređajem. Ako ne budete slijedili

navedene upute, može doći do strujnog

udara, požara i/ili teških ozljeda.

36 HR

2) Ovaj električni alat nije prikladan

za brušenje brusnim papirom ni

poliranje. Primjene za koje nije predviđen

električni alat mogu uzrokovati opasnosti i

ozljede.

3) Nemojte upotrebljavati pribor koji

proizvođač nije specijalno predvidio

i preporučio za električni alat. Čak i

kao se pribor može učvrstiti na vaš električni

alat, to ne jamči sigurnu primjenu.

4) Dopušteni broj okretaja radnog

alata mora biti najmanje

jednak najvišem broju okretaja

navedenom na radnom alatu. Pribor

koji se vrti brže od dopuštene brzine može

se slomiti i odletjeti.

5) Vanjski promjer i debljina opreme

moraju odgovarati veličini

vašeg električnog alata. Pogrešno

dimenzionirani radni alat ne može se

dovoljno zaštititi ili kontrolirati.

6) Radni alati s navojnim umetkom

moraju točno odgovarati navoju

brusnog vretena. Kod radnih alata

koji se montiraju s prirubnicom,

promjer rupe radnog alata mora

odgovarati promjeru prihvata

prirubnice. Radni alat, koji ne

pristaje točno na električni alata, vrti se

neravnomjerno, snažno vibrira i može

izazvati gubitak kontrole.

7) Nemojte rabiti oštećen radni alat.

Prije svake primjene radnog alata

provjerite sljedeće: eventualne

razbijene dijelove ili pukotine

na brusnim pločicama, pukotine,

znakove istrošenosti ili jakog

trošenja na brusnim diskovima,

labavih ili slomljenih žica na žičanim

četkama. Ako električni alat ili radni

alat padne, provjerite je li oštećen

ili upotrijebite neoštećeni radni

alat. Ako ste opremu provjerili i

primijenili, vi i druge osobe u blizini

budite izvan ravnine rotirajuće

opreme i ostavite uređaj da radi

1 minutu na maksimalni broj

okretaja. Oštećeni radni alati uglavnom se

lome unutar tog vremena testiranja.

8) Nosite osobnu zaštitnu opremu.

Ovisno o primjeni koristite se

štitnikom čitavog lica, štitnicima

za oči ili zaštitnim naočalama. Ako

je potrebno, nosite masku protiv

prašine, zaštitu sluha, zaštitne

rukavice ili posebnu pregaču koja

će vas zaštititi od malih čestica