Page 1

IAN 90981

ROUTER POF 1200 A1

OBERFRÄSE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

ΚΑΘΕΤΗ ΦΡΕΖΑ

Υποδείξει χειρισού και ασφαλεία

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

ROUTER

Operation and Safety Notes

Translation of original operation manual

Page 2

GB / CY Operation and Safety Notes Page 5

GR / CY Υποδείξει χειρισού και ασφαλεία Σελίδα 15

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 27

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τι δυο σελίδε ε τι εικόνε και εξοικειωθείτε ε όλε τι

λειτουργίε τη συσκευή.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

Page 3

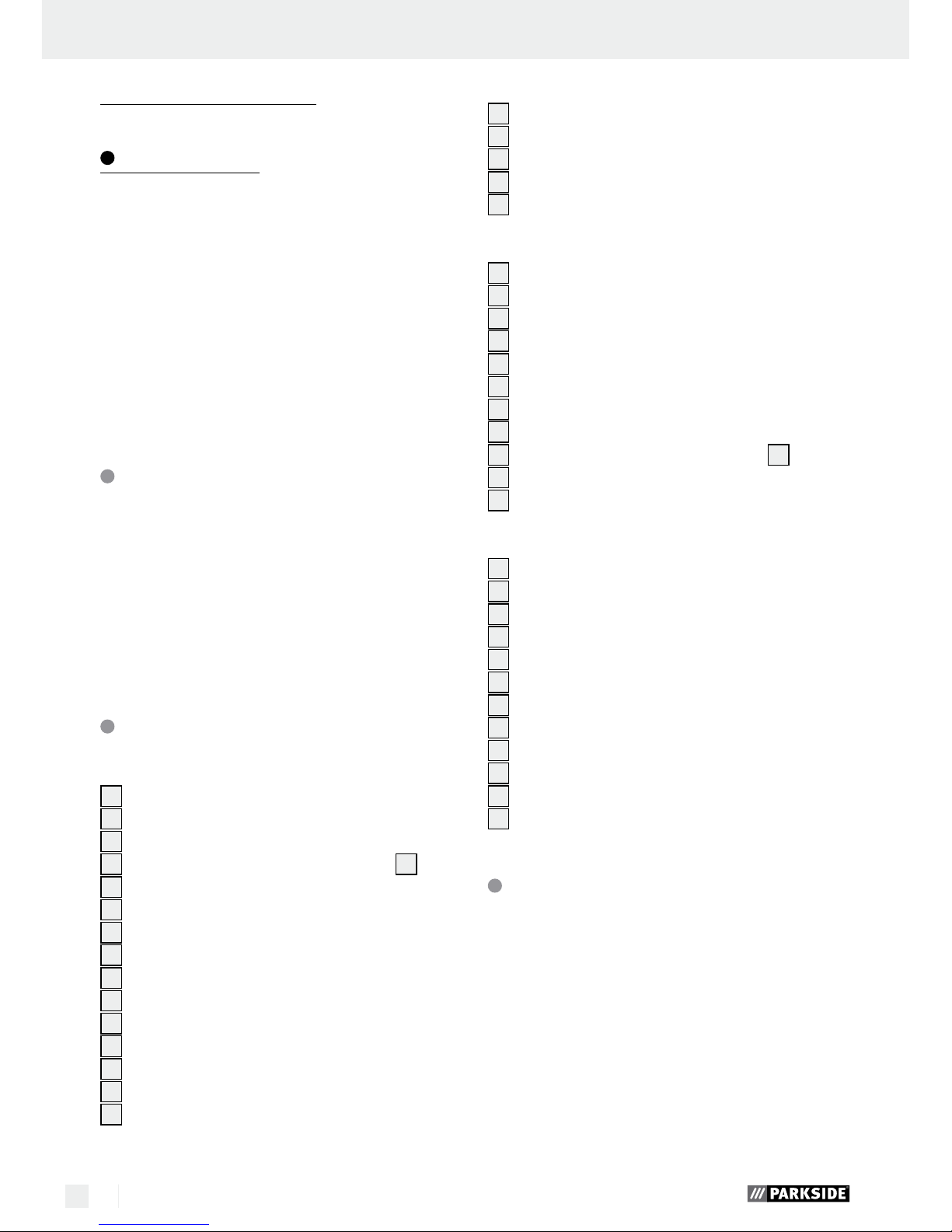

DC

272625242321

A

B

4

5

6

2

3

7

8

9

13

15

10

11

12

14

16

2

18

17

20

19

5

6

26 222522

29

1

22

30 28

31

Page 4

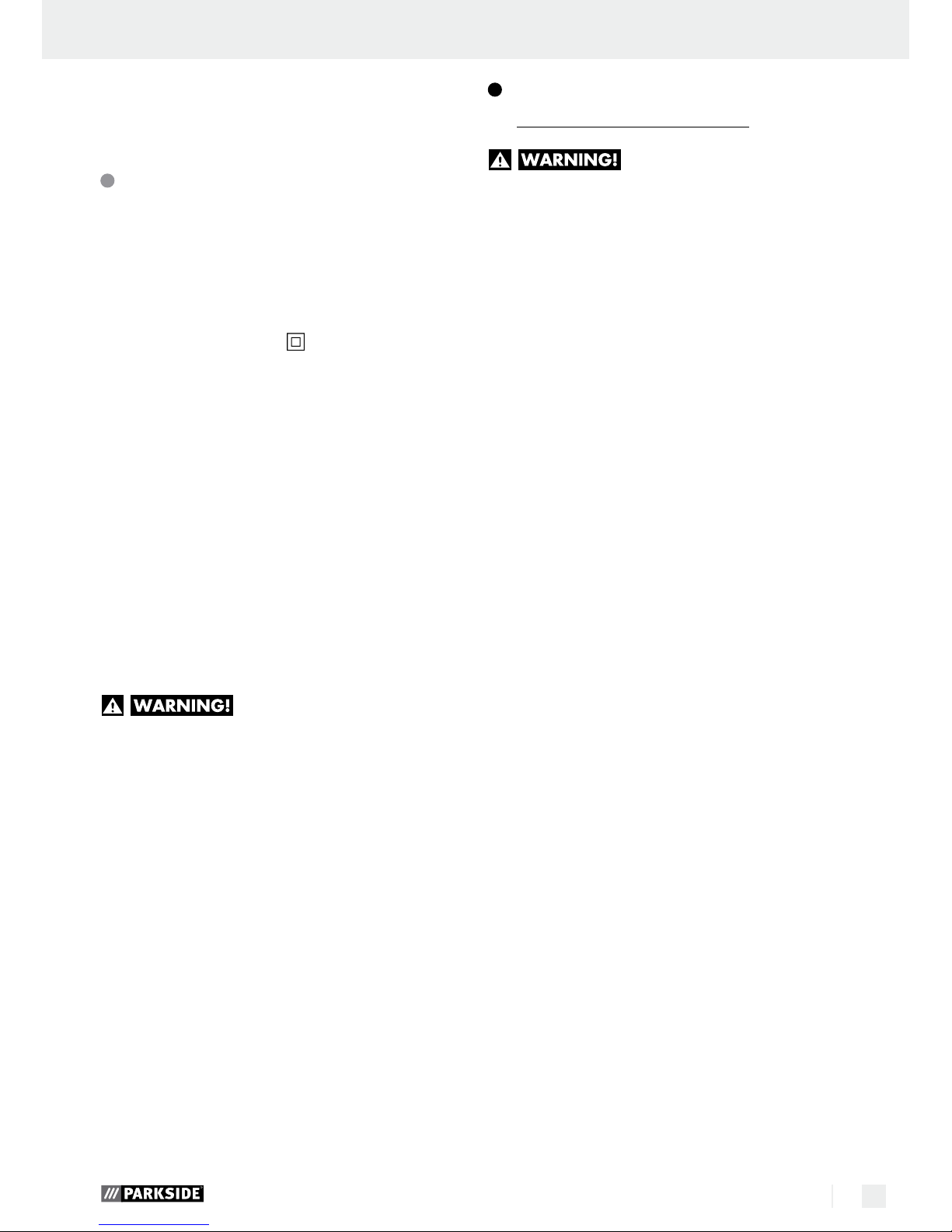

F

G

E

H

I J

35 3736

32 33 34

40

38 39

42

41

43

Page 5

5 GB/CY

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Scope of delivery ................................................................................................................................ Page 6

Technical Data ....................................................................................................................................Page 7

General safety advice for electrical power tools

1. Workplace safety ........................................................................................................................... Page 7

2. Electrical safety ............................................................................................................................... Page 7

3. Personal safety ................................................................................................................................ Page 8

4. Careful handling and use of electrical power tools .....................................................................Page 8

5. Service ............................................................................................................................................. Page 9

Safety notices specific to routers ........................................................................................................ Page 9

Supplementary Instructions ................................................................................................................. Page 9

Original accessories / tools ................................................................................................................Page 9

Start-up

Router set / Applications ..................................................................................................................... Page 10

Using the router tool ...........................................................................................................................Page 10

Attaching the extractor adapter ......................................................................................................... Page 10

Reducer ................................................................................................................................................ Page 10

Changing the collet ............................................................................................................................. Page 10

Fitting the guide fence .........................................................................................................................Page 10

Operation

Switching on and off ........................................................................................................................... Page 10

Presetting the speed ............................................................................................................................ Page 11

Set the milling depth ...........................................................................................................................Page 11

Readjust the Milling depth .................................................................................................................. Page 11

Set the milling depth with the step stop .............................................................................................Page 11

Milling direction ..................................................................................................................................Page 11

Milling Process ....................................................................................................................................Page 12

Set the copy casing .............................................................................................................................Page 12

Milling with the copy casing ..............................................................................................................Page 12

Milling with a rip fence ....................................................................................................................... Page 12

Milling with a circular compass .........................................................................................................Page 12

Maintenance and Cleaning .............................................................................................. Page 12

Warranty ......................................................................................................................................... Page 12

Disposal ............................................................................................................................................ Page 13

Declaration of conformity / Manufacturer ..........................................................Page 14

Page 6

6 GB/CY

Introduction

Router POF 1200 A1

Introduction

We congratulate you on the purchase of your new

device. You have chosen a high quality product. The

instructions for use are part of the product. They

contain important information concerning safety,

use and disposal. Before using the product, please

familiarise yourself with all of the safety information

and instructions for use. Only use the unit as de

scribed

and for the specified applications. If you pass the

product on to anyone else, please ensure that you

also pass on all the documentation with it.

Intended use

This device is intended to mill grooves, edges, profiles and slots on a wooden, plastic or light surface,

as well as copy milling. This device is not intended

for outdoor use. Any other uses, and / or modifications to the appliance, are deemed to be improper

usage and may result in serious physical injury. Not

for commercial applications.

Features

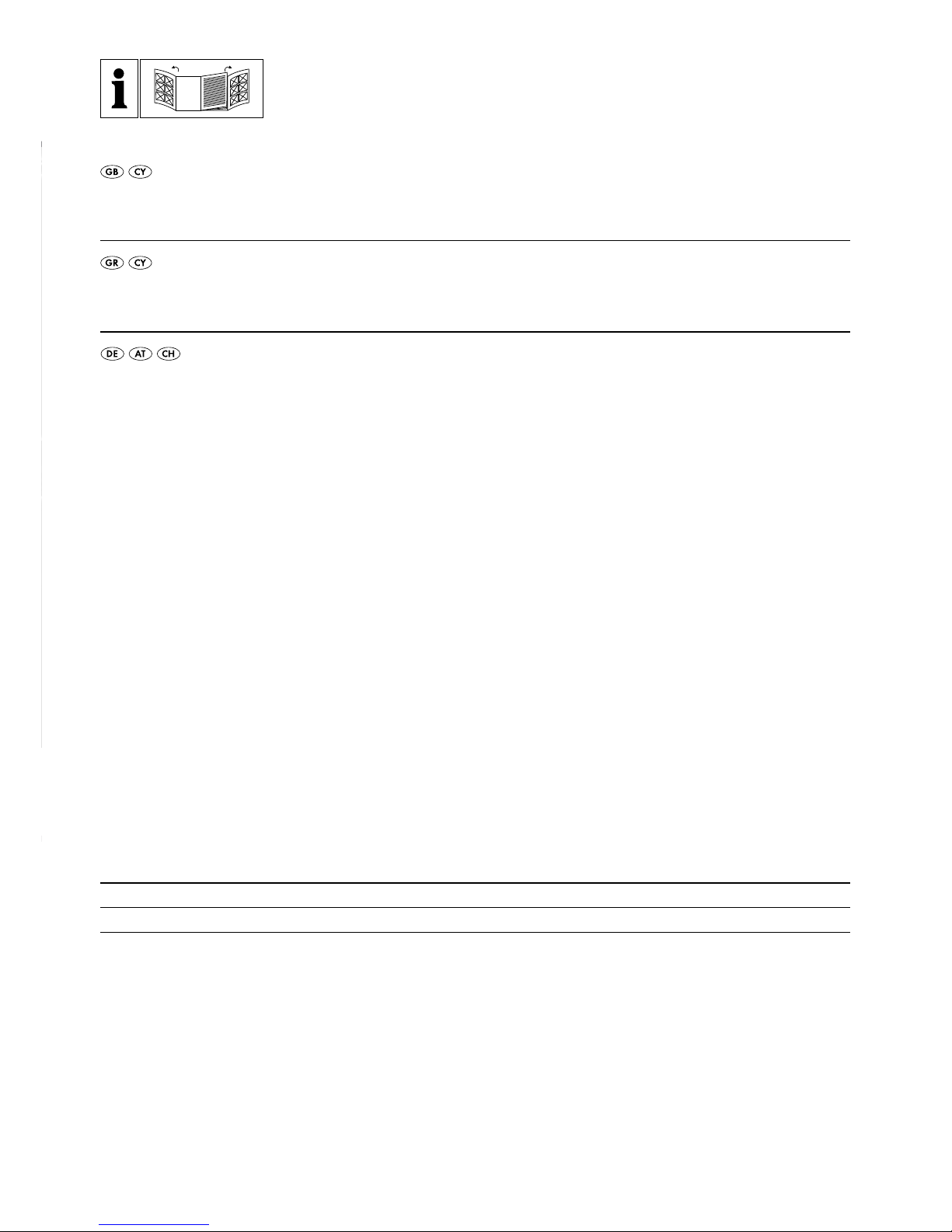

Front view figure A

1

Speed setting

2

Handle

3

Union nut

4

Collet 8 mm (preinstalled in union nut 3)

5

Locking screw

6

Guide rail

7

Base plate

8

Sliding plate

9

Step stop

10

Spindle-lock key

11

Lock screw

12

Depth stop

13

Index indicator

14

Dial milling depth adjustment

15

Control dial (milling depth-fine adjustment)

Back view figure B

16

Clamping lever

17

Router tool

18

Drilling extractor adapter

19

ON / OFF switch

20

Start lockout

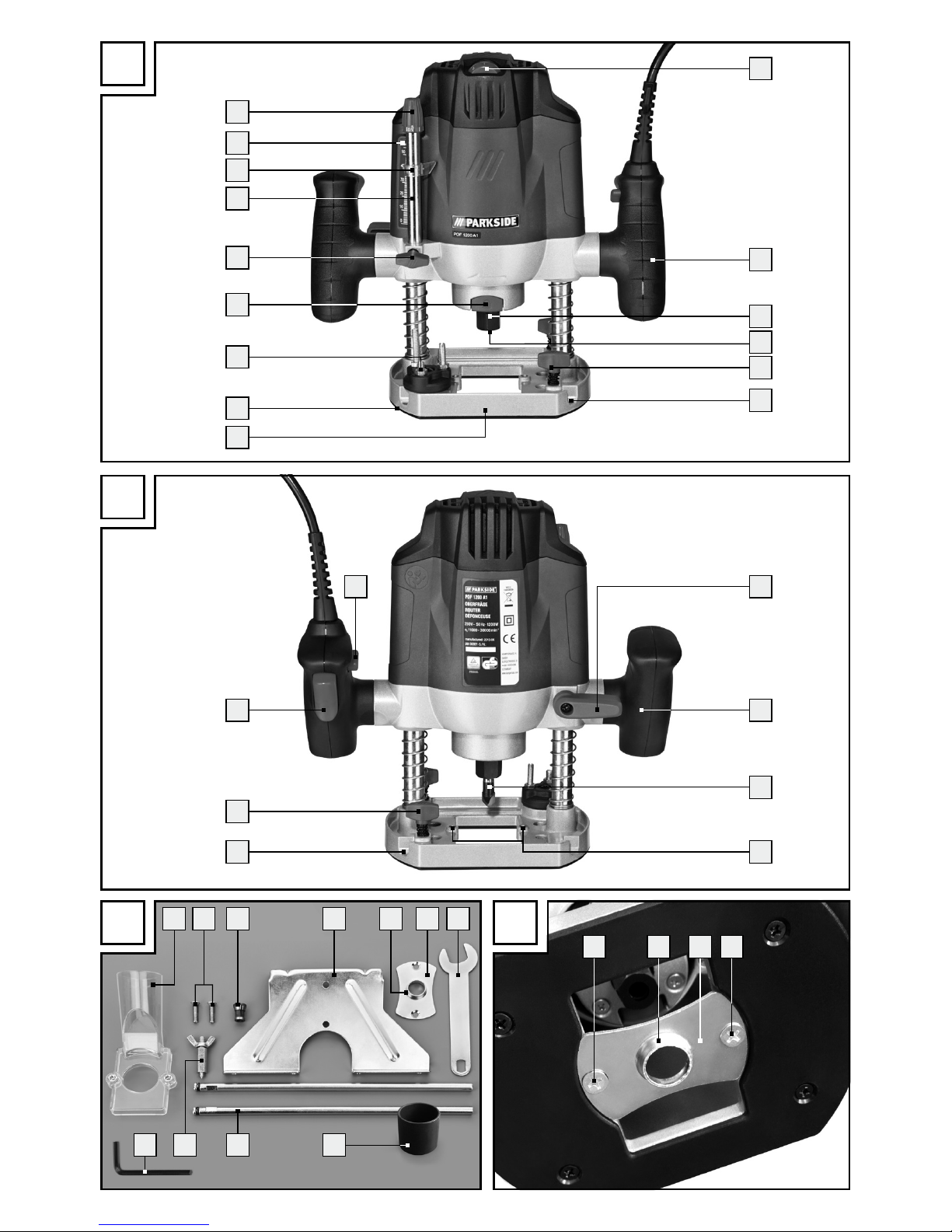

Parts figure C

21

Extractor

22

Screw

23

Collet 6 mm

24

Rip fence

25

Thrust ring

26

Copy casing

27

Open-ended spanner with slot

28

Reducer

29

Sliding bar with screw for rip fence

24

30

Centring pin

31

Socket head wrench

Router set figure D

32

Round and profile cutter 24.7 mm

33

Round and profile cutter 28.6 mm

34

Round and profile cutter 28.6 mm (R-4)

35

Hollow cutter 12 mm

36

Hollow cutter 24.7 mm

37

V-groove cutter 9.5 mm

38

V-groove cutter 16 mm

39

Bevel cutter 32 mm

40

Dovetail cutter 14.3 mm

41

Flush cutter 12.7 mm

42

Slot cutter 6 mm

43

Slot cutter 12 mm

Scope of delivery

1 Router

1 Open-ended spanner with slot

1 Collet 6 mm

1 Collet 8 mm (installed)

1 Extractor

1 Rip fence

1 Copy casing

1 Centring pin

1 Milling set 12 parts (with socket head wrench)

1 Reducer

Page 7

7 GB/CY

Introduction / General safety advice for electrical power tools

1 Socket head wrench

1 Set of operating instructions

Technical Data

Rated power input: 1200 W

Rated voltage: 230 V∼, 50 Hz

Idle speed: n

0

11000–30000 min

-1

Plunge depth: 55 mm

Tool holder: 6/8 mm

Protection class: II /

Noise and vibration data:

Measured sound value determined according to

EN 60745. The A-rated noise levels of the electrical

power tool are typically at:

Sound pressure level: 84.7 dB(A)

Sound power level: 95.7 dB(A)

Uncertainty K: 3 dB

Wear hearing protection!

Evaluated acceleration, typically:

Hand / arm vibration a

h

= 6.437 m / s²

Instability K = 1.5 m / s²

The vibration level specified in

these instructions was measured in accordance with

an EN 60745 standardised measurement process

and can be used to compare equipment. The vibration emission value specified can also serve as a

preliminary assessment of the exposure.

The vibration level will change according to the application of the electrical tool an in some cases may

exceed the value specified in these instructions. Regularly using the electric tool in such a way may

make it easy to underestimate the vibration.

Note: If you wish to make an accurate assessment

of the vibration loads experienced during a particular period of working, you should also take into

account the intervening periods of time when the

device is switched off or is running but is not actually in use. This can result in a much lower vibration

load over the whole of the period of working.

General safety advice for

electrical power tools

Read all the safety advice

and instructions! Failure to observe the safety

advice and instructions may result in electric shock,

fire and / or serious injury.

Keep all the safety advice and instructions

in a safe place for future reference!

The term “electrical tool” used in the safety advice

refers to electrical tools powered by mains electricity (by means of a mains lead) and electrical tools

powered by rechargeable batteries (without a

mains lead).

1. Workplace safety

a) Keep your working area clean and

well lit. Untidy or poorly lit working areas can

lead to accidents.

b) Do not work with the device in poten-

tially explosive environments in which

there are inflammable liquids, gases

or dusts. Electrical power tools create sparks,

which can ignite dusts or fumes.

c) Keep children and other people away

while you are operating the electrical

tool. Distractions can cause you to lose control

of the device.

2. Electrical safety

a)

The mains plug on the device must match

the mains socket. The plug must not be

modified in any way. Do not use an

adapter plug with devices fitted with

a protective earth. Unmodified plugs and

matching sockets reduce the risk of electric shock.

b) Avoid touching earthed surfaces such

as pipes, radiators, ovens and refrigerators with any part of your body.

There is an increased risk of electric shock if

your body is earthed.

Page 8

8 GB/CY

General safety advice for electrical power tools

c) Keep the device away from rain or

moisture. Water entering an electrical device

increases the risk of electric shock.

d) Do not use the mains lead for any pur-

pose for which it was not intended,

e.g.

to carry the device, to hang up the device or to pull the mains plug out of

the mains socket. Keep the mains lead

away from heat, oil, sharp edges or

moving parts of the device. Damaged

or tangled mains leads increase the risk of

electric shock.

e) When working outdoors with an

electrical power tool always use extension cables that are also approved

for use outdoors. The use of an extension

cable suitable for outdoor use reduces the risk

of electric shock.

f) Use a residual current device (RCD)

for protection if operating the electrical power tool in a moist environment

is unavoidable. The use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Remain alert at all times, watch what

you are doing and always proceed

with caution. Do not use the device if

you are tired or under the influence of

drugs, alcohol or medication. One mo

ment

of carelessness when using the device can lead

to serious injury.

b) Wear personal protective equipment

and always wear safety glasses. The

wearing of personal protective equipment such

as dust masks, non-slip safety shoes, safety helmets or ear protectors, appropriate to the type

of electrical power tool used and work undertaken, reduces the risk of injury.

c) Avoid unintentional operation of the

device. Check that the electrical power

tool is switched off before you connect

it to the mains, pick it up or carry it.

Accidents can happen if you carry the device

with your finger on the ON / OFF switch or with

the device switched on.

d) Remove any setting tools or spanners

before you switch the device on. A tool

or spanner left attached to a rotating part of a

device can lead to injury.

e) Avoid placing your body in an unnat-

ural position. Keep proper footing and

balance at all times. By doing this you will

be in a better position to control the device in

unforeseen circumstances.

f) Wear suitable clothing. Do not wear

loose clothing or jewellery. Keep your

hair, clothing and gloves clear of moving parts. Loose clothing, jewellery or long

hair can become trapped in moving parts.

g) If vacuum dust extraction and collection

devices are fitted do not forget to

check

that they are properly connected and

correctly used. The use of these devices

reduces the hazard presented by dust.

4. Careful handling and use

of electrical power tools

a) Do not overload the device. Always

use an electrical power tool that is

intended for the task you are undertaking. By using the right electrical power

tool for the job you will work more safely and

achieve a better result.

b) Do not use an electrical power tool if

its switch is defective. An electrical power

tool that can no longer be switched on and off

is dangerous and must be repaired.

c) Pull the mains plug from the socket

before you make any adjustments to

the device, change accessories or when

the device is put away. This precaution is

intended to prevent you from unintentionally

starting the device.

d) When not in use always ensure that

electrical power tools are kept out of

reach of children. Do not let anyone use

the device if he or she is not familiar

with it or has not read the instructions

and advice. Electrical power tools are dan-

gerous when they are used by inexperienced

people.

Page 9

9 GB/CY

General safety advice for electrical power tools

e) Look after the device carefully. Check

that moving parts are working properly and move freely. Check for any

parts that are broken or damaged

enough to detrimentally affect the

functioning of the device. Have damaged parts repaired before you use

the device. Many accidents have their origins

in poorly maintained electrical power tools.

f) Keep cutting tools clean and sharp.

Carefully maintained cutting tools with sharp

cutting edges are less likely to jam and are

easier to control.

g) Use the electrical power tool, accesso-

ries, inserted tools etc. in accordance

with these instructions and advice, and

the stipulations drawn up for this particular type of device. In doing this, take

into account the working conditions

and the task in hand. The use of electrical

power tools for purposes other than those intended can lead to dangerous situations.

5. Service

a) Have your device repaired at the ser-

vice centre or by qualified specialist

personnel using original manufacturer

parts only. This will ensure that your device

remains safe to use.

S

afety notices specific to routers

Only hold the power tool by the insu-

lated handle areas as the router may

touch the tool’s mains cable. Contact

with a live wire could cause metal parts of the

device to become live and lead to electric shock.

Fix and secure the work piece to a

stable surface using clamps or other

means. When only securing the work piece

by hand or against your body it will remain

unstable, which could lead to loss of control.

Supplementary Instructions

The permissible rotational speed of the

router tool must be at least as high as

the maximum speed indicated on the

electrical power tool. Parts used at higher

than permissible speeds may be ruined.

The router or other parts must fit pre-

cisely in the collet (shaft diameter 6/8)

of your electric power tool. Cutting tools

which do not fit precisely in the collet of the

electric power tool turn unevenly, vibrate strongly and can lead to a loss of control.

Always switch on the electrical power

tool before placing it against the workpiece. There is also the risk of kickback if the

electric power tool becomes caught in the

work-piece.

Keep your hands away from the cut-

ting area and the router. Keep your

second hand on the additional handle

or on the engine housing. If you hold the

router with both hands, they cannot be injured

by the router.

Never use on metal objects, nails or

screws. The router can become damaged

and this may lead to higher vibrations.

Use suitable detectors in order to look

for hidden supply lines, or consult your

local power authority. Contact with elec-

tric lines can lead to fire and electric shocks.

Damage to a gas line can lead to explosions.

Breaking a water line can cause damages.

Original accessories / tools

U

se only the accessories and attachment

s

detailed in the operating instructions,

or those which are compatible with

the device.

Page 10

10 GB/CY

Start-up / Operation

Start-up

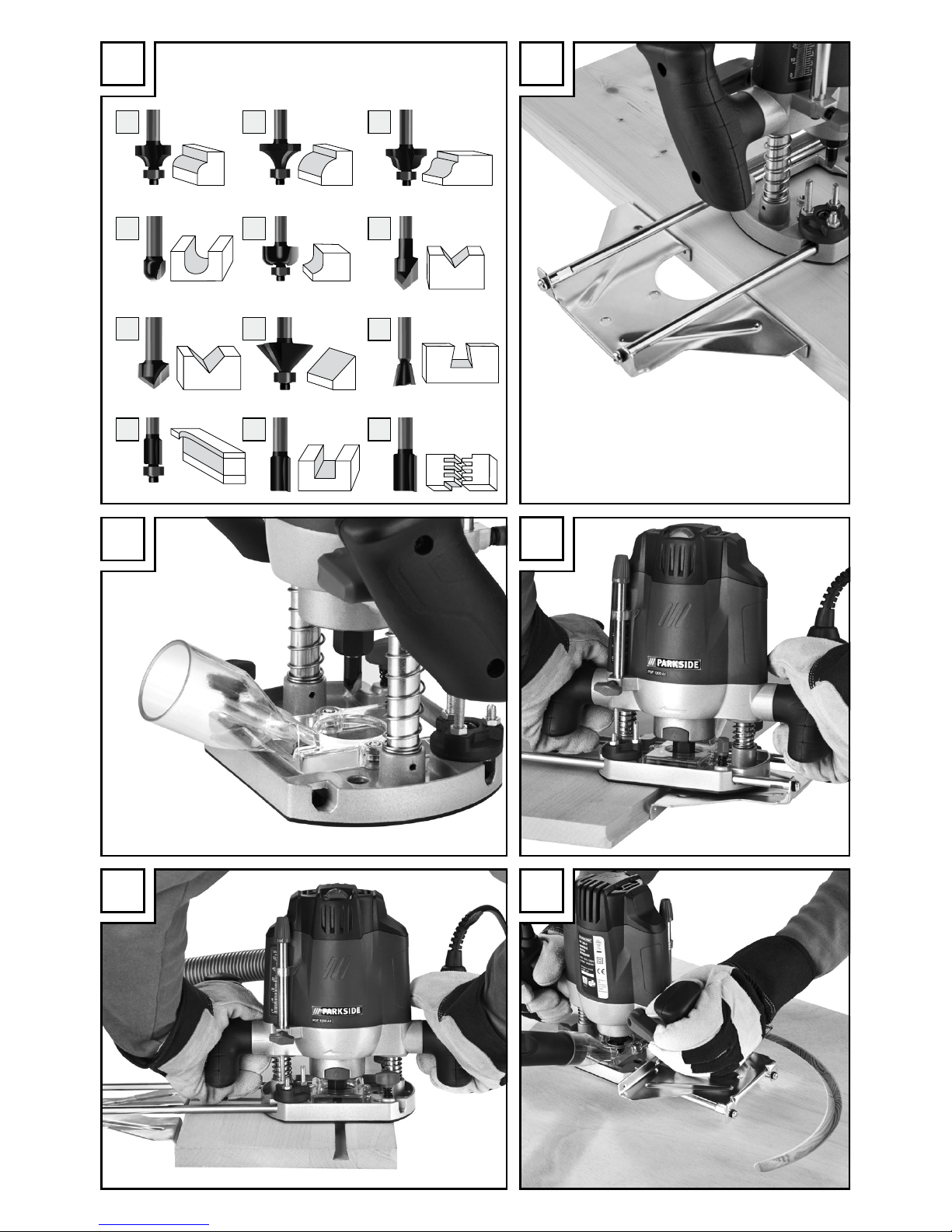

Router set / Applications

Original attachment included in delivery:

To profile:

32

Round and profile cutter, 24.7 mm

33

Round and profile cutter, 28.6 mm

34

Round and profile cutter 28.6 mm (R–4)

35

Hollow cutter, 12 mm

36

Hollow cutter, 24.7 mm

37

V-groove cutter, 9.5 mm

38

V-groove cutter, 16 mm

39

Bevel cutter, 32 mm

To connect:

40

Dovetail cutter, 14.3 mm

41

Flush cutter, 12.7 mm

42

Slot cutter, 6 mm

43

Slot cutter, 12 mm

Note: Provided the router’s ball bearing has loosened, tighten it with the Allen key provided in the

router set.

Using the router tool

Press and hold the spindle lock key 10.

Release the union nut 3 with the open-ended

spanner

27

by turning it anticlockwise.

Release the spindle-lock key 10.

Then use the router tool. This must be inserted

at least 20 mm (shaft length).

Tighten the union nut 3 firmly with the open-

ended spanner

27

.

Attaching the extractor adapter

Put the extractor adapter 21 on the drilling ex-

tractor

18

provided.

Screw together the extractor’s screws 22 and

the under side of the base plate

7

.

Connect a vacuum device approved for the

extraction of sawdust and splinters to the extractor

21

(see Fig. G).

Reducer

Connecting:

Slide the reducer 28 in to the suction adapter 21.

Slide the hose for an approved dust extraction

unit (e.g. a workshop vacuum) onto the reducer

28

.

Removal:

Pull the hose of the vacuum unit off of the re-

ducer

28

.

Pull off the reducer 28.

Changing the collet

Note: All router bits of the router sets have a 8 mm

shaft.

Start with the already installed collet 8 mm

4

.

Change the collet for a router bit with a 6 mm shaft

as described below.

Release the union nut by turning it anticlock-

wise using the open-ended spanner

27

until

the collet 8 mm

4

is removed.

Insert the collet 6 mm 23.

ATTENTION! Tighten the union nut 3 firmly

with the open-ended spanner

27

once the rout-

er bit

17

is inserted. Otherwise the collet might

be damaged.

Fitting the guide fence

Unscrew the both of the sliding bar’s 29

screws with a Philips screw driver.

Secure the sliding bar 29 to the rip fence 24

and tighten the screws.

Operation

Switching on and off

Switching on:

Press and hold the start lockout 20.

Activate the ON / OFF switch 19. Once the

machine has started, release the start lockout

20

.

Page 11

11 GB/CY

Operation

Switching off:

Release the ON / OFF switch 19.

Presetting the speed

Set the desired speed using the speed setting

wheel

1

.

1–2 = low speed

3–4 = middle speed

5–7 = high speed

Set the milling depth

1.

Ensure that the clamping lever 16 is locked down

.

If it is loose turn it anti-clockwise until it is locked.

2. P

lace the device on the work piece to be wo

rked

upon.

3. Turn the step stop

9

until it locks into the lowest

position.

4. Loosen the lock screw

11

.

5. Loosen the clamping lever

16

by turning it

clockwise and pushing the device down until the

route bit touches the surface of the work-piece.

6. Lock the clamping lever in place

16

by turning

it anti-clockwise.

7. Push the depth stop

12

down until it reaches

the lowest position of the step stop

9

. Move

the index indicator

13

to the position “0“ on

the dial milling depth adjustment

14

.

8. Adjust the depth stop

12

to the desired depth,

tighten the lock screw

11

. Afterwards the index

indicator

13

should no longer be adjustable.

9. Loosen the clamping lever

16

and and lead the

device back up.

Readjust the Milling depth

The milling depth can be adjusted with the con-

trol dial

15

.

Loosen the clamping lever 16 by turning it

clockwise and pushing the device down until

the depth stop

12

touches the step stop 9.

Lock the clamping lever in place 16 by turning

it anti-clockwise.

Set the milling depth with the control dial 15.

Loosen the clamping lever 16 by turning it

clockwise and lead the device back up. Check

the milling depth through a further practical test.

Set the milling depth with the

step stop

You can use the step stop 9 with deeper depths in

several steps with less takeoff.

Set the desired milling depth with the lowest

step of the step stop

9

(as described above).

Then set it at higher level for the first attempt.

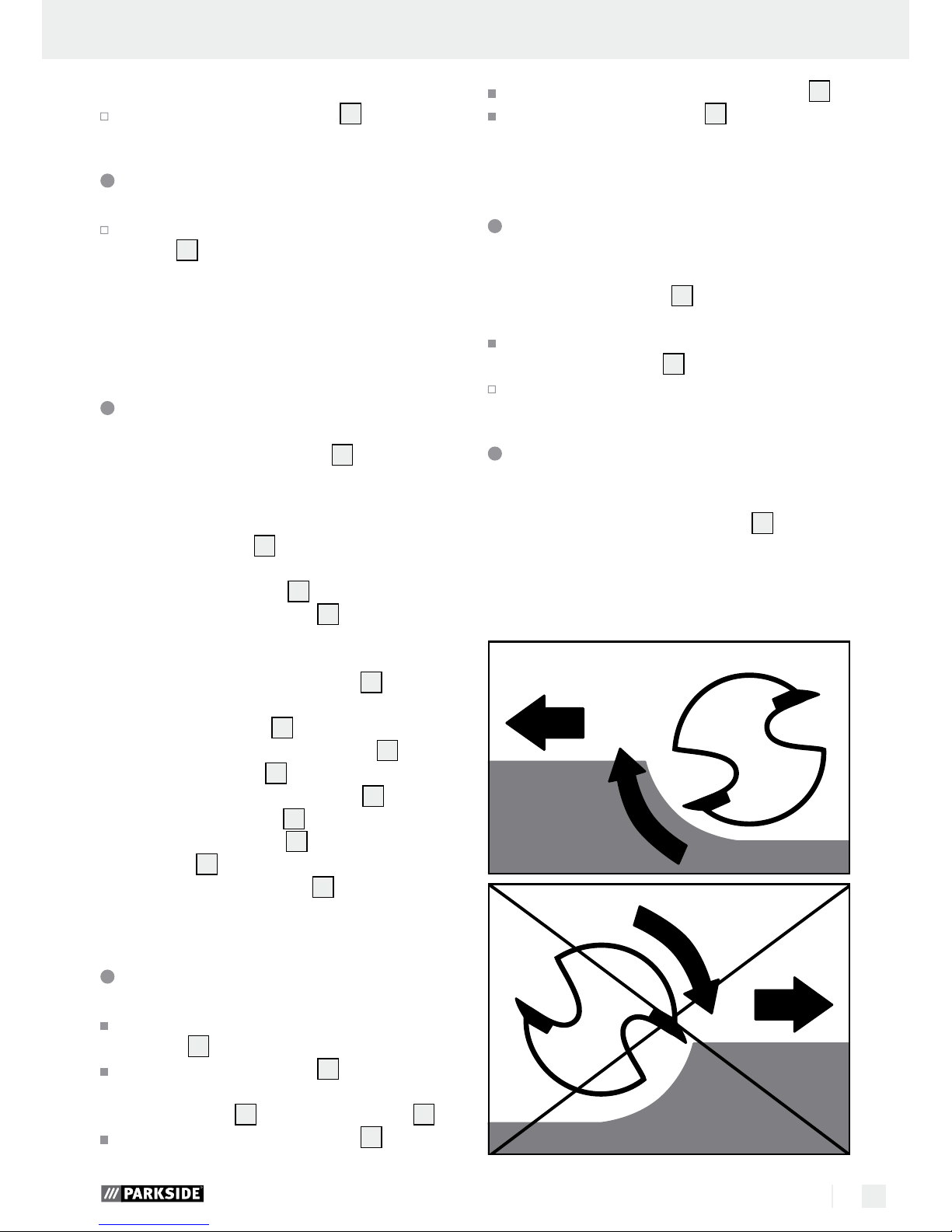

Milling direction

The milling process must always go against the

rotationary direction on the router bit

17

(Counter

rotation).

ATTENTION: When milling in the direction of the

router bit (counter rotation) the device fly out of

your hand.

Page 12

12 GB/CY

Operation / Maintenance and Cleaning / Warranty

Milling Process

Set the milling depth as previously described.

Place the device on the desired work-piece and

switch it on.

Loosen the clamping lever 16 by turning it clock-

wise and pushing the device down until it touches

the surface of the depth stop

12

on the step

stop

9

.

Lock the device into place by turning the clamp

lever

16

anti-clockwise.

Mill with even speed and even pressure (see fig. I).

Set the copy casing

Set the copy casing 26 from below on the slid-

ing bar

8

.

Secure the copy casing 26 with the two screws

22

of the extractor adapter on the base plate 7.

Ensure that the copy casing

26

is set the right

way round - the thrust ring

25

must be pointing

down (see fig. D).

Milling with the copy casing

Note! The pattern must be at least as high as the

copy casing’s

26

thrust ring 25.

Note! Chose the router bit as small as the inner

diameter of the copy casing.

When using a copy casing

26

the pattern can be

transferred onto the work piece.

Place the router with the copy casing on the

pattern.

Loosen the clamping lever 16 by turning it

clockwise and lower the device until it reaches

predetermined depth.

Lead the device with the protecting copy cas-

ing along the pattern. Apply pressure lightly.

Milling with a rip fence

Push the rip fence 24 along the guide rail 6 of

the base plate

7

and tighten the screws 5.

Put the rip fence 24 on the edge of the work

piece (see fig. F, H).

Milling with a circular compass

(see fig. J)

Put the centring pin 30 in the marked mid point

of the circle.

Turn the rip fence 24 over, i.e.the fence side is

facing upwards.

Screw together the centre pin and the rip fence

with a wing bolt. Lock the centre pin to the s

crews

with the slot of the open-ended spanner

27

.

Maintenance and Cleaning

RISK OF INJURY! Switch the

device off and pull the plug out of the mains socket

before carrying out any work on the device.

Always keep the device clean, dry and free of

oil or grease.

Use a dry cloth to clean the housing.

If the connection cable needs

to be replaced, this repair must be performed

by the manufacturer or a representative to prevent safety hazards.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile compo-

Page 13

13 GB/CY

Warranty / Disposal

nents, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering

not carried out by our authorized service branch. Your

statutory rights are not restricted in any way by this

warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.co.uk

IAN 90981

CY

Service Cyprus

Tel.: 8009 4409

e-mail: kompernass@lidl.com.cy

IAN 90981

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

Do not dispose of electrical power

tools with the household rubbish!

In

accordance with European Directive 2002 / 96 / EC,

worn out electrical power tools must be collected

separately and taken for environmentally compatible

recycling.

Contact your local refuse disposal authority for more

details of how to dispose of your worn-out devices.

Page 14

14 GB/CY

Declaration of conformity / Manufacturer

Declaration of conformity /

Manufacturer

We, KOMPERNASS HANDELS GMBH, the person

responsible for documents: Mr Semi Uguzlu, BURGSTRASSE 21, 44867 BOCHUM, GERMANY, hereby

declare that this product complies with the following

standards, normative documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

RoHS Directive

(2011 / 65 / EU)

Applicable harmonized standards

EN 60745-1:2009+A11

EN 60745-2-17:2010

EN 55014-1:2006+A1+A2

EN 55014-2:1997+A1+A2

EN 61000-3-2:2006+A1+A2

EN 61000-3-3:2008

Type / Device description:

Router POF 1200 A1

Date of manufacture (DOM): 08–2013

Serial number: IAN 90981

Bochum, 31.08.2013

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications in the course of further development.

Page 15

15 GR/CY

Εισαγωγή

Χρήση σύμφωνα με τις προδιαγραφές ..........................................................................................Σελίδα 16

Εξοπλισμός ......................................................................................................................................Σελίδα 16

Περιεχόμενα παράδοσης ................................................................................................................Σελίδα 16

Τεχνικά χαρακτηριστικά ...................................................................................................................Σελίδα 17

Γενικέ υποδείξει ασφάλεια για ηλεκτρικά εργαλεία

1. Θέση εργασίας-ασφάλεια ...........................................................................................................Σελίδα 17

2. Ηλεκτρική ασφάλεια ....................................................................................................................Σελίδα 18

3. Ασφάλεια ατόμων ........................................................................................................................Σελίδα 18

4. Ασφαλής λειτουργία και χρήση ηλεκτρονικών συσκευών.........................................................Σελίδα 19

5. Σέρβις ..........................................................................................................................................Σελίδα 19

Ειδικές για τη συσκευή υποδείξεις ασφαλείας για το φρεζάρισμα ..............................................Σελίδα 19

Συμπληρωματικές οδηγίες ...............................................................................................................Σελίδα 20

Αυθεντικός πρόσθετος εξοπλισμός / πρόσθετες συσκευές .........................................................Σελίδα 20

Θέση σε λειτουργία

Σετ φρεζαρίσματος / περιοχές εφαρμογής ....................................................................................Σελίδα 20

Τοποθέτηση εργαλείου φρεζαρίσματος .........................................................................................Σελίδα 20

Σύνδεση προσαρμογέα αναρρόφησης .........................................................................................Σελίδα 21

Εξάρτημα συστολής ........................................................................................................................Σελίδα 21

Αντικατάσταση λαβίδας σύσφιξης .................................................................................................Σελίδα 21

Συναρμολόγηση παράλληλου αναστολέα ....................................................................................Σελίδα 21

Χειρισό

Ενεργοποίηση και απενεργοποίηση ...............................................................................................Σελίδα 21

Προεπιλογή αριθμού στροφών ......................................................................................................Σελίδα 21

Ρύθμιση βάθους φρεζαρίσματος ...................................................................................................Σελίδα 22

Επαναρύθμιση του βάθους φρεζαρίσματος .................................................................................Σελίδα 22

Ρύθμιση του βάθους φρεζαρίσματος με αναστολέα βάθους με βαθμίδες .................................Σελίδα 22

Κατεύθυνση φρεζαρίσματος ...........................................................................................................Σελίδα 22

Διαδικασία φρεζαρίσματος ............................................................................................................Σελίδα 23

Τοποθέτηση χιτωνίου αντιγραφής ..................................................................................................Σελίδα 23

Φρεζάρισμα με χιτώνιο αντιγραφής ...............................................................................................Σελίδα 23

Φρεζάρισμα με παράλληλο αναστολέα .........................................................................................Σελίδα 23

Φρεζάρισμα με διαβήτη ..................................................................................................................Σελίδα 23

Συντήρηση και καθαρισό .........................................................................................Σελίδα 23

Εγγύηση ........................................................................................................................................Σελίδα 24

Απόσυρση ...................................................................................................................................Σελίδα 24

ήλωση συόρφωση / Kατασκευαστή .........................................................Σελίδα 25

Πίνακας περιεχομένων

Page 16

16 GR/CY

Eισαγωγή

Καθετη φρεζα POF 1200 A1

Q

Εισαγωγή

Σας συγχαίρουμε για την αγορά της νέας σας

συσκευής. Επιλέξατε ένα προϊόν υψηλών προδιαγραφών. Οι οδηγίες χρήσης είναι μέρος αυτού του

προϊόντος. Περιέχουν σημαντικές πληροφορίες

σχετικά με την ασφάλεια, το χειρισμό και την απόρριψη

.

Πριν τη χρήση του προϊόντος εξοικειωθείτε με όλες

τις οδηγίες χρήσης και ασφαλείας. Χρησιμοποιείτε

το προϊόν μόνο με τον τρόπο που περιγράφεται

και για τον τομέα εφαρμογής που αναφέρεται. Σε

περίπτωση μεταβίβασης του προϊόντος σε τρίτους

παραδώστε μαζί και όλα τα έγγραφα.

Χρήση σύφωνα ε τι

προδιαγραφέ

Η συσκευή προορίζεται σταθερά στερεωμένη να

φρεζάρει αυλακώσεις, ακμές, προφίλ και επιμήκεις

οπές σε ξύλο, πλαστικό και ελαφρά υλικά, καθώς

και να φρεζάρει με αντιγραφή. Η συσκευή δεν προορίζεται για χρήση σε εξωτερικό χώρο. Οποιαδήποτε άλλη χρήση ή τροποποίηση του μηχανήματος

θεωρείται ως αντικανονική και εγκυμονεί σοβαρούς

κινδύνους ατυχημάτων. Αντενδείκνυται η επαγγελματική χρήση.

Εξοπλισό

Μπροστινή όψη Εικόνα A

1

Προεπιλογή αριθμού στροφών

2

Χειρολαβή

3

Παξιμάδι ρακόρ

4

Λαβίδα σύσφιξης 8 mm (προτοποθετημένη σε

παξιμάδι ρακόρ

3

)

5

Βίδα στερέωσης

6

Ράγα οδηγός

7

Πλάκα έδρασης

8

Πλάκα ολίσθησης

9

Αναστολέας βάθους με βαθμίδες

10

Κουμπί ασφάλισης ατράκτου

11

Βίδα ασφάλισης

12

Αναστολέας βάθους

13

Ενδείκτης

14

Κλίμακα ρύθμισης βάθους φρεζαρίσματος

15

Ρυθμιστής στροφών (ρύθμιση ακριβείας βά-

θους φρεζαρίσματος)

Πίσω όψη Εικόνα B

16

Μοχλός σύσφιξης

17

Εργαλείο φρεζαρίσματος

18

Οπές προσαρμογέα αναρρόφησης

19

Διακόπτης ΟΝ / ΟFF

20

Διάταξη ασφάλισης ενεργοποίησης

Πρόσθετο εξοπλισό Εικόνα C

21

Προσαρμογέας αναρρόφησης

22

Βίδα

23

Λαβίδα σύσφιξης 6 mm

24

Παράλληλος αναστολέας

25

Δακτύλιος εδράνου κύλισης

26

Χιτώνιο αντιγραφής

27

Ανοικτό κλειδί με επιμήκη οπή

28

Εξάρτημα μείωσης

29

Ράβδος ολίσθησης με βίδα για τον παράλληλο

αναστολέα

24

30

Άξονας κεντραρίσματος

31

Κλειδί Άλεν

Σετ φρεζαρίσατο Εικόνα D

32

Φρέζα στρογγύλευσης / με σταθερό προφίλ

24,7 mm

33

Φρέζα στρογγύλευσης / με σταθερό προφίλ

28,6 mm

34

Φρέζα στρογγύλευσης / με σταθερό προφίλ

28,6 mm (R–4)

35

Φρέζα κοίλης αυλάκωσης 12 mm

36

Φρέζα κοίλης αυλάκωσης 24,7 mm

37

Φρέζα αυλάκωσης σχήματος V 9,5 mm

38

Φρέζα αυλάκωσης σχήματος 16 mm

39

Φρέζα κοπής απολήξεων οδόντων 32 mm

40

Φρέζα με όδοντες 14,3 mm

41

Επίπεδη φρέζα 12,7 mm

42

Φρέζα αυλακώσεων 6 mm

43

Φρέζα αυλακώσεων 12 mm

Περιεχόενα παράδοση

1 Καθετη φρεζα

1 Ανοικτό κλειδί με επιμήκη κοπή

Page 17

17 GR/CY

1 Λαβίδα σύσφιξης 6 mm

1 Λαβίδα σύσφιξης 8 mm (τοποθετημένη)

1 Προσαρμογέας αναρρόφησης

1 Παράλληλος αναστολέας

1 Χιτώνιο αντιγραφής

1 Άξονας κεντραρίσματος

1 Σετ φρέζας 12 τεμαχίων (με κλειδί Άλεν)

1 Εξάρτημα συστολής

1 Κλειδί Άλεν

1 Οδηγίες χρήσης

Τεχνικά χαρακτηριστικά

Ονομαστική ισχύς: 1200 W

Ονομαστική τάση: 230 V∼, 50 Hz

Αριθμός στροφών ρελαντί:

n0 11000–30000 min

–1

Διαδρομή κάτω μέρους

φρέζας: 55 mm

Υποδοχή εργαλείου: 6 / 8 mm

Κλάση προστασίας: II /

Πληροφορίε θορύβου και κραδασών:

Τιμή μέτρησης για θόρυβο εξακριβωμένη σύμφωνα

με EN 60745. Η αξιολογημένη με Α στάθμη ηχητικ

ής

πίεσης του ηλεκτρικού εργαλείου ανέρχεται τυπικά σε:

Στάθμη ηχητικής πίεσης: 84,7 dB(A)

Στάθμη ηχητικής ισχύος: 95,7 dB(A)

Αβεβαιότητα μέτρησης K: 3 dB

Φοράτε ωτασπίδε!

Αξιολογηένη επιτάχυνση, τυπικά:

Κραδασμοί στο χέρι / βραχίονα a

h

= 6,437 m / s²

Αβεβαιότητα μέτρησης K = 1,5 m / s²

Η αναφερόμενη στις

παρούσες οδηγίες στάθμη δονήσεων μετρήθηκε με

τυποποιημένη μέθοδο μέτρησης σύμφωνα με το

πρότυπο EN 60745 και μπορεί να χρησιμοποιηθεί

για τη σύγκριση της συσκευής. Η δεδομένη τιμή

εκπομπής δονήσεων μπορεί επίσης να χρησιμοποιηθ

εί

σε μια εισαγωγική εκτίμηση της έκθεσης.

Η στάθμη δονήσεων μεταβάλλεται ανάλογα με τη

χρήση του ηλεκτρικού εργαλείου και σε μερικές

περιπτώσεις ενδέχεται να υπερβαίνει την τιμή που

αναφέρεται στις παρούσες οδηγίες. Η επιβάρυνση

δονήσεων ενδέχεται να υποτιμηθεί, σε περίπτωση

που το ηλεκτρικό εργαλείο χρησιμοποιείται τακτικά

με τέτοιο τρόπο.

Υπόδειξη: Για τον ακριβή υπολογισμό της επιβάρυνσης κραδασμών κατά τη διάρκεια ενός ορισμένου χρονικού διαστήματος εργασίας θα πρέπει να

ληφθούν υπόψη και οι χρόνοι κατά τους οποίους

η συσκευή είναι απενεργοποιημένη ή λειτουργεί χωρίς όμως να παράγει πραγματικά έργο. Αυτό μπορεί

να μειώσει σημαντικά την επιβάρυνση κραδασμών για

το συνολικό χρονικό διάστημα εργασίας.

Γενικέ υποδείξει ασφάλεια

για ηλεκτρικά εργαλεία

ιαβάστε όλε τι

υποδείξει ασφάλεια και οδηγίε! Οι πα-

ραβιάσεις κατά την τήρηση των υποδείξεων ασφάλειας και των οδηγιών ενδέχεται να προκαλέσουν

ηλεκτροπληξία, πυρκαγιά ή / και σοβαρούς τραυματισμούς.

ιαφυλαξτε ολε τι υποδειξει ασφαλεια

και τι οδηγιε για ελλοντικη χρηση!

Ο ορος που χρησιμοποιειται στις υποδειξεις ασφαλ

ειας «ηλεκτρονικο εργαλειο» αναφερεται σε ηλεκτρικ

α

εργαλεια που λειτουργουν με το δικτυο (με καλωδιο

δικτυου) και σε αυτa που λειτουργουν με μπαταρια

(χωρις καλωδιο δικτυου).

1. Θέση εργασία-ασφάλεια

α) ιατηρείτε το χώρο εργασία σα κα-

θαρό και καλά φωτισένο. Η ακαταστασία

καθώς και ο ελλιπής φωτισμός του χώρου εργασίας μπορεί να οδηγήσει σε ατυχήματα.

β) Μην εργάζεστε ε τη συσκευή σε περι-

βάλλον όπου υφίστα ται κίνδυνο

έκρηξη, στο οποίο υπάρχουν εύφλεκτα υγρά, αέρια ή σκόνη. Τα ηλεκτρονικά

εργαλεία παράγουν σπίθες, οι οποίες μπορεί

να αναφλέξουν τη σκόνη ή τους ατμούς.

γ) Κρατήστε τα παιδιά και άλλα άτοα

ακριά από το ηλεκτρο νικό εργαλείο

κατά τη διάρκεια χρήση του. Σε περί-

Eισαγωγή / Γενικές υποδείξεις ασφάλειας για ηλεκτρικά εργαλεία

Page 18

18 GR/CY

Γενικές υποδείξεις ασφάλειας για ηλεκτρικά εργαλεία

πτωση μη τήρησης ίσως χάσετε τον έλεγχο της

συσκευής.

2. Ηλεκτρική ασφάλεια

α) Το βύσα σύνδεση συσκευή θα πρέ-

πει να ταιριάζει στην πρίζα. Απαγορεύεται η τροποποίηση ε οποιοδήποτε

τρόπο του βύσατο. Απαγορεύεται η

χρήση βύσατο προσαρογέα αζί

ε συσκευέ ε προστατευτική γείωση.

Το ανέπαφο βύσμα και η κατάλληλη πρίζα μειώνουν τον κίνδυνο πρόκλησης ηλεκτροπληξίας.

β) Αποφύγετε τη σωατική επαφή ε

γειωένε επιφάνειε, όπω σωλήνε,

θεραντικά σώατα, εστίε και ψυγεία.

Υφίσταται υψηλός κίνδυνος ηλεκτροπληξίας

όταν το σώμα σας γειωθεί.

γ) Κρατήστε τη συσκευή ακριά από τη

βροχή και την υγρασία. Η εισχώρηση νε

ρού

μέσα σε μία ηλεκτρονική συσκευή αυξάνει τον

κίνδυνο ηλεκτροπληξίας.

δ) Μην χρησιοποιείτε το καλώδιο για

άλλο λόγο, για να εταφέρετε τη συσκευή, για να την αναρτήσετε ή για να

τραβήξετε το βύσα από την πρίζα.

Κρατήστε το καλώδιο ακριά από θερότητα, λάδι, αιχηρέ ακέ ή κινούενα εξαρτήατα συσκευή. Κατεστραμμένο

ή τυλιγμένο καλώδιο αυξάνει τον κίνδυνο πρόκλησης ηλεκτροπληξίας.

ε) Για χρήση ηλεκτρονική συσκευή σε

εξωτερικού χώρου, χρησιοποιήστε

όνο καλώδιο επέκταση που είναι

κατάλληλο για εξωτερική χρήση. Η

χρήση ενός καλωδίου κατάλληλο για εξωτερική

χρήση μειώνει τον κίνδυνο ηλεκτροπληξίας.

ζ) Σε περίπτωση που είναι αναπόφευκτη

η λειτουργία του ηλεκτρικού εργαλείου

σε υγρό περιβάλλον, χρησιοποιείτε

προστατευτικό διακόπτη συνολικού

ρεύατο προ το σφάλα. Η χρήση

προστατευτικού διακόπτη συνολικού ρεύματος

προς το σφάλμα μειώνει τον κίνδυνο ηλεκτροπληξίας.

3. Ασφάλεια ατόων

α) Επιδείξτε εγάλη προσοχή, έχετε πάντο-

τε επίγνωση των πράξεών σα και δείξτε ιδιαίτερη συναίνεση στην εργασία

που πραγατοποιείτε ε το ηλεκτρονικό εργαλείο. Μην χρησιοποιείτε τη

συσκευή όταν δεν

είσαστε συγκεντρω-

ένοι ή όταν

νοιώθετε κούραση ή ενώ

βρίσκεστε υπό

την επήρεια ναρκωτικών,

αλκοόλ ή φαράκων. Ακόμα και μόλις μία

στιγμή

αφηρημάδας κατά τη χρήση της συσκευής

μπορεί να οδηγήσει σε σοβαρούς τραυματι

σμούς.

β) Φοράτε προσωπικό προστατευτικό εξο-

πλισό και πάντα προστατευτικά γυαλιά. Ο προσωπικός προστατευτικός εξοπλισμός

όπως είναι αναπνευστική μάσκα, προστατευτικά

παπούτσια που δεν γλιστράνε, προστατευτικό

κράνος ή ωτοασπίδες, ανάλογα με το είδος και

την εφαρμογή του μειώνουν τον κίνδυνο πρόκλησης τραυματισμών.

γ) Αποφεύγετε την αθέλητη θέση σε λει-

τουργία. Βεβαιωθείτε ότι το ηλεκτρικό

εργαλείο είναι απενεργοποιηένο προτού το συνδέσετε στην ηλεκτρική τροφοδοσία ή το πάρετε και το εταφέρετε.

Εάν κατά τη μεταφορά της συσκευής έχετε το

δάκτυλό σας στο διακόπτη ΕΝΤΟΣ / ΕΚΤΟΣ ή

η συσκευή είναι ενεργοπ οιημένη, ενδέχεται να

προκληθούν ατυχήματα.

δ) Αποακρύνετε τα εργαλεία ρύθιση ή

τα κλειδιά προτού ενεργοποιήσετε τη

συσκευή. Ενα εργαλείο ή ένα κλειδί που βρί-

σκεται πάνω σε ένα περιστρεφόμενο εξάρτημα

συσκευής μπορεί να προκαλέσει τραυματισμούς.

ε) Αποφεύγετε αντικανονική στάση του

σώατό σα. Φροντίζετε ώστε να

υπάρχει πάντα σταθερή θέση και διατηρείτε ανά πάση στιγή την ισορροπία

σα. Ετσι μπορείτε να ελέγχετε καλύτερα τη συ-

σκευή και ιδιαίτερα σε απρόσμενες καταστάσεις.

ζ) Φοράτε κατάλληλο ρουχισό. Μην

φοράτε φαρδιά ρούχα και κοσήατα.

Κρατήστε τα αλλιά, το ρουχισό και

τα γάντια ακριά από τα κινούενα

εξαρτήατα. Ο φαρδύς ρουχισμός που δεν

έχει στενή εφαρμογή, τα κοσμήματα ή τα μαλλιά

μπορεί να πιαστούν από τα κινούμενα εξαρτήματα.

Page 19

19 GR/CY

Γενικές υποδείξεις ασφάλειας για ηλεκτρικά εργαλεία

η) Κατά τη συναρολόγηση διατάξεων

αναρρόφηση και συλλογή, φροντί

στε ώστε αυτέ να έχουν συνδεθεί και

να χρησιοποιούνται σωστά. Η χρήση

τέτοιου είδους διατάξεων μειώνει τον κίνδυνο

από τη σκόνη.

4. Ασφαλή λειτουργία και χρήση

ηλεκτρονικών συσκευών

α) Μην υπερφορτώνετε τη συσκευή. Χρη-

σιοποιήστε το ηλεκτρονικό εργαλείο

που είναι κατάλληλο για την εργασία

σα. Με το κατάλληλο ηλεκτρονικό εργαλείο

μπορείτε να εργαστείτε καλύτερα και με μεγαλύτερη ασφάλεια εντός του καθορισμένου τομέα

απόδοσης.

β) Μην χρησιοποιείτε ηλεκτρονικό

εργαλείο, του οποίου ο διακόπτη

είναι ελαττωατικό. Ενα ηλεκτρονικό

εργαλείο που δεν μπορεί να ενεργοποιηθεί ή να

απενεργοποιηθεί είναι επικίνδυνο και θα πρέπει

να επιδιορθωθεί.

γ)

Πριν προβείτε σε ρυθίσει τη ηχανή

,

σε αντικατάσταση εξαρτηάτων ή σε

απόθεση τη ηχανή, αποσυνδέετε το

βύσα από την ηλεκτρική πρίζα. Αυτά

τα προστατευτικά μέτρα μειώνουν τον κίνδυνο

αθέμιτης εκκίνησης της συσκευής.

δ) Φυλάξτε τα ηλεκτρονικά εργαλεία που

δεν χρησιοποιείτε ακριά από παιδιά.

Μην επιτρέπετε τη χρήση τη συσκευή

σε άτοα, τα οποία δεν είναι έπιστα ή

τα οποία δεν έχουν διαβάσει τι οδηγίε.

Τα ηλεκτρονικά εργαλεία είναι επικίνδυνα όταν

χρησιμοποιούνται από άπειρα άτομα.

ε) Φροντίστε τη συσκευή ε προσοχή.

Ελέγχετε αν τα κινούενα εξαρτήατα

λειτουργούν άψογα και δεν πλοκάρουν, αν υπάρχουν σπασένα ή κατεστραένα εξαρτήατα έτσι ώστε να

επηρεάζεται αρνητικά η λειτουργία

τη

συσκευή. Αναθέστε την επιδιό ρθωση

των ελαττωατικών εξαρτη άτων πριν

από τη χρήση στη συσ κευή. Πολλά

ατυχήματα οφείλονται σε ηλεκτρονικές συσκευές

που δεν έχουν συντηρηθεί σωστά.

ζ) ιατηρήστε τα εργαλεία κοπή αιχηρά

και καθαρά. Τα προσεγμένα εργαλεία κοπής

μπλοκάρουν λιγότερο και κόβουν πιο εύκολα.

η) Χρησιοποιήστε το ηλεκτρονικό εργα-

λείο, το εξάρτηα, τα εργαλεία εφαρογή κ.τ.λ. σύφωνα ε τι οδηγίε

του και ε τον τρόπο που περιγράφεται για αυτό τον ειδικό τύπο συσκευή.

Λάβετε υπόψη σα τι συνθήκε εργασία και τι δραστηριότητε που πρέπει

να πραγατοποιηθούν. Η χρήση ηλεκτρο-

νικών εργαλείων για εφαρμογή άλλη από αυτή

που προδιαγράφεται μπορεί να οδηγήσει σε

επικίνδυνες καταστάσεις.

5. Σέρβι

α) Αναθέστε την επιδιόρθωση τη συσκευ-

ή σα σε υπηρεσία εξυπηρέτηση πελατών ή σε εξειδικευένο ηλεκτρολόγο

και χρησιοποιήστε όνο αυθεντικά

ανταλλακτικά. Με τον τρόπο αυτό μπορεί

να

διασφαλιστεί το γεγονός ότι διατηρείται το επίπεδο ασφάλειας της συσκευής.

Ειδικέ για τη συσκευή

υποδείξει ασφαλεία για

το φρεζάρισα

Πιάνετε το ηλεκτρικό εργαλείο όνο

από τι ονωένε επιφάνειε λαβή,

καθώ η ηχανή φρεζαρίσατο πορεί να ακουπήσει το καλώδιο δικτύου

τη. Η επαφή με έναν αγωγό που φέρει τάση

μπορεί να θέσει υπό τάση τα μεταλλικά εξαρτήματα της συσκευής και να οδηγήσει σε ηλεκτροπληξία.

Στερεώστε και ασφαλίστε το τεάχιο

εργασία έσω πίεση ή κατά άλλο τρόπο σε ένα σταθερό υπόστρωα. Αν κρατάτε

το τεμάχιο εργασίας μόνο με το χέρι ή κόντρα

στο σώμα, παραμένει ασταθές, κάτι που μπορεί

να οδηγήσει σε απώλεια ελέγχου.

Page 20

20 GR/CY

Συπληρωατικέ οδηγίε

Ο επιτρεπτό αριθό στροφών των

εργαλείων φρεζαρίσατο πρέπει να

είναι τουλάχιστον ίσο ε το έγιστο

α

ριθό στροφών που αναγράφεται στ

ο

ηλεκτρικό εργαλείο. Ο πρόσθετος εξοπλι-

σμός, που περιστρέφεται γρηγορότερα από το

επιτρεπόμενο, μπορεί να καταστραφεί.

Η ηχανή φρεζαρίσατο ή ο άλλο

πρόσθετο εξοπλισό πρέπει να ταιριάζουν ακριβώ στη λαβίδα σύσφιξη

(διάετρο κορού 6 / 8 mm) του ηλεκτρικού εργαλείου σα. Τα εργαλεία φρε-

ζαρίσματος, τα οποία δεν ταιριάζουν ακριβώς

στη λαβίδα σύσφιξης του ηλεκτρικού εργαλείου

σας, περιστρέφονται ανομοιόμορφα, δονούνται

πολύ και μπορούν να οδηγήσουν σε απώλεια

του ελέγχου.

Οδηγείτε το ηλεκτρικό εργαλείο στο τε-

άχιο εργασία όνο όταν είναι ενεργοποιηένο. Διαφορετικά υφίσταται κίνδυνος

ανάκρουσης, όταν το εργαλείο τοποθέτησης

αγκιστρώνεται στο τεμάχιο εργασίας.

Μην τοποθετείτε τα χέρια σα στην πε-

ριοχή φρεζαρίσατο και στη ηχανή

φρεζαρίσατο. Με το δεύτερό σα χέρι

κρατάτε την πρόσθετη λαβή ή το περίβληα οτέρ. Όταν κρατάτε τη μηχανή φρε-

ζαρίσματος και με τα δυο σας χέρια, τα χέρια

σας δεν είναι δυνατό να τραυματιστούν από τη

μηχανή φρεζαρίσματος.

Ποτέ ην φρεζάρετε εταλλικά αντικείε-

να, καρφιά ή βίδε. Η μηχανή φρεζαρίσματος

μπορεί να υποστεί βλάβη και να προκληθού

ν

πολύ έντονοι κραδασμοί.

Χρησιοποιήστε κατάλληλε συσκευέ

αναζήτηση, για να εντοπίσετε κρυφά

καλώδια τροφοδοσία ή συβουλευτείτε την τοπική εταιρεία ηλεκτροδότηση.

Η επαφή με ηλεκτρικά καλώδια μπορεί να οδηγήσει σε πυρκαγιά ή ηλεκτροπληξία. Η πρόκληση βλάβης σε έναν αγωγό αερίου μπορεί να

οδηγήσει σε έκρηξη. Η εισροή σε έναν αγωγό

νερού μπορεί να προκαλέσει υλικές ζημίες.

Αυθεντικό πρόσθετο εξοπλι-

σό / πρόσθετε συσκευέ

Χρησιοποιείτε όνο πρόσθετο εξο-

πλισό και συσκευέ, οι οποίε αναφέρονται στο εγχειρίδιο λειτουργία ή η

υποδοχή των οποίων είναι συβατή ε

τη συσκευή.

Θέση σε λειτουργία

Σετ φρεζαρίσατο / περιοχέ

εφαρογή

Οι αυθεντικέ πρόσθετε συσκευέ περιλαβάνονται στα παραδοτέα:

Για την κοπή προφίλ:

32

Φρέζα στρογγύλευσης / με σταθερό προφίλ,

24,7 mm

33

Φρέζα στρογγύλευσης / με σταθερό προφίλ,

28,6 mm

34

Φρέζα στρογγύλευσης / με σταθερό προφίλ,

28,6 mm (R–4)

35

Φρέζα κοίλης αυλάκωσης, 12 mm

36

Φρέζα κοίλης αυλάκωσης, 24,7 mm

37

Φρέζα αυλάκωσης σχήματος V, 9,5 mm

38

Φρέζα αυλάκωσης σχήματος V, 16 mm

39

Φρέζα κοπής απολήξεων οδόντων, 32 mm

Για τη σύνδεση:

40

Φρέζα με όδοντες, 14,3 mm

41

Επίπεδη φρέζα, 12,7 mm

42

Φρέζα αυλακώσεων, 6 mm

43

Φρέζα αυλακώσεων, 12 mm

Υπόδειξη: Εάν ο ένσφαιρος τριβέας μιας μηχαν

ής

φρεζαρίσματος έχει χαλαρώσει, σφίξτε τον με το

κλειδί Άλεν που περιλαμβάνεται στο σετ μηχανής

φρεζαρίσματος.

Τοποθέτηση εργαλείου

φρεζαρίσατο

Πατήστε το κουμπί ασφάλισης ατράκτου 10 και

κρατήστε το πατημένο.

Γενικές υποδείξεις ασφάλειας για ηλεκτρικά εργαλεία / Θέση σε λειτουργία

Page 21

21 GR/CY

Χαλαρώστε με το ανοικτό κλειδί 27 το παξιμά-

δι ρακόρ

3

περιστρέφοντας αριστερόστροφα.

Αφήστε τώρα το κουμπί ασφάλισης ατράκτου 10.

Τοποθετήστε το εργαλείο φρεζαρίσματος. Πρέπει

να ωθηθεί τουλάχιστον 20 mm (μήκος κορμού).

Σφίξτε το παξιμάδι ρακόρ 3 με το ανοικτό

κλειδί

27

.

Σύνδεση προσαρογέα

αναρρόφηση

Τοποθετήστε τον προσαρμογέα αναρρόφησης 21

στις προκαθορισμένες οπές για τον προσαρμογέα αναρρόφησης

18

.

Τώρα βιδώστε τις βίδες του προσαρμογέα

αναρρόφησης

22

από την κάτω πλευρά της

πλάκας έδρασης

7

.

Συνδέστε τον επιτρεπτό προσαρμογέα αναρρό-

φησης σκόνης και ρινισμάτων στον προσαρμογ

έα

αναρρόφησης

21

(βλέπε εικ. G).

Εξάρτηα συστολή

Σύνδεση:

Ωθήστε το εξάρτημα συστολής 28 στον προ-

σαρμογέα αναρρόφησης

21

.

Ωθήστε τον εύκαμπτο αγωγό μιας επιτρεπτής

διάταξης αναρρόφησης σκόνης (π.χ. μιας διάταξης αναρρόφησης εργοστασίου) στο εξάρτημα συστολής

28

.

Αποάκρυνση:

Αφαιρέστε τον εύκαμπτο αγωγό της διάταξης

αναρρόφησης σκόνης από το εξάρτημα συστολής

28

.

Αφαιρέστε το εξάρτημα συστολής 28.

Αντικατάσταση λαβίδα

σύσφιξη

Υπόδειξη: Όλες οι μηχανές φρεζαρίσματος του

σετ φρεζαρίσματος που περιλαμβάνεται στα παραδοτέα παρέχονται με κορμό 8 mm.

Για το σκοπό αυτό χρησιμοποιήστε ήδη προτοποθετημένη λαβίδα σύσφιξης 8 mm

4

. Για τις μηχανές

φρεζαρίσματος με κορμό 6 mm αντικαταστήστε τη

λαβίδα σύσφιξης, όπως περιγράφεται παρακάτω.

Με το ανοικτό κλειδί 27 χαλαρώστε το παξιμά-

δι ρακόρ αριστερόστροφα, έως ότου η λαβίδα

σύσφιξης 8 mm

4

αφαιρεθεί.

Τοποθετήστε λαβίδα σύσφιξης 6 mm 23.

ΠΡΟΣΟΧΗ! Μόνο τότε σφίξτε το παξιμάδι

ρακόρ

3

με ανοικτό κλειδί 27, όταν τοποθετη-

θεί εργαλείο φρεζαρίσματος

17

. Διαφορετικά

η λαβίδα σύσφιξης μπορεί να υποστεί βλάβη.

Συναρολόγηση παράλληλου

αναστολέα

Ξεβιδώστε και τις δύο βίδες των ράβδων ολί-

σθησης

29

με σταυροκατσάβιδο.

Στερεώστε τις ράβδους ολίσθησης 29 στον

παράλληλο αναστολέα

24

και για το σκοπό

αυτό σφίξτε τις βίδες.

Χειρισό

Ενεργοποίηση και

απενεργοποίηση

Ενεργοποίηση:

Πατήστε τη διάταξη ασφάλισης ενεργοποίησης

20

και κρατήστε την πατημένη.

Πατήστε το διακόπτη ΟΝ/ OFF 19. Μόλις το

μηχάνημα ξεκινήσει να λειτουργεί, μπορείτε να

απελευθερώσετε και πάλι τη διάταξη ασφάλισης

ενεργοποίησης

20

.

Απενεργοποίηση:

Αφήστε ελεύθερο το διακόπτη ON / OFF 19.

Προεπιλογή αριθού στροφών

Ρυθμίστε τον απαιτούμενο αριθμό στροφών με

τον τροχό ρύθμισης προεπιλογής αριθμού

στροφών

1

.

1–2 = χαμηλός αριθμός στροφών

3–4 = μέσος αριθμός τροχών

5–7 = υψηλός αριθμός στροφών

Θέση σε λειτουργία / Χειρισμός

Page 22

22 GR/CY

Ρύθιση βάθου φρεζαρίσατο

1. Βεβαιωθείτε ότι ο μοχλός σύσφιξης 16 είναι

ασφαλισμένος. Εάν χαλαρώσει, στρέψτε τον

αριστερόστροφα, μέχρι να ασφαλίσει.

2. Θέστε τη συσκευή στο προς επεξεργασία τεμάχιο εργασίας.

3. Στρέψτε τον αναστολέα βάθους

9

, μέχρι να

ασφαλίσει στην κατώτατη θέση.

4. Χαλαρώστε τη βίδα ασφάλισης

11

.

5. Χαλαρώστε το μοχλό σύσφιξης

16

περιστρέφοντας δεξιόστροφα και πιέστε τη συσκευή προς

τα κάτω, μέχρι η μηχανή φρεζαρίσματος να αγγίξει την επάνω επιφάνεια του τεμαχίου εργασίας.

6. Ασφαλίστε το μοχλό σύσφιξης

16

περιστρέ-

φοντας αριστερόστροφα.

7. Ωθήστε τον αναστολέα βάθους

12

προς τα

κάτω, μέχρι να τοποθετηθεί στην κατώτατη θέση

του αναστολέα βάθους με βαθμίδες

9

. Ωθή-

στε τον ενδείκτη

13

στη θέση „0“ της κλίμακας

ρύθμισης βάθους φρεζαρίσματος

14

.

8. Ρυθμίστε τον αναστολέα βάθους με βαθμίδες

12

στο επιθυμητό βάθος φρεζαρίσματος, σφίξτε τη

βίδα ασφάλισης 11. Στη συνέχεια ο ενδείκτης 13

δεν πρέπει να μετακινηθεί πλέον.

9. Τώρα χαλαρώστε το μοχλό σύσφιξης

16

και

επαναφέρετε τη συσκευή προς τα επάνω.

Επαναρύθιση του βάθου

φρεζαρίσατο

Το βάθος φρεζαρίσματος μπορεί να επανα-

ρυθμιστεί μέσω του ρυθμιστή περιστροφής

15

.

Χαλαρώστε το μοχλό σύσφιξης 16 περιστρέ-

φοντας δεξιόστροφα και πατήστε τη συσκευή

προς τα κάτω, μέχρι ο αναστολέας βάθους

12

να εφαρμόσει στον αναστολέα βάθους με βαθμίδες

9

.

Ασφαλίστε το μοχλό σύσφιξης 16 περιστρέ-

φοντας αριστερόστροφα.

Ρυθμίστε το βάθος φρεζαρίσματος με ρυθμιστή

περιστροφής

15

.

Χαλαρώστε το μοχλό σύσφιξης 16 περιστρέφο-

ντας δεξιόστροφα και επαναφέρετε τη συσκευή

προς τα επάνω. Ελέγξτε το βάθος φρεζαρίσματος με μια ακόμη πρακτική προσπάθεια.

Ρύθιση του βάθου φρεζαρί-

σατο ε αναστολέα βάθου

ε βαθίδε

Εάν τα βάθη φρεζαρίσματος είναι μεγαλύτερα χρησιμοποιήστε τον αναστολέα βάθους με βαθμίδες

9

σε περισσότερες βαθμίδες με χαμηλότερη απομάκρυνση ρινισμάτων.

Ρυθμίστε το επιθυμητό βάθος φρεζαρίσματος με

την κατώτατη βαθμίδα του αναστολέα βάθους

με βαθμίδες 9 (όπως περιγράφεται παραπάνω).

Στη συνέχεια ρυθμίστε τις υψηλότερες βαθμίδες

για τα πρώτα βήματα επεξεργασίας.

Κατεύθυνση φρεζαρίσατο

Η διαδικασία φρεζαρίσματος πρέπει να πραγματοποιείται πάντα με κατεύθυνση αντίθετη προς την

κατεύθυνση περιστροφής της μηχανής φρεζαρίσματος

17

(αντίστροφή κίνηση).

ΠΡΟΣΟΧΗ: Κατά το φρεζάρισμα με κατεύθυνση

περιστροφής (σταθερή ταχύτητα) το ηλεκτρικό εργαλείο μπορεί να φύγει από το χέρι σας.

Χειρισμός

Page 23

23 GR/CY

ιαδικασία φρεζαρίσατο

Ρυθμίστε το βάθος κοπής, όπως περιγράφεται παραπάνω.

Ρυθμίστε τη συσκευή στο προς επεξεργασία

τεμάχιο εργασίας και ενεργοποιήστε τη.

Χαλαρώστε το μοχλό σύσφιξης 16 περιστρέ-

φοντας δεξιόστροφα τη συσκευή μέχρι να εφαρμόσει ο αναστολέας βάθους

12

στον αναστολέα

βάθους με βαθμίδες

9

προς τα κάτω.

Ασφαλίστε τη συσκευή περιστρέφοντας το μο-

χλό σύσφιξης

16

αριστερόστροφα.

Εκτελέστε τη διαδικασία φρεζαρίσματος με ίση

ταχύτητα και ίση πίεση επαφής (βλέπε εικ. I).

Τ

οποθέτηση χιτωνίου αντιγραφή

Τ

οποθετήστε το χιτώνιο αντιγραφής 26 από κά

τω

στην πλάκα ολίσθησης

8

.

Στερεώστε το χιτώνιο αντιγραφής 26 με τις δύο

βίδες

22

του προσαρμογέα αναρρόφησης στην

πλάκα έδρασης

7

. Προσέξτε, ώστε να τοπο-

θετήσετε σωστά το χιτώνιο αντιγραφής

26

– ο

δακτύλιος εδράνου κύλισης

25

πρέπει να δεί-

χνει προς τα κάτω (βλέπε εικ. D).

Φρεζάρισα ε χιτώνιο

αντιγραφή

Υπόδειξη! Το ύψος της καλίμπρας πρέπει να είναι

τουλάχιστον ίσο με το ύψος του δακτυλίου εδράνου

κύλισης

25

του χιτωνίου αντιγραφής 26.

Υπόδειξη! Επιλέξτε μικρότερη μηχανή φρεζαρίσματος από την εσωτερική διάμετρο των χιτωνίων

αντιγραφής.

Με τη χρήση ενός χιτωνίου αντιγραφής

26

οι

καλίμπρες μπορούν να μεταφερθούν στο τεμάχιο

εργασίας.

Τοποθετήστε την επάνω φρέζα με το χιτώνιο

αντιγραφής στην καλίμπρα.

Χαλαρώστε το μοχλό σύσφιξης 16 περιστρέφο-

ντας δεξιόστροφα και κατεβάζοντας τη συσκευή

προς τα κάτω, μέχρι να επιτευχθεί το προηγουμένως το ρυθμισμένο βάθος φρεζαρίσματος.

Τώρα οδηγήστε τη συσκευή με το προεξέχον

χιτώνιο αντιγραφής κατά μήκος της καλίμπρας.

Κατά τη διαδικασία αυτή εργαστείτε με ήπια πίεσ

η.

Φρεζάρισα ε παράλληλο

αναστολέα

Ωθήστε τον παράλληλο αναστολέα 24 στις

ράγες οδήγησης

6

της πλάκας έδρασης 7

και σφίξτε τις βίδες

5

.

Αποθέστε τον παράλληλο αναστολέα 24 στην

ακμή του τεμαχίου εργασίας (βλέπε εικ. F, H).

Φρεζάρισα ε διαβήτη

(βλέπε εικ. J)

Τρυπήστε τον άξονα κεντραρίσματος 30 στο

επισημασμένο κέντρο ενός κύκλου.

Περιστρέψτε τον παράλληλο αναστολέα 24,

δηλαδή η ακμή του αναστολέα να δείχνει προς

τα επάνω.

Βιδώστε με τη βοήθεια της πεταλούδας τον άξο-

να κεντραρίσματος με παράλληλο αναστολέα.

Κρατήστε κόντρα για τη σύσφιξη του άξονα

κεντραρίσματος με την επιμήκη οπή του ανοικτού κλειδιού

27

.

Συντήρηση και καθαρισό

ΚΙΝΥΝΟΣ ΤΡΑΥ-

ΜΑΤΙΣΜΟΥ! Αποσυνδέστε το βύσμα δικτύου από

την πρίζα πριν από όλες τις εργασίες στη συσκευή.

Η συσκευή θα πρέπει να είναι πάντοτε καθαρή,

στεγνή και χωρίς λάδια ή γράσα λίπανσης.

Χρησιμοποιήστε για τον καθαρισμό του περι-

βλήματος ένα στεγνό πανί.

Όταν είναι απαραίτητη

η αντικατάσταση της σύνδεσης παροχής, τότε

αυτή πρέπει εκτελείται από τον κατασκευαστή ή

τον αντιπρόσωπο του, για να αποφεύγονται

κίνδυνοι ασφάλειας.

Χειρισμός / Συντήρηση και καθαρισμός

Page 24

24 GR/CY

Q

Εγγύηση

Έχετε για αυτή τη συσκευή 3 χρόνια εγγύηση από την ηεροηνία αγορά. Η συσκευή

κατασκευάστηκε και ελέγχθηκε προσεκτικά πριν από την αποστολή. Παρακαλούε

φυλάξτε την απόδειξη ταείου ω απόδει

ξη

για την αγορά. Παρακαλούε επικοινωνήστε τηλεφωνικά ε την υπηρεσία σέρβι σε

περίπτωση εγγύηση. Μόνο έτσι πορεί

να εξασφαλιστεί ια δωρεάν αποστολή

του επορεύατό σα.

Η απόδοση εγγύησης ισχύει μόνο για σφάλματα

υλικού ή κατασκευής, όχι όμως για ζημιές από τη

μεταφορά, για εξαρτήματα φθοράς ή για βλάβες

σε εύθραυστα εξαρτήματα, π.χ. διακόπτες ή συσσωρευτές. Το προϊόν προορίζεται μόνο για την

ιδιωτική και όχι για την επαγγελματική χρήση.

Σε περίπτωση κακής μεταχείρισης και ακατάλληλης

χρήσης, σε χρήση βίας και σε παρεμβάσεις οι οποίες δεν διεξήχθησαν από το εξουσιοδοτημένο μας

τμήμα σέρβις, η εγγύηση παύει να ισχύει. Τα νομικά

σας δικαιώματα δεν περιορίζονται μέσω αυτής της

εγγύησης.

Ο χρόνος εγγύησης δεν επεκτείνεται μέσω της απόδοσης εγγύησης. Αυτό ισχύει και για εξαρτήματα

τα οποία έχουν αντικατασταθεί ή επισκευαστεί.

Ενδεχόμενες ήδη υπάρχουσες κατά την αγορά, ζημιές και ελλείψεις πρέπει να αναφέρονται αμέσως

μετά την αποσυσκευασία, το αργότερο όμως δύο

ημέρες μετά την ημερομηνία αγοράς. Επισκευές που

εμφανίζονται μετά τη λήξη του χρόνου εγγύησης

χρεώνονται.

GR

Σέρβι Ελλάδα

Tel.: 801 5000 019

(0,03 EUR/Min.)

e-mail: kompernass@lidl.gr

IAN 90981

CY

Σέρβι Κύπρο

Tel.: 8009 4409

e-mail: kompernass@lidl.com.cy

IAN 90981

Q

Απόσυρση

Η συσκευασία αποτελείται αποκλειστικά

από υλικά που σέβονται το περιβάλλον.

Αποσύρετέ τη με τη βοήθεια των κατά

τόπους υπηρεσιών ανακύκλωσης.

Απαγορεύεται η απόσυρση

ηλεκτρονικών εργαλείων αζί

ε τα οικιακά απορρίατα!

Σύμφωνα με την Ευρωπαϊκή Οδηγία 2002 / 96 / EC

σχετικά με τις ηλεκτρονικές συσκευές και τις παλιές

ηλεκτρονικές συσκευές και την αναφορά στο εθνικό δίκαιο θα πρέπει οι χρησιμοποιημένες ηλεκτρονικές συσκευές να συλλέγονται σε ξεχωριστό χώρο

και να ανακυκλώνονται οικολογικά.

Δυνατότητες απόσυρσης των χρησιμοποιημένων

συσκευών θα πληροφορηθείτε από τη διαχείριση

κοινότητας ή πόλης σας.

Εγγύηση / Απόσυρση

Page 25

25 GR/CY

Q

ήλωση συόρφωση /

Kατασκευαστή

Εμείς, η εταιρία KOMPERNASS HANDELS GMBH,

υπεύθυνος εγγράφων: Κύριος Semi Uguzlu, BURGSTRASSE 21, 44867 BOCHUM, GERMANY, δηλώνουμε με το παρόν ότι το προϊόν αυτό συμφωνεί

με τα ακόλουθα πρότυπα, κανονιστικά έγγραφα

και οδηγίες ΕΚ:

Οδηγία ηχανηάτων

(2006 / 42 / EC)

Οδηγία περί χαηλή τάση ΕΚ

(2006 / 95 / ΕC)

Ηλεκτροαγνητική συβατότητα

(2004 / 108 / ΕC)

RoHS Οδηγία

(2011 / 65 / EU)

Εφαροσθέντα εναρονισένα πρότυπα

EN 60745-1:2009+A11

EN 60745-2-17:2010

EN 55014-1:2006+A1+A2

EN 55014-2:1997+A1+A2

EN 61000-3-2:2006+A1+A2

EN 61000-3-3:2008

Τύπο / χαρακτηρισό συσκευή:

Καθετη φρεζα POF 1200 A1

Date of manufacture (DOM): 08–2013

Αριθό σειρά: IAN 90981

Bochum, 31.08.2013

Semi Uguzlu

- Διαχειριστής ποιότητας -

Διατηρούμε το δικαίωμα τεχνικών αλλαγών στα

πλαίσια της τεχνικής εξέλιξης.

Δήλωση συμμόρφωσης / Kατασκευαστής

Page 26

26

Page 27

27 DE/AT/CH

Inhaltsverzeichnis

Einleitung

Bestimmungsgemäßer Gebrauch .......................................................................................................Seite 28

Ausstattung ..........................................................................................................................................Seite 28

Lieferumfang ........................................................................................................................................ Seite 28

Technische Daten ................................................................................................................................ Seite 29

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

1. Arbeitsplatz-Sicherheit .................................................................................................................... Seite 29

2. Elektrische Sicherheit ...................................................................................................................... Seite 29

3. Sicherheit von Personen .................................................................................................................Seite 30

4. Verwendung und Behandlung des Elektrowerkzeugs .................................................................. Seite 30

5. Service ............................................................................................................................................. Seite 31

Gerätespezifische Sicherheitshinweise Fräsen .................................................................................. Seite 31

Ergänzende Anweisungen .................................................................................................................Seite 31

Originalzubehör / -zusatzgeräte ........................................................................................................ Seite 32

Inbetriebnahme

Fräser-Set / Einsatzbereiche ................................................................................................................ Seite 32

Fräswerkzeug einsetzen .....................................................................................................................Seite 32

Absaugadapter anschließen .............................................................................................................. Seite 32

Reduzierstück.......................................................................................................................................Seite 32

Spannzange wechseln .......................................................................................................................Seite 32

Parallelanschlag montieren ................................................................................................................Seite 33

Bedienung

Ein- und ausschalten ............................................................................................................................ Seite 33

Drehzahl vorwählen ............................................................................................................................Seite 33

Frästiefe einstellen ............................................................................................................................... Seite 33

Frästiefe nachjustieren ........................................................................................................................Seite 33

Frästiefe einstellen mit Stufenanschlag ..............................................................................................Seite 33

Fräsrichtung .........................................................................................................................................Seite 34

Fräsvorgang ........................................................................................................................................Seite 34

Kopierhülse einsetzen ......................................................................................................................... Seite 34

Fräsen mit Kopierhülse ........................................................................................................................ Seite 34

Fräsen mit Parallelanschlag ................................................................................................................ Seite 34

Fräsen mit Kreiszirkel ..........................................................................................................................Seite 35

Wartung und Reinigung .....................................................................................................Seite 35

Garantie ........................................................................................................................................... Seite 35

Entsorgung ..................................................................................................................................... Seite 35

Konformitätserklärung / Hersteller ..........................................................................Seite 36

Page 28

28 DE/AT/CH

Einleitung

Oberfräse POF 1200 A1

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres neuen

Gerätes. Sie haben sich damit für ein hochwertiges

Produkt entschieden. Die Bedienungsanleitung ist

Teil dieses Produkts. Sie enthält wichtige Hinweise für

Sicherheit, Gebrauch und Entsorgung. Machen Sie

sich vor der Benutzung

des Produkts mit allen Bedien-

und Sicherheitshinw

eisen vertraut. Benutzen Sie das

Produkt nur wie beschrieben und für die angegebenen Einsatzbereiche. Händigen Sie alle Unterlagen

bei Weitergabe des Produkts an Dritte mit aus.

Bestimmungsgemäßer Gebrauch

D

as Gerät ist dazu bestimmt, auf einer festen Auflag

e

in Holz, Kunststoff und Leichtbaustoffe Nuten, Kanten,

Profile und Langlöcher zu fräsen, sowie zum Kopierfräsen. Das Gerät ist nicht für den Betrieb im Freien

bestimmt. Jede andere Verwendung oder Veränderung der Maschine gilt als nicht bestimmungsgemäß

und birgt erhebliche Unfallgefahren. Nicht zum gewerblichen Gebrauch.

Ausstattung

Frontansicht Abbildung A

1

Drehzahlvorwahl

2

Handgriff

3

Überwurfmutter

4

Spannzange 8 mm (in Überwurfmutter 3

vormontiert)

5

Feststell-Schraube

6

Führungsschiene

7

Grundplatte

8

Gleitplatte

9

Stufenanschlag

10

Spindel-Arretiertaste

11

Arretierschraube

12

Tiefenanschlag

13

Indexzeiger

14

Skala Frästiefeneinstellung

15

Drehregler (Frästiefen-Feineinstellung)

Rückansicht Abbildung B

16

Spannhebel

17

Fräswerkzeug

18

Bohrungen Absaugadapter

19

EIN- / AUS-Schalter

20

Einschaltsperre

Zubehör Abbildung C

21

Absaugadapter

22

Schraube

23

Spannzange 6 mm

24

Parallelanschlag

25

Laufring

26

Kopierhülse

27

Maulschlüssel mit Langloch

28

Reduzierstück

29

Gleitstange mit Schraube für Parallelanschlag

24

30

Zentrierdorn

31

Innensechskantschlüssel

Fräser-Set Abbildung D

32

Abrund- / Profilfräser 24,7 mm

33

Abrund- / Profilfräser 28,6 mm

34

Abrund- / Profilfräser 28,6 mm (R–4)

35

Hohlkehlfräser 12 mm

36

Hohlkehlfräser 24,7 mm

37

V-Nutfräser 9,5 mm

38

V-Nutfräser 16 mm

39

Fasenfräser 32 mm

40

Zinkenfräser 14,3 mm

41

Bündigfräser 12,7 mm

42

Nutfräser 6 mm

43

Nutfräser 12 mm

Lieferumfang

1 Oberfräse

1 Maulschlüssel mit Langloch

1 Spannzange 6 mm

1 Spannzange 8 mm (montiert)

1 Absaugadapter

1 Parallelanschlag

1 Kopierhülse

1 Zentrierdorn

1 Fräser-Set 12-teilig (mit Innensechskantschlüssel)

1 Reduzierstück

Page 29

29 DE/AT/CH

Einleitung / Allgemeine Sicherheitshinweise für Elektrowerkzeuge

1 Innensechskantschlüssel

1 Bedienungsanleitung

Technische Daten

Nennaufnahme: 1200 W

Nennspannung: 230 V∼, 50 Hz

Leerlaufdrehzahl: n

0

11000–30000 min

–1

Fräskorbhub: 55 mm

Werkzeugaufnahme: 6 / 8 mm

Schutzklasse: II /

Geräusch- und Vibrationsinformationen:

Messwert für Geräusch ermittelt entsprechend

EN 60745. Der A-bewertete Geräuschpegel des

Elektrowerkzeugs beträgt typischerweise:

Schalldruckpegel: 84,7 dB(A)

Schallleistungspegel: 95,7 dB(A)

Unsicherheit K: 3 dB

Gehörschutz tragen!

Bewertete Beschleunigung, typischerweise:

Hand- / Armvibration ah = 6,437 m / s²

Unsicherheit K = 1,5 m / s²

Der in diesen Anweisungen

angegebene Schwingungspegel ist entsprechend

einem in EN 60745 genormten Messverfahren gemessen worden und kann für den Gerätevergleich

verwendet werden. Der angegebene Schwingungsemissionswert kann auch zu einer einleitenden Einschätzung der Aussetzung verwendet werden.

Der Schwingungspegel wird sich entsprechend dem

Einsatz des Elektrowerkzeugs verändern und kann in

manchen Fällen über dem in diesen Anweisungen

angegebenen Wert liegen. Die Schwingungsbelast

ung

könnte unterschätzt werden, wenn das Elektrowerkzeug regelmäßig in solcher Weise verwendet wird.

Hinweis: Für eine genaue Abschätzung der

Schwingungsbelastung während eines bestimmten

Arbeitszeitraumes sollten auch die Zeiten berücksichtigt werden, in denen das Gerät abgeschaltet ist oder

zwar läuft, aber nicht tatsächlich im Einsatz ist. Dies

kann die Schwingungsbelastung über den gesamten

Arbeitszeitraum deutlich reduzieren.

Allgemeine Sicherheitshinweise

für Elektrowerkzeuge

Lesen Sie alle Sicherheits-

hinweise und Anweisungen. Versäumnisse

bei der Einhaltung der Sicherheitshinweise und

Anweisungen können elektrischen Schlag, Brand

und / oder schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise

und Anweisungen für die Zukunft auf!

Der in den Sicherheitshinweisen verwendete Begriff

„Elektrowerkzeug“ bezieht sich auf netzbetriebene

Elektrowerk

zeuge (mit Netzkabel) und auf akkube-

triebene Elektrowerkzeuge (ohne Netzkabel).

1. Arbeitsplatz-Sicherheit

a) Halten Sie Ihren Arbeitsbereich sauber

und gut beleuchtet. Unordnung und unbeleuch-

tete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerk-

zeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube befinden.

Elektrowerkzeuge erzeugen Funken, die den

Staub oder die Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen

während der Benutzung des Elektrowerkzeugs fern. Bei Ablenkung können

Sie die Kontrolle über das Gerät verlieren.

2. Elektrische Sicherheit

a) Der Anschlussstecker des Elektrowerk-

zeuges muss in die Steckdose passen.

Der Stecker darf in keiner Weise verändert werden. Verwenden Sie keine

Adapterstecker gemeinsam mit

schutzgeerdeten Elektrowerkzeugen.

Unveränderte Stecker und passende Steckdosen

verringern das Risiko eines elektrischen Schlages.

b) Vermeiden Sie Körperkontakt mit ge-

erdeten Oberflächen, wie von Rohren,

Heizungen, Herden und Kühlschränken.

Page 30

30 DE/AT/CH

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

Es besteht ein erhöhtes Risiko durch elektrischen