Page 1

IAN 115720

FILE BELT SANDER PBF 400 A1

BANDFEILE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

FILE BELT SANDER

Operation and Safety Notes

Translation of the original instructions

ЛЕНТОВА ПИЛА

Инструкции за обслужване и безопасност

Превод на оригиналното ръководство за

експлоатация

Page 2

GB Operation and Safety Notes Page 5

BG Инструкции за обслужване и безопасност Страница 13

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 23

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Преди да прочетете отворете двете страници с фигурите и след това се запознайте с всички

функции на уреда.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

Page 3

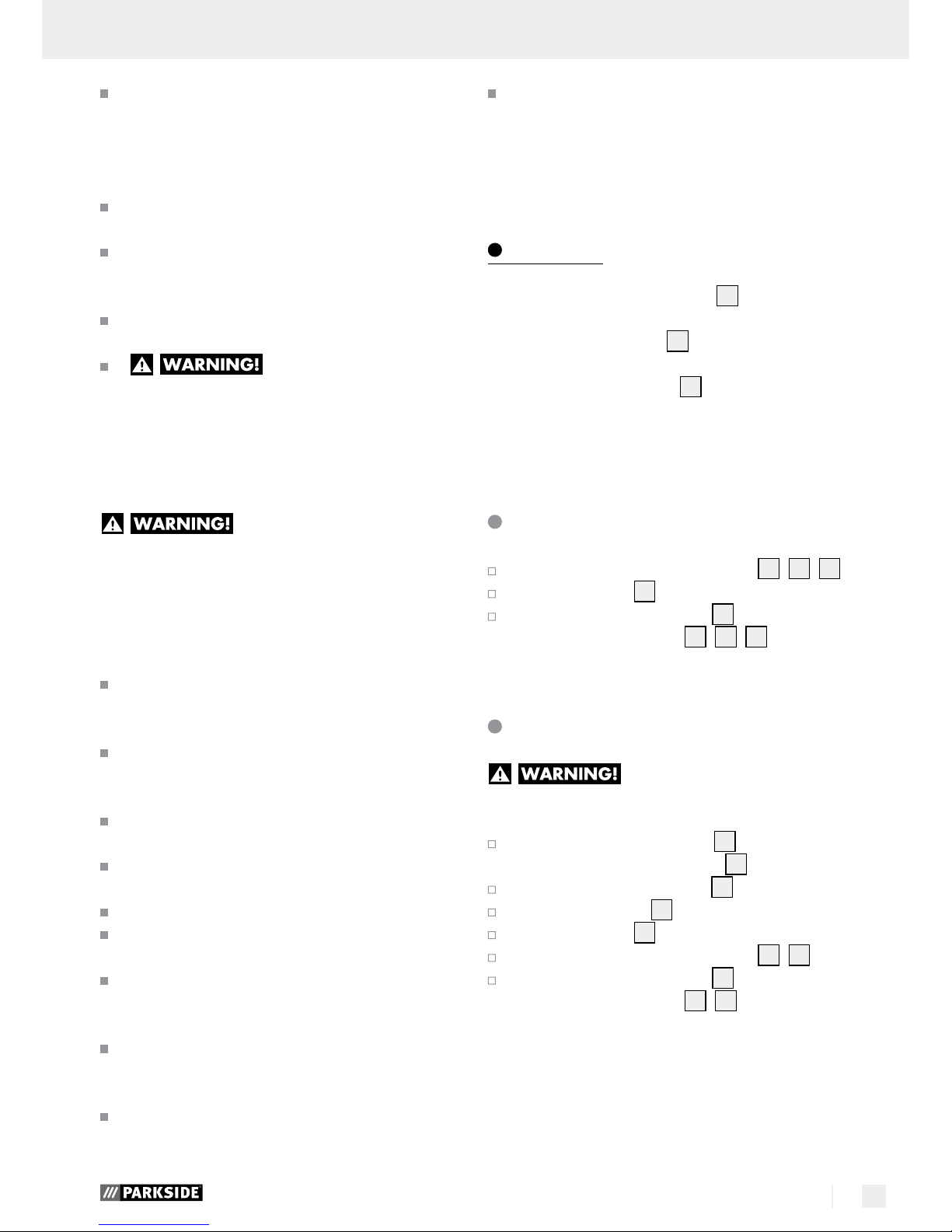

9

8

7

1 2 398

5

10

11

13

12

B

9

A

14

4

x 10

6

Page 4

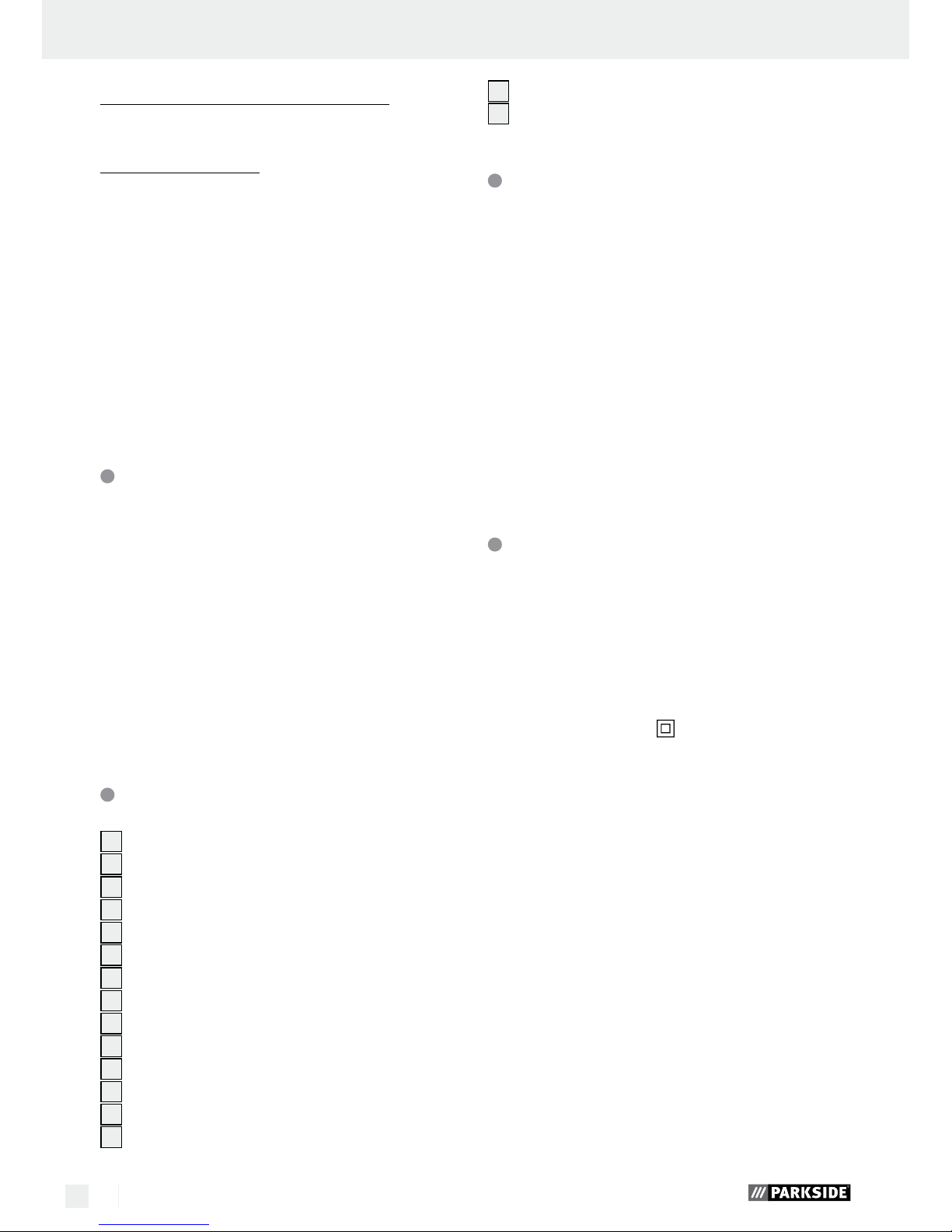

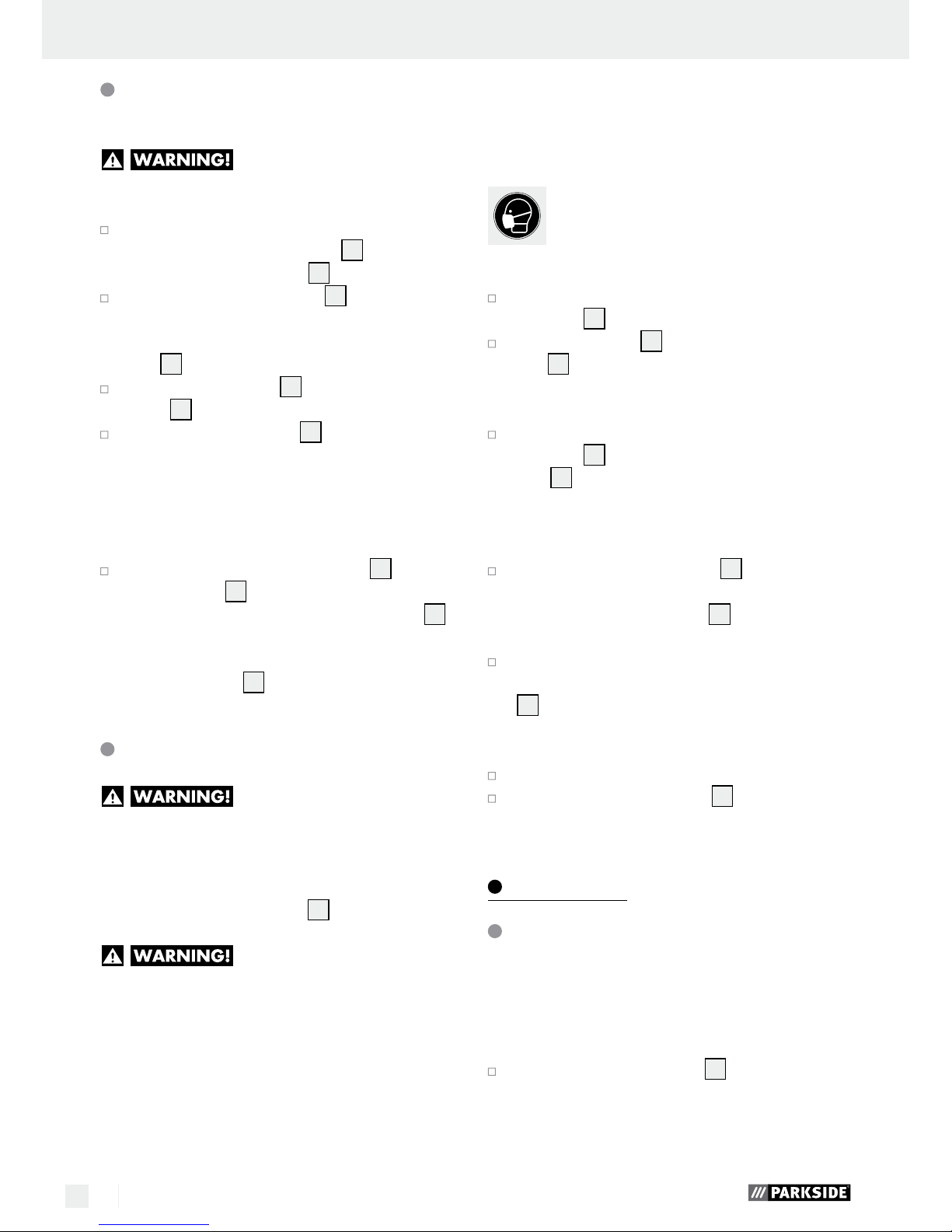

C

D E

F G

915

516

12

8 13

Page 5

5 GB

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Scope of delivery ................................................................................................................................ Page 6

Technical Data ....................................................................................................................................Page 6

General power tool safety warnings

1. Work area safety............................................................................................................................Page 7

2. Electrical safety ............................................................................................................................... Page 7

3. Personal safety ................................................................................................................................ Page 7

4. Power tool use and care ................................................................................................................ Page 8

5. Service ............................................................................................................................................. Page 8

Safety instructions for band files ........................................................................................................Page 8

Start-up

Installing the grinding frame ............................................................................................................... Page 9

Changing the grinding frame ............................................................................................................. Page 9

Clamping / changing the abrasive belt .............................................................................................Page 10

Dust extraction .....................................................................................................................................Page 10

Operation

Switching on and off ........................................................................................................................... Page 10

Selecting the speed and abrasive belt ..............................................................................................Page 11

Tips and tricks ...................................................................................................................................... Page 11

Maintenance and Cleaning .............................................................................................. Page 11

Service centre ..............................................................................................................................Page 11

Warranty ......................................................................................................................................... Page 11

Disposal ............................................................................................................................................ Page 12

Translation of the original declaration of conformity /

Manufacturer ............................................................................................................................... Page 12

Table of contents

Page 6

6 GB

Introduction

File belt sander PBF 400 A1

Q

Introduction

We congratulate you on the purchase of your new

device. You have chosen a high quality product.

The instructions for use are part of the product. They

contain important information concerning safety,

use and disposal. Before using the product, please

familiarise yourself with all of the safety information

and instructions for use. Only use the unit as described and for the specified applications. If you pass

the product on to anyone else, please ensure that

you also pass on all the documentation with it.

Intended use

The band file is designed for filing, particularly hard

to reach areas, of wood, plastic, metal and filler, as

well as painted surfaces. Be sure to use different

grits for working on the different materials and to

also adjust the speed according to the material. The

device is not intended for commercial use. Any other

uses, and / or modifications to the tool are considered improper use and may result in serious hazards.

The manufacturer is not liable for any damages

caused by improper use.

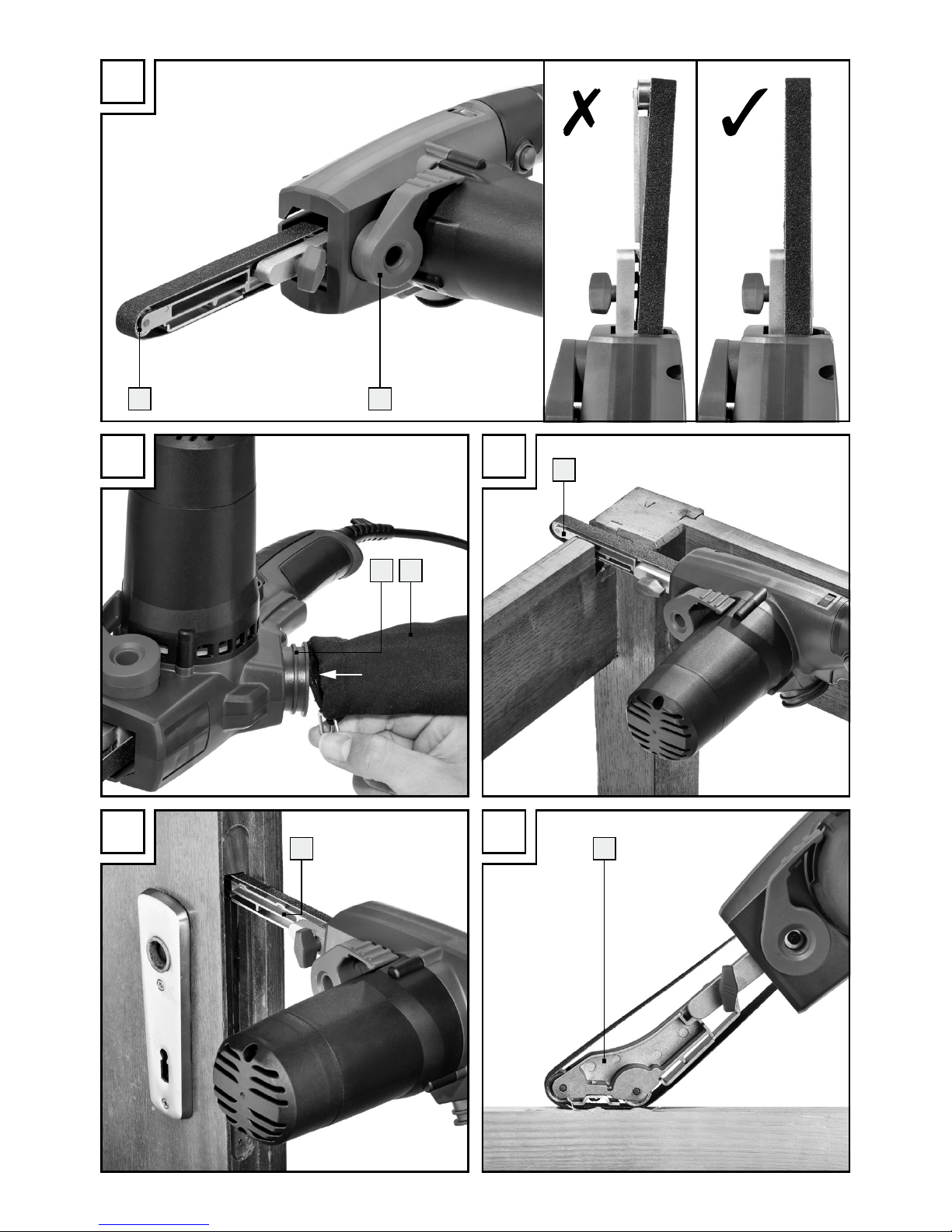

Features

1

Speed control

2

Locking button

3

Handle

4

ON / OFF switch

5

Dust bag

6

Side handle

7

Mounting and adjusting screw

8

Grinding frame, large

9

Clamping lever

10

Extraction adapter

11

Abrasive belt

12

Grinding frame, small

13

Grinding frame, angled

14

Spring

15

Front roller

16

Adapter connection

Scope of delivery

1 File belt sander PBF 400 A1

5 Abrasive belts for metal, wood, 8 x 455 mm

(2 x 60 grit, 2 x 80 grit, 1 x 120 grit)

5 Abrasive belts for metal, wood, 13 x 455 mm

(2 x 60 grit, 2 x 80 grit, 1 x 120 grit)

1 Dust bag

1 Extraction adapter (for external dust collection)

1 Straight frame, 8 mm

1 Straight frame, 13 mm

1 Angled frame, 13 mm

1 Carrying case

1 Set of instructions for use

Technical Data

File belt sander PBF 400 A1

Rated voltage: 230 V∼ 50 Hz

Rated power input: 400 W

Idle speed: n

0

2350–3600 rpm

Idle belt speed: 1070–1650 m / min

Abrasive belt: 8 x 455 mm and 13 x 455 mm

Protection class: II /

Noise and vibration data:

Measured sound value determined according to

EN ISO 4871. The A-rated noise levels of the electrical power tool are typically at:

Sound pressure level L

pA

: 82 dB(A)

Sound power level L

WA

: 93 dB(A)

Uncertainty K: 3 dB

Wear ear protection!

The total vibration (vector sum of three directions) is

calculated in accordance with EN 60745:

Vibration emission value: a

h

= 4.0 m / s

2

Uncertainty K = 1.5 m / s

2

Page 7

7 GB

Introduction / General power tool safety warnings

Note: The vibration emission value specified in these

instructions was measured in accordance with an

EN 60745 standardised measurement procedure

and can be used to compare tools. The vibration

emission value specified can also serve as a preliminary assessment of the exposure.

Different uses of the power tool

give rise to different vibration emission values and

in many cases they may exceed the values specified

in these instructions. It is easy to underestimate the

vibration load if the power tool is used regularly in

particular circumstances.

Try to keep the vibration loads as low as possible.

Measures to reduce the vibration load are, e.g.

wearing gloves during use and limiting the working

time. All states of operation must be included (e.g.

times when the power tool is switched off and times

where the power tool is switched on but running

without load).

General power tool

safety warnings

Read all safety

warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and / or

serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) D

o not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distractio

ns

can cause you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plug

s

and matching outlets will reduce risk of electric

shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or

wet conditions. Water entering a power tool

will increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e)

When operating a power tool outdo

ors,

use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing

and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

Page 8

8 GB

General power tool safety warnings

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and / or

battery pack, picking up or carrying

the tool. Carrying power tools with your fing

er

o

n the switch or energising power tools that hav

e

the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper foot-

ing and balance at all times. This enables

better control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collection

can reduce dust-related hazards.

4. Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your applica

tion.

The correct power tool will do the job better

and safer at the rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and / or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

5. Service

a) Have your power tool serviced by a

qualified repair person using only

iden-

tical replacement parts. This will ensure

that the safety of the power tool is maintained.

Safety instructions

for band files

Hold the device by the insulated han-

dle surfaces as the sanding belt could

strike the device’s own mains lead.

Damaging a live wire could result in the metal

parts of the device also becoming live and

could lead to an electric shock.

DANGER OF FIRE FROM FLYING SPARKS!

Sanding metal creates flying sparks. For this

reason, always make sure that nobody is placed

in any danger and that there are no inflammable

materials near the working area.

Page 9

9 GB

General power tool safety warnings / Start-up

When undertaking prolonged sanding of wood,

and in particular when working on materials

that give rise to dusts that are hazardous to

health, the sander must be connected to a

suitable external dust extraction device.

Ensure that there is adequate ventilation when

working on plastic, paint, varnish etc.

The band file is designed for dry grinding wood,

plastic, metal and filler, as well as painted surfaces. Only use the device for dry grinding.

Do not sand materials containing asbestos.

Asbestos is a known carcinogen.

Sanding e.g. lead paint,

some types of wood and metal can release

harmful / toxic dust. Touching or breathing in

these dusts can present a danger to the user or

persons nearby. Use suitable personal protective equipment such as dust mask, etc. to prevent

this risk.

POISONOUS DUSTS!

Sanding paints containing lead, some types of

wood and metal for example may give rise to

hazardous or poisonous dusts and represents a

risk to the health of the person operating the

device and to anyone near the work area.

Wear safety glasses and a dust protection mask!

Securely support the workpiece. Use clamps or

a vice to grip the workpiece firmly. This is much

safer than holding it with your hand.

Never support yourself by placing your hands

near or in front of the device or the workpiece

surface. A slip can result in injury.

If a dangerous situation arises, pull the mains

plug immediately out of the mains socket.

Always work with the mains lead leading

away from the rear of the device.

Avoid contact with the moving sanding belt.

Do not work on moistened materials or damp

surfaces.

Always switch on the device before placing it

against the workpiece. After sanding, lift the device from the workpiece before switching it off.

When working always hold the device securely

with both hands. Always keep proper footing

and balance.

Switch the device off and allow it to come to

a complete standstill before you put it down.

When taking a break from your work, before

carrying out any tasks on the device itself (e.g.

changing the sanding belt) and when you are

not using the device, always pull the mains plug

out of the mains socket.

Start-up

Note: the small grinding frame 12 is designed for

fine jobs, cutting and carving (see Fig. E).

The large grinding frame

8

is suitable for general

applications, slotting and making joints (see Fig. F).

The angled grinding frame

13

is suitable for grooving and sanding the middle of the work piece and

confined areas. Also use it to smooth bent areas

(see Fig. G).

Installing the grinding frame

Attach the desired grinding frame 8, 12, 13.

Insert the spring 14 into the mounting hole.

Tighten the adjusting screw 7 on the device

until the grinding frame

8, 12, 13

is in line

with the tool (see Fig. A).

Changing the grinding frame

RISK OF INJURY! Always un-

plug from the mains before working on the band file.

Unscrew the adjusting screw 7 from the device.

Be sure not to lose the spring

14

.

Remove the grinding frame 8.

Remove the spring 14.

Insert the spring 14 into the mounting hole.

Attach the desired grinding frame 12, 13.

Tighten the adjusting screw 7 on the device

until the grinding frame

12, 13

is in line with

the tool (see Fig. A).

Page 10

10 GB

Start-up / Operation

Clamping / changing

the abrasive belt

RISK OF INJURY! Always un-

plug from the mains before working on the band file.

Loosen the clamping device for the abrasive belt

by moving the clamping lever

9

forward (see

Fig. B). The abrasive belt

11

can be removed.

Slide the new abrasive belt 11 through the slot

in the housing of the tool. Important: The direction of the arrow on the inside of the abrasive

belt

11

and the housing of the tool must match.

Slip the abrasive belt 11 over the rear and front

roller

15

.

Push the clamping lever 9 back into the start-

ing position.

Manually adjusting the abrasive belt:

If the path of the belt does not straighten after

switching on, it may need to be adjusted manually.

To do so, turn the adjusting screw 7 until the

abrasive belt

11

is centred.

IMPORTANT: Be sure the abrasive belt

11

does not grind into the housing. Regularly

check the path of the belt and adjust with the

adjusting screw

7

if necessary (see Fig. C).

Dust extraction

EXPLOSION HAZARD!

A special dust extractor must be used for explosive

dust / air mixtures.

FIRE HAZARD DUE TO SPARKING! Do not

use dust extraction (dust bag

5

or vacuum) when

grinding metal.

FIRE HAZARD! Fire hazard

when using electric devices with dust bag or connected to a vacuum via dust extraction! Unfavourable

conditions, e.g. sparking - when grinding metal or

metal pieces in wood - wood dust inside the dust

bag (or inside the dust bag of the vacuum) can

spontaneously ignite. This can particularly occur if

the wood dust comes is mixed with paint particles

or other chemicals and the ground product is hot

after long work periods. Therefore be sure to avoid

the ground materials and the device from overheating and always empty the dust bag resp. the dust

bag of the vacuum before taking breaks.

Wear a dust

mask!

Dust extraction by dust bag (see Fig. D):

Compress the handles of the wire ring on the

dust bag

5

to make it larger.

Slip the dust bag 5 onto the adapter connec-

tion

16

.

Uninstalling / removing the dust bag:

Compress the handles of the wire ring on the

dust bag

5

to make it larger. Remove the dust

bag

5

from the device.

Adapter for external extraction

Connecting:

Place the extraction adapter 10 onto the file so

the teeth fit into the designated notches. Now

turn the extraction adapter

10

clockwise to

tighten.

Slide the hose of a reliable dust extractor (e.g.

workshop vacuum) onto the extraction adapter

10

.

Removal:

Pull the hose out of the dust extraction unit.

Turn the extraction adapter 10 counter-clock-

wise and remove from the file.

Operation

Switching on and off

When operating the device you can select between

intermittent or continuous operation:

Switching on temporary operation:

Push the ON / OFF switch 4.

Page 11

11 GB

Operation / Maintenance and cleaning / Service centre / Warranty

Switching off temporary operation:

Release the ON / OFF switch 4.

Engaging continuous operation:

Press and hold the ON / OFF switch 4 and

press the locking button

2

.

Disabling continuous operation:

Press the ON / OFF switch 4 and release.

Selecting the speed and

abrasive belt

You can select the speed using the speed control 1.

The optimal belt speed depends on the material you

will be working on. Always determine the respective

best speed yourself on a test piece.

Tips and tricks

Never use the same abrasive belt for wood

and metal.

Worn or torn abrasive belts can damage the

work piece. Therefore, regularly replace the

abrasive belts.

Only hang the abrasive belts to store, as folds

etc. render them useless.

Maintenance and Cleaning

RISK OF INJURY! Always un-

plug from the mains before working on the band file.

The band file is maintenance-free.

Clean the device immediately after finishing

your work.

Use a dry cloth to clean the device. Never use

petrol, solvent or cleaners which attack plastic.

Emptying / cleaning the dust bag:

Compress the handles of the wire ring on the

dust bag

5

to make it larger. Remove the dust

bag

5

from the device.

Tap the dust bag 5 to completely empty it,

then reattach it to the adapter connection

16

.

Always keep the vents clear.

Remove dust clinging to the device with a brush.

Q

Service centre

Have your device

repaired only by qualified specialist

personnel using original manufacturer

parts only. This will ensure that your device

remains safe to use.

If the power cable of this

tool is damaged, it must be replaced by the

manufacturer or its customer service, or a similarly qualified person, to prevent hazards.

Note: Spare parts not listed (e.g. carbon brushes,

switches) can be ordered through our call centre.

Q

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering

not carried out by our authorized service branch. Your

statutory rights are not restricted in any way by this

warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

Page 12

12 GB

… / Disposal / Translation of the original declaration of conformity / Manufacturer

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0.10 GBP/Min.)

e-mail: kompernass@lidl.co.uk

IAN 115720

Q

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

Do not dispose of electrical power

tools with the household rubbish!

In accordance with European Directive 2012 / 19 / EU

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn

out electrical power tools must be collected sepa

rately

and taken for environmentally compatible recycling.

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Translation of the original

declaration of conformity /

Manufacturer

We, KOMPERNASS HANDELS GMBH, the person

responsible for documents: Mr Semi Uguzlu, BURGSTRASSE 21, 44867 BOCHUM, GERMANY, hereby

declare that this product complies with the following

standards, normative documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

RoHS Directive (2011 / 65 / EU)

Applicable harmonized standards

EN 60745-1:2009/A11:2010

EN 60745-2-4:2009/A11:2011

EN 62233:2008

EN 55014-1:2006/A2:2011

EN 55014-2:1997/A2:2008

EN 61000-3-2:2014

EN 61000-3-3:2013

Type / Description of product:

File belt sander PBF 400 A1

Date of manufacture (DOM): 07–2015

Serial number: IAN 115720

Bochum, 31.07.2015

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications

in the course of further development.

Page 13

13 BG

Съдържание

Увод

Употреба по предназначение............................................................................................... Stranica 14

Оборудване ............................................................................................................................. Stranica 14

Обем на доставката ............................................................................................................... Stranica 14

Технически данни ................................................................................................................... Stranica 14

Общи инструкции за безопасност при работа

с електроуреди

1. Работно място-безопасност .............................................................................................. Stranica 15

2. Електрическа безопасност ................................................................................................ Stranica 15

3. Безопасност на хората ...................................................................................................... Stranica 16

4. Употреба и обслужване на електроуреда .................................................................... Stranica 16

5. Сервиз .................................................................................................................................. Stranica 17

Указания за безопасност при работа с лентови пили ...................................................... Stranica 17

Пускане в действие

Монтиране на рамката за шлифоване ............................................................................... Stranica 18

Смяна на рамката за шлифоване ........................................................................................ Stranica 18

Затягане / смяна на шлифовъчната лента ........................................................................... Stranica 18

Прахоулавяне.......................................................................................................................... Stranica 19

Обслужване

Включване и изключване ...................................................................................................... Stranica 19

Избиране на обороти и шлифовъчна лента ...................................................................... Stranica 20

Съвети ....................................................................................................................................... Stranica 20

Поддръжка и почистване .................................................................................... Stranica 20

Сервиз ...................................................................................................................................... Stranica 20

Гаранция .............................................................................................................................. Stranica 20

Изхвърляне на уреда ............................................................................................... Stranica 21

Превод на оригиналната ЕО Декларация за

съответствие / Производител .............................................................................. Stranica 22

Page 14

14 BG

Лентова пила PBF 400 A1

Увод

Поздравяваме Ви за покупката на Вашия нов

уред. Вие избрахте висококачествен продукт.

Ръководството за експлоатация е част от този

продукт. То съдържа важни указания за безопасност, употреба и изхвърляне. Преди употребата

на продукта се запознайте с всички инструкции

за обслужване и безопасност. Използвайте продукта

само съгласно описанието и за посочените

области на употреба. Когато предавате продукта

на трети лица, предавайте заедно с него и всички

документи.

Употреба по предназначение

Лентовата пила е предназначена за изпиляване

най-вече в трудно достъпни места, за работа по

дърво, пластмаса, метал и шпакловъчна маса,

както и боядисани повърхности. Моля, обърнете

внимание, че при обработка на различни видове материали трябва да поставяте съответни

шлифовъчни ленти с различна едрина на абразивните зърна и да настройвате оборотите също

съобразно материала. Уредът не е предназначен

за професионални цели. Всяко друго приложени

е

или промяна на уреда се считат за нецелесъобразни и крият значителни опасности от злополуки. Производителят не носи отговорност за ще

ти,

възникнали поради нецелесъобразна употреба.

Оборудване

1

Регулатор на оборотите

2

Фиксиращ бутон

3

Ръкохватка

4

Превключвател ВКЛ. / ИЗКЛ.

5

Колектор за прах

6

Странична ръкохватка

7

Монтажен и регулиращ винт

8

Рамка за шлифоване, голяма

9

Затегателен лост

10

Адаптер за прахоулавяне

11

Шлифовъчна лента

12

Рамка за шлифоване, малка

13

Рамка за шлифоване, под ъгъл

14

Пружина

15

Предна ролка

16

Връзка за адаптер

Обем на доставката

1 лентова пила PBF 400 A1

5 шлифовъчни ленти за метал, дърво, 8 x 455 mm

(2 x 60 едрина на зърното, 2 x 80 едрина на

зърното, 1 x 120 едрина на зърното)

5 ш

лифовъчни ленти за метал, дърво 13 x 455 mm

(2 x 60 едрина на зърното, 2 x 80 едрина на

зърното, 1 x 120 едрина на зърното)

1 колектор за прах

1 адаптер за прахоулавяне (за външно прахоу-

лавяне)

1 права рамка, 8 mm

1 права рамка, 13 mm

1 рамка под ъгъл, 13 mm

1 куфарче за носене

1 ръководство за експлоатация

Технически данни

Лентова пила PBF 400 A1

Номинално напрежение: 230 V∼ 50 Hz

Номинална консумирна

мощност: 400 W

Обороти на празен ход: n

0

2350–3600 min

-1

Скорост на лентата на

празен ход: 1070–1650 m / min

Шлифовъчна лента: 8 x 455 mm и

13 x 455 mm

Клас на защита: II /

Информация за нивото на шума и

вибрациите:

Стойността на нивото на шума е определена в

съответствие с EN ISO 4871. Стойността на изчисленото А-ниво на електроуреда обикновено е:

Увод

Page 15

15 BG

Ниво на силата на звука LpA: 82 dB(A)

Логаритмична величина

на мощността на звука L

WA

: 93 dB(A)

Неопределеност К: 3 dB

Носете антифони!

Общата стойност на вибрациите (векторна сума

в тр

ите посоки) е определена съгласно EN 60745:

Стойност на вибрационните емисии: ah 4,0 m / s

2

Неопределеност K = 1,5 m / s

2

Указание: Стойността на вибрационните емисии, посочена в настоящите указания, е измерена в съответствие с метод, стандартизиран в

EN 60745 и може да се използва за сравняване

на уреди. Посочената стойност на вибрационни

емисии може да се използва като предварителн

а

оценка на експозицията.

Стойността на вибрационните емисии се променя според употребата на електроуреда и в някои случаи може да

бъде по-високо от посочената в тази инструкция

стойност. Вибрационното натоварване може да

бъде подценено, ако уредът се използва редовно

по такъв начин.

Старайте са да намалите максимално натоварването вследствие вибрации. Примерни мерки

за намаляване на вибрационното натоварване

са носенето на ръкавици при използване на инструмента и ограничаването на работното врем

е.

При това следва да се вземат предвид всички

етапи на работния цикъл (например, времето,

в което електрическият инструмент е изключен

и времето, в което е включен, но работи без натоварване).

Общи инструкции за

безопасност при работа

с електроуреди

Прочетете всички инструкции за безопасност и указанията. Пропуските

при спазване на инструкциите за безопасност и

указанията може да причинят токов удар, пожар

и / или тежки наранявания.

За в бъдеще спазвайте всички указания

и инструкции за безопасност!

Използването на понятието „електроуред” в инструкциите за безопасност се отнася за електрически инструменти, включвани в електрическата

мрежа (посредством мрежов кабел), както и за

захранвани от акумулатор електрически инструменти (без мрежов кабел).

1. Работно място-безопасност

a) Поддържайте работното място чисто

и добре осветено. Безпорядъкът и лошото

осветление на зоната, в която се работи, могат да доведат до злополуки.

б) Не работете с електроуреди във

взривоопасни зони, в които се намират запалими течности, газове или

прахообразни вещества. Електроуре-

дите могат да възпроизведат искра, която да

възпламени праха или изпаренията.

в) По време на работа с електроуреда

дръжте децата и странични лица

настрани. Ако отклоните вниманието си

може да загубите контрола върху уреда.

2. Електрическа безопасност

a) Щепселът за включване на електро-

уреда трябва да е съвместим с контакта. По щепсела в никакъв случай

не бива да се предприемат промени.

Не използвайте адаптиращи щепсели

при заземени електроуреди. Щепсе-

лите, по които няма направени промени и

подходящите контакти намаляват риска от

електрически удар.

б) Избягвайте допир на тялото до зазе-

мени повърхности, като тръби, радиатори, кухненски печки и хладилниц

и.

Съществува голям риск от токов удар, ако

Вашето тяло е заземено.

Увод / Общи инструкции за безопасност при работа с електроуреди

Page 16

16 BG

в) Предпазвайте вашите електроуреди

от дъжд и влага. Проникването на влага

в електроуреда повишава опасността от токов удар.

г) Не използвайте кабела извън негово-

то предназначение, за да носите, да

окачвате уреда или да издърпвате с

него щепсела от контакта. Дръжте

кабела надалеч от горещи предмети,

масло, остри ръбове или подвижните

части на уреда. Повредените или оплете-

ни кабели повишават риска от токов удар

.

д) Ако работите с електроуред на от-

крито, използвайте само удължаващи

кабели, разрешени за условия на открито. Използването на подходящ удължава

щ

кабел за употреба на открито намалява риска

от токов удар.

е) Ако работата с електроуреда във

влажна среда е неизбежна, използвайте автоматичен защитен изключв

ател. Употребата на автоматичен защите

н

изключвател намалява риска от електрически удар.

3. Безопасност на хората

a) Бъдете винаги внимателни, обръщай-

те внимание на това, което правите

и извършвайте разумно работата си

с електроуреда. Не използвайте

електроуреди, когато сте уморени

или сте под въздействието на дрога,

алкохол или лекарства. Един момент

невнимание при употребата на електроуреда може да доведе до сериозни наранявания.

б)

Носете предпазна екипировка и вина-

ги защитни очила. Носенето на лична

предпазна екипировка като предпазна маска

против прах, предпазни обувки, които не се

хлъзгат, защитна каска или шумозаглушители,

според вида и употребата на електроуреда,

намалява риска от наранявания.

в)

Избягвайте неволно включване. Избя

г-

в

айте неволно включване. Уверете с

е,

че електроуредът е изключен, преди

за го свържeте към захранването и /

или батерията, да го вземете или

носите. Ако по времето, когато носите уре-

да, пръстът ви е на бутона, или ако уредът е

бил включен в електрическата мрежа, може

да стане злополука.

г) Оставете настрана всички инструмен-

ти за настройване и гаечни ключове

преди да включите електроуреда.

Инструмент или ключ, който се намира на

въртяща се част от уреда може да причини

наранявания.

д)

Избягвайте необичайното положение

на тялото. Погрижете се за стабилна

стойка и по всяко време пазете равновесие. Така ще можете да контролирате

електроуреда в неочаквани ситуации.

е) Носете подходящо облекло. Не но-

сете широки дрехи или украшения.

Пазете косите, облеклото и ръкавиците от въртящите се части. Свободното

облекло, украшенията или дългите коси

може

да бъдат захванати от въртящите се части.

ж) Ако трябва да бъдат монтирани пра-

хоизсмукващи и прахоулавящи

приспособления се уверете, че те са

закрепени и се използват правилно.

Употребата на прахоизсмукващи приспособления може да ограничи вредите от прах.

4. Употреба и обслужване

на електроуреда

a) Не преотстъпвайте уреда. За Вашата

работа използвайте правилния уред.

С подходящия уред ще работите по-добре и

по-безопасно в определената област.

б) Не използвайте електроуред с повре-

ден изключвател. Електроуред, който не

може да се включи и изключи е опасен и

трябва да се ремонтира.

в) Изключете щекера от контакта и /

или отстранете батерията, преди да

предприемете настройки по уреда,

да сменяте части или да приберете

уреда. Тази мярка за безопасност предо-

твратява неумишлен старт на електроуреда.

Общи инструкции за безопасност при работа с електроуреди

Page 17

17 BG

г) Съхранявайте неупотребявани елек-

троуреди на места недостъпни за

деца. Не оставяйте лица, които не

са запознати или не са прочели тази

инструкция, да работят с уреда.

Елек-

троуредите са опасни, когато се използват

от

неопитни лица.

д) Поддържайте грижливо електро-

уредите. Проверявайте дали подвиж

ните части функционират безу-

пречн

о и не са затегнати, дали има

счупени части или части, които са

повредени по начин, който пречи

на правилното функциониране на

уреда. Преди употреба дайте повредените части на ремонт. Много от

злополуките се случват поради лошо поддържани електроуреди.

е) Режещите инструменти следва да се

поддържат остри и чисти. Внимателно

поддържани режещи инструменти с остри

режещи елементи по-рядко се заклинват и

се

управляват по-лесно.

ж) Използвайте електроуреди, принад-

лежности към тях, инструменти и.т.н.

в съответствие с тези указания. При

това се съобразявайте с условията за работа и извършваните действия. Употребата на

електроуреди за цели, различни от тези, за

които те са предвидени, може да доведе до

опасни ситуации.

5. Сервиз

a) Предавайте уреда за ремонт на ква-

лифициран персонал и използвайте

само оригинални резервни части. С

това се гарантира запазването на сигурността на уреда.

Указания за безопасност при

работа с лентови пили

Хващайте уреда за изолираните ръ-

кохватки, защото шлайфащата лента

може да закачи мрежовия си кабел.

Повреда на захранващия кабел, може да

доведе до поставяне под напрежение на

металните части на уреда и да предизвика

токов удар.

ОПАСНОСТ ОТ ЗАПАЛВАНЕ ПОРАДИ

ХВЪРЧАЩИ ИСКРИ! Когато шлифовате

метал възникват искри. Затова внимавайте,

никой да не бъде изложен на опасност и в

близост до работното място да няма леснозапалими материали.

При обработката на дърво и особено на

материали, при които възниква увреждащо

здравето запрашаване, включвайте уреда

към подходяща външна засмукваща уредба.

При обработка на пластмаси, бои, лакове

и др. се погрижете да има достатъчно проветряване.

Лентовата пила е предназначена за сухо

повърхностно шлифоване на дърво, пластмаса, метал и шпакловъчна маса, както и

на боядисани повърхности. Уредът може да

се използва само за сухо шлифоване.

Материали, съдържащи азбест, не бива да

се обработват. Азбестът се счита за канцерогенен.

При шлайфане

напр. на бои, съдържащи олово, на някои

видове дървесина и метал може да се образува вреден / отровен прах. Контактът или

вдишването на този прах може да представлява опасност за оператора или намиращи

се в близост лица. Използвайте подходящи

лични предпазни средства, като противопрахова маска и др., за да избегнете риска.

ОТРОВЕН

ПРАХ! При шлифоването на например

съдържащи олово мазилки, някои видове

дървесина, и метали възниква вреден / отровен прах, който представлява заплаха за

оператора на машината или за намиращи

се в близост лица.

Носете защитни очила и маска за прах!

Обезопасете инструмента. Използвайте за-

тягащи съоръжения / менгеме, за да закрепите

изделието. Така то се крепи по-стабилно,

отколкото в ръката ви.

В никакъв случай не подпирайте ръцете си

в близост до или пред уреда или обработ-

Общи инструкции за безопасност при работа с електроуреди

Page 18

18 BG

ваната повърхност, тъй като има опасност

от нараняване в случай на подхлъзване.

При опасност веднага извадете щепсела от

контакта.

Кабелът за захранването да се извежда

винаги зад уреда.

Избягвайте контакт с движещата се шлифо-

въчна лента.

Не обработвайте навлажнени или мокри

повърхности.

Инструментът се води по изделието само

при включен уред. След обработката на изделието първо отстранете уреда от него и

едва след това го изключете.

Дръжте уреда по време на работа винаги

здраво с две ръце. Съблюдавайте безопасното му разположение.

Изчакайте уреда да спре напълно и го из-

ключете преди да го оставите.

Винаги изваждайте щепсела от контакта при

работните паузи, особено при работи по

самия уред (например смяна на шлифовъчната хартия), както и когато не го ползвате.

Пускане в действие

Указание: Малката рамка за шлифоване 12

е разработена за фина работа, за рязане и резбоване (виж фиг. E).

Голямата рамка за шлифоване

8

е подходяща

за общо приложение, за назъбване и изработване на съединения (виж фиг. F).

Рамката за шлифоване под ъгъл

13

е подходяща

за изработване на канали и шлифоване в среда

та

на детайлите и в ограничени участъци. Използвайте я също и заглаждане на извити повърхности (виж фиг. G).

Монтиране на рамката

за шлифоване

Поставете необходимата рамка за шлифо-

ване

8, 12, 13

.

Поставете пружината 14 в монтажния отвор.

Затегнете регулиращия винт 7 в уреда, до-

като рамката за шлифоване

8, 12, 13

заста-

не в една линия с инструмента (виж фиг. A).

Смяна на рамката за

шлифоване

ОПАСНОСТ ОТ

НАРАНЯВАНЕ! Винаги изключвайте щепсела

от контакта преди извършване на дейности по

лентовата пила.

Развийте регулиращия винт 7 от уреда.

При това внимавайте да не изгубите пружината

14

.

Отстранете рамката за шлифоване 8.

Отстранете пружината 14.

Поставете пружината 14 отново в монтаж-

ния отвор.

Поставете необходимата рамка за шлифо-

ване

12, 13

.

Затегнете отново регулиращия винт 7 в

уреда, докато рамката за шлифоване

12, 13

застане в една линия с инструмента (виж

фиг. A).

Затягане / смяна на

шлифовъчната лента

ОПАСНОСТ ОТ

НАРАНЯВАНЕ! Винаги изключвайте щепсела

от контакта преди извършване на дейности по

лентовата пила.

Освободете затегателния механизъм на

шлифовъчната лента, като изместите затегателния лост

9

напред (виж фиг. B). Шлифо-

въчната лента

11

може да се извади.

Вкарайте новата шлифовъчна лента 11

през отвора в корпуса на уреда. Важно:

Посоката на стрелките от вътрешната страна на шлифовъчната лента

11

и върху кор-

пуса на уреда трябва да съвпадат.

Прокарайте шлифовъчната лента 11 над

задната и предната ролка

15

.

Общи инструкции за безопасност при работа … / Пускане в експлоатация

Page 19

19 BG

Натиснете затегателния лост 9 отново в

изходно положение.

Ръчно регулиране на шлифовъчната

лента:

Ако след включване лентата не е центрирана,

следва да регулирате хода й ръчно, ако е необходимо.

За целта завийте регулиращия винт 7,

докато шлифовъчната лента

11

се движи

центрирано.

ВАЖНО: Задължително съблюдавайте

шлифовъчната лента

11

да не се трие в корпуса. Проверявайте редовно хода на лентата и при нужда извършвайте допълнително

настройване чрез регулиращия винт

7

(виж

фиг. C).

Прахоулавяне

ОПАСНОСТ ОТ

ЕКСПЛОЗИЯ! При взривоопасен прах / въз-

душна смес трябва да използвате подходящ за

целта аспиратор.

ОПАСНОСТ ОТ ПОЖАР ПОРАДИ ПРЕХВЪРЧАЩИ ИСКРИ! При шлайфане на метали

не използвайте аспиратори (колектор за прах

5

или прахосмукачка).

ОПАСНОСТ ОТ

ПОЖАР! При работа с електрически уреди,

които са оборудвани с колектор за прах или

могат да бъдат свързани чрез аспиратор с прахосмукачка, съществува опасност от пожар!

При неблагоприятни условия, като напр. прехвърчащи искри - при шлайфане на метал или

метални остатъци в дървесина - дървесният прах

в колектора (или в торбата на прахосмукачката)

може да се възпламени от само себе си. Това

може да се случи най-вече тогава, когато дървесният прах е смесен с остатъци от боя или

други химични вещества и шлифованият детайл

се загрее след продължителна работа. Затова

задължително избягвайте прегряване на шлифования детайл и на уреда и преди почивка винаги изпразвайте колектора за прах или торбата

на прахосмукачката.

Носете противопрахова маска!

Прахоулавяне с колектор за прах (виж

фиг. D):

Притиснете дръжките на теления пръстен на

колектора за прах

5

, така че обиколката

му да се увеличи.

Сега поставете колектора за прах 5 във

връзката за адаптер

16

.

Демонтиране / сваляне на колектора

за прах:

Притиснете дръжките на теления пръстен

на колектора за прах

5

, така че обиколката му да се увеличи. Издърпайте колектора

за прах

5

от уреда.

Адаптер за външно прахоуловително

устройство

Свързване:

Поставете адаптера за прахоулавяне 10 вър-

ху пилата, така че зъбите му да паснат в

предвидените прорези. Завийте адаптера

за прахоулавяне

10

по посока на часовни-

ковата стрелка.

Поставете маркуча на разрешено за упо-

треба прахоуловително устройство (напр.

на индустриална прахосмукачка) върху

адаптера

10

.

Отстраняване:

Издърпайте маркуча на прахоуловителното

устройство.

Развийте адаптера за прахоулавяне 10 об-

ратно на часовниковата стрелка и го издърпайте от пилата.

Обслужване

Включване и изключване

Можете да избирате между моментен и непрекъснат работен режим на лентовата пила.

Пускане в експлоатация / Обслужване

Page 20

20 BG

Включване на моментен работен режим:

Натиснете превключвателя ВКЛ. / ИЗКЛ. 4.

Изключване на моментен работен режим:

О

свободете превключвателя ВКЛ. / ИЗКЛ. 4.

Включване на непрекъснат работен

режим:

Натиснете превключвателя ВКЛ. / ИЗКЛ. 4,

задръжте го и натиснете фиксиращия бутон 2.

Изключване на непрекъснат работен

режим:

Натиснете превключвателя ВКЛ. / ИЗКЛ 4

и го отпуснете.

Избиране на обороти

и шлифовъчна лента

Посредством регулатора 1 можете да избирате оборотите. Оптималната скорост на лентата

зависи от обработвания материал. Винаги определяйте най-подходящите обороти чрез практически опит.

Съвети

Никога не обработвайте дърво и метал с

една и съща шлифовъчна лента.

Износените или частично разкъсани шли-

фовъчни ленти могат да повредят детайла.

Затова редовно подменяйте шлифовъчните

ленти.

Съхранявайте шлифовъчните ленти само във

висящо положение, тъй като от прегъването

те стават негодни за употреба.

Поддръжка и почистване

ОПАСНОСТ ОТ

НАРАНЯВАНЕ! Винаги изключвайте щепсела

от контакта преди извършване на дейности по

лентовата пила.

Лентовата пила не изисква поддръжка.

Почиствайте уреда веднага след приключ-

ване на работа.

За почистване на уреда използвайте суха

кърпа и в никакъв случай бензин, разтворители или почистващи препарати, които разяждат пластмаса.

Изпразване / почистване на колектора

за прах:

Притиснете дръжките на теления пръстен на

колектора за прах

5

, така че обиколката

му да се увеличи. Издърпайте колектора за

прах

5

от уреда.

Изпразнете напълно колектора за прах 5

чрез почукване и след това го поставете отново във връзката за адаптер

16

.

Дръжте вентилационните отвори винаги

свободни.

Отстранявайте полепналия прах с четка.

Q

Сервиз

Ремонтирай-

те вашите уреди в сервиз или от квалифициран електротехник само с

оригинални резервни части. Така се

гарантира, че ще се запази безопасността

на уреда.

Ако захранва-

щият кабел на уреда е повреден, той трябва

да се подмени от производителя, сервиза или

лице със сходна квалификация, за да се избегнат опасности.

Указание: Резервни части, които не са изброе

ни

(като напр. графитни четки, превключватели),

можете да поръчвате в нашите кол центрове.

Гаранция

За този уред получавате 3 години гаранция, считано от датата на покупката.

Уредът е произведен с необходимото

внимание и тестван добросъвестно. Мо

ля,

Обслужване / Поддръжка и почистване / Сервиз / Гаранция

Page 21

21 BG

пазете касовата бележка като доказателство за покупката. В случай на гаранционно събитие се свържете по телефона

с вашия сервиз. Само така може да се

гарантира безплатно изпращане на вашия уред.

Гаранцията се отнася само за дефекти на материалите и фабрични дефекти, но не и за повреди,

възникнали по време на транспорта, за износващи се части или повреди по чупливите части,

например изключвател или акумулаторни батерии. Продуктът е предназначен за ваша лична

употреба, но не и за употреба за стопански цели.

П

ри зловредно и неправомерно отношение, употр

еба на сила и посегателство, които не са извършени

от нашите сервизи, гаранцията отпада. Ва

шите за-

конни права не се ограничават от тази гаранция.

Гаранционният период не се удължава след извършени гаранционни услуги. Това се отнася и з

а

подменени и ремонтирани части. За евентуални

налични повреди в момента на покупката трябва

да бъде съобщено веднага след разопаковането,

но най-късно до два дни след датата на закупуване. След изтичане на гаранцията ремонтите

се заплащат.

BG

Сервизно обслужване България

Тел.: 00800 1114920

e-мейл: kompernass@lidl.bg

IAN 115720

Q

Изхвърляне на уреда

Опаковката е изработена от екологични материали, които може да предадете за рециклиране по местоживеене.

Не изхвърляйте електроуреди

заедно с битовите отпадъци!

Според Европейската директива 2012 / 19 / EU

за стари електрически и електронни уреди и

прилагане на националното законодателство,

излезлите от употреба електроуреди се събират

разделно и се предават за екологично рециклиране.

За възможностите за предаване на излезлия от

употреба уред може да се информирате от общинската или градска управа.

Гаранция / Изхвърляне на уреда

Page 22

22 BG

Превод на оригиналната ЕО Декларация за съответствие / Производител

Превод на оригиналната ЕО

Декларация за съответствие /

Производител

Ние, KOMPERNASS HANDELS GMBH, отговорно

лице за документацията: г-н Semi Uguzlu, BURGSTRASSE 21, 44867 BOCHUM, GERMANY, Германия, декларираме, че този продукт съответства

на следните норми, нормативни документи и

ЕО-директиви:

Директива за машините

(2006 / 42 / EC)

Οδηγία περί χαηλή τάση ΕΚ

(2006 / 95 / ΕC)

Електромагнитна съвместимост

(2004 / 108 / EC)

RoHS Директива

(2011 / 65 / EU)

Приложени хармонизирани норми

EN 60745-1:2009/A11:2010

EN 60745-2-4:2009/A11:2011

EN 62233:2008

EN 55014-1:2006/A2:2011

EN 55014-2:1997/A2:2008

EN 61000-3-2:2014

EN 61000-3-3:2013

Тип / Обозначение на продукта:

Лентова пила PBF 400 A1

Date of manufacture (DOM): 07–2015

Сериен номер: IAN 115720

Bochum, 31.07.2015

Semi Uguzlu

- Мениджър по качеството -

Запазваме си правото на технически промени

с цел усъвършенстване на уреда.

Page 23

23 DE/AT/CH

Einleitung

Bestimmungsgemäßer Gebrauch .......................................................................................................Seite 24

Ausstattung ..........................................................................................................................................Seite 24

Lieferumfang ........................................................................................................................................ Seite 24

Technische Daten ................................................................................................................................ Seite 24

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

1. Arbeitsplatz-Sicherheit .................................................................................................................... Seite 25

2. Elektrische Sicherheit ...................................................................................................................... Seite 25

3. Sicherheit von Personen .................................................................................................................Seite 26

4. Verwendung und Behandlung des Elektrowerkzeugs .................................................................. Seite 26

5. Service ............................................................................................................................................. Seite 27

Sicherheitshinweise für Bandfeilen ..................................................................................................... Seite 27

Inbetriebnahme

Schleifrahmen montieren ....................................................................................................................Seite 28

Schleifrahmen wechseln .....................................................................................................................Seite 28

Schleifband einspannen / wechseln ...................................................................................................Seite 28

Staubabsaugung ................................................................................................................................. Seite 29

Bedienung

Ein- und ausschalten ............................................................................................................................ Seite 29

Drehzahl und Schleifband wählen.....................................................................................................Seite 30

Tipps und Tricks ................................................................................................................................... Seite 30

Wartung und Reinigung .....................................................................................................Seite 30

Service ...............................................................................................................................................Seite 30

Garantie ........................................................................................................................................... Seite 30

Entsorgung ..................................................................................................................................... Seite 31

Original-EG-Konformitätserklärung / Hersteller ............................................ Seite 31

Inhaltsverzeichnis

Page 24

24 DE/AT/CH

Einleitung

Bandfeile PBF 400 A1

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres neuen

Gerätes. Sie haben sich damit für ein hochwertiges

Produkt entschieden. Die Bedienungsanleitung ist

Teil dieses Produkts. Sie enthält wichtige Hinweise

für Sicherheit, Gebrauch und Entsorgung. Machen

Sie sich vor der Benutzung des Produkts mit allen

Bedien- und Sicherheitshinweisen vertraut. Benutzen Sie das Produkt nur wie beschrieben und für

die angegebenen Einsatzbereiche. Händigen Sie

alle Unterlagen bei Weitergabe des Produkts an

Dritte mit aus.

Bestimmungsgemäßer

Gebrauch

Die Bandfeile ist für Feilarbeiten, besonders an

schwer

zugänglichen Stellen, an Holz, Kunststoff, Metall und

Spachtelmasse sowie lackierten Oberflächen ausgelegt. Beachten Sie bitte, dass Sie zur Bearbeitung

der verschiedenen Materialien entsprechende Schleifbänder mit unterschiedlicher Körnung einsetzen und

die Drehzahl ebenfalls dem Material anpassen. Das

Gerät ist nicht für den gewerblichen Einsatz bestimmt.

Jede andere Verwendung oder Veränderung der

Maschine gilt als nicht bestimmungsgemäß und birgt

erhebliche Unfallgefahren. Für aus bestimmungswidriger Verwendung entstandene Schäden übernimmt

der Hersteller keine Haftung.

Ausstattung

1

Drehzahlregler

2

Feststelltaste

3

Handgriff

4

EIN- / AUS-Schalter

5

Staubbeutel

6

seitlicher Handgriff

7

Montage- und Justierschraube

8

Schleifrahmen, groß

9

Spannhebel

10

Absaugadapter

11

Schleifband

12

Schleifrahmen, klein

13

Schleifrahmen, gewinkelt

14

Feder

15

vordere Rolle

16

Adapteranschluss

Lieferumfang

1 Bandfeile PBF 400 A1

5 Schleifbänder für Metall, Holz, 8 x 455 mm

(2 x 60er Körnung, 2 x 80er Körnung,

1 x 120er Körnung)

5 Schleifbänder für Metall, Holz 13 x 455 mm

(2 x 60er Körnung, 2 x 80er Körnung,

1 x 120er Körnung)

1 Staubbeutel

1 Absaugadapter (zur externen Staubabsaugung)

1 gerader Rahmen, 8 mm

1 gerader Rahmen, 13 mm

1 angewinkelter Rahmen, 13 mm

1 Tragekoffer

1 Bedienungsanleitung

Technische Daten

Bandfeile PBF 400 A1

Nennspannung: 230 V∼ 50 Hz

Nennaufnahme: 400 W

Leerlaufdrehzahl: n

0

2350–3600 min

-1

Leerlauf-Bandge schwindigkeit: 1070–1650 m / min

Schleifband: 8 x 455 mm und 13 x 455 mm

Schutzklasse: II /

Geräusch- und Vibrationsinformationen:

Messwert für Geräusch ermittelt entsprechend

EN ISO 4871. Der A-bewertete Geräuschpegel

des Elektrowerkzeugs beträgt typischerweise:

Schalldruckpegel L

pA

: 82 dB(A)

Schallleistungspegel L

WA

: 93 dB(A)

Unsicherheit K: 3 dB

Gehörschutz tragen!

Page 25

25 DE/AT/CH

Einleitung / Allgemeine Sicherheitshinweise für Elektrowerkzeuge

Schwingungsgesamtwerte (Vektorsumme dreier

Richtungen) ermittelt entsprechend EN 60745:

Schwingungsemissionswert: a

h

4,0 m / s

2

Unsicherheit K = 1,5 m / s

2

Hinweis: Der in diesen Anweisungen angegebene

Schwingungsemissionswert ist entsprechend einem

in EN 60745 genormten Messverfahren gemessen

worden und kann für den Gerätevergleich verwendet

werden. Der angegebene Schwingungsemissionswert kann auch zu einer einleitenden Einschätzung

der Aussetzung verwendet werden.

Der Schwingungsemissionswert

wird sich entsprechend dem Einsatz des Elektrowerkzeugs verändern und kann in manchen Fällen über

dem in diesen Anweisungen angegebenen Wert

liegen. Die Schwingungsbelastung könnte untersch

ätzt

werden, wenn das Elektrowerkzeug regelmäßig in

solcher Weise verwendet wird.

Versuchen Sie, die Belastung durch Vibrationen so

gering wie möglich zu halten. Beispielhafte Maßnahmen zur Verringerung der Vibrationsbelastung

sind das Tragen von Handschuhen beim Gebrauch

des Werkzeuges und die Begrenzung der Arbeitszeit. Dabei sind alle Anteile des Betriebszyklus zu

berücksichtigen (beispielsweise Zeiten, in denen

das Elektrowerkzeug abgeschaltet ist, und solche,

in denen es zwar eingeschaltet ist, aber ohne Belastung läuft).

Allgemeine Sicherheitshinweise

für Elektrowerkzeuge

Lesen Sie alle

Sicherheitshinweise und Anweisungen. Versäumnisse bei der Einhaltung

der Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und / oder schwere Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise

und Anweisungen für die Zukunft auf!

Der in den Sicherheitshinweisen verwendete Begriff

„Elektrowerkzeug“ bezieht sich auf netzbetriebene

Elektrowerk

zeuge (mit Netzkabel) und auf akkube-

triebene Elektrowerkzeuge (ohne Netzkabel).

1. Arbeitsplatz-Sicherheit

a) Halten Sie Ihren Arbeitsbereich sauber

und gut beleuchtet. Unordnung und unbeleuch-

tete Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerk-

zeug nicht in explosionsgefährdeter

Umgebung, in der sich brennbare Flüssigkeiten, Gase oder Stäube befinden.

Elektrowerkzeuge erzeugen Funken, die den

Staub oder die Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen

während der Benutzung des Elektrowerkzeugs fern. Bei Ablenkung können

Sie die Kontrolle über das Gerät verlieren.

2. Elektrische Sicherheit

a) Der Anschlussstecker des Elektrowerk-

zeuges muss in die Steckdose passen.

Der Stecker darf in keiner Weise verändert werden. Verwenden Sie keine

Adapterstecker gemeinsam mit

schutzgeerdeten Elektrowerkzeugen.

Unveränderte Stecker und passende Steckdosen

verringern das Risiko eines elektrischen Schlages.

b) Vermeiden Sie Körperkontakt mit ge-

erdeten Oberflächen, wie von Rohren,

Heizungen, Herden und Kühlschränken.

Es besteht ein erhöhtes Risiko durch elektrischen

Schlag, wenn Ihr Körper geerdet ist.

c) Halten Sie Elektrowerkzeuge von Re-

gen oder Nässe fern. Das Eindringen von

Wasser in ein Elektrogerät erhöht das Risiko

eines elektrischen Schlages.

d) Zweckentfremden Sie das Kabel nicht,

um das Elektrowerkzeug zu tragen,

aufzuhängen oder um den Stecker aus

der Steckdose zu ziehen. Halten Sie

das Kabel fern von Hitze, Öl, scharfen

Kanten oder sich bewegenden Geräteteilen. Beschädigte oder verwickelte Kabel

erhöhen das Risiko eines elektrischen Schlages.

Page 26

26 DE/AT/CH

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

e) Wenn Sie mit einem Elektrowerkzeug

im Freien arbeiten, verwenden Sie nur

Verlängerungskabel, die auch für den

Außenbereich zugelassen sind. Die

Anwendung eines für den Außenbereich

geeigneten Verlängerungskabels verringert

das Risiko eines elektrischen Schlages.

f) Wenn der Betrieb des Elektrowerk-

zeuges in feuchter Umgebung nicht

vermeidbar ist, verwenden Sie einen

Fehlerstromschutzschalter. Der Einsatz

eines Fehlerstromschutzschalters vermindert

das Risiko eines elektrischen Schlages.

3. Sicherheit von Personen

a)

Seien Sie stets aufmerksam, achten Sie

darauf, was Sie tun und gehen Sie mit

Vernunft an die Arbeit mit einem Elek

trowerkzeug. Benutzen Sie kein Elektrowerkzeug, wenn Sie müde sind oder

unter dem Einfluss von Drogen, Alkohol oder Medikamenten stehen. Ein

Moment der Unachtsamkeit beim Gebrauch

des Elektrowerkzeuges kann zu ernsthaften

Verletzungen führen.

b)

Tragen Sie persönliche Schutzausrüstung

und immer eine Schutzbrille. Das Tragen

persönlicher Schutzausrüstung wie Staubmask

e,

rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des

Elektrowerkzeuges, verringert das Risiko von

Verletzungen.

c) Vermeiden Sie eine unbeabsichtigte

Inbetriebnahme. Vergewissern Sie sich,

dass das Elektrowerkzeug ausgeschaltet ist, bevor Sie es an die Stromversorgung und / oder den Akku anschließen,

es aufnehmen oder tragen. Wenn Sie

beim

Tragen des Elektrowerkzeuges den Finger am

Schalter haben oder das Gerät bereits eingeschaltet an die Stromversorgung anschließen,

kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder

Schraubenschlüssel, bevor Sie das

Elektrowerkzeug einschalten. Ein Werk-

zeug oder Schlüssel, der sich in einem drehenden

Geräteteil befindet, kann zu Verletzungen führen.

e) Vermeiden Sie eine abnormale Körper-

haltung. Sorgen Sie für einen sicheren

Stand und halten Sie jederzeit das

Gleichgewicht. Dadurch können Sie das

Elektrowerkzeug in unerwarteten Situationen

besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen

Sie keine weite Kleidung oder Schmuck.

Halten Sie Haare, Kleidung und Handschuhe fern von sich bewegenden

Teilen. Lockere Kleidung, Schmuck oder lange

Haare können von sich bewegenden Teilen

erfasst werden.

g) Wenn Staubabsaug- und -auffangein-

richtungen montiert werden können,

vergewissern Sie sich, dass diese

angeschlossen sind und richtig verwendet werden. Die Verwendung einer

Staubabsaugung kann Gefährdungen durch

Staub verringern.

4. Verwendung und Behandlung

des Elektrowerkzeugs

a) Überlasten Sie das Gerät nicht. Ver-

wenden Sie für Ihre Arbeit das dafür

bestimmte Elektrowerkzeug. Mit dem

passenden Elektrowerkzeug arbeiten Sie besser

und sicherer im angegebenen Leistungsbereich.

b) Benutzen Sie kein Elektrowerkzeug,

dessen Schalter defekt ist. Ein Elektrowerk-

zeug, das sich nicht mehr ein- oder ausschalten

lässt, ist gefährlich und muss repariert werden.

c) Ziehen Sie den Stecker aus der Steck-

dose und / oder entfernen Sie den Akku,

bevor Sie Geräteeinstellungen vornehmen, Zubehörteile wechseln oder

das Gerät weglegen. Diese Vorsichtsmaß-

nahme verhindert den unbeabsichtigten Start

des Elektrowerkzeuges.

d) Bewahren Sie unbenutzte Elektrowerk-

zeuge außerhalb der Reichweite von

Kindern auf. Lassen Sie Personen das

Gerät nicht benutzen, die mit diesem

Page 27

27 DE/AT/CH

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

nicht vertraut sind oder diese Anweisungen nicht gelesen haben. Elektrowerk-

zeuge sind gefährlich, wenn sie von unerfahrenen

Personen benutzt werden.

e) Pflegen Sie Elektrowerkzeuge mit

Sorgfalt. Kontrollieren Sie, ob bewegliche Teile einwandfrei funktionieren

und nicht klemmen, ob Teile gebrochen

oder so beschädigt sind, dass die Funktion des Elektrowerkzeuges beeinträchtigt ist. Lassen Sie beschädigte Teile vor

dem Einsatz des Gerätes reparieren.

Viele Unfälle haben ihre Ursache in schlecht

gewarteten Elektrowerkzeugen.

f) Halten Sie Schneidwerkzeuge scharf

und sauber. Sorgfältig gepflegte Schneid-

werkzeuge mit scharfen Schneidkanten verklemmen sich weniger und sind leichter zu führen.

g) Verwenden Sie Elektrowerkzeug,

Zubehör, Einsatzwerkzeuge usw.

entsprechend diesen Anweisungen.

Berücksichtigen Sie dabei die Arbeitsbedingungen und die auszuführende

Tätigkeit. Der Gebrauch von Elektrowerkzeu-

gen für andere als die vorgesehenen Anwendungen kann zu gefährlichen Situationen führen.

5. Service

a) Lassen Sie Ihr Elektrowerkzeug nur von

qualifiziertem Fachpersonal und nur

mit Original-Ersatzteilen reparieren.

Damit wird sichergestellt, dass die Sicherheit

des Elektrowerkzeugs erhalten bleibt.

Sicherheitshinweise

für Bandfeilen

Halten Sie das Gerät an den isolierten

Griffflächen, da das Schleifband das

eigene Netzkabel treffen kann. Das Be-

schädigen einer spannungsführenden Leitung

kann metallene Geräteteile unter Spannung

setzen und zu einem elektrischen Schlag führen.

BRANDGEFAHR DURCH FUNKENFLUG!

Wenn Sie Metalle schleifen entsteht Funkenflug.

Achten Sie deshalb unbedingt darauf, dass

keine Personen gefährdet werden und sich keine

brennbaren Materialien in der Nähe des Arbeitsbereiches befinden.

Schließen Sie beim Bearbeiten von Holz und

insbesondere wenn Materialien bearbeitet

werden, bei denen gesundheitsgefährdende

Stäube entstehen, das Gerät an eine geeignete

externe Absaugvorrichtung an.

Sorgen Sie bei der Bearbeitung von Kunststoffen,

Farben, Lacken etc. für ausreichende Belüftung.

Die Bandfeile ist für trockenes Flächenschleifen

von Holz, Kunststoff, Metall und Spachtelmasse

sowie lackierten Oberflächen ausgelegt. Das

Gerät darf nur für Trockenschliff verwendet

werden.

Asbesthaltiges Material darf nicht bearbeitet

werden. Asbest gilt als krebserregend.

Beim Schleifen von z.B.

bleihaltigen Anstrichen, einigen Holzarten und

Metall können schädliche / giftige Stäube entstehen. Die Berühung oder das Einatmen dieser

Stäube kann eine Gefährdung für die Bedienperson oder in der Nähe befindliche Personen

darstellen. Verwenden Sie geeignete persönliche

Schutzausrüstungen, wie Staubschutzmaske, usw.,

um die Gefährdung zu vermeiden.

GIFTIGE STÄUBE! Die beim

Schleifen von z. B. bleihaltigen Anstrichen,

einigen Holzarten und Metallen entstehenden

schädlichen / giftigen Stäube stellen eine

Gesundheitsgefährdung für die Bedienperson

oder in der Nähe befindliche Personen dar.

Tragen Sie Schutzbrille und Staubschutzmaske!

Sichern Sie das Werkstück. Benutzen Sie

Spannvorrichtungen / Schraubstock, um das

Werkstück festzuhalten. Es ist damit sicherer

gehalten, als mit Ihrer Hand.

Stützen Sie auf keinen Fall die Hände neben

oder vor dem Gerät und der zu bearbeitenden

Fläche ab, da bei einem Abrutschen Verletzungsgefahr besteht.

Ziehen Sie bei Gefahr sofort den Netzstecker

aus der Steckdose.

Führen Sie das Netzkabel immer nach hinten

vom Gerät weg.

Vermeiden Sie den Kontakt mit dem laufenden

Schleifband.

Page 28

28 DE/AT/CH

Allgemeine Sicherheitshinweise für Elektrowerkzeuge / Inbetriebnahme

Bearbeiten Sie keine angefeuchteten Materialien

oder feuchte Flächen.

Führen Sie das Gerät immer eingeschaltet gegen

das Werkstück. Heben Sie das Gerät nach der

Bearbeitung vom Werkstück ab und schalten

Sie es erst dann aus.

Halten Sie das Gerät während der Arbeit immer

fest mit beiden Händen. Sorgen Sie für einen

sicheren Stand.

Lassen Sie das Gerät vollständig zum Stillstand

kommen und schalten Sie es aus, bevor Sie

es ablegen.

Ziehen Sie bei Arbeitspausen, vor allen Arbeiten

am Gerät (z. B. Wechsel des Schleifpapiers)

und bei Nichtgebrauch immer den Netzstecker

aus der Steckdose.

Inbetriebnahme

Hinweis: Der kleine Schleifrahmen 12 ist für

feinere

Arbeiten, zum Schneiden und zum Schnitzen konzipiert (s. Abb. E).

Der große Schleifrahmen

8

ist für allgemeine

Anwendungen geeignet, zum Auskerben und zur

Herstellung von Verbindungen (s. Abb. F).

Der gewinkelte Schleifrahmen

13

ist zum Furchen

und Schleifen in der Mitte der Werkstücke und in

begrenzten Bereichen geeignet. Benutzen Sie ihn

auch, um gekrümmte Flächen zu glätten (s. Abb. G).

Schleifrahmen montieren

Setzen Sie den gewünschten Schleifrahmen 8,

12, 13

ein.

S

etzen Sie die Feder 14 in das Montageloch ei

n.

Schrauben Sie die Justierschraube 7 am Gerät

fest, bis sich der Schleifrahmen

8, 12, 13

in

einer Linie mit dem Werkzeug befindet (siehe

Abb. A).

Schleifrahmen wechseln

VERLETZUNGSGEFAHR!

Ziehen Sie den Netzstecker immer aus der Steckdose, bevor Sie Arbeiten an der Bandfeile

durchführen.

Schrauben Sie die Justierschraube 7 vom Ge-

rät ab. Achten Sie dabei darauf, dass Sie nicht

die Feder

14

verlieren.

Entfernen Sie den Schleifrahmen 8.

Entfernen Sie die Feder 14.

Setzen Sie die Feder 14 wieder in das Monta-

geloch ein.

Setzen Sie den gewünschten Schleifrahmen 12,

13

ein.

Schrauben Sie die Justierschraube 7 wieder am

Gerät fest, bis sich der Schleifrahmen

12, 13

in

einer Linie mit dem Werkzeug befindet (s. Abb. A).

Schleifband einspannen /

wechseln

VERLETZUNGSGEFAHR!

Ziehen Sie den Netzstecker immer aus der Steckdo

se,

bevor Sie Arbeiten an der Bandfeile durchführen.

Lösen Sie die Spannvorrichtung für das Schleif-

band, indem Sie den Spannhebel

9

nach

vorne schieben (siehe Abb. B). Das Schleifband

11

lässt sich entnehmen.

Schieben Sie das neue Schleifband 11 durch

den Schlitz im Gerätegehäuse. Wichtig: Die

Pfeilrichtungen auf der Innenseite des Schleifbandes

11

und am Gerätegehäuse müssen

übereinstimmen.