Page 1

PNEUMATIC SAW PDKS 6.0 A1

DRUCKLUFT-SÄGE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

PNEUMATIC SAW

Operation and Safety Notes

Translation of the original instructions

SAV MED TRYKLUFT

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

TRYCKLUFTSÅG

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

PAINEILMASAHA

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

IAN 110140

110140_par_Druckluft-Saege PDKS 6.0 A1_cover_FI_SE_DK.indd 3 08.07.15 09:00

Page 2

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 15

SE Bruksanvisning och säkerhetsanvisningar Sidan 25

DK Brugs- og sikkerhedsanvisninger Side 35

DE / AT / CH Bedienungs- und Sicher heitshinweise Seite 45

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista molemmat kuvalliset sivut esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut båda bildsidorna och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend begge sidene med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

110140_par_Druckluft-Saege PDKS 6.0 A1_cover_FI_SE_DK.indd 4 08.07.15 09:00

Page 3

A

7

4

2

3

1

568

110140_par_Druckluft-Saege PDKS 6.0 A1_cover_FI_SE_DK.indd 5 08.07.15 09:00

Page 4

D

E

C

B

F

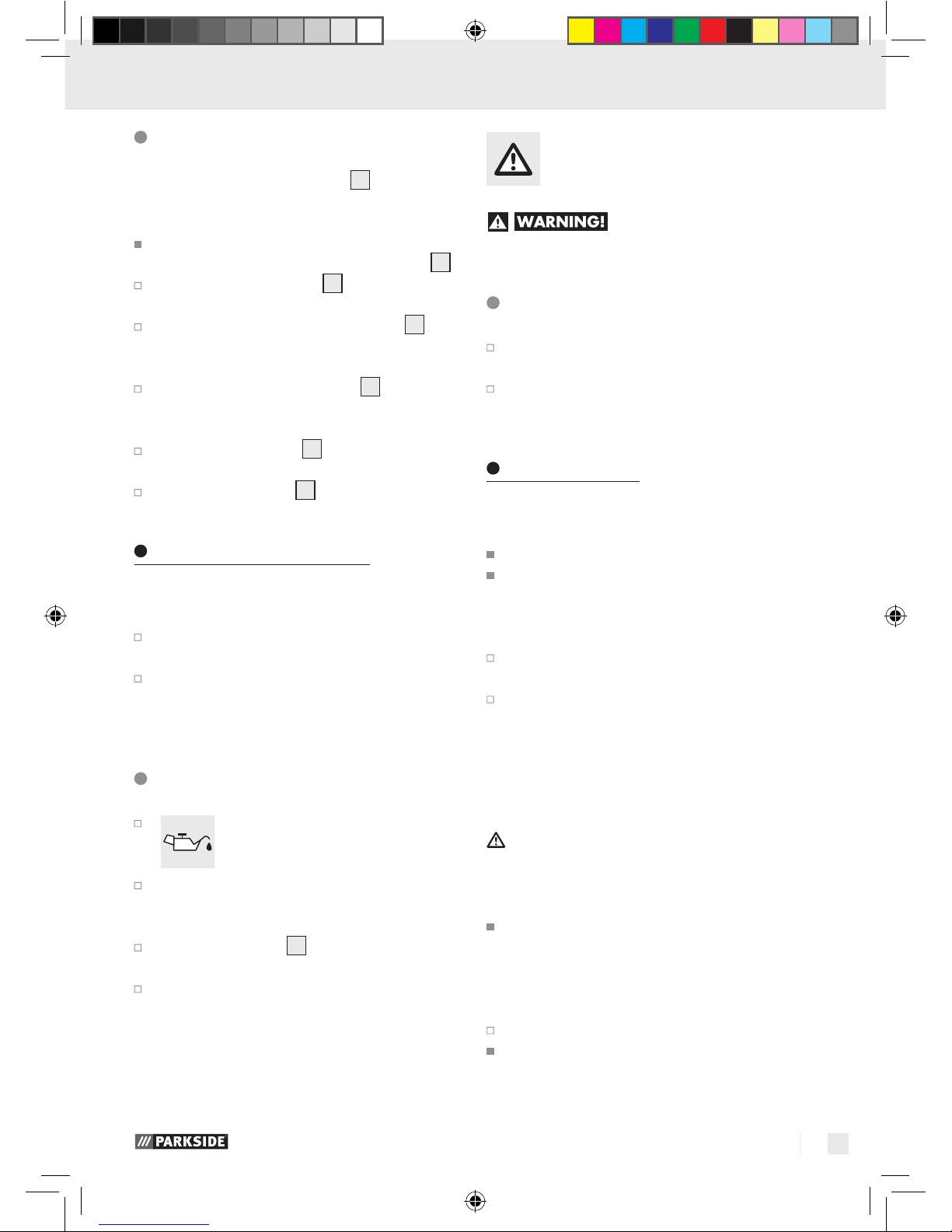

Pressurised air hose / Druckluftschlauc h

Quick-release socket /

Schnellverschluss-Stecker

Quick-release socket /

Schnellverschluss-Stecker

Pressure regulator / Druckregler

Lubricator /

Öler

Filter / Filter

Quick-opening sleeve / Schnellverschluss-Muffe

Compressor / Kompressor

110140_par_Druckluft-Saege PDKS 6.0 A1_cover_FI_SE_DK.indd 8 08.07.15 09:00

Page 5

5 GB/IE

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Technical Data ....................................................................................................................................Page 6

Scope of delivery ................................................................................................................................ Page 7

General safety rules

Risks due to projected parts ...............................................................................................................Page 7

Hazards from entanglement ............................................................................................................... Page 7

Operating hazards .............................................................................................................................Page 7

Hazards due to repetitive motions ..................................................................................................... Page 8

Risks associated with accessories ......................................................................................................Page 8

Hazards in the work environment ...................................................................................................... Page 8

Hazards due to dust and vapours .....................................................................................................Page 8

Noise hazards ..................................................................................................................................... Page 9

Hazard due to vibration ..................................................................................................................... Page 9

Before use

Installation ...........................................................................................................................................Page 10

Start-up

Connecting the compressed air tool .................................................................................................. Page 10

Cutting .................................................................................................................................................Page 10

After initial use ...........................................................................................................................Page 10

Replacing the saw blade .................................................................................................................... Page 11

Cleaning and storage

Lubricating the air saw ........................................................................................................................ Page 11

Storing the air saw .............................................................................................................................. Page 11

Maintenance ................................................................................................................................. Page 11

Warranty and service information

Warranty terms ...................................................................................................................................Page 12

Extent of warranty ............................................................................................................................... Page 12

Processing of warranty claims ............................................................................................................ Page 12

Environmental instructions and disposal information ..............................Page 13

Declaration of Conformity ................................................................................................ Page 13

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 5 08.07.15 09:10

Page 6

6 GB/IE

Introduction / General safety rules

Introduction

Pneumatic saw PDKS 6.0 A1

Introduction

Congratulations!

You have chosen high-quality device by

our company. Familiarise yourself with

the product before using it for the first time. In addition, please carefully refer to the operating instructions

and the safety advice below. Initial operation of this

tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

The air saw is an air-powered tool for handyman use.

It is designed for bodywork, automotive and shop

use. The user should wear safety goggles to protect

from fragments and safety gloves to protect from

accidental contact with potentially sharp edges. K

eep

these instructions in a safe place. When passing this

product on to others, please also include all the documents. Any use other than the intended is prohibited

and potentially dangerous. Damages resulting from

noncompliance or misuse are not covered by the

warranty and are not included in the manufacturer‘s

liability. This device has been designed for household use and may not be used for commercial or

industrial purposes.

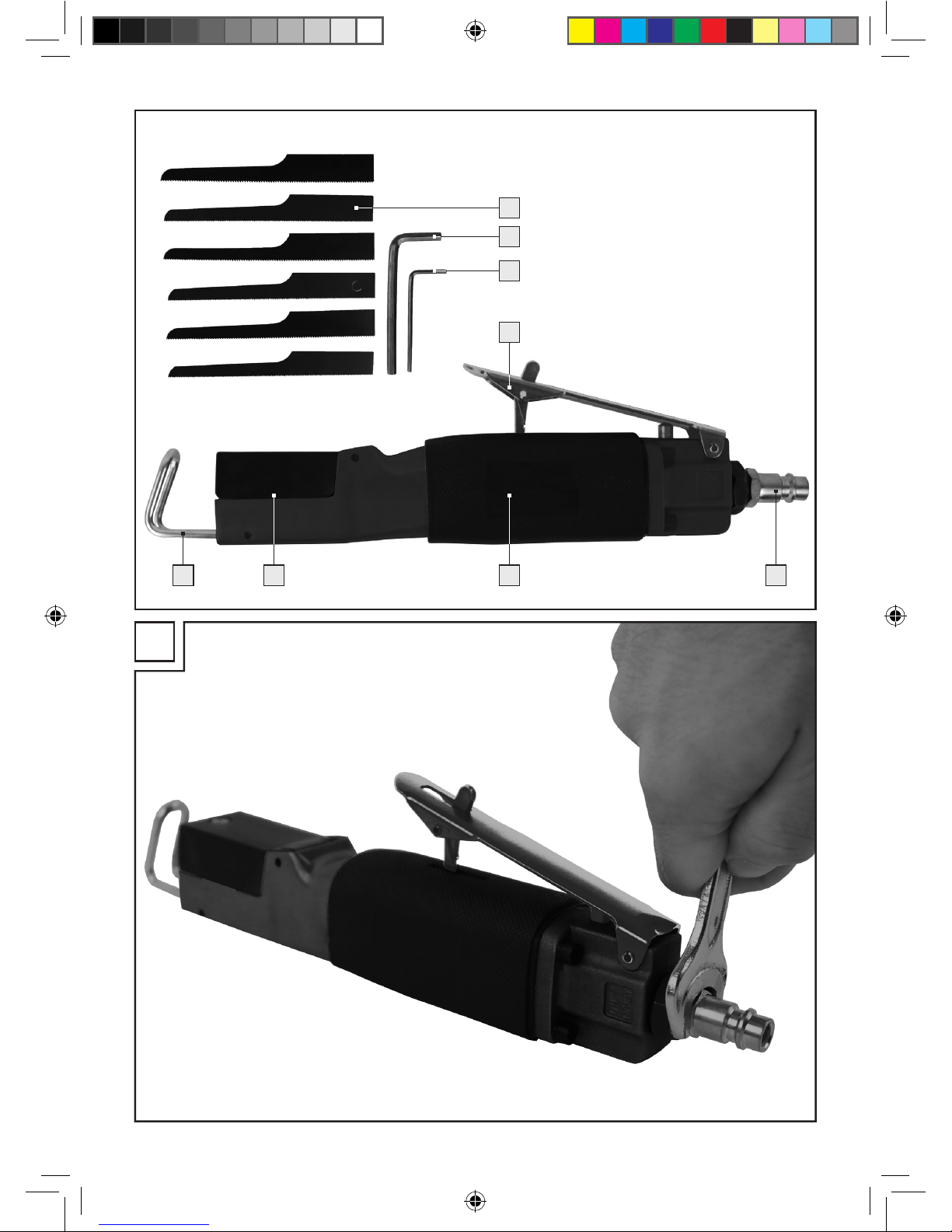

Features

Check that all the items are present and that the

product is in perfect condition immediately after

unpacking. Never use the product if it is defective.

1

Saw blade

2

Socket head wrench 4 mm

3

2 mm socket head wrench for installing /

removing the stop bracket

8

4

Trigger with safety stop

5

Threaded plug nipple

6

Housing

7

Cover (socket head screw)

8

Stop bracket

Technical Data

Max. working pressure: 6 bar

Max. speed: 8500

rpm

Air intake: ¼

Stroke: 10 mm

Weight: 620 g

Noise and vibration

ATTENTION!

Always wear hearing protection!

Noise parameter per EN15744:2008

Noise level L

pA

: 80.6 dB(A)

Sound power level L

WA

: 91.6 dB(A)

Uncertainty K = 3 dB

These original operating instructions / the device uses the following pictograms:

Please read the operating instructions!

Oil daily

Observe the warning and safety

instructions!

Note

Wear ear protection, dust mask, safety glasses and protective gloves.

Dispose of packaging and device in

an environmentally-friendly way!

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 6 08.07.15 09:10

Page 7

7 GB/IE

Vibration parameters per EN 12096, ISO

28927-7

Hand-arm vibration level: 20.8 m / s

2

Uncertainty K: 1.5 m / s

2

Scope of delivery

1 Pneumatic saw

1 2 mm socket head wrench for installing / removing

the stop bracket

8

1 Socket head wrench 4 mm

6 Saw blades (3 saw blades for wood (HCS),

3 saw blades for metal (BIM))

1 Set of instructions for use

General safety rules

Multiple hazards! Read and understand

the safety notices before setting up, operating,

repairing, maintaining and replacing accessories

on circular, oscillating or reciprocating saws,

as well as before working near the machine.

Failure to observe this may result in severe

physical injuries.

Circular, oscillating and reciprocating saws

should only be set up, adjusted and used by

adequately qualified and trained persons.

Do not modify these circular, oscillating and re-

ciprocating saws. Modifications may reduce the

effectiveness of safety measures and increase

operator risks.

Never lose the safety notices – and pass on to

the user.

Never use a damaged circular, oscillating or

reciprocating saw.

The machines must be inspected regularly to ver-

ify the machine is labelled with clearly legible

rated values and markings. If necessary, the user

must contact the manufacturer for replacement

labels.

Risks due to projected parts

If the work-piece, one of the accessories or the

tool itself breaks, parts may be projected at

great speed.

Always wear impact-proof eye protec-

tion when using circular, oscillating,

or reciprocating saws. The level of

required protection required should be assessed

individually for each application.

It must be ensured that the work-piece is prop-

erly secured.

Be sure sparks and metal cuttings are directed

so they do not produce a hazard.

Be sure the saw blade is installed correctly

and firmly.

Hazards from entanglement

Failure to keep loose fitting clothing, jewellery,

necklaces / scarves (etc.), hair or gloves away

from the machine or accessories can pose a risk

of suffocation, scalping and / or cuts.

Operating hazards

Avoid contact with the saw blade to prevent cuts

to the hands or other body parts.

Guards must be safely installed and in good

working order.

Defective, bent or severely worn guards must

be replaced with guards recommended by the

manufacturer.

Be sure the retractable guard does not snap

from the fully opened position to the fully closed

position after being released.

Never lock or tie guards in an open position or

otherwise disable.

When using the machine the user‘s

hands may be exposed to hazards

such as cuts as well as abrasion and

heat. Wear suitable gloves to protect hands.

The operator and the maintenance personnel

must be physically capable of managing the

size, weight and power of the machine.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 7 08.07.15 09:10

Page 8

8 GB/IE

General safety rules

Hold the machine correctly: be prepared

to counteract typical or sudden movements –

keep both hands ready.

Be sure your body is well balanced and you

maintain a solid grip.

Prevent injuries from cutting: Avoid con-

tact with the saw blade when the machine is

connected to the air supply. Wear protective

equipment such as gloves, apron and helmet.

Uncontrolled machine movement can

cause injuries: Always be sure to hold the

guide plate (if attached) firmly against the

work piece.

Cutting with these machines will create sharp

edges. Wear gloves to protect your hands.

In the event of power failure release the start-

or stop control.

Only use the lubricants recommended by the

manufacturer.

Protective equipment such as safety goggles

must be used; suitable gloves and protective

clothing are recommended.

Be aware the rotating built-in tool will start up

after activating the start- and stop control.

Hazards due to

repetitive motions

When using circular, oscillating or reciprocating

saws for work related tasks the operator may

experience discomfort of the hands and arms,

as well as the neck and shoulders or other

body parts.

When using circular, oscillating or reciprocating

saws the operator should maintain a comfortable

posture, ensuring a secure grip and avoiding

uncomfortable postures or postures making it

difficult to maintain balance. The operator should

change his posture when working for extended

periods to help prevent discomfort and fatigue.

If the operator experiences symptoms such as

persistently or repeatedly feeling unwell, discomfort, palpitations, pain, tingling, numbness, a

burning sensation or stiffness, these warning si

gns

should not be ignored. The operator should consult a suitably qualified healthcare professional.

Risks associated with

accessories

Disconnect circular, oscillating and reciprocating

saws from power before installing or replacing

tools or accessories.

Only use accessory and material sizes and

types recommended by the manufacturer of the

circular, oscillating or reciprocating saw. Never

use other sizes and types of accessories and

materials.

Avoid direct contact with accessories before

and after using the equipment, as these may

be warm or sharp.

Inspect the saw blade prior to use. Do not use

saw blades which may have been dropped or

with chipped, cracked or otherwise defective

parts.

Hazards in the work

environment

Slipping, tripping and falling are the main causes

of injuries at the workplace. Keep in mind that

surfaces may have become slippery during

machine use, and remember tripping hazards

caused by the air- or hydraulic hose.

Proceed with caution in unfamiliar surroundings.

There may be hidden dangers due to electrical

cables or other supply lines.

These circular, oscillating or reciprocating saws

are not suitable for use in explosive environments

and are not insulated against contact with electric lines.

Verify there are no electric lines, gas lines, etc.

which may pose a hazards if damaged by use

of this equipment.

Hazards due to dust

and vapours

Dust and vapour produced when using circular,

oscillating and reciprocating saws can be dangerous to the health (e.g. cancer, birth defects,

asthma and / or dermatitis; it‘s imperative to

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 8 08.07.15 09:10

Page 9

9 GB/IE

General safety rules

perform a risk assessment in this respect and implement the respective regulatory mechanisms.

The risk assessment should include dust generat

ed

by machine use and the dust already present in

the area, which is possibly being blown around.

Operate and maintain the circulating, oscillating

and reciprocating saws as recommended in these

instructions to minimise the risk of releasing dust

and vapours.

Exhaust air must be extracted so as to minimise

dust being blown about in dusty environments.

If dust or vapours are produced, controlling these

at their point of release is a priority.

Any machine parts or accessories to collect,

extract or eliminate airborne dust or vapours

should be used and maintained according to

manufacturer instructions.

Select, maintain and replace consumables /

machine tools as recommended in the instructi

ons

for use to prevent an unnecessary increase in

the production of dust or vapours.

Warnings regarding the risk of explosion or fire

related to the materials being worked on must

be observed.

Use respiratory protection as in-

structed and as required by occupational health and safety regulations.

Working on certain materials emits dust and

vapour, resulting in a potentially explosive environment.

Noise hazards

With inadequate ear protection the impact of

high noise levels may result in permanent hearing damage, hearing loss and other problems,

e.g. tinnitus (ringing, whistling or buzzing in the

ear). A risk assessment and implementing the

respective regulatory mechanisms for these

hazards is imperative.

Suitable regulatory mechanisms to minimise the

risk include measures such as using insulation

to prevent pinging sounds on work pieces.

Use hearing protection.

Operate and maintain circular, oscillating and

reciprocating saws as recommended in the instructions for use to prevent an unnecessary increase in the noise level.

Select, maintain and replace consumables /

tools as recommended in the instructions for

use to prevent an unnecessary increase in the

noise level.

If the circular, oscillating or reciprocating saws

feature a silencer, always ensure it is installed

and functional when the machine is in use.

Hazard due to vibration

Exposure to vibration may cause damage to

the nerves and disturb blood circulation in hands

and arms.

Wear warm clothing and keep your hands warm

and dry when working in cold environments.

If you notice numbness, tingling or pain in your

fingers or hands, or the skin in your fingers or

hands turns white, stop using the circular, oscillating or reciprocating saw and consult a physician.

Operate and maintain the circular, oscillating

or reciprocating saws as recommended in these

instructions for use to prevent an unnecessary

increase in vibration.

Select, maintain and replace the consumables /

machine tools according to these instructions to

prevent an unnecessary increase in vibration.

Whenever possible, use a support, clamp or

equaliser to support the weight of the machine.

Hold the machine firmly, but not too tightly,

maintaining the necessary hand reaction forces,

as the vibration hazard typically increases when

firming the grip.

Attaching the saw blade incorrectly can cause

excess vibration.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 9 08.07.15 09:10

Page 10

10 GB/IE

Before use / Start-up / After initial use

Before use

Installation

The device itself is fully functional at delivery. Using

the device may require (unless already installed) installing a threaded plug nipple

5

(note the data

under technical details for the fit / size).

Wrap the threaded plug nipple 5 with Teflon

tape (not included) before screwing it into the

air tool. Wrap the tape around the thread as

tight as possible. This will minimise the likelihood

of air leaking and optimise the work process.

Now screw the threaded plug nipple 5 into

the power tool.

Tighten the threaded plug nipple 5 to the air

tool with a size 14 key using moderate force

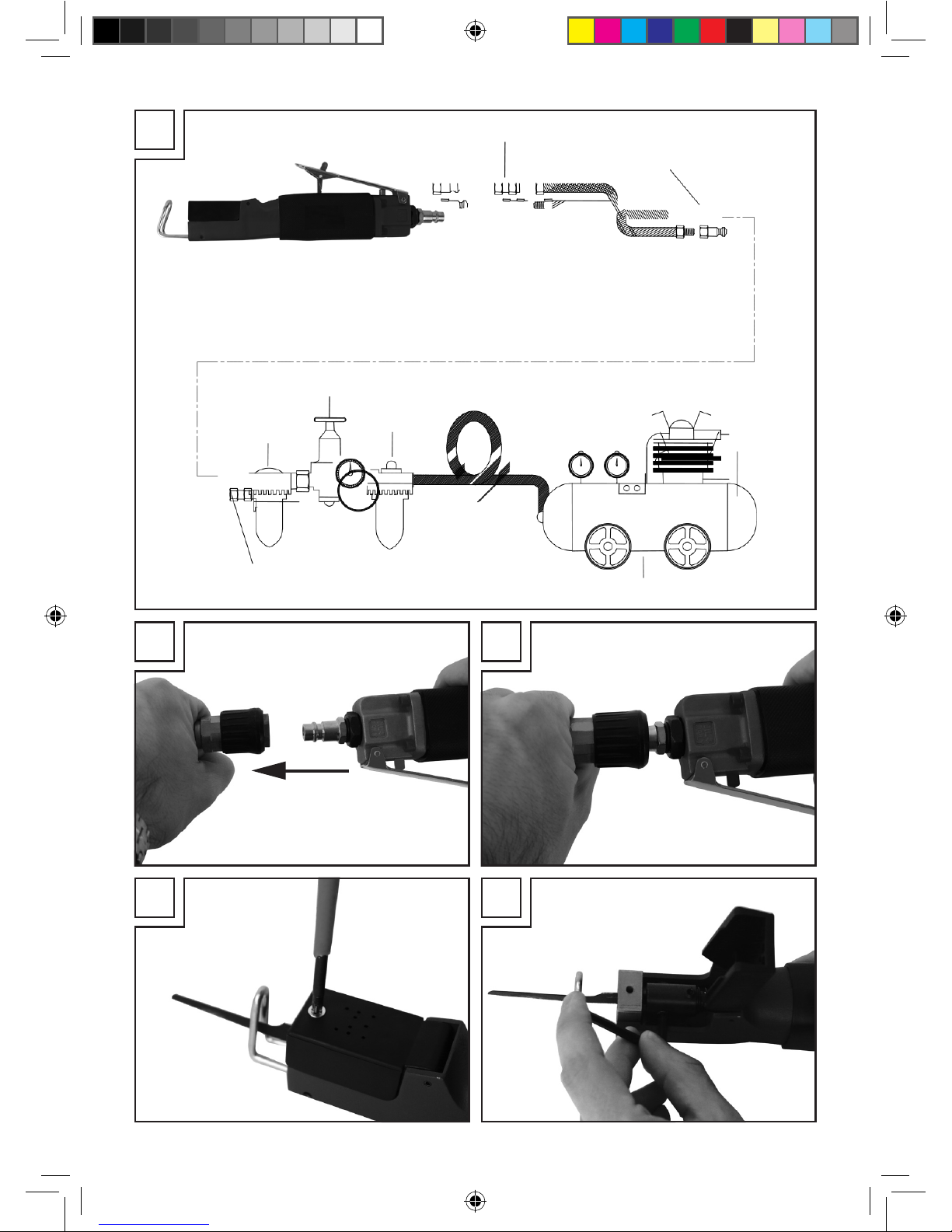

(see Fig. A).

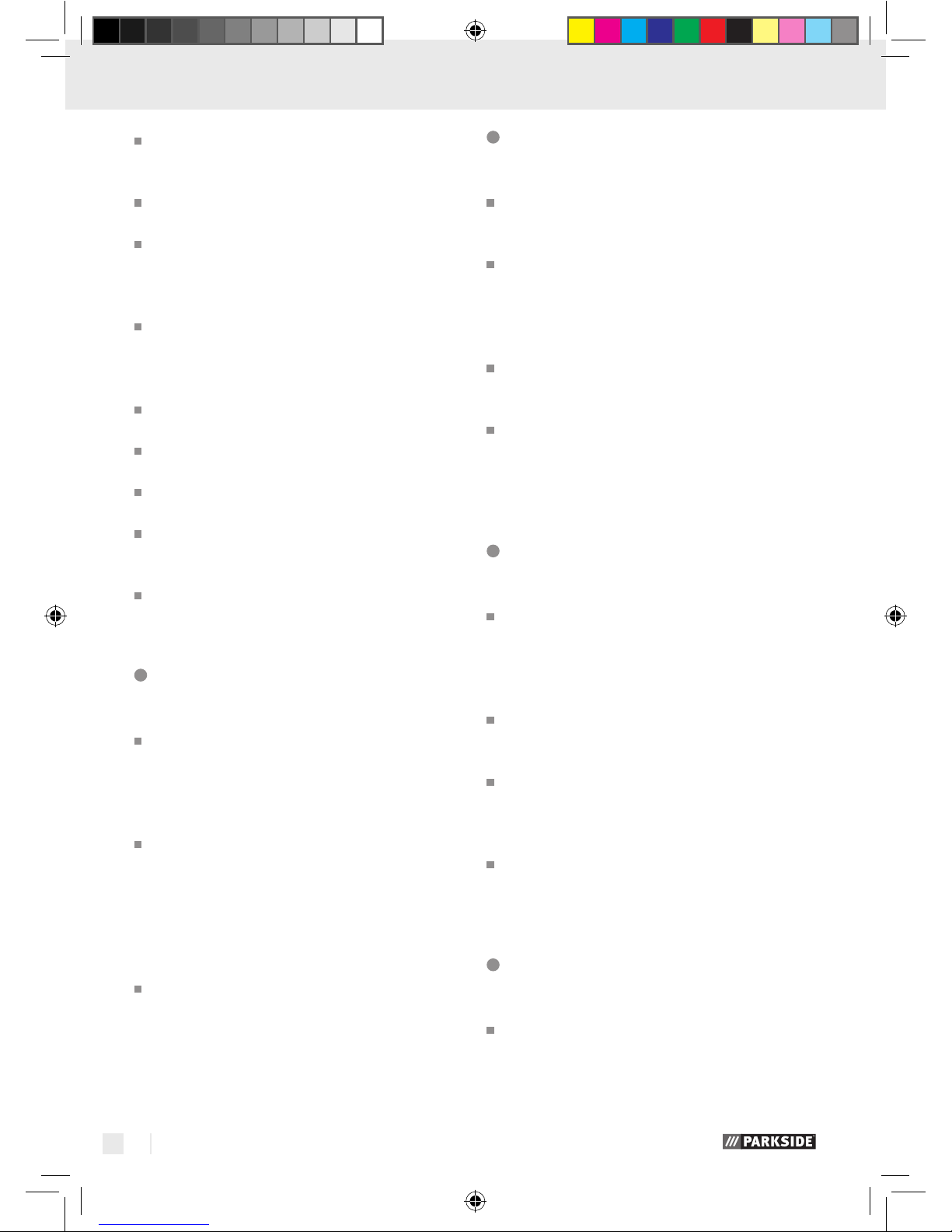

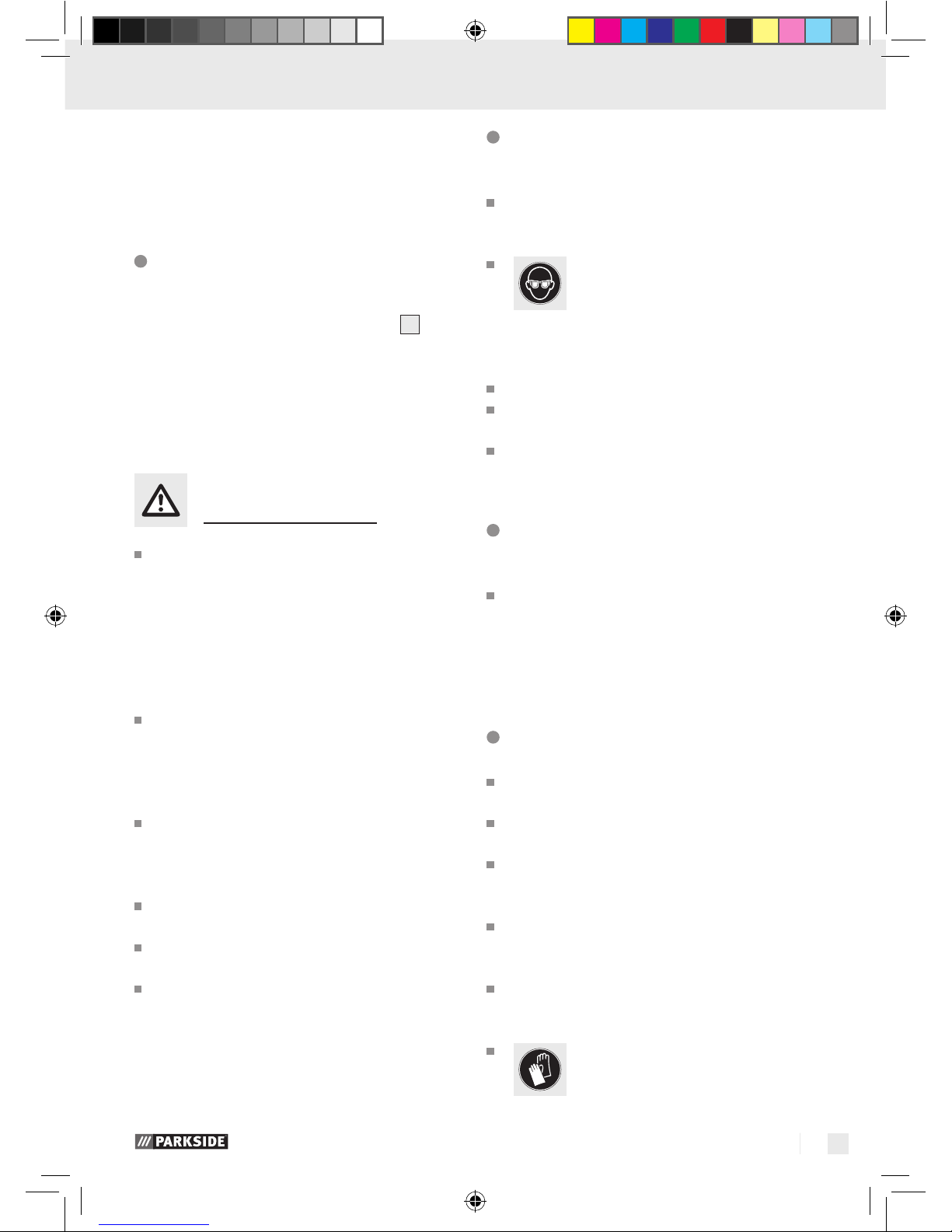

Adjusting the compressed air supply and

connections

Only use filtered, lubricated and regulated

compressed air.

Connect to the compressed air system using the

method shown in Figure B. This will increase

the effectiveness and life of the tool.

Set your compressor to the working pressure

specified for the device under technical data.

Please note, on average the pressure for 10 m

of hose will decrease by about 0.5 bar.

Excessive pressure is

dangerous! Never exceed the specified

pressure!

Add a few drops of air tool oil or SAE 10–20

engine oil to the compressed air connection of

the air tool before first use and in regular interva

ls.

Using other oil (particularly higher viscosity) will

result in damage or even total loss of the device.

Start-up

Connecting the

compressed air tool

Verify the work piece is correctly supported.

Connect to compressed air by pushing on the

quick couple of the hose using a little force

(see Fig. C).

Always verify the compressed air hose is properly

connected (see Fig. D). A loose hose whipping

about out of control presents a major hazard.

The threaded plug nipple

5

must be firmly

seated for the same reason. This must also be

checked.

Cutting

Note: The trigger 4 features a safety stop. Using

the trigger

4

requires pushing the lever on the trig-

ger

4

(safety stop) forward whilst pushing down

on the trigger

4

.

Activate the trigger 4 to operate the saw.

Note: Metal slivers flying about can be very

dangerous!

Note: If the compressed air supply is temporarily cut off due to power failure or temporary

compressor failure, immediately release the

trigger

4

. You must now first pull the saw all

the way out of the work piece to continue working. You can then continue working.

Always check the saw blade position after

2 minutes of continuous operation.

After finishing the task, release the trigger 4 to

stop the saw from running.

After initial use

Once the task has been finished the device must be

disconnected from the compressed air connection.

This first requires the pressure to be completely released from the lines.

Briefly activate the trigger 4 on the device to

release any remaining compressed air.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 10 08.07.15 09:10

Page 11

11 GB/IE

After initial use / Cleaning and storage / Maintenance

Replacing the saw blade

Immediately replace the saw blade 1 if dull, wa

rped

or defective.

Always be sure the compressed air supply is dis-

connected when replacing the saw blade

1

!

First open the front cover 7 with a screwdriver

(see Fig. E).

Use the included socket head wrench 2 to

loosen the socket head screws on the saw blade

holder (see Fig. F) and remove the saw blade.

Then insert the new saw blade 1 into the saw

blade holder and tighten the socket head screws

again.

Ensure the saw blade 1 is correctly seated in

the saw blade holder and cannot be pulled out.

Then close the cover 7 with the screwdriver.

Cleaning and storage

To ensure a long life and trouble-free operation, it‘s

important to observe the following instructions.

Always disconnect the tool from the compressed

air supply before cleaning.

Clean your tool with a dry, soft cloth or lightly

blow it out with compressed air. Never use

caustic cleaners.

Lubricating the air saw

Note: Regular lubrication is required

to ensure the longest possible life to

air tools.

Turn the tool over so the air connection is facing

up and add a few drops of air tool oil or SAE

10–20 engine oil to the tool‘s air connection.

Activate the trigger 4 to allow the oil to dis-

perse better.

Hold a rag or absorbent paper towel in front

of the exhaust opening and run the tool on idle

for a few seconds.

ATTENTION! Remove the compressed

air connection before performing maintenance!

Excess oil will be blown out.

Keep persons or objects away from the discharge.

Storing the air saw

Store the air tool in a dry location, protected from

the weather and out of the reach of children.

Be sure moisture does not enter the inside of

the air tool.

Maintenance

The device should be regularly maintained (after

about 1–2 uses).

Always wear suitable work gloves.

Maintenance must be performed by trained per-

sons. Adhering to these maintenance instructions

will ensure a long life and proper operation of

this quality product.

Disconnect equipment from the compressed air

source when performing maintenance and care.

Check the condition of wear and tear items

and accessories with every maintenance.

Note: Daily cleaning and regular lubrication

are absolutely required for smooth operation.

Only use special tool oil with a high viscosity

(thin) for this purpose. Oil for compressed air

equipment or motor oil SAE10–20 are suitable.

ATTENTION! Do not use any other (especially

high viscosity) lubricant. Otherwise there will

be a danger of functional disturbance or permanent damage.

Operate the device with clean air. Corrosion

residue, dust and dirt from the supply line impact

performance and result in technical problems.

Such contamination can be countered using a

service unit with filter, reducer valve and oiler.

If necessary, clean your device with a damp cloth.

Do not use chemical cleaners containing aggres-

sive substances such as petrol, thinner, etc., as

these may damage the plastic.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 11 08.07.15 09:10

Page 12

12 GB/IE

... / Environmental instructions and disposal information / Declaration of Conformity

Maintenance / Warranty and service information

Ensure fluids do not enter the saw.

Regularly check all screws, the stop bracket and

saw blade are firmly seated. Further regularly

check the speed and vibration level of the device.

Regularly check the condition of the saw blade.

The saw blade must not be defective or deformed.

Warranty and service

information

Creative Marketing Consulting GmbH

warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you

have legal rights against the retailer of this product.

Your statutory rights are not limited in any way by

our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This document

is required as your proof of purchase.

Should this device show any defect in materials or

manufacture within 3 years from the date of purch

ase,

we will repair or replace it - at our discretion - free

of charge. This warranty is conditional on the defective device and the receipt of purchase being presented within the three year warranty period, and

that there is a brief written description of the nature

of the defect and of the date it arose.

If the defect is covered by our warranty, we will

return the repaired device or replacement thereof.

A repair or exchange of the device does not extend

a new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality

guidelines and meticulously examined before delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage to

fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All instructions provided in the instructions for use must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

use of force and changes not performed by our authorized service branch will void the warranty.

Processing of warranty claims

Please follow the instructions below to ensure quick

processing of your claim:

Please have your receipt and the item number

(e.g. IAN) ready as your proof of purchase when

enquiring about the product.

The item number can be found on the type plate, engraving, the cover page of your instructions (bottom

left) or the decal at the back or bottom.

In the event of malfunctions or other defects, please

first contact the service department below by phone

or e-mail.

A product determined defective may then be returned

t

o the specified service address free of charge, incl

uding the proof of purchase (receipt) and information

about the defect and when it occurred.

Notice:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 12 08.07.15 09:10

Page 13

13 GB/IE

... / Environmental instructions and disposal information / Declaration of Conformity

How to contact us:

GB, IE

Name: C. M. C. GmbH

Internet address: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Phone: 0-808-189-0652 (standard

rates for German landlines)

Registered office: Germany

IAN 110140

Please note that the following address is not a

service address.

Please first contact the service point named above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Environmental instructions

and disposal information

Don‘t waste, recycle!

Device, accessories and packaging should

be recycled in an environmentally friendly

manner.

Do not dispose of the air tool with your household

waste, or throw it into the fire or water. If possible,

devices which are no longer functioning should be

recycled. Contact your local retailer for information.

Declaration of Conformity

We,

C. M. C. GmbH

Responsible for documentation: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

declare in our sole responsibility the product

Pneumatic saw

Serial number: 1839

Year of manufacture: 2015 / 35

IAN: 110140

MODEL: PARKSIDE PNEUMATIC SAW

PDKS 6.0 A1

meets the basic safety requirements of European

Directives

Machinery Directive

EC directive 2006 / 42 / EC

and its amendments.

The conformity assessment is based on the following

harmonised standards:

DIN EN ISO 11148-12:2012

St. Ingbert, 31.07.2015

Markus Zimmer

- Quality Control Manager -

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 13 08.07.15 09:10

Page 14

14

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 14 08.07.15 09:10

Page 15

15 FI

Sisällysluettelo

Johdanto

Tarkoituksenmukainen käyttö .............................................................................................................. Sivu 16

Tuotteen osat ........................................................................................................................................ Sivu 16

Tekniset tiedot ....................................................................................................................................... Sivu 16

Toimituksen sisältö ................................................................................................................................ Sivu 17

Yleiset turvallisuusohjeet

Sinkoavista osista aiheutuvat riskit ...................................................................................................... Sivu 17

Kiinnitarttumisesta aiheutuvat riskit ...................................................................................................... Sivu 17

Käytöstä aiheutuvat riskit ..................................................................................................................... Sivu 17

Toistuvista liikkeistä aiheutuvat riskit .................................................................................................... Sivu 18

Lisävarusteista aiheutuvat riskit ............................................................................................................ Sivu 18

Riskit työpaikalla .................................................................................................................................. Sivu 18

Pölystä ja höyryistä aiheutuvat riskit ................................................................................................... Sivu 19

Melusta aiheutuvat riskit ...................................................................................................................... Sivu 19

Tärinästä aiheutuvat riskit .................................................................................................................... Sivu 19

Ennen käyttöönottoa

Asennus ................................................................................................................................................ Sivu 20

Käyttöönotto

Paineilmatyökalun liittäminen .............................................................................................................. Sivu 20

Sahaaminen ......................................................................................................................................... Sivu 20

Käytön jälkeen ............................................................................................................................ Sivu 20

Sahanterän vaihtaminen ...................................................................................................................... Sivu 21

Puhdistus ja säilytys

Paineilmasahan voitelu ........................................................................................................................ Sivu 21

Paineilmasahan säilytys ....................................................................................................................... Sivu 21

Huolto.................................................................................................................................................. Sivu 21

Takuutiedot ja toimintaohjeet

Takuuehdot ........................................................................................................................................... Sivu 22

Takuun kattavuus .................................................................................................................................. Sivu 22

Toimiminen takuutapauksessa ............................................................................................................. Sivu 22

Ympäristötietoa ja tuotteen hävittäminen .......................................................... Sivu 23

EY-vaatimusten-mukaisuusvakuutus ........................................................................ Sivu 23

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 15 08.07.15 09:10

Page 16

16 FI

Johdanto / Yleiset turvallisuusohjeet

Johdanto

Paineilmasaha PDKS 6.0 A1

Johdanto

Onnittelumme!

Olet valinnut valmistamamme korkea-

luokkaisen tuotteen. Tutustu tuotteeseen

ennen ensimmäistä käyttöä. Lue huolellisesti tämä

käyttöohje ja turvallisuusohjeet. Vain tuotteen käyttöön opastetut henkilöt saavat käyttää tuotetta.

ÄLÄ JÄTÄ TUOTETTA LASTEN ULOTTUVILLE!

Tarkoituksenmukainen käyttö

Paineilmasaha on paineilmalla toimiva työkalu

erilaisiin sahaustöihin. Se on tarkoitettu työkaluksi

autonkorin, auton ja muiden osien korjaustöihin.

Työkalun käyttäjän tulee käyttää suojalaseja murtuvien osien ja suojakäsineitä terävien reunojen vuoksi.

Säilytä käyttöohje huolellisesti. Liitä kaikki ohjeet

tuotteen mukaan, jos annat sen muiden henkilöiden

käyttöön. Kaikki muu käyttö, joka poikkeaa määräystenmukaisesta käytöstä on kielletty ja saattaa

aiheuttaa vaaratilanteen. Takuu ei kata vahinkoja,

jotka johtuvat ohjeiden laiminlyömisestä tai virheellisestä käytöstä eikä valmistaja ota niistä vastuuta.

Tuote on suunniteltu yksityiskäyttöön eikä sitä saa

käyttää kaupallisesti tai teollisesti.

Tuotteen osat

Tarkista heti pakkauksen purettuasi, että mikään osa

ei puutu ja että tuote on moitteettomassa kunnossa.

Älä käytä tuotetta, jos se on vaurioitunut.

1

Sahanterä

2

Kuusiokoloavain 4 mm

3

Kuusiokoloavain 2 mm pysäytyssangan 8

kiinnitykseen / irrotukseen

4

Laukaisuvipu, jossa laukaisuvarmistin

5

Kierrenippa

6

Kotelo

7

Suojus (kuusiokoloruuvi)

8

Pysäytyssanka

Tekniset tiedot

Maksimi käyttöpaine: 6 baaria

Maksimi kierrosluku: 8500 min

-1

Ilmanotto: ¼

Isku: 10 mm

Paino: 620 g

Melu ja tärinä

HUOMIO! Käytä aina

kuulosuojaimia!

Melun ominaisarvot standardin EN 15744:2008

mukaan

Äänenpainetaso L

pA

: 80,6 dB(A)

Äänen tehotaso L

WA

: 91,6 dB(A)

Epävarmuus K = 3 dB

Tässä käyttöohjeessa / laitteessa käytetään seuraavia piktogrammeja:

Lue käyttöohje!

Öljyä päivittäin

Noudata varoituksia ja turvallisuusohjeita!

Huomautus

Käytä kuulonsuojainta, hengitys- /

pölysuojainta, suojalaseja ja suojakäsineitä.

Hävitä pakkaus ja laite ympäristöystävällisesti!

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 16 08.07.15 09:10

Page 17

17 FI

Tärinän ominaisarvot standardien EN 12096, ISO

28927-7 mukaan

Käden / käsivarren tärinätaso: 20,8 m / s

2

Epävarmuus K: 1,5 m / s

2

Toimituksen sisältö

1 paineilmasaha

1 kuusiokoloavain 2 mm pysäytyssangan

8

kiinni-

tykseen / irrotukseen

1 kuusiokoloavain 4 mm

6 sahanterää (3 sahanterää puulle (HCS),

3 sahanterää metallille (BIM))

1 käyttöohje

Yleiset

turvallisuusohjeet

Moninkertaiset riskit! Turvallisuusohjeet

täytyy lukea ja ymmärtää ennen asennusta, käyttöä, korjausta, huoltoa sekä pyörö- ja värähteleviin sahakoneisiin ja edestakaisin liikkuvilla

sahanterillä varustettuihin sahakoneisiin tarvittavien lisävarusteiden vaihtoa että ennen laitteen

läheisyydessä työskentelyä. Jos näin ei toimita,

siitä saattaa seurata vakavia ruumiillisia vammoja.

Ainoastaan pätevät ja tehtävään koulutetut lait-

teenkäyttäjät saavat asentaa, säätää ja käyttää

pyörö- ja värähteleviä sahakoneita tai edestakaisin liikkuvalla sahanterällä varustettuja sahakoneita.

Näihin sahakoneisiin ei saa tehdä mitään

muutoksia. Muutokset voivat alentaa turvallisuusohjeiden vaikutusta ja lisätä käyttäjään

kohdistuvia riskejä.

Turvallisuusohjeet eivät saa joutua hukkaan –

anna ne käyttäjän säilytettäviksi.

Älä koskaan käytä näitä sahakoneita, jos ha-

vaitset niissä vaurioita.

Laitteet täytyy tarkastaa säännöllisesti, jotta

niissä on selvästi luettavissa vaadittavat mittausarvot ja tunnukset. Käyttäjän täytyy ottaa yhteyttä valmistajaan, jos hän tarvitsee varakilpiä.

Sinkoavista osista

aiheutuvat riskit

Työstettävän kappaleen, lisävarusteen tai itse

laitteen murtuessa ilmaan voi singota osia suurella nopeudella.

Käytä aina iskunkestävää silmäsuo-

justa kun käytät pyörö- ja värähtelevää

sahakonetta tai sahakonetta, jossa

on edestakaisin liikkuva sahanterä. Tarvittavien

suojainten määrä tulisi arvioida erikseen jokaista

käyttöä varten.

Varmista, että työkappale on kiinnitetty kunnolla.

Kipinät ja metallilastut täytyy ohjata niin, etteivät

ne aiheuta vaaratilanteita.

Varmista, että sahanterä on kiinnitetty oikein ja

tukevasti.

Kiinnitarttumisesta

aiheutuvat riskit

Seurauksena saattaa olla kuristuminen ja / tai

viiltoja ihoon, jos löysiä vaatteita, koruja, kaulaketjuja/kaulaliinoja, pitkiä hiuksia tai käsineitä

ei pidetä tarpeeksi etäällä koneesta tai sen lisävarusteista.

Käytöstä aiheutuvat riskit

Älä koske sahanterään, jotta vältät käsiin tai

muihin ruumiinosiin syntyviä viiltoja.

Suojusten täytyy olla tukevasti paikallaan ja

toimia moitteettomasti.

Vaurioituneet, käyristyneet tai erittäin kuluneet

suojukset täytyy korvata uusilla valmistajan suosittamilla suojuksilla.

Varmista, että takaisin vetäytyvä suojus sulkeu-

tuu avoimesta asennosta välittömästi sen jälkeen

kun se vapautetaan.

Takaisin vetäytyviä suojuksia ei saa koskaan

kiinnittää avoimeen asentoon tai deaktivoida

muilla tavoin.

Laitteen käytön aikana käyttäjän

kädet ovat alttiina riskeille kuten

viilloille, hankautumiselle ja kuumuudelle. Käytä sopivia suojakäsineitä.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 17 08.07.15 09:10

Page 18

18 FI

Yleiset turvallisuusohjeet

Laitteen käyttäjän ja huoltohenkilöstön fyysisen

kunnon täytyy riittää laitteen koon, painon ja

tehon käsittelyyn.

Pidä laitetta oikein kädessä: valmistaudu

laitteen tavallisiin ja yllättäviin liikkeisiin – pidä

molemmat kädet toimintavalmiina.

Huomioi, että vartalosi on tasapainossa ja seisot

tukevasti paikoillasi.

Vältä sahauksesta ja katkaisusta ai-

heutuvaa loukkaantumista: älä koske

sahanterään, kun ilmansyöttö on liitetty laitteeseen. Käytä suojavarusteita kuten suojakäsineitä,

-esiliinaa ja -kypärää.

Laitteen hallitsemattomat liikkeet voi-

vat johtaa loukkaantumiseen: varmista

aina, että ohjauslaattaa (jos asennettu) pidetään

tukevasti työkappaletta vasten.

Laitteella leikkauksesta jää terävät reunat. Käytä

sopivia suojakäsineitä.

Aktivoi käynnistystä ja pysäytystä ohjaava laite,

jos sähkönsyöttö keskeytyy.

Käytä vain valmistajan suosittelemia voiteluai-

neita.

Suojavarusteiden kuten suojalasien käyttö on

pakollista; suojakäsineiden ja -vaatetuksen käyttö

on suositeltavaa.

Ota huomioon, että työkalu käynnistyy, sen jäl-

keen kun käynnistystä ja pysäytystä ohjaava

laite on aktivoitu.

Toistuvista liikkeistä

aiheutuvat riskit

Pyörö- ja värähtelevän sahakoneen sekä edes-

takaisin liikkuvalla sahanterällä varustetun

sahakoneen käyttäjä saattaa tuntea työstön

aikana epämiellyttävää tunnetta käsissä ja

käsivarsissa, kaulassa ja olkapäillä tai muissa

ruumiinosissa.

Tällaisia sahakoneita käytettäessä käyttäjän

tulisi ottaa mukava asento, seisoa tukevasti

paikallaan ja välttää huonoja sekä sellaisia

asentoja, joissa on vaikea pitää tasapainoa.

Käyttäjän tulisi pitkään jatkuvan työstön aikana

muuttaa asentoa, mikä auttaa välttämään epämukavaa oloa ja väsymystä.

Jos käyttäjä tuntee esim. jatkuvaa tai ajoittaista

pahanolon tunnetta, rasitusta, sykkimistä, kipuja,

pistelyä, tunnottomuuta, polttoja tai jäykkyyttä,

tulisi nämä oireet ottaa vakavasti. Käyttäjän

tulisi ottaa yhteyttä asiantuntevaan lääkäriin.

Lisävarusteista

aiheutuvat riskit

Irrota pyörö- ja värähtelevä sahakone sekä

edestakaisin liikkuvalla sahanterällä varustettu

sahakone sähköverkosta ennen laitteen asennusta tai lisävarusteiden vaihtoa.

Käytä ainoastaan oikeankokoisia ja -tyyppisiä

lisävarusteita ja käyttötarvikkeita, joita edellä

mainittujen sahakoneiden valmistaja suosittelee.

Älä käytä muunkokoisia tai -tyyppisiä lisävarusteita ja käyttötarvikkeita.

Vältä koskemasta konetyökalun lisävarusteisiin

ennen ja jälkeen käytön, sillä ne voivat olla

kuumia tai teräväreunaisia.

Tarkista sahanterä ennen käyttöä. Älä käytä

sahanteriä, jotka ovat pudonneet lattialle tai

joissa on irronneita, murtuneita tai muuten

vaurioituneita osia.

Riskit työpaikalla

Liukastuminen, kompastuminen ja kaatuminen

ovat yleisimpiä syitä työpaikalla loukkantumisiin.

Huomioi laitteen käytöstä liukkaaksi tulleet pinnat ja mahdolliset vaaratilanteet, jotka aiheutuvat ilma- ja hydrauliletkuihin kompastumisista.

Toimi varovasti vieraissa työympäristöissä. Vaa-

ratilanteita saattavat aiheuttaa sähköjohdot tai

muut johdot.

Pyörö- ja värähteleviä sahakoneita tai edestakai-

sin liikkuvalla sahanterällä varustettuja sahakoneita ei saa käyttää räjähdysalttiissa ympäristössä

eikä niitä ole eristetty sähköjohtoja vastaan.

Varmista, että työstettävässä paikassa ei ole

esim. sähköjohtoja tai kaasuputkia, jotka laitteen

käytön seurauksena voisivat vahingoittua ja

johtaa vaaratilanteeseen.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 18 08.07.15 09:10

Page 19

19 FI

Yleiset turvallisuusohjeet

Pölystä ja höyryistä

aiheutuvat riskit

Pyörö- ja värähtelevien sahakoneiden sekä

edestakaisin liikkuvalla sahanterällä varustettujen sahakoneiden käytöstä syntyvä pöly ja höyryt

voivat aiheuttaa sairauksia (esim. syöpää, epämuodostumia sikiölle, astmaa ja/tai ihotulehduksen); siksi on välttämätöntä tehdä selvitys

riskeistä ja ottaa käyttöön sopivat suojatoimenpiteet.

Riskien selvittämisessä tulisi ottaa huomioon sekä

koneen käytöstä syntyvät pölyt että mahdollisesti

ilmassa leijuvat pölyhiukkaset.

Edellä mainittuja sahakoneita tulee käyttää ja

huoltaa käyttöohjeen suositusten mukaisesti,

jotta pölyn ja höyryjen synty voidaan vähentää

minimiin.

Poistoilma tulee johtaa niin, että pölyn lentämistä

pölyisessä ympäristössä voidaan vähentää

minimiin.

Jos pölyä ja höyryjä syntyy käytössä, tärkeintä

olisi valvoa niitä niiden syntypaikassa.

Kaikki laitteeseen asennetut osat ja lisävarusteet,

jotka ottavat talteen, imevät tai ehkäisevät pölyn

ja höyryjen syntyä, tulisi käyttää ja huoltaa

asianmukaisesti valmistajan ohjeiden mukaan.

Käyttötarvikkeet/konetyökalut tulee valita, huol-

taa ja korvata uusilla käyttöohjeen suositusten

mukaisesti, jotta tahaton pölyn ja höyryjen lisäys

voidaan välttää.

Työstettävän materiaalin räjähdys- tai paloris-

kistä täytyy ilmoittaa.

Käytä hengityssuojainta ohjeiden

sekä työsuojelu- ja terveysmääräysten mukaan.

Tietyn materiaalin työstäminen aiheuttaa pöly-

ja höyrypäästöjä, mikä voi johtaa räjähdysalttiiseen tilanteeseen.

Melusta aiheutuvat riskit

Korkea melutaso saattaa ilman riittäviä kuulo-

suojaimia johtaa pysyvään kuulon heikentymiseen, menetykseen tai muihin vaurioihin kuten

esim. tinnitukseen (korvien soimiseen, huminaan

tai suhinaan). Siksi on välttämätöntä selvittää

näiden riskien arviointi ja ottaa käyttöön sopivat suojatoimenpiteet.

Riskiä voidaan vähentää sopivilla suojatoimen-

piteillä kuten eristysaineiden käytöllä, jolla

voidaan estää työkappaleista syntyvät äänet.

Käytä kuulosuojaimia.

Pyörö- ja värähteleviä sahakoneita sekä edes-

takaisin liikkuvalla sahanterällä varustettuja

sahakoneita tulee käyttää ja huoltaa käyttöohjeen suositusten mukaisesti, jotta melutason

tahaton nousu voidaan välttää.

Käyttötarvikkeet / työkalut tulee valita, huoltaa

ja korvata uusilla käyttöohjeen suositusten mukaisesti, jotta melutason tahaton nousu voidaan

välttää.

Varmista aina, jos edellä mainitut sahakoneet

on varustettu äänenvaimentimella, että se on

asetettu paikalleen ja toimintakuntoinen, kun

laitetta käytetään.

Tärinästä aiheutuvat riskit

Tärinä saattaa vahingoittaa hermoja ja haitata

käsien ja käsivarsien verenkiertoa.

Pukeudu lämpimästi työskennellessäsi kylmässä

ja pidä kätesi lämpiminä ja kuivina.

Jos havaitset sahakonetta käyttäessäsi, että

käsiesi iho on tunnoton, pistelee, särkee tai värjäytyy valkoiseksi, keskeytä työskentely ja ota

yhteyttä lääkäriin.

Pyörö- ja värähteleviä sahakoneita sekä edes-

takaisin liikkuvalla sahanterällä varustettuja

sahakoneita tulee käyttää ja huoltaa käyttöohjeen suositusten mukaisesti, jotta tärinän tahaton

voimistuminen voidaan välttää.

Käyttötarvikkeet / konetyökalut tulee valita, huol-

taa ja korvata uusilla käyttöohjeen suositusten

mukaisesti, jotta tärinän tahaton voimistuminen

voidaan välttää.

Käytä aina kun mahdollista laitteen painon pi-

tämiseksi telinettä, kiinnitintä tai tasauslaitetta.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 19 08.07.15 09:10

Page 20

20 FI

Käytön jälkeen / Puhdistus ja säilytys / Huolto

Yleiset turvallisuusohjeet / Ennen käyttöönottoa / Käyttöönotto / Käytön jälkeen

Pidä laitteesta varmasti mutta ei liian lujasti kiinni,

sillä tärinän riski yleensä nousee mitä lujemmin

laitteesta pidetään kiinni.

Sahanterän virheellinen kiinnitys voi lisätä täri-

nää.

Ennen käyttöönottoa

Asennus

Laite on täysin käyttövalmis toimitettaessa. Jotta

laitetta voidaan käyttää, siihen täytyy asentaa (jos

ei ole integroitu) kierrenippa

5

(tarkista sovitus-

tarkkuus / koko laitteen teknisistä tiedoista).

Kääri teflonnauha (ei sisälly toimitukseen) kier-

renipan

5

ympärille, ennen kuin ruuvaat sen

kiinni paineilmalaitteeseen. Kääri nauha mahdollisimman tiukalle kierteen ympärille. Todennäköisyys, että ilmaa purkautuu ulos, voidaan

minimoida ja työvaihe optimoida.

Ruuvaa kierrenippa 5 paineilmalaitteeseen

kiinni.

Kiristä kierrenippa 5 14 mm:n avaimella sopi-

van tiukalle paineilmalaitteeseen (ks. kuva A).

Paineilman syöttö ja liitännät

Käytä vain suodatettua, voideltua ja säädettyä

paineilmaa.

Tee liitäntä paineilmajärjestelmään kuvan B

osoittaman menetelmän mukaisesti. Se nostaa

työkalun toimintakykyä ja pidentää käyttöikää.

Säädä kompressoriin laitteeseen sopiva käyttö-

paine, joka on annettu teknisissä tiedoissa.

Huomioi, että paine pienenee 10 m:n letkussa

noin 0,5 baaria.

Liian korkea paine

on vaarallinen! Älä koskaan ylitä annettua

painetta!

Voitele paineilmalaitteen liitäntä ennen ensim-

mäistä käyttöä ja säännöllisin väliajoin muutamalla tipalla paineilmalaitteeseen sopivalla

öljyllä tai moottoriöljyllä SAE 10–20. Muun

öljyn käyttö (varsinkin sitkeäjuoksuisen) aiheuttaa toimintahäiriöitä, vaurioita tai jopa laitteen

vioittumisen korjauskelvottomaksi.

Käyttöönotto

Paineilmatyökalun liittäminen

Tarkista, että työkappale soveltuu laitteella

työstettäväksi.

Suorita paineilman liitos painamalla kevyesti

letkun pikaliitinkytkentää (ks. kuva C).

Varmista ehdottomasti, että paineilmaletkun

kiinnitys on tukeva (ks. kuva D). Irronnut tai

hallitsemattomasti sinkoileva letku voi aiheuttaa

vakavia vaaratilanteita. Samasta syystä myös

kierrenipan

5

täytyy olla tukevasti kiinnitetty.

Tarkista siis myös kierrenippa.

Sahaaminen

Huomautus: laukaisuvipu 4 on varustettu lau-

kaisuvarmistimella. Jotta laukaisuvipua

4

voidaan

käyttää, pieni vipu (laukaisuvarmistin) täytyy painaa

eteenpäin samalla kun laukaisuvipua

4

painetaan

alaspäin.

Käytä laukaisuvipua 4 sahan käynnistämi-

seen.

Huomautus: sinkoutuvat metallisirut voivat

olla vaarallisia!

Huomautus: jos paineilman tulo keskeytyy

sähkökatkoksen tai tilapäisen kompressorihäiriön vuoksi, laukaisuvipu

4

täytyy vapauttaa

välittömästi. Jos haluat jatkaa työstöä, saha

täytyy ensin irrottaa kokonaan työstettävästä

kappaleesta. Tämän jälkeen voit jatkaa työstöä.

Tarkista sahanterän kiinnitys kun laitetta käyte-

tään tauotta 2 minuuttia.

Kun olet lopettanut työstön vapauta laukaisuvipu

4

, jotta saha pysähtyy.

Käytön jälkeen

Käytön jälkeen laite täytyy irrottaa paineilmaliitännästä.

Ennen sitä paine täytyy poistaa letkuista.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 20 08.07.15 09:10

Page 21

21 FI

Jotta jäljellä oleva paineilma pääsee poistumaan

laitteesta, paina lyhyesti laukaisuvivusta

4

.

Sahanterän vaihtaminen

Jos sahanterä 1 on tylsä, vääntynyt tai viallinen,

se täytyy välittömästi vaihtaa uuteen.

Varmista aina kun vaihdat sahanterää 1, että

paineilman tulo on katkaistu!

Avaa ensin edessä oleva suojus 7 ruuvimeis-

selillä (ks. kuva E).

Löysää sitten toimitukseen sisältyvällä kuusioko-

loavaimella

2

sahanterän kiinnittimessä olevat

kuusiokoloruuvit (ks. kuva F) ja irrota sahanterä.

Aseta uusi sahanterä 1 kiinnittimeen ja kiristä

kuusiokoloruuvit.

Tarkista vielä, että sahanterä 1 on kiinnitetty

tukevasti eikä se irtoa sahasta.

Sulje sitten suojus 7 ruuvimeisselillä.

Puhdistus ja säilytys

Jotta laitteen pitkä käyttöikä ja häiriötön käyttö voidaan taata, noudata ehdottomasti seuraavia ohjeita.

Irrota työkalu paineilmalähteestä aina ennen

puhdistusta.

Puhdista työkalu kuivalla, pehmeällä liinalla tai

puhdista se kevyesti paineilmalla. Älä missään

tapauksessa käytä syövyttävää puhdistusainetta.

Paineilmasahan voitelu

Huomautus: jotta paineilmakäyt-

töisten laitteiden käyttöikä olisi mahdollisimman pitkä, ne täytyy öljytä

säännöllisin väliajoin.

Käännä työkalu toisin päin, niin että paineilma-

liitin näyttää ylöspäin. Voitele paineilmaliitin

muutamalla tipalla paineilmalaitteeseen sopivalla öljyllä tai SAE 10–20 -moottoriöljyllä.

Paina laukaisuvipua 4, jotta öljy levittyy tasai-

sesti.

Pidä liinaa tai imukykyistä talouspaperia imu-

aukkojen edessä ja käynnistä laite muutamaksi

sekunniksi tyhjäkäynnille.

HUOMIO! Poista paineilmaliitin ennen

huoltotöitä!

Ylimääräinen öljy puhalletaan

pois. Pidä poistoaukko etäällä henkilöistä ja esineistä.

Paineilmasahan säilytys

Säilytä paineilmatyökalua kuivassa paikassa

sääoloilta suojassa ja lasten ulottumattomissa.

Varmista, että paineilmatyökalun sisään ei

pääse kosteutta.

Huolto

Laite tulisi huoltaa säännöllisin väliajoin (noin 1–2

käyttökerran jälkeen).

Käytä aina sopivia työkäsineitä.

Laitteen huollon saa suorittaa vain tehtävään

koulutettu henkilö. Noudattamalla annettuja

huolto-ohjeita voit pidentää tämän laatutuotteen

käyttöikää ja taata sen häiriöttömän käytön.

Irrota laite paineilmalähteestä huollon ja puh-

distuksen ajaksi.

Tarkista jokaisen huollon yhteydessä tarvikkei-

den ja lisävarusteiden kunto.

Huomautus: jotta laite toimisi moitteettomasti,

se tulisi ehdottomasti puhdistaa päivittäin ja

rasvata säännöllisin väliajoin. Käytä erikoistyökaluöljyä, jossa on korkea viskositeetti (ohutjuoksuinen). Sopivia ovat paineilmalaitteiden

öljyt tai moottoriöljyt SAE10-20.

HUOMIO! Älä käytä muita (erityisesti sitkeä-

juoksuisia) voiteluaineita. Muutoin laitteen

toiminta voi häiriintyä tai laite voi vaurioitua

pahasti.

Käytä laitteessa puhdasta ilmaa. Syöttöjohdosta

aiheutuvat syöpymisjäljet, pöly ja lika heikentävät tehoa ja aiheuttavat teknisiä ongelmia.

Suodattimella, paineenalennusventtiilillä ja

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 21 08.07.15 09:10

Page 22

22 FI

... / Ympäristötietoa ja tuotteen hävittäminen / EY-vaatimustenmukaisuusvakuutus

Huolto / Takuutiedot ja toimintaohjeet

voitelulaitteella varustetulla huoltoyksiköllä

voidaan estää tällainen likaantuminen.

Puhdista laite tarvittaessa kostealla liinalla.

Älä käytä kemiallisia puhdistusaineita, jotka si-

sältävät voimakkaita, muovipintaa vahingoittavia aineita kuten bensiiniä, ohennusainetta tms.

Varmista, että sahaan ei pääse mitään nesteitä.

Tarkista säännöllisesti ruuvien, pysäytyssangan

ja sahanterän kiinnitys. Tarkista lisäksi kierrosluku ja laitteen tärinätaso säännöllisesti.

Tarkista säännöllisesti sahanterän kunto. Sa-

hanterä ei saa olla vioittunut eikä vääntynyt.

Takuutiedot ja toimintaohjeet

Creative Marketing Consulting GmbH:n

myöntämä takuu

Arvoisa asiakas, laitteelle myönnetty takuu on voimassa 3 vuotta ostopäivästä lukien. Jos tuote on

virheellinen, sinulla on ostajana lakisääteiset oikeudet esittää vaatimuksia tuotteen myyjää kohtaan.

Seuraavassa esitetty takuu ei rajoita lakisääteisiä

oikeuksiasi.

Takuuehdot

Takuun voimassaolo alkaa tuotteen ostopäivästä.

Säilytä aina alkuperäinen kassakuitti. Se toimii

todisteena tehdystä ostoksesta.

Jos kolmen vuoden sisällä tuotteen ostopäivästä alkaen tuotteesta löytyy materiaali- tai valmistusvirhe,

korjaamme tuotteen ilmaiseksi tai toimitamme tilalle

uuden tuotteen harkintamme mukaan. Takuusuoritus

edellyttää, että vioittunut laite ja ostotodistus (kassakuitti) toimitetaan meille kolmen vuoden sisällä

ja siihen liitetään lyhyt kirjallinen selvitys laitteessa

havaitusta viasta ja milloin se on ilmaantunut.

Jos takuumme kattaa vian, toimitamme sinulle korjatun tai uuden laitteen. Tuotteen korjauksesta tai

vaihdosta uuteen takuuaika ei ala uudelleen.

Takuun kattavuus

Laite on valmistettu huolellisesti tiukkojen laatudirektiivien mukaan ja tarkistettu huolella ennen toimitusta.

Takuu koskee materiaali- ja valmistusvirheitä. Takuu

ei koske tuotteen osia, jotka kuluvat normaalisti ja

joita voidaan sen vuoksi pitää kuluvina osina eikä

myöskään rikkoutuvia osia, joita ovat esim. kytkin,

akut ja lasista valmistetut osat.

Takuu raukeaa, jos tuote on vioittunut, sitä on käytetty tai huollettu tarkoituksenvastaisesti. Tuotteen

asianmukainen käyttö tarkoittaa, että kaikkia käyttöohjeessa annettuja ohjeita noudatetaan tarkasti.

Käyttötarkoituksia tai toimenpiteitä, joista käyttöohjeessa varoitetaan, on ehdottomasti vältettävä.

Tuote on tarkoitettu ainoastaan yksityiseen, ei ammattimaiseen käyttöön. Väärä tai asiaton käyttö,

väkivalloin suoritetut toimenpiteet ja muiden kuin

valtuutetun huoltopisteen suorittamat korjaukset

johtavat takuun raukeamiseen.

Toimiminen takuutapauksessa

Jotta asiasi nopea käsittely voidaan taata, pyydämme

sinua toimimaan seuraavien ohjeiden mukaisesti:

Säilytä kassakuitti ja tuotenumero (esim. IAN) todisteena tekemästäsi ostoksesta.

Tuotenumero löytyy tyyppikilvestä, kaiverruksesta,

käyttöohjeen kansilehdestä (vasemmasta alakulmasta)

tai takaosaan tai alapuolelle liimatusta tarrasta.

Jos tuotteessa ilmenee toimintahäiriöitä tai muita

puutteita, ota yhteys alla olevaan huoltopisteeseen

joko puhelimitse tai sähköpostitse.

Vioittuneen tuotteen voi lähettää ostotodistuksen

(kassakuitin) kanssa maksutta huolto-osastolle. Lähetyksen tulee sisältää myös tiedot siitä, mikä tuotteessa on vikana ja milloin vika ilmeni. Lähetys on

maksuton, kun se osoitetaan oheiseen huollosta

vastaavaan osoitteeseen.

Huomautus:

Osoitteesta www.lidl-service.com voit

ladata tämän ja muita käyttöoppaita,

tuotevideoita ja tietokoneohjelmistoja.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 22 08.07.15 09:10

Page 23

23 FI

... / Ympäristötietoa ja tuotteen hävittäminen / EY-vaatimustenmukaisuusvakuutus

Yhteystietomme:

FI

Yrityksen nimi: C. M. C. GmbH

Internet: www.cmc-creative.de

Sähköposti: service.fi@cmc-creative.de

Puhelin: +49 (0) 6894 9989752

(normaalihinta Saksan lankapuhelinverkosta)

Kotipaikka: Saksa

IAN 110140

Huomioi, että seuraava osoite ei ole huoltopisteen

osoite.

Ota ensin yhteyttä yllä mainittuun huoltopisteeseen.

Osoite:

C. M. C. GmbH

Katharina-Loth-Str. 15

D-66386 St. Ingbert

Saksa

Ympäristötietoa ja

tuotteen hävittäminen

Raaka-aineen kierrätystä

jätehuollon sijasta!

Laite, lisävarusteet ja pakkaus tulisi kierrättää ympäristöystävällisellä tavalla.

Älä hävitä paineilmatyökalua talousjätteiden mukana,

polttamalla tai upottamalla vesistöön. Mahdollisuuksien mukaan käytöstä poistetut laitteet tulisi

kierrättää. Kysy lisätietoja paikalliselta jälleenmyyjältä.

EY-vaatimusten-

mukaisuusvakuutus

Me,

C. M. C. GmbH

Asiakirjavastuullinen: Markus Zimmer

Katharina-Loth-Str. 15

D-66386 St. Ingbert

takaamme yksin vastuullisina, että tuote

paineilmasaha

Sarjanumero: 1839

Valmistusvuosi: 2015 / 35

IAN: 110140

Malli: PARKSIDE-PAINEILMASAHA PDKS

6.0 A1

vastaa olennaisia suojavaatimuksia, jotka on

määritelty eurooppalaisissa direktiiveissä

konedirektiivissä

EY-direktiivissä 2006 / 42 / EY

ja sen muutoksissa.

Yhdenmukaisuuden arvioinnissa on käytetty seuraavia harmonisoituja standardeja:

DIN EN ISO 11148-12:2012

St. Ingbertissä, 31.07.2015

Markus Zimmer

- Laadunvarmistuspäällikkö -

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 23 08.07.15 09:10

Page 24

24

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 24 08.07.15 09:10

Page 25

25 SE

Innehållsförteckning

Inledning

Ändamålsenlig användning ..............................................................................................................Sidan 26

Utrustning ............................................................................................................................................Sidan 26

Tekniska specifikationer .....................................................................................................................Sidan 26

Leveransens omfattning .....................................................................................................................Sidan 27

Allmänna säkerhetsregler

Risker genom delar som slungas ut ...................................................................................................Sidan 27

Risker genom att fastna......................................................................................................................Sidan 27

Risker vid drift .....................................................................................................................................Sidan 27

Risker genom upprepade rörelser .....................................................................................................Sidan 28

Risker genom tillbehör .......................................................................................................................Sidan 28

Risker på arbetsplatsen ......................................................................................................................Sidan 29

Risker genom damm och ångor ........................................................................................................Sidan 29

Risker genom buller ............................................................................................................................Sidan 29

Risker genom vibrationer ...................................................................................................................Sidan 30

Före idrifttagning

Montering ...........................................................................................................................................Sidan 30

Idrifttagning

Anslutning av tryckluftsverktyg ..........................................................................................................Sidan 31

Sågning ..............................................................................................................................................Sidan 31

Efter idrifttagning

Byte av sågblad .................................................................................................................................Sidan 31

Rengöring och förvaring

Smörjning av den tryckluftsdrivna sågen ..........................................................................................Sidan 31

Förvaring av tryckluftsdriven såg.......................................................................................................Sidan 32

Underhåll .......................................................................................................................................Sidan 32

Information om garanti och service

Garantivillkor ......................................................................................................................................Sidan 32

Garantins omfattning .........................................................................................................................Sidan 33

Handläggning av garantianspråk ....................................................................................................Sidan 33

Miljöinformation och uppgifter om avfallshantering ...............................Sidan 34

EG-försäkran om överensstämmelse .....................................................................Sidan 34

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 25 08.07.15 09:10

Page 26

26 SE

Inledning / Allmänna säkerhetsregler

Inledning

Tryckluftsåg PDKS 6.0 A1

Inledning

Grattis!

Du har valt en produkt av hög kvalitet.

Gör dig bekant med produkten innan

du använder den för första gången. Läs för detta

ändamål noga igenom följande bruksanvisning

och säkerhetsinformation. Idrifttagning av denna

produkt får endast utföras av instruerade personer.

MÅSTE HÅLLAS UTOM RÄCKHÅLL FÖR

BARN!

Ändamålsenlig användning

Mejselhammaren är ett tryckluftsdrivet verktyg för

många användningsområden. Den är avsedd att

användas vid arbeten på karosserier och för

verkstadsarbeten. Användaren bör skydda sig med skyddsglasögon

mot små delar som slungas omkring och

med handskar mot temporär kontakt med eventuella

skarpa kanter. Förvara denna bruksanvisning på

säker plats. Lämna även över alla handlingar om du

överlåter produkten till en tredje person. Alla användningar som avviker från den avsedda användningen

är förbjudna och kan vara farliga. Skador som uppstår på grund av icke fackmässig hantering och på

grund av att bruksanvisningen ej beaktats omfattas

inte av garantin eller tillverkarens ansvar. Produkten

har konstruerats för privat bruk och får ej användas

för kommersiella eller industriella ändamål.

Utrustning

Kontrollera alltid omedelbart när du packar upp att

produkten är i felfritt skick. Använd inte produkten

om den är defekt.

1

Sågblad

2

Insexnyckel 4 mm

3

Insexnyckel 2 mm för montering / demontering

av stoppbygeln

8

4

Avtryckararm med utlösningsspärr

5

Gängnippel

6

Hus

7

Skydd (insexskruv)

8

Stoppbygel

Tekniska specifikationer

Max. arbetstryck: 6 bar

Max. varvtal: 8500 min

-1

Luftintag: ¼

Slag: 10 mm

Vikt: 620 g

Buller och vibration

OBS! Använd alltid hörselskydd!

I denna originalbruksanvisning / på maskinen används följande piktogram:

Läs bruksanvisningen!

Ska smörjas dagligen

Beakta varningarna och säkerhetsanvisningarna!

Hänvisning

Använd hörselskydd, andnings- /

skyddsmask, skyddsglasögon och

skyddshandskar.

Lämna förpackningen och produkten

till miljövänlig återvinning!

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 26 08.07.15 09:10

Page 27

27 SE

Bullernivå enligt EN15744:2008

Ljudtrycksnivå L

pA

: 80,6 dB(A)

Ljudeffekt L

WA

: 91,6 dB(A)

Osäkerhet K = 3 dB

Vibrationsnivå enligt EN 12096, ISO 28927-7

Hand-arm-vibrationsnivå: 20,8 m / s

2

Osäkerhet K: 1,5 m / s

2

Leveransens omfattning

1 tryckluftsdriven såg

1 insexnyckel 2 mm för montering / demontering av

stoppbygeln

8

1 insexnyckel 4 mm

6 sågblad (3 sågblad för trä (HCS), 3 sågblad för

metall (BIM))

1 bruksanvisning

Allmänna

säkerhetsregler

Olika risker! Säkerhetsinformationen måste

läsas och förstås före installation, drift, reparation,

underhåll och byte av tillbehörsdelar på cirkelsågar och oscillerande sågar samt på sågar med

sågblad som körs fram och tillbaka. Det samma

gäller för arbeten i närheten av sågar. Annars

föreligger risk för allvarliga personskador.

Cirkelsågar och oscillerande sågar samt sågar

med sågblad som körs fram och tillbaka bör

endast installeras, ställas in och användas av

kvalificerad och undervisad driftspersonal.

Dessa cirkelsågar och oscillerande sågar samt

sågar med sågblad som körs fram och tillbaka

får inte förändras. Förändringar kan reducera

säkerhetsåtgärdernas verkan och därmed öka

riskerna för operatören.

Säkerhetsinformationen får inte gå förlorad –

och måste överlämnas till den som använder

maskinen.

Använd aldrig skadade cirkelsågar och oscille-

rande sågar eller sågar med sågblad som körs

fram och tillbaka.

Maskinerna måste inspekteras regelbundet, för

att kontrollera, att maskinen är utrustad med de

tydligt läsbara markeringar och mätvärden som

krävs i detta dokument. Användaren måste vända

sig till tillverkaren för att vid behov erhålla ny

skyltar.

Risker genom delar

som slungas ut

Vid brott i ett arbetsstycke eller i ett tillbehör

eller till och med i själva maskinverktyget kan

delar slungas ut med hög hastighet.

Bär alltid slagfasta ögonskydd vid

användning av cirkelsågar och oscil-

lerande sågar eller sågar med sågblad som körs fram och tillbaka. Omfattningen

på det skydd som krävs bör bestämmas individuellt beroende på respektive användning.

Det är viktigt att säkerställa, att arbetsstycket

sitter ordentligt fast.

Der är viktigt att se till, att gnistor och metallspån

styrs, så att de inte kan orsaka risker.

Se till att, sågblad eller sågklinga är korrekt

och säkert fastspända.

Risker genom att fastna

Det kan föreligga risk för kvävning, skalpering

och / eller skärskador, om löst sittande kläder,

smycken, halsband / halsdukar (och liknande),

hår eller handskar inte hålls borta från maskinen

och dess tillbehör.

Risker vid drift

Undvik kontakt med sågbladet, för att undvika

att du skär dig i händer eller andra kroppsdelar.

Skyddshuvar måste vara i felfritt skick och finnas

på plats.

Skadade, bockade eller mycket slitna skydds-

huvar måste ersättas med skyddshuvar som

rekommenderas av maskinens tillverkare.

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 27 08.07.15 09:10

Page 28

28 SE

Allmänna säkerhetsregler

Förvissa dig om, att skyddshuven som kan dras

tillbaka snabbt går tillbaka från det fullständigt

öppna läget till helt stängt läge när den släpps.

Skyddshuvar som kan dras tillbaka får aldrig

fixeras, bindas fast i öppet läge eller avaktiveras på annat sätt.

Vid maskinens användning kan ope-

ratörens händer vara utsatta för risker

t.ex. genom skärning samt skavning

och värme. Skydda dina händer med lämpliga

handskar.

Operatören och underhållspersonalen måste

besitta de fysiska förutsättningarna för att kunna

hantera maskinens storlek, vikt och prestanda.

Håll maskinen korrekt: Var beredd på att

motverka vanliga eller plötsliga rörelser – håll

båda händerna beredda.

Se till att din kropp är i jämvikt och att du står

stadigt.

Undvik personskador genom att skära

och kapa: Undvik kontakt med sågblad eller

sågklinga när lufttillförseln är ansluten till maskinen. Använd skyddsutrustning som handskar,

förkläde och hjälm.

Maskinens okontrollerade rörelser

kan orsaka personskador: Se alltid till,

att en styrplatta (om en sådan har monterats)

hålls stadigt mot arbetsstycket.

Det uppstår skarpa kanter när man skär med

denna maskin. Använd handskar för att skydda

dina händer.

Frige manöverorganet för aktivering eller

avstängning vid avbrott i energiförsörjningen.

Använd endast de smörjmedel, som rekommen-

deras av tillverkaren.

Skyddsutrustning som t.ex. skyddsglasögon

måste användas, lämpliga handskar och skyddskläder rekommenderas.

Var medveten om, att det inbyggda roterande

verktyget går igång, när manöverorganet för

aktivering eller avstängning släppts.

Risker genom

upprepade rörelser

Vid användning av cirkelsågar eller oscillerande

sågar eller av sågar där sågbladet körs fram

och tillbaka för att genomföra yrkesmässig

verksamhet kan det i vissa fall förekomma att

operatören känner obehag i sina händer och

armar, samt i hals och axlar eller i andra

kroppsdelar.

Vid användning av cirkelsågar eller oscillerande

sågar eller av sågar där sågbladet som körs

fram och tillbaka bör operatören inta en bekväm

kroppshållning, se till att han / hon står stadigt

och undviker ogynnsamma kroppshållningar

eller sådana som gör det svårt att hålla balansen. I samband med arbeten som tar lång tid

bör operatören förändra sin kroppshållning då

och då. På detta sätt kan man ofta undvika

obehag och trötthet.

Om operatören känner av symptomer som t.ex.

ihållande eller upprepat illamående, besvär,

hjärtklappningar, smärta, avdomning, stelhet

eller om det kliar eller bränner bör detta inte

ignoreras. Operatören bör konsultera en lämplig kvalificerad läkare.

Risker genom tillbehör

Skilj din cirkelsåg eller oscillerande såg eller

såg där sågbladet körs fram och tillbaka från

energiförsörjningen innan du börjar montera

eller byta maskinverktyget eller tillbehörsdelar.

Använd uteslutande tillbehör och förbruknings-

material av en typ och storlek som rekommenderas av tillverkaren av dessa cirkelsågar eller

oscillerande sågar eller sågar där sågbladet

körs fram och tillbaka. Använd inga tillbehör

och förbrukningsmaterial av annan typ eller

storlek.

Undvik direkt kontakt med tillbehören efter

användning av maskinverktyget, då dessa kan

vara varma och ha skarpa kanter.

Kontrollera sågbladet för användning. Använd

inga sågblad, som kanske fallit ner och där

110140_par_Druckluft-Saege PDKS 6.0 A1_content_FI_SE_DK.indd 28 08.07.15 09:10

Page 29

29 SE

Allmänna säkerhetsregler

delar brytits av, spruckit eller skadats på annat

sätt.

Risker på arbetsplatsen

Halka, snubbla och falla är huvudorsakerna

för personskador på arbetsplatsen. Se upp för

ytor, som kan ha blivit hala genom maskinens

användning, och glöm inte hur lätt det är att

man snubblar över luft- och hydraulslangar.

Var försiktig i okända omgivningar. Det kan

uppstå dolda risker genom strömkablar eller

andra försörjningsledningar.

Dessa cirkelsågar och oscillerande sågar eller

sågar med sågblad som körs fram och tillbaka

är inte avsedda för användning i explosiva

atmosfärer och inte isolerade mot kontakt med

elledningar.

Se till, att det inte finns några elledningar, gas-

ledningar osv., som kan innebära en risk om de

skadas genom maskinens användning.

Risker genom damm

och ångor

Damm och ånga som uppstår vid användning

av cirkelsågar och oscillerande sågar eller sågar med sågblad som körs fram och tillbaka

kan förorsaka hälsoskador (som t.ex. cancer,