Page 1

IAN 100684

CABLE WINCH PSZ 250 B2

SEILHEBEZUG

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

CABLE WINCH

Operation and Safety Notes

Translation of original operation manual

ΓΕΡΑΝΑΚΙ ΑΝΥΨΩΣΗΣ ΦΟΡΤΙΟΥ

Υποδείξεις χειρισμού και ασφαλείας

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

100684_par_Seilhebelzug_cover_GB_IE_CY.indd 3 24.06.14 15:55

Page 2

GB / IE / CY Operation and Safety Notes Page 5

GR / CY Υποδείξεις χειρισμού και ασφαλείας Σελίδα 13

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 21

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τις δυο σελίδες με τις εικόνες και εξοικειωθείτε με όλες τις

λειτουργίες της συσκευής.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

100684_par_Seilhebelzug_cover_GB_IE_CY.indd 4 24.06.14 15:55

Page 3

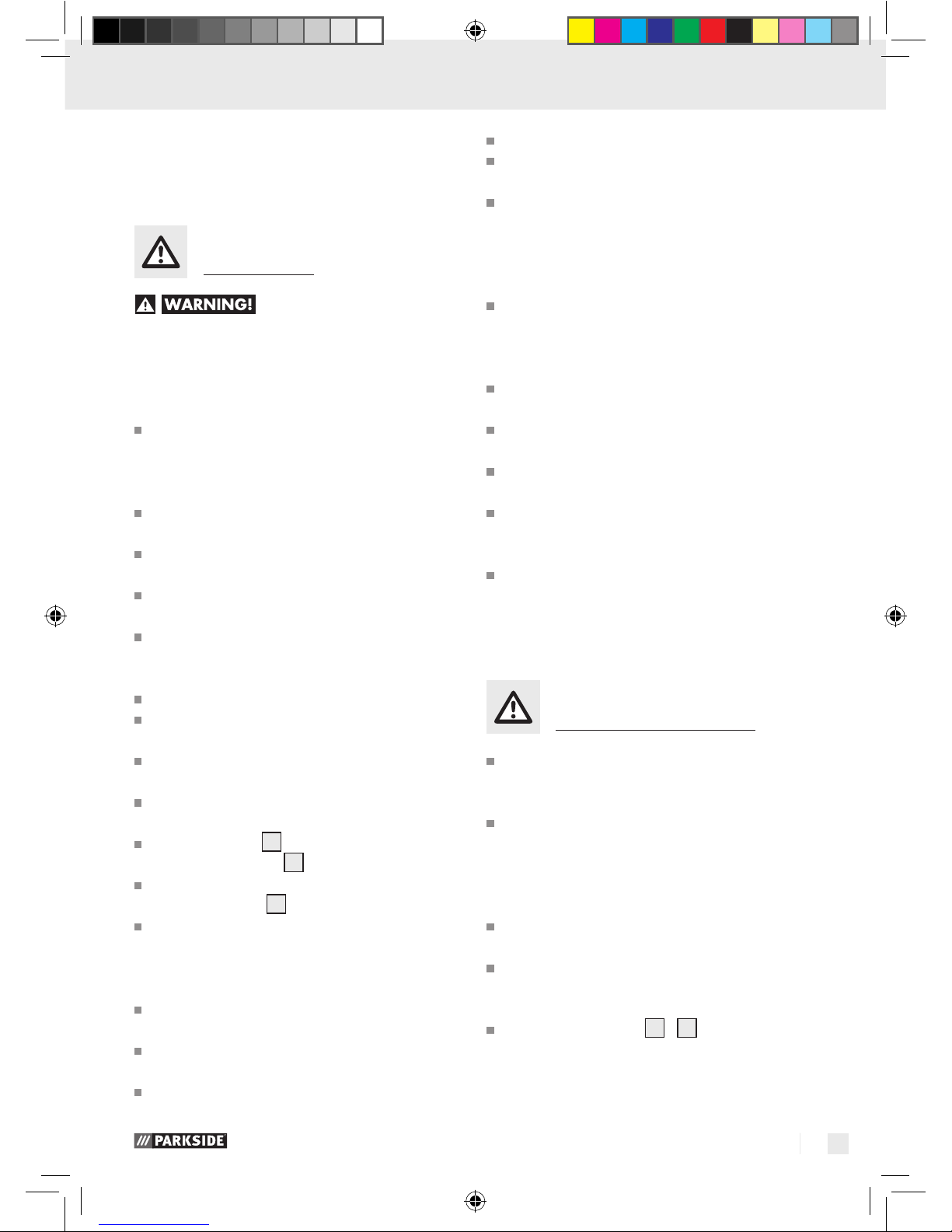

A

9

8

9

10

11

12

6

1 1

B C

A

7

8

15

16

1

3

4

5

2

1

100684_par_Seilhebelzug_cover_GB_IE_CY.indd 5 24.06.14 15:55

13

14

Page 4

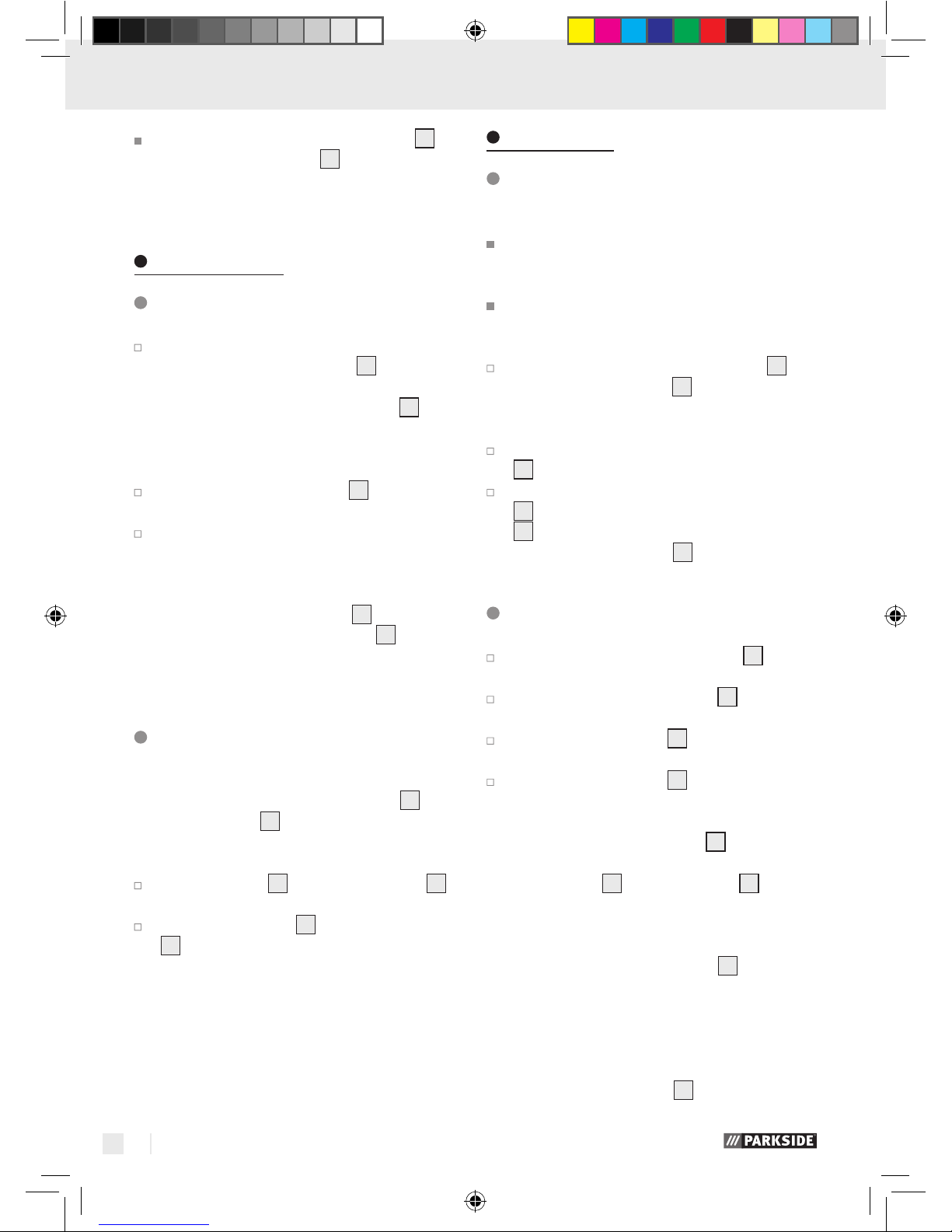

D E

F G

H I

6

15

16

16

15

16

6

6 15

5

7

15

16

9

10

11

8

2

100684_par_Seilhebelzug_cover_GB_IE_CY.indd 8 24.06.14 15:55

4

Page 5

5 GB/IE/CY

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Parts description .................................................................................................................................. Page 6

Scope of delivery ................................................................................................................................ Page 6

Technical Data ....................................................................................................................................Page 6

Important safety instructions ......................................................................................... Page 7

Safety notices specific to the device ......................................................................... Page 7

Before using

Mounting .............................................................................................................................................Page 8

Setting up the pulley function ............................................................................................................. Page 8

Operation

Putting the cable hoist into service .....................................................................................................Page 8

Operating the cable hoist ................................................................................................................... Page 8

Cleaning, maintenance and ordering spare parts

Cleaning ..............................................................................................................................................Page 9

Maintenance .......................................................................................................................................Page 9

Disposal ............................................................................................................................................ Page 9

Warranty / Service centre

Ordering spare parts .......................................................................................................................... Page 10

Declaration of conformity ................................................................................................. Page 10

100684_par_Seilhebelzug_content_GB_IE_CY.indd 5 02.07.14 12:41

Page 6

6 GB/IE/CY

Introduction / Important safety instructions / Safety notices specific to the device

Introduction

Cable winch PSZ 250 B2

Introduction

Please familiarise yourself with the appliance before preparing it for use and using

it for the first time. To do so, please carefully read the following operating instructions and

the important safety information. Use the product

only as described and for the indicated purpose.

Keep these instructions in a safe place. If you pass

the device on to anyone else, please ensure that

you also pass on all the documentation.

Intended use

The cable hoist is used to hoist and lower loads in

indoor spaces in accordance with the equipment

power. Only use the device as described. Any other

use is not intended. The user / operator, not the man

ufacturer, is liable for damages or any type of inju

ry

resulting from any other use. Please note that our devices were not constructed for commercial, manual,

or industrial use. We do not accept any warranty liability if the device is used for commercial, manual,

or industrial operations, or activities similar to these.

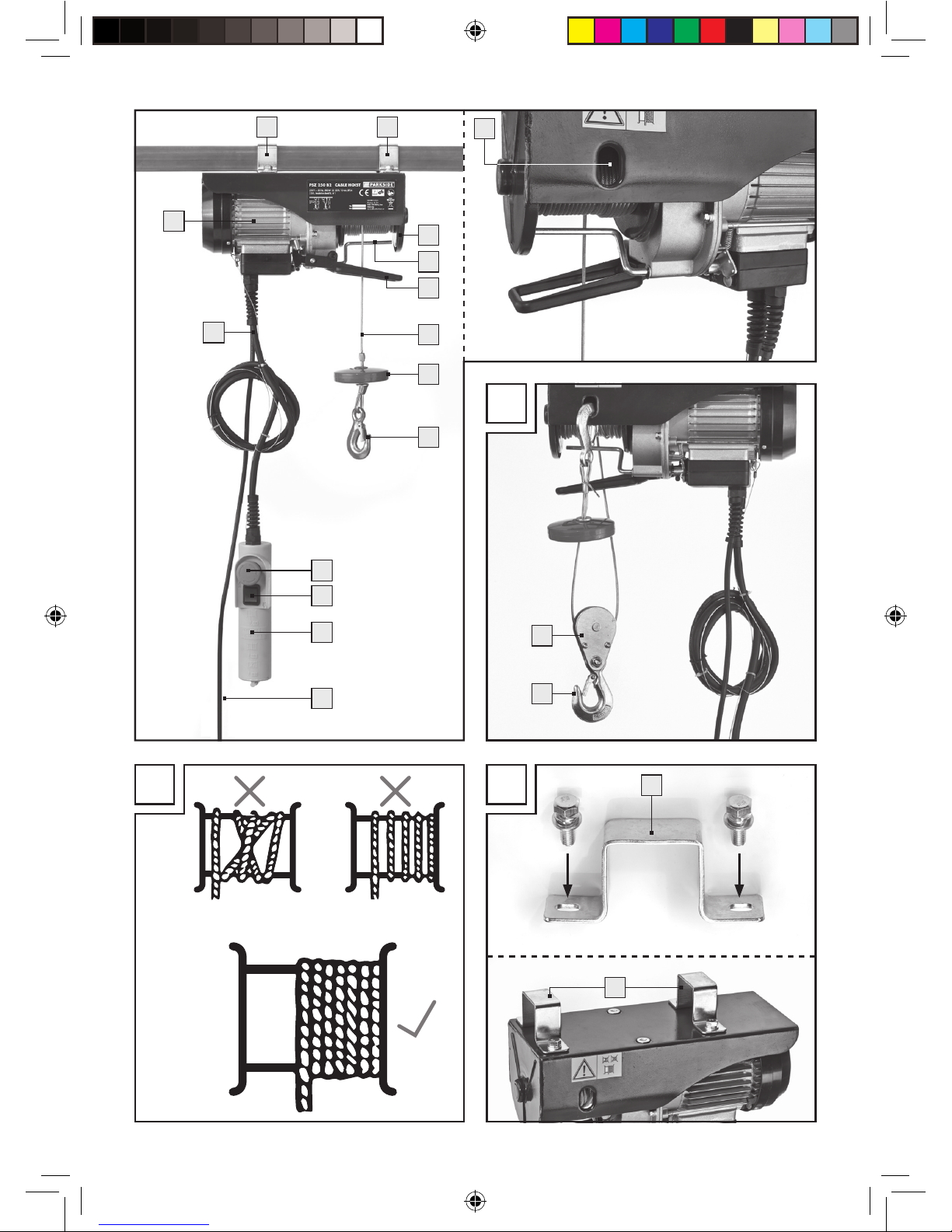

Parts description

1

Mounting bracket

2

Mounting opening for hook in deflection

operation

3

Hoisting drum

4

Maximum cable length lever

5

Auto-stop mechanism lever

6

Steel cable

7

Shut-off weight

8

Hook

9

Emergency stop switch

10

Push button

11

Remote control unit

12

Mains lead

13

Control lead

14

Motor

15

Deflection pulley

16

Additional hook

Scope of delivery

1 Cable hoist

2 Mounting bracket with mounting materials (Fig. C)

1 Deflection pulley with additional hook and moun-

ting materials (see Fig. D)

1 Set of instructions for use

Technical Data

Voltage: 230 V~ 50 Hz

Rated current: 2.2 A

Power input: 500 W

Duty type: S3 20 % 10 min

Rated load: 125 / 250 kg (without / with

deflection pulley)

Hoisting height: 11.5 / 5.7 m (without / with

deflection pulley)

Rated speed: 8 / 4 m / min (without / with

deflection pulley)

Steel cable

diameter: 3.0 mm

Steel cable

tensile strength: 1870 N / mm

2

Insulating level: B

Degree of

protection: IP54

Power unit class: M1

Net weight: 9.3 kg

Gross weight: 10.5 kg

Duty type 3–20 % - 10 min: S3 = Intermittent duty

without the effect of starting. During a 10 min period

the max. operating time is 20 % (2 min).

Mechanical group M1.

The rated power of the device does not vary with

the position of the load.

The value of the A-rated noise emission in the oper

ator

position is less than 70 dB.

The cable hoist must be operated at ambient temperatures from 0 °C to 40 °C and a relative humidity

below 85 %. Height above sea level: max. 1000 m.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 6 02.07.14 12:41

Page 7

7 GB/IE/CY

During transport and storage the temperature may

be between -25 °C and 55 °C. The maximum permissible temperature is 70 °C.

Important safety

instructions

Please read all safety informati

on

and instructions. Failure to observe the safety information and instructions can result in electric shock,

fire and / or serious injury. Keep all safety instruc

tions

and directions for future use!

Always verify the mains voltage matches the

voltage on the nameplate. If the mains voltage

is not suitable, abnormal device operation and

personal injury may result.

The power supply must have earthing and be

protected by an earth leakage circuit breaker.

Hoisting loads exceeding the rated load is pro-

hibited.

Only use the device for the intended purpose.

Never hoist persons with the cable hoist.

Do not unplug from the socket by the cable.

Keep the cable away from heat, oil, and sharp

edges.

Never attempt to hoist fixed or blocked loads.

Remove the mains plug from the socket after

every use.

Keep children and other unauthorised persons

away from the device.

Pulling loads sideways or from one side is pro-

hibited. Prevent the load from swinging.

Ensure the hook 8 moves in the direction shown

on the push button

10

.

Regularly check the cable hoist for damage.

The push button

10

must be in good condition.

Always have repairs and maintenance performed

by an electrician at an authorised specialist

workshop. repairs must be performed by an

electrician to prevent operator accidents.

Avoid rapid start-up and powering off (inching

mode).

Always be attentive whilst operating the cable

hoist.

Never stand or work below the hoisted load.

Hoisting stuck or jammed loads is prohibited.

Always pull the mains plug before executing

settings on the device.

The cable hoist is not suitable for transporting

hot and / or molten materials; the cable hoist is

further not suitable for use in low temperatures

or in environments with severe weather (see

Technical Data).

The service life of the cable hoist is approx.

8000 cycles (excl. wear parts). Once the hoist

has reached 8000 cycles all mechanical parts

must be inspected and overhauled.

Read and understand the operating instructions

before using the cable hoist.

Ensure the operator is familiar with the functiona-

lity of the device and how it should be operated.

The user must always operate the device in

accordance with the operating instructions.

The hoist is not intended for continuous operation.

The duty type is:

Intermittent duty without the effect of starting.

After opening the packaging, please inspect the

device, the steel cable, the hooks, the maximum

cable length lever and the auto-stop mechanism

lever for transport damage.

Safety notices

specific to the device

The user must hoist the load from the ground at

the slowest possible speed. The cable must be

tightened when the load is being hoisted.

The electric cable hoist is not equipped with

a rated power limit. Therefore do not continue

attempting to hoist the load if the overheat protection limits operation. In this event the load

exceeds the rated power of the cable hoist.

Do not leave suspended loads unattended wit-

hout taking the appropriate safety precautions.

Secure the device with a 10 A fuse or a 10 A

earth leakage circuit breaker to protect the

electric circuit.

Do not use the lever 4 / 5 as a routine stop.

These are only intended as emergency stopping

devices.

Introduction / Important safety instructions / Safety notices specific to the device

100684_par_Seilhebelzug_content_GB_IE_CY.indd 7 02.07.14 12:41

Page 8

8 GB/IE/CY

Before beginning, verify the steel cable 6 is

wound around the drum

3

correctly and the

clearance between the turns is smaller than the

steel cable (Fig. B).

Before using

Mounting (see Fig. C)

Secure the cable hoist to a square pipe / boom

using the 2 mounting brackets

1

. The dimensions of the square pipe / boom must correspond

with the size of the mounting bracket

1

and

must be able to bear double the rated load.

Note: We recommend contact a qualified

technician for this purpose.

Screw the mounting brackets 1 to the cable

hoist (also see Fig. C).

Tighten all screws.

Note: A qualified technician should inspect

the anchor of the square tube / boom before

putting the device into service.

Note: The cable hoist motor

14

is equipped

with a thermostat switch. The motor 14 may

therefore stop whilst operating the cable hoist; it will

automatically restart once it has cooled down.

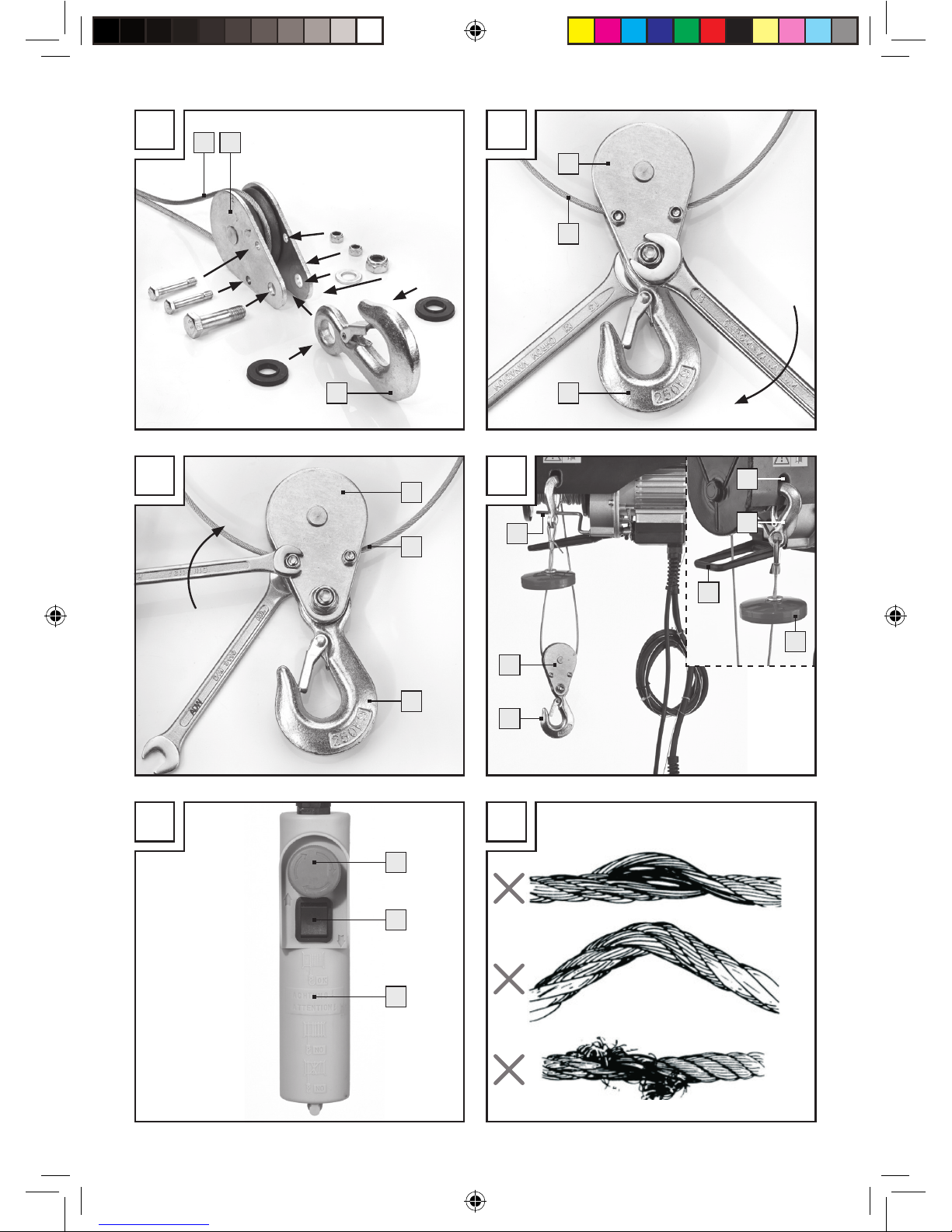

Setting up the pulley function

(see Fig. D–G)

The cable hoist is equipped with a pulley 15 and

an additional hook

16

. When used correctly, the

cable hoist can lift double the load.

Install the pulley 15 and additional hook 16

as shown in figures D–G.

Hook the fixed hook 8 into the fixing opening

2

(see Fig. G). The load will now be lifted with

two steel cables and the cable hoist can therefore lift double the load.

Operation

Putting the cable hoist

into service

The user must hoist the load from the ground at

the slowest possible speed. The cable must be

tightened when the load is being hoisted.

Secure the device with a 10 A fuse or a 10 A

earth leakage circuit breaker to protect the

electric circuit.

Before beginning, verify the steel cable 6 is

wound around the drum

3

correctly and the

clearance between the turns is smaller than the

steel cable (Fig. B).

Remove the adhesive tape from the cable drum

3

prior to first use.

Ensure the load is properly secured to the hook

8

or, for pulley operation, the additional hook

16

, and always maintain a distance to the

load and the steel cable

6

.

Operating the cable hoist

Check if the emergency stop switch 9 is

pressed.

Turn the emergency stop switch 9 clockwise

to release.

Press the push button ▲ 10 to hoist the load

(see Fig. H).

Press the push button ▼ 10 to lower the load

(see Fig. H).

Auto-stop mechanism lever

5

When the maximum hoisting height has been

reached,

the shut-off weight 7 will push the lever 5 up

ward.

This engages a limit switch and the load can no

longer be hoisted.

Maximum cable length lever

4

When the load reaches the lowest possible position,

an end switch is activated, preventing the load from

being lowered further. This end switch also prevents

the cable hoist from being operated in the wrong

direction (hook moving opposite of the direction

indicated on the push button

10

).

Operation / Cleaning, maintenance and ordering spare parts / Disposal

Safety notices specific to the device / Before using / Operation

100684_par_Seilhebelzug_content_GB_IE_CY.indd 8 02.07.14 12:41

Page 9

9 GB/IE/CY

ATTENTION! In the event of an emergency, immediately activate the emergency stop switch

9

to stop

the cable hoist. The cable hoist cannot be operated

if the emergency stop switch has been activated.

Cleaning, maintenance and

ordering spare parts

Cleaning

ATTENTION! Unplug the mains plug from the

socket before cleaning.

Do not use cleaners or solvents; these could

affect the plastic parts of the device.

Ensure water cannot penetrate the housing.

Keep safety devices, venting slots and the motor

housing as dust and dirt free as possible.

Rub the device down with a clean cloth or

blow out with compressed air at a low pressure

setting.

Regularly clean the device with a damp cloth and

a little soft soap.

Note: We recommend cleaning the device

immediately after every use.

Maintenance

ATTENTION! Verify the device is not connected to

the mains when performing care.

Below: A cycle corresponds to moving a load up

and down once.

Periodic inspection corresponds to an inspection

after 100 cycles.

Periodically check the end switches on the cable

hoist are working properly (check without load).

Test as follows: When the cable reaches the

maximum hoisting height the auto-stop mecha-

nism lever

5

is activated. The motor 14 must

now stop. When the steel cable

6

is unwound

as far as possible, the maximum cable length

lever

4

is activated. The motor 14 must now

stop.

Periodically check the power cable 12 and the

control lead

13

.

Lubricate the steel cable 6 and pulley 15 every

200 cycles.

Every 30 cycles verify the entire steel cable 6

is in good working order in accordance with Figure I. If damaged, it must be replaced with a

steel cable corresponding with the technical data.

Every 1000 cycles check the screws on the

mounting bracket

1

and pulley 15 are tight.

Every 1000 cycles verify the hooks 8 / 16

and the pulley

15

are in good condition.

Verify the emergency stop switch 9 and push

buttons

10

are in good condition before every

use.

Check the brake system every 1000 cycles. If

the motor

14

emits unusual noises or is unable

to hoist the rated load, the brake system may

need to be overhauled:

- Replace damaged or worn parts and keep

the associated maintenance documentation.

- Please contact an authorised service centre

for unscheduled maintenance work.

Disposal

The device is packaged to protect it from transport

damage. This packaging is a raw material and therefore reusable or may be recycled. The device and

its accessories are made from various materials, e.g.

metal and plastics.

Dispose of defective components through toxic waste

disposal. Contact the speciality retailer or your municipal government for information!

Do not dispose of power

tools in household waste!

In accordance with European Directive 2012 / 19 /

EU

on waste electrical and electronic equipment and

its implementation into national legislation, worn

out power tools must be collected separately and

recycled in an environmentally friendly fashion.

Operation / Cleaning, maintenance and ordering spare parts / Disposal

100684_par_Seilhebelzug_content_GB_IE_CY.indd 9 02.07.14 12:41

Page 10

10 GB/IE/CY

Alternate recycling option for return

request:

The owner of the electrical equipment is alternatively

obligated to contribute to proper recycling in place

of a return in the case of abandonment. For this purpose the used equipment may also be taken to a

collection site disposing within the terms of the national Closed Substance Cycle Waste Management

Act. This does not apply to accessories attached to

the used equipment and implements without electri

cal

components.

Warranty / Service centre

We provide a 3-year warranty covering faults in

materials or manufacture of the device from the

purchase date.

The warranty does not cover:

· Damage from improper use.

· Wear parts.

· Defects the customer was aware of at the time

of purchase.

· Damage caused by the customer.

T

his warranty does not affect the customer‘s legal rights.

The customer must provide proof of purchase in order

for any warranty claims within the warranty period to

be honoured. Warranty claims must be filed within

3 years from the date of purchase.

In the event of a warranty claim, the customer has

the right to have the goods repaired by our own

workshop or a workshop authorised by us. The device must not be opened for any reason. Opening

or modifying the device invalidates the warranty.

This warranty does not grant any additional rights to

the customer (based on the warranty). Complaints

are often initiated by difficulties encountered during

use. Many of these complaints can be resolved by

telephone or email. Please contact our Service Hotline in the first instance, before you return the device

to the manufacturer.

GB

Unit 55 Romsey Industrial Estate, Romsey

GB - Hampshire SO51 OHR

T: +44 845 0766158

F: +44 1794 514882

IE

Unit 55 Romsey Industrial Estate, Romsey

GB - Hampshire SO51 OHR

T: +44 1794 834250

F: +44 1794 514882

IAN 100684

Please have your receipt and the article number

(e.g. IAN 12345) ready as your proof of purchase

when enquiring about your product.

Ordering spare parts

When ordering replacement parts you

should give the following information:

- Device model

- Device item number

- device ID number

Declaration of conformity

We, MATRIX GMBH, officer responsible for documentation: Mr. Joachim Lichtl, POSTAUER STR. 26,

84109 WÖRTH / ISAR, GERMANY, hereby declare

this product to comply with the following standards,

normative documents and EC directives:

2006 / 42 / EC

2006 / 95 / EC

2004 / 108 / EC

2011 / 65 / EU

Disposal / Warranty / Service centre / Declaration of conformity

100684_par_Seilhebelzug_content_GB_IE_CY.indd 10 02.07.14 12:41

Page 11

11 GB/IE/CY

Declaration of conformity

applicable harmonised standards

EN 14492-2+A1

EN 60204-32

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

Type / Description of product:

Cable winch PSZ 250 B2

Year of manufacture: 2014

Wörth / Isar, 31.05.2014

Joachim Lichtl

- Managing Director -

We reserve the right to make technical modifications

in the course of product development.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 11 02.07.14 12:41

Page 12

12

100684_par_Seilhebelzug_content_GB_IE_CY.indd 12 02.07.14 12:41

Page 13

13 GR/CY

Sicherheit / BedienungΠίνακας περιεχομένων

Εισαγωγή

Χρήση σύμφωνα με τις προδιαγραφές ..........................................................................................Σελίδα 14

Περιγραφή μερών ............................................................................................................................Σελίδα 14

Περιεχόμενα παράδοσης ................................................................................................................Σελίδα 14

Τεχνικά χαρακτηριστικά ...................................................................................................................Σελίδα 14

Σημαντικές υποδείξεις ασφαλείας ...........................................................................Σελίδα 15

Ειδικές για τη συσκευή υποδείξεις ασφαλείας ...............................................Σελίδα 16

Πριν από τη θέση σε λειτουργία

Εγκατάσταση ....................................................................................................................................Σελίδα 16

Ορισμός λειτουργίας τροχαλίας ....................................................................................................Σελίδα 16

Χειρισμός

Θέση σε λειτουργία του ανυψωτήρα καλωδίου .............................................................................Σελίδα 16

Λειτουργία ανυψωτήρα ....................................................................................................................Σελίδα 17

Καθαρισμός, συντήρηση και παραγγελία ανταλλακτικών

Καθαρισμός .....................................................................................................................................Σελίδα 17

Συντήρηση ........................................................................................................................................Σελίδα 17

Απόρριψη ....................................................................................................................................Σελίδα 18

Εγγύηση / Service ..................................................................................................................Σελίδα 18

Παραγγελία ανταλλακτικών .............................................................................................................Σελίδα 19

Δήλωση συμμόρφωσης ....................................................................................................Σελίδα 19

100684_par_Seilhebelzug_content_GB_IE_CY.indd 13 02.07.14 12:41

Page 14

14 GR/CY

Εισαγωγή

Γερανακι ανυψωσης φορτιου

PSZ 250 B2

Εισαγωγή

Πριν από τη θέση σε λειτουργία και την

πρώτη χρήση εξοικειωθείτε με τη συσκευή.

Για τον σκοπό αυτό διαβάστε προσεκτικά

τις παρακάτω οδηγίες χρήσης και τις σημαντικές

υποδείξεις ασφαλείας. Χρησιμοποιείτε την συσκευή

μόνον, όπως περιγράφεται και για τους δεδομένους

τομείς εφαρμογής. Φυλάξτε τις παρούσες οδηγίες.

Σε περίπτωση παράδοσης της συσκευής σε τρίτους

παραδώστε επίσης και όλα τα έγγραφα.

Χρήση σύμφωνα με τις

προδιαγραφές

Ο ανυψωτήρας καλωδίου για ανύψωση και χαμήλωμα

φορτίων σε κλειστούς χώρους αντίστοιχα με την ισχύ

της συσκευής. Η συσκευή επιτρέπεται να χρησιμοποιείται

μόνο όπως περιγράφεται. Οποιαδήποτε περαιτέρω

χρήση δεν είναι σύμφωνη με τις προδιαγραφές. Για

ζημιές ή τραυματισμούς οποιουδήποτε είδους που

προκύπτουν από αυτό ευθύνεται ο χρήστης / χειριστή

ς

και όχι ο κατασκευαστής. Παρακαλούμε προσέχετε

ότι οι συσκεύες μας δεν είναι σχεδιασμένες για

οικιακή, εργαστηριακή ή βιομηχανική χρήση. Δεν

αναλαμβάνουμε καμία παροχή εγγύησης αν η συσκευ

ή

χρησιμοποιηθεί σε επαγγελματικές, εργαστηριακές

ή βιομηχανικές επιχειρήσεις καθώς και σε όμοιες

δραστηριότητες.

Περιγραφή μερών

1

Πλαίσιο στερέωσης

2

Άνοιγμα στερέωσης για άγκιστρο κατά την

λειτουργία αντιστροφής ταχυτήτων

3

Τύμπανο περιέλιξης

4

Μοχλός για μέγιστο μήκος καλωδίου

5

Μοχλός τουη αυτόματου μηχανισμού παύσης

6

Ατσάλινο καλώδιο

7

Βάρος απενεργοποίησης

8

Άγκιστρο

9

Διακόπτης απενεργοποίησης εκτάκτου ανάγκης

10

Κομβίο πίεσης

11

Τηλεχειριστήριο

12

Καλώδιο ηλεκτρικού δικτύου

13

Σύρμα πιλότος

14

Κινητήρας

15

Τροχαλία αναστροφής

16

Πρόσθετα άγκιστρα

Περιεχόμενα παράδοσης

1 Ανυψωτήρας καλωδίου

2 Πλαίσια στερέωσης με υλικό εγκατάστασης (Εικ. C)

1 Τροχαλία αναστροφής με πρόσθετα άγκιστρα

και υλικό εγκατάστασης (β. Εικ. D)

1 Οδηγίες χρήσης

Τεχνικά χαρακτηριστικά

Τάση: 230 V∼ 50 Hz

Ονομαστικό ρεύμα: 2,2 A

Κατανάλωση ισχύος: 500 W

Είδος λειτουργίας: S3 20 % 10 λεπτά

Ονομαστικό φορτίο: 125 / 250 kg (χωρίς / με

τροχαλία αναστροφής)

Ύψος ανύψωσης: 11,5 / 5,7 m (χωρίς / με

τροχαλία αναστροφής)

Ονομαστική ταχύτητα: 8 / 4 m / min (χωρίς/με

τροχαλία αναστροφής)

Διάμετρος

του ατσάλινου καλωδίου: 3,0 mm

Αντοχή εφελκυσμού

του ατσάλινου καλωδίου: 1870 N / mm

2

Κατηγορία μόνωσης: B

Είδος προστασίας: IP54

Κατηγορία κινητήρα: Μ1

Καθαρό βάρος: 9,3 kg

Bruttogewicht: 10,5 kg

Είδος λειτουργίας 3–20 % - 10 τουλ.: S3 = Περιοδική λειτουργία χωρίς επίδραση της διαδικασίας

εκκίνησης. Κατά την διάρκεια ενός χρονικού διαστήματος 10 λεπτών κυμαίνεται ο μέγ. χρόνος

λειτουργίας στο 20 % 2 λεπτά.

Η μηχανική ομάδα είναι Μ1.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 14 02.07.14 12:41

Page 15

15 GR/CY

Η ονομαστική ισχύς της συσκευής δεν μεταβάλλεται

με την θέση του φορτίου.

Η τιμή της Α-βαθμολογημένης εκπομπής θορύβου

στην θέση λειτουργίας είναι χαμηλότερη από 70 dB.

Ο ανυψωτήρας καλωδίου πρέπει να λειτουργεί σε

εύρος θερμοκρασιών μεταξύ 0 °C και 40 °C σχετικής

υγρασίας κάτω από 85 %. Ύψος πάνω από την

στάθμη της θάλασσας: μέγ. 1000 m.

Για μεταφορά και αποθήκευση επιτρέπεται να

κυμαίνεται η θερμοκρασία μεταξύ -25 °C και 55 °C.

Η μέγιστη επιτρεπτή θερμοκρασία είναι 70 °C.

Σημαντικές υποδείξεις

ασφαλείας

Διαβάστε όλες τις

υποδείξεις ασφάλειας και οδηγίες. Αδυναμία τήρηση

ς

των υποδείξεων ασφάλειας και των οδηγιών μπορεί

να έχει ηλεκτροπληξία, πυρκαγιά και / ή σοβαρούς

τραυματισμούς ως συνέπειες. Φυλάξτε όλες τις

υποδείξεις ασφάλειας και τις οδηγίες για μελλοντική

χρήση!

Ε

λέγχεται πάντοτε αν η ονομαστική τάση αντιστοι

χεί

στην τάση της πινακίδας τύπου. Για την περίπτωση

,

που η ονομαστική τάση δεν είναι κατάλληλη,

μπορεί αυτή να οδηγήσει σε ανώμαλη εργασία

της συσκευής και σε ζημιές σε πρόσωπα.

Η παροχή ρεύματος πρέπει να διαθέτει μια

γείωση και να είναι ασφαλισμένη με εναν διακόπ

τη

προστασίας ρεύματος βραχυκύκλωσης.

Απαγορεύεται να ανυψώνετε φορτία, που

υπερβαίνουν το ονομαστικό φορτίο.

Χρησιμοποιείτε την συσκευή μόνο για τον σκοπό,

για τον οποίο προορίζεται. Ποτέ μην ανυψώνετε

πρόσωπα με τον ανυψωτήρα καλωδίου.

Μην χρησιμοποιείτε το καλώδιο, για να τραβήξετε

τον ρευματολήπτη από την πρίζα. Κρατήστε το

καλώδιο μακριά από θερμότητα, λάδι, αιχμηρές

ακμές.

Ποτέ μην προσπαθείτε να ανυψώσετε σταθερά

ή μπλοκαρισμένα φορτία.

Έπειτα από κάθε χρήση, βγάλτε τον ρευματολήπτη

από την πρίζα.

Κρατάτε παιδιά και άλλα μη εξουσιοδοτημένα

άτομα μακριά από την συσκευή.

Απαγορεύεται να τραβάτε φορτία πλευρικά ή α

πό

μία άλλη πλευρά. Αποφεύγετε μια ταλάντωση

του φορτίου.

Βεβαιωθείτε ότι το άγκιστρο 8 κινείται στην

ίδια κατεύθυνση όπως δείχνει το κομβίο

πίεσης

10

.

Ελέγχετε τον ανυψωτήρα καλωδίου τακτικά για

φθορές. Το κομβίο πίεσης

10

πρεπει να είναι

σε καλή κατάσταση.

Επιτρέπεται επισκευές και εργασίες συντήρησης

να πραγματοποιούνται μόνο από εξουσιοδοτημένα

συνεργεία μέσω ενός ηλεκτροτεχνίτη. Επισκευές

επιτρέπεται να πραγματοποιούνται μόνο από

ηλεκτροτεχνικό προσωπικό, διαφορετικά μπορούν

να προκύψουν ατυχήματα για τον χειριστή.

Απφεύγετε μια γρήγορη ενεργο- και

απενεργοποίηση (λειτουργία Jog).

Να είστε πάντοτε προσεκτικοί κατά την

λειτουργία του ανυψωτήρα καλωδίου.

Μην στέκεστε ή εργάζεστε κάτω από το ανυψωμέ

νο

φορτίο.

Δεν επιτρέπεται να ανυψώνετε σταθερά ή

κολλημένα φορτία.

Τραβήξτε πάντα τον ρευματολήπτη, προτού

εκτελέσετε ρυθμίσεις στη συσκευή.

Ο ανυψωτήρας καλωδίου δεν είναι κατάλληλος

για μεταφορά θερμών και / ή λιωμένων μαζών,

επιπλέον ο ανυψωτήρας δεν είναι κατάλληλος

για την εφαρμογή σε χαμηλές θερμοκρασίες

και σε περιβάλλον έντονης κακοκαιρίας (β.

τεχνικά χαρακτηριστικά).

Η διάρκεια χρήσης του ανυψωτήρα καλωδίου

είναι περ. 8000 κύκλοι (εξαιρ. αναλώσιμων

μερών). Αν η παρτίδα των 8000 κύκλων έχει

λήξει, πρέπει όλα τα τα μηχανικά μέρη να

ελέγχονται και να αντικαθίστανται πλήρως.

Διαβάστε και καταλάβετε αυτές τις οδηγίες

χ

ρήσης, προτού χρησιμοποιήσετε τον ανυψωτήρα

καλωδίου.

Βεβαιωθείτε ότι ο χειριστής ξέρει, πως λειτουργεί

η συσκευή, και πως θα έπρεπε να γίνεται ο

χειρισμός της.

Ο χρήστης πρέπει πάντα να λειτουργεί σε

συμφωνία με τις οδηγίες χρήσης.

Ο ανυψωτήρας δεν είναι σχεδιασμένος για

συνεχή λειτουργία. Το είδος λειτουργίας είναι:

Εισαγωγή / Σημαντικές υποδείξεις ασφαλείας

100684_par_Seilhebelzug_content_GB_IE_CY.indd 15 02.07.14 12:41

Page 16

16 GR/CY

Περιοδική λειτουργία χωρίς επιρροή της

διαδικασίας εκκίνησης.

Μετάτο άνοιγμα της συσκευασίας επιθεωρήστε

παρακαλούμε την συσκευή, το ατσάλινο καλώδιο

,

τα άγκιστρα, τον μοχλό για μέγιστο μήκος

καλωδίου και τον μοχλό του αυτόματου

μηχανισμού παύσης για πιθανές ζημιές

μεταφοράς.

Ειδικές για τη συσκευή

υποδείξεις ασφαλείας

Ο χρήστης πρέπει να ανυψώνει το φορτίο από

το έδαφος με την χαμηλότερη δυνατή

ταχύτητα. Το καλώδιο πρέπει να είναι τεντωμένο

όταν ανυψώνεται το φορτίο.

Ο ηλεκτρικός ανυψωτήρας καλωδίου δεν είναι

εξοπλισμένος με έναν περιοριστή ονομαστικής

ισχύος. Για αυτό μην συνεχίζετε να προσπαθείτε

να ανυψώσετε το φορτίο όταν η προστασία

υπερθέρμανσης περιορίζει την λειτουργία. Το

φορτίο υπερβαίνει σε αυτή την περίπτωση την

ονομαστική ισχύ του ανυψωτήρα καλωδίου.

Μην αφήνετε κρεμασμένα φορτία χωρίς

επιτήρηση χωρίς να έχουν ληφθεί οι αντίστοιχες

προδιαγραφές ασφάλειας.

Ασφαλίστε τη συσκευή με μια ασφάλεια 10 A

ή με έναν διακόπτη προστασίας ρεύματος

βραχυκυκλώματος 10 A για να προστατέψετε

το κύκλωμα ρεύματος.

Μην χρησιμοποιείτε τους μοχλούς 4 / 5 ως

διάταξη παύσης ρουτίνας. Αυτοί λειτουργούν

μόνο ως διάταξη παύσης σε έκτακτη ανάγκη.

Προτού ξεκινήσετε, βεβαιωθείτε, ότι το ατσάλινο

καλώδιο

6

είναι ορθά ξετυλιγμένο από το

τύμπανο περιέλιξης

3

και η απόσταση μεταξύ

των στροφών είναι μικρότερη από το ατσάλινο

καλώδιο (Εικ. B).

Πριν από τη θέση σε λειτουργία

Εγκατάσταση (β. Εικ. C)

Στερεώστε τον ανυψωτήρα καλωδίου με τα

2 πλαίσια στερέωσης

1

σε έναν βραχιόνα

τετράγωνου σωλήνα / κούνια. Οι διαστάσεις

του βραχίονα τετράγωνου σωλήνα / κούνιας

πρέπει να συμφωνούν με το μέγεθος του

πλαισίου

στερέωσης

1

και αυτός / αυτή πρέπει να μπορεί

να φέρει το διπλό ονομαστικό φορτίο.

Υπόδειξη: Σας συνιστούμε, επ‘ αυτού να

επικοινωνήσετε με έναν εξειδικευμένο τεχνικό.

Βιδώστε το πλαίσιο στερέωσης 1 στον

ανυψωτήρα καλωδίου (β. επίσης Εικ. C).

Σφίξτε όλες τις βίδες.

Υπόδειξη: Πριν την θέση σε λειτουργία ένας

εξειδικευμένος τεχνικός πρέπει να ελέγξει την

αγκύρωση του τετράγωνου σωλήνα / βραχίονα.

Υπόδειξη: Ο κινητήρας

14

του ανυψωτήρα

είναι εξοπλισμένος με έναν διακόπτη θερμοστάτη.

Κατά την διάρκεια της λειτουργίας του ανυψωτήρα

καλωδίου μπορεί για αυτό να προκύψει παύση

του κινητήρα

14

, αυτός θα λειτουργήσει πάλι

αυτόματα μόλις κρυώσει.

Ορισμός λειτουργίας

τροχαλίας (β. Εικ. D–G)

Ο ανυψωτήρας καλωδίου είναι εξοπλισμένος με

μια τροχαλία αναστροφής

15

και ένα πρόσθετο

άγκιστρο

16

. Σε ορθή χρήση μπορεί ο ανυψωτήρας

καλωδίου να ανυψώσει το διπλάσιο φορτίο.

Εγκαταστήστε την τροχαλία αναστροφής 15 και

τα πρόσθετα άγκιστρα

16

όπως παρουσιάζεται

στις εικόνες D–G.

Αναρτήστε το σταθερά εγκατεστημένο άγκιστρο 8

στο άνοιγμα στερέωσης 2 (β. Εικ. G). Ανυψώστ

ε

τώρα το φορτίο με την βοήθεια των δυο ατσάλινω

ν

καλωδίων, έτσι μπορεί ο ανυψωτήρας καλωδίου

να ανυψώσει το διπλάσιο φορτίο.

Χειρισμός

Θέση σε λειτουργία του

ανυψωτήρα καλωδίου

Ο χρήστης πρέπει να ανυψώνει το φορτίο από

το έδαφος με την χαμηλότερη δυνατή ταχύτητα.

Το καλώδιο πρέπει να είναι τεντωμένο όταν

ανυψώνεται το φορτίο.

… / Ειδικές για τη συσκευή … / Πριν από τη θέση σε λειτουργία / Χειρισμός

100684_par_Seilhebelzug_content_GB_IE_CY.indd 16 02.07.14 12:41

Page 17

17 GR/CY

Ασφαλίστε τη συσκευή με μια ασφάλεια 10 A ή

με έναν διακόπτη προστασίας ρεύματος

βραχυκυκλώματος 10 A για να προστατέψετε

το κύκλωμα ρεύματος.

Προτού ξεκινήσετε, βεβαιωθείτε, ότι το ατσάλινο

καλώδιο

6

είναι ορθά ξετυλιγμένο από το

τύμπανο περιέλιξης

3

και η απόσταση μεταξύ

των στροφών είναι μικρότερη από το ατσάλινο

καλώδιο (Εικ. B).

Απομακρύνετε πριν την πρώτη χρήση την αυτοκόλ

-

λητη ταινία από το τύμπανο περιέλιξης

3

.

Βεβαιωθείτε, ότι το φορτίο είναι ασφαλισμένο

σύμφωνα με τις προδιαγραφές στο άγκιστρο

8

ή κατά την λειτουργία τροχαλίας στο πρόσθετο

άγκιστρο

16

και κρατάτε πάντα απόσταση από

το φορτίο και το ατσάλινο καλώδιο

6

.

Λειτουργία ανυψωτήρα

Ελέγχετε, αν ο διακόπτης απενεργοποίησης

εκτάκτου ανάγκης

9

είναι πιεσμένος.

Στρέψτε τον διακόπτη απενεργοποίησης εκτάκτου

ανάγκης 9 δεξιόστροφα για να τον ξεκλειδώσετε.

Πιέστε το κομβίο πίεσης στην φορά ▲ 10 για

ανύψωση του φορτίου (β. Εικ H).

Πιέστε το κομβίο πίεσης στην φορά ▼ 10 για

χαμήλωμα του φορτίου (β. Εικ H).

Μοχλός του αυτόματου μηχανισμού

παύσης

5

‚Οταν επιτευχθεί το μέγιστο ύψος ανύψωσης, πιέζει

το βάρος απενεργοποίησης 7 τον μοχλό 5

προς

τα πάνω. Με αυτό αγγίζεται ένας τερματικός διακόπτη

ς

και το φορτίο δεν μπορεί να ανυψωθεί περισσότερο.

Μοχλός για μέγιστο μήκος καλωδίου

4

Όταν το φορτίο έχει φτάσει στην όσο το δυνατόν πιο

χαμηλή θέση, αγγίζεται ένας τερματικός διακόπτης,

ο οποίος καθιστά αδύνατο ένα περαιτέρω χαμήλωμα

του φορτίου. Αυτός ο τερματικός διακόπτης

αποτρέπει επίσης μια λειτουργία του ανυψωτήρα

καλωδίου στην λάθος κατεύθυνση (το άγκιστρο

κινείται στην αντίθετη προς το κομβίο πίεσης

10

εμφανιζόμενη κατεύθυνση).

ΠΡΟΣΟΧΗ! Σε περίπτωση έκτακτης ανάγκης

πιέστε αμέσως τον διακόπτη απενεργοποίησης

έκτακτής ανάγκης

9

για να σταματήσετε τον

ανυψωτήρα καλωδίου. Η λειτουργία του ανυψωτήρα

καλωδίου δεν είναι δυνατή, όταν έχει πιεστεί ο

διακόπτης απενεργοποίησης έκτακτης ανάγκης.

Καθαρισμός, συντήρηση και

παραγγελία ανταλλακτικών

Καθαρισμός

ΠΡΟΣΟΧΗ! Τραβήξτε πριν από όλες τις εργασίες

καθαρισμού το βύσμα δικτύου από την πρίζα.

Μην χρησιμοποιείτε καθαριστικό ή διαλυτικό

μέσο; αυτά θα μπορούσαν να ερεθίσουν τα

πλαστικά μέρη της συσκευής.

Προσέχετε ώστε να μην μπορεί να καταλήξει

καθόλου νερό στο εσωτερικό της συσκευής.

Διατηρείτε τις διατάξεις ασφάλειας, σχισμές

αερισμού και περίβλημα κινητήρα όσο το

δυνατόν καθαρές από σκονη και βρωμιά.

Τρίβετε την συσκευή με ένα καθαρό πανί ή

καθαρίστε την με πεπιεσμένο αέρα σε χαμηλή

πίεση.

Καθαρίζετε την συσκευή τακτικά με ένα υγρό

πανί και λίγο μαλακό σαπούνι.

Υπόδειξη: Συνιστάται να καθαρίζετε την

συσκευή απευθείας μετά από κάθε χρήση.

Συντήρηση

ΠΡΟΣΟΧΗ! Πάντα να βεβαιώνεστε, ότι η συσκευή

δεν είναι συνδεδεμένη με το δίκτυο ρεύματος, όταν

την φροντίζετε.

Παρακάτω: Ένας κύκλος αντιστοιχεί σε μια

ανοδικη και καθοδική κίνησης ενός φορτίου.

Περιοδική εξέταση αντιστοιχεί σε μια εξέταση μετά

από 100 κύκλους.

Εξετάζεται περιοδικά, ότι ο τερματικός

διακόπτης του ανυψωτήρα καλωδίου λειτουργεί

σύμφωνα με τις προδιαγραφές (εξετάστε χωρίς

φορτίο).

Χειρισμός / Καθαρισμός, συντήρηση και παραγγελία ανταλλακτικών

100684_par_Seilhebelzug_content_GB_IE_CY.indd 17 02.07.14 12:41

Page 18

18 GR/CY

Η εξέταση πραγματοποιείται ακολούθως:

Όταν το καλώδιο φτάσει το μέγιστο ύψος

ανύψωσης, αγγίζεται ο μοχλός του αυτόματου

μηχανισμού παύσης

5

. Ο κινητήρας 14 πρέπει

τώρα να σταματάει. Αν το ατσάλινο καλώδιο

6

είναι όσο το δυνατό περισσότερο ξετυλιγμένο,

ενεργοποιείται ο μοχλός για μέγιστο μήκος

καλωδίου

4

. Ο κινητήρας 14 πρέπει τώρα να

σταματάει.

Εξετάζετε περιοδικά το καλώδιο δικτύου 12

και το σύρμα πιλότο

13

.

Λ

ιπαίνετε κάθε 200 κύκλους το ατσάλινο καλώδ

ιο

6

και την τροχαλία αναστροφής 15.

Ελέγχετε κάθε 30 κύκλους σύμφωνα με την

εικόνα I, αν το συνολικό ατσάλινο καλώδιο

6

είναι σε καλή κατάσταση. Σε περίπτωση που

είναι φθαρμένο, πρέπει να αντικατασταθεί από

ένα αντίστοιχο τεχνικών χαρακτηριστικών

ατσάλινο καλώδιο.

Εξετάζετε κάθε 1000, αν οι βίδες του πλαισίου

στερέωσης

1

και της τροχαλίας αντιστροφής

15

είναι καλά σφιγμένες.

Εξετάζετε κάθε 1000 κύκλους, αν τα άγκιστρα

8

/ 16 και η τροχαλία αντιστροφής 15 είναι

σε καλή κατάσταση.

Ελέγχετε πριν από κάθε χρήση του ανψωτήρα

καλωδίου αν ο διακόπτης απενεργοποίησης

έκτακτης ανάγκης

9

και το κομβίο πίεσης 10

είναι σε άθικτη κατάσταση λειτουργίας.

Κάθε 1000 κύκλους ελέγξτε το σύστημα φρένου.

Αν ο κινητήρας

14

κάνει ασυνήθιστους

θορύβους ή δεν μπορεί να ανυψώσει το

ονομαστικό φορτίο, είναι δυνατό, ότι το σύστημα

φρένου πρέπει να αντικατασταθεί πλήρως:

- Αντικαταστείτε ελαττωματικά ή φθαρμένα μέρη,

και αποθηκεύεται τα συναφή έγγραφα

συντήρησης.

- Για εργασίες συντήρησης εκτός σχεδίου

απευθυνθείτε παρακαλούμε σε ένα

εξουσιοδοτημένο κέντρο σέρβις.

Απόρριψη

Η συσκευή βρίσκεται για προστασία από

ζημιές μεταφοράς σε μια συσκευασία. Αυτή η

συσκευασία είναι πρώτη ύλη και μπορεί έτσι να

ξαναχρησιμοποιηθεί ή μπορεί να επιστραφεί στον

κύκλο πρώτων υλών. Η συσκευή και τα εξαρτήματα

της αποτελούνται από διάφορα υλικά, π.χ. μέταλλο

και πλαστικά.

Παραδώστε ελαττωματικά συστατικά μερη στην

απόρριψη ειδικών απορριμμάτων. Ενημερωθείτε

στο εξειδικευμένο κατάστημα ή στην κοινοτική

διαχείριση!

Απαγορεύεται η απόσυρση

ηλεκτρονικών εργαλείων μαζί

με τα οικιακά απορρίμματα!

Σύμφωνα με την Ευρωπαϊκή Οδηγία 2012 / 19 / EU

περί ηλεκτρικών συσκευών και παλιών ηλεκτρικών

συσκευών και της αναφοράς στο εθνικό δίκαιο, θα

πρέπει τα χρησιμοποιημένα ηλεκτρικά εργαλεία να

συλλέγονται σε ξεχωριστό χώρο και να ανακυκλώνοντα

ι

με οικολογικό τρόπο.

Εναλλακτικές ανακύκλωσης για απαίτηση

επιστροφής:

Ο ιδιοκτήτης της ηλεκτρικής συσκευής υποχρεούται

εναλλακτικά στην θέση της επιστροφής στην συνδρομ

ή

για την ανακύκλωση στην περίπτωση της αποποίησης

ιδιοκτησίας. Η παλιά συσκευή μπορεί για αυτό να

παραδοθεί σε ένα σημείο επιστροφής, το οποίο

πραγματοποιεί απόρριψη σύμφωνα με το εθνικό

εμπορικό δίκαιο και του νόμου απορριμάτων.

Ανεπηρέαστα είναι τα συμπεριλαμβανόμενα εξαρτήματ

α

παλιών συσκεύων και βοηθητικά μέσα χωρίς

συστατικά μέρη ηλεκτροδίων.

Εγγύηση / Service

Παρέχουμε εγγύηση 3 ετών από την ημερομηνία

αγοράς για σφάλματα υλικού και κατασκευής της

συσκευής.

Η εγγύηση δεν ισχύει:

· Σε περίπτωση βλαβών, οι οποίες οφείλονται

σε ανάρμοστη χρήση.

· Για εξαρτήματα που υπόκεινται σε φθορές.

· Για ελλείψεις, τις οποίες ο πελάτης γνώριζε

κατά την αγορά.

· Σε περίπτωση ευθύνης του πελάτη.

Καθαρισμός, συντήρηση και παραγγελία … / Απόρριψη / Εγγύηση / Service

100684_par_Seilhebelzug_content_GB_IE_CY.indd 18 02.07.14 12:41

Page 19

19 GR/CY

Εγγύηση / Service / Δήλωση συμμόρφωσης

Οι νομικές αξιώσεις του πελάτη δεν επηρεάζονται

από την εγγύηση.

Για αξίωση εγγυοδοσίας εντός του χρόνου απόδοσ

ης

εγγύησης, ο πελάτης πρέπει να υποβάλλει το

παραστατικό αγοράς. Η εγγύηση παρέχεται για

διάστημα 3 ετών από την ημερομηνία αγοράς από

την ημερομηνία αγοράς.

Ο πελάτης σε περίπτωση εγγύησης έχει το δικαίωμα

επισκευής του προϊόντος στα συνεργεία επισκευών

της εταιρείας μας ή σε εξουσιοδοτημένα συνεγεία

επισκευών. Απαγορεύεται αυστηρά το άνοιγμα της

συσκευής – σε περίπτωση ανοίγματος ή παραποίηση

ς

παύει να ισχύει η αξίωση εγγυοδοσίας. Δεν

παραχωρούνται συμπληρωματικά δικαιώματα στον

πελάτη (λόγω εγγύησης). Σε πολλές περιπτώσεις

αιτία παραπόνων αποτελούν τα σφάλματα χειρισμού.

Τ

α παραπάνω μπορούν να αντιμετωπιστούν τηλεφωνικ

ά

ή μέσω e-mail. Παρακαλούμε σε τέτοια περίπτωση

επικοινωνήστε με τη γραμμή επικοινωνίας σέρβις,

προτού υποβάλλετε παράπονο στον κατασκευαστή

για τη συσκευή.

D.Nikolaou S.A.

Flemig 33, Koropi

Athens, Greece

T: +30 210 9753757

F: +30 210 9737423

E: info@nikolaoutools.gr

www.nikolaoutools.gr

IAN 100684

Σε περίπτωση ερωτήματος παρακαλείσθε να έχετε

διαθέσιμο το παραστατικό αγοράς και τον κωδικό

προϊόντος (π.χ. IAN 12345) ως αποδεικτικό της

αγοράς σας.

Παραγγελία ανταλλακτικών

Κατά την παραγγελία ανταλλακτικών

πρέπει να γίνονται οι ακόλουθες

καταχωρήσεις:

- Τύπος της συσκευής

- Αριθμός προϊόντος της συσκευής

- Αριθμός ταυτότητας της συσκευής

Δήλωση συμμόρφωσης

Εμείς η, MATRIX GMBH, υπεύθυνος εγγράφων:

κύριος Joachim Lichtl, POSTAUER STR. 26, 84109

WÖRTH / ISAR, ΓΕΡΜΑΝΊΑ, δηλώνουμε με το

παρόν, ότι αυτό το προϊόν συμφωνεί με τα ακόλουθα

πρότυπα, κανονιστικά έγγραφα και οδηγίες ΕΕ:

2006 / 42 / EC

2006 / 95 / EC

2004 / 108 / EC

2011 / 65 / EU

εφαρμοσθέντα εναρμονισμένα πρότυπα

EN 14492-2+A1

EN 60204-32

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

Τύπος / Χαρακτηρισμός συσκευής:

Γερανακι ανυψωσης φορτιου PSZ 250 B2

Έτος κατασκευής: 2014

Wörth / Isar, 31.05.2014

Joachim Lichtl

- Διευθυντής -

Διατηρούμε το δικαίωμα τεχνικών αλλαγών στο

πλαίσιο της τεχνικής εξέλιξης.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 19 02.07.14 12:41

Page 20

20

100684_par_Seilhebelzug_content_GB_IE_CY.indd 20 02.07.14 12:41

Page 21

21 DE/AT/CH

Sicherheit / BedienungInhaltsverzeichnis

Einleitung

Bestimmungsgemäßer Gebrauch ....................................................................................................... Seite 22

Teilebeschreibung ...............................................................................................................................Seite 22

Lieferumfang ........................................................................................................................................ Seite 22

Technische Daten ................................................................................................................................ Seite 22

Wichtige Sicherheitshinweise ........................................................................................Seite 23

Gerätespezifische Sicherheitshinweise .................................................................Seite 24

Vor der Inbetriebnahme

Montage .............................................................................................................................................. Seite 24

Flaschenzugfunktion einrichten ..........................................................................................................Seite 24

Bedienung

Seilhebezug in Betrieb nehmen..........................................................................................................Seite 24

Seilzug bedienen ................................................................................................................................Seite 25

Reinigung, Wartung und Ersatzteilbestellung

Reinigung ............................................................................................................................................. Seite 25

Wartung ..............................................................................................................................................Seite 25

Entsorgung ..................................................................................................................................... Seite 26

Garantie / Service ..................................................................................................................... Seite 26

Ersatzteilbestellung ..............................................................................................................................Seite 27

Konformitätserklärung ....................................................................................................... Seite 27

100684_par_Seilhebelzug_content_GB_IE_CY.indd 21 02.07.14 12:41

Page 22

22 DE/AT/CH

Einleitung

Seilhebezug PSZ 250 B2

Einleitung

Machen Sie sich vor der Inbetriebnahme

und dem ersten Gebrauch mit dem Ge-

rät vertraut. Lesen Sie hierzu aufmerksam die nachfolgende Bedienungsanleitung und

die wichtigen Sicherheitshinweise. Benutzen Sie das

Gerät nur wie beschrieben und für die angegebenen

Einsatzbereiche. Bewahren Sie diese Anleitung gut

auf. Händigen Sie alle Unterlagen bei Weitergabe

des Geräts an Dritte ebenfalls mit aus.

Bestimmungsgemäßer Gebrauch

Der Seilhebezug dient zum Heben und Absenken

von Lasten in geschlossenen Räumen entsprechend

der Geräteleistung. Das Gerät darf nur wie beschrieben verwendet werden. Jede weitere darüber

hinausgehende Verwendung ist nicht bestimmungsgemäß. Für daraus hervorgerufene Schäden oder

Verletzungen aller Art haftet der Benutzer/Bediener und nicht der Hersteller. Bitte beachten Sie,

dass unsere Geräte bestimmungsgemäß nicht für

den gewerblichen, handwerklichen oder industriellen Einsatz konstruiert wurden. Wir übernehmen

keine Gewährleistung, wenn das Gerät in Gewerbe-, Handwerks- oder Industriebetrieben sowie

bei gleichzusetzenden Tätigkeiten eingesetzt wird.

Teilebeschreibung

1

Befestigungsbügel

2

Befestigungsöffnung für Haken bei Umlenkbetrieb

3

Seiltrommel

4

Hebel für maximale Seillänge

5

Hebel des automatischen Stoppmechanismus

6

Stahlseil

7

Abschaltgewicht

8

Haken

9

Not-Aus-Schalter

10

Drucktaster

11

Fernbedienung

12

Netzkabel

13

Steuerleitung

14

Motor

15

Umlenkrolle

16

Zusatzhaken

Lieferumfang

1 Seilhebezug

2 Befestigungsbügel mit Montagematerial (Abb. C)

1 Umlenkrolle mit Zusatzhaken und

Montagematerial (s. Abb. D)

1 Bedienungsanleitung

Technische Daten

Spannung: 230 V ~ 50 Hz

Nennstrom: 2,2 A

Leistungsaufnahme: 500 W

Betriebsart: S3 20 % 10 min

Nennlast: 125 / 250 kg (ohne / mit

Umlenkrolle)

Hebehöhe: 11,5 / 5,7 m (ohne / mit

Umlenkrolle)

Nenngeschwindigkeit: 8 / 4 m / min (ohne / mit

Umlenkrolle)

Durchmesser

des Stahlseiles: 3,0 mm

Zugfestigkeit

des Stahlseils: 1870 N/ mm

2

Isolationsklasse: B

Schutzart: IP54

Triebwerksklasse: M1

Nettogewicht: 9,3 kg

Bruttogewicht: 10,5 kg

Betriebsart 3–20 % - 10 min: S3 = Aussetzbetrieb

ohne Einfluss des Anlaufvorganges. Während eines

Zeitraums von 10 min beträgt die max. Betriebszeit

20 % (2 Min).

Mechanische Gruppe ist M1.

Die Nennleistung des Geräts variiert nicht mit der

Position der Belastung.

Der Wert der A-bewerteten Lärmemission an der

Betreiberposition ist niedriger als 70 dB.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 22 02.07.14 12:41

Page 23

23 DE/AT/CH

Der Seilhebezug ist bei Umgebungstemperaturen

zwischen 0 °C und 40 °C relative Luftfeuchtigkeit

unter 85 % zu betreiben. Höhe über dem Meeresspiegel: max. 1000 m.

Für Transport und Lagerung darf die Temperatur

zwischen -25 °C und 55 °C betragen. Die höchste

zulässige Temperatur ist 70 °C.

Wichtige

Sicherheitshinweise

Lesen Sie alle Sicherheitshinweise

und Anweisungen. Versäumnisse bei der Einhaltung

der Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere Verletzungen zur Folge haben. Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf!

Kontrollieren Sie stets ob die Netzspannung

der Spannung auf dem Typenschild entspricht.

Für den Fall, dass die Netzspannung nicht geeignet ist, kann dies zu abnormalem Arbeiten

des Geräts und zu Personenschäden führen.

Die Stromversorgung muss eine Erdung besit-

zen und mit einem Fehlerstrom-Schutzschalter

abgesichert sein.

Es ist verboten, Lasten die die Nennlast über-

schreiten, anzuheben.

Verwenden Sie das Gerät nur für den vorgese-

henen Zweck. Nie Personen mit dem Seilhebezug anheben.

Benutzen Sie das Kabel nicht, um den Stecker

aus der Steckdose zu ziehen. Halten Sie das

Kabel fern von Hitze, Öl, scharfen Kanten.

Versuchen Sie nie, feste oder blockierte Lasten

anzuheben.

Ziehen Sie nach jedem Gebrauch den Netzste-

cker aus der Steckdose.

Halten Sie Kinder und andere nicht autorisierte

Personen vom Gerät fern.

Es ist verboten Lasten seitwärts oder von einer

Seite zu ziehen. Vermeiden Sie ein Schwingen

der Last.

Stellen Sie sicher, dass sich der Haken 8 in

dieselbe Richtung wie auf dem Drucktaster

10

angezeigt bewegt.

Kontrollieren Sie den Seilhebezug regelmäßig

auf Beschädigungen. Der Drucktaster

10

muss

in gutem Zustand sein.

Lassen Sie Reparaturen und Wartungsarbeiten

nur in autorisierten Fachwerkstätten durch einen

Elektrofachmann durchführen. Reparaturen dürfen nur von einer Elektrofachkraft ausgeführt

werden, andernfalls können Unfälle für den

Betreiber entstehen.

Vermeiden Sie schnelles Ein- und Ausschalten

(Tippbetrieb).

Seien Sie bei der Bedienung des Seilhebezuges

stets aufmerksam.

Stehen oder arbeiten Sie nicht unter der geho-

benen Last.

Es ist unzulässig, festsitzende oder verklemmte

Lasten anzuheben.

Ziehen Sie immer den Netzstecker, bevor Sie

Einstellungen am Gerät vornehmen.

Der Seilhebezug ist nicht für den Transport von

heißen und / oder geschmolzenen Massen geeignet, des Weiteren ist der Seilhebezug nicht

für den Einsatz bei niedrigen Temperaturen und

in witterungsintensiver Umgebung geeignet

(s. Technische Daten).

Die Nutzungsdauer des Seilhebezuges ist ca.

8000 Zyklen (exkl. Verschleißteile). Wenn der

Zug 8000 Zyklen durchlaufen hat, müssen alle

mechanischen Teile kontrolliert und überholt

werden.

Lesen und verstehen Sie die Bedienungsanlei-

tung, bevor Sie den Seilhebezug benutzen.

Stellen Sie sicher, dass die Bedienperson weiß,

wie das Gerät funktioniert, und wie es betrieben

werden sollte.

Der Nutzer muss immer in Übereinstimmung mit

der Bedienungsanleitung operieren.

Der Hebezug ist nicht für den Dauereinsatz

vorgesehen. Die Betriebsart ist:

Aussetzbetrieb ohne Einfluss des Anlaufvorganges.

Nach dem Öffnen der Verpackung inspizieren

Sie bitte das Gerät, das Stahlseil, die Haken,

den Hebel für die maximale Seillänge und den

Hebel des automatischen Stoppmechanismus

auf mögliche Transportschäden.

Einleitung / Wichtige Sicherheitshinweise

100684_par_Seilhebelzug_content_GB_IE_CY.indd 23 02.07.14 12:41

Page 24

24 DE/AT/CH

Gerätespezifische

Sicherheitshinweise

Der Nutzer muss die Last vom Boden mit der

geringsten möglichen Geschwindigkeit anhe

ben.

Das Seil muss gestrafft sein, wenn die Last angehoben wird.

Der elektrische Seilhebezug ist nicht mit einem

Nennleistungsbegrenzer ausgestattet. Deshalb,

nicht weiter versuchen die Last anzuheben, wenn

der Überhitzungsschutz den Betrieb begrenzt.

Die Last überschreitet in diesem Fall die Nennleistung des Seilhebezuges.

Lassen Sie keine hängenden Lasten unbeauf-

sichtigt ohne entsprechende Sicherheitsvorkehrungen getroffen zu haben.

Sichern Sie das Gerät mit einer 10 A Sicherung

oder einem 10 A Fehlerstrom-Schutzschalter ab

um den Stromkreis zu schützen.

Verwenden Sie die Hebel 4 / 5 nicht als

Routine-Stoppvorrichtung. Diese dienen nur als

Stoppvorrichtung für den Notfall.

Bevor Sie beginnen, stellen Sie sicher, dass das

Stahlseil 6 korrekt um die Trommel 3 gewi

ckelt

ist und der Abstand zwischen den Windungen

kleiner als das Stahlseil ist (Abb. B).

Vor der Inbetriebnahme

Montage (s. Abb. C)

Befestigen Sie den Seilhebezug mit den

2 Befestigungsbügeln

1

an einem Vierkantrohr /

Schwenkarm. Die Abmessungen des

Vierkantrohres / Schwenkarms müssen in Übereinstimmung mit der Größe der Befestigungsbügel

1

sein und es / er muss die zweifache

Nennlast tragen können.

Hinweis: Wir empfehlen Ihnen, hierzu Kontakt

mit einem qualifizierten Techniker aufzunehmen.

Verschrauben Sie die Befestigungsbügel 1 am

Seilhebezug (s. auch Abb. C).

Ziehen Sie alle Schrauben fest an.

Hinweis: Vor der Inbetriebnahme sollte ein

qualifizierter Techniker die Verankerung des

Vierkantrohrs / Schwenkarms überprüfen.

Hinweis: Der Motor 14 des Seilhebezuges

ist mit einem Thermostatschalter ausgestattet.

Während des Betriebes des Seilhebezuges

kann es daher zum Stoppen des Motors

14

kommen, dieser läuft automatisch wieder an

wenn er abgekühlt ist.

Flaschenzugfunktion

einrichten (s. Abb. D–G)

Der Seilhebezug ist mit einer Umlenkrolle 15 und

einem Zusatzhaken

16

ausgestattet. Bei richtiger

Verwendung kann der Seilhebezug die doppelte

Last heben.

Montieren Sie Umlenkrolle 15 und Zusatzhaken

16

wie in den Abbildungen D–G dargestellt.

Hängen Sie den fest montierten Haken 8 an

der Befestigungsöffnung

2

ein (s. Abb. G).

Die Last wird nun mit Hilfe von zwei Stahlseilen

angehoben, der Seilhebezug kann somit die

doppelte Last anheben.

Bedienung

Seilhebezug in Betrieb nehmen

Der Nutzer muss die Last vom Boden mit der

geringsten möglichen Geschwindigkeit anheben.

Das Seil muss gestrafft sein, wenn die Last angehoben wird.

Sichern Sie das Gerät mit einer 10 A Sicherung

oder einem 10 A Fehlerstrom-Schutzschalter

ab um den Stromkreis zu schützen.

Bevor Sie beginnen, stellen Sie sicher, dass das

Stahlseil

6

korrekt um die Trommel 3 gewickelt

ist und der Abstand zwischen den Windungen

kleiner als das Stahlseil ist (Abb. B).

Entfernen Sie vor der ersten Benutzung das

Klebeband von der Seiltrommel

3

.

Stellen Sie sicher, dass die Ladung ordnungs-

gemäß am Haken

8

beziehungsweise bei

Flaschenzugbetrieb dem Zusatzhaken

16

gesichert ist und halten Sie stets Abstand zur

Last und dem Stahlseil

6

.

Gerätespezifische Sicherheitshinweise / Vor der Inbetriebnahme / Bedienung

100684_par_Seilhebelzug_content_GB_IE_CY.indd 24 02.07.14 12:41

Page 25

25 DE/AT/CH

Seilzug bedienen

Überprüfen Sie, ob der Not-Aus-Schalter 9

gedrückt ist.

Drehen Sie den Not-Aus- Schalter 9 im

Uhrzeigersinn um ihn zu entriegeln.

Drücken Sie den Drucktaster in Richtung ▲ 10

zum Anheben der Last (s. Abb H).

Drücken Sie den Drucktaster in Richtung ▼ 10

zum Senken der Last (s. Abb H).

Hebel des automatischen

Stoppmechanismus

5

Wenn die maximale Hebehöhe erreicht ist, drückt

das Abschaltgewicht

7

den Hebel 5 nach oben.

Dadurch wird ein Endschalter betätigt und die Last

kann nicht weiter angehoben werden.

Hebel für maximale Seillänge

4

Wenn die Last die niedrigste mögliche Position

erreicht hat, wird ein Endschalter betätigt, der ein

weiteres Absenken der Last unmöglich macht. Dieser Endschalter verhindert auch einen Betrieb des

Seilhebezuges in falscher Richtung (Haken bewegt

sich entgegengesetzt zur am Drucktaster

10

ange-

zeigten Richtung).

ACHTUNG! Im Falle eines Notfalls sofort NotAus- Schalter

9

betätigen um den Seilhebezug

anzuhalten. Die Bedienung des Seilhebezuges ist

nicht möglich, wenn der Not-Aus-Schalter betätigt

wurde.

Reinigung, Wartung und

Ersatzteilbestellung

Reinigung

ACHTUNG! Ziehen Sie vor allen Reinigungsarbeiten den Netzstecker aus der Steckdose.

Verwenden Sie keine Reinigungs- oder Lösungs-

mittel; diese könnten die Kunststoffteile des

Gerätes angreifen.

Achten Sie darauf, dass kein Wasser in das

Geräteinnere gelangen kann.

Halten Sie Schutzvorrichtungen, Luftschlitze

und Motorengehäuse so staub- und schmutzfrei

wie möglich.

Reiben Sie das Gerät mit einem sauberen Tuch

ab oder blasen Sie es mit Druckluft bei niedrig

em

Druck aus.

Reinigen Sie das Gerät regelmäßig mit einem

feuchten Tuch und etwas Schmierseife.

Hinweis: Es wird empfohlen, das Gerät direkt

nach jeder Nutzung zu reinigen.

Wartung

ACHTUNG! Stellen Sie stets sicher, dass das Gerät nicht mit dem Stromnetz verbunden ist, wenn Sie

es pflegen.

Nachstehend: Ein Zyklus entspricht einer Aufund Abwärtsbewegung einer Last.

Periodische Prüfung entspricht einer Prüfung nach

100 Zyklen.

Überprüfen Sie periodisch, dass die Endschalter

des Seilhebezugs ordnungsgemäß funktionieren

(ohne Last prüfen).

Die Prüfung erfolgt folgendermaßen: Wenn das

Seil die maximale Hebehöhe erreicht, wird der

Hebel des automatischen Stoppmechanismus 5

betätigt. Der Motor

14

muss nun stoppen.

Wenn das Stahlseil

6

so weit wie möglich

abgewickelt ist, wird der Hebel für maximale

Seillänge

4

betätigt. Der Motor 14 muss nun

stoppen.

Prüfen Sie periodisch das Netzkabel 12 und die

Steuerleitung

13

.

Schmieren Sie alle 200 Zyklen Stahlseil 6 und

Umlenkrolle

15

.

Kontrollieren Sie alle 30 Zyklen, ob das gesamte

Stahlseil

6

in gutem Zustand ist. Falls es beschädigt ist (s. Abb. I), muss es durch ein den

technischen Daten entsprechendes Stahlseil

ersetzt werden.

Alle 1000 Zyklen prüfen, ob die Schrauben

der Befestigungsbügel

1

und Umlenkrolle 15

gut angezogen sind.

Bedienung / Reinigung, Wartung und Ersatzteilbestellung

100684_par_Seilhebelzug_content_GB_IE_CY.indd 25 02.07.14 12:41

Page 26

26 DE/AT/CH

Alle 1000 Zyklen prüfen, ob die Haken 8 /

16

und die Umlenkrolle 15 in gutem Zustand

sind.

Kontrollieren Sie vor jeder Benutzung des

Seilhebezuges, ob Not-Aus-Schalter

9

und

Drucktaster

10

in einwandfreiem Betriebszu-

stand sind.

Alle 1000 Zyklen das Bremssystem überprüfen.

Wenn der Motor

14

ungewöhnliche Geräusche macht oder die Nennlast nicht anheben

kann, ist es möglich, dass das Bremssystem

überholt werden muss:

- Ersetzen Sie beschädigte oder abgenutzte

Teile, und bewahren Sie die dazugehörige

Wartungsdokumentation auf.

- Für außerplanmäßige Instandhaltungsarbeiten wenden Sie sich bitte an ein autorisiertes

Servicecenter.

Entsorgung

Das Gerät befindet sich zum Schutz vor Transportschäden in einer Verpackung. Diese Verpackung ist

Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus verschiedenen Materialien, wie z.B. Metall und Kunststoffe.

Führen Sie defekte Bauteile der Sondermüllentsorgung zu. Fragen Sie im Fachgeschäft oder in der

Gemeindeverwaltung nach!

Werfen Sie Elektrowerkzeuge

nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2012 / 19 / EU

über Elektro- und Elektronik-Altgeräte und Umsetzung in nationales Recht müssen verbrauchte

Elektrowerkzeuge getrennt gesammelt und einer

umweltgerechten Wiederverwertung zugeführt

werden.

Recycling-Alternative zur

Rücksendeaufforderung:

Der Eigentümer des Elektrogerätes ist alternativ anstelle Rücksendung zur Mitwirkung bei der sachgerechten Verwertung im Falle der Eigentumsaufgabe

verpflichtet. Das Altgerät kann hierfür auch einer

Rücknahmestelle überlassen werden, die eine

Beseitigung im Sinne der nationalen Kreislaufwirtschafts- und Abfallgesetze durchführt. Nicht betroffen sind den Altgeräten beigefügte Zubehörteile

und Hilfsmittel ohne Elektrobestandteile.

Garantie / Service

Wir leisten 3 Jahre Garantie ab Kaufdatum für

Material- und Fabrikationsfehler des Geräts.

Die Garantie gilt nicht:

· Im Falle von Schäden, die auf unsachgemäßer

Bedienung beruhen.

· Für Verschleißteile.

· Für Mängel, die dem Kunden bereits bei

Kauf bekannt waren.

· Bei Eigenverschulden des Kunden.

Die gesetzlichen Gewährleistungen des Kunden

bleiben durch die Garantie unberührt.

Für Geltendmachung eines Garantiefalles innerhalb der Garantiezeit ist durch den Kunden der

Nachweis des Kaufes zu führen. Die Garantie ist

innerhalb eines Zeitraumes von 3 Jahren ab Kaufdatum geltend zu machen.

Der Kunde hat im Garantiefall das Recht zur Reparatur der Ware bei unseren eigenen oder bei von

uns autorisierten Werkstätten. Das Gerät aus

keinem Grund öffnen – im Falle von Öffnung oder

Veränderung erlischt der Garantieanspruch. Weitergehende Rechte werden dem Kunden (aufgrund

der Garantie) nicht eingeräumt. In vielen Fällen

liegt der Grund für Reklamationen in Bedienungsfehlern. Diese könnten ohne Weiteres telefonisch

oder per E-Mail behoben werden. Bitte wenden

Sie sich an die für Sie eingerichtete Service-Hotline,

bevor Sie das Gerät beim Hersteller reklamieren.

Reinigung, Wartung und Ersatzteilbestellung / Entsorgung / Garantie / Service

100684_par_Seilhebelzug_content_GB_IE_CY.indd 26 02.07.14 12:41

Page 27

27 DE/AT/CH

Garantie / Service / Konformitätserklärung

DE:

Matrix GmbH Service

Postauer Str. 26

D – 84109 Wörth/Isar

Germany

Tel.: +49 (0) 1806/841090

Fax: +49 (0) 8702/45338 98

E-mail: service@matrix-direct.net

AT:

Magedon

Bildstöcklstraße 18

AT - 9500 Villach

T: +43 720 11 6465

F: +43 720 11 6464

E: service@matrix-direct.at

CH:

Winkler Arnold AG ($)

Technischer Großhandel

Madetswilerstr. 18

CH – 8332 Russikon

T: +41 449548383

F: +41 449548384

E: contact@arwin.ch

IAN 100684

Bitte halten Sie für alle Anfragen den Kassenbon

und die Artikelnummer (z. B. IAN 12345) als

Nachweis für den Kauf bereit.

Ersatzteilbestellung

Bei der Ersatzteilbestellung sollten

folgende Angaben gemacht werden:

- Typ des Gerätes

- Artikelnummer des Gerätes

- Ident-Nummer des Gerätes

Konformitätserklärung

Wir, MATRIX GMBH, Dokumentenverantwortlicher:

Herr Joachim Lichtl, POSTAUER STR. 26

,

84109 WÖRTH / ISAR, DEUTSCHLAND, erklären

hiermit, dass dieses Produkt mit den folgenden

Normen, normativen Dokumenten und EG-Richtlinien

übereinstimmt:

2006 / 42 / EC

2006 / 95 / EC

2004 / 108 / EC

2011 / 65 / EU

angewandte harmonisierte Normen

EN 14492-2+A1

EN 60204-32

EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

Typ / Gerätebezeichnung:

Seilhebezug PSZ 250 B2

Baujahr: 2014

Wörth / Isar, 31.05.2014

Joachim Lichtl

- Geschäftsführer -

Technische Änderungen im Sinne der

Weiterentwicklung sind vorbehalten.

100684_par_Seilhebelzug_content_GB_IE_CY.indd 27 02.07.14 12:41

Page 28

28

100684_par_Seilhebelzug_content_GB_IE_CY.indd 28 02.07.14 12:41

Page 29

IAN 100684

MATRIX GMBH

Postauer Str. 26

D-84109 Wörth / Isar

Germany

Last Information Update

Έκδοση των πληροφοριών · Stand

der Informationen: 06 / 2014

Ident.-No.: PSZ250B2062014-6

100684_par_Seilhebelzug_cover_GB_IE_CY.indd 2 24.06.14 15:55

Loading...

Loading...