Page 1

OPERATING

INSTRUCTIONS

12"

AND

PARTS

LIST

FOR

PARKS

THICKNESS

PLANER

THE

IM PORT

to

secure

avoid unnecessary

We

suggest

valuable papers.

PARKS

Manufacturer~

ANT:

WOODWORKING

This

prompt

that

of

Quality

Cincinnati,

list

is

valuable. It

service on

correspondence

you keep

Woodworking

it

Ohio

replacement

45223

with our factory.

filed away with

MACHINE

Machines

will

enable you

parts

other

Since

and

COMPANY

1887

Apr. 1, 1975

Page 2

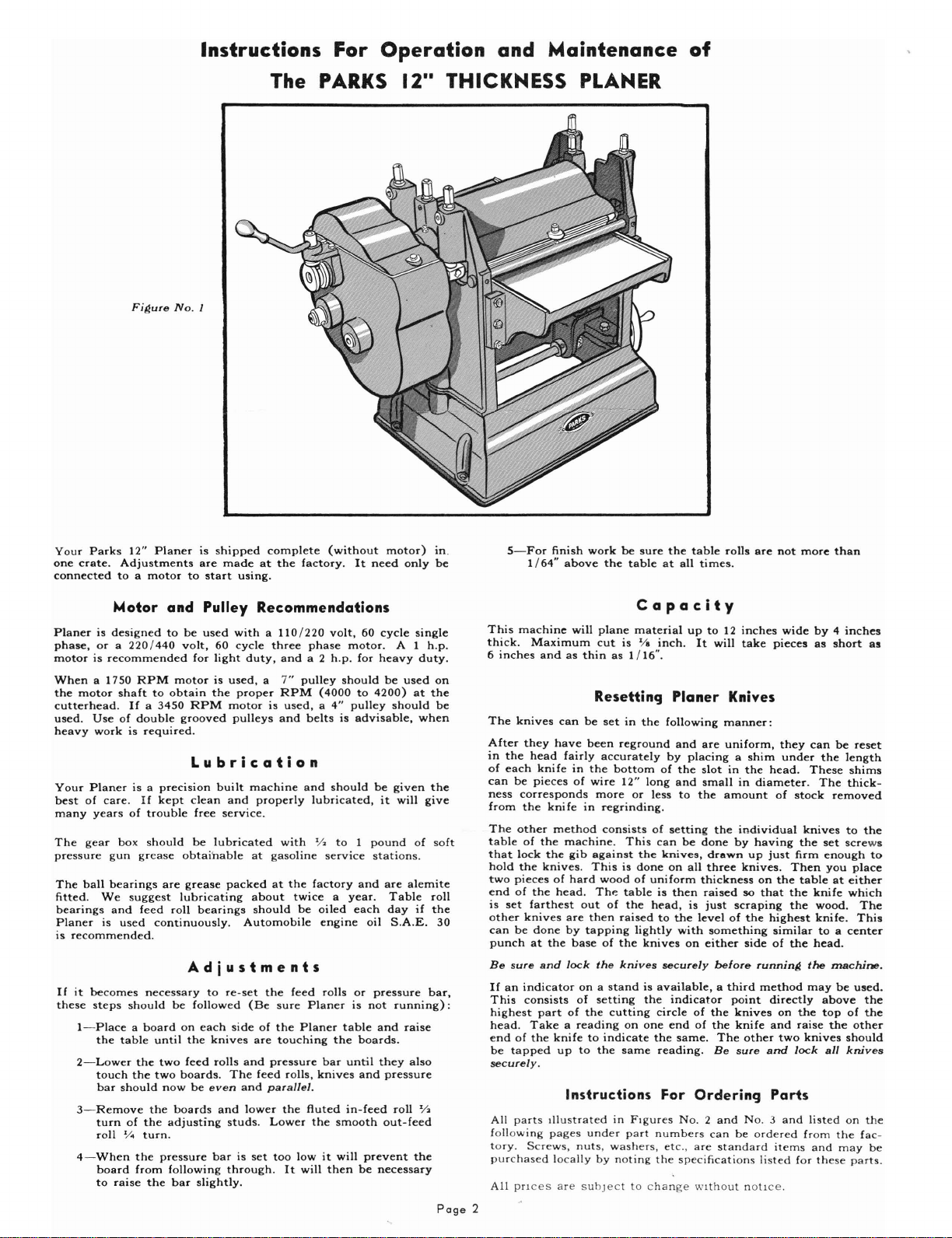

Figure

Instructions

No.

J

For

Operation

11

The PARKS THICKNESS PLANER

12

and Maintenance

of

Your

Parks

one

crate.

connected

Motor and Pulley Recommendations

Planer

is

phase,

motor

When

the

cutterhead.

used.

heavy

Your

best

many

The

pressure

The

fitted.

bearings

Planer

is

If

these

designed

or a 220/440

is

recommended

a 1750

motor

Use

work

Planer

of

care.

years

gear

gun

ball

bearings

We

and

is

recommended.

it

becomes

steps

I-Place a board

the

2-Lower

touch

bar

3-Remove

turn

roll

4-When

board

to

raise

12"

Planer

Adjustments

to a motor

to

RPM

shaft

to

obtain

If

a

3450

of

double

is

required.

is a precision

If

kept

of

trouble

box

should

grease

are

suggest

feed

used

continuously.

necessary

should

table

until

the

two

the

two

should

now

the

of

the

adjusting

1/.

turn.

the

pressure

from

following

the

is

shipped

are

made

to

start

using.

be

used

for

RPM

60

light

is

the

with a 110/220

cycle

used, a 7"

proper

motor

pulleys

volt,

motor

grooved

Lubrication

built

clean

and

free

service.

be

lubricated

obtainable

grease

packed

lubricating

roll

bearings

Adjustments

to

followed

on

each

the

feed

boards.

be

even

slightly.

re-set

side

knives

rolls

The

and

studs.

bar

through.

is

be

boards

bar

complete

at

the

three

duty,

and

RPM

is

used, a 4"

and

machine

properly

with

at

gasoline

at

the

about

should

Automobile

the

(Be

sure

of

the

are

touching

and

pressure

feed

rolls,

and

parallel.

lower

the

Lower

set

too

It

(without

factory.

a 2

pulley

belts

and

twice a year.

be

feed

Planer

Planer

fluted

low

will

volt,

phase

motor.

h.p.

should

(4000

pulley

is

should

lubricated,

1/.

to 1 pound

service

factory

oiled

engine

rolls

table

the

bar

until

knives

in-feed

the

smooth

it

will

then

It

for

to

advisable,

and

each

or

is

boards.

and

be

motor)

need

60

cycle

heavy

be

4200)

be

it

stations.

are

day

oil

pressure

not

and

they

pressure

out-feed

prevent

necessary

only

single

A 1

h.p.

duty.

used

at

should

when

given

will

give

of

alemite

Table

if

S.A.E.

bar,

running):

raise

also

roll

%

the

in.

be

on

the

be

the

soft

roll

the

30

Page

This

thick.

6

The

~fter

tn

of

can

ness

from

The

table

that

hold

two

end

is

other

can

punch

Be

If

This

highest

head.

end

be

securely.

All

following

tory.

purchased

All

2

5-For

1/64"

machine

Maximum

inches

and

knives

they

the

head

each

knife

be

pieces

corresponds

the

other

of

the

lock

the

knives.

pieces

of

the

set

farthest

knives

be

done

at

sure

and

an

indicator

consists

part

Take a reading

of

the

tapped

parts

Screws,

prIces

finish

work

be

sure

the

table

rolls

above

the

table

at

all

times.

are

Capacity

will

plane

as

thin

cut

as

is

material

YB

1/16".

inch.

up

to

12

inches

It

will

take

Resetting Planer Knives

can

be

set

in

the

have

fairly

knife

method

machine.

the

of

head.

are

by

the

lock

knife

up

been

accurately

in

the

of

wire

more

in

regrinding.

consists

gib

against

This

hard

wood

Thp.

out

then

tapping

base

of

the

on a stand

of

setting

of

the

to

indicate

to

the

reground

bottom

12"

or

This

is

table

of

the

raised

the

knives

cutting

on

same

following

and

by

of

long

and

less

of

setting

can

the

knives,

done

on

of

uniform

is

then

head,

to

the

lightly

knives

securely

is

available, a third

the

indicator

circle

one

end

the

reading.

manner:

are

uniform,

placing a shim

the

slot

in

small

the

amount

the

done

drawn

three

thickness

raised

just

level

something

either

before

of

the

of

the

The

Be

in

individual

by

knives.

so

scraping

of

point

knives

knife

other

sure

to

be

all

is

with

on

same.

the

diameter.

having

up

on

the

side

running

Instructions For Ordering Parts

Illustrated

pages

locally

are

under

nuts,

by

suhJect

in

FIgures

part

washers,

noting

to

numbers

etc.,

the

specifications

change

No.2

are

WIthout

and

can

standard

No.3

be

notIce.

ordered

not

wide

pieces

they

under

head.

of

just

the

that

highest

similar

of

method

directly

on

and

two

and

and

items

listed

more

by 4 inches

as

can

the

These

The

stock

knives

the

firm

Then

table

the

knife

the

wood.

knife.

to a center

the

head.

the

may

above

the

raise

knives

lock

listed

from

and

for

these

than

short

be

length

shims

thick-

removed

to

set

screws

enough

you

place

at

either

which

machine.

be

top

of

the

other

should

all

knives

on

the

may

parts.

as

reset

the

to

The

This

used.

the

the

the

fac-

be

Page 3

Figure

No.2

Part

No.

A-l

A-2

A-3

A-4

A-5

A-6

A-7

A-8

A-9

A-10

A-11

A-12

Minimum

Name

of

Part

Gear

Box

Shaft

Hollow

x

12

Shaft

88

Throw

1-1/8"

Throw

E

ccentri c brocket

(2

Eccentric

Throw

Throw

{casting

collar

3/4"

head

3/8" -3/8

tooth

sprocket

spacer

tooth

gear,

out

sleeve

bore

out

sleeve

req.)

...•..•..•••.•••.•..••..•...

brocket

out

handle

out

eccentric

charge

of

only)

..••.••.•

bore

(3

thread

(2

req.)

req)

3/8"

.•.•.•.•

set

screw

-16

................•.......

slotted

hub

bearing

.............•......•.

...............••.

studs

..••.•••.••..•...

.•..•..•.•..•.

$5.00

..

.

.

on

Price

each

79.80

3.60

1.00

11.90

2.20

15.30

6.20

24.20

1.85

3.85

7.50

9.00

all

orders

Part

No.

A-J3

A-14

A-15

A-16

A-17

A-18

A-19

A-20

A-21

A-22

A-23

A-24

A-25

Lower

1/2"

88

tooth

Short

Gear

20

tooth

Gear

(2

req.)

Long

128

tooth

Gear

Gear

Smooth

Felt

Head

Name

of

Part

gear

shaft

bore

...•••.••.••••.••••.•.•..

gear,

shaft

bear'g

gear

bear'g

plain

•..•••...•......•.•.

(3

req.)

gear

shaft

shaft

••••........•..........••..•

gear

shaft

..••..•••••.•••.•..

gear

box

box

washer

shaft

.•.••••.•...•..•••.••

cover

..••.••.••.•.••••.•••

cover

feed

studs

roil

•••.•.•.•.•...••..•

••••••.••..••••••..••••.

sleeve

Page

bearing

hub

••.••..••

1/2"

bore

••.•••.•••••

3/4"

bore

(2

req.)...

•.•••••••....•••

3

•.•

Price

each

5.80

15.80

8.70

5.30

9.70

5.30

9.70

24.10

15.75

.90

50.80

.40

5.20

Part

No.

A

-26

A-27

A-28

A-29

A-30

A-31

A-32

A-33

A-34

A-35

Name

Head

ball

(2

req.)

Head

shaft

12"

Head

Slotted

Fluted

Hollow

12"

12"

head

x

5/16" -5/16

feed

head

(used

on

Chip

High

(set

of 3)

Complete

Connecting

of

Part

bearing

No.

320"

.....••..•••••.••••••..•.•.•

spacer

with

head)

breaker

speed

.••••.•••.••.•.•

shaft

•••••••.••••••

set

screw

-18

roil

set

thread

••.••.••.•••.•••••••

screw

.•.........•••.•.••

{3

req.).......

knives

5/16"

1/2"

..••.••••.••.•.•••••••••••

roller

chain

for

•.••••.•.••.

chain

link

...

.

Price

each

8.50

2.20

131.00

.45

38.50

.75

5.80

32.50

7.15

1.20

Page 4

k43

·60

Part

No.

A.36

A.37

A-38

A-39

A.40

A-41

A-42

A.43

A.44

A-45

A-46

A-47

A-48

A-71

A.72

A.73

Name of

Pressure

Hood

Shoving

Lock

Adjusting

Table

Table

Table

Table

Lock

Locknut

Table

Lock

Half

3" V pulley

bar

stud

(2

hood

nut

for

stud

roller

roll

bearing

gib

(2

nut

for

stud

roller

nut

for

moon key

3/8" x 11/16"

thick

3/8

.16

Part

req.l..

hood

for

hood

(2

req.)

(4

req.)

table

gib............

adjusting

table

roller.........

The

3/16"

3/4"

bore

jam

thread

req.)

stud.....

following

nut

5116"

Price

each

19.25

28.80

11.00

139.00

ports

5.75

1.75

.75

1.40

5.80

5.00

.75

75

.65

.75

.35

.50

k61

shown

Part

No.

A·49

5/8"

3/8

A-50

Spring

A-51

Compression

A·52

Roll

A-53

A-54

A-55

A-56

A.57

A.58

on

A·74

A-75

bearing

Pressure

Smooth

(2

req. -specify r or

Stud

collar

Fluted

(2req.-specify

Bearing

Bearing

(specify

figures 2 and 3 are

3/8" x 11/16"

thick

Hex

head

1/2

Name

hex

-16

collar

feed

feed

3/8

-13

of

nut

thread

bar

cop

cop

right

.16

bolts

thread

Part

1"

long A-59

(6

req.)

spring

(6

(4

(2

bearing

bearing

ror

(2

or

left)

standard

jam

nut

112"x

4

req.)

req.)

req.)

I)

I)

req.)

and

3116"

1-3/4"

stud

stud

roll

(2

roll

studs

Page

req.)

thread

Price

each

3.85

1.45

3.85

3.30

4.40

7.00

1.50

8.25

1.20

11.45

can

.50

1.20

Part

No.

A-60

A-61

A-62

A·63

A-64

A-65

A-66

A-67

A-68

A-69

A·70

be

purchased

A·76

A-77

Figure

Name

Left

side

Right

side

Bose

Elevating

Shaft

collar

Bevel

gear

Elevating

specify

Column

Hand

wheel

Depth

indicator

Depth

scale

1/4"

oiler

locally

Hex

nuts

1/2

-13

Alemite

No.3

of

Part

costing

costing

shaft

5/8"

(4

req.)

(4

req.)

(2

req.

or

left)

(2

req.)

handle

req.)................

tie

L102

screw

right

rod

and

(4

1/2" x 5/16" x 7/8"

thread

fitting

Price

each

86.90

86.90

54.50

5.50

2.65

-

8.75

4.60

5.70

15.40

1.00

1.20

.75

1.20

.65

Loading...

Loading...