Parkray DERWENT, CONSORT 4, CONSORT 5, CONSORT 5 COMPACT, CONSORT 5 SLIMLINE Maintenance Manual

...

1

DERWENT

CONSORT 4

CONSORT 5

COMPACT 5

5 SLIMLINE

CONSORT 7

9 SLIMLINE

CONSORT 9

CONSORT 15

MULTIFUEL AND WOOD CE VII MODELS

Instructions for:

Installation/Operating/Maintenance/Servicing

JINCNSDA REV B 06/06/2019

2

STOVE MODELS

DERWENT CONSORT 4 CONSORT 5

CVSDR05FM CVCN04FM/CVCN04FW CVSCS05FM/CVSCS05FW

CONSORT 5 COMPACT CONSORT 5 SLIMLINE CONSORT 7

CVSCNC05FM/CVSCNC05FW CVCNS05FM/CVSCNS05FM CVCN07FM/CVSCN07FM

CVCNS05FW/CVSCNS05FW CVCN07FW/CVSCN07FW

CONSORT 9 SLIMLINE CONSORT 9 CONSORT 15

CVCNS09FM/CVSCNS09FM CVCN09FM/CVSCN09FM CVCN15FM/CVSCN15FM

CVCNS09FW/CVSCNS09FW CVCN09FW/CVSCN09FW CVCN15FW/CVSCN15FW

3

CONTENTS INDEX:

STOVE MODELS…………………………………………………………………………………………………. 2

TECHNICAL SPECIFICATION………………………………………………………………………………. 4/5

IMPORTANT INFORMATION…………………………………………………………………………….. 6/7

SAFETY…………………………………………………………………………………………………………….. 7

REMOVE INTERNAL COMPONENTS………………………………………………………………….. 8/9

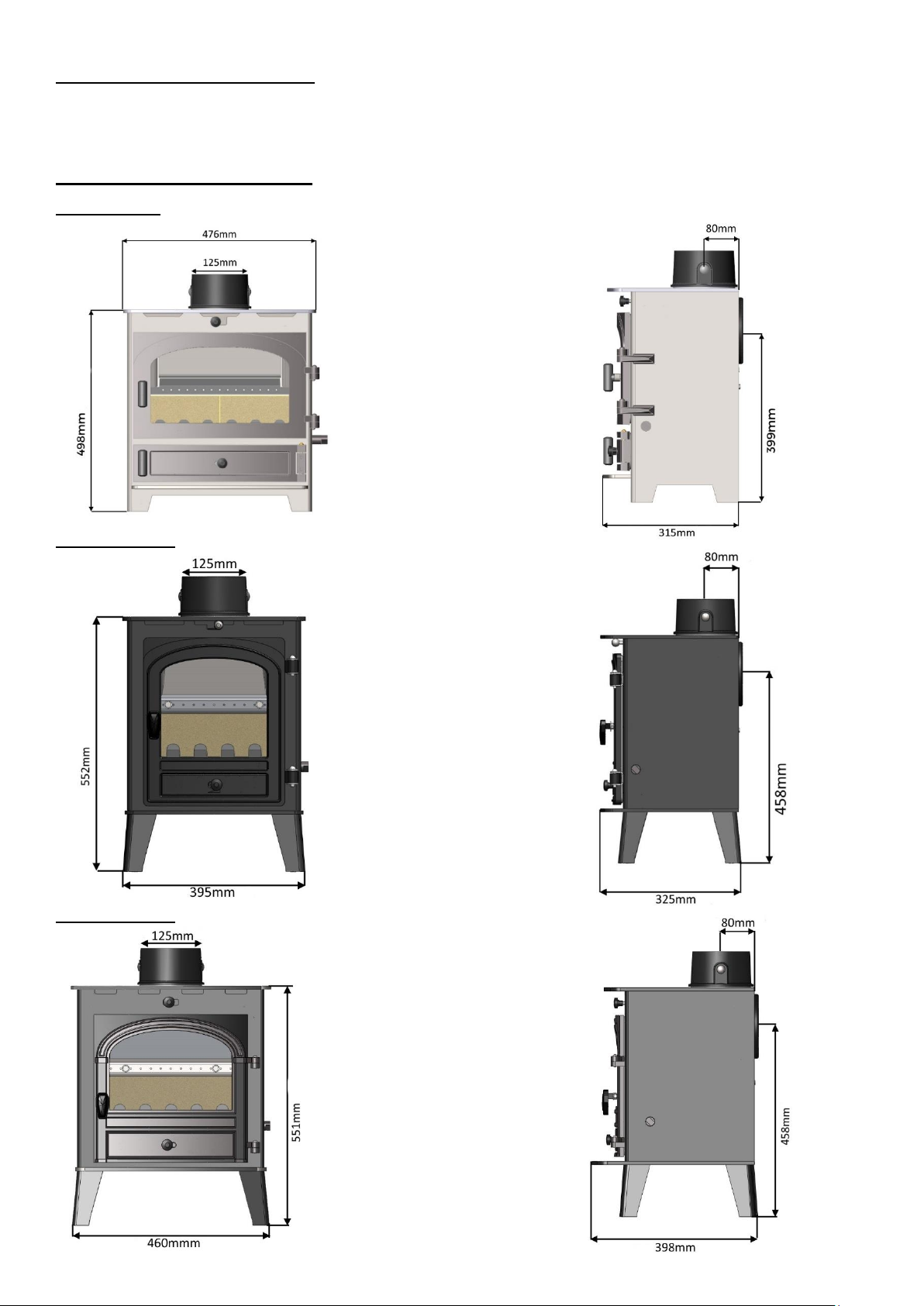

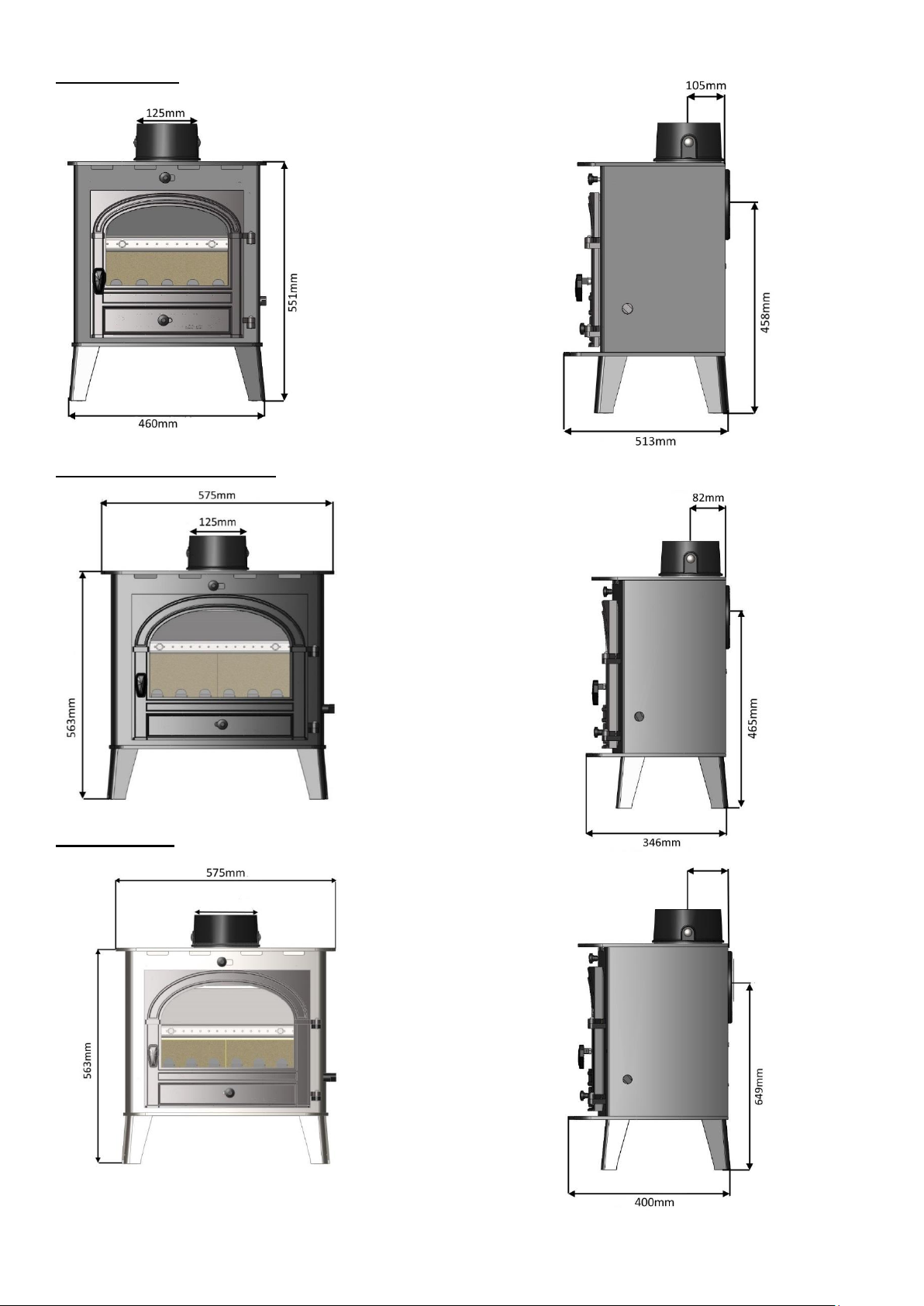

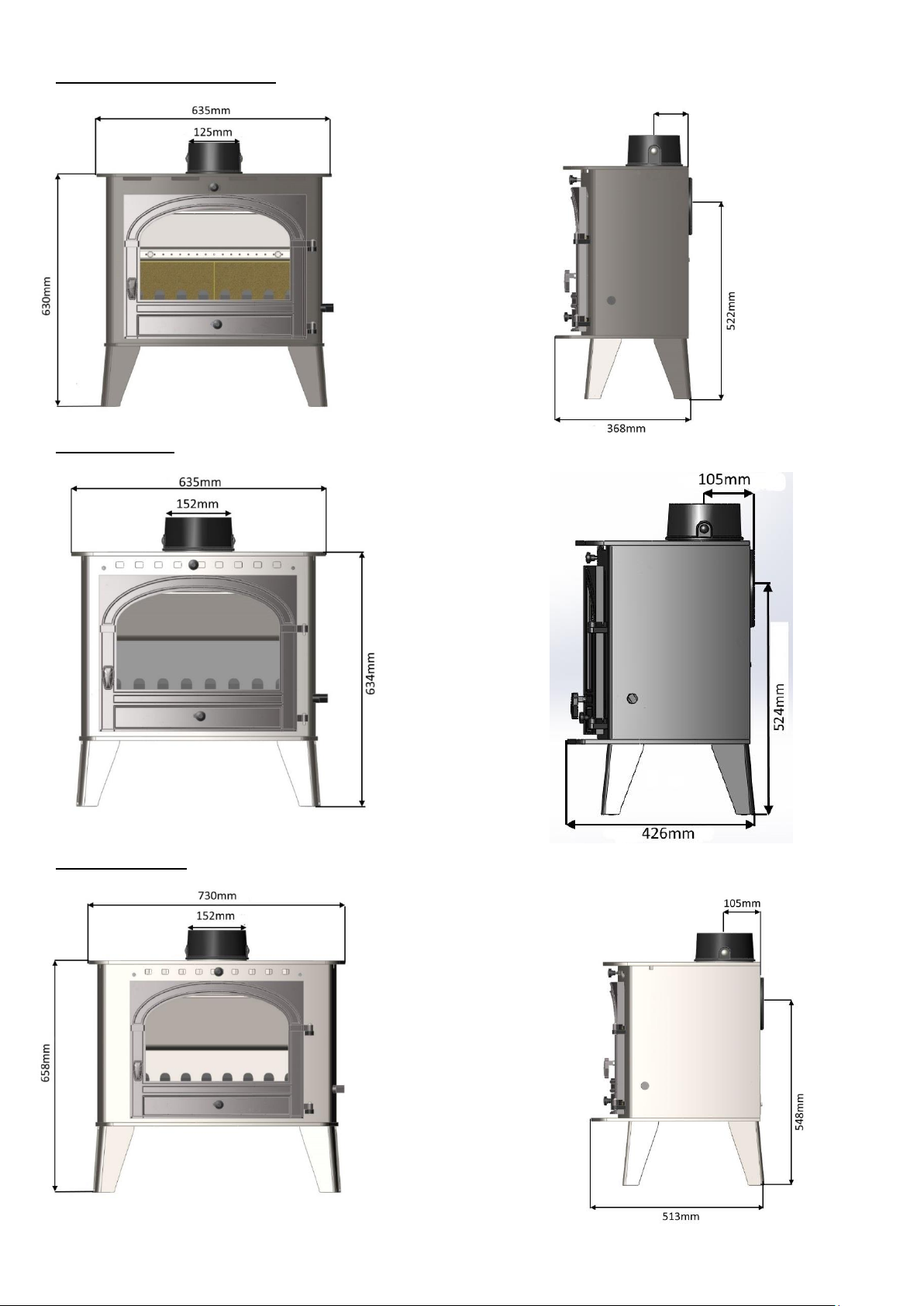

APPLIANCE DIMENSIONS…………………………………………………………………………………. 10-12

PRE INSTALLATION REQUIRMENTS………………………………………………………………….. 13

LEGAL REQUIREMENTS……………………………………………………………………………………. 14

CLEARANCES……………………………………………………………………………………………………. 15/16

COMMISSIONING AND HANDOVER…………………………………………………………………. 16/17

OPERATING INSTRUCTIONS…………………………………………………………………………….. 17-21

MAINTENANCE & SERVICING………………………………………………………………………….. 21/22

TROUBLESHOOTING……………………………………………………………………………………….. 23/24

SPARES………………………………………………………………………………………………… …………. 25-36

INSTALLATION & COMMISSIONING CHECK LIST………………………………………………. 37

SERVICE RECORDS…………………………………………………………………………………………… 38

FULL WARRANTY INFORMATION…………………………………………………………………….. 39/40

Welcome to the Hunter Stoves family and thank you for purchasing a Parkray

Consort stove. This stove was designed and built to be a high-performance

heating appliance, and we hope it will bring you great enjoyment. The

natural environment is important to us, so our stoves are manufactured to

provide you with a clean and efficient burn that will keep you warm through

cold winter nights.

4

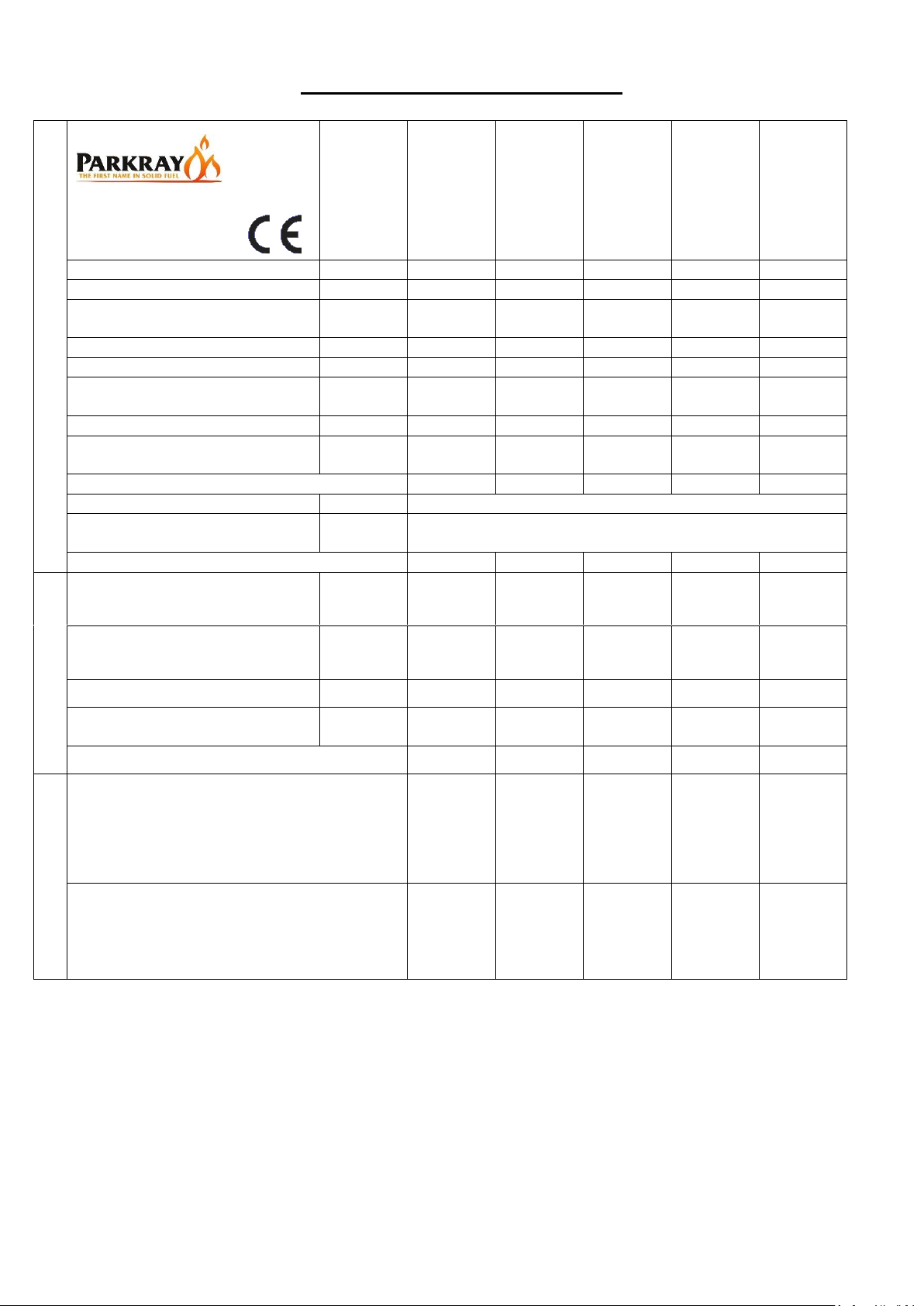

Technical Specification

GENERAL

DERWENT

CONSORT 4

CONSORT 5

COPMACT

CONSORT 5

CONSORT 5

SLIMLINE

Energy Efficiency Class

A A A A A Nominal Heat Output

Wood

4.8kW

4.7kW

4.7kW

4.0kW

4.4kw

Smokeless

Fuel

NA

3.0kW

NA

NA

NA

Energy Efficiency

102

97

101

104

98

Efficiency

Wood

76.8%

72.8%

76.0%

78.0%

74.1%

Efficiency

Smokeless

Fuel

NA

66.7%

NA

NA

NA

Mean CO (@13% O₂)

Wood

0.43%

0.27%

0.30%

0.44%

0.32%

Mean CO (@13% O₂)

Smokeless

Fuel

NA

0.54%

NA

NA

NA

Appliance Mass

62kg

64kg

95kg

88kg

88kg

Recommended Fuels

Wood

Seasoned Wood (less than 20% moisture content)

Smokeless

Fuel

Anthracite or a manufactured briquette smokeless fuel which is

suitable for closed door appliances.

Log Length

258mm

280mm

330mm

280mm

400mm

FLUES

Mean Flue Gas Temperature

Wood

271°C

270°C

269˚C

246˚C

268˚C

Mean Flue Gas Temperature

Smokeless

Fuel

NA

332˚C

NA

NA

NA

Flue Gas Mass Flow

Wood

4.3 g/s

5.7 g/s

4.7 g/s

3.8 g/s

5.0 g/s

Flue Gas Mass Flow

Smokeless

Fuel

NA

7.9 g/s

NA

NA

NA

Flue Outlet Size (Top or Rear Option)

125mm

125mm

125mm

125mm

125mm

VENTILATION

- Where leakage is greater than

5m³/hour/m²

- Ventilation normally required =

550mm² per kW output over 5kW

NONE

NONE

NONE

NONE

NONE

- Where leakage is less than or equal to

5m³/hour/m²

- Ventilation normally required =

550mm² per kW output

2640mm²

2255mm²

2585mm²

2200mm²

2420mm²

For further information on ventilation please refer to Building Regulations Document J or your installer.

This stove has been designed and assembled so that it may be used to burn wood logs in a Smoke Control Area.

Find out if you are in a Smoke Control Area by contacting your Local Authority.

The Derwent, Consort 4, Consort 5 and Compact 5 and Consort 5 Slimline have been fitted with a permanent stop

that prevents closure of the secondary air slider. Removal of this will lead to the appliance potentially causing smoke

emissions. Without the permanent stop in place the appliance is not an exempt appliance and so may leave the

householder liable for a fine up to £1000.

5

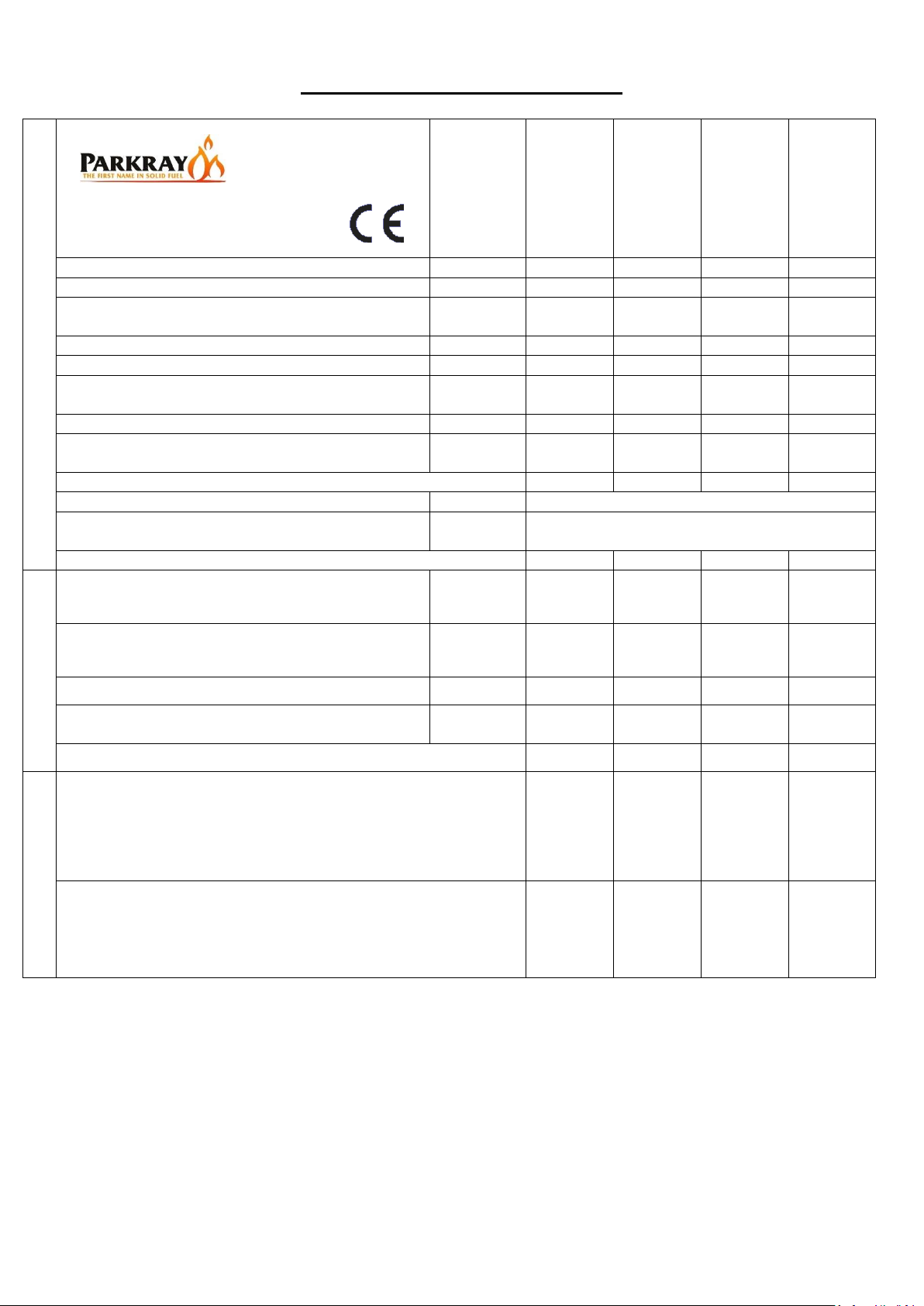

Technical Specification

GENERAL

CONSORT 7

CONSORT 9

SLIMLINE

CONSORT 9

CONSORT 15

Energy Efficiency Class

A A A A

Nominal Heat Output

Wood

5.4kW

4.9kW

9.1kW

11.9kW

Smokeless

Fuel

6.5kW

NA

7.8kW

9.0kW

Energy Efficiency

101

96

105

105

Efficiency

Wood

75.9%

72.4%

78.9%

78.6%

Efficiency

Smokeless

Fuel

67.3%

NA

68.5%

79.4%

Mean CO (@13% O₂)

Wood

0.27%

0.25%

0.38%

0.57%

Mean CO (@13% O₂)

Smokeless

Fuel

0.22%

NA

0.35%

0.18%

Appliance Mass

111kg

108kg

120kg

163kg

Recommended Fuels

Wood

Seasoned Wood (less than 20% moisture content)

Smokeless

Fuel

Anthracite or a manufactured briquette smokeless

fuel which is suitable for closed door appliances.

Log Length

380mm

400mm

500mm

500mm

FLUES

Mean Flue Gas Temperature

Wood

265°C

271°C

293˚C

339˚C

Mean Flue Gas Temperature

Smokeless

Fuel

332

NA

304˚C

275˚C

Flue Gas Mass Flow

Wood

5.7 g/s

6.2 g/s

6.4 g/s

6.4 g/s

Flue Gas Mass Flow

Smokeless

Fuel

NA

NA

8.5 g/s

7.2 g/s

Flue Outlet Size (Top or Rear Option)

150mm

125mm

150mm

150mm

VENTILATION

- Where leakage is greater than 5m³/hour/m²

- Ventilation normally required = 550mm² per kW output

over 5kW

825mm²

NONE

2255mm²

3795mm²

- Where leakage is less than or equal to 5m³/hour/m²

- Ventilation normally required = 550mm² per kW output

2970mm²

2750mm²

5005mm²

6545mm²

For further information on ventilation please refer to Building Regulations Document J or your installer.

This stove has been designed and assembled so that it may be used to burn wood logs in a Smoke Control Area.

Find out if you are in a Smoke Control Area by contacting your Local Authority.

The Consort 7 and Consort 9 Slimline have been fitted with a permanent stop that prevents closure of the secondary

air slider. Removal of this will lead to the appliance potentially causing smoke emissions. Without the permanent

stop in place the appliance is not an exempt appliance and so may leave the householder liable for a fine up to

£1000.

6

General Guidance

It is important that your stove is correctly installed and operated as Hunter Stoves Group cannot accept

responsibility for any fault arising through incorrect installation, use, maintenance or servicing.

These instructions cover the basic principles to ensure satisfactory installation of the stove, although detail may

need slight modification to suit particular local site conditions.

The installation must comply with current Building Regulations, National and European Standards, Local Authority

Byelaws and other specifications or regulations as they affect the installation of the appliance.

The Building Regulations requirements may also be met by adopting the relevant recommendations in the current

issues of British Standards BS 8303 and BS EN 15287-1.

Only use approved fuels on this appliance. Information about this can be found on Page 20.

This is a Domestic Appliance and must only be used in accordance with these instructions. Do not place articles that

are affected by high temperatures on, or near, this appliance. Do not place furniture or other items within 1 metre

of the front of this appliance. See the note on material clearances on pages 15/16.

Fitting a stove in a room which also contains an extractor fan and/or cooker hood should be avoided where

possible. If this is unavoidable, the suitability of the space for fitting this appliance must be decided at the discretion

of a qualified installer, and a flue draught interference test must be performed.

Do not obstruct the ventilation required for the safe use of this appliance.

Competent Persons Scheme

Hunter Stoves Group recommend that this stove is installed by a member of an accredited competent persons

scheme e.g. HETAS.

If the installer is not a member of a competent person’s scheme, it is a legal requirement, in the UK, to notify your

Local Building Control Officer in advance of any installation work starting.

Health and Safety Precautions

Special care must be taken when installing the stove such that the requirements of the Health and Safety at Work

Act are met.

Handling

This appliance is very heavy. Adequate facilities must be available for loading, unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should not be allowed to come into contact with the skin. In case of

contact, wash immediately with plenty of water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of installation, then

please seek specialist guidance and use appropriate protective equipment.

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND OPERATION. KEEP THESE

INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE AND SERVICING.

THIS APPLIANCE WILL BECOME VERY HOT WHEN USED IN ACCORDANCE WITH THESE INSTRUCTIONS,

HUNTER STOVES RECOMMEND THAT AN APPROVED GUARD IS USED TO PROTECT THE YOUNG, ELDERLY

OR INFIRM FROM HARM.

THE INSTALLER COMMISSIONING SHEET CAN BE FOUND ON THE BACK COVER. PLEASE ENSURE THAT IT IS

COMPLETED PRIOR TO USE.

7

Metal Parts

When installing or servicing this stove, care should be taken to avoid the possibility of personal injury.

Modification

No unauthorised modification of this appliance should be carried out.

Safety

WARNING – This appliance will be hot when in operation and due care should be taken. The supplied operating tool

or glove may be used to open the door and operate the air controls.

Aerosols

Do not use an aerosol spray on or near the stove when it is alight.

Fireguards

Always use a fireguard in the presence of children, the elderly or the infirm. The fireguard should be manufactured in

accordance with BS8423 – Fireguards for use with solid fuel appliances.

Do not Over-Fire

It is possible to fire the stove beyond its design capacity. This could damage the stove so watch for signs of overfiring. If any part of the stove starts to glow red, the stove is in an over-fire situation and the controls should be

adjusted accordingly. Never leave the stove unattended for long periods without first adjusting the controls to a

safe setting. Careful air supply control should be exercised at all times.

Fume Emission

Properly installed, operated, this appliance will not emit fumes. Occasional fumes from de-ashing and refuelling may

occur. Persistent fume emission must not be tolerated.

This appliance should not be operated with the door open.

If fume emission persists, then the following immediate action should be taken: -

➢ Open doors and windows to ventilate the room.

➢ Let the fire go out or eject and safely dispose of fuel from the appliance.

➢ Check for flue/chimney blockage and clean if required.

➢ Do not attempt to re-light the fire until the cause of the fume emission has been identified and corrected.

If necessary, seek expert advice.

Adverse Weather

In a small number of installations, occasional local weather conditions (e.g. wind from a particular direction) may

cause downdraught in the flue and cause the stove to emit fumes. In these circumstances, the stove should not be

used. A professional flue installer will be able to advice on solutions to this problem (e.g. anti-downdraught cowl).

Carbon Monoxide Detector

Hunter Stoves recommend a Carbon Monoxide Detector that conforms to the latest issue of BS EN 50292 is placed

in the same room as the appliance. The installation of such an alarm is not considered as a substitute for regular

maintenance or servicing or the appliance and Flue system.

IN THE EVENT OF A CHIMNEY FIRE:

➢ Raise the alarm

➢ Call the Fire Brigade

➢ Close appliance air controls

➢ Move furniture, ornaments etc. away

➢ Place a fireguard in front of stove

➢ Check the chimney breast for signs of excessive heat.

If the wall is becoming excessively hot, move furniture away.

Ensure the Fire Brigade can gain access to your roof space in order to check for fire spread.

8

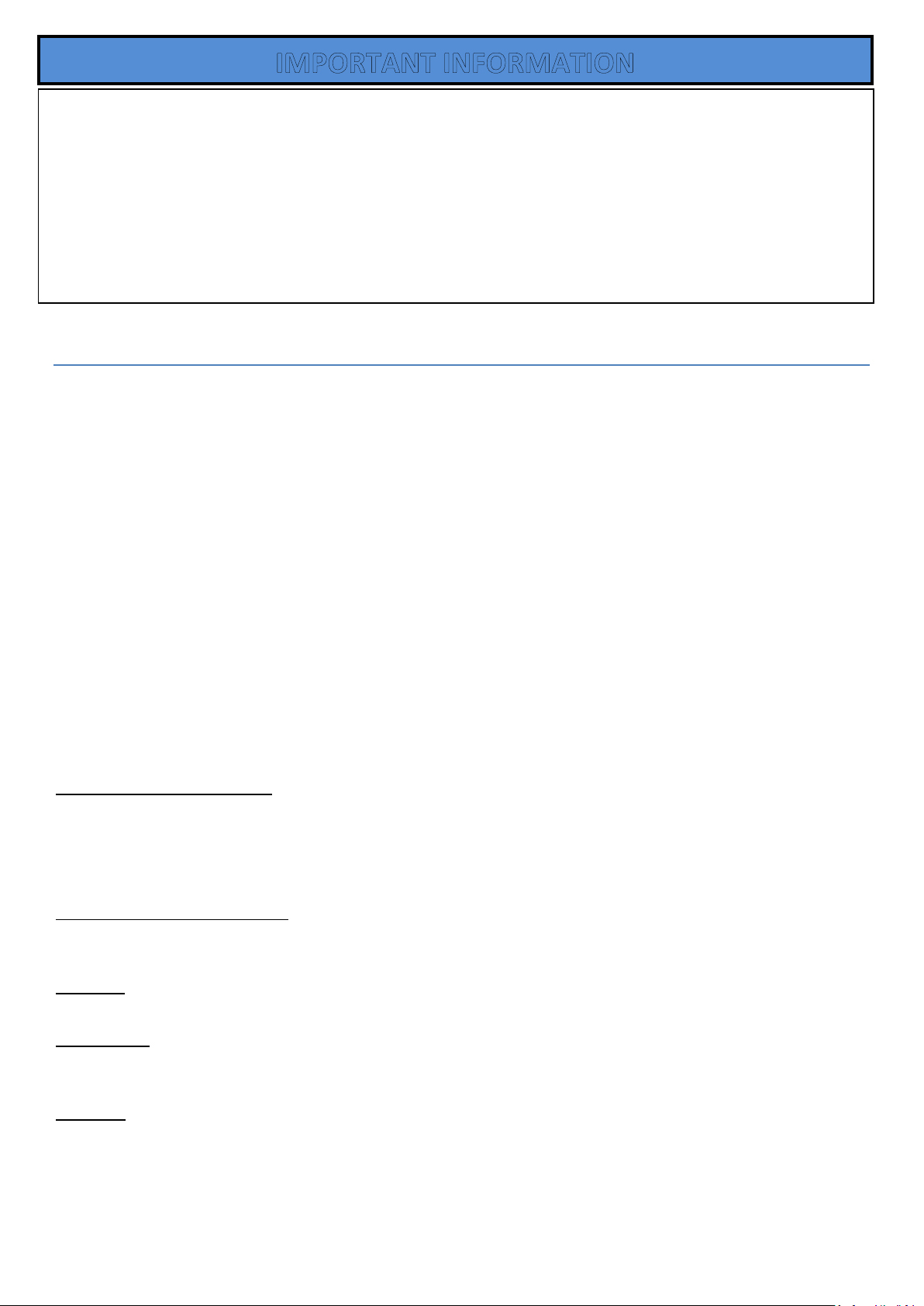

Removing Internal Components

All internal components must be removed prior to fitting the stove. This will make handling the stove easier; allow

access to fixings and the flue outlet; as well as protect the internal components from damage during the installation

process.

1. Open the door and remove the ashpan.

2. Remove the grate bars by lifting the front up off the cam bar and sliding forward off the rear grate support and lift

out of the firebox.

3. Remove the cam bar by lifting the left-hand end of it upwards until it clears the side casting. Pull the left-hand end

towards the front of the stove and then slide all the way out. Take care not to lose the cam hole plate.

4. Remove the catch bar by lifting upwards and pulling forwards out of the stove body.

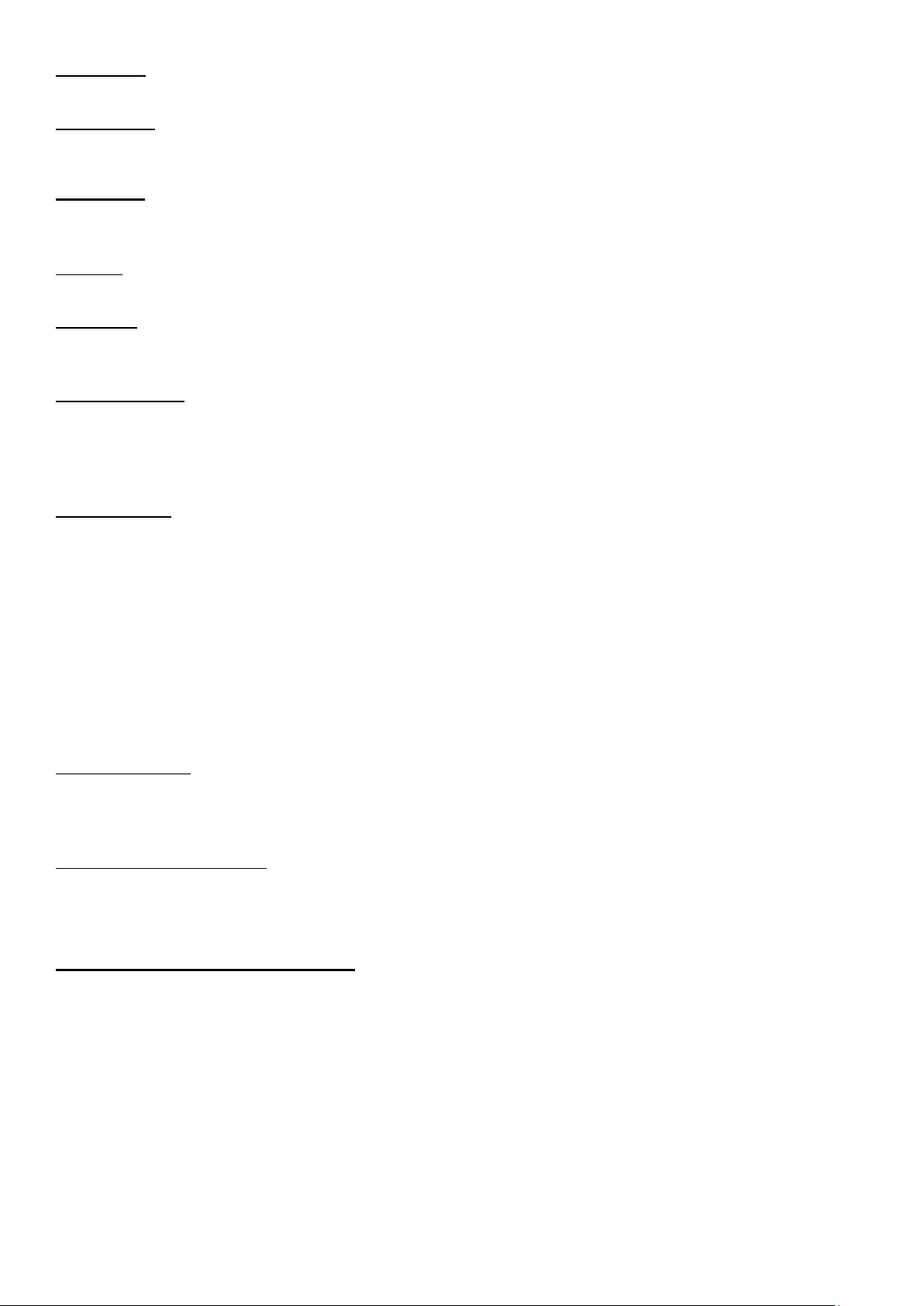

Side Plates

Side Bricks

Rear Brick

Pull the top edge of the Rear

Brick forward and lift the

brick out of the Stove.

Slide the base of the

Side Brick towards the

centre of the stove and

remove.

Slide out both

Side Plates

9

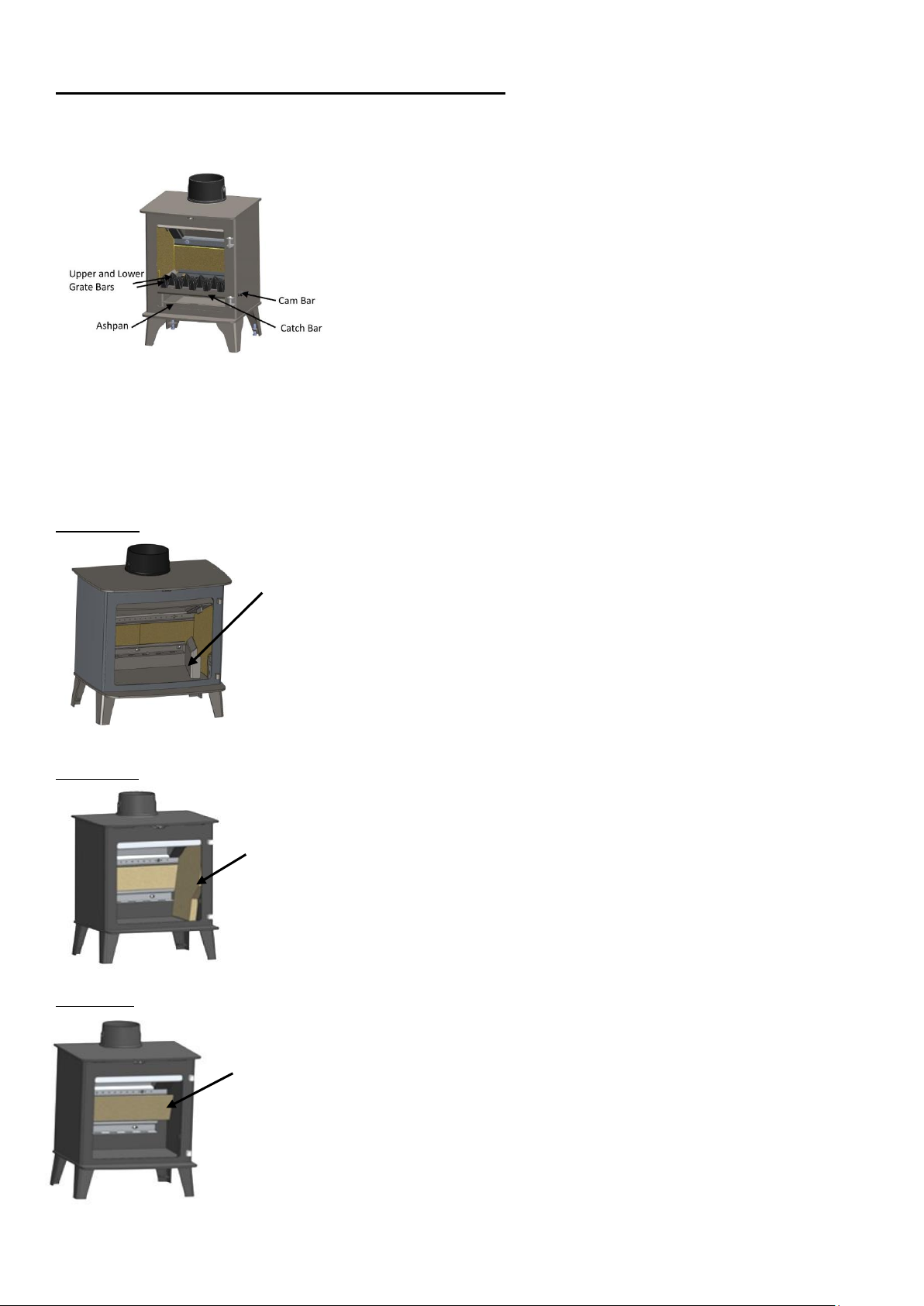

Baffle/Throat Plate

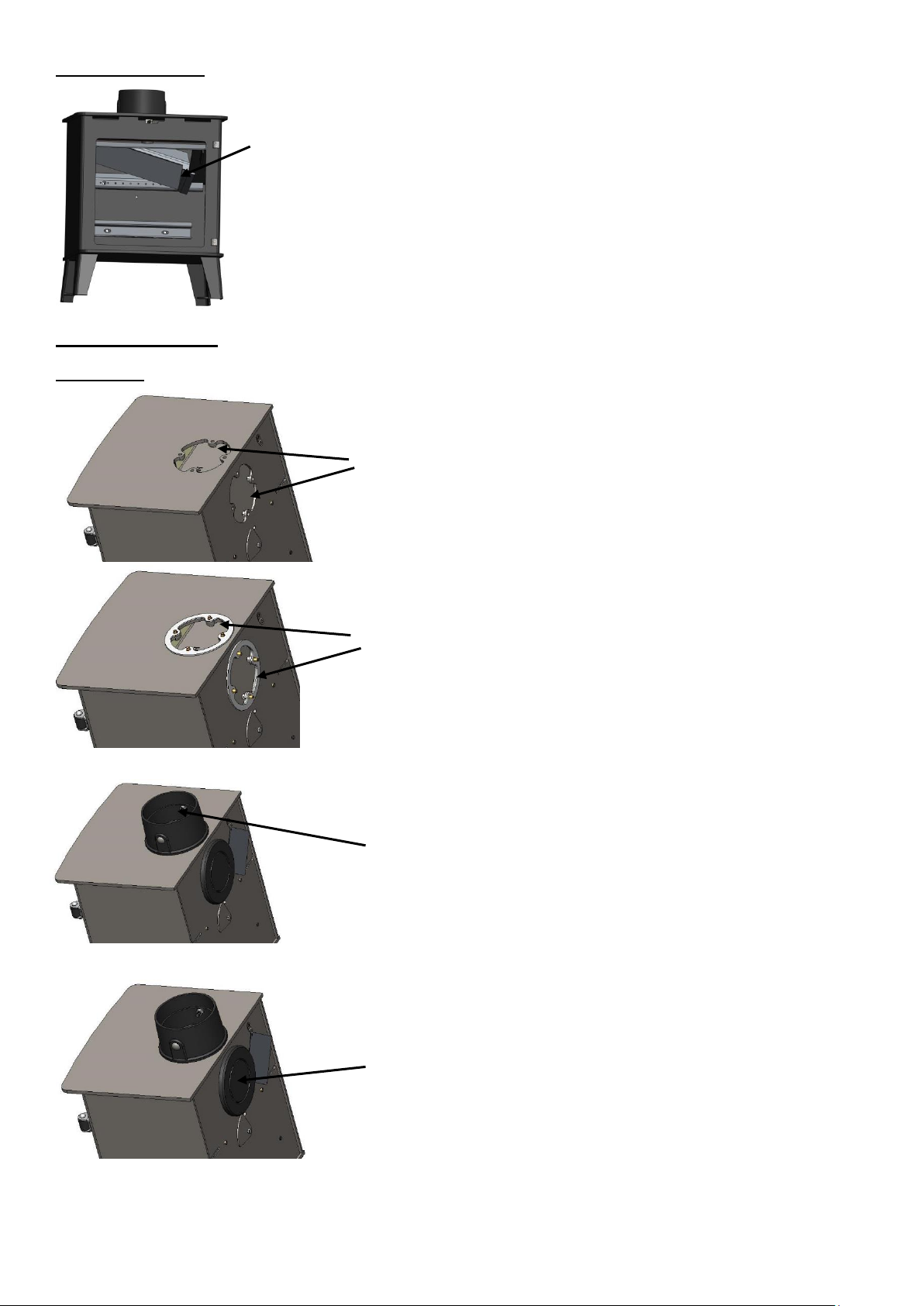

Stove Assembly

Flue Collar

Blanking Plate

Lift the Baffle and slide to

the left. When the right

side of the Baffle clears the

Baffle Support, lower the

Baffle into the Fire Box and

remove.

Place the bolts downwards through the fixing holes (head side

upwards). Then tighten by using supplied nuts from inside stove.

Place the gasket on the outlet and put blanking plate on top of this.

Screw the bolts from the inside of the stove into the blanking plate.

Place the flue collar gasket on the outlet to be used.

Top or rear outlet

10

Re-Assembling The Stove

Refit all the internal parts by following the ‘removing internal component’ instructions in

reverse order.

APPLIANCE DIMENSIONS

DERWENT

CONSORT 4

CONSORT 5

11

COMPACT 5

CONSORT 5 SLIMLINE

CONSORT 7

12

CONSORT 9 SLIMLINE

CONSORT 9

CONSORT 15

Loading...

Loading...