Page 1

Page 2

Introduction

Introduction

This gas cooker has been designed and manufactured to all the

necessary British Standards. This cooker complies with European

Council Directive 90/396/EEC. It also carries the C.E. mark.

cooker properly before you use it for the first time.

booklet thoroughly before you use the cooker. Keep the booklet in a

safe place so that anyone who uses the cooker can read it. Pass the

booklet on with the cooker if you give or sell it to someone else.

L Y R I C 5 0 G X

It is important that you understand how to use and care for the

We have written this booklet with your safety in mind. Read the

For your safety

This cooker is designed for domestic use to cook food. You

must not use it for any other purpose. It is not designed for

commercial use.

Keep children, babies and toddlers away from the cooker at all

times.

The installation instructions that came with the cooker tell you

how and where it can be fitted. If the cooker is already installed

you must make sure that all instructions have been followed. If

you are in any doubt ask a registered person. More details on

installation on page 28.

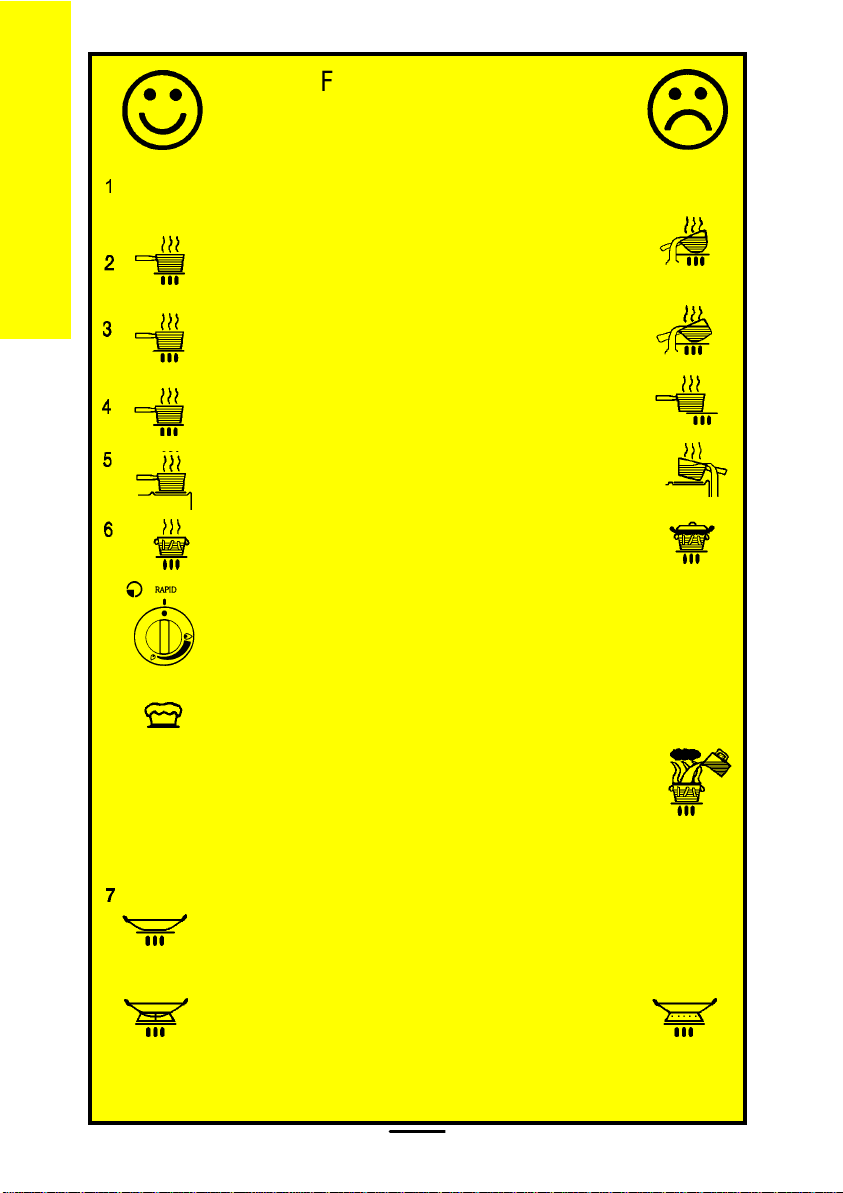

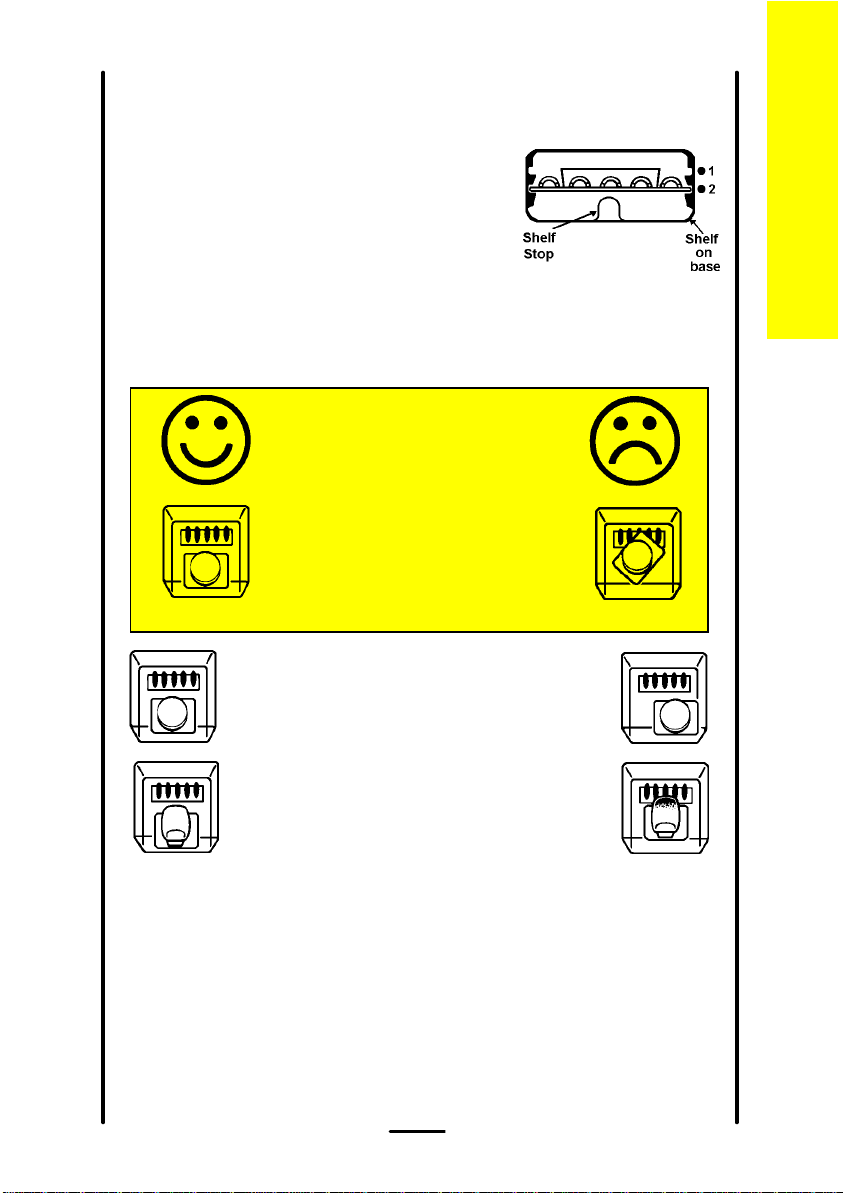

We have included several drawings to show the right and wrong way

of doing things.

The right way will have a smiling face by it.

A sad face shows something is wrong.

Important: Make sure you remove the sales stickers before you use

this cooker.

2

Page 3

L Y R I C 5 0 G X

Contents

Contents

Lighting the cooker 4

The grill 7

The hotplate 9

The ovens 12

Oven cooking chart - main oven 15

- top oven 18

Slow cooking 21

Care and cleaning 23

Installing the cooker 28

General information 30

What is wrong and why? 32

Servicing 33

Installation Instructions 34

Technical Data 35

Safety requirements/ventillation 36

Location of appliance/installation 37

Page

Testing 39

3

Page 4

L Y R I C 5 0 G X

Lighting the cooker

The system works by means of a battery. Details on how to replace the

battery are given on page 30.

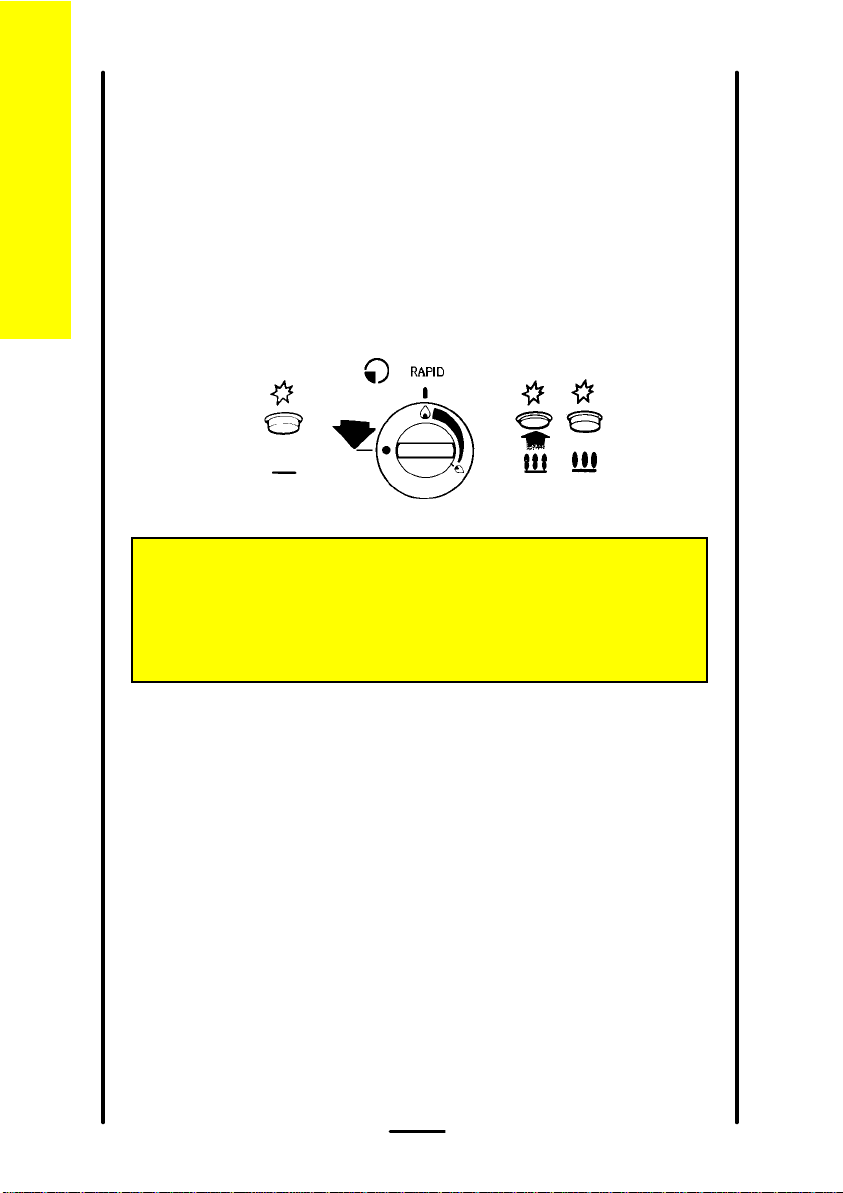

Hotplate and Grill

Lighting the cooker

To light:

1 Push in the control knob and turn it to the large flame symbol

(highest setting), and press the ignition button immediately. When

the burner has lit release the button.

For your safety

Never cover the grill pan or grid with foil as this can lead to

grill fires.

Warning: If the ignition button is not pressed immediately a build up of

gas may cause the flame to spread.

4

Page 5

L Y R I C 5 0 G X

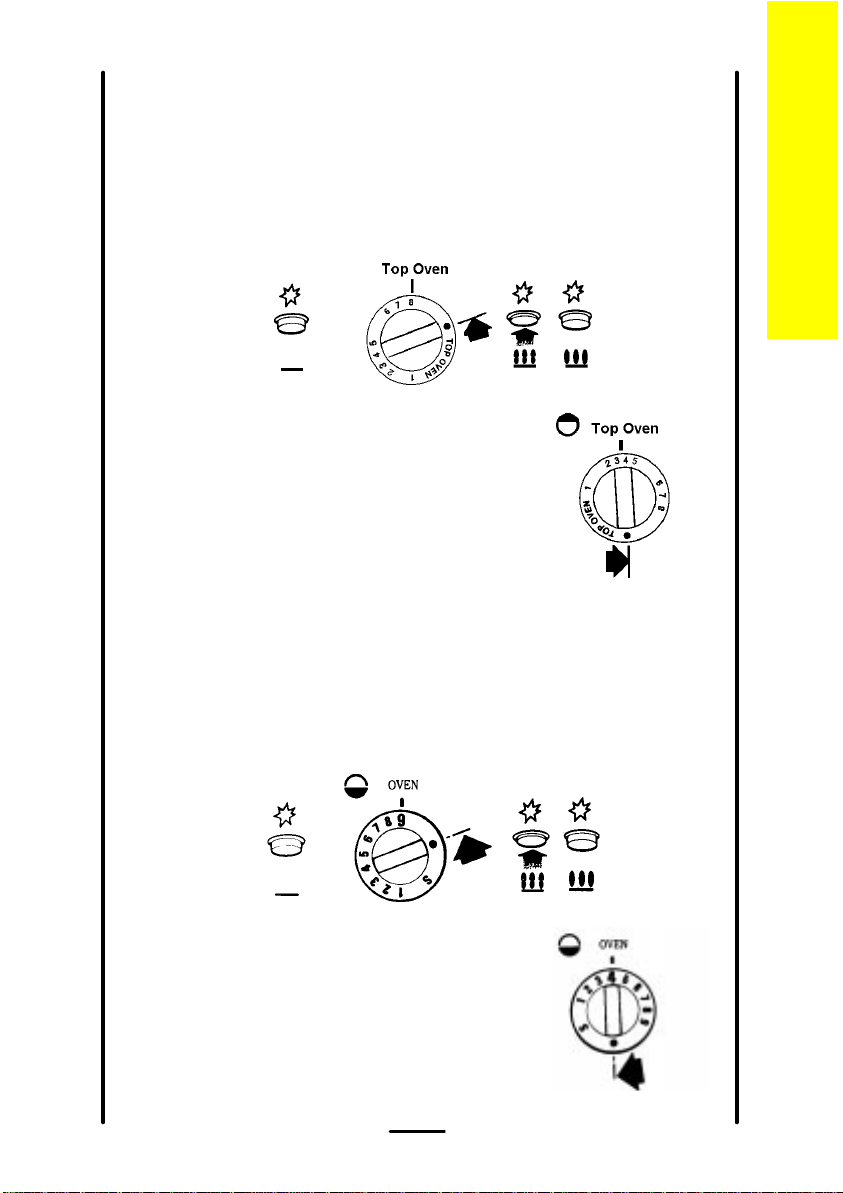

Top oven

To light:

1 Open the oven door.

2 Push in the control knob and turn it to the left to gas mark 8, and

press the ignition button immediately. When the burner has lit

release the button. There will only be small flames at first.

3 Now turn the control knob to the gas

mark you want.

4 Wait until the burner is showing large

flames.

5 Close the oven door.

Main oven

Lighting the cooker

To light:

1 Open the oven door.

2 Push in the control knob and turn it to gas mark 9, and press the

ignition button immediately. When the burner has lit release the

button. There will only be small flames at first.

3 Now turn the control knob to the gas

mark you want.

4 Wait until the burner is showing large

flames.

5 Close the oven door.

5

Page 6

Li

h

i

h

k

er

L Y R I C 5 0 G X

To turn off any burner

e coo

ng t

t

g

1 Push in the control knob and turn it to the off position. This is shown

by a large dot.

For your safety

When you are lighting any burner check that it has lit before

you leave the cooker.

When you are turning off a burner, do not leave the cooker

until the flame has gone out.

6

Page 7

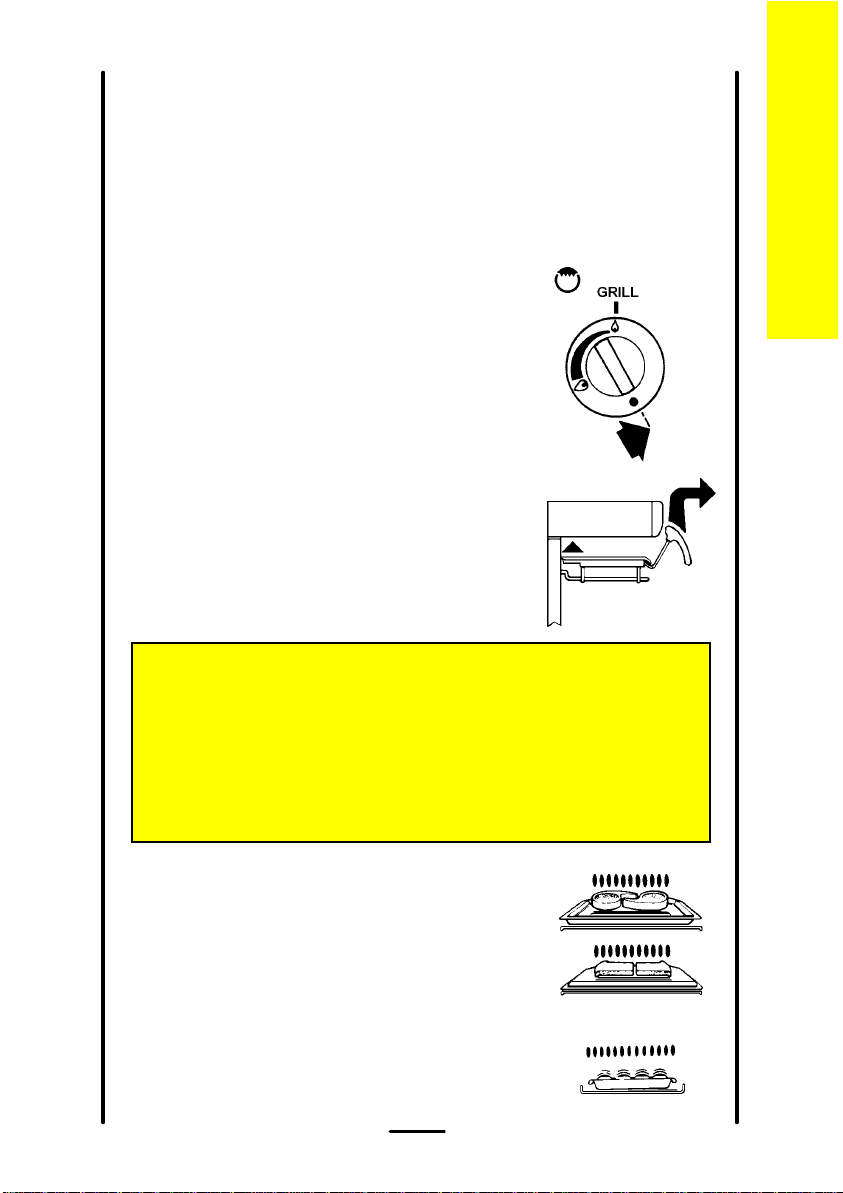

The grill

L Y R I C 5 0 G X

The grill is a high-speed grill. The instructions below tell you how to vary

the heat setting and how to change the height of the trivet to suit the

food you are cooking. You should remember to turn the food regularly.

You should not use the grill to keep food warm as it will continue to

cook the food.

Heat control

The grill control has two heat settings.

The control knob turns to the left from 'OFF'

to 'HIGH' and then to 'LOW'. Use the high

setting for fast cooking such as toast. Use the

low setting to cook thicker food such as chicken

after you have browned it on the high setting.

Grill pan

The pan is designed so that you can pull it

forward but it will stay supported. To remove the

pan push it back as far as possible and lift it off.

Replace it in reverse order.

For your safety

After replacing the pan, pull it out to make sure it has fitted back

properly.

Never cover the grill pan or grid with foil as this can lead to grill

fires.

The grill

Cooking positions

Most food should be cooked on the trivet in

the grill pan. You can turn the trivet over to suit

different thicknesses of food.

You can place some dishes straight on to

the grill shelf. This is useful when you are

browning the top of food such as cauliflower

cheese.

7

Page 8

Preheating

L Y R I C 5 0 G X

The grill

You don't usually need to preheat the grill. You may wish to preheat it for

a couple of minutes when you are cooking steak or browning food.

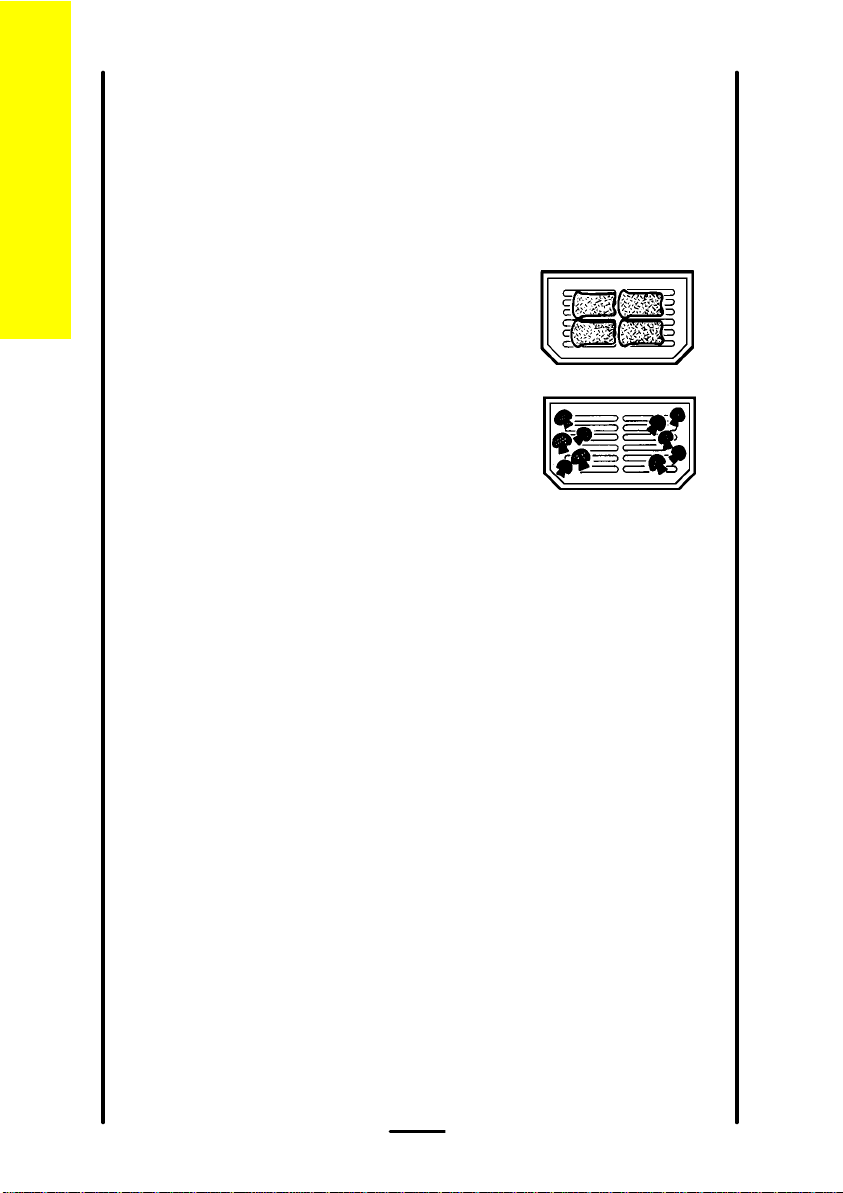

Putting food on the trivet

Place food such as toast, tea-cakes and muffins

towards the centre of the trivet.

Place food which needs a gentle heat, such as

tomatoes and mushrooms towards the edge of

the trivet.

Arrange meat, meat products and fish to suit

their thicknesses and how you like them

cooked.

Warming plates

When using the cooker you can use the shelf below the grill pan to

warm two plates. Do not put plates on the shelf when the grill burner is

turned on and the grill pan is not in place. The heat from the burner will

damage the plates.

8

Page 9

L Y R I C 5 0 G X

The hotplate

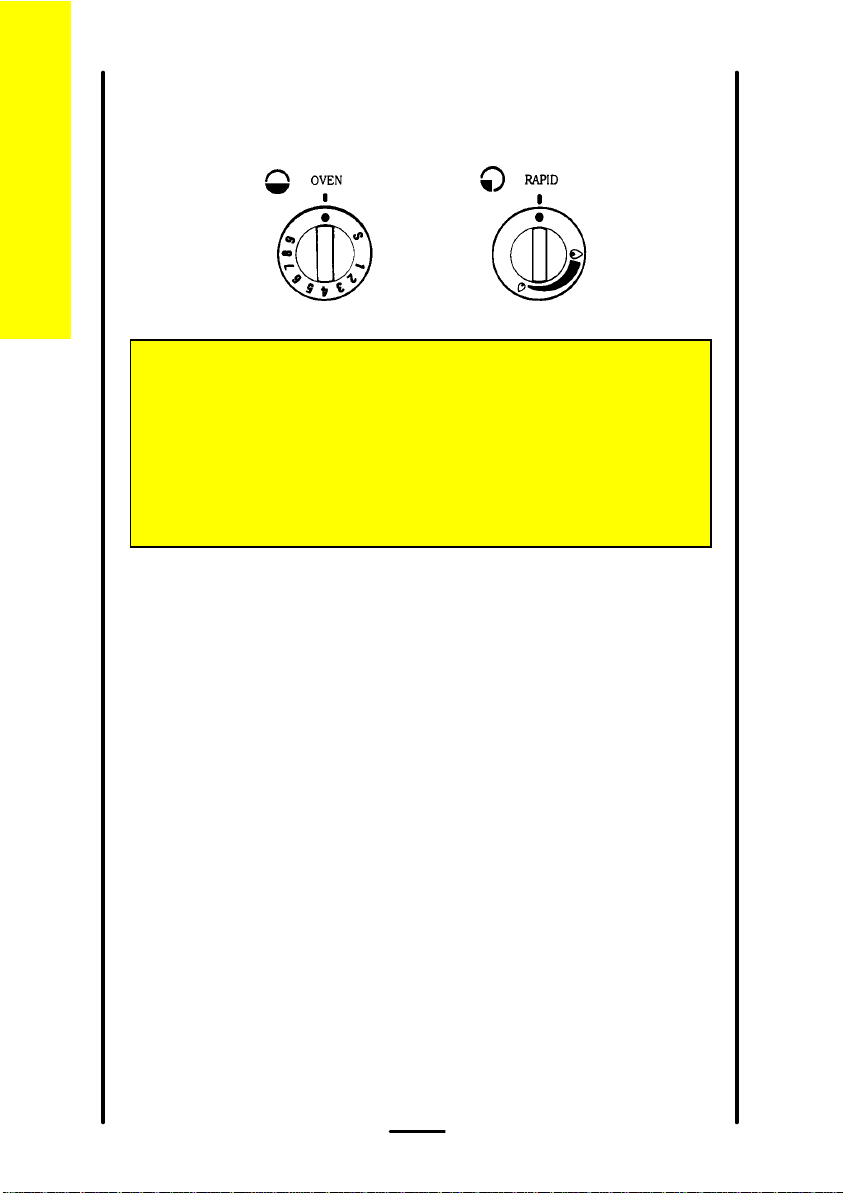

Heat control

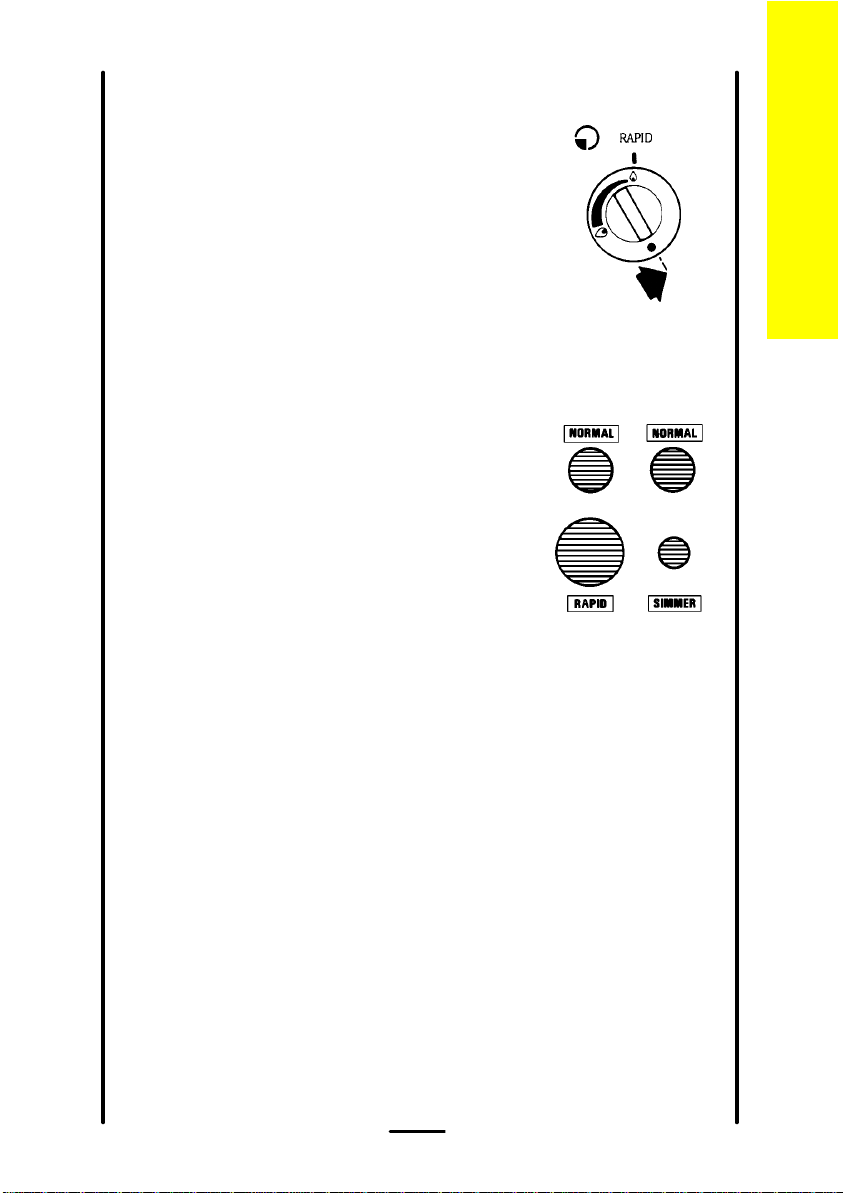

The hotplate control knobs turn to the left from

'OFF' to 'HIGH' and then to 'LOW'. You can

adjust the heat by turning the control between

the highest and lowest settings. These are

shown as a large and a small flame symbol.

Burner sizes

The hotplate has three burner sizes to suit

different types of cooking:

Largest burner (Rapid) - use a large pan for

food such as chips.

Medium burners (Normal) - use for everyday

cooking.

The hotplate

Small burner (Simmer) - use for simmering food

such as soups and stews.

The largest pan which you should use on any burner is 230mm (9").

The base of the smallest pan should not measure less than 100mm (4").

9

Page 10

Th

h

l

ate

otp

e

L Y R I C 5 0 G X

For your safety

1

Take care to avoid burns and scalds when you

are reaching across the hotplate.

Use pans with flat bases. They are more stable

than pans which are warped.

Do not use pans with very heavy handles which

cause the pan to tip.

Put pans on the centre of the burners.

Position pan handles so they cannot be

accidentally knocked.

Take extra care when you are deep fat frying. Do

not cover the pan with a lid.

Do not leave a pan unattended. If the pan

catches fire, leave it where it is and turn off all

controls.

Place a damp cloth or a fitting lid over the pan to

smother the flames.

Never put water on the fire.

Leave the pan to cool for 30 minutes.

7

7

If you are using a Wok we recommend it has a flat

base as it will stand stable on the pan supports. If

you use a round based Wok with a collar support,

the collar must be of the open wire work type. A

closed collar will affect the performance of the

burner. Before you use the Wok make sure that

the collar is stable on the pan supports. Always

follow the instructions that come with the Wok.

10

Page 11

L Y R I C 5 0 G X

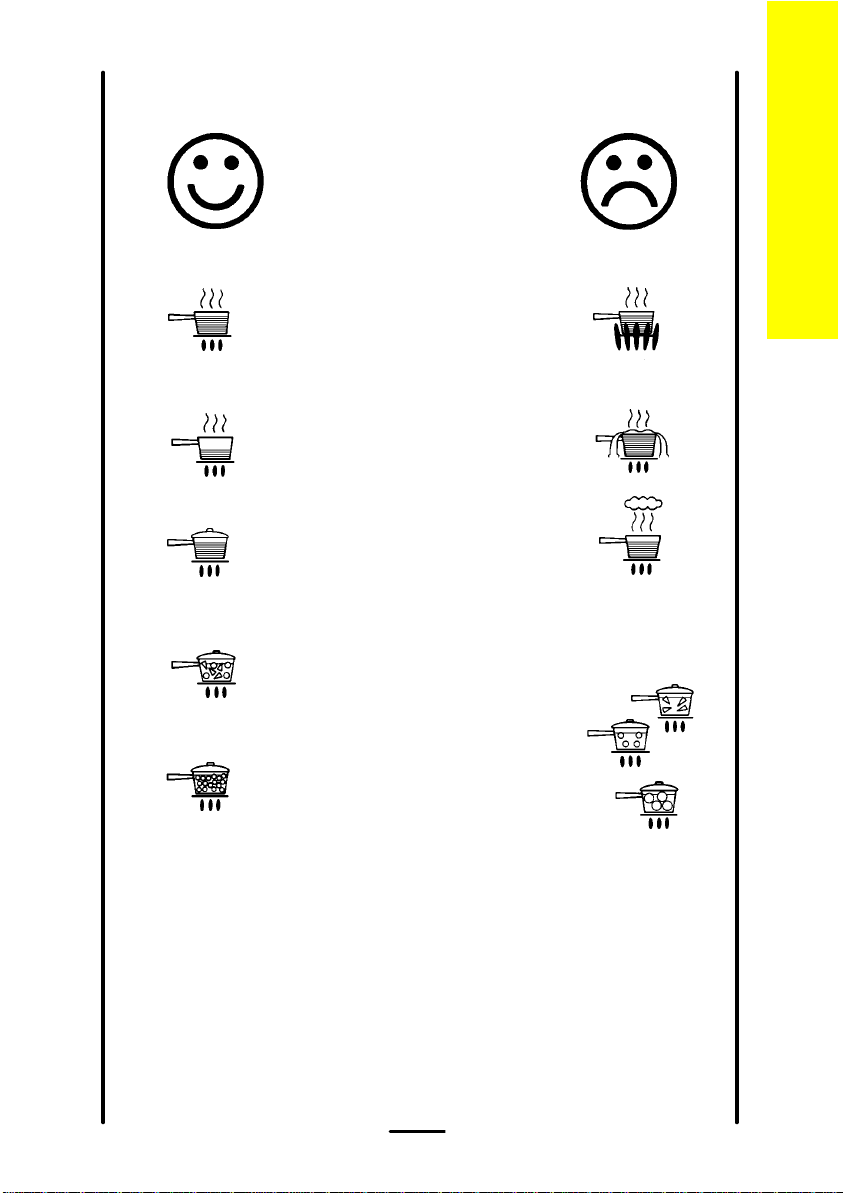

Helpful hints

The hotplate

1

2 Only heat the amount of liquid you

3 Cover pans with a lid whenever

4 Try cooking more than one

5 Cut vegetables into smaller pieces.

Keep flames under the base of

pans. If the flames lick round the

sides of the pans you are wasting

gas.

need. Do not overfill pans.

possible. The food will heat up

more quickly and there will be less

steam in the kitchen.

vegetable in the same pan, for

example potatoes and carrots.

This way they will cook more

quickly.

6 A pressure cooker will save time

and energy.

11

Page 12

The ovens

Before you use the oven you should wipe it

out with a damp cloth to remove any dust.

The ovens

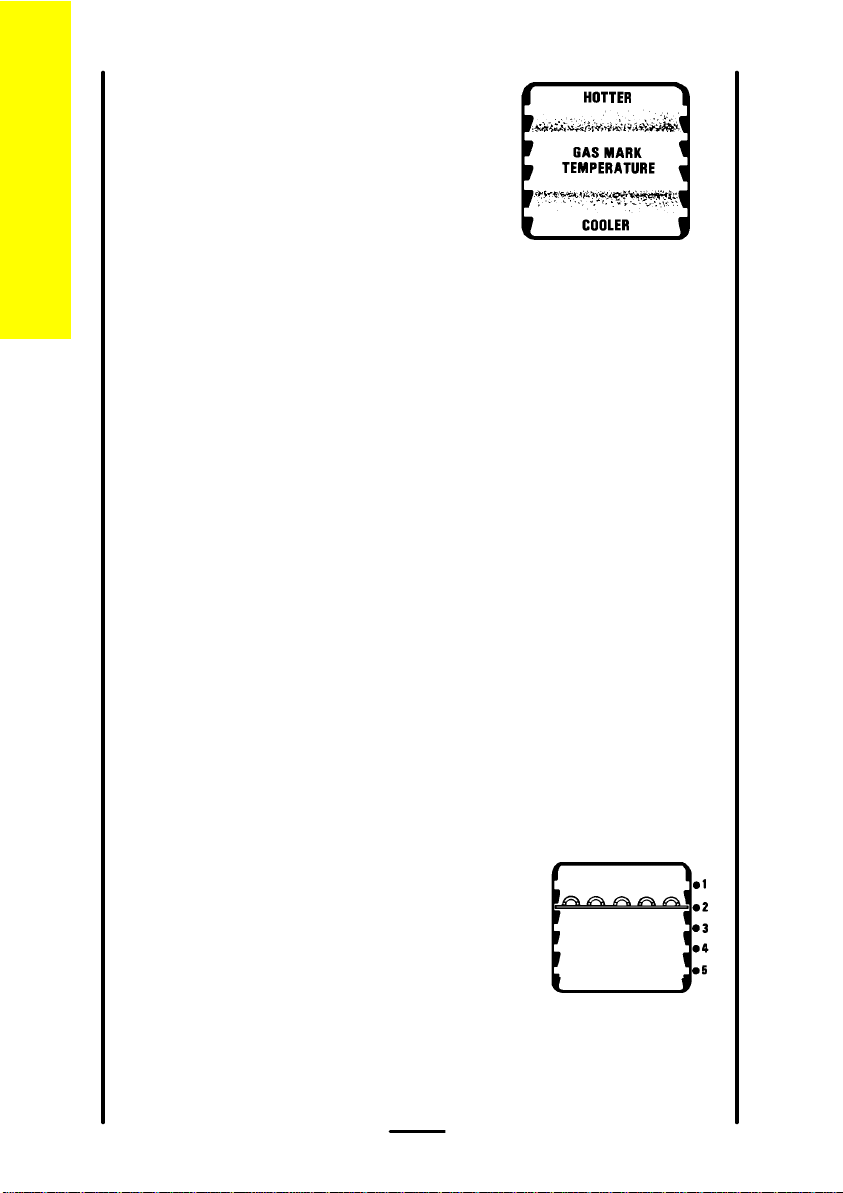

Heat zones

Main Oven - There are zones of heat

within the oven. The temperature in the

middle is the gas mark you have chosen. The top of the oven is slightly

hotter and the lower shelf slightly cooler. The base of the oven is quite

a lot cooler. You can make use of these heat zones when you are

cooking foods requiring different temperatures all at the same time.

cakes or biscuits, swap the trays around during cooking. Or you could

remove the top tray when the food is cooked and move the lower tray to

the higher shelf to finish cooking.

Top Oven - You can only cook on one shelf at a time. You should turn

food round during the cooking time.

Preheating

You do not need to preheat the main or top oven for casseroling and so

on.

such as Yorkshire puddings, soufflés and yeast mixtures.

instructions on the packaging. When you are using the top oven to cook

or reheat convenience food you should preheat the oven to gas mark 8.

20 minutes.

L Y R I C 5 0 G X

If you are cooking more than one tray of similar items, for example

Preheat the ovens for baking or when you are cooking sensitive food

When you are cooking or reheating frozen or chilled food read the

When you need to preheat the oven, we recommend you do so for

Oven shelves

The shelf in the top oven is different from the

shelves in the main oven. You can distinguish

the top oven shelf from the main oven shelves

because it has a metal plate attached to it. The

shelves provided for the main oven should only

be used in the main oven. Similarly, only use

the top oven shelf in the top oven.

You can slot the oven shelves into any of

five positions in the main oven and any of two

positions in the top oven.

12

Page 13

L Y R I C 5 0 G X

Shelf positions are counted from the top

downwards.

Most top oven cooking should be carried out

using the shelf provided in shelf position 2.

However, when cooking a small joint or a deep

cake you can use the top oven shelf on the

base of the top oven to allow enough air to

circulate around the food. There is a stop at the

back of the top oven. You should not try and

push the shelf back beyond this stop.

Baking trays and dishes

For your safety

Never place cooking dishes, trays

and so on over the oven burners.

This will damage the cooker as

well as the ovenware and possibly

the floor covering underneath the

cooker.

The ovens

Leave a gap of 13mm (½") between all

dishes and the sides of the oven so the

heat can circulate properly.

Do not push dishes too far back as food

will burn if it overhangs the burner flames.

For the best results from the main oven we recommend that you use

a baking tray which is 310mm (12") square. If you use a tray or tin

which is larger than this, you may need to turn it around during cooking.

The size of tray which should be used in the second oven should

measure no more than 310mm x 230mm (12" x 9"). Position the longest

side parallel with the door.

Place single dishes on the centre of the shelf. You may need to turn

large items around during cooking.

13

Page 14

Condensation

Condensation may form on the cooker. This is quite normal and nothing

The ovens

to worry about. The condensation forms when heat and moisture are

present, for example during cooking. Whenever possible try to make

sure that food which contains a lot of moisture for example casseroles

are covered. If you do notice any condensation, wipe it up straight

away.

Roasting

For best results we recommend open roasting using minimal fat or oil to

prevent splashing.

It is not necessary to cover meat or poultry or wrap food in foil when

roasting as this restricts the circulation of heat and will lead to extended

cooktimes.

If you are using a roasting bag or cover chicken breast with foil, be

prepared to allow an extra 10 - 15 minutes for each 1/2kg (1lb).

When cooking large items such as turkeys, the use of foil may be

required to prevent the breast becoming dry before the rest of the bird is

fully cooked.

L Y R I C 5 0 G X

14

Page 15

L Y R I C 5 0 G X

30 mins. per ½kg (1 lb) and 30 mins.

25 mins. per ½kg (1 lb) and 25 mins.

20 mins. per ½kg (1 lb) and 30 mins.

25 mins. per ½kg (1 lb) and 25 mins.

30 mins. per ½kg (1 lb) and 30 mins.

30 mins. per ½kg (1 lb) and 30 mins.

35 mins. per ½kg (1 lb) and 35 mins.

Oven cooking chart

Approximate

cooking time

Shelf

position

Gas

mark

Medium:

Well Done:

Well Done:

Lamb 5 4 Medium:

Well Done:

Thoroughly thaw frozen joints before cooking them

Pork and Veal 5 4 Medium:

Food

Oven cooking chart - Main oven

These instructions are for cooking in the oven after it has been pre-heated for 20 minutes.

If you are cooking more than one tray of similar items, for example cakes or biscuits, swap the trays around during cooking or you

can take the top tray out of the oven when the food is cooked and move the lower tray to the higher shelf to finish cooking.

Always leave at least one shelf position between shelves to allow heat to circulate.

The recommended shelf positions give the best results.

Put the dishes in the centre of the shelf.

You can change the gas marks and cooking times to suit your own tastes.

It is important to check that food is piping hot before serving.

If you are using both ovens at the same time you may need to adjust the cooking times.

Roasting meat: Beef 5 4 Rare:

15

Page 16

L Y R I C 5 0 G X

Oven cooking chart

Approximate

cooking time

Shelf

position

25 - 35 mins.

15 - 25 mins.

4 - 5 hours.

2

2

44432 & 4

2¼ - 2½ hours.

2½ - 2¾ hours.

1 hour.

15 - 25 mins.

10 - 20 mins.

2 & 4

20 - 30 mins.

20 - 35 mins.

2 & 4

2 & 4

Gas

mark

5 4 20 mins. per ½kg (1 lb) and 20 mins.

4 4 25 mins. per ½kg (1 lb) and 25 mins.

4 4 or 5 15 mins. per ½kg (1 lb) and 15 mins.

5 4 25 mins. per ½kg (1 lb).

Turkey below 4.5kg (10lbs)

over 4.5kg (10lbs)

Duck and duckling

Food

Poultry: Chicken

Cook as above but calculate weight including stuffing.

Thoroughly thaw frozen joints before cooking them.

Stuffed poultry

7

7

- individual

The times given above are for open roasting in a preheated oven. If you cover the food with foil or a lid allow an extra 10 - 15 minutes for

each ½kg (1lb).

Yorkshire pudding - large

22245

Rich fruit, 180mm (7")

205mm (8")

Cakes: Christmas Cake (8")

16

7

4

4

Madeira, 180mm (7")

Small cakes

Scones

Victoria sandwich

180mm (7")

205mm (8")

Page 17

To help pastry brown on the underside

Approximate

cooking time

25 - 35 mins.

Shelf

position

2

L Y R I C 5 0 G X

cook on a metal plate, or if plates are flat

and have no rim underneath, place on

baking tray.

25 - 35 mins.

15 - 25 mins.

2

2& 4

2 hrs. approx.

45 - 60 mins.

50 - 60 mins.

30 - 40 mins.

3

4

4

3

30 - 40 mins.

10 - 20 mins.

3

2

Oven cooking chart

Gas

mark

6

6

5

Fruit pie (shortcrust)

Mince pies (flan pastry)

Pastries: Plate tart (shortcrust)

Food

2

4

3

8 *

8 *

8 *

Baked sponge pudding

Baked custard

Puddings: Milk puddings

0.90kg (2lb loaves)

Rolls and buns

Yeast mixtures: Bread 0.45kg (1lb loaves)

17

When baking bread cook for 10 minutes at Gas Mark 8 then reduce to Gas Mark 6 for the remaining cook time.

Note: You must soak dried beans then boil them in an open pan for 15 minutes before you add them to any dish.

Page 18

L Y R I C 5 0 G X

Oven cooking chart

20 mins. per ½kg (1 lb) and 30 mins.

Approximate

Rare:

cooking time

30 mins. per ½kg (1 lb) and 30 mins.

25 mins. per ½kg (1 lb) and 25 mins.

25 mins. per ½kg (1 lb) and 25 mins.

30 mins. per ½kg (1 lb) and 30 mins.

Medium:

Well Done:

30 mins. per ½kg (1 lb) and 30 mins.

Medium:

Well Done:

35 mins. per ½kg (1 lb) and 35 mins.

Medium:

Well Done:

Shelf

position

Gas

mark

Oven cooking chart - Top oven

These instructions are for cooking in the oven after it has been pre-heated for 20 minutes.

The recommended shelf positions give the best results.

Put the dishes centrally on the shelf.

You can change the gas marks and cooking times to suit your own tastes.

It is important to check that food is piping hot before serving.

If you are using both ovens at the same time you may need to adjust the cooking times.

Food

oven base

Roasting meat: Beef 5 Shelf on

oven base

Lamb 5 Shelf on

oven base

Pork and Veal 5 Shelf on

Thoroughly thaw frozen joints before cooking them.

18

Page 19

L Y R I C 5 0 G X

Approximate

cooking time

20 mins. per ½kg (1 lb) and 20 mins.

25 mins. per ½kg (1 lb).

Shelf

position

Shelf on

oven base

Shelf on

oven base

3 -4 hours.

2 - 2½ hours.

1 hour.

Shelf

on

oven base22

15 - 25 mins.

8 - 12 mins.

20 - 30 mins.

2

Oven cooking chart

To help pastry brown on the underside

cook on a metal plate, or if plates are flat

and have no rim underneath, place on

baking tray.

25 - 35 mins.

25 - 35 mins.

15 - 25 mins.

222

Gas

mark

Food

5

5

Duck and duckling

Poultry: Chicken

2 2457

Thoroughly thaw frozen joints before cooking them.

Stuffed poultry Cook as above but calculate weight including stuffing.

The times given above are for open roasting in a preheated oven. If you cover the food with foil or a lid allow an extra 10 - 15 minutes for

each ½kg (1lb).

Rich fruit, 180mm (7")

Madeira, 180mm (7")

Small cakes

Yorkshire pudding - individual 7 2 20 - 30 mins.

Cakes: Christmas cake (7")

4

665

Scones

Victoria sandwich

180mm (7")

Pastries: Plate tart (shortcrust)

Fruit pie (shortcrust)

Mince pies (flan Pastry)

19

Page 20

L Y R I C 5 0 G X

Oven cooking chart

2 hrs. approx.

45 - 60 mins.

2

2

50 - 60 mins.

2

Approximate

cooking time

Shelf

position

Gas

2

mark

Puddings: Milk pudding

Food

3

3

Baked sponge pudding

Baked custard

Note: You must soak dried beans then boil them in an open pan for 15 minutes before you add them to any dish.

20

Page 21

L Y R I C 5 0 G X

Slow cooking

Please note: There is no slow cook on the top oven.

The slow cook setting gives a very low heat in the oven. It is

particularly useful when you are cooking soups, stews and casseroles

because the long slow cooking will make cheaper, tougher cuts of meat

more tender.

You need to cook food at gas mark 6 for 30 minutes before you turn

the oven down to the slow cook setting. This makes sure that the

temperature of the food gets hot enough to start the food cooking.

Some foods such as pastry and biscuits are not suitable for slow

cooking because the temperature is too low.

Cover all food during cooking to prevent it from drying out. You can

uncover food for the last half hour if it is normally served golden brown.

Slow cooking

Food preparation - slow cooking

Joints of meat and poultry

l

Do not cook meat joints over 2.7kg (6lb).

l

Do not cook poultry over 2 kg (4lb 8oz).

l

Cook on the middle shelf of the oven or above.

l

Cook stuffing separately.

l

Cook for at least 6 hours.

l

Only cook joints of pork if you can make sure, by using a meat

thermometer, that the temperature inside the joint is at least 88°C.

l

For good air circulation always stand joints on a rack in the roasting

tin or casserole.

l

Thaw all frozen meat and poultry before you cook it.

l

Prime cuts of meat do not benefit from slow cooking.

l

Cut off unwanted fat and skin unless it is browned first.

l

Cook for 30 minutes at gas mark 6, then reduce to the slow cook

setting.

21

Page 22

Soups, casseroles and stews

l

Do not cook casseroles over 3 kg (6lb).

l

Bring to the boil on the hotplate then cook on slow cook.

l

Cook in the middle of the oven or above.

Slow cooking

Vegetables

l

Cut into small pieces.

l

Dried beans must be pre-soaked then boiled in an open pan for 15

minutes before adding to any dish.

l

Place vegetables under meat in casseroles.

l

Cook for 30 minutes at gas mark 6, then reduce to the slow cook

setting.

Milk puddings

l

Cover the cereal with boiling water and leave it to stand for 30

minutes.

l

Drain and make the pudding in the usual way.

l

Cook for 30 minutes at gas mark 6, then reduce to the slow cook

setting.

General points for slow cooking

Frozen foods

Thaw thoroughly before cooking.

L Y R I C 5 0 G X

Thickening

Toss meat in flour for casseroles. Blend cornflour with water and add it

at the end of cooking.

Flavouring

Flavours are held in the food because there is little evaporation. Adjust

flavouring at the end of the cooking time.

Liquid

Use slightly less liquid as there is little evaporation during cooking.

Milk and milk products, for example cream

Add these towards the end of cooking to prevent them from curdling.

Reheating

Cool left over food quickly and then put it in the fridge. Do

not reheat food using the slow cook setting. Reheat food in the usual

way or in a microwave.

Only reheat food once.

22

Page 23

L Y R I C 5 0 G X

Care and cleaning

For your safety

For hygiene and safety reasons you must keep this gas cooker

clean. A build up of fat or other foodstuff could cause a fire.

Try to mop up spills and splashes as soon as they happen.

But be careful as parts of the appliance will be hot.

Do not use any polishes, caustic cleaners, abrasives, washing soda

or soap powder except those recommended in this booklet.

Please note: If we recommend

you use hot soapy water we mean

hot water with washing up liquid in it

and not any other cleaning product.

If you own a dishwasher please

read the operating instructions for

the machine before you wash any

part of your cooker.

Clean your cooker regularly using a cloth that has been wrung out in

hot soapy water. Rinse and polish it dry using a soft cloth.

When you remove parts of your cooker for cleaning do not plunge

them into water whilst they are very hot as this may damage the finish of

the parts.

Care and cleaning

The hotplate

Clean the hotplate top using a mild abrasive such as 'Jif'. Take care not

to damage the spark electrodes. If the spark electrodes are damaged

the burners will not light.

You can remove the pan supports, burner caps and burner crowns

to clean them. Again take care not to damage the spark electrodes.

If any food spills do occur during cooking you can place the pan on

another burner to finish cooking. Then you can remove the dirty parts

and clean them before the spill 'burns on'.

23

Page 24

C

d

l

i

ng

ean

c

are an

L Y R I C 5 0 G X

You can wash the removable parts in very hot soapy water. You may

use mild abrasives. Make sure that the electrode and the hole and slots

in the crown are not blocked with food or cleaning materials.

Clean the burner crowns by soaking them in very hot soapy water.

You can remove any stubborn stains by scouring with a soap filled pad

such as 'Brillo'. If you look after the burner crowns in this way they will

stay reasonably clean. However the surface will dull with time.

Aluminium based saucepans can leave shiny metal marks on the

pan supports. Clean the pan supports regularly to remove the marks

using a mild abrasive like 'Jif' with a soft scourer. For more stubborn

marks you can use a soap filled pad such as 'Brillo'.

After cleaning the cooker parts, dry them

thoroughly before you put them back.

When replacing hotplate burner parts

1. Crown to body (Do not try to force the

crown on to the body). Make sure that the

hole in the crown is over the electrode.

Check that the two longer location pegs

sit in the slots in the body. When the

crown is in this position let it fall freely on

to the body. Check that the crown can be

moved slightly from side, to side.

2. Cap to crown

Place cap centrally on the top of crown

(enamel side up). Move sideways and

front to back to check the cap is properly

fitted.

3. Check for ignition

If a burner will not light then you need to check the crown and cap

positions.

The grill

Clean the area around the grill frequently using hot soapy water.

After use you can soak the pan for a few

minutes and then clean it using mild

abrasives or a soap filled pad such as

'Brillo'.

Clean the shelf using hot soapy water. Mild abrasives can be used if

necessary. If the grill shelf is removed it must be replaced the right way

up. The outer wires must be curved upwards.

24

Page 25

L Y R I C 5 0 G X

The top oven

Clean the oven and shelf frequently using hot soapy water. Mild

abrasives can be used if necessary. The heat in the oven will change

the colour of the metal plate on the shelf. You must not remove the solid

plate from the shelf. You can soak the shelf for a few minutes in hot

soapy water to make cleaning easier.

The main oven

The top, sides and back of your oven are coated in a special material

which helps to keep itself clean.

Follow these simple rules to maintain the appearance of the special

finish.

Do not overfill dishes or they will boil

over.

Do not put dishes too high in the

oven. If you do they may stick to the

oven roof.

Care and cleaning

Cover your roasting tins with foil.

This will prevent fat splashing.

Use a roasting tin which is just large

enough for the meat and potatoes.

This will help to reduce fat

splashing.

Dry any vegetables that you are

going to roast. If they are wet there

will be more fat splashing.

6

Follow the oven cleaning cycle

regularly.

25

Page 26

Oven cleaning cycle

C

Please note: The oven cleaning cycle can only be used in the main

oven.

You need to follow the cycle to keep the inside of the main oven in

good condition. The type of cooking you do will affect how often you

are and cleaning

need to follow the cycle.

If you do a lot of roasting and very little other baking you should

follow the cleaning cycle once a week. If you do very little roasting you

will only need to follow the cleaning cycle every 2-3 weeks.

To carry out a cleaning cycle:

1. Remove the oven shelves.

2. Set the oven to mark 5 for at

least 30 minutes.

3. Turn the temperature up to

mark 7 for 2 hours or until the

oven is presentably clean.

Some staining will remain.

L Y R I C 5 0 G X

Do not use any cleaning agents

or scrapers on the inside of the

oven. Do not wash the special

finish.

General

Clean the base of the oven, the oven shelves and the oven door while

they are still slightly warm. This way you can easily remove any

splashes and spills. Wipe the base with a cloth that has been wrung

out in hot soapy water. You may use mild abrasives.

26

Page 27

L Y R I C 5 0 G X

Cleaning between the outer and inner glass

doors

You can remove the glass from both oven doors if you need to.

Note: For top oven door it is important not to open the door when the

glass is removed because the door is lighter and it will spring shut.

To remove the outer glass

1 Open the oven door so you can get at the two cross head screws on

the top of the oven door.

Note: Open top oven door slightly to access screws.

2 Loosen these two screws using a pozidrive screwdriver .

3 You should hold the door glass securely in place with one hand,

whilst removing the screws completely, with the other hand. If you do

not do this, the door glass could fall forward.

4 Using both hands, gently tilt the top of the door glass towards you.

Lift it slightly to disengage the locators at the bottom of the door.

Care and cleaning

5 Clean the outer and inner glass using hot soapy water and mild

abrasives such as 'Jif'. DO NOT try to clean the aluminium foil which

is inside the door. The foil is there to help keep the door cool, if it is

damaged it will not work.

6 Replace the glass by holding it in both hands and gently placing the

locators into the holes of the brackets at the bottom of the door. Push

the top of the glass towards the oven door, and make sure the screw

location holes line up.

7 Hold the glass in place with one hand and replace the cross head

screws into the location holes, with the other hand. Give the screws

one turn to make sure the glass is held in place.

8 Tighten the screws using a pozidrive screwdriver. Close the door.

27

Page 28

I

t

ll

ti

on

a

a

ns

L Y R I C 5 0 G X

Installing the cooker

For your safety

This cooker must be installed and serviced by a competent

person as stated in the Gas Safety (Installation & Use)

regulations current editions.

It is important that the cooker is suitable for your gas supply.

Your installer should check the data badge.

Ensure that a stability bracket is fitted.

Location

For your safety

The use of a gas cooking appliance results in the production

of heat and moisture in the room in which it is installed.

Ensure that the kitchen is well ventilated: keep natural

ventilation holes open or install a mechanical ventilation

device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for

additional ventilation, for example opening of a window, or

more effective ventilation, for example increasing the level of

mechanical ventilation where present.

28

Page 29

L Y R I C 5 0 G X

Positioning

The diagram shows how close to the cooker cupboards, shelves,

curtains and so on can be fitted. Refer to the diagram and carefully read

the instructions to make sure your cooker is fitted safely. If you are in

doubt your installer will give you advice.

l

Do not fit any materials which may catch fire for example wood or

curtains behind the cooker.

l

Base units which are higher than the hotplate must be 100mm away.

l

We recommend that cabinets fitted next to or above the cooker meet

British Standards. Your installer will give you advice if you are not

sure.

Installation

All dimensions in mm

Cooker dimensions

Height to hotplate: 902mm - 920mm

(adjusted by four screw feet)

Width: 498mm

Depth: 603mm (to front of door panel)

29

Page 30

General information

G

For your safety

Do not block any of the cooker vents.

Never line any part of the cooker with aluminium foil.

eneral information

Do not let items which can catch fire or electric mains leads

such as kettle flexes trail over any part of the cooker.

Moving your cooker

You may damage some soft or badly fitted floor coverings when you

move the cooker. The floor covering under the cooker should be

securely fixed so it does not ruck up when you move the cooker across

it. Alternatively you could remove the floor covering.

To move the cooker open the grill door. Raise the cooker off its front

feet by lifting from inside the grill. Pull the cooker forward. When you

replace the cooker push it back to the stop and make sure there is the

same gap at each rear corner.

The battery

L Y R I C 5 0 G X

The battery for the ignition will

usually last for many months. If the

ignition system doesn't work you

probably need to replace the

battery.

The battery is at the base of the

cooker on the left-hand side of the

front.

When you need to replace the

battery, open the main oven door,

lift up the battery holder lid and

replace the battery as shown in the

diagram. The battery you need is

AA size.

When you fit the new battery, make sure the positive end (marked with a

+ sign) is next to the (+) sign on the battery holder. Close the lid of the

battery holder.

You can light the burners with a match until you have time to change

the battery.

30

Page 31

L Y R I C 5 0 G X

Reversing the main oven door

You can turn the oven door so that it opens on the other side. Your

supplier can arrange this.

General information

31

Page 32

What is wrong and why?

We strongly recommend that you carry out the following checks on your

cooker before calling a Service Engineer.

Problem

The oven, grill or hotplate will not light.

Check

l

If you cannot hear any sparking or if the sparking is slow when you

press the ignition button it may not be strong enough to light the

What is wrong and why?

cooker. You will probably need to replace the battery. For

instructions on how to do this see page 30. You can light the

burners with a match until you have time to change the battery.

l

Check that there is not a problem with your gas supply. You can do

this by making sure that other gas appliances such as your central

heating or gas fire are working.

l

If only the hotplate burners will not light, make sure that the burner

parts have been replaced correctly. See instructions on page 24.

Problem

Food is cooking too quickly or too slowly.

Check

l

Check that you are using the recommended gas marks and shelf

positions. See pages 15 - 20. Be prepared to adjust the gas mark

up or down to achieve the results you want.

Problem

The ovens are not cooking evenly.

Check

l

Check that the cooker is installed properly and is level.

l

Check that you are using the recommended temperatures and shelf

positions.

l

If you are using a tin or tray which is larger than the one we

recommend, be prepared to turn it round during cooking.

l

If you are cooking a large item be prepared to turn it round during

cooking.

l

To suit your own tastes you may prefer to turn some foods round

when cooking in the top oven.

Problem

Having difficulty cleaning any part of the cooker.

Check

l

Check that you are following the instructions for care and cleaning

(see page 23).

L Y R I C 5 0 G X

32

Page 33

L Y R I C 5 0 G X

Servicing

For your safety

Maintenance work must only be done by a competent person. Do

not try to repair the cooker yourself. This could be dangerous. It

is dangerous to alter or modify the product in any way.

We recommend that your cooker has an annual gas safety

check carried out by our approved service organisation.

Before you call a service engineer check through the 'What is wrong

and why?' information on page 32. If you still feel there is a problem you

should contact Parkinson Cowan on 08705 929929. Your call will be

routed to the Service Centre covering your postcode area.

Parkinson Cowan will arrange for the cooker to be serviced. Customers

in Ireland should telephone (10) 4565666.

You can get service and spares from Parkinson Cowan. If you don't

use manufacturers original spares the normal product approval of the

cooker may not be valid.

When you report a problem try to describe the nature of the fault.

Always give your cookers full name and serial number which you can

see when the door is opened.

Make a note of this information in this space:

Servicing

Name:

Serial Number:

The Gas Consumers' Council

The Gas Consumers' Council (GCC) is an independent organisation

which protects the interests of gas users. If you need advice, you will

find the telephone number in your local telephone directory under Gas.

33

Page 34

INSTALLATION INSTRUCTIONS

Serial number on

front frame. Data

badge on top rear

of panel

For your safety

Natural Gas and L.P. Gas versions of this appliance are available.

Check that this model is suitable for the type of supply available.

In the interest of safety this appliance must be installed and/or

serviced by a competent person, as stated in the Gas Safety

(Installation and Use) Regulations Current Editions.

34

Page 35

TECHNICAL DATA

DIMENSIONS

Overall 1462mm (nominal) 498mm 600mm

Height to hotplate 907mm nominal -

Space for fixing at hotplate level 2mm minimum 600mm

Space for fixing above hotplate level 100mm each side

Minimum space above grill 500mm

Minimum distance from rear wall 20mm

Weight of appliance 64.0kg

Height Width Depth

(from elbow

to front of door panel)

see important note 'Location of the Appliance' (see Page 37).

clearance Nominal

of appliance

CONNECTIONS

Gas Rear left hand side of appliance at hotplate level

Electric None

Rc½ (½" B.S.P. female)

IGNITION

Spark Generator APCO 7BG6893

Battery 1.5 volt AA size

GRILL

Heat Input 3.3kW (11263 Btu/h) 3.55kW (255g/h)

Injector Marking

Natural Gas L.P. Gas

138 95

35

Page 36

HOTPLATE

Natural Gas

Heat Input 1.0kW 2.0kW 2.0kW 2.8kW

Injector Marking 079 104 104 130

Heat Input 1.0kW 2.0kW 2.0kW 2.7kW

Injector Marking 51 72 72 83

MAIN OVEN

Heat Input 2.4kW (8189 Btu/h) 2.4kW (172.4g/h)

Injector Marking 108 78

Flame Supervision Device Diamond 'H' GSD 100/28 Diamond 'H' GSD 100-30

Thermostat Diamond 'H' 1100126/B2 Diamond 'H' 1100127/B2

Thermostat By-pass Marking 69 78

R.H.F. R.H.R. L.H.R. L.H.F

(3412 Btu/h) (6824 Btu/h) (6824 Btu/h) (9554 Btu/h)

L. P. Gas

R.H.F. R.H.R. L.H.R. L.H.F.

(71.8g/h) (143.7 g/h) (143.7 g/h) (194 g/h)

Natural Gas L P. Gas

TOP OVEN Natural Gas L.P.Gas

Heat Input 1.8kW (6142 Btu/h) 2.4kW (172.4 g/h)

Injector Marking 095 78

Flame Supervision Device Diamond 'H' GSD 100/44 Diamond 'H' GSD 100/46

Thermostat Diamond 'H' GSD 1100-112/B2 Diamond 'H' GSD 1100-99/B2

Thermostat By-Pass 73 79

GENERAL

Ignition H.T. Spark H.T. Spark

Spark Gap 3-4mm 3-4mm

IMPORTANT - SAFETY REQUIREMENTS

This appliance must be installed in accordance with the Gas Safety (Installation and Use) Regulations

Current Editions. Detailed recommendations are contained in the following British Standard Codes of Practice

- BS.6172, BS.5440: Part 2 and BS.6891. All British Standards must be 'Current Editions'.

PROVISION FOR VENTILATION

This appliance is not connected to a combustion products evacuation device. It shall be installed and

connected in accordance with the current installation regulations. Particular attention shall be given to the

relevant requirements regarding ventilation.

The room containing the appliance should have an air supply in accordance with BS. 5440: Part 2 Current

Edition. All rooms require an openable window or equivalent and some rooms will require a permanent vent

as well. For room volumes up to 5m³ an air vent of 100cm² is required: for room volumes between 5m³ and

10m³ an air vent of 50cm² is required. If the room has a door that opens directly to the outside, no air vent is

required. For room volumes that exceed 11m³ no air vent is required. If there are other fuel burning

appliances in the same room, BS.5440: Part 2 Current Edition should be consulted to determine the requisite

air vent requirements.

Prolonged intensive use of the appliance may call for additional ventilation, for example opening a window, or

more effective ventilation, for example increasing the level of mechanical ventilation where present.

36

Page 37

LOCATION OF APPLIANCE

This appliance must not be installed in a bed-sitting room of volume less than 20m³ or in a bathroom or

shower room. It is essential that the appliance is positioned as stated below. The appliance must be a

minimum of 20mm from the rear wall (note that this dimension is provided by the inlet elbow). Shelves, wall

cabinets and cooker hoods must not be fitted closer than 500mm to the top of the grill canopy or within

100mm of the sides of the grill. Curtains must not be fitted immediately behind the appliance or within 200mm

of the sides of the grill. If fitted next to or between two base units a minimum space of 1mm must be left

between the units and the sides of the appliance. The hotplate must be set to a minimum of 7mm above the

adjacent units (note that the levelling feet fitted to the appliance will achieve a nominal height to hotplate level

of 907mm -5+13mm). Base units not meeting the above conditions must be a minimum of 100mm away from

the hotplate. L.P.G. cookers MUST NOT be installed below ground level, i.e in a basement, or aboard any

boat, yacht or other vessel.

INSTALLATION

1. PARTS REQUIRED

The loose hotplate parts are packed in the polystyrene fitment on the top

of the hotplate. The grill pan, grill pan handle, fixing screws and

splashplate fixing screws can be found in the furniture pack which is

located in the bottom compartment. The grill pan requires assembly

before use (see Fig. 1).

2. GRILL ASSEMBLY

The two splashplate screws should be screwed into the back of the

appliance about halfway in (see Fig. 1a.) Engage the keyhole slots in the

splashback behind the two screws taking care not to trap the H.T. wire

(see Fig. 1b).

Tighten 6 off splashplate screws (see Fig.1c).

Connect the grill supply union at the back of the appliance and pull the

grill H.T. lead through the opening in the splashplate and connect on to

the spark generator.

Fig.1

Grill Pan Handle Assembly:-

Assemble grill pan (see Fig.1)

and secure four screws and

washers provided.

Fig.1a

Fig.1c

Fig.1b

37

Page 38

3. LEVELLING THE APPLIANCE

Adjustable levelling feet at the front and rear are provided on the base of the appliance.

Adjustment to suit floor conditions is obtained by rotating in or out the hexagonal feet from the underside of

the appliance.

A spirit level should be placed on one of the oven shelves to confirm that the appliance is correctly levelled.

4. FITTING THE STABILITY BRACKET

It is recommended that if the appliance is to be installed with a flexible supply pipe a stability bracket

(SK.4729.A) is fitted and is available from your supplier (see Important Safety Requirements, Page 36).

These instructions should be read in conjunction with the leaflet packed with the stability bracket.

1. Place the appliance in its intended position and level appliance.

2. Mark off 250mm from the left hand side of the appliance as shown in (Dimension 'A'), Fig 2a. This is the

centre line of the fixing bracket.

3. Draw a line 100mm from the front edge of the levelling feet (see Fig 2a) and remove appliance from its

position. Mark off dimension 'B' (see Fig 2a) back from this line on the centre line of the bracket to

locate the front edge of the lower bracket. Fix lower bracket (with two fixing holes) to the floor then

measure the height from floor level to engagement edge on back of appliance, dimension 'C' of Fig. 2b.

4. Assemble upper bracket to lower bracket so that underside of bracket is dimension 'C' +3mm above

floor level.

Reposition appliance and check that top bracket engages into appliance back as shown in Fig. 2b.

38

Page 39

5. CONNECTING TO GAS

This appliance is designed to be installed with an

appliance flexible connection only. Supply piping should

not be less than R³/8 (³/8" B.S.P.). Connection is made

to the Rc½ (½" B.S.P.) female threaded entry pipe

located just below the hotplate level on the rear left hand

side of the appliance.

Check for gas soundness after connecting the gas

supply.

The gas bayonet connector must be fitted in the shaded

area indicated in Fig. 3. Take into account that it must be

possible to pull the appliance forward sufficiently. The

hose must not get caught on the stability bracket.

Fig.3

All dimensions in mm

IMPORTANT: FLEXIBLE TUBING USED MUST COMPLY WITH BS. 669 CURRENT EDITION. L.P.G.

FLEXIBLE CONNECTIONS MUST BE OF A TYPE SUITABLE FOR L.P.G. AND CAPABLE OF

OPERATION UP TO 50MBAR AND TO CARRY A RED STRIPE, BAND OR LABEL.

NOTE: ONLY LIQUID SEALANTS CAN BE USED IN THREADED GAS CONNECTIONS. DO NOT USE

P.T.F.E. TAPE.

6. FITTING THE BATTERY

1. The battery holder is located on the left hand side of the

front plinth.

2. To gain access to the battery, open the main oven door

and lift up the battery holder lid.

3. Fit the new battery ensuring positive (+) terminal is next

to the (+) sign on the battery holder. See Fig.4.

4. Close the lid of the battery holder.

Fig.4

7. PRESSURE TESTING

1. The oven injector is used as the pressure test point.

Remove the oven furniture. Remove oven burner box retaining clips (one spring clip from each side)

and remove box front cover. Replace one clip back into the right hand side of the burner box.

Remove oven burner by removing the spring clip from the right hand side of the oven burner and slide

the burner off the injector whilst easing it towards the front of the appliance, taking care not to strain the

F.S.D. phial.

2. Connect the pressure gauge to the oven injector.

3. Check the supply pressure by turning the thermostat on and one hotplate tap full on and light the

appropriate burner.

The pressure should be either:

(i) For Natural Gas 20mbar

(ii) For LP.Gas The pressure must be set to 28 mbar for use on butane or 37 mbar for use

4. Turn off the taps, disconnect the pressure gauge and replace oven burner and cover, ensuring that the

F.S.D. phial is correctly located into the bracket on the burner.

5. Check operation of oven.

on propane.

39

Page 40

8. CHECKING THE GRILL

Remove the protective film from the grill pan shelf. Fit the grill pan shelf to the splashplate.

Place the grill pan containing the grid on to the grill pan shelf. Light the grill burner by turning the tap to its'

full on position and pressing the ignition button. As soon as the burner is lit the button can be released.

9. CHECKING THE HOTPLATE

Fit the burner crowns, caps and pan supports ensuring that they are correctly seated. Check each of the

hotplate burners in turn by turning each hotplate tap to its full on position and pressing the ignition button. As

soon as the burner is lit the button can be released.

10. CHECKING THE MAIN OVEN

1. Turn the oven thermostat knob to Mk 9 and press the ignition button. As soon as the burner is alight the

button can be released.

2. There should now be a low gas rate to the burner, which is the F.S.D. by-pass rate.

3. When the F.S.D. phial has heated up it opens the F.S.D. valve which allows the main gas supply to the

oven burner.

4. Set the oven control to Mk 2, close the oven door and check that after about 10 minutes the flame size

has reduced.

5. Turn off the control and check that the oven flames go out.

11. CHECKING THE TOP OVEN

1. Turn the top oven thermostat knob to mark 8. Press ignition button. As soon as the burner is alight the

button can be released.

2. When the oven burner lights up there should be a low gas rate at first to the oven burner which is the

F.S.D. by-pass rate.

3. When the F.S.D. phial has heated up it opens the F.S.D. valve and the main gas stream flows to the

burner.

4. Set the oven control to mark 2, close the oven door and check that after approximately 10 minutes the

flame size has reduced.

5. Turn off the control knob and check that the oven flame goes out.

GENERAL NOTE

Instruct the user on how to use the appliance and its ignition system.

Refer the user to the wording in the inside cover which gives advice on the safe operation of the appliance.

40

Page 41

N O T E S

41

Page 42

N O T E S

LYRIC 50GX - 311206011

42

Page 43

Contents Check List

The loose contents of this pack include:-

No. OFF DESCRIPTION

1 Top Oven Shelf with Baffle

2 Oven Shelves (Main Oven)

1 P.C. Guarantee Card

1 Hotplate operation card

1 Servery Shelf (large)

1 Twin handled grill pan (large)

1 Grill pan trivet (large)

1 Servery Runner R/H

1 Servery Runner L/H

1 Yellow screw pack

4 Burner crowns

4 Burner caps

2 Pan supports

1 Battery

Page 44

This handbook was correct on the date it was printed. But this handbook will be

replaced if the specification or appearance change as the cooker is improved.

Description

Burner Cap - Rapid

Burner Cap - Normal

Burner Cap - Simmer

Burner Crown - Rapid - N.G.

Burner Crown - Rapid - L.P.G.

Burner Crown - Normal

Burner Crown - Simmer

Pan Support

NOTE :

Failure to use manufacturers original spares could negate normal BSI approval of the product

No.

Off

1

2

1

1

1

2

1

2

Maker's Part

Number

354000610

354000609

354000608

359039100

337000302

337000402

337000502

359033202

Parkinson Cowan

Customer Care

P.O. Box 47, Newbury, Berkshire RG14 5XL

Telephone: 01635 525542

Fax: 01635 42970

Drawing No. 311206011

Page 45

INSTALLATION AND SERVICING INSTRUCTIONS

NATURAL GAS AND L.P. GAS VERSIONS OF THIS APPLIANCE ARE AVAILABLE.

CHECK THAT THIS MODEL IS SUITABLE FOR THE TYPE OF SUPPLY

AVAILABLE.

IN THE INTEREST OF SAFETY THIS APPLIANCE MUST BE INSTALLED AND/OR

SERVICED BY A COMPETENT PERSON AS STATED IN THE GAS SAFETY

(INSTALLATION AND USE) REGULATIONS CURRENT EDITIONS.

Serial number on

front frame. Data badge on

top rear of panel.

LEAVE THESE INSTRUCTIONS WITH THE USER.

1

Page 46

CONTENTS

INSTALLATION INSTRUCTIONS

page

SERVICING INSTRUCTIONS

page

Technical Data 2 Fault Finding 11

Safety Requirements 3 Servicing Notes 12

Provision for Ventilation 3 Spare Parts List 17

Location of Appliance 4

Installation 4

Testing 6

TECHNICAL DATA

DIMENSIONS

Overall 1462mm (nominal) 500mm (nominal) 600mm

Height to hotplate 907mm nominal -

Space for fixing at hotplate level 2mm minimum 600mm

Space for fixing above hotplate level 100mm each side

Minimum space above grill 500mm

Minimum distance from rear wall 20mm

Weight of appliance 64 kg

Height Width Depth

(from elbow

to front of door panel)

see important note 'Location of the Appliance' (see Page 4).

clearance Nominal

of appliance

CONNECTIONS

Gas Rear left hand side of appliance at hotplate level

Electric None

Rc½ (½" B.S.P. female)

IGNITION

Spark Generator Turnright GL507/APCO 7BG 6893

Battery 1.5 volt AA size

GRILL

Heat Input 3.3kW (11263 Btu/h) 3.55kW (255g/h)

Injector Marking 138 95

Cone Height Not applicable as flame burns on surface of gauze

Natural Gas L.P. Gas

2

Page 47

HOTPLATE

R.H.F. R.H.R. L.H.R. L.H.F

Heat Input 1.0kW 2.0kW 2.0kW 2.8kW

(3412 Btu/h) (6824 Btu/h) (6824 Btu/h) (9554 Btu/h)

Injector Marking 079 104 104 130

Natural Gas

Heat Input 1.0kW 2.0kW 2.0kW 2.7kW

Injector Marking 51 72 72 83

MAIN OVEN

Heat Input 2.4kW (8189 Btu/h) 2.4kW (172.4g/h)

Injector Marking 108 78

Flame Supervision Device Diamond 'H' GSD 100/28 Diamond 'H' GSD 100-30

Thermostat Diamond 'H' 1100-94/B2 Diamond 'H' 1100-99/B2

Thermostat By-pass Marking 69 78

TOP OVEN

Heat Input 1.8kW (6142 Btu/h) 2.4kW (172.4 g/h)

Injector Marking 095 78

Flame Supervision Device Diamond 'H' GSD 100/44 Diamond 'H' GSD 100/46

Thermostat Diamond 'H' GSD 1100-112/B2 Diamond 'H' GSD 1100-99/B2

Thermostat By-Pass 73 79

R.H.F. R.H.R. L.H.R. L.H.F.

(71.8g/h) (143.7 g/h) (143.7 g/h) (194 g/h)

Natural Gas L P. Gas

Natural Gas L.P.Gas

L. P. Gas

GENERAL

Ignition H.T. Spark H.T. Spark

Spark Gap 3-4mm 3-4mm

IMPORTANT - SAFETY REQUIREMENTS

This appliance must be installed in accordance with the Gas Safety (Installation and Use) Regulations

Current Editions. Detailed recommendations are contained in the following British Standard Codes of

Practice - BS.6172, BS.5440: Part 2 and BS.6891. All British Standards must be 'Current Editions'.

PROVISION FOR VENTILATION

This appliance is not connected to a combustion products evacuation device. It shall be installed and

connected in accordance with the current installation regulations. Particular attention shall be given to the

relevant requirements regarding ventilation.

The room containing the appliance should have an air supply in accordance with BS. 5440: Part 2 Current

Edition. All rooms require an openable window or equivalent and some rooms will require a permanent

vent as well. For room volumes up to 5m³ an air vent of 100cm² is required: for room volumes between

5m³ and 10m³ an air vent of 50cm² is required. If the room has a door that opens directly to the outside,

no air vent is required. For room volumes that exceed 11m³ no air vent is required. If there are other fuel

burning appliances in the same room, BS.5440: Part 2 Current Edition should be consulted to determine

the requisite air vent requirements.

Prolonged intensive use of the appliance may call for additional ventilation, for example opening a window,

or more effective ventilation, for example increasing the level of mechanical ventilation where present.

3

Page 48

LOCATION OF APPLIANCE

This appliance must not be installed in a bed-sitting room of volume less than 20m³ or in a bathroom or

shower room. It is essential that the appliance is positioned as stated below. The appliance must be a

minimum of 20mm from the rear wall (note that this dimension is provided by the inlet elbow). Shelves, wall

cabinets and cooker hoods must not be fitted closer that 500mm to the top of the grill canopy or within

100mm of the sides of the grill. Curtains must not be fitted immediately behind the appliance or within

200mm of the sides of the grill. If fitted next to or between two base units a minimum space of 1mm must

be left between the units and the sides of the appliance. The hotplate must be set to a minimum of 7mm

above the adjacent units (note that the levelling feet fitted to the appliance will achieve a nominal height to

hotplate level of 907mm -5+13mm). Base units not meeting the above conditions must be a minimum of

100mm away from the hotplate. L.P.G. cookers MUST NOT be installed below ground level, i.e. in a

basement.

INSTALLATION

1. PARTS REQUIRED

The loose hotplate parts are packed in the polystyrene fitment on the

top of the hotplate. The grill pan, grill pan handle, fixing screws and

splashplate fixing screws can be found in the oven pack which is

located in the oven compartment. The grill pan requires assembly

before use (see Fig. 1).

2. GRILL ASSEMBLY

The two splashplate screws should be screwed into the back of the

appliance about halfway in (see Fig. 1a.) Engage the keyhole slots in

the splashback behind the two screws taking care not to trap the H.T.

wire (see Fig. 1b).

Fig.1

Tighten 6 off splashplate screws (see Fig.1c).

Connect the grill supply union at the back of the appliance and pull the

grill H.T. lead through the opening in the splashplate and connect on

to the spark generator.

Fig.1a

Fig.1b

4

Grill Pan Handle Assembly:-

Assemble grill pan (see Fig.1)

and secure four screws and

washers provided.

Fig.1c

Page 49

3. LEVELLING THE APPLIANCE

Adjustable levelling feet at the front and rear are provided on the base of the appliance.

Adjustment to suit floor conditions is obtained by rotating in or out the hexagonal feet from the underside of

the appliance.

A spirit level should be placed on one of the oven shelves to confirm that the appliance is correctly levelled.

4. FITTING THE STABILITY BRACKET

It is recommended that if the appliance is to be installed with a flexible supply pipe a stability bracket

(SK.4729.A) is fitted and is available from your supplier (see Important Safety Requirements, Page 3).

These instructions should be read in conjunction with the leaflet packed with the stability bracket.

1. Place the appliance in its intended position and level appliance.

2. Mark off 250mm from the left hand side of the appliance as shown in (Dimension 'A'), Fig 2a. This is

the centre line of the fixing bracket.

3. Draw a line 100mm from the front edge of the levelling feet (see Fig 2a) and remove appliance from

its position. Mark off dimension 'B' (see Fig 2a) back from this line on the centre line of the bracket to

locate the front edge of the lower bracket. Fix lower bracket (with two fixing holes) to the floor then

measure the height from floor level to engagement edge on back of appliance, dimension 'C' of Fig.

2b.

4. Assemble upper bracket to lower bracket so that underside of bracket is dimension 'C' +3mm above

floor level.

Reposition appliance and check that top bracket engages into appliance back as shown in Fig. 2b.

Fig.2a

All dimensions in mm

Fig.2b

5

Page 50

5. CONNECTING TO GAS

This appliance is designed to be installed with an

appliance flexible connection only. Supply piping

should not be less than R³

made to the Rc½ (½" B.S.P.) female threaded entry

pipe located just below the hotplate level on the rear

left hand side of the appliance.

Check for gas soundness after connecting the gas

supply.

The gas bayonet connector must be fitted in the

shaded area indicated in Fig. 3. Take into account that

it must be possible to pull the appliance forward

sufficiently. The hose must not get caught on the

stability bracket.

IMPORTANT: FLEXIBLE TUBING USED MUST COMPLY WITH BS. 669 CURRENT EDITION. L.P.G.

FLEXIBLE CONNECTIONS MUST BE OF A TYPE SUITABLE FOR L.P.G. AND CAPABLE OF

OPERATION UP TO 50mbar AND TO CARRY A RED STRIPE, BAND OR LABEL.

NOTE: ONLY LIQUID SEALANTS CAN BE USED IN THREADED GAS CONNECTIONS. DO NOT USE

P.T.F.E. TAPE.

/8

(³/8" B.S.P.). Connection is

Fig.3

All dimensions in mm

6. FITTING THE BATTERY

1. The battery holder is located on the left hand

side of the front plinth and can be viewed

through a slot between the oven and the plinth.

2. To gain access to the battery, open the main

oven door, rotate the battery holder clockwise

(90°).

3. Fit the new battery ensuring positive (+) terminal

is next to the (+) sign on the battery holder. See

Fig.4.

4. Return the battery to its original position by rotating it anti-clockwise.

Fig.4

7. PRESSURE TESTING

1. The oven injector is used as the pressure test point.

Remove the oven furniture. Remove oven burner box retaining clips (one spring clip from each side)

and remove box front cover. Replace one clip back into the right hand side of the burner box.

Remove oven burner by removing the spring clip from the right hand side of the oven burner and

slide the burner off the injector whilst easing it towards the front of the appliance, taking care not to

strain the F.S.D. phial.

2. Connect the pressure gauge to the oven injector.

3. Check the supply pressure by turning the thermostat on and one hotplate tap full on and light the

appropriate burner.

The pressure should be either:

(i) For Natural Gas 20mbar

(ii) For LP.Gas The pressure must be set to 28 mbar for use on butane or 37 mbar for use

4. Turn off the taps, disconnect the pressure gauge and replace oven burner and cover, ensuring that

the F.S.D. phial is correctly located into the bracket on the burner.

5. Check operation of oven.

6

on propane.

Page 51

8. CHECKING THE GRILL

Remove the protective film from the grill pan shelf. Fit the grill pan shelf to the splashplate.

Place the grill pan containing the grid on to the grill pan shelf. Light the grill burner by turning the tap to its'

full on position and pressing the ignition button. As soon as the burner is lit the button can be released. If

there is a fault refer to Fault Finding Guide on Page 10.

9. CHECKING THE HOTPLATE

Fit the burner crowns, caps and pan supports ensuring that they are correctly seated. Check each of the

hotplate burners in turn by turning each hotplate tap to its full on position and pressing the ignition button.

As soon as the burner is lit the button can be released. If there is a fault refer to Fault Finding Guide on

Page 10.

10. CHECKING THE MAIN OVEN

1. Turn the oven thermostat knob to Mk 9 and press the ignition button. As soon as the burner is alight

the button can be released. If there is a fault refer to the Fault Finding Guide on Page 10.

2. There should now be a low gas rate to the burner, which is the F.S.D. by-pass rate.

3. When the F.S.D. phial has heated up it opens the F.S.D. valve which allows the main gas supply to

the oven burner.

4. Set the oven control to Mk 2, close the oven door and check that after about 10 minutes the flame

size has reduced.

5. Turn off the control and check that the oven flames go out. If there is a fault refer to the Fault Finding

Guide on Page 10.

11. CHECKING THE TOP OVEN

1. Turn the top oven thermostat knob to mark 8. Press ignition button. As soon as the burner is alight

the button can be released. If there is a fault refer to the Fault Finding Guide on Page 10.

2. When the oven burner lights up there should be a low gas rate at first to the oven burner which is the

F.S.D. by-pass rate.

3. When the F.S.D. phial has heated up it opens the F.S.D. valve and the main gas stream flows to the

burner.

4. Set the oven control to mark 2, close the oven door and check that after approximately 10 minutes

the flame size has reduced.

5. Turn off the control knob and check that the oven flame goes out.

GENERAL NOTE

Instruct the user on how to use the appliance and its ignition system.

Refer the user to the wording in the inside cover of the Users Instructions which gives advice on the safe

operation of the appliance.

7

Page 52

FUNCTIONAL FLOW DIAGRAM

COLOUR CODES

bblue

br brown

w white

8

Page 53

ILLUSTRATED WIRING DIAGRAM

KEY TO PARTS

1. Hotplate Electrode

2. Grill Electrode

3. Ignition Switch

4. Spark Generator

5. Oven Electrode

6. Battery Box

COLOUR CODES

b blue

br brown

w white

9

Page 54

10

Page 55

Page 56

C. REMOVAL OF SIDE PANEL

1. Pull appliance forward and disconnect from gas

supply.

2. Remove fascia panel (see Section A).

3. With a fine screwdriver or penknife acting on the

rear flange gently prise off the side trim at

positions, A.B. and C. (see Fig.9).

4. Remove three screws and the edge clips.

5. Remove the two screws at the rear of the side

panel and lift off the side panel.

6. Reassemble in reverse order ensuring that:A) The side panel bottom flange is located over

the plinth tags.

B) The side trim is located at the front first and

then pushed into place at the rear.

Fig.9

D. REMOVAL OF EITHER MAIN OR TOP OVEN THERMOSTAT

1. Pull appliance forward and disconnect from the gas supply.

2. Remove fascia panel, hotplate tray and right hand side panel (see Sections A, B and C).

3. Remove oven furniture from main oven. Note the top oven roof is secured by two screws central at the

front of the oven. Note position of roof on rear shelf before removing screws and roof. Unclip

thermostat phial and feed the phial through the hole in the oven.

4. Disconnect the oven supply pipe from the rear of

the thermostat body.

5. Remove two screws and saddle bracket securing

thermostat to the gas rail and remove thermostat

assembly.

6. Reassemble in reverse order ensuring that:a) A new seal is correctly fitted between the

thermostat and the gas rail.

b) The thermostat phial is securely fitted and

central in the oven clips.

7. Check for gas leaks before replacing the hotplate

and fascia panel.

E. REMOVAL OF GRILL TAP/

HOTPLATE TAP

1. Remove fascia panel and hotplate tray (see

Sections A and B).

2. Disconnect the supply pipe from the rear of the

tap (see Fig. 10).

3. Remove the two screws securing the tap to the gas

rail and remove saddle bracket (see Fig. 11).

4. Reassemble in reverse order ensuring that a new

seal and the saddle bracket are correctly fitted.

5. Check for gas leaks before replacing the hotplate

and fascia panel.

NOTE: Gas taps are colour coded.

12

Fig.10

Page 57

F. REMOVAL OF MAIN OVEN BURNER/

FLAME SUPERVISION DEVICE

1. Pull appliance forward and disconnect from gas

supply.

2. Remove the oven furniture.

3. Remove the oven burner box retaining clips,

(one spring clip from each side) and remove the

box front cover.

4. Replace spring clips to secure box burner.

5. From inside the oven aperture disconnect supply

pipe from the flame supervision device (see

Fig.12).

6. Remove the spring clips.

7. Remove the burner box assembly from within the oven disconnecting the H.T. lead from the oven

electrode. This is best done by moving the burner

assembly as far left as possible before lifting the side

of the assembly clear of the aperture.

8. Reassemble in reverse order ensuring that F.S.D.

phial is correctly positioned.

9. Check for gas leaks.

G. REMOVAL OF TOP OVEN BURNER/

FLAME SUPERVISION DEVICE

1. Pull appliance forward and disconnect from gas

supply and remove battery.

2. Remove fascia panel and right hand side panel (see

Section A and C).

3. From right hand side of the appliance disconnect top

union from F.S.D. (see Fig.13).

4. Remove oven furniture.

5. Remove the oven burner box retaining clip from each side of the box front cover.

6. From inside the oven carefully remove box assembly so that it drops through the oven aperture and

rests on the main cavity. Ease oven burner and F.S.D. assembly outwards from the right hand side of

the appliance.

7. Unclip F.S.D. phial from bracket.

8. Disconnect F.S.D. from oven pipe.

9. Reassemble in reverse order. Ensure that the tag on the thermostat phial cover plate is correctly

located into the relevant burner box hole.

10. Check for gas leaks before replacing the side panel.

Fig.13

H. REMOVAL OF MAIN OVEN DOOR

1. Remove top oven door (see Section I).

2. Open oven door and support by handle and remove

the top securing nut (see Fig.14).

3. Lift off and pull away oven door from the bottom

locator.

4. Reassemble in reverse order.

Fig.14

13

Page 58

I. REMOVAL OF TOP OVEN DOOR

1. Open door fully.

2. Engage both hinge locking pins (see Fig.15).

3. To remove the door, clear the hinges by raising the door

slightly whilst pulling towards you.

4. Reassemble in reverse order.

J. REMOVAL OF OVEN DOOR HANDLE

1. Remove the two slotted head screws from top door

edge.

2. Gently pull outer glass and lift upwards out of bottom

locators.

3. Reassemble in reverse order ensuring bottom locators

are correctly positioned.

K. REMOVAL OF EITHER MAIN OR TOP

OVEN DOOR SEAL

Refer to instructions, Section 13 on page 8 (Remove

and replace oven door seal).

Take care to note the position of the seal before

removal. As a guide the break in the door seal is on the

hinged side of the door.

There is no clip on the Top Oven.

NOTE:

L. REMOVAL OF IGNITION SWITCH

1. Follow Sections J, items 1 and 2.

2. Then place the door on a flat surface and remove

four screws retaining the door handle (see Fig.16).

Reassemble in reverse order.

Fig.15

HINGE

LOCKING PIN

Fig.16

M. REMOVAL OF GRILL BURNER

1. Remove grill pan and shelf.

2. Remove grill canopy by unscrewing four screws on

the underside of the canopy.

3. Disconnect H.T. lead from grill electrode (rear left

of grill).

4. Support the burner and remove the two outer

screws securing the grill burner. Remove burner.

5. Reassemble in reverse order ensuring that burner

is correctly located.

N. REMOVAL OF IGNITION SWITCH

1. Remove fascia panel (see Section A).

2. Push in ignition switch tags from the rear of the

fascia and remove switch (see Fig.17).

3. Reassemble in reverse order.

14

Fig.17

Page 59

O. REMOVAL OF SPARK GENERATOR

1. Pull appliance forward and disconnect from the gas

supply.

2. Pull off all the connections from the spark

generator.

3. Remove the two screws and remove the generator.

4. Reassemble in reverse order. Rewire as wiring

diagram.

P. REMOVAL OF HOTPLATE

ELECTRODE

1. Remove hotplate tray (see Section B).

2. Disconnect H.T. lead from electrode.

3. Insert an electrical screwdriver down beneath the

underside of the burner body and the electrode

securing clip, push the screwdriver down to close

the clip and withdraw. Then remove the electrode

(see Fig.18).

4. Reassemble in reverse order ensuring electrode is

correctly positioned and is secure.

Fig.18

Q. REMOVAL OF OVEN BURNER ELECTRODE

1. Remove the oven furniture.

2. Remove oven burner box retaining clips (one spring clip from each side) and remove the box front

cover. Replace one clip back into the right hand side of the burner box..

3. From inside the oven remove the oven electrode fixing screw and pull off the H.T. wire. Take care that

the H.T. lead is retained, otherwise it may become inaccessible.

4 Reassemble in reverse order.

R. REMOVAL OF GRILL ELECTRODE

1. Remove grill pan and shelf.

2. Unscrew the electrode fixing screw and pull off H.T. wire.

3. Reassemble in reverse order.

15

Page 60

SPARE PARTS LIST

No.

Description

Burner Cap - Rapid

Burner Cap - Normal

Burner Cap - Simmer

Burner Crown - Rapid - N.G.

Burner Crown - Rapid - L.P.G.

Burner Crown - Normal

Burner Crown - Simmer

Pan Support

Failure to use manufacturers original spares could negate normal BSI approval of the

NOTE :

product

Off

1

2

1

1

1

2

1

2

Maker's Part

Number

354000610

354000609

354000608

359039100

337000302

337000402

337000502

359033202

P.O. BOX 47, NEWBURY, BERKSHIRE RG14 5XL

Drg. No. 311214210

16

Page 61

documentation manual, user maintenance, brochure, user reference, pdf manual

This file has been downloaded from:

User Manual and User Guide for many equipments like mobile phones, photo cameras, monther board, monitors, software, tv, dvd, and othes..

Manual users, user manuals, user guide manual, owners manual, instruction manual, manual owner, manual owner's, manual guide,

manual operation, operating manual, user's manual, operating instructions, manual operators, manual operator, manual product,

Loading...

Loading...