Parker Hydraulics PGM 300, PGP315, PGP 300, PGP330, PGM315 Service Manual

...

Service Manual HY09-SM300/US

Service Manual

PGP/PGM315, 330, 350, 365

Effective: April 15, 2002

Supersedes: July 1, 1998

PGP/PGM 300 Series

PGP/PGM 300 Series

Service Manual HY09-SM300/US

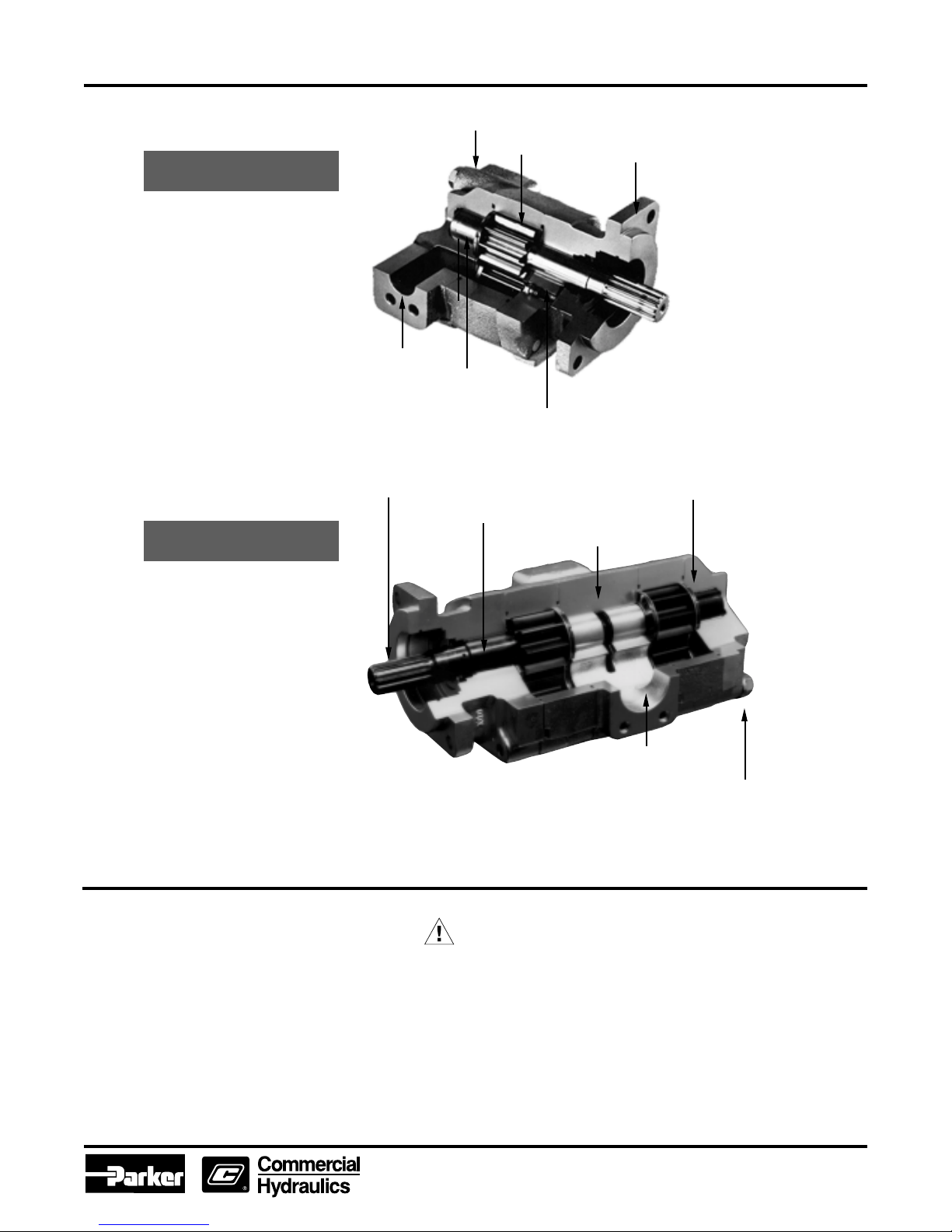

Single Pump

Split-flange or ODT

Ports

High Temperature

Cast Iron

Housings

Case Hardened Gears

Seals

Low-friction

Bushing Coating

SAE 2- or 4-Bolt

Mountings

Multiple Pump

One-piece Drive

Shaft & Gear

Long Shaft Journals Superior

Bearing Surface

Internal Passage Constantly

Lubricates Bushings

Balanced Thrust Plates

Minimize Friction and Leakage

Large Passages for

Better Pump Feed

Extended Studs

Available for Mounting

Support

Use Genuine Parker Replacement parts

Legal Notification

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users

having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due

to the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its

subsidiaries at any time without notice.

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed

by the provisions stated in the “Offer of Sale”.

© Copyright 2002, Parker Hannifin Corporation, All Rights Reserved.

WARNING

Offer of Sale

2

Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

315/330/350/365

Service Manual

General Instructions

These service instructions will familiarize you with

Parker's single and multiple pumps

• their component parts

• the relative position of each part

• proper methods for assembly or disassembly of

the units

To facilitate the repair of these units and before any

work is done, we suggest that you first read all of the

steps used in disassembly and assembly.

Dirt is the enemy of any hydraulic system. The first

requirement for good maintenance of hydraulic

equipment is cleanliness. MAKE SURE YOU

DISASSEMBLE AND ASSEMBLE YOUR

HYDRAULIC EQUIPMENT IN A CLEAN AREA.

PGP/PGM 300 Series

Service Manual HY09-SM300/US

The pictures show Model PGP365. Notes in the

text cover variations between this unit and the

other models.

It is important to airblast all parts and wipe them with

a clean, lintless cloth before assembly.

USE CAUTION IN GRIPPING ALL PARTS

IN THE VISE TO AVOID DAMAGING

MACHINED SURFACES.

A pump must be driven in the direction of rotation for

which it was built; otherwise, pressure will blow the

shaft seal. Check the exploded view and notes at right

for proper direction of rotation.

Parker's

Replacement Parts

Parker's replacement parts are of original equipment

standards. For assured quality of material and workmanship, and for compatibility in assembly, USE

ONLY GENUINE PARTS.

Check all replacement parts before installing them to

be certain that they were not damaged in shipment.

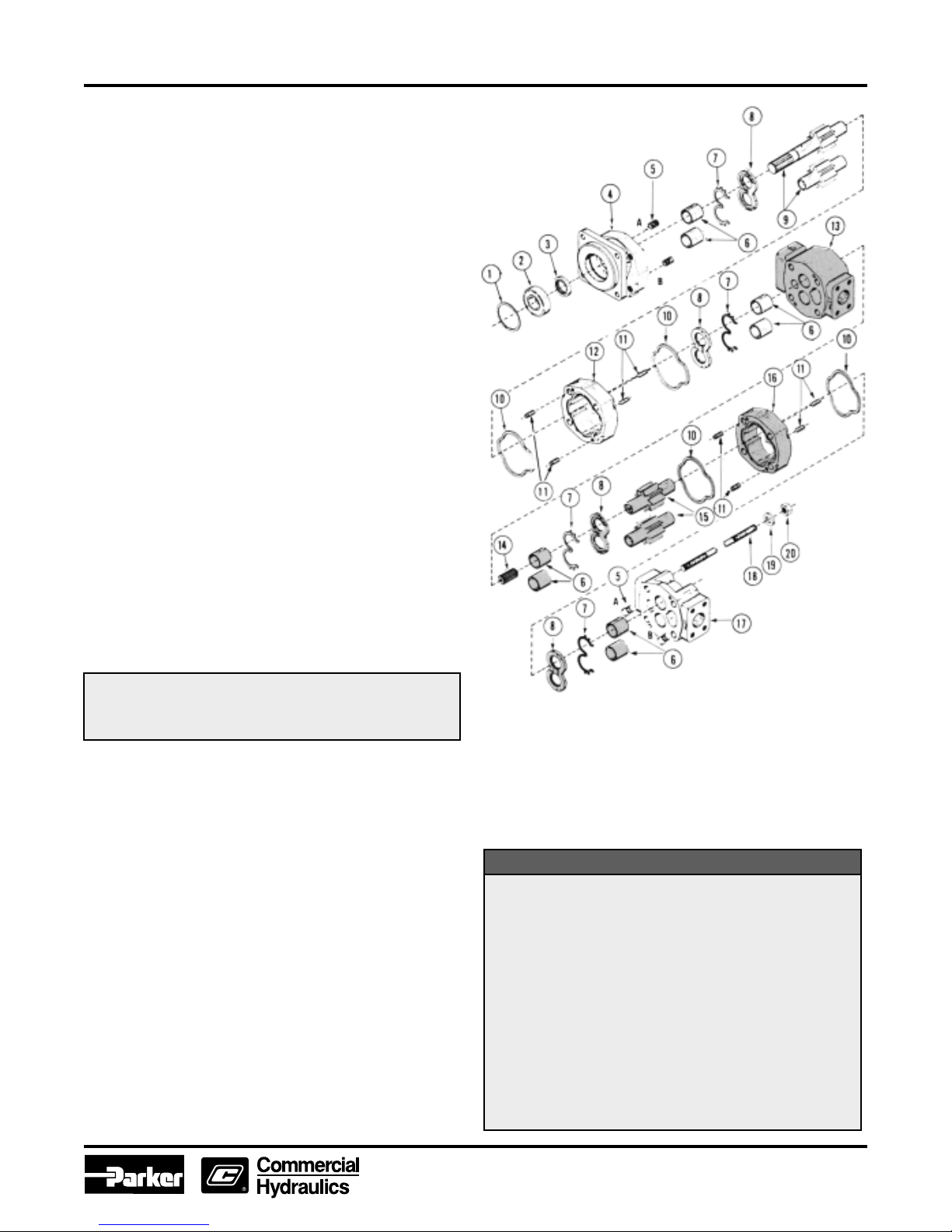

Items shaded apply to

multiple assemblies only.

NOTE:

For PGP315 and PGP330 ONLY - Plug 5

required in position A and position B.

For PGP350 and PGP365 ONLY - Plug 5 in

position B gives clockwise rotation. Plug 5 in

position A gives counterclockwise rotation.

PARTS LIST

1. Snap Ring

2. Outboard Bearing

3. Seal

4. Shaft End Cover

5. Plug

6. Bushings

7. Channel Seal

8. Thrust Plates

9. Integral Drive Shaft

and Gear Set

10. Gasket Seal

11. Dowel Pins (Solid for

PGP/PGM 315, 330 and

350. Hollow for PGP/PGM

365 ONLY.)

12. Gear Housing

13. Bearing Carrier

14. Connecting Shaft

15. Matched Gear Set

16. Gear Housing

17. Port End Cover

18. Studs or Cap Screws

19. Washers

20. Nuts

3

Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

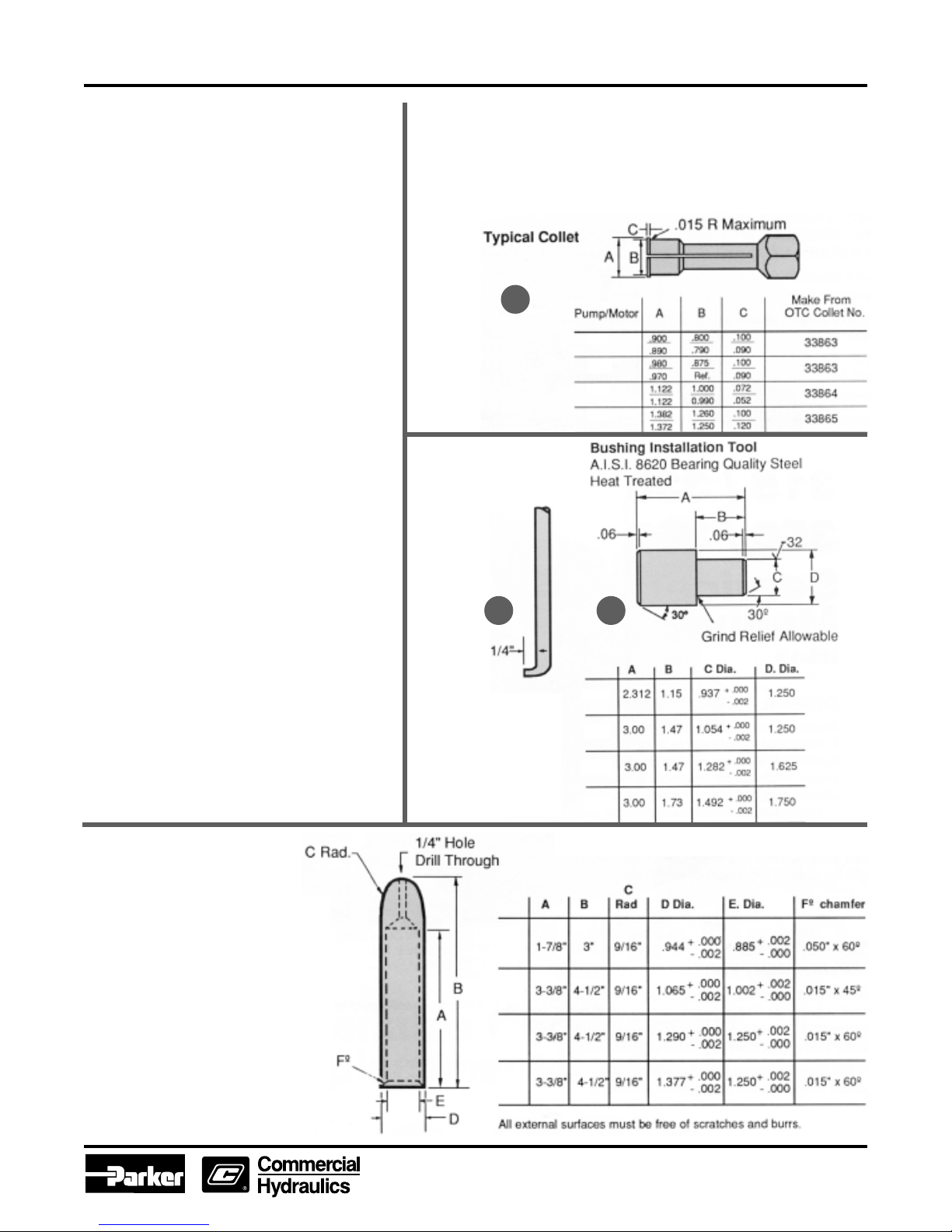

Tool List

• Arbor press

• Awl

• 1 1/2" Dia. steel ball

• Bearing puller (Owatonna Tool Co.

M D - 956 or equivalent)

• Bushing remover tool (See A)

• Clean, lintless cloths

• Deburring tool (an old file with

cutting teeth ground off)

• Machinist's hammer

• Soft hammer

• Permatex Aviation Form-A-Gasket

No. 3 non-hardening sealant or equivalent

• Medium grit carborundurn stone

• Seal removal tool (See B)

• Oil and grease

• Snap ring pliers

• Prick punch

• Bushing installation tool (See C)

• Scale ( 1/32" or 1/64" graduations)

• Small screw driver

• Torque wrench

• Vise with 6" minimum opening.

•

Bar for lip seal installation

Note: For PGP/PGM315 use 1 5/8" dia. x 2" bar.

For PGP/PGM330 use 1 3/4" d ia. x 2" bar.

For PGP/PGM350 use 2 1/2" dia. x 2" bar

For PGP/PGM365 use 2 1/2" dia. x 2" bar.

• Special steel sleeve ( see sketch )

TM

Bushing Puller: The bushings in

PGP/PGM

315, 330, 350 and 365

pumps may be removed from their bores, using blind hole collet-type

bushing pullers similar to those manuf actured b y Ow atonna Tool Co .

The table below illustrates the modifications necessary to adapt the

OTC collets to this task. Equivalent pullers from other suppliers may

be modified in similar fashion.

A

PGP/PGM

315

PGP/PGM

330

PGP/PGM

350

B

Seal Removal Tool

Easily made from an

old screw driver. Heat

the tip and bend as

shown. Grind the tip

to fit the notch behind

the shaft seal.

C

PGP/PGM

315

PGP/PGM

330

PGP/PGM

350

PGP/PGM

365

Special Steel Sleeve

The special steel sleeve is

used to insert the drive shaft

through the lip seal without

damage and can be made

from bar stock: For the

PGM

315 use a 1 " dia. x 3-1/

8" bar; for the

PGP/PGM

PGP/

330

use a 1-1/8" or 1-1/4" dia. x

4- 5/8" bar; for the

PGM

350 use a 1-3/8" dia. x

4-5/8" bar; for the

PGM

365 use a 1- 1 /2" dia. x

PGP/

PGP/

4-5/8" bar. The drawing and

chart give details for making

this special tool.

PGP/PGM

315

PGP/PGM

330

PGP/PGM

350

PGP/PGM

365

4

Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Start Disassembly Here

CAUTION:

1. If prying off sections becomes necessary, take extreme care not to mar or damage machined surfaces. Excessive force while prying

can result in misalignment and seriously damage parts.

2. If parts are difficult to fit during assembly , tap gently with a soft hammer (ne ver use an iron hammer).

3. Gears are closely matched, therefore the y must be k ept together as sets when remov ed from a unit. Handle with care to a voi d

damage to the journals or teeth. Avoid touching gear journals.

4. Ne ver hammer b ushings into bores; use an arbor press.

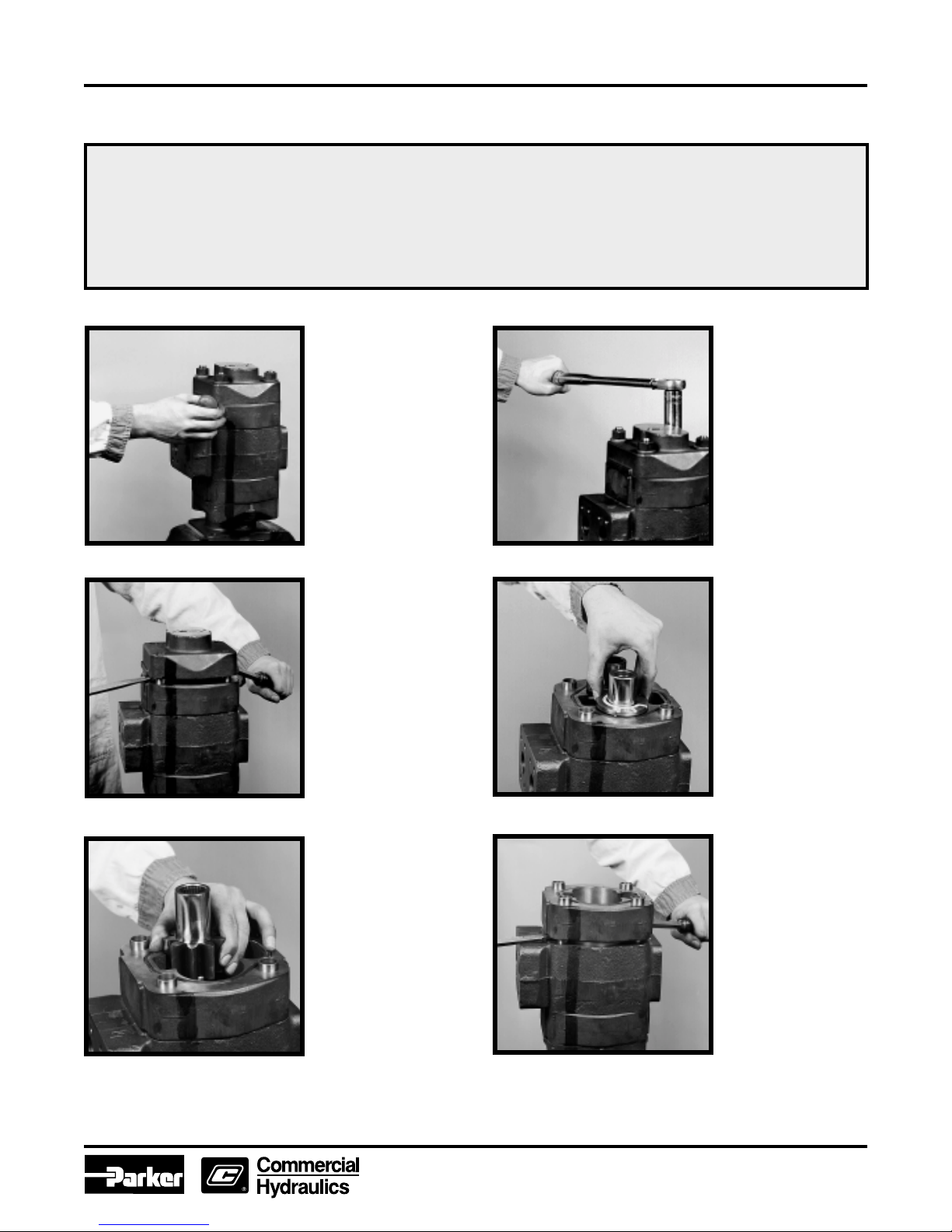

1) Place the pump in a

vise with the drive shaft

pointIng down. Caution:

DO NOT GRIP ON OR

NEAR ANY MACHINED

SURFACES DURING

ASSEMBLY OR

DISASSEMBLY.

Match-mark all sections.

Be sure to align these

marks when

reassembling.

3) Lift off the port end

cover. If prying is

necessary, be careful not

to damage the machined

surfaces. Dowel pins will

remain in either the port

end cover or the gear

housing.

2) Use a socket wrench

to remove the 4 cap

screws on single units or

the 4 hex nuts, studs

and washers of multiple

units.

4) Remove the thrust

plate. Examine and

replace if necessary.

See wear guide page 10.

5) Carefully remove the

drive and driven gears.

Avoid tapping the gear teeth

together or against other

hardened surfaces. Keep

these gears together

because they are a matched

set. Examine and replace if

necessary. (See page 10).

Remove the thrust plate

from the bearing carrier.

Examine and replace if

necessary.

For multiple assemblies only

6) Lift the gear housing

from the bearing carrier.

If prying is necessary,

take care not to damage

machined surfaces.

Examine and replace

if necessary.

(See page 10)

For multiple assemblies

only

5

Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

Loading...

Loading...