Parker Automation Gemini GV6K, Gemini GT6K Command Reference Manual

p/n 88-019933-01 A

G

e

m

A

utomation

ini

G

e

m

ini

C

o

mmand

Effective: October 1, 2001

GV6K

GT6K

R

eference

a

nd

F

N

I

R

I

D

T

GF

R

T

W

AR

ST

SF

A

T

H

RR

E

GOW

NC

IT

A

O

O

H

LI

N

TP

M

R

E

O

R

N

U

M

E

E

TF

NC

F

TPE

RA

E

AD

TST

TI

NC

D

EF

D

SE

NCCN

M

T

A

TFSF

N

LS

A

L

EL

D

T

A

TIO

C

H

PS

ND

E

OY

J

FOL

KA

TS

H

O

W

ESET

R

J

FOLE

S

A

M

GTE

R

ST

C

X

ELP

N

I

N

E

H

GO

OG

N

DD

M

N

BU

V

TO

R

I

GO

P

AR

V

U

DR

T

U

O

M

O

C

F

RUN

P

S

AR

T

ES

TSSF

DA

ILE

H

W

IF

P

ELSE

SF

ARB

V

M

FE

DR

ES

R

E

TSIZ

B

C

N

SOFFS

V

EV

R

T

S

www.comoso.com

GOTO

K

TI

N

OF

U

Gem6K Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and

may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

©

2001

, P

arke

All

R

ights

se

Gem6K Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion

system for safety under all potential conditions. Failure to do so can result

in damage to equipment and/or serious injury to personnel.

r

H

a

nnifin

R

eserve

d

r

I

!!

C

orporation

nform

W

ARNIN

G

ation

Motion Planner and Servo Tuner are trademarks of Parker Hannifin Corporation.

Microsoft and MS-DOS are registered trademarks, and Windows, Visual Basic, and Visual C++ are trademarks of Microsoft Corporation.

T

ec

hnical

N

ort

h

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

A

utomation

A

merica a

A

ssistance

nd

A

sia

:

Contact your local automation technology center (ATC) or distributor,

E

urop

e

Parker Digiplan

(non-German speaking)

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

E

-

mail

:

G

erman

y

,

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

T

ech nical

:

T

ech

A

S

_

H

elp@cmotor.com

ustri

upport

a

, S

o

witzerla

r

nd

...

:

www.comoso.com

Introduction

Purpose of this Document

This document is a reference for all the Gem6K Series commands. To gain a full understanding of how the

Gem6K Series commands are used together to implement specific features, refer to the Gem6K Series

Programmer’s Guide (p/n 88-019934-01). For hardware-related information (e.g., electrical wiring

connections, specifications, tuning, etc.), refer to the Gem6K Series Hardware Installation Guide

019932-01). Information on the Gem6K communicatio ns server (COM6SRVR) is provided in the

Communications Server Programmer’s Reference.

(p/n 88-

NOTE

The contents of this document are

available from the Motion Planner

help system. To access the help

system, use the Info window

(right), or press the F1 key.

This document is also

available in Adobe Acrobat PDF

format from our web site:

http://www.compumotor.com

Table of Contents

Page 1 Introduction:

Command Description Format

Syntax -- Letters and Symbols

Syntax -- General Guidelines

Syntax -- Command Value Substitutions

Programmable I/O Bit Patterns

Programming Error Messages

S-Curve Accel/Decel Profiling

Units of Measure and Scaling

Page 23 Special Programming Characters: Operator symbols for multi-tasking, math and bitwise

operations, relational expressions, bit select operations, etc.

Page 39 Command Descriptions: Operator symbols are described first, followed by the rest of the

Gem6K Series commands in alphabetical order.

Page 343 Appendix A: Gem6K Series Command List: Alphabetical list of all Gem6K Series commands.

Page 349 Appendix B: ASCII Character Table

Page 351 Index

Introduction

www.comoso.com

1

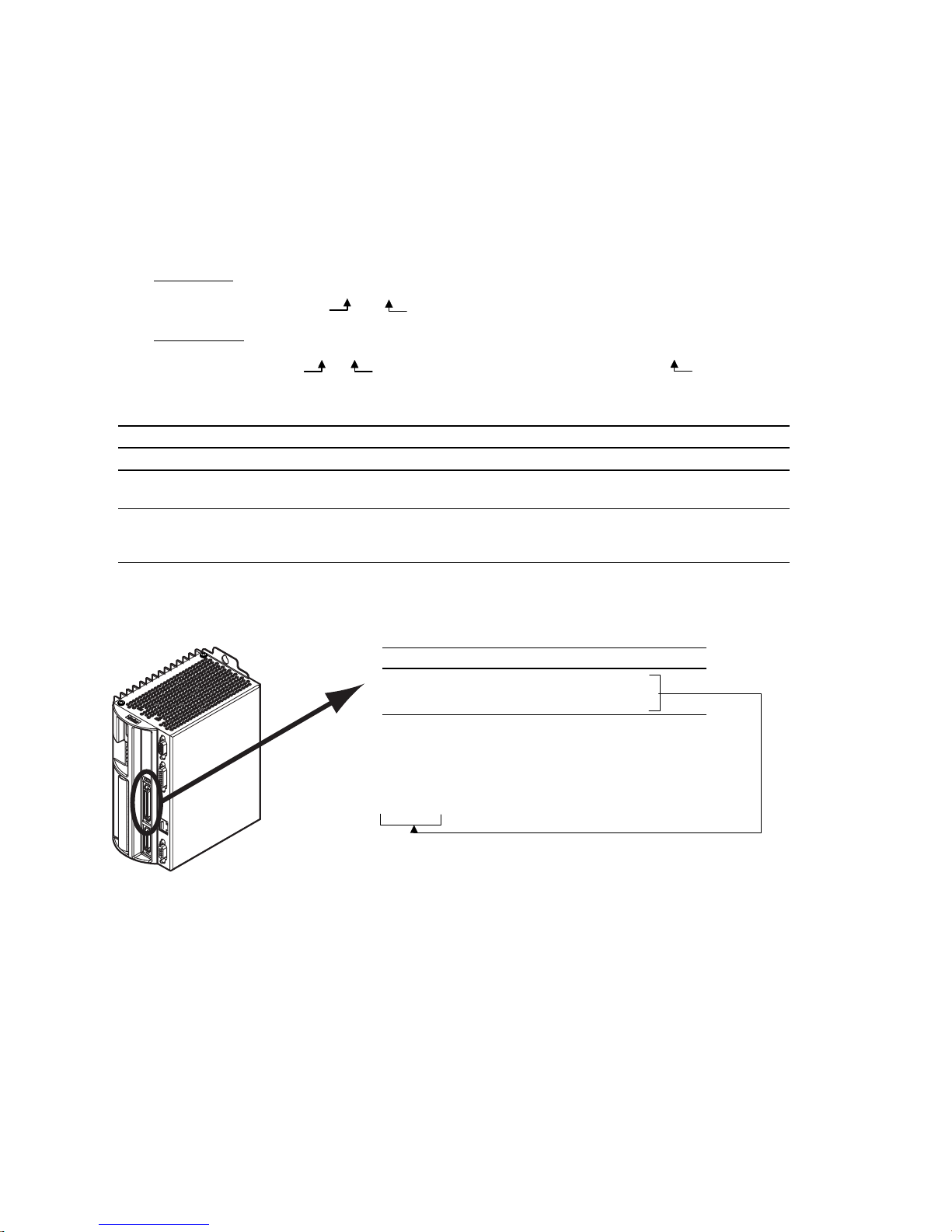

Description of Format

1. 2. 3.

INEN

4. Type Inputs or Program Debug Tools

5. Syntax <!><B>INEN<d><d><d>...<d>

6. Units d = 0, 1, E, or X

7. Range 0 = off, 1 = on, E = enable, X = don't care

8. Default E

9. Response INEN: *INENEEEE_EEEE_EEEE_EEEE_EEEE_EEEE_EEEE

10. See Also [IN], INFNC, INLVL, INPLC, INSTW, TIN, TIO

Item Number Description

1. Mnemonic Code: This field contains the command's mnemonic code. If the command is

2. Full Name: This field contains the command's full name.

3. Valid Product & Revision: This field lists the Gem6K Series products and the revision of

You can use the TREV command to determine which product revision you are using. For

4. Type: This field contains the command’s type.

5. Syntax: The proper syntax for the command is shown here. The specific parameters

Input Enable

in brackets (e.g., [

command (e.g., IN may be used in a conditional expression like IF(IN.3=b1)).

each product when this command was incorporated or modified per the description. If the

command does not apply to that particular product, the Rev is specified as “n/a”.

example, if the TREV response is *TREV92-016740-01-6.0, the product revision is 6.0.

associated with the command are also shown. Definitions of the parameters are described

in the Syntax sections below.

Product Rev

GT6K 6.0

GV6K 6.0

IN

]), it is an operator that must be used within the syntax of another

6. Units: This field describes what unit of measurement the parameter (b, d, i, r, or t) in the

command syntax represents.

7. Range: This is the range of valid values that you can specify for an argument (or any

other parameter specified).

8. Default: The default setting for the command is shown in this field. A command will

perform its function with the default setting if you do not provide a value.

9. Response: Some commands allow you to check the status of the command. In the

example above, entering the INEN command by itself, you will receive the response

*INENEEEE_EEEE_EEEE_EEEE_EEEE_EEEE_EEEE (response indicates all inputs are

enabled). The example responses provided are based on the default error level, Error

Level 4, established with the ERRLVL4 command.

10. See Also: Commands related or similar to the command described are listed here.

2 Gemini GV6K/GT6K Command Reference

www.comoso.com

t

Syntax – Letters and Symbols

The command descriptions provided within this manual use alphabetic letters and ASCII symbols within

the

description (see example below) to represent different parameter requirements.

Syntax

INEN

Type Inputs or Program Debug Tools

→ Syntax <!><%><B>INEN<d><d><d>...<d>

Units d = 0, 1, E, or X

Range 0 = off, 1 = on, E = enable, X = don't care

Default E

Response INEN: *INENEEEE_EEEE_EEEE_EEEE_EEEE_EEEE_EEEE

See Also [IN], INFNC, INLVL, INPLC, INSTW, TIN, TIO

Letter/Symbol Description

a_ ........Represents an address specifier, numeric value from 0 to 99. An address specifier is required if

B ...........Represents the number of the product's I/O brick. External I/O bricks are represented by numbers 1

b *.........Represents the values 1, 0, X or x; does not require field separator between values.

c ...........Represents a character (A to Z, or a to z)

d ...........Represents the values 1, 0, X or x, E or e ; does not require field separator between values. E or e

i ...........Represents a numeric value that cannot contain a decimal point (integer values only). The numeric

r ...........Represents a numeric value that may contain a decimal point, but is not required to have a decimal

t ...........Represents a string of alpha numeric characters from 1 to 6 characters in length. The string must

! ...........Represents an immediate command. Changes a buffered command to an immediate command.

% ...........(Multitasking Only) Represents a task identifier. To address the command to a specific task, prefix the

, ...........Represents a field separator. Commands with the symbol r or i in their Syntax description require

@ ...........Represents a global specifier, where only one field need be entered. Applicable to all commands with

< > ......Indicates that the item contained within the < > is optional, not required by that command.

[ ] ......Indicates that the command between the [ ] must be used in conjunction with another command,

* The ASCII character b can also be used within a command to precede a binary number. When the b is used in this

context, it is not to be replaced with a 0, 1, X, or x. Examples are assignments such as VARB1=b10001, and

comparisons such as IF(3IN=b1001X1).

Input Enable

Product Rev

GT6K 6.0

GV6K 6.0

multiple Gem6K drives are connected in a daisy-chain or multi-drop configuration; in fact, leaving off

the address specifier will cause parameter assignment commands to affect all units and

response/transfer commands to request information from all units at the same time (multiple units

transmitting characters at one time will garble the communication). To assign unique unit addresses

to multiple drives, refer to the ADDR command.

through n (to connect external I/O bricks, refer to the Installation Guide). On-board I/O are address at

brick location zero (Ø). If the brick identifier is omitted from the command, the controller assumes the

command is supposed to affect the onboard I/O.

enables a specific command field. X or x leaves the specific command field unchanged or ignored. In

the ANIEN command, the “d” symbol may also represent a real numeric value.

range varies by command. Field separator required.

point. The numeric range varies by command. Field separator required.

start with a alpha character.

Immediate commands are processed immediately, even before previously entered buffered

commands.

command with “i%”, where “i” is the task number. For example, the 4%CUT command uses task #4 to

execute the program called “CUT”.

field separators. Commands with the symbol b or d in their Syntax description

separators (but they may be included). See General Guidelines table below.

multiple command fields. (e.g.,

NOTE: Do not confuse with <cr>, <sp>, and <lf>, which refer to the ASCII characters

corresponding to a carriage return, space, and line feed, respectively.

and cannot be used by itself.

@OUT1

sets output #1 on for all I/O bricks).

do not

require field

Order of Precedence for Command Prefix Characters (from left to right):

s

1

: Immediate

nd

2

: Task number

rd

3

: Apply to all I/O bricks, etc.

rd

3

: Address number

rd

3

: I/O brick number

Introduction

<!><%><@><a_><B>

www.comoso.com

3

Syntax – General Guidelines

Guideline Topic Guideline Examples

Command Delimiters

(<cr>, <lf>, and :)

Neutral Characters

(<sp> and <tab>)

Case Sensitivity

Comment Delimiter (;)

Field Separator (,)

All commands must be separated by a

delimiter. A carriage return is the most

commonly used. The colon (:)allows you to

place multiple commands on one line of code.

Using neutral characters anywhere within a

command will not affect the command.

There is no case sensitivity. Use upper or

lower case letters within commands.

Set acceleration to 10 rev/sec/sec:

A10<cr>

A10<lf>

A10:

V25 : D25000 : GO<cr>

Set velocity to 10 rps:

V<sp>10<cr>

Initiate motion:

GO1

go1

All text between a comment delimiter and a

command delimiter is considered program

Add a comment to the command:

V10<tab> ;set velocity

comments.

Commands with the symbol r or i in their

Syntax description require field separators.

Display variable #1 on the RP240 at the current

cursor location with 3 characters displayed to

the left of the decimal, 2 to the right of the

decimal, and the sign:

DVAR1,3,2,1

Commands with the symbol b or d in their

Syntax description

do not

require field

separators (but they may be included).

Enable error checking for hard limits and drive

faults:

ERROR0101

Global Command

Identifier (@)

Bit Select Operator (.)

Left-to-right Math

Binary and Hexadecimal

Values

Multi-tasking Task

Identifier (%)

When you wish to set the command value

equal on all outputs, add the @ symbol at the

beginning of the command (enter only the

value for one command field).

The @ symbol is also useful for checking

the status of all inputs or

outputs on all I/O bricks.

The bit select operator allows you to affect

one or more binary bits without having to

enter all the preceding bits in the command.

Syntax for setup commands:

[command name].[bit #]-[binary value]

Syntax for conditional expressions:

[command name].[bit #]=[binary value]

All mathematical operations assume

left-to-right precedence.

When making assignments with or

comparisons against binary or hexadecimal

values, you must precede the binary value

with the letter “b” or “B”, and the hex value

with “h” or “H”. In the binary syntax, an “x”

simply means the status of that bit is ignored.

Use the % command prefix to identify the

command with a specific task.

Set the digital outputs (#1 & #2) active on all

digital outputs (onboard and external):

@OUT11

Check the status of all digital outputs (onboard,

and on external I/O bricks):

@OUT

Enable error-checking bit #9:

ERROR.9-1

Enable error-check bits #9-12:

ERROR.9-1,1,1,1

IF statement based on value of axis status bit

#12 for axis #1:

IF(1AS.12=b1)

VAR1=5+3*2

Result: Variable 1 is assigned the value of 16

(8*2), not 11 (5+6)

.

Binary: IF(IN=b1x01)

Hexadecimal: IF(IN=h7F)

Launch the “move1” program in Task 1:

1%move1

Check the error status for Task 3:

3%TER

Check the system status for Task 3:

3%TSS

: The command line is limited to 80 characters (excluding spaces).

NOTE

4 Gemini GV6K/GT6K Command Reference

www.comoso.com

Syntax – Command Value Substitutions

Many commands can substitute one or more of its command field values with one of these substitution

items (demonstrated in the programming example below):

VAR............. Places current value of the numeric variable in the corresponding field of the command.

VARB........... Uses the value of the binary variable to establish all

VARI........... Places current value of the integer variable in the corresponding field of the command.

READ........... Information is requested at the time the command is executed.

DREAD ........ Reads the RP240’s numeric keypad into the corresponding field of the command.

DREADF...... Reads the RP240’s function keypad into the corresponding field of the command.

TW ............... Places the current value set on the thumbwheels in the corresponding field of the command.

DAT............. Places the current value of the data program (DATP) in the corresponding field of the command.

(NOTE: The substitution item must be enclosed in parentheses.)

Programming Example:

VAR1=15 ; Set variable 1 to 15

A(VAR1) ; Set acceleration to 15

VARB1=b101XX ; Set binary variable 1 to 101XX (bits 4 & 5 not affected)

OUT(VARB1) ; Turn on ouputs 1 & 3, turn off output 2, don’t change outputs 4 &

VARS1="Enter Velocity" ; Set string variable 1 to the message "Enter Velocity"

V(READ1) ; Read in the velocity, output variable string 1 as the prompting

; 1. Operator sees "ENTER VELOCITY" displayed on the screen.

; 2. Operator enters velocity prefixed by !' (e.g., !'20).

HOMV(TW1) ; Read in the home velocity from thumbwheel set 1

HOMVF(DAT1) ; Read home final velocity from data program 1.

VARI1=2*3 ; Set integer variable 1 to 6 (2 multiplied by 3)

D(VARI2) ; Set the distance equal to the value of

; integer variable 2.

5.

message

the fields in the command.

Rule of Thumb

Not all of the commands allow command field substitutions. In

general, commands with a binary command field (

syntax) will accept the

or integer command field (

VAR, VARI, READ, DREAD, DREADF, TW

VARB

substitution. Commands with a real

<r>

or

<i>

in the syntax) will accept

DAT

or

<b>

in the

.

Introduction

www.comoso.com

5

Programming Interface Tools

Motion Planner, a graphical programming interface, is provided as a tool for programming your Gem6K

drive. These are the functions provided:

• Configuration (motor selection, tuning, motor matching and damping, etc.)

• Terminal emulation for sending commands and checking drive status

• Program editor for developing program files to send to the drive

• Downloading and uploading program and operating system files to/from the drive

Motion Planner runs on the Windows 95, Windows 98 an d Windows NT operating systems.

Motion Planner is installed from the “Motion Planner” CD which is included in your Gem6k drive

shipment (unless you ordered the -NK option).

Communications Server: Also available on the Motion Planner CD is the Communications Server

(COM6SRVR.EXE). COM6SRVR.EXE is a 32-bit OLE automation server that allows you to add Gem6K

(as well as Gemini and 6K) communication capability to your cu stom applications created with

programming languages such as Visual Basic, Visual C++, and Delphi. The Motion Planner installation

program installs

COM6SRVR.EXE

functions are provided in the COM6SRVR Communications Server User Guide.

in the Motion Planner directory. Details on the Communication Server

NOTE

The Gem6K commands described in this document can be used only with Motion

Planner or the COM6SRVR Communications Server.

Using Motion Planner with a Gem6K Drive

Motion Planner is a programming interface for the Gemini product family, as well as the 6K product

family. Motion Planner runs on the Windows 95, Windows 98 and Windows NT operating systems.

Below are instructions on how to use Motion Planner with your Gem6K.

Installing Motion Planner:

System Requirements:

• IBM-compatible PC with a Pentium 166 MHz or higher processor.

• Operating system: Microsoft Windows 95, Microsoft Windows NT Workstation 4.0, or

Microsoft Windows 98.

• 32MB RAM.

• Hard disk space: 16MB minimum.

• PCI VGA with 800 x 600 resolution or higher.

• CD-ROM drive or internet access for installation.

• Mouse or pointing device.

• RS-232C serial port for using serial RS-232C communications.

Insert the Motion Planner CD in your CD-ROM player. The installation program

automatically launches and displays this dialog:

6 Gemini GV6K/GT6K Command Reference

www.comoso.com

Updating the Drive’s Operating System:

Gem6K drives are digital motor drives that run under an internal software operating system. The

operating system was loaded into your drive during the manufacturing process, and under

ordinary circumstances you will not need to update your drive’s operating system. However,

because Compumotor continues to add enhancements and address software bugs, you may want

to upgrade the operating system. You may obtain a new operating system file from the

Compumotor web site, or from Technical Support (see phone numbers on the inside cover of this

manual).

Web Site Download:

The operating system file is located in the software download section of the Compumotor

Online web site (

For example, the operating system file for version 1.50 is called GEM_1_50.ops. Download

the file to the Motion Planner directory on your hard drive.

Update Procedure:

1. Using the Gem6K’s RS-232 connector (COM 2), connect to your computer’s RS-232

serial communication port (see instructions in the Hardware Installation Guide).

NOTE: You can download the operating system to only one drive unit at a time and you

must use RS-232 communication (no daisy chains).

NOTE: You must use the Gem6K’s RS-232 connector (COM 2), not the RS-232/485

connector (COM 1).

2. Launch Motion Planner.

3. In the Default Communications Settings dialog box, select your Gem6K drive and select

the serial port to which the drive is connected, then click “OK”.

4. Click on the Terminal tab to expose the terminal emulator.

5. From the

the

Locate Gem6K Operating System

button. This initiates the download to the drive and displays th e download status

Open

dialog.

6. When the download is completed successfully, Motion Planner displays a confirmation

message. Also, the drive automatically resets itself and displays the

the terminal emulator window. Check the

system revision is now in the drive (e.g., the response “

indicates that the drive is using OS revision 1.05, denoted by “

http://www.compumotor.com

Communications

). The file name is in this format: GEM_n_nn.ops.

pull-down menu, select

dialog, locate the operating system file and click the

report to verify that the proper operating

TREV

Download OS

*TREV-GV-L3E_D1.05_F1.00

. When presented with

response in

TREV

”).

D1.05

”

NOTE: If the download is interrupted or corrupted, the drive will

flash the left LED (red) until a valid operating system is downloaded.

Introduction

7

www.comoso.com

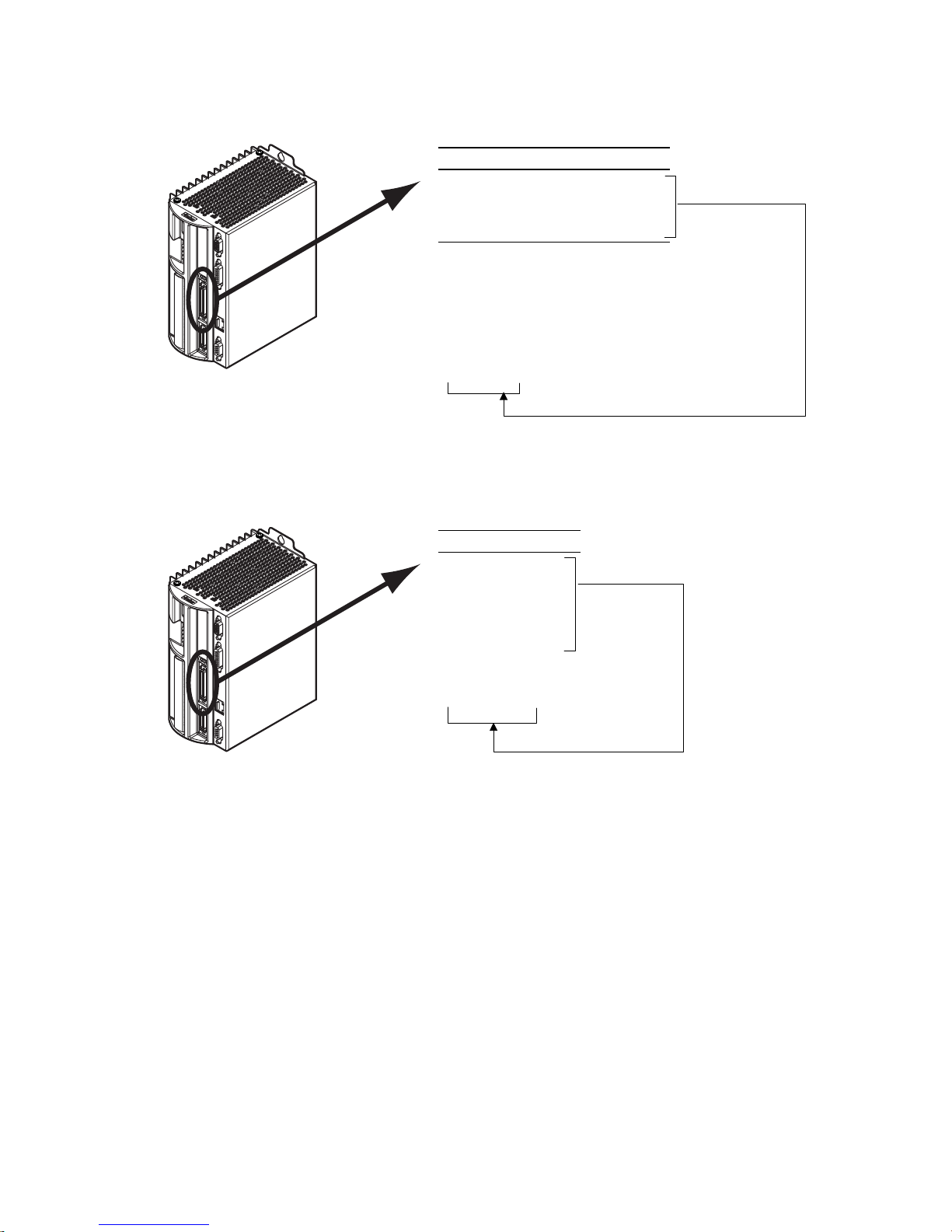

Programmable I/O Bit Patterns

The Gem6K has programmable inputs and outputs. The total number of onboard inputs and outputs (analog

inputs, digital inputs and digital outputs) is fixed. The total number of expansion inputs and outputs depends on

your configuration of expansion I/O bricks.

These programmable I/O are represented by binary bit patterns, and it is the bit pattern that you reference when

programming and checking the status of specific inputs and outputs. The bit pattern is referenced 1 to n, from

left to right.

• Onboard I/O

An example response is:

• Expansion I/O

An example response is:

Onboard I/O

I/O Location Programming Status Report, Assignment

Limit Inputs “

Inputs (digital) “DRIVE I/O” connector

Outputs (digital) “DRIVE I/O” connector

. For example, the status command to check all onboard inputs is

*TIN0100_0

Bit 1

.

Bit 5

TIN

.

. For example, the status command to check all digital inputs on I/O brick 2 is

*2TIN0010_0110_1100_0000_XXXX_XXXX_XXXX_XXXX

I/O Brick 2

Bit 1

DRIVE I/O

” connector

LIMFNC, LIMEN, LIMLVL TLIM, LIM

INFNC, INLVL, INEN, ONIN,

INPLC, INSTW

OUT, OUTFNC, OUTLVL,

OUTEN, OUTALL, OUTPLC,

OUTTW, POUT

TIN, IN

TOUT, [OUT]

.

Bit 32

2TIN

.

Limit Inputs

(“DRIVE I/O” connector)

Input bit pattern for

Bit # Pin # Function

1 28 Positive end-of-travel limit

2 29 Negative end-of-travel limit

3 31 Home limit

* The functions listed are the factory default functions; other

functions may be assigned with the

Sample response to

*TLIM110

LIM, TLIM, LIMEN, LIMFNC

*

(limit inputs status) command:

TLIM

LIMFNC

, and

LIMLVL:

command.

8 Gemini GV6K/GT6K Command Reference

www.comoso.com

(“DRIVE I/O” connector)

Inputs

Outputs

(“DRIVE I/O” connector)

Input bit pattern for

INEN, INPLC, INSTW

Bit # Pin # Function

1 37 Input 1 (if assigned, TRIG-A)

2 38 Input 2 (if assigned, TRIG-B)

3 39 Input 3

4 34 Input 4

5 35 Input 5 (if assigned, TRIG-M)

* If the input is assigned the “trigger

interrupt” function with the

command:

TRIG-A must be on Input 1

TRIG-B must be on Input 2

TRIG-M must be on input 5

Sample response to

*TIN0010_1

TIN, IN, INFNC, INLVL

, and

ONIN:

*

INFNCi-H

(input status) command:

TIN

,

Output bit pattern for

OUTLVL, OUTEN, OUTALL, OUTPLC, OUTTW, POUT:

Bit # Pin # Function

1 41 Output 1.

2 43 Output 2.

3 45 Output 3.

4 46 Output 4.

5 48 Output 5.

6 49 Output 6.

7 Relay Output 7.

TOUT, [OUT], OUT, OUTFNC

,

Sample response to

(onboard outputs status) command:

*TOUT0000_000

TOUT

Introduction

www.comoso.com

9

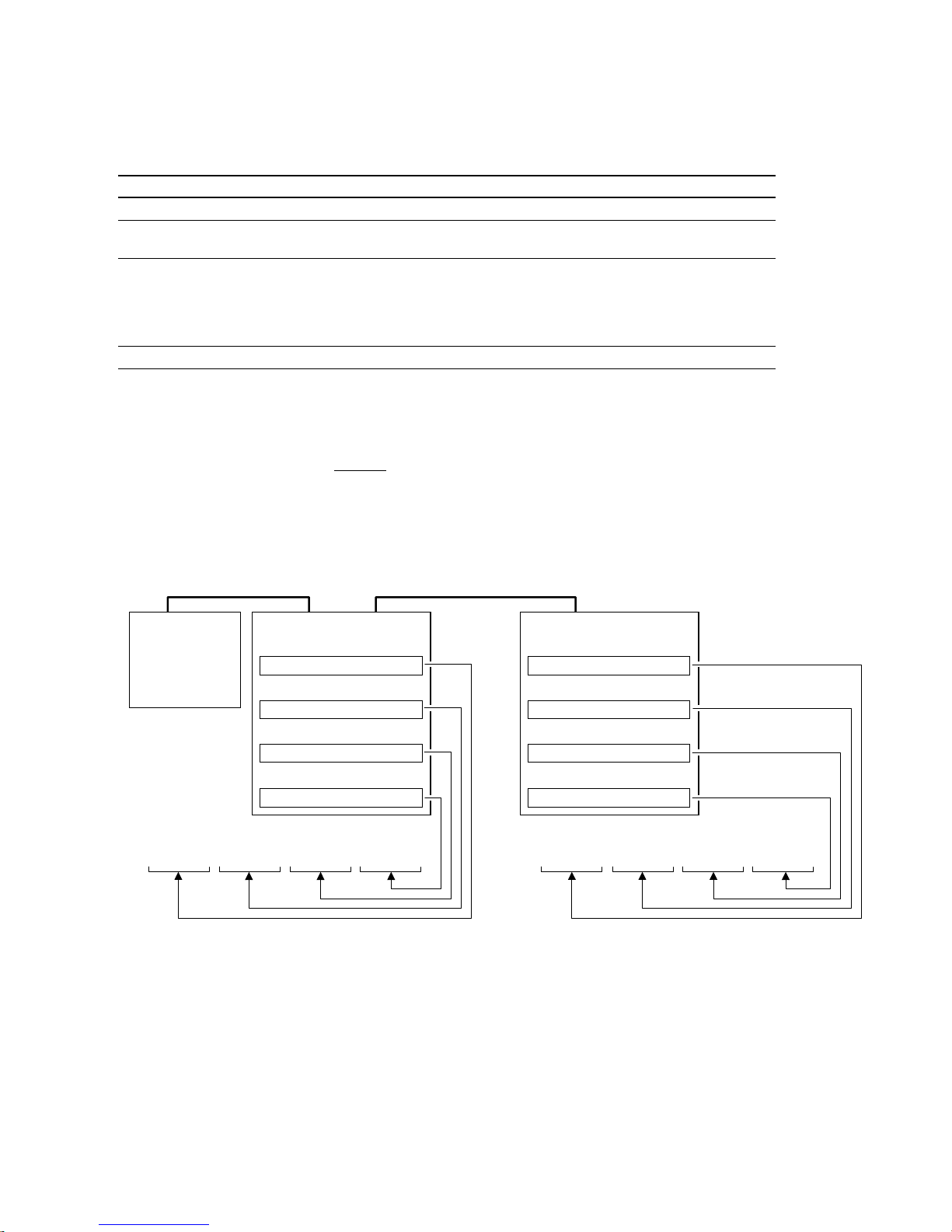

Expansion I/O Bricks

The Gem6K allows you to expand your system I/O by connecting up to eight I/O bricks (see Installation

Guide for connections). Expansion I/O bricks may be ordered separately (referred to as the “EVM32”). Each

I/O brick can hold from 1 to 4 of these I/O SIM modules in any combination:

SIM Type Programming Status Report, Assignment

Digital Inputs SIM (8 inputs)

Digital Outputs SIM (8 outputs)

Analog Inputs SIM (8 inputs)

Analog Outputs SIM (8 outputs)

Each I/O brick has a unique “brick address”, denoted with the “

I/O bricks are connected in series to the “

address #1, the next brick has address #2, and so on. (NOTE: If you leave out the brick address in the

command, the Gem6K will assume you are addressing the command to the onboard I/O.) Each I/O brick

has 32 I/O addresses, referenced as absolute

• SIM slot 1 = I/O points 1-8

• SIM slot 2 = I/O points 9-16

• SIM slot 3 = I/O points 17-24

• SIM slot 4 = I/O points 25-32

INFNC, INLVL, INEN, ONIN, INPLC, INSTW TIN, IN, TIO

OUT, OUTFNC, OUTLVL, OUTEN, OUTALL,

OUTPLC, OUTTW, POUT

• Enable/Disable: ANIEN.

• Voltage range: ANIRNG.

• Joystick setup: JOYAXH, JOYCDB,

JOYCTR, JOYEDB, JOYZ.

• Following master source: ANIMAS, FOLMAS

ANO

” symbol in the command syntax. The

<B>

EXPANSION I/O

” connector on the Gem6K. The 1st I/O brick has

TOUT, [OUT], TIO

• Voltage: TANI, ANI, TIO

TANO, [ANO], TIO

I/O point locations:

Example:

Gem6K

Drive/Controller

Sample response to

*1TIN0000_0010_1100_0000_0100_0001_XXXX_XXXX

command identifies the connected I/O bricks (and installed SIMs), including the status of each I/O point:

TIO

The

*BRICK 1: SIM Type Status Function

1-8: DIGITAL INPUTS 0000_0000 AAAA_AAAA

9-16: DIGITAL INPUTS 0000_0000 AAAA_AAAA

17-24: DIGITAL INPUTS 0000_0000 AAAA_AAAA

25-32: ANALOG INPUTS 0.000,0.000,0.000,0.000,0.000,0.000,0.000,0.000

*BRICK 2: SIM Type Status Function

1-8: DIGITAL OUTPUTS 0000_0000 AAAA_AAAA -- SINKING

9-16: DIGITAL INPUTS 0000_0000 AAAA_AAAA

17-24: NO SIM PRESENT

25-32: DIGITAL OUTPUTS 0000_0000 AAAA_AAAA -- SOURCING

I/O Brick #1

Slot #1 (I/O points 1-8)

Digital Inputs SIM

Slot #2 (I/O points 9-16)

Digital Inputs SIM

Slot #3 (I/O points 17-24)

Digital Inputs SIM

Slot #4 (I/O points 25-32)

Analog Inputs SI M

(digital inputs status) command:

1TIN

I/O Brick #2

Slot #1 (I/O points 1-8)

Digital Outputs SIM

Slot #2 (I/O points 9-16)

Digital Inputs SIM

Slot #3 (I/O points 17-24)

No S IMM insta lled

Slot #4 (I/O points 25-32)

Digital Outputs SIM

Sample response to

*2TOUT0000_0000_XXXX_XXXX_XXXX_XXXX_0000_0000

(digital outputs status) command:

2TOUT

10 Gemini GV6K/GT6K Command Reference

www.comoso.com

Programming Error Messages

Depending on the error level setting (set with the

ERRLVL

command), when a programming error is created,

the Gem6K will respond with an error message and/or an error prompt. A list of all possible error messages is

provided in a table below. The default error prompt is a question mark (

ERRBAD

At error level 4 (

the error prompt. At error level 3 (

Error Response Possible Cause

ACCESS DENIED

ALREADY DEFINED FOR THUMBWHEELS

ALTERNATIVE TASK NOT ALLOWED

AXES NOT READY

COMMAND NOT IMPLEMENTED

COMMAND NOT ALLOWED IN PROGRAM

COMMAND/DRIVE MISMATCH

ERROR: MOTION ENDS IN NON-ZERO

VELOCITY

command if you wish.

ERRLVL4

—the factory default setting) the Gem6K responds with both the error message and

ERRLVL3

), the Gem6K responds with only the error prompt.

Program security feature enabled, but the program access input (INFNCi-Q or

LIMFNCi-Q) is not activated.

Attempting to assign an I/O function to an I/O that is already defined as a

thumbwheel I/O.

Attempting to execute a LOCK command directed to another task.

Compiled Profile path compilation error.

Command is not applicable to the Gem6K Series product.

Command is not allowed inside a program definition (between DEF and END).

The command is not appropriate to the type of drive being used (e.g.,

attempting to execute a servo tuning command on a stepper axis)

Compiled Motion: The last GOBUF segment within a PLOOP/PLN loop does not

end at zero velocity, or there is no final GOBUF segment

), but you can change it with the

?

placed outside the loop

.

FOLMAS NOT SPECIFIED

INCORRECT AXIS

INCORRECT BRICK NUMBER

INCORRECT DATA

INPUT(S) NOT DEFINED AS

JOYSTICK INPUT

INSUFFICIENT MEMORY

INVALID COMMAND

No FOLMAS for the axis is currently specified. It will occur if FMCNEW, FSHFC, or

FSHFD commands are executed and no FOLMASØ command was executed, or

FOLMAS0 was executed.

Axis specified is incorrect.

Attempted to execute a command that addresses an I/O brick that is not

connected to your Gem6K controller.

Incorrect command syntax.

Following: Velocity (V), acceleration (A) or deceleration (AD) command is zero

(used by FSHFC & FSHFD).

Attempted to execute JOYCDB, JOYCTR, JOYEDB, or JOYZ before executing

JOYAXH to assign the analog input.

Not enough memory for the user program or compiled profile segments. This

may be remedied by reallocating memory (see MEMORY command description).

Command is invalid because of existing conditions

Introduction

www.comoso.com

11

Programming Error Messages

Error Response Possible Cause

INVALID CONDITIONS FOR COMMAND

INVALID CONDITIONS FOR

S_CURVE ACCELERATION—FIELD n

INVALID DATA

(continued)

System not ready for command (e.g., LN command issued before the L

command).

Following (these conditions can cause an error during Following):

• The FOLMD value is too small to achieve the preset distance and still

• A phase shift cannot be performed:

• The FOLEN1 command was given while a profile was suspended by a

Average (AA) acceleration or deceleration command (e.g., AA, ADA, HOMAA,

HOMADA, etc.) with a range that violates the equation ½A ≤ AA ≤ A (A is the

max. accel or decel command—e.g., A, AD, HOMA, HOMAD, etc.)

Data for a command is out of range.

Following (these conditions can cause an error during Following):

• The parameter supplied with the command is valid.

• Error if a GO command is given in the preset positioning mode (MCØ) and:

remain within the FOLRN/FOLRD ratio.

FSHFD.... Error if already shifting or performing other time based move.

FSHFC.... Error if currently executing a FSHFD move, or if currently

GOWHEN.

FFILT Error if: smooth number is not 0-4

FMCLEN.. Error if: master steps > 999999999 or negative

FMCP ......Error if: master steps > 999999999 or < -999999999

FOLMD.... Error if: master steps > 999999999 or negative

FOLRD.... Error if: master steps > 999999999 or negative

FOLRN.... Error if: follower steps > 999999999 or neg ative

FSHFC.... Error if: number is not 0-3

FSHFD.... Error if: follower steps > 999999999 or < -999999999

GOWHEN.. Error if: position > 999999999 or < -999999999

WAIT ......Error if: position > 999999999 or < -999999999

FOLRN = zero

FOLMD = zero, or too small

(see Following chapter in the Programmer’s Guide)

executing another FSHFC move in the opposite direction.

INVALID FOLMAS SPECIFIED

INVALID RATIO

INVALID TASK IDENTIFIER

LABEL ALREADY DEFINED

MASTER SLAVE DISTANCE MISMATCH

MAXIMUM COMMAND LENGTH EXCEEDED

MAXIMUM COUNTS PER SECOND

EXCEEDED

MOTION IN PROGRESS

NEST LEVEL TOO DEEP

Following: An illegal master was specified in FOLMAS. A follower may never

use its own commanded position or feedback source as its master.

Following: Error if the FOLRN:FOLRD ratio after scaling is > 127 when a GO is

executed.

Attempting to launch a PEXE or EXE command into the supervisor task (task 0).

Defining a program or label with an existing program name or label name.

Attempting a preset Following move with a FOLMD value that is too small.

Command exceeds the maximum number of characters.

Velocity value is greater than 1,600,000 counts/sec.

Attempting to execute a command not allowed during motion (see Restricted

Commands During Motion section in the Programmer's Guide.)

Following: The FOLEN1 command was given while that follower was moving in

a non-Following mode.

IFs, REPEATs, WHILEs, or GOSUBs nested greater than 16 levels

12 Gemini GV6K/GT6K Command Reference

(for each type).

www.comoso.com

Programming Error Messages

Error Response Possible Cause

NO MOTION IN PROGRESS

NO PATH SEGMENTS DEFINED

NO PROGRAM BEING DEFINED

NOT ALLOWED IN PATH

NOT VALID DURING FOLLOWING

MOTION

NOT VALID DURING RAMP

OUTPUT USED AS OUTFNC

PROFILE ALREADY MOVING

PROFILE NOT COMPILED

(continued)

Attempting to execute a command that requires motion, but motion is not in

progress.

Compiled Profile compilation error.

END command issued before a DEF command.

Compiled Profile path compilation error.

A GO command was given while moving in the Following mode (FOLEN1) and

while in the preset positioning mode (MCØ).

A GO command was given while moving in a Following ramp and while in the

continuous positioning mode (MC1). Following status (FS) bit #3 will be set to 1.

A FOLEN command was given during one of these conditions:

• During a shift (FSHFC or FSHFD)

• During a change in ratio (FOLRN/FOLRD)

• During deceleration to a stop

Attempting to change an output that is not an OUTFNCi-A output.

Compiled Profile compilation error.

Attempting to execute a profile that has not been compiled.

STRING ALREADY DEFINED

STRING IS A COMMAND

UNDEFINED LABEL

WARNING: POINTER HAS WRAPPED

AROUND TO DATA POINT 1

WARNING: ENABLE INPUT INACTIVE

WARNING: DEFINED WITH ANOTHER

TW/PLC

A string (program name or label) with the specified name already exists.

Defining a program or label that is a command or a variant of a command.

Command issued to product is not a command or program name.

During the process of writing data (DATTCH) or recalling data (DAT), the pointer

reached the last data element in the program and automatically wrapped

around to the first datum in the program.

ENABLE

Duplicate I/O in multiple thumbwheel definitions.

input is no longer connected to ground (

GND

).

Introduction

www.comoso.com

13

Identifying Bad Commands

To facilitate program debugging, the Transfer Command Error (

TCMDER

) command allows you to transfer

the first command that the controller detects as an error. This is especially useful if you receive an error

message when running or downloading a program, because it catches and remembers the command that

caused the error.

Using Motion Planner

will detect the bad command and respond with an error message, followed by the

prompt (

automatically (see example below).

). If the bad command was detected on download, the bad command is reported

?

NOTE: If you are not using Motion Planner, you'll have to type in the TCMDER

: If you are typing the command in a live terminal emulator session, the controller

ERRBAD

error

command at the error

prompt to display the bad command.

Once a command error has occurred, the command and its fields are stored and system status bit #11

(reported in the

TSSF, TSS

and SS commands) is set to 1. The status bit remains set until the

TCMDER

command is issued.

Example Error Scenario:

1. In Motion Planner's program editor, create and save a program with a programming error:

DEL badprg ; Delete a program before defining and downloading

DEF badprg ; Begin definition of program called badprg

MA1 ; Select the absolute preset positioning mode

A25 ; Set acceleration

AD11 ; Set deceleration

V5 ; Set velocity

VAR1=0 ; Set variable #1 equal to zero

GO1 ; Initiate move

IF(VAR1<)16 ; MISTYPED IF STATEMENT - should be typed as "IF(VAR1<16)"

VAR1=VAR1+1 ; If variable #1 is less than 16, increment the counter by 1

NIF ; End IF statement

END ; End programming of program called badprg

2. Using Motion Planner's terminal emulator, download the program to the Gem6K Series product. Notice

that an error response identifies the bad command as an “

> *NO ERRORS

*INCORRECT DATA

> *IF(VAR1<)16

INCORRECT DATA

” item and displays it:

14 Gemini GV6K/GT6K Command Reference

www.comoso.com

S-Curve Acceleration/Deceleration Profiling

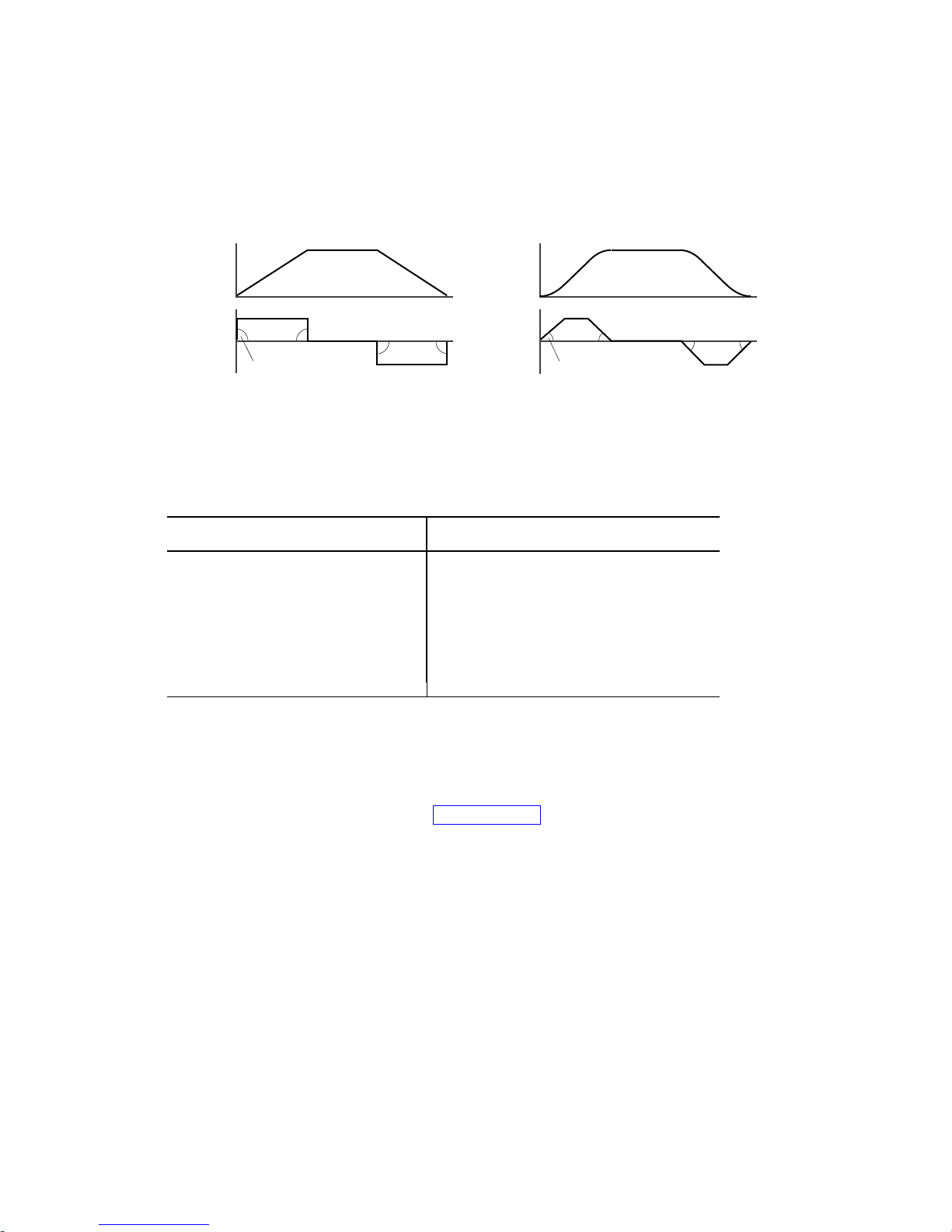

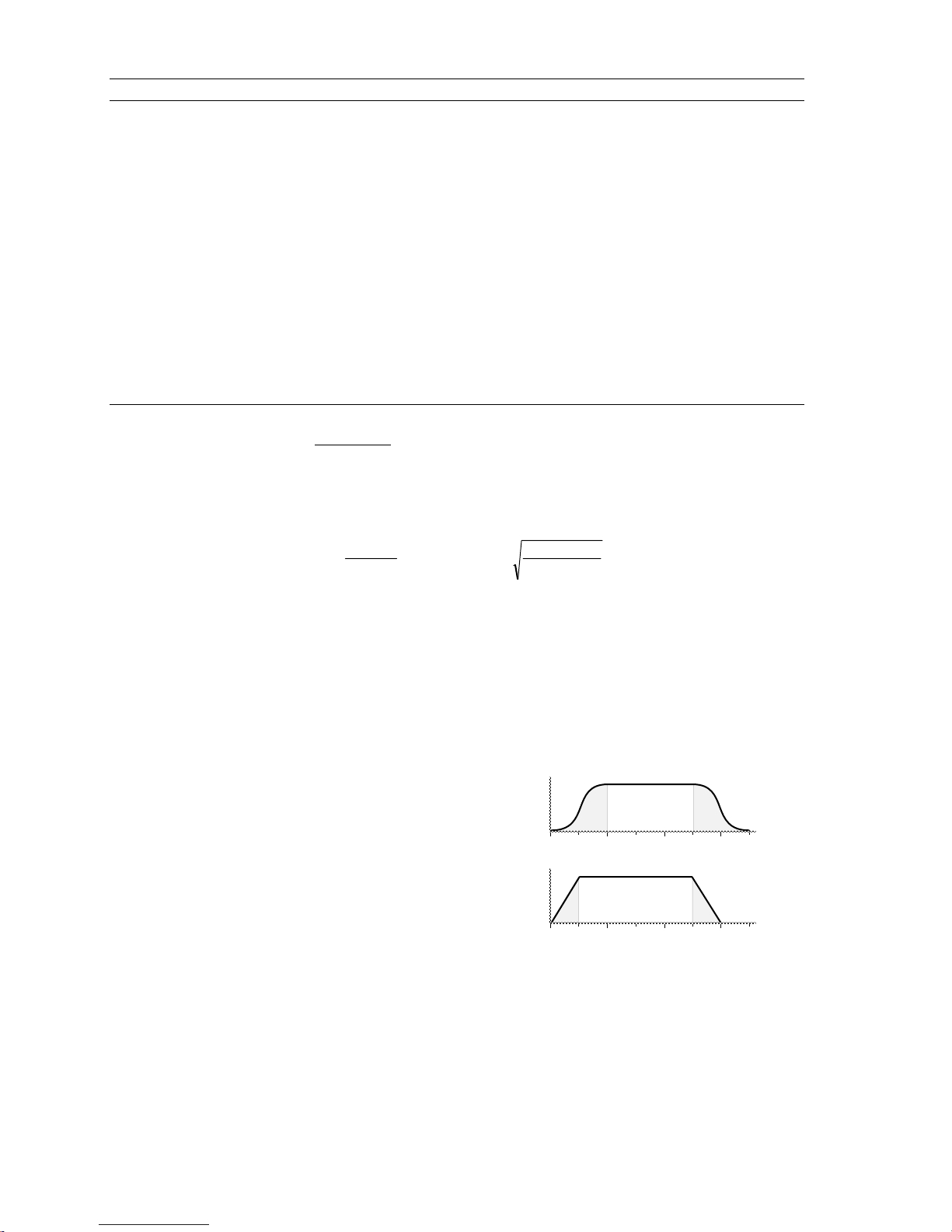

The Gem6K allows you to perform S-curve move profiles, in addition to the usual trapezoidal profiles.

S-curve profiling provides smoother motion control by reducing the jerk (rate of change) in acceleration

and deceleration portions of the move profile (see drawing below). Because S-curve profiling reduces jerk,

it improves position tracking performance, especially in linear interpolation applications.

Accel

Maximum Jerk

Decel Velocity

Trapezoidal

Time

Time

Velocity

Decel Accel

Less Jerk

S-Curve

Time

Time

S-Curve Programming Requirements

To program an S-curve profile, you must use the average accel/decel commands provided in the Gem6K

programming language. For every maximum accel/decel command (e.g., A, AD,

JOGAD

, etc.) there is an average command for S-curve profiling (see table below).

Maximum Accel/Decel Commands:

Command Function

A

AD

HOMA

HOMAD

JOGA

JOGAD

JOYA

JOYAD

LHAD

LSAD

Acceleration

Deceleration

Home Acceleration

Home Deceleration

Jog Acceleration

Jog Deceleration

Joystick Acceleration

Joystick Deceleration

Hard Limit Deceleration

Soft Limit Deceleration

Average (“S-Curve”) Accel/Decel Commands:

Command Function

AA

ADA

HOMAA

HOMADA

JOGAA

JOGADA

JOYAA

JOYADA

LHADA

LSADA

Average Acceleration

Average Deceleration

Average Home Acceleration

Average Home Deceleration

Average Jog Acceleration

Average Jog Deceleration

Average Joystick Acceleration

Average Joystick Deceleration

Average Hard Limit Deceleration

Average Soft Limit Deceleration

HOMA, HOMAD, JOGA

,

Determining the S-Curve Characteristics

The command values for average accel/decel (AA,

the characteristics of the S-curve. To smooth the accel/decel ramps, you must enter average accel/decel

command values that satisfy the equation ½

AA represents average accel/decel. Given this requirement, the following conditions are possible:

Introduction

A ≤ AA < A , where A represents maximum accel/decel and

, etc.) and maximum accel/decel (A, AD, etc.) determine

ADA

15

www.comoso.com

Acceleration Setting Profiling Condition

AA > ½ A, but AA < A S-curve profile with a variable period of constant acceleration. Increasing the AA value above

AA = ½ A Pure S-curve (no period of constant acceleration—smoothest motion).

AA = A Trapezoidal profile (but can be changed to an S-curve by specifying a new AA value less than A).

AA < ½ A; or AA > A When you issue the GO command, the move will not be executed and an error message,

AA = zero S-curve profiling is disabled. Trapezoidal profiling is enabled. AA tracks A. (Track means the

AA ≠ zero and AA ≠ A S-curve profiling is enabled

AA > ½ A Average accel/decel is raised above the pure S-curve level; this decreases the time required to

No AA value ever entered Profile will default to trapezoidal. AA tracks A.

If you never change the A or

However, once you change

For example, if you never change the

once you change

AD

the pure S-curve level (AA > ½ A), the time required to reach the target velocity and the target

distance is decreased. However, increasing AA also increases jerk.

*INVALID CONDITIONS FOR S_CURVE ACCELERATION—FIELD n, will be displayed.

command’s value will match the other command’s value and will continue to match whatever

the other command's value is set to.) However, if you enter an average decel command (e.g.,

ADA, HOMADA, etc.) equal to zero, you will receive the “INVALID DATA-FIELD n” error.

axis must comply with this equation: ½ A ≤ AA < A.

reach the target velocity and distance. However, increasing AA also increases jerk. After

increasing AA, you can reduce jerk by increasing A, but be aware that increasing A requires a

greater torque to achieve the commanded velocity at the mid-point of the acceleration profile.

deceleration commands,

AA

only for standard moves.

deceleration will track

AA

All subsequent standard moves for that

acceleration.

AA

A deceleration, AA deceleration will no longer track changes in AA acceleration.

or

, the

AD

command value will no longer track the changes in the

ADA

command values,

ADA

will track the

ADA

command value. But

AA

command value.

AA

Calculating Move Times. The calculation for determining S-curve average accel and decel move times is

as follows (calculation method identical for S-curve and trapezoidal moves):

Time =

Velocity

A

avg

or Time =

2 Distance

∗

A

avg

Scaling affects the

acceleration (

A, AD

AA average acceleration (

AA, ADA

, etc.). See page 19 for details on scaling.

, etc.) the same as it does for the A maximum

NOTE: Equations for calculating jerk are provided on page 17.

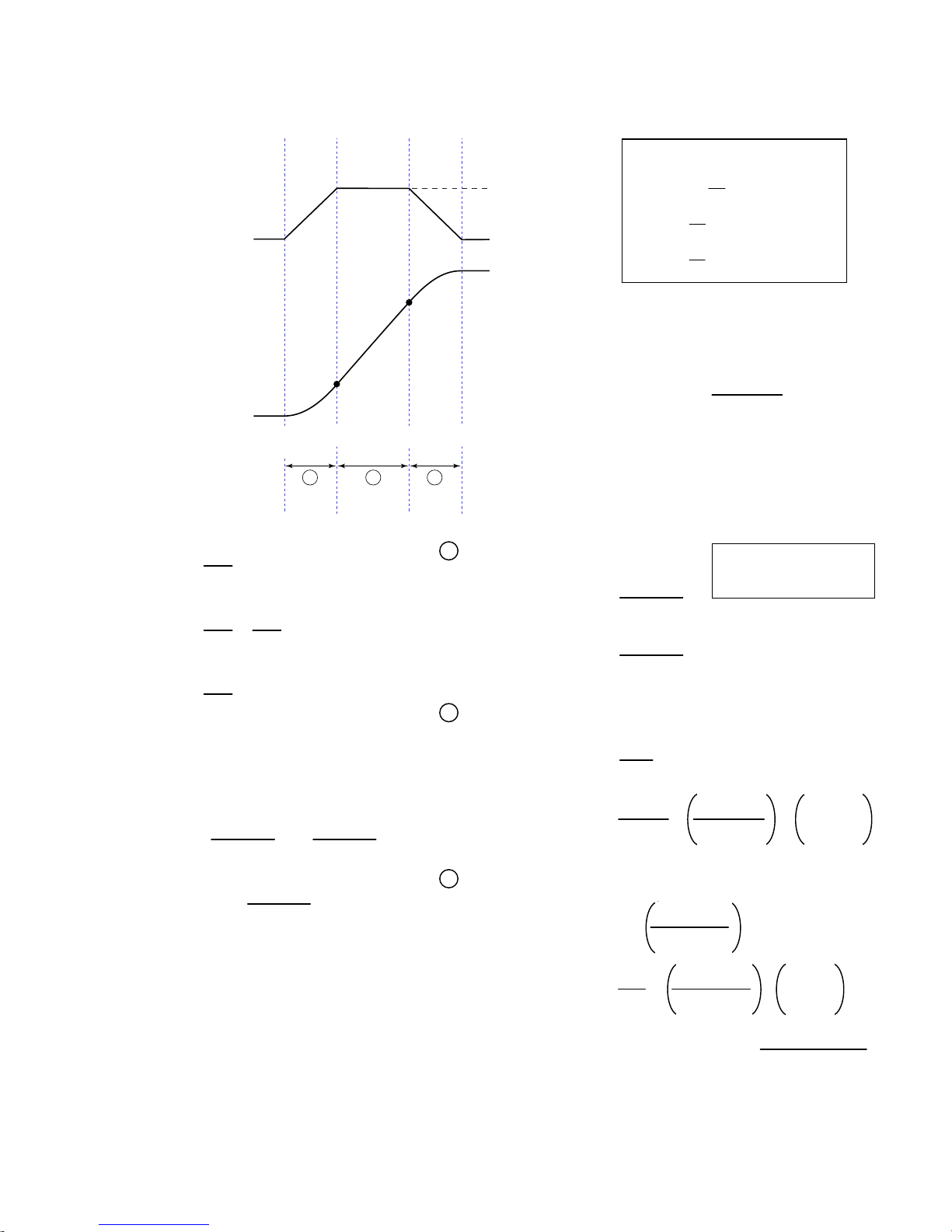

Programming Example (see move profile drawings below)

; In this example, prog1 executes a pure S-curve and takes 1 second

; to reach a velocity of 5 rps; prog2 executes a trapezoidal profile

; and takes 0.5 seconds to reach a velocity of 5 rps.

SCALE0 ; Disable scaling

DEL Prog1 ; Delete program called prog1

DEF Prog1 ; Begin definition of prog1

MA0 ; Select incremental positioning mode

D40000 ; Set distance to 40,000

A10 ; Set max. accel to 10 revs/sec/sec

AA5 ; Set avg. accel to 5 revs/sec/sec

AD10 ; Set max. decel to 10 revs/sec/sec

ADA5 ; Set avg. decel to 5 revs/sec/sec

V5 ; Set velocity to 5 revs/sec

GO1 ; Execute motion

END ; End definition of prog1

DEL Prog2 ; Delete program called prog2

DEF Prog2 ; Begin definition of prog2

MA0 ; Select incremental positioning mode

D40000 ; Set distance to 40,000

A10 ; Set max. accel to 10 revs/sec/sec

AA10 ; Set avg. accel to 10 revs/sec/sec

AD10 ; Set max. decel to 10 revs/sec/sec

ADA10 ; Set avg. decel to 10 rev/sec/sec

V5 ; Set velocity to 5 revs/sec

GO1 ; Execute motion

END ; End definition

of program #2

V

0

V

0

Move profiles

123

123

S-Curve

T

Trapezoidal

T

16 Gemini GV6K/GT6K Command Reference

www.comoso.com

2

2

2

A

2

3

2

3

2

2

2

3

Calculating Jerk

Rules of Motion:

A

(Programmed Accel)

a

Zero Acceleration

V

(Programmed Velocity)

V

2

Assuming the accel profile starts

when the load is at zero velocity and

the ramp to the programmed velocity

is not compromised:

Zero Velocity

V

1

Ø

(zero)

t

1

A B C

t

2

t

3

Jerk

A = programmed acceleration

AA = average acceleration

V = programmed velocity

t1 =

A

J

A

t1 ≥ t ≥ Ø

a (t) = JA * t

J

* t

A

v (t) =

V

=

t

2

AA

V

=

t

3

AA

NOTE: t

A

J

- t2 = t1

3

A

B

t2 ≥ t > t1

d (t) =

a (t) = A

2

J

* t

A

6

A

v (t) = + A * (t - t1)

2J

V1 =

V2 = V -

J

* t

A

1

A

d (t) = + + V1 * (t - t1)

=

2

A

2 * J

2 * J

A

C

t3 ≥ t > t2

A

a (t) = A - (JA * (t - t2))

v (t) = V -

A

* t

J

A

6

V

d (t) = + - V * (t3 - t)

2AA

Starting at a Non-Zero Velocity

initial velocity, the move comprises two components: a constant velocity component, and

an s-curve component. Typically, the change of velocity should be used in the S-curve

calculations. Thus, in the calculations above, you would substitute “(VF - VO)” for “V”

(VF = final velocity, VO = initial velocity). This is shown in the jerk equation (right).

: If starting the acceleration profile with a non-zero

da

=

Jerk

dt

dv

=

dt

dx

= (x = distance)

v

dt

A2 * AA

=

= J

A

V (A-AA)

(A, AD, HOMAD, etc.)

(AA, ADA, HOMAA, etc.)

(V, HOMV, etc.)

a (t) = acceleration at time t

(t) = velocity at time t

v

(t) = distance at time t

d

1

A * (t - t

)

1

2

* (t3 - t)

J

A

2

JA (t3 - t)

6

= J

Jerk

=

A

A2 * AA

- VO) (A-AA)

(V

F

Introduction

www.comoso.com

17

Units of Measure and Scaling

Units of Measure without Scaling

Scaling is disabled (

• Stepper axes: All distance values entered are in commanded counts (sometimes referred to as motor

steps), and all acceleration, deceleration and velocity values entered are internally multiplied by the

DRES

command value.

• Servo axes:

Accel/Decel Revs/sec/sec *

Velocity Revs/sec *

Distance Counts **

SCALEØ

Motion Attribute Encoder or Resolver

* All accel/decel & velocity values are internally multiplied by the ERES command value.

** Distance is measured in the counts received from the feedback device.

) as the factory default condition:

Units of Measure

What is Scaling?

Scaling allows you to program acceleration, deceleration, velocity, and position values in units of measure

that are appropriate for your application. The

SCALE1

(

to enable,

SCALEØ

to disable). The motion type(s) you are using in your application determines

which scale factor commands you need to configure:

Type of Motion Accel/Decel Scaling Velocity Scaling Distance Scaling

Standard Point-to-Point Motion

Following

SCLA SCLV SCLD

SCLA SCLV

SCALE

command is used to enable or disable scaling

SCLD for follower distances

SCLMAS for master distances

When Should I Define Scaling Factors?

Scaling calculations are performed when a program is defined or downloaded. Consequently, you must

enable scaling (

DEF

(

), uploading (

SCLD, SCLV

RECOMMENDED

SCALE1

and

) and define the scaling factors (

TPROG

SCLMAS

), or running (

) are automatically saved in the Gem6K’s battery-backed RAM.

RUN

) the program. NOTE: All scaling settings (

: Place the scaling commands at the beginning of your program file, before the location

of any defined programs. This ensures that the motion parameters in subsequent programs in your program

file are scaled correctly. When you use Motion Planner’s scaling setup wizard, the scaling commands are

automatically placed in the appropriate location in your program file.

ALTERNATIVE

: Scaling factors could be defined via a terminal emulator just before defining or

downloading a program. Because scaling command values are saved in battery-backed RAM (remembered

after you issue a

command or cycle power to the Gem6K), all subsequent program definitions and

RESET

downloads will be scaled correctly.

• Scaling commands are not allowed in a program. If there are scaling commands in a program, the Gem6K

will report an error message (“COMMAND NOT ALLOWED IN PROGRAM”) when the program is downloaded.

• If you intend to upload a program with scaled motion parameters, be sure to use Motion Planner. Motion

Planner automatically uploads the scaling parameters and places them at the beginning of the program file

containing the uploaded program from the Gem6K. This ensures correct scaling when the program file is later

downloaded.

SCLD, SCLA, SCLV, SCLMAS

NOTES

) prior to defining

SCALE, SCLA

,

18 Gemini GV6K/GT6K Command Reference

www.comoso.com

Acceleration & Deceleration Scaling (SCLA)

Stepper Axes: If scaling is enabled (

SCALE1

), all accel/decel values entered are internally multiplied by

the acceleration scaling factor to convert user units/sec/sec to commanded counts/sec/sec.

The scaled values are always in reference in commanded counts, regardless of the existence

of an encoder.

Servo Axes: If scaling is enabled (

SCALE1

), all accel/decel values entered are internally multiplied by

the acceleration scaling factor to convert user units/sec/sec to encoder or resolver

counts/sec/sec.

All accel/decel commands (e.g., A, AA, AD,

HOMA, HOMAD, JOGA

, etc.) are multiplied by the

SCLA

command value.

As the accel/decel scaling factor (

changes, the resolution of the accel and decel

values and the number of positions to the right of

the decimal point also change (see table at right).

An accel/decel value with greater resolution than

allowed will be truncated (e.g., if scaling is set to

SCLA1Ø

, the

truncated to

A9.9999

A9.9

command would be

).

SCLA

)

SCLA value

1 - 9 ............................................ 0

10 - 99 ........................................ 1

100 - 999 .................................... 2

1000 - 9999 ................................ 3

10000 - 99999 ............................ 4

100000 - 999999........................5

(counts/unit/unit) Decimal Places

The following equations can help you determine the range of acceleration and deceleration values.

Axis Type Min. Accel or Decel (resolution) Max. Accel or Decel

Stepper

Servo

0.001 ∗DRES

SCLA

Encoder Feedback:

0.001 ∗ ERES

SCLA

999.9999 ∗DRES

SCLA

Encoder Feedback:

999.9999 ∗ ERES

SCLA

Velocity Scaling (SCLV)

Stepper Axes: If scaling is enabled (

velocity scaling factor to convert user units/sec to commanded counts/sec. The scaled

values are always in reference to commanded counts (sometimes referred to as “motor

steps”).

Servo Axes: If scaling is enabled (

velocity scaling factor to convert user units/sec to encoder or resolver counts/sec.

All velocity commands (e.g., V,

command value.

As the velocity scaling factor (

change (see table below). A velocity value with greater resolution than allowed will be truncated. For

example, if scaling is set to

SCLV Value

(counts/unit)

1 - 9

10 - 99

100 - 999

1000 - 9999

10000 - 99999

100000 - 999999

SCLV10

SCALE1

SCALE1

HOMV, HOMVF, JOGVH, JOGVL

SCLV

) changes, the velocity command's range and its decimal places also

, the

), all velocity values entered are internally multiplied by the

), all velocity values entered are internally multiplied by the

, etc.) are multiplied by the

V9.9999

Velocity Resolution

(units/sec)

1

0.1

0.01

0.001

0.0001

0.00001

command would be truncated to

Decimal Places

0

1

2

3

4

5

V9.9

SCLV

.

Introduction

www.comoso.com

19

Use the following table to determine the maximum velocity for your product type.

Max. Velocity for Stepper Axes Max. Velocity for Servo Axes

50 revs/sec 200 revs/sec

: These velocity limitations are hardware based. Make sure the velocity scaling value used with the desired velocity

NOTE

(V command) does not exceed these velocities. The Gem6K will generate an error message if you try to exceed these

maximums. The maximum servo velocity may also be limited when using encoder feedback, depending on the encoder

resolution `used. Refer to the Gem6K Hardware Installation Guide for the maximum encoder input frequency.

Distance Scaling (SCLD and SCLMAS)

Stepper Axes: If scaling is enabled (

SCALE1

), all distance values entered are internally multiplied by the

distance scaling factor to convert user units to commanded counts (“motor steps”).

Servo Axes: If scaling is enabled (

SCALE1

), all distance values entered are internally multiplied by the

distance scaling factor to convert user units to encoder or analog input counts.

All standard motion distance commands (e.g.,

command value. The only exception is for master distance values (see table below):

SCLD

Scaling for Following Motion:

SCLMAS command defines the master’s distance scale factor. The Following-related commands that are affected

by SCLD and SCLMAS are listed in the table below.

Commands Affected by Master Scaling (

FMCLEN: Master Cycle Length

FMCP: Master Cycle Position Offset

FOLMD: Master Distance

FOLRD: Follower-to-Master Ratio (Denominator)

GOWHEN: Conditional GO (left-hand variable is PMAS)

TPMAS & [

TVMAS & [

SCLD

As the

]: Position of Master Axis

PMAS

]: Velocity of Master Axis

VMAS

SCLMAS

or

scaling factor changes, the distance command’s range and its decimal places also

The SCLD command defines the follower axis distance scale factor, and the

D, PSET, REG, SMPER, STRGTD

SCLMAS

Commands Affected by Follower Scaling (

)

FOLRN: Follower-to-Master Ratio (Numerator)

FGADV: Geared Advance

FSHFD: Preset Phase Shift

GOWHEN: Conditional GO (left-hand variable ≠ PMAS)

TPSHF & [

TPSLV & [

PSHF

PSLV

) and are multiplied by the

SCLD

]: Net Position Shift of Follower

]: Position of Follower Axis

change (see table below). A distance value with greater resolution than allowed will be truncated. For

example, if scaling is set to

SCLD4000

D105.2776

, the

command would be truncated to

D105.277

)

.

SCLD or SCLMAS

(counts/unit)

1 - 9 1.0 0 - ±999999999 0

10 - 99 0.10 0.0 - ±99999999.9 1

100 - 999 0.010 0.00 - ±9999999.99 2

1000 - 9999 0.0010 0.000 - ±999999.999 3

10000 - 99999 0.00010 0.0000 - ±99999.9999 4

100000 - 999999

NOTE FRACTIONAL STEP TRUNCATION NOTE

Value

If you are operating in the incremental mode (MAØ), or specifying master distance values with

FOLMD, when the distance scaling factor (SCLD or SCLMAS) and the distance value are multiplied,

a fraction of one step may be left over. This fraction is truncated when the distance value is used

in the move algorithm. This truncation error can accumulate over a period of time, when

performing incremental moves continuously in the same direction. To eliminate this truncation

problem, set SCLD or SCLMAS to 1, or a multiple of 10.

20 Gemini GV6K/GT6K Command Reference

Distance Resolution

(units)

0.00001 0.00000 - ±9999.99999 5

Distance Range *

(units)

www.comoso.com

Decimal

Places

Scaling Example — Steppers (GT6K)

We configure for a 25,000 step/rev system attached to 5-pitch leadscrew. The user wants to program

motion parameters in inches; therefore the scale factor calculation is: 25,000 steps/rev x 5 revs/inch =

125,000 steps/inch. For instance, with a scale factor of 125,000, the operator could enter a move distance

value of 2.000 and the controller would send out 250,000 pulses, corresponding to two inches of travel.

SCALE1 ; Enable scaling

DRES25000 ; Set drive resolution to 25,000 steps/rev

SCLD125000 ; Allow user to enter distance in inches

SCLV125000 ; Allow user to enter velocity in inches/sec

SCLA125000 ; Allow entering accel/decel in inches/sec/sec

DRESET ; Reset the drive so the DRES value is accepted

Scaling Example — Servos (GV6K)

We configure for a 4,000 count/rev servo motor/drive system (using a 1000-line encoder) attached to a 5pitch leadscrew. The user wants to position in inches; therefore, the scale factor calculation is 4,000

counts/rev x 5 revs/inch = 20,000 counts/inch.

SFB1 ; Select encoder feedback

ERES4000 ; Set encoder resolution to 4000 steps/rev (post quadrature)

SCALE1 ; Enable scaling

SCLD20000 ; Allow user to enter distance values in inches

SCLV20000 ; Allow user to enter velocity values in inches/sec

SCLA20000 ; Allow user to enter accel/decel values in inches/sec/sec

DRESET ; Reset the drive so the DRES value is accepted

Scaling Example — Following

Typically, the master and follower scale factors are programmed so that master and follower units are the

same, but this is not required. Consider the scenario below as an example.

The master is a 1000-line encoder (4000 counts/rev post-quadrature) mounted to a 50 teeth/rev pulley

attached to a 10 teeth/inch conveyor belt, resulting in 80 counts/tooth (4000 counts/50 teeth = 80

counts/tooth). To program in inches, you would set up the master scaling factor with the

command (80 counts/tooth ∗ 10 teeth/inch = 800 counts/inch).

The follower is a servo motor with position feedback from a 1000-line encoder (4000 counts/rev). The

motor is mounted to a 4-pitch (4 revs/inch) leadscrew. Thus, to program in inches, you would set up the

follower scaling factor with the

SCLD16000

command (4000 counts/rev ∗ 4 revs/inch = 16000

counts/inch).

SCALE1 ; Enable scaling

SCLMAS800 ; Master scaling (80 counts/tooth * 10 teeth/inch = 800 counts/inch)

SCLD16000 ; Follower scaling (4000 counts/rev * 4 revs/inch = 16000 counts/inch)

SCLMAS800

Introduction

www.comoso.com

21

www.comoso.com

Special Programming

Characters

%

Type Multi-Tasking

Syntax <a_>i%<command>

Units i = task number

Range 1-10

Default 1

Response n/a

See Also

LOCK, [SWAP], [TASK], TSKAX, TSKTRN, TSWAP, TTASK

Task Identifier

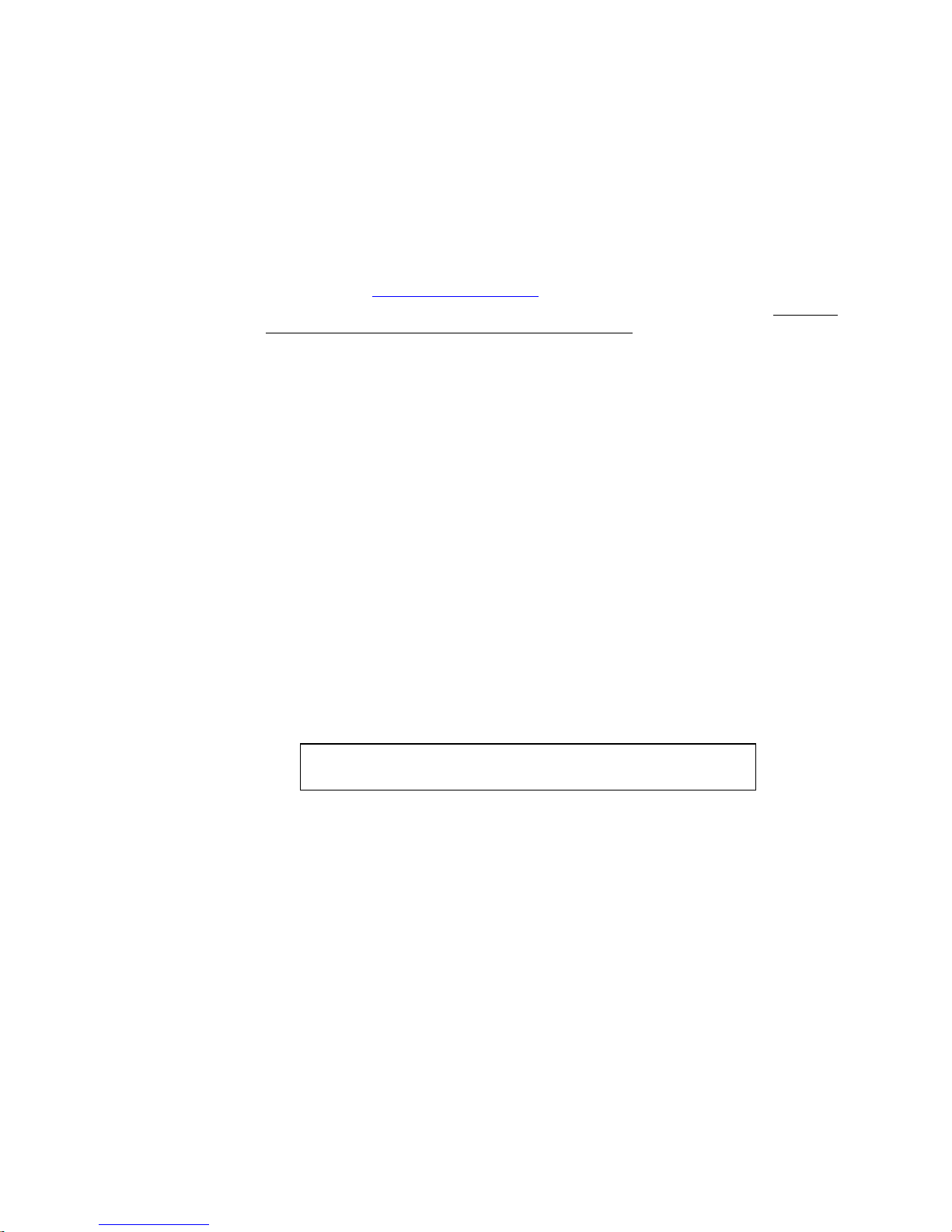

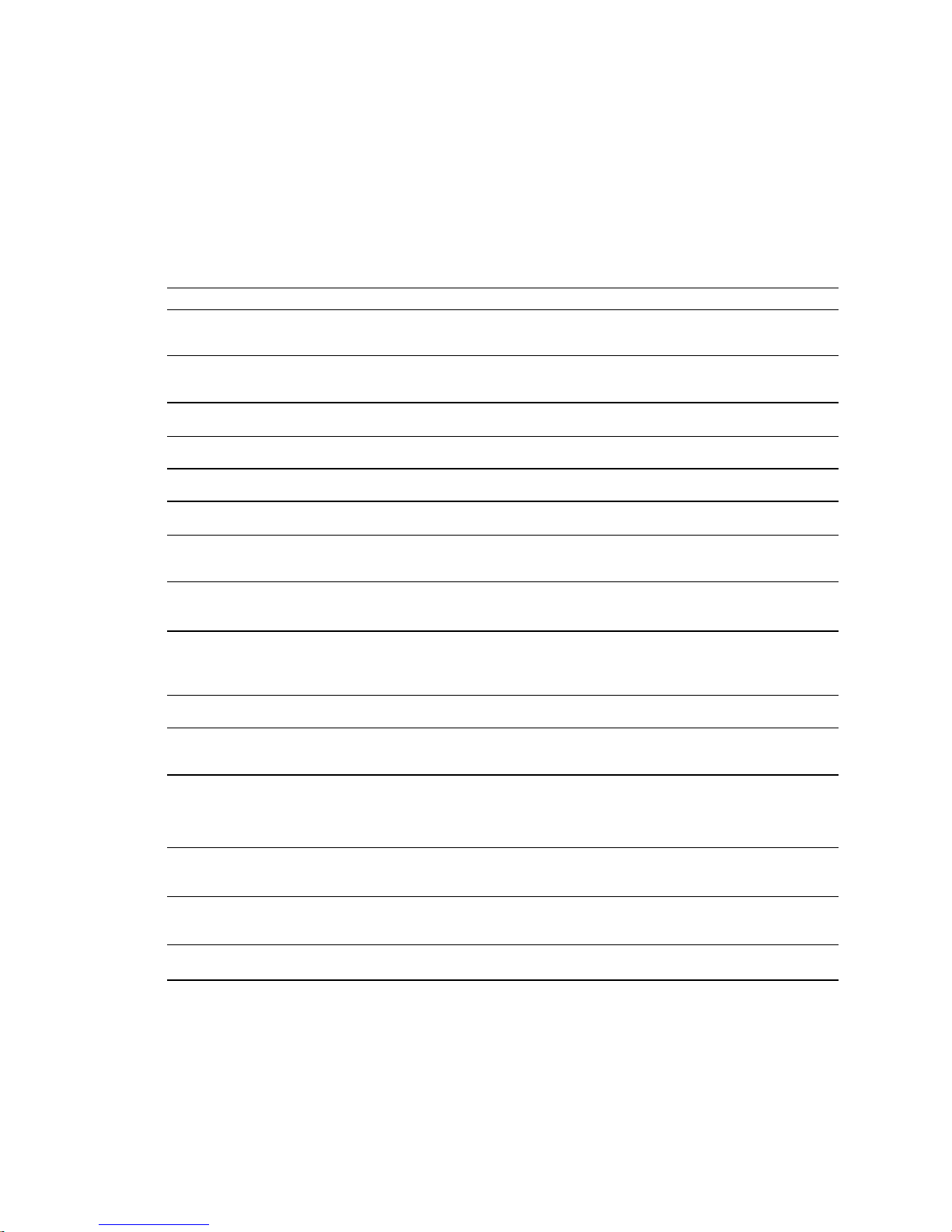

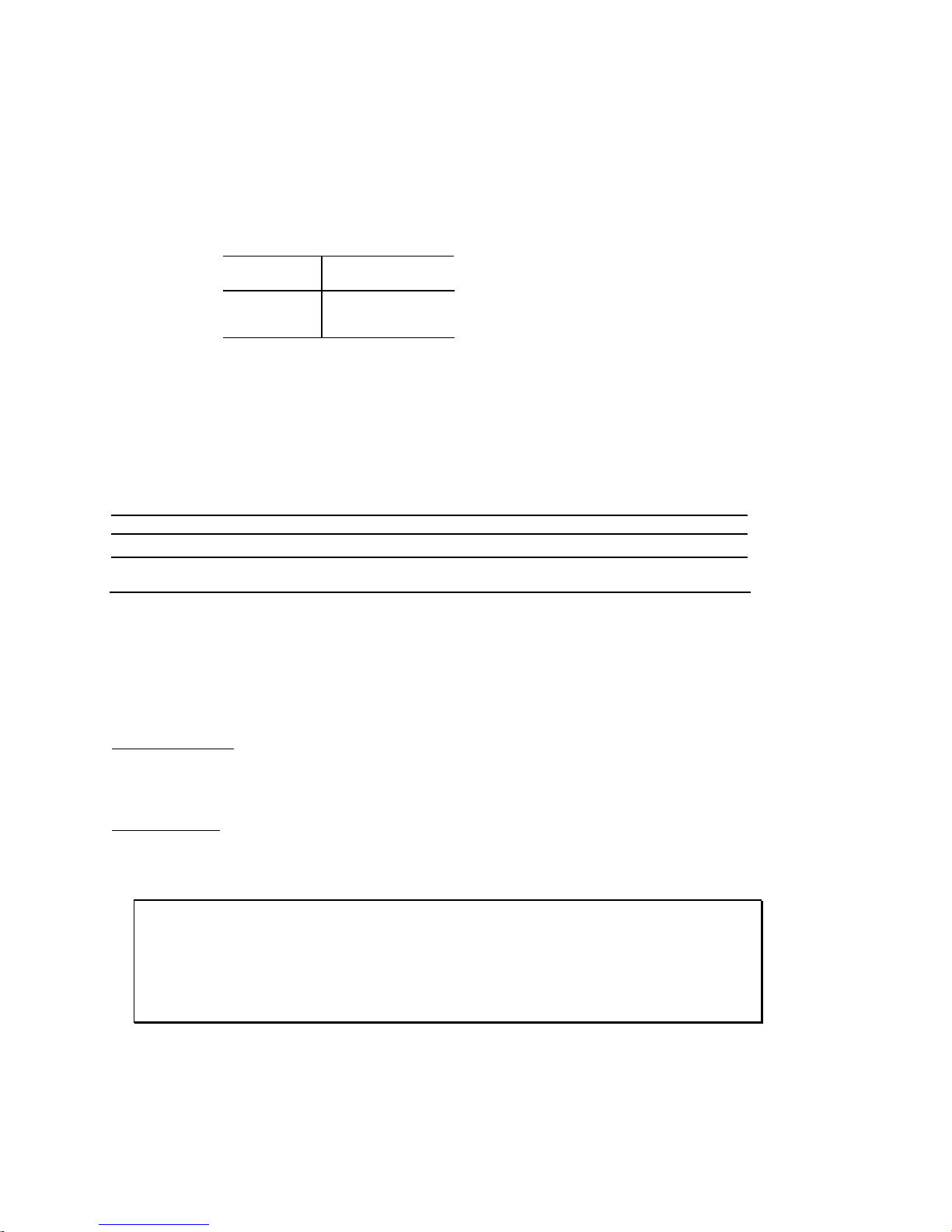

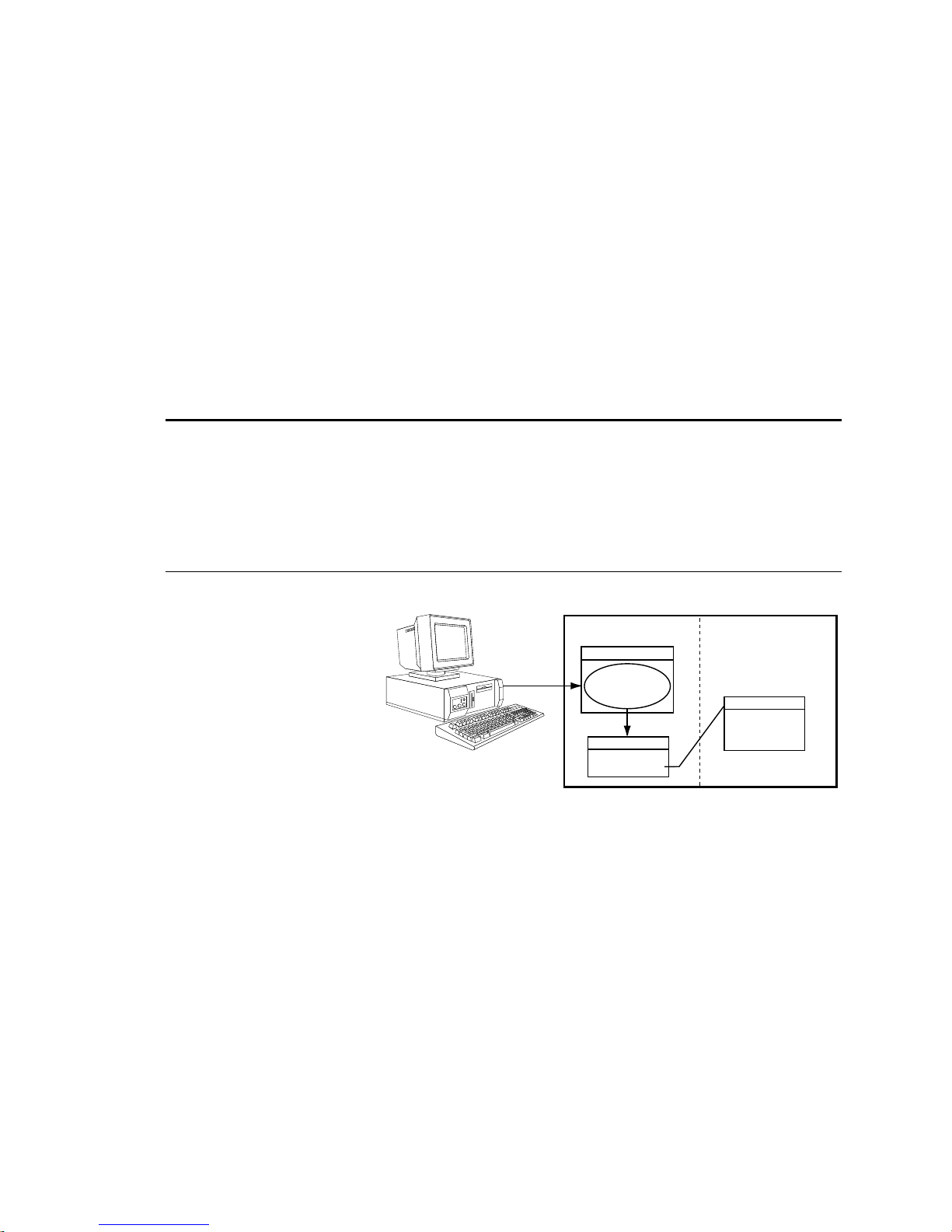

Use the Task Identifier (%)

prefix to specify that the

associated command will affect

the indicated task number. For

most simple multi-tasking

applications, the

prefix is

%

used to start a program running

in a specific task. For example,

the drawing on the right

illustrates how the

1%move1

command starts the program

called “

(specified with the

move1

” in task 1

prefix).

1%

1%move1

Gx6K Drive

Supervisor

Assign Task 1 to

execute the

"move1" program

Task 1

Execute the

"move1" program.

Product Rev

GT6K 6.0

GV6K 6.0

Program MemoryTask Management

Program: move1

DEF move1

---

---

--END

Command Descriptions 23

www.comoso.com

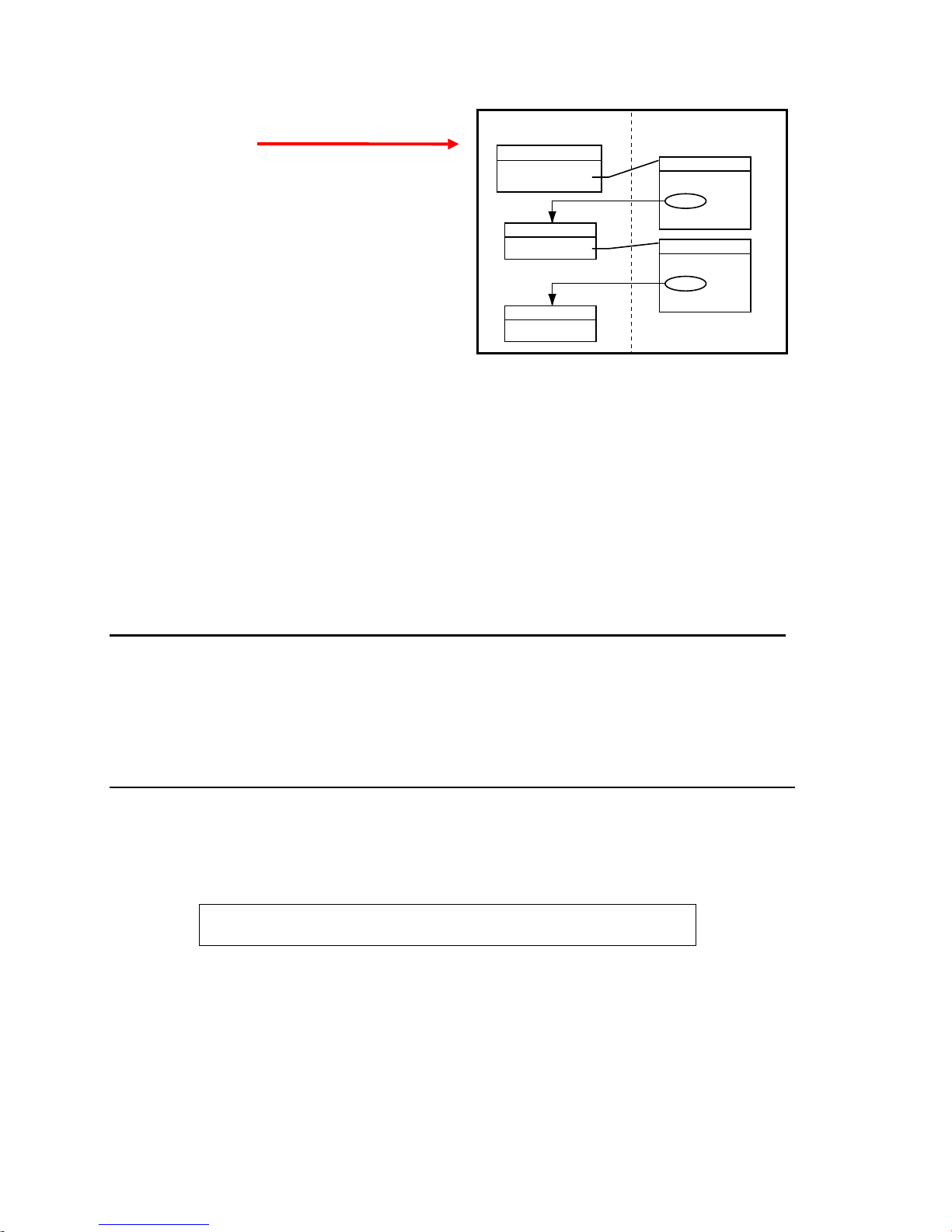

Because the

associated command will affect, new tasks can be

started from within other tasks, as shown in the

drawing on the right.

Within a program in a task, it is not necessary to use

the % prefix unless trying to initiate a program or

command in a different task. For example, if the

program running in task 3 executes a

fill

command, only task 3 is placed into

If the

fill

command, task 3 executes the command, but the

2%PS

program being executed in task 2 is paused, not task 3.

prefix specifies the task number that the

%

COMEXC1

COMEXC1

mode.

program running in task 3 also executes a

Gx6K Drive

Program MemoryTask Management

Supervisor

Running "main"

Task 1

Execute "move1"

Task 3

Execute "fill"

Program: main

DEF main

---

--1%move1

---

--END

Program: move1

DEF move1

---

--3%fill

---

--END

How the Task Supervisor Works: The “Task Supervisor” (also referred to as Task Ø

execution environment. It contains the command buffer and parser. Immediate commands and commands

executed from the communications buffer are implicitly directed to affect the supervisor unless exp licitly

directed to a task with the

prefix. Only the supervisor executes buffered commands from the

%

communications buffer. If the supervisor is executing a program, incoming commands will be buffered,

not executed. If the supervisor is not executing a program, it will execute commands from the input

command buffer, even if the other tasks are executing programs. If a command in the command buffer has

a task prefix, it is still executed by the supervisor, but affects the task specified by the prefix.

) is the main program

[ ! ]

Type Operator (Other)

Syntax <a_>!<command>

Units n/a

Range n/a

Default n/a

Response n/a

See Also COMEXC

mmediate Command Identifier

Product Rev

GT6K 6.0

GV6K 6.0

The Immediate Command Identifier (!) changes a buffered command into an immediate command. All

immediate commands are processed immediately, even before previously entered buffered commands.

All Gem6K commands are buffered.

The commands that use the

identifier are identified in the

!

portion of the command description.

Syntax

NOTE

A command with the ! prefix cannot be stored in a program.

24 Gemini GV6K/ GT6K Command Reference

www.comoso.com

[ @ ]

Type Operator (Other)

Syntax @<command><field1>

Units n/a

Range n/a

Default n/a

Response n/a

See Also ANIEN, ANIRNG, INEN, INLVL, OUT, OUTALL, OUTEN, OUTLVL, TANI,

TANO, TIN, TIO, TOUT

Global Command Identifier

Product Rev

GT6K 6.0

GV6K 6.0

The Global Command Identifier (@) is used to set the value of all fields to the value entered only in the first

field. For example,

commands can use the

;

Type Operator (Other)

Syntax ;<this is a comment>

Units n/a

Range n/a

Default n/a

Response n/a

See Also None

@OUT1 sets output #1 on for all I/O bricks. If you have any doubts about which

symbol, refer to the

@

Begin Comment

portion of the command description.

Syntax

Product Rev

GT6K 6.0

GV6K 6.0

The Begin Comment (;) command is used to comment application programs. The comment begins with a

semicolon (

) and is terminated by a command delimiter. The comment is not stored in a program. An

;

example of using the comment delimiter is as follows:

DEF pick ; Begin definition of program pick<cr>

$

Type Operator (Other)

Syntax <a_><!>$<t>

Units t = text name

Range Text name of 6 characters or less

Default n/a

Response n/a

See Also DEF, DEL, END, GOSUB, GOTO, JUMP, RUN, TLABEL

Label Declaration

Product Rev

GT6K 6.0

GV6K 6.0

The Label Declaration ($) command defines the current location as the label specified. A label consists of 6

or fewer alpha-numeric characters and must start with an alpha-character, not a number. Labels can only be

defined within a program or subroutine. The

label. The

deleted by a

command can also be used to start executing statements at a label. The label cannot be

RUN

command. However, when the program that contains the label is deleted, all labels

DEL

GOTO, GOSUB

or

commands can be used to branch to a

JUMP

contained within the program will be deleted.

NOTE: The maximum number of labels possible is 600.

A label declaration cannot consist of any of the following characters:

!, _, #, $, %, ^, &, *, (, ), +, -, {, }, \, |, ", :, ;, ', <, >, ,, ., ?, /, =

A label cannot have the same name as a Gem6K command. For example, $A and

NOTE:

are illegal

$A123

labels.

Command Descriptions 25

www.comoso.com

Example

DEF pick ; Begin definition of program called pick

GO1 ; Initiate motion

IF(VAR1=5) ; If variable 1 = 5 then do commands between IF and ELSE,

; otherwise commands between ELSE and NIF

GOTO pick1 ; Goto label pick1

ELSE ; Else part of IF command

GOTO pick2 ; Goto label pick2

NIF ; End IF command

$pick1 ; Label declaration for pick1

TAS ; Report axis status

BREAK ; Break out of current subroutine or program

$pick2 ; Label declaration for pick2

TPC ; Report commanded position

END ; End program definition

RUN pick ; Execute program named pick

[ # ]

Type Operator (Other)

Syntax <a_>!#<i>

Units i = number of commands to execute from the buffer

Range i = 1 - 200

Default 1

Response n/a

See Also DEF, HELP, STEP, TRACE, TRANS

Step Through a Program

Product Rev

GT6K 6.0

GV6K 6.0

This command controls the execution of a program or sequence when the single step mode is enabled

(

buffer will be executed. A

). Each time you enter the

STEP1

command followed by a delimiter, i commands in the sequence

!#<i>

followed by a delimiter will cause one command to be executed.

!#

Single step mode can be advantageous when trying to debug a program.

Example:

DEF tst ; Begin definition of program named tst

V1 ; Set velocity to 1 unit/sec

A10 ; Set acceleration to 10 units/sec/sec

D1 ; Set distance to 1 unit

GO1 ; Initiate motion

OUT11X1 ; Turn on on-board programmable outputs 1, 2, and 4,

; leave 3 unchanged

END ; End program definition

STEP1 ; Enable single step mode

RUN tst ; Execute program named tst

After entering the command

NOTE:

no action will occur because single step mode has been enabled.

RUN

Single step operation is as follows:

!#2 ; First 2 commands in the program tst are executed,

; commands to be executed are V1 and A10.

!# ; Execute 1 command from program; command to execute is D1

!#1 ; Execute 1 command from program; command to be executed is GO1

!#2 ; Execute 2 commands from program; commands to be executed are

; OUT11X1 and END

26 Gemini GV6K/ GT6K Command Reference

www.comoso.com

'

Type Operator (Other)

Syntax !'<numeric data>

Units Numeric data is command-dependent

Range Numeric data is command-dependent

Default n/a

Response n/a

See Also [ READ ], VARI, VARS

Enter Interactive Data

Product Rev

GT6K 6.0

GV6K 6.0

To enter data interactively, two operations must occur. First, numeric information must be requested.

Requesting the numeric information is accomplished with the

numeric variable to place the data into, and the

specifies the string variable to transmit before the data is

y

entered. Numeric information can also be requested by placing the

argument (e.g.,

A(READ1),12.52,(READ2),5.62

). After the data has been requested, a numeric

VARx=READy

READ

response must be provided. The numeric response must be preceded by the interactive data specifier (

command. The x specifies the

command in place of a command

)

!'

and followed by a delimiter (<cr> or <lf>).

Command processing will pause while waiting for data.

Example:

VARS1="Enter the count > " ; Set string variable 1 equal to the message

VAR5=READ1 ; Transmit string variable 1, and wait for numeric data in the

; form of !'<data>. Once numeric data has been received, place

; it in numeric variable 5

!'65.12 ; Variable 5 will receive the value 65.12

[ . ]

Type Operator (Other)

Syntax <command>.i

Units i = bit number

Range Command-dependent

Default None

Response n/a

See Also [ AS ], [ ER ], ERROR, [ IN ], INEN, INLVL, [ INO ], INTHW, LIMLVL,

[ MOV ], ONIN, ONUS, OUT, OUTEN, OUTLVL, POUT, [ SS ], TAS, TER, TIN,

TINO, TIO , TOUT, TSS, TUS, [ US ]

Bit Select

Product Rev

GT6K 6.0

GV6K 6.0

The Bit Select (.) operator specifies which bit to select. The primary purpose of this command is to let the

user specify a specific bit (or range), instead of having to type in an entire bit string.

When using the bit operator in a comparison, the bit operator must always come to the left of the

comparison. For example, the command

Command Shortcut Examples (affect only one binary bit location):

• Activate outputs at I/O location Brick 3, I/O point 9:

• Enable analog input at I/O location Brick 2, I/O point 2:

• Enable error-checking bit 6 for task 3:

Example:

VARB2=ER.12 ; Error status bit 12 assigned to binary variable 2

VARB2 ; Response (if bit 12 is set to 1):

2OUT.5=1 ; Activate the output at location Brick 2, I/O point 5

Command Descriptions 27

; *VARB2=XXXX_XXXX_XXX1_XXXX_XXXX_XXXX_XXXX_XXXX

IF(AS.12=b1)

is legal, but

www.comoso.com

IF(b1=AS.12)

3OUT.9=1

2ANIEN.2=E

3%ERROR.6=1

is illegal.

[ " ]

Type Operator (Other)

Syntax "<message>" (see below for possibilities)

Units n/a

Range n/a

Default n/a

Response n/a

See Also DWRITE, VARS, WRITE, WRVARS

Begin and End String

Product Rev

GT6K 6.0

GV6K 6.0

There are three commands that deal with string variables, or messages. The first of these commands is the

command. This command sets a string variable equal to a specific message (e.g.,

VARS

part count"

WRITE

first day of the rest of your life"

Syntax possibilities:

There are three ASCII characters that cannot be used within the quotes (

be specified in the string by using the backslash character (

for the character. For example, if you wanted to display the message

use the following syntax:

). The message must be placed in quotes for it to be recognized. The same can be said for the

and

DWRITE

commands. Their messages must also be placed in quotes (e.g.,

).

VARSn="<message>"

WRITE"<message>"

DWRITE"<message>"

WRITE"\34WHY ASK WHY\34"

where n equals the string variable number

:, "

) in combination with the ASCII decimal value

\

"WHY ASK WHY"

.

VARS1="Enter

WRITE"Today is the

, and ;). These characters can

in quotes, you would

An ASCII table is provided in Appendix B. Common characters and their ASCII equivalent value:

Character Description ASCII Decimal Value

<lf> Line Feed 10

<cr> Carriage Return 13

" Quote 34

: Colon 58

; Semi-colon 59

\ Backslash 92 (cannot be used with DWRITE)

[ \ ]

Type Operator (Other)

Syntax See below

Units n/a

Range n/a

Default n/a

Response n/a

See Also VARS, WRITE, WRVARS

ASCII Character Designator

Product Rev

GT6K 6.0

GV6K 6.0

The ASCII Character Designator (\) operator is used to place a character in a string that is normally not

represented by a keyboard character. The (

commands. The syntax for the (

WRITE"\<i>"

VARS1="\<i>"

, Where

, Where

<i>

<i>

) operator is as follows:

\

is the ASCII decimal equivalent of the character to be placed in the string.

is the ASCII decimal equivalent of the character to be placed in the string.

) operator can be used within the

\

There are three ASCII characters that cannot be used within the quotes (

be specified in the string by using the backslash character (

) in combination with the ASCII decimal value

\

:, ;

VARS