Vansco Multiplexing Module

VMM2404

U s er G u i d e

HY33-5011-IB/US

UG-VMM2404-0837001-201705-002

Parker Hannifin Canada

Electronic Controls Division

1305 Clarence Avenue

Winnipeg, MB R3T 1T4 Canada

office +1 204 452 6776

Fax +1 204 478 1749

http://www.parker.com/ecd

Copyright 2017 © Parker Hannifin Corporation. All rights reserved. No part of this work may be

reproduced, published, or distributed in any form or by any means (electronically, mechanically,

photocopying, recording, or otherwise), or stored in a database retrieval system, without the prior

written permission of Parker Hannifin Corporation in each instance.

Warning!

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS

DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized

distributors provide product and/or system options for further investigation by users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the final selection of the

system and components and assuring that all performance, endurance, maintenance, safety and warning

requirements of the application are met. The user must analyze all aspects of the application, follow applicable

industry standards, and follow the information concerning the product in the current product catalog and in any

other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options

based upon data or specifications provided by the user, the user is responsible for determining that such data

and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the

components or systems.

Offer of Sale

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries

or its authorized distributors. This offer and its acceptance are governed by the provisions stated in the "Offer of

Sale" elsewhere in this document, or available at www.parker.com.

User Guide iii

Publication History .............................................................................................................. vi

Safety ................................................................................................................................... vii

Safety symbols ................................................................................................................................ vii

General safety regulations .............................................................................................................. vii

Welding after installation ................................................................................................................ viii

Construction regulations ................................................................................................................ viii

Safety during installation ................................................................................................................ viii

Safety during start-up ....................................................................................................................... ix

Safety during maintenance and fault diagnosis ............................................................................... ix

1. About the VMM2404 .......................................................................................................... 1

1.1. Diagram conventions ................................................................................................................ 2

2. Quick Start ......................................................................................................................... 5

2.1. Overview ................................................................................................................................... 5

2.2. Gather Required Materials ........................................................................................................ 5

2.3. Install the Required Software Tools .......................................................................................... 6

2.3.1. Install the Data Link Adapter Driver Software ............................................................. 6

2.4. Connect the VMM2404 multiplexing module to a Development System .................................. 7

2.4.1. Power Up the Development System ........................................................................... 8

2.5. Create and Download Ladder Logic Applications ..................................................................... 9

3. Inputs ............................................................................................................................... 10

3.1. Programmable Multi-Purpose Inputs ...................................................................................... 10

3.1.1. Multi-Purpose Used as Programmable Digital Input ................................................. 10

3.1.2. Multi-Purpose Used as Analog Input ......................................................................... 12

3.1.3. Multi-Purpose Used as AC-Coupled Frequency Input .............................................. 16

3.1.4. Multi-Purpose Used as DC-Coupled Frequency Input .............................................. 18

3.2. Digital Inputs ........................................................................................................................... 21

3.2.1. Programmable Digital Inputs ..................................................................................... 21

3.2.2. Power Control Digital Inputs ...................................................................................... 23

3.2.3. Addressing Digital Inputs ........................................................................................... 25

4. Outputs ............................................................................................................................ 28

4.1. High-side outputs .................................................................................................................... 28

4.1.1. High-Side Output Capabilities ................................................................................... 28

4.1.2. High-Side Output Installation Connections ................................................................ 29

4.1.3. High-Side Output Diagnostics and Fault Protection .................................................. 30

Contents

iv VMM2404

Contents

4.2. Low-Side Outputs with Current Sense .................................................................................... 31

4.2.1. Low-Side Outputs with Current Sense Capabilities ................................................... 31

4.2.2. Low-Side Outputs with Current Sense Configuration Options ................................... 33

4.2.3. Low-Side Outputs with Current Sense Installation Connections ............................... 33

4.2.4. Low-Side Outputs with Diagnostics and Fault Protection .......................................... 34

5. Power ............................................................................................................................... 35

5.1. Logic and output power ........................................................................................................... 35

5.1.1. Logic and Output Power Capabilities ......................................................................... 35

5.1.2. Logic and output power connections ......................................................................... 36

5.2. Sensor supply .......................................................................................................................... 37

5.2.1. Sensor Power Capabilities ......................................................................................... 37

5.2.2. Sensor Power Connections........................................................................................ 38

6. Communication ............................................................................................................... 39

6.1. Controller area network ........................................................................................................... 39

6.1.1. J1939 CAN Capabilities ............................................................................................. 39

6.1.2. J1939 CAN Installation Connections ......................................................................... 39

7. Diagnostic LEDs ............................................................................................................. 42

7.1. Input LEDs ............................................................................................................................... 42

7.2. Output LEDs ............................................................................................................................ 42

7.3. Power LED............................................................................................................................... 42

7.4. Network LED............................................................................................................................ 43

8. Connectors ...................................................................................................................... 44

8.1. Mating Connector Part Numbers ............................................................................................. 45

8.2. Pinouts ..................................................................................................................................... 45

9. Installation ....................................................................................................................... 48

9.1. Mechanical Installation Guidelines .......................................................................................... 48

9.1.1. Dimensions ................................................................................................................ 48

9.1.2. Selecting a Mounting Location ................................................................................... 48

9.1.3. Mounting the VMM2404 to a Vehicle ......................................................................... 50

9.2. Electrical Installation Guidelines .............................................................................................. 50

9.2.1. Designing and Connecting the Vehicle Harness ....................................................... 50

10. Application Examples ................................................................................................... 51

10.1. Implementing Safety Interlocks ............................................................................................. 51

10.2. Controlling Indicator Lights .................................................................................................... 52

10.3. Controlling a Proportional Valve ............................................................................................ 53

10.4. Controlling Motor Speed ........................................................................................................ 55

10.5. Using one Analog Input as Two Digital Inputs ....................................................................... 56

10.6. Controlling a Linear Actuator ................................................................................................. 57

10.7. Connecting Various Sensors ................................................................................................. 58

10.7.1. Open Collector ......................................................................................................... 58

10.7.2. Variable Resistance ................................................................................................. 60

10.7.3. Variable Reluctance ................................................................................................. 61

10.7.4. Switch ....................................................................................................................... 61

10.7.5. Voltage ..................................................................................................................... 62

User Guide v

Contents

10.7.6. CMOS ...................................................................................................................... 63

10.7.7. Potentiometer (Ratiometric) ..................................................................................... 64

11. Tests ............................................................................................................................... 65

12. Frequently Asked Questions (FAQ) ............................................................................ 67

13. Troubleshooting ............................................................................................................ 71

14. Glossary ......................................................................................................................... 72

15. Index ............................................................................................................................... 79

User Guide vi

The following table provides an overview of the changes made to this document

over the course of its publication history.

Revision

Description of Change

Rev. 001

First release of this document

Rev. 002

New template, minor edits 05/2017

Publication History

User Guide vii

Do not perform the procedures in this manual unless you are experienced in the

handling of electronic equipment.

Contact the manufacturer if there is anything you are not sure about or if you have

any questions regarding the product and its handling or maintenance.

The term "manufacturer" refers to Parker Hannifin Corporation.

Safety symbols

The following symbols are used in this document to indicate potentially

hazardous situations:

Danger! Risk of death or injury.

Warning! Risk of damage to equipment or degradation of signal

When you see these symbols, follow the instructions carefully and proceed with

caution.

General safety regulations

Work on the hydraulics control electronics may only be carried out by trained

personnel who are well-acquainted with the control system, the machine, and its

safety regulations.

Follow the manufacturer's regulations when mounting, modifying,

repairing, and maintaining equipment. The manufacturer assumes no

responsibility for any accidents caused by incorrectly mounted or

incorrectly maintained equipment. The manufacturer assumes no

responsibility for the system being incorrectly applied, or the system

being programmed in a manner that jeopardizes safety.

Safety

viii VMM2404

Safety

Do not use the product if electronic modules, cabling, or connectors are

damaged or if the control system shows error functions.

Electronic control systems in an inappropriate installation and in

combination with strong electromagnetic interference fields can, in

extreme cases, cause an unintentional change of speed of the output

function.

Welding after installation

Complete as much as possible of the welding work on the chassis before the

installation of the system. If welding has to be done afterwards, proceed as

follows:

Do not place the welding unit cables near the electrical wires of the

control system.

1. Disconnect the electrical connections between the system and external

equipment.

2. Disconnect the negative cable from the battery.

3. Disconnect the positive cable from the battery.

4. Connect the welder's ground wire as close as possible to the place of the

welding.

Construction regulations

The vehicle must be equipped with an emergency stop which disconnects the

supply voltage to the control system's electrical units. The emergency stop must

be easily accessible to the operator. If possible, the machine must be built so that

the supply voltage to the control system's electrical units is disconnected when the

operator leaves the operator’s station.

Safety during installation

Incorrectly positioned or mounted cabling can be influenced by radio

signals, which can interfere with the functions of the system.

User Guide ix

Safety

Safety during start-up

Danger! Risk of death or injury. Do not start the machine's engine

before the control system is mounted and its electrical functions have

been verified.

Do not start the machine if anyone is near the machine.

Safety during maintenance and fault diagnosis

Before performing any work on the hydraulics control electronics, ensure that

The machine cannot start moving.

Functions are positioned safely.

The machine is turned off.

The hydraulic system is relieved from any pressure.

Supply voltage to the control electronics is disconnected.

User Guide 1

The Vansco Multiplex Module (VMM) 2404 is a software-programmable,

multiplexing, input/output controller that monitors dedicated and general-purpose

inputs, and controls solid-state-switch outputs.

The VMM modules can be configured to meet many system requirements through

I/O configuration options and ladder logic software.

Figure 1: VMM2404

The VMM2404 is designed to communicate through a J1939-based Controller

Area Network (CAN). Custom CAN messaging can be created in software, and

the VMM2404 can be used in any CAN 2.0B application.

The VMM2404 is controlled by ladder logic software.

You can write the software in ladder logic using the Vansco Multiplex

Module Software (VMMS) tool. Contact your Parker Vansco Account

Representative for more details about the VMMS.

The VMM2404 has many features, as follows

The VMM2404 can monitor up to 30 inputs:

15 general-purpose inputs (can be used as digital, analog, or frequency)

9 programmable digital inputs (can be active-high or active-low)

1. About the VMM2404

2 VMM2404

About the VMM2404

5 digital inputs (active-low inputs used for harness addressing)

1 power control input

The VMM2404 has 8 outputs, rated at 3 A maximum current:

4 high-side outputs

4 low-side outputs with current sense (these outputs monitor current, and

can be used for current feedback if a high-side output is used for pulsewidth modulation)

The VMM2404 has two Ampseal connectors (23 pin and 35 pin) that are used

to interface with the inputs, outputs, and CAN

The VMM2404 has 30 LEDs that can be used to indicate the state and fault

status of inputs, outputs, power, and CAN

The VMM2404 can detect and log the following faults:

Short-circuit

Overcurrent

Open load

Short-to-battery

Short-to-ground

This manual describes the hardware components of the VMM2404, but does not

explain how to write or configure the software. For more information about

software, refer to the appropriate software manual or contact your Parker Vansco

Account Representative.

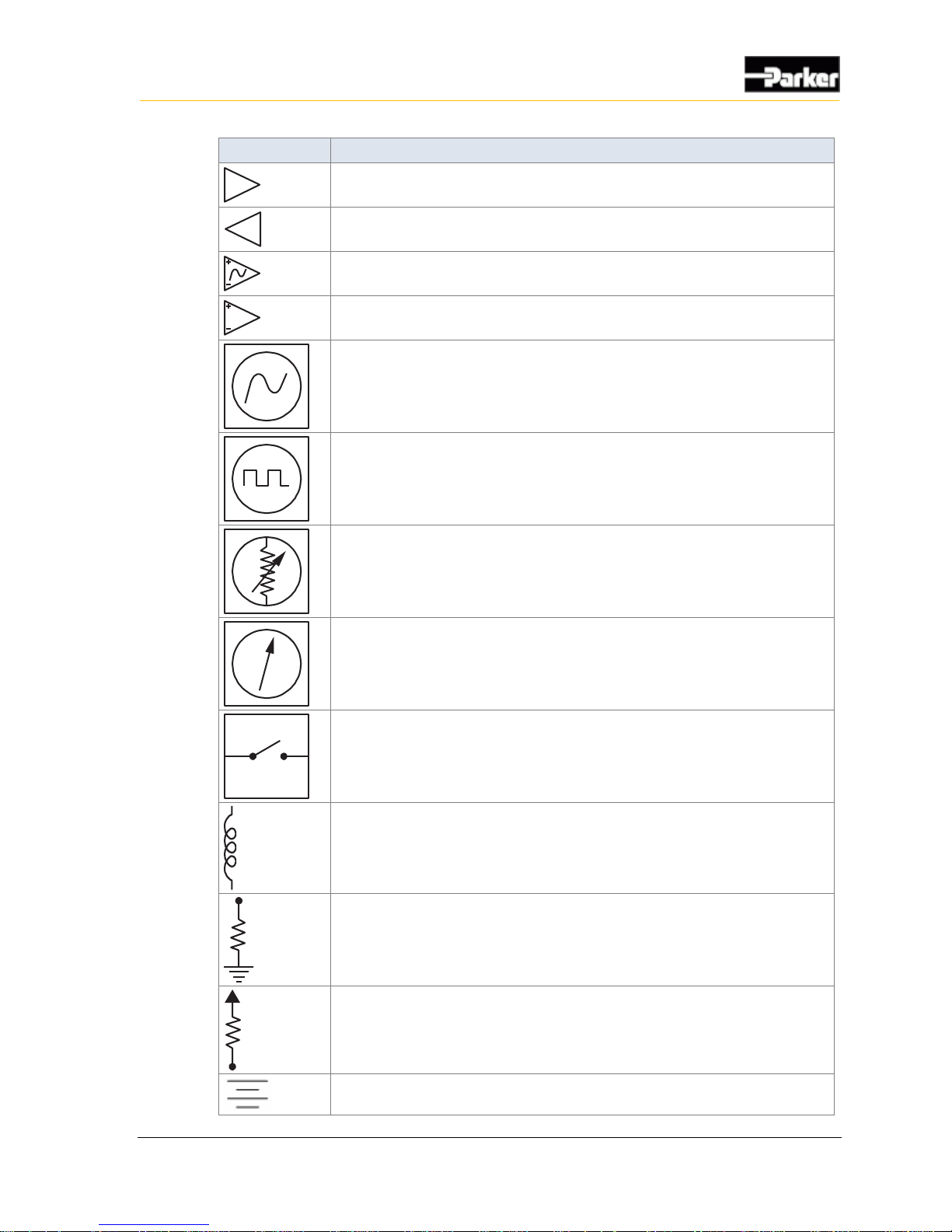

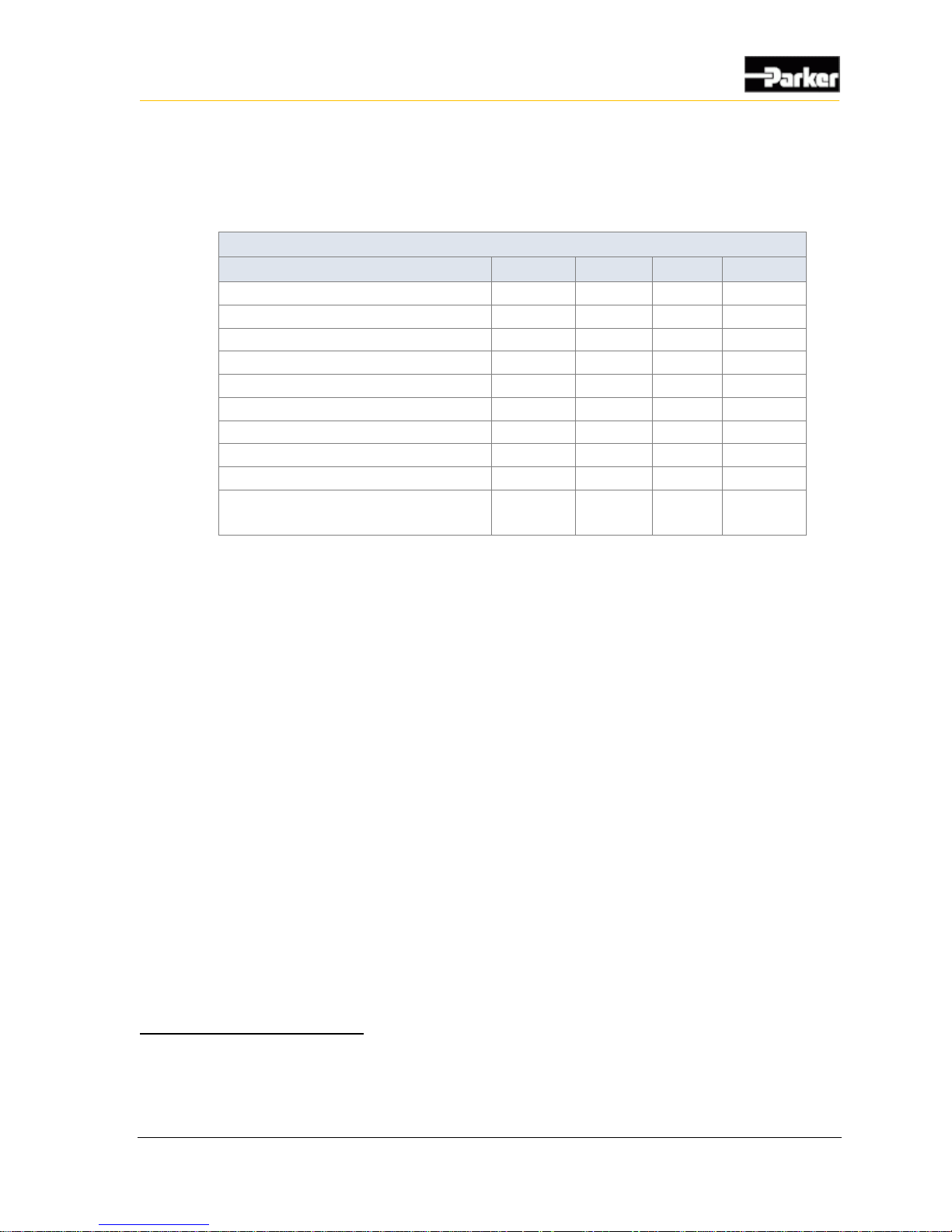

1.1. Diagram conventions

The following symbols are used in the schematic diagrams in this document:

User Guide 3

About the VMM2404

Symbol

Meaning

General input

General output

Frequency input

Analog input

Frequency sensor

Pulse sensor

Resistive sensor

General sensor

Application switch

Load

Pull-down resistor

Pull-up resistor

Battery

4 VMM2404

About the VMM2404

Symbol

Meaning

Fuse

Resistor

Ground

Chassis ground

User Guide 5

Quick Start

This section provides step-by-step instructions on how to connect the VMM2404

multiplexing module to a development system, install the required software tools,

and download the application software.

2.1. Overview

The following is a high-level overview of the steps involved with this section:

1. Gather the required materials.

2. Install the required software tools provided by Parker Vansco.

3. Connect the VMM2404 to a development system (desktop) and power it up.

4. Download application software.

2.2. Gather Required Materials

The following materials are required for the procedures in this section:

VMM2404 multiplexing module

personal computer (PC)

controller I/O board

controller I/O harness (connects the VMM2404 to the controller I/O board)

evaluation kit power harness (connects the controller I/O board to the power

supply)

Data Link Adapter (DLA) kit (comes with cables needed for connecting the

DLA to your PC and to the rest of the system)

desktop power supply compatible with the VMM2404 and controller I/O

board loads (a 12 V DC, 3 A fixed voltage supply is generally suitable, unless

driving more significant loads)

procurement drawing for the version of VMM2404 you are using, indicating

the configuration options for your variant of the product.

2. Quick Start

6 VMM2404

Quick Start

software tools and files required for programming and downloading software

for the VMM2404.

Note: With the exception of the PC and desktop power supply, all materials

and software are available from Parker Vansco. Please consult your Parker

Vansco Account Representative for specific details and pricing information.

2.3. Install the Required Software Tools

Before using the VMM2404 multiplexing module, install the following software

tools onto your PC:

Data Link Adapter (DLA) drivers

The DLA acts as the interface between the PC and the VMM2404. Before

using the DLA, you must install the DLA drivers.

Parker Vansco Software Tools

Parker Vansco provides the VMMS software tool to create and download

software for the VMM2404 multiplexing module. Contact your Parker

Vansco Account Representative, or visit the Parker website to get further

information on how obtain a product key.

2.3.1. Install the Data Link Adapter Driver Software

A Data Link Adapter (DLA) is needed when connecting the VMM2404

multiplexing module in a development system.

Note: Parker Vansco provides the latest DLA software releases through its

web site. Please contact your Parker Vansco Account Representative for

details on how to download the latest DLA driver software.

The Parker Vansco DLA requires the installation of drivers on your PC. To install

the Parker Vansco DLA drivers:

1. Download the driver, run the extracted file, and follow the Install Wizard. Do

not connect the USB-DLA until the driver installation is completed.

2. Connect the USB-DLA to a USB port on your PC. The Found New Hardware

screen opens.

3. Select Install the software automatically (Recommended), and then click

Next. If the driver is not detected automatically, you can browse to the folder

containing the driver.

4. After installation is finished, click Finish. The USB-DLA is now recognized

and ready to be used.

See the Parker Vansco USB-DLA kit user manual for more detailed instructions.

User Guide 7

Quick Start

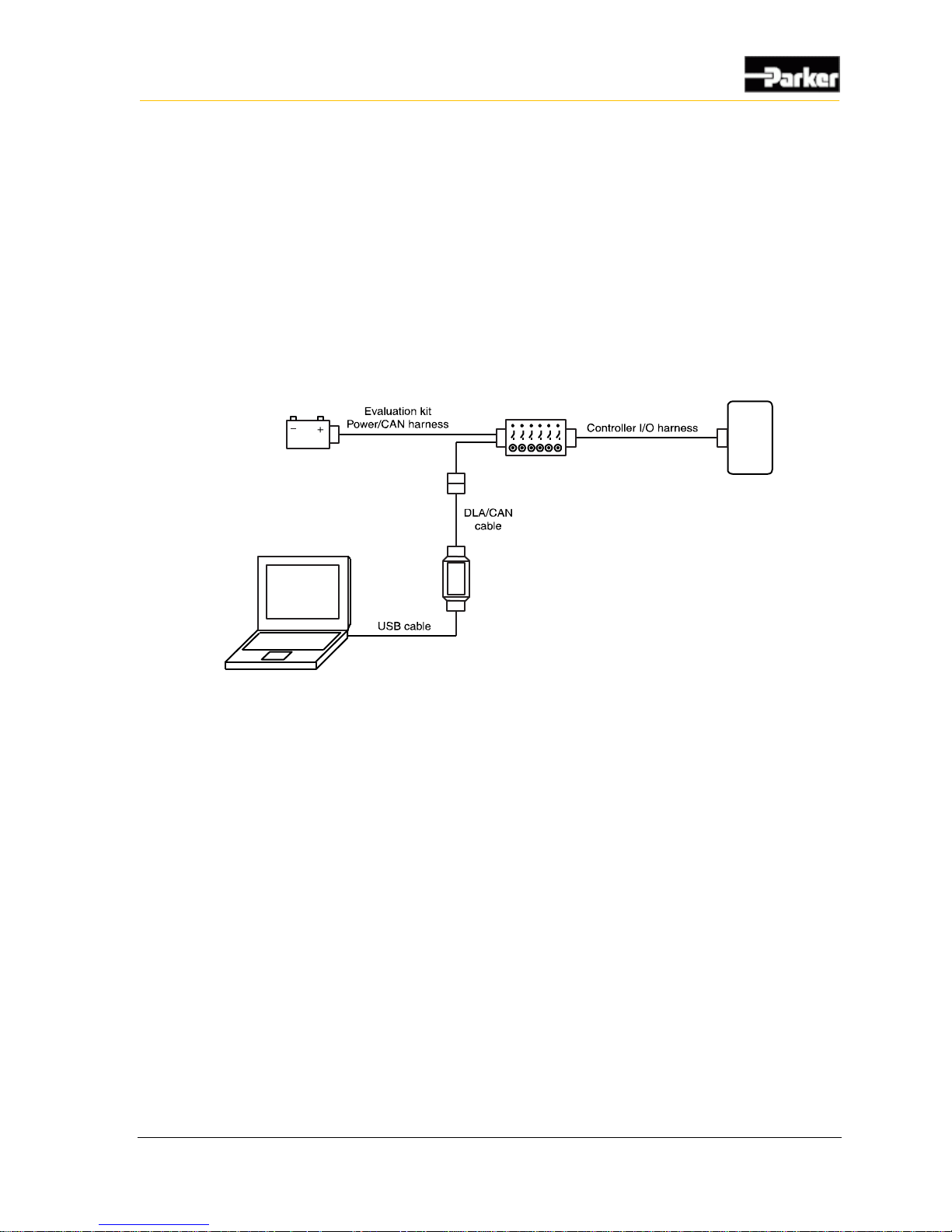

2.4. Connect the VMM2404 multiplexing module to a

Development System

It is a good idea to connect the VMM2404 multiplexing module to a development

system (PC, Controller I/O Board, power source, and DLA) to verify your

application. The development system is an ideal environment for creating and

downloading software applications.

The following shows how to connect the VMM2404 multiplexing module in a

development system:

Controller

DLA

I/O Board

Power

PC

Figure 2: Development system connection

To connect the VMM2404 multiplexing module in a development system, do the

following:

Note: Before connecting anything in the development system, ensure that the

power supply is set to a voltage that is less than 32 V DC.

8 VMM2404

Quick Start

1. Connect the Controller I/O harness to the VMM2404 multiplexing module.

2. Connect the Controller I/O harness to the controller I/O board connectors.

3. Connect the evaluation kit power/CAN harness to the controller I/O board’s

JP3 connector.

4. Do not connect the power wire (RED) from the evaluation kit power/CAN

harness to the power supply (+) terminal at this time.

5. Connect the ground wire (BLACK) from the evaluation kit power/CAN

harness to the power supply (-) terminal.

6. Connect the CAN connector from the evaluation kit power/CAN harness to

the corresponding mating connector and harness on the DLA.

Note: Do not proceed to the next step before the DLA drivers have been

installed. See Install the Data Link Adapter Driver Software on page 6.

7. Connect the DLA to a personal computer via the USB port.

2.4.1. Power Up the Development System

Once the VMM2404 is connected in a development system, you need to power it

up.

To power up the VMM2404 multiplexing module, do the following:

1. Ensure all controller I/O board digital inputs, jumpers, and dip switches are

properly configured for the VMM2404. Refer to the Controller I/O Board

Reference Manual for further details.

2. Connect the power wire (red) from the evaluation kit power/CAN harness to

the power supply (+), and turn the power supply on.

3. Turn on the controller I/O board switch that corresponds with the power

control input on the VMM2404 (refer to the Controller I/O Board Reference

Manual for details). The VMM2404 will power up.

Note: If the module does not power up and you are unsure if a power control

input is set on the VMM2404, try switching all the inputs on the controller I/O

board to high, and then to low. If you continue to have problems, consult the

Troubleshooting/FAQ section in the Controller I/O Board Reference Manual

for help.

User Guide 9

Quick Start

2.5. Create and Download Ladder Logic

Applications

Software applications can be created and downloaded to the VMM2404

multiplexing module.

The software applications for the VMM2404 can be created with the Vansco

Multiplexing Module Software (VMMS) tool, using ladder logic.

Consult your Parker Vansco Account Representative for information about your

software programming options.

10 VMM2404

Inputs

The VMM2404 has 3 main types of inputs, as follows:

Programmable digital inputs (can be used as active high, active low, or power

control)

Dedicated addressing inputs

Programmable multi-purpose inputs (can be used as analog, digital, or

frequency)

Note: Do not connect inputs directly to unprotected inductive loads such as

solenoids or relay coils, because they can produce high voltage spikes that

may damage the VMM2404. If an inductive load must be connected to an

input, use a protective diode or transorb.

3.1. Programmable Multi-Purpose Inputs

The VMM2404 has programmable multi-purpose inputs that can be configured

either as analog, digital, or frequency (ADF) through software, as follows:

INPUT1_ADF through INPUT15_ADF

3.1.1. Multi-Purpose Used as Programmable Digital Input

Digital inputs are typically used for electrical signals that are either on or off.

The following multi-purpose inputs can be used as digital inputs:

INPUT1_ADF to INPUT15_ADF

Note: There are 15 other digital inputs in addition to these inputs (refer to

Digital Inputs on page 21 for more details).

3. Inputs

User Guide 11

Inputs

3.1.1.1. Digital Input Capabilities

The following table provides specifications for the VMM2404’s standard digital

inputs:

Standard Digital Input Capabilities

Item

Min

Nom

Max

Unit

Input voltage range

0 - 32

V

Pull-up / pull-down resistance

3.1 k

-

3.5 k

Ω

Minimum negative going threshold

0.8 - -

V

Maximum positive going threshold

- - 1.19

V

Cutoff frequency (hardware)1

-

12

-

kHz

De-bounce time (software)2

25 - 50

ms

Overvoltage

- - 36

V

Wetting current @ 12 V

3.43

-

3.87

mA

Amplifier gain3

-

1.00

-

V/V

Leakage current sleep mode

- pin @ 12 V

- - 4.1

mA

3.1.1.2. Digital Input Configuration Options

Digital inputs can be programmed as either active high or active low, and they can

have a pull-up or pull-down resistance of 3.3 kΩ.

If the input is configured as active high, an internal pull-down resistor will be

used, and the input will be active when it is switched to battery voltage.

If the input is configured as active low, an internal pull-up resistor will be

used, and the input will be active when it is switched to ground.

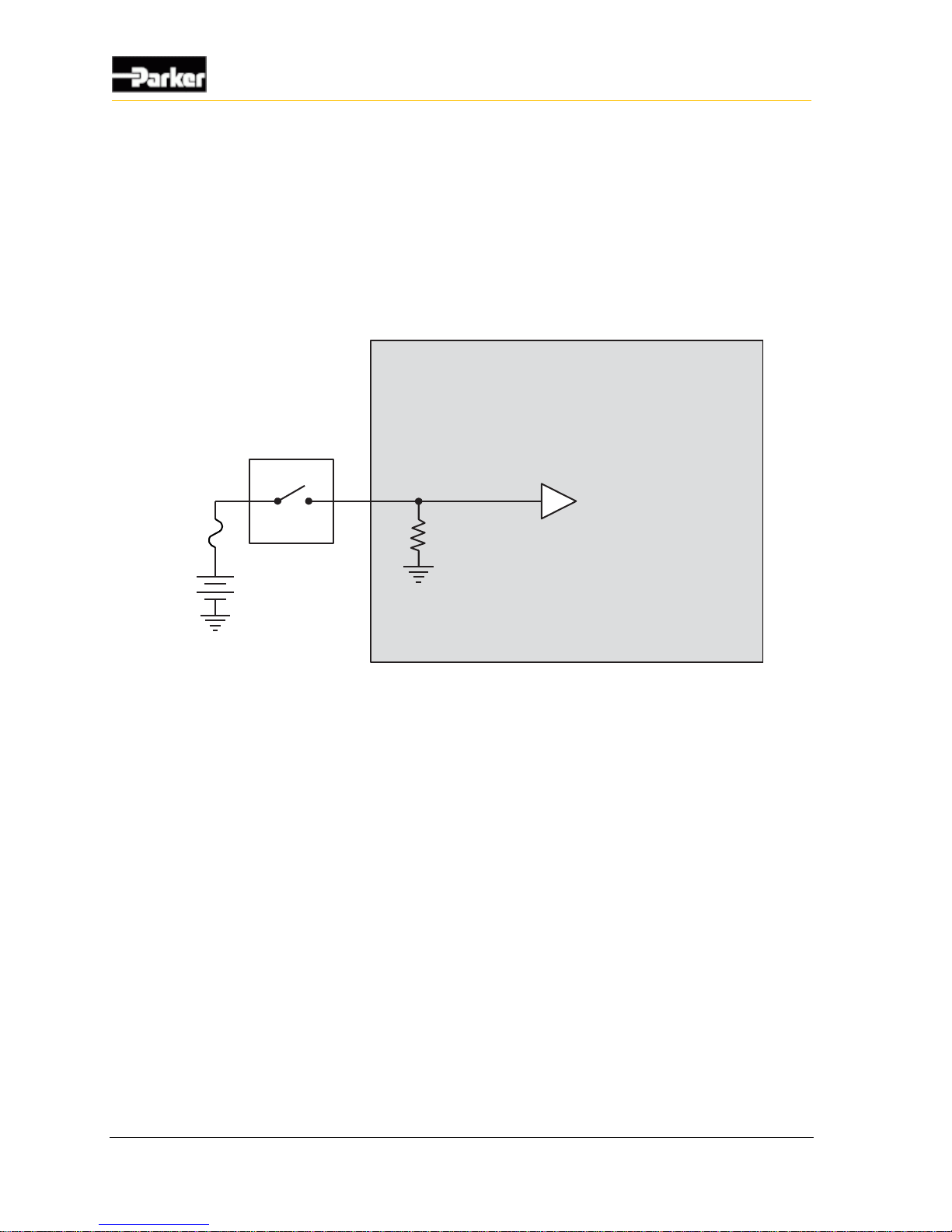

3.1.1.3. Active-High Digital Input Connections

A digital input is typically connected to a switch that is either open or closed.

When an active-high switch is open, the pull-down resistor ensures that no

voltage exists on the input signal, which will be interpreted by the VMM2404

as inactive.

When the switch is closed, the input is connected to battery voltage, which

will be interpreted by the VMM2404 as active.

1

Assumes there is a zero ohm source impedance from driving source. The actual cutoff in the application will be partially

determined from the source impedance and VMM input capacitance.

2

De-bounce time is based on a sampling rate of 40 Hz.

3

Amplifier gain on digital inputs is only adjustable in "black box" software. It is only pre-set to the value in the table if using

ladder logic.

12 VMM2404

Inputs

For an input that is active-high

It must be connected to battery power so that there is a battery connection

when the state of the input changes.

The power provided to the digital switch connected to the input must be

provided through a fuse in the wire harness.

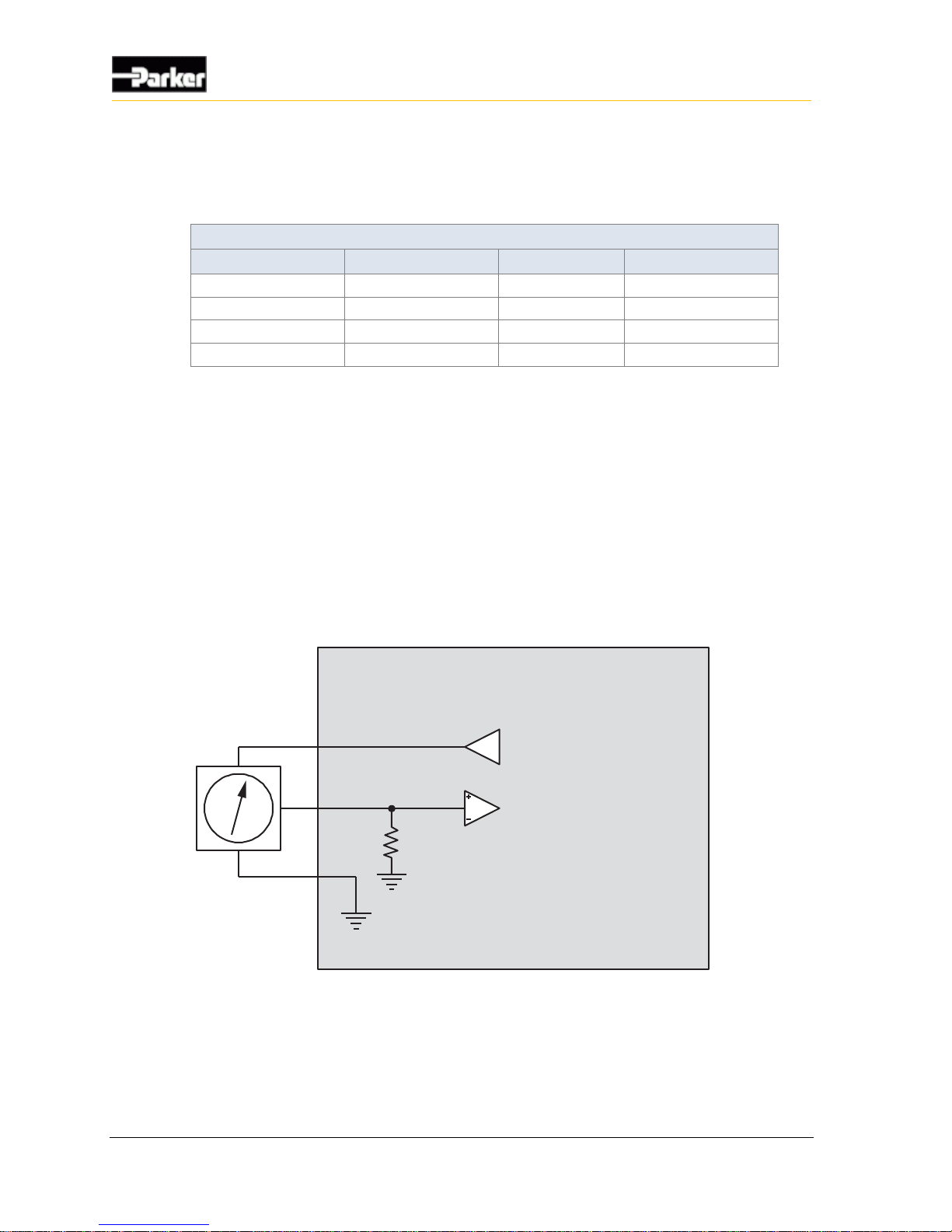

A typical active-high digital input connection is shown below:

Internal to product

Active High

Digital Input

Battery

Application Switch

Figure 3: Active high digital input

3.1.2. Multi-Purpose Used as Analog Input

Analog inputs are typically used to read electrical signals that span a voltage

range.

The following multi-purpose inputs can be used as analog inputs:

INPUT1_ADF to INPUT15_ADF

User Guide 13

Inputs

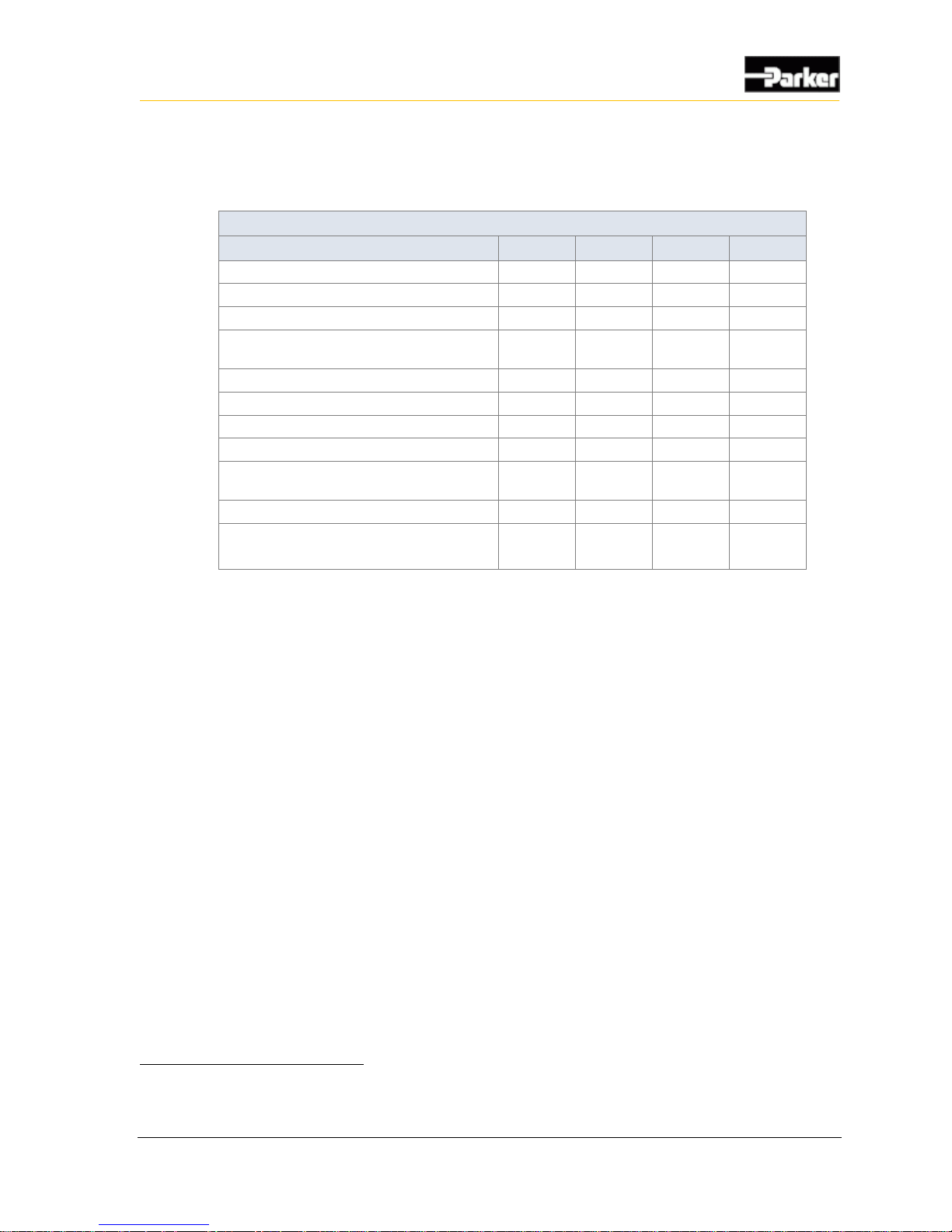

3.1.2.1. Analog Input Capabilities

The following table provides specifications for the VMM2404 analog inputs:

Analog Input Specifications

Item

Min

Nom

Max

Unit

Input voltage range

0 - 32

V

Overvoltage

- - 36

V

Pull-up / down resistance

3.1 k

-

3.5 k

Ω

Input resistance – pull-up/pull-down

disabled

81 k - -

Ω

Input capacitance

9

10

11

nF

Cutoff frequency (hardware)4

-

12

-

kHz

Accuracy - -

3

%

Resolution5

4.375

-

4.422

mV

Analog gain

-

Program-

mable

-

V/V

Reference voltage

2.984

3.0

3.016

V

Leakage current sleep mode

- pin @ 12 V

- - 4.1

mA

3.1.2.2. Analog Input Configuration Options

If one of the VMM2404’s multi-purpose inputs is configured as an analog input,

the input will be converted by the microprocessor using a 10-bit analog to digital

converter (ADC) that is referenced to 3.0 V.

There are 4 programmable gain and attenuation factors (shown in the table below)

that allow you to optimize the voltage resolution for each analog input, by

converting the maximum external voltage signal expected on an analog input to as

close to 3.0 V as possible.

The attenuation and gain columns in the following table represent the state of the

attenuation transistor and gain transistor on each analog input circuit.

4

Assumes there is a zero ohm impedance from driving source. The actual cutoff in the application will be partially determined

from the source impedance and VMM input capacitance.

5

10 bit ADC at worst case reference voltage, with 0.5 LSB fault.

14 VMM2404

Inputs

The pull-up or pull-down resistors for analog inputs can be enabled or disabled;

however, both pull-up and pull-down cannot be enabled at the same time. The

pull-up and pull-down resistance is 3.3 kΩ.

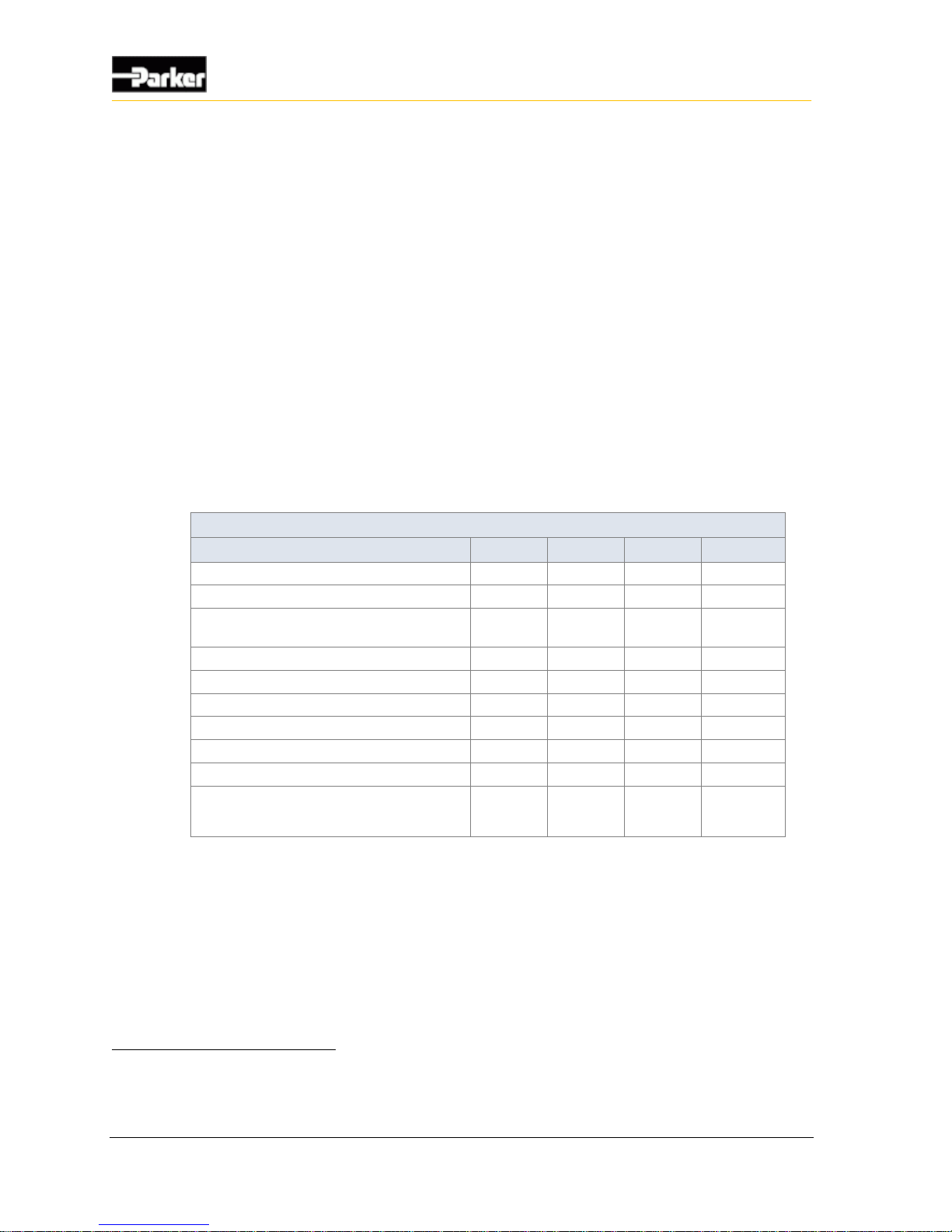

Gain and Attenuation Factors

Amp Gain

Max Voltage

Attenuation 1

Gain 1

3.313

0.906

OFF

ON

1.000

3.00

OFF

OFF

0.599

5.011

ON

ON

0.181

16.60

ON

OFF

3.1.2.3. Analog input connections

Analog inputs are susceptible to system noise, which can affect the accuracy of

the signal. Signal accuracy can also be affected by ground level shift, which can

cause inputs to activate when they shouldn't.

System noise

To prevent noise pickup on the sensors,

Use the shortest possible wires when connecting analog inputs to sensors.

The following shows how to connect an analog input to reduce system noise:

Internal to product

+5 Vdc Sensor Supply

Sensor Ground

Sensor

Analog Input

Figure 4: Analog input system noise reduction

User Guide 15

Inputs

Ground level shift

To reduce ground level shift:

1. Dedicate one of the 4 system ground inputs (GND) to sensors that have

dedicated ground wires, and connect all sensor grounds to this system ground

input.

2. Splice the other system ground inputs together in the vehicle harness (close to

the connector) to provide a better ground for the noisier low-side outputs and

digital circuits.

3. Position the sensor’s ground connection near the system ground connections

to ensure that the signal remains within the digital activation range of the

input.

Note 1: The system ground inputs are rated for low-current signals, which

ensures the sensor's ground is very close in voltage potential to the system

ground.

Note 2: Sensors that don’t have a dedicated ground wire are typically

grounded to the vehicle chassis through the sensor’s body.

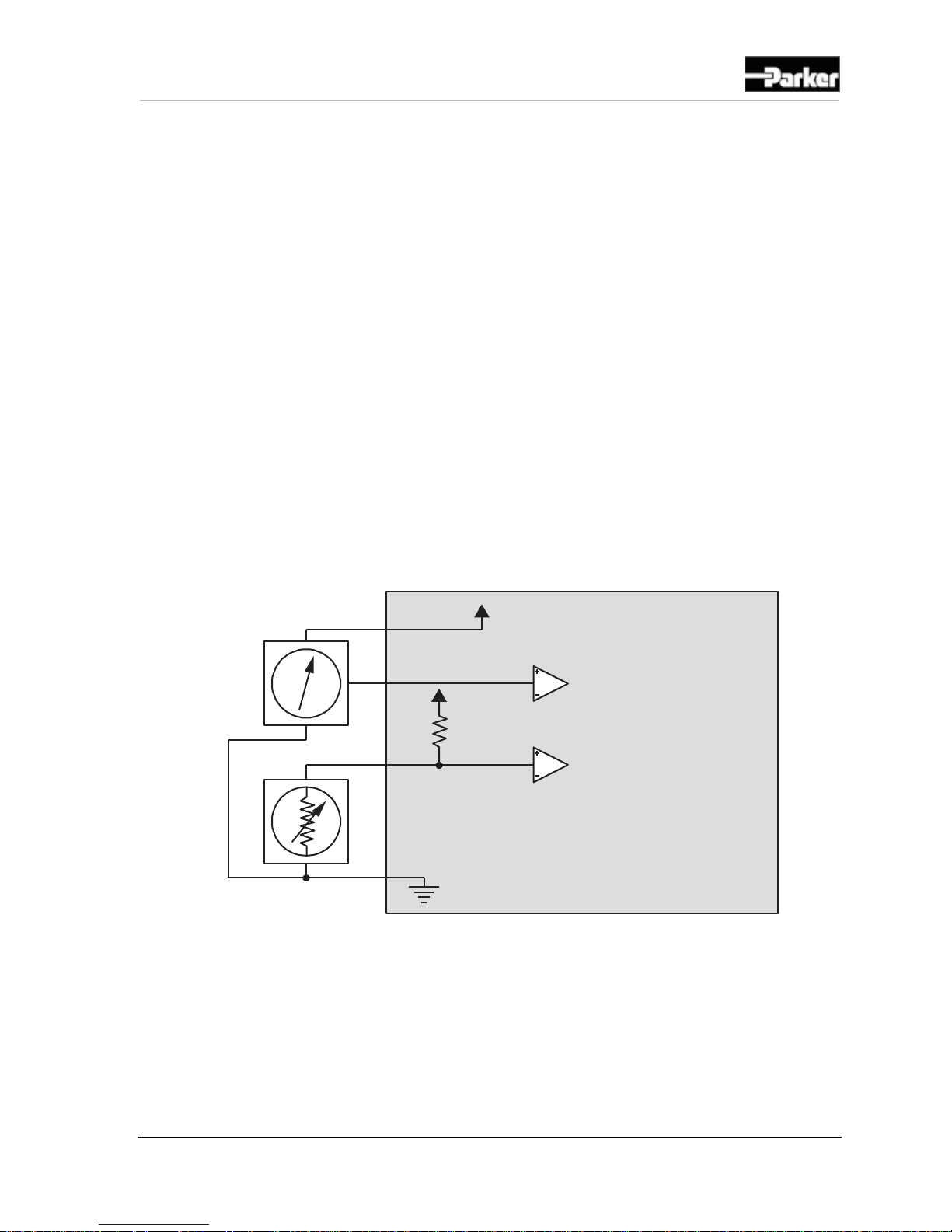

Internal to product

Sensor Power

Resistive Sensor

Pull-up

Resistor

Active Sensor

Analog Input

Analog Input

Figure 5: Analog input ground shift connection for sensors that have dedicated ground wires

16 VMM2404

Inputs

3.1.3. Multi-Purpose Used as AC-Coupled Frequency Input

The following multi-purpose inputs can be used as AC-coupled frequency inputs:

INPUT1_ADF and INPUT2_ADF

3.1.3.1. AC-Coupled Frequency Input Capabilities

AC-coupled frequency inputs provide AC-coupling, which allows you to read the

frequency of external signals that have either large DC offsets, or no ground

reference. These inputs are ideal for use with variable reluctance and inductive

pickup sensors.

Quadrature and pulse counting is possible; however, we recommend that you not

use these functions with AC-coupled frequency inputs.

The following table provides specifications for the VMM2404 general purpose

inputs when used as AC-coupled frequency inputs:

AC-Coupled Frequency Input Specifications

Item

Min

Nom

Max

Unit

Input voltage range6

-90 - 90

V

Pull-up / down resistance

3.1 k

-

3.5 k

Ω

Input resistance – pull-up/pull-down

disabled

81 k - -

Ω

Input capacitance

9

10

11

nF

AC-coupling capacitance

-

0.3

-

uF

Frequency range @ 0.25 Vp-p

5 - 10000

Hz

Accuracy - -

5

%

Resolution

0.1 - -

Hz

Switching threshold voltage7

-

1.65

-

V

Leakage current sleep mode

- pin @ 12 V

- - 4.1

mA

3.1.3.2. AC-Coupled Frequency Input Configuration Options

AC-coupled frequency inputs have 4 programmable gain and attenuation factors.

The pull-up or pull-down resistors for AC-coupled frequency inputs can be

enabled or disabled; however, both pull-up and pull-down cannot be enabled at

the same time. The pull-up and pull-down resistance is 3.3 kΩ.

6

Input voltage range assumes that the inductive pickup will increase in voltage as flywheel speed increases. Analog input pull-

up configuration options must be selected accordingly to prevent damage on those components at these voltage extremes.

7

The switching threshold on AC-coupled inputs is not programmable, and is set internally to ensure proper conversion of the

input signal through a comparator circuit. The value given in the table is not a physical value on the product's input pin.

User Guide 17

Inputs

3.1.3.3. AC-Coupled Frequency Input Connections

When connecting AC-coupled frequency inputs, be aware of system noise and

ground level shift.

System Noise

AC-coupled frequency inputs are more susceptible to system noise than digital

inputs.

To reduce system noise:

Connect AC-coupled frequency inputs to sensors with significant DC offset.

Use the shortest possible wires when connecting AC-coupled frequency inputs

to sensors to prevent noise pickup on the sensors.

Ground Level Shift

Ground level shift affects the accuracy of AC-coupled frequency inputs. Ground

level shift refers to the difference between the system ground input (GND)

voltage, and the sensor ground voltage.

To reduce ground level shift:

If there are more than 1 GND pins in the system, dedicate one of them to

sensors that have ground wires, and connect all sensor grounds to that system

ground pin.

Splice the other system ground inputs together in the vehicle harness (close to

the connector), to provide a better ground for the noisier low-side outputs and

digital circuits.

Ensure the sensor’s ground connection is close to the system ground

connections. This will help ensure the signal remains within the digital

activation range of the input.

Note 1: The VMM2404 system ground inputs are rated for low-current

signals, which ensures the sensor’s ground is very close in voltage potential to

the system ground.

Note 2: Sensors that don’t have a dedicated ground wire are typically

grounded to the vehicle chassis through the sensor’s body.

18 VMM2404

Inputs

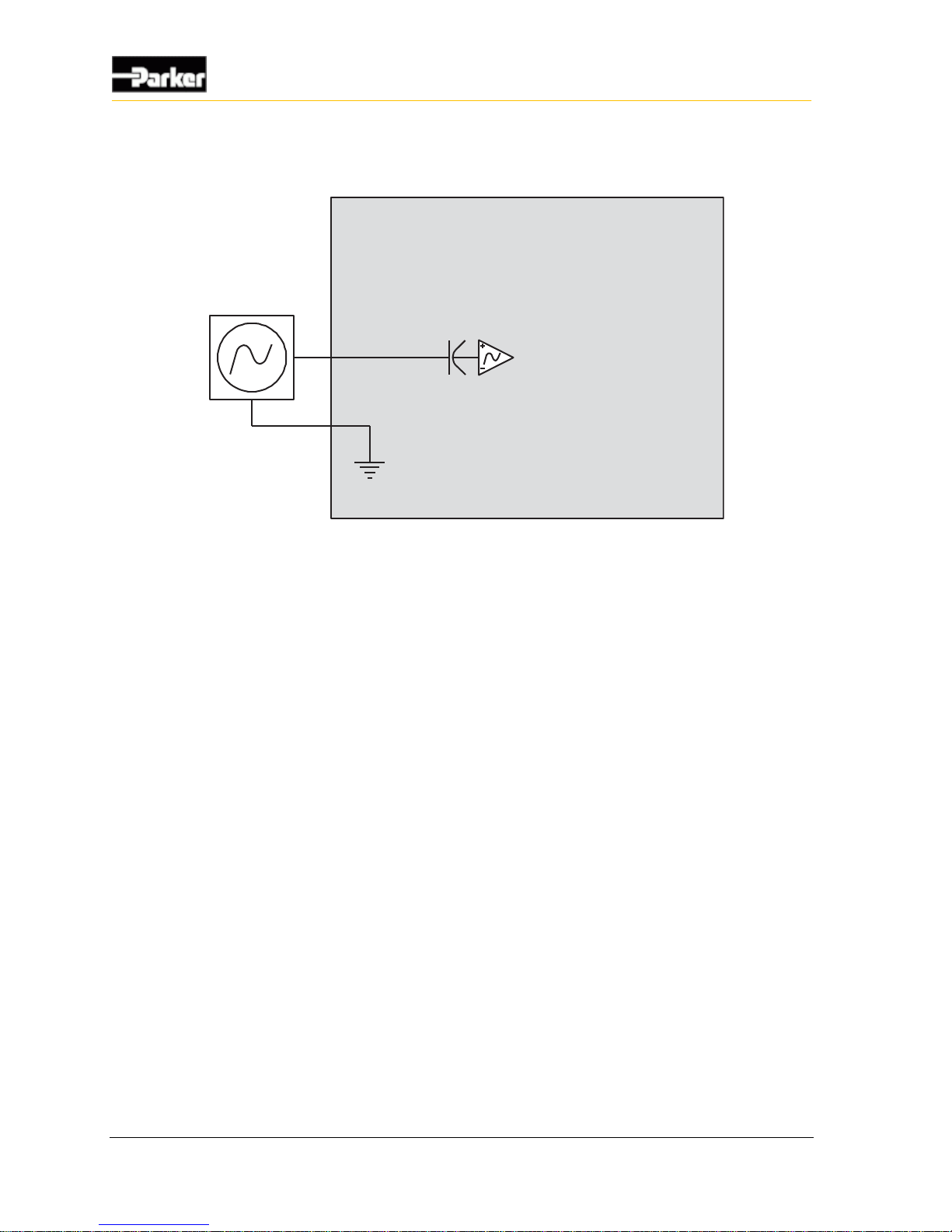

The following shows a typical AC-coupled frequency input connection:

Internal to product

Sensor Ground

Variable Reluctance

Sensor

AC Coupled

Frequency Input

Figure 6: AC-coupled frequency input installation connections

3.1.4. Multi-Purpose Used as DC-Coupled Frequency Input

The following multi-purpose inputs can be used as DC-coupled frequency inputs:

INPUT3_ADF to INPUT_15_ADF

3.1.4.1. DC-Coupled Frequency Input Capabilities

DC-coupled frequency inputs allow you to read the frequency of external signals

that have a ground reference and no DC offset. These inputs are ideal for use with

hall-effect type sensors.

Quadrature and pulse counting is possible with DC-coupled frequency inputs.

Loading...

Loading...