Parker V12 Service Manual

Bulletin HY30-5506-M1/UK

Service Manual

Series V12

Effective: February, 2014

Supersedes: May, 2013

HY30-5506-M1/UK

Service Manual

Series V12

List of contents Page

Specications and cross section ...............................................................3

Assembling shaft package ..................................................................4 - 5

Assembling cylinder barrel, joint shaft and cover ...................................... 5

Assembling control cover .......................................................................6-7

Assembling end cap ............................................................................. 8-11

Assembling complete unit ..................................................................12-14

End-cap location .....................................................................................15

Parts specication and split view ........................................................16-20

Seal kit specication ................................................................................ 21

Test procedure ......................................................................................... 22

Gauge and pilot ports AC and AH control ................................................ 23

Gauge and pilot ports EO and EP control ...............................................24

Gauge and pilot ports HO and HP control ............................................... 25

Conversion factors

1 kg = 2.2046 lb

1 N = 0.22481 lbf

1 bar = 14.504 psi

1 l = 0.21997 UK gallon

1 l = 0.26417 US gallon

3

1 cm

= 0.061024 in

1 m = 3.2808 feet

1 mm = 0.03937 in

1 °C = 1.8°F + 32

3

HY30-5506-M1/UK

Specications

V12 frame size

Displacement [cm³/rev]

at 35° (max)

at 6,5° (min)

Operating pressure [bar]

max intermittent ¹

max continuous

Operating speed [rpm]

max intermittent at 35° ¹

max continuous at 35°

max intermittent at 6.5°-20° ¹

max continuous at 6.5°-20°

min continuous

Flow [l/min]

max intermittent ¹

max continuous

Output torque [Nm]

at 100 bar (theor.)

Max output power [kW]

max intermittent ¹

max continuous

Corner power [kW]

max intermittent ¹

continuous

Mass moment of inertia

(x10-3) [kg m2]

Weight [kg]

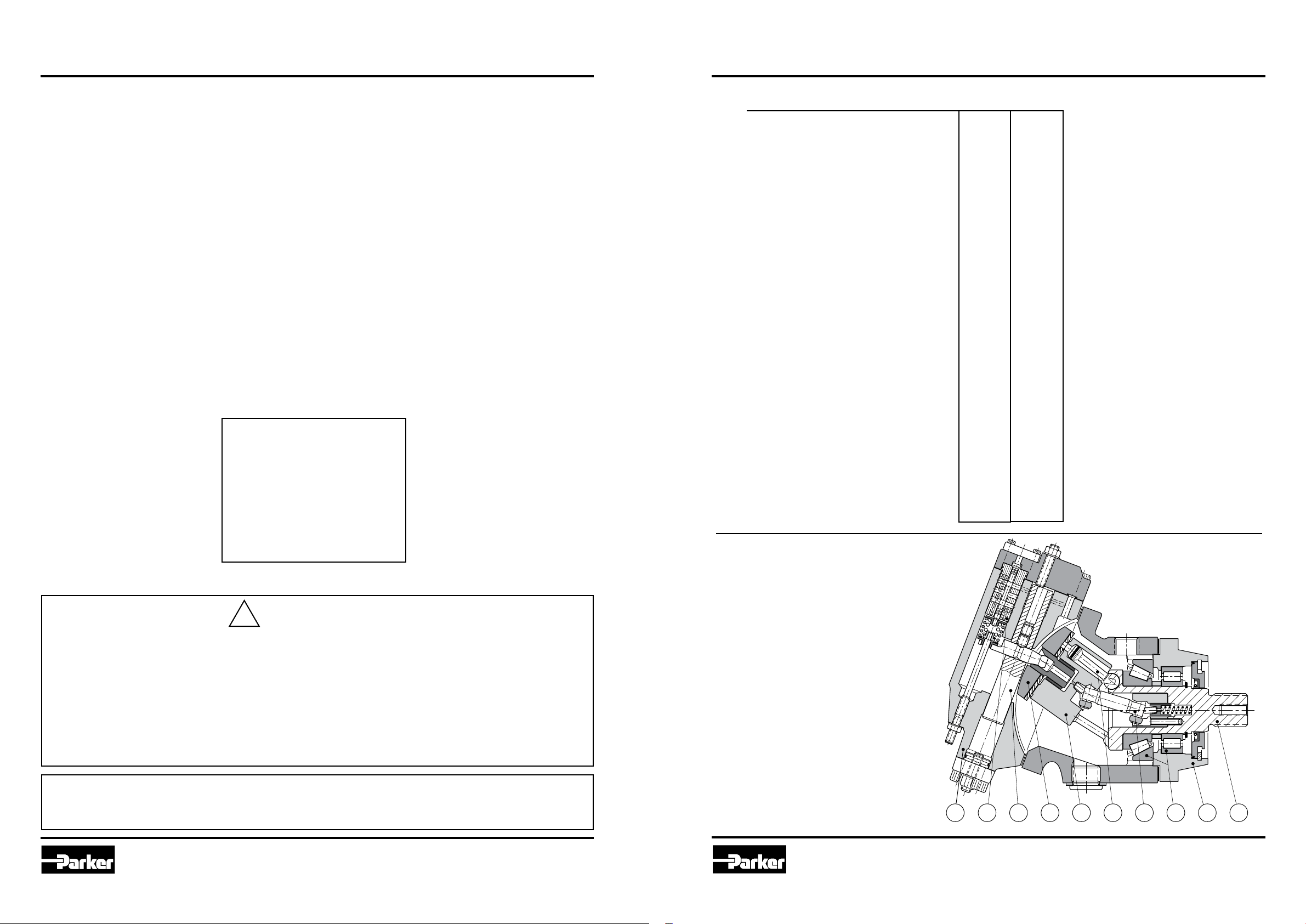

V12 cross section

Service Manual

Series V12

60

60

12

)

480

420

)

4400

3600

)

7000

5600

50

)

265

215

95

)

150

95

)

335

235

3.1

28

80

80

16

480

420

4000

3100

6250

5000

50

¹) Max 6 seconds in any one minute.

320

250

127

175

105

400

280

4.4

33

!

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED

HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannin Corporation, its subsidiaries and authorized distributors provide

product and/or system options for further investigation by users having technical expertise. It is important that you analyze all

aspects of your application, including consequences of any failure, and review the information concerning the product or system in the current product catalogue. Due to the variety of operating conditions and applications for these products or systems,

the user, through its own analysis and testing, is solely responsible for making the nal selection of the products and systems

and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specications, designs, availability and pricing,

are subject to change by Parker Hannin Corporation and its subsidiaries at any time without notice.

Offer of Sale

Please contact your Parker representation for a detailed ”Offer of Sale”.

2

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

1. End cap

2. Servo control valve

3. Setting piston

4. Valve segment

5. Cylinder barrel

6. Spherical piston with

laminated piston ring

7. Synchronizing shaft

8. Heavy-duty roller bearings

9. Bearing housing

10. Output shaft

12345678910

3

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

HY30-5506-M1/UK

Service Manual

Series V12

HY30-5506-M1/UK

Service Manual

Series V12

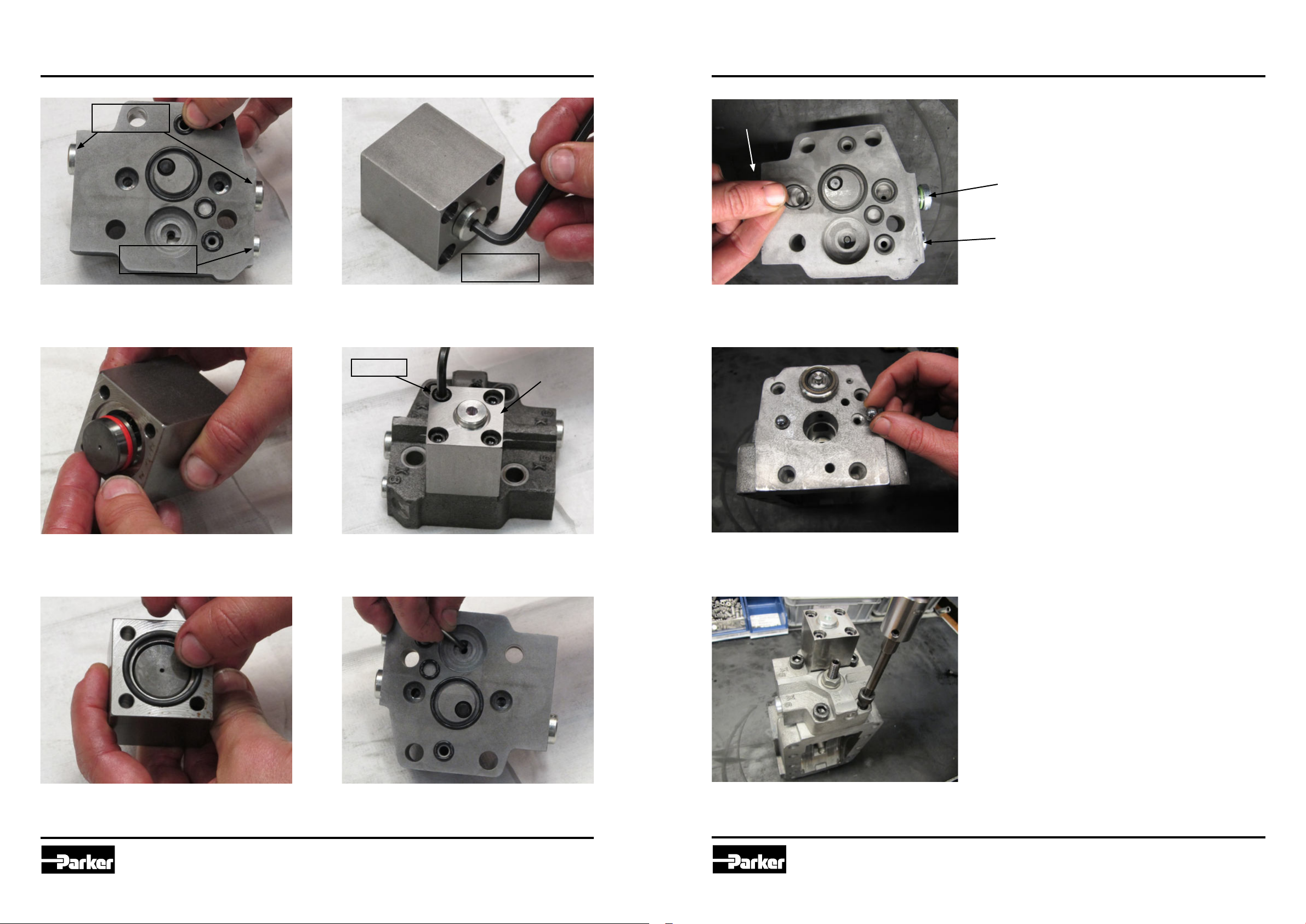

Assembling, shaft package

1. Press down the big tappered roller bearing

and the inner ring for the roller bearing in two

steps. Note! On V12-060 there is a distance

between the bearings.

4. Assemble the shim.

Assembling, shaft package, cylinder barrel, joint shaft and cover

7. Press down the shafts seal in the seal carrier and assemble the retaining ring.

10. Assemble the sliding plate.

2. Press down the roller bearing with the text

upwards into the ange and assemble it on

the shaft package.

3. Assemble the bearing ring with the text

downwards.

5. Assemble the retaining ring. Make sure

it is all the way into the groove. Check the

pre-load of the bearings, not to tight and no

back-lash.

6. Assemble the O-ring.

4

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

8. Assemble the seal carrier with shaft seal

and the retaining ring. Make sure it is all the

way into the groove.

9. Assemble the guide pins.

11. Assemble the joint rollers on the joint

shaft. Make sure the step on the joint rollers

is tted inwards.

12. Assemble the displacement setting screw,

seal nut and the O-ring.

5

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

HY30-5506-M1/UK

Service Manual

Series V12

HY30-5506-M1/UK

Service Manual

Series V12

Assembling, control cover

DIN 38±8 Nm

SAE 25±5 Nm

DIN 13±3 Nm

(AHI-I)

13. Assemble the O-rings and plugs that are

required for the specic control cover. AH-

control is shown in the picture.

DIN 38±8 Nm

SAE 25±5 Nm

16. Assemble the hexagon plug.

12±3 Nm

Narrow side

Assembling, control cover, New version without valve cones and valve guides

DIN 38±8 Nm

SAE 25±5 Nm

A. Assemble the O-rings and plugs that are

required for the specic control cover. AH-

control is shown in the picture.

The control cover shown in picture is bidirectional.

DIN 38±8 Nm

SAE 25±5 Nm

DIN 13±3 Nm

(AHI-I)

14. Assemble the control piston in the AHhousing.

15. Assemble the O-ring.

17. Assemble the AH-housing. The narrow

side against X5.

18. Put some grease on the guide pin and

assemble it in the control cover.

6

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

B. Assemble the check balls.

C. Assemble the control cover and torque

the screws to 65±10 Nm for V12-60, -80

and -110. 105±20 Nm for V12-160.

7

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

HY30-5506-M1/UK

Service Manual

Series V12

HY30-5506-M1/UK

Service Manual

Series V12

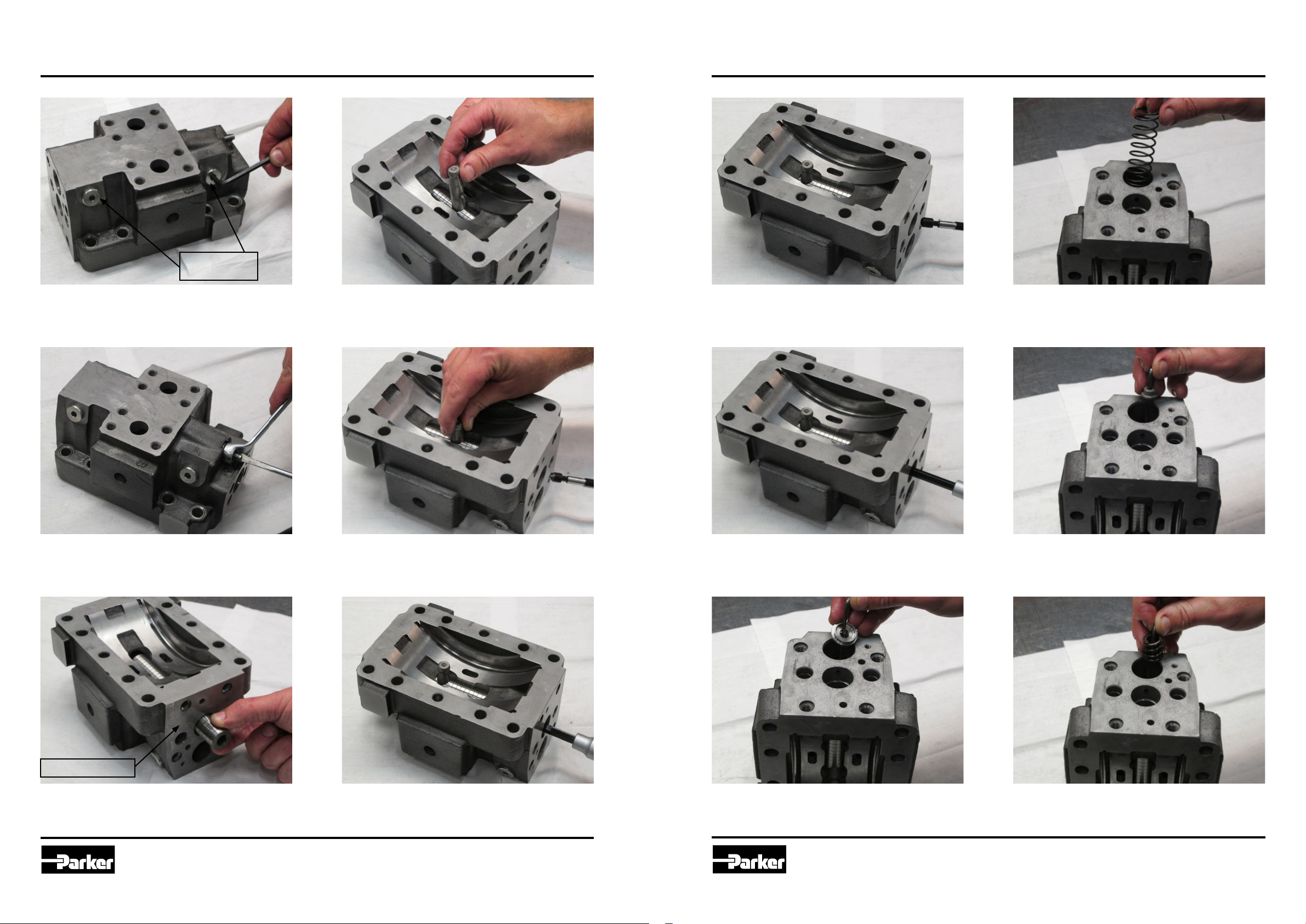

Assembling, end cap

DIN 38±8 Nm

SAE 25±5 Nm

19. Assemble the hexagon plugs.

22. Assemble the companion pin in the setting piston. Make sure the location hole is

against the control cover side.

Assembling, end cap

25. Assemble the set screw with the at end.

28. Assemble the modulating spring.

20. Assemble the adjusting screw and seal

nut.

Control cover side

21. Assemble the setting piston in the end

cap. Make sure the thread is against the control cover side.

23. Assemble the set screw with the pointed

end. Make sure that it hits the location hole in

the companion pin.

24. Torque the set screw to 14±4 Nm.

8

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

26. Torque the set screw to 26±6 Nm. Move

the companion pin back and forward to make

sure it moves smooth.

27. Assemble the spring guide. Use a long

allen key to locate the spring guide.

29. Assemble the spring seat.

30. Assemble the threshold spring.

9

Parker Hannin

Pump and Motor Division

Trollhättan, Sweden

Loading...

Loading...