Page 1

SciLog® SciPres

®

Pressure Monitor & Sensor

Installation, Operating & Maintenance Instructions

Page 2

SciLog® and SciPres® are registered trademarks of Parker Hannifin Corporation.

Parker domnick hunter has a continuous policy of product development and although the Company reserves the right to change

specification, it attempts to keep customers informed of any alterations. This publication is for general information only and

customers are requested to contact our Process Filtration Sales Department for detailed information and advice on a product’s

suitability for specific applications. All products are sold subject to the company’s Standard conditions of sale.

2

Page 3

Contents

Maintenance & Cleaning .............................................................................................................. 7

SciPres® Specifications - Monitor ............................................................................................... 8

SciPres® Specifications - Sensors .............................................................................................. 9

SciDoc Documentation Software for PC ................................................................................... 10

Part A: SciPres® Pressure Sensor Hardware............................................................................ 11

1.0 Overview ................................................................................................................................ 11

2.0 Front Panel: Data Entry & Display ....................................................................................... 12

3.0 Back Panel: Interface Options ............................................................................................. 13

4.0 Pin Out of the DB25 Female ‘Output’ Connector ................................................................. 14

5.0 Single-Use Pressure Sensors .............................................................................................. 16

Part B: SciPres® Pressure Sensor Monitor Software ............................................................... 17

1.0 Software Overview ................................................................................................................ 17

2.0 Main Menu ........................................................................................................................... 18

3.0 Custom Calibration ............................................................................................................. 20

4.0 Reduced Pump Pulsation: Improved Sensor Precision .................................................... 22

5.0 SciPres® Pressure Sensor Printout Format ...................................................................... 23

Part C: SciPres® Data ................................................................................................................. 24

1.0 Data Collection .................................................................................................................... 24

1.1 SciPres® SciDoc Data Collection Software ......................................................................... 24

1.2 PC Terminal Program Settings ........................................................................................... 28

3

Page 4

Precautions

READ this manual BEFORE operating or servicing this equipment.

FOLLOW these instructions carefully.

SAVE this manual for future reference.

DO NOT allow untrained personnel to operate, clean, inspect, service or tamper with

this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or

performing maintenance.

Contact Parker domnick hunter for parts, information and service.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE

INSTALLING, SERVICING, CLEANING OR REMOVING

THE FUSE. FAILURE TO DO SO COULD RESULT IN

BODILY HARM AND/OR PROPERTY DAMAGE.

CAUTION

OBSERVE PRECAUTIONS FOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES.

WARNING

ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE

THIS EQUIPMENT. EXERCISE CARE WHEN MAKING

CHECKS, TEST AND ADJUSTMENTS THAT MUST BE

MADE WITH POWER ON. FAILING TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN BODILY HARM.

WARNING

FOR CONTINUED PROTECTION AGAINST SHOCK

HAZARD, CONNECT TO PROPERLY GROUNDED

OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

CAUTION

USE ONLY CLASS 2 LISTED AC/DC POWER SUPPLIES

WITH THIS DEVICE.

Parker domnick hunter # 070017TOR, OR ITS

EQUIVALENT IS RECOMMENDED.

4

Page 5

Précautions

LISEZ ce manual AVANT de faire fonctionner ou d’entretenir cet équipment.

SUIVEZ attentivement ces instructions.

CONSERVEZ ce manuel pour future référence.

NE LAISSEZ PAS du personnel non qualifié utiliser, nettoyer, inspecter, entretenir, réparer

ou manipuler cet équipement.

DÉBRANCHEZ TOUJOURS cet équipement de la source de courant avant de nettoyer ou

d’exécuter l’entretien.

APPELEZ PARKER pour pièces détachées, renseignements et entretien.

ATTENTION

DÉBRANCHEZ TOUT COURANT DE CETTE UNITÉ AVANT DE FAIRE

L’INSTALLATION, D’EFFECTUER L’ENTRETIEN, LE NETTOYAGE OU

AVANT DE RETIRER LE FUSIBLE. NE PAS OBSERVER CES

PRÉCAUTIONS RISQUERAIT DE CAUSER DES BLESSURES

CORPORELLES OU/ET D’ENDOMMAGER L’ÉQUIPEMENT.

PRUDENCE

SOYEZ PRUDENT LORSQUE VOUS MANIPULEZ DES

APPAREILS SENSIBLES À L’ÉLECTROSTATIQUE.

ATTENTION

AUTORISEZ SEULEMENT LE PERSONNEL QUALIFIÉ À ENTRETENIR

CET ÉQUIPEMENT. SOYEZ PRUDENT LORSQUE DES VÉRIFICATIONS,

TESTS ET AJUSTEMENTS DOIVENT ÊTRE EFFECTUÉS SOUS TENSION.

NE PAS OBSERVER CES PRÉCAUTIONS RISQUERAIT DE CAUSER DES

BLESSURES CORPORELEES.

ATTENTION

POUR ASSURER UNE PROTECTION CONTINUE CONTRE UNE DÉCHARGE

ÉLECTRIQUE, BRANCHEZ UNIQUEMENT SUR UNE PRISE CORRECTEMENT RELIÉE Á LA TERRE. NE RETIREZ PAS LA FICHE DE TERRE.

PRUDENCE

UTILISEZ UNIQUEMENT LA CLASSE 2 CI ALIMENTATIONS AC /

DC AVEC CET APPAREIL .

Parker domnick hunter # 070017TOR, OU SON ÉQUIVALENT

EST RECOMMANDÉ.

5

Page 6

Introduction

You will find the SciPres® pressure sensors easy to use. The state-of-the-art hardware and

software design of the SciPres® pressure sensor and monitor combination allows you to measure

and document the pressure of many filtration / separation processes. With proper maintenance,

the SciPres® pressure monitor will provide many years of excellent service and performance.

Please read the following instructions carefully!

Inspections: Remove the products carefully from the shipping container. Check the contents against

the purchase order to verify that all parts are included and undamaged.

Please do the inspection now, even if the products are not used immediately. Many carriers must

receive damage claims within seven days of delivery. Please retain all packing material so unit may

be shipped safely, if necessary.

Customer Service: Parker domnick hunter customer service: If assistance is required, please contact

us at:

Parker Hannifin Manufacturing Ltd Parker Hannifin Corporation

Parker domnick hunter Parker domnick hunter

Process Filtration - Europe Process Filtration - North America

Durham Road 2340 Eastman Avenue

Birtley, Co. Durham Oxnard, California, USA 93030

DH3 2SF, England toll free: 877 784 2234

phone +44 (0)191 4105121 phone: +1 805 604 3400

fax +44 (0)191 4105312 fax: +1 805 604 3401

email: dhprocess@parker.com email: dhpsales.na@parker.com

www.parker.com/dhpharma www.parker.com/dhsingleuse

Parker domnick hunter customer service personnel will be able to serve you more efficiently if you

have the following information:

• Serial number and model name of the equipment

• Installation procedure being used

• Concise list of symptoms

• List of operating procedures and conditions in use when problem arose

Calibration

The SciPres® monitor is a calibrated device, and is calibrated with test equipment that is traceable to NIST.

A Calibration Certificate is included with each unit, and has a one year expiration date.

It is highly recommended that the monitor be calibrated on an annual basis or more often if your

Metrology Department deems it necessary.

Parker domnick hunter provides this Calibration Service, complete with a new certificate, showing the

“as found” and “as left” data.

Contact your local Parker domnick hunter representative.

6

Page 7

Warranty

Country specific information can be found at: www.parker.com/termsandconditions

Standards

The SciPres® monitor and sensor conform

to the following standards:

• EN 61326-1:2006, Class B

• EN 6100-3-2:2006

• EN 6100-3-3:1995 +A1:2001 +A2:2006

• EN 61010-1 Issued: 2001/03/01

• UL 61010-1 Issued: 2004/07/12 Ed.2

• And is certified to: CAN/CSA-C22.2 No 61010-1 Ed.2

Caution: The maximum recommended pressure for the sensors is 60 psi.

If this is exceeded, problems with leakage and functionality can occur.

Installation & Start Up

Installation of the SciLog® SciPres® monitor must be carried out only by trained personnel in

accordance with the relevant regulations and this operations manual.

Make sure that the technical specifications and input ratings of the SciPres® pressure sensor are

observed. See “SciPres® Pressure Sensor Specifications”.

The protection provided by this equipment may be impaired if the SciPres® pressure sensor is used in

a manner inconsistent with this manual or for purposes not specified by the manufacturer.

Maintenance & Cleaning

The SciPres® pressure monitor is maintenance free. The single-use SciPres® sensors come

pre-calibrated from the factory and require no maintenance.

To remove dust, dirt and stains, the outer surfaces of the SciPres® pressure monitor may be wiped

using a soft, non-fluffing cloth moistened with water. If required, you may also use a mild detergent

or 2-propanol.

The single-use sensors may be sanitized with 0.1 Molar NaOH, or 2-propanol. They may be

autoclaved up to 2 times, or gamma-irradiated with exposure up to 45 kGy.

7

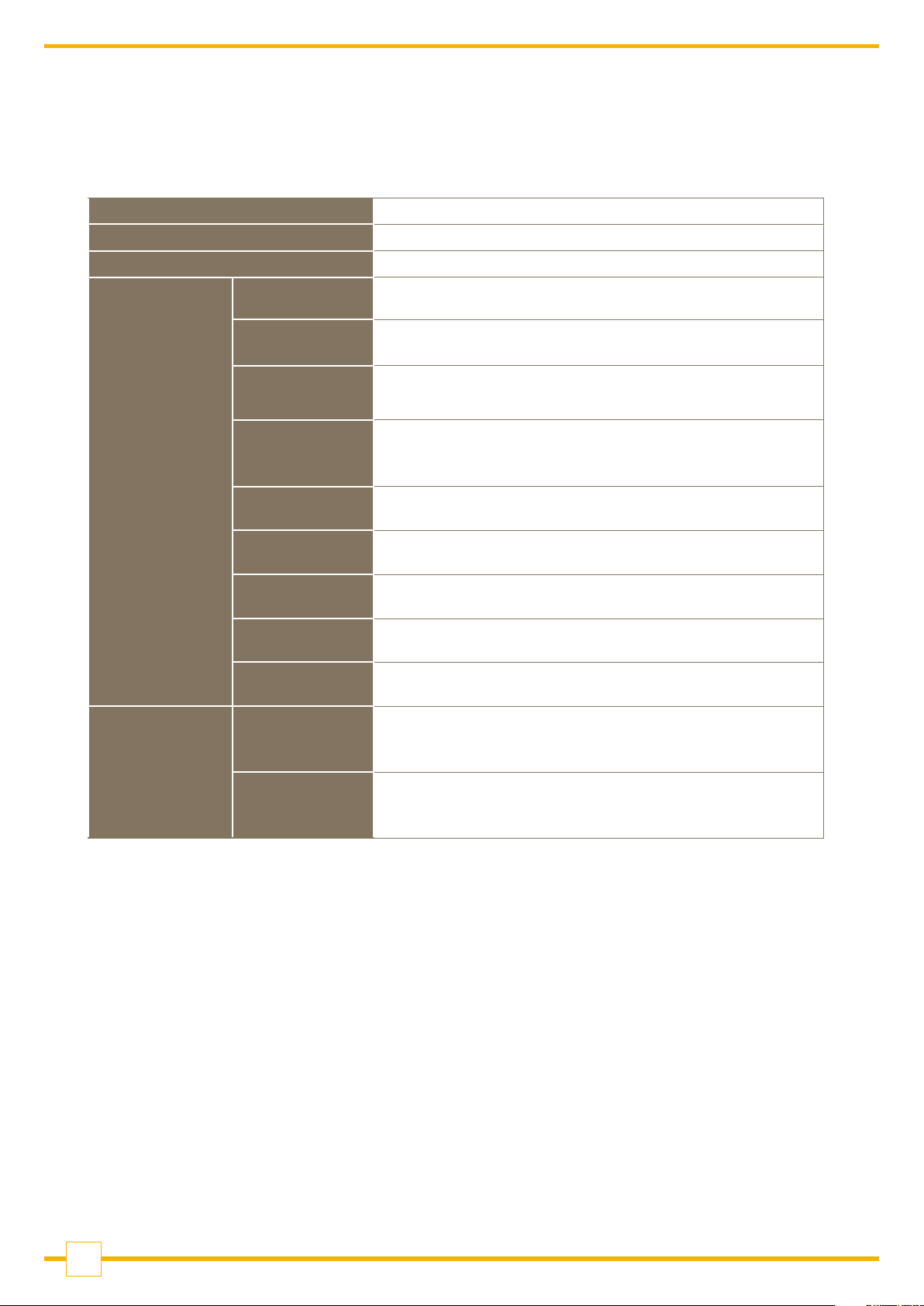

Page 8

Hardware

Specifications - Monitor

Electrical

Dimensions

Weight

Enclosure

Power

Operational

Range

Sensor

I/O Port - 1

I/O Port - 2

I/O Port - 3

I/O Port - 4

I/O Port - 5

W: 6.0¨ (15.2 cm); Height 2.75¨ (7.0 cm); D: 5.5¨ (14.0 cm)

1.5 lb (0.69 Kg)

Molded Plastic / Stainless Steel

110-120 or 220-240 V , 60/50 Hz AC Adaptor, 12 VDC, 500 ma Output,

Centre positive. Use only Class 2 listed AC/DC power supplies.

6 to 60 ° C, 100% Humidity.

3

/4” Tri-Clover (TC) Sanitary and 1” Tri-Clover (‘Ladish’) Sanitary.

Note: Please use care connecting the monitor end of the sensor cable to

these ports as the male cable end can be damaged if mishandled.

‘Output’ - Female DB25, four TTL outputs for alarms, four 4-20 ma Analog

‘Printer / PC’ - Female DB9, RS-232 output for serial printer or PC.

Choice of five sizes: Luer, 3/8" Barb, 1/2” Barb,

‘P1, P2 and P3’ Female Switchcraft 9 pin twist-lock,

connectors for sensor cables.

output signals, 18 bit resolution.

‘Serial I/O’ - Female DB9 (disabled).

‘RS-485’ - 3 wire terminal block. RS-485 output (disabled).

Software

Two

Operational

Modes

I/O Port - 6

Pressure

Mode

Custom

Calibration

Mode

‘12VDC 500ma’ - DC Input for AC Adaptor.

Captures stored calibration data from the sensors, digital display of up to

three pressure sensor values and either Differential or Trans Membrane

pressure, with four user-definable alarms.

Used to perform custom calibrations, selecting User-Defined Zero

and Calibration Pressure.

8

Page 9

Specifications - Sensors

Power

Fluid Connections

Wetted Materials

Sensor Type

Sensor Isolation

Pressure Range

Accuracy

Resolution

Temperature Range

Sensor Microchip

Sensor Connector & Cables

5 VDC provided by SciPres® Pressure Monitor.

3

/4” Tri-Clover (TC) Sanitary and 1” Tri-Clover (‘Ladish’) Sanitary.

Polysulphone meets USP Class VI and FDA 21 CFR 177.1520, all wetted

Insoluble silicone dielectric gel isolates sensing element from process

solution. The gel is a non-toxic, non-allergenic elastomeric system.

+/- 0.30 psi at -5 to 30 psi for 2 point calibrated sensors (can be improved

Choice of five sizes: Luer, 3/8” Barb, 1/2” Barb,

materials made with animal-free compounds.

Medical grade, silicone piezoresistive sensing element

with on-chip temperature compensation.

-5 to 60 psi (-0.34 to 4.14 bar).

to -5 to 60 psi with 3 point calibration, also available)

0.01 psi (0.001 bar).

0 to 60 °C (0 to 140 °F).

EPROM, Stores Sensor ID, and Calibration Factor.

Lockable and Waterproof.

9

Page 10

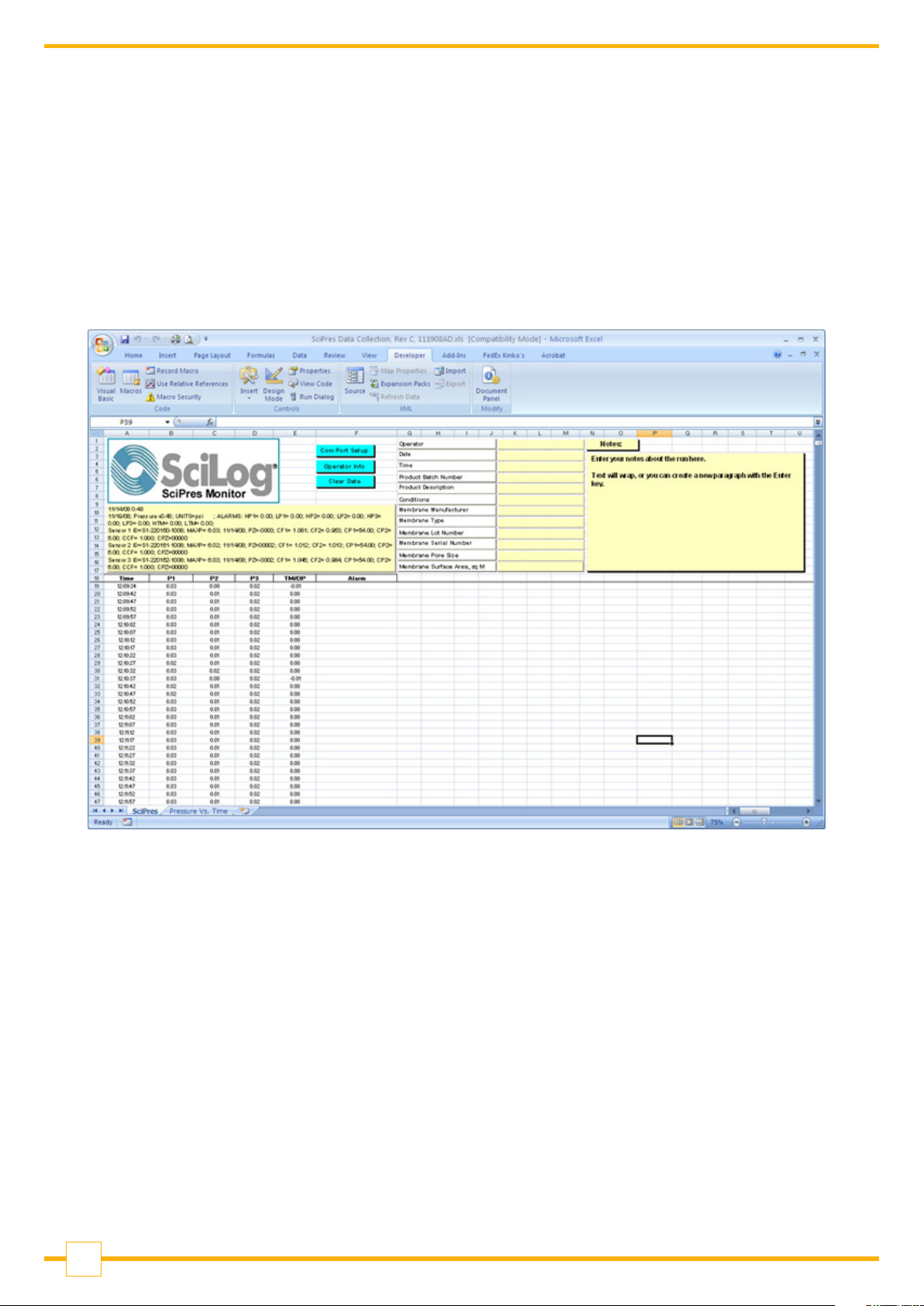

SciDoc Documentation Software for PC

SciPres® Pressure Sensor System Documentation Software Package - purchased separately.

• Excel spreadsheet with custom macros for data compilation.

Includes WinWedge interface software. Sent ready-to-use.

• Complete process analysis with graphing of data.

• Real-time verification and documentation of process parameters.

• Includes graph of: Pressure versus Time.

Spreadsheet example:

10

Page 11

Part A: SciPres®

Pressure Sensor Hardware

1.0 Overview

The SciLog® SciPres® pressure sensor system consists of two major components, the SciPres®

pressure monitor, with its power supply, and the single-use SciPres® pressure sensor, with its cable.

The monitor is a small desktop package with a backlit display and seven buttons for easy interface and

menu selections. It displays up to three measured pressures and one calculated pressure in real time.

The monitor’s output signals are in both analog and digital forms. It comes with a small wall adapter

as a universal power supply.

The monitor reads and utilizes calibration data from SciPres® sensors that have been calibrated to two

points, 0 and 30 psi, or three points, 0, 54 and 6 psi depending upon the sensor purchased. It has also

been equipped with a Supervisor Password, a Max Pressure Watchdog, and a Noise Filter setting.

The “Max Pressure Watchdog” feature records in the sensor’s memory the maximum pressure seen

by the sensor while it is connected to the SciPres® Monitor. This value is displayed for a few seconds

along with the Sensor ID and calibration information when the Monitor is powered up after a sensor is

connected.

Caution: Disconnection and reconnection of the sensor while in operation may cause

corruption of the sensor’s memorys and consequent loss of calibration. Please turn the

monitor off when connecting / disconnecting the sensors.

Note: The maximum recommended pressure for the sensors is 60 psi (4.14 bar). If this is

exceeded, problems with leakage and functionality can occur.

The Filter setting is used to average the pressure signals when peristaltic pump heads are used. This

makes the display readings easier to interpret, and produces cleaner graphs that are easier to read. At

the lowest setting, the data is “live”, and at the highest, it is averaged over a four second period.

The SciPres® pressure sensors utilize a silicone piezoresisitive sensing element in a polysulphone tube

available in five sizes: Luer, 3/8" or 1/2" Barb, 3/4" and 1" ‘Ladish’ Sanitary TC connections.

All sensors are pre-calibrated at the factory, and retain the calibration data on a small chip embedded

in the sensor body. The following information is retained and is accessed upon connection to the

sensor:

• ID number (Contains Size, Lot number, Mfr Code, and Calibration date)

• Calibration Factors

• Calibration Points

• Pressure Zero Offset

• Max Pressure Value

11

Page 12

2.0 Front Panel: Data Entry & Display

The front panel includes an alphanumeric display and a membrane keypad to select operational

modes and alarm settings. The display is a two line, 20 character, liquid crystal display (LCD). The

display is backlit to allow easy viewing over a wide range of lighting conditions.

The keypad consists of seven keys whose function does not change. These keys are used for basic

control and programming of the SciPres® pressure monitor. The basic key definitions are:

MENU: Allows entry into the parameter settings menu.

ENTER: Accepts the selected parameter setting.

EXIT: Exits the menu, returning to the main operational screen.

SENSOR: Recaptures the factory calibration settings stored on the sensor, and allows entry into the

custom calibration menu. This allows the user to zero and/or custom calibrate the upper span value

using equipment traceable to SI through NIST.

ON/STBY: Turns the monitor on and off.

Up and Down arrows used to change parameters within the menus.

One LED is also on the front panel, on the ON/STBY key. This indicates the monitor is connected to

power.

12

Page 13

3.0 Back Panel: Interface Options

The SciPres® pressure sensor back panel provides interfacing ports for:

• Single-use SciPres® pressure sensor sensors: Female 9 pin twist-lock,

labelled “Sensor P1, P2, and P3”.

• Analog and TTL Output: Female DB25, labelled “Output”.

• RS-232 Data Output: Female DB9, labelled “Printer/PC”.

• 2nd RS-232: Female DB9, labelled “Serial I/O” (Disabled).

• RS-485: 3 wire terminal block, labelled “RS-485”, (Disabled).

• Input Power: Round male connector for AC Adapter, labelled “12 VDC / 500 mA”.

SENSOR PORTS: The single-use pressure sensors are connected to these three using the included

cables.

Note: Please use care connecting the monitor end of the cable to these ports as the male cable

end can be damaged if mishandled.

OUTPUT PORT: Provides four 4-20 mA analog outputs and TTL outputs for the four alarms,

Hi / Low for each pressure channel. TTL outputs provide a 0 / 5 VDC control signal, carry minimal

current. (See Pin out on next page.)

PRINTER / PC PORT: To connect the SciPres® pressure monitor to your PC for data archival.

Alternatively, you may connect to a serial printer via this port.

SERIAL I/O PORT: RS-232 – Disabled.

RS-485 PORT: Disabled.

POWER INPUT JACK: Connect the AC adapter here.

13

Page 14

4.0 Pin Out of the DB25 Female ‘Output’ Connector

3

4

P1

1

14

15

16

17

18

19

20

21

22

10

23

11

24

12

25

13

2

3

4

5

6

7

8

9

27

26

Vpwr

OUT1N

OUT2N

OUT3N

OUT4N

F1

0.1A

R4 1.0K

1 2

R3 1.0K

1 2

R2 1.0K

1 2

R1 1.0K

1 2

Analog1+

Analog1-

Analog2+

Analog2-

Analog3+

Analog3-

Analog4+

Analog4-

OUT1

OUT2

OUT3

OUT4

D Connector 25

Analog Outputs

For 4-20 ma output of Pressure at P1 (Analog 1), use pins 2 (4-20 -) and 14 (4-20 +). If excitation is

needed in the loop, connect pin 1 (Vpwr) to pin 14 (4-20 +), and connect the output cable to pin 2

(4-20 -) and pin 15 (Gnd).

For 4-20 ma output of Pressure at P2 (Analog 2), use pins 4 (4-20 -) and 16 (4-20 +). If excitation is

needed in the loop, connect pin 3 (Vpwr) to pin 16 (4-20 +), and connect the output cable to pin 4

(4-20 -) and pin 17 (Gnd).

For 4-20 ma output of Pressure at P3 (Analog 3), use pins 6 (4-20 -) and 18 (4-20 +). If excitation is

needed in the loop, connect pin 5 (Vpwr) to pin 18 (4-20 +), and connect the output cable to pin 6

(4-20 -) and pin 19 (Gnd).

For 4-20 ma output of Pressure at TM or DP (Analog 4), use pins 8 (4-20 -) and 20 (4-20 +).

If excitation is needed in the loop, connect pin 7 (Vpwr) to pin 20 (4-20 +), and connect the output

cable to pin 8 (4-20 -) and pin 21 (Gnd).

14

Page 15

The use of an end-user supplied analog loop power source is presented below:

TTL Alarm Outputs

P1 Hi / Lo Alarm: TTL 1 Pins 11 (Out0) and 13 (Gnd)

P2 Hi / Lo Alarm: TTL 2 Pins 24 (Out1) and 13 (Gnd)

P3 Hi / Lo Alarm: TTL 3 Pins 12 (Out2) and 13 (Gnd)

TM or DP Hi / Lo Alarm: TTL 4 Pins 25 (Out3) and 13 (Gnd)

TTL outputs are either 0 or 5 VDC, and carry minimal current. They are for TTL inputs on a PLC, or

control of a 5 VDC solid state relay, with an enable voltage of 3 VDC.

15

Page 16

5.0 Single-Use Pressure Sensors

Luer

Connector Type

Luer 080-699PSX-5 080-699PSX-3P-5 ID 0.03¨ to 0.31¨ 1.0 0.26 0.23 60 psi

3

/8¨ Barb 080-694PSX-5 080-694PSX-3P-5 ID 0.31¨ to 0.38¨ 8.0 2.11 1.81 60 psi

1

/2¨ Barb 080-695PSX-5 080-695PSX-3P-5 ID 0.50¨ 17.0 4.49 3.86 60 psi

3

/4¨ Tri-Clover (TC) 080-696PSX-5 080-696PSX-3P-5 Tubing with 3/4¨ TC 31.0 8.19 7.03 60 psi

1¨ Tri-Clover ‘Ladish’ 080-697PSX-5 080-697PSX-3P-5 Tubing with 1¨ TC Ladish 60.0 15.9 13.6 60 psi

* Maximum flow rate at 1 psi

2-pt. Calibration 3-pt. Calibration

3

/8¨ Barb

Part Code (Packs of 5)

1

/2¨ Barb

Compatible

Tubing Sizes

3

/4¨ Tri-Clover 1¨ Tri-Clover ‘Ladish’

Max. Flow Rate*

(L / min) (gpm / psi) (m3 / h / bar)

Max. Operating

Pressure

16

Page 17

Part B: SciPres® Pressure Sensor Monitor Software

1.0 Software Overview

The SciPres® pressure monitor digitally displays inputs from up to three SciPres® pressure sensors

simultaneously, while also calculating and displaying either trans-membrane or differential pressure.

It has also been equipped with a “Supervisor Password”, a “Max Pressure Watchdog”, and a

“Filter” setting.

The “Max Pressure Watchdog” feature records in the sensor’s memory the maximum pressure seen

by the sensor while it is connected to the SciPres® monitor. The maximum recommended pressure

for the sensors is 60 psi (4.14 bar). If this is exceeded, problems with leakage and functionality can

occur. This value is displayed for a few seconds along with the Sensor ID and Cal information when

the monitor is powered up and a sensor connected.

The “Filter” setting is used to average the pressure signals when peristaltic pump heads are used.

This increases the sensor precision as well as accuracy and makes the display readings easier to

interpret when compared to ever changing values caused by pulsation. Thus it produces cleaner

graphs that are easier to read. At the lowest setting, the data is ‘live’, and at the highest, it is

averaged over a 4 second period. Please refer to the graph in section 4.0.

The “Supervisor Password” is a number between 1 and 9999 that must be entered to access the

Menu and its settings. Setting the password to 0 disables it.

The “Main Menu” allows you to change the pressure units, (psi, kPa, bar, mmHg are available) the

high and low analog range settings, adjust the baud rate and print time, change the mode between

trans-membrane, differential and none, adjust the “Filter” setting, as well as configure user-defined

hi / low pressure alarms for all four displayed values.

The SciPres® pressure monitor will also allow custom zero and single point full span calibration of

the sensors through the use of the “Sensor” button on the front panel. This is a modification of the

existing factory two or three point calibration. This can be reset or cleared if desired.

17

Page 18

2.0 Main Menu

Main Screen

P1: 0.00 P2: 0.00

P3: 0.00 TM: 0.00

Menu

psi, kPa, bar, mmHg

PRES UNITS: psi

689.4 kPa, 6.80 bar

Menu

5171 mmHg

RANGE HI: 100 psi

Analog out at 100%

Menu

Min 0.00

RANGE LO: 0.0 psi

Analog out at 0%

1200, 2400, 4800,

9600, 19200, 28800,

Menu

38400, 57600

SERIAL: BR: 9600

WL: 8 SB: 2 PT: N

See 3.1

See 3.2

See 3.3

See 3.4

See 3.5

Menu

See HI Range above

HI-ALARM P1: 0.0 psi

Menu

Min: 0.00

LO-ALARM P1: 0.0 psi

Press Menu to

Enter

bypass to Password

SET TIME / DATE...

Enter

24 Hour Time

TIME: 16:10

Enter

MONTH: DECEMBER

See 3.11

See 3.12

See 3.13

See 3.14

See 3.15

Menu

1 to 60 seconds

PRINT TIME: 5 Seconds

Transmembrane,

Menu

Differential, None

MODE: TRANSMEMBRANE

Menu

SciPres®, OEM

TYPE: SCIPRES

Menu

Off, P1, P2, P3, TM, DP

CONSTANT PRESSURE:

OFF

Menu

1 min, 12 max

FILTER: 9

See 3.6

See 3.7

See 3.8

See 3.9

See 3.10

Enter

DAY OF MONTH: 28

Enter

YEAR: 2006

Menu

Yes, No

FACTORY RESET: NO

YES & ENTER TO RESET

Enter

Yes, No

ARE YOU SURE: NO

Enter

PASSWORD: 0

See 3.16

See 3.17

See 3.18

See 3.19

18

Page 19

2.0 Main Menu, Continued:

SUMMARY: This menu allows the setting of various parameters as they relate to your process.

Use “Menu” to scroll through the menu, the up/down arrow keys to scroll through choices, and

“Enter” to select the choice.

2.1 MAIN SCREEN: Displays all three pressures, P1, P2, P3 and the calculated Trans-Membrane

pressure, TM, or Differential pressure DP.

2.2 PRESSURE UNITS: Use the up / down arrows to select between psi (pounds/square inch),

kPa (kilo Pascal), bar, or mmHg (millimeters of Mercury). Default = psi.

2.3 RANGE HI: Use to set the upper range limit of the Analog output signal (100% full scale).

Allowable maximums are 100 psi, 689.4 kPa, 6.80 bar, 5171 mmHg. Default = 100.0 psi.

Do Not pressurize beyond 60 psi. (This setting is to make replacing a 0-100 psi transmitter

easy to replace without having to re-scale the interface.)

2.4 RANGE LO: Use to set lower range limit of the Analog output signal (0.0% of full scale).

Default minimum is 0.0 regardless of scale.

2.5 SERIAL: Displays the RS-232 serial output parameters. Only baud rate can be changed.

Available rates are 1200, 2400, 4800, 9600, 19200, 28800, 38400 and 57600. Default = 9600.

2.6 PRINT TIME: Used to set the data output interval, 1 to 60 sec. Default = 5 sec.

2.7 MODE: Use to set display and output mode. Trans-membrane will display and output TM,

Differential will display and output DP, None will only display and output P1, P2 and P3.

Default = TM.

2.8 TYPE: Sets type of pressure sensor in use, Default is Calibrated. OEM is under development.

2.9 CONSTANT PRESSURE: Controls 4-20 ma Analog Output 4 inversely as the pressure source

changes between the Hi and Lo Alarm settings. Default = OFF.

2.10 FILTER: Used to filter out (average) pulsations from peristaltic pumps. Pressure changes are

delayed slightly based on setting. Range is 1-12, with 1 = No filter, 12 = Max filter. Default = 9.

2.11 HI-ALARM P1: Used to set High Pressure Alarm, Max value of 60.0 psi. Hi-Alarms exist for all

four pressure outputs. Default = 0.0 psi.

2.12 LO-ALARM P1: Used to set Low Pressure Alarm. Lo-Alarms exist for all four pressure

outputs. Default = 0.0 psi.

2.13 SET TIME / DATE: Press “Enter” to enter this submenu, press Menu to bypass to Password.

2.14 TIME: Use up / down arrows to set current time in 24 hour format, HH:mm, and press “Enter”.

2.15 MONTH: Use up / down arrows to set current Month, and press “Enter”.

2.16 DAY OF MONTH: Use up / down arrows to set current Date, and press “Enter”.

2.17 YEAR: Use up / down arrows to set current Year, and press “Enter”.

2.18 FACTORY RESET: Used to restore the SciPres® pressure sensor pressure monitor to the

factory default values. Change No to Yes using the arrow keys and press “Enter” to reset,

change No to Yes on the “Are You Sure?” screen and press “Enter” again to finish the process.

2.19 PASSWORD: Used to set a Supervisor password. Requires entry of the password to enter the

Menus. Choose a number from 1-9999, setting of 0 disables the password feature.

19

Page 20

3.0 Custom Calibration Menu

Press “Sensor” button. The

following will be displayed:

SENSOR PORT: P1

Use up / down arrows to

choose port, press “Enter”, and

calibration data will reload.

CUSTOM CAL....

Press Enter

SENSOR PORT: P1

Enter

SENSOR ZERO: NO

YES & ENTER TO ZERO

Enter

CAL PRESS: 60.00 psi

Enter

CUSTOM CAL SENSOR

PRESS ENTER TO CAL

Enter

CALL IN PROGRESS

Please Wait: 1...2...

See 3.1

See 3.2

See 3.3

See 3.4

See 3.5

Enter

CUSTOM CAL FACTORS:

CF: 0.511 PZ: 0.0

CALIBRATION ERROR!

OUT OF RANGE

SENSOR RESET: NO

YES & ENTER TO RESET

20

See 3.6

See 3.7

Page 21

3.0 Custom Calibration Menu, Continued:

SUMMARY: This menu shows the settings used for performing a custom calibration of a given

SciPres® pressure sensor. This allows you to calibrate zero the unit for existing pressure offsets,

and re-span the unit with a NIST traceable pressure source if you wish. This procedure adds a

modification to the existing Factory Calibration, it does not modify it, and it can be reset if needed.

After connecting the sensor, press the “Sensor” button, you will be prompted for the sensor to

re-load, choose the sensor and press “Enter”. After reloading the data from the sensor, the

“Custom Cal…” screen appears. Press the “Enter” key to enter the Custom Cal menu, use the

“Exit” key to bypass it.

3.1 SENSOR PORT: Use the up/down arrows to select from P1, P2 or P3 and press “Enter”.

Default = 0.0 °C (0.0 °F).

3.2 SENSOR ZERO: To zero the sensor, use the up/down arrows to change “NO” to “YES” and

press “Enter”. To bypass, leave the setting at NO and press “Enter”. Default = NO.

3.3 CAL PRESS: To Re-span the sensor at the upper limit, use the up/down arrows to select the

pressure being used for the custom calibration and press enter. To bypass, press “Exit”.

3.4 CUSTOM CAL PRESS: When you reach this screen, and are ready to perform the custom

calibration at the upper limit. Be sure you have pressurized the sensor using a NIST traceable

pressure source (gauge). Press the “Enter” key to do the calibration. You may press “Exit” to

cancel the process.

3.5 CAL IN PROGRESS: This screen is displayed during the calibration, and will count up to 10

to complete the custom calibration.

3.6 CUSTOM CAL FACTORS: This screen displays the custom calibration data, the Custom Cal

Factor, (CCF) can the Custom Zero Offset (PZ).

3.7 CALIBRATION ERROR! / OUT OF RANGE: This message will be displayed if the pressure is out

of range, i.e. you’ve tried to perform a custom calibration at an elevated pressure with the

sensor un-pressurized.

3.8 SENSOR RESET: Used to reset / remove the custom calibration. Press the “Sensor” key to

reload the sensor data, and while the custom cal factors are displayed, press the “Enter” key.

The Sensor Reset screen will be displayed, and you can change the No to Yes with the

Up/Down Arrows, and press the “Enter” key to reset / remove the custom calibration.

There is an “Are you sure?” screen that will also need a Yes answer to complete this task.

21

Page 22

4.0 Reduced Pump Pulsation: Improved Sensor Precision

Pressure versus Time

7.00

FILTER-1 FILTER-2

6.00

FILTER-3

5.00

PRESSURE

4.00

3.00

15:27:22 15:28:48 13:30:14 15:31:41 15:33:07 15:34:34 15:36:00 15:37:26

TIME

FILTER-4

FILTER-6

FILTER-5

This graph shows the effects of the Filter setting on the SciPres® monitor and the incoming signal

from the SciPres® sensors.

This provides the added benefit of improving the precision and accuracy of the sensor reading

by eliminating the need to interpret between ever changing high and low values caused by

pump-generated pulsation. It makes the processes easier to control and the cleaner graphs

are easier to read.

Data was collected at 1 second intervals. A peristaltic pump running at 100 mL / min was

connected to the SciPres® sensors and back pressure was applied.

The Filter setting was changed from 1 through 6 over the course of the run. Data was stable at that

point, and it was not increased further due to lack of noticeable effect at these flows and pressures.

As the Filter setting is increased, a small delay occurs in the response of the filtered data when the

pressure is changing. The maximum delay at a setting of 12 is 4 seconds. A setting of 1 yields “live”

data with no delay and no filtering.

22

Page 23

5.0 SciPres® Pressure Sensor Printout Format

RS-232 Output as sent to Serial Printer or Windows HyperTerminal:

03/16/09 0.51

07/07/15; Pressure v0.51; UNITS=psi ; ALARMS: HP1= 0.00; LP1= 0.00; HP2= 0.00; LP2= 0.00;

HP3= 0.00; LP3= 0.00; HTM= 0.00; LTM= 0.00;

Sensor 1 ID=S5-210246-0314; MAXP=15.90; 10/07/14; PZ=-0015; CF1= 1.035; CCF= 1.000;

CPZ=00000

Sensor 2 ID=S5-210248-0314; MAXP=17.97; 08/21/14; PZ=-0014; CF1= 1.030; CCF= 1.000;

CPZ=00000

Sensor 3 Disconnected;

RT, P1, P2, P3, TM

11:24:44, 0.04, 0.05, -.--, 0.05,

11:24:50, 0.04, 0.05, -.--, 0.05,

11:24:55, 0.04, 0.05, -.--, 0.05,

11:25:00, 0.30, 0.05, -.--, 0.17,

11:25:05, 0.28, 0.05, -.--, 0.17,

11:25:10, 0.04, 0.05, -.--, 0.04,

11:25:15, 0.29, 0.28, -.--, 0.29,

11:25:20, 0.37, 0.36, -.--, 0.36,

11:25:25, 0.32, 0.31, -.--, 0.32,

11:25:30, 0.04, 0.05, -.--, 0.05,

Abbreviations

RT = Real Time P1 = Pressure at Sensor P1

P2 = Pressure at Sensor P2 P3 = Pressure at Sensor P3

TM = Trans-Membrane Pressure DP = Differential Pressure (P1 - P2)

CF1 = Calibration Factor 1

CF2 = Calibration Factor 2 Alarm: HP1 / LP1 = Hi / Low Pressure @ P1

PZ = Zero Offset Alarm: HP2 / LP2 = Hi / Low Pressure @ P2

CP1 = Calibration Point 1 (High point) Alarm: HP3 / LP3 = Hi / Low Pressure @ P3

CP2 = Calibration Point 2 (Low Point) Alarm: HTM/ LTM = Hi / Low Pressure @ TM or DP

CCF = Custom Calibration Factor

CPZ = Custom Zero Offset -.— Indicates a disconnected sensor

Note: SciPres® SciDoc Software is available to collect this data automatically into an Excel

spreadsheet. See Part C.

23

Page 24

Part C: SciPres® Data

1.0 Data Collection

SUMMARY: The SciPres® pressure monitor has two serial ports. The serial port which is labelled

“Printer / PC,” is used for RS-232 serial communication with a PC or serial printer. The second

serial port is disabled.

SciDoc software is available and includes an Excel spreadsheet with custom macros that is

automatically populated when data is received. It also automatically populates a graph in real-time

as the data is generated. Discussion of this package begins on the next page.

Alternatively, when a PC is connected to this serial port, all data generated can be sent to a

“HyperTerminal” program. HyperTerminal is OK for viewing the data in real time, but can be a

challenge for actually capturing and retrieving the data. The HyperTerminal settings are provided

for you in section 1.2 entitled “PC HyperTerminal Settings”.

1.1 SciPres® SciDoc Data Collection Software:

SciPres® offers SciDoc software to capture the data output of the SciPres® pressure monitor and

place it in an Excel spreadsheet in real-time. This spreadsheet also populates a graph to aid you in

the analysis of your process. It consists of a copy of WinWedge and a customized spreadsheet with

built in macros. It requires the use of a SciPres® RS-232 cable to connect your SciPres

pressure sensor to an available Com Port on your PC.

Minimum system requirements are Windows 98, Excel 2000 and WinWedge v3.4, which is

included in the package.

Once installed, click on the shortcut for the spreadsheet, and Excel will launch.

Press “Enable Macros” or “Enable Content”to begin the process for data collection. One may

choose to have the computer recognize this as a trusted document, if desired.

Note: If you are opening a previously saved data set, choose “Disable Macros” or “Disable

Content” instead.

®

24

Page 25

The following screen will be displayed:

Choose the Com Port you have the SciPres® pressure monitor connected to. Click on the “OK”

button and WinWedge will start, showing itself as an icon in your system tray.

You are then presented with the next screen:

WinWedge Icon

Enter all of the approprite Operator information in this dialog box and click on “OK”.

Note: The “Clear Data” button on the spreadsheet does not affect the information in these

fields. You may click on the “Operator Info” button and update these fields as needed.

Clicking on “OK” leaves the next screen, ready to get started collecting data from the SciPres®

pressure sensors.

25

Page 26

When ready, turn on the SciPres® pressure monitor, pressing the “On / Stby” button. The monitor

will load the calibration data from the sensors, and place that information in the spreadsheet. All

remaining data generated will automatically be placed in the cells of the spreadsheet, and the

charts populated with the same data. The text box in the upper left of the spreadsheet contains the

header information that is generated by the SciPres® pressure sensors and monitor. This will list

the version, the calibration data, all operating parameters, alarm settings and alarm limits.

Note: If you have clicked on “Cancel” on either of the two previous screens, you may click on

the “Com Port Setup” or “Operator Info” buttons to complete these tasks.

A chart of Pressure versus Time has been included for your use, and you may view it by clicking on

the appropriate tab at the bottom of the worksheet.

You may, of course, create your own charts or modify those included by adding trend lines,

changing titles, etc.

26

Page 27

When you are finished with a run, the screen will look similar to this one:

Click on “File”, “Save As” and choose an appropriate file name based on your needs and store it in

a different folder. When ready for another run, simple press the “Clear Data” button, or close and

re-open the original file.

27

Page 28

1.2 PC Terminal Program Settings

SciPres® pressure monitor to PC: PC communications via the Serial Port labeled “Printer / PC”

requires a SciPres® RS-232 Cable.

NOTE: When you are not using the SciPres® with a printer, this allows process data to be “dumped”

into your PC for archiving. The list of settings below must match those in serial section of the

SciPres® pressure sensor main menu.

The following terminal setting procedure is intended for PCs with a Windows 95/98/XP software

installation (for any other operating system, download and use a terminal or Telenet program and set

it up in a similar manner). Press the “START” button in the lower left corner of your screen, select

“All Programs” then select and open “Accessories”, select “HyperTerminal”, double-click at the

HyperTerminal icon.

1. From the “Connection Description” screen, select an icon and enter a file name, i.e. SciPres®

pressure sensor. Press “OK”.

2. From the “Phone Number” screen, select “Direct to Com 1” in the box labelled Connect Using: or

select any other available Com port. Press “OK”.

3. From the “Com 1 Property” screen, select the following parameters

Bits per Second: 9600

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Control: None

Press “Ok”

4. Go to “File” and open “Properties”, from the “SciPres® Pressure Sensor Property” screen, select

the “Setting” screen, enter the following:

Terminal Keys: Select

Emulation: TTY

Backscroll Buffer: 500

While still in the “Setting” screen, press “ASCII Setup” key & select the following from the “ASCII

Setup” screen:

Send Line Ends with Line Feed: Select

Echo Typed Characters Locally: Select

Line Delay 10 msec

Character Delay: 10 msec

Append Line Feeds….....: No Selection

Force Incoming…............: No Selection

Wrap Lines That Exceed …..: Select

Press “OK” at the bottom of the “SciPres® Pressure Sensor Setup” screen.

Press “OK” at the bottom of the “SciPres® Pressure Sensor Property – Setting” screen.

28

Page 29

Notes:

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

29

Page 30

Notes:

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

30

Page 31

Notes:

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

........................................................................................................................................................................................................................

31

Page 32

© 2015 Parker Hannifin Corporation. All rights reserved.

IOMI-AK1-001_RevA

Parker Hannifin Manufacturing Ltd

domnick hunter

Process Filtration - Europe

Durham Road

Birtley, Co. Durham

DH3 2SF, England

phone +44 (0)191 4105121

fax +44 (0)191 4105312

email: dhprocess@parker.com

www.parker.com/dhsingleuse

Parker Hannifin Corporation

domnick hunter

Process Filtration - North America

2340 Eastman Avenue

Oxnard, California, USA 93030

toll free: 877 784 2234

phone: +1 805 604 3400

fax: +1 805 604 3401

email: dhpsales.na@parker.com

www.parker.com/dhsingleuse

Loading...

Loading...