Page 1

P1/PD Series: B-Mod Service Information

Medium Pressure Axial Piston Pumps

Bulletin HY28-2708-02/SVC/EN

Effective: July 2019 Replaces: March 29, 2019

Page 2

Bulletin HY28-2708-02/SVC/EN | July 2019

Contents

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Contents

B-Mod Pump Identication ..................................................................................................................................... 3

B-Mod Controls vs A-mod Controls ........................................................................................................................ 4

General Information ................................................................................................................................................. 5

Typical Characteristics ............................................................................................................................................ 6

Parts Data

018, 028 B-mod Pump Exploded View ................................................................................................................... 7

045 B-mod Pump Exploded View ........................................................................................................................... 8

018, 028, 045 B-mod Pump Parts .......................................................................................................................... 9

060, 075, 085, 100, 140 B-mod Pump Exploded View ......................................................................................... 10

060, 075, 085, 100, 140 B-mod Pump Parts ........................................................................................................ 11

Volume Stop Control ............................................................................................................................................. 12

Thru Drive Couplings and O-rings ......................................................................................................................... 13

C0 B-mod Control Exploded View ........................................................................................................................ 14

L0 B-mod Control Exploded View ......................................................................................................................... 15

L2 B-mod Control Exploded View ......................................................................................................................... 16

AM B-mod Control Exploded View ....................................................................................................................... 17

C0 to L0 B-mod Conversion Guide ....................................................................................................................... 18

C0 to L2 B-mod Conversion Guide ....................................................................................................................... 19

C0 to AM B-mod Conversion Guide ..................................................................................................................... 20

L0 / L2 to C0 B-mod Conversion Guide .............................................................................................................. 21

L0 to L2 B-mod Conversion Guide ....................................................................................................................... 22

L2 to L0 B-mod Conversion Guide ....................................................................................................................... 23

L0 to AM B-mod Conversion Guide ...................................................................................................................... 24

L2 to AM B-mod Conversion Guide ...................................................................................................................... 25

AM to C0 B-mod Conversion Guide ..................................................................................................................... 26

AM to L0 B-mod Conversion Guide ...................................................................................................................... 27

AM to L2 B-mod Conversion Guide ...................................................................................................................... 28

075, 085, 100, 140 Torque Limiter ......................................................................................................................... 29

Electronic Unload Control B-mod Exploded View ................................................................................................ 30

Parts Kits ............................................................................................................................................................... 32

Assembly/Disassembly information

Compensator Procedures ..................................................................................................................................... 33

Pump Service Procedures ..................................................................................................................................... 35

Pump Inspection Procedures ................................................................................................................................ 37

Component Rework Limits .................................................................................................................................... 38

018, 028, 045 Assembly Procedures .................................................................................................................... 39

060, 075, 085, 100, 140 Assembly Procedures .................................................................................................... 43

Assembly Tools ..................................................................................................................................................... 47

Rotation Change ................................................................................................................................................... 51

Test Procedure ...................................................................................................................................................... 53

Test Criteria & Start-up Procedures....................................................................................................................... 55

Trouble Shooting ................................................................................................................................................... 56

Conversions and Formulas ................................................................................................................................... 58

Warning ................................................................................................................................................................. 59

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

2

Marysville, Ohio USA

Page 3

Bulletin HY28-2708-02/SVC/EN | July 2019

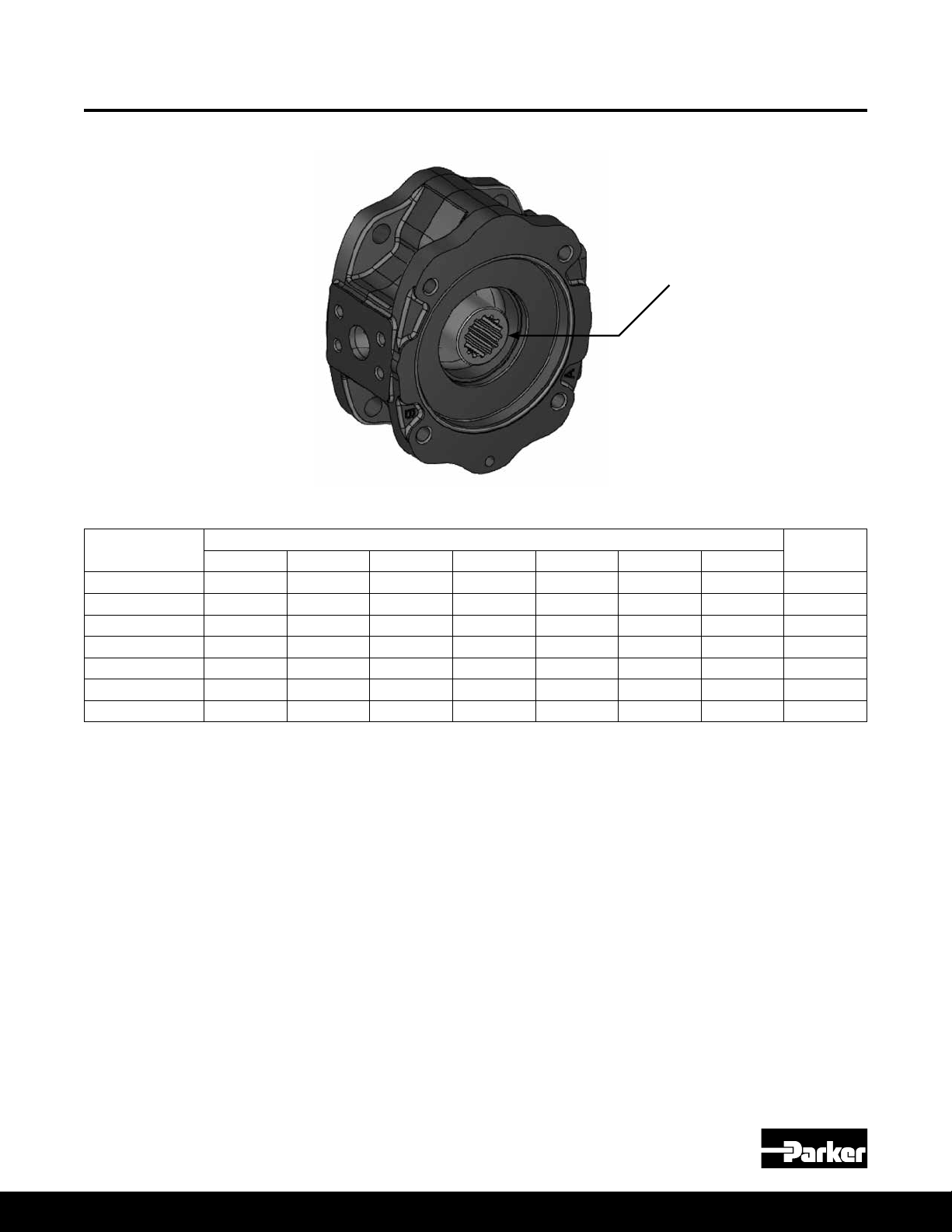

B-Mod Pump Identification

This service manual is to be used for P1/PD Design Series B (B-mod) pumps.

In order to identify which series of pump you have, please refer to the Series

Designation spot in the P1/PD model code as shown below.

The design series is based on the type of control selected. B-mod pumps use

the C, L, and AM controls. All other control types are Design Series A (A-mod).

There are however two exceptions. Both exceptions are on the 45 & 60cc pumps.

One exception is when the load sense (L) or remote compensator (AM) is used

in combination with the torque limiting control (ALT or AMT). The ALT or AMT on

the 45 & 60cc pumps is still the A-mod design series. The other exception is if

the Universal “U” conguration model code option is selected with the 45 or 60cc

pump. On those two displacements, the Universal “U” option is also still an A-mod

design series.

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Design Series Designation

"U" Universal Designation

For service information on A-mod pumps please refer to

Bulletin HY28-2665-02/SVC/EN. The latest edition can be found at

www.parker.com/HPS.

NOTE: A-mod and B-mod controls are NOT Interchangeable! Adapter block

is required to put a B-mod control on an A-mod or an A-mod control on a

B-mod pump. See Parts Kits page for adapter block part numbers.

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

3

Page 4

Bulletin HY28-2708-02/SVC/EN | July 2019

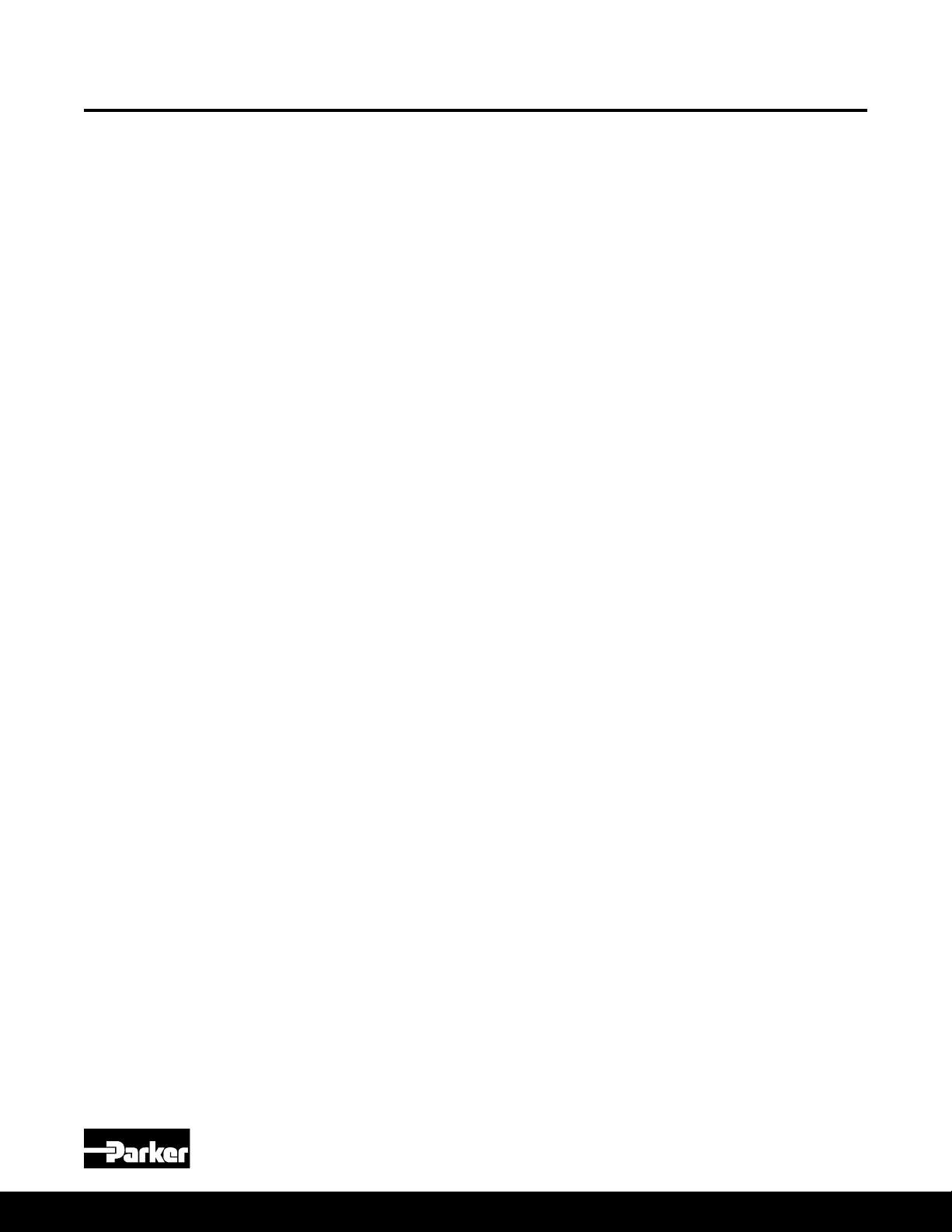

B-Mod Controls vs A-mod Controls

Design Series A Design Series B

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Pressure Limiter:

C00, C10 (Left)

Pressure sense:

L00, L20 (Left)

Pilot operated

pressure limiter:

AM (Left)

Pressure Limiter:

C00, C10 (Right)

Pressure sense:

L00, L20 (Right)

Pilot operated

pressure limiter:

AM (Right)

"All in one compensator":

C00, (C00 replaces C10) L00,

L20, AM (Left and Right)

Control

or Bias

Tank

Pressure

Tank

Pressure LS

Bias or

Control

Pressure

Pmax

Control

Standard NG6/D03 Pattern Custom Control Pad Pattern

NOTE: Bolt pattern & size remains the same. No change to housing casting required.

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

4

Marysville, Ohio USA

Page 5

Bulletin HY28-2708-02/SVC/EN | July 2019

General Information

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Model Coding Information

Mounting

Side Load Capability

Fluid Connections

System Relief Valves

Recommended Fluids

Viscosity Index

Temperature

Maintenance

Fluid Cleanliness

For model code designation meaning and general model code information please see

P1/PD sales catalog HY28-2665-01/P1/EN.

These pumps are designed to operate in any position. For shaft up, contact factory.

The pump shaft must be in alignment with the shaft of the source driver and should be

checked with a dial indicator. The mating pilot bore and coupling must be concentric.

This concentricity is particularly important if the shaft is rigidly connected to the driven

load without a exible coupling.

Splined: The shafts will accept a maximum misalignment of 0.005 in (0.15mm) total

indicator reading. Angular misalignment at the external and internal spline axis must be

less than ± 0,002 mm per mm of shaft radius, ± 0.002 inches per inch of shaft radius.

The coupling interface must be lubricated. PARKER recommends lithium molydisulde

or similar grease. The internal coupling should be hardened to Rc 27-34 and must conform

to SAE-J498c, class 5 at root side t.

Keyed: High strength heat treated keys must be used. Replacement keys must be hardened

to 27-34 Rc. The key corners must be chamfered 0.032-0.040 in (0.81-1.0 mm) at 45° to

clear radii that exist in the keyway.

The P1/PD series is designed for inline-drive. Side loading on the shaft is not recommended.

If this is unavoidable consult your nearest Parker representative.

Connect inlet and outlet lines to the port block of the pump. The maximum case pressure is

2 bar (30 psi) continuous, 4 bar (60 psi) intermittent. The case pressure must never exceed

inlet pressure by more than .5 bar (7 psi). When connecting case drain line make certain

that drain plumbing passes above highest point of the pump before passing to the reservoir.

The case leakage line must be of sufcient size to prevent back pressure in excess of 2 bar

(30 psi) and returned to the reservoir below the surface of the oil as far from the supply inlet

as possible. All uid lines, whether pipe, tubing, or hose must be adequate size and strength

to assure free ow through the pump. An undersize inlet line will prevent the pump from

operating properly at full rated speed. An undersize outlet line will cause back pressure and

cause heat generation and increased noise. Flexible hose lines are recommended. If rigid

piping is used, the workmanship must be accurate to eliminate strain on the pump port block

or to the uid connections. Sharp bends in the lines must be eliminated wherever possible.

All system piping must be cleaned and ushed before installing pump. Make sure the entire

hydraulic system is free of dirt, lint, scale, or other foreign material.

CAUTION: Do not use galvanized pipe. Galvanized coating can ake off with continued use.

Although the P1/PD series pumps have very fast off-stroke compensator response, system

relief valves are recommended in all cases for safety considerations.

The uid recommended for use in these pumps has a petroleum base and contains agents

which provide oxidation inhibition and anti-rust, anti-foam and de-aerating properties as

described in Parker standard HF-1. Where anti-wear additive uids are specied, see

Parker standard HF-0.

90 V. I. minimum. Higher values extend the range of operating temperature but may reduce

the service life of the uid. Viscosity cannot be lower than 7 cSt.

Determined by the viscosity characteristics of the uid used. Because high temperatures

degrade seals, reduce the service life of the uid and create hazards, uid temperature

should not exceed 230°F (110°C) at the case drain.

The pump is self-lubricating and preventative maintenance is limited to keeping system

uid clean by changing lters frequently. Keep all ttings and screws tight. Do not operate

at pressures and speeds in excess of the recommended limit. If the pump does not

operate properly, check the troubleshooting chart before attempting to overhaul the unit.

Overhauling may be accomplished by referring to the disassembly, rework limits of wear

parts, and assembly procedures as provided in this service manual.

Fluid must be cleaned before and continuously during operation, by lters that maintain a

cleanliness level of ISO 20/18/14. Better cleanliness levels will signicantly extend the life

of the components. As contaminant generation may vary with each application, each must

be analyzed to determine proper ltration to maintain the required cleanliness level.

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

5

Page 6

Bulletin HY28-2708-02/SVC/EN | July 2019

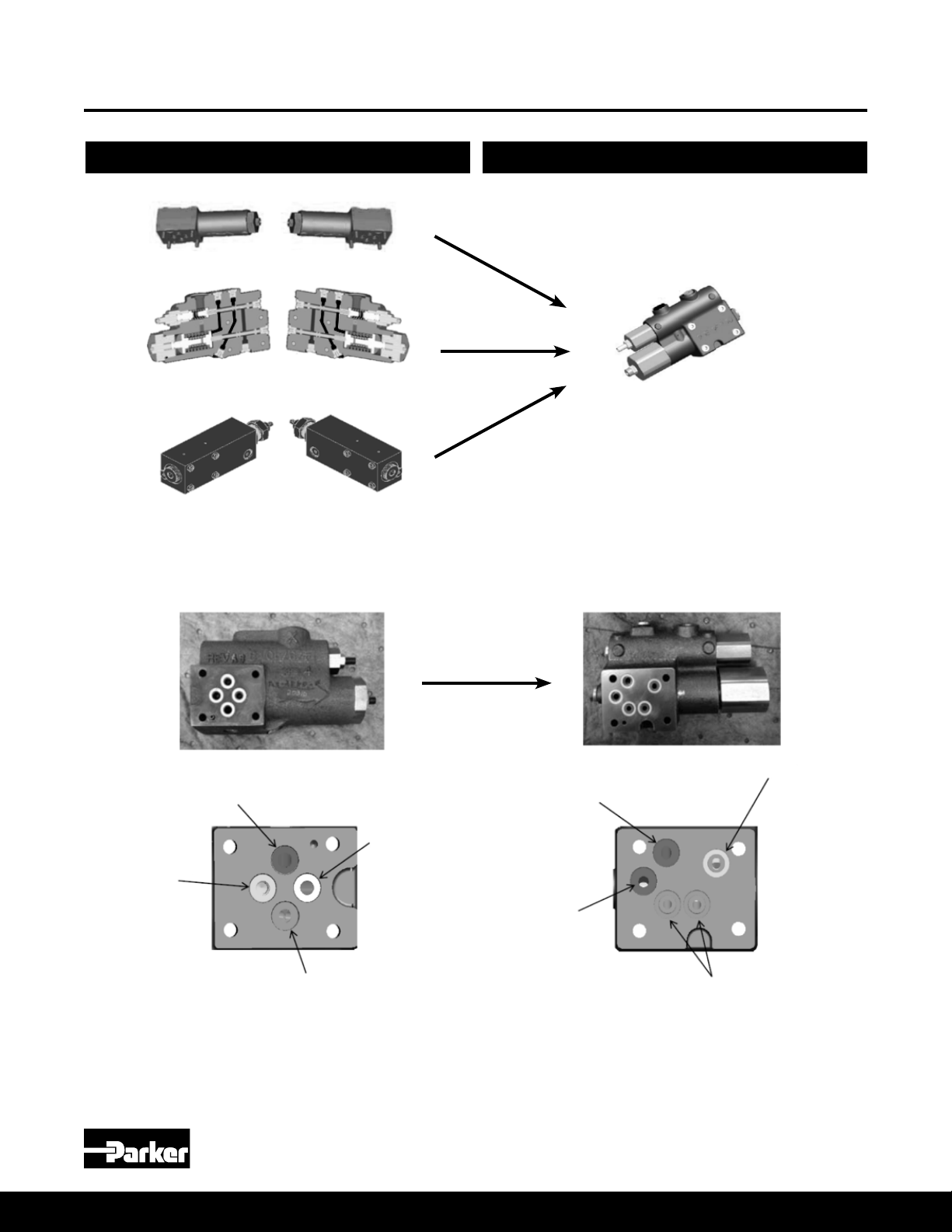

Typical Characteristics

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Technical Data

/rev

P1/PD

018

3500 3400 3100 2800 2700 2700 2500 2400

°F

2

760 1555 3208 4548 5041 5041 12027 21400

2

793 1618 3268 4687 5207 5207 12402 22343

Model

Maximum Displacement, cm

Outlet Pressure – Continuous

P1 Maximum Speed (1.3 bar abs inlet), rpm

P1 (1.0 bar abs inlet), rpm 3300 3200 2800 2500 2400 2400 2250 2100

P1 (0.8 bar abs inlet), rpm 2900 2900 2400 2200 2100 2100 1900 1800

PD Maximum Speed (1.0 bar abs inlet), rpm

PD (0.8 bar abs inlet), rpm 1800

Minimum Speed, rpm 600

Inlet Pressure – Maximum 11 bar absolute (160 psi)

Case Pressure – Peak, bar 4.0 bar absolute (58 psi) and less than 0.5 bar (7.3 psi) above inlet pressure

Fluid Temperature Range, °C

Fluid Viscosity – Rated, cSt 7 to 160

Optimum Range, cSt 14-50 cSt.

Max. Intermittent, cSt 5000 (for cold starting)

Min. Intermittent, cSt 5

Fluid Contamination – Rated, ISO 20/18/14

Weight – End Port, kg (lb) 13.4 (29.5) 17.7 (39.0) 23 (50) 29 (64) 30 (66) 30 (66) 51 (112) 66 (145)

Side Port, kg (lb) 14.2 (31.3) 18.1 (40.0) 24 (52) 30 (67) 31 (68) 31 (68) 53 (117) 67 (147)

Thru-Drive, kg (lb) 15 (34) 22 (48) 27 (59) 34 (75) 35 (77) 35 (77) 55 (121) 82 (180)

Moment of Inertia kg·mm

Moment of Inertia Thru-Drive kg·mm

*Intermittent pressure is dened as less than 10% of operation time, not exceeding 6 successive seconds.

3

cu.in./rev181.10

Intermittent*

Peak

Rated 1.0 bar absolute (14.5 psi)

Minimum 0.8 bar absolute (11.6 psi)

Rated, bar 2.0 bar absolute (29 psi) and less than 0.5 bar (7.3 psi) above inlet pressure

P1/PD

028

28

1.71

P1/PD

045

45

2.75

280 bar

(4060 psi)

320 bar

(4640 psi)

350 bar

(5075 psi)

P1/PD

060

60

3.66

-40 to +95

-40 to +203

P1/PD

1800

075

75

4.58

P1/PD

085

85

5.19

250 bar

(3600 psi)

300 bar

(4350 psi)

320 bar

(4600 psi)

P1/PD

100

100

6.01

P1/PD

140

140

8.54

280 bar

(4060 psi)

320 bar

(4640 psi)

350 bar

(5075 psi)

Typical Adjustment Ranges and Initial Settings for B-Mod Controls (Unless Customer Specified at Time of Order)

Function Adjustment Range Adjustment Value Recommended or Initial Setting

Pressure compensator settings

C, L, AM Controls 26-280 bar (380-4060 PSI) 55 bar/turn (800 PSI/turn) Default factory setting = 1000 PSI

Load sense differential settings

"L0" and “L2” 10-40 bar (150-580 PSI) 16 bar/turn (230 PSI/turn) 20 bar (290 PSI)

Maximum volume stop

018 100-40% 9% per turn (1.6 cc/turn) 100%

028 100-40% 8.2% per turn (2.3 cc/turn) 100%

045 100-20% 7.5% per turn (3.4 cc/turn) 100%

060 100-30% 6.8% per turn (4.1 cc/turn) 100%

075/085 100-35% 6.2% per turn (4.65 cc/turn) 100%

100 100-50% 5.5% per turn (5.5 cc/turn) 100%

140 100-50% 4.8% per turn (6.72 cc/turn) 100%

Minimum volume stop

018 0-68% 10% per turn (1.8 cc/turn) 0%

028 0-40% 9% per turn (2.6 cc/turn) 0%

045 0-40% 8.2% per turn (3.7 cc/turn) 0%

060 0-50% 4.6% per turn (2.76 cc/turn) 0%

075/085 0-45% 4.3% per turn (3.23 cc/turn) 0%

100 0-45% 3.9% per turn (3.9 cc/turn) 0%

140 0-25% 3.3% per turn (4.62 cc/turn) 0%

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

6

Marysville, Ohio USA

Page 7

Bulletin HY28-2708-02/SVC/EN | July 2019

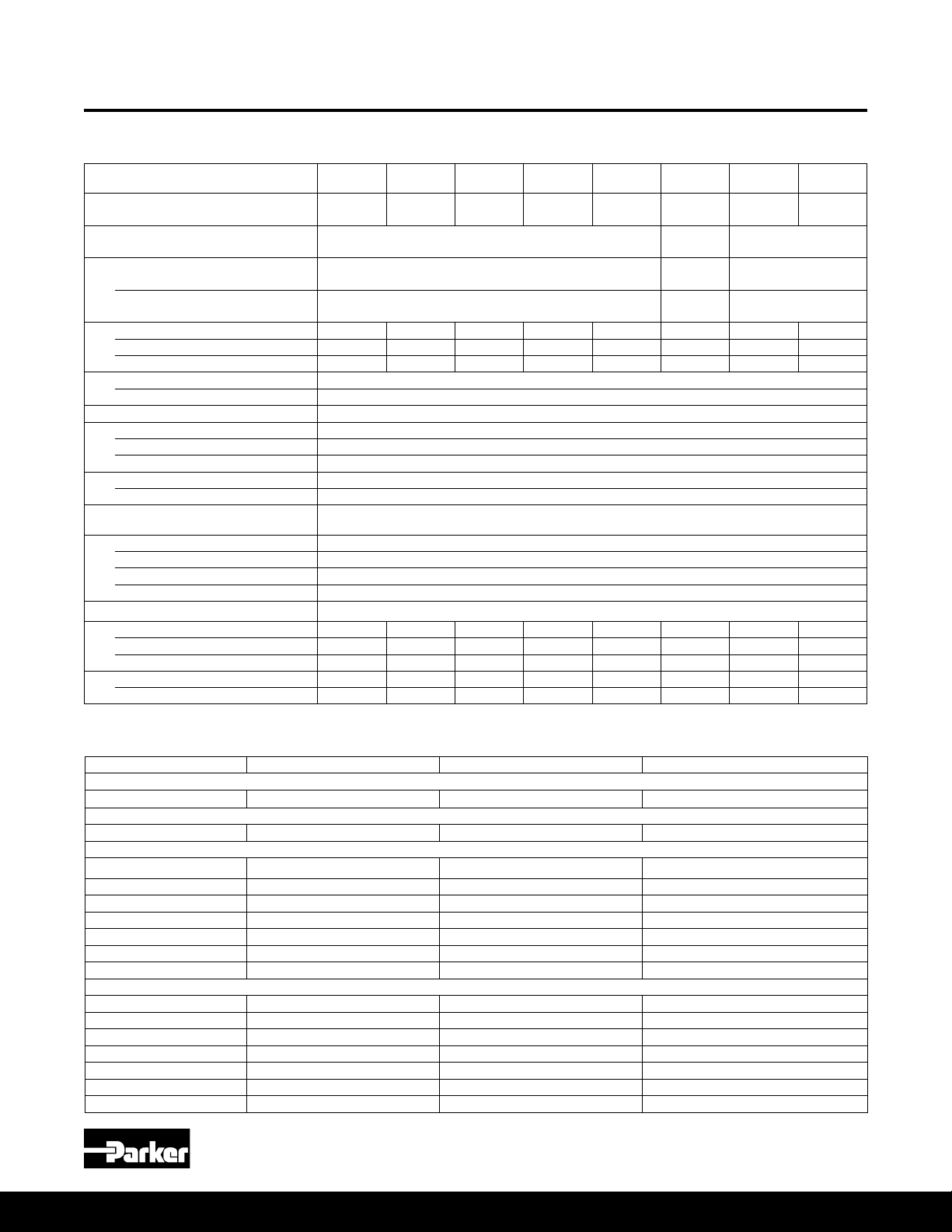

018, 028 B-mod Pump Exploded View

* Clockwise Rotation Shown

5

7

16

8

14

15

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

36

1

2

12

13

11

4

27

20

17

18

19

22

23

9

21

24

25

2930

26

34

36

35

Item

2 52 ft-lbs 52 ft-lbs

3 45 ft-lbs 45 ft-lbs

5 6 ft-lbs 6 ft-lbs

6 25 in-lbs 25 in-lbs

16 12 in-lbs 70 in-lbs

19 45 ft-lbs 45 ft-lbs

30 30 in-lbs 30 in-lbs

34 70 in-lbs 70 in-lbs

36 16 ft-lbs 45 ft-lbs

37 14 ft-lbs 14 ft-lbs

38 70 in-lbs 70 in-lbs

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

18 28

Torque Torque

28

38

41

37

39

40

7

30

31

32

42

43

46

36

Page 8

Bulletin HY28-2708-02/SVC/EN | July 2019

045 B-mod Pump Exploded View

* Clockwise Rotation Shown

7

17

8

10

14

15

9

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

6

3

1

5

2

19

18

16

12

Item

1 63 ft-lbs

2 45 ft-lbs

5 6 ft-lbs

6 25 in-lbs

11 105 ft-lbs

14 105 ft-lbs

16 10 ft-lbs

19 46 ft-lbs

30 30 in-lbs

34 70 in-lbs

36 75 ft-lbs

37 14 ft-lbs

45

Torque

27

13

11

41

40

37

39

10

17

26

4

42

25

36

24

35

23

34

36

30

32

22

31

21

30

20

28

29

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

8

Marysville, Ohio USA

Page 9

Bulletin HY28-2708-02/SVC/EN | July 2019

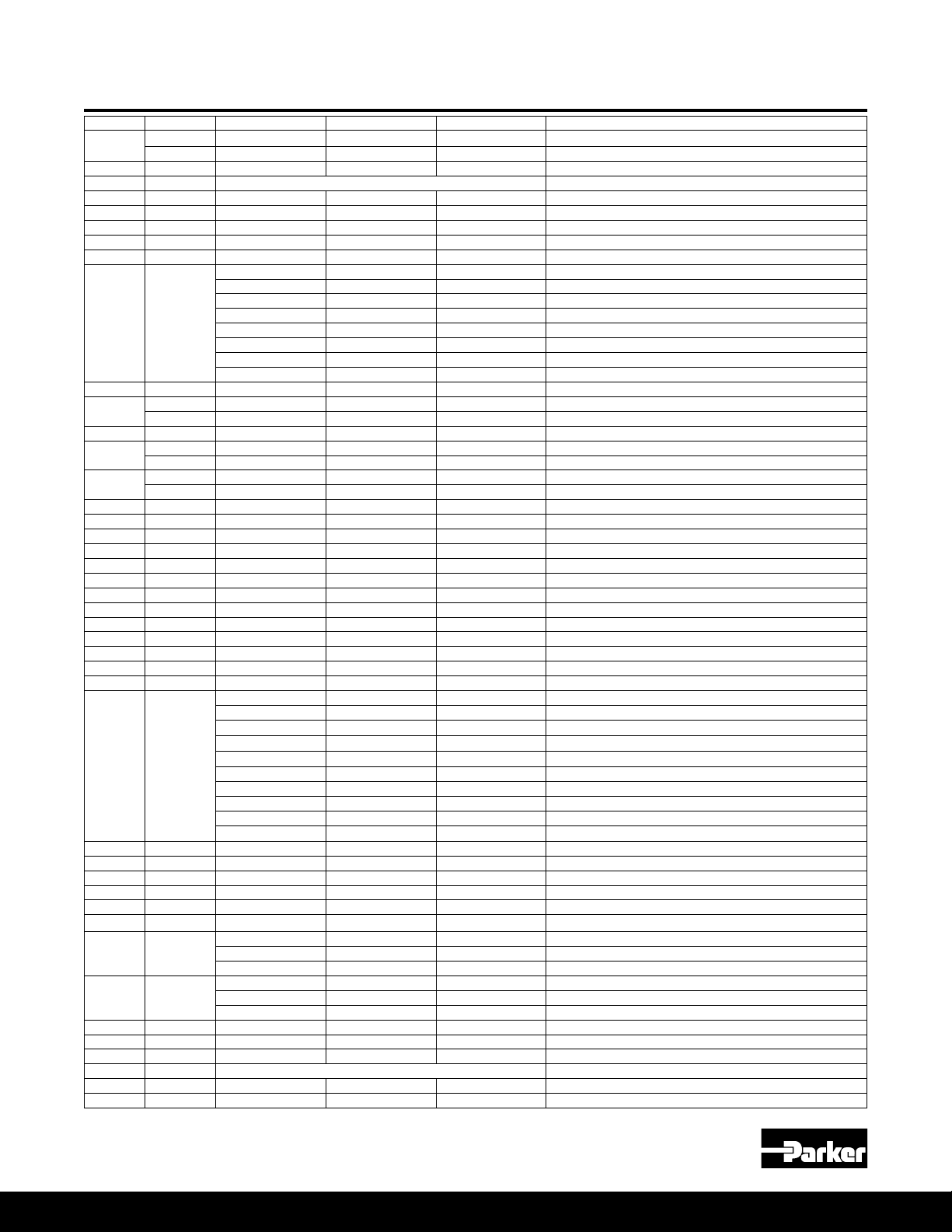

018, 028, 045 Pump Parts

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Item No Qty 018 Part No 028 Part No 045 Part No Description

1

2* 2 108X8V 108X8V 108X8V Volume stop boss plug & O-ring

3 1 Contact factory for port block ordering information. Port block

4* 1 2050V-7 2160V-7 675-00162-0 Port block O-ring

5* 4 108X2V 108X2V 108X2V Boss plug & O-ring

6 1 226X42 226X42 226X42 M5X6 Control Flow Set Screw

7 1 299X67 324-30014-0 324-30014-0 Port plate pin

8* 3 605-10077-0 605-10077-0 605-10077-0 Control pressure passage o-rings

9*** 1

10* 2 ** ** 695-00912-0 Bias and control rod O-ring

11

12 1 03E-94428-0 03E-94391-0 03E-94354-0 Bias piston

13

14

15 1 03E-94426-0 03E-94389-0 03E-94352-0 Control piston

16 1 226X14 226X56 102x1 Ripple chamber plug (side ported version only)

17 2 299X123 299X123 299X123 Cover dowel pin

18 1 216-10013-0 789814 230-82227-0 Port block bushing

19 1 102X8V 102X8V 108X10V Ripple chamber plug

20 1 256X521 256X525 356-65144-0 Retaining ring, internal

21 1 787635 03E-94387-0 03E-94350-0 Barrel hold down spring

22 2 (1:045) 786996 03E-94388-0 03E-94351-0 Barrel hold down washer

23 1 03E-94717-0 03E-94375-0 03E-94338-0 Barrel

24 3 787000 03E-94386-0 03E-95903-0 Barrel hold down pin

25 1 787002 03E-94385-0 03E-96852-0 Spherical washer

26 1 786994 03E-97011-0 03E-96988-0 Retainer plate

27 9 789641 S2E-18415-0 S2E-18413-0 Piston and shoe assembly

28 1

29 1 S2E-19079-0 S2E-18414-0 S2E-18412-0 Cam

30 2 03E-94359-0 03E-94359-0 03E-94359-0 Bearing retainer screws

31 2 03E-94432-0 03E-94395-0 03E-94358-0 Cam bearing

32 1 230-82515-0 789815 230-82516-0 Cylindrical roller bearing

34 1 226X56 226X56 226X56 M6X6 bias ow set screw

35 1 ** ** ** Housing (not sold separately)

36* 2

37* 1

38* 1 P2-000-3506-08 P2-000-3506-08 ** M6X6 set screw with 0.8mm orice

39* 1 787140 P2-060-3304 620-82125-5 Shaft seal

40 1 256X535 256X544 356-65158-0 Seal retainer

41 1 See separate compensator ordering information Compensator

42 1 256X222 256X222 356-65159-0 External retaining ring (shaft)

43 1 256X544 256X544 ** Internal retaining ring (housing)

* Denotes seal or O-ring is included in the seal kit

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

4 210x209 210x211 361-12229-0 Socket head cap screws

4 ** 210x209 ** Socket head cap screws (28cc thru drive version only)

03E-94415-0 03E-94969-0 03E-94339-0 Port plate, CW, industrial (PD)

03E-94414-0 03E-94970-0 03E-94340-0 Port plate, CCW, industrial (PD)

03E-94413-0 03E-94969-0 03E-94341-0 Port plate, CW, mobile (P1)

03E-94416-0 03E-94970-0 03E-94342-0 Port plate, CCW, mobile (P1)

03E-94963-0 03E-94376-0 03E-95374-0 Port plate, CW, industrial (PD), ripple chamber

03E-94964-0 03E-94377-0 03E-95080-0 Port plate, CCW, industrial (PD), ripple chamber

03E-94965-0 03E-94378-0 03E-95374-0 Port plate, CW, mobile (P1), ripple chamber

03E-94966-0 03E-94379-0 03E-95375-0 Port plate, CCW, mobile (P1), ripple chamber

1 03E-94427-0 03E-94390-0 03E-94355-0 Bias guide

1 ** ** 03E-95658-0 Bias guide (overcenter option)

1 03E-94430-0 03E-94393-0 03E-94356-0 Bias spring

1 ** ** 03E-95656-0 Bias spring (overcenter option)

1 03E-94427-0 03E-94390-0 03E-94353-0 Control guide

1 ** ** 03E-95657-0 Control guide (overcenter option)

03E-94409-0 03E-97070-0 03E-97070-0 01 shaft option, no thru drive

03E-94411-0 03E-94374-0 03E-94337-0 01 shaft option with thru drive

S2E-19657-0 S2E-19661-0 S2E-19665-0 02 shaft option assembly with key (no thru drive)

S2E-19658-0 S2E-19662-0 S2E-19666-0 02 shaft option assembly (thru drive)

S2E-19659-0 S2E-19663-0 S2E-19667-0 04 shaft option assembly with key (no thru drive)

S2E-19660-0 S2E-19664-0 S2E-19668-0 04 shaft option assembly (thru drive)

03E-94718-0 ** ** 06 shaft option assembly (no thru drive)

03E-96233-0 ** ** 06 shaft option assembly (thru drive)

03E-94804-0 03E-95166-0 03E-94990-0 08 shaft option, (no thru drive)

03E-94762-0 03E-95492-0 03E-95197-0 08 shaft option (thru drive)

108X6V 108X8V 108X10V Case drain plug & O-ring - SAE ORB

788153V 788161V 788161V Case drain plug & O-ring - BSPP

788516-06V 788516-10V 788516-10V Case drain plug & O-ring - ISO

108X4V 108X4V 108X4V BG port plug & O-ring - SAE ORB

789189V 789189V 789189V BG port plug & O-ring - BSPP

788516-04V 788516-04V 788516-04V BG port plug & O-ring - ISO

| *** Contact factory for 045 overcenter "X" port plate part number information

9

Page 10

Bulletin HY28-2708-02/SVC/EN | July 2019

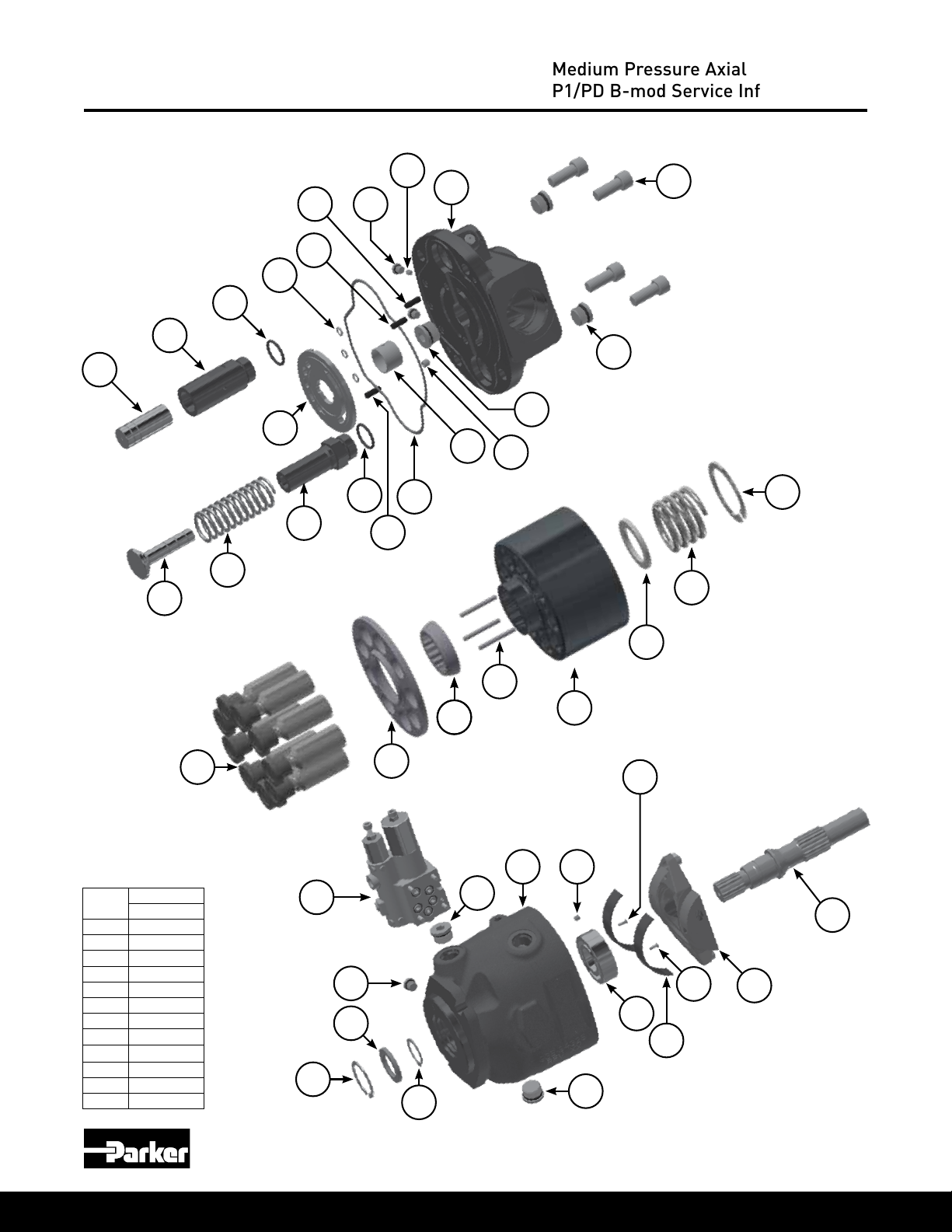

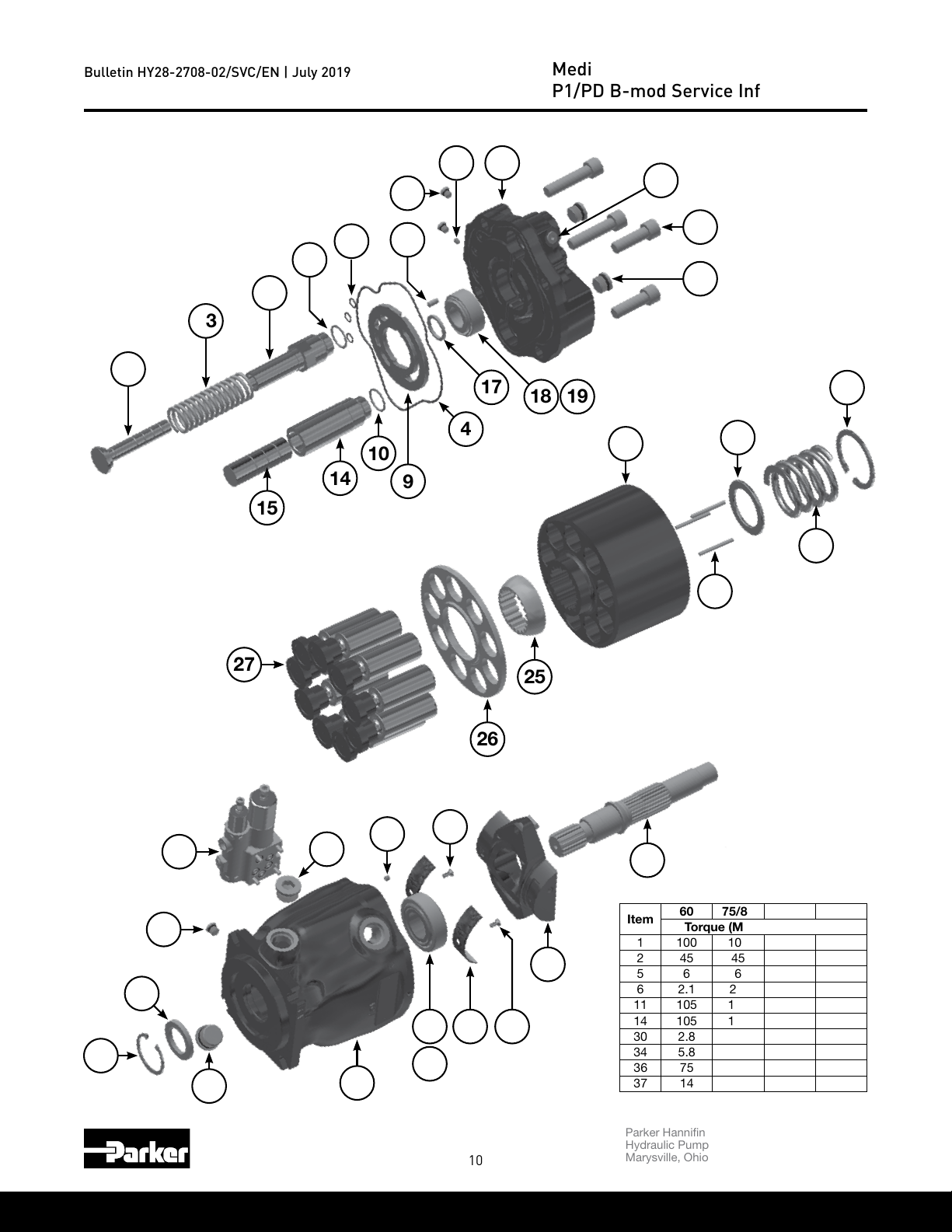

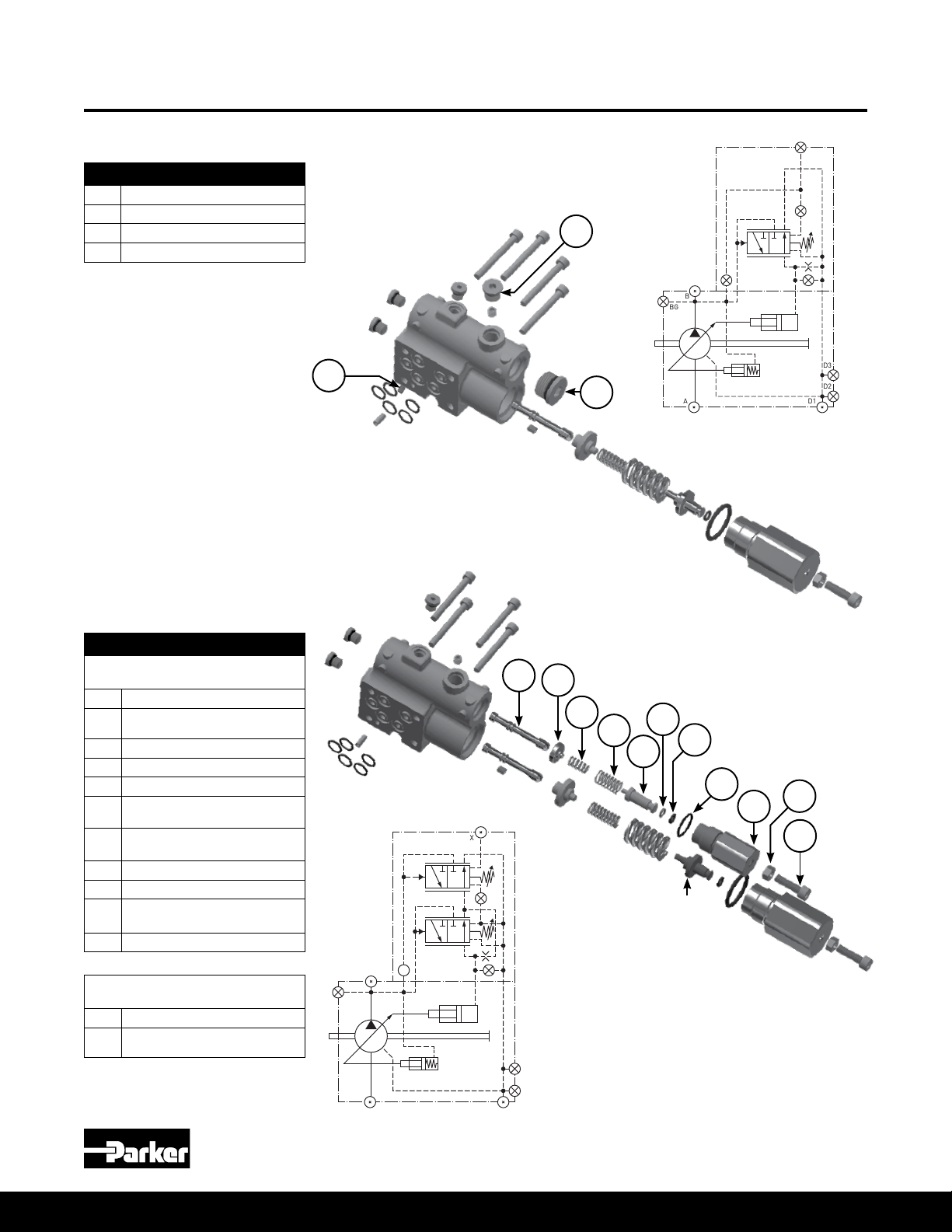

060, 075, 085, 100, 140 B-mod Pump Exploded View

* Counter-clockwise Rotation Shown

36

5

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

16

12

13

27

11

15

10

14

8

7

1

2

10

17

4

18 19

23

22

20

9

21

24

25

40

39

37

41

36

36

35

34

32

33

30

31 30

10

26

29

28

Item

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

60 75/85 100 140

Torque (Measured in ft-lbs)

1 100 100 170 205

2 45 45 45 45

5 6 6 6 6

6 2.1 2.1 2.1 2.1

11 105 105 136 170

14 105 105 136 170

30 2.8 2.8 2.8 2.8

34 5.8 5.8 5.8 5.8

36 75 85 85 135

37 14 14 14 14

Page 11

Bulletin HY28-2708-02/SVC/EN | July 2019

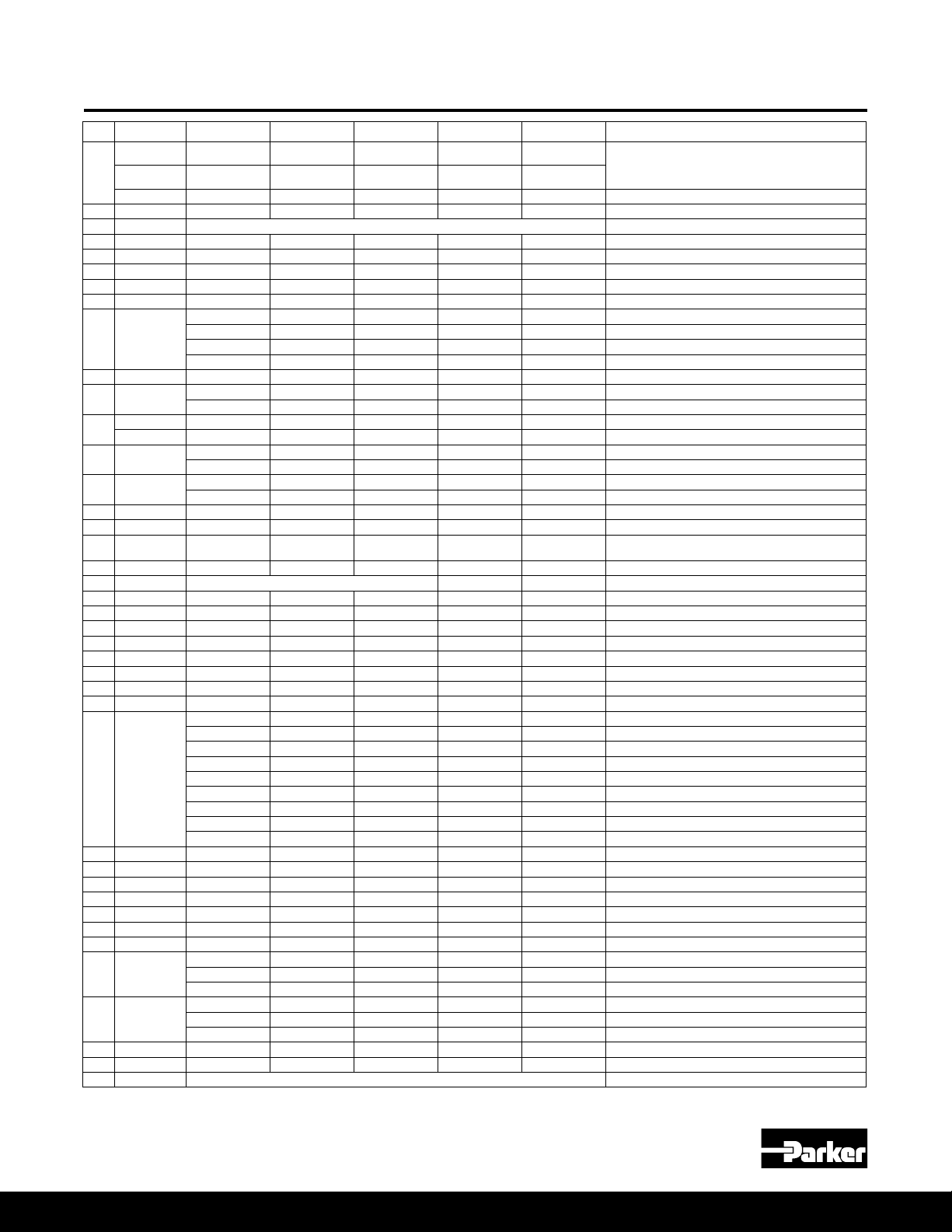

060, 075, 085, 100, 140 Pump Parts

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Item

No

2* 2 108X8V 108X8V 108X8V 108X8V 108X8V Volume stop boss plug & O-ring

4* 1 675-00164-0 675-00165-0 675-00165-0 675-00169-0 675-00173-0 Port block O-ring

5* 2 108X2V 108X2V 108X2V 108X2V 108X2V Boss plug & O-ring

8* 3 605-10070-0 605-10070-0 605-10070-0 605-10070-0 605-10070-0 Control pressure O-rings

9*** 1

10* 2 695-00912-0 695-00912-0 695-00912-0 695-00914-0 695-00916-0 Bias and control rod O-ring

11 1

12

13 1

14 1

15 1 03E-94051-0 03E-93147-0 03E-93147-0 03E-93797-0 03E-94751-0 Control piston

16* 2 108X4V 108X4V 108X4V 108X4V 108X4V Boss plug & O-ring

17 1 S2E-18591-0K S2E-18591-0K S2E-18591-0K S2E-18640-0K S2E-18527-0K

18 1 230-82237-0 230-82237-0 230-82237-0 230-82244-0 230-82239-0 Tapered roller bearing cup

19 1 INCLUDED IN ITEM 18 230-82518-0

20 1 356-65152-0 356-65144-0 356-65144-0 356-65146-0 356-65147-0 Retaining ring, internal

21 1 03E-94049-0 03E-93145-0 03E-93145-0 03E-93795-0 03E-93959-0 Barrel hold down spring

22 1 03E-94050-0 03E-93146-0 03E-93146-0 03E-93796-0 03E-93244-0 Barrel hold down washer

23 1 03E-94036-0 03E-93129-0 03E-95465-0 03E-95603-0 03E-93242-0 Barrel

24 3 03E-95904-0 03E-95905-0 03E-95905-0 03E-95906-0 03E-95907-0 Barrel hold down pin

25 1 03E-94047-0 03E-93142-0 03E-93142-0 03E-93794-0 03E-93241-0 Spherical washer

26 1 03E-97012-0 03E-93139-0 03E-95501-0 03E-93793-0 03E-93240-0 Retainer plate

27 9 S2E-18296-0 S2E-17003-0 S2E-19330-0 S2E-17912-0 S2E-17323-0 Piston and shoe assembly

28 1

29 1 S2E-18411-0 S2E-17443-0 S2E-17443-0 S2E-17961-0 S2E-17957-0 Cam

30 2 03E-93763-0 03E-93763-0 03E-93763-0 03E-93763-0 03E-93763-0 Bearing retainer screws

31 2 03E-94057-0 03E-93950-0 03E-93950-0 03E-93952-0 03E-93953-0 Cam bearing

32 1 230-82236-0 230-82236-0 230-82236-0 230-82519-0 230-82241-0 Tapered roller bearing cone (and cup 140)

33 1 230-82235-0 230-82235-0 230-82235-0 230-82245-0 ** Tapered roller bearing cup

34 1 226X56 226X56 226X56 226X56 226X56 M6X6 bias ow set screw

35 1 ** ** ** ** ** Housing (not sold separately)

36* 2

37* 1

39* 1 620-82118-5 620-82118-5 620-82118-5 620-82121-5 620-82120-5 Shaft seal

40 1 356-65146-0 356-65146-0 356-65146-0 356-65147-0 356-65148-0 Seal retainer

41 1 See separate compensator ordering information. Compensator

Qty 060 Part No 075 Part No 085 Part No 100 Part No 140 Part No Description

4

(2: 075/085)

0

1

(2: 075/085)

4 361-13250-0 361-13250-0 361-13250-0 361-14290-0 361-15267-0 Socket head cap screws (thru drive version only)

3 1 Contact factory for port block ordering information. Port block

6 1 226X42 226X42 226X42 226X42 226X42 M5X6 control ow set screw

7 1 324-30014-0 324-30014-0 324-30014-0 324-30014-0 324-30014-0 Port plate pin

1 03E-94053-0 03E-93149-0 03E-93149-0 03E-93799-0 03E-94658-0 Bias piston

1 03E-94835-0 03E-93149-0 ** 03E-93799-0 03E-94658-0 Bias piston (overcenter option "X")

361-13250-0 361-13270-0 361-13270-0 361-14290-0 361-15270-0

361-13250-0 361-13250-0 361-13250-0 361-14290-0 361-15270-0

03E-94038-0 03E-93169-0 03E-93169-0 03E-95605-0 03E-93252-0 Port plate, CW, industrial (PD)

03E-94039-0 03E-93170-0 03E-93170-0 03E-95606-0 03E-93253-0 Port plate, CCW, industrial (PD)

03E-94040-0 03E-93171-0 03E-93171-0 03E-95607-0 03E-93254-0 Port plate, CW, mobile (P1)

03E-94041-0 03E-93172-0 03E-93172-0 03E-95608-0 03E-93255-0 Port plate, CCW, mobile (P1)

03E-94054-0 03E-93150-0 03E-93150-0 03E-93800-0 03E-93248-0 Bias guide

03E-94832-0 03E-94498-0 ** 03E-94827-0 03E-94743-0 Bias guide (overcenter option “X”)

03E-94055-0 03E-93151-0 03E-93151-0 03E-93801-0 03E-93963-0 Bias spring

03E-94834-0 03E-94499-0 ** 03E-94829-0 03E-94752-0 Bias spring (overcenter option “X”)

03E-94052-0 03E-93148-0 03E-95471-0 03E-93798-0 03E-97335-0 Control guide

03E-94833-0 03E-94608-0 ** 03E-94828-0 03E-93246-0 Control guide (overcenter option “X”)

INCLUDED IN ITEM 18

03E-94032-0 03E-97070-0 03E-97070-0 03E-93779-0 03E-93227-0 01 shaft, no thru drive

03E-94033-0 03E-94000-0 03E-94000-0 03E-93780-0 03E-93228-0 01 shaft with thru drive

S2E-19669-0 S2E-19673-0 S2E-19673-0 S2E-19677-0 S2E-19681-0 02 shaft assembly with key (no thru drive)

S2E-19670-0 S2E-19674-0 S2E-19674-0 S2E-19678-0 S2E-19682-0 02 shaft assembly (thru drive)

S2E-19671-0 S2E-19675-0 S2E-19675-0 S2E-19679-0 S2E-19683-0 04 shaft assembly with key (no thru drive)

S2E-19672-0 S2E-19676-0 S2E-19676-0 S2E-19680-0 S2E-19684-0 04 shaft assembly (thru drive)

03E-95611-0 ** ** 03E94500-0 ** 06 (100cc) & 09 (60cc) shaft, no thru drive

03E-96177-0 ** ** 03E-94462-0 ** 06 (100cc) & 09 (60cc) shaft, thru drive

03E-96216-0 ** ** ** ** 10 shaft, no thru drive

108X10V 108X12V 108X12V

788175V 788175V 788175V 788175V 447-00038-5 Case drain plug & O-ring - BSPP

788516-10V 788516-12V 788516-12V 788516-12V 788516-16V Case drain plug & O-ring - ISO

108X4V 108X4V 108X4V 108X4V 108X4V BG port plug & O-ring - SAE ORB

789189V 789189V 789189V 789189V 789189V BG port plug & O-ring - BSPP

788516-04V 788516-04V 788516-04V 788516-04V 788516-04V BG port plug & O-ring - ISO

108X12V 108X16V Case drain plug & O-ring - SAE ORB

Socket head cap screws (non-thru drive version)

Bearing shim kit (includes all standard shim

sizes)

Tapered roller bearing cone

* Denotes seal or O-ring is included in the seal kit | *** Contact factory for overcenter "X" port plate part number information

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

11

Page 12

Bulletin HY28-2708-02/SVC/EN | July 2019

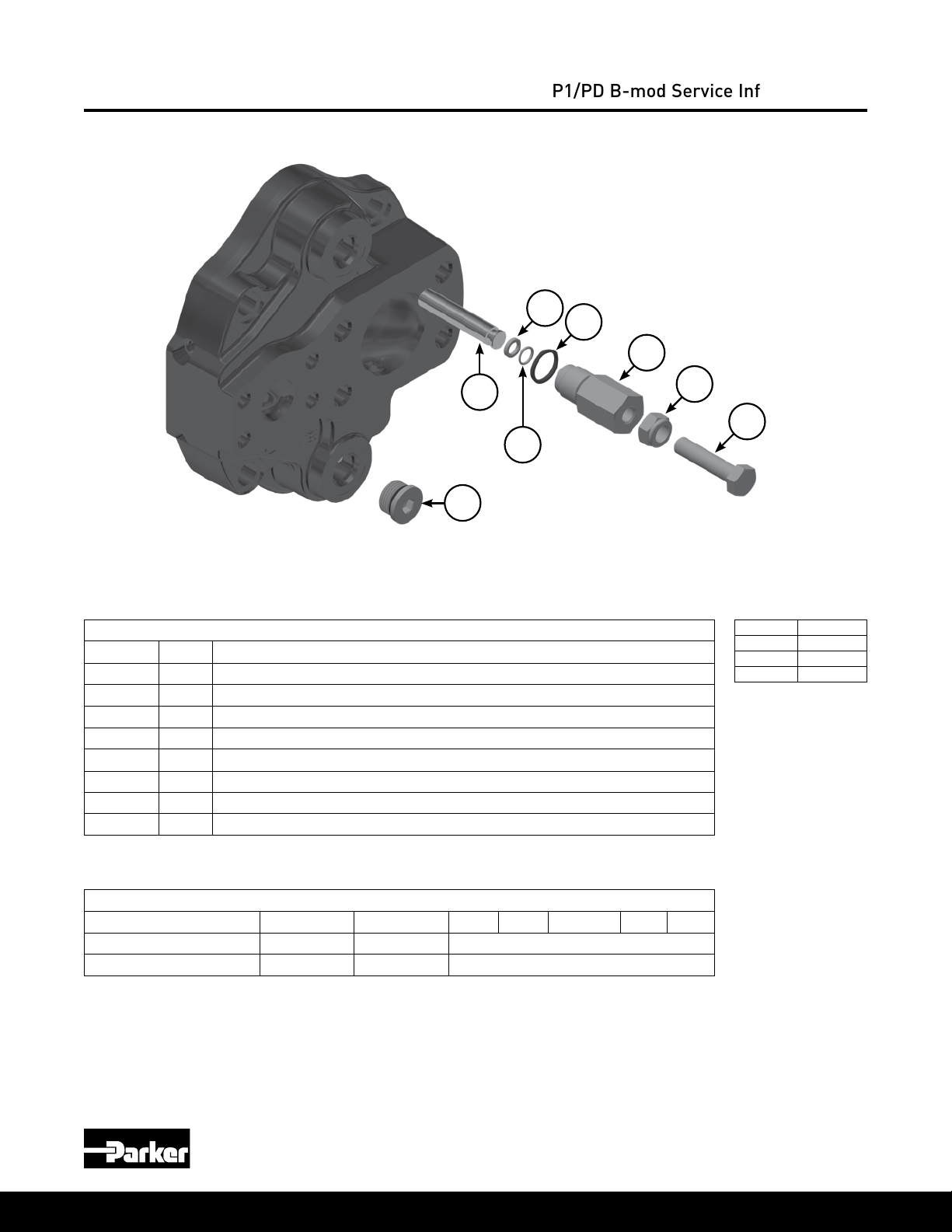

Volume Stop Control

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

59

57

56

60

58

2

NOTE: Picture shows max volume stop location for counter-clockwise rotation and min volume stop

location for clockwise rotation. Plug and stop assembly locations would be switched for opposite rotation.

Volume Stop Parts

Item No Qty Description

2 1 Plug with O-ring (no volume stop)

54 1 Adjusting screw

55 1 Adjusting screw lock nut

56 1 Volume stop plug

57 1 Volume stop plug O-ring

58 1 Backup ring

59 1 Volume stop rod O-ring

60* 1 Volume stop rod

*Min & max rods same for the 45 thru 140, but different on the 18 & 28. See table below for kit part number.

55

54

Item Torque

2 45 ft-lbs

55 18 ft-lbs

56 45 ft-lbs

Volume Stop Kits

Size 018 028 045 060 075/085 100 140

Maximum volume stop kit S2E-19203-5K S2E-19204-5K S2E-19115-5K

Minimum volume stop kit S2E-19608-5K S2E-19609-5K S2E-19115-5K

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

12

Marysville, Ohio USA

Page 13

Bulletin HY28-2708-02/SVC/EN | July 2019

Thru Drive Couplings and O-rings

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Thru Drive

Pad Coupling

Thru Drive

Pad Coupling

SAE A, 9 Tooth S2E-19538-0 S2E-19364-0 03E-94942-0 03E-93278-0 03E-93278-0 03E-94274-0 03E-93947-0 695-00237-0

SAE A, 11 Tooth S2E-19726-0 S2E-19391-0 03E-94943-0 03E-94724-0 03E-94724-0 03E-94657-0 03E-95706-0 695-00237-0

SAE B, 13 Tooth ** S2E-19365-0 03E-94945-0 03E-93277-0 03E-93277-0 03E-94273-0 03E-93946-0 695-00243-0

SAE BB, 15 Tooth ** S2E-19409-0 03E-94361-0 03E-93279-0 03E-93279-0 03E-94272-0 03E-93945-0 695-00243-0

SAE C, 14 Tooth ** ** ** 03E-93276-0 03E-93276-0 03E-94271-0 03E-93944-0 695-00251-0

SAE CC, 17 Tooth ** ** ** ** ** 03E-94270-0 03E-93943-0 695-00251-0

SAE D&E, 13 Tooth ** ** ** ** ** ** 03E-93942-0 695-00259-0

018 028 045 060 075/085 100 140

Thru Drive Couplings

O-ring

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

13

Page 14

Bulletin HY28-2708-02/SVC/EN | July 2019

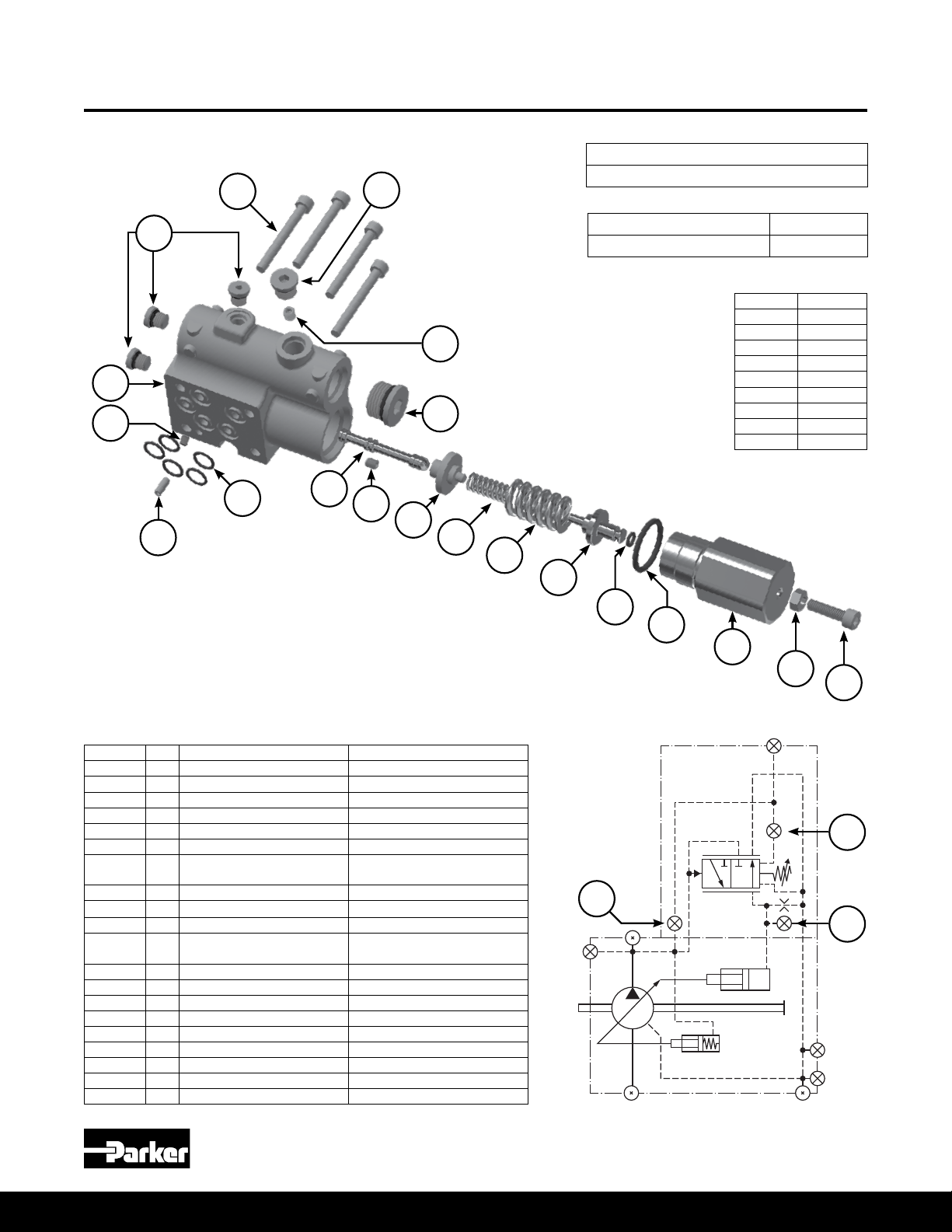

C0 B-mod Control Exploded View

12

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

C0 Controller Assembly Part Number

S2E-20171-5T

18

31

17

13

15

14

Pmax Spool Kit* S2E-20821-5K

Seal Kit (C, L, & AM controls) S2E-20363-5K

* Includes items 1-11, 16 & 17

Item Torque

2 30 in-lbs

16

19

9 85 ft-lbs

10 70 in-lbs

12 45 in-lbs

13 35 in-lbs

16 40 in-lbs

17 12 in-lbs

18 11 ft-lbs

19 50 ft-lbs

1

2

3

4

5

6

7

8

9

10

11

Item Qty Part Number Description

1 1 03E-95926-0 Pmax spool

2 1 226X42 M5 x 6 set screw

3 1 Available in kit only Pmax inner spring guide

4 1 Available in kit only Pmax inner spring

5 1 Available in kit only Pmax outer spring

6 1 Available in kit only Pmax outer spring guide

7* 1 Available in kit only

8* 1 Available in kit only Pmax main O-ring

9 1 03E-95570-0 Pmax outer cap

10 1 340-00063-0 Pmax adjustment lock nut

11 1 361-08275-0

12 4 361-07253-8 M5 x 45 SHCS

13* 3 108X2V SAE Boss Plug & O-ring

14* 5 Available in kit only Compensator teon O-ring

15 1 325-36001-0 Compensator M4 x 10 roll pin

16 1 226X56 M6 x 6 set screw

17 1 226X26 M4 x 5 set screw

18 1 108X4V Boss plug & O-ring - SAE

19 1 108X8V Boss plug & O-ring

31 1 Not sold separately Compensator housing

*Included in C, L, & AM controls seal kit

Pmax outer spring guide

O-ring

Pmax M6x22 adjustment

screw

14

X

16

17

2

B

BG

D3

D2

D1A

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 15

Bulletin HY28-2708-02/SVC/EN | July 2019

X

B

BG

D3

D2

D1A

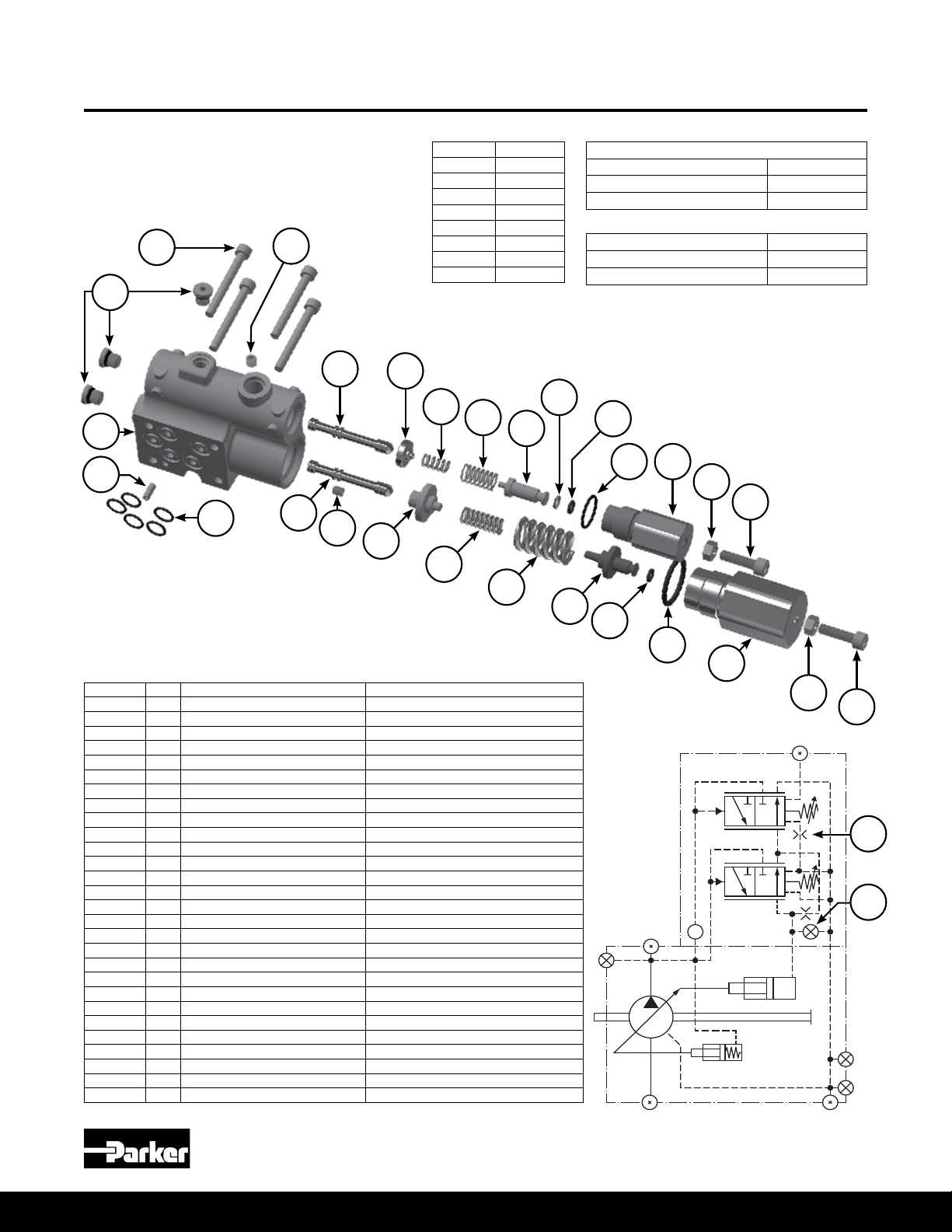

L0 B-mod Control Exploded View

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

13

31

15

12

14

16

Item Torque

2 30 in-lbs

9 85 ft-lbs

10 70 in-lbs

12 45 in-lbs

13 35 in-lbs

16 40 in-lbs

28 50 ft-lbs

29 70 in-lbs

20

21

22

23

25

24

1

2

L0 Controller Assembly Part Numbers

SAE* S2E-19440-5T

Metric* S2E-20186-5T

BSPP* S2E-20189-5T

* Designates load sense port thread type

Pmax Spool Kit** S2E-20821-5K

Load Sense Spool Kit*** S2E-20822-5K

Seal Kit (C, L, & AM controls) S2E-20363-5K

** Includes items 1-11, 16 & 17

*** Includes items 2, 16, 20-30

26

28

27

29

30

3

4

5

6

7

8

9

Item Qty Part Number Description

1 1 03E-95926-0 Pmax spool

2 1 226X42 M5 x 6 set screw

3 1 Available in kit only Pmax inner spring guide

4 1 Available in kit only Pmax inner spring

5 1 Available in kit only Pmax outer spring

6 1 Available in kit only Pmax outer spring guide

7* 1 Available in kit only Pmax outer spring guide O-ring

8* 1 Available in kit only Pmax main O-ring

9 1 03E-95570-0 Pmax outer cap

10 1 340-00063-0 Pmax adjustment lock nut

11 1 361-08275-0 Pmax M6x22 adjustment screw

12 4 361-07253-8 M5 x 45 SHCS

13* 3 108X2V SAE Boss Plug & O-ring

14* 5 Available in kit only Compensator teon O-ring

15 1 325-36001-0 Compensator M4 x 10 roll pin

16 1 226X56 M6 x 6 set screw

20 1 03E-95926-0 Differential spool

21 1 Available in kit only Differential inner spring guide

22 1 Available in kit only Differential inner spring

23 1 Available in kit only Differential outer spring

24 1 Available in kit only Differential outer spring guide

25* 1 Available in kit only Differential inner spring guide O-ring

26* 1 Available in kit only Differential inner spring guide O-ring

27* 1 Available in kit only Differential main O-ring

28 1 03E-95572-0 Differential outer cap

29 1 340-00063-0 Differential adjustment lock nut

30 1 361-08275-0 Differential M6x22 adjustment screw

31 1 Not sold separately Compensator housing

*Included in C, L, & AM controls seal kit

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

15

10

11

16

2

Page 16

Bulletin HY28-2708-02/SVC/EN | July 2019

X

B

BG

D3

D2

D1A

L2 B-mod Control Exploded View

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

13

31

15

12

14

16

Item Torque

2 30 in-lbs

9 85 ft-lbs

10 70 in-lbs

12 45 in-lbs

13 35 in-lbs

16 40 in-lbs

28 50 ft-lbs

29 70 in-lbs

20

21

22

23

25

24

1

2

L2 Controller Assembly Part Numbers

SAE* S2E-20196-5T

Metric* S2E-20187-5T

BSPP* S2E-20190-5T

* Designates load sense port thread type

Pmax Spool Kit** S2E-20821-5K

Load Sense Spool Kit*** S2E-20822-5K

Seal Kit (C, L, & AM controls) S2E-20363-5K

** Includes items 1-11, 16 & 17

*** Includes items 2, 16, 20-30

26

28

27

29

30

3

4

5

6

7

8

9

Item Qty Part Number Description

1 1 03E-95926-0 Pmax spool

2 1 226X42 M5 x 6 set screw

3 1 Available in kit only Pmax inner spring guide

4 1 Available in kit only Pmax inner spring

5 1 Available in kit only Pmax outer spring

6 1 Available in kit only Pmax outer spring guide

7* 1 Available in kit only Pmax outer spring guide O-ring

8* 1 Available in kit only Pmax main O-ring

9 1 03E-95570-0 Pmax outer cap

10 1 340-00063-0 Pmax adjustment lock nut

11 1 361-08275-0 Pmax M6x22 adjustment screw

12 4 361-07253-8 M5 x 45 SHCS

13* 3 108X2V SAE Boss Plug & O-ring

14* 5 Available in kit only Compensator teon O-ring

15 1 325-36001-0 Compensator M4 x 10 roll pin

16 1 P2-000-3506-04 M6 x 6 set screw with 0.4mm orice

20 1 03E-95926-0 Differential spool

21 1 Available in kit only Differential inner spring guide

22 1 Available in kit only Differential inner spring

23 1 Available in kit only Differential outer spring

24 1 Available in kit only Differential outer spring guide

25* 1 Available in kit only Differential inner spring guide O-ring

26* 1 Available in kit only Differential inner spring guide O-ring

27* 1 Available in kit only Differential main O-ring

28 1 03E-95572-0 Differential outer cap

29 1 340-00063-0 Differential adjustment lock nut

30 1 361-08275-0 Differential M6x22 adjustment screw

31 1 Not sold separately Compensator housing

*Included in C, L, & AM controls seal kit

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

16

Marysville, Ohio USA

10

11

16

2

Page 17

Bulletin HY28-2708-02/SVC/EN | July 2019

X

B

BG

D3

D2

D1A

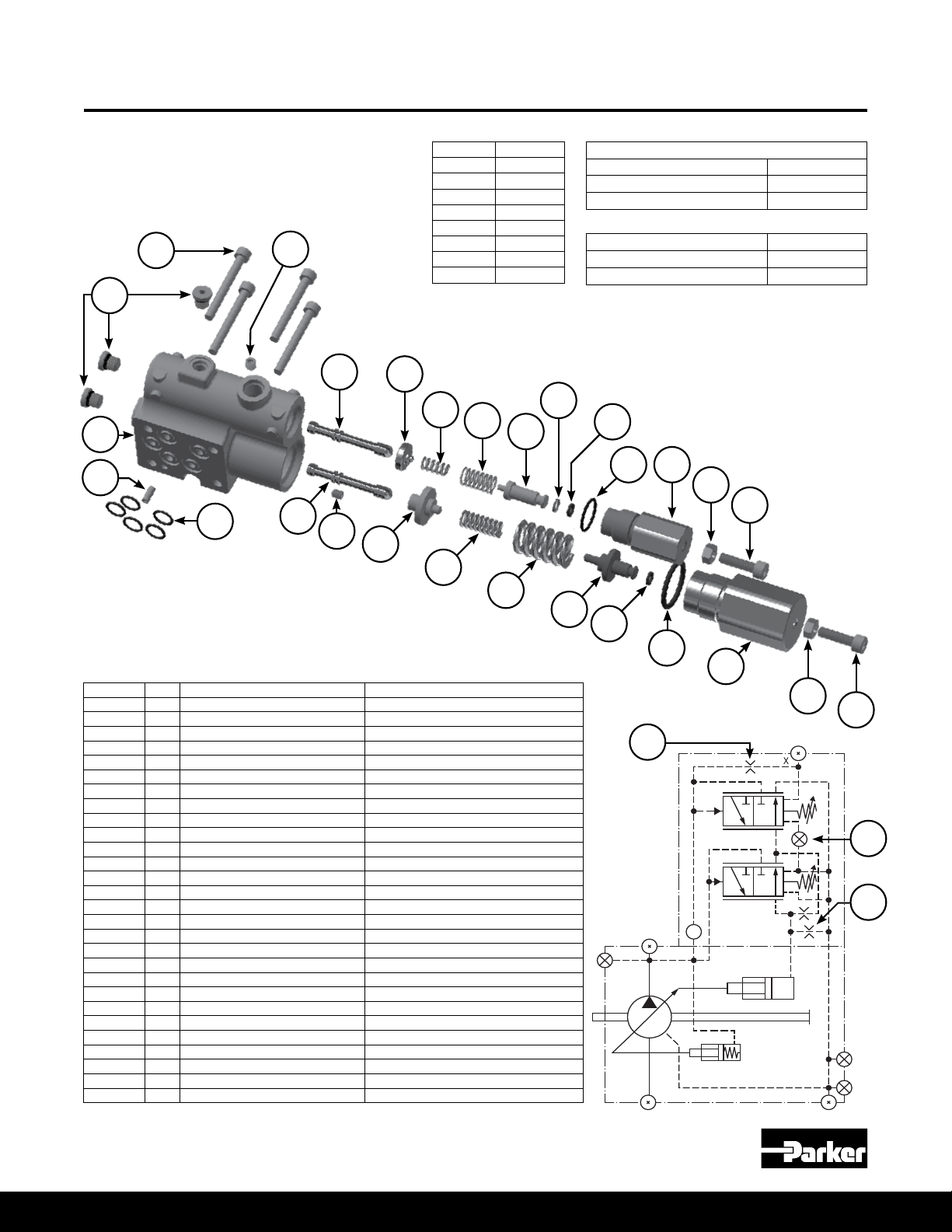

AM B-mod Control Exploded View

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

13

31

15

12

14

16

Item Torque

2 30 in-lbs

9 85 ft-lbs

10 70 in-lbs

12 45 in-lbs

13 35 in-lbs

16 40 in-lbs

28 50 ft-lbs

29 70 in-lbs

20

21

22

23

25

24

1

2

AM Controller Assembly Part Numbers

SAE* S2E-20172-5T

Metric* S2E-20188-5T

BSPP* S2E-20191-5T

* Designates remote port thread type

Pmax Spool Kit** S2E-20821-5K

AM Spool Kit*** S2E-20823-5K

Seal Kit (C, L, & AM controls) S2E-20363-5K

** Includes items 1-11, 16 & 17

*** Includes items 2, 16, 20-30

26

28

27

29

30

3

4

5

6

7

8

9

Item Qty Part Number Description

1 1 03E-95926-0 Pmax spool

2 1 03E-93269-0 M5 x 6 set screw with 0.8mm orice

3 1 Available in kit only Pmax inner spring guide

4 1 Available in kit only Pmax inner spring

5 1 Available in kit only Pmax outer spring

6 1 Available in kit only Pmax outer spring guide

7* 1 Available in kit only Pmax outer spring guide O-ring

8* 1 Available in kit only Pmax main O-ring

9 1 03E-95570-0 Pmax outer cap

10 1 340-00063-0 Pmax adjustment lock nut

11 1 361-08275-0 Pmax M6x22 adjustment screw

12 4 361-07253-8 M5 x 45 SHCS

13* 3 108X2V SAE Boss Plug & O-ring

14* 5 Available in kit only Compensator teon O-ring

15 1 325-36001-0 Compensator M4 x 10 roll pin

16 1 226X56 M6 x 6 set screw

20 1 03E-95860-0 Differential spool

21 1 Available in kit only Differential inner spring guide

22 1 Available in kit only Differential inner spring

23 1 Available in kit only Differential outer spring

24 1 Available in kit only Differential outer spring guide

25* 1 Available in kit only Differential inner spring guide O-ring

26* 1 Available in kit only Differential inner spring guide O-ring

27* 1 Available in kit only Differential main O-ring

28 1 03E-95572-0 Differential outer cap

29 1 340-00063-0 Differential adjustment lock nut

30 1 361-08275-0 Differential M6x22 adjustment screw

31 1 Not sold separately Compensator housing

*Included in C, L, & AM controls seal kit

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

17

20

10

11

16

2

Page 18

Bulletin HY28-2708-02/SVC/EN | July 2019

C0 to L0 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

C0

Remove

Item Description

17 M4 x 5 set screw

18 Boss plug & O-ring - SAE

19 Boss plug & O-ring

17

18

19

X

B

BG

D3

D2

D1A

L0

Add

Kit #1

S2E-20463-5K

Item Description

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

Differential inner spring guide

25

O-ring

Differential inner spring guide

26

O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

30 Differential adjustment screw

Kit #4

S2E-20466-5K

Item Description

20 Load sense differential spool

20

21

22

23

X

B

BG

D3

D2

D1A

24

25

26

27

28

29

30

18

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 19

Bulletin HY28-2708-02/SVC/EN | July 2019

C0 to L2 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

C0

Remove

Item Description

16 M6 x 6 set screw

17 M4 x 5 set screw

18 Boss plug & O-ring SAE

19 Boss plug & O-ring

17

16

18

19

16

X

B

BG

D3

D2

D1A

L2

Add

Kit #1

S2E-20463-5K

Item Description

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

Differential inner spring guide

25

O-ring

Differential inner spring guide

26

O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

30 Differential adjustment screw

Kit #4

S2E-20466-5K

Item Description

M6 x 6 set screw with 0.4mm

16

orice

20 Load sense differential spool

20

21

22

23

X

B

BG

D3

D2

D1A

24

25

26

27

28

29

30

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

19

Page 20

Bulletin HY28-2708-02/SVC/EN | July 2019

C0 to AM B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

C0

Remove

Item Description

2 M5 x 6 set screw

17 M4 x 5 set screw

18 Boss plug & O-ring SAE

19 Boss plug & O-ring

17

X

18

B

BG

D3

19

D2

D1A

2

AM

Add

Kit #1

S2E-20463-5K

Item Description

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

Differential inner spring guide

25

O-ring

Differential inner spring guide

26

O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

Kit #2

S2E-20464-0K

Item Description

M5 x 6 set screw with 0.8mm

2

orice

20 AM remote differential spool

20

21

22

23

2

X

B

BG

D3

D2

D1A

24

25

26

27

28

29

30

20

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 21

Bulletin HY28-2708-02/SVC/EN | July 2019

L0 or L2 to C0 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

L0/l2

Remove

Item Description

L0 & L2 load sense differential

20

spool

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

Differential inner spring guide

25

O-ring

Differential inner spring guide

26

O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

30 Differential adjustment screw

20

21

22

18

23

24

25

26

X

B

BG

D3

D2

D1A

L0 Schematic

27

28

29

30

C0

Add

Kit #3

S2E-20465-5K

Item Description

17 M4 x 5 set screw

18* Boss plug & O-ring

19 Boss plug & O-ring

*Choose SAE, Metric, or BSPP boss

plug based on the load sense port

type. All three come in Kit #3.

17

19

X

B

BG

D3

D2

D1A

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

21

Page 22

Bulletin HY28-2708-02/SVC/EN | July 2019

L0 to L2 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

L0

Remove

Item Description

16 M6 x 6 set screw

16

16

X

B

BG

D3

D2

D1A

L2

Add

Kit #4

S2E-20466-5K

Item Description

M6 x 6 set screw with 0.4mm

16

orice

X

B

BG

D3

D2

D1A

22

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 23

Bulletin HY28-2708-02/SVC/EN | July 2019

L2 to L0 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

L2

Remove

Item Description

M6 x 6 set screw with 0.4mm

16

orice

16

16

X

B

BG

D3

D2

D1A

L0

Add

Kit #2

S2E-20464-0K

Item Description

16 M6 x 6 set screw

X

B

BG

D3

D2

D1A

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

23

Page 24

Bulletin HY28-2708-02/SVC/EN | July 2019

L0 to AM B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

L0

Remove

Item Description

2 M5 x 6 set screw

20 Load sense differential spool

X

B

BG

20

D3

D2

D1A

2

AM

Add

Kit #2

S2E-20464-0K

Item Description

M5 x 6 set screw with 0.8mm

2

orice

20 AM remote differential spool

20

2

X

B

BG

D3

D2

D1A

24

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 25

Bulletin HY28-2708-02/SVC/EN | July 2019

L2 to AM B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

L2

Remove

Item Description

2 M5 x 6 set screw

M6 x 6 set screw with 0.4mm

16

orice

20 Load sense differential spool

16

2

16

20

X

B

BG

D3

D2

D1A

AM

Add

Kit #2

S2E-20464-0K

Item Description

M5 x 6 set screw with 0.8mm

2

orice

16 M6 x 6 set screw

20 AM remote differential spool

20

2

X

B

BG

D3

D2

D1A

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

25

Page 26

Bulletin HY28-2708-02/SVC/EN | July 2019

AM to C0 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

AM

Remove

Item Description

M5 x 6 set screw with 0.8mm

2

orice

L0 & L2 load sense differential

20

spool

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

Differential inner spring guide

25

O-ring

Differential inner spring guide

26

O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

30 Differential adjustment screw

X

B

BG

D3

20

21

22

23

2

24

25

26

27

28

29

D2

D1A

30

18

C0

Add

Kit #3

S2E-20465-5K

Item Description

2 M5 x 6 set screw

17 M4 x 5 set screw

18* Boss plug & O-ring

19 Boss plug & O-ring

*Choose SAE, Metric, or BSPP boss

plug based on the load sense port

type. All three come in Kit #3.

17

19

2

X

B

BG

D3

D2

D1A

26

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 27

Bulletin HY28-2708-02/SVC/EN | July 2019

AM to L0 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

AM

Remove

Item Description

M5 x 6 set screw with 0.8mm

2

orice

20 AM remote differential spool

X

B

BG

20

D3

D2

D1A

2

L0

Add

Kit #4

S2E-20466-5K

Item Description

2 M5 x 6 set screw

20 Load sense differential spool

20

2

X

B

BG

D3

D2

D1A

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

27

Page 28

Bulletin HY28-2708-02/SVC/EN | July 2019

AM to L2 B-mod Conversion Guide

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

AM

Remove

Item Description

M5 x 6 set screw with 0.8mm

2

orice

16 M6 x 6 set screw

20 AM remote differential spool

L2

16

2

16

20

X

B

BG

D3

D2

D1A

Add

Kit #4

S2E-20466-5K

Item Description

2 M5 x 6 set screw

M6 x 6 set screw with 0.4mm

16

orice

20 Load sense differential spool

20

2

X

B

BG

D3

D2

D1A

28

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 29

Bulletin HY28-2708-02/SVC/EN | July 2019

075, 085, 100, 140 Torque Limiter

B-mod Torque Limiter Control Kits 075/085 100 140

Torque Limiter Kit for L0, AM Controls - CCW Rotation S2E-20297-5 S2E-20215-5 S2E-20252-5

Torque Limiter Kit for L0, AM Controls - CW Rotation S2E-20296-5 S2E-20290-5 S2E-20243-5

Torque Limiter Kits include cartridge assembly, tubing and ttings.

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Item Qty Description

61* 1 Torque limiter port SAE -6 boss plug & O-ring

62* 1 Torque limiter body O-ring - ARP 906

63 1 Torque limiter body

64 1 Jam nut 13/16-16UN

65 1 Torque limiter cam pin

66 1 Torque limiter sleeve

67 1 Compression spring

68* 1 Adjustment screw O-ring - ARP 111

69 1 Torque limiter screw

70 1 Torque limiter spring

71 1 Torque limiter guide

72 1 Torque limiter spool

73 1 Torque limiter spool retaining ring

74 1 Torque limiter adjustment nut

75 2 Retaining rings

76* 2 O-ring - ARP 904

77 1 SAE 10-24 set screw with .032" orice

78 1 SAE -4 tee with 10-24 ORF thread

79 1 Torque limiter tubing assembly

80 1 SAE -4 str thd elbow tting with 37 deg are

Parts available only in kits listed at top of page

* Included in B-mod pump seal kits

41

AMT Schematic

Item Torque

61 29 ft lbs

63 29 ft lbs

64 29 ft lbs

77 23 in lbs

78 12 ft lbs

79 25 ft lbs

80 12 ft lbs

35

Turn CCW to increase

79

torque setting and

CW to decrease

torque setting

73

78

71

76

77

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

75

72

74

70

69

68

8076

67

66

29

65

64

63

62

61

For counter-clockwise

rotation, the torque limiter kit

is inserted in this SAE-6 port

* Clockwise Rotation Shown

Page 30

Bulletin HY28-2708-02/SVC/EN | July 2019

Electronic Unload Control B-mod Exploded View

9

8

7

21

10

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Control Assembly

Part Numbers

C03 S2E-20764-5T

C06 S2E-20765-5T

L03 SAE S2E-20756-5T

L03 BSPP S2E-20757-5T

L03 Metric S2E-20758-5T

L06 SAE S2E-20759-5T

L06 BSPP S2E-20760-5T

L06 Metric S2E-20761-5T

29

22

30

24

2

4

1

3

C0* Pressure Compensator Control

with Unloading Valve

25

26

27

2

6

5

11

12

13

23

28

19

20

14

15

16

17

18

L0* Load Sense Control

with Unloading Valve

6

19

Item

Torque

5 11 ft lbs

6 40 in lbs

8 6 ft lbs

9 22 ft lbs

10 5 ft lbs

18 85 ft lbs

20 70 in lbs

28 50 ft lbs

29 50 ft lbs

20

30

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 31

Bulletin HY28-2708-02/SVC/EN | July 2019

Electronic Unload Control B-mod Exploded View

B-Mod Unload Control Assembly Part Numbers

Item No Qty C0* Part No L0* Part No Description

1 5 605-10070-0 605-10070-0 Teon O-ring - ARP 012

2 2 325-36002-0 325-36002-0 Locator Pin - M3x10

3 1 S2E-20325-0 S2E-20325-0 Adapter Block Assembly

4 4 605-10069-0 605-10069-0 Teon O-ring - ARP 011

5 1 108X4V 108X4V Boss plug & O-ring

6 1 ** 226X56 Load Sense Isolation Set screw - M6x6

7 1 03E-95186-0 03E-95186-0 Control Housing

8 1 108X4V ** Load Sense port plug - SAE #4

9 1

10 4 361-07313-8 361-07313-8 Socket head cap Screws - M5x75

11 1 03E-93156-0 03E-93156-0 Pmax spool

12 1 Available in kit only Available in kit only Pmax inner spring guide

13 1 Available in kit only Available in kit only Pmax outer spring

14 1 Available in kit only Available in kit only Pmax inner spring

15 1 Available in kit only Available in kit only Pmax outer spring guide

16 1 675-00009-0 675-00009-0 Pmax outer spring guide O-ring - ARP 009

17 1 695-00912-0 695-00912-0 Pmax plug O-ring - ARP 912

18 1 03E-93173-0 03E-93173-0 Pmax cap

19 2 311-50003-0 311-50003-0 Adjustment screw - M6x25

20 2 340-00056-0 340-00056-0 Adjustment lock nut - M6

21 1 03E-93157-0 03E-93157-0 Differential spool

22 1 Available in kit only Available in kit only Differential spring inner guide

23 1 Available in kit only Available in kit only Differential spring

24 1 Available in kit only Available in kit only Differential spring outer guide

25 1 675-00009-0 675-00009-0 O-ring - ARP 009

26 1 618-15022-0 618-15022-0 Back-up ring - ARP 009

27 1 695-00906-0 695-00906-0 Differential plug O-ring - ARP 906

28 1 03E-93174-0 03E-93174-0 Differential cap

29 1 517-00172-5 517-00172-5 Cartridge valve body

30

1 517-00186-5 517-00186-5 Unload 12VDC cartridge valve coil

1 517-00174-5 517-00174-5 Unload 24VDC cartridge valve coil

** 492-15528-0 Load Sense port adapter tting (Metric) - SAE #4 to M12x1

** 492-15527-0 Load Sense adapter tting (BSPP) - SAE #4 to "1/4 BSPP

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Unload Control Service Kit* S2E-20824-5K

Seal Kit S2E-20825-5K

*Includes items 6 and 11-28

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

B-Mod Unload Control Kits

31

Page 32

Bulletin HY28-2708-02/SVC/EN | July 2019

Parts Kits

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Rotating Group

Kits

CW Mobile P1 S2E-18710-0K S2E-19119-0K S2E-19067-0K S2E-18698-0K S2E-18032-0K S2E-18485-0K S2E-18489-0K

CW Mobile P1

w/ Ripple Chamber

CCW Mobile P1 S2E-18711-0K S2E-19120-0K S2E-19068-0K S2E-18699-0K S2E-18033-0K S2E-18486-0K S2E-18490-0K

CCW Mobile P1

w/ Ripple Chamber

CW Industrial PD S2E-18712-0K S2E-19121-0K S2E-19069-0K S2E-18700-0K S2E-18483-0K S2E-18487-0K S2E-18491-0K

CW Industrial PD

w/ Ripple Chamber

CCW Industrial PD S2E-18713-0K S2E-19122-0K S2E-19070-0K S2E-18701-0K S2E-18484-0K S2E-18488-0k S2E-18492-0K

CCW Industrial PD

w/ Ripple Chamber

Rotating Group Kit includes barrel s/a, pistons, retainer, washer, pins and port plate.

B-mod Seal Kits

Note: Seal kits contain all the seals required for any pump conguration including controls.

018 028 045 060 075/085 100 140

S2E-19205-0K S2E-19209-0K S2E-19235-0K ** ** ** **

S2E-19206-0K S2E-19210-0K S2E-19236-0K ** ** ** **

S2E-19207-0K S2E-19211-0K S2E-19126-0K ** ** ** **

S2E-19208-0K S2E-19212-0K S2E-19127-0K ** ** ** **

018 028 045 060 075/085 100 140

S2E-20278-5K S2E-20279-5K S2E-20280-5K S2E-20281-5K S2E-20282-5K S2E-20283-5K S2E-20284-5K

B-mod Control Conversion Kits and Contents

Kit #1

S2E-20463-5K

Item Description

21 Differential inner spring guide

22 Differential inner spring

23 Differential outer spring

24 Differential outer spring guide

25 Differential inner spring guide O-ring

26 Differential inner spring guide O-ring

27 Differential main O-ring

28 Differential outer plug

29 Differential adjustment lock nut

30 Differential adjustment screw

B-mod control on A-mod CW Pump S2E-20301-5

B-mod control on A-mod CCW Pump S2E-20302-5

A-mod control on B-mod Pump (CW or CCW) S2E-20325-5

Kit #2

S2E-20464-0K

Item Description

2 M5 x 6 set screw with 0.8mm orice

16 M6 x 6 set screw

20 AM remote differential spool

Kit #4

S2E-20466-5K

Item Description

2 M5 x 6 set screw

16 M6 x 6 set screw with 0.4mm orice

20 L0 & L2 load sense differential spool

Control Adapter Block Assemblies

Kit #3

S2E-20465-5K

Item Description

2 M5 x 6 set screw

16 M5 x 6 set screw

17 M4 x 5 set screw

18 Boss plug & O-ring - SAE

18 Boss plug & O-ring - Metric

18 Boss plug & O-ring - BSPP

19 Boss plug & O-ring

32

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 33

Bulletin HY28-2708-02/SVC/EN | July 2019

Compensator Procedures

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Compensator Disassembly

(C, L & AM B-mod control options)

NOTES:

Access plugs on end of compensator spool bores are hardened plugs.

Do not interchange with other plugs in the control.

For rotation change, the complete compensator assembly will need to

be replaced.

The Pmax spool and inner spring are NOT interchangeable with the load sense or

remote differential spools and springs.

The differential compensator spool and springs are not interchangeable with the main

pressure compensator spool and inner spring. Also, the “L” differential spool is not

interchangeable with the “AM” differential spool.

Compensator Disassembly:

1. Measure and record the extension of the two (only one for “C” control) pressure

adjusting screws.

2. Carefully remove the main compensator (Pmax) spring cap (#9) with outer spring

guide (#6). For “L” and “AM” controls, the Pmax spring cap is the larger of the

two caps. Remove the two springs (#4 & 5). Remove the inner spring guide (#3)

and the Pmax spool (#1) from the compensator housing.

3. For the “L” and “AM” controls, carefully remove the differential compensator

spring cap (#28) with the outer spring guide (#24). The load sense spring cap is

the smaller of the two caps, and the one closer to the top of the controller body.

Remove the inner spring guide (#21) and differential compensator spool (#20) from

the housing.

4. To disassemble the Pmax cap (#9) and outer spring guide (#6) assembly, thread

a long M6 screw through the hole of the Pmax cap to push the outer spring

guide out of the cap.

5. To disassemble the differential cap (#28) and outer spring guide (#24) assembly,

thread a long M6 screw threw the hole of the differential cap to push the outer

spring guide out of the cap.

6. Remove all O-ring boss access plugs (#13 & 18).

7. Remove all internal set screws and plugs (#2, 15, & 16).

Compensator Inspection

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

NOTE: The compensator is supplied as an assembly. Some individual parts may only

be available in kits. See the controls section of this manual for details.

1. Inspect the main compensator (Pmax) spool (#1) and the differential spool (#20)

for scratches, damage, or contamination particles.

2. Inspect the springs for proper free extension length (see chart).

3. Inspect the spool bores for scratches, damage, or contamination. Apply a light

oil lm on the spool(s) and check their t in the appropriate bore. The spool

should t snugly in the bore and not have any radial play.

4. Inspect orices for any contamination particles that may be blocking the orice.

Item No Component Description

4 Pmax Inner Spring 28.85 0.66

5 Pmax Outer Spring 35 0.66

22 Differential Inner Spring 14.9 0.66

23 Differential Outer Spring 21 0.66

Reference item numbers on page 13-16.

Table 1 - P1/PD B-Mod C, L, & AM Compensator Free Spring Length

Free Length

[mm]

Tolerance Ref. ±

[mm]

33

Page 34

Bulletin HY28-2708-02/SVC/EN | July 2019

Compensator Procedures

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Compensator Assembly

Carefully clean and dry all parts prior

to assembly. Use caution to ensure

that spools and other parts are not

damaged during the cleaning process.

Use clean oil to lubricate seals and

spools for easier assembly.

1. Remove and discard all O-rings. Install new O-rings on SAE boss plugs (#13),

and install SAE boss plugs (#13) into their respective cavities.

2. Apply a light lm of oil to the main compensator (Pmax) spool outer spring guide

O-ring (#7), and install it on the Pmax spool outer spring guide (#6).

3. Apply a light oil lm to the Pmax outer cap O-ring (#8), and install it on the

Pmax outer cap (#9).

4. Apply petroleum jelly to the Pmax outer spring guide (#6) and push it into Pmax

outer cap (#9).

NOTE: Make sure the orientation of the guide matches the orientation in the control

assembly exploded view section.

5. If possible, turn the compensator housing so that the spool bores face upward.

Install set screw (#2) and Pmax spool (#1). Next, place Pmax inner spring guide

(#3) inside the Pmax spool bore on top of the Pmax spool (#1). Make sure

the orientation of the guide matches the orientation in the control assembly

exploded view section. Place the Pmax outer spring (#5) on top of the inner

spring guide (#3) in the spool bore. Place the Pmax inner spring (#4) inside the

outer spring (#5) so that it sits on top of the inner spring guide (#3).

6. Thread the Pmax outer cap assembly from steps 2-4 into the Pmax spool bore.

As the assembly is threaded in the bore, the outer spring (#5) should seat itself

on the outer spring guide (#6).

7. Install the Pmax adjustment screw (#11) and lock nut (#10) into the Pmax outer

cap (#9).

8. Install the “X” port set screw/orice (#16) into the “X” port located on top of the

compensator.

9. For “C” compensators install the SAE boss plug (#18) in the “X” port on top of

the compensator, and set screw plug (#17) into the control port on the bottom of

the compensator. Install boss plug (#19) in the differential spool bore.

Steps 10-15 apply to the “L” or “AM” compensators.

10. Apply a light lm of oil to the differential outer spring guide O-rings (#25 &

26) and install them on the differential outer spring guide (#24).

11. Apply a light lm of oil to the differential cap O-ring (#27) and install it on

the differential cap (#28).

12. Apply petroleum jelly to the differential outer spring guide (#24) and push it

into the differential cap (#27).

NOTE: Make sure the orientation of the guide matches the orientation in the

control assembly exploded view section.

13. With compensator housing upright, if possible, so that the bore faces

upward, insert the differential spool (#20) into the spool bore. Next, place

the differential inner spring guide (#21) on top of the differential spool (#20)

inside the spool bore. Make sure the orientation of the guide matches the

orientation in the control assembly exploded view section. Then place the

differential outer spring (#23) on top of the differential inner spring guide

(#21). Then place the differential inner spring (#22) inside the differential

outer spring (#22) so that it sits on the differential inner spring guide (#21).

14. Thread the differential cap assembly from step 12 into the differential spool

bore. As the assembly is threaded in the bore, the outer spring (#23) should

seat itself on the outer spring guide (#24).

15. Install the differential adjustment screw (#30) and lock nut (#29) into the

differential outer cap (#28).

16. Install the ve O-rings (#14) on compensator ports on the compensator.

17. Using bolts (#12), bolt down compensator assembly onto pump housing.

Make sure locating pin (#15) is properly aligned to locating pin hole on the

compensator mounting pad on the pump housing.

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

34

Marysville, Ohio USA

Page 35

Bulletin HY28-2708-02/SVC/EN | July 2019

Pump Service Procedures

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Pump Disassembly Notes

Pump Disassembly Procedure

A. Pump disassembly for inspection should be limited to the

following cases:

a.) Malfunction or oil leakage resulting from damage or wear

and tear.

b.) Troubleshooting steps/actions listed towards the end of the

manual do not solve the problem.

B. For rotation change or shaft conversion, disassembly should be done only as

far as necessary to complete the conversion.

C. Disassembly and reassembly should be performed in a clean environment.

After disassembly, the internal parts should be coated with a lm of clean oil

and protected from dirt and moisture. Care must be taken to avoid dropping,

damaging, or contaminating the machined parts and control valve.

D. It is usually not necessary to replace spring (20) tted in cylinder barrel.

Do not replace the spring unless absolutely necessary.

CAUTION: Spring assemblies in the pump are normally set under high

compression and bodily injury may occur if caution is not taken

during disassembly.

1. Identify the pump from the information on the data tag. See Figure 1.

2. Drain uid from housing. Fluid drained from pump should be disposed of properly.

3. Mount pump in xture to prevent movement while removing the main housing

bolts (#1).

4. Remove the four bolts holding the compensator assembly to the pump housing.

Additional uid may drain out of the passages when the compensator is removed.

For compensator disassembly instructions, see Compensator Disassembly

Procedures section.

5. Remove the four bolts (#1) attaching the port block to the main housing.

6. Carefully remove the port block (#3) assembly. Except for the 18 & 28cc pump,

the control piston guide (#14) and bias guide (#11) are threaded with Loctite into

the block (#3). Use caution to avoid dropping the port plate (#9). Note the location

of the bias spring (#13) and piston (#12) assembly and the control piston (#15)

assembly. The control piston (#15), bias piston (#12), and bias spring (#13) may

remain in the pump when the port block is removed. Remove these items from

inside the pump if they remained in the pump when the port block was removed.

Remove and discard the white Teon O-rings (#8) on the port block. These seals

should be replaced every time the pump is disassembled.

NOTE: For rotation change, do not disassemble further. See Rotation

Change Procedure.

7. For the 60-140cc pumps, remove the tapered roller bearing cone (#18) and

shims (#17).

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Figure 1 Pump Data Tag

35

Page 36

Bulletin HY28-2708-02/SVC/EN | July 2019

Pump Service Procedures

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Pump Disassembly Procedure

(Continued)

8. Position the pump horizontally and remove the rotating group. Avoid

separating the pistons (#27) from the barrel (#23) if possible. This will assist

in identifying damage between an individual piston and barrel bore during

component inspection.

NOTE: If completing a seal change or complete overhaul on a 45cc pump or

larger, turn the housing over and remove the seal retainer snap ring (#40) and

shaft seal (#39) from the housing before moving to step 9.

NOTE: For shaft change only on 45cc pumps or larger, no further

disassembly is required. Proceed to Step 7 of the assembly procedure.

9. Remove the cam (#29) from the housing by tilting it and carefully extracting it

from the pump housing. See Figure 2.

Large Pocket

Pressure Control

Side of Pump

Figure 2

10. For sizes 60-140cc remove the front tapered roller bearing cone (#32). If there

is excessive wear or damage, remove the tapered roller bearing cup (#33)

from the bottom of the housing.

11. Remove the cam bearing screws (#30) and two cam bearings (#31).

12. Remove the housing snap ring (#43) and shaft bearing assembly (#32).

13. If completing a seal change or complete overhaul, turn the housing over

and remove the seal retainer snap ring (#40) and shaft seal (#39) from the

housing. For a 45cc pump or larger, this step was already completed as part

of step 8.

14. If there is excessive wear on the port block bearing (#18) (bushing for sizes

18, 28 & 45), remove the bearing or bushing from the port block (#3).

36

Parker Hannin Corporation

Hydraulic Pump and Power Systems Division

Marysville, Ohio USA

Page 37

Bulletin HY28-2708-02/SVC/EN | July 2019

Pump Inspection Procedures

Medium Pressure Axial Piston Pumps

P1/PD B-mod Service Information

Pump Inspection Procedures

1. Carefully clean and dry all parts prior to inspection.

2. Examine piston diameters for scratches or gouges. If any piston is severely

damaged, note which piston bore it came out of. Extra attention should be

given to that bore in Step 4.

3. Check end play of piston shoe assembly. Check bottom surface of the shoes

for damage or excessive scratching. The shoe surface should be square and

at. Measure the depth of the pocket of the shoe. Shoes may be lapped as a