Page 1

© 2013 Parker Hannifin, SSD Drives Division

All rights strictly reserved. No part of this document may be stored in a

retrieval system, or transmitted in any form or by any means to persons not

employed by a Parker SSD Drives company without written permission from

Parker SSD Drives, a division of Parker Hannifin. Although every effort has

been taken to ensure the accuracy of this document it may be necessary,

without notice, to make amendments or correct omissions. Parker SSD

Drives cannot accept responsibility for damage, injury, or expenses resulting

therefrom.

WARRANTY

Parker SSD Drives warrants the goods against defects in design, materials

and workmanship for the period of 24 months from the date of manufacture,

or 12 months from the date of delivery (whichever is the longer period), on

the terms detailed in Parker SSD Drives Standard Conditions of Sale. Parker

SSD Drives reserves the right to change the content and product

specification without notice.

Mobile Products

MA3 Series Mobile Inverter

User Manual

HA473434 Issue 3

Page 2

Table of Contents

Table of Contents ..................................................................................................... 2

1 Safety ................................................................................................................. 4

1.1 Requirements.................................................................................................. 4

1.1.1 INTENDED USERS ........................................................................................... 4

1.1.2 User Safety Responsibility Statement for All Parker Products ....................... 5

1.1.3 PERSONNEL ......................................................................................................... 5

1.1.4 PRODUCT WARNING ........................................................................................... 5

1.1.5 HAZARDS .............................................................................................................. 5

1.1.6 User Safety Responsibility Statement for All Parker Products ....... 7

2 Scope of Delivery ........................................................................................... 8

2.1 Product Code .................................................................................................. 8

2.2 Equipment Inspection .................................................................................. 9

Storage and Shipping Temperatures ..................................................................... 9

Packaging and Lifting Information ...................................................................... 9

3 Product Introduction ................................................................................... 10

Product Overview .................................................................................................... 10

Specification ............................................................................................................ 10

Electrical ....................................................................................................................... 10

Environment ................................................................................................................. 13

3.1 General Product Description .................................................................... 15

3.1.1 J1 Connector – I/O Wiring Information ................................................... 15

3.1.2 J2 Connector – Motor Feedback Wiring Information ......................... 16

3.1.3 Block Diagram ................................................................................................ 17

3.1.4 Example System Diagram........................................................................... 18

4 Product Installation ..................................................................................... 19

4.1 Mechanical Installation in a Mobile Environment ............................. 19

4.1.1 Dimensions and Weight ............................................................................... 19

4.1.2 Mounting ........................................................................................................... 20

4.1.3 Installation Orientation ............................................................................... 20

4.2 Cooling Requirements ................................................................................ 20

4.2.1 Specification ................................................................................................... 21

4.2.2 Hose Clamping Instructions ...................................................................... 22

4.2.3 Parallel Configuration .................................................................................. 23

4.3 Wiring Power Cables ................................................................................... 24

4.4 J1/J2 Mating Connectors .......................................................................... 27

4.5 Pre-Charge Circuit ....................................................................................... 28

4.6 Grounding ....................................................................................................... 29

Page 2

Page 3

5 Operations ...................................................................................................... 30

5.1 Commissioning ............................................................................................. 30

5.2 Power-Up Sequence .................................................................................... 31

6 Software .......................................................................................................... 31

6.1 Introduction ................................................................................................... 31

6.2 Installation .................................................................................................... 32

6.3 Connecting to the Inverter ....................................................................... 33

6.4 Configurations .............................................................................................. 34

6.4.1 Creating a Configuration ............................................................................. 34

6.4.2 Modifying a Configuration........................................................................... 36

6.4.3 Installing a Configuration ........................................................................... 40

6.4.4 Updating a Configuration ............................................................................ 40

6.5 Charting Functions ...................................................................................... 42

6.6 CANopen......................................................................................................... 44

6.6.1 Introduction ..................................................................................................... 44

6.6.2 Configuring a CANopen System ............................................................... 44

6.6.3 External Control of Inverter ....................................................................... 52

6.6.4 CANopen Termination .................................................................................. 57

7 Appendix ......................................................................................................... 58

7.1 DSE Lite/CANopen Conversion Rule....................................................... 58

7.1.1 Regulatory Compliance ............................................................................... 61

7.1.2 European Compliance .................................................................................. 62

7.2 EMC Installation Guidance ....................................................................... 63

7.2.1 Protective Earth (PE Connections) .......................................................... 63

7.2.2 MITIGATING THE EFFECTS OF RADIATED INTERFERENCE ....................... 63

7.2.3 CABLING REQUIREMENTS ......................................................................... 64

7.3 Environmental .................................................................................................. 65

7.3.1 RESTRICTIONS, EVALUATION, AUTHORISATION AND

RESTRICTION OF CHEMICALS (REACH)................................................ 65

7.3.2 WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE) .................. 65

7.4 North American Compliance ........................................................................... 66

7.4.1 Requirements for North American Compliance .................................. 66

Page 3

Page 4

1 Safety

Safety Information

Please read these important Safety notes before installing and operating this equipment

DANGER

DANGER – High risk – Notes in the manual warn of danger to personnel typically severe injury

or death

WARNING

WARNING – Medium risk - Notes in the manual warn of danger to personnel typically injury

CAUTION

CAUTION – Low risk - Notes in the manual warn of potential equipment damage

Note: notifications assist the user with helpful tips for making operations and maintenance

easier and more efficient.

1.1 Requirements

1.1.1 INTENDED USERS

This manual is to be made available to all persons who are required to install, configure or service

equipment described herein, or any other associated operation.

The information given is intended to highlight safety issues, and to enable the user to obtain maximum

benefit from the equipment.

Page 4

Page 5

INSTALLATION DETAILS

Model Number

(see product

label)

Where installed

(for your own

information)

Unit used as a:

(refer to

Certification)

Component

Relevant Apparatus

Unit fitted:

Cubicle mounted

Through Panel Mounted

DANGER - Ignoring the following may result in server injury or death

This equipment can endanger life by

exposure to rotating machinery and high

voltages.

The equipment must be permanently earthed

due to the high earth leakage current, and the

drive motor must be connected to an

appropriate safety earth.

Ensure all incoming supplies are isolated

before working on the equipment. Be aware

that there may be more than one supply

connection to the drive.

There may still be dangerous voltages

present at power terminals (motor output,

supply input phases, DC bus and the brake,

where fitted) when the motor is at standstill or

is stopped.

For measurements use only a meter to IEC

61010 (CAT III or higher). Always begin using the

highest range.

CAT I and CAT II meters must not be used on

this product.

Allow at least 5 minutes for the drive's capacitors

to discharge to safe voltage levels (<50V). Use

the specified meter capable of measuring up to

1000V dc & ac rms to confirm that less than 50V

is present between all power terminals and

between power terminals and earth.

Unless otherwise stated, this product must NOT

be dismantled. In the event of a fault the drive

must be returned. Refer to "Routine Maintenance

and Repair".

DANGER

Risk of electric shock

WARNING

Hot surfaces

Caution

Refer to documentation

Earth/Ground

Protective Conductor Terminal

Complete the following table for future reference detailing how the unit is to be installed and used.

1.1.2 User Safety Responsibility Statement

for All Parker Products

The equipment described is intended for industrial motor speed control utilising AC induction motors or

AC permanent magnet synchronous machines.

1.1.3 PERSONNEL

Installation, operation and maintenance of the equipment should be carried out by competent personnel.

A competent person is someone who is technically qualified and familiar with all safety information and

established safety practices; with the installation process, operation and maintenance of this equipment;

and with all the hazards involved.

1.1.4 PRODUCT WARNING

1.1.5 HAZARDS

Page 6

WARNING - Ignoring the following may result in injury or equipment damage

SAFETY

Where there is conflict between EMC and Safety requirements, personnel safety shall always take

precedence.

Never perform high voltage resistance checks

on the wiring without first disconnecting the drive

from the circuit being tested.

Whilst ensuring ventilation is sufficient,

provide guarding and /or additional safety

systems to prevent injury or damage to

equipment.

When replacing a drive in an application and

before returning to use, it is essential that all user

defined parameters for the product’s operation

are correctly installed.

All control and signal terminals are SELV, i.e.

protected by double insulation. Ensure all external

wiring is rated for the highest system voltage.

Thermal sensors contained within the motor must

have at least basic insulation.

All exposed metalwork in the Inverter is protected

by basic insulation and bonded to a safety earth.

RCDs are not recommended for use with this

product but, where their use is mandatory, only Type

B RCDs should be used.

CAUTION - Ignoring the following may result in injury or damage to equipment

APPLICATION RISK

The specifications, processes and circuitry described herein are for guidance only and may need

to be adapted to the user’s specific application. We can’t guarantee the suitability of the equipment

described in this Manual for individual applications.

RISK ASSESSMENT

Under fault conditions, power loss or unintended operating conditions, the drive may not operate as

intended. In particular:

Stored energy might not discharge to safe

levels as quickly as suggested, and can still

be present even though the drive appears

to be switched off

The motor's direction of rotation might not be

controlled

The motor speed might not be controlled

The motor might be energised

A drive is a component within a drive system that may influence its operation or effects under a fault

condition. Consideration must be given to:

Stored energy

Supply disconnects

Sequencing logic

Unintended operation

Page 6

Page 7

1.1.6 User Safety Responsibility Statement

for All Parker Products

This document and other information from Parker Hannifin Corporation, its subsidiaries,

and authorized distributors, provide product and/or system options for further

investigation by users having technical expertise.

Through their own analysis and testing, users are solely responsible for making the final

selection of system and components, and assuring that all performance, endurance,

maintenance, safety, and warning requirements of the application are met. The user must

analyze all aspects of the application, follow applicable industry standards, and follow the

information concerning the product in the current product catalog and in any other

materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component

or system options based upon data or specifications provided by the user, the user is

responsible for determining that such data and specifications are suitable and sufficient

for all applications and reasonably foreseeable uses of the components or systems.

The products described herein, including without limitation, product features,

specifications, designs, availability, and pricing, are subject to change by Parker Hannifin

Corporation and its subsidiaries at any time without notice.

Page 8

Qty

Item

1

Mobile Inverter

1

Software CD - DSE Lite

1

USB Cable

12

Screws M3 x 8

5

Terminal Ferrules

2 Scope of Delivery

2.1 Product Code

Part Number Breakdown

Page 8

Page 9

Storage

-40°C to +80°C (-40°F to +176°F)

Shipping

-40°C to +80°C (-40°F to +176°F)

Caution - Packaging is combustible. Igniting the packaging results in toxic

fumes.

2.2 Equipment Inspection

When inspecting equipment:

Check for signs of transit damage

Check the product code on the rating label to make sure it conforms to your requirement

If you do not install the unit immediately, store it in a well-ventilated location, away from

extreme temperatures, humidity, dust, or metal particles.

Storage and Shipping Temperatures

Packaging and Lifting Information

Save packaging for returning the product if needed.

Improper packaging may result in transit damage!

Use safe and suitable lifting procedures when moving the unit.

Never lift the unit by its terminal connections!

Prepare an open, flat surface to place the inverter before attempting to move it.

Do not damage any terminal connections when placing the inverter.

Page 10

Nominal Voltage

7 Vdc to 32 Vdc

Overvoltage

36 Vdc (max 5 min)

Reverse Voltage

-36 Vdc (max 5 min)

Max Control Current @ 7V

8 Adc

Max Control Current @ 32 V

0.7 Adc

Max Inrush Current

18.9 Adc (max 50ms)

3 Product Introduction

Product Overview

The Parker SSD MA3 inverter is designed to control standard 3-phase permanent magnet

synchronous motors and AC induction motors. The inverter is capable of 4-quadrant motor

control which enables the motor to also act as a generator. The MA3 normally operates in a

Closed-Loop Vector mode; however the inverter can be configured to operate in Sensorless and

V/Hz mode.

Motor speed feedback is provided by a resolver or quadrature encoder mounted on the motor

shaft. The speed loop has amendable bi-directional speed demand, ramp, and torque limits.

When regenerating, motors operate with a saturated speed loop, such as in torque mode with a

speed limit.

Specification

Electrical

Input Voltage – Control Supply

Page 10

Page 11

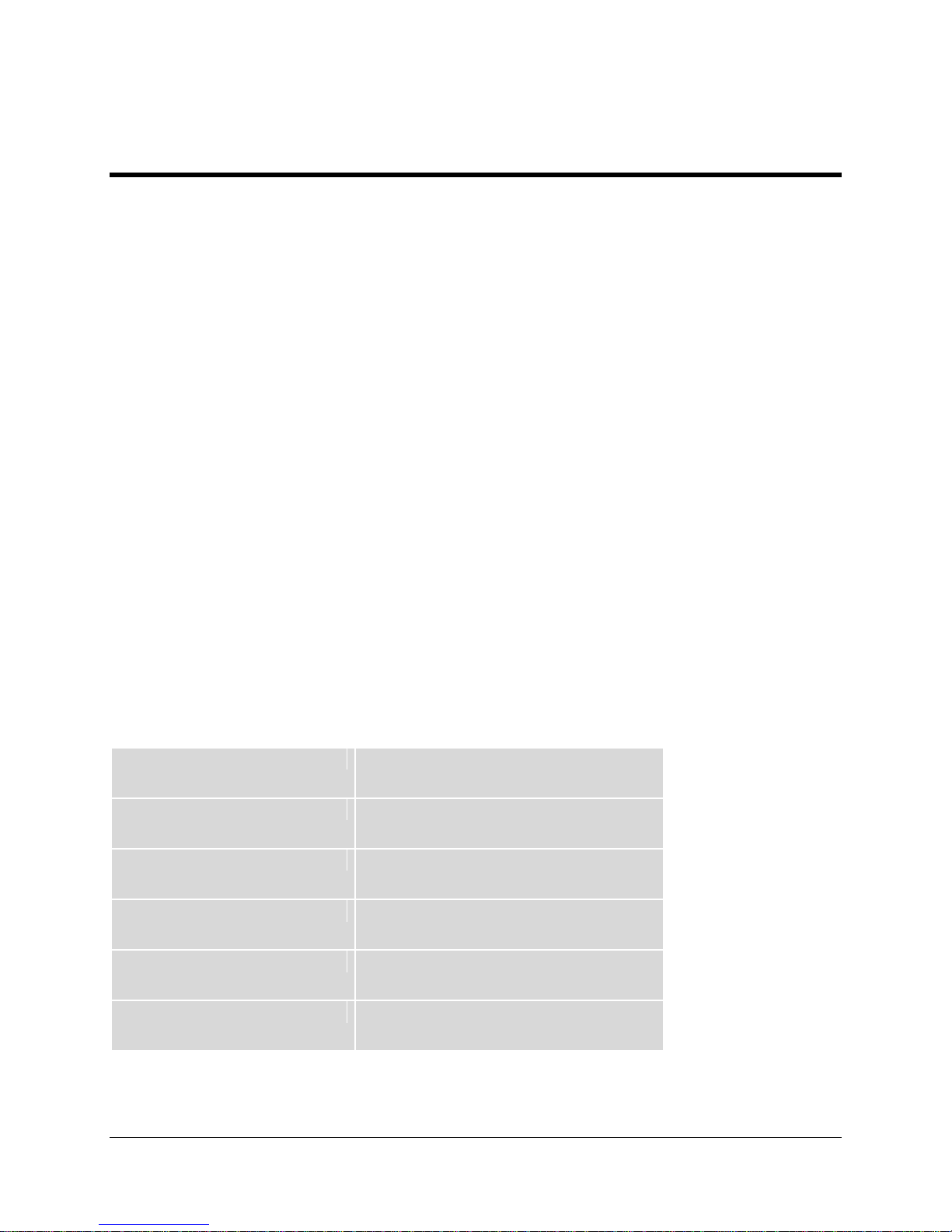

Inverter

Operating Range

(Vdc)

Nominal

(Vdc)

Undervoltage

Trip (Vdc)

Overvoltage

Trip (Vdc)

MA3-40-xxxx

210 - 400

320

205

410

MA3-60-xxxx

315-600

480

310

615

MA3-80-xxxx

420-800

640

410

820

Model

DC link capacitance

MA3-40-xxxx

600 μF

MA3-60-xxxx

600 μF

MA3-80-xxxx

400 μF

DANGER - THESE DEVICES CONTAIN STORED ENERGY, LETHAL

VOLTAGES PERSIST AFTER DE-ENERGISATION.

CARELESSLY HANDLING THESE DEVICES MAY CAUSE DEATH, PERSONAL

INJURY, AND PROPERTY DAMAGE!

Input Voltage – DC Bus Ratings

DC Bus Capacitance

The bus must be discharged prior to removal or working on or near the inverter. Use a voltmeter

to measure DC bus voltage at the ± DC input terminals before performing any further action.

Ensure that the bus is decayed to less than 50 VDC.

Page 12

Model Disharge Time

MA3-40 2 min 30 sec

MA3-60 3 min

MA3-80 2 min 15 sec

DISCHARGE TIME WILL VARY DEPENDING ON THE VOLTAGE LEVEL

AT THE BEGINNING OF THE DISCHARGE TIME.

CARELESSLY HANDLING THE DEVICE WHILE VOLTAGE LEVELS ARE HIGH MAY

CAUSE PERSONAL INJURY OR DEATH!

MA3-40-0325

MA3-40-0400

Inverter

Continuous

Current (A rms)

Peak Current

(A rms)

Continuous

Power (kW)

Peak Power

(kW)

MA3-40-0225

130

185

225

225

325

400

54

77

93

93

135

160

Inverter

Continuous

Current (A rms)

Peak Current

(A rms)

Continuous

Power (kW)

Peak Power

(kW)

MA3-60-0225

130

22590155

MA3-60-0325

185

325

128

225

MA3-60-0400

225

400

156

270

Typical Discharge Time from Nominal to 50 VDC

Output Ratings

Page 12

Page 13

Inverter

Continuous

Current (A rms)

Peak Current

(A rms)

Continuous

Power (kW)

Peak Power

(kW)

MA3-80-0225

130

225

108

187

MA3-80-0325

185

325

154

270

MA3-80-0400

225

400

187

325

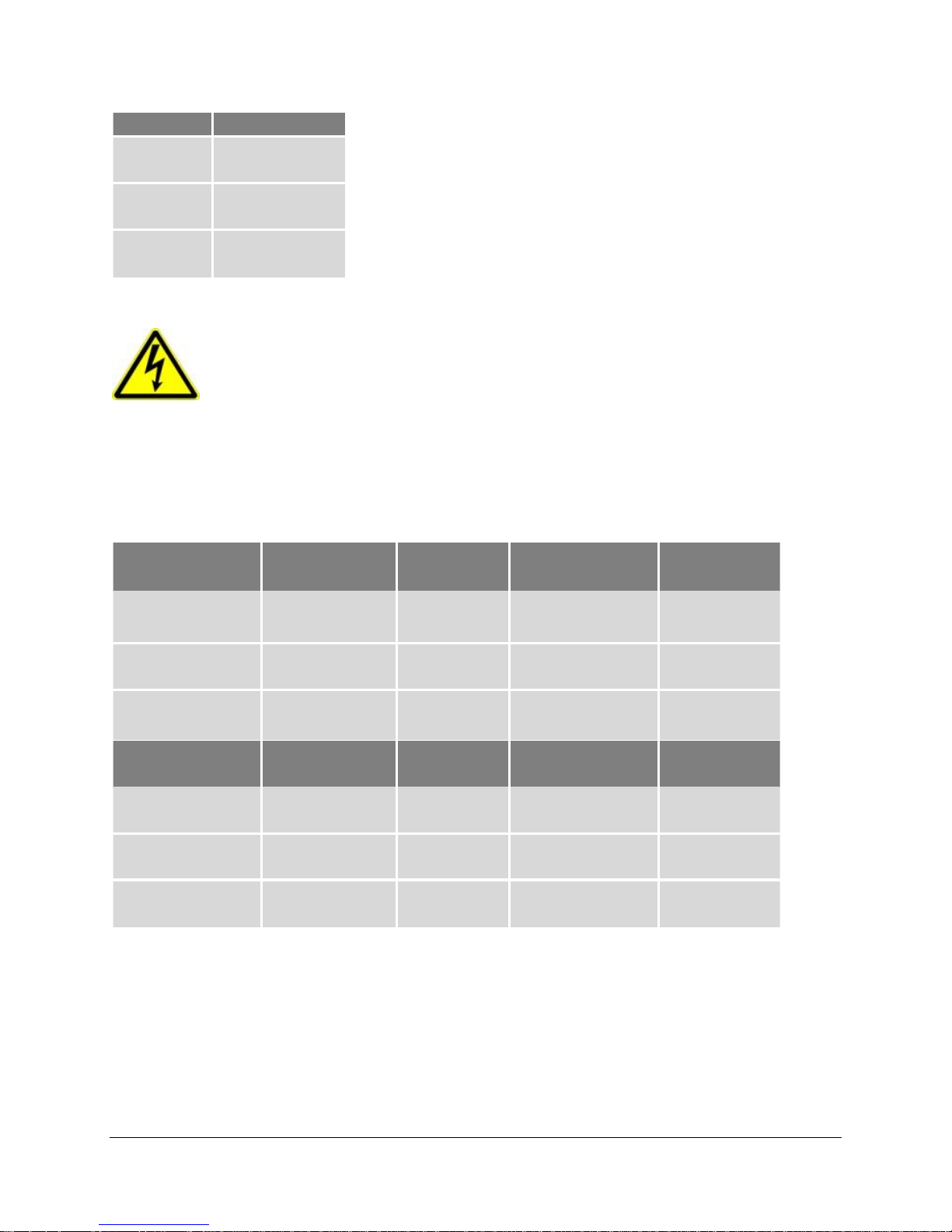

Temperature

Operating

Operating temperature is defined as the surrounding air temperature of the drive,

when the drive and other equipment adjacent to it is operating at worst case

conditions.

-40 °C to +55°C (-40 °F to +131 °F)

Note: If the inverter is to be placed in an enclosure, please consult factory

Coolant

-40 °C to +55°C (-40 °F to +131 °F)

Storage

-40 C to +80 C (-40 °F to +176 °F)

Shipping

-40 C to +80 C (-40 °F to +176 °F)

Product Enclosure Rating

IP65

Altitude

Maximum of 2000m

Humidity

100% at 40°C (104°F)

Atmosphere

Non-flammable and non-corrosive

Climatic Conditions

Minimum Class 3k6, as defined by EN60721-3-3

Vibration

Storage and Transport

Test Fc of EN60068-2-6

10Hz<=f<=57Hz sinusoidal 0.075mm amplitude

57Hz<=f<=150Hz sinusoidal 1g

10 sweep cycles per axis on each of three mutually perpendicular axis

Operating

Repetitive Shock

TBA

Drop

TBA

Bump

TBA

Vibration

TBA

Random Vibration

TBA

Safety Overvoltage Category

Overvoltage Category I (numeral defining an impulse withstand level)

Pollution Degree

Pollution Degree III (dirty air rating)

North America/Canada

Complies with the requirements of UL508C Type 1

Environment

Page 14

Page 14

Page 15

Pin Name Ratings Comments

1 OV (signal) Analog Ground

2 Analog In 2

0-10 V or ±10V, Absolute maximum input voltage

range: -15V to +30V

Range Set in Software

3 Analog In 3

0-10 V, 10V, 0-20mA or 4-20mA. Absolute maximum

input voltage range: -15V to +30V

Range Set in Software

4 Analog In 4

0-10 V, 10V, 0-20mA or 4-20mA. Absolute maximum

input voltage range: -15V to +30V

Range Set in Software

5 Analog Out 1 0-10 V, ± 10V (10 mA maximum) Range Set in Software

6 OV (power) Control Supply Ground

7 Digital Out 4B 24V, 3A resistive load

Normally-open relay contacts. Default

function DOUT4 closed = healthy

8 Digital Out 5B 24V, 3A resistive load

Normally-open relay contacts. Default

function DOUT5 closed = running

9 Digital In 1 24V, Max Range: -15V to +30V, 7.3mA ±10% @ 24 V

10 Digital In 2 24V, Max Range: -15V to +30V, 7.3mA ±10% @ 24 V

11 24 V (digital)

Output Voltage: 18V to 24V, Max Output Current:

160mA

Provides power to external equipment or

for powering digital inputs

12 12/24 VDC (power)

Nominal 24Vdc, 7 to 32 Vdc Range, 0.7A - 8 A, Max

Inrush Current: 18.9A, max 50ms

Control Supply

13 CAN Low Signal Connection (dominant low)

14 10 V (analog) Load 10mA maximum 10V reference for analog I/O

15 Digital Out 4A 24V, 3A resistive load

Normally-open relay contacts. Default

function DOUT4 closed = healthy

16 Digital Out 5A 24V, 3A resistive load

Normally-open relay contacts. Default

function DOUT4 closed = healthy

17 OV (digital) Ground

18 CAN High Signal Connection (dominant high)

19 CAN Shield Optional CAN shield

3.1 General Product Description

3.1.1 J1 Connector – I/O Wiring

Information

Pin Assignment

Page 16

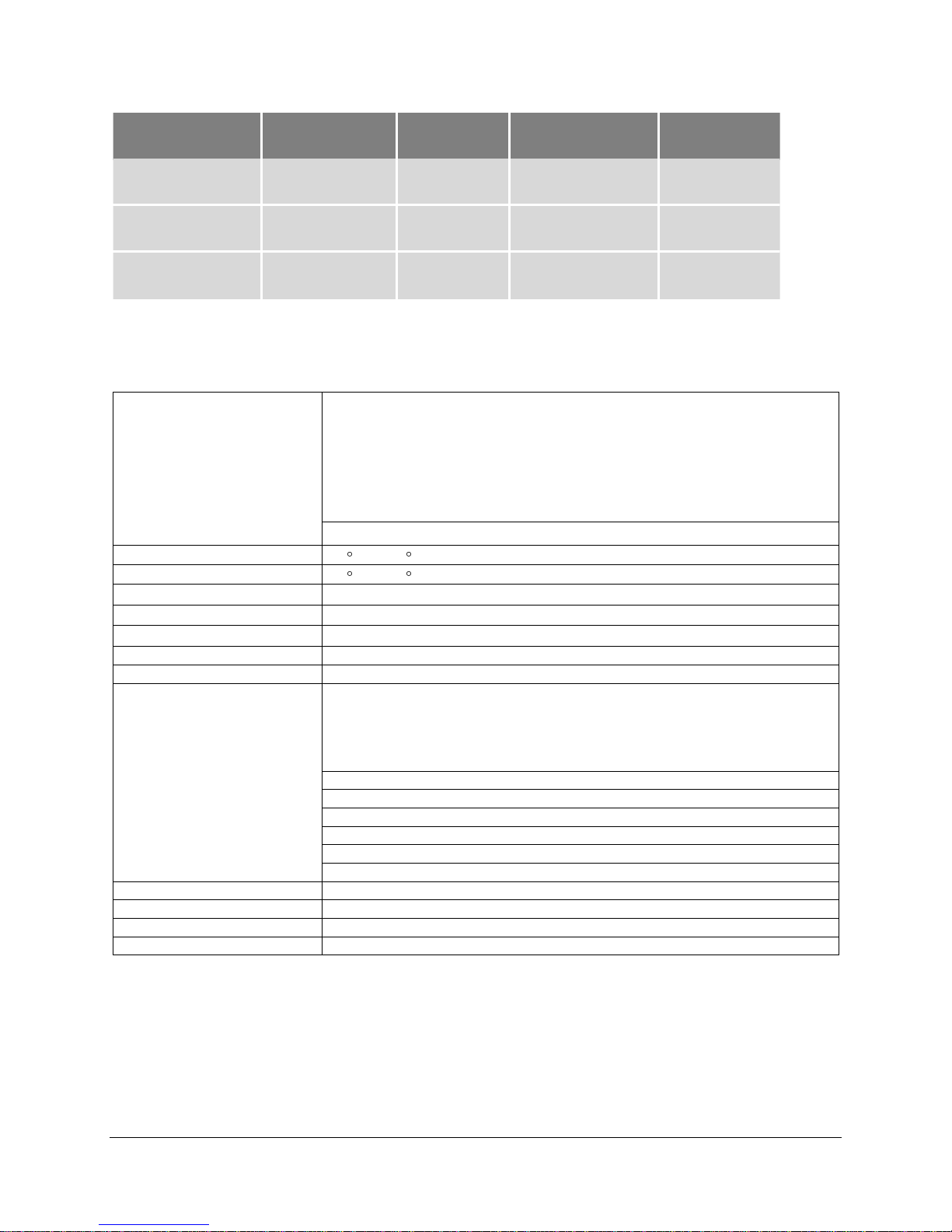

Pin

Feedback Options

Resolver R0

Encoder E1

Line Sync

Function

Function

Function

1

Sin -

CH A-

CH A-

2

Sin +

CH A+

CH A+

3

4

5

6

7

V0 ground

V0 ground 8

Vcc

Vcc

9

mtr therm ptc

mtr therm ptc

mtr therm ptc

10

11

Cos +

CH B+

CH B+

12

Cos -

CH B-

CH B-

13

mtr therm ptc

mtr therm ptc

mtr therm ptc

14

Ref+

15

mtr therm ntc

mtr therm ntc

mtr therm ntc

16

mtr therm ntc

mtr therm ntc

mtr therm ntc

17

ref-

3.1.2 J2 Connector – Motor Feedback

Pin Assignment:

Wiring Information

Page 16

Page 17

3.1.3 Block Diagram

Refer to the following diagram that displays connections between the DC bus, motor, feedback

and I/O connections to the MA3 inverter.

Page 18

3.1.4 Example System Diagram

As shown in the diagram on the following page, Parker inverters can be used to convert and

control power in many applications, converting from alternating current (AC) to direct current

(DC) and from DC to AC power with controlled torque, speed, and dynamic performance.

Typical applications also include Parker PMAC motor/generators, induction motors, energy

storage systems along with battery management systems, and hydraulic components.

With these components, the Parker inverter lets a user take the best of both the hydraulic world

in power and the electrical world in control and reporting. Combining these technologies

enables an application to achieve unparalleled performance.

Example of Inverters Used in a Series Hybrid System

Page 18

Page 19

Weight: 16.8 kg/37 lbs

4 Product Installation

4.1 Mechanical Installation in a Mobile

Environment

4.1.1 Dimensions and Weight

Page 20

4.1.2 Mounting

While mounting the inverter, take care to place

the inverter in a location and orientation that

allows for access to both cooling port

connections and electrical connections as

protected by the gasket plate. MA3 inverters are

typically mounted with legs and/or spacers at the four (4)

M10 mounting points on 250 mm (9.84″) x 300 mm (11.81″) centers.

4.1.3 Installation Orientation

The MA3 inverter can be installed in any orientation. It has no preferred orientation for

mounting. The installer must exercise care so that debris will not build up between the inverter

housing and mounting surfaces. Debris buildup degrades cooling of the device, and may have a

possible impact of freezing to the device casing. Assume the standard axis configuration

whenever this document refers to it.

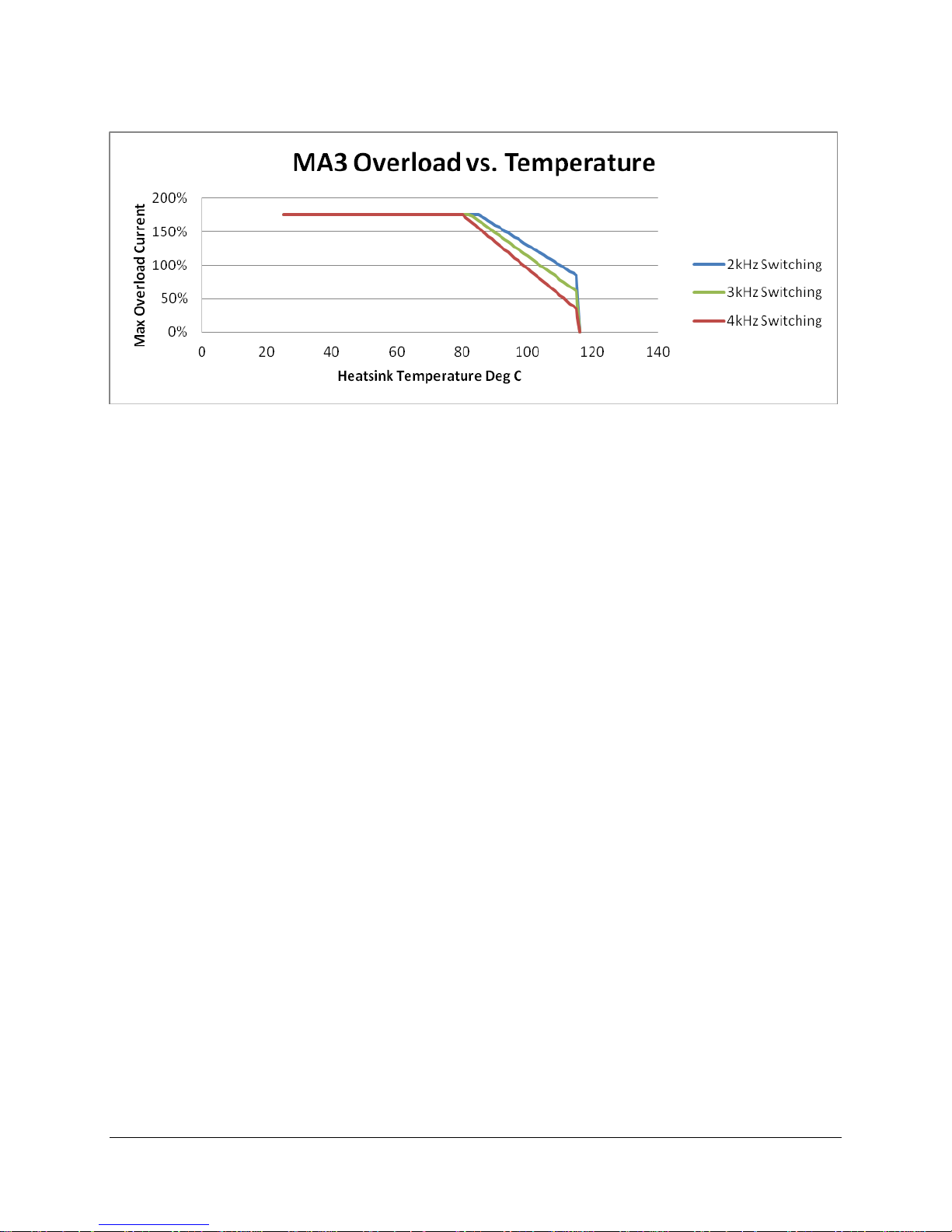

4.2 Cooling Requirements

The MA3 inverter is enclosed in an IP65-rated aluminum casting that has an embedded cooling

system capable of using ethylene glycol- or hydraulic oil-based coolants.

Details of the inverter cooling system requirements using pre-diluted ethylene glycol (EG) (50%

EG, 50% water) and temperature ratings are presented in the following table.

Page 20

Page 21

Minimum flow 3.8 lpm (1.0 gpm)

Maximum flow 7.6 lpm (2.0 gpm)

Maximum inlet temperature 55°C (131°F)

∆T @ continuous current and minimum flow 5°C (41°F)

∆P @ 25°C (77°F) and 7.6 lpm (1.67 gpm) 13.79 kPa (2 psi)

4.2.1 Specification

Recommended: Use aluminum and brass anticorrosion protection additives such as Dow®

Dowtherm™ SR-1 heat transfer fluid or Prestone® Dex-Cool® coolant.

The inverter coolant ports are located below the power and motor terminal box. Either port can

be used as the input or output of the inverters cooling system.

Frame 3 Cooling Loop Ports

Page 22

Hose Size Hose Clamp A

3/16" 97 HC-3 1/4"

1/4" 97 HC-3 1/4"

5/16" 97 HC-6 1/4"

3/8" 97 HC-6 1/8"

1/2" 97 HC-8 1/8"

5/8" 97 HC-12 1/8"

3/4" 97 HC-12 1/8"

Hose Clamp

Part Number

D

Max

D

Min

C

Hex

C

Max

W

97HC-3 .62 .25 .25 1.00 .31

97HC-6 .87 .38 .31 1.40 .50

97HC-8 1.00 .44 .31 1.53 .50

97HC-12 1.25 .50 .31 1.80 .50

4.2.2 Hose Clamping Instructions

Assembly Instructions

1. Cut hose cleanly and squarely to length.

2. Slide clamp on hose.

3. Lubricate hose. Push hose on fitting until hose bottoms against stop ring or hex.

4. Position hose clamp as shown below and secure with a screwdriver or wrench. Maintain

“A” dimension noted below for proper clamp positioning.

Proper Clamp Position

Stainless Steel Worm Drive Clamp (97HC Series)

Page 22

Page 23

y = 0.808x2+ 0.1383x + 0.01 28

0.00

2.00

4.00

6.00

0.00 0 .50 1.00 1 .50 2.00 2.50 3 .00

Pressure Drop (psi)

Flow (gpm)

50% E/G flow in MA3 Casting

DP (psi)

Poly. (DP (psi))

4.2.3 Parallel Configuration

The only acceptable cooling loop configuration is parallel, as shown in the following figure.

Orifice sizing depends on provided total cooling flow.

The pressure drop across the inverter cooling loop

Example Inverter and Motor Parallel Cooling Loop Schematic

Page 24

+ DC Input

U Out

W Out

– DC Input

V Out

4.3 Wiring Power Cables

Power and Motor Connections

Power and Motor Connections on the Inverter

Compression Terminal with Shielded Strain Relief Grommet

Power cables terminated to the inverter require bracing and support other than the actual

connector itself. Take care when routing cables to avoid strain on cables.

Page 24

Page 25

1. Fit the dome and clamping insert

down on the cable end and strip the

cable jacket 36 mm (113/32″).

Expose braided shield by expanding

and folding back over the cable.

2. Strip conductor insulation 18-20 mm

(¾″).

Fold braided shielding over the

clamping insert and O-ring, then trim

braiding with scissors.

Make sure that the braided shield

overlaps the O-ring by 2 mm (3/32″)

and does not overlap the back part of

the clamping insert.

Inverter Terminations

All connectors for controls, communications, and motor feedback are done through J1 and J2

connectors. No screw or other terminations are required. DC input and AC output are done

through gland connections.

The access plate needs to be removed to gain access to these power-related connections, internal

to the inverter. After termination, reinstall the plate, making sure that the O-ring is properly

seated and compressed. Also make sure that screws are torqued to 0.9 Nm (8 in-lbs).

Wire the power cables in the following sequence:

Page 26

3. Insert the cable and clamp into the

housing of the inverter, fitting the

stripped end of the cable to the power

connector ferrule.

Make sure that power cable insulation

is visible in the ferrule; it should not

be exposed more than 1.6 mm (1/16″).

Tighten the dome nut with a 23 mm

(⅞″) open end wrench so that the

cable is tight and the white plastic

teeth of the clamp are just visible from

the end.

4. Make sure that the outer insulation of

the cable is flush with the inside of the

fitting.

Recheck that the insulation is clear of

the power connection, then torque the

terminal to 15.8 Nm (140 in-lb) with a

5 mm hex torque wrench.

Page 26

Page 27

Model Gland, OD Max Wire AWG

MA3-xx-225 PG13; 6-12 mm 10 awg - 4 awg

MA3-xx-325 PG21; 13-18 mm 2 AWG - 2/0 AWG

MA3-xx-400 PG21; 13-18 mm 2 AWG - 2/0 AWG

Connector Function Description Parker P/N MFG P/N (Hummle)

J1 I/O M23 19 Pole Socket CCW C1472244U002 PHKIT-06 (M23 F)

Straight Shell 7-12 mm 7.106.500.000

19 CCW Female Insert 7.003.919.102

3 x 1.5 mm Crimp Socket 22-17 AWG 7.010.901.502

16 x 1.0 mm Crimp Socket 22-17 AWG 7.010.901.002

J2 Feedback M23 17 Pole Pin CCW C1472244U003 PHKIT-07 (M23 F)

Straight Shell 6-10 mm 7.106.500.000

17 CCW Male Insert 7.004.917.101

17 x 1 mm Crimp Pin 26-17 AWG 7.010.901.001

Mating Cable Connectors

Acceptable cable outside / insulation diameter

4.4 J1/J2 Mating Connectors

Page 28

4.5 Pre-Charge Circuit

The pre-charge kit is the recommended set of components required for pre-charging direct

current (DC) capacitors in the inverter. In an actual application, the proper engineering and

interlocks must be engineered as part of the DC bus system. Component values in the diagram

below depend on the model chosen for the application. If assistance is needed in determining the

values, please consult factory. Failure to provide this circuit can potentially result in decreased

life of inverter.

MA3 Inverter Pre-charge Diagram

Page 28

Page 29

Danger - Protective Earth (PE) / Ground Connections.

Only one protective earth conductor is permitted at each protective earth

terminal contacting point.

The product requires a protective earth conductor cross section of at least

10mm² (0.0155 sq. in.), where this is not possible a second protective earth

terminal provided on the VSD (Variable Speed Drive) shall be used. The

second conductor should be independent but electrically in parallel.

4X M10

mounting point

M6 protective

ground connection

12.7 mm (½″)

beaded hose

4.6 Grounding

The inverter has an M6 ground stud and nut.

Inverter Connections

Page 30

5 Operations

5.1 Commissioning

Before continuing:

Read the Safety section at the front of the User Manual.

Ensure that you meet all applicable electric codes.

Check for damage to equipment.

Check for loose ends, clippings, filings, and drill shavings lodged in the inverter and

system.

Check all external wiring circuits and connections on the system:

○ Ground

○ Power

○ Control

○ Motor

Make sure cooling loop is properly connected to the inverter.

Make sure that any unexpected rotation of the motor in either direction does not result in

damage, bodily harm, or injury.

If possible, disconnect the load from the motor shaft.

Make sure that external speed set points are all at zero (0).

Make sure that nobody is working on another part of the system or machine that would be

affected by powering up.

Make sure that other equipment is not adversely affected by powering up.

Make sure that motor stator connections are correctly wired for Star or Delta as

necessary for inverter output voltage.

When you have completed checking all connections, it is time to power up the inverter.

Page 30

Page 31

5.2 Power-Up Sequence

1. Switch on the 24VDC control power supply to the MA3 inverter.

2. Apply DC power through pre-charge circuit.

6 Software

6.1 Introduction

DSE Lite is the software tool for the MA3 Mobile Inverter. By utilizing straightforward block

programming you can very quickly become a confident user of DSE Lite. The inverter supports

user defined applications in conjunction with fixed motor control blocks. DSE Lite allows the

user to create, parameterize, and configure user defined applications as well as parameterize and

connect fixed Motor Control blocks:

I/O Elements: the MA3 supports a wide variety of I/O

which includes built in analog and digital support as

well as resolver and CANopen interfacing.

Application: this is the working space, external of the

Motor Control environment. DSE Lite can create well

structured, multilayered applications using the Macro

feature, which allows the user to create a compound

block representing an entire block diagram

Motor Control: this is a fixed environment compromising inverter and motor parameters

organized into blocks. The user can parameterize these blocks, or read and write to them by

linking their parameters with blocks in the Application environment.

Page 32

6.2 Installation

The MA3 Inverter is supplied with a CD containing the DSE Lite Configuration Tool. The

install file is also available at www.parker.com/ssdusa. DSE Lite can be installed on any Intel

based PC with the following minimum specification:

Running native Windows XP, Home or Professional Edition

100 Mb of free hard drive space

A USB port, which is required for interfacing with the inverter

Insert the CD and execute the “setup.exe” file on the disk to install the latest LINK database DSE

Lite. Follow the on-screen instructions.

Installing the USB Driver

The DSE Lite installation program “setup.exe” will copy TI USB driver files into the appropriate

Windows directories. This driver is needed to connect to an MA3 via its USB port. When

connecting to the inverter for the first time, Windows will acknowledge that it has found new

hardware with the "New Hardware Found" wizard. When prompted for a driver, select the

"Install Automatically" option and select "OK".

The DSE Lite installation program "setup.exe" will also install a copy of the Texas Instruments

USB drivers into: C:\Program Files\Texas Instruments\USB-Serial Adapter

If the automatic install method fails, select the "Browse" option and select the directory above

once prompted for a driver by the Found New Hardware Wizard.

If you have already plugged in the inverter and Windows has determined it to be an

"Unknown/Other" device, you must select the device in the Windows Device Manager (under

the Unknown/Other Device Class). Display the properties for the device (by double-clicking it),

and then click the "Update Driver" button on the "Driver" properties tab. This will then bring up

a Wizard and you need to point to the directory of driver files as described previously.

Page 32

Page 33

Caution - Make sure all components on the system are properly

grounded, BEFORE connecting any cables to the inverter or

computer. Failure to properly ground the system will result in

damage to the inverter, computer and cables.

6.3 Connecting to the Inverter

Connecting to the MA3 inverter is accomplished

through a USB connection. The USB cable is a

standard type A to mini-B, which

should not be longer than 3 meters

and of good quality shielded cable.

Connect the type A connector to any

open USB port on the computer and the mini-B connector to the inverter. In

the Comm Port drop down list, there are two things that need to be setup for

USB communications; Comm port and baud rate. Make sure there is a check

mark next to the port in which the inverter is connected. The baud rate should

have a check mark next to Auto.

Page 34

6.4 Configurations

DSE Lite allows the user to design their own application (user selected Function Blocks) in

addition to pre-defined Function Block Diagram. What this creates is more options available for

configuring the inverter.

6.4.1 Creating a Configuration

For starters we are going to create an 890 configuration. The MA3 inverter utilizes the 890 drive

firmware. Therefore when starting inside of DSE Lite following the following sequence. From

the “File” menu, select “New 890 VerX vXX_DFLT.890”. This is the default template for

version 7, 890 firmware within the MA3 inverter. Consult factory if current version is unknown.

Page 34

Page 35

This should open the following window (your view may be different depending on your setup)

Notice that the template has multiple function blocks representing various inverter functions and

that they are prewired for a default configuration

The example shown is a Window view which allows multiple windows to be shown at once. If

you are only editing one configuration; you may want to expand the window to the whole view

by clicking the Maximize button.

The configuration can be saved by clicking on the Save Icon in the main tool bar, or

selecting "Save" in the "File" menu. A standard Windows Save dialog will pop up. You can

rename the configuration and save it in any directory in your file system. Once saved, the

asterisk ‘*’ at the end of the name will disappear.

Page 36

6.4.2 Modifying a Configuration

A configuration can be modified by editing blocks and links, by inserting or deleting blocks

inserting text, graphics and forms.

Editing Function Blocks

You can view the contents of any function block

in the configuration by double clicking on the

block. For example, double clicking "Analog

Input 3" will open the dialog to the right.

Click on a parameter’s name to select it. This will

cause the field at the bottom of the dialog to be

updated with information about that parameter. If

the parameter is enumerated or a boolean click on

to select a new value, otherwise you can directly edit the numeric.

When you have finished making changes click on "OK" to exit, otherwise click on "Cancel" to

exit and disregard any changes you may have made. Note that the button acts the same as

the “Cancel” button.

Function blocks can be renamed. To rename a function block, right click with the mouse in the

center of the block. A popup menu should appear. Click on “Rename Block” to rename the

function block. You will also notice that the popup menu contains an item labeled “Help”. You

can click on this to bring up a data sheet for that function block.

To select a function block either click on it or hold down the SHIFT key and drag the mouse

over the function block. You can select multiple function blocks by holding the SHIFT key down

while clicking on them, or dragging the mouse over them so that some portion of the function

block to be selected are contained in the rectangle drawn on the screen.

Selected item(s) can be moved by clicking on an item in the selection and moving them while the

mouse button is still down (dragging). Let up on the mouse button to finish the move. If you hold

down the CTRL key before letting up on the mouse button, the selected item will continue to

Page 36

Page 37

follow the mouse until it is clicked again to finish the move. This allows you to move items from

one page to another page by changing the current page before clicking the mouse again. If you

depress the ESC key while the items are being moved, but before the move is finished, the move

will be cancelled and the items will go back to their original location.

Editing Links

A link (also known as a connection) ‘transfers’ the output of one function block to the input of

another (or same) function block.

To select a link click on it. It will change color, purple by default, to

indicate that it is selected. Once the link is selected, you can delete

it by depressing the Backspace or Delete key or by selecting Delete

from the popup menu created when you right click on the link.

Using this popup you can also Split the link. Splitting is covered in more detail below.

Links are made by connecting an output to an input, in that order. You start by placing the mouse

cursor near an output of a function block. DSE Lite detects this and changes the shape of the

cursor to an ‘x’ to give visual feedback that the cursor is over an output and that the user can start

drawing a connection. While holding the left mouse button down, drag the mouse cursor to start

drawing the link. The link being drawn will be displayed in red, by default, and when you move

the cursor over a valid input it will turn green, by default, to indicate that you have a valid link

selected. Let up on the mouse button to make the connection. If you want to change the shape or

routing of a link, left click on the link and hold down the mouse button.

The line will change color to indicate that it is selected. Drag the mouse while holding down the

mouse button to change the shape of the link.

You can also split a link. This will separate the link into two pieces with a label at the end of

each piece. To split the link either double click on it or right click on it and select Split. If

Page 38

you double click the link; you will initially be asked if you want to split the connection. If you do

not want to see this dialog again, check the “Do not ask again” box before clicking

on the “OK” button.

When you first split the link, DSE Lite will provide default labels. These labels behave very

much like function blocks. You can move them around to clean up your drawing. If you double

click or right click on either label, you can Rename them to your own labels.

You can also connect function blocks that reside on different sheets. To do this, start making the

connection the same way that you would for linking two function blocks that are on the same

sheet. Then go to the sheet that contains the destination function block. You will notice that the

connection line(s) will follow you to the next sheet even though the source function block is not

there. Select the destination input to finish the connection. Split links will be created on each

sheet to represent the connection. Just as described above, you can change the name of the

split link as well.

Selecting Function Blocks

You can select a single function block by simply clicking on it with the mouse. Additional

blocks may be added to the selection by hold down the SHIFT key while clicking on them with

the mouse. Clicking on an already selected block while holding down the SHIFT key will

remove it from the selection. It is also possible to select a group of block by holding down the

SHIFT key and left clicking the mouse on an empty part of the page, holding down the mouse

button, dragging it over the blocks to be selected and letting up on the mouse button (and SHIFT

key) when done. You will notice that a rectangle will outline the area to be selected while you

are dragging the mouse.

Moving Function Blocks

Once you have a block or group of blocks selected, you can move them by clicking on one of the

selected blocks and while holding down the left mouse button, move the block(s) to a new

location on the same page. To move to another page, move the mouse cursor to the lower left

page number display, and click the right or left arrow to select the destination page. Let up on the

mouse button to end the move.

Page 38

Page 39

Inserting New Function Blocks

There are many ways to create new function blocks in the configuration. One way is to insert a

new function block by selecting it from the

“Block” menu. Move it to where you want on

the screen and click again to place the function

block. For example: Click on the Block menu at

the top of the screen. Move the cursor down to

select "Logic Counter".

You can also use Edit Copy (Ctrl+C), Edit Paste

(Ctrl+V) or Edit Duplicate (Ctrl+D) to insert

another copy of the currently selected block(s)

or Edit Import to insert a previously exported (Edit Export) block(s).

Renaming Function Blocks

Right clicking on a function block with the mouse will cause a popup menu to appear

from which you can select various operations related to that function block. One of these

operations is to Rename the block. If you select ‘Rename Block’ you will be asked for a

new name. Names must be unique.

Deleting Function Blocks

Select a block(s) and press the “Delete” or “Backspace” key. Selected function blocks can also

be deleted by selecting Edit Delete, Edit Cut (which also places the selection in the clipboard

for Pasting) or right clicking on a block and selecting Delete Block from the popup menu.

Function Block Data Sheets (Help)

Right clicking on a function block with the mouse will cause a popup menu to appear from

which you can select various operations related to that function block. One of these operations is

to access the data sheet for the block. If you select ‘Help’, the data sheet for the function block

will be brought up in an Adobe Reader® window.

Page 40

Connecting to Other Devices

There are three ways to connect to other devices: through the built in digital and analog I/O,

motor feedback cards, and CANopen card. For each of these options there are pre-defined

function blocks that support these inputs

6.4.3 Installing a Configuration

Once you have created your own configuration, it can be installed into a drive. If the

configuration is not already open, you will first have to open it. You can open the configuration

from the “File Open” menu or by clicking on the “Open” button in the main Tool Bar.

Instructions

Make sure the inverter is connected to your PC via a USB cable: A to mini-B and that the

USB driver is installed.

Select the “AUTO” baud rate from the Comms Icon in the standard tool bar (or in the

Properties View).

Select the correct port if it is not already selected. If “AUTO” baud and the correct port is

selected, the inverter type and current running status will be displayed in the Scratch Pad

and Status Bar (located at the bottom of the screen)

Select "Command Install At Selected" to install the currently opened configuration into

a inverter.

The installation progress is displayed on the Status Bar and noted in the Scratch Pad.

6.4.4 Updating a Configuration

There are several ways to update a configuration. One is to directly modify it as described in a

previous section.

Another is to extract inverter parameters from a connected inverter into an open configuration

using the ‘Command Extract Drive Parameters’ command. This command extracts all of the

predefined inverter parameters from any of the supported inverters and does not require that the

Page 40

Page 41

open configuration is the one installed in the inverter. It will not, however, extract user defined

application parameters from MA3 configurations.

It is also possible to extract the configuration from the connected inverter using the

‘File Extract’ command. The extracted configuration is updated with the current value of all

application and inverter parameters. This extracted configuration can then be saved to make a

copy of the current state of the inverter that can be used for installing into a new inverter if the

current inverter fails.

Page 42

6.5 Charting Functions

The Oscilloscope will set-up a real-time data

acquisition facility inside the inverter

firmware, wait for data to be ready, retrieve the

data and display it. This is a tool to capture and

display fast signals from external or internal triggers.

Adding Parameters to the Oscilloscope

You can add a parameter to the Oscilloscope either from an ONLINE configuration or from the

ONLINE Parameter View, e.g. adding the speed feedback in rpm from MOTOR CONTROL /

FEEDBACKS / SPEED FBK RPM result in the following oscilloscope view.

Another way to add parameters to the oscilloscope is to right-click on "Nodes", which will bring

up a menu with three choices:

Add Address Add a physical address in the firmware to scope

Add Special Add a special parameter from a pick list

Page 42

Page 43

Add Pref Add a parameter reference number

In all three cases you will be prompted to enter the module node number with a dialog.

In the case of Add Address, you will be prompted to enter a memory address as a

hexadecimal number, e.g. 0x0010.

In the case of Add Special, a pick list will appear, show opposite. This pick list will

depend on the type of configuration, e.g. Permanent Magnet Motor configuration will be

different from a Volts/Hertz one.

In the case of Add Pref, a dialog will prompt for a parameter reference number, which

expects the format: BLOCKNUMBER.PARAMETERNUMBER

Using the Oscilloscope

1. Set the Trace Mode.

2. Set-up the trigger conditions: Trigger Direction, Source, Value, and Type.

3. Set the Trigger Delay (the percentage of total number of samples occurring before the

trigger).

4. Set the Sample Number (the total number of samples to be captured)

5. Download the oscilloscope set-up to the inverter. This will begin the data acquisition.

6. When a trigger occurs, data acquisition continues until the total number of samples are

acquired. At this point, the trace facility will go into a HELD status.

7. DSE Lite will upload and display the captured data.

Page 44

6.6 CANopen

6.6.1 Introduction

CANopen is a CAN-based higher layer protocol. It was developed as a standardized embedded

network with highly flexible configuration capabilities. CANopen was designed for motionoriented machine control networks, such as handling systems.

The CANopen application layer and communication profile (EN 50325-4; CiA 301) supports

direct access to device parameters and transmission of time-critical process data. The CANopen

network management services simplify project design, system integration, and diagnostics. In

each decentralized control application, different communication services and protocols are

required. CANopen defines all these services and protocols as well as the necessary

communication objects.

6.6.2 Configuring a CANopen System

You can configure your CANopen Option using DSE. Follow the instructions below.

Step 1: Inserting a CANopen Function Block

Display your configuration page. Click on the Block menu at the top of the screen.

1. Move the cursor down to select "890 Comms" and select "CANopen".

2. Click to select the CANopen block. Move this to where you want on the screen then click

again to place the block.

Page 44

Page 45

Page 46

Step2: Attaching Fieldbus Connectors

Seven fieldbus connector types are available:

FB Logic Input FB Integer Input FB Value Input

FB Logic Output FB Integer Output FB Value Output FB Val to Int Output

Input connector: the data is sent to the inverter

Output connector: the data is sent from inverter

The fieldbus connectors must be added before they will appear in the CANopen function block.

Note: The function block and connectors can be renamed by using the right mouse button and

selecting Rename Block.

Page 46

Page 47

Step 3: Configuring the Fieldbus Connectors

Double-click on the function block to display the dialog below. The fieldbus connectors (inputs

and outputs) are assignable in the function block along with their data type to/from the controller.

The option slot and Address can also be selected.

To configure the input and output connectors you have placed in the configuration:

1. Expand the Inputs and Outputs trees to reveal the registers. By default the trees each have

one register. To add more registers click on New!

Select the drop-down menu adjacent to Input

to choose the required input/output connector

Page 48

on the Register. For example below, Register 1 "Input" is shown with the possible fieldbus

selections that have been placed in the configuration: FII.1 (Fieldbus Integer Input 1),

FLI.1 (Fieldbus Logic Input 1), FVI.1 (Fieldbus Value Input 1) etc

Set up all the input/output registers in a similar way.

The Baud rate can be selected to be either 125k, 250k, 500k or 1000k

Note: The Baud rate set in DSE Lite will only be used if all switches on the Option are set to

ON.

5. The Address can be selected in the range 0 - 127.

Page 48

Page 49

Data Type Description Range

LOGIC Logic False (F) and True (T)

INTEGER 32-bit signed integer -2,147,483,648 to 2,147,483,647

VALUE 32-bit fixed point value -32768.0 to 32767.9999

Data Type

Description

Range

Boolean

8-bit boolean

False (0x00) and True (0x01)

Integer8

8-bit signed integer

-128 to 127

Integer16

16-bit signed integer

-32768 to 32,767

Integer32

32-bit signed integer

-2,147,438,648 to 2,147,438,647

Unsigned8

8-bit unsigned integer

0 to 255

Unsigned16

16-bit unsigned integer

0 to 65,535

Unsigned32

32-bit unsigned integer

0 to 4,294,967,295

Real32

32-bit IEEE-754 floating point

value

1.19209290e-38 to 3.4028235e+38

Note: The Address set in DSE Lite will only be used if all switches on the Option are set to ON.

If the Address is set to zero and the switches on the CANopen Option are all set to ON, the

option is disabled and will not appear on the network.

FB Input and Output Data Types

CANopen Data Types

Page 50

Sub-Index CANopen Data Type

1 Boolean

2 Integer8

3 Integer16

4 Integer32

5 Unsigned8

6 Unsigned16

7 Unsigned32

8

Real32

Fieldbus Connector CANopen Type

LOGIC Boolean

INTEGER Integer32

VALUE Real32

Conversion of DSE Lite Type < > CANopen Type

Each FB Input, regardless of type, can be written to over CANopen using any of the CANopen

data types. FB Outputs can be similarly both read and written. The selection of the CANopen

data type is not part of the DSE Lite configuration, but depends on which Sub-Index is used for

access.

The conversion between the DSE Lite type and the CANopen type is performed automatically

(refer to DSE/CANopen Conversion Rules). Some recommended controller type assignments to

fieldbus connectors are given in the table below:

Page 50

Page 51

CANopen Status Information

The CANopen function block in DSE Lite provides status information about the CANopen

network interface.

When online, the actual baud rate or Address in use can be found by clicking the right mouse

button over the "Baud" or “Address” text and selecting Get. This may be different to that set in

the function block configuration if the switches on the Option are not all set in the ON position.

The function block also provides three status outputs that can be wired to: STATUS RUN,

STATUS ERR and OPERATIONAL.

For example, the OPERATIONAL output could be ANDed with the motor START causing the

inverter to stop if the controller connection is lost.

OPERATIONAL

Logic value: True (T) indicates that the CANopen interface is in the Data

Exchange state.

The STATUS RUN and STATUS ERR outputs could be used with the LOGIC::LOOKUP

function block to determine a particular state.

STATUS RUN

Enumerated value: Status Run

0: STOPPED

1: PRE-OPERATIONAL

2: OPERATIONAL

STATUS ERR

Enumerated value: Status Run

0: NO ERROR

1: WARNING LI MIT

2 : AUTOBAUD OR LSS

3 : CONTROL EVENT

4 : SYNC ERROR

5 : BUS OFF

Page 52

Bit Name Description Supported Required Value

0 Switch On OFF1 Operational

1 (Not) Disable Voltage OFF2 Coast Shop

2 (Not) Quick Stop OFF3 Fast Stop

3 Enable Operation

4 Enable Ramp Output = 0 to set ramp output to zero 1

5 Enable Ramp = 0 to hold ramp 1

6 Enable Ramp Input = 0 to set ramp input to zero 1

7

Reset Fault Reset on 0 to 1 transition

8 0

9 0

10 Remote = 1 to control remotely 1

11 0

12 0

13 0

14 0

15 0

6.6.3 External Control of Inverter

Communications Command

When sequencing is in the Remote Comms mode, the sequencing of the Inverter is controlled by

writing to the COMMS COMMAND (PREF 95.05).

The COMMS COMMAND parameter is a 16-bit word based on standard fieldbus inverter

profiles. Some bits are not implemented in this release (see “Supported” column of the table

below).

Page 52

Page 53

Switch On

Replaces the RUN FWD, RUN REV and NOT STOP parameters of the SEQUENCING

LOGIC function block. When Set (=1) is the same as:

RUN FWD = TRUE

RUN REV = FALSE

NOT STOP = FALSE

When Cleared (= 0) is the same as:

RUN FWD = FALSE

RUN REV = FALSE

NOT STOP = FALSE

(Not) Disable Voltage

ANDed with the NOT COAST STOP parameter of the SEQUENCING LOGIC function block.

When both Set (=1) is the same as:

NOT COAST STOP = TRUE

When either or both Cleared (= 0) is the same as:

NOT COAST STOP = FALSE

(Not) Quick Stop

ANDed with the NOT FAST STOP parameter on the SEQUENCING LOGIC function block.

When both Set (=1) is the same as:

NOT FAST STOP = TRUE

When either or both Cleared (= 0) is the same as:

NOT FAST STOP = FALSE

Enable Operation

ANDed with the DRIVE ENABLE parameter on the SEQUENCING LOGIC function block.

When both Set (=1) is the same as:

DRIVE ENABLE = TRUE

Page 54

When either or both Cleared (= 0) is the same as:

DRIVE ENABLE = FALSE

Enable Ramp Output, Enable Ramp, Enable Ramp Input

Not implemented. The state of these bits must be set (=1) to allow this feature to be added in the

future.

Reset Fault

Replaces the REM TRIP RESET parameter on the SEQUENCING LOCIC function block.

When Set (=1) is the same as:

REM TRIP RESET = TRUE

When Cleared (= 0) is the same as:

REM TRIP RESET = FALSE

Remote

Not implemented. It is intended to allow the PLC to toggle between local and remote. The state

of this must be set (=1) to allow this feature to be added in the future.

Communications Status

The COMMS STATUS parameter (PREF 95.08) in the COMMS CONTROL function block

monitors the sequencing of the Inverter. It is a 16-bit word based on standard fieldbus inverter

profiles. Some bits are not implemented in the initial release and are set to 0 (see “Supported”

column of the table below).

Page 54

Page 55

Bit Name Description Supported

0 Ready To Switch On

1 Switched On

Ready for operation (refer control bit 0)

2 Operation Enabled (refer control bit 3)

3 Fault Tripped

4 (Not) Voltage Disabled OFF 2 Command pending

5 (Not) Quick Stop OFF 3 Command pending

6 Switched On Disable Switch On Inhibited

7

Warning Reset on 0 to 1 transition

8 SP/PV in Range

9 Remote = 1 if Inverter will accept Command Word

10 Setpoint Reached = 1 if not ramping

11 Internal Limit Active

=1 if current limit active or speed loop is

in torque limit

12

13

14

15

Ready To Switch On

Same as the SWITCH ON ENABLE output parameter of the SEQUENCING LOGIC function

block.

Switched On

Same as the SWITCHED ON output parameter of the SEQUENCING LOGIC function block.

Page 56

Operation Enabled

Same as the RUNNING output parameter of the SEQUENCING LOGIC function block.

Fault

Same as the TRIPPED output parameter of the SEQUENCING LOGIC function block.

(Not) Voltage Disabled

If in Remote Comms mode, this is the same as Bit 1 of the COMMS COMMAND parameter.

Otherwise it is the same as the NOT COAST STOP input parameter of the SEQUENCING

LOGIC function block.

(Not) Quick Stop

If in Remote Comms mode, this is the same as Bit 2 of the COMMS COMMAND parameter.

Otherwise it is the same as the NOT FAST STOP input parameter of the SEQUENCING LOGIC

function block.

Switch On Disable

Set (=1) only when in START DISABLED state.

Remote

This bit is set (= 1) if the inverter is in Remote mode AND the parameter REMOTE COMMS

SEL of the COMMS CONTROL function block is Set (= 1).

Setpoint Reached

This bit is set (=1) if the Reference Ramp is not ramping.

Internal Limit Active

This bit is set (=1) if, while in vector control mode, the speed limit has reached the torque limit;

or, while in Volts/Hz mode, the open loop current limit is active.

Page 56

Page 57

6.6.4 CANopen Termination

If the drive is at the end of the trunk it must have a terminating resistor. All other drives in the

system should not have a terminator. Connect terminating resistors to the last drive as shown

below. (resistor is ±1%, minimum ¼ Watt).

The CANopen specification recommends 124 Ω, but it should be chosen to equal as closely as

possible the characteristic impedance of the cable.

IMPORTANT: Failing to fit terminating resistors correctly may result

in unreliable operation.

Page 58

Data from CANopen Data to MA3

False False

True True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

Zero

False

Non-Zero True

From UNSIGNED 16 to LOGIC

From UNSIGNED 32 to LOGIC

From BOO LEAN to LOGIC

From REAL32 to LOGIC

From INTEGER 8 to LOGIC

From INTEGER 16 to LOGIC

From INTEGER 32 to LOGIC

From UNSIGNED 8 to LOGIC

Data from MA3

Data to CANopen

From LOGIC to BOOLEAN

False

False

True

True

From LOGIC to REAL32

False

0.0

True

1.0

From LOGIC to INTEGER 8

False

0

True

1

From LOGIC to INTEGER 16

False

0

True

1

From LOGIC to INTEGER 32

False

0

True

1

From LOGIC to UNSIGNED 8

False

0

True

1

From LOGIC to UNSIGNED 16

False

0

True

1

From LOGIC to UNSIGNED 32

False

0

True

1

7 Appendix

7.1 DSE Lite/CANopen Conversion Rule

The rules governing the conversion between inverter data types and CANopen data types are

given below. Note carefully that some conversions will result in rounding, limiting and

truncation of the original value.

LOGIC Type Connector

Page 58

Page 59

Data from CANopen Data to MA3

False 0X0000 0000

True 0X0000 0001

32-bit IEEE floating point

0 to 2,147,483,647

limits apply

-32768 to 32767

-2,147,483,648 to

2,147,483,547

0 to 255

0 to 65,535

From UNSIGNED 16 to INTEGER

From UNSIGNED 32 to INTEGER

-2,147,483,648 to

2,147,438,547

Fractional part rounded

-128 to 127

-32768 to 32767

-2,147,483,648 to

2,147,483,547

0 to 255

0 to 65,535

0 to 4,294,967,295

-128 to 127

From BOO LEAN to INTEGER

From REAL32 to INTEGER

From INTEGER 8 to INTEGER

From INTEGER 16 to INTEGER

From INTEGER 32 to INTEGER

From UNSIGNED 8 to INTEGER

Data from MA3 Data to CANopen

Zero True

Non-zero False

-128 to 127

limits apply

-32768 to 32767

limits apply

0 to 255

limits apply

0 to 65,535

limits apply

From INTEGER to UNSIGNED 32

-2,147,483,648 to

2,147,483,547

0 to 2,147,483,547

-2,147,483,648 to

2,147,438,547

Fractional part rounded

From INTEGER to UNSIGNED 8

-2,147,483,648 to

2,147,483,547

From INTEGER to UNSIGNED 16

-2,147,483,648 to

2,147,483,547

From INTEGER to INTEGER 16

-2,147,483,648 to

2,147,483,547

From INTEGER to INTEGER 32

-2,147,483,648 to

2,147,483,547

-2,147,483,648 to

2,147,483,547

From INTEGER to BO OLEAN

From INTEGER to REAL32

32-bit IEEE floating point

From INTEGER to INTEGER 8

-2,147,483,648 to

2,147,483,547

INTEGER Type Connector

Page 60

Data from CANopen Data to MA3

False 0.0

True 1.0

32-bit IEEE floating point

-32768.0 to 32767.0

limits apply

0 to 32767.0

limits apply

0 to 32767.0

limits apply

From UNSIGNED 32 to VALUE

0 to 4,294,967,295

From UNSIGNED 8 to VALUE

0 to 255

0.0 to 255.0

From UNSIGNED 16 to VALUE

0 to 65,535

From INTEGER 16 to VALUE

-32768 to 32767

-32768.0 to 32767.0

From INTEGER 32 to VALUE

-2,147,483,648 to

2,147,483,547

From BOO LEAN to VALUE

From REAL32 to VALUE

-32,768.0 to 32,767.9999

From INTEGER 8 to VALUE

-128 to 127

-128.0 to 127.0

Data from MA3 Data to CANopen

Zero False

Non-zero T rue

-128.0 to 127.0

limits apply/rounding applies

-32,768 to 32,767

limits apply/rounding applies

-32,768 to 32,767

limits apply/rounding applies

0 to 255

limits apply/rounding applies

0 to 32767

limits apply/rounding applies

0 to 32767

limits apply/rounding applies

From VALUE to UNSIGNED 16

-32,768.0 to 32,767.9999

From VALUE to UNSIGNED 32

-32,768.0 to 32,767.9999

-32,768.0 to 32,767.9999

From VALUE to INTEGER 16

-32,768.0 to 32,767.9999

From VALUE to INTEGER 32

-32,768.0 to 32,767.9999

From VALUE to UNSIGNED 8

-32,768.0 to 32,767.9999

From VALUE to BOOLEAN

From VALUE to REAL32

32-bit IEEE floating point

From VALUE to INTEGER 8

-32,768.0 to 32,767.9999

VALUE Type Connector

Page 60

Page 61

7.1.1 Regulatory Compliance

This Chapter outlines the compliance requirements and product certifications.

Applicable Standards

2006/95/EC European Directive - Low Voltage

*2009/19/EC European Vehicle Directive – Suppression of radio interference

*UNECE ECE Vehicle Regulation 10 – Environmental Compatibility

EN 61800-3:2004 Adjustable speed electrical power drive systems – Part 3: EMC

requirements and specific test methods.

EN 61800-5-1:2007 Adjustable speed electrical power drive systems – Part 5-1: Safety

requirements – Electrical, thermal and energy.

*UL508C Standard for Safety, Power Conversion Equipment, third edition.

* Tests and evaluations complete – Approval pending

Page 62

Local wiring regulations always take precedence.

Where there are any conflicts between regulatory standards for example

earthing requirements for electromagnetic compatibility, safety shall always

take precedence.

7.1.2 European Compliance

The CE marking is placed upon the product by Parker Hannifin Manufacturing Ltd to

facilitate its free movement within the European Economic Area (EEA). The CE marking

provides a presumption of conformity to all applicable directives. Harmonized standards

are used to demonstrate compliance with the essential requirements laid down in those

relevant directives.

It must be remembered that there is no guarantee that combinations of compliant

components will result in a compliant system. This means that compliance to harmonised

standards will have to be demonstrated for the system as a whole to ensure compliance

with the directive.

Low Voltage Directive

When installed in accordance with this manual the product will comply with the low voltage

directive 2006/95/EC.

Protective Earth (PE) Connections

Only one protective earth conductor is permitted at each protective earth terminal

contacting point.

The product requires a protective earth conductor cross section of at least 10mm², where

this is not possible a second protective earth terminal provided on the VSD (Variable

Speed Drive) shall be used. The second conductor should be independent but electrically

in parallel.

EMC Directive

When installed in accordance with this manual the product will comply with the

electromagnet compatibility directive 2004/108/EC.

The following information is provided to maximise the Electro Magnetic Compatibility (EMC)

of VSDs and systems in their intended operating environment, by minimising their

emissions and maximising their immunity.

VCA / ECE Regulation 10

Approval pending

Page 62

Page 63

7.2 EMC Installation Guidance

7.2.1 Protective Earth (PE Connections)

Local wiring regulations take precedence and may require the protective earth

connection of the motor to be connected locally, i.e. not as specified in these

instructions. This will not cause shielding problems because of the relatively high

RF impedance of the local earth connection.

Earthing

A star-point earthing policy separates ‘noisy’ and ‘clean’ earths.

1. 0V/Signal Grounding

The “0V/signal ground” is required to be separately earthed, for multiple products these terminals

should be connected together at a single, local earthing point.

2. Control/Signal and Encoder Cables

Control/signal and encoder cables, all analogue inputs, and communications require screening

with the screen connected only at the VSD end. However, if high frequency noise is still a

problem, earth the screen at the non-VSD end via a 0.1 F capacitor. Connect the screen (at the

VSD end) to the VSD protective earth point and not to the control board terminals.

3. Chassis

The chassis is used as this main earth, and should provide earthing points for all parts of the

system. The chassis is also used for power screened cables which terminate near to (10cm) or

directly into a VSD- such as motor cables, braking choppers and their resistors, or between VSDs

- refer to the appropriate product manual to identify these. Use U-clips to clamp the screened

cables to the back panel to ensure optimum HF connection.

7.2.2 MITIGATING THE EFFECTS OF

RADIATED INTERFERENCE

Equipment Placement

Do not place magnetic/electric field sensitive equipment within 0.25 meters of the following parts of

the VSD system:

Variable Speed Drive (VSD)

The cable between VSD and motor (even when screened/armored)

AC/DC brushed motors (due to commutation)

Battery connections (even when screened/armored)

Relays and contactors (even when suppressed)

Radiated magnetic and electric fields inside the vehicle may be high and any components fitted in

close proximity must be sufficiently immune.

All cable entry and exits (power, control, and communication) should use screened cable.

Earth screen at both ends connecting to the motor frame and chassis.

Use of screened/armored cable between VSD/chassis and motor containing the motor

protective earth (PE) connection is most important.

Page 64

Use 360° screen terminations.

Figure 0-1 360 Degree Screened Connection (Motor/DC)

Keep unshielded cable as short as possible inside the cubicle.

Always maintain the integrity of the shield. If the cable is interrupted to insert disconnects

etc., re-connect the screen using the shortest possible route. Some motor gland boxes

and conduit glands are made of plastic, if this is the case, then braid must be connected

between the screen and the chassis.

Keep the length of screen stripped-back as short as possible when making screen

connections.

7.2.3 CABLING REQUIREMENTS

Refer to “Recommended Wire Size” chapter 4.3 for calculating wire sizes.

Cable Routing

Cables are considered to be electrically sensitive, clean or noisy. You should already

have planned your cable routes with respect to segregating these cables for EMC

compliance.

Use the shortest possible motor cable lengths.

When connecting multiple motors to a single VSD, use a star junction point for motor

cable connections. Use a metal box with entry and exit cable glands to maintain shield

integrity.

Keep electrically noisy and sensitive cables apart.

Keep electrically noisy and sensitive parallel cable runs to a minimum. Separate parallel

cable runs by at least 0.25 metres. Sensitive cables should cross noisy cables at 90 .

Never run sensitive cables close or parallel to the motor, dc link and braking chopper

circuit for any distance.

Page 64

Page 65

7.3 Environmental

7.3.1 RESTRICTIONS, EVALUATION,