Parker Compax3, Compax3 S150 V4, Compax3 S300 V4, Compax3 S025 V2, Compax3 S063 V2 Installation Manual

...Page 1

DATASHEET

C3S025V2 F10 I20 T30 M00

PARKER HANNIFIN

OTHER SYMBOLS:

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

www.rgbelektronika.pl

www.rgbautomatyka.pl

Page 2

YOUR

PARTNER IN

MAINTENANCE

Repair this product with RGB ELEKTRONIKA

LINEAR

ENCODERS

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

OUR SERVICES

PLC

SYSTEMS

CNC

CONTROLS

ORDER A DIAGNOSIS

INDUSTRIAL

COMPUTERS

POWER

SUPPLIERS

∠

MOTORS

SERVO

DRIVERS

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

Buy this product at RGB AUTOMATYKA

OPERATOR

PANELS

BUY

∠

Page 3

Compax3 Installation Manual

Single axis devices

Paper version

Electromechanical Automation

192-120102 N7 - February 2004

890-130001 Compax3

Unterlagen / Software

user guides / tools

manuels / tools:

! Compax3 - CD (english, deutsch, français)

+

! Compax3 Installations-Handbuch deutsch

! Compax3 Installation Manual english

! Manuel technique Compax3 français

Release 1/2004 (as from firmware V2.03)

We reserve the right to make technical changes. 10.02.04 08:50 192-120102 N7 - February 2004

The data contained correspond to the current status at the time of printing.

Page 4

Notes on the Documents Supplied

____________________________

Copyright © 2003 Parker Hannifin GmbH EME

All rights reserved.

Microsoft Word, Microsoft Office, Windows®, Window 95™, Window 98™,

Windows NT®, Window 2000™, Window XP™ and MS-DOS™ are trademarks of

Microsoft Corporation.

EME - Electromechanical Automation Europe

Germany:

England:

Italy:

Parker Hannifin GmbH

Electromechanical Automation

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Tel.: +49 (0)781 509-0

Fax: +49 (0)781 509-176

E-mail: sales.hauser@parker.com mailto:sales.hauser@parker.com

Internet: www.parker-eme.com http://www.parker-eme.com

Parker Hannifin plc

Electromechanical Automation

21 Balena Close

Poole, Dorset England, BH17 /DX UK

Tel.: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

E-mail: sales.digiplan@parker.com mailto:sales.digiplan@parker.com

Internet: www.parker-eme.com http://www.parker-eme.com

Parker Hannifin S. p. A

Electromechanical Automation

Via Gounod 1

I-20092 Cinisello Balsamo (MI), Italy

Tel.: +39 (0)2660 12459

Fax: +39 (0)2660 12808

E-mail: sales.sbc@parker.com mailto:sales.sbc@parker.com

Internet: www.parker-eme.com http://www.parker-eme.com

EMN - Electromechanical Automation North America

USA:

2 192-120102 N7 - February 2004

Parker Hannifin Corporation

Electromechanical Automation

5500 Business Park Drive

Rohnert Park, CA 94928

Phone #: (800) 358-9068

FAX #: (707) 584-3715

E-mail: CMR_help@parker.com mailto:CMR_help@parker.com

Internet: www.compumotor.com http://www.compumotor.com

Page 5

Parker EME

r

Notes on the Documents Supplied

1. Notes on the Documents

Supplied

Compax3 –

Installtion manual

C3 ServoManage

Online help system

Manuals

Catalogs

The present manual contains the installation instructions for the associated

Compax3 device series (refer to Chapter “Device Assignment”).

Compax3 CD

The enclosed self-starting* CD contains the “C3 ServoManager” software tool for

configuring, optimizing etc. Compax3.

Please use always the latest C3 ServoManager version,

which can be found on the latest Compax3 CD enclosed.

The installation of ServoManager also copies an online help system to your PC that

can be started directly from ServoManager. You will find the complete description

of the selected device type in these online help files.

The CD also contains additional help files as well as manuals in PDF format that

can be printed to compile a complete hardcopy version of the respective manual.

Please note that the help files and the manuals are associated with defined device

and software versions.

The catalogs supplied provide an overview of and information on the Compax3

device series.

Adobe Acrobat

Reader®

The "Adobe Acrobat Reader®" is also included on the CD. It is free software that

lets you view and print "Adobe Portable Document Format" (PDF) files and it is

distributed and generally accepted throughout the world. You can also download it

directly from the Adobe website at: www.adobe.com/products/acrobat.

* If your PC has not been set up accordingly, start the "default.htm" file on the CD.

192-120102 N7 - February 2004 3

Page 6

Notes on the Documents Supplied

1.1 C3 ServoManagers

Installation of the C3

ServoManager

The Compax3 ServoManager can be installed directly from the Compax3 CD.

Click on the appropriate hyperlink or start the installation program

"C3Mgr_Setup_V.... .exe" and follow the instructions.

Minimum requirements

For successful installation, your PC must meet the following minimum

requirements:

! Windows 98, Windows Me, Windows NT 4.0 (Intel) with Service Pack 6, Windows

2000 or Windows XP.

! Administrator authorization* on the system

! Microsoft Internet Explorer 4.01 (SP2) or higher

! Pentium-PC (300 MHz or faster is recommended)

! 64 MB RAM (128 MB recommended)

! Required HD capacity

♦ CD-Installation: 350 MB before installation, 200 MB after installation

! Super VGA-Monitor (with a resolution of at least 800 x 600, setting: small fonts)

Connection between

PC and Compax3

Device selection

Configuration

* you do not need administrator authorization for an update version!

Your PC is connected with Compax3 over an RS232 cable (SSK1) (COM ½

interface on the PC based on X10 Compax3).

Start the Compax3 ServoManager and make the setting for the selected interface

in the menu Options: Port (RS232) COM 1 or COM 2.

In the menu tree under device selection you can read the device type of the

connected device (Online Device Identification) or select a device type (Device

Selection Wizard).

Then you can double click on "Configuration" to start the configuration wizard. The

wizard will lead you through all input windows of the configuration.

4 192-120102 N7 - February 2004

Page 7

Parker EME

C3 ServoManagers

New Compax3 functions

Contents

1. Notes on the Documents Supplied ........................................................3

1.1 C3 ServoManagers................................................................................... 4

2. Introduction .............................................................................................7

2.1 Device assignment .................................................................................. 7

2.2 Type specification plate .......................................................................... 8

2.3 Release 1/2004 ......................................................................................... 9

2.3.1. New Compax3 functions ................................................................................... 9

2.3.1.1 Direct drives ............................................................................................ 9

2.3.1.2 Switching frequency of the power output stage can be set .................... 9

2.3.1.3 Optimization of the predefined external setpoint via the analog

input ........................................................................................................ 9

2.3.1.4 UL - certification ...................................................................................... 9

2.3.1.5 New machine zero modes .................................................................... 10

2.3.1.6 RS485 / RS232 - interface .................................................................... 10

2.3.2. New functions of the Compax3 - Software - tools........................................ 10

2.3.2.1 C3 ServoManager: configuring Compax3 , setup and optimization ..... 10

2.3.2.2 C3 MotorManager: configuration of almost any motor ........................ 11

2.3.2.3 C3 IEC61131-3 - Debugger .................................................................. 11

2.3.2.4 CoDeSys - IEC61131-3 – development tool ......................................... 11

2.3.2.5 CamEditor: cam creation for C3 T40 .................................................... 11

2.3.3. Complements/corrections in manual and online help ................................. 11

2.4 Safety Instructions................................................................................. 12

2.4.1. General hazards ............................................................................................... 12

2.4.2. Safety-conscious working .............................................................................. 12

2.4.3. Special safety instructions ............................................................................. 13

2.5 Warranty conditions .............................................................................. 13

2.6 Conditions of utilization ........................................................................ 14

2.6.1. Conditions of utilization for CE-conform operation..................................... 14

2.6.2. Conditions of utilization for UL certification................................................. 16

2.7 Manufacturer's Declaration of Conformity........................................... 17

3. Compax3 device description................................................................18

3.1 State of delivery ..................................................................................... 18

3.2 Plug and connector assignment Compax3.......................................... 19

3.2.1. Function of the LEDs on the front panel ....................................................... 20

3.2.2. Power supply plug X1 for 230VAC devices................................................... 20

3.2.3. Power supply plug X1 for 400 VAC devices.................................................. 21

192-120102 N7 - February 2004 5

Page 8

Notes on the Documents Supplied

New Compax3 functions

3.2.4. Ballast resistor / high voltage supply plug X2 for 230VAC devices........... 21

3.2.5. Ballast resistor / high voltage supply plug X2 for 400VAC devices........... 22

3.2.6. Motor / Motor brake (plug X3)......................................................................... 23

3.2.7. Control voltage 24VDC / enable (plug X4) ..................................................... 24

3.2.8. RS232 / RS485 interface (plug X10) ............................................................... 25

3.2.9. Analog / Encoder (plug X11)........................................................................... 26

3.2.9.1 Wiring of analog outputs ....................................................................... 26

3.2.9.2 Wiring of the analog input ..................................................................... 27

3.2.10. Digital inputs/outputs (plug X12) ................................................................... 27

3.2.10.1 Output wiring of digital outputs.............................................................. 28

3.2.10.2 Input wiring of digital inputs................................................................... 28

3.2.11. Resolver / Feedback (connector X13)............................................................ 29

3.3 Installation and dimensions Compax3................................................. 30

3.3.1. Installation and dimensions of Compax3 S0xx V2....................................... 30

3.3.2. Installation and dimensions of Compax3 S038 and S075 V4...................... 31

3.3.3. Installation and dimensions of Compax3 S150 V4....................................... 32

3.3.4. Installation and dimensions of Compax3 S300 V4....................................... 33

3.4 Safety function – safe standstill - ......................................................... 34

3.4.1. Safety instructions for the “safe standstill” function .................................. 36

3.4.2. Application examples for “safe standstill” ................................................... 37

3.4.2.1 Sample circuit example of Compax3 devices without fieldbus

option .................................................................................................... 37

3.4.2.2 Sample circuit example of Compax3 devices with fieldbus option ....... 43

3.4.2.3 Sample circuit for C3 powerPLmC multi-axis application ..................... 46

4. Technical Data.......................................................................................51

5. Index.......................................................................................................57

6 192-120102 N7 - February 2004

Page 9

Parker EME

2. Introduction

You can read about the following in this chapter:

Device assignment ...........................................................................................................................7

Type plate ........................................................................................................................................8

Release 1/2004 ................................................................................................................................9

Safety instructions ..........................................................................................................................12

Warranty conditions........................................................................................................................13

Conditions of utilization...................................................................................................................14

Manufacturer’s declaration of conformity ........................................................................................17

2.1 Device assignment

Introduction

This manual applies to the following devices:

! Compax3 S025 V2 + supplement

! Compax3 S063 V2 + supplement

! Compax3 S038 V4 + supplement

! Compax3 S075 V4 + supplement

! Compax3 S150 V4 + supplement

! Compax3 S300 V4 + supplement

192-120102 N7 - February 2004 7

Page 10

Introduction

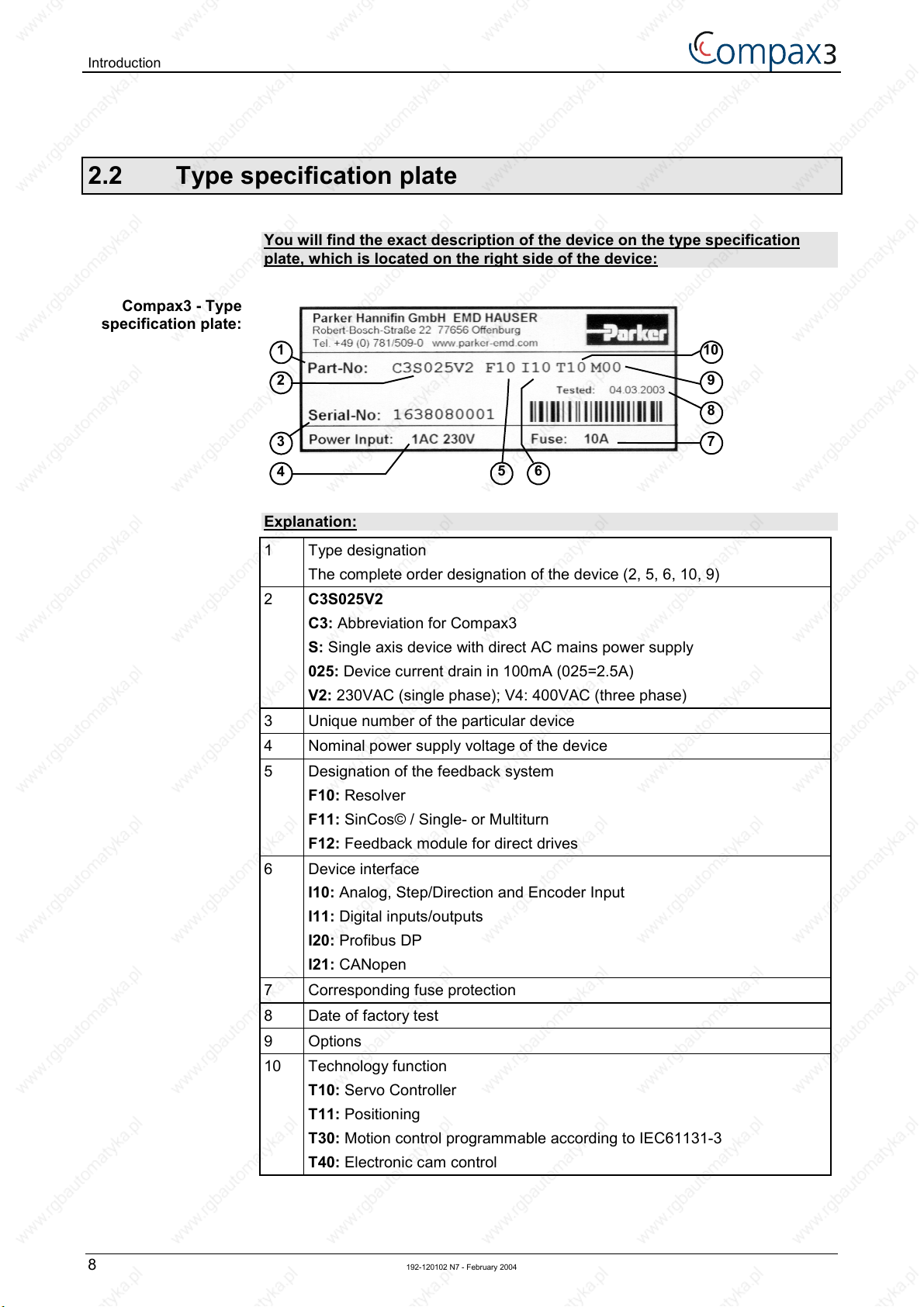

2.2 Type specification plate

You will find the exact description of the device on the type specification

plate, which is located on the right side of the device:

Compax3 - Type

specification plate:

1

10

2

3

4

56

Explanation:

1 Type designation

The complete order designation of the device (2, 5, 6, 10, 9)

C3S025V2

2

C3: Abbreviation for Compax3

S: Single axis device with direct AC mains power supply

025: Device current drain in 100mA (025=2.5A)

V2: 230VAC (single phase); V4: 400VAC (three phase)

3 Unique number of the particular device

4 Nominal power supply voltage of the device

5 Designation of the feedback system

F10: Resolver

F11: SinCos© / Single- or Multiturn

F12: Feedback module for direct drives

6 Device interface

I10: Analog, Step/Direction and Encoder Input

I11: Digital inputs/outputs

I20: Profibus DP

I21: CANopen

7 Corresponding fuse protection

8

Date of factory test

9 Options

10 Technology function

T10: Servo Controller

T11: Positioning

T30: Motion control programmable according to IEC61131-3

T40: Electronic cam control

9

8

7

8 192-120102 N7 - February 2004

Page 11

Parker EME

2.3 Release 1/2004

You can read about the following in this chapter:

New Compax3 functions...................................................................................................................9

New functions of the Compax3 software tools ................................................................................10

Complements / corrections in manual and online help ....................................................................11

2.3.1. New Compax3 functions

You can read about the following in this chapter:

Direct drives .....................................................................................................................................9

Switching frequency of the power output stage can be set................................................................9

Optimization of the predefined external setpoint via the analog input................................................9

UL certification..................................................................................................................................9

New machine zero modes .............................................................................................................. 10

RS485 / RS232 interface ................................................................................................................10

Introduction

2.3.1.1 Direct drives

The feedback module F12 supports the following feedback systems:

! Distance coding with 1VSS - Interface

! Distance coding with RS422 - Interface (Encoder)

2.3.1.2 Switching frequency of the power output stage can be set

The switching frequency of the power output stage can be increased if necessary.

This helps mainly to reduce motor sounds.

Please note that power output stage losses increase with rising switching

frequency. Therefore the nominal device currents must be reduced.

2.3.1.3 Optimization of the predefined external setpoint via the analog

input

Given an external discrete signal read in via the analog input (possible with I10 T10

and T40), signal steps can only be avoided by averaging.

2.3.1.4 UL - certification

Compax3 now with UL certification. (see on page 16)

192-120102 N7 - February 2004 9

Page 12

Introduction

2.3.1.5 New machine zero modes

! Several new machine zero modes with limit switch: MN-Mode 1,2 7-10, 11-14,

17,18, 23-26, 27-30

! New machine zero modes in connection with the feedback module F12 F12

(direct drives) and distance coded feedback system: MN-Mode 130 - 133

! Limit switch can be configured

2.3.1.6 RS485 / RS232 - interface

Compax3 objects can be read and written in via RS232 and RS485.

2.3.2. New functions of the Compax3 - Software - tools

You can read about the following in this chapter:

C3 ServoManager: configuring Compax3, setup and optimization ..................................................10

C3 MotorManager: configuration of almost any motors...................................................................11

C3 IEC61131-3 - Debugger............................................................................................................11

CoDeSys - IEC61131-3 – development tool .................................................................................11

CamEditor: Cam creation for C3 T40..............................................................................................11

2.3.2.1 C3 ServoManager: configuring Compax3 , setup and

optimization

A modified recipe array can be loaded separately (without complete download) into

the device.

Firmware - Download

The Compax3 firmware can only be modified resp. updated with the aid of the C3

ServoManager.

For this you will need a so-called “firmware-package” (File: .*.fwp).

Setup - support

You can set up all Compax3 technology functions easily in the optimization

window.

10 192-120102 N7 - February 2004

Page 13

Parker EME

2.3.2.2 C3 MotorManager: configuration of almost any motor

New:

! Integration of distance coded feedback systems

! Export / Import of user defined (customer’s) motor

! Calibration of commutation also for linear motors with small travel path

Changes

! Linear motors with brakes can be configured

! Calculation of the recommended number of poles was corrected

! Calibration of SinCos motors was corrected

! The minimum moment of inertia was reduced from 10kgmm

! Configuration of rotatory motors with analog hall sensors was completed

2.3.2.3 C3 IEC61131-3 - Debugger

2

to 1kgmm

Introduction

2

Forcing of the inputs for T30 and T40 is possible.

2.3.2.4 CoDeSys - IEC61131-3 – development tool

New CoDeSys version 2.3.2.6

2.3.2.5 CamEditor: cam creation for C3 T40

-

2.3.3. Complements/corrections in manual and online help

New structure of the manual:

! All technology functions are described in a help.

! Manuals (PDF files) have a new structure:

! I10 T10 manual

! I11 T11 manual

! I20 T11 manual

! I21 T11 manual

! A single manual for all devices programmable according to IEC

(I11 T30, I20 T30, T21 T30, I11 T40, I20 T40, I21 T40)

The assignment of the respective chapters is indicated.

192-120102 N7 - February 2004 11

Page 14

Introduction

2.4 Safety Instructions

You can read about the following in this chapter:

General hazards.............................................................................................................................12

Working safely................................................................................................................................12

Special safety instructions ..............................................................................................................13

2.4.1. General hazards

General Hazards on Non-Compliance with the Safety Instructions

The device described in this manual is designed in accordance with the latest

technology and is safe in operation. Nevertheless, the device can entail certain

hazards if used improperly or for purposes other than those explicitly intended.

Electronic, moving and rotating components can

! constitute a hazard for body and life of the user, and

! cause material damage

Usage in accordance with intended purpose

The device is designed for operation in electric power drive systems (VDE0160).

Motion sequences can be automated with this device. Several motion sequences

can be can combined by interconnecting several of these devices. Mutual

interlocking functions must be incorporated for this purpose.

2.4.2. Safety-conscious working

This device may be operated only by qualified personnel.

Qualified personnel in the sense of these operating instructions consists of:

! Persons who, by virtue to their training, experience and instruction, and their

knowledge of pertinent norms, specifications, accident prevention regulations and

operational relationships, have been authorized by the officer responsible for the

safety of the system to perform the required task and in the process are capable

of recognizing potential hazards and avoiding them (definition of technical

personnel according to VDE105 or IEC364),

! Persons who have a knowledge of first-aid techniques and the local emergency

rescue services.

! Persons who have read and will observe the safety instructions.

! Those who have read and observe the manual or help (or the sections pertinent

to the work to be carried out).

This applies to all work relating to setting up, commissioning, configuring,

programming, modifying the conditions of utilization and operating modes, and to

maintenance work.

This manual and the help information must be available close to the device during

the performance of all tasks.

12 192-120102 N7 - February 2004

Page 15

Parker EME

2.4.3. Special safety instructions

! Check the correct association of the device and its documentation.

! Never detach electrical connections while voltage is applied to them.

! Safety devices must be provided to prevent human contact with moving or

rotating parts.

! Make sure that the device is operated only when it is in perfect condition.

! Implement and activate the stipulated safety functions and devices.

! Operate the device only with the housing closed.

! Ensure that motors and any linear drives present are mounted securely.

! Check that all live terminals are secured against contact. Fatal voltage levels of to

750V occur.

2.5 Warranty conditions

! The device must not be opened.

! Do not make any modifications to the device, except for those described in the

manual.

! Make connections to the inputs, outputs and interfaces only in the manner

described in the manual.

! When installing the device, make sure the heat dissipater receives sufficient air.

! Attach the devices according to the mounting instructions, using the provided

fixing holes. We cannot provide any guarantee for any other mounting methods.

Introduction

Note on exchange of options

Compax3 options must be exchanged in the factory to ensure hardware and

software compatibility.

192-120102 N7 - February 2004 13

Page 16

Introduction

r

2.6 Conditions of utilization

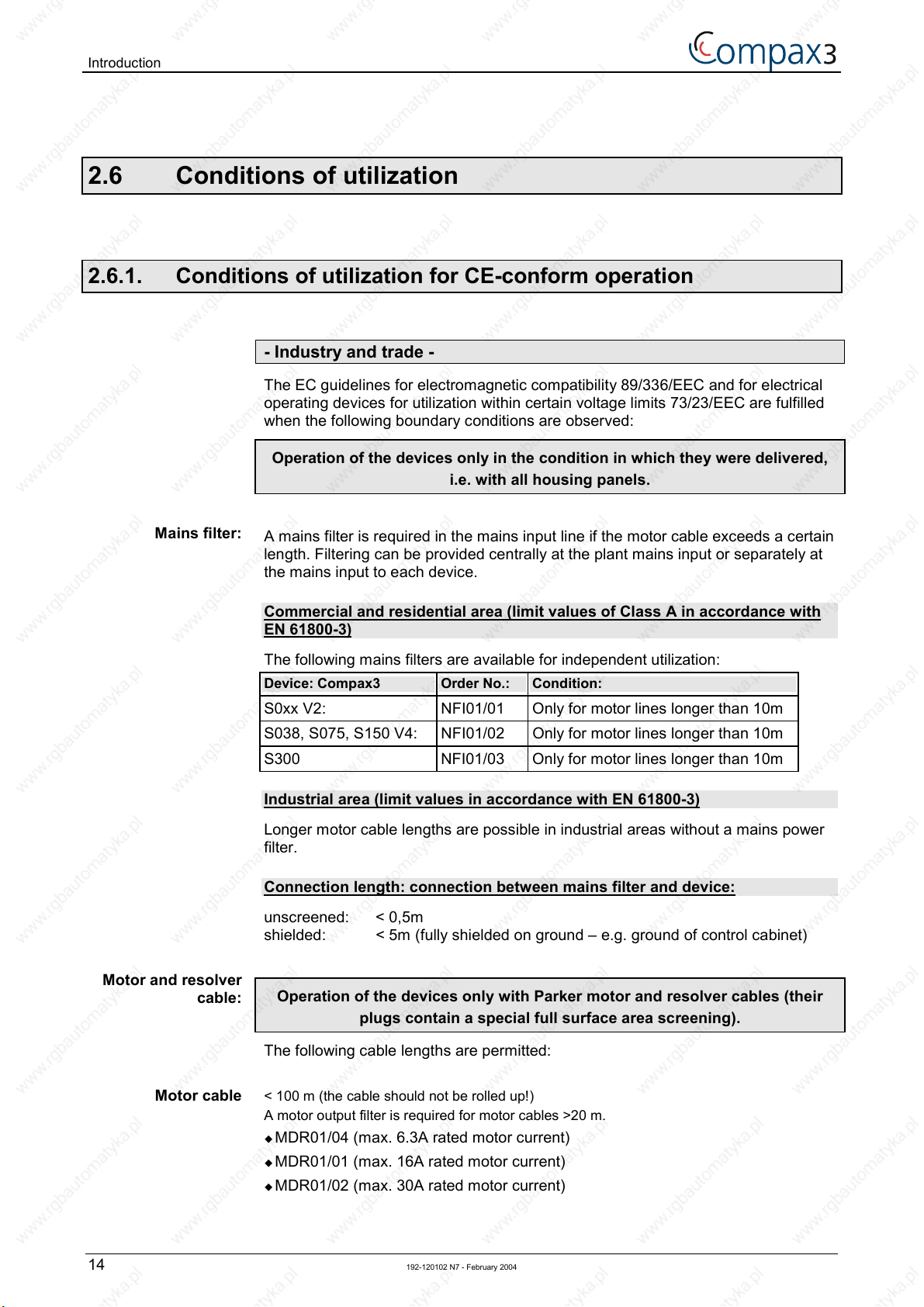

2.6.1. Conditions of utilization for CE-conform operation

- Industry and trade -

The EC guidelines for electromagnetic compatibility 89/336/EEC and for electrical

operating devices for utilization within certain voltage limits 73/23/EEC are fulfilled

when the following boundary conditions are observed:

Operation of the devices only in the condition in which they were delivered,

i.e. with all housing panels.

Mains filter:

Motor and resolve

cable:

A mains filter is required in the mains input line if the motor cable exceeds a certain

length. Filtering can be provided centrally at the plant mains input or separately at

the mains input to each device.

Commercial and residential area (limit values of Class A in accordance with

EN 61800-3)

The following mains filters are available for independent utilization:

Device: Compax3 Order No.: Condition:

S0xx V2: NFI01/01 Only for motor lines longer than 10m

S038, S075, S150 V4: NFI01/02 Only for motor lines longer than 10m

S300 NFI01/03 Only for motor lines longer than 10m

Industrial area (limit values in accordance with EN 61800-3)

Longer motor cable lengths are possible in industrial areas without a mains power

filter.

Connection length: connection between mains filter and device:

unscreened: < 0,5m

shielded: < 5m (fully shielded on ground – e.g. ground of control cabinet)

Operation of the devices only with Parker motor and resolver cables (their

plugs contain a special full surface area screening).

The following cable lengths are permitted:

Motor cable

< 100 m (the cable should not be rolled up!)

A motor output filter is required for motor cables >20 m.

! MDR01/04 (max. 6.3A rated motor current)

! MDR01/01 (max. 16A rated motor current)

! MDR01/02 (max. 30A rated motor current)

14 192-120102 N7 - February 2004

Page 17

Parker EME

Introduction

Screening connection of the motor cable

The motor cable should be fully screened and connected to the Compax3 housing.

We offer a special shield connecting terminal as accessory item.

Resolver cable

Motors:

Control:

Grounding:

Cable installation:

Accessories:

Warning:

< 100 m

Operation with standard motors.

Use only with aligned controller (to avoid control loop oscillation).

Connect the filter housing and the Compax3 (grounding screw on the underside) to

the cabinet frame, making sure that the contact area is adequate and that the

connection has low resistance and low inductance.

Never mount the filter housing and the device on paint-coated surfaces!

Signal lines and power lines should be installed as far apart as possible.

Signal leads should never pass close to excessive sources of interference (motors,

transformers etc.).

Make sure to use only the accessories recommended by Parker

Connect all cable shields at both ends, ensuring large contact areas!

This is a product in the restricted sales distribution class according to EN

61800-3. In a domestic area this product can cause radio frequency

disturbance, in which case the user may be required to implement

appropriate remedial measures.

192-120102 N7 - February 2004 15

Page 18

Introduction

2.6.2. Conditions of utilization for UL certification

UL certification

conform to UL:

Certified

! according to UL508C

! E-File_No.: E235 342

The UL certification is documented by a UL logo on the

device (type specification plate)

"UL" - logo:

Conditions of utilization

! The devices are only to be installed in a degree of contamination 2 environment

(maximum).

! The devices must be appropriately protected (e.g. by a switching cabinet).

! The terminals are suitable for field wiring.

! Tightening torque of the field wiring terminals (green Phoenix plugs)

! C3SxxxV2 0.57-0.79Nm 5 - 7Lb.in

! C3SxxxV4 exept C3S300V4 0.57-0.79Nm 5 - 7Lb.in

! C3S300V4 1.25-1.7Nm 11 - 15Lb.in

! Temperature rating of field installed conductors shall be at least 60°C Use

copper conductors only. Please use the cables described in the accessories

chapter; they do have a temperature rating of at least 60°C

! Maximum ambient temperature: 45°C.

! Suitable for use on a circuit capable of delivering not more than 500 rms

symmetrical amperes, 400 volts maximum.

ATTENTION

Danger of electric shock.

Discharge time of the bus capacitator is 5 minutes.

! The drive provides internal motor overload protection.

This must be set so that 200% of the nominal motor current are not exceeded.

! Cable cross-sections

! Mains input: corresponding to the recommended fuses (see on page 51)

! Motor cables: corresponding to the nominal output currents (see on page 51)

! Maximum cross-section limited by the terminals mm

! C3SxxxV2 2.5mm

! C3SxxxV4 exept C3S300V4 4.0mm

! C3S300V4 6.0mm

! Circuit protection

2

/ AWG

2

2

2

AWG 12

AWG 10

AWG 7

In addition to the branch circuit protection, the devices have to be protected with

the supplementary protector S 261 L, manufactured by ABB.

! C3S025V2: ABB, nominal 400V 10A, 6kA

! C3S063V2: ABB, nominal 400V, 16A, 6kA

! C3S038V4: ABB, nominal 400V, 10A, 6kA

! C3S075V4: ABB, nominal 400V, 16A, 6kA

! C3S150V4: ABB, nominal 400V, 20A, 6kA

! C3S300V4: ABB, nominal 400V, 25A, 6kA

! C3S300V4: ABB, nominal 400V, 25A, 6kA

16 192-120102 N7 - February 2004

Page 19

Parker EME

2.7 Manufacturer's Declaration of Conformity

As defined by the EC Electromagnetic Compatibility (EMC) Directive

89/336/EEC and

the EC Directive relating to electrical equipment designed for use

within

certain voltage limits (Low Voltage Directive)

73/23/EEC

We (the manufacturer)

Parker Hannifin GmbH

hereby declare that the product(s) listed below:

Introduction

Device type: intelligent servo drives

Model: Compax3

to which this declaration relates, including the product model placed on the market

by us, have been designed and manufactured in conformity with the essential

requirements of the Standards and other Normative Documents listed in the

following.

Applied harmonized Standards, especially:

Electromagnetic Compatibility

EN 61 800-3

VDE 0160 part 100

Safety

EN 50 178/

VDE 0160

EMC product standard for a

power drive systems including special testing

procedures

Electronic equipment for use in power installations.

djustable speed electrical

Caution!

The present Manufacturer's Declaration of Conformity is valid only if the master

conditions for operation described in the "Conditions of Use" section have been

met.

In the case of non-conformity with these conditions or upon modification of the

product, the present declaration will become invalid.

192-120102 N7 - February 2004 17

Page 20

Compax3 device description

3. Compax3 device description

You can read about the following in this chapter:

State of delivery..............................................................................................................................18

Plug and connector assignment Compax3......................................................................................19

Installation and dimensions Compax3.............................................................................................30

Safety function – safe standstill ......................................................................................................34

3.1 State of delivery

Compax3 is delivered without configuration!

After switching on the 25VDC supply, the red LED is flashing while the green LED

is dark.

Please configure the device with the help of the Windows-Software “Compax3 –

ServoManager”!

18 192-120102 N7 - February 2004

Page 21

Parker EME

Plug and connector assignment Compax3

Conditions of utilization for UL certification

3.2 Plug and connector assignment Compax3

You can read about the following in this chapter:

Function of the LEDs on the front panel..........................................................................................20

Power supply plug X1 for 230VAC devices.....................................................................................20

Power supply plug X1 for 400VAC devices.....................................................................................21

Ballast resistor / High voltage supply plug X2 for 230VAC devices .................................................21

Ballast resistor / High voltage supply plug X2 for 400VAC devices .................................................22

Motor / Motor brake (plug X3) .........................................................................................................23

Control voltage 24 VDC / enable (plug X4) .....................................................................................24

RS 232 / RS485 interface (plug X10)..............................................................................................25

Analog / Encoder (plug X11)...........................................................................................................26

Digital inputs /outputs (plug X12) ....................................................................................................27

Resolver / Feedback (plug X13)......................................................................................................29

Connection assignment based on the example of Compax3 S025 V2:

X1

AC Versorgung

AC Supply

X2

Ballast / DC LS

Ballast / DC HV

X3

Motor / Bremse

Motor / Brake

X4

24VDC / Freigabe

24VDC / Enable

X10

RS232 / RS485

X11

Analog/Encoder

Analogue/Encoder

X12

Ein-/Ausgänge

Inputs/Outputs

X13

Geber

Feedback

Always switch devices off before wiring them!

Dangerous voltages are still present until 5 minutes after

switching off the power supply!

192-120102 N7 - February 2004 19

Page 22

Compax3 device description

Function of the LEDs on the front panel

Caution!

When the control voltage is missing there is no indication whether or

not high voltage supply is available.

3.2.1. Function of the LEDs on the front panel

State LED red LED green

Voltages missing off off

While booting alternately flashing

! No configuration present.

! SinCos feedback not detected.

! IEC program not compatible with the

firmware.

! For F12: Hall signals invalid.

Axis without current excitation off Flashes slowly

flashing off

Power supplied to axis; commutation calibration

off Flashes quickly

running

Axis with current excitation off on

Axis in fault status / fault present on off

3.2.2. Power supply plug X1 for 230VAC devices

PIN Description

1

2N

3PE

Mains connection: Compax3 S0xx V2

Controller type S025 V2 S063 V2

Mains voltage

Rated input current

Maximum fuse rating per device

L

Single phase 230VAC + 10%

80-230VAC+10% / 50-60Hz

6Aeff 16Aeff

10A (automatic circuit

breaker K)

16 A (automatic circuit

breaker K)

Always switch devices off before wiring them!

Dangerous voltages are still present until 5 minutes after

switching off the power supply!

20 192-120102 N7 - February 2004

Page 23

Parker EME

Plug and connector assignment Compax3

Power supply plug X1 for 400 VAC devices

3.2.3. Power supply plug X1 for 400 VAC devices

PIN Description

1L1

2L2

3L3

4

PE

Mains connection Compax3 Sxxx V4

Controller type S038 V4 S075 V4 S150 V4 S300 V4

Mains voltage

Rated input current

Maximum fuse rating per

device

Three-phase 3*400VAC

80-480 VAC+10% / 50-60 Hz

6Aeff 10 Aeff 16Aeff 22Aeff

10A (automatic

circuit breaker

K)

16 A (automatic circuit

breaker K)

25A (automatic

circuit breaker

K)

Always switch devices off before wiring them!

Dangerous voltages are still present until 5 minutes after

switching off the power supply!

3.2.4. Ballast resistor / high voltage supply plug X2 for 230VAC

devices

PIN Description

1 + Ballast resistor

2 - Ballast resistor

3PE

4

+ DC high voltage supply

5

- DC high voltage supply

Caution! The connector assignment of X2 is changed!

Please note the screen printing on the front plate of the

device: this is valid

192-120102 N7 - February 2004 21

Page 24

Compax3 device description

Ballast resistor / high voltage supply plug X2 for 400VAC devices

Brake operation Compax3 Sxxx V2

Controller type S025 V2 S063 V2

Capacitance / storable energy

Minimum ballast - resistance

Recommended nominal power rating

Pulse power rating for 1s

560µF / 15Ws 1120µF /30Ws

100Ω 56Ω

20 ... 60W 60 ... 180W

1kW 2.5kW

Caution!

The power voltage DC of two Compax3 V2 devices (230V devices) must not

be connected.

3.2.5. Ballast resistor / high voltage supply plug X2 for 400VAC

devices

PIN Description

1

+ Ballast resistor

2 - Ballast resistor

3PE

4 + DC high voltage supply

5

- DC high voltage supply

Caution! The connector assignment of X2 is changed!

Please note the screen printing on the front plate of the

device: this is valid

Compax3 Sxxx V4 brake operation

Controller type S038 V4 S075 V4 S150 V4 S300 V4

Capacitance / storable

energy

Minimum ballast -

resistance

Recommended nominal

power rating

Pulse power rating for 1s

235µF / 37Ws 470µF / 75Ws 690µF /

110Ws

100Ω 56Ω 22Ω 15Ω

60 ... 250W 60 ... 500 W 60 ... 1000 W 60 ... 1000 W

2.5kW 5kW 10 kW 42kW

1100µF /

176Ws

22 192-120102 N7 - February 2004

Page 25

Parker EME

Plug and connector assignment Compax3

Motor / Motor brake (plug X3)

Connection of the power voltage of 2 Compax3 V4 devices (400V

devices)

In order to improve the conditions during brake operation, the DC power voltage of

2 devices may be connected.

The capacity as well as the storable energy are increased; furthermore the braking

energy of one device may be utilized by a second device, depending on the

application.

Please connect as follows:

Device 1 X2/4 to device 2 X2/4

Device 1 X2/5 to device 2 X2/5

Please note the following:

Caution! In case of non-compliance with the following instructions, the

device may be destroyed!

! You can only connect two similar devices (same power supply; same rated

currents)

! Connected devices must always be fed separately via the AC power supply.

3.2.6. Motor / Motor brake (plug X3)

PIN Description

1 U (motor)

2 V (motor)

3 W (motor)

4 PE (motor)

5

BR+ Motor holding brake

6 BR- Motor holding brake

Screening connection of the motor cable

The motor cable should be fully screened and connected to the Compax3 housing.

We offer a special shield connecting terminal as accessory item.

Connect the brake only on motors which have a holding

brake! Otherwise make no brake connections at all.

Motor holding brake output

Controller type Compax3

Voltage range

Maximum output current (short circuit

proof)

192-120102 N7 - February 2004 23

21 – 27VDC

1.6 A

Page 26

Compax3 device description

3.2.7. Control voltage 24VDC / enable (plug X4)

PIN Description

1 +24 V

2 Gnd24 V

3 Enable_in

4

Enable_out_a

5

Enable_out_b

Control voltage 24 VDC

Controller type Compax3

Voltage range

Current drain of the device

Total current drain

Ripple

Requirement according to safe extra

low voltage (SELV)

21 - 27VDC

0.8 A

0.8 A + Total load of the digital outputs +

current for the motor holding brake

0.5Vpp

yes

Power stage enable: X4/3=24 VDC

Tolerance range: 18.0 V – 33.6 V / 720 Ω

The +24V supply can be taken, for example, from Pin 1.

Safe standstill (X4/3=0V)

For implementation of the "Safe standstill" safety feature in accordance with the

“protection against unexpected start-up“ described in EN1037. Please refer to the

respective chapter (see on page 34) (can be found in the paper version

"installation manual Compax3) with the circuitry examples!

The energy supply to the drive is reliably shut off, the motor has no torque.

A relay contact is located between X4/4 and X4/5 (normally closed contact)

Enable_out_a - Enable_out_b Power output

stage is

Contact opened activated

Contact closed deactivated

Series connection of these contacts permits certain determination of whether all

drives are de-energized.

Relay contact data:

Switching voltage (AC/DC): 100 mV – 60 V

Switching current: 10 mA – 0.3 A

24 192-120102 N7 - February 2004

Page 27

Parker EME

3.2.8. RS232 / RS485 interface (plug X10)

Interface selectable by contact functions assignment of X10/1:

X10/1=0V RS232

X10/1=5V RS485

RS232

Compax3 device description

PIN

X10

1 (Enable RS232) 0V

2RxD

3

4DTR

5

6DSR

7

8CTS

9

RS232 (Sub D)

TxD

GND

RTS

+5V

RS485 2-wire

PIN

X10

1 Enable RS485 (+5V)

2

3TxD_RxD/

4

5GND

6

7TxD_RxD

8res.

9+5V

RS485 two wire (Sub D)

Pin 1 and 9 jumpered externally

res.

res.

res.

RS485 4-wire

PIN

X10

1

2RxD

3TxD/

4res.

5GND

6

7TxD

8

9+5V

RS485 four wire (Sub D)

Pin 1 and 9 jumpered externally

Enable RS485 (+5V)

res.

RxD/

192-120102 N7 - February 2004 25

Page 28

Compax3 device description

3.2.9. Analog / Encoder (plug X11)

PIN X11 Reference

High Density Sub D

1 +24V (output for encoder) max. 70mA

2

Ain1 -: analogue input - (14-bit)

3 D/A monitor channel 1 (±10V, 8-bit resolution)

4 D/A monitor channel 0 (±10V, 8-bit resolution)

5 +5V (output for encoder) max. 150mA

6

7

- Input: steps RS422 (5V - level)

+ Input: steps RS422 (5V - level)

8 + Input: direction RS422 (5V - level)

A/ (encoder input/emulation)

A (encoder input/emulation)

B (encoder input/emulation)

9 Ain0 +: analogue input + (14-bit)

10 Ain1 +: analogue input + (14-bit)

11

12

13 Reserved

14 Reserved

15 GND

Ain0 -: analogue input - (14-bit)

- Input: direction RS422 (5V - level)

B/ (encoder input/emulation)

N/ (Encoder simulation)

N (Encoder simulation)

The exact assignment depends on the the device type!

You will find the description of the device-specific assignment in the online help

which can be opened from the Compax3 – ServoManager.

3.2.9.1 Wiring of analog outputs

332Ω

X11/4

X11/3

+/-10V/1mA

(max: 3mA)

X11/15

26 192-120102 N7 - February 2004

Page 29

Parker EME

3.2.9.2 Wiring of the analog input

2.2K

Ω

10nF

10K

Ain+

Ain-

X11/9

X11/11

10K

2.2K

Ω

Ω

10nF

Ω

3.2.10. Digital inputs/outputs (plug X12)

Compax3 device description

PIN

X12/

Input/output I/O /X12

High density/Sub D

1 O +24VDC output (max. 400mA)

2 O0 Output 0 (max. 100mA)

3 O1 Output 1 (max. 100mA)

4 O2 Output 2 (max. 100mA)

5

O3 Output 3 (max. 100mA)

6 I0 Input 0

7 I1 Input 1

8 I2 Input 2

9 I3 Input 3

10

I4 Input 4

11 I 24V input for the digital outputs Pins 2 to 5

12 I5 Input 5

13 I6 Input 6

14

15

I7 Input 7

O Gnd 24 V

All inputs and outputs have 24V level.

Maximum capacitive load on the outputs: 50 nF (max. 4 Compax3 inputs)

The exact assignment depends on the the device type!

You will find the description of the device-specific assignment in the online help

which can be opened from the Compax3 – ServoManager.

192-120102 N7 - February 2004 27

Page 30

Compax3 device description

3.2.10.1 Output wiring of digital outputs

24V

0V

F1

X4/1

18.2K

X4/2

F2

X12/1

X12/11

X12/2

Ω

X12/15

The circuit example is valid for all digital outputs!

The outputs are short circuit proof; a short circuit generates an error.

F1: Delayed action fuse

F2: Quick action electronic fuse; can be reset by switching the 24VDC supply off

and on again.

3.2.10.2 Input wiring of digital inputs

SPS/PLC

X12/1

F2

SPS/

PLC

F1

X4/1

24V

Ω

10K

100K

Ω

X4/2

0V

X12/6

22K

X12/15

Ω

22K

Ω

22K

Ω

The circuit example is valid for all digital inputs!

F1: Delayed action fuse

F2: Quick action electronic fuse; can be reset by switching the 24VDC supply off

and on again.

28 192-120102 N7 - February 2004

Page 31

Parker EME

3.2.11. Resolver / Feedback (connector X13)

Compax3 device description

PIN

X13

1

2 res. res. Sense +

3 GND GND Hall1

4 REFres+ Vcc (+8V) Vcc (+5V) (controlled on the encoder

5 +5V (for temperature sensor) +5V (for temperature and hall

6

7 SIN- SIN- SIN- / A- (Encoder)

8 SIN+ SIN+ SIN+ / A+ (Encoder)

9 CLKfbk/ CLKfbk/ Hall3

10

11 COS- COS- COS- / B- (Encoder)

12 COS+ COS+ COS+ / B+ (Encoder)

13 res. DATAfbk N+

Feedback /X13

High Density /Sub D (dependent on the Feedback Module)

Resolver (F10) SinCos (F11) Direct drives (F12)

res. res. Sense -

side) max. 200mA load

sensors)

CLKfbk CLKfbk Hall2

Tmot Tmot Tmot

14 res. DATAfbk/ N-

15

REFres- GND (Vcc) GND (Vcc)

Note on F12:

+5V (Pin 4) is measured and controlled directly at the end of the line via Sense –

and Sense +.

Maximum length of cable: 100m

Caution! Pin 4 and Pin 5 must under no circumstances be connected!

Resolver cable

SinCos cable

192-120102 N7 - February 2004 29

Page 32

Compax3 device description

3.3 Installation and dimensions Compax3

You can read about the following in this chapter:

Installation and dimensions Compax3 S0xx V2...............................................................................30

Installation and dimensions Compax3 S038 and S075 V4 ..............................................................31

Installation and dimensions Compax3 S150 V4 ..............................................................................32

Installation and dimensions Compax3 S300 V4 ..............................................................................33

3.3.1. Installation and dimensions of Compax3 S0xx V2

Mounting:

3 socket head screws M5

Mounting spacing:

Device separation 15 mm

30 192-120102 N7 - February 2004

Page 33

Parker EME

Compax3 device description

3.3.2. Installation and dimensions of Compax3 S038 and S075 V4

Mounting:

3 socket head screws M5

Mounting spacing:

Device separation 15 mm

40

7

9

6

7

2

8

4

2

9

5

2

65

Compax3 S038 V4:

8

0

100

Compax3 S075 V4:

115

2

7,5

192-120102 N7 - February 2004 31

Page 34

Compax3 device description

3.3.3. Installation and dimensions of Compax3 S150 V4

Mounting:

4 socket head screws M5

Mounting spacing:

Device separation 15 mm

7

8

4

9

5

2

2

80

158

39

9

6

7

2

2

32 192-120102 N7 - February 2004

Page 35

Parker EME

Compax3 device description

3.3.4. Installation and dimensions of Compax3 S300 V4

Mounting:

4 socket head screws M5

Mounting spacing:

Device separation 15 mm

1

9

3

0

8

3

80

175

0

2

0

1

4

4

6

Compax3 S300 V4 is force-ventilated via a fan integrated into the heat

dissipater!

192-120102 N7 - February 2004 33

Page 36

Compax3 device description

3.4 Safety function – safe standstill -

You can read about the following in this chapter:

Safety instructions concerning the function „Safe Standstill“ ........................................................... 36

Application examples „Safe Standstill“............................................................................................37

Compax3 is equipped with the "Safe Standstill" safety feature.

The “protection against unexpected start-up“ described in EN1037 can be

implemented with this feature.

Principle:

To ensure safe protection against a motor starting up unexpectedly, the flow of

current to the motor and thus to the power output stage must be prevented.

This is accomplished for Compax3 with two measures independent of each other

(Channel 1 and 2), without disconnecting the drive from the power supply:

Channel 1:

Activation of the power output stage can be disabled in the Compax3 controller by

means of a digital input or with a fieldbus interface (depending on the Compax3

device type) (deactivation of the energize input).

Channel 2:

The power supply for optocouplers and drivers of power output stage signals is

disconnected by a safety relay activated by the “ENABLE“ (X4/3) input and

equipped with force-directed contacts. This prevents control signals from being

transferred to the power output stage.

The „Safe Standstill“ safety function as defined by EN 954-1 Category 3

is only possible if both channels are used.

34 192-120102 N7 - February 2004

Page 37

Parker EME

Compax3 device description

Circuit diagram illustrating working principle:

Energise

controller

Notes

Controller

Feedback

Feedback

power

supply

safety relay

Enable Feedback

X4/3 X4/5X4/4

power

supply

L1 L2 L3

X1/1 X1/2 X1/3

motor

! In normal operation of Compax3, 24 V DC of power is supplied to the "Enable"

input (X4/3). The drive is then controlled by the inputs/outputs or the fieldbus.

! When used properly, the “Safe standstill“ safety function is only used when the

motor is at a standstill, since it is not capable of braking a motor or bringing it to a

standstill by itself.

Compax3-specific inputs and outputs

The "Energize" input and the "Controller Feedback" output depend on the

Compax3 device type:

! Compax3 I10 T10, I11 T11: a permanently assigned digital input and output (see

in the application examples).

! Compax3 T30, T40: "Energize" and "Controller Feedback" are applied to the I/Os

by way of the IEC program.

! Compax3 with Fieldbus: "Energize" and "Controller Feedback" are activated or

queried by the fieldbus (via control and status word).

192-120102 N7 - February 2004 35

Page 38

Compax3 device description

3.4.1. Safety instructions for the “safe standstill” function

! Safety functions must be tested 100%.

! Only qualified staff members are permitted to install the „Safe Standstill“ feature

and place it in service.

! For all applications in which the first channel of the „Safe Standstill“ is

implemented by means of a PLC, care must be taken that the part of the program

that is responsible for current flowing to or not flowing to the drive is programmed

with the greatest possible care. The „Safe Standstill“ application example of

Compax3 with fieldbus should be considered.

The designer and operator responsible for the system and machine must refer

programmers who are involved to these safety-related points.

! Terminal X4/2 (GND 24 V and at the same time the reference point for the safety

relay bobbin) must be connected with the PE protective lead. This is the only way

to ensure protection against incorrect operation through earth faults (EN60204-1

Section 9.4.3)!

! All conditions necessary for CE-conform operation (see on page 14 must be

observed.

! It should be noted in connection with the „Safe Standstill“ application example

illustrated here that after the Emergency Power-off switch has been activated, no

galvanic isolation in accordance with EN 60204-1 Section 5.5 is guaranteed. This

means that the entire system must be disconnected from the mains power supply

with an additional main switch or mains power contactor for an “Emergency

Power-off" (for example for repair jobs). Please note in this regard that even after

the power is disconnected, dangerous electrical voltages may still be present in

the Compax3 drive for about 5 minutes.

! When using an external Emergency Stop module with adjustable delay time, (as

illustrated in the „Safe Standstill“ application example), it must be ensured that

the delay time cannot be adjusted by persons not authorized to do so (for

example by applying a lead seal).

The adjustable delay time on the Emergency Power-off module must be set to a

value greater than the duration of the braking ramp controlled by the Compax3

with maximum load and maximum speed.

If the setting range for the specified Emergency power-off module is not sufficient,

the Emergency power-off module must be replaced by another comparable

module.

! All safety-related external leads (for example the control lead for the safety relay

and feedback contact) must absolutely be laid so they are protected, for example

in a cable duct. Short circuits and crossed wires must be reliably excluded!

! If there are external forces operating on the drive axes, additional measures are

required (for example additional brakes). Please note in particular the effects of

gravity on suspended loads!

! If the power fails, the possibility must be considered that for the application with

stop category K1, such as is described in the application example, it will no longer

be possible to execute the braking ramp controlled to speed 0.

! It is important to note that if the drive is being activated (Energize) by the RS232

(RS485) interface, it may not be possible to execute switch-off by a controlled

braking ramp. For example, this is true when the set-up window of the C3

ServoManager is used. If set-up mode is turned on, the digital I/O interface and

fieldbus interface are automatically disabled.

36 192-120102 N7 - February 2004

Page 39

Parker EME

3.4.2. Application examples for “safe standstill”

You can read about the following in this chapter:

Circuit example for Compax3 – devices without bus option.............................................................37

Circuit ecample for Compax3 devices with bus option ....................................................................43

Circuit example for C3 powerPLmC – multi-axis application ...........................................................46

The application examples described here correspond to Stop Category 1 as

defined by EN60204-1.

A Stop Category 0 in accordance with EN 60204-1 can be implemented, for

example by setting the delay time on the Emergency power-off switch to 0. The

Compax3 drive will then be turned off immediately in 2 channels and will not be

able to generate any more torque. Please take into consideration that the motor will

not brake and a coasting down of the motor may result in hazards. If this is the

case, then a „Safe Standstill“ is not permitted in Stop Category 0.

Compax3 device description

3.4.2.1 Sample circuit example of Compax3 devices without fieldbus

option

Sample circuit for the following Compax3 devices:

Compax3 I10 T10

! Input "Energize": I0: X12/6

! Output "Controller Feedback": O2: X12/4

The Stop Category 1 described here cannot be used in the „Torque

Controller“ operating mode.

At least Firmware Version V02.01.12 is required to be able to implement

the application described here for the Compax3 I10T10 device (the

Firmware Version of Compax3 can be seen with the C3 ServoManager

under "Online Device Identification").

192-120102 N7 - February 2004 37

Page 40

Compax3 device description

Compax3 I11 T11:

! Input "Energize": I2: X12/8

! Output "Controller Feedback": O2: X12/4

Compax3 Ixx T30 and Compax3 Ixx T40:

! Input "Energize": apply the Enable Input of the MC_Power - module (IEC-

program) to a Compax3 input.

! Output "Controller Feedback": apply the Status output of the MC_Power -

module (IEC-program) to a Compax3 output.

If the Compax3 „Safe Standstill“ feature is required or used for a

system or machine, the two error messages „Motor_Stalled“ and

„Tracking“ must not be turned off for a programmable Compax3 drive

(T30, T40) with the „C3_Errormask“ function module.

38 192-120102 N7 - February 2004

Page 41

Parker EME

Compax3 device description

Structure of Compax3 devices without fieldbus option:

! 2 Compax3 devices (the sample circuit also applies to one or more devices with

appropriate adjustments)

! 1 Emergency Power-off module (BH5928.47)

! 1 safety door monitor (BD5985N)

Note: With safety door monitor BD5985N, the safety door must be opened and

closed again every time after turning on the 24 V power supply so that the

Emergency power-off module can be acknowledged and reset. To avoid this,

safety door monitors with an additional simulation entry can also be used.

! 4 relays (K1, ... K4)

! 1 Emergency power-off switch

! Hazardous area accessible via a safety door with safety door switch S1 and S2

! 3 buttons (S3, ... S5)

192-120102 N7 - February 2004 39

Page 42

Compax3 device description

L3 L2 L1

K1

L1

L2

L3

L1

L2

L3

Gerät 1

controller

X1/1

X1/2

X1/3

Gerät 2

controller

X1/1

X1/2

X1/3

S

4

Feedback

power

supply

I10T10:E0: X12/6

I11T11:E2: X12/8

A2: X 12/4

Energise

Controller

Feedback

Kanal 1

Channel 1

K3

GND24V

safety

relay

Enable

Feedback

power

supply

power

supply

I10T10:E0: X12/6

I11T11:E2: X12/8

A2: X12/4

X4/3

X4/4

X4/5

Feedback

Energise

Controller

Feedback

+24V

S

5

K4

GND24V

safety

relay

Enable

X4/3

Kanal 2

power

supply

Channel 2

X4/4

Feedback

X4/5

K2

GND24V

K2 K3

S

3

Not-Aus-Modul

Emergency power-off modul

BH5928.47

K4

3

3

S

3

4

S

Y39 Y40

A1(+ )

57

58

+24V

13

14

S11

A2(-)

GND24V

S21

S22

S31

S32

Switches and buttons:

S1: Closed when the safety door is closed

S2: Closed when the safety door is closed

S3: Activate Emergency power-off module

S4: Guide Device 1 to a currentless state

S5: Guide Device 2 to a currentless state

4

4

Gefahrenbereich

Danger Zone

Not-Aus- Schalter

Emergency

power-off switch

motor

motor

K1

+24V

1323

1424

GND24VGND24V

Schutztür offen

Safety door open

S1

S2

S13

S23

2-kanaliger

Schutztürwächter

2-channel safety

door control

BD5985N

+24V

GND24V

K2

S14S24

A2(-)Y1 Y2

A1(+ )

+24V

40 192-120102 N7 - February 2004

Page 43

Parker EME

Compax3 device description

Basic functions:

Compax3 devices disabled by:

Channel 1: Energize – input to “0” through open contacts of Emergency Power-off

Module (13-14)

Channel 2: Enable input to "0" through open contacts of Emergency power-off

module (57 -58)

Activate Emergency power-off module

Before the Compax3 can be placed in operation, the Emergency power-off module

must be activated by a pulse to Input S33/S34.

Prerequisite:

! S3 closed

! Safety door closed: This is required before the safety door monitor enables the

Emergency power-off module via Input S11 (by closing the contacts between 23

and 24).

! Current to K2, K3 and K4

! K2: receives current if all Compax3's are currentless (contact closed in

currentless state) = Channel 2 feedback

! K3: receives current if Compax3 Device 1 is currentless (output = „1“ in

currentless state) = Channel 1 feedback

! K4: receives current if Compax3 Device 2 is currentless (output = „1“ in

currentless state) = Channel 1 feedback

If S33 and S34 of the Emergency power-off module are briefly connected (pulse)

the contacts will be closed (between 13 and 14 and between 57 and 58)

Supplying current to Compax3

! Compax3 devices are enabled by the Energize input and the Enable input via the

Emergency power-off module. (If a fault is still pending on Compax3, it must

previously be reset. The acknowledge/reset function depends on the type of the

Compax3 device).

! Power is supplied to K1 and the mains power voltage is switched on by a K2

contact or by the closed safety door.

! The motors are energized with current.

Summary: Compax3 is not energized with current unless the feedback functions

via K2, K3 and K4 are capable of functioning.

Case 1: Normal access to the hazardous area

Activate Emergency power-off switch

Disconnecting the connection between S11 and S31 /S32 (2 channels) deactivates

the Emergency power-off module and causes Contacts 13 - 14 to open

immediately.

Channel 1: Compax3 devices receive the command via the Energize input to guide

the drive to a currentless state (using the ramp configured in the C3 ServoManager

for "drive disable").

Channel 1 feedback: The "Controller Feedback" Compax3 outputs supply current

to Relays K3 and K4.

Channel 2: After the delay time set in the Emergency power-off module, (this time

must be set so that all drives are stopped after it has elapsed) the contacts

192-120102 N7 - February 2004 41

Page 44

Compax3 device description

between 57 and 58 open, which in turn deactivates the Enable inputs of the

Compax3 devices.

Channel 2 feedback: Power is only supplied to the K2 relay via the series circuit of

the Feedback contacts if all Compax3's are currentless: “Safe standstill” state

reached.

Now the safety door can be opened and access to the hazardous area is possible.

After the safety door is opened, the safety door monitor opens its contacts.

Mains power continues to be supplied to Compax3 devices if the K2 relay is

receiving current (so that current is supplied to K1) and the "Safe Standsill" is thus

acknowledged.

Case 2: Opening the safety door directly

After the safety door is opened, the safety door monitor opens its contacts.

The supply of mains power is disconnected by the safety door monitor.

After the storage capacity of the power DC bus is used up, the motors gradually

come to a standstill.

Caution! The mains power voltage is turned on again by the feedback from

Channel 2, since the feedback contacts are closed in the basic state. A "Safe

Standstill" is nevertheless still ensured after the motors have come to a standstill.

Function of the K1 relay

The effect of the K1 relay in the event of a fault is as follows: If the Feedback

contact (Channel 2 feedback) cannot be closed because of a defective Compax3

device, the supply of mains power is interrupted when the safety door is open

(safety door monitor contacts open; no feedback via Channel 2).

42 192-120102 N7 - February 2004

Page 45

Parker EME

Compax3 device description

3.4.2.2 Sample circuit example of Compax3 devices with fieldbus

option

Sample circuit for the following Compax3 devices:

Compax3 I20 T11

Compax3 I20 T11

Layout:

! 2 Compax3 devices

! 1 Emergency Power-off module (BH5928.47)

! 1 safety door monitor (BD5985N)

Note: With safety door monitor BD5985N, the safety door must be opened and

closed again every time after turning on the 24 V power supply so that the

Emergency power-off module can be acknowledged and reset. To avoid this,

safety door monitors with an additional simulation entry can also be used.

! 3 relays (K1, ... K3

! 1 Emergency power-off switch

! Hazardous area accessible via a safety door with safety door switch S1 and S2

! 1 button (S3)

192-120102 N7 - February 2004 43

Page 46

Compax3 device description

L3 L2 L1

K1

L1

L2

L3

Gerät 1

controller

X1/1

X1/2

X1/3

Gerät 2

controller

Feedback

power

supply

Feedback

power

supply

Feldbus

Schnittstelle

Fieldbus

Interface

safety

relay

Feldbus

Schnittstelle

Fieldbus

Interface

power

supply

Energise

Controller

Feedback

Enable

X4/3

X4/4

Feedback

X4/5

Energise

Controller

Feedback

Kanal 1

Channel 1

c

h

S

n

i

s

t

t

u

s

b

t

e

d

l

l

l

e

e

F

F

e

i

e

c

l

a

d

f

b

r

e

u

t

s

n

I

Kanal 2

Channel 2

4

s

u

b

d

l

e

F

s

u

b

d

l

e

i

F

e

l

l

e

t

s

t

t

i

n

h

c

S

e

c

a

f

r

e

t

n

I

motor

K2

GND24V

K3

GND24V

SPS

PLC

safety

relay

Enable

X4/3

power

supply

X4/4

Feedback

X4/5

X1/1

L1

X1/2

L2

X1/3

L3

K2 K3

S

3

Not-Aus-Modul

Emergency power-off modul

BH5928.47

S

S

+24V

3

3

4

3

57

58

+24V

Y39 Y40

A1(+ )

13

14

S11

A2(-)

GND24V

S21

S22

S31

S32

4

Not-Aus- Schalter

Emergency

power-off switch

motor

Gefahrenbereich

Danger Zone

K1

+24V

1323

1424

GND24VGND24V

Schutztür offen

Safety door open

S1

S2

S13

S23

2-kanaliger

Schutztürwächter

2-channel safety

door control

BD5985N

A2(-)Y1 Y2

GND24V

S14S24

A1(+ )

+24V

Switches and buttons:

S1: Closed when the safety door is closed

S2: Closed when the safety door is closed

S3: Activate Emergency power-off module

44 192-120102 N7 - February 2004

Page 47

Parker EME

Compax3 device description

Basic functions:

Compax3 devices disabled by:

Channel 1: Energize deactivated by PLC due to open contacts of the Emergency

power-off module (13 -14)

Channel 2: Enable input to "0" through open contacts of Emergency power-off

module (57 -58)

Activate Emergency power-off module

Before the Compax3 can be placed in operation, the Emergency Power-off module

must be activated by a pulse to Input S33/S34.

Prerequisite:

! S3 closed

! Safety door closed: This is required before the safety door monitor enables the

Emergency power-off module via Input S11 (by closing the contacts between 23

and 24).

! K2 and K3 via PLC program:

! K2: receives current if Compax3 Device 1 and 2 are currentless (evaluation of

Compax3 status word) = Channel 1 feedback

! K3: receives current if Compax3 Device 1 and 2 are currentless (evaluation of

Channel 2 feedback) = Channel 2 feedback

If S33 and S34 of the Emergency power-off module are briefly connected (pulse)

the contacts will be closed (between 13 and 14 and between 57 and 58).

Supplying current to Compax3

! The PLC enables the Compax3 devices by means of the control word and the

Emergency power-off module enables the Compax3 devices by means of the

Enable input. (if a fault is still pending on Compax3, it must be previously

acknowledged/reset)

! Power is supplied to K1 and the mains power voltage is switched on by the

feedback output (Channel 2) or by the closed safety door.

! The motors are energized with current.

Summary: Compax3 is not energized with current unless the feedback functions

via K2 and K3 are capable of functioning.

Case 1: Normal access to the hazardous area

Activate Emergency power-off switch

Disconnecting the connection between S11 and S31 /S32 (2 channels) deactivates

the Emergency power-off module and causes Contacts 13 - 14 to open

immediately.

The PLC evaluates this and responds as follows:

Channel 1: Compax3 devices receive the command via the control word

1

to guide

the drive to a currentless state (using the ramp configured in the C3 ServoManager

for "drive disable").

Channel 1 feedback: The Compax3 feedback via the status word

2

is evaluated by

the PLC.

1

Example for the assignment of the control word (CW) to guide the drive to a stop and switch: Profibus: CW.2 = “0” (OFF3) standstill via

ramp (FSTOP3) and then currentless-switch. CANopen: CW.3 = “0” standstill via STOP ramp, then with CW.0 currentless-switch.

2

Example for the assignment of the status word (SW) to guide the drive to a standstill and switch: Profibus: SW.6 = “1” switch-on

disable (motor currentless). CANopen: SW.1 = “02” Ready to Switch on (motor currentless).

192-120102 N7 - February 2004 45

Page 48

Compax3 device description

Channel 2: After the delay time set in the Emergency power-off module, (this time

must be set so that all drives are stopped after it has elapsed) the contacts

between 57 and 58 open, which in turn deactivates the Enable inputs of the

Compax3 devices.

Channel 2 feedback: „Safe Standstill“ is reported back as feedback through the

series circuit of the Feedback contacts if all Compax3's are currentless. The PLC

evaluates this and activates the K2 and K3 relays if the feedback was from

Channel 1 and 2.

Now the safety door can be opened and access to the hazardous area is possible.

After the safety door is opened, the safety door monitor opens its contacts.

Compax3 devices continue to receive mains power via the feedback from Channel

2.

Case 2: Opening the safety door directly

After the safety door is opened, the safety door monitor opens its contacts.

The supply of mains power is disconnected by the safety door monitor.

After the storage capacity of the power DC bus is used up, the motors gradually

come to a standstill.

Caution! The mains power voltage is turned on again by the feedback from

Channel 2, since the feedback contacts are closed in the basic state. A "Safe

Standstill" is nevertheless still ensured after the motors have come to a standstill.

Function of the K1 relay

The effect of the K1 relay in the event of a fault is as follows: If the Feedback

contact (Channel 2 feedback) cannot be closed because of a defective Compax3

device, the supply of mains power is interrupted when the safety door is open

(safety door monitor contacts open; no feedback via Channel 2).

3.4.2.3 Sample circuit for C3 powerPLmC multi-axis application

If the Compax3 “Safe Standstill” feature is required or used for a

system or machine, the two error messages “Motor_Stalled” and

“Tracking” must not be turned off with the “C3_Errormask” function

module.

46 192-120102 N7 - February 2004

Page 49

Parker EME

Compax3 device description

Layout:

! 1 Compax3 with powerPLmC

! n Compax3 devices

! 1 Emergency Power-off module (BH5928.47)

! 1 safety door monitor (BD5985N)

Note: With safety door monitor BD5985N, the safety door must be opened and

closed again every time after turning on the 24 V power supply so that the

Emergency power-off module can be acknowledged and reset. To avoid this,

safety door monitors with an additional simulation entry can also be used.

! 3 relays (K1, ... K3)

! 1 Emergency power-off switch

! Hazardous area accessible via a safety door with safety door switch S1 and S2

! 1 button S3