Page 1

6000 Series

Programmer’s Guide

Compumotor Division

Compumotor

Parker Hannifin Corporation

p/n 88-014540-01

Page 2

User Information

!

WARNING

!

Because software controls machinery, test any software control for safety

under all potential operating conditions. Failure to do so can result in

damage to equipment and/or serious injury to personnel.

6000 Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and

may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

© 1991-97, Parker Hannifin Corporation

All Rights Reserved

Motion Architect is a registered trademark, and Motion Builder, Servo Tuner, Motion OCX Toolkit, CompuCAM and DDE6000 are trademarks

of Parker Hannifin Corporation.

Microsoft and MS-DOS are registered trademarks, and Windows, DDE, Visual Basic, and Visual C++ are trademarks of Microsoft Corporation.

Wonderware is a registered trademark, and InTouch and NetDDE are trademarks of Wonderware Corporation.

Motion Toolbox is a trademark of Snider Consultants, Inc.

LabVIEW is a registered trademark of National Instruments Corporation.

Technical Assistance

North America and Asia:

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

BBS: (707) 584-4059

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

Motion & Control

Contact your local automation technology center (ATC) or distributor, or ...

Europe

Parker Digiplan

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

(non-German speaking)

:

Germany, Austria, Switzerland:

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

Product Feedback Welcome

E-mail: 6000user@cmotor.com

Page 3

Change Summary

6000 Series Programmer’s Guide

Re v D

Rev D – summary of changes (minor)

• Removed references to the Motion Architect User Guide. Motion Architect no longer

ships with the printed manual. An on-line Adobe Acrobat PDF version is available from our web

site (http://www.compumotor.com).

• Clarified Command Value Substitution guidelines with a “rule of thumb” (see page 6).

• Error programming correction:

the error program (see page 31).

• DLL documentation clarification and correction (see pages 51-62):

- WN956000.DLL is a

- The DLL functions SetNTParam, SetNTMultiCardAddress, and SetDevice return FALSE (“0”) if

the function is successful and TRUE (non-zero value) if the function is unsuccessful.

• Sending ERRLVL1 to the first unit in an RS-232 daisy-chain does not set all other units to

ERRLVL1. You must send ERRLVL1 to each unit individually. (see page 72)

• GOWHEN correction: A preset GO command that is already in motion

new profile using the GOWHEN and GO sequence of commands. (this is true as of rev 4.1 firmware)

DO NOT use the ERRORP CLR command to cancel the branch to

32-bit DLL to be used for Windows 95.

can (not “cannot”) start a

Rev C – summary of changes (MAJOR)

• Updated to accommodate 4.x firmware enhancements (see topics below) and the ZETA6104.

• The presentation of programming examples was modified so that you can copy them from the

Help system (in Motion Architect) or from the PDF file (on our www.compumotor.com web

site) and paste them directly into your program.

• Added documentation to support

• Incorporated the Following User Guide (see Chapter 6).

• New sections:

- Programming Scenario....................................................... Page 8

- Controlling Multiple Serial Ports ......................................... Page 70

- RS-485 Multi-drop............................................................ Page 75

- Setup Parameters

- ZETA610n Internal Drive Setup ............................................ Page 82

- Servo Setup..................................................................... Page 98

- RP240 Remote Operator Panel ............................................. Page 130

- Host Computer Interface..................................................... Page 143

- Graphical User Interface (GUI) Development Tools.................... Page 144

- Compiled Motion Profiling................................................. Page 163

- On-the-Fly Motion ........................................................... Page 178

- Registration.................................................................... Page 182

- Synchronizing Motion ...................................................... Page 186

- Chapter 6: Following

- Status Commands ............................................................. Page 232

• New back cover with quick-reference material.

(list of commands for common setup parameters)........ Page 78

(incorporated the Following User Guide ).......... Page 191

all 6000 products.

READ ON ...

for a summary of the enhancements implemented in firmware revision 4.x.

mmm

Page 4

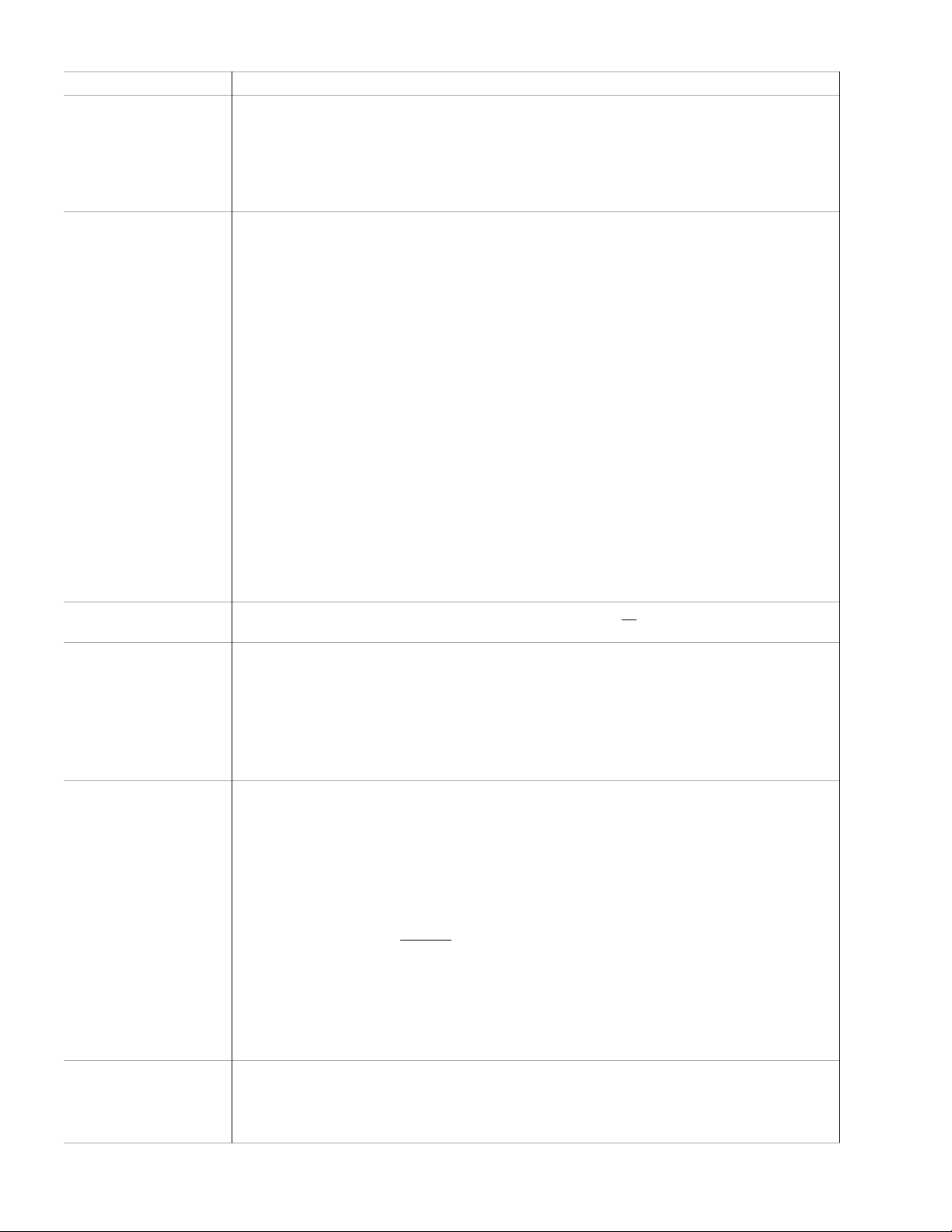

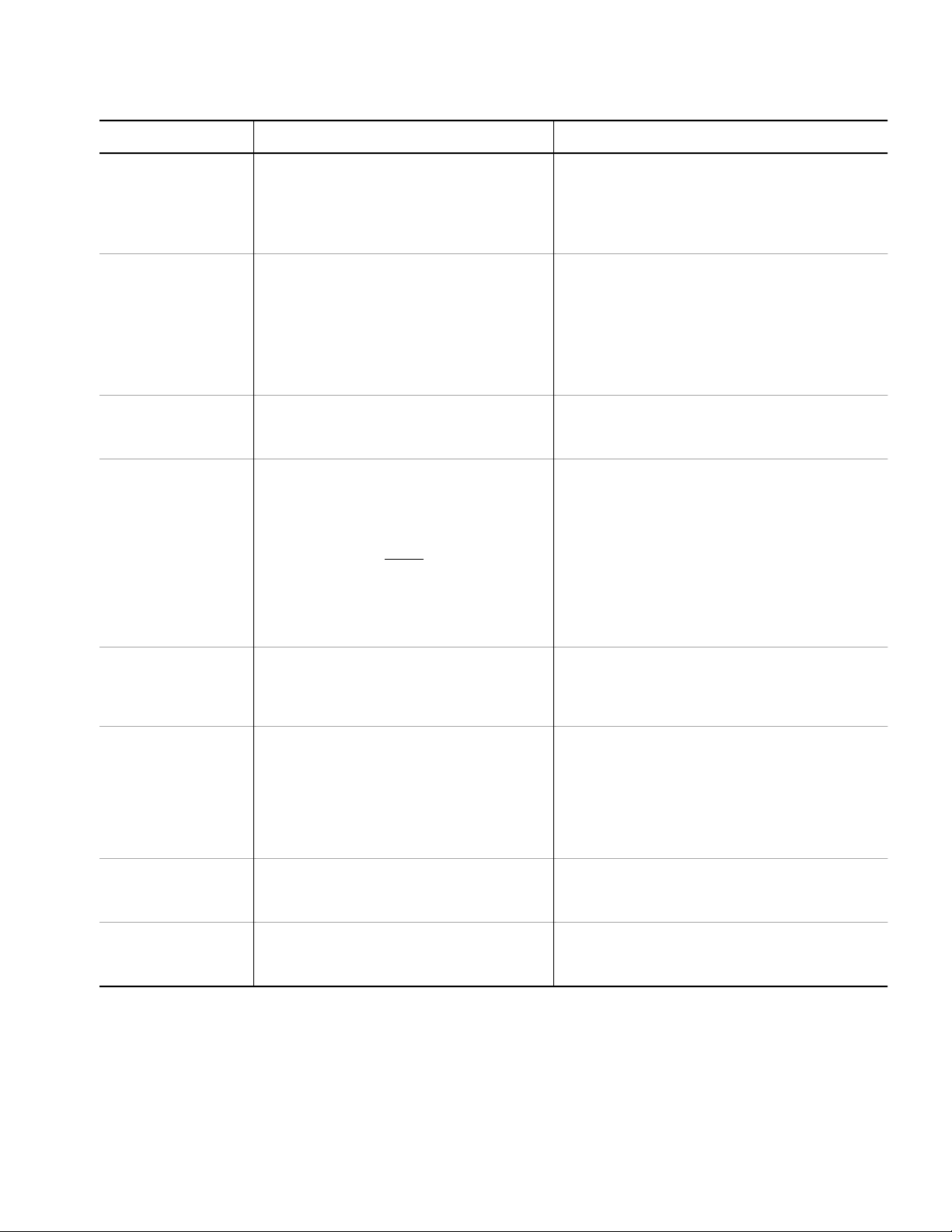

Topic Description

Commanded Direction

Reversal (CMDDIR)

Enhancement: The commanded direction polarity reversal command (CMDDIR) is available for the

615n series, the 6270, and all stepper products (610n, AT6n00, 620n). The CMDDIR command

allows you to reverse the direction that the controller considers to be the “positive” direction; this

also reverses the polarity of the counts from the feedback devices. Thus, using the CMDDIR command,

you can reverse the referenced direction of motion without the need to (a) change the connections to

the drive or motor and the feedback device, or (b) change the sign of motion-related commands in

your program.

(SEE_PG._97_OR_101)

Compiled Motion New Feature: (SEE_PG._163)

Related commands (new):

FOLRNF .... Numerator of Final Slave-to-Master Ratio, Preset Moves

GOBUF...... Store a Motion Segment in Compiled Memory

PLN ......... Loop End, compiled motion

PLOOP...... Loop Start, compiled motion

POUTA...... Output on Axis 1, compiled motion

POUTB...... Output on Axis 2, compiled motion

POUTC...... Output on Axis 3, compiled motion

POUTD...... Output on Axis 4, compiled motion

[

SEG ]..... Number of Segments Available In Compiled Memory

TSEG........ Transfer Number of Segments Available, Compiled Memory

VF ........... Final Velocity

Existing commands, modified to support compiled motion:

GOWHEN .... Conditional GOs allowed in compiled motion

PCOMP...... Pre-Compile a Program

PRUN........ Run a Pre-Compiled Program

PUCOMP .... Un-Compile a Program

[

SS ] ...... Bit #29 set if compiled memory 75% full, bit #30 set if 100% full

.............. Bit #31 is set if a compile (PCOMP) failed; cleared on power-up,

.............. reset, or after a successful compile. (See Status Reporting,

.............. Additions below for a list of typical causes.)

TRGFN...... Execute GOWHENs or start new master cycle in compiled motion

TSS ......... (see [ SS ] description above)

Contouring (Circular

Interpolation)

Continuous Command

Execution Mode

(COMEXC1)

Enhancement: As of Rev 4.1, contouring is now available for all multi-axis products, steppers

and servos.

(SEE_PG._153)

Enhancement: On-The-Fly changes (pre-emptive motion). In addition to velocity (V),

acceleration (A & AA), and deceleration (AD & ADA), you may now change the positioning mode (MC &

MA), the distance (D), and the Following ratios (FOLRN & FOLRD). These changes will affect the

subsequent GO command executed while moving; thus, this new enhancement is referred to as “preemptive GOs.” (SEE_PG._178)

When pre-processing subsequent moves, the subsequent move may now be executed as soon as the

next GO command is executed. Previous to revision 4.0, the subsequent move could not be executed

until all moves on all axes were completed.

Drive Configuration

& Reset

Enhancements:

New commands added to set up the drive component of the 610n: (SEE_PG._82)

DACTDP .... Enable/disable active damping for speeds greater than 3 rps.

.............. (config. procedure: see the ZETA6104 Installation Guide)

DAREN...... Enable/disable anti-resonance. Anti-resonance is inhibited at or

.............. below 3 rps, and if active damping is enabled.

DELVIS .... Enable/disable electronic viscosity for speeds at or below 3 rps.

.............. (config. procedure: see the ZETA6104 Installation Guide)

DAUTOS .... Enable/disable automatic current standby mode in which current

.............. to the motor (

& torque) is reduced by 50% if no pulses are sent

.............. for 1 second. Full current is restored upon the next pulse.

DMTIND .... Motor inductance (used only for active damping—DACTDP).

DMTSTT .... Motor static torque (used only for active damping—DACTDP).

DWAVEF .... Motor waveform (required for matching the motor to the drive).

615n only: As of Rev 4.1, you may use the new DRESET command to reset the internal drive

independent of the internal controller. The purpose of the DRESET command is to clear fault

conditions with the internal drive.

Encoder Polarity Reversal

(ENCPOL)

Enhancement: The encoder polarity reversal command (ENCPOL) is now available to all 6000

stepper products (AT6n00, 620n, & 610n). Previous to 4.0 the ENCPOL command was only

applicable to the 6270. The ENCPOL command is used to reverse the polarity (counting direction) of

the encoder feedback counts. This is an alternative to reversing the A+ and A- connections to the

encoder. (SEE_PG._97_OR_100)

Change Summary, page 2

Page 5

Topic Description

Error Checking

Conditions

Enhancements: (SEE_PG._31)

• 610n: The drive fault error (reported with error status bit #4 and axis status bit #14) can be caused

by any one or combination of the factors list below. To ascertain the exact cause, use the extended

axis status (TASX or ASX):

- Motor fault (disconnected/faulty motor cable or short in motor) — bit #1

- Low-voltage (power) — bit #2

- Maximum drive temperature (131°F, 55°C) exceeded — bit #3

• Error status enhancements

- Error bit #8 is set if a stop input (assigned with INFNCi-D) is activated.

- Error bit #10 is set if the target position specified for a pre-emptive GO or a registration move is

not achievable at the time the pre-emptive GO command is executed or the registration input is

activated. This condition also sets bit #30 in the axis status register (reported with TAS & AS).

To clear error bit #10 and axis bit #30, execute another GO command.

- Error bit #16 is set if a bad command was detected; clear with TCMDER.

• Related commands:

[

ER ]...... Error Status (assignment or comparison)

ERROR ..... Error-Checking Enable

ERRORP.... Error Program Assignment

TER......... Transfer Error Status

Fast Status

(bus-based products)

Correction: The bit assignments for the Limits status in block 5 are

TLIM report. (SEE_PG._43)

Clarification: The input buffer is 256 bytes.

Following

Enhancements:

• The new Following Kill (FOLK) command allows you to limit what will kill the Following profile.

That is, it allows the slave to remain in synchronization with the master even after the occurrence

of a drive fault, user fault input, excess position error, or enable input.

• The new Numerator of Final Slave-to-Master Ratio, Preset Moves (FOLRNF) command designates

that the motor will move the load the distance assigned in the preset GOBUF segment, completing

the move at a final ratio of zero. FOLRNF applies only to the first subsequent GOBUF, which marks

an inter-mediate “end of move” within a Following profile. The FOLRNF command is only useful

for

compiled Following moves. (SEE_PG._166)

• The Following User Guide has been incorporated into this document (SEE_PG._192).

Homing

Clarification: Avoid using pause and resume functions during the homing operation. A pause

command (PS or !PS) or pause input (input configured with the INFNCi-E command) will pause the

homing motion. However, when the subsequent resume command (C or !C) or resume input

(INFNCi-E input) occurs, motion will resume at the

Memory Management

Enhancements:

• Compiled Memory status commands:

- System status (TSS & SS) bit #29 is set if compiled memory is 75% full,

bit #30 is set if compiled memory is 100% full

- TSEG & SEG report the number of available segments in compiled memory

• All stand-alone products are shipped with 150,000 bytes of memory. The -M option has thus been

eliminated for these products.

• The second field in the MEMORY command is re-defined to be for “compiled memory” (i.e., anything

compiled with the PCOMP command). (SEE_PG._12)

• These commands are automatically saved in non-volatile memory: (SEE_PG._33)

CMDDIR.... Commanded Direction Polarity (6104, 615n, 620n, 6270 only)

DMTIND.... Motor Inductance (6104 only)

DMTSTT.... Motor Static Torque (6104 only)

DRPCHK.... RP240 check (6104, 615n, 620n, & 625n only)

ENCPOL.... Encoder Polarity (6104, 620n, & 6270 only)

On-The-Fly Motion

(AKA: Pre-Emptive GOs)

Enhancements: (SEE_PG._178)

• The two basic ways of creating a complex profile are with compiled buffered motion, or with preemptive GOs. With compiled buffered motion, portions of a profile are built piece by piece, and

stored for later execution. Compiled buffered motion is appropriate for motion profiles with

motion segments of pre-determined velocity, acceleration and distance. With pre-emptive GOs, the

motion profile underway is pre-empted with a new profile when a new GO is issued. The new GO

both constructs and launches the pre-empting profile. Pre-emptive GOs are appropriate when the

desired motion parameters are not known until motion is already underway.

not the same as those for the

Servo products only.

beginning of the homing motion sequence.

Continued on next page

Change Summary, page 3

Page 6

Topic Description

On-The-Fly Motion

(continued)

• Affected Commands:

COMEXC .... COMEXC1 mode allows pre-emptive motion with buffered commands

GO ........... Allows pre-emptive D, MC, MA, FOLRN, & FOLRD changes

TAS & AS .. Bit #30 is set if the load has already passed the target position

.............. (D) specified in a pre-emptive GO. (also sets error status bit #10)

TER & ER .. Error status bit #10 is set if axis status bit #30 is set.

Registration

Enhancements: (SEE_PG._182)

• New Commands:

REGLOD .... Registration Lock-Out Distance. Establishes a lock-out distance (measured from

.............. the start of motion to the current actual position) to be traveled before a

.............. registration move is allowed.

REGSS...... Registration Single-Shot. Allows only one registration move on the specified axis.

.............. Prevents other triggers from interrupting the registration move in progress.

• Axis status bit #28, reported by the TAS and AS commands, is set to 1 when a registration move

has been initiated by any registration input (trigger). Bit #28 is cleared (set to Ø) upon the next GO

command for that axis.

• If, when the registration input is activated, the registration move profile cannot be performed with

the specified parameters, the 6000 controller will kill the move in progress and set axis status bit

#30 (see TAS & AS). If error-checking bit #10 is enabled with the ERROR command, the controller

will also set error status bit #10 (see TER & ER) and branch to the assigned ERRORP error-handling

program. Axis status bit #30 and error status bit #10 are cleared (set to Ø) upon the next GO

command for that axis.

• As of revision 4.1, Registration is now available

all 6000 products (previous to 4.1, Registration

was available only for stepper products).

Serial Communication

Enhancements: (SEE_PG._70)

• BOT command was created to control the beginning-of-transmission characters for all

responses from the 6000 product.

• XONOFF command (new) enables/disables XON/XOFF ASCII handshaking.

• Additional features to control multiple serial ports on stand-alone products:

[............. Send response from the subsequent command to both ports.

]............. Send response from the subsequent command to the alternate

.............. port from the one selected with the most recent PORT command.

DRPCHK .... Configures the serial port (specified with the last PORT command)

.............. to be used with an RP240, or 6000 commands, or both.

PORT........ Determines which serial port is affected by the subsequent DRPCHK, E, ECHO,

.............. BOT, EOT, EOL, ERRORK, ERRBAD, ERRDEF, ERRLVL, and XONOFF commands.

• As of 4.0, the ECHO command was enhanced with options 2 and 3. The purpose is to

accommodate an RS-485 multi-drop configuration in which a host computer communicates

to the “master” 6000 controller over RS-232 (COM1 port) and the master 6000 controller

communicates over RS-485 (COM2 port) to the rest of the units on the multi-drop. For this

configuration, the echo setup should be configured by sending to the master the following

commands executed in the order shown. In this example, it is assumed that the master's

device address is set to 1. Hence, each command is prefixed with “1_” to address only the

master unit.

1_PORT2... Subsequent command affects COM2, the RS-485 port

1_ECHO2... Echo characters back through the other port, COM1

1_PORT1... Subsequent command affects COM1, the RS-232 port

1_ECHO3... Echo characters back through both ports, COM1 and COM2

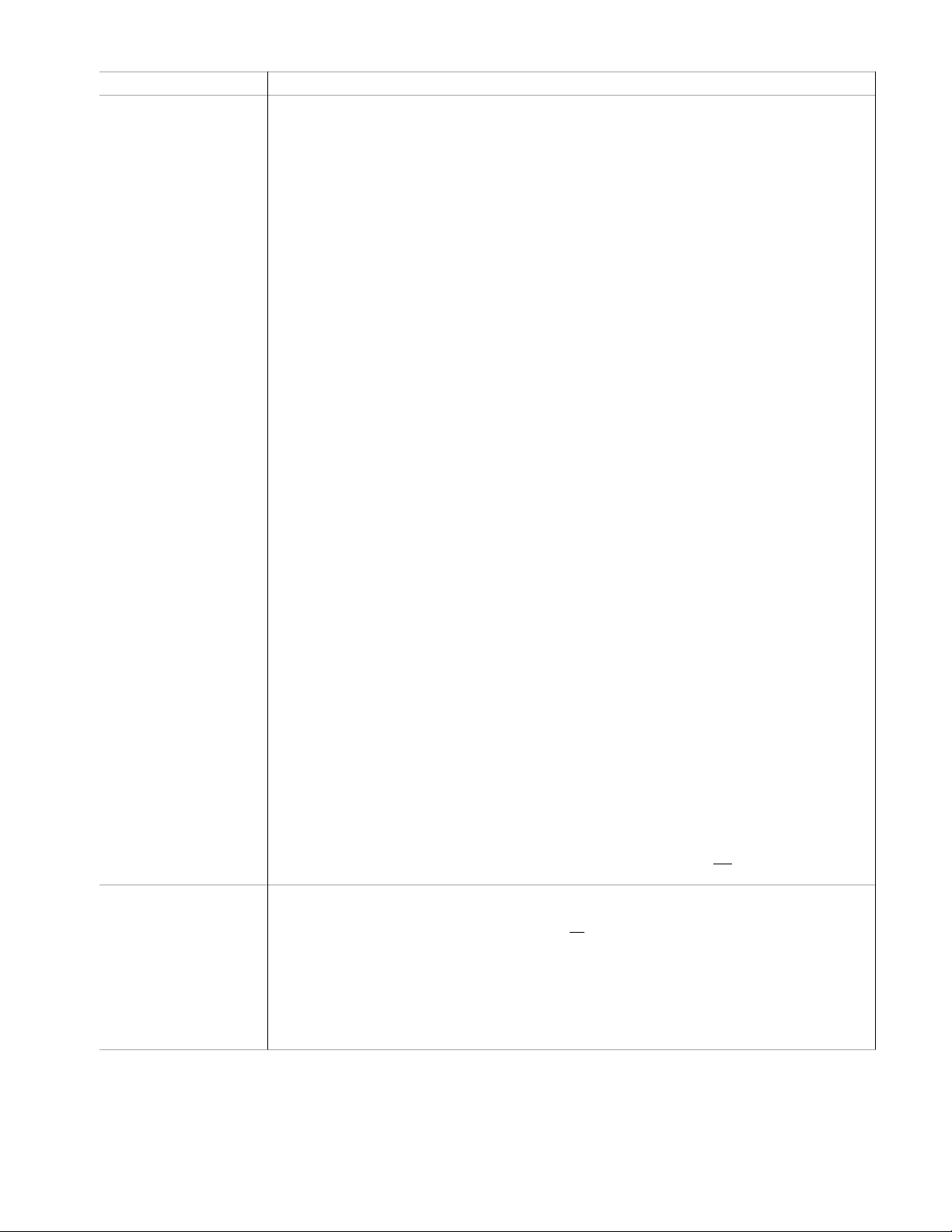

Servo Updates Changed (see

(Servo Products Only) Servo Sampling Update Motion Trajectory Update System Update

SSFR

command description for full explanation of table contents)

# of Axes

(INDAX)

Default, Single-Axis 1 4 6250 160 1563 640 520 1920

Default, Two-Axis 2 4 3571 280 893 1120 446 2400

Default, Four-Axis 4 4 2000 500 500 2000 500 2000

SSFR

Frequency

Setting

1 1 3030 330 3030 330 757 1320

1 2 5405 185 2703 370 675 1480

1 8 6667 150 833 1200 417 2400

2 1 2353 425 2352 425 588 1700

2 2 3571 280 1786 560 446 2400

2 8 3571 280 446 2240 446 2400

3 1 1667 600 1667 600 555 1800

3 2 2222 450 1111 900 555 1800

3 4 2353 425 588 1700 588 1700

4 1 1250 800 1250 800 417 2400

4 2 1667 600 833 1200 417 2400

(samples/sec.)

Period

(µsec)

Frequency

(samples/sec.)

Period

(µsec)

Frequency

(samples/sec.)

Period

(µsec)

Change Summary, page 4

Page 7

Topic Description

Status Reporting

Target Zone

Enhancements: (SEE_PG._232)

• New transfer (display status) commands:

TASX ....... Transfer extended axis status. Bit assignments are as follows:

.............. Bit #1: Motor fault (6104 only)

.............. Bit #2: Drive low voltage fault (6104 only)

.............. Bit #3: Drive over-temperature fault (6104 only)

.............. Bit #4: Drive fault input is active

TSEG ....... Transfer number of segments available in compiled memory

• New assignment/comparison operators:

SEG .......... Number of segments available in compiled memory

ASX .......... Extended axis status information

• Pre-emptive Motion and Registration status:

TAS & AS ... Axis status bit #28 is set if a registration move occurs.

................ Bit #30 is set if the profile specified for a pre-emptive GO or registration move

................ is not possible at the time of the GO or the registration input

................ (also sets error status bit #10).

TER & ER .... Error status bit #8 is set if a stop input (INFNCi-D) is activated.

................ Bit #10 is set if axis status bit #30 is set.

................ Bit #16 is set if a bad command is detected; cleared with TCMDER.

• Compiled profile status:

TSS & SS .... System status bit #29 is set if compiled memory is 75% full.

................ Bit #30 is set if compiled memory is 100% full.

................ Bit #31 is set if a compile (PCOMP) failed, cleared on power-up,

................ reset, or after a successful compile. Possible causes include:

................ - Errors in profile design (e.g., change direction while at non-

................ zero velocity, distance & velocity equate to < 1 count/system

................ update, preset move profile ends in non-zero velocity)

................ - Profile will cause a Following error (see TFS & FS status)

................ - Out of memory (see system status bit #30)

................ - Axis already in motion at the time of the PCOMP command

................ - Loop programming errors (e.g., no matching PLOOP or PLN,

................ more than 4 embedded PLOOP/END loops)

TSEG & SEG Report number of available segments in compiled memory.

• Drive Fault Input Status: As of revision 4.1, extended axis status ( TASX & ASX) bit #4 is now

available to check the drive fault input status whether or not the drive is enabled (DRIVE1) or

disabled (DRIVEØ). Previous to revision 4.1, the status of the drive fault input could only be

checked while the drive was enabled (DRIVE1) and was reported only with axis status (TAS & AS) bit

#14 and error status (TER & ER) bit #4. The branch to the error program has not been changed—the

error program is called only if the drive fault occurs while the drive is enabled.

• The INDUST command (which allows you to create your own custom status word based on other

status registers) now allows you to use the status bits from the extended axis status (see TASX

description above). In the syntax INDUSTi-ic, the options for “c” (the status register source) now

include L, M, N and O, representing the extended axis status registers for axes 1, 2, 3 and 4,

respectively. For additional details on creating a custom user status word, refer to the INDUST

command description.

• As of Rev 4.1, the TVELA command is now applicable to all stepper controllers using encoder

feedback (previously only for servos). For steppers, the TVELA command reports the current

velocity (in revs/sec) as derived from the encoder. The reported value is

The VELA assignment/comparison operator for TVELA is now available as of rev 4.0.

• The Target Zone mode allows you to define what the controller considers a “completed move,”

based on specified end-of-move distance, velocity, and settling time parameters. As of revision

4.0, the Target Zone mode is now applicable to

mode was available only for servo products). NOTE: Steppers require encoder feedback (and ENC1

mode) for this feature. (SEE_PG._105)

• Target Zone Commands:

STRGTE.... Target Zone Mode Enable/Disable

STRGTD.... Target Distance Zone

STRGTT.... Target Settling Timeout Period

STRGTV.... Target Velocity Zone

not affected by scaling.

all 6000 products (previous to 4.0, the Target Zone

Change Summary, page 5

Page 8

New Commands in Revision 4.x

(including product compatibility)

Command Name

[ Send Response to All Ports X X X X X

] Send Response to Alternate Port X X X X X

ASX Extended Axis Status X X X X X X X X X

BOT Beginning of Transmission Characters X X X X X X X X X

DACTDP Active Damping X

DAREN Anti-Resonance X

DAUTOS Auto Current Standby X

DELVIS Electronic Viscosity X

DMTIND Motor Inductance X

DMTSTT Motor Static Torque X

DRESET Drive Reset X

DRPCHK Remote Port Check X X X X X

DWAVEF Waveform X

FOLK Following Kill X X X X X

FOLRNF Numerator of Final Slave-to-Master Ratio X X X X X X X X X

FOLSND Following Step & Direction S S X X X X X X X

GOBUF Store a Motion Segment in a Buffer X X X X X X X X X

PCOMP * Compile a Program X X X X X X X X X

PLN Loop End, Compiled Motion X X X X X X X X X

PLOOP Loop Start, Compiled Motion X X X X X X X X X

PORT Designate Communications Port X X X X X

POUTA Output on Axis 1, Compiled Motion X X X X X X X X X

POUTB Output on Axis 2, Compiled Motion X X X X X X X

POUTC Output on Axis 3, Compiled Motion X X

POUTD Output on Axis 4, Compiled Motion X X

PRUN * Run a Compiled Program X X X X X X X X X

PUCOMP * Un-Compile a Program X X X X X X X X X

REGLOD Registration Lock-Out Distance X X X X X X X X X

REGSS Registration Single Shot X X X X X X X X X

[ SEG ] Number of Free Segment Buffers X X X X X X X X X

TASX Transfer Extended Axis Status X X X X X X X X X

TSEG Transfer Number of Free Segment Buffers X X X X X X X X X

[ VELA ] Velocity (Actual) Assignment S S X X X X X X X

VF Final Velocity X X X X X X X X X

XONOFF Enable/Disable XON/XOFF X X X X X

AT6200

AT6400

AT6250

AT6450

610n

615n

620n

625n

6270

*

Modified to support compiled motion (previously, these commands supported only path contouring).

S

Applicable only to the standard (not OEM) version of the product.

Change Summary, page 6

Page 9

TABLE OF CONTENTS

Overview

About This Manual.................................................... i

Organization of This Manual ................................. i

Programming Examples...................................... ii

Reference Documentation................................... ii

Assumptions of Technical Experience................... ii

Product Name References (What’s in a Name?)....... iii

Before You Begin .................................................... iii

Support Software .................................................... iii

Motion Architect................................................ iii

Motion Builder.................................................. iv

Motion Toolbox ................................................ iv

DOS Support Software ...................................... iv

Technical Support .................................................. iv

Variables.............................................................. 18

Converting Between Binary and Numeric Variables . 19

Using Numeric Variables.................................... 19

Using Binary Variables...................................... 22

Program Flow Control.............................................. 23

Unconditional Looping and Branching................... 23

Conditional Looping and Branching...................... 24

Program Interrupts (ON Conditions)........................... 29

Error Handling ....................................................... 30

Enabling Error Checking.................................... 30

Defining the Error Program................................. 30

Canceling the Branch to the Error Program............ 31

Error Program Set-up Example............................ 32

Non-Volatile Memory (Stand-Alone Products Only) ....... 33

System Performance .............................................. 33

Chapter 1. Programming Fundamentals

Motion Architect Programming Environment.................. 2

Side-by-Side Editor and Terminal Windows ............. 2

Command Syntax.................................................... 3

Overview......................................................... 3

Description of Syntax Letters and Symbols ............ 4

General Guidelines for Syntax ............................. 5

Command Value Substitutions ............................. 6

Assignment and Comparison Operators................. 6

Programmable Inputs and Outputs Bit Patterns....... 8

Creating Programs................................................... 8

Program Development Scenario ........................... 8

Storing Programs .................................................. 12

Storing Programs in Stand-Alone Products........... 12

Storing Programs in Bus-Based Products............. 12

Memory Allocation........................................... 12

Checking Memory Status.................................. 13

Executing Programs (options).................................. 14

Creating and Executing a Set-up Program .................. 14

Set-up Program Execution

Set-up Program Execution

Program Security .................................................. 15

Controlling Execution of Programs and the Command

Buffer............................................................. 16

Continuous Command Execution........................ 16

Continue Command Execution on Kill................... 16

Save Command Buffer on Limit........................... 17

Pause Command Execution Until In Position Signal 17

Effect of Pause/Continue Input .......................... 17

Save Command Buffer on Stop........................... 17

Restricted Commands During Motion......................... 18

for Stand-Alone Controllers

for Bus-Based Controllers

. 15

.. 15

Chapter 2. Communication

Motion Architect Communication Features.................. 36

DOS Support Software for Stand-Alone Products......... 37

DOS Support for Bus-Based Products........................ 38

Downloading the Operating System ..................... 39

Terminal Emulation........................................... 41

Downloading Application Programs from the DOS

prompt..................................................... 41

Creating

PC-AT Bus Communication Registers......................... 43

Fast Status Register (Base+2, Base+3)................ 43

Card Status and Interrupts to/from PC-AT (Base+4) 49

Reading and Writing to the 6000 Controller ............ 50

DDE6000.............................................................. 50

DLLs ................................................................... 51

Visual Basic™ Support...................................... 52

Visual C++™ Support........................................ 58

Motion OCX Toolkit™.............................................. 62

PC-AT Interrupts.................................................... 63

AT6nnn Interrupt Path....................................... 63

How to Use Interrupts ...................................... 65

Interrupt-Driven Terminal Emulator ...................... 68

Controlling Multiple Serial Ports................................. 70

Configuring the COM Port .................................. 70

Selecting a Destination Port for Transmitting from the

RS-232C Daisy-Chaining ......................................... 72

Daisy-Chaining from a Computer or Terminal.......... 73

Daisy-Chaining from a Master 6000 Controller........ 74

Daisy-Chaining and RP240s............................... 74

RS-485 Multi-Drop.................................................. 75

Your Own DOS-Based Application Program. 42

Controller ................................................. 71

Page 10

Chapter 3. Basic Operation Setup

Before You Begin................................................... 78

Setup Parameters Discussed in this Chapter......... 78

Using a Setup Program...................................... 79

Motion Architect.............................................. 79

Resetting the Controller..................................... 79

Participating Axes.................................................. 79

Memory Allocation.................................................. 80

Drive Setup........................................................... 80

Drive Fault Level.............................................. 80

Drive Resolution (steppers only) ......................... 81

Step Pulse (steppers only)................................. 81

Start/Stop Velocity (steppers only)...................... 82

Disable Drive On Kill (servos only)....................... 82

ZETA610n Internal Drive Setup........................... 82

Axis Scaling.......................................................... 83

When Should I Define Scaling Parameters?........... 83

Acceleration & Deceleration Scaling

(SCLA and PSCLA)..................................... 84

Velocity Scaling

(SCLV and PSCLV)..................................... 84

Distance Scaling

(SCLD and PSCLD)..................................... 85

Scaling Examples ............................................ 86

Positioning Modes.................................................. 87

Preset Positioning Mode.................................... 88

Continuous Positioning Mode ............................. 89

End-of-Travel Limits ............................................... 90

Homing ................................................................ 91

Closed-Loop Stepper Setup (steppers only) ................ 95

Encoder Resolution.......................................... 95

Encoder Step Mode.......................................... 95

Position Maintenance ....................................... 95

Position Maintenance Deadband......................... 95

Stall Detection & Kill-on-Stall.............................. 96

Stall Deadband................................................ 96

Encoder Set Up Example................................... 96

Use the Encoder as a Counter ............................ 96

Encoder Polarity .............................................. 97

Commanded Direction Polarity............................ 97

Servo Setup.......................................................... 98

Tuning ........................................................... 99

Feedback Device Polarity ................................ 100

Commanded Direction Polarity.......................... 101

Dither .......................................................... 101

DAC Output Limits.......................................... 102

Servo Control Signal Offset.............................. 102

Servo Setup Examples.................................... 103

Target Zone Mode ................................................ 105

Programmable Inputs and Outputs (including triggers and

auxiliary outputs) ............................................. 106

Programmable I/O Bit Patterns ......................... 107

Input Functions ............................................. 108

Output Functions ........................................... 116

Variable Arrays (teaching variable data) ................... 120

Basics of Teach-Data Applications .................... 120

Summary of Related 6000 Series Commands....... 122

Teach-Data Application Example....................... 122

Chapter 4. User Interface Options

Safety Features.................................................. 126

Options Overview (application examples)................. 127

Stand-Alone Interface Options ......................... 127

Programmable Logic Controller......................... 127

Host Computer Interface ................................. 127

Custom Graphical User Interfaces (GUIs)........... 127

Programmable I/O Devices.................................... 128

Programmable I/O Functions............................ 128

Thumbwheels................................................ 129

PLCs........................................................... 130

RP240 Remote Operator Panel............................... 130

Configuration................................................ 131

Operator Interface Features............................ 131

Using the Default Menus ................................. 132

Joystick and Analog Inputs ................................... 138

Joystick Control ............................................ 138

Feedrate Override

ANI Analog Input Interface

Auxiliary Analog Output (“half axis” — AT6n50 only) ... 142

Host Computer Interface ....................................... 143

Graphical User Interface (GUI) Development Tools..... 144

(multi-axis steppers only)

(products with ANI option)

....... 141

. 142

Chapter 5. Custom Profiling

S-Curve Profiling (servos only)............................... 146

Timed Data Streaming (bus-based steppers only)....... 148

Time-Distance Streaming Example.................... 149

Linear Interpolation .............................................. 152

Contouring (Circular Interpolation)........................... 153

Path Definition .............................................. 153

Participating Axes ......................................... 154

Path Acceleration, Deceleration, and Velocity ..... 155

Segment End-point Coordinates ....................... 155

Line Segments.............................................. 156

Arc Segments ............................................... 157

Segment Boundary ........................................ 158

Using the C Axis (4-axis products only).............. 159

Using the P Axis (4-axis products only) .............. 159

Outputs Along the Path................................... 160

Paths Built Using 6000 Series Commands........... 160

Compiling the Path......................................... 160

Executing the Path ........................................ 161

Possible Programming Errors........................... 161

Programming Examples .................................. 161

Compiled Motion Profiling ...................................... 163

Compiled Following Profiles.............................. 166

Dwells and Direction Changes .......................... 168

Compiled Motion Versus On-The-Fly Motion ........ 169

Related Commands........................................ 169

Compiled Motion — Sample Applications ............ 170

On-the-Fly Motion (pre-emptive GOs) ...................... 178

OTF Error Conditions...................................... 179

OTF Sample Application.................................. 180

Registration........................................................ 182

Registration Move Accuracy ............................ 182

Preventing Unwanted Registration Moves........... 182

Registration Move Status & Error Handling.......... 183

How to Set up a Registration Move .................... 183

Registration – Sample Applications ................... 184

Synchronizing Motion ........................................... 186

Conditional “GO”s (GOWHEN).......................... 186

Trigger Functions (TRGFN) .............................. 189

Page 11

Chapter 6. Following

Ratio Following – Introduction ................................. 192

What can be a master?.................................... 192

Performance Considerations ............................ 193

Following Status............................................. 193

Implementing Ratio Following.................................. 194

Ratio Following Setup Parameters...................... 194

Slave vs. Master Move Profiles......................... 199

Performing Phase Shifts .................................. 201

Summary of Ratio Following Commands .............. 203

Electronic Gearbox Application ......................... 204

Trackball Application....................................... 205

Master Cycle Concept........................................... 207

Master Cycle Commands ................................. 207

Summary of Master Cycle and Wait Commands .... 210

Continuous Cut-to-Length Application ................ 211

Technical Considerations for Following ..................... 213

Master Position Prediction............................... 214

Master Position Filtering .................................. 214

Following Error............................................... 215

Maximum Velocity and Acceleration................... 216

Dynamic Position Maintenance ......................... 216

Factors Affecting Following Accuracy................. 216

Preset vs. Continuous Following Moves.............. 219

Master and Slave Distance Calculations ............. 220

Using Other Features with Following................... 221

Troubleshooting for Following.................................. 223

Following Commands............................................. 225

Chapter 7. Troubleshooting

Troubleshooting Basics......................................... 228

Solutions to Common Problems............................... 228

Program Debug Tools............................................ 231

Status Commands.......................................... 232

Error Messages............................................. 236

Trace Mode................................................... 239

Single-Step Mode........................................... 240

Simulating I/O Activation ................................. 240

Simulating Analog Input Channel Voltages .......... 242

Motion Architect's Panel Module ....................... 242

Downloading Error Table (bus-based controllers only).. 243

Technical Support................................................ 244

Product Return Procedure ..................................... 244

Index.............................................................. 245

Page 12

O V E R V I E W

About This Manual

This manual is designed to help you implement the 6000 Series Product's features in your

application. Detailed feature descriptions are provided, including application scenarios and

programming examples. For details on each 6000 Series command, refer to the 6000 Series

Software Reference.

Organization of This Manual

The feature descriptions are grouped into chapters as listed below.

Chapter Information

Chapter 1.

Chapter 2.

Chapter 3.

Chapter 4.

Chapter 5.

Chapter 6.

Chapter 7.

Programming Fundamentals

Communication

Basic Operation Setup

User Interface Options

Custom Profiling

Following

Troubleshooting

Discussion of essential programming guidelines and standard

programming features such as branching, variables, interrupts, error

handling, etc.

Communication considerations, such as using Motion Architect,

DDE, DLL and OCX tools, bus communication registers, PC-AT

interrupts, DOS Support Disk communication files, RS-232 daisychains and RS-485 multi-drops, etc.

General operation setup conditions, such as number of axes, scaling

factors, feedback device setup, end-of-travel limits, homing, etc.

Considerations for implementing various user interfaces such as

programmable I/O, a joystick, an RP240, etc.

Descriptions of custom profiling features such as S-Curves, timed

data streaming, linear and circular interpolation, compiled profiles,

on-the-fly motion profiling, registration, and synchronized motion.

Feature descriptions and application examples for using Following

features.

Methods for isolating and resolving hardware and software

problems.

User Guide Feedback Please send your comments to our email address: 6000user@cmotor.com

Overview

i

Page 13

Programming Examples

Programming examples are provided to demonstrate how the 6000 product's features may be

implemented. These examples are somewhat generalized, due to the diverse nature of the

family of 6000 Series products and their application; consequently, some attributes, such as

the number of axes used or the I/O bit pattern referenced, may differ from those available with

your particular 6000 product.

Additional sample programs can be found in the APP_PRGS sub-directory of the Motion

Architect directory (MA6000\APP_PRGS). These files may be opened and edited in Motion

Architect's Editor module, then downloaded using Motion Architect's Terminal module.

TIP: From the Help menu in Motion Architect and from our web site (www.compumotor.com),

you can access the online versions of this Programmer's Guide and the Software Reference. You

can copy the programming examples from these online documents and paste them into Motion

Architect's Program Editor. Then you can edit the code for your application requirements and

download the program using the Terminal Emulator. For additional tips on using the Editor and

Terminal, refer to page 2 in this manual or to the Motion Architect User Guide.

Reference Documentation

This document is intended to accompany the documents listed below, as part of the 6000

product user documentation set.

Reference Document Information

6000 product installation guide Hardware-related information specific to the 6000 Series product.

ONLINE ACCESS:

Online versions of this

Programmer's Guide and

the Software Reference

are available from the Help

menu in Motion Architect.

6000 Series Software Reference

INTERNET ACCESS:

These documents are also

available to view and print

from our web site

(www.compumotor.com).

Motion Architect User Guide

RP240 User Guide

User guides for optional software tools: ☞

• Product description

• Installation instructions

• Drive information (packaged controller/drive products only)

• Hardware reference

• Troubleshooting procedures

• Servo tuning (procedures for tuning without Servo Tuner™)

• Electrical noise reduction techniques

* Detailed descriptions of all 6000 Series commands. Quick-

reference tables are also provided:

• Product-to-command compatibility table

• X-to-6000 language compatibility table

• ASCII table

Overview and user tips for Motion Architect features, and

guidelines for using the dynamic link library (DLL). This manual

is only available in Acrobat PDF format from our web site.

Detailed user instructions for the RP240 remote operator panel

(optional peripheral device for serial based products only).

Motion Builder Startup Guide

☞

Servo Tuner User Guide

☞

CompuCAM User Guide

☞

Motion Toolbox User Guide

☞

Motion OCX Toolkit User Guide

* Also available as an on-line hypertext utility, accessed from the Help menu in Motion Architect.

Assumptions of Technical Experience

To effectively use the information in this manual, you should have a fundamental

understanding of the following:

• Electronics concepts such as voltage, switches, current, etc.

• Motion control concepts such as motion profiles, torque, velocity, distance, force, etc.

• Programming skills in a high-level language such as C, BASIC, or Pascal is helpful

• IBM/compatible bus architecture and communication protocol (bus-based products only)

• If you are new to the 6000 Series Programming Language, read Chapter 1 thoroughly.

ii

6000 Series Programmer's Guide

Page 14

Product Name References (What’s in a Name?)

This document sometimes uses one product name to reference an entire subset of the 6000

family (e.g, “AT6n50” refers to the AT6450 and the AT6250; “AT6n00” refers to the AT6200

and the AT6400). Unless otherwise noted, references to a standard product are applicable to the

OEM version as well (e.g., AT6400 and OEM-AT6400; 6200 and OEM6200).

Before You Begin

Before you begin to implement the 6000 controller's features in your application you should

complete the items listed below.

• Complete all the installation and test procedures provided in your 6000 product's

Installation Guide.

• If you are using a servo control product, complete the tuning procedures. If you are using

Servo Tuner, use the instructions in the Servo Tuner User Guide. If you are using

an empirical tuning method (not Servo Tuner), refer to the procedures provided in the

Tuning appendix of the product's Installation Guide.

• Keep the 6000 Series Software Reference close at hand to answer questions about

specific 6000 Series commands. If you are new to the 6000 Series Programming

Language, read Chapter 1 (Programming Fundamentals) thoroughly.

Support Software

These software development tools are available to help you program your 6000 Series product.

• Motion Architect, and these add-on modules:

- Servo Tuner (tuning and data capture)

- CompuCAM (CAD-to-Motion)

• Motion Builder (graphical icon-based programming software)

• Motion Toolbox (Motion VIs for LabVIEW)

• DOS Support Software

Motion Architect

®

All 6000 Series products are shipped with Motion Architect, an intuitive Microsoft® Windows™

based programming tool. A brief description of Motion Architect's basic features is provided

below. For more detailed user information, refer to the Motion Architect User Guide.

• System Configurator and Code Generator: Automatically generate controller

code of basic system set-up parameters (I/O definitions, feedback device operations, etc.).

• Program Editor: Create blocks or lines of 6000 controller code, or copy portions of

code from previous files. You can save program editor files for later use in BASIC, C,

etc., or in the terminal emulator or test panel.

• Terminal Emulator: Communicating directly with the 6000 controller, the terminal

emulator allows you to type in and execute controller code, transfer code files to and from

the 6000 product. If you are using a bus-based 6000 controller, you can use this module

to transfer (download) the soft operating system.

• Test Panel and Program Tester: You can create your own test panel to run your

programs and check the activity of I/O, motion, system status, etc. This can be invaluable

during start-ups and when fine tuning machine performance.

• On-line Context-sensitive Help and Command Reference: These on-line

resources provide help information about Motion Architect, as well as interactive access

to the contents of the 6000 Series Programmer's Guide (this document) and the

6000 Series Software Reference.

• Dynamic Link Libraries: DLL device drivers are provided for bus-based controller

customers who wish to create a Windows-based application to interface with the controller.

Overview

iii

Page 15

Add-On

Modules

Motion Builder™

Motion Toolbox™

Add-on modules for Motion Architect are available to aide in other programming and setup

tasks. These modules are available from your local Automation Technology Center (ATC) or

distributor. For detailed user information, please refer to the respective user guide.

• Servo Tuner™ (Tuning and Data Gathering Tool): Tune the servo drives and the 6000

servo controller and receive instant data feedback on customizable displays.

• CompuCAM™: CAD-to-Motion (CAM) software allows you to translate DXF,

HP-GL, and G-Code files into 6000 Series Language motion programs.

Motion Builder, a Microsoft Windows-based iconic

programming environment, allows expert and novice

programmers to easily program Compumotor’s 6000 Series

products without learning a new programming language or

syntax. Use Motion Builder to completely configure the

motion controller; program the motion with drag-and-drop

visual icons; compile, run and debug the program.

Motion Toolbox is a library of LabVIEW® virtual instruments (VIs) for Compumotor's 6000

Series controllers. Motion Toolbox allows LabVIEW programmers to develop motion

control systems for a wide range of applications including automated test and manufacturing,

medical and biotech, metering and dispensing, machine control, and laboratory automation.

Motion Toolbox provides developers with these capabilities:

• Motion control, including velocity, acceleration, deceleration, go, stop, kill, etc.

• Setup, control, and command file transfer

• Counter and timer configuration and control

• Indexer, encoder, and drive configuration

• Home, hardware limit, and soft limit configuration

• Jogging and joystick configuration

• I/O setup and function configuration

• Fast status querying of I/O, limit, home, motor and encoder position, velocity, etc.

DOS Support Software

In addition to Motion Architect, support software written for the DOS environment is

available for all 6000 Series products.

Details about these

software tools are

provided in Chapter 2,

Communication

.

The 6000 DOS Support Disk, which provides a program for terminal emulation and program

editing for serial (“stand-alone”) products, is available from your local ATC or distributor.

Bus-based products are shipped with a DOS support disk (see diskette labeled with the

product's name) that includes the soft operating system (.OPS file) and programs that

demonstrate how to communicate with the 6000 product.

Technical Support

For solutions to your questions about implementing 6000 product software features, first look

in this manual. Other aspects of the product (command descriptions, hardware specs, I/O

connections, graphical user interfaces, etc.) are discussed in the respective manuals listed above

in Reference Documentation (see page ii).

iv

If you cannot find the answer in this documentation, contact your local Automation

Technology Center (ATC) or distributor for assistance.

If you need to talk to our in-house application engineers, please contact us at the numbers

listed on the inside cover of this manual. (The phone numbers are also provided when you

issue the HELP command to the 6000 controller.)

6000 Series Programmer's Guide

Page 16

CHAPTER ONE

Programming

Fundamentals

1

IN THIS CHAPTER

This chapter is a guide to general 6000 programming tasks. It is divided into these main topics:

• Motion Architect programming environment .............. 2 • Restricted commands during motion .................... 18

• Command syntax ................................................. 3 • Using Variables............................................. 18

• Creating programs (program development scenario) ...... 8 • Program flow control ...................................... 23

• Storing programs................................................. 12 • Program interrupts.......................................... 29

• Executing programs .............................................. 14 • Error handling............................................... 30

• Creating and executing a set-up program..................... 1 4 • Non-volatile memory (stand-alone products) ......... 33

• Program Security.................................................. 1 5 • System performance considerations .................... 33

• Controlling execution – programs & command buffer .... 16

Page 17

Motion & Control

Motion Architect Programming Environment

Every 6000 Series controller is shipped with Motion Architect, a Windows-based

programming tool designed to simplify your programming efforts. The main features of

Motion Architect are briefly described below. For detailed user information, refer to the

Motion Architect User Guide.

• Setup Module: Provides dialog boxes for you to select basic system setup parameters

(I/O definitions, position feedback, etc.) and then automatically generates a fullycommented “setup program.”

• Editor Module : Create blocks or lines of 6000 controller code, or copy portions of

code from previous files. You can save program editor files for later use in BASIC, C,

etc., or in the terminal emulator or test panel.

• Terminal Module: Communicating directly with the 6000 controller, the terminal

emulator allows you to type in and execute controller code and transfer code files to and

from the 6000 controller.

• Panel Module: You can create your own test panel to run your programs and check

the activity of I/O, motion, system status, etc. This can be invaluable during start-ups

and when fine tuning machine performance.

• On-line Help and User Documentation: Under the Help menu, you will find

user information about Motion Architect, as well as interactive access to the contents of

the 6000 Series Programmer's Guide (the document you are reading right now)

and the 6000 Series Command Reference.

Add-on modules for Motion Architect are available to aide in other programming and set-up

tasks. These modules are available through your local Automation Technology Center.

• Servo Tuner™: Tune your servo controller and the attached servo drives and receive

instant data feedback on customizable displays. For detailed user information, refer to the

Servo Tuner User Guide.

• CompuCAM™: CompuCAM allows you to import 2D geometry from CAD

programs (DXF), plotter files (HP-GL), or NC programs (G-Code), and then translate the

geometry into 6000 motion programs. These programs can be further edited in Motion

Architect's Program Editor module and dowloaded to the 6000 controller from the

Terminal Emulator or Test Panel modules. A typical use of CompuCAM is to automate

the process for developing 6000 Series contouring code for an application. For detailed

user information, refer to the CompuCAM User Guide.

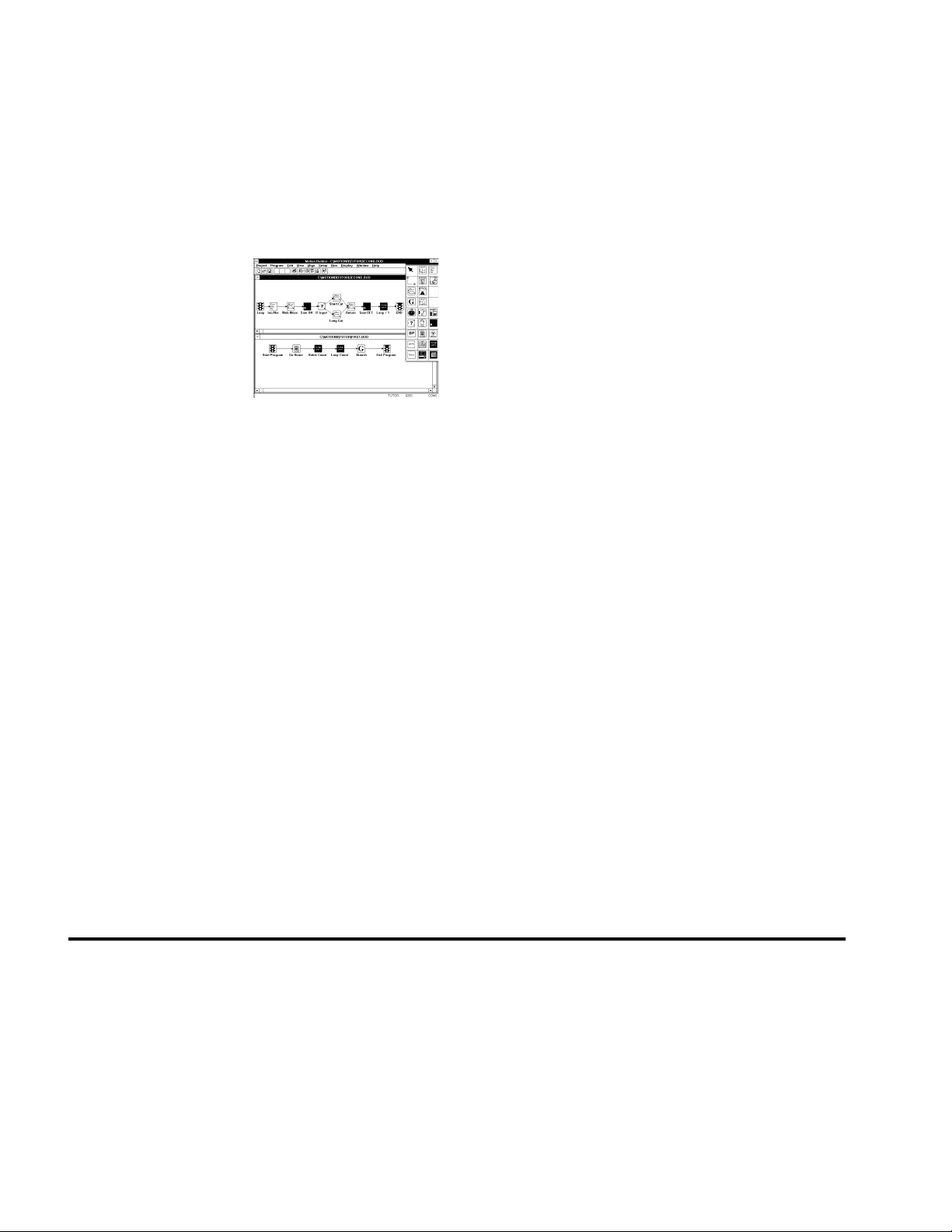

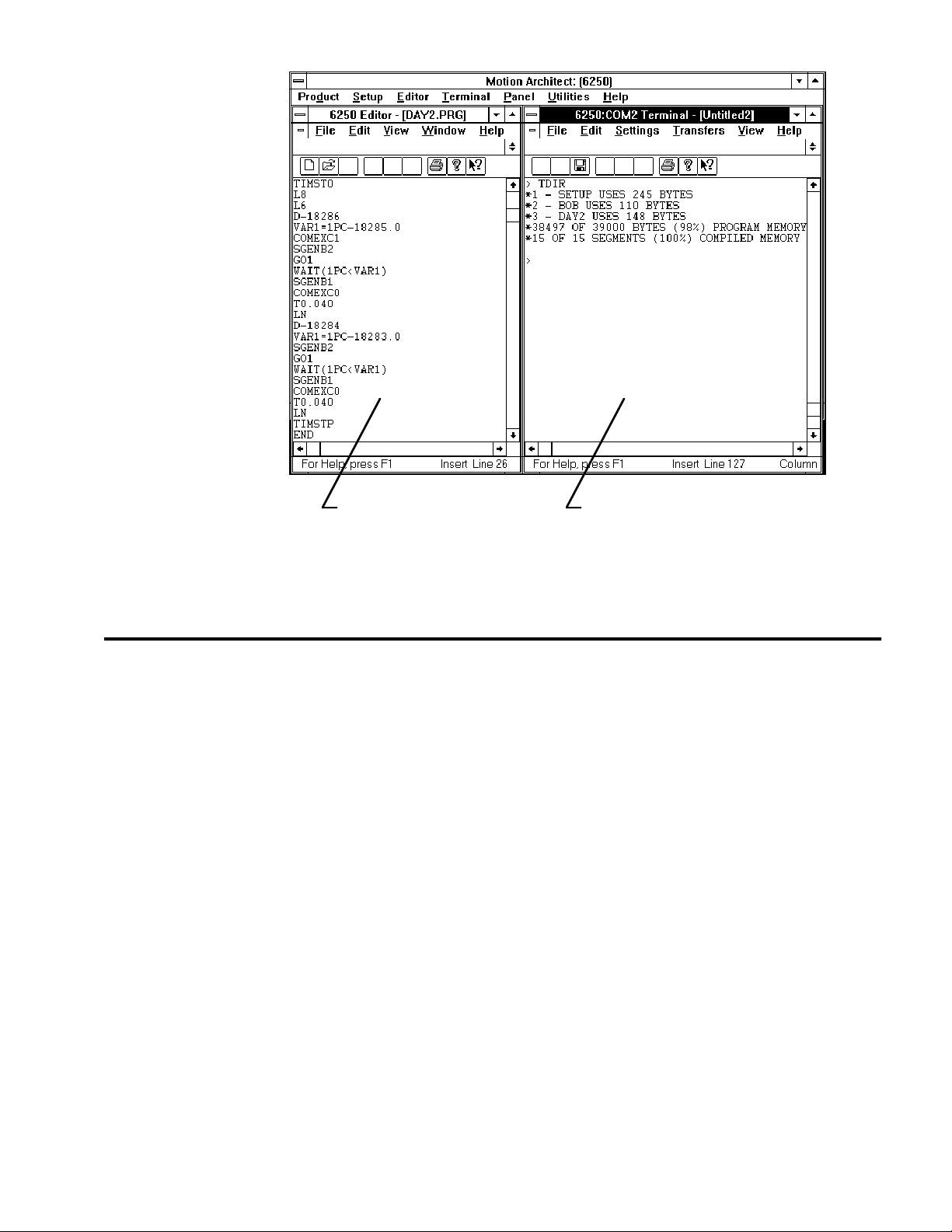

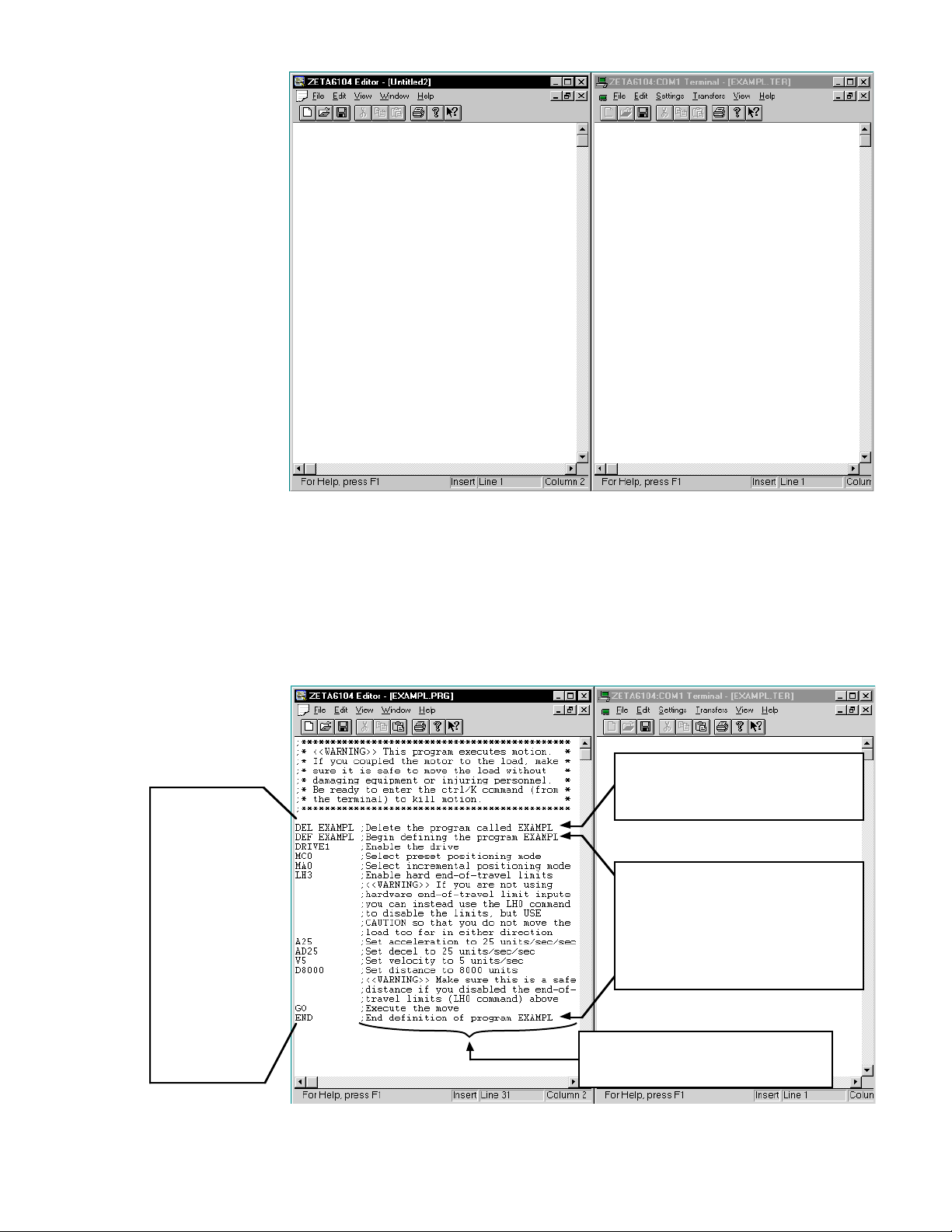

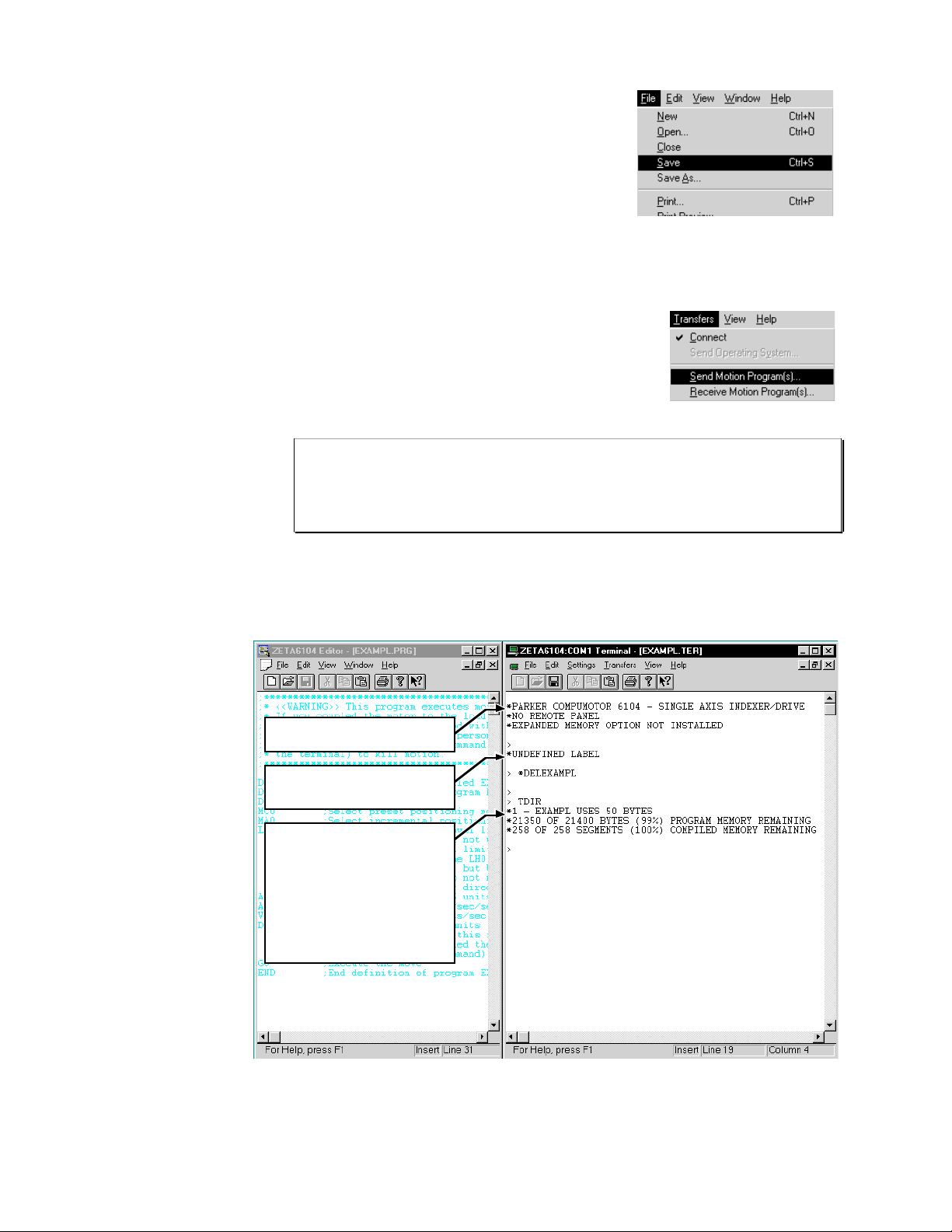

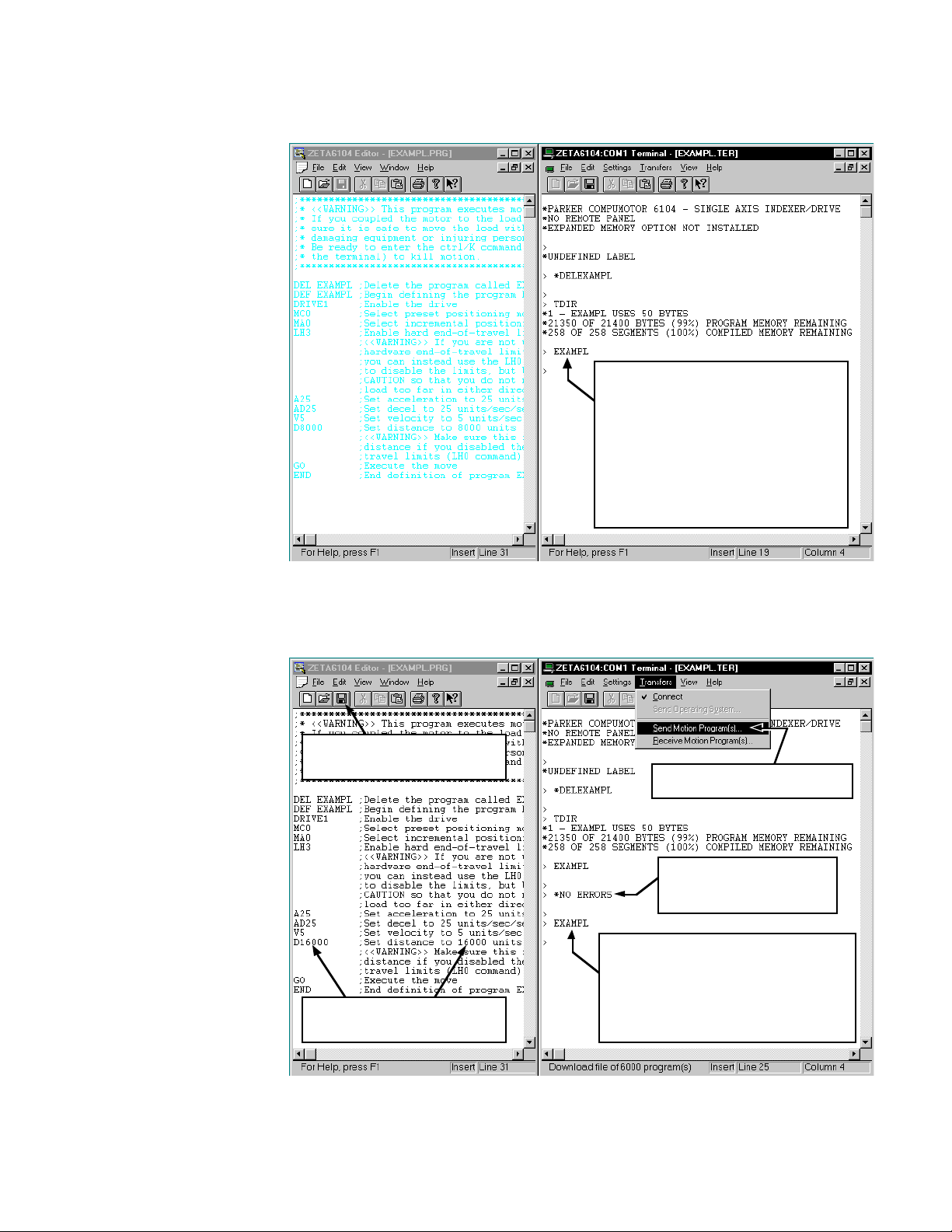

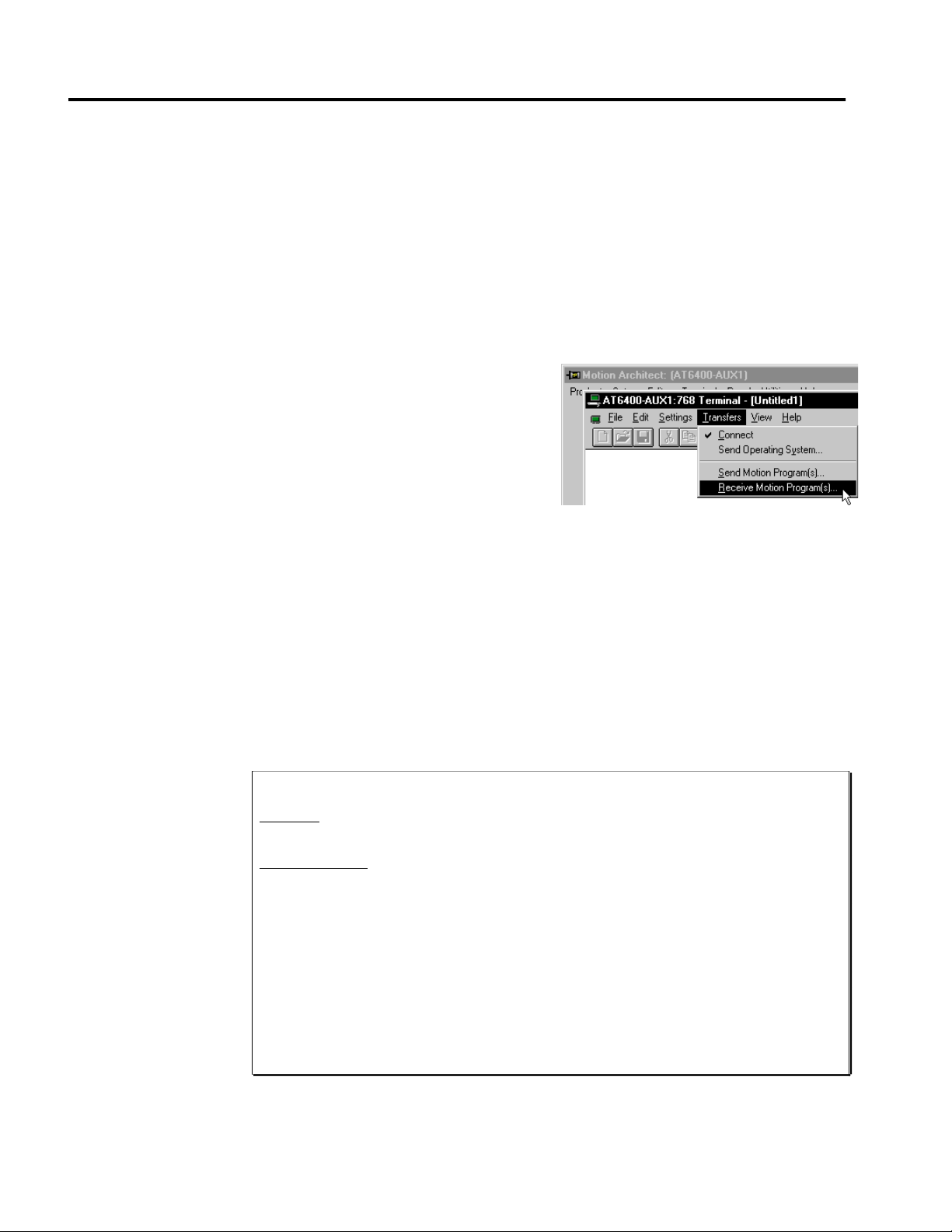

Side-by-Side Editor and Terminal Windows

Typically, the programming process is an iterative exercise in which you create a program,

This side-by-side

technique is

demonstrated in the

programming

scenario on page 8.

2

6000 Series Programmer's Guide

test it, edit it, test it ... until you are satisfied with the results. To help with this iterative

process, we suggest using Motion Architect's Editor and Terminal modules in a side-by-side

fashion (open an Editor session and a Terminal session and re-size the windows so that you

can see both at the same time). In doing so you can quickly jump back and forth between

editing a program (Editor function) and downloading it to the product and checking

programming responses and error messages (Terminal functions).

(see illustration below)

Page 18

Command Syntax

Overview

The 6000 Series language provides high-level constructs as well as basic motion control

building blocks. The language comprises simple ASCII mnemonic commands, with each

command separated by a command delimiter. Upon receiving a command followed by a

command delimiter, the 6000 controller places the command in its internal command queue.

Here the command is executed in the order in which it is received. The command may be

specified as immediate by placing an optional exclamation point (!) in front of the command.

When a command is specified as an immediate command, it is placed at the front of the

command queue, where it is executed immediately.

The command delimiter can be one of three characters, a carriage return, a line-feed, or a colon

(:). Spaces and tabs within a command are processed as neutral characters. Comments can be

specified with the semicolon (;) character — all characters following the semicolon until the

command delimiter are considered program comments.

There is no case sensitivity with the command language. For instance, the command TSTAT

is the same as the command tstat.

Program Editor: Create and edit

programs, save them, and then

download them from the Terminal

module.

Terminal Emulator: Communicate directly with the

6000 controller. Download files containing

stand-alone commands and/or complete programs

or subroutines. Check system responses. Upload

programs from the 6000 controller.

Some commands contain one or more data fields in which you can enter numeric or binary

values or text. The A command (syntax: A<r>,<r>,<r>,<r>) is an example of a

command that requires you to enter numeric values (e.g., the A5,6,7,8 command assigns

acceleration values of 5, 6, 7, and 8 units/sec2 to axes #1, #2, #3, and #4 respectively). The

DRIVE command (syntax: DRIVE<b><b><b><b>) is an example of a command that

requires binary values (e.g., the DRIVE11ØØ command enables drives #1 and #2 and disables

drives #3 and #4). The STARTP command (syntax: STARTP<t>) is an example of a

command that requires text (e.g., the STARTP powrup command assigns the program called

“powrup” as the start-up program).

Chapter 1. Programming Fundamentals

3

Page 19

Description of Syntax Letters and Symbols

The command descriptions provided within the 6000 Series Software Reference use

alphabetic letters and ASCII symbols within the Syntax description to represent different

parameter requirements (see example below).

INEN Input Enable

Type Inputs or Program Debug Tools

Syntax Symbology

☞

Syntax <!>INEN<d><d><d>...<d>>

Units d = Ø, 1, E, or X

Range Ø = off, 1 = on, E = enable, X = don't change

Default E

Response INEN: *INENEEEE_EEEE_EEEE_EEEE_EEEE_EEEE_EEEE

See Also [ IN ], INFEN, INFNC, INLVL, INPLC, INSTW, TIN

Letter /

Symbol Description

Product Rev

AT6n00 1.0

AT6n50 1.0

610n 1.0

615n 1.0

620n 1.0

625n 1.0

6270 1.0

a Represents an axis specifier, numeric value from 1 to 4 (used only to elicit a

b

c Represents a character (A to Z, or a to z)

d Represents the values 1,Ø, X or x, E or e ; does not require field separator

i Represents a numeric value that cannot contain a decimal point (integer values

r Represents a numeric value that may contain a decimal point, but is not required

t Represents a string of alpha numeric characters from 1 to 6 characters in length.

! Represents an immediate command. Changes a buffered command to an

, Represents a field separator. Commands with the symbol r or i in their Synt ax

response from the indexer)

*

Represents the values 1,Ø, X or x; does not require field separator between

values.

between values. E or e enables a specific command field. X or x leaves the

specific command field unchanged or ignored.

only). The numeric range varies by command. Field separator (,) required.

to have a decimal point. The numeric range varies by command. Field separator

(,) required.

The string must start with an alpha character.

immediate command. Immediate commands are processed immediately, even

before previously entered buffered commands.

description require field separators. Commands with the symbol b or d in their

Synt ax description do not require field separators (but they may be included).

See

General Guidelines

table below for more information.

@ Represents a global specifier, where only one field need be entered. Applicable

< > Indicates that the item contained within the < > is optional, not required by that

[ ] Indicates that the command between the [ ] must be used within the syntax of

*

The ASCII character b can also be used within a command to precede a binary number. When the b is

used in this context, it is not to be replaced with a Ø, 1, X, or x. Examples are assignments such as

VARB1=b1ØØØ1, and comparisons such as IF(IN=b1ØØ1X1).

4

6000 Series Programmer's Guide

to all commands with multiple command fields. (e.g., @V1 sets velocity on all

axes to 1 rps)

command. NOTE: Do not confuse with <cr>, <sp>, and <lf>, which refer to the

ASCII characters corresponding to a carriage return, space, and line feed,

respectively.

another command, and cannot be used by itself.

Page 20

General Guidelines for Syntax

Topic Guideline Examples *

Neutral Characters:

• Space (

• Tab (

Command Delimiters:

• Carriage rtn (

• Line feed (

• Colon (:)

Comment Delimiter (;) All text between a comment delimiter and a

Field Separator (,) Commands with the symbol r or i in their

<sp>

<tab>

)

)

<cr>

<lf>

Using neutral characters anywhere within a

command will not affect the command.

(In the examples on the right, a space is

represented by

carriage return is

All commands must be separated by a

)

command delimiter. A carriage return is the

)

most commonly used delimiter. To use a line in

a live terminal emulator session, press ctrl/J.

The colon (:) delimiter allows you to place

multiple commands on one line of code, but

only if you add it in the program editor (not

during a live terminal emulator session).

command delimiter is considered

comments

Synt ax description require field separators.

Commands with the symbol b or d in their

Synt ax description do not require field

separators (but they may be included).

Axes not participating in the command need

not be specified; however, field separators

that are normally required must be specified.

<sp>

, a tab is

<cr>

.)

.

<tab>)

program

, and a

Set velocity on axis 1 to 10 rps and axis 2 to 25 rps:

V

<sp>

1Ø,

<sp>

25,,

<cr>

Add a comment to the command:

V 1Ø, 25,,

Set acceleration on axis 2 to 10 rps

A,1Ø,,

A,1Ø,,

A,1Ø,, : V,25,, : D,25ØØØ,, : @GO

Add a comment to the command:

V1Ø<tab> ;set velocity

Set velocity on axes 1-4 to 10, 25, 5 and 10 rps,

respectively:

V1Ø,25,5,1Ø

Initiate motion on axes 1, 3 and 4:

GO1Ø11

GO1,Ø,1,1

Set velocity on axis 2 to 5 rps:

V,5,,

<cr>

<lf>

<cr>

<cr>

<tab>

;set accel

<cr>

<cr>

2

:

<cr>

<cr>

<cr>

Global Command

Identifier (@)

Bit Select Operator (.) The bit select operator allows you to affect

Case Sensitivity There is no case sensitivity. Use upper or

Left-to-right Math All mathematical operations assume left-to-

* Non-visible characters are represented: space =

NOTE: The command line is limited to 80 characters (excluding spaces).

When you wish to set the command value

equal on all axes, add the @ symbol at the

beginning of the command (enter only the

value for one command field).

one binary bit without having to enter all the

preceding bits in the command.

Syntax for setup commands:

[command name].[bit #]-[binary value]

Syntax for conditional expressions:

[command name].[bit #]=[binary value]

lower case letters within commands.

right precedence.

<sp>

, tab =

<tab>

, carriage return (or enter key) =

Set velocity on all axes to 10 rps:

@V1Ø

<cr>

Enable error-checking bit #9:

ERROR.9-1

IF statement based on value of axis status bit #12:

IF(1AS.12=b1)

Initiate motion on axes 1, 3 and 4:

GO1Ø11

go1Ø11

VAR1=5+3*2

Result: Variable 1 is assigned the value of 16

(8*2), not 11 (5+6).

<cr>

<cr>

<cr>

<cr>

<cr>

<cr>

, line feed =

<lf>

.

Chapter 1. Programming Fundamentals

5

Page 21

Command Value Substitutions

Many commands can substitute one or more of its command field values with one of these

substitution items (demonstrated in the programming example below):

VARB...... Uses the value of the binary variable to establish all the command fields.

VAR ....... Places current value of the numeric variable in the corresponding command field.

READ...... Information is requested at the time the command is executed.

DREAD.... Reads the RP240's numeric keypad into the corresponding command field.

DREADF .. Reads the RP240's function keypad into the corresponding command field.

TW ......... Places the current value set on the thumbwheels in the corresponding command field.

DAT ....... Places the current value of the data program (DATP) in the corresponding command field.

Programming Example: (NOTE: The substitution item must be enclosed in parentheses.)

VAR1=15 ; Set variable 1 to 15

A5,(VAR1),4,4 ; Set acceleration to 5,15,4,4 for axes 1-4, respectively

VARB1=b1101XX1 ; Set binary variable 1 to 1101XX1 (bits 5 & 6 not affected)

GO(VARB1) ; Initiate motion on axes 1, 2 & 4 (value of binary

; variable 1 makes it equivalent to the GO1101 command)

OUT(VARB1) ; Turn on outputs 1, 2, 4, and 7

VARS1="Enter Velocity" ; Set string variable 1 to the message "Enter Velocity"

V2,(READ1) ; Set the velocity to 2 on axis 1. Read in the velocity for

; axis 2, output variable string 1 as the prompting message

; 1. Operator sees "ENTER VELOCITY" displayed on the screen.

; 2. Operator enters velocity prefixed by !' (e.g., !'20).

HOMV2,1,(TW1) ; Set homing velocity to 2 and 1 on axes 1 and 2, respectively.

; Read in the home velocity for axis 3 from thumbwheel set 1

HOMV2,1,(DAT1) ; Set homing velocity to 2 and 1 on axes 1 and 2, respectively.

; Read home velocity for axis 3 from data program 1.

Not all of the commands allow command field substitutions. In general, commands with a

binary command field (<b> in the command syntax) will accept the VARB substitution.

Commands with a real or integer command field (<r> or <i> in the command syntax) will

accept VAR, READ, DREAD, DREADF, TW or DAT.

Assignment and Comparison Operators

Comparison and assignment operators are used in command arguments for various functions

such as variable assignments, conditional branches, wait statements, conditional GOs, etc.

Some examples are listed below:

• Assign to numeric variable #6 the value of the encoder position on axis #3 (uses the PE

operator): VAR6=3PE

• Wait until inputs #3 & #6 become active (uses the IN operator): WAIT(IN=bxx1xx1)

• Continue until the value of numeric variable #2 is less than 36: UNTIL(VAR2<36)

• IF condition based on if a target zone timeout occurs on axis 2 (uses the AS axis status

operator, where status bit #25 is set if a target zone timeout occurs): IF(2AS.25=b1)

The available comparison and assignment operators are listed below. For full descriptions,

refer to their respective descriptions in the 6000 Series Software Reference

(be sure to refer only to the commands in brackets—e.g., A is the acceleration setup command,

but [ A ] is the acceleration assignment/comparison operator).

RULE OF THUMB

6

6000 Series Programmer's Guide

Page 22

* denotes operators that

have a correlated status

display command.

(e.g., To see a full-text

description of each axis

status bit accessed with

the AS operator, send

the TASF command to

the 6000 controller.)

See page 232.

A........... Acceleration

AD ......... Deceleration

ANI........ Voltage at the ANI analog inputs (servos with ANI option) *

ANV........ Voltage at the joystick analog channels *

AS ......... Axis status *

ASX........ Extended axis status (additional axis status items) *

CA ......... Captured ANI analog input voltage *

CNT........ Counter value (steppers only) *

D........... Distance

DAC........ Digital-to-analog converter (output voltage) value (servos only) *

DAT........ Data program number

DPTR...... Data pointer location *

DREAD .... Data from the numeric keypad on the RP240 (stand-alone products only)

DREADF... Data from the function keypad on the RP240 (stand-alone products only)

ER ......... Error status *

FB ......... Position of current selected feedback sources *

FS ......... Following status *

IN ......... Input status (input bit patterns provided in Chapter 3, page 107) *

INO........ “Other” input status (joystick inputs, and P-CUT or ENBL input) *

LDT........ Position of the LDT (hydraulic servos only) *

LIM........ Limit status (end-of-travel limits and home limits) *

MOV........ Axis moving status

NMCY...... Current master cycle number *

OUT........ Output status (output bit patterns provided in Chapter 3, page 107) *

PANI...... Position of ANI analog input, at 819 counts/volts unless otherwise scaled (servos) *

PC ......... Commanded position (servos only) *

PCA........ Captured ANI input position (servos with ANI option only) *

PCC........ Captured commanded position (servos only) *

PCE........ Captured encoder position *

PCL........ Captured LDT position (hydraulic servos only) *

PCM........ Captured motor position (steppers only) *

PE ......... Position of encoder *

PER........ Position error (n/a to OEM-AT6400) *

PM ......... Position of motor (steppers only) *

PMAS...... Current master cycle position *

PSHF...... Net position shift since constant following ratio *

PSLV...... Current commanded position of the slave axis *

READ...... Read a numeric value to a numeric variable (VAR)

SEG........ Number of segments available in Compiled Profile memory *

SS ......... System status *

TIM........ Timer value *

TW ......... Thumbwheel data read

US ......... User status *

V........... Velocity (programmed)

VAR........ Numeric variable substitution

VARB...... Binary variable substitution

VEL........ Velocity (commanded by the controller) *

VELA...... Velocity (actual, as measured by a position feedback device) *

VMAS...... Current velocity of the master axis *

Bit Select

Operator

Binary and Hex

Values

The bit select operator (.) makes it easier to base a command argument on the condition of one

specific status bit. For example, if you wish to base an IF statement on the condition that a

user fault input is activated (error status bit #7 is a binary status bit that is “1” if a user fault

occurred and “Ø” if it has not occurred), you could use this command: IF(ER=bxxxxxx1).

Using a bit select operator, you could instead use this command: IF(ER.7=b1).

Side Note: You can use a bit select operator to set a particular status bit (e.g., to turn on

programmable output #5, you would type the OUT.5-1 command; to enable error-checking

bit #4 to check for drive faults, you would type the ERROR.4-1 command). You can also

check specific status bits (e.g., to check axis 2's axis status bit #25 to see if a target zone

timeout occurred, type the 2TAS.25 command and observe the response).

When making assignments with or comparisons against binary or hexadecimal values, you

must precede the binary value with the letter “b” or “B”, and the hex value with “h” or “H”.

Examples: IF(IN=b1xØ1) and IF(IN=h7F). In the binary syntax, an “x’ simply means

the status of that bit is ignored. Refer also to Using Binary Variables (page 22).

Chapter 1. Programming Fundamentals

7

Page 23

Related

Operator

Symbols