Page 1

T6T VHF 100 W Transmitter

User Documentation

Page 2

Errata

Any errors found in this handbook are promulgated through the Park Air FTP network. Any

user can access this information by logging on to:

ftp.parkairsystems.com

When logged on, select the public (Pub) folder, then the Handbook Errata Sheets folder,

and then select the required equipment model.

[Adobe Acrobat™ must be loaded on your PC to use this facility]

Handbook Title: T6T VHF 100 W Transmitter User Documentation

Handbook Part Number: 31-3T6T100V

Handbook Version: 2.0

Date of Issue: February 2005

Equipment Modification Level 7

Published By: Park Air Systems

Northfields

Market Deeping

Peterborough PE6 8UE

England

Telephone: From UK, 01778 345434

From outside UK, 44 1778 345434

Fax: From UK, 01778 342877

From outside UK, 44 1778 342877

www.parkairsystems.com

Page ii T6T VHF 100 W Transmitter

Page 3

Health and Safety

Warnings

A warning is used to indi cate possibl e danger to personnel. Th roughout P ark Air hand books, war nings

are indicated by the following symbols:

Indicates electrical danger to personnel.WARNING

WARNING

WARNING

WARNING

Indicates a hazardous material.

Indicates a non-ionizing radiation hazard.

Indicates a specified danger to personnel.

Cautions

A caution is used to indicate possible danger to the equipment.

Indicates the presence of electrostatic sensitive devices (ESSD). Caution

Indicates a specified danger to the equipment. Caution

Trademarks

The following tradenames are used in this handbook.

IBM This is a registered trademark of International Business Machines.

Microsoft This is a registered trademark of Microsoft Corporation in the USA and other

countries.

Windows This is a registered trademark of Microsoft Corporation in the USA and other

countries.

T6T VHF 100 W Transmitter Page iii

Page 4

List of Abbreviations

ac alternating current

AGC automatic gain control

AM amplitude modulation

ATC air traffic control

BER bit error rate

BIT built-in test

C celsius

CD compact disk

dB decibel

dc direct current

DSB double sideband

E-BIT external bit signal

ESSD electrostatic se nsiti ve devices

Fig figure

FM frequency modulation

Hz hertz

RF radio frequency

ROM read-only memory

RSE2 remote site equipment

RSSI receiver signal strength indication

Vvolt

VFP virtual front panel

VHF very high frequency

VOGAD voice-operated gain adjusting device

VSWR voltage standing wave ratio

Wwatt

IF intermediate frequency

kg kilogramme

kHz kilohertz

LCD liquid crystal display

mmetre

mA milliamp

MARC multi-access remote control

mm millimetre

mW milliwatt

MHz megahertz

MSK minimum shift keying

PA power amplifier

PC personal computer

PCB printed circuit board

pk-pk peak-to-peak

ppm parts per million

PSU power supply unit

PTT press to transmit

Page iv T6T VHF 100 W Transmitter

Page 5

Approvals and Standards T6T VHF 100 Watt Transmitters

This Class B digital apparatus complies with Canadian ICES-003

Approvals:

The equipment is designed to meet the essential requirements of Directives

1999/5/EC, 89/336EEC as amended by Directive 93/68/EEC, and 72/23/EEC.

Standards:

The following standards are applied:

EMC EN 301 489-1; EN 301 489-22.

Health & Safety, EN 60950, CAN/CSA-C22.2 No. 60950, UL 60950.

Radio EN 300 676, IC RSS141, FCC part 15 and 87.

Telecom CS-03.

FCC Statement:

This device has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and the receiver.

-Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

-Consult the supplier or an experienced radio/TV technician for help.

Operation on 8.33 kHz channel spacing is restricted to European customers.

Page 6

About This Hard Copy

This document, apart fr om the preface, is a hard copy of the files contai ned on the CD and co mprises

the following parts:

Preface (not on CD)

Introduction

Specification

Operation

Installation

Maintenance.

Page vi T6T VHF 100 W Transmitter

Page 7

Introduction

Back to Transmitter

Main Page

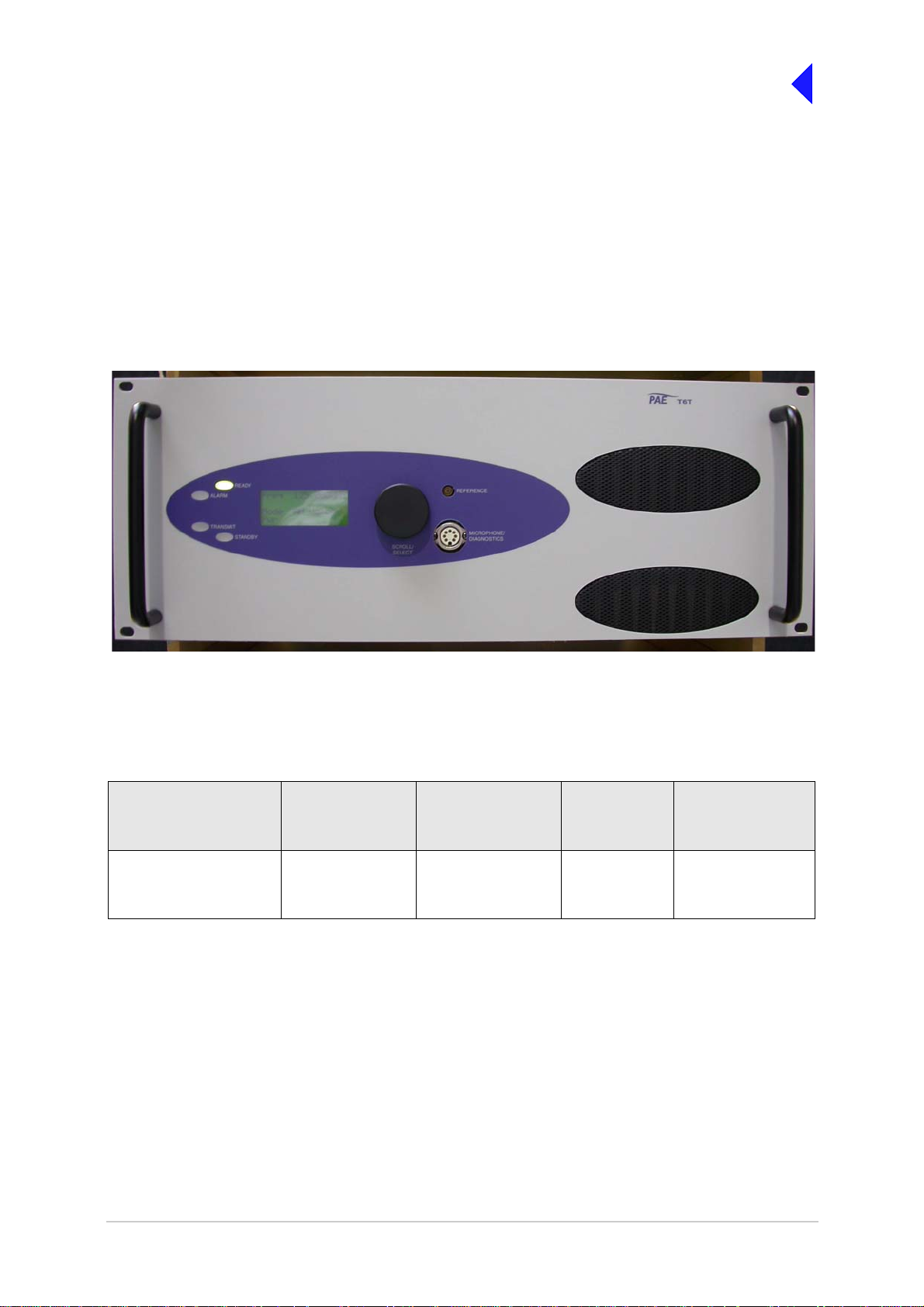

This topic gives a brief introduction to the T6T VHF 100 W Multimode Transmitter.

Page 8

Back to Transmitter

Main Page

Purpose

The T6T VHF multim ode 100 W transmitter i s intended for use in fixed ground envir onments such as

airports and en-route centres. The transmitter operates in voice and ICAO defined data modes at

frequencies between 118 and 136.975 MHz.

Dependent on the software loaded into the radio, the following operating modes can be selected:

❑ AM-Voice. All transmitters have this mode

❑ AM-MSK (optional)

❑ Mode 2 (optional)

❑ Mode 3 (optional).

Fig 1 T6T VHF 100 W Transmitter

Models and Part Numbers

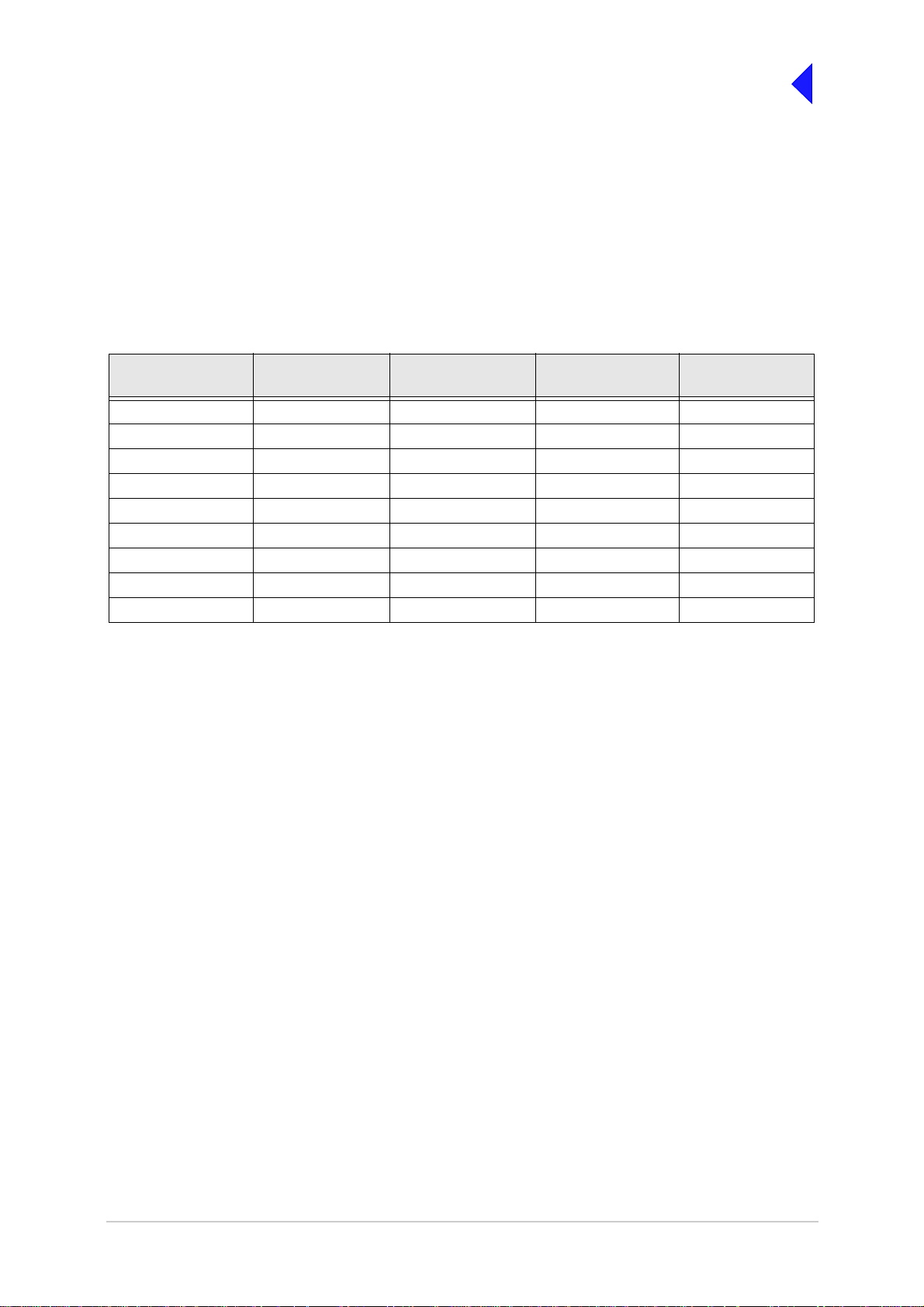

The following table identifies the T6T VHF 100 W transmitters:

Description Part Number Frequency Range Channel

T6T 100 W standard

frequency coverage high

stability transmitter

B63100HS/NB 118 to 136.975 MHz 25 kHz or

Spacing

(AM-Voice)

8.33 kHz

Special

Applications

Supports 5-offset

carrier operation

Mechanical Installation

The transmitter fits i nto a n i ndu strial standard 19 in ch (483 mm) equipment cabine t an d o cc upies 4U of

space.

T6T VHF 100 W Transmitter Page 2 Introduction

Page 9

Back to Transmitter

Main Page

Frequency Selection

T6 radios operate with 8.33 kHz and 25 kHz channel spacing. The radios recognize frequencies entered

in ICAO format and automa tically ad just to t he corr ect channe l spaci ng. For m ultichan nel operati on up

to 100 preset frequency cha nnels can be stored in the radi o for immediate recall; any combina tion of

8.33 kHz and 25 kHz channel spacing can be stored. Any valid operating frequency can be selected from

the radio’s front panel or a compatible remote control equipment.

Operating Parameters

The transmitter’s o per at ing pa ra mete rs a re se t us ing the front panel multi- purpose Scroll/Select swi tc h,

or by using the Park Air Virtual Front Panel (VFP) software in conjunction with a Personal Computer (PC).

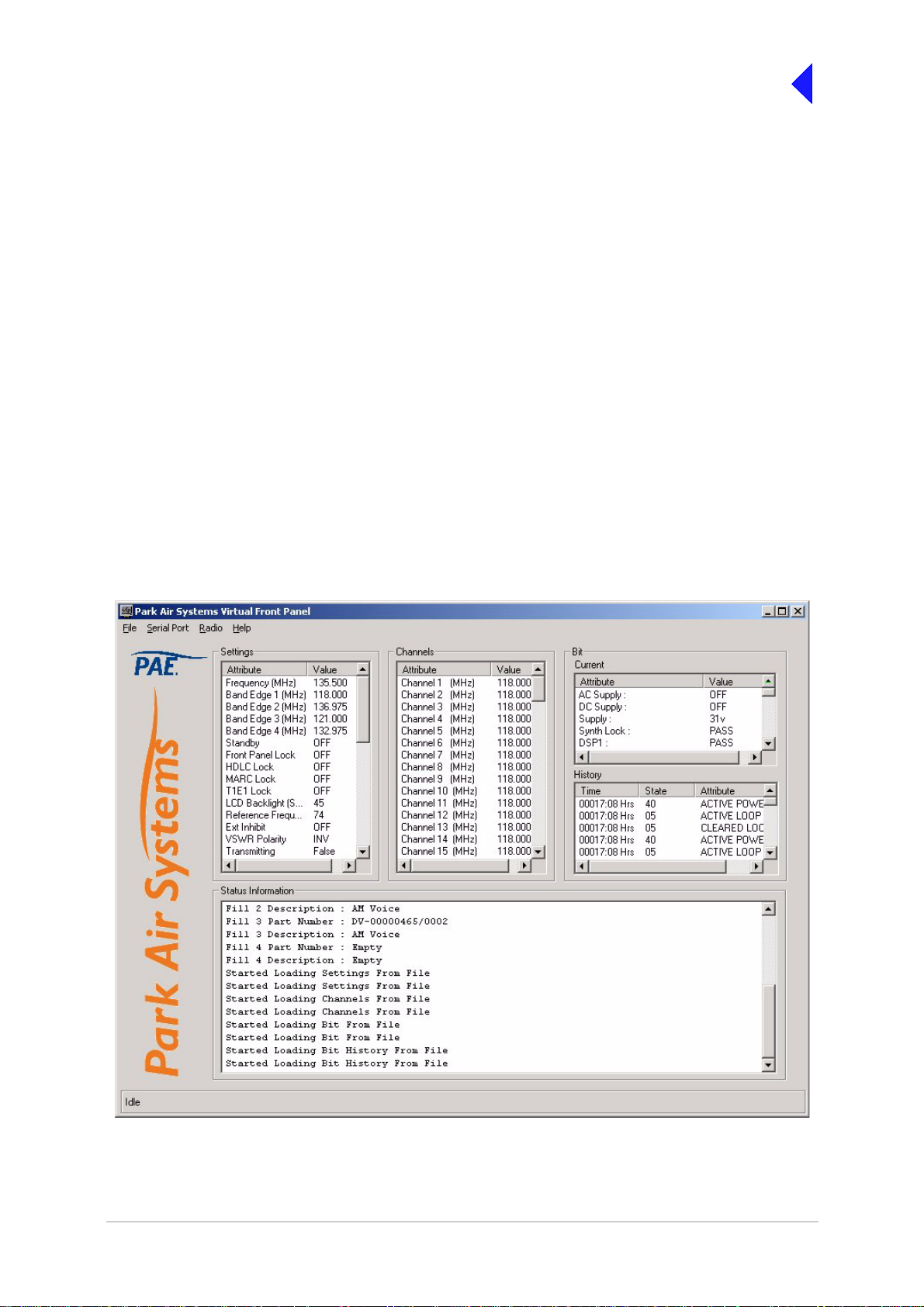

Virtual Front Panel

The Virtual Front Panel (VFP) software supplied on CD with the radio is compatible with any PC or laptop

running Windows 2000™ or Windo ws XP ™. T he VFP allo ws ch ang es to a rad io’ s setti ngs and cha nne l

information, it dis plays the curre nt BIT state, display s BIT history, allo ws security lo cks to be set, and

provides maintenance facilities. A typical VFP presentation is shown in Fig 2. Using the VFP has s ever al

advantages over setting a radio from the front panel; these are:

❑ A profile of the operati onal setti ngs an d chann el inform ation c an be cr eated, stored on di sk, and

then recalled to download into other radios.

❑ A print out of the radio’s profile can be made from the VFP.

❑ The front panel controls can be locked. Front Panel Lock is available only when using the VFP.

Fig 2 Typical VFP Presentation

T6T VHF 100 W Transmitter Page 3 Introduction

Page 10

Back to Transmitter

Main Page

Intentionally Blank

Page 11

Specification

Back to Transmitter

Main Page

This section gives the specification applicable to the T6T VHF 100 W Multimode Transmitter

operating in AM modes, Mode 2 and Mode 3.

All radios operate in AM-Voice mode. Additional software must be loaded to allow AM-MSK,

Mode 2 and Mode 3 operation.

Page 12

Back to Transmitter

Main Page

General Specification

The general speci fication applies t o the T6T 100 watt trans mitter irr espective of the sele cted op erating

mode. Separate listings are given for AM modes, Mode 2 and Mode 3. One model of the T6T VHF 100 W

Multimode Transmitter is available as detailed in Table 1.

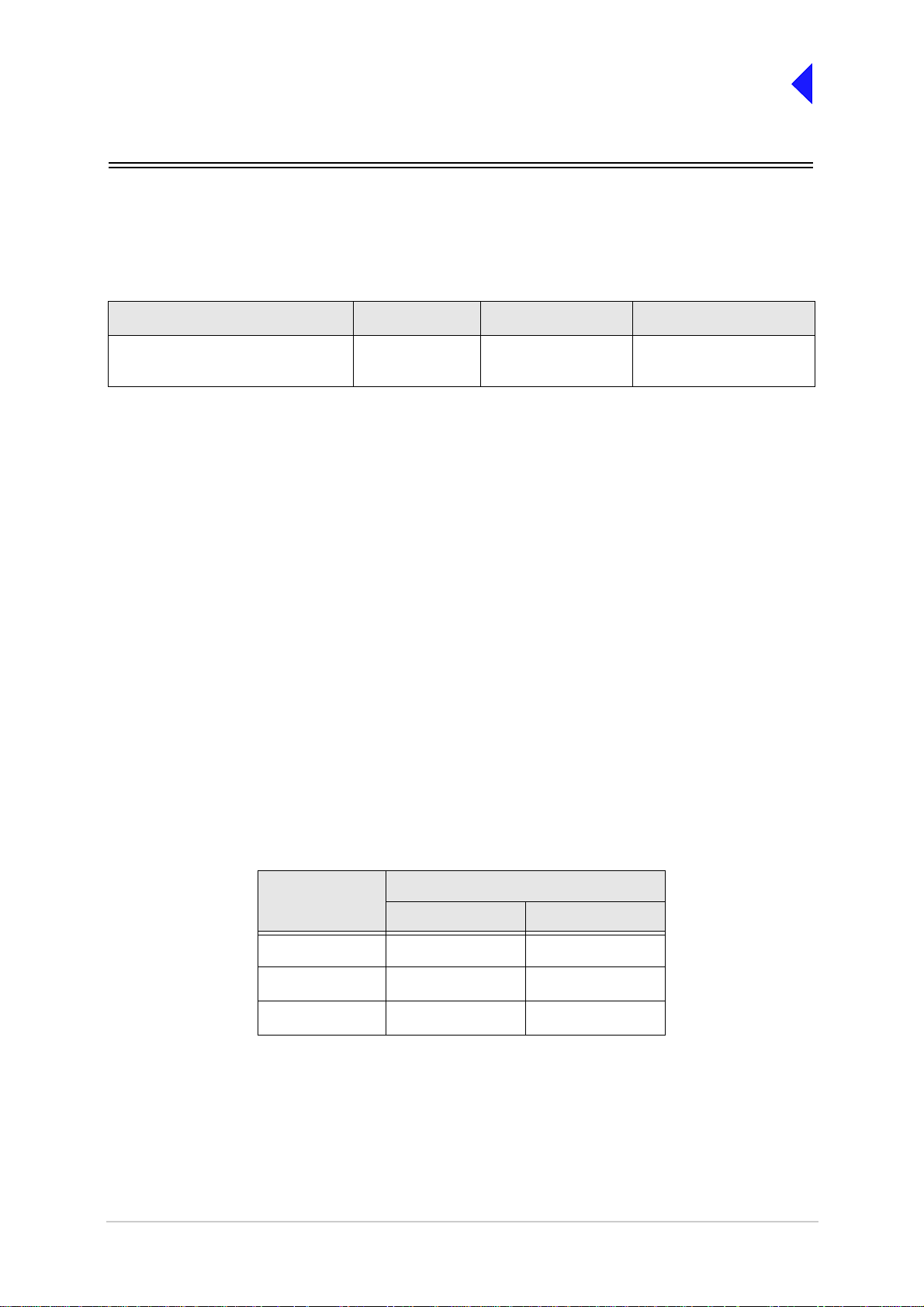

Table 1 100 Watt T6 Transmitter

Description Part Number Frequency Range Special Applications

100 watt, high stability, standard

frequency coverage transmitter

B63100HS/NB 118 to 136.975MHz Supports 5-offset carrier

operation

Frequency accuracy

The frequency accuracy is better than 0.3 ppm.

Number of Channels

The transmitter has a multichannel capability. 100 channels can be stored and recalled.

Power Requirements

The transmitter operates from an ac mains supply, or a dc input supply. When both supplies are

connected, the dc input acts as an automatic backup for the ac mains.

ac input supply The transmitter operates from a 48 to 62 Hz single-phase ac supply

and automatically adjusts to operate from any supply voltage ranging

from 110 Vac to 230 Vac ±10%. The power consumption figures are

given in Table 2.

dc input supply The transmitter operates from a dc input supply between 21.6 and

32 V (measured at the radio’s input). Current loading is given in

Table 2.

Table 2 Power Consumption

Requirement 100 Watt T rans mitte r Normal Operation

ac dc

Maximum 1000 VA 24 A

Typical 600 VA 17 A

Not Transmitti ng 90 VA 1.5 A

T6T VHF 100 W Transmitter Page 2 Specification

Page 13

Back to Transmitter

Main Page

Dimensions and Weight

The dimensions and weight of the 100 watt transmitter are:

Width 483 mm (19 inches).

Height 177.8 mm (7 inches). The height occupies 4U of equipment cabinet

space.

Depth 430 mm (16.9 inches) measured from front panel to rear panel.

465 mm (18.3 inches) measured from front panel to rear RF

connectors.

Weight 25 kg (55 pounds).

Environmental

Temperature range The transmitter operates to specification across the temperature

range of -20°C to +55°C.

The transmitter can be stored at temperatures ranging from

-30°C to +70°C without caus ing any dama ge.

Humidity The transmitter operates to specification at a relative humidity

between 5% and 90% non-condensing.

Altitude The transmitter operates to specification up to 15,000 feet.

Additionally it is capable of storage at altitudes up to 50,000 feet

without damage.

Shock and vibration The transmitter complies with shock and vibration protection

MIL-STD-810E, method 516.4, procedure VI - Bench Handling.

Ventilation The transmitter is cooled by integral fans, which normally runs at half

speed. At an RF PA temperature of 45°C this is increased to full speed

and at 40°C it reduces to half speed again.

The transmitter power supply units also use internal fans.

Warm up time The transmitter is fully operational within 20 seconds but can take up

to 10 minutes to achieve frequency accuracy for offset carrier.

T6T VHF 100 W Transmitter Page 3 Specification

Page 14

Back to Transmitter

Main Page

AM Modes

The transmitter can oper at e in A M-Vo ic e mo de (st anda rd ) and A M- MS K mo de (opti on al) . The fo ll owi ng

specifications apply to both modes unless stated otherwise.

Transmitter RF Characteristics

RF Power Output

The RF car r ier ou tp ut po w e r i s ad j us t ab le in 2 W s te p s fr om 10 W t o 10 0 W.A s an op tio n, th e maxi mum

selectable power can be limited. Output power is automatically controlled under the following conditions:

Frequency range Variations in power remain within 0 to +1 dB over the operational

frequency range.

Low supply voltage Variations in power remain within ±1 dB for supply voltages between

24 Vdc and 32 Vdc.

High VSWR Loop error can reduce power progressively by up to 3 dB. Variations

in power remain within ±1 dB into a VSWR of up to 2.5:1. At a VSWR

greater than this the output power may be reduced by 10 dB ±1 dB.

High RF PA temperature If the RF PA temperature sensor exceeds 80°C the output power is

reduced by 3 dB ±1 dB. If the RF PA temperature sensor exceeds

90°C the transmitter is de-keyed and automatically re-keyed at 70°C.

PA Module Failure If one of the two PA modules fails, the transmitter will continue to

operate at half power, 50 watts.

Duty Cycle

Both modes 100% continuous operation.

Channel Spacing

AM-Voice mode The transmitter is capable of both 25 kHz channel spacing and

8.33 kHz channel spacing.

AM-MSK mode 25 kHz.

Offset Carrier

AM-Voice mode The transmitter is capable of offsetting the carrier frequency to provide

2, 3, 4 and 5-carrier offset.

AM-MSK mode Offset carrier is not available.

Harmonic Outputs

Both modes Second harmonic outputs are less than -36 dBm, third harmonic

outputs are less than -46 dBm and fourth harmonic outputs and above

up to 4 GHz, are less than -56 dBm.

T6T VHF 100 W Transmitter Page 4 Specification

Page 15

Back to Transmitter

Main Page

Spurious Outputs

Both modes The spurious outputs are less than -46 dBm for modulation depths up

to 90%, measured at greater than 500 kHz from carrier in the

frequency range 9 kHz to 4 GHz. There are no coherent spurious

outputs above the spectral mask at less than 500 kHz.

Intermodulation

Both modes Intermodulation products, caused by an interfering signal with the

same power as the transmitter isolated by 30 dB, are at least -40 dBc

at ≥±150 kHz and -50 dBc at ≥±500 kHz.

Transmitter Modulation Characteristics

The transmitter modulation characteristics are as follows:

Mode

AM-Voice AM-Voice mode uses Double Sideband (DSB) Amplitude Modulation

(AM) full carrier; emission designator 6K80A3EJN for 25 kHz

channels and 5K00A3EJN for 8.33 kHz channels.

AM-MSK AM-MSK mode uses Double Sideband (DSB) Amplitude Modulation

(AM) full carrier; emission designator 13K0A2DJN.

Modulation Depth

Both modes The transmitter is capable of modulation depths up to 95%.

Hum and Noise

Both modes The hum and noise is more than 45 dB below the signal level for line

input levels <-13 dBm, and more than 50 dB below the signal level for

line input levels ≥-13 dBm, for a carrier modulated by a 1 kHz signal

with a modulation depth of 90%.

Frequency Response

25 kHz channel spacing AM-Voice and AM-MSK: The variation in frequency response with

reference to a 1 kHz signal is within +0.5 dB and -1.5 dB across the

frequency range 300 to 3400 Hz. The response is also less than

-20 dB at 100 Hz and below, and less than -30 dB at 4 kHz and above.

8.33 kHz channel spacing AM-Voice only: The variation in frequency response with reference to

a 1 kHz signal is within +0.5 dB and -1.5 dB across the frequency

range 350 Hz to 2500 Hz. The response is also less than -10 dB at

100 Hz and below, and less than -30 dB at 3200 Hz and above.

Distortion

25 kHz channel spacing The total harmonic distortion is less than 5% due to signals with a

modulation depth of 90%, within the frequency range 300 Hz to

3400 Hz.

8.33 kHz channel spacing AM-Voice only: The total harmonic distortion is less than 5% due to

signals with a modulation depth of 90%, within the frequency range

350 Hz to 2500 Hz.

T6T VHF 100 W Transmitter Page 5 Specification

Page 16

Back to Transmitter

Main Page

Residual FM

Both modes For a test signal of 1 kHz set at 80% modulation depth applied to the

line input of the transmitter, the unwanted peak frequency modulation

does not exceed ±500 Hz.

VOGAD

AM-Voice The VOGAD has an operational range of 30 dB. The VOGAD can be

disabled.

AM-MSK The VOGAD is disabled.

Mute

AM-Voice The mute level is set at 15 dB below the average speech line level

setting. The mute can be disabled.

AM-MSK The mute is disabled.

Differential Group Delay

AM-MSK There is less than 60 µs differential group delay for signals in the

range 1200 to 2400 Hz.

Transmitter Control

Transmitter control characteristics are as follows:

Audio Inputs

Voice can be connected t o the transmi tter via the fr ont panel mi crophon e connec tor. Vo ice ca n also be

connected via the line inputs. Line level setting from -30 to +10 dBm.

PTT Time O u t

The time out period is adjustable from 2 to 510 seconds in 2 second steps or it can be disabled.

T6T VHF 100 W Transmitter Page 6 Specification

Page 17

Back to Transmitter

Main Page

Mode 2

This section gives the transm itter spe cificati on appl icable to Mo de 2 op eration. Mo de 2 para meters ar e

identical to AM-Voice mode parameters with the following exceptions:

RF Power Rise Time

The transmitter pr oduces more than 90% of full power output within the first 2 symbols of th e power

stabilization segment, which is the first segment of the training sequence and consists of 4 symbols each

representing 000.

RF Power Decay Time

The output power decays by more than 20 dB within 2.5 symbols of the middle of the final symbol.

Channel Spacing

25 kHz channel spacing only.

Transmitter Modulation Characteristics

Mode 2 uses Carrier Sense Multiple Access (CSMA) differentially encoded 8-phase shift keying

(D8PSK), using a raised cosine filter with α=0.6 (nominal value), emission designator 14K0G1DE.

Information is differ en tial ly en co ded with 3 bi ts p er sy mb ol t ra nsm it ted a s changes in phase rather th an

absolute phase. T he data stream i s divided in to groups of 3 con secutive data bits, least si gnificant bit

first. Zeros are padded to the end of transmissions if needed for the final channel symbol.

Modulation Rate

The symbol rate is 10,500 symbols/second (±0.005%), resulting in a nominal bit rate of 31,500 bits/s.

RMS Phase Error

The RMS phase error is less than 3°. The error vector magnitude is less than 6%.

Phase Acceleration

The total frequency change during the transmission of the unique word is less than 10 Hz. After this, the

phase acceleration is less than 500 Hz/s.

T6T VHF 100 W Transmitter Page 7 Specification

Page 18

Back to Transmitter

Main Page

Mode 3

This section gives the transm itter spe cificati on appl icable to Mo de 3 op eration. Mo de 3 para meters ar e

identical to AM-Voice mode parameters with the following exceptions:

RF Power Rise Time

The transmitter pr oduces more than 90% of full power output within the first 2 symbols of th e power

stabilization segment, which is the first segment of the training sequence and consists of 4 symbols each

representing 000.

RF Power Decay Time

The output power decays by more than 20 dB within 2.5 symbols of the middle of the final symbol.

Channel Spacing

25 kHz channel spacing only.

Transmitter Modulation Characteristics

Mode 3 uses Time Division Multiple Access (TDMA) differentially encoded 8-phase shift keying (D8PSK),

using a raised cosine filter with α=0.6 (nominal value), emission designator 14K0G7WET. Information is

differentially encoded with 3 bits per symbol transmitted as changes in phase rather than absolute phase.

The data stream is div ided into groups of 3 consecutiv e data bits, least significant bi t first. Zeros are

padded to the end of transmissions if needed for the final channel symbol.

Modulation Rate

The symbol rate is 10,500 symbols/second (±0.005%), resulting in a nominal bit rate of 31,500 bits/s.

RMS Phase Error

The RMS phase error is less than 3°. The error vector magnitude is less than 6%.

Phase Acceleration

The total frequency change during the transmission of the unique word is less than 10 Hz. After this, the

phase acceleration is less than 500 Hz/s.

T6T VHF 100 W Transmitter Page 8 Specification

Page 19

Operation

Back to Transmitter

Main Page

This topic describes the transmitter’s operating controls and indicators.

It also details how to set up the transmitter’s operating parameters.

Page 20

Back to Transmitter

Main Page

Controls, Indicators and Front Panel Connectors

This section describes the transmitter’s controls, indicators and front panel connectors.

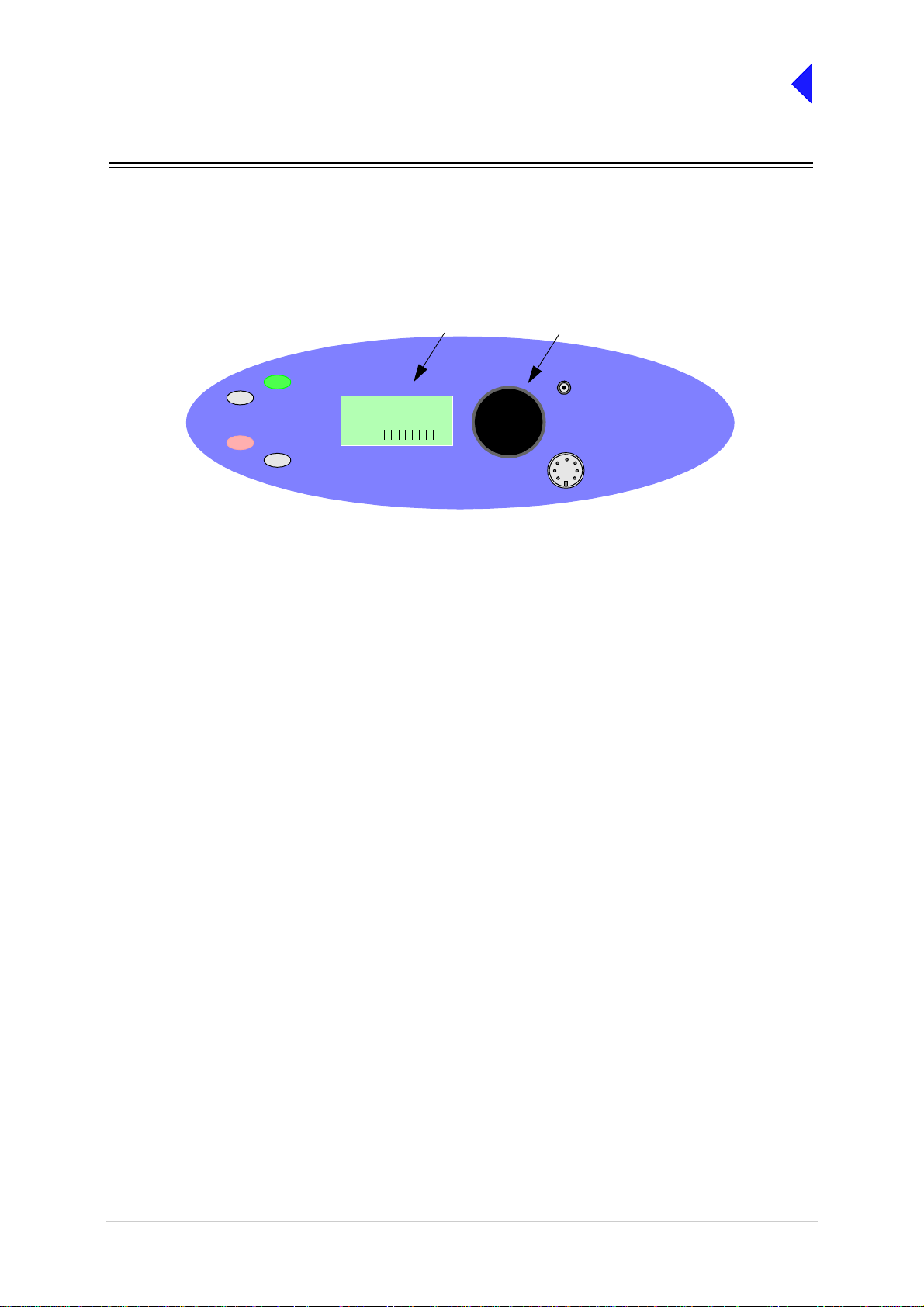

Front Panel

The transmitter’s front panel is illustrated below.

Scroll/Select SwitchLCD

ALARM

TRANSMIT

READY

STANDBY

F r e q 1 1 8 .0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

M o d e A M V o i c e 1

P w r

SCROLL/

SELECT

REFERENCE

MICROPHONE/

DIAGNOSTICS

Scroll/Select Switch and LCD

The Scroll/Select switch is used in conjunction with the LCD to select most of the transmitter's operational

settings. During nor mal operati on, the LCD shows th e operating frequency , the channel number (if the

channel store faci lity is used), the carrier offset (if us ed), and displays a graphical rep resentation of

instantaneous peak power.

The example LCD s creen above sho ws the transmitter operating on 11 8.000 MHz; the frequency has

been preset as channel 100 and offset at +7.3 kHz.

Ready Indicator

A green indicator that lights when the transmitter is ready for use and no BIT faults have been detected.

Transmit Indicator

An amber indicator that lights when the transmit circuit is keyed and producing output power.

Alarm Indicator

A red indicator that eit her flashes, or lights, when a BIT fault ha s been detected. BIT indications are

classified as either Alarms or Alerts.

If an ‘alert’ conditi on is detected, the Alarm i ndicator flashes, the Ready i ndicator remains lit, and t he

transmitter remains operational. A BIT ‘alert’ is indicated if:

❑ The transmitter RF output power has reduced from its setting by more than 1 dB but not more than

3 dB.

❑ The supply volts falls below a pre-defined level.

Any other BIT condit ion results in an alarm. When detected, the Alarm indicator lights and the Ready

indicator becomes unlit; the transmitter cannot be used.

T6T VHF 100 W Transmitter Page 2 Operation

Page 21

Back to Transmitter

Main Page

Standby Indicator

A red indicator that lights whe n the tran smitte r is in stan dby mode. Whe n in stand by mode , most of the

radio's circuits are inactive, the front panel LCD is blanked, and the transmitter cannot be keyed.

Standby mode is selected and deselected using the front panel Scroll/Select switch and LCD, by initiating

an instruction th rough a MARC sys tem, th rough a T6 contr oller or th rough th e VF P. For details of front

panel selection and deselection see page 14.

Reference Connector

An SMB jack soc ket that allows a freq uency counter to moni tor the transmitter 's reference frequen cy.

This connector is used onl y for mainte nance purpos es. The instr uctions for checking and adjusting the

reference frequency are given in the Maintenance section.

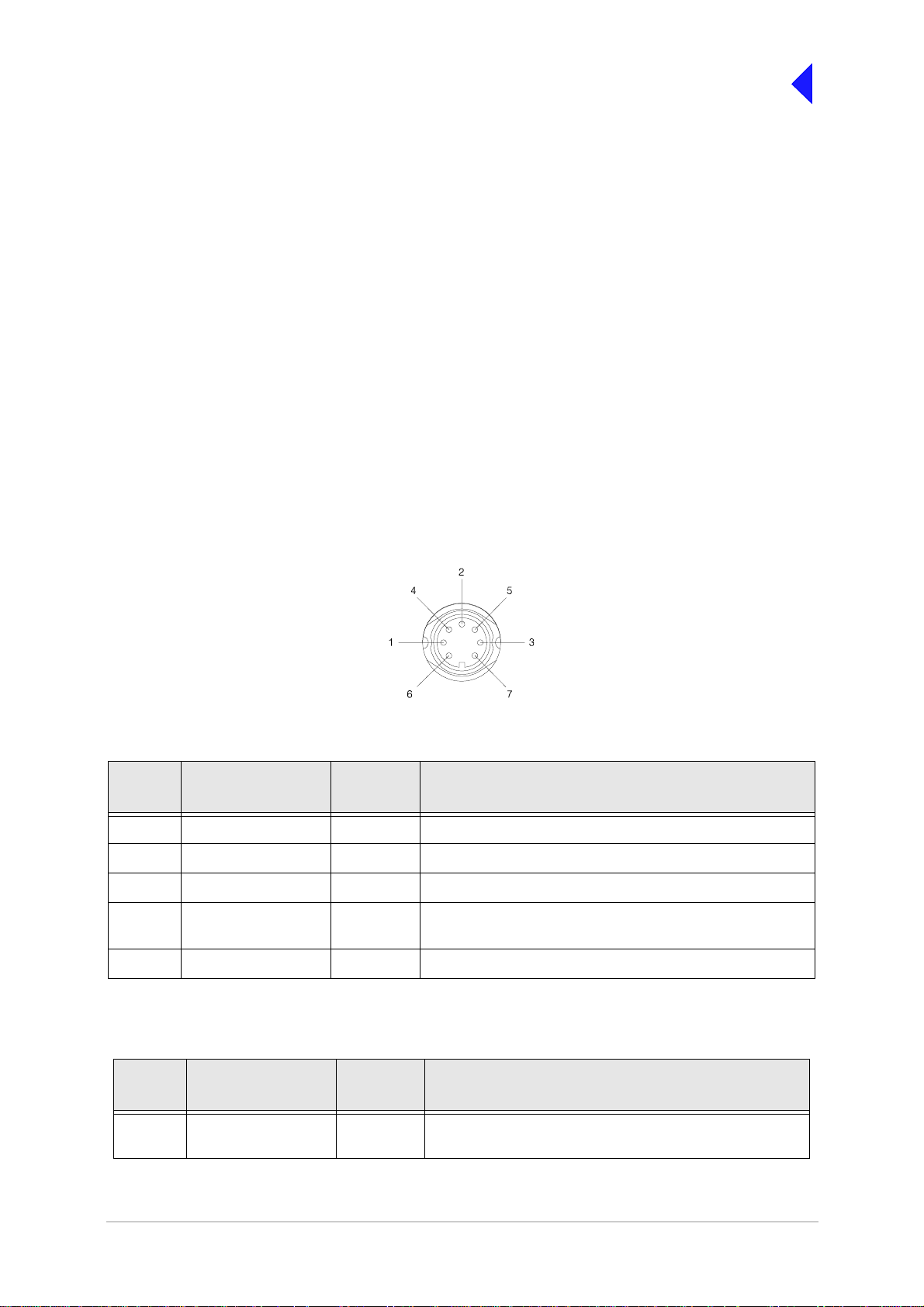

Microphone/Diagnostics Connector

A dual purpose conne ctor that allows either a micro phone, o r a PC, t o be connec ted to the trans mitter.

The connector is a 7-pin self-locking DIN socket; the pin-out is shown in Table 1.

A microphone is fitted to thi s conn ector to enab le the t ransmit ter to be ope rated in AM loca l mod e. The

connections are detailed in Table 1. A PC can also be connected to allow the VFP to be displayed. Using

the VFP is detailed in the Maintenance section. The PC connections at the transmitter a re shown in

Table 2 on the following page.

Viewed from front

Table 1 Microphone/Diagnostics Connector - Audio Connections

Pin

Number

1 Microphone ground - 0 V.

3 Microphone PTT Input 0 V to PTT.

5 Sidetone Output 0 to 3 V pk-pk.

6 Microphone input Input 2 to 35 mV rms on Passive setting and 8 to 140 mV rms on

7Ground - 0V.

Signal

Input or

Output

Description

Active setting to remain in VOGAD range.

Table 2 Microphone/Diagnostics Connector - PC Connections

Pin

Number

2 Transmit data Output RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

T6T VHF 100 W Transmitter Page 3 Operation

Signal

Input or

Output

Description

handshaking.

Page 22

Back to Transmitter

Main Page

Table 2 Microphone/Diagnostics Connector - PC Connections

Pin

Number

4 Receive data Input RS232, 115200 baud, 8 data bits, 1 stop bit, no parity, no

7 Ground - 0 V.

Signal

Input or

Output

Description

handshaking.

Rear Panel Power Switch

The rear panel power switch is a 2-way rocker switch used to select between power on, and standby.

WARNING

When the Power switch is set to the Standby position, dangerous voltages are still present

in the transmitter's internal power supply circuitry. To ensure safe working, the transmitter

must be isolated from the ac and dc input supplies.

Dangerous Voltages

= Standby= On

T6T VHF 100 W Transmitter Page 4 Operation

Page 23

Back to Transmitter

Main Page

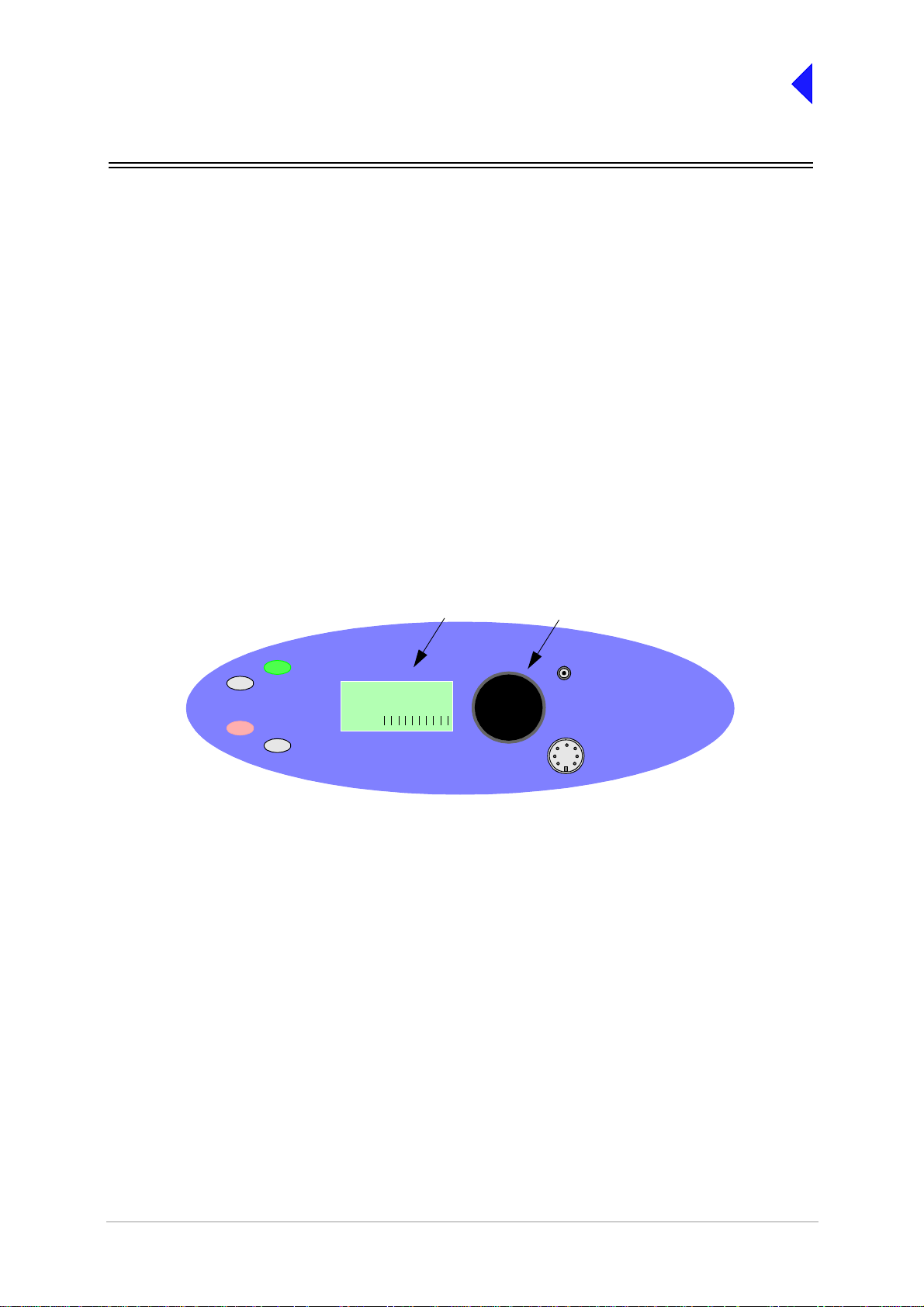

Setting Up and Operation

Introduction

Setting up the transmi tter involves using the front panel Sc roll/Select switch to specify th e operating

parameters.

Operating parameters can also be set using the Virtual Front Panel (VFP), through a Multi-Access

Remote Control (MARC) sys tem, from an assoc iated T6 controlle r. VFP operatio n is described on this

disk under Maintenance; MARC and T6 controller functionality is described in separate handbooks.

Table 9 on page 32 details the functions and parameters that can be set from all sources.

No attempt to set up the transmitter should be made until the installation procedures, given in the

Installation topic, are completed.

Normal Operation

During normal operation, the LCD displays the Main screen. This screen shows the operating frequency,

the channel number (i f the channel store facility is used), the c arrier offset (if used), and displays a

graphical representation of output power when the transmitter is keyed. If the transmitter has been set to

Standby mode, which is shown by the front panel Standby indicator being lit, the LCD is blanked.

Scroll/Select SwitchLCD

ALARM

TRANSMIT

READY

STANDBY

F r e q 1 1 8 .0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

M o d e A M V o i c e 1

P w r

SCROLL/

SELECT

REFERENCE

MICROPHONE/

DIAGNOSTICS

Using the Scroll/Select Switch

The Scroll/Select switc h (referred to throughout this sec tion as the ‘Switch’) is used to leav e the Main

screen and display the Control screen (see page 8). Further use of the Sw itch d ispla ys va rious s ele ction

menus and allows t he required parameters to be set. Th e switch has three actions: it can b e turned

clockwise, anti-clockwise, or momentarily pushed in.

T6T VHF 100 W Transmitter Page 5 Operation

Page 24

Back to Transmitter

Main Page

Screen Protocol

The following protocol is applicable to all screens described in this document.

Main Screen During normal operation, the Main screen (an example of which is shown below

whilst the transmitter is transmitting) is displayed.

F r e q 1 1 8 . 0 0 0 M H z

C h 1 0 0 + 7 . 3 k H z

M o d e A M V o i c e

P w r I I I I I I I I I I

Switch Refers to the front panel Scroll/Select switch. The switch is turned clockwise to scroll

through fields from left to right, and from top to bottom. The switch is turned

anti-clockwise to scroll through fields from right to left, and from bottom to top. The

switch is pressed to make a selection.

Time out If during any setting up procedure the Scroll/Select switch is not operated for

30 seconds, the display returns to the Main screen. If editing any parameter has not

been completed, the transmitter stays on the original setting.

>> Indicates m ore fields are available other than those currently displayed. To access

those fields, turn the switch clockwise through the last displayed field.

<< Indicates m ore fields are available other than those currently displayed. To access

those fields, turn the switch anti-clockwise through the first displayed field.

Back When Back is selected, you are returned to the previous menu.

Exit When Exit is selected, you are returned to the Main screen.

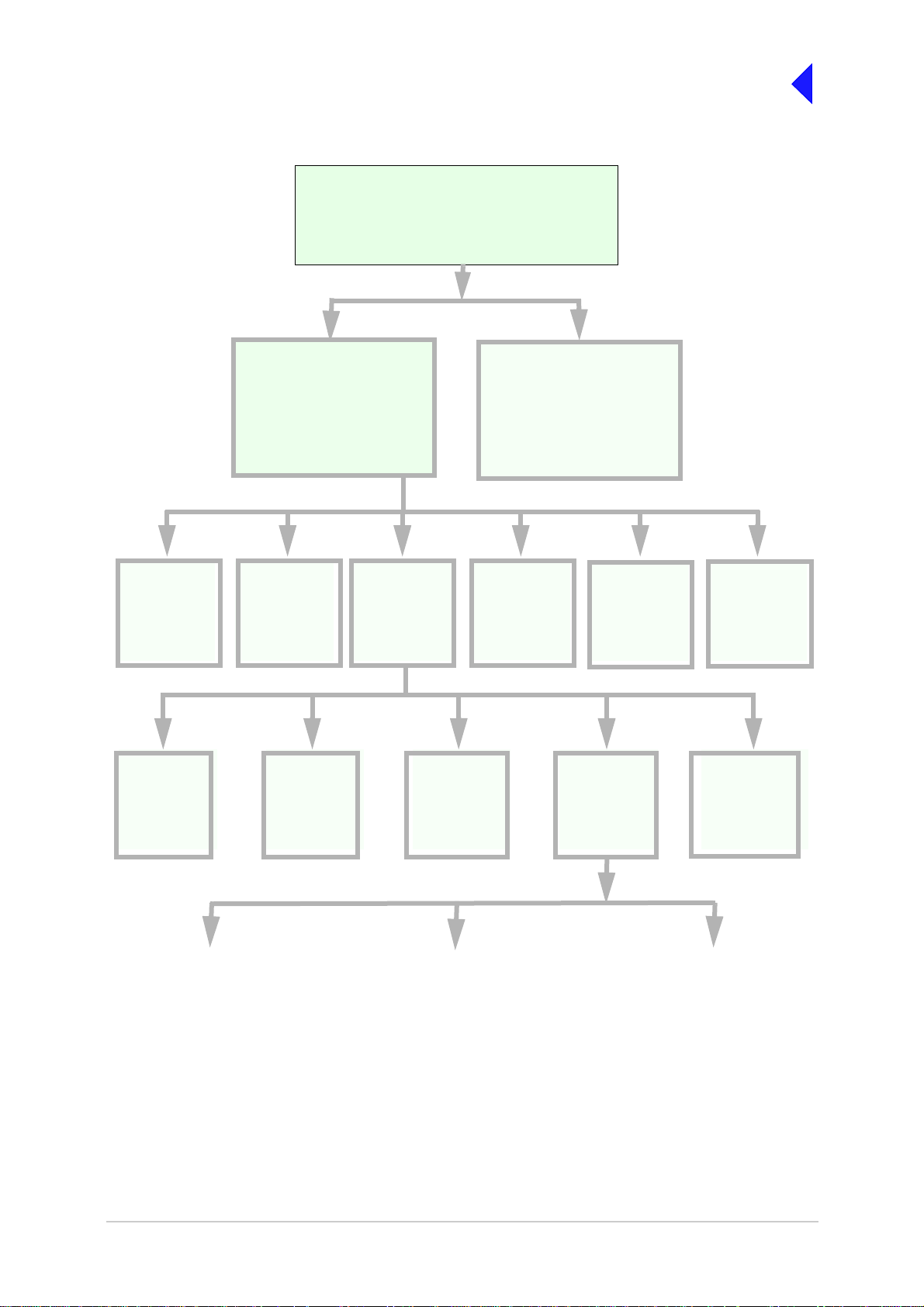

Menu System

The front panel control of the radio is implemented through a hierarchical menu system as shown on the

following page.

T6T VHF 100 W Transmitter Page 6 Operation

Page 25

Back to Transmitter

Main Page

Frequency

Set the

transmitter

operating

frequency

F r e q 1 1 8 . 0 0 0 M H z

C h 1 0 0

M o d e A M V o i c e

P w r I I I I I I I I I I

Control Screen

Configure the transmitter

operating parameters, ac cess

the BIT facility or view the

software configuration

Channel

Set or recall up

to 100 preset

frequency

channels

.

Settings

Set the

transmitter

operational

settings

Menu Lock Screen

BIT

Initiate a BIT

test and view

results

Displayed during normal

transmitter operation

S/W Config

View the

transmitter

software

configuration

Main Screen

(Example)

Standby

Enter or Exit

standby mode

Backlight

Adjust the

display’s

backlight

AM-Voice Mode

Settings

(see page 17)

Ref Freq

Adjust the

transmitter

reference

frequency

Band Edges

Set up the

transmitter

band edges

AM-MSK Mode

Settings

(see page 19)

Menu System

Mode and

Mode

Settings

Select Mode

Polarities

Set the active

polarity for

certain hardwire

connections

Digital Modes

(see page 20)

T6T VHF 100 W Transmitter Page 7 Operation

Page 26

Back to Transmitter

Main Page

Menu Lock Screen

A security facility available only from the VFP allows the transmitter front panel to be ‘locked’. When this

facility is active, no op erational set tings can be ma de from the front panel until an ‘unlo ck’ command is

sent from the VFP.

The following screen is displayed when ‘lock’ is active, and the front panel switch is pressed.

S E C U R I T Y M E S S A G E

F r o n t P a n e l

L o c k e d

O K

To exit the system lock screen:

❑ Select OK, then press the switch. You are returned to the Main screen.

or,

❑ Wait for the 30 second time out to expire. You are returned to the Main screen.

Control Screen

The Control screen is entered from the Main screen by pressin g the switch. The following screen is

displayed:

Change the transmitter operating frequency.

Store or recall preset channel frequencies.

Select operating mode and mode se ttin gs .

Initiate a BIT test and view results.

View software configuration.

Enter or exit standby mode.

F r e q u e n c y

C h a n n e l

S e t t i n g s

E x i t > >

B I T

S / W C o n f i g

S t a n d b y

E x i t < <

T6T VHF 100 W Transmitter Page 8 Operation

Page 27

Back to Transmitter

Main Page

Notes for Setting Up the Transmitter

The following notes should be read before setting up the transmitter. They advise on the special

frequency display when using 8 .33 kHz chann el spacing , and give guidan ce on the op timum line le vel

settings. Note that for operation in the United States of America, this equipment is certified only for

operation using 25 kHz channel spacing.

Front Panel Display for 25 kHz and 8.33 kHz Channel Spacing

When setting the op erating fr equency of the trans mitter and 8.33 kHz channe l spacing is requi red, the

displayed frequency differs from the actual channel frequency. Table 3 shows the pattern used for

25 kHz and 8.33 kHz spaced channel frequencies from 118.000 MHz to 118.141 MHz. The pattern is the

same for any frequency within the transmitter's frequency range. The display conforms to ICAO

convention for 8.33 kHz operation.

T able 3 25 kHz and 8.33 kHz Channel Spacing Displays

Actual Frequency

(to 4 decimal places)

118.0000 MHz

118.0000 MHz

118.0083 MHz

118.0166 MHz

118.0250 MHz

118.0250 MHz

118.0333 MHz

118.0416 MHz

118.0500 MHz

118.0500 MHz

118.0583 MHz

118.0666 MHz

118.0750 MHz

118.0750 MHz

118.0833 MHz

118.0916 MHz

118.1000 MHz

118.1000 MHz

118.1083 MHz

118.1166 MHz

Channel Spacing Displayed Frequency

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

at Transmitter's Front Panel

118.0 00 MH z

118.005 MHz

118.010 MHz

118.015 MHz

118.0 25 MH z

118.030 MHz

118.035 MHz

118.040 MHz

118.0 50 MH z

118.055 MHz

118.060 MHz

118.065 MHz

118.0 75 MH z

118.080 MHz

118.085 MHz

118.090 MHz

118.1 00 MH z

118.105 MHz

118.110 MHz

118.115 MHz

118.1250 MHz

118.1250 MHz

118.1333 MHz

118.1416 MHz

T6T VHF 100 W Transmitter Page 9 Operation

25 kHz

8.33 kHz

8.33 kHz

8.33 kHz

118.1 25 MH z

118.130 MHz

118.135 MHz

118.140 MHz

Page 28

Back to Transmitter

Main Page

Line Level Setting

The input line leve l s ett ing di spl ay ed on th e fr on t pan el is equivalent to the average s peech l ev el wit h a

peak-to-average ratio of 13 dB. This corresponds to the level specified for the lines.

When testing the transmitter using a sine wave, the line input level should be set to 10 dB above the line

level setting. The VOGAD and mute thresholds are preset at 10 dB and 15 dB respectively below the line

level setting.

Table 4 shows the relationship between the input line level, VOGAD threshold and mute threshold.

Table 4 Relationship Between Line Level, VOGAD Threshold and Mute Threshold

Line Level Setting

(dBm)

+10 +10 +20 0 -5

+5 +5 +15 -5 -10

00+10-10-15

-5 -5 +5 -15 -20

-10 -10 0 -20 -25

-15 -15 -5 -25 -30

-20 -20 -10 -30 -35

-25 -25 -15 -35 -40

-30 -30 -20 -40 -45

Average Speech

Level (dBm)

Sine Wave Level

(dBm)

VOGAD Threshold

(dBm)

Mute Threshold

(dBm)

T6T VHF 100 W Transmitter Page 10 Operation

Page 29

Back to Transmitter

Main Page

Changing the Transmitter Operating Frequency

The transmitter frequency can be changed in two ways: either from the frequency screen, or by recalling

a preset channel. This procedure details the use of the Frequency screen.

(1) From the Control screen, select

frequency to display the Frequency

screen.

(2) Turn the switch to highlight the digit to

be changed, then press the switch.

(3) Turn the switch until the required digit

is shown, then press the switch.

(4) Repeat until the required frequenc y is

shown, then highlight OK and press the

switch.

(5) Only frequencies that fall betwee n the

band edge settings can be selected.

F r e q 1 1 8 . 0 0 0 M H z

C a n c e l O K

T6T VHF 100 W Transmitter Page 11 Operation

Page 30

To Store and Recall Frequency Channels

Up to 100 frequency channels can be stored in the transmitter.

To store a Channel Frequency:

Back to Transmitter

Main Page

(1) From the Control screen, select

Channel to display the Channel

screen. Highlight Channel, press the

switch and then turn it until the required

channel number is displayed; press the

switch.

(2) Highlight the MHz frequency value

(see Example 2) press the switch and

then turn it until the required MHz value

is shown. Press the switch.

(3) Highlight the kHz frequency value (see

Example 3), press the swi tch and the n

turn it until the required kHz value is

shown. Press the switch.

(4) Highlight Store and press the switch.

The new frequency is now stored in the

selected channel number.

To recall a Stored Frequency Channel:

(1) From the Control screen, select

Channel to display the Channel

screen.

(2) To make the transmitter operate on

any preset channel frequency,

highlight Channel and press the switch.

Turn the switch until the required

channel number/frequency is

displayed, then press the switch.

(3) Turn the switch to highlight Recall, then

press the switch . Exit the screen. Th e

transmitter now operates on the

recalled channel frequency.

C h 1 0 0

F r e q 1 2 1 . 5 0 0 M H z

R e c a l l

B a c k E x i t

Channel Screen - Example 1

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

S t o r e

B a c k E x i t

Channel Screen - Example 2

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

O u t s i d e B a n d E d g e

B a c k E x i t

Channel Screen - Example 3

C h 1 0 0

F r e q 1 1 8 . 0 0 0 M H z

I n v a l i d f o r M o d e

B a c k E x i t

Channel Screen - Example 4

Notes:

If a frequency ou tside the band edge limits is

entered, a message (see Channel Screen Example 3) is displayed.

If a frequency not valid for the mode of

operation is entere d, a m es sage ( se e Cha nne l

Screen - Example 4) is displayed.

T6T VHF 100 W Transmitter Page 12 Operation

Page 31

Back to Transmitter

Main Page

To Initiate a BIT Test

Use the following procedure to initiate an interruptive BIT test from the transmitter front panel. A BIT test

cannot be initiated while the transmitter is keyed. After a BIT test has been run, the BIT screen is

displayed (see AM-Voice and AM-M SK BIT Screen on page 25). An interruptive BIT test cannot be

initiated in Mode 2 or Mode 3.

During an interruptive B IT test, t he tran smitt er radia tes mo dulate d carrier wav es at the set powe r.

Users should therefore obtain the necessary authority before initiating a test.

If the test is to be carried out with the antenna disconnected, ensure a load is fitted to the

transmitter's antenna connector.

In order to test the line input stages, an internally generated 1 kHz tone is injected into the line input

circuit. Any other audio present on the line input will cause the test to be inaccurate. Therefore the

transmitter must not be keyed during the test.

(1) From the Main screen , pres s the s witch to dis play the C ontrol scree n. Tur n the s witch until BIT

is highlighted. Press the switch.

B I T

S / W C o n f i g

S t a n d b y

E x i t < <

(2) Ensure the BIT menu is displayed. Turn the switch until BIT Initiate is highlighted. Press the

switch.

B I T I n i t i a t e

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

E x i t > >

(3) During the test, which takes approximately two seconds, the Testing screen is displayed.

T e s t i n g

P l e a s e W a i t

T6T VHF 100 W Transmitter Page 13 Operation

Page 32

Back to Transmitter

Main Page

(4) On completion, and if the interruptive test was initiated from the front panel, one of the following

screens will be shown.

T e s t S t a t u s

P A S S

O K

(5) Selecting OK takes the user back to the BIT screen.

T e s t S t a t u s

F A I L

O K

(6) Selecting OK takes the user back to the BIT screen. The user can then scroll through the screen

to check out transmitter parameters for failure.

Standby Mode

Standby mode is a power saving feature that can be used for non-operational transmitters. When in

standby mode, most of the transmitter's circuits are inactiv e, the LCD is blanked, and the transmi tter

cannot be keyed. To put the transmitter into standby mode, use the following procedure.

When the transmitter is in Standby mode, the red front panel Standby indicator is lit.

To Enter Standby Mode

(1) From the Control screen select

Standby.

(2) At the Standby screen, select Yes.

(3) Check that the displ ay blanks and

the front panel Sta ndby indica tor is

lit.

To Exit Standby Mode

(1) Press the Switch.

(2) Select Yes.

(3) Check that the Main screen is

displayed and that the front panel

Standby indicator is unlit.

E n t e r S t a n d b y ?

Y e s N o

E x i t S t a n d b y ?

Y e s N o

T6T VHF 100 W Transmitter Page 14 Operation

Page 33

Back to Transmitter

Main Page

Settings

Operational settings for the T6T 100 W VHF transmitter a re configured at the front panel, thr ough the

VFP, and through an associated MARC system (or compatible control system). Some settings can also

be made remotely via a T6 controller. The Settings screen is entered from the Control screen.

The settings that can be selected at the front panel Settings screen are:

❑ Mode - either AM-Voice, AM-MSK, Mode 2 or Mode 3

❑ Mode settings - allows the selected mode parameters to be set

❑ Polarities

❑ Band edges

❑ Backlight

❑ Reference frequency.

Note that the mode selec tion, refer ence frequen cy and ba cklight ar e set from th is screen. W hen mode

settings, polarities and band edges are selected the user is taken to other screens.

M o d e A M V o i c e

M o d e S e t t i n g s

P o l a r i t i e s

E x i t > >

B a n d E d g e s

R e f F r e q 5 0 . 0 %

B a c k l i g h t 0 3 0 s

E x i t < < > >

B a c k

E x i t

Notes:

Select between AM-Voice, AM-M SK, Mode 2 or Mode 3.

Select to take you to the mode specific Settings menu.

Select to take you to the Polarities menu.

Set the transmitter’s frequency band edges.

Align the transmitter’s reference frequency (Note 1).

Adjust the LCD’s backlight time out (Note 2).

1. Setting the transmitter reference frequency is a maintenance operation. The current value

should not be reset unless the correct test equipment is connected. See the Maintenance

section.

2. The LCD bac k light ca n b e s et for pe rmane ntl y on, off, or ti med to st ay on for a pe ri od betw een

15 and 120 seconds.

General and mode specifi c sett ings, s how ing de fault valu es, ar e refe renced i n Table 5 on the following

page. Click on any required parameter by page number for further references.

T6T VHF 100 W Transmitter Page 15 Operation

Page 34

Table 5 Operational Settings from the Front Panel

Back to Transmitter

Main Page

Parameter Mode Adjustment Range Factory Default Setting Further

Reference

Menu lock screen All Locked or unlocked Unlocked page 8

Enter standby

mode

Exit standby mode All Yes or No - page 14

Set mode of

operation

Set polarities AM-Voice,

Band edges All 118.000 to 136.975 MHz 118.000 and 136.975 MHz page 29

LCD backlight All 15 to 120 s, On or Off 30 s page 15

RF power All 10 to 100 W 100 W page 17

Audio line in level AM-Voice,

Inhibit AM-Voice,

PTT (key) AM-Voice,

Tx time out AM-Voice,

Modulation depth AM-Voice,

Mute AM-Voice On or Off On page 17

VOGAD AM-Voice On or Off On page 17

Antenna C/O delay AM-Voice

Offset AM-Voice 0, ±2.5, ±4, ±5, ±7.3, ±7.5,

Step AM-Voice 8.33 kHz, 25 kHz or both 25 kHz page 18

Mic AM-Voice Active or Passive Passive page 18

Key priority AM-Voice,

Local PTT AM-Voice,

Remote PTT AM-Voice,

Remote phantom

PTT

All Yes or No - page 14

All AM-Voice, AM-MSK, Mode

2 or Mode 3

STD or INV STD page 21

AM-MSK

-30 to +10 dBm -13 dBm page 17 and

AM-MSK

On or Off Off page 17 and

AM-MSK

On (key), Off (de-key) Off page 17 and

AM-MSK

2 to 510 s or Off 180 s page 17 and

AM-MSK

5 to 95% 85% page 17 and

AM-MSK

On or Off On

AM-MSK

±8 kHz

Local-Remote or

AM-MSK

AM-MSK

AM-MSK

AM-Voice,

AM-MSK

Remote-Local

Enabled or D isabled Enabled page 18 and

Enabled or D isabled Enabled page 18 and

Enabled or D isabled Enabled page 18 and

AM-Voice page 15

page 19

page 19

page 19

page 19

page 19

page 17

Off

0 (No offset) page 18

Local-Remote page 18 and

page 19

page 19

page 19

page 19

page 19

T6T VHF 100 W Transmitter Page 16 Operation

Page 35

Back to Transmitter

Main Page

AM-Voice Settings Procedure

During this procedure, the following parameters, applicable to AM-Voice operation, can be set:

❑ RF power output

❑ Audio line input level

❑ Inhibit

❑ PTT on (key) or off (de-key)

❑ Transmitter time out

❑ Modulation depth

❑ Mute (on or off)

❑ VOGAD (on or off)

❑ Antenna c/o delay (on or off)

❑ Offset

❑ Step

❑ Mic

❑ Key priority (local or remote)

❑ Enable or disable local PTT

❑ Enable or disable remote PTT

❑ Enable or disable remote phantom PTT.

AM-Voice Mode Settings Screen

The AM-Voice mode setti ng screen is accessed from the Settings screen. Use the Scroll/Se lect switch

to select the parameter, then enter the required setting(s).

Adjustments

P o w e r 1 0 0 W

L i n e I n - 1 3 d B m

I n h i b i t O F F

E x i t > >

P T T O F F

T X T i m e o u t 1 8 0 s

M o d D e p t h 8 5 %

E x i t < < > >

RF power between 10 W to 100 W.

Audio line in level between -30 to +10 dBm.

On or Off.

On (key), Off (de-key).

2 to 510 s.

5 to 95%.

M u t e O N

V O G A D O N

A n t C / O D e l O N

On or Off.

On or Off.

On or Off.

E x i t < < > >

T6T VHF 100 W Transmitter Page 17 Operation

Page 36

Adjustments

Back to Transmitter

Main Page

O f f s e t 0 . 0 k H z

S t e p 2 5 k H z

M i c P A S S I V E

E x i t < < > >

K e y P r i o r i t y L - R

L o c a l P T T E N

R e m o t e P T T E N

E x i t < < > >

R e m P h a n P T T E N

B a c k

E x i t < <

0, ±2.5, ±4, ±5, ±7.3, ±7.5, ± 8 kHz.

25 kHz, 8.33 kHz or both.

Active or Passive.

Local-remote or Remote-local.

Enabled or Disabled.

Enabled or Disabled.

Enabled or Disabled.

Return to Settings screen.

T6T VHF 100 W Transmitter Page 18 Operation

Page 37

Back to Transmitter

Main Page

AM-MSK Mode Settings Procedure

During this procedure, the following parameters, applicable to AM-MSK operation, can be set:

❑ RF power output

❑ Audio line input level

❑ Inhibit

❑ PTT on (key) or off (de-key)

❑ Transmitter time out

❑ Modulation depth

❑ Antenna c/o delay (on or off)

❑ Key priority (local or remote)

❑ Enable or disable local PTT

❑ Enable or disable remote PTT

❑ Enable or disable remote phantom PTT.

AM-MSK Mode Settings Screens

The AM-MSK mode setting screen is accessed from the Settings screen. Use the Scroll/Select switch to

select the parameter, then enter the required setting(s).

P o w e r 1 0 0 W

L i n e I n - 1 3 d B m

I n h i b i t O F F

E x i t > >

P T T O F F

T X T i m e o u t 1 8 0 s

M o d D e p t h 8 5 %

E x i t < < > >

A n t C / O D e l O N

K e y P r i o r i t y L - R

L o c a l P T T E N

E x i t < < > >

Adjustments

RF power between 10 W to 100 W.

Audio line in level between -30 to +10 dBm.

On or Off.

On (key), Off (de-key).

2 to 510 s.

5 to 95%.

On or Off.

Local-remote or Remote-local.

Enabled or Disabled.

R e m o t e P T T E N

R e m P h a n P T T E N

Enabled or Disabled.

Enabled or Disabled.

B a c k

E x i t < <

T6T VHF 100 W Transmitter Page 19 Operation

Page 38

Mode 2 Settings Screen

This is an advisory screen. Pressing OK returns the user to the Main screen.

M o d e 2 p a r a m e t e r s

a r e s e t v i a t h e

H L D C i n t e r f a c e

O K

Mode 3 Settings Screen

This is an advisory screen. Pressing OK returns the user to the Main screen.

M o d e 3 p a r a m e t e r s

a r e s e t v i a t h e

T 1 / E 1 i n t e r f a c e

O K

Back to Transmitter

Main Page

T6T VHF 100 W Transmitter Page 20 Operation

Page 39

Back to Transmitter

Main Page

Polarities Screens AM-Voice and AM-MSK

A number of remote in dic ati on and c ontrol s ig nals can be hardwire co nne cted to the transmitter. Thes e

signals include a transmitter ready indication, a PTT control signal, a phantom PTT control signal, a PTT

out indication, a tran smitter inhibi t control signal, a n E-BIT input, a BI T test initiation c ontrol signal, an

external VSWR fault indication and antenna C/O. The following paragraphs detail the signals applicable

to the operational mode of the transmitter.

The Polarities screen is accessed from the Settings screen.

AM-Voice and AM-MSK Polarity Settings

Each of ten polarity settings applicable to AM-Voice and AM-MSK can be set to the default STD

(standard) setting or INV (inverted).

The signal connections are shown in Table 6 along with the conditions when STD or INV is selected.

The settings for the PTT Reference voltage are also shown in Table 6.

R e a d y O u t S T D

E - B I T I n S T D

I n h i b i t I n S T D

E x i t > >

B I T S t a r t I n S T D

P T T R e f + 1 4 V

P T T I n S T D

E x i t > >

P h a n P T T I n S T D

P T T O u t S T D

F a s t P T T O u t S T D

E x i t < < > >

E x t V S W R I n S T D

A n t C / O O u t S T D

B a c k

E x i t < <

T6T VHF 100 W Transmitter Page 21 Operation

Page 40

Back to Transmitter

Main Page

Table 6 AM-Voice and AM-MSK Polarity Settings

Signal Connector Polarity set to STD Polarity set to INV

Ready Out Facilities, pin 13 An open collector grounded

output when the radio is ready

to transmit and no BIT faults

are detect ed.

E-BIT In Facilities, pin 2 TTL input. 0 V indicates an

external fault.

Inhibit In Facilities, pin 10 TTL input. 0 V inhibits

transmitter operation.

BIT Start In Facilities, pin 11 TTL input. 0 V initiates an

interruptive BIT test.

PTT In MARC, pin 4

MARC Audio, pin 6

Phantom PTT In

(Phan PTT In)

MARC or

MARC Audio, pin 2

Active when input differs from

reference by more than 10 V.

Inactive when input dif fers from

reference by less than 1 V.

Maximum input level ±60 V

with respect to referen ce. Inpu t

will draw no more than 6 mA,

requires at least 1 mA to

operate.

Active when input differs from

reference by more than 10 V.

Inactive when input dif fers from

reference by less than 1 V.

Maximum input level ±60 V

with respect to referen ce. Inpu t

will draw no more than 6 mA,

requires at least 1 mA to

operate.

An open collector high

impedance output when the

radio is ready to transmit and

no BIT faults are detected.

TTL input. 5 V indicates an

external fault.

TTL input. 5 V inhibits

transmitter operation.

TTL input. 5 V initiates an

interruptive BIT test.

Active when input differs from

reference by less than 1 V.

Inactive when inpu t diff ers from

reference by more than 10 V.

Maximum input level ±60 V

with respect to reference. Inp ut

will draw no more than 6 mA,

requires at least 1 mA to

operate.

Active when input differs from

reference by less than 1 V.

Inactive when inpu t diff ers from

reference by more than 10 V.

Maximum input level +60 V

with respect to reference. Inp ut

will draw no more than 6 mA,

requires at least 1 mA to

operate.

PTT Out Facilities, pin 3 Grounding solid state relay.

+60 to -60 V, ac or dc, 100 mA

max, n/o. Activated 20 ms

(±1 ms) before the start of the

power ramp up to allow for the

antenna relay to pull-in time.

External VSWR

Input

(Ext VSWR In)

Antenna

Changeover

(Ant c/o out)

T6T VHF 100 W Transmitter Page 22 Operation

Facilities, pin 4 TTL input. 0V active. TTL input. 5 V active.

Facilities, pin 5

(Common pin 6)

Solid state relay. +60 to -60V,

ac or dc, 100 mA max, n/o.

Activated 35 ms (± 1 ms) before

the start of the power ramp up

to allow for the antenna relay

pull-in time.

Grounding solid state relay.

+60 to -60 V, ac or dc, 100 mA

max, n/c. Activated 20 ms

(±1 ms) before the start of the

power ramp up to allow for the

antenna relay to pull-in time

Solid state relay. +60 to -60V,

ac or dc, 100 mA max, n/c.

Activated 35 ms (±1 ms) before

the start of the power ramp up

to allow for the antenna relay

pull-in time.

Continued >>

Page 41

Back to Transmitter

Main Page

Table 6 AM-Voice and AM-MSK Polarity Settings (Continued)

Signal Connector Polarity set to STD Polarity set to INV

Fast PTT Output

(antenna

change-over)

PTT Ref - PTT Ref can be set to +14 V,

MARC Audio, pin 3 Open collector NPN transistor

grounding output, 200 mA max,

n/o.

0 V or -14 V. PTT. Maximum

input level ±60 V with respect

to PTT reference. Input will

draw no more than 6 mA, and

requires at least 1 mA to

operate.

When the input PTT signal and

the PTT reference dif fer by

more than 10 V the radio keys.

When the input PTT signal and

the PTT reference are within

1 V, the radio dekeys.

Other conditions are

indeterminable.

Open collector NPN transistor

grounding output, 2 00 mA max,

n/c.

PTT Ref can be set to +14 V,

0 V or -14 V. PTT. Maximum

input level ±60 V with respect

to PTT reference. Input will

draw no more than 6 mA, and

requires at least 1 mA to

operate.

When the input PTT signal an d

the PTT reference differ by

more than 10 V the radio

dekeys.

When the input PTT signal an d

the PTT reference are within

1 V, the radio keys.

Other conditions are

indeterminable.

T6T VHF 100 W Transmitter Page 23 Operation

Page 42

Mode 2 and Mode 3 Polarity Settings

Back to Transmitter

Main Page

R e a d y O u t S T D

E - B I T I n S T D

E x t V S W R I n S T D

E x i t > >

Each of the three polar ity settings applicable to

Mode 2 an d Mode 3 can be s et to t he def ault ST D

(standard) setting or INV (inverted).

The signal connections are detailed in Table 7

along with the conditions when STD or INV is

selected.

B a c k

E x i t

< <

Table 7 Mode 2 and Mode 3 Polarity Settings

Signal Connector Polarity set to STD Polarity set to INV

Ready Out Facilities, pin 13 An open collector grounded

output when the r adio is ready

to transmit and no BIT faults

are detected.

An open collector high

impedance output whe n the radio

is ready to transmit and no BIT

faults are detected.

E-BIT In Facilities, pin 2 TTL input. 0 V indicates an

external fault.

External VSWR

Input

Facilities, pin 4 TTL input. 0 V active. TTL input. 5 V active.

TTL input. 5 V indicates an

external fault.

T6T VHF 100 W Transmitter Page 24 Operation

Page 43

AM-Voice and AM-MSK BIT Screen

The AM-Voice and AM-MSK BIT screen is accessed from the Control screen.

Back to Transmitter

Main Page

B I T I n i t i a t e

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

E x i t > >

D C S u p p l y O N

S u p p l y 2 8 V

S y n t h L o c k P A S S

E x i t < < > >

P A T e m p 5 0 d e g C

P A C o o l i n g P A S S

B a s e b a n d P A S S

E x i t < < > >

R F D r i v e P A S S

P A O u t p u t P A S S

P A L o o p P A S S

E x i t < < > >

Select to initiate BIT test.

Shows elapsed time 0:00 to 99999:59 (Hrs:Min).

Shows state of ac supply (On or Off).

Shows state of dc supply (On or Off).

dc supply 0 to 40 V, <21.6 V Alert, <19 V Alarm.

Pass or Fail (Out-of-Lock).

PA temperature -20°C to +150°C.

Pass or Fail.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

M o d D e p t h P A S S

R F F i l t e r s P A S S

V S W R P A S S

E x i t < < > >

L o o p E r r o r P A S S

A u d i o I n P A S S

D S P 1 P A S S

E x i t < < > >

T6T VHF 100 W Transmitter Page 25 Operation

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass, Fail or Not Tested.

Pass or Fail.

Pass, Fail or Not Tested.

Pass or Fail.

Page 44

Back to Transmitter

Main Page

D S P 2 P A S S

X i l i n x 1 P A S S

X i l i n x 2 P A S S

E x i t < < > >

E E P R O M P A S S

S t a r t U p P A S S

C a l i b r a t i o n P A S S

E x i t < < > >

U n k e y e d P w r P A S S

E - B I T P A S S

M A R C A C T I V E

E x i t < < > >

H D L C I N A C T I V E

T 1 / E 1 I N A C T I V E

B a c k

E x i t < <

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Active or Inactive.

Active or Inactive.

Active or Inactive.

T6T VHF 100 W Transmitter Page 26 Operation

Page 45

Mode 2 and Mode 3 BIT Screen

The Mode 2 and Mode 3 BIT screen is accessed from the Control screen.

Back to Transmitter

Main Page

E T I 0 0 0 0 0 : 0 0 h r s

A C S u p p l y O N

D C S u p p l y O N

E x i t > >

S u p p l y 2 8 V

S y n t h L o c k P A S S

P A T e m p 5 0 d e g C

E x i t < < > >

P A C o o l i n g P A S S

V S W R P A S S

L o o p E r r o r P A S S

E x i t < < > >

D S P 1 P A S S

D S P 2 P A S S

X i l i n x 1 P A S S

E x i t < < > >

Shows elapsed time 0:00 to 99999:59 (Hrs:Min).

Shows state of ac supply (On or Off).

Shows state of dc supply (On or Off).

Shows value of dc supply.

Synth lock (Pass or Fail) .

Indicates the PA temperature.

Pass or Fail.

Pass, Fail or Not Tested.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

X i l i n x 2 P A S S

E E P R O M P A S S

S t a r t U p P A S S

E x i t < < > >

C a l i b r a t i o n P A S S

E - B I T P A S S

M A R C A C T I V E

E x i t < < > >

H D L C I N A C T I V E

T 1 / E 1 I N A C T I V E

B a c k

E x i t < <

T6T VHF 100 W Transmitter Page 27 Operation

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Pass or Fail.

Active or Inactive.

Active or Inactive.

Active or Inactive.

Page 46

Software Configuration Screens

Software configuration screens are as follows:

Back to Transmitter

Main Page

T 6 V H F 1 0 0 W T X

1 1 8 - 1 3 6 . 9 7 5 M H z

H i g h S t a b i l i t y

E x i t > >

B o o t S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

B a s e S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

M o d e S o f t w a r e

6 5 - x x x x x x x x / v v

E x i t < < > >

The first screen defines the radio.

65-xxxxxxxx represents the software part

number and /v v represents its version.

65-xxxxxxxx represents the software part

number and /v v represents its version.

Current mode running. 65-xxxxxxxx

represents the software part number and /v v

represents its version.

F i l l 1 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

E x i t < < > >

F i l l 2 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

E x i t < < > >

T6T VHF 100 W Transmitter Page 28 Operation

65-xxxxxxxx represents the software part

number and /v v represents its version.

65-xxxxxxxx represents the software part

number and /v v represents its version.

Page 47

F i l l 3 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

F i l l 4 S o f t w a r e

6 5 - x x x x x x x x / v v

[ D e s c r i p t i o n ]

Back to Transmitter

Main Page

65-xxxxxxxx represents the software part number

and /v v represents its version.

65-xxxxxxxx represents the software part number

and /v v represents its version.

T6T VHF 100 W Transmitter Page 29 Operation

Page 48

Back to Transmitter

Main Page

Band Edges

The frequency range of the T6 100 W tr ansmitter i s 118 to 136.975 MHz. If required , transmiss ion can

be limited to either one or two smaller par ts of the frequency band by setting the band edge s, BE1 to

BE4. Transmission is possible between BE1 and BE2 frequencies, and between BE3 and BE4

frequencies.

B E 1 1 1 8 . 0 0 0 M H z

B E 2 1 3 6 . 9 7 5 M H z

B E 3 1 1 8 . 0 0 0 M H z

E x i t > >

The Band Edge screen is accessed from the

Control screen.

Band edge frequencies can be set only in

increments of 25 kHz.

If the transmitter is required to operate ove r the

full range, the band edge parameters must be set

B E 4 1 3 6 . 9 7 5 M H z

to the lowest and highest values in the range (see

Table 8).

E x i t < <

Table 8 Band Edge Settings

B63100HS/NB set so that the full frequency range can be

transmitted.

Example: Transmitter set to transmit only those frequencies

in the range 120 to 130MHz.

Example: Transmitter set to transmit only those frequencies

in the ranges 120 to 125 MHz and 130 to 135 MHz.

BE1 BE2 BE3 BE4

118.000 136.975 118.000 136.975

120.000 130.000 120.000 130.000

120.000 125.000 130.000 135.000

T6T VHF 100 W Transmitter Page 30 Operation

Page 49

Back to Transmitter

Main Page

BIT Status Warning Screens

The following shows some example BIT screens. These screens alternate with the Main screen when an

alert or alarm conditi on is present. Only the par ameters caus ing the a lert o r alarm a re disp layed , and if

both an alert and alarm condition exists simultaneously only the alarm information is displayed. If multiple

parameters are si gnalling an alert or alar m condition, multiple scr eens are used to display th e status

alternating with the Main screen.

A L E R T

S u p p l y 2 1 V

A L E R T

R F P o w e r R e d u c e d

L o o p E r r o r

S u p p l y 2 1 V

A L E R T

R F P o w e r R e d u c e d

P A T e m p 8 5 d e g C

A L A R M

R F P o w e r R e d u c e d

V S W R F A I L

Alert:

There is no RF power reduction. The Alarm

indicator is flashing.

Alert:

The RF output power is reduced between 1 and

3 dB. The Alarm indicator is flashing.

Alert:

The RF output power is reduced between 1 and

3 dB. The Alarm indicator flashing

Alarm:

The RF output power reduced by more than 3

dB. The Alarm indicator is lit.

A L A R M

R F P o w e r R e m o v e d

L o o p E r r o r F A I L

S u p p l y 1 8 V

A L A R M

R F P o w e r R e m o v e d

P A T e m p 9 5 d e g C

T6T VHF 100 W Transmitter Page 31 Operation

Alarm:

The RF output power is shu t down. The Alarm

indicator is lit.

Alarm:

The RF output power is shu t down. The Alarm

indicator is lit.

Page 50

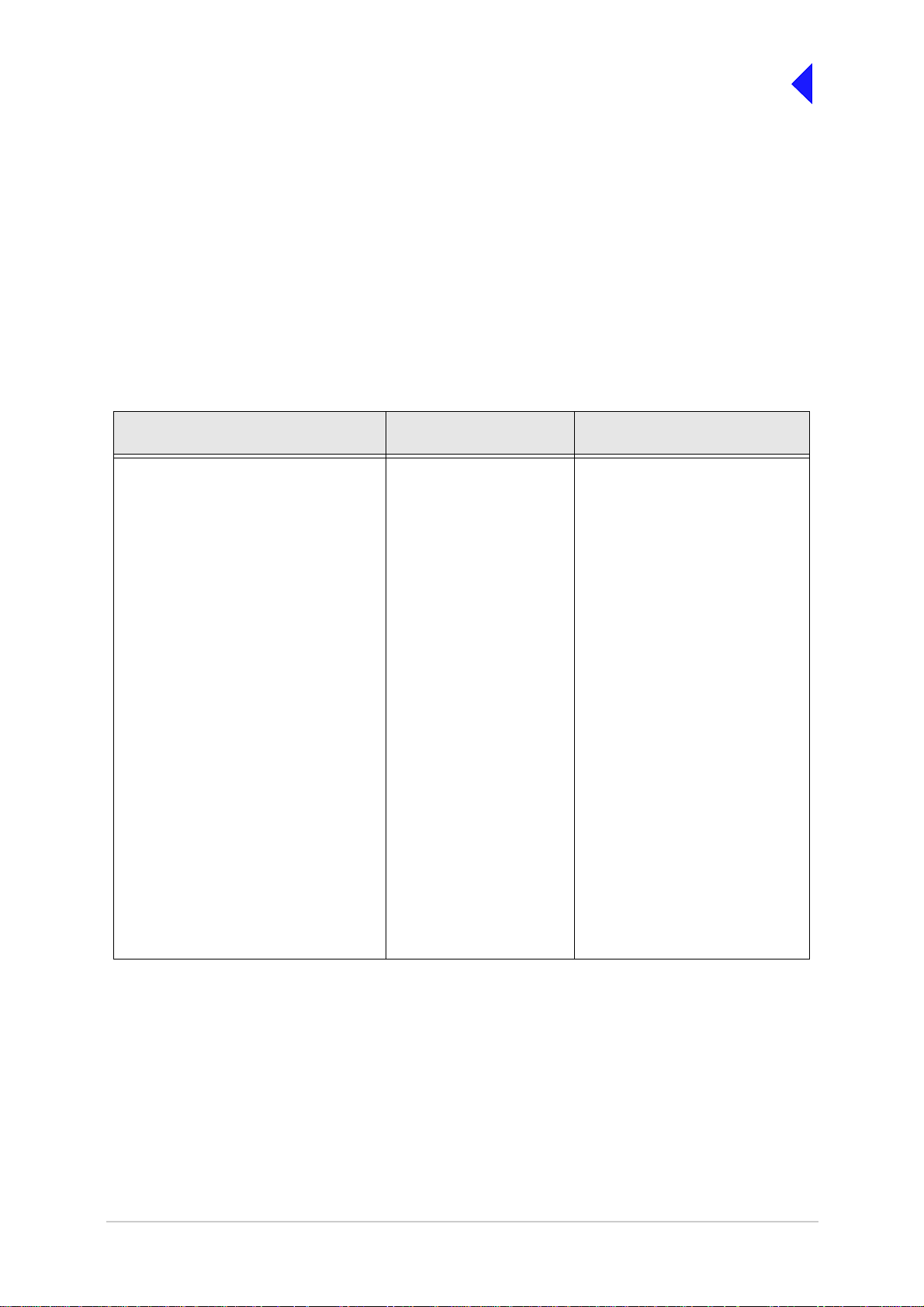

Table 9 Functions and Parameters

Back to Transmitter

Main Page

Function Front

FREQUENCY

Change frequency

FREQUENCY CHANNELS

Store/Recall preset

frequency channels

SETTINGS

Set modulation

mode

Radio Settings (AM Modes)

Set RF output

power

Set audio input line

level

Set inhibi t on or off

Panel

VFP MARC T6

Controller

T1/E1 HDLC Default Setting

118.000 MHz

-

AM-Voice

100 W

-13 dBm

Off

PTT test facility

on (key), off (dekey)

Set Tx time out

Set modulation

depth

Set mute on or off

(AM-Voice only)

Set VOGAD on

or off

(AM-Voice only)

Set antenna C/O

delay on or off

Set frequency offset

(AM-Voice only)

Set frequency step

size

(AM-Voice only)

View

state

Off

180 s

85%

On

On

AM-Voice - On

AM-MSK - Off

0 (No offset)

25 kHz

Continued >>

T6T VHF 100 W Transmitter Page 32 Operation

Page 51

Table 9 Functions and Parameters (Continued)

Back to Transmitter

Main Page

Function Front

Set microphone

type

(active or passive)

(AM-Voice only)

Set keying priority

(local or remote)

Enable or disable

local PTT

Enable or disable

remote PTT

Enable or disable

remote phantom

PTT

Radio Settings (Digital Modes)

MAC TM1 (inter

access delay)

MAC TM2 (channel

busy)

Panel

VFP MARC T6

Controller

T1/E1 HDLC Default Setting

Passive

Local-Remote

Enabled

Enabled

Enabled

2.5 ms

60 s

MAC p

(persistance)

MAC M1 (maximum

number of access

attempts)

Scramble vector

Tx enable On

Polarities

Ready out

Set PTT input

polarity

(AM modes only)

Set phantom PTT

input polarity

(AM modes only)

View

state

View

state

View

state

13/256

135

4D4B

19787

STD

STD

STD

Continued >>

T6T VHF 100 W Transmitter Page 33 Operation

Page 52

Table 9 Functions and Parameters (Continued)

Back to Transmitter

Main Page

Function Front

Set PTT reference

voltage

(AM modes only)

Set PTT output

polarity

(AM modes only)

Set fast PTT

antenna changeover output polarity

(AM modes only)

Set antenna

change-over output

polarity

(AM modes only)

Set external VSWR

input polarity

(All modes)

Set inhibit input

polarity

(AM modes only)

Panel

VFP MARC T6

View

state

View

state

View

state

View

state

View

state

View

state

Controller

T1/E1 HDLC Default Setting

+14 V

STD

STD

STD

STD

STD

BIT interruptive test

input polarity

(AM modes only)

E-bit input polarity

(All modes)

Band Edges

Set band edges

Reference Frequency

Adjust transmitter’s

reference frequency

LCD Backlight

Adjust LCD

backlight

View

state

View

state

STD (active low)

STD (active low)

118.000 and 136.975 MHz

-

30 s

Continued >>

BIT

T6T VHF 100 W Transmitter Page 34 Operation

Page 53

Table 9 Functions and Parameters (Continued)

Back to Transmitter

Main Page

Function Front

Initiate BIT

interrup tive test

STANDBY

Enter and exit

standby facility

SOFTWARE CONFIGURATION

View the

transmitter’s

software

configuration

LOCK FACILITIES

Front panel lock

MARC lock

T1/E1 lock

HDLC lock

Panel

VFP MARC T6

Controller

T1/E1 HDLC Default Setting

-

Not in Standby

-

Off

Off

Off

Off

T6T VHF 100 W Transmitter Page 35 Operation

Page 54

Back to Transmitter

Main Page

Intentionally Blank

Page 55

Installation

Back to Transmitter

Main Page

This topic gives the information required to install a T6T VHF 100 W Multimode Transmitter.

Page 56

Back to Transmitter

Main Page

Warnings and Cautions

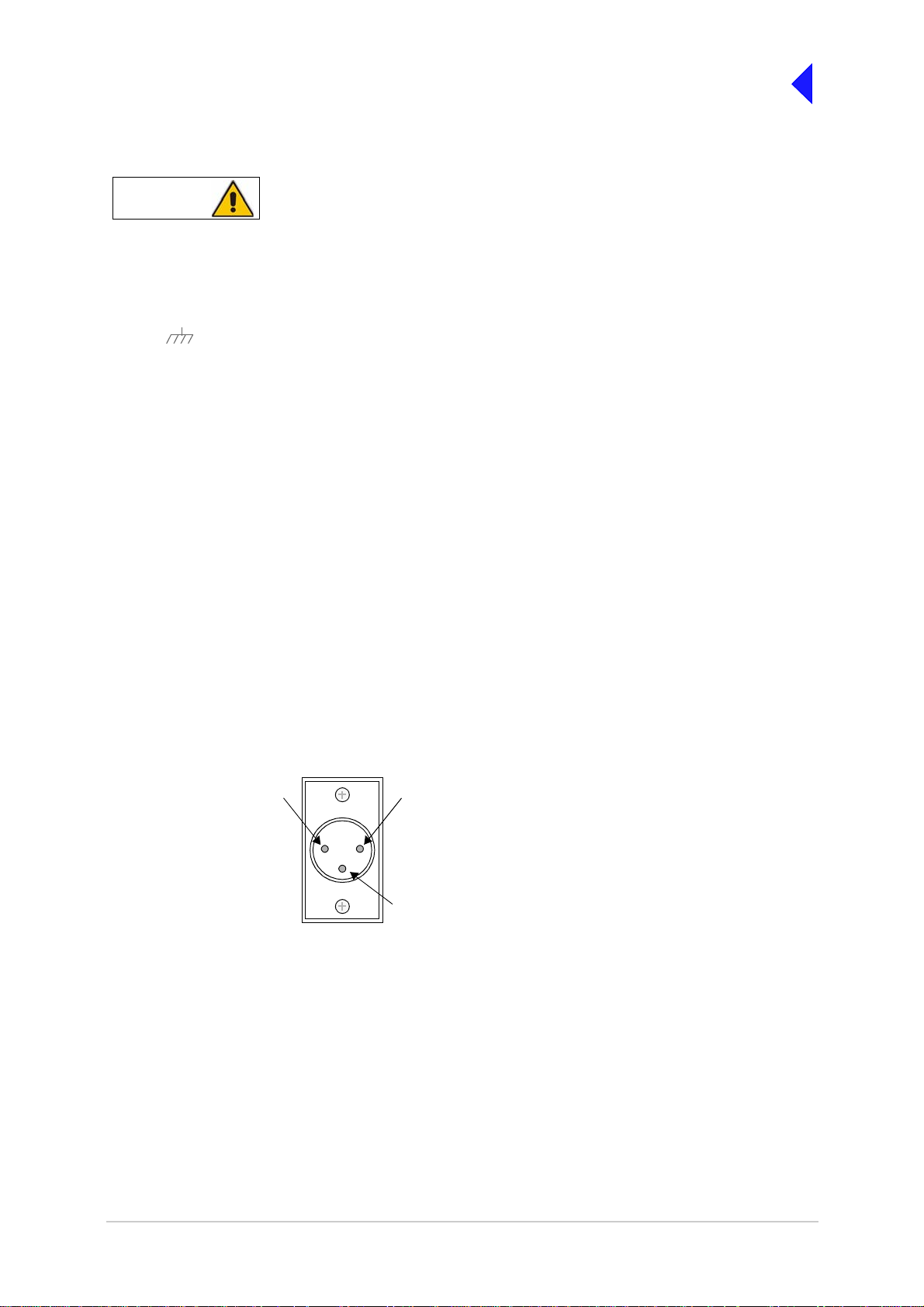

WARNING Dangerous Voltages

The instructions given in this topic involve connecting dangerous voltages to the transmitter

and should be carried out only by suitably qualified personnel.

WARNING Dangerous Voltages

The equipment is permanently connected to the mains supply when the mains connector is

attached. Switchin g the rear panel Power switch to off does not is olate all internal c ircuits

from the mains supply. For this reason, a mains isolating switch should be fitted close to,

and easily accessible from, the transmitter's position. The isolation switch should isola te

both live and neutral supplies, be clearly labelled, and adequately rated to protect the

equipment.

WARNING

The antenna used with the transmitter must be installed such that the resultant radiated field

strength is below 10 W/m² in areas normally accessible to personnel.

Caution

The T6T transmitter's circu itry co ntains E lectro static S ensitive Devices (E SSDs). P ersonne l

must be aware of the precautions necessary to prevent damage to such devices. During

installation all precautions necessary to prevent ESSD damage must be taken.

Caution Unauthorized Modifications

Changes or modifications made to this equipment that are not expressly approved by

Park Air, o r parties authorized by Park Air, cou ld void the user’s authority to o perate the

equipment.

Antenna Radiation

ESSDs

T6T VHF 100 W Transmitter Page 2 Installation

Page 57

Back to Transmitter

Main Page

Introduction

The procedures necessary to install a transmitter are listed in Table 1.

Table 1 Installation Procedures

Procedure Reference

1 Read and understand the warnings and cautions given on page2.

2 Perform an i nit ial ins pe cti on o f the tr ans mitte r and f it th e co rrec t ac input fuse. page 9

3 Fit the transmitter into an equipment cabinet. page 9

4 Make external signal connections. See Fig 1 to Fig 5 to determine which

external connections are required for the particular configuration.

5 Connect the chassis stud to the cabinet or system earth. page 22

6 Connect the antenna. page 22

7 Connect the dc input suppl y (if required). page 22

8 Connect the ac input suppl y (if required). page 23

page 10

Fuses and Connectors

The following list details the radio’s supply fuses and connectors. Some of the connectors (depending on

your particular configuration) are required during installation.

Table 2 Fuses and Connectors

Component Type Park Air Part Number

Fuses:

AC input fuses, F3, F4 for 110/120 V input

AC input fuses, F3, F4 for 220/230 V input

DC input fuses, F1, F2 15A size 0 29-01350201

Connectors:

AC supply connectors IEC 20-02030102

T4A, 125V, UL

T4A, 250V, IEC

29C11120102S

29E01120108S

DC supply connectors XLR 3-pin 20-01030106

Antenna connector N-type plug 19-01030301

MARC connector 9-way D-type plug Plug: 20-01090100

Cover: 20-09090101

MARC audio RJ48 plug 20K01080100

MARC data RJ48 plug 20K01080100

Facilities connector 15-way D-type plug Plug: 20-01150100

Cover: 20-09150101

HDLC connector RJ48 plug 20K01080100

T1/E1 connector RJ48 plug 20K01080100

Reference connector SMB connector 19C01050300

Microphone/Diagnostics connector 7-pin DIN plug 20-01070101

T6T VHF 100 W Transmitter Page 3 Installation

Page 58

Back to Transmitter

Main Page

Configuration

Connection of external equipment depends on the configuration required. Possible configurations are:

❑ T6T transmitter configured for local operation (see Fig 1).

❑ T6T transmitter configured for remote operation (see Fig 2).

❑ T6T transmitter configured for use with MARC (see Fig 3).

❑ T6T Mode 2 configuration (see Fig 4).

❑ T6T Mode 3 configuration. (see Fig 5).

T6T Transmitter

Optional Facilities that

can be used if required

E-BIT input

PTT relay out put

External VS WR input

dc supply output

Inhibit input

BIT interruptive test input

Antenna change-over output

Ready output

Tape output

Facilities

Connector

Frequency Counter

required only for

maintenance

Reference

Connector

Antenna

Connector

Microphone/Diagnostics

Connector

Mic/Headset for

local operation

Laptop (or PC) required

only for maintenance

For local operation, the transmitter is operated from the front panel using a microphone/headset.

Any of the optional facilities may be connected.

Fig 1 T6T Transmitter Configured for Local Operation

T6T VHF 100 W Transmitter Page 4 Installation

Page 59

T6T Transmitter

Back to Transmitter

Main Page

Optional Facilities that

can be used if required

E-BIT input

PTT relay output

External VSWR input

dc supply output

Inhibit input

BIT interruptive test input

Antenna change-over output

Ready output

Tape output

Audio

PTT

MARC Connector

or,

MARC Audio Connector

Facilities

Connector

Frequency Counter

required only for

maintenance

Reference

Connector

Antenna

Connector

Microphone/Diagnostics

Connector

Mic/Headset for

engineering use

Laptop (or PC) required

only for maintenance

For remote operation, Audio and PTT signals from the control equipment terminate on the MARC