Page 1

Series 3000DV2 Radios

/ FCC

User Guide

ISSUE 2

Page 2

Handbook Title: Series 3000DV2 Radios User Guide

/ FCC

Handbook Part Number: 31-33000DTR

Issue Number: 2

Date of Issue July 2000

Page ii 3000DV2 Radios

Page 3

Handbook Amendment Record

Amendments to this handbook, originated by Park Air Electronics, are listed in the following table.

Amendment

Number

Date Brief Details PAE Change

Note Number

Equipment Modification Record

Modifications to the 3000DV2 radios are detailed in the following table.

Modification

Number

1

Date Brief Details PAE Change

Note Number

March '99 RF PA capacitors C17, C26, C39, C40 changed.

3590

3000DV2 Radios Page iii

Page 4

Warnings

Warning. Lethal Voltages!

Installation involves the connection of lethal voltages. The instructions detailed in this

handbook must be carried out only by suitably qualified personnel.

Warning. Heavy Item!

The 3000DV2 series radios weigh in e xcess of 25 kg; care must be taken when lifting

and handling these units. At least two people must be used to lift the equipment.

Warning. Antenna Radiation!

Antennas used with 3000DV2 transmitters and transceivers must be installed such

that the resultant radiated field strength is below 10 watt per square metre in areas

normally accessible to personnel.

Warning. Beryllium/Beryllia!

The equipment covered by this handbook contains components incorporating the

highly toxic material Beryllium and/or its oxide Beryllia. No instructions within this user

guide require the removal of the radio's top or bottom covers so users are not exposed

to a potential beryllium hazard. If the radio is to be disposed of, users must be aware of

current disposal regulations regarding equipment containing Beryllium/Beryllia.

Caution

Caution. Electrostatic Sensitive Devices!

The equipment covered by this handbook contains electrostatic sensitive devices

some of which are exposed when the rear panel is hinged down to obtain access to the

mains voltage selector (see section 3 page 8 ). Observe handling precautions to avoid

static charges which may damage these devices.

FEDERAL COMMUNICATIONS COMMISSION (FCC) REGULATIONS

q This device complies with Part 15 of the FCC Rules. Operation is subject to the

condition that this device does not cause harmful interference.

q You are required to obtain a station licence before transmitting from your base station.

q This equipment is only licenced for operation on 25 kHz channel spacing in the

VHF aeronautical band of 118 MHz to 136.975MHz employing amplitude modulation.

q The base station power output must not exceed the output necessary for satisfactory

technical operation taking account of local conditions and the area to be covered.

q The base station's frequency and parameters should be checked by authorized service

personnel before use, and at least yearly thereafter.

-----------------------------------------------------------------------------------------------------------------------Page i v 3000DV2 Radios

Page 5

Contents

This handbook is divided into the following sections

Section 1 General Information

Section 2 Specification

Section 3 Installation and Setting-Up Instructions

Section 4 Operation

Section 5 Spares

Section 6 Figures

3000DV2 Radios Page v

Page 6

Contents

Paragraph

1 Introduction

4 Equipment overview

8 Power supplies

10 Built-in test facility

12 Types of installation

13 Control of equipment

16 Options

17 VHF/UHF guard receiver (option 01)

18 Configurable antenna port (option 04)

19 Fill gun port (option 05)

20 External power amplifier/filter drive (option 06)

21 Internal have quick (option 07)

22 VHF frequency extension (option 08)

23 Maritime band (option 10)

24 Internal quick fox module (option 12)

25 User maintenance

General Information

Table Page

1-1 Options - Model Applicability 5

INTRODUCTION

1 This handbook describes the installation and operation of the Park Air Electronics (PAE) series

3000DV2 radios. The series comprises the following models:

❏

3040V2 UHF transmitter/receiver

❏

3070V2 VHF transmitter/receiver

❏

3060V2 VHF/UHF transmitter/receiver

❏

3140V2 UHF transmitter

❏

3170V2 VHF transmitter

❏

3160V2 VHF/UHF transmitter

❏

3240V2 UHF receiver

❏

3270V2 VHF receiver

❏

3260V2 VHF/UHF receiver

3000DV2 Radios Section 1

Page 1

Page 7

2 The purpose of this handbook is to provide sufficient information to successfully install and operate

the radios. No topics covered in this book involve power being applied with any equipment covers

removed. A full technical description, to component level, of each radio is provided in an associated

technical handbook. Details of how to order copies of the technical handbooks are given in section 5.

3 This handbook is divided into six sections. The sections cover the following topics:

Section 1. Provides an overview of the equipment, and details the various installation options.

❏

Section 2. Provides the technical specification of the equipment.

❏

Section 3. Provides installation and commissioning instructions for the equipment. It must be

❏

noted that the installation involves the connection of lethal voltages to the equipment.

Installation must therefore be carried out only by suitably qualified personnel.

Section 4. Describes the purpose of the equipment’s controls, connectors and indicators.

❏

Also provided is an example setting-up procedure, operating instructions, and user

maintenance procedures.

Section 5. Lists the spare parts applicable to the topics covered in this handbook (each

❏

equipment’s full parts-listing is contained in the associated technical handbook).

Section 6. PAE drawings applicable to this handbook. The drawings are referenced in the text

❏

as Fig. 1, Fig. 2 etc. It should be noted that in-text illustrations are referenced by the section and

figure number; for example, Fig. 3-1.

EQUIPMENT OVERVIEW

4 Series 3000DV2 radios can operate in the VHF 100 to 163 MHz and/or UHF 225 to 339.975 MHz

frequency bands, with 25 kHz channel spacing. 8.33 kHz channel spacing is also available in the VHF

band between 118.000 MHz and 136.975 MHz. Standard operating modes are amplitude modulation

(AM) or frequency modulation (FM) with both clear voice and data (16 kBit cypher) modes selectable.

When 8.33 kHz channel spacing is used, the radio automatically defaults to AM, clear voice mode.

5 The radios are suitable for use in voice encryption systems and Link 11 applications. All UHF sets

can be equipped with an internal ECCM module to provide Have Quick II frequency hopping operation

(for Have Quick operating instructions refer to document PAE 31B33060SUP).

6 The equipment’s operating frequency is selected using the front panel’s numeric data keys. Up to

99 pre-set channels can be stored in the equipment’s memory. Each stored channel contains frequency

and operating mode information. Pre-set channels can be recalled for operational use, or recalled for

display without altering the operational frequency.

7 The transceiver and transmitter equipments produce a maximum output of 40 watts in AM mode

and 60 watts in FM mode. The output power can be reduced by using a front panel control. If a PAE

3640 power amplifier is used in conjunction with a 3000DV2 transmitter or transceiver, the radio’s FM

output is automatically reduced to 40 watts to produce a 100 watt output from the power amplifier.

Power Supplies

8 The radios can be operated from standard ac input supplies, or from a low voltage dc supply (refer

to section 2, specification). Both ac and dc input supplies can be simultaneously connected to the

equipment.

Section 1 3000DV2 Radios

Page 2

Page 8

9 When both ac and dc supplies are connected, operation from the ac supply takes priority; automatic

change-over to the dc supply will occur if the ac supply fails. On restoration of the ac supply, the

equipment reverts to ac operation.

Built-in Test Facility

10 A built-in test (BIT) facility monitors essential parameters within the equipment, and displays an

error message if a fault is found. The BIT functions in three different ways:

It allows certain equipment parameters to be displayed only when selected by the user.

❏

It continuously performs certain test routines while the equipment is operating.

❏

It provides a complete check of the equipment when selected to do so by the user. During this

❏

operation, normal operation of the equipment is suspended.

11 Full details of BIT operation and the resultant error messages are given in section 4.

TYPES OF INSTALLATION

12 The series 3000DV2 radios can be installed in one of four ways:

❏ Mounted on fixed runners within a standard 483 mm (19 inch) equipment rack.

❏ Fitted on telescopic slides within a standard 483 mm (19 inch) equipment rack.

❏ As a free-standing desktop equipment using the PAE free-standing accessory kit.

❏ In mobile applications using the PAE free-standing accessory kit plus an anti-vibration mount

kit.

Control of Equipment

13 The radios can be controlled in local, or remote modes. In local mode, control of the equipment is by

using the front panel controls and indicators as detailed in section 4. In addition to the front panel

controls, a number of inputs, outputs and control facilities can be configured through the rear panel

facilities socket. A full list of the facilities can be found in section 3.

14 As an alternative to local control, a PAE series 3000V2 Remote Control Unit (RCU) can be used; the

RCU replicates many of the radio’s front panel controls and indicators. The radio’s remote control

module can be configured for operation through dc or ac (tone) circuits. When configured for dc

operation, the RCU can be located (using suitable land lines) up to 1 km (1043 yards) from the

equipment. When configured for ac operation, no dc path is required between the equipment and the

RCU; this enables the control circuits to be routed, for example, through a microwave link.

15 For remote management of the equipment, and when part of a communication system, the PAE

Multi-Access Remote Control (MARC) system can be used.

3000DV2 Radios Section 1

Page 3

Page 9

OPTIONS

16 In addition to the standard operational functions the following options are available (see Table 1-1

for applicability to your model). Some of the options require additional hardware; others are built-in the

radio and are available when the option is selected from the front panel. Table 1-1 details which options

can be fitted to which radio.

VHF/UHF Guard Receiver (Option 01)

17 Guard receiver module operating on 121.5 or 243.00 MHz AM. Can be configured for independent

or combined (with main receiver) antenna operation. This option requires an additional module to be

fitted in the radio.

Configurable Antenna Port (Option 04)

18 Configurable antenna switching. This includes single and multi-antenna options configured to a

customer’s requirements.

Fill Gun Port (Option 05)

19 Provides a front panel fill gun port (for use with Have Quick radios).

External Power Amplifier/Filter Drive (Option 06)

20 A multi-purpose interface for use with an external power amplifier, or an auto-tune filter. This option

is built-in and becomes operational when selected from the radio’s front panel.

Internal Have Quick (Option 07)

21 Option 07 provides a Have Quick II ECCM capability. This option requires an additional module to

be fitted in the radio.

VHF Frequency Extension (Option 08)

22 Provides for extension of the VHF frequency range to cover 100 to 163 MHz. This option is built-in

and becomes operational when selected from the radio’s front panel.

Maritime Band (Option 10)

23 Provides pre-programmed international maritime channels within the frequency range of 156 MHz

to 163 MHz. Information regarding maritime frequency channels is given in section 4 of this handbook.

This option is built-in and becomes operational when selected from the radio’s front panel.

Section 1 3000DV2 Radios

Page 4

Page 10

Internal Quick Fox Module (Option 12)

24 Option 12 provides a Quick Fox ECCM capability. This option requires minor modification to the

standard radio and an additional module to be fitted.

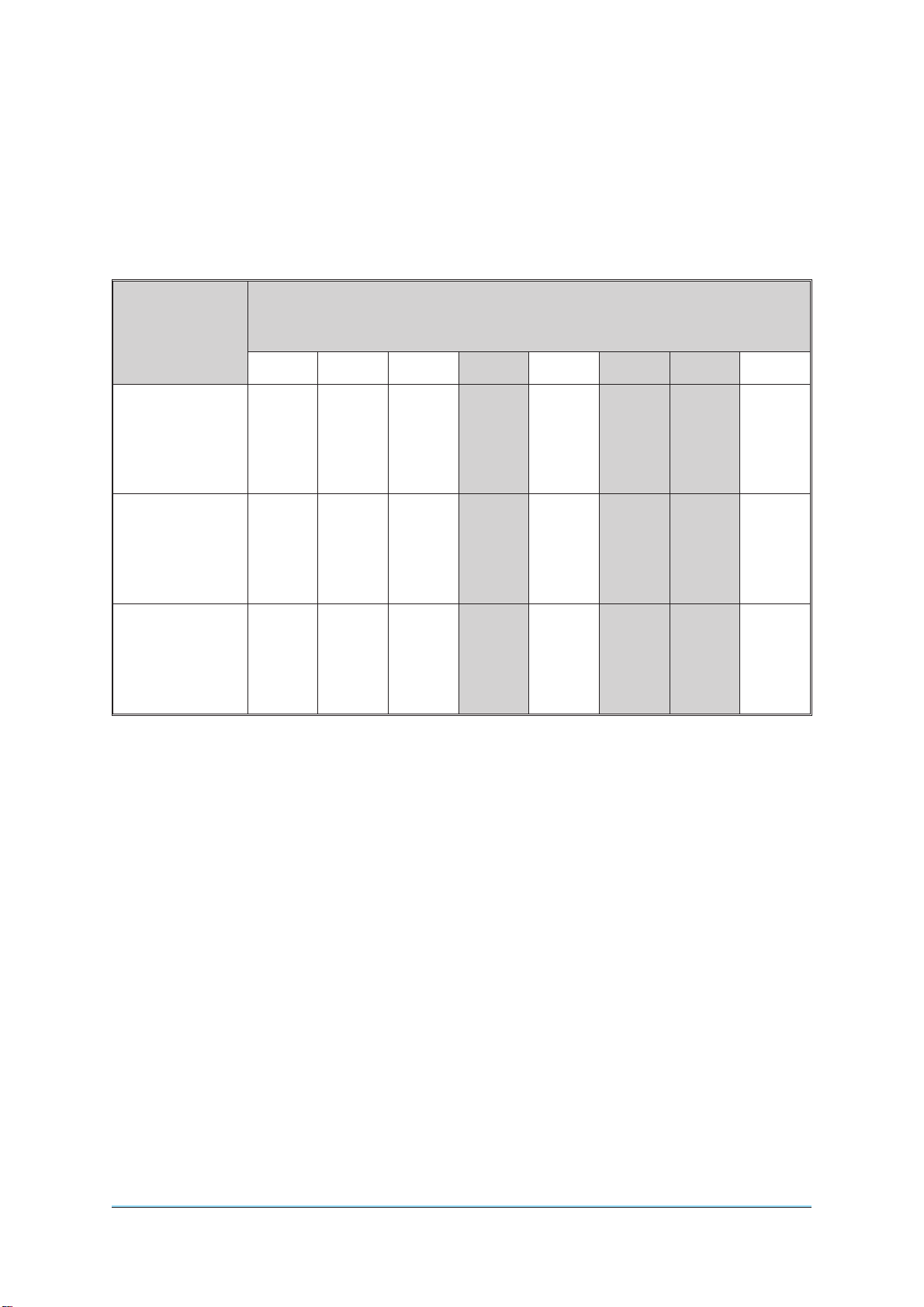

Table 1-1 Options - Model Applicability

Options

Model

01 04 05 06 07 08 10 12

Transceivers:

3070V2 VHF

3040V2 UHF

3060V2 V/UHF

Transmitters:

3170V2 VHF

3140V2 UHF

3160V2 V/UHF

4

4

4

7

7

7

4

4

4

4

4

4

7

4

4

7

4

4

4

4

4

4

4

4

7

4

4

7

4

4

4

7

4

4

7

4

4

7

4

4

7

4

7

4

4

7

4

4

Receivers:

3270V2 VHF

3240V2 UHF

3260V2 V/UHF

4

4

4

Options shown shaded are built-in to all applicable radios

and can be made operational from the front panel (see section 4)

4

4

4

4 = available 7 = not available

7

4

4

4

4

4

7

4

4

4

7

4

4

7

4

7

4

4

USER MAINTENANCE

25 User maintenance is limited to cleaning the rear panel air filter and checking the frequency accuracy

of the equipment. The procedures for user maintenance are provided in section 4.

3000DV2 Radios Section 1

Page 5

Page 11

Paragraph

1 General

2 Input supplies

3 Dimensions and weight

4 Environmental

5 RF characteristics

6 Modulation characteristics (speech A3E, F3E)

7 Modulation characteristics (data AXX, FXX)

8 RF characteristics

9 AF characteristics (speech A3E, F3E)

10 AF characteristics (data AXX, FXX)

11 Remote control decoder

12 Guard receiver specification

Specification

Contents

Transmitter

Receiver

GENERAL

1 This section provides the specification for the series 3000DV2 radios. The specification covers all

models, therefore, users should only read those parts of the specification applicable to their equipment.

Frequency range:

VHF 100 to 155.975 MHz

100 to 163 MHz when Option 08 is selected

UHF 225 to 399.975 MHz

Frequency error

Ageing

Channel spacing 25 kHz

pre-set channels 99

£1.5 ppm (-20°C to +0°C)

£ 1 ppm (0°C to +55°C)

£ 1 ppm/year

8.33 kHz (only available between 118 and

136.975 MHz, AM voice band. See FCC Warning)

Time for frequency change

3000DV2 Radios Section 2

£8ms

Page 1

Page 12

Classes of emission A3E, AXX, F3E, FXX

Link 11 to STANAG 5511

Have Quick to STANAG 4246 (Option 07)

Antenna configuration Independent VHF and UHF antenna ports are

provided as standard, other configurations are

optional (Option 04)

INPUT SUPPLIES

2 The equipment operates from an ac or dc input supply. The voltage ranges and system readiness

data are:

Power supply

DC 22 to 32 V. Negative earth

System readiness <10 seconds

110/120 V or 220/240 V, 45 to 65 Hz ±10% from

selected tap

Consumption: 700 VA (Tx/TR models)

175 VA (Rx models)

Consumption: 18 A (Tx/TR models)

3 A (Rx models)

DIMENSIONS AND WEIGHT

3 The dimensions and weight of the equipment are:

Width (W) 430 mm (width to the extremities of side heatsink

fins)

Height (H) 178 mm

Depth (D) 597 mm (depth from rear mounting face). Front

panel projections 41 mm (from mounting face)

Weight 32 kg

ENVIRONMENTAL

4 The temperature and relative humidity ranges, and other environmental data are:

Temperature range:

Operating -20°C to +55°C

Storage -40°C to +70°C

Section 2 3000DV2 Radios

Page 2

Page 13

Duty cycle Continuous operation up to +55°C

Relative humidity:

Operating 95% at 55°C MIL STD 810C

Storage 85% at 40°C MIL STD 810C

Salt fog Complies with MIL STD 810C

Vibration and shock:

Shock 40 g, 6 ms

Vibration 10 to 500 Hz MIL STD 810C

EMC To MIL STD 461/462D part 4

TRANSMITTER

RF Characteristics

5 The characteristics of the transmitter’s RF output are:

Carrier power output 40 W AM; 60 W FM. FM power is automatically

reduced to 40 watts when a serviceable PAE 3640

power amplifier is connected to a UHF transmitter or

transceiver.

±0.5 dB over operating band

±1 dB over temperature range

0 to 10 dB front panel adjustment

Power reduction Output power is automatically reduced under the

following conditions:

❏

when VSWR exceeds 2.5:1 (gradual reduction to

-10 dB at infinite VSWR)

❏

when dc supply falls below 26 V (1 dB nominal

reduction)

❏

when the temperature exceeds 80°C (6 dB

reduction)

❏

when the temperature exceeds 90°C (9 dB

reduction)

Permissible mismatch Infinite VSWR

Harmonic outputs Better than -70 dBc (-60 dBc between 225 and

230 MHz)

3000DV2 Radios Section 2

Page 3

Page 14

Spurious outputs Better than -80 dBc >500 kHz from carrier

See FCC Warning page iv

Broadband noise Better than -155 dBc/Hz, 3 MHz from carrier

Modulation Characteristics (Speech A3E, F3E)

6 The characteristics of the transmitter’s speech modulation are:

Frequency response:

25 kHz channel spacing

8.33 kHz channel spacing 300 Hz -2.5 kHz, +2, -4 dB (ref. 1 kHz)

Modulation index

Distortion

Line input See - Remote Control Decoder

Microphone input 600 ohms adjustable 0.5 mV to 30 mV

Speech processing:

VOGAD (switchable)

RF clipper

Mute Adjustable to open from 3 mV mic input.

300 Hz to 3.4 kHz, +1.5, -3 dB (ref. 1 kHz)

75 Hz, -20 dB; 6.8 kHz, -30 dB

75 Hz, -20 dB; 3.2 kHz, -25 dB

M = 0.9 AM, ±5 kHz FM

£5% THD at M = 0.9

Dynamic range 30 dB for ±2% change in modulation

depth

Attack time <10 ms

Decay time >1 second for 10 dB step input

Clipping depth 6 dB ±2 dB. Provides increase in

average modulation depth

Response time 5 ms for 20 dB step input from 10 dB

below VOGAD threshold.

Hang time 1.5 sec nominal

Modulation Characteristics (Data AXX, FXX)

7 The characteristics of the transmitter’s data modulation are:

Modulation index M = 0.9 AM, 20 kHz FM

Frequency response

Differential group delay

Section 2 3000DV2 Radios

Page 4

25 Hz to 20 kHz ±3 dB (ref. 5.5 kHz)

20 Hz to 24 kHz ±5 dB (ref. 5.5 kHz)

<100ms, 600 Hz to 20 kHz

<100ms, 300 Hz to 600 Hz

Page 15

Line input 600 ohms nominal balanced

See FCC Warning page iv

Level adjustable -20 dBm +10 dBm

Link 11 input

(UHF models only)

600 ohms nominal balanced input level adjustable

between -20 dBm and +10 dBm for ±20 kHz

deviation

RECEIVER

RF Characteristics

8 The characteristics of the receiver’s RF circuitry are:

Sensitivity (for S+N:N of 10 dB)

A3E: £2 mV (-101 dBm); M= 0.3 at 1 kHz modulation

F3E: £1.5 mV (-104 dBm): deviation 3.5 kHz with

1 kHz modulation

AXX: £4.0 mV (-95 dBm); M=0.6

FXX: £4.0 mV (-95 dBm); 5.5 kHz deviation

Note: depending on antenna configuration,

sensitivity may be reduced by 3 dB when optional

guard receiver is fitted.

Spurious suppression

Desensitisation

(for S+N:N ³6 dB)

Cross modulation (for 20 dB ratio)

Intermodulation (ref 1 mV emf) ³80 dB for equal amplitude signals, ±100 kHz or

Antenna radiation

Maximum RF input 20 V without damage (<30 seconds)

IF Bandwidth:

A3E, F3E with 25 kHz

channel spacing

A3E with 8.33 kHz

channel spacing

AXX, FXX

³80 dB (two exceptions 70 dB)

Wanted signal: 2 mV M=0.3

Interfering signal: 0 dBm at 5 MHz

³100 dB at ±5 MHz (ref 1 µV emf)

greater from fc

£20 mV at antenna connector

³24 kHz for 3 dB

£50 kHz for 70 dB

³7 kHz for 6 dB

£16.66 kHz for 50 dB

³75 kHz for 6 dB

£150 kHz for 60 dB

3000DV2 Radios Section 2

Page 5

Page 16

AGC:

RF

AF

£3 dB change in audio output for input signals in the

range 2 mV to 700 mV. Time constant 10 to 30 ms

attack, 75 to 150 ms release

£1 dB change in audio output for M=0.3 to M=0.9

AF Characteristics (Speech A3E, F3E)

9 Speech characteristics of the receiver’s audio are:

Line output 600 ohms balanced transformer. Level adjustable

-20 dBm to +6 dBm. Frequency response 300 Hz

to 3.4 kHz ±3 dB (ref 1 kHz); -20 dB at 75 Hz; -30 dB

at 6.8 kHz

Loudspeaker output 8 ohms, 1.5 W into internal loudspeaker

Distortion:

AM

FM

M=0.3 £5% THD, M=0.9 £10% THD

F=3.5 kHz £5% THD

Linearity (FM) With 935 Hz and 1045 Hz tones of 10 kHz deviation

the level of the third order products is less than -30 dB

relative to the other tone

Noise blanking Impulse noise removed by audio blanker that

operates for M=0.9 or greater

Mute S/N operated with carrier override adjustment.

Range 6 to 16 dB S+N:N

Response time: £50 ms with step input 10 dB above

the threshold

Hang time: £50 ms

Hysteresis: £3dB

Quieting: >40 dB

8.33 kHz channel spacing uses carrier operated

mute.

AF Characteristics (Data AXX, FXX)

10 Data characteristics of the receiver’s audio are:

Wideband output 600 ohm nominal balanced. Adjustable -20 dBm to

0 dBm

Frequency response

Differential group delay

Section 2 3000DV2 Radios

Page 6

25 Hz to 20 kHz ±3 dB ref. 5.5 kHz; 20 Hz to 24 kHz

±5 dB (ref. 5.5 kHz)

£20 ms 600 Hz to 20 kHz

Page 17

Link 11 output

(UHF models only)

600 ohm balanced. Adjustable from -20 dBm to

0 dBm for ±20 kHz deviation at 1 kHz

REMOTE CONTROL DECODER

11 Remote control can be configured for operation over ac or dc data circuits as follows:

DC control:

Data circuits 4-wire serial control interface, RS422 compatible.

Operable up to a distance of 2 km

Audio circuits 4-wire 600 ohms nominal balanced transformer. Level

adjustable -20 dBm to +10 dBm

PTT Via separate contact closure or phantom audio link

AC control:

Data circuits 4-wire 600 ohms nominal serial control interface,

CCITT V23 compatible (internal modem). Level fixed

at -13 dBm, automatic gain adjustment for line losses

up to 17 dB

Audio circuits 4-wire 600 ohms nominal balanced transformer.

PTT Via 2930 Hz tone on audio circuit

GUARD RECEIVER SPECIFICATION

12 The specification of the optional guard receiver is:

Mode AM speech only

Frequencies 121.5 MHz and 243 MHz

Frequency error

Sensitivity

(for S+N:N of 10 dB)

May be degraded by 3 or 6 dB

depending on the antenna

configuration

IF bandwidth

£10 ppm

£1.0 mV (weighted to CCITT)

£1.5 mV (non-weighted)

M=0.9 at 1 kHz

³22 kHz for 6 dB

IF selectivity

Mute Mute adjustable for S+N:N, 6 dB to 16 dB

Mute indication Separate front panel indicator and rear panel signal

3000DV2 Radios Section 2

£50 Hz for 60 dB

output

Page 7

Page 18

Audio output Mixable with normal receiver audio with separate line

output

Line output (narrow-band) 600 ohm balanced transformer. Adjustable -20 dBm

to +6 dBm (for M =0.3)

Frequency response

300 Hz to 3.4 kHz ±3 dB (ref. 1 kHz ); -20 dB at

75 Hz; -30 dB at 6.8 kHz.

Section 2 3000DV2 Radios

Page 8

Page 19

Paragraph

1 INTRODUCTION

2 Preliminary checks

5 Mechanical Installation

6 Fixed runner

7 Telescopic slides

8 Desktop installation

9 Mobile installation

11 External selections and connections

12 ac voltage selection

13 Supply fuses

15 ac supply connection

19 dc supply connection

20 Chassis stud connection

21 Facilities 2 connections

38 Remote PTT configurations

40 Remote control connections

43 Microphone/headset connection

44 PA/filter drive connection (option 06)

46 External clock connections

48 Unused connection CN6

49 Antenna connection

Installation and Setting-Up Instructions

Contents

INSTALLATION

51 SETTING-UP

52 Preliminary checks

54 Switching on, and ac and dc change-over checks

56 Selecting options

57 Set radio ID

60 View radio ID

63 Set equipment baud rate

66 View equipment baud rate

68 View band edges

72 Functional checks

3000DV2 Radios Section 3

Page 1

Page 20

Table Page

3-1 3000DV2 radio standard settings 4

3-2 Rear panel fuse ratings 9

3-3 Facilities 2 connector (CN2) pin-out for transceivers 13

3-4 Facilities 2 connector (CN2) pin-out for receivers 14

3-5 Facilities 2 connector (CN2) pin-out for transmitters 15

3-6 Remote connector (CN5) pin-out 17

3-7 Transceiver mic/headset connector pin-out 18

3-8 Receiver mic/headset connector pin-out 19

3-9 Transmitter mic/headset connector pin-out 19

3-10 Power amplifier/auto-tune filter connections at CN3 20

3-11 External clock interface connector (CN4) pin-out 21

Section 3 3000DV2 Radios

Page 2

Page 21

INTRODUCTION

Warning!

Installation involves the connection of lethal voltages. The instructions detailed in this

section must be carried out only by suitably qualified personnel.

Warning!

The series 3000DV2 radios weigh in excess of 25 kg; care must be taken when lifting

and handling these units. At least two people must be used to lift the equipment.

1 This section details the installation and setting-up instructions for the equipment. It is recommended

that the instructions given in this section are carried out in the order presented.

INSTALLATION

PRELIMINARY CHECKS

2 Carefully remove the transit packaging from the equipment and carry out a visual inspection of the

unit for signs of damage that may have occurred during shipment.

Note ...

It is recommended that if a claim for damage in transit is to be made the packaging and/or containers

should be retained to substantiate the claim.

3 Table 3-1 details the internal user adjustments for series 3000DV2 radios with column (3) showing

the manufacturers standard settings. Check that settings applicable to your equipment meet the

required operational conditions.

Note that the radio(s) are normally configured to a user’s requirements during manufacture at

Park Air Electronics. Table 3-1 is therefore given for informational purposes only. If there is a need

to alter any settings reference to the appropriate technical handbook(s) may be required.

4 If adjustments are required to be made to the internal standard settings remove the top cover and

locate the appropriate module as indicated in Table 3-1. If the equipment is configured as a desktop or

module installation, the olive green top cover will have to be removed prior to the removal of the

equipment top cover. To access the components locate and loosen the two securing slotted head

screws and withdraw the module. Refitting is the reverse of removal.

3000DV2 Radios Section 3

Page 3

Page 22

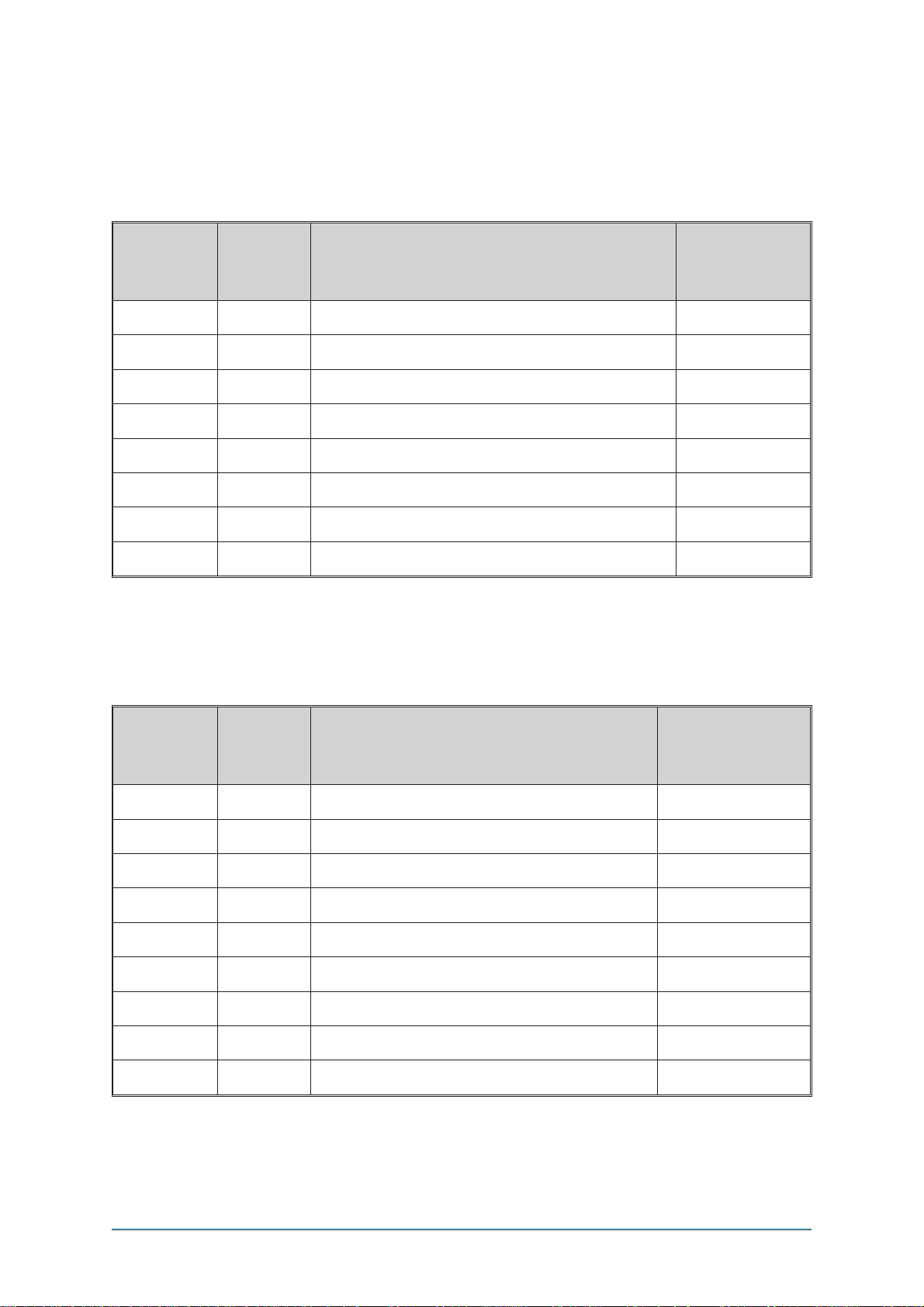

Table 3-1 3000DV2 Radio Standard Settings

Module/Component

(1)

Tx Control (Module 2)

RV3

RV8

RV6

RV2

RV4

RV1

Link J1

Link J5

Link J2

Link J6

Rx IF and Audio (Module 8)

RV1

RV9

RV7

Link Lk3

Link Lk2

Function

(2)

Set tape output

Modulation depth for wideband AM

Modulation depth for wideband FM

Modulation depth for narrow-band

Set mute

Microphone gain

VOGAD

Factory set

Mute

RF drive level detect override

Wideband output level

Mute carrier override

VOGAD threshold level

VOGAD

Noise blanker

Standard Setting

(3)

-8 dBm

AM = 80%

FM=20kHz

AM = 80% FM = 5 kHz

1mV

5mV

On

Off

Off

Off

-8 dBm for 30% AM

30 µV pd

30% AM

Off

Off

Guard Receiver (Module 4)

(if fitted)

RV9

RV8

Link J1

Link J2

Remote Control (Module 5)

(if fitted)

-

-

Links J1 to J11

Mute level

Audio line output level

Noise blanker

VOGAD

Line input level

Line output level

Mode configuration

1µVpd

-8 dBm for 30% AM

Off

Off

-13 dBm

-13 dBm

Set for required mode of

operation. Refer to the

Remote Control section of

the 3000DV2 Technical

Handbook.

Section 3 3000DV2 Radios

Page 4

Page 23

MECHANICAL INSTALLATION

5 The equipment can be installed in one of the following ways:

On fixed runners within a standard 483 mm (19 inch) equipment rack.

❏

On telescopic slides within a standard 483 mm (19 inch) equipment rack.

❏

As a desktop equipment by using the PAE free-standing accessory kit.

❏

In mobile applications by using the PAE free-standing accessory kit plus an anti-vibration

❏

mount accessory kit.

Caution!

It is essential that the chosen mechanical installation provides adequate support along

the depth (front to rear) of the radio. Under no circumstances must the radio be

supported by the front panel; doing so can cause irreparable damage.

Fixed Runner

6 If using fixed runners, they must provide adequate support along the depth (front to rear), at both

sides of the unit. The unit is secured to the rack through the four front panel fixing holes using suitable

hardware. The front panel fixing holes must not be used at any time to support the equipment.

Telescopic Slides

7 If using telescopic slides, reference should be made to Fig. 5. Four M4 tapped holes, each 10 mm

deep, are provided each side of the equipment for fitting the runners. Dependent on the rack/slide

combination used, it may be necessary to fit a spacer bar between the runner and the equipment. The

width of the spacer must be such that the runners locate correctly within the slide assemblies.

Note ...

Details of suitable telescopic slides are available from PAE.

3000DV2 Radios Section 3

Page 5

Page 24

Desktop Installation

8 The following installation instructions configure the equipment for desktop operation using a

free-standing accessory kit (PAE part no. 70-3060TR1). With reference to Fig. 6 locate and identify the

components of the free-standing kit.

(a) At the front of the equipment locate and remove the four securing screws from the left and

right rack mounting brackets. Separate the handles from the brackets by removing the two

securing screws. Retain the handles.

(b) Attach the handles, removed in (a), to the left handle plate (item 3) and the right handle plate

(item 2) using the four (two per handle) M5 x 16 mm cap head screws (item 10). Secure the

handle plates to the unit using the eight (four per plate) M4 x 16 mm pan head screws (item 9)

and M4 crinkle washers (item 14).

(c) At the rear of the equipment locate and remove the ten rear panel assembly retaining screws

(item A) and carefully lower the rear panel assembly.

(d) On the left and right-hand side of the PSU compartment locate the four symmetrically placed

holes, note that the two rearmost holes are countersunk. Fit the eight hexagonal M3 x 12 mm

spacers (item 4) to the sides using the four M3x6mmpanhead screws (item 11), four

M3x6mmcountersunk screws (item 8) and eight M4 crinkle washers (item 14).

(e) Raise and secure the rear panel with the ten retaining screws (item A) removed in (c).

(f) Fit the two side covers (item 7) to the hexagonal spacers using the M3x6mmcountersunk

screws (item 8).

(g) Fit the top cover support bracket (item 5) to the rear panel above the filter using the two

M4x6mmpanhead screws (item 12) and crinkle washers (item 14).

(h) Fit the top cover (item 6) using the M3x6mmcountersunk screws (item 8).

(i) On the underside of the equipment locate the four front and rear M4 countersunk crosshead

screws that secure the base plate. Remove the two outer screws from both the front and rear

locations and fit the feet (item 15).

Section 3 3000DV2 Radios

Page 6

Page 25

Mobile Installation

9 The following instructions configure the equipment for mobile operation using a free-standing

accessory kit (PAE part number 70-3060TR1) and anti-vibration mount accessory kit (PAE part number

70-3060TR2). Before the anti-vibration mounts can be fitted, the equipment must have the free-standing

accessory kit fitted (refer to previous paragraphs detailing desktop installation).

10 Referring to Fig. 7, identify the anti-vibration mount accessory kit components, then complete the

following steps:

(a) Ensure that the free-standing accessory kit is fitted as detailed in the desktop installation

procedures. Fit the front location plate (item 2) to the bottom of the handle blocks of the

equipment using four M4x8mmcskscrews (item 11). The return should be at the front of

the equipment and projecting downwards.

(b) Before fitting the rear location plate (item 5) it is necessary to remove two screws from the

bottom cover as detailed in Fig. 7 (note 3). Fit the rear location plate (item 5) to the bottom of

the equipment using six M4x8mmcskscrews (item 11), ensure that the return projects

upwards.

(c) Fit the four shock mounts (item 9) to the bottom rails (item 10) using 16 M5 x 10 mm csk

screws, nuts and washers (item 4).

(d) Fit the shock mount tray (item 7) to the shock mounts using the four M6 x 20 mm hexagonal

headed screws (item 8).

(e) Using the dimensions detailed on Fig. 7, select a suitable position on the vehicle and mark

out the centres for the fixing holes. Prior to drilling the fixing holes, position the assembled

shock mount tray and ensure that there is sufficient clearance for the equipment when fitted

(allowing for rear panel connectors).

Note ...

The mounting holes can be drilled and tapped M6 and the tray fitted with 16 M6 x 20 mm

hexagonal headed screws (item 12), or drilled out to 6.5 mm and the tray fitted using the

hexagonal headed screws (item 12), nuts and washers (item 13).

(f) Fit the anti-vibration mount assembly into the vehicle and secure firmly.

(g) Attach the two guide pin bushes (item 6) to the equipment mounted rear location plate

(item 5).

(h) Attach the two locating guide pins (item 6), facing forward, to the shock mount tray rear rail

(item 7).

(i) Carefully position the equipment onto the shock mount tray, slide the unit rearward and

ensure that the guide pins and guide pin bushes are securely located. Secure the equipment

to the tray using the three knurled screws (item 3) located on the front location plate (item 2).

3000DV2 Radios Section 3

Page 7

Page 26

EXTERNAL SELECTIONS AND CONNECTIONS

11 The following external connections must be made to the equipment (dependent on how the

equipment is operated):

ac and/or dc supplies.

❏

Facilities connections (as required).

❏

Remote control (if remote control facility is to be used).

❏

Power amplifier or auto-tune filter connection (if required)

❏

Antenna.

❏

Note ...

The radio operates from either an ac or dc supply. When both ac and dc are connected, operation

from the ac supply takes priority; automatic change-over to the dc supply will occur if the ac supply

fails. On restoration of the ac supply, the equipment reverts to ac operation.

ac Voltage Selection

12 The equipment can operate with an ac input of 110/120 V or 220/240 V (refer to section 2

specification). The mains voltage selector, fitted under the rear panel top plate must correspond to the

local ac voltage. If the selector’s current setting is incorrect, complete the following steps:

(a) Remove four screws securing the top of the rear panel to the main chassis.

(b) Remove the two securing screws on both the left and right-hand sides of the rear panel and

remove the two screws securing the rear panel to the antenna assembly.

(c) Hinge the rear panel down to expose the mains voltage selector.

(d) Remove the mains selector cover plate.

(e) Set the two switches as required.

(f) Refit the cover plate ensuring that the voltage displayed in the plate’s cut-out agrees with the

required switch setting.

(g) Replace the rear cover using the reverse of the procedure detailed in (a), (b), and (c).

Section 3 3000DV2 Radios

Page 8

Page 27

Supply Fuses

13 Three fuses are fitted to the equipments rear panel (see Fig. 4):

The ac input supply fuse F3 (fitted in the ac input connector).

❏

The dc input fuse F1.

❏

The dc equipment fuse F2.

❏

14 Noting that different value ac input supply fuses are fitted dependent on the local ac supply, ensure

that the fuses conform to the values detailed in Table 3-2.

Table 3-2 Rear Panel Fuse Ratings

Fuse Rating Size PAE Part Number

Fuse 1

Fuse 2

Fuse 3 (110/120 V)

Fuse 3 (220/240 V)

20 amp. F20A 32 V BS

4 amp. F4A 250 V IEC

8 amp. T8A 250 V IEC

4 amp. T4A 250 V IEC

Size 0 (1¼ inch)

20 mm

20 mm

20 mm

29-01450201

29-01120101

29-01210102

29-01120102

ac Supply Connection

Warnings!

This equipment must be earthed. The earth terminal of the ac connector should be

used as the safety earth.

A chassis stud, marked is fitted to the equipment’s rear panel. This stud is for

connecting the equipment to the equipment rack or user’s system earth point. The

stud is not intended to be used as the safety earth.

15 The ac supply connector is fitted to the radio’s rear panel (see Fig. 4). The minimum rating of the ac

supply cable is: 3-core (to IEC227) rated 250 V ac at 13 amps, and having a minimum cross-sectional

area of 1.25 mm

be fitted with an IEC approved equipment connector (for example, PAE part number 20-02030102) and

conform to the following specification.

2

per core. PAE recommends the use of polyvinyl chloride (PVC) cable. The cable must

❏

If PVC insulated, be not lighter than ordinary polyvinyl chloride sheathed flexible cord

according to IEC publication 227 (designation H05 VV-F, or H05 VVH2-F).

❏

If rubber insulated, be of synthetic rubber and not lighter than ordinary tough rubber-sheathed

flexible cord according to IEC Publication 245: Rubber Insulated Cables of Rated Voltages up

to and including 450/750 V, (designation H05 RR-F).

3000DV2 Radios Section 3

Page 9

Page 28

16 The series 3000DV2 transmitters, receivers and transceivers are Class 1 equipments. The ac

supply cable must have a green-and-yellow protective earthing conductor electrically connected to the

protective earthing terminal of the equipment connector, and the mains plug.

17 PAE recommends the ac supply cable is colour coded in accordance with the electrical appliance

(colour code) regulations for the UK. That is:

Line: Brown

Neutral: Blue

Earth: Green-and-yellow

18 The cores of the power supply cable should be connected to the equipment connector provided,

and your plug as follows:

The core that is coloured green-and-yellow must be connected to the terminal in the plug which

❏

is marked with the letter E or by the earth symbol or coloured green-and-yellow.

The core that is coloured blue must be connected to the terminal that is marked with the letter N

❏

or coloured black.

The core that is coloured brown must be connected to the terminal that is marked with the letter

❏

L or coloured red.

dc Supply Connection

19 The dc supply connector is fitted to the equipment’s rear panel as shown in Fig. 4. The

recommended minimum rating of the dc supply cable is: 2-core, each having a cross-sectional area of

not less than 6.0 mm

2

per core and fitted with an AMP 3 series connector. The dc supply is connected to

the rear panel DC SUPPLY AXR-PDN style connector, with its associated fuse, as detailed in Table 3-2

and colour coded as follows:

Pin 1 +28 V Red

Pin 2 0 V (ground) Black

Chassis Stud Connection

20 In order not to compromise the equipment’s Electromagnetic Capability (EMC) the chassis stud

marked fitted to the rear panel must be connected to the equipment rack (if a rack is being used) or to

the user’s system earth point. The connection must be made using a single tri-rated, green-and-yellow

cable having a cross-sectional area of 2.5 mm

be connected to the chassis stud through an M6 eyelet (for example, PAE part number 20-08010103).

Failure to comply with this instruction could result in non-compliancy with

the European Commission EMC Directive 89/336/EEC.

2

. The cable should have CSA and UL1015 approval, and

Section 3 3000DV2 Radios

Page 10

Page 29

Facilities 2 Connections

21 The facilities 2 connector CN2, fitted to the equipment’s rear panel (refer to Fig. 4), provides a

number of control and monitoring signals that can be configured by the user as required. The connector

pin-outs are detailed in Tables 3-3 to 3-5 and described in the following paragraphs.

22 When making connections to rear panel D-type connector CN2, and in order not to compromise the

equipment’s Electromagnetic Compatibility (EMC), users must:

use a D-type connector that has a screened cover.

❏

use screened multi-way cable, with the cable’s screen connected to the connector’s shell or

❏

body.

Rx Audio 1 and 2, Wideband Output

23 Pins 1 and 2 provide a 600 ohm balanced wideband data output. The output can be adjusted

between -20 and +10 dBm.

Tx Audio 1 and 2, Wideband Input

24 Pins 3 and 4 provide a 600 ohm balanced wideband data input. The input can be adjusted between

-20 to +10 dBm.

Tape Output

25 Pin 5 provides a 600 ohm single-ended audio output for use with suitable tape recording equipment.

The output contains both the transmit and receive audio.

Guard Mute State

26 Pin 6 provides an active low TTL compatible output when the guard receiver’s (if fitted) mute

threshold is exceeded. This output can be used to indicate when a signal is being received.

PTT State

27 Pin 7 provides an active low TTL compatible output on PTT (pin not used if option 06 fitted).

Guard Rx, Audio 1 and 2 Output

28 The guard Rx audio output, available between pins 8 and 9, provides a 600 ohm balanced audio

output from the guard receiver (if fitted).

Input to Receiver Audio Filter

29 Pins 10 and 11 provide an input to the receiver’s audio filter circuits. These inputs are usually used

to route the plain language output from an external encryption unit, to the receiver’s audio frequency

stages. This facility is not available on standard equipments; advice should be sought from PAE if the

facility is required.

3000DV2 Radios Section 3

Page 11

Page 30

Mute State Output

30 Pin 12 provides an active low TTL output when the receiver’s mute threshold is exceeded. This

output can be used to indicate when a signal is being received.

DPTT

31 Pin 13 provides a delayed PTT that may be required in Have Quick and/or encryption system

applications.

Hardwire PTT

32 Pin 15 provides a connection for keying the transmitter from an external source (for example, a Link

11 modem). A ground potential on this connection will key the transmitter.

Tx Audio 1 and 2 Narrow-band Input

33 Pins 16 and 17 provide a 600 ohm balanced narrow-band audio input. The input can be adjusted in

the range -20 dBm to +10 dBm.

Rx Audio 1 and 2 Narrow-band Output

34 Pins 18 and 19 provide a 600 ohm balanced narrow-band audio output. The output can be adjusted

in the range -20 dBm to +10 dBm.

Link 11 Tx Audio 1 and 2 Input

35 Pins 20 and 21 provide a 600 ohm balanced input. The input can be adjusted in the range -20 dBm

to +10 dBm.

Link 11 Rx Audio 1 and 2 Output

36 Pins 22 and 23 provide a 600 ohm balanced output. The output can be adjusted in the range

-20 dBm to +10 dBm.

BIT Output

37 Pin 24 is a memory fault output that provides a TTL low potential when the BIT detects a transmitter

or receiver fault. This output can be configured as an equipment fault indicator.

Section 3 3000DV2 Radios

Page 12

Page 31

Table 3-3 Facilities 2 Connector (CN2) Pin-Out for Transceivers

Pin Function Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Rx wideband audio line L1

Rx wideband audio line L2

Tx wideband audio line L1

Tx wideband audio line L2

Tape output

Guard mute state Open collector with 10k pull-up resistor to 5 V

PTT state (pin 7 not used if

option 06 is selected)

Guard receiver audio line L1

Guard receiver audio line L2

Rx encryption audio input line L1

Rx encryption audio input line L2

Mute state output Active low TTL output

DPTT Delayed PTT input

Not used -

600 ohm balanced output (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm balanced input (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm single-ended output. Combined Tx

and Rx audio at -8 dBm (nominal)

Open collector with 10k pull-up resistor to 5 V

600 ohm balanced audio output from guard

receiver (if fitted) at -8 dBm (adjustable)

For decrypted audio processing

15

16

17

18

19

20

21

22

23

24

25

Hardwire PTT 0 volt input keys transmitter

Tx narrow-band audio line L1

Tx narrow-band audio line L2

Rx narrow-band audio line L1

Rx narrow-band audio line L2

Link 11 Tx audio line L1 (UHF only)

Link 11 Tx audio line L2 (UHF only)

Link 11 Rx audio line L1 (UHF only)

Link 11 Rx audio line L2 (UHF only)

BIT output Memory fault output. Active low TTL

0 volt Ground

600 ohm balanced input (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm balanced output (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm balanced Link 11 audio input

(adjustable -20 dBm to +10 dBm for

F = 20 kHz)

600 ohm balanced Link 11 audio output

(adjustable -20 dBm to +10 dBm for

F = 20 kHz)

3000DV2 Radios Section 3

Page 13

Page 32

Table 3-4 Facilities 2 Connector (CN2) Pin-Out for Receivers

Pin Function Description

1

2

5

6

8

9

10

11

12

18

19

22

23

24

25

Rx wideband audio line L1

Rx wideband audio line L2

Tape output

Guard mute state Open collector with 10k pull-up resistor to 5 V

Guard receiver audio line L1

Guard receiver audio line L2

Rx encryption audio input line L1

Rx encryption audio input line L2

Mute state output Active low TTL output

Rx narrow-band audio line L1

Rx narrow-band audio line L2

Link 11 Rx audio line L1 (UHF only)

Link 11 Rx audio line L2 (UHF only)

BIT output Memory fault output. Active low TTL

0 volt Ground

600 ohm balanced output (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm single-ended output. Rx audio at

-8 dBm (nominal)

600 ohm balanced audio output from guard

receiver (if fitted) at -8 dBm (adjustable)

For decrypted audio processing

600 ohm balanced output (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm balanced Link 11 audio output

(adjustable -20 dBm to +10 dBm for

F = 20 kHz)

Section 3 3000DV2 Radios

Page 14

Page 33

Table 3-5 Facilities 2 Connector (CN2) Pin-Out for Transmitters

Pin Function Description

3

4

5

7

13

15

16

17

20

21

24

25

Tx wideband audio line L1

Tx wideband audio line L2

Tape output

PTT state (pin 7 not used if

option 6 is selected)

DPTT Delayed PTT input

Hardwire PTT 0 volt input keys transmitter

Tx narrow-band audio line L1

Tx narrow-band audio line L2

Link 11 Tx audio line L1 (UHF only)

Link 11 Tx audio line L2 (UHF only)

BIT output Memory fault output. Active low TTL

0 volt Ground

600 ohm balanced input (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm single-ended output. Tx audio at

-8 dBm (nominal)

Open collector with 10k pull-up resistor to 5 V

600 ohm balanced input (adjustable

-20 dBm to +10 dBm for m = 0.9)

600 ohm balanced Link 11 audio input

(adjustable -20 dBm to +10 dBm for

F = 20 kHz)

Remote PTT Configurations

38 Remote PTT configurations (reference transceivers and transmitters) are shown in Fig. 3-1 and are

as follows:

❏

dc Phantom keying (Low to PTT)

❏

dc Phantom keying (High to PTT)

❏

ac Tone keying

❏

Direct keying (Low to PTT)

❏

Direct keying (High to PTT)

39 Connections shown in Fig. 3-1 are to the transceivers facilities 2 connector CN2. Additionally,

phantom keying and ac tone keying can be configured through the remote connector CN5. If using this

method, use those connections shown in Fig. 3-1 that are in brackets. All links and circuitry shown are on

the remote control module.

Note that the radio(s) are normally configured to a user’s requirements during manufacture at

Park Air Electronics. PTT configurations are therefore given for informational purposes only. If

there is a need to alter any settings reference to the appropriate technical handbook(s) may be

3000DV2 Radios Section 3

Page 15

Page 34

Fig. 3-1 Remote Interface PTT Configurations

Section 3 3000DV2 Radios

Page 16

Page 35

Remote Control Connections

40 As an alternative to local operation, the equipment can be operated from a remote position using a

PAE 3000V2 Series Remote Control Unit (RCU). Connections to the RCU are made from the radio’s

rear panel 9-way D-type remote connector CN5 (see Fig. 4).

41 The pin-out of the remote connector is detailed in Table 3-6. Pins 1 to 4 and 9 are used by all

models; pins 5 and 6 by transceivers and receivers only, and pins 7 and 8 by transceivers and

transmitters only.

42 When making connections to rear panel D-type connectors, and in order not to compromise the

equipment’s Electromagnetic Compatibility (EMC), users must:

use a D-type connector that has a screened cover.

❏

use screened multi-way cable, with the cable’s screen connected to the connector’s shell or

❏

body.

Table 3-6 Remote Connector (CN5) Pin-Out

Pin Function Description

AC Control DC Control

1

2

3

4

5

6

7

8

9

Transmit data

Transmit data

Receive data

Receive data

Receive audio line L1

Receive audio line L1

Transmitter audio line L1

Transmitter audio line L2

0 volt connection Ground Ground

CCITT V23 serial interface

over ac lines with maximum

line loss of 17 dB

4-wire operation. 600 ohm

nominal.

Operating line level with

Automatic Level Control

(ALC) is -13 dBm.

PTT signal is a 2930 Hz

tone superimposed on the

audio circuit.

Serial RS422 interface for

operation up to 2 km when

used with PAE 3000V2 Series

Remote Control Unit (RCU)

Line output adjustable

between -20 dBm and

+10 dBm

Line input adjustable

between -20 dBm and

+10 dBm

3000DV2 Radios Section 3

Page 17

Page 36

Microphone/Headset Connection

43 To operate the equipment in local mode using the front panel, a suitable microphone/headset, or

headset is connected to the front panel’s MIC/HEADSET connector. The connectors location is shown

in Figs. 7 to 9 and the connector’s pin-outs are detailed in Table 3-7 to 3-9. Fig. 3-2 shows the

connector’s pin-out.

Fig. 3-2 Mic/Headset Connector Pin-Out

Table 3-7 Transceiver Mic/Headset Connector Pin-Out

Pin Function Description

1

2

3

4

5

6

7

Microphone ground Microphone return

Not used -

PTT

Not used -

Sidetone

Microphone live 600 ohm. 3 mV to 30 mV

0 volt PTT grounding signal

Local PTT line (0 volt keys

transmitter)

Receive + Transmit audio to

headset. 100 mW into 100 ohm.

Section 3 3000DV2 Radios

Page 18

Page 37

Table 3-8 Receiver Mic/Headset Connector Pin-Out

Pin Function Description

1to4

5

6

7

Pin Function Description

1

2

3

4

5

Not used -

Receiver audio

Not used -

0 volt Ground

Table 3-9 Transmitter Mic/Headset Connector Pin-Out

Microphone ground Microphone return

Not used -

PTT Local PTT line (0 volt keys transmitter)

Not used -

Sidetone

Receiver audio to headset.

100 mW into 100 ohm.

Transmit audio to headset.

100 mW into 100 ohm.

6

7

Microphone live 600 ohm. 3 mV to 30 mV

0 volt PTT grounding signal

PA/Filter Drive Connection (Option 06)

44 With this option, the 37-way D-type connector CN3 on the rear panel (refer to Fig. 4) is used to

interface the radio to an external auto-tune filter or power amplifier (such as a PAE 3640). The pin-out of

the connector is detailed in Table 3-10.

45 When making connections to the rear panel D-type connector CN3, and in order not to compromise

the equipment’s Electromagnetic Compatibility (EMC), users must:

❏

use a D-type connector that has a screened cover.

❏

use screened multi-way cable, with the cable’s screen connected to the connector’s shell or

body.

Note ...

When the optional Have Quick module is fitted in the radio, the function of connector CN3 pins 24

and 25 changes. These changes are detailed in Table 3-10. Note also the radio's front panel PCB

DIP switch SW1-5 must be correctly set: On when a Have Quick module is fitted; Off when a Have

Quick module is not fitted.

3000DV2 Radios Section 3

Page 19

Page 38

Table 3-10 Power Amplifier/Auto-Tune Filter Connections at CN3

Pin Condition Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

Not used

Not used

Not used

0 volt

0 volt

0 volt

0 volt

TTL

TTL

25 kHz

50 kHz

100 kHz

200 kHz

400 kHz

800 kHz

1 MHz

2 MHz

4 MHz

8 MHz

Amplifier present

-

-

0 volt

0 volt

0 volt

Filter detect

10 MHz

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

TTL

Not used

Not used

28Vdc

28Vdc

28Vdc

20 MHz

40 MHz

80 MHz

100 MHz (HQ module fitted: 200/300 MHz. High = 300 MHz selected)

200 MHz (HQ module fitted: No connection)

Filter tune

VHF/UHF state

AM/FM state

EBIT

Reset bypass/HQ AJ state

Inhibit

Fast PTT

-

28Vdc

28Vdc

28Vdc

Note ...

The frequency output pins (pins 1-10 and 20-25) are positive logic and represent the

current frequency of the radio. For example if the radio was operating on 225.000 MHz,

CN3 pins 7, 9, 21 and 25 would be logic high.

Section 3 3000DV2 Radios

Page 20

Page 39

External Clock

46 The rear panel connector CN4 (see Fig. 4) is for use with transceivers with the Have Quick option

that require an external clock. The connector allows an external timing source to be connected (see

Table 3-11).

47 When making connections to the rear panel D-type connector CN4, and in order not to compromise

the equipment’s Electromagnetic Compatibility (EMC), users must:

use a D-type connector that has a screened cover.

❏

use screened multi-way cable, with the cable’s screen connected to the connector’s shell or

❏

body.

Table 3-11 External Clock Interface Connector (CN4) Pin-Out

Pin Number Signal Function

1

2

3

4

5

6

7

8to15

Ext +5V In

Ext TOD Out

Ext CLK In

Ext CLK Shield

Ext TOD In

Gnd

Ext CLK En

Not used

+5 volt external oscillator supply

External TOD output

External clock input

External clock 0 volt/screen

External time-of-day input

0 volt signal return

External clock enable input

-

Unused Connection CN6

48 Connector CN6 is fitted on the rear panel, but is reserved for future development.

Antenna Connection

Warning!

Antennas used with 3000DV2 transmitters and transceivers must be installed such

that the resultant radiated field strength is below 10 watt per square metre in areas

normally accessible to personnel.

49 The antenna is connected through the appropriate rear panel VHF and/or UHF ANTENNA N-type

coaxial connectors, (see Fig. 4). Connection to the antenna sockets should be made using coaxial cable

type RG213 (PAE accessory part no. 10-05120600) fitted with the appropriate N-type plug (PAE part no.

19-01030301), see Fig. 8 for assembly details.

50 An alternative coaxial cable (PAE accessory part no. 10-05120200) with equivalent or better loss

and power handling characteristics, fitted with an appropriate N-type plug (PAE part no. 19-01030306),

can be used. Ensure that any coaxial cable connected to the equipment has a characteristic impedance

of 50 ohms.

3000DV2 Radios Section 3

Page 21

Page 40

SETTING-UP

51 If available the following test equipment is recommended for carrying out the setting-up instructions:

RF Power Meter

or

Dummy Load

Note ...

When making key entries during the following procedures, do not pause more than 5 seconds

between key strokes or new data will be lost and the system will revert to default settings.

PRELIMINARY CHECKS

52 Prior to the application of ac and/or dc supplies, ensure that the front panel AC and DC SUPPLY

switches are in their OFF positions (down). Carry out a physical check of the transmitter verifying the

following:

❏ All connections and connectors are secure.

❏ All cable assemblies are properly supported.

❏ No cable is trapped or kinked.

❏ The transmitter/receiver is secured in its operational position.

❏ Tools used during installation have been removed.

❏ The impedance of the antenna feed cable is correct.

❏

The supply voltages and ratings are correct.

53 If available connect a suitable RF power meter or dummy load to the appropriate rear panel N-type

ANTENNA connector.

Warning ...

On application of ac and/or dc supplies lethal voltages are present within the

equipment. Care must be taken by personnel to avoid contact with exposed circuitry

during any setting-up or maintenance procedures.

Section 3 3000DV2 Radios

Page 22

Page 41

SWITCHING ON, AND AC AND DC CHANGE-OVER CHECKS

54 If both ac and dc supplies are connected to the equipment carry out the following change-over

check:

(a) At the front panel, set both AC and DC SUPPLY switches to on. Confirm that both AC and

DC SUPPLY indicators, located on the front panel, are lit.

(b) Isolate the radio from the ac supply and confirm that the following conditions exist:

AC SUPPLY indicator is unlit.

DC SUPPLY indicator is lit.

Frequency display shows a frequency.

(c) Restore the ac supply to the equipment and confirm that both SUPPLY indicators are lit.

When both ac and dc supplies are present the equipment will automatically select the ac

supply.

55 If only one supply is used, set the appropriate front panel SUPPLY switch to its on position and

confirm that the SUPPLY indicator above the switch is lit. Check also that the frequency display shows a

frequency.

SELECTING OPTIONS

56 Options available on a radio are described in section 1 of this handbook. Before becoming

operational, the options must be selected at the radio’s front panel. How to do this is fully described in

section 4 on page 21. No options become operational until this procedure has been completed.

SET RADIO ID

57 If the radio is to be used as part of a system, controlled remotely by an RCU, it must be identified by

its own unique ID that is a number in the range 0 and 254.

Key sequence: ID number, SHIFT s,8

Example. Setting the Radio’s ID

58 To set the ID to 2, enter the following key sequence:

2, SHIFT s,8

59 Error 38 is displayed if an invalid ID is entered.

3000DV2 Radios Section 3

Page 23

Page 42

VIEW RADIO ID

60 The previous sequence can be used to both set, and view, the current ID of a radio. If a number

does not prefix the key sequence then the ID is displayed for 5 seconds, but can be cancelled before the

5 seconds have elapsed by pressing the CE key.

Example. Viewing the Radio’s ID

61 To view the current ID, enter the following key sequence:

SHIFT s,8

62 The radio’s front panel displays show the ID as shown below.

FREQUENCY

002

CHANNEL

Id

MONITOR

SET EQUIPMENT BAUD RATE

63 If the radio is to be remotely controlled at a baud rate other than the default 1200 rate, a key

sequence can be entered to select the required baud rate. Valid baud rates are: 1200, 2400, 4800 and

9600.

Key sequence: baud rate, SHIFT s,9

64 Error 38 (Err 38) is displayed if an invalid baud rate is selected.

Example. Setting the Baud Rate

65 To set the baud rate to 9600, enter the following key sequence:

9600, SHIFT s,9

VIEW EQUIPMENT BAUD RATE

66 The previous sequence is used to set, and view, the baud rate of the radio being remotely

controlled. If a number does not prefix the key sequence, the current baud rate setting is displayed for 5

seconds, but can be cancelled before the 5 seconds have elapsed by pressing the CE key.

Example. Viewing the Current Baud Rate

67 To view the current ID, enter the following key sequence:

SHIFT s,9

The radio’s front panel displays show the baud rate as illustrated below.

FREQUENCY

9600

Section 3 3000DV2 Radios

Page 24

CHANNEL

--

MONITOR

bAUd

Page 43

VIEW BAND EDGES

68 The highest and lowest frequencies that a radio can operate on are called the band edges. These

can be viewed using the following key sequences:

SHIFT s, 4 View band edge 1 (lowest VHF frequency)

SHIFT s, 5 View band edge 2 (highest VHF frequency)

SHIFT s, 6 View band edge 3 (lowest UHF frequency)

SHIFT s, 7 View band edge 4 (highest UHF frequency)

69 Viewing band edges 1 and 2 is only available on VHF equipments and viewing band edges 3 and 4

is only available on UHF equipments. VHF/UHF radios, for example the 3060V2 transceiver, can display

all band edges.

70 Band edges cannot be programmed, only viewed. Following each valid key sequence the display

shows the band edge for five seconds. The display can be returned to normal before 5 seconds have

elapsed by pressing the CE key.

Example. Viewing a Band Edge

71 To view band edge 1 (lowest VHF frequency that in this example is 100 MHz) enter key sequence

SHIFT s, 4. The radio’s displays are shown below.

Before key sequence, displays show

operating frequency and channel

Enter key sequence, SHIFT s,4

After five seconds, or if the CE key is

pressed, displays show original values

FREQUENCY CHANNEL MONITOR

325.000 21

FREQUENCY CHANNEL MONITOR

100 E1

FREQUENCY CHANNEL MONITOR

325.000 21

3000DV2 Radios Section 3

Page 25

Page 44

FUNCTIONAL CHECKS

72 The following checks are for transceivers and transmitters only. At the front panel TX control pad

set the FWD button to its on position, indicated by the associated indicator being lit (refer to Figs. 1

and 2). Operate the PTT button (red) and confirm that a reading of approximately 40 W (AM) or 60 W

(FM) is indicated on the front panel MONITOR display, unless connected to a serviceable 3640 power

amplifier in which case a reading of approximately 40 W AM and FM is indicated.

73 Connect a microphone (with integral PTT switch) to the front panel MIC/HEADSET socket, set the

MOD button to its on position, operate the PTT and speak into the microphone (maintaining a constant

tone). Confirm that a reading of greater than 30(%) is indicated in the MONITOR display, release the

PTT switch.

74 Remove the dummy load and reconnect the antenna. Carry out an interruptive BIT test as detailed

in section 4, operating instructions.

Section 3 3000DV2 Radios

Page 26

Page 45

Contents

Paragraph

1 INTRODUCTION

FRONT PANEL CONTROLS AND INDICATORS

3 Front panel layout

4 Transmitter (Tx) controls and indicators

11 Receiver (Rx) controls and indicators

19 Synthesiser controls and indicators

41 Mainframe controls and indicators

50 Auxiliary controls

55 Rear panel connections

SETTING-UP AND OPERATING PROCEDURES

63 Switching on

64 Frequency selection

65 Channel frequency setting

67 Channel recall

68 Channel verification

69 8.33 kHz channel operation

72 Frequency selection for 8.33 kHz channel spacing

73 Channel frequency setting for 8.33 kHz channel spacing

75 System reset

77 Auto-calibrate

78 Guard receiver operation

81 Options, software versions, and radio type menus

83 Options

88 Viewing software versions

89 Radio type menu

90 Screen blanking

93 Transmit operation (for transmitters and transceivers only)

97 Receive operation (for receivers and transceivers only)

Operation

MARITIME BAND - ADDITIONAL OPERATING INFORMATION

100 General

101 Normal mode

102 Ship/Shore modes

105 Ship/shore view modes

106 Channel change

107 Frequency change

108 External RF filter

109 Key sequences

3000DV2 Radios Section 4

Page 1

Page 46

110 BUILT-IN TEST (BIT) OPERATION

111 Power on self test

117 Continuously monitored functions

119 Interruptive self-test routine

122 Fault memory

USER MAINTENANCE

125 Filter cleaning

126 Lamp test

127 Frequency accuracy check

Table Page

4-1 8.33 kHz channel spacing - special frequency designations 17

4-2 Options, software versions and radio type menus 21

4-3 Maritime function key sequences 28

4-4 Maritime frequencies 29

4-5 Error message codes 34

Section 4 3000DV2 Radios

Page 2

Page 47

INTRODUCTION

1 This section details the radio’s controls and indicators, and explains how to operate the equipment

using the front panel controls. All of this section is applicable to 3000DV2 transceivers. Series 3000DV2

transmitter and receiver users should only read those parts of this section applicable to their type of

equipment.

2 As an alternative to operating the equipment using the front panel controls, a suitable Remote

Control Unit (RCU) can be employed. Although the RCU replicates many of the equipment’s front panel

controls and indicators, reference should always be made to the operating instructions supplied with the

RCU.

FRONT PANEL CONTROLS AND INDICATORS

FRONT PANEL LAYOUT

3 For the purposes of describing the controls and indicators, the front panel can be divided into the

following five sections (see Figs. 1, 2, and 3). Each section is described in the following paragraphs.

❏ Transmitter (Tx) controls and indicators.

❏ Receiver (Rx) controls and indicators.

❏ Synthesiser controls and indicators.

❏ Mainframe controls and indicators.

❏ Auxiliary controls and indicators.

3000DV2 Radios Section 4

Page 3

Page 48

Transmitter (Tx) Controls and Indicators

4 The transmitter’s controls and indicators (see Fig. 4-1) comprise a

SET PWR control, PTT switch and the four monitor switches LINE, FWD,

RFL and MOD. It should be noted that only one monitor function can be

selected at any one time; to deselect a selected function, press the

selected function switch or select the other function or press the RESET

switch.

SET PWR

5 The maximum output power from the transmitter is 40 W (AM) or

60 W (FM). The set power control allows a reduction of output power

between 0 and 10 dB. Note that when the radio is connected to a PAE

3640 power amplifier, the FM output is reduced to 40 W.

PTT

6 A momentary action press-to-operate switch: When the switch is

pressed, the transmitter becomes keyed, and the adjacent indicator lights.

LINE

7 Two-position push-to-select (push again to deselect) line monitor

switch. When selected, the adjacent indicator is lit and the front panel

monitor display shows the transmitter’s line input level (in dBm).

Fig. 4-1

FWD

8 Two-position push-to-select (push again to deselect) forward power monitor switch. When

selected, the adjacent indicator is lit and the front panel monitor display shows the transmitter’s forward

output power (in watts).

RFL

9 Two-position push-to-select (push again to deselect) reflected power monitor switch. When

selected, the adjacent indicator is lit and the front panel monitor display shows the transmitter’s reflected

output power (in watts).

MOD

10 Two-position push-to-select (push again to deselect) modulation depth monitor switch. When

selected, the adjacent indicator is lit and the front panel monitor display shows the transmitter’s

modulation depth (as a % when AM is selected, or in kHz when FM is selected).

Transmitter Controls

Section 4 3000DV2 Radios

Page 4

Page 49

Receiver (Rx) Controls and Indicators

11 The receiver’s controls and indicators (see Fig. 4-2) comprise a SET

MUTE (narrow-band) and SET MUTE (wideband) controls, MUTE control,

two monitor switches LINE and AGC, and guard receiver controls ON and

MUTE. It should be noted that only one of the two monitor functions can be

selected at any one time; to deselect a selected function, press the selected

function switch or select the other function or press the RESET switch.

SET MUTE (Narrow-band)

12 The set mute (narrow-band) control allows the receiver’s mute

threshold to be adjusted between a 6 dB and 16 dB signal-to-noise (S+N:N)

ratio.

SET MUTE (Wideband)

13 The set mute (wideband) control allows the receiver’s mute threshold to

be adjusted over the RF input range 1.5 mV to 50 mV emf.

MUTE

14 Two-position push-to-select (push again to deselect) mute defeat

switch. When in the defeat position, the adjacent indicator is lit, and the

receiver’s mute circuit is disabled. When the switch is in the other position,

the indicator lights when audio is present, and the mute circuit operates at

the threshold determined by the SET MUTE control operative at the time.

Fig. 4-2

Receiver Controls

LINE

15 Two-position push-to-select (push again to deselect) line monitor switch. When selected, with the

receiver operational, the adjacent indicator is lit and the front panel monitor display shows the receiver’s

line output level (in dBm).

AGC

16 Two-position push-to-select (push again to deselect) AGC monitor switch. When selected, the

adjacent indicator is lit and the front panel monitor display shows the receiver’s automatic gain control

(AGC) level (in volts).

GUARD ON

17 Two-position push-to-select (push again to deselect) switch. This switch is only operational when

the guard option is fitted. When selected, the adjacent indicator is lit and the guard receiver audio can be

monitored on the loudspeaker or headphones (if connected). The presence of audio is dependent on

the guard receiver’s mute status.

GUARD MUTE

18 Two-position push-to-select (push again to de-select) guard mute defeat switch. When in the

defeat position, the adjacent indicator is always lit, and the guard receiver’s mute circuit is disabled.

When the switch is in the other position, the indicator lights when audio is present and the mute circuit is

operational.

3000DV2 Radios Section 4

Page 5

Page 50

Synthesiser Controls and Indicators

19 The synthesiser controls and indicators panel (see Fig. 4-3) comprises:

A frequency and a channel display.

❏

A triple function keypad providing primary, secondary and tertiary key functions. The primary

❏

function of the keypad is engraved on the key(s) (0-9). The keys allow frequencies and

channels to be entered and stored in the equipment’s memory, and provide for the selection of

different display functions. Keys with lettering above them provide a second function and

provide the means by which a number of operational functions are carried out. Keys with

lettering below them have a third function that is used in sets when option 07 (Have Quick) or

option 12 (Quick Fox) is fitted.

Three mode selection keys: AM/FM, Narrow-band/Wideband (NB/WB) and Link 11.

❏

Fig. 4-3 Synthesiser Controls

Section 4 3000DV2 Radios

Page 6

Page 51

FREQUENCY and CHANNEL Displays

20 The synthesiser provides a six-digit frequency display and a two-digit channel display. The displays

have four functions:

Monitor Function. The displays show the current operating frequency and channel number.

❏

Edit Function. The edit function is indicated by a flashing decimal point at the bottom

❏

right-hand end of the frequency display. Edit function shows information being entered from

the keypad, not the radio’s current operating parameters.

View Function. View facilities allow channel information to be displayed without affecting the

❏