Instructions for

Contractor’s Special™ 2000CS/2001CS

Please read before use.

Register your product

at www.mytee.com/help

2000CS p.2

2001CS p.8

General & Maintenance information p.14

Model #

Serial #

Form # ADM-CS

3-12

13655 Stowe Dr., Poway, CA. 92064

1

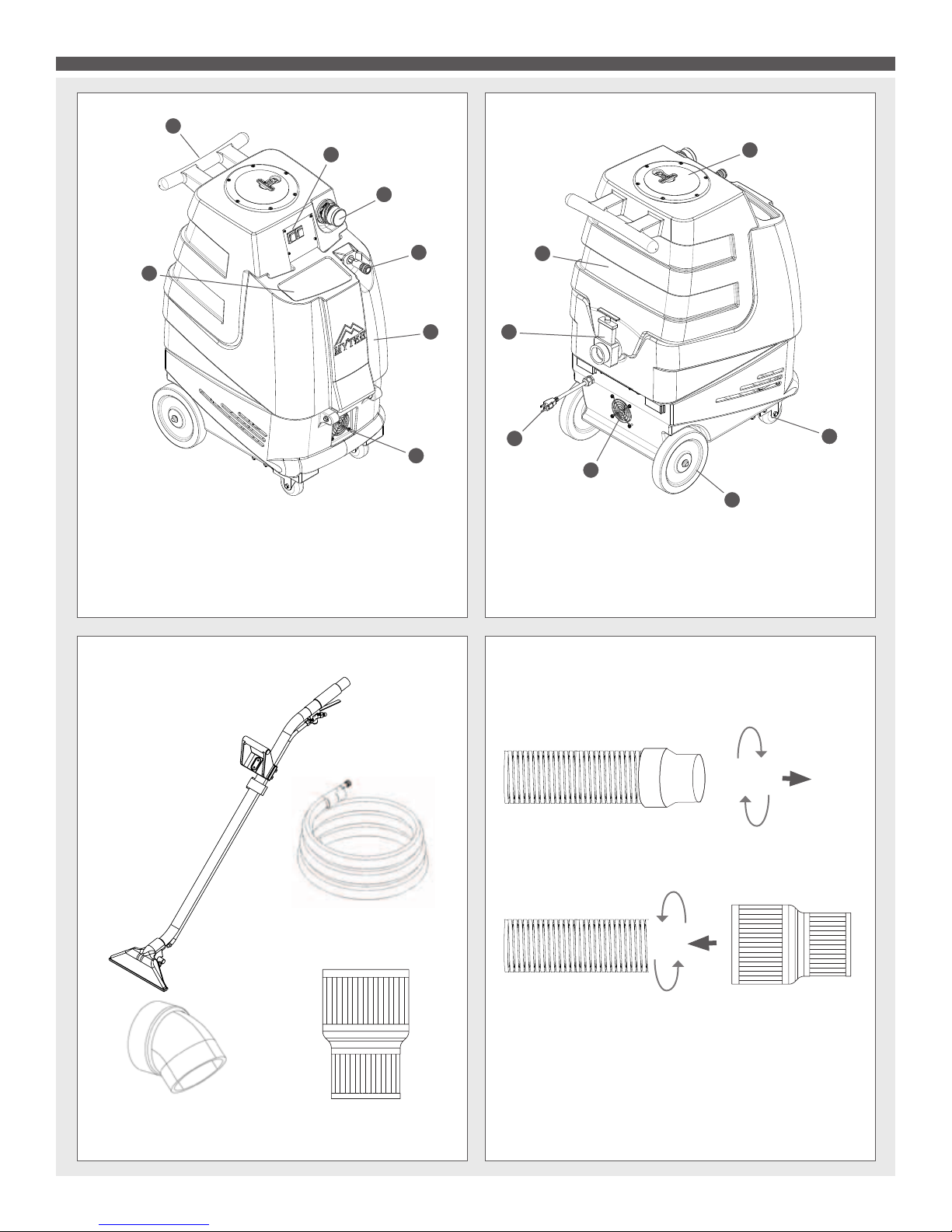

CONTRACTOR’S SPECIAL™ 2000CS

7

6

1. Waist high controls

2. 2” Male Cuff-Lynx™

3. Female QD

4. Solution tank

5. Front vent

6. Solution lid

7. Push handle

2000CS FRONT

2000CS BACK

1

8

2

3

4

13

12

14

9

5

11

8. Recovery tank lid

9. 3” casters

10. 8” wheels

11. Rear vent

12. 25’ Power cord

13. Bucket-high drain valve

14. Recovery tank

10

2000CS ACCESSORIES

8300 EZ C - 12” Wand

H226 - Drain Elbow

8501- 15’ 1-1/2” Vac/Sol Hose

H141 - 1 1/2” Cuff-Lynx™

REPLACING HOSE CUFFS WITH CUFF-LYNX™

Twist clock-wise to remove standard cuffs.

Twist counter clock-wise to attach Cuff-Lynx™ to vac. hose.

Once you receive your Contractor’s Special™, you will need to

replace the cuffs on your vacuum hose. To remove old cuffs, twist

clock-wise. To attach reducer Cuff-lynx™ to vacuum hose twist

counter clock-wise.

2

CONTRACTOR’S SPECIAL™ 2000CS

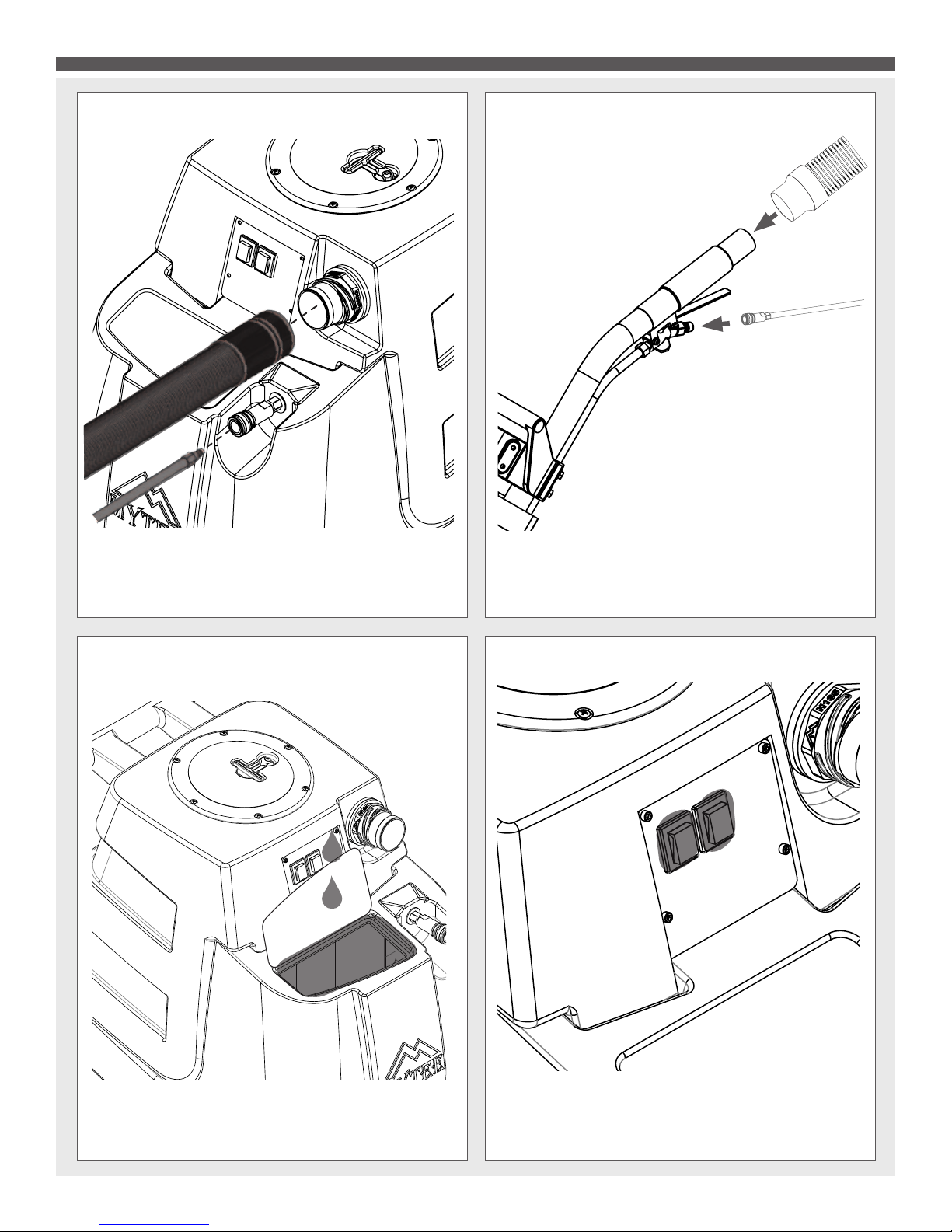

2000CS ATTACH HOSES

Firmly attach hose and quick disconnect. Make sure quick disconnects snap together rmly. Once attached to unit connect Q.D. to

upholstery tool. Always inspect hoses for cracks or fraying.

ATTACH VAC & SOLUTION HOSE TO WAND

Attach hose cuff to end of wand tube. Attach female QD to male

QD located near the wand trigger.

2000CS FILL SOLUTION TANK

Lift lid to ll. For best results, ll with warm water (140o F).

2000CS VACUUM & PUMP

VACUUM PUMP

To use vacuum, turn on vacuum. To use pump, turn on pump.

3

CONTRACTOR’S SPECIAL™ 2000CS

2000CS RECOVERY DRAIN

When the oat shuts off vacuum, empty tank. Pull lever located at

the back of the machine to release water.

2000CS LOCKING CASTERS

Locking casters help keep the machine remain stationary during

use.

Add a defoamer in the recovery tank to reduce foam, prolonging

the life of the Contractor’s Special™ vacuum motor .

2000CS SYSTEM MAINTAINER2000CS ADDING DEFOAMER

Weekly ushing of the solution system with Mytee® System

Maintainer helps keep lines clean and prevents chemical build-up,

improving pump life, performance and pressure.

4

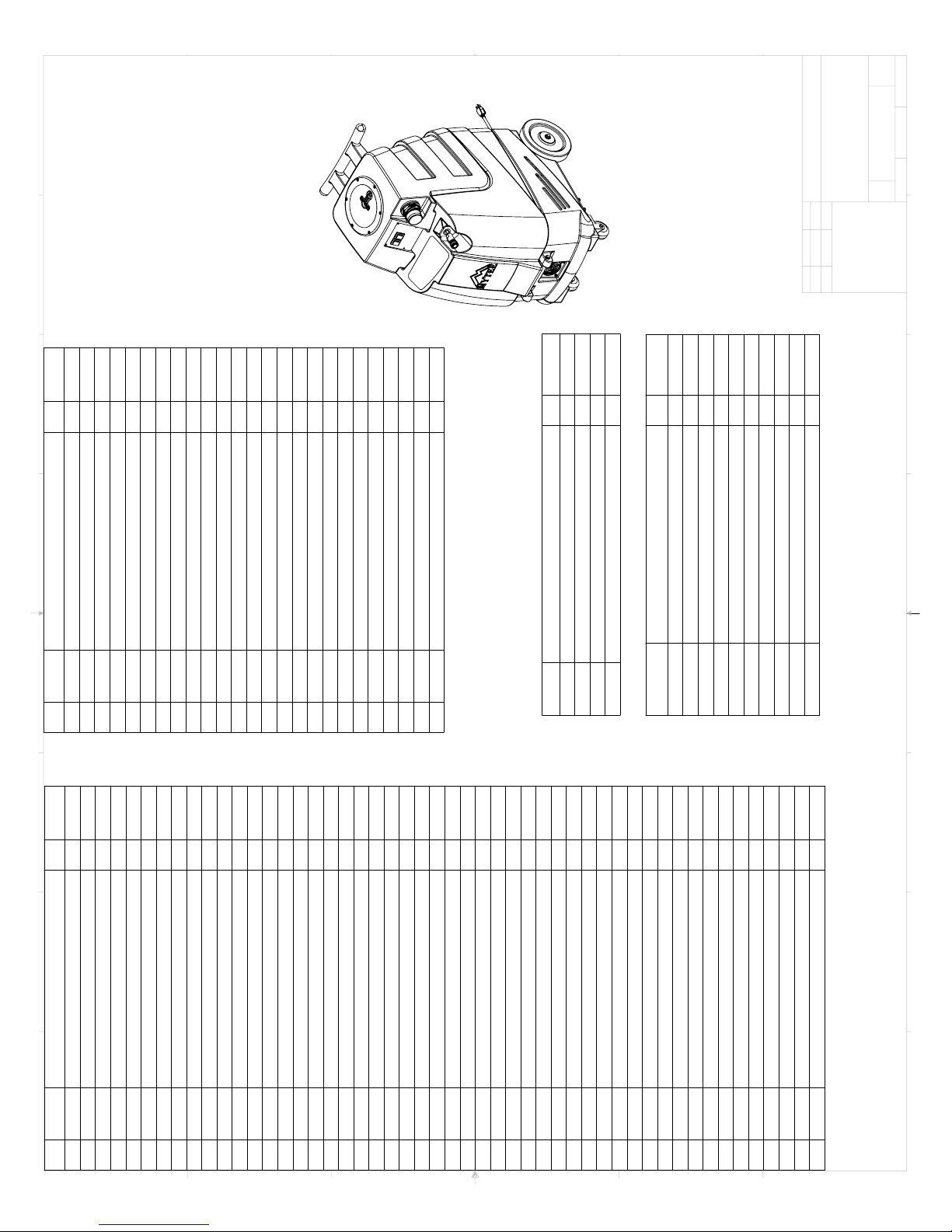

CONTRACTOR’S SPECIAL™ 2000CS PARTS & PRICING

D

C

B

E

F

A

REV

1

2

MSRP

3

1 $2.49 ea

1 $6.49 ea

QTY.

2 $4.49 ea

4 $0.99 ea

2 $3.19 ea

1 $17.99 ea

1 $3.49 ea

1 $31.99 ea

$4.99/Ft

1 $4.99 ea

1

3 $0.99 ea

1 $8.99 ea

1 $19.99 ea

1 $11.99 ea

1 $36.99 ea

6 $0.99 ea

1 $2.49 ea

1 $3.99 ea

1 $186.99 ea

1 $15.99 ea

1 $20.99 ea

2 $6.99 ea

1 $5.99 ea

1 $6.99 ea

2 $13.99 ea

2 $4.48 ea

MSRP

QTY.

1 $3.99 ea

1 $159.99 ea

1 $3.19 ea

1 $71.99 ea

1 $8.49 ea

MSRP

1 $9.99 ea

2 $4.99 ea

1 $3.49 ea

QTY.

1 $17.99 ea

5 $3.49 ea

PRODUCTS, INC.

858-679-1191

mytee

TITLE:

DATE

2/28/12

NAME

D. Cano

CHECKED

DRAWN

n/a

n/a

1

1

OD

SHEET 1 OF 2

1

DO NOT

SCALE DRAWING

2000CS

contractors special

DWG. NO.

C

SCALE: 1:8

SIZE

2

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS

PROHIBITED.

3

4

DESCRIPTION

filter, strainer, 1/2"

bushing, brass, 1/2"mpt x 3/8" fpt, hex

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

B210

B103

B107 nipple, brass, 1/4"m, hex

H212 washer, 9/16"id x 1"od, flat, s/s

PART NO.

NO.

ITEM

MSRP

QTY.

B119A

51

52

1 $147.99

12 $0.99

54

53

2 $14.99 ea

18 $0.99 ea

55

5

6

7

qd, brass, 1/4" f

pipe, pvc, 1-1/2"

hose, 3/8" x 17-1/2", (OAL)

adapter, pvc, 1-1/2" fms x fmpt

float, 1.5", ball style

elbow, U, 180, 1-1/2", float

screw, 8 x 1/2", hex head, zinc

gasket, 7", vac lid

gasket, 2" inlet

lid, vac tank, black, 7"

screw, #8 x 5/8 phil oval, s/s

Cuff-Lynx, 2" m cuff x 2" mpt

adapter, brass, extender, 1/4" mpt x 1/4" fpt, hex

B102

B111

56

H244

AH105

58

59

57

H297

PH633-11

60

61

P755

62

H235

63

G091

64

G090

65

H304

66

H135

67

G083

68

$8.99/ft

9 $0.99 ea

1 $151.99 ea

1 $9.49 ea

4 $0.99 ea

2 $2.99 ea

1

1 $3.49 ea

4 $1.99 ea

4 $0.99 ea

4 $0.99 ea

1 $4.99 ea

1 $26.49 ea

vac tank, firebird

valve, drain, 1-1/2"

elbow, inlet assembly 2"

P758

A926

69

70

3 $0.99

5 $0.99 ea

plate, switch, 3 hole, fb

bracket, "L" (all extracters)

fitting, inlet, pvc, 1-1/2", gray

H225

H229

H326

H390A

71

72

73

74

1 $7.99 ea

3 $4.99 ea

1 $14.99 ea

1 $8.99 ea

switch, rocker, 2 position

E515

75

$6.49/ft

1 $139.99 ea

1 $1.99 ea

1 $4.99 ea

1

1 $5.99 ea

2 $1.49 ea

DESCRIPTION

strap, velcro, w/buckle

gasket strip, 3/4" x 36" x 1/8"

filter, bag, vac tank, drawstring

G010

G085

G147

PART NO.

Items Not Shown

1 $3.19 ea

1 $44.99 ea

2 $0.99 ea

1 $9.99 ea

2 $28.99 ea

2 $0.99 ea

DESCRIPTION

plug, vent, heyco, 1/2"

cuff-lynx, 2" to 1.5" reducer

wand, 12" collapsable, w/disconnects

H141

8350C

PART NO.

H434

Accessories

4 $1.99 ea

2 $0.99 ea

4 $0.99

1 $9.99 ea

1 $149.99 ea

2 $0.99 ea

spout, drain, 45 degree

sol hose, 1/4" x 16', 3000psi

quick disconnect, male, 1/4" male x 1/4" fpt

B101

H295

H226

A942

cuff-lynx instruction guide

stop sign register your product

quick disconnect, 1/4" female x 1/4" fpt

B102

G147

AD127

strap, velcro, w/buckle

vac hose, 1-1/2" 15' SW 1 $42.00 ea

ADM-CUFF-LYNX

4 $0.99 ea

8 $0.99 ea

1 $8.99 ea

2 $0.99 ea

2 $0.99

1 $8.99 ea

5 $0.99 ea

1 $1.99 ea

4

5

6

7

DESCRIPTION

base, firebird

washer, 1/4" flat, s/s

8

bolt, 1/4-20 x 1" hex head, s/s 8 $0.99

nut, lock, 1/4-20, nylon insert, s/s

caster, 3", Black Hub, Gray Tread

P756

H216

H210

H667

PART NO.

NO.

ITEM

1

H342

4

3

2

5

F

washer, 1/4" lock, s/s

guard, cooling fan, wire

sol hose, 1/2" kuri, 100 psi

pump, 120psi, demand, 115V

screw, #10 x 5/8" hex head, zinc

elbow, brass, 90 deg, 1/2" barb x 3/8"mpt

B172

H296

H343

H213

C305

PH615-26

6

7

8

9

10

11

nut, kep, #10-32 zinc

clamp, hose, 5/16-29/32

bushing, brass, 3/8"mpt x 1/4" 1 $3.19 ea

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

screw, #10-32 x 1-1/4" phil pan head, zinc

adapter, brass, 1/2" barb x 3/8" fsw, ball end

B160

12

H347

13

E

H222

14

H273

15

B105

16

B136

17

cuff, black 1-1/2"

clamp, hose, 2-1/4 dia

bolt, 1/4x20x3/4" hex head

sol hose, 1/4" x 24 1/2", (OAL)

bolt, 1/4-20 x 3/4" serrated hex flange, zinc

H202

H768

AH108S

19

18

20

gasket, vacuum motor

vac support, 3 stage, 4-1/16"

plate, single manifold, 6.5" x 9"

manifold, single vac, no gasket

vac hose, 1-1/2", black, wire reinforced

P735

H330

H501

21

22

D

H300

H217

G004

PH627-24

24

23

25

26

27

nut, lock, 1/2" steel

exhaust boot, plastisol

fitting, strain relief, cord

washer, axle, cut 1/2" id

axle, 17.50" x .50" dia, fb

power cord, end, 25', 14/3

E532

H221

H220

H254

C302 vac motor, 3 stage, 120V, tangential

G059

29

30

28

H224

31

32

33

34

C

5

wheel, 8"

sol tank, firebird

P757

H239

H219 cap, axle, 1/2"

35

36

37

nut, hex, 1/4-20 s/s

bolt, 1/4-20 x 1 1/4"

bracket, rear, fb/spy

washer, 1/4"id x 1"od, flat, s/s

washer, star, 1/4" steel zinc

washer, buna 1-1/8" od x 3/16" id

bolt, 1/4-20 x 1/2" serrated hex flange, zinc

H203

H912

H307

H215

38

H211

39

G052

40

Part prices are subject to change.Order parts at: www.mytee.com/products/product.php?id=2000CS

H770

41

42

43

44

B

bracket, front hinge, sp/fb

bolt, 1/4-20 x 1/2", hex head, zinc

H378

H201

45

46

nipple, brass, 3/8" x close

bolt, 1/4-20 x 1 3/4" hex head, s/s

washer, 11/16"id x 1-1/2"od x .075, s/s

elbow, brass, 90 deg, 3/8"mpt x 3/8" fmpt

B186

B216

H204

H299

47

49

50

48

A

8

CONTRACTOR’S SPECIAL™ 2000CS PARTS & PRICING

1

2

3

4

5

6

7

2000CS

SCALE: 1:5

DWG. NO.

D

SIZE

TITLE:

NAME

DATE

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS PROHIBITED.

mytee

PRODUCTS, INC.

858-679-1191

D Cano

2/28/12

DO NOT SCALE

DRAWING

contractors special

71

69

70

72

66

44

65

73

64

63

62

60

59

61

68

67

75

74

to pump "OUT"

thru AH108S-25 (#18)

53

55

43

54

44

58

53

54

55

42

54

56

57

41

39

40

40

39

38

6

45

to pump "IN"

thru B160 (#12)

48

49

49

49

49

37

47

46

50

6

3

49

3

49

51

52

36

32

35

2

34

28

27

31

30

33

1

20

21

8

19

23

26

25

29

24

22

20

to sol tank

thru B103 (#53)

13

3

17

18

3

16

15

9

14

10

4

3

5

7

8

12

11

to sol tank

thru B186 (#48)

6

CONTRACTOR’S SPECIAL™ 2000CS WIRING DIAGRAM

7

CONTRACTOR’S SPECIAL™ 2001CS

7

6

1. Waist high controls

2. 2” Male Cuff-Lynx™

3. Female QD

4. Solution tank

5. Front vent

6. Solution lid

7. Push handle

2001CS FRONT

2001CS BACK

1

8

2

3

4

13

12

14

9

5

11

8. Recovery tank lid

9. 3” casters

10. 8” wheels

11. Rear vent

12. 25’ Power cord

13. Bucket-high drain valve

14. Recovery tank

10

2001CS ACCESSORIES

8300 EZ C - 12” Wand

H226 - Drain Elbow

8501- 15’ 1-1/2” Vac/Sol Hose

H141 - 1 1/2” Cuff-Lynx™

REPLACING HOSE CUFFS WITH CUFF-LYNX™

Twist clock-wise to remove standard cuffs.

Twist counter clock-wise to attach Cuff-Lynx™ to vac. hose.

Once you receive your Contractor’s Special™, you will need to

replace the cuffs on your vacuum hose. To remove old cuffs, twist

clock-wise. To attach reducer Cuff-lynx™ to vacuum hose twist

counter clock-wise.

8

CONTRACTOR’S SPECIAL™ 2001CS

2001CS ATTACH HOSES

Firmly attach hose and quick disconnect. Make sure quick disconnects snap together rmly. Once attached to unit connect Q.D. to

upholstery tool. Always inspect hoses for cracks or fraying.

ATTACH VAC & SOLUTION HOSE TO WAND

Attach hose cuff to end of wand tube. Attach female QD to male

QD located near the wand trigger.

2001CS FILL SOLUTION TANK

Lift lid to ll. For best results, ll with warm water (140o F).

2001CS VACUUM, PUMP & HEATER

VACUUM PUMP HEATER

To use vacuum, turn on vacuum. To use pump, turn on pump.

For heater, turn on heater.

9

CONTRACTOR’S SPECIAL™ 2001CS

2001CS RECOVERY DRAIN

When the oat shuts off vacuum, empty tank. Pull lever located at

the back of the machine to release water.

2001CS LOCKING CASTERS

Locking casters help keep the machine remain stationary during

use.

Add a defoamer in the recovery tank to reduce foam, prolonging

the life of the Contractor’s Special™ vacuum motor .

2001CS SYSTEM MAINTAINER2001CS ADDING DEFOAMER

Weekly ushing of the solution system with Mytee® System

Maintainer helps keep lines clean and prevents chemical build-up,

improving pump life, performance and pressure.

10

CONTRACTOR’S SPECIAL™ 2001CS PARTS & PRICING

4

4

8

ITEM

PART NO.

NO.

1

H273

2

H230

3

H528

4

E571

5

F

E

D

C

B

A

H275

6

H274

7

E574

8

E573

9

H903A

10

B103

11

AH108S

12

AH156

13

B207

14

B108

15

AH103

16

B136

17

B105

18

C305

19

B172

20

PH615

21

H347

22

B160

23

H217

24

PH627 vac hose, 1-1/2", wire reinforced

25

H300

26

H770

27

C302 vac motor, 3 stage, 120V, tangential

28

H343

29

G004

30

H501

31

H330

32

H204

33

H201

34

P735

35

H768

36

H216

37

H222

38

H210

39

PH628

40

H020

41

H135

42

H229

43

H667

44

H342

45

H296

46

P756

47

H221

48

H220

49

E531

50

H254

51

H224

52

H239

53

H219

54

P757

55

G061

56

H215

57

H213

58

H211

59

G052

60

H203

61

H316

62

H378

63

B119A

64

B210

65

H299

66

B216

67

B186

68

B111

69

H212

70

B102

71

H413

72

B107

73

AH105

74

H912

75

H244

76

PH633-11

77

H297

78

P755

79

H235

80

G091

screw, #6 x 3/16, phil pan head, self-tapping

Thermostat, 310°F ± 10°F, Manual, 1/4"

elbow, brass, 90 deg, 1/4"mpt x 1/4" fpt

sol hose, 1/4" x 24 1/2", (OAL), f x fsw, 3000psi

hose, 3/8" x 6.5", (OAL), f x fsw, 5400 Gray

elbow, brass, 90 deg, 1/4" fpt x 1/4" fpt 1

hose, 3/8" x 10", (OAL), f x fsw, surge, 1600psi

elbow, brass, 90 deg, 1/4" mpt x 1/4" mpt

elbow, brass, 90 deg, 1/2" barb x 3/8"mpt

adapter, brass, 1/2" barb x 3/8" fsw, ball end

bolt, 1/4-20 x 1/2" serrated hex flange, zinc

bolt, 1/4-20 x 3/4" serrated hex flange, zinc

screw, #10-32 x 1-1/4" phil pan head, zinc

bushing, brass, 1/2"mpt x 3/8" fpt, hex

washer, 11/16"id x 1-1/2"od x .075, s/s

elbow, brass, 90 deg, 3/8"mpt x 3/8" fmpt

adapter, brass, extender, 1/4" mpt x 1/4" fpt, hex

washer, nylon, 9/16id x 1-1/16od x .031

hose, 3/8" x 17-1/2", (OAL), f x -fsw, surge, 1600psi

DESCRIPTION

nut, kep, #10-32 zinc

screw, 10-32 x 1/2 phil pan

bracket, heater mounting, dual

heating rod, 600W, 115V

6-32 x 3/16 p-pan internal sem zinc

Thermostat, 200°, Auto, 1/4"

heater, aluminum cast, single

valve, brass, 1/4" check

bushing, brass, 3/8"mpt x 1/4" 1

pump, 120psi, demand, 115V

sol hose, 1/2" kuri 100psi

clamp, hose, 5/16-29/32

clamp, hose, 2-1/4 dia

cuff, black 1-1/2"

screw, #10 x 5/8" hex head, zinc

gasket, vacuum motor

vac support, 3 stage, 4-1/16"

plate, single manifold, 6.5" x 9"

bolt, 1/4-20 x 1-3/4" hex head, s/s

bolt, 1/4-20 x 1/2", hex head, zinc

manifold, single vac, no gasket

nut, lock, 1/4-20, nylon insert, s/s

washer, 1/4" flat, s/s

vac hose, 2", wire reinforced

nut, lock, 2", steel

Cuff-Lynx, 2" m cuff x 2" mpt

fitting, inlet, pvc, 1-1/2", gray

caster, 3", Black Hub, Gray Tread

bolt, 1/4-20 x 1" hex head, s/s 8

guard, cooling fan, wire

base, firebird

nut, lock, 1/2" steel

fitting, strain relief, cord

power cord, end, 25', 12/3 black

washer, axle, cut 1/2" id

axle, 17.50" x .50" dia, fb

wheel, 8"

cap, axle, 1/2"

sol tank, firebird

cover, sol tank, fb

nut, hex, 1/4-20, s/s

washer, 1/4" lock, s/s

washer, 1/4"id x 1"od, flat, s/s

washer, buna 1-1/8" od x 3/16" id

bolt, 1/4-20 x 1-1/4" hex head

bolt, 1/4-20 x 1-1/2" hex head, s/s

bracket, front hinge, sp/fb

filter, strainer, 1/2"

nipple, brass, 3/8" x close

washer, 9/16"id x 1"od, flat, s/s

qd, brass, 1/4" f

nipple, brass, 1/4"m, hex

bracket, rear, fb/spy

adapter, pvc, 1-1/2" fms x fmpt

pipe, pvc, 1-1/2"

screw, #8 x 1/2", hex head, zinc

elbow, U, 180, 1-1/2", float

float, 1.5", ball style

gasket, 7", vac lid

7

QTY.

MSRP

6

$0.99 ea

2

$0.99 ea

1

$29.99 ea

2

$49.99 ea

8

$0.99 ea

2

$0.99 ea

2

$17.99 ea

2

$16.49 ea

2

$78.99 ea

5

$4.49 ea

1

$26.49 ea

1

$23.99 ea

$5.99 ea

1

$13.99 ea

1

$30.49 ea

1

$4.99 ea

$3.19 ea

1 $151.99 ea

1

$9.49 ea

1

$8.99 ea

4

$1.99 ea

1

$3.49 ea

3

$1.49 ea

1

$6.49 ea

1

$5.99 ea

11

$0.99 ea

1 $139.99 ea

9

$0.99 ea

1

$8.99 ea

3

$4.99 ea

1

$7.99 ea

3

$0.99 ea

2

$0.99 ea

1

$14.99 ea

3

$0.99 ea

13

$0.99 ea

4

$0.99 ea

16

$0.99 ea

1

$8.99/ft

1

$4.99 ea

2

$3.99 ea

1

$5.99 ea

2

$14.99 ea

$0.99 ea

2

$2.99 ea

1 $147.99

1

$1.99 ea

1

$3.19 ea

1

$52.99 ea

4

$0.99 ea

1

$9.99 ea

2

$28.99 ea

2

$0.99 ea

1 $149.99 ea

1

$12.99 ea

2

$0.99 ea

4

$0.99 ea

4

$0.99 ea

4

$1.99 ea

2

$0.99 ea

2

$0.99 ea

1

$8.99 ea

1

$6.49 ea

1

$2.49 ea

4

$0.99 ea

1

$1.99 ea

1

$8.99 ea

1

$3.49 ea

4

$0.99 ea

1

$17.99 ea

2

$0.99 ea

2

$3.19 ea

1

$31.99 ea

1

$9.99 ea

1

$4.99 ea

1

$4.99/Ft

3

$0.99 ea

1

$8.99 ea

1

$19.99 ea

1

$11.99 ea

ITEM

PART NO.

NO.

81

G090

82

H304

83

G002

84

A926

85

P758

86

H225

87

H226

88

H390A

89

H326

90

H246

91

E515

ITEMS NOT SHOWN:

PART NO.

ADM-HP60

AD127

6

DESCRIPTION

lid, vac tank, black, 7"

screw, #8 x 5/8 phil oval, s/s

gasket, cam fitting polyethylene, 2.35" OD 1.90" ID

elbow, inlet assembly 2"

vac tank, firebird

valve, drain, 1-1/2"

spout, drain, 45 degree

bracket, "L" (all extracters)

plate, switch, 3 hole, fb

screw, #8-32 x 3/8" SHCS, alloy

switch, rocker, 2 position

DESCRIPTION

manual, spyder

A935

A942

B101

B102

G008

G029

G085

G147

H230

H282

H375

H701

stop sign, register your product

sol hose, pig tail, 1/8" x 7 1/2"

sol hose, 1/4" x 16', 3000 psi

quick disconnect, male, 1/4" male x 1/4" fpt

quick disconnect, 1/4" female x 1/4" fpt

screw, 10-32 x 1/2" phil pan head, s/s 4

piglet filter

banana bag, mesh bag, yellow

gasket, strip, 3/4" x 36" x 1/8"

strap, velcro, w/buckle

tool, upholstery, s/s w/valve

hanger, wire formed, hose

hose, vac, 15' x 1-1/4" w/1-1/2" black cuffs

5

QTY.

1

6

1

1

1 $186.99 ea

1

1

2

1

4

3

QTY.

1

1

1

1

2

1

1

1

1

5

1

2

1

MSRP

$36.99 ea

$0.99 ea

$6.49 ea

$15.99 ea

$20.99 ea

$3.19 ea

$6.99 ea

$6.99 ea

$0.99 ea

$13.99 ea

MSRP

$14.99 ea

$71.99 ea

$8.49 ea

$17.99 ea

$6.29 pak

$3.99 ea

$4.99 ea

$3.49 ea

$0.99 ea

$98.99 ea

$10.99 ea

$44.99 ea

8

7

6

5

Part prices are subject to change.Order parts at: www.mytee.com/products/product.php?id=2001CS

11

CONTRACTOR’S SPECIAL™ 2001CS PARTS & PRICING

D

C

B

A

1

2

3

4

5

6

7

8

E

F

2001CS

SHEET 2 OF 2

Contractor’s

SCALE: 1:5

REV

DWG. NO.

D

SIZE

TITLE:

CHECKED

DRAWN

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

MYTEE PRODUCTS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

MYTEE PRODUCTS, INC. IS PROHIBITED.

A

mytee

PRODUCTS, INC.

858-679-1191

V. LaBarbera

7/2011

OD

DO NOT SCALE

DRAWING

Special

84

83

82

81

80

41

79

78

76

77

75

87

86

85

42

85

90

91

74

26

26

73

10

69

71

72

88

26

26

69

72

71

69

68

70

69

10

11

#

thru AH108S

To heater "OUT"

DATE

NAME

60

58

59

59

58

To inlet

16

on base

15

14

13

57

56

33

57

54

62

38

36

38

67

65

65

66

65

65

64

63

61

41

#

52

53

49

48

51

50

47

46

To vac

thru H244

motor exhaust

40

#

41

43

36

38

44

55

23

39

23

40

31

32

30

29

27

28

26

25

24

23

20

21

67

#

thru B186

To filter in sol tank

22

36

35

38

34

1

37

17

18

19

20

22

#

thru B160

To pump "IN"

10

#

thru B103

To female q.d.

11

10

12

10

45

28

10

9

8

7

4

1

2

3

*

12

CONTRACTOR’S SPECIAL™ 2001CS WIRING DIAGRAM

Heater 2

Gr een

White

T hermal Switch

GN D

E571E571

L 2

L 1

Thermal Switch

Orange

Mytee Products

13655 Stowe Dr.

Poway, CA

92064

---1

Revision:

0000 A

L egal

2001CS

Title

Size: Number:

1

Sheet of

Time:

3/11/2011 4:38:47 PM

Z:\Engineering\GHI\GHI Projects\MYTEE\Mytee Schematics\HP100\HP100 Schematic.SCHDOC

Date:

File:

Gr een

W hite

T hermal Switch

GN D

L 2

L 1

Thermal Switch

Orange

E515

SW- DPST

Heater 1

C302

Inline Conn.

W h

ite

GN D

Gr een

L 2

B lack

L 1

B lack

Inline Conn.

Y ellow

E515

SW- DPST

Vacuum Motor 1

Inline Conn.

White White

Green Green Green

GND

L 1

L 2

Inline Conn.

Gr een

W h

ite

B lack

Inline Conn.

Cord Input Primary

C305

GN D

L 2

L 1

Switch

Pressure

B lack

Inline Conn.

B lue

E515

SW- DPST

Pressure Pump

Black Black Black

B lack

13

GENERAL INFORMATION

Dear Customer:

Congratulations on the purchase of your new Contractor’s Special™. As you are

already aware, the scene of the equipment world is becoming more high tech, and

we at Mytee Products Inc. strive to keep you on the cutting edge with superior

quality and technology.

Keep in mind that the Contractor’s Special™ is a machine, so neglect or abuse

will cause unnecessary damage and void the warranty. However with simple

maintenance the Contractor’s Special™ will give quality performance for many

years to come.

If warranty questions arise, please consult your user manual or get in touch with

your distributor. If you have questions about maintenance, replacing parts or

ordering parts, please call an authorized Mytee Products Inc. Service Center.

To see an updated list, visit our website at www.mytee.com

Before you begin cleaning, please read your manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

Grounding Instructions

This machine must be grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electrical shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed in accordance

with all local code and ordinances. Do not remove ground pin; if missing, replace

plug before use.

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualied electrician or service person if you are in doubt

as to whether the outlet is properly grounded. Do not modify the plug provided with

the machine. If it will not t the outlet, have a proper outlet installed by a qualied

electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug

that looks like the plug illustrated in Figure 1 below. A temporary adapter illustrated

in Figures 2 and 3 may be used~to connect this plug to a 2-pole receptacle as

shown in Figure 2 if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet (Figure 1) can be

installed by a qualied electrician. The green colored rigid ear, tab or the like

extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is used, it must be held

in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or GreenYellow) wire in the cord is the grounding wire. When replacing

a plug, this wire must be attached to the grounding pin only.

DO NOT use extension cords.

Please Note for America use only

Grounding Pin

Figure 1

Grounded Outlet

Metal

Screw

Grounded Outlet Box

Figure 2 Figure 3

Adapter

Tab for Grounding

Screw

Parts and Service

Repairs, when required, should be performed by Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accessories.

Call Mytee for repair parts or service. Please specify the Model and Serial Number

when discussing your machine.

Name Plate

The Model and Serial Number of your machine are shown on the Nameplate on the

back panel of the machine. This information is needed when ordering repair parts

for the machine. Use the space provided on the front cover to note the Model and

Serial Number of your machine for future reference.

Unpacking the Machine

When the machine is delivered, carefully inspect the shipping carton and the

machine for damage. If damage is evident, save the shipping carton so that it can

be inspected by the carrier that delivered it. Contact the carrier immediately to le a

freight damage claim.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always

read this information carefully and take the necessary steps to protect personnel

and property.

Is used to warn of immediate hazards that will cause severe personal injury or death.

Is used to call attention to a situation that could cause severe personal injury.

Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property. When using an electrical appliance, basic

precautions should always be followed, including the following: Read all instructions

before using this machine. This product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

3. Always unplug power cord from electrical outlet before attempting any adjustments

or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

5. Do not pull or carry by cord. Do not close a door on cord or pull cord around sharp

edges or corners.

6. Do not run appliance over cord. Keep cord away from heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

8. Do not use outdoors or on wet surfaces and or standing water.

9. Always unplug or disconnect the appliance from power supply when not in use.

10. Do not allow to be used as a toy. Close attention is necessary when used by or

near children.

11. Do not use in areas where ammable or combustible material may be present.

12. Do not leave the unit exposed to harsh weather elements. Temperatures below

freezing may damage components and void warranty.

13. Use only the appropriate handles to move and lift unit. Do not use any other parts

of this machine for this purpose.

14. Keep hair, loose clothing, ngers, and all parts of the body away from all

openings and moving parts.

15. Use extra care when cleaning on stairs.

16. To reduce the risk of re or electric shock, do not use this machine with a solidstate speed control device.

17. The voltage and frequency indicated on the name plate must correspond to the

wall receptacle supply voltage.

18. When cleaning and servicing the machine, local or national regulations may apply

to the safe disposal of liquids which may contain: chemicals, grease, oil, acid, alkalines, or other dangerous liquids.

19. Do not leave operating unattended.

Filling the Solution Tank

1. Fill the solution tank with the approved cleaning solution.

2. Do not ll up the solution tank completely: 1” should be left free at the top.

3. Typically, the solution should be a mixture of water and a cleaning chemical

appropriate for the type of job.

4. Always follow the dilution instructions on the chemical container label.

5. The temperature of the cleaning solution must not exceed 70

Use only non-ammable liquid in this machine.

o

C/160oF.

14

Setup

1. Open lid of solution tank. Fill solution with water or approved cleaning agent. For

best results, ll with warm water (140

o

).

Flammable materials can cause an explosion or re. Do not use ammable solutions

or materials in tank(s).

FOR SAFETY: When using machine, follow mixing and handling instructions on

chemical containers.

ATTENTION: If using powdered cleaning chemicals, mix prior to adding.

2. Attach solution hose (located front of machine). NOTE: Make sure the quick

disconnect snap together rmly. As you do this, always inspect hoses for cracks or

fraying. Do not use if hoses are damaged.

3. Attach other end of solution hose to wand.

4. Attach vacuum hose to recovery tank.

5. Plug machine’s cord into a grounded wall outlet. FOR SAFETY: Do not operate

machine unless cord is properly grounded. FOR SAFETY: Do not operate machine

with the use of an extension cord.

6. Turn on pump. Key tool until you have a steady ow.

7. Release tool trigger. Turn on heater.

8. Wait 8–10 minutes for unit to pre-heat.

9. Re-key upholstery tool until hot water begins owing.

10. Once hot water is owing, release trigger and pre-heat an additional 4–5 minutes.

11. Turn on vacuum motor.

12. Begin cleaning. Make two dry passes to every wet pass.

13. For oor cleaning, unplug tool and attach oor wand.

14. Work away from cords to avoid damage.

15. Use a defoamer in your recovery tank.

16. To clean heavily soiled areas, repeat cleaning from different directions.

17. When oat shuts off vacuum, empty tanks.

18. When work is complete, unplug cords and hoses.

19. Wrap and clean hoses. Clean all tanks.

Pre-Operation

1. Vacuum carpet and upholstery and remove other debris.

2. Perform machine setup procedures.

3. Inspect power cord for damage.

Operation

1. Turn pump switch on.

2. Pull up on tool lever to release air in the line. Hold lever until a steady ow of water

comes out of the wand.

3. Once pump is primed and there is pressure in the solution line, turn on heater switch

(if model is equipped with heater) and wait a few minutes for water to heat up.

4. Once water is heated, turn on vacuum and begin cleaning.

Note: When cleaning upholstery, always check manufacturer’s cleaning instructions.

1. Work away from outlet and power cord to prevent cord damage.

2. Use a recommended foam control solution in the recovery tank to prevent vacuum

motor damage. Periodically check for excessive foam buildup in solution tank, and

recovery tank.

3. To clean heavily soiled areas, repeat cleaning path from different direction.

4. When ball oat shuts off vacuum, it is time to empty the dirty water from the

recovery tank, and rell solution tank.

5. After cleaning, relieve water pressure from tool before disconnecting hose.

Squeeze trigger for ve seconds after turning main power switch off.

After Use

1. Unplug.

2. Empty solution tank and rinse it with clean water.

3. Inspect hoses and replace if damaged.

4. Inspect solution lter. Clean or replace if damaged.

5. Store the machine in a clean, dry place.

6. Open recovery tank cover to promote air circulation.

Maintenance Schedule

Maintenance item Daily Once a week

Clean and inspect Tanks

Clean and inspect Hoses

Check lters

Check power supply cable

Clean machine with all purpose cleaner and cloth

Check spray nozzles

Flush solution system with Mytee system maintainer

Remove and clean oat shut-off screen from tank

Inspect vacuum hoses for holes and loose cuffs

x

x

x

x

x

x

x

x

x

Trouble Shooting

There is no power.

1. Plug machine in proper outlet.

2. Check circuit breaker; reset circuit breaker, other items should not run on the

same circuit as machine. Outlet must be a 20-amp circuit.

Pump does not work properly.

1. Snap quick disconnects rmly together.

2. Check solution tank; may be empty.

3. Jets clogged, remove jet and ush clean.

4. Filters clogged, remove lters and rinse clean with water.

5. Heater is blocked; ush out with Mytee’s system maintainer.

6. If brass check valve is stuck replace valve.

7. Check pump wire. May need to reconnect wire.

8. Switch plate switch may need to be replaced.

9. If pump motor brushes are worn, replace pump.

Heater does not work properly.

1. If sensor mounted on the heater has popped, reset sensor by pushing in button.

2. Heating element may need to be replaced.

Vacuum motor does not work properly.

1. Check that hose is tightly connected.

2. Close drain hose valve completely.

3. Secure the vacuum tank tightly.

4. If ball oat is shut off, empty vacuum tank of all wastewater.

5. Make sure ball oat is rmly installed on the elbow.

6. If water is coming out of vacuum motor, use a low foaming detergent.

7. Clean upholstery tool or oor wand jets.

FAQs

Q: How much does the Contractor’s Special™ weigh and what are the shipping

dimensions?

2000CS

A: 79 Pounds - Box dimensions are 29 3/4” x 19” x 46 1/4”. Must ship motor freight.

2001CS

A: 85 Pounds - Box dimensions are 29 3/4” x 19” x 46 1/4”. Must ship motor freight.

Q: What comes standard with the Contractor’s Special™?

A: The Contractor’s Special™ comes with 15’ 1-1/4” Vacuum/Solution Hose and a

12” wand and Cuff-Lynx™ reducer.

Q: Where do I plug the machine in?

A: The Contractor’s Special™ requires a 20A grounded circuit. Please note: GFI

outlets may trip before the breaker setting.

Q: What is the proper pre heat cycle for the 2001CS?

A: Turn pump switch to the on position and prime pump through the solution hose

and the tool. Then turn the heater switch to the on position. Let the machine sit idle

for 8-10 minutes. Spray tool until you feel the hot water from the jet. Let machine sit

idle for an additional 3-5 minutes. This will insure the water in the heater and hoses

will be at the hottest point to start cleaning.

Q: Are the pumps re-buildable for the Contractor’s Special™?

A: Yes, both the seals and the pistons have repair kits available.

Please see the pump manual that shipped with your machine for the

maintenance schedule.

Q: Is there anything I can do to increase the expected life of my machine?

A: Running the vacuum motors with the tank empty and lid off will allow excess

moisture in the vacs to dry off. You should also run a System Maintainer through

the system to keep the hoses, pump, and heater clean and free of debris.

15

Warranty

Mytee Products, Inc. endeavors to provide high quality products and product support

to its customers and therefore backs up all of its new products purchased from Mytee

Products Inc. (Mytee) or any authorized Mytee distributor/service center with this

limited warranty.

This limited warranty begins on the date of the customer purchase and is valid and

available to the original purchaser only. Mytee products are for commercial use only

and are not intended for personal, family or household uses.

HOWEVER, OTHER THAN SET FORTH HEREIN, MYTEE GIVES NO WARRANTY,

EXPRESS OR IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY,

FITNESS FOR ANY PARTICULAR PURPOSE, PRODUCTIVENESS, INFRINGEMENT, OR OTHER MATTER, OF ANY GOODS WHICH MYTEE SHALL SUPPLY.

THERE ARE NO WARRANTIES, WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. MYTEE SHALL IN NO WAY BE RESPONSIBLE FOR THE

PROPER USE AND APPLICATION OF THE GOODS. MYTEE NEITHER ASSUMES

NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR MYTEE ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF MYTEES GOODS. THIS LIMITED WARRANTY POLICY MAY BE CHANGED OR WITHDRAWN BY MYTEE AT

ANY TIME WITHOUT NOTICE.

90-DAY PARTS AND LABOR LIMITED WARRANTY: Mytee will cover parts and labor

on all components for 90 days from the date of original purchase. This warranty covers the cost of replacement and labor only, and does not cover shipping costs.

WEAR PARTS 90-DAY LIMITED WARRANTY: Mytee will replace all wear parts for

90 days from the date of original purchase. Wear parts are items which wear out

as a result of usage or the passage of time and are consumed despite attempts to

maintain them, such as gaskets, wheels, brass, cords, wires, electrical terminals,

hoses, switches, thermostats, plastisol parts, lters, bearings, brushes, solenoids, orings, bulbs, heating elements, castors, or other parts deemed wear items in Mytees

sole discretion. This warranty covers the cost of replacement only and does not cover

shipping or labor costs.

without violating the law.

The validity, construction and performance of this warranty policy shall be governed

by the laws of the State of California, without respect to conicts of laws principles.

The exclusive jurisdiction of any legal action arising from or related to this warranty

policy shall be in the State of California and no legal action shall be commenced

elsewhere.

Return Material Authorization Procedure

It is the responsibility of any Authorized Service Center (ASC) or Distributor with

written authorization to ensure the Customers equipment is repaired as soon as

possible. Only Mytee Products Inc. or it’s authorized dealers with written authorization, service centers, and agents may make warranty repairs on these products. All

others do so at their own risk and expense.

The Distributor must follow Mytee Products, Inc. standard RMA procedure:

1. When a repair falls within the Warranty time period for a piece of equipment, the

Distributor will ll out a RMA/Warranty claim form. This form will act as a repair order

to replace any defective parts.

2. All defective parts must be returned to Mytee Products, Inc. with the RMA/claim

form for evaluation at the customer’s expense. This shipping is non-refundable. All

warranty claims are subject to an evaluation by Mytee Products, Inc. to determine if

warranty will be approved. Any credit for repair and/or parts will only be issued upon

evaluation and approval from Mytee Products, Inc.

3. When Warranty is approved, the Distributor’s account will be credited for the

replacement part(s). Mytee Products, Inc. will ship the warranted replacement part(s)

to the Distributor prepaid. If Warranty is denied the Distributor’s account will not be

credited for any parts sent for this claim.

1-YEAR MAJOR COMPONENTS WARRANTY: Mytee warrants that pumps, vacuum

and oor machine motors, and heaters are covered for a one (1) year limited warranty from the date of original purchase. This warranty does not apply and is void if

the pump, vacuum motor, or heater has worn brush motors, water damage, chemical

build-up, chemical damage, or evidence of abuse, neglect or tampering. This warranty covers the cost of replacement only, and does not cover shipping or labor costs.

HOUSING LIFETIME LIMITED WARRANTY: Mytee warrants that all rotationally

molded housing and tanks will be free from manufacturing defects, defects in workmanship, and defects in material for the life of the part. Replacement cost does not

include the cost of shipping or labor.

LIMITATION OF DAMAGES: THE REMEDY OF REPLACEMENT OR REPAIR

OF ANY DEFECTIVE GOODS SHALL BE THE EXCLUSIVE REMEDY UNDER

ANY WARRANTY MADE BY MYTEE, WHETHER EXPRESS OR IMPLIED. IN NO

EVENT SHALL MYTEE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES, PROPERTY DAMAGES, OR PERSONAL INJURIES.

All limited warranties are void for, and Mytee does not warrant in any way, any product that evidences misapplication, improper installation, abuse, lack of maintenance,

negligence in use or care, abnormal use, alteration of design, use of incompatible

or corrosive chemicals, use in a rental service, and/or servicing, installation of parts,

or repairs by anyone other than Mytee or a Mytee authorized distributor or service

center. Mytee may make changes in products it manufactures and markets at any

time; these changes are made without obligation to change, retrot, or upgrade any

product previously sold or manufactured.

Mytee has no obligation to honor the limited warranties set forth herein unless the

original purchaser, promptly upon discovering the warranty claim and prior to continuing to use the product, contacts Mytee or a Mytee authorized distributor or service

center to describe the claim and to receive and follow instructions for documenting

and resolving the claim. In addition, the purchaser must provide the product to which

the claim applies to Mytee or a Mytee authorized distributor or service center for a

thorough inspection.

If any provision or portion of this limited warranty policy is found to be unenforceable,

then the remaining provisions and portions shall remain valid and enforceable.

If any provision or portion of this limited warranty policy is found to be limited by

law, then that provision or portion shall be construed to make it effective within the

bounds of law. For example, if there are legal limitations on the duration of

warranties, the warranties made herein shall be construed to have the minimum

duration required by law, or, if there are legal limitations of exclusion of remedies,

the exclusions made herein shall be construed to apply to the fullest extent possible

16

Loading...

Loading...