Page 1

JC 1 Amplifier

Owner’s Guide

Page 2

THANK YOU!

Congratulations and Thank You for Choosing Parasound

Your new Parasound Halo Series JC 1 mono block power amplier represents the latest

advancements in amplier technology. The JC 1 was designed by CTC builders and it uses higher

quality parts and achieves higher performance than any amplier we’ve made since Parasound

was founded in 1981. We’re proud to offer you this exceptional audio component, knowing that it

will bring you many years of enjoyment and dependability.

Here at Parasound, we design our products to perform at a higher level of exibility and sonic

performance than you may have expected. We encourage you to read this entire manual to learn

all the features and capabilities of your new JC 1 Amplier.

If you’re eager to get up and running right away, simply follow the basic step-by-step instructions

to connect and operate the JC 1. If you want to learn more about the technical and design aspects

of your JC 1, refer to the Technically Speaking and Design Overview sections in the back of the

manual. If you run into difculties, the Troubleshooting Chart should help you quickly remedy the

problem.

We appreciate you taking the time to read these instructions and thank you for selecting

Parasound for your listening pleasure.

1

The Parasound Staff

Unpacking Your JC 1

Unpack your JC 1 from the shipping carton, remove the enclosed AC power cord, the small

“L” shaped metal rack mounts, and the gray control wire with a sub-mini 2.5 mm plug on each

end. (This is the trigger connection wire). While you are unpacking your new amplier, inspect

it thoroughly for possible shipping damage. If you see any, contact your Parasound dealer right

away. Be sure to save and store both the inner and outer cartons and the packing inserts for

possible future transport. To save

room for storage, you can cut the seams on the bottom of the cartons and atten them.

Keeping Records for Future Reference

Record the serial number located on the bottom of your JC 1 in the space below. Also note

your Parasound Dealer’s name and phone number. We recommend that you keep your purchase

receipt with this manual and store them both in a safe place. You may need to refer to this

information sometime in the future.

Parasound JC 1 Amplier Serial #: ____________________________________

Parasound Dealer: ___________________________________________________

Phone Number______________________________________________________

Date of Purchase: ___________________________________________________

YOU SHOULD KNOW

There is no Parasound warranty for this unit if it was not purchased from an Authorized Parasound

Dealer. Investigate any claims of warranty coverage made by unauthorized dealers very carefully

as you will need to depend entirely upon the dealer, and NOT upon Parasound. Unauthorized

dealers may lack the capability to arrange repairs of Parasound equipment. Authorized Parasound

Dealers are listed at www.parasound.com or you can call 415-397-7100 between 8:30 am and 4:30

pm Pacic time.

A missing or tampered serial number could indicate that this unit was stolen or sold by an

unauthorized dealer. You should return it to your dealer immediately for replacement or a full refund.

Page 3

TABLE OF CONTENTS

JC 1 Amplifier

1

PLACEMENT GUIDELINES FOR YOUR JC 1

_________________________________________________________________________________

CONNECTING A STEREO PREAMPLIFIER OR A SURROUND

CONTROLLER TO THE BALANCED INPUT ON YOUR JC 1

_________________________________________________________________________________

CONNECTING A STEREO PREAMPLIFIER OR A SURROUND

CONTROLLER TO THE UNBALANCED INPUT ON YOUR JC 1

_________________________________________________________________________________

CONNECTING A SPEAKER TO YOUR JC 1

_________________________________________________________________________________

MANUAL AND AUTOMATIC TURN ON-OFF OPTIONS

_________________________________________________________________________________

CONNECTING AN EXTERNAL DC SOURCE FOR AUTOMATIC TURN ON-OFF

_________________________________________________________________________________

CONNECTING THE JC 1 TO TRIGGER ANOTHER COMPONENT

_________________________________________________________________________________

UNDERSTANDING THE INDICATORS ON THE JC 1

_________________________________________________________________________________

1

2

3

4

5

6

7

8

CONNECTING THE AC POWER CORD

_________________________________________________________________________________

MAINTAINING YOUR JC 1

_________________________________________________________________________________

TROUBLESHOOTING GUIDE

_________________________________________________________________________________

SERVICING YOUR JC 1

_________________________________________________________________________________

TECHNICALLY SPEAKING

_________________________________________________________________________________

PARASOUND JC 1 DESIGN OVERVIEW

_________________________________________________________________________________

PARASOUND JC 1 SPECIFICATIONS

_________________________________________________________________________________

9

10

11

12

13

15

17

Page 4

1

PLACEMENT GUIDELINES FOR YOUR JC 1

Power ampliers are usually heavier and generate more heat than other components. To avoid

damage to the JC 1 or other equipment and to reduce risk of re, you must follow these guidelines:

• Place the JC 1 on a separate shelf that will adequately support its weight.

• Keep it away from heat sources such as air ducts or radiators.

• Avoid placing it on carpeting or another material that might obstruct airow into the openings

in the chassis bottom.

• Leave at least 3” of space around both sides and 6” of space above the top. The bottom

clearance can be a little less.

• Do not block the front of the JC 1 behind closed cabinet doors during use.

• Do not stack the JC 1 with other components inside a cabinet unless you use a fan to circulate

and exhaust the warm air that builds up between them.

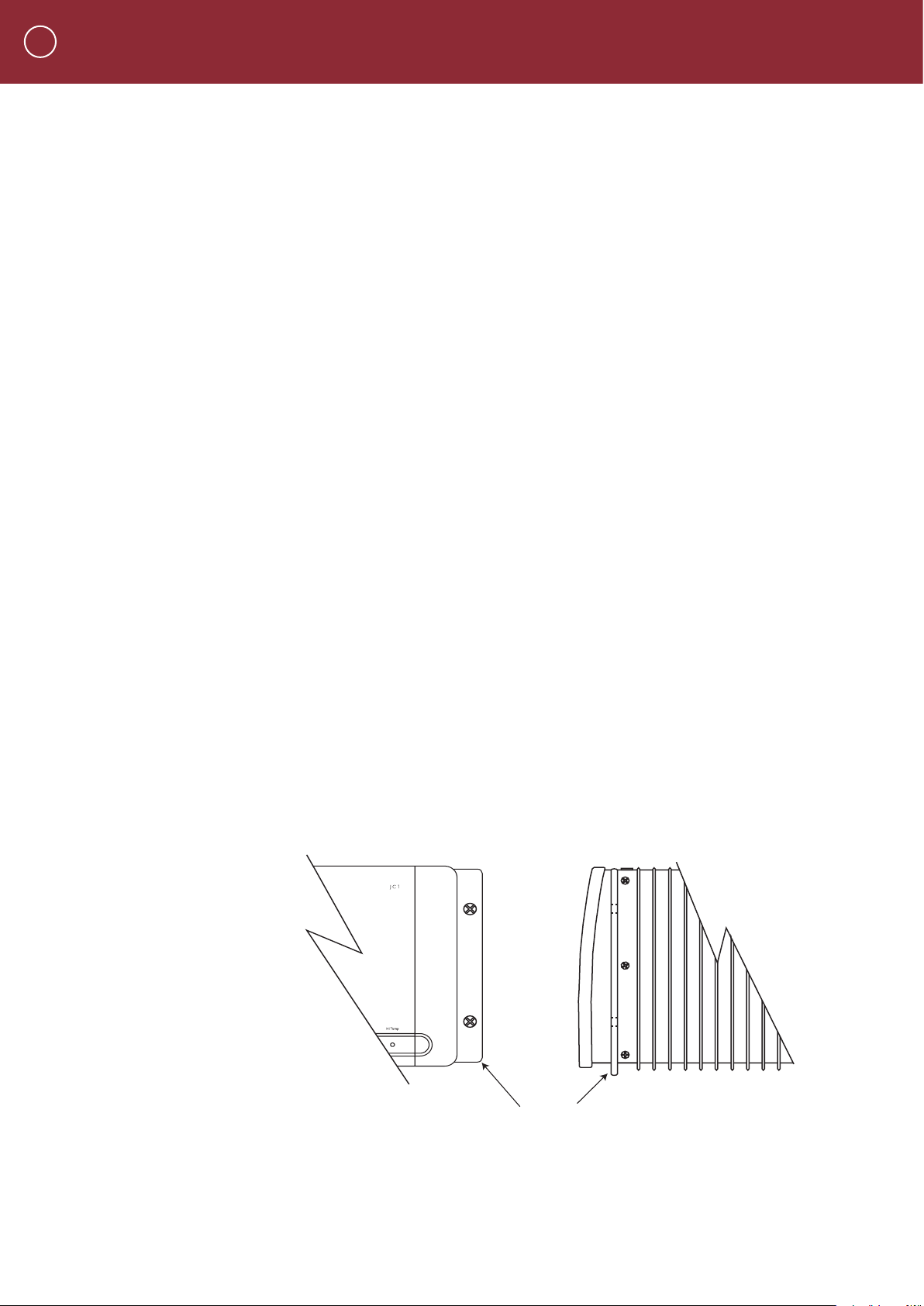

Rack Mounting Your Parasound JC 1

To mount the JC 1 into a 19” wide equipment rack, you must rst attach its Rack Mount Adapters

(provided). With its four feet removed, the JC 1 chassis and front panel height occupies four rack

spaces (7” or 176 mm). When mounting equipment below the JC 1, you will also need to allow

about 1/8” below the unit for the bottom chassis screws.

To attach the rack mount adaptors

• Remove the three shiny screws from each side of the JC 1. These are arranged vertically,

behind its front panel and in front of its rst heatsink n.

• The angled part of the brackets that attaches to the rack should be just behind the front

panel.

• Line up the holes on each rack mount adaptor with the holes on the unit and reinsert the

three screws.

• Make sure the screws holding the rack mounts are tight because they will support the entire

weight of the JC 1 when it’s installed into the equipment rack.

Rack Adapter Mounted on JC 1

A single standard rack space allows 1-3/4” vertical inches in a 19-inch wide equipment rack.

This measurement standard was developed by the EIA (Electronic Industries Association) so

manufacturers of electronic components and equipment racks could build products in standardized

heights that would t in a uniform space. Please call your Parasound dealer or Parasound Technical

Services if you need additional advice about rack mounting the JC 1.

Page 5

CONNECTING A STEREO PREAMPLIFIER OR A SURROUND

4

3

Right

Left

COMPONENTS

SUR ROUN D

SOU ND

CON TROL LER

PRE AMP

OUTPUTS

or

None

4

8

12

20 50

100

200

Auto Turn On

Delay

Seconds

Sensitivity

Input mV

Select

<

<

Select

<

<

Audio

Signal

<

Manual

12V Input

12 Volt

Trigger

Trigger

Output

CONTROLLER TO THE BALANCED INPUTS ON YOUR JC 1

Balanced Input Jack

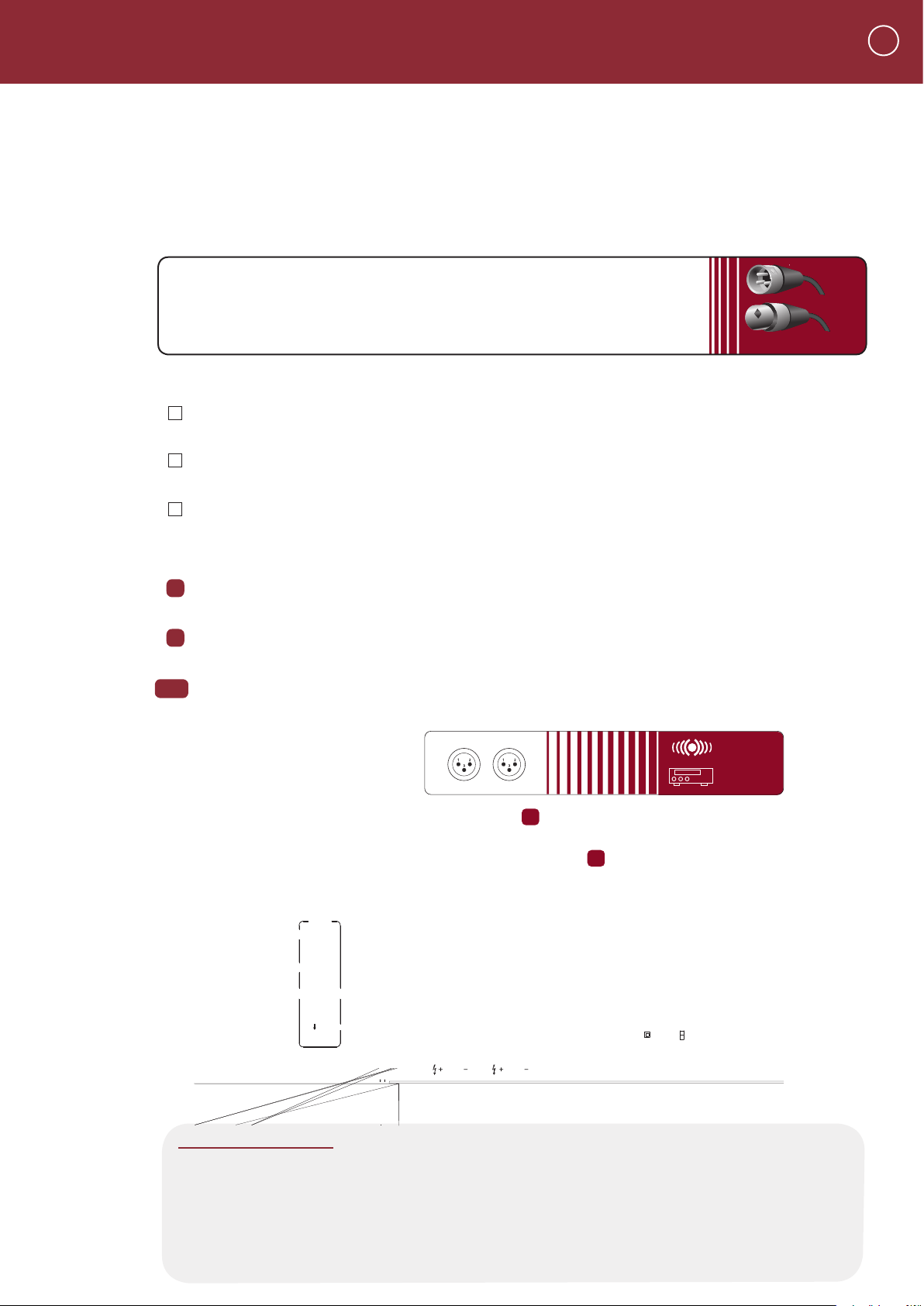

Balanced connections will give you the best sound in most instances. If your preamplier or

surround controller has balanced XLR output jacks, we recommend that you use them. Refer to

the Balanced and Unbalanced Lines in the Technically Speaking section for additional information

about why we recommend using balanced lines.

What You’ll Need:

• One balanced interconnect cable with XLR connectors

• A preamplier or surround controller with balanced outputs

Before Connecting

Leave the JC 1’s AC cord disconnected until you have made all other connections to prevent

any surprise burst of sound.

Make sure that all your cables are long enough so they are not strained or stretched once

they are connected.

2

Make sure the Select switch on the JC 1 is in its Balanced Input (right) position.

To Connect

1

Plug the male end of the balanced interconnect cable into the Balanced Input jack on the JC 1.

Plug the female end of this cable into the desired channel balanced output jack on your

2

preamplier or surround controller.

Repeat steps 1 and 2 above to connect additional JC 1s to other controller channels.

3&4

YOU SHOULD KNOW

Balanced XLR Jacks and Their Pin Conguration

The balanced input on the JC 1 uses an XLR jack that conforms to the industry standard

of: Pin 1: Ground, Pin 2: Positive (+), Pin 3: Negative (--). The balanced outputs on some

components use terminals with 3 screws instead of XLR jacks. These are compatible with the

JC 1 as long as you match the bare wires to the corresponding pins on the XLR plug: + to

pin 2, - to pin 3, and Ground to pin 1.

Page 6

3

CONNECTING A PREAMPLIFIER OR A SURROUND

CONTROLLER TO THE UNBALANCED INPUT ON YOUR JC 1

1

2

Page 7

CONNECTING SPEAKERS TO YOUR JC 1

2

1

Speaker

None

4

8

12

20 50

100

200

Auto Turn On

Delay

Seconds

Sensitivity

Input mV

Select

<

<

Select

<

<

Audio

Signal

<

Manual

12V Input

12 Volt

Trigger

Trigger

Output

Stripped

AWG wire

Dual

Banana Plug

Common Speaker Connectors

Single

Banana Plug

Spade Lug

Red ususally

designates right

The GND notch

signifies ground

or speaker left

4

Speaker Terminals

The two ve-way binding post speaker terminals on the JC 1 are connected in parallel and accept most

speaker wire terminations including single or dual banana plugs or 1/4” spade lugs. The openings in

the terminals are too small to accommodate bare ends of the gauge speaker wire you should use.

What You’ll Need:

• Speaker wire (AWG 16 or thicker)

with banana plugs or spade lugs.

Stripped bare ends won't t terminals.

• Α Loudspeaker

Before Connecting

Remove power to all the components in your audio system.

To Connect

Connect the wire with the ridge or other marking to either red + (positive) speaker terminal

1

on the JC 1. Connect the wire without the ridge or other marking to the corresponding black

-- (negative) speaker terminal on the JC 1.

Insert the other end of the wire with the ridge or other marking into the red + (positive)

2

terminal on the speaker. Insert the wire without the ridge or other marking into the black -(negative) terminal on the speaker.

Repeat steps 1 and 2 with the other JC 1 speaker terminal to bi-wire your speaker.

3&4

YOU SHOULD KNOW

Correct Speaker Polarity is Important

Polarity refers to the + and - connections. Speaker wires are coded with printing or a ridge on the

insulation on one of the leads so you know which lead was connected to the + and - terminals at the

other end. This coding will help you keep the + and - polarity consistent for all channels. Refer to Speaker

Polarity in the Technically Speaking section for additional information.

Page 8

5

Switch in right Audio Signal position

Start Sensitivity at 3 o'clock

None

4

8

12

20 50

100

200

Auto Turn On

Delay

Seconds

Sensitivity

Input mV

Select

<

<

Audio

Signal

<

Manual

12V Input

12 Volt

Trigger

Trigger

Output

MANUAL AND AUTOMATIC TURN ON-OFF OPTIONS

The JC 1 can be turned on and off manually or automatically for your convenience.

Using the Front Panel On-Off Button

For manual operation, the JC 1 rear panel Auto Turn On switch must be in its Manual (middle) position.

Connecting an Active Audio Source for Automatic Turn On-Off

The JC 1 can be turned on and off with an audio signal, or by an external trigger voltage. You can also adjust

how long the JC 1 delays its actual turn on after it’s been triggered.

Audio for Automatic Turn On-Off

To automatically turn on the JC 1 whenever music is playing (an audio signal is present), select the Audio trigger

by moving the Auto Turn On switch right to its Audio Signal position. Refer to Audio Trigger Sensitivity Adjustment

in Technically Speaking for more information about adjusting the level of audio required to turn the JC 1.

What You’ll need:

An active audio source connected to the Balanced or Unbalanced Input jack on the JC 1

Before Connecting

Remove power to all the components in your audio system.

Make sure the Auto Turn On switch on the JC 1 is in its Audio Signal (right) position.

Set the Audio triggering Sensitivity adjustment knob on the rear panel to the desired level.

Start with the 3 o’clock detent (click stop) position.

To Connect

Connect an active audio source to either the Balanced or Unbalanced Input jack. (Refer

to pages 2 and 3)

YOU SHOULD KNOW

Turn Off Delay in the Audio Mode

When the music (audio signal) stops, the JC 1 will remain turned on for about ve minutes. This

delay prevents unwanted turn-off during silent passages in music or pauses between tracks.

Page 9

If you want to automatically turn on the JC 1 with an external DC voltage, select the DC trigger by

moving the Auto Turn On switch on the rear panel left to its 12 Volt Trigger position.

What you’ll need:

A wire with a 2.5 mm sub-mini plug on each end (provided)

A “control” component with +9Vdc to +12 Vdc trigger voltage

Before Connecting

Remove power to all the components in your audio system.

Make sure the Auto Turn On switch on the rear panel is in its 12 Volt Trigger

Page 10

7

2.5 mm sub-mini plug

COMPONENT

TO POWER

Input

2

1

None

4

8

12

20 50

100

200

Auto Turn On

Delay

Seconds

Sensitivity

Input mV

Select

<

<

Audio

Signal

<

Manual

12V Input

12 Volt

Trigger

Trigger

Output

CONNECTING THE JC 1 TO TRIGGER ANOTHER COMPONENT

Whenever the JC 1 is turned on either manually or automatically, it generates 12 Vdc at its 12 V Trigger Out jack so it can trigger

additional JC 1 ampliers or other components on and off.

What You’ll Need:

(

A second wire with a 2.5 mm sub-mini plug on each end (not provided)

A component that can be triggered with an external +9 Vdc to +12 Vdc source.

The JC 1 DC Trigger output provides up to 150 mA of current.)

Before Connecting

Remove power to all the components in your audio system.

To Connect

Plug one end of this trigger wire into the 12 V Output jack on the JC 1

Plug the other end of this wire into the component that you want the JC 1 to trigger.

1

2

Automatic Turn On Delay Time

You can delay the JC 1 turn on time so it doesn’t turn on at the same instant as your

other components (or other JC 1s). This avoids turn-on surges and brownouts that might

cause units with microprocessors to lock up, or even trip house wiring circuit breakers. If

you’re lucky enough to own more than one JC 1, select a different delay time for each

unit. Turn the Delay knob for the desired delay time from None (fully counterclockwise) to

12 Seconds (fully clockwise).

YOU SHOULD KNOW

If the device use your JC 1 controls doesn’t have a 2.5 mm trigger output connector, you can cut

one plug off the trigger wire and terminate the end as required. The lead with the stripe is positive

and the lead without the stripe is negative.

Page 11

UNDERSTANDING THE INDICATORS AND CONTROLS ON THE JC 1

A

B

C

D

None

4

8

12

20 50

100

200

Auto Turn On

Delay

Seconds

Sensitivity

Input mV

Select

<

<

Select

<

<

Audio

Signal

<

Manual

12V Input

12 Volt

Trigger

Trigger

Output

A

AC Present Indication

When the JC 1 is plugged into a live AC outlet, a soft blue halo glows behind its On-Off button and its

red “P” Badge glows faintly. These indicate that the JC 1 is plugged into a live AC outlet, even when it is

turned off.

B

On and Off Indications for Both Manual and Automatic Modes

When the JC 1 is rst turned on, the soft blue glow behind its On-Off button turns red for about ve

seconds and then becomes a brighter blue.

C

High-Temp Indicator

This indicator is near the right side of the panel recess. It will glow red if the JC 1 overheats.

D

Ground Switch

The Ground switch can assist in reducing audible hum caused by ground loops in your system. Leave

this switch in its Normal (right) position unless you hear hum through your speakers (you’ll only be able

to hear this hum after your entire system is installed and operating). You can try the Lift (left) position to

eliminate it. Refer to the Technically Speaking section for detailed technical information about the causes

of ground loops and what you can do about them.

8

E

Bias Level Switch

The Bias Level switch offers two bias setting for the output transistors. In its Low (left) position, extremely

generous bias idle current and class A operation make crossover and higher-order odd harmonic

distortion inaudible. In its High (right) switch position, bias idle current is increased to perfectly match

the characteristics of the JC 1s output devices. This all but banishes these distortions. With its Bias Level

switch set to High, the JC 1 will run quite warm and consume more AC power when it is idling or playing

at low listening levels. If your JC 1 is VERY well ventilated, you may nd the high bias offers a sonic

improvement. If your JC 1 is mounted in a cabinet, or ventilation is restricted in any way, we recommend

you leave the Bias Level Switch in its Low position.

Page 12

9

1

2

JC 1 A mpl if ier

Parasound Produc ts. Inc.

San Franscisco, CA U SA

Ground

Normal

Lift

Fuse

T15A/250V-115V Area

T8A/250V-230V Area

Power Consumption: 1200W

AC 115V 6 0Hz

AC 230V 5 0Hz

CONNECTING THE AC POWER CORD

AC Power Connections

We recommend that you plug your JC 1 into the same AC wall outlet or power strip that

powers your other audio components, especially the preamplier or system controller.

Having all the audio components on the same power circuit helps prevent hum caused

by possible ground loops. The JC 1 requires AC power that is continuous rather than

switched on and off.

What you’ll need:

An IEC 65 AC Cord (provided)

An AC outlet or high quality AC power strip within reach of the AC cord

Before Connecting

Remove power to all the components in your audio system.

To Connect

1

Plug the female end of the AC cord to the AC receptacle on the rear of the JC 1.

2

Plug the male end of the AC cord to an AC outlet or power strip.

Page 13

MAINTAINING YOUR PARASOUND JC 1

Your Parasound JC 1 power amplier requires no periodic maintenance and has no userserviceable parts inside. To avoid the risk of electric shock, do not remove its top cover. The

amplier’s exterior can easily be cleaned with a soft cloth pre-moistened only with a few drops

of water or glass cleaner.

Main Power Fuse

If this fuse blows, please contact Parasound Technical Service for further advice.

Notes:

10

Page 14

11

JC 1 will not turn off when

audio signal is removed

PROBABLE CAUSE

Power cord is disconnected

REMEDY

Hum and / or buzz

through speakers

Ground loop between preamplifier

and JC 1 or at the equipment rack

Move the Ground Lift switch to its Lift position

Install nylon shoulder washers on both sides of

the panels of all equipment to insulate metal

from touching the rack

Check polarity of DC source with a voltmeter

Try connecting a 9 V battery to the 12V DC input

Make sure Auto On

TROUBLESHOOTING GUIDE

Page 15

SERVICING YOUR JC 1

If All Else Fails-Call Us fo Help

Call your Parasound dealer or Parasound’s Technical Service Department toll free at 1-866-770-TECH

(8324) between 8am and 4pm Pacic Time. We can often solve the problem with simple diagnostic

tests you can perform yourself. If we determine that your JC 1 will need further inspection or

servicing, we will:

a) refer you to an authorized Parasound repair center near you, or

b) authorize return of the unit to us and advise you of the correct procedure.

Procedure for Returning Your JC 1 to Parasound for Service

If Parasound determines that you should send your JC 1 to Parasound, you will be given a Return

Authorization (RA) number. This RA number must be clearly marked on the outer carton only.

IMPORTANT: Enclose a copy of your original purchase receipt. A unit is eligible for warranty

repair ONLY when the purchase receipt shows that the unit was purchased from an Authorized

Parasound Dealer. A unit obtained through unauthorized channels is not eligible for warranty

repair. Parasound is not responsible for any sellers’ misrepresentations about our warranties or

other service policies.

12

We do not accept any of the following:

Units with collect shipping charges

Units without a valid RA number

Units without a suitable shipping carton

Units for which we see or hear evidence of improper packing

For a non-warranty repair, contact us for an estimate of the repair charges before you ship the unit

to us. The same packing and Return Authorization number procedures apply.

Important Notice - Shipping the JC 1

Before shipping the unit to Parasound, you MUST re-pack the unit into its tted molded foam

insert sandwich and its original carton. If you do not have the original packing cartons and foam

inserts, call us for new packing materials that we can provide to you for a nominal charge. Use

of any other carton and packing materials will probably result in shipping damage, and refusal of

the unit. Common carriers such as UPS seldom pay claims for damage incurred during shipment

when a product is surrounded only with Styrofoam “peanuts” or otherwise improperly packed. We

cannot stress enough the importance of properly packing your JC 1. Shipping damage resulting

from inadequate packing can cost you a lot of money and signicantly increase the time required

for repair. Ship the unit with adequate insurance. After repair under warranty, the unit will be

returned to you via prepaid UPS within the continental United States.

Page 16

13

TECHNICALLY SPEAKING

Audio Trigger Sensitivity Adjustment

The Auto Turn On Audio Sensitivity Control sets the

threshold of the audio trigger signal. You can adjust

this level from a maximum sensitivity of 50 mV (fully

counterclockwise) to a minimum sensitivity of of 250

mV (fully clockwise). If you set this control to 50 mV,

the JC 1 might be falsely triggered on by non-musical

or noisy signals that can appear in the system, such as

when you switch preamp inputs at high volume levels.

If you set this control to 250 mV, the JC 1 might not

turn on during quiet musical passages. The detented

position (click stop) at 3 o’clock is a good starting point

and will be suitable in most systems.

Balanced and Unbalanced Input Lines

Recording and broadcast studios use balanced

connections exclusively because of their inherent

ability to reject noise and hum, thus assuring the best

sound. Certain high quality preampliers and surround

controllers built for residential use utilize balanced

connections with XLR jacks for the same reasons. All

Parasound Halo Series power ampliers have balanced

inputs with XLR jacks so you can take full advantage of

their inherent noise reduction capability and superior

sound quality.

Unbalanced connections with RCA jacks are found

on all home audio equipment. RCA jacks and twoconductor wires are less costly than the additional

circuitry, higher priced XLR connectors and threeconductor wiring required for balanced connections.

In an unbalanced line, the positive audio signal appears

at the center pin of the RCA jack and the negative

signal on the outer shield wire, which also functions

as the ground connection. Unbalanced interconnect

cables are vulnerable to hum from an AC line, or

other noise, such as RF (Radio Frequency), which

can be reproduced through your loudspeakers. Since

the unbalanced line’s ground also carries the audio

signal, there is no way for the connected amplier or

preamplier to distinguish between the audio signals

you want and unwanted noise emanating from external

sources.

Balanced lines are superior because they utilize

separate conductors for audio and ground: two inner

conductors carry the positive and negative audio

signal, and a third outer wire connects the grounds

and also shields the two signal conductors. When the

positive and negative signals appear at the component

receiving the signal they are equal, but 180 degrees

out of phase with each other with respect to ground.

To send and receive balanced signals requires special

differential circuitry.

the differential input “sees” a positive 1 Volt minus a

negative 1 Volt, or 2 Volts total. External hum and noise

that somehow gets into a balanced line is common to

both its positive and negative conductors with respect

to ground. Therefore, it is canceled or rejected by the

differential input circuit.

This phenomenon of rejecting noise signals common

to both positive and negative conductors is called

common-mode rejection. Differential inputs are

specied according to how well they reject signals

common to both conductors. This is measured in dB

and is called the common mode rejection ratio or

CMRR.

Choosing Interconnect Cables and Speaker Wire

We are often asked to recommend specic brands of

interconnect cables and speaker wire. It’s true that

with some ampliers, sound quality will vary greatly

according to interconnect cables and speaker wires.

However, Parasound ampliers use robust circuitry

that sounds superb regardless of interconnects and

speaker wires. Therefore, we feel that choosing a brand

of cable for Parasound ampliers is largely a matter of

personal taste.

Signal Polarity

The JC 1 does not invert polarity. Therefore, if you

know that your preamplier or surround controller

inverts polarity, you may connect your speaker + and opposite of the above instructions to reverse polarity.

This applies to all speakers in your system driven by

ampliers that don’t invert polarity. Contact the maker

of your preamplier or surround controller to verify its

polarity if this is not mentioned in its owner’s manual.

Speaker Wire Length and Gauge (thickness)

When selecting speaker wire, follow these guidelines:

• Keep the length of your speaker wire as short as

possible

• Use the thickest wire practical. For lengths greater

than 50 feet, use speaker wire with an AWG (gauge) of

14 or lower. The smaller the AWG, the thicker the wire.

•

Do not use speaker wire that is thinner than 16 AWG.

• Use the same length of speaker wire between each

JC 1 amplier and speaker, regardless of the actual

distance between them.

A differential input circuit amplies only the difference

between the positive and negative signals. For example,

when a 1 Volt signal arrives at a balanced input stage,

Page 17

TECHNICALLY SPEAKING continued

Eliminating Ground Loops - Hum and Buzz

Audible hum and buzzing noises in a system are usually

related to issues with the component grounds. Ground

(sometimes called common) is a point of reference for

voltages in virtually all audio and video components.

Ground is supposed to remain at zero volts while the

audio signal swings positive (voltage above ground)

and negative (voltage below ground). If ground isn’t

at zero, there can be an audible 60 Hz hum (or 50 Hz

hum in regions with 50 Hz AC). The harmonics of these

frequencies (120 Hz, 240 Hz, 480 Hz or 100 Hz, 200 Hz,

400 Hz) may add buzz in addition to the hum.

The ideal of zero voltage ground for all the components

in a system is practically impossible, because some

resistance between the ground points of different

components is inevitable. By keeping components

close together with their power cords plugged into

a common AC outlet or power strip, you’ll avoid the

problems created by resistance in the house’s wiring.

14

Hum and buzz is also caused when unwanted voltage

ows through multiple component ground points

called ground loops. Here are three tips to avoid ground

loops:

1. Use a balanced input line with your Parasound JC 1.

(See Balanced and Unbalanced Lines in this section).

2. When rack mounting, always use the included

insulated “shoulder” washers. These break the ground

loops caused by metal-to-metal contact between the

rack, the units, and their rack-mount bolts. Extras

are available from rack manufacturer Middle Atlantic

Products, www.middleatlantic.com.

3. Use the Ground switch on the JC 1 to eliminate most

ground loops. This separates the JC 1’s signal input

ground from its chassis ground to isolate unwanted

voltage in the ground shield of the unbalanced (RCA)

input cable. Be sure your system installation is nished

before you try moving the Ground Lift switch from its

“Normal” to its “Lift” position.

Level Control - Omitted by Design

There is no level (gain) control on the JC 1 to avoid

compromising the audio signal. We expect you’ll be

using a preamplier or surround controller with a high

quality volume control and S/N ratio.

Two Sets of Binding Posts

The JC 1 is equipped with a second set of binding

posts to facilitate bi-wiring. This feature enables you to

“bi wire,” or connect two lengths of speaker cables to

the same speaker for improved performance. Refer to

the owner’s manual of your loudspeaker to determine

if the manufacturer recommends bi-wiring.

Page 18

15

PARASOUND JC 1 DESIGN OVERVIEW

Designed by John Curl and CTC Builders

Parasound has worked with legendary designer John

Curl since 1989. John has been a legend among

audiophiles and electronic engineers since the mid

‘70s. He pioneered measurements to correlate musical

accuracy with the materials used in component parts,

worked with world-class touring companies, and has

designed highly coveted audio classics. These designs

include the original Mark Levinson JC-2, Denneson

JC-80, Vendetta Phono Preamplier, master recorders

for Wilson Audio and Mobile Fidelity; and the mixing

consoles used in live concerts by The Grateful Dead

and at the Montreux Jazz Festival in Switzerland.

In 2000 John formed CTC Builders to develop totally

uncompromised analog products. CTC’s products have

earned the utmost respect from the most discerning

audiophiles and high end magazine reviewers.

The Power Supply

The heart of the power supply is a 10 Ampere

(continuous!) toroid transformer, chosen for its

efciency, low hum eld, and high power rating.

Encapsulating this massive power transformer in an

epoxy-lled steel canister assures ultra-quiet

performance.

To create the high voltage B+ and B- supply rails for

the output stage, we use high-speed, fast-recovery

rectier diodes and four enormous 33,000 uF Nichicon

"Gold Tune" series electrolytic lter capacitors, chosen

for their low Equivalent Series Resistance (ESR) and

dielectric absorption. In addition, these lter capacitors

are bypassed with smaller polypropylene capacitors

to reduce AC ripple in the DC supply and to further

eliminate noise and interference that is generated in

AC power lines from computers and other appliances

in the home.

Relay-Bypassed Soft Start Circuit

When the JC 1 is rst turned on, there is a signicant

amount of in-rush current to required to charge up

the enormous power supply capacitors. In order to

suppress this in-rush current and keep nuisance

tripping of circuit breakers, we employ NTC (negative

temperature coefcient) resistors. These resistors cut

the in-rush current by about 50%. Once they heat up,

they essentially become a jumper with zero ohms

resistance. However, the JC 1 goes one step further

for this circuit. After the NTC resistors have done their

job of suppressing in-rush current a gold contact relay

automatically is activated to jump across the NTC

resistors to completely bypass them. This extra step

insures that the resistors do not restrict any current

whatsoever to the power supply once the JC 1 is in full

operation.

Complementary Configuration

Each stage of amplication has transistors fed by

the positive DC power supply and complementary

transistors fed by the negative DC power supply.

Thus, half of the devices amplify the positive half

of the musical waveform while the other half of the

devices amplify the negative half. This complementary

topology is inherently linear, and reduces distortion

and improves sonic accuracy.

The Input Stage

The JC 1’s input stage uses matched pairs of discrete

JFETs arranged in a differential conguration. JFETs

are ideal for the input stage because their inherently

high impedance is unaffected by the impedance of

source components. Differential conguration provides

superior noise reduction. These precision input JFETs

are also cascoded to produce the current necessary to

drive the MOSFET drivers in the following stage.

The Driver Stage

The driver stage provides critical amplication for which

we employ complementary matched pairs of MOSFETs

selected for their tube-like sonic qualities. MOSFETs

tend to generate less odd-order harmonic distortion

than bipolar transistors. This is important because

odd-order distortion sounds unnatural and fatiguing

to the human ear, whereas even-order distortion is

less offensive because it is consonant, rather than

dissonant. Our MOSFET driver stage prevents the

harshness and brittle sound so often found in other

ampliers.

The B+ and B- power for our input and driver stage

cannot sag under load because it is supplied by

independent transformer secondary windings with

independent rectication, ltering, and voltage

regulation. This preserves soundstage width and depth

even when the JC 1 output stage is drawing enormous

current.

The Output Stage

The amplier’s sonic characteristics are established by

its input and driver stages. Now, the sole job of its

output stage is to deliver the enormous current and

voltage from its power supply to the speakers. Bipolar

output transistors are better than MOSFETS in the

output stage because of their higher safe operating

area (SOA) and inherent ruggedness. The JC 1’s output

stage employs nine pairs of high current (15-ampere)

bipolar transistors to insure long-term reliability, even

with continuous high power operation and challenging

speaker loads. Lightning-fast (60 MHz) transistors

respond instantly to complex demands in the musical

signal, virtually eliminating distortions that occur with

slower transistors. Slew rate limiting and Transient

Intermodulation Distortion (TIM) are simply not an

issue in the JC 1.

Page 19

PARASOUND JC 1 DESIGN OVERVIEW continued

16

Class A/AB Operation

Pure class A operation provides the purest sound.

However, an amplier operating entirely in class A

operation would be enormous, highly inefcient, and

generate far too much heat. Class AB combines some

of the advantages of Class A with the efciency of

Class B operation. It is a compromise that reduces the

heat generated in pure class A operation and the oddorder harmonic distortion created in class B. In class

AB, the driver and output stages are always turned

on, which provides a nominal amount of pure class A

operation. At higher power levels, when the musical

waveform swings from positive to negative and vice

versa, each bank of transistors is allowed to rest

momentarily. This resting, or quiescent time, makes

it possible to deliver high amounts of power without

overheating. It also makes it possible to use passive

cooling and avoid fans, whose noise can be heard

over the music. The JC 1 input and driver stages are

always on for 100% pure Class A while its output

stage provides up to 25 watts of pure Class A - more

than ampliers selling for three or four times its price.

The result is less fatiguing, more natural sound at a

refreshing price.

Total Protection - Relays

The JC 1 has a high-quality protection relay with

gold-plated contacts for long-term reliability. This relay

functions to protect either the amplier, the speaker,

or both. When the JC 1 is rst powered on, the relay

remains open for three seconds as the positive and

negative power supplies stabilize and reach equilibrium.

This prevents annoying popping or other transient

noises. Relay protection also prevents speaker damage

in case of a catastrophic amplier failure. Any amplier

that doesn’t use relay protection for its speaker outputs

compromises the safety of the amplier and your

speakers.

Total Protection - Current Overload

Specialized current-sensing transistors are connected

to the output stage of the JC 1 to constantly monitor

the current ow through the output transistors. If the

current drawn by this stage exceeds a predetermined

safe level due to a load impedance below 1 ohm or a

short circuit at the speaker terminals, the output relay

will open immediately to prevent the output transistors

or other parts from failing.

Total Protection - DC Servos

Direct Current (DC) burns out speakers. Therefore,

every power amplier must have some way to insure

that DC from its power supply never reaches its + or

- speaker terminals. Most ampliers simply use trim

controls to reduce their DC offset or capacitors to block

DC. Unfortunately, trim controls can allow DC offset

to increase over time, and even the most expensive

capacitors in the audio signal path will “veil” sonic

clarity and attenuate bass response.

Parasound power ampliers incorporate ingenious

and fast-acting DC servo circuits, which completely

eliminate the need for coupling and blocking capacitors.

The JC 1 is direct-coupled from its input jack to its

speaker terminals. This advanced circuitry never needs

adjustment or maintenance. It operates outside the

audio signal path to keep the DC offset at the output of

the JC 1 at a constant 0.00 Vdc. The results are startling

clarity, freedom from listening fatigue, and formidable

bass response.

Total Protection - Fuses

The JC 1 has separate fuses for its positive and

negative DC voltage rails. These fuses provide backup

protection in case the over-current protection does not

work in time, or if an internal part fails. In the event of

a part failure, these fuses halt operation to minimize

damage to additional parts.

Chassis

The JC 1 chassis is heavy gauge steel with an aluminum

rear panel where its critical input circuit board mounts.

Aluminum is non-magnetic and cannot be energized

by nearby high voltage and current ow, thereby

removing a potential cause of “smearing” or other

audible intrusions.

Page 20

17

PARASOUND JC 1 SPECIFICATIONS

Power Output. 20 Hz - 20 kHz

400 watts continuous, 8 Ω

800 watts continuous, 4 Ω

Class A Power Output

25 watts, bias set to High

10 watts, bias set to Low

Current Capacity

135 amperes peak

Slew Rate

> 130 volts per microsecond

Frequency Response

2 Hz - 120 kHz, +0/-2 dB

Total Harmonic Distortion

< 0.15 % at full power

< 0.018 % at typical levels

IM Distortion

< 0.03 %

TIM

Unmeasureable

Dynamic Headroom

> 1.8 dB

Input Sensitivity for 28.28 V Output into 8 Ω

Balanced: 1 V per leg

Unbalanced: 1 V

Signal-to-Noise Ratio, input shorted

> 122 dB, IHF A-weighted, bias set to Low

> 120 dB, IHF A-weighted, bias set to High

> 113 dB, Unweighted, bias set to Low

> 111 dB, Unweighted, bias set to High

Damping Factor

> 1200 at 20 Hz

Auto On DC Trigger Requirements

+9 Vdc to +12 Vdc, 2 mA

Auto On Audio Trigger Threshold

50 - 250 mV AC

Dimensions

Width: 17-1/2” (445 mm)

Panel height: 7” (178 mm)

Height with feet: 7-5/8” (194 mm)

Depth: 19-1/8” (485 mm)

Power Requirement

Standby: 25 watts

Idle: 250 watts

Full Power into 8 Ω: 1280 watts

Input Impedance

Balanced: 100 kΩ

Unbalanced: 50 kΩ

Features and specifications subject to change

without notice.

Net Weight

64 lb. (29.1 kg)

Shipping Weight

78 lb. (35.5 kg)

© Parasound Products, Inc., 2002.

v 1.1

Page 21

Page 22

Parasound Products, Inc. 950 Battery Street, San Francisco, CA 94111

415-397-7100 / Fax 415-397-0144 www.parasound.com

Loading...

Loading...