P

PP

PE

EE

ERRRRFFFFOOOORRRRM

MM

MAAAANNNNCCCCE

EE

E XL

XL XL

XL

IIIIN

NN

NSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOON

NN

N M

M M

MA

AA

ANNNNUUUUAAAALLLL

I NNOVATIVE STRENGTH SYSTEMS

2

Thank you for selecting the Paramount XL-Performance Series. Because of the many unique

features included in this product line, this manual was created to prov ide y ou with inf ormation on

how to properly install and maintain your equipment. Proper maintenance will ensure that your

new equipment will last for years.

For your con v eni ence, pr oduc t qu es tion s can be an sw ered b y an A uthor ized Paramount Deale r or

by contacting a Paramount Customer Service Representative at 1-800-721-2121.

Paramount Fitness Corporation

6450 East Bandini Blvd.

Los Angeles, CA 90040

IMPORTANT

IMPORTANTIMPORTANT

IMPORTANT

REVIEW THE GENERAL MAINTENANCE MANUAL FOR IMPORTANT SAFETY AND

REVIEW THE GENERAL MAINTENANCE MANUAL FOR IMPORTANT SAFETY AND REVIEW THE GENERAL MAINTENANCE MANUAL FOR IMPORTANT SAFETY AND

REVIEW THE GENERAL MAINTENANCE MANUAL FOR IMPORTANT SAFETY AND

MAINTENANCE TIPS. THE MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER

MAINTENANCE TIPS. THE MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER MAINTENANCE TIPS. THE MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER

MAINTENANCE TIPS. THE MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER

AND CAN ALSO BE DOWNLOADED FROM OUR WEBSITE AT:

AND CAN ALSO BE DOWNLOADED FROM OUR WEBSITE AT: AND CAN ALSO BE DOWNLOADED FROM OUR WEBSITE AT:

AND CAN ALSO BE DOWNLOADED FROM OUR WEBSITE AT:

http://www.paramountfitness.com

http://www.paramountfitness.comhttp://www.paramountfitness.com

http://www.paramountfitness.com

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

A MESSAGE TO OUR CUSTOMERS

!

3

SAFETY............................................................................................................. 4

G

ENERAL CARE AND MAINTENANCE..................................................................... 5

L

AYOUT AND SPACING - MACHINE DIMENSIONS & WEIGHTS.................................... 6

I

NSTALLATION AND ASSEMBLY

REQUIRED TOOLS..................................................................................... 8

U

NPACK THE HARDWARE BAG.................................................................. 8

F

OOT INSTALLATION................................................................................. 9

W

EIGHT STACK INSTALLATION................................................................... 9

W

EIGHT STACK LABEL INSTALLATION......................................................... 13

OPTIONAL F

RONT PANEL KIT.................................................................. 14

OPTIONAL F

OREIGN LANGUAGE LABELS................................................... 16

A

NCHORING THE MACHINES TO THE FLOOR................................................ 16

F

INAL ASSEMBLY..................................................................................... 16

M

ACHINE MAINTENANCE

REPLACEMENT PARTS: CABLES AND UPHOLSTERED PADS........................... 17

C

ABLES.................................................................................................. 17

XL0300 L

EG PRESS ROLLER ADJUSTMENT............................................... 18

W

ARNING LABELS.............................................................................................. 19

S

ERVICE........................................................................................................... 21

P

ARAMOUNT LIMITED WARRANTY........................................................................ 23

TABLE OF CONTENTS

4

1. Review and understand

Review and understandReview and understand

Review and understand all of the warning labels affixed to the machines and the facility safety

sign. Replace any warning label at first sign of wear. Labels and the Facility Safety Sign may be

obtained from Paramount free of charge.

2. Be certain that machine operation is understood

Be certain that machine operation is understoodBe certain that machine operation is understood

Be certain that machine operation is underst o od bef ore machi ne is use d. R efe r t o the in stru ctio n

label provided with the machine.

3. Keep children away

Keep children awayKeep children away

Keep children away from this equipment. Supervise use by teenagers.

4. DO NOT

DO NOTDO NOT

DO NOT high-pin or double-pin the weight stack. DO NOT

DO NOTDO NOT

DO NOT allow the machine to be used if the top

plate or weight stack is pinned in a raised position. Use an assistant and carefully return the

machine to the proper position with the cap plate resting on the top weight. Inspect the cable to

ensure that it is seated in all of the pulleys.

5. Use ONLY

Use ONLY Use ONLY

Use ONLY Paramount weight selector pins

weight selector pins weight selector pins

weight selector pins. Other manufacturer’s pins may work free of the weight

stack causing possib le injury. Be certain the pin is c o mpletely inser ted p rior to use.

Be certa in the pin is completely inserted p rior to use. Be certa in the pin is completely inserted p rior to use.

Be certa in the pin is completely inserted p rior to use.

6. Cables

CablesCables

Cables: Inspect the entire cabl e w ee kly and the end fittings daily . P ay close attention to the area

going over pulleys and to the en d connections. When adjusting cables at threaded inserts make

sure all connections are tight. Adjust tension on cables as needed. Replace al l cabl es at fi rst signs

of wear or on an annual basis. Use only Paramount supplied replacement cables. Ensure that the

dimension from under the bolt head to the top surface of the selector bar is no greater than 1-3/8

inches. Ensure that the cable tension bolt & nut are tight.

7 . Nuts, Bolts, and Fasteners:

Nuts, Bolts, and Fast eners: Nuts, Bolts, and Fast eners:

Nuts, Bolts, and Fasteners: Check tightness week ly. If any hardware has become loose, reti ght en

and/or use Loctite

™

Threadlocker 242.

8. Frames and Lifting Arms:

Frames and Lifting Arms:Frames and Lifting Arms:

Frames and Lifting Arms: Inspect weekly for integrity and functi on. Replace any component at f irst

signs of wear.

9. DO NOT

DO NOTDO NOT

DO NOT attempt to free any jammed assemblies by yourself as this may cause injury.

10. Use ONLY

Use ONL Y Use ONLY

Use ONL Y Paramount adder weights or adder weight syst ems

adder weights or adder weight systems adder weights or adder weight systems

adder weights or adder weight systems for incre mental resi stance

adjustment. NEVER

NEVERNEVER

NEVER use dumbbells or other means to do this.

11. The Maximum

MaximumMaximum

Maximum user weight for this equipment is 300 lbs. (136 kg.)

12. Instruct Users

Instruct UsersInstruct Users

Instruct Users not to wear loose or dangling clothes or have headphone wire hanging when using

this equipment.

13. It is recommended

It is recommended It is recommended

It is recommended that users receive a thorough medical exam before commencing an ex er cise

program. All medical issues should be reviewed to ensure that weight training will not aggravate

pre-existing medical conditions.

14. Check regularly

Check regularlyCheck regularly

Check regularly the functionality of your machine by verifying the following:

• Cables and end fittings are intact and tensioned properly.

• All adjustments are possible and carried out with ease.

• The proper selector pin is in the weight stack.

• The exercise is performed smoothly, free of noise and/or binding.

• And the guide rods and linear bearings are properly lubricated.

15. Follow the installation guidelines

Follow the installation guidelinesFollow the installation guidelines

Follow the installation guidelines provided with the produc ts.

16. Retain these instructions

Retain these instructionsRetain these instructions

Retain these instructions for future reference.

17. If you have any questions, do not hesi tate to contac t your P aramount dealer or Paramount Fitness

Corp. at (800)721-2121 or www.paramountfitness.com.

18. Refer to Maintenance Schedule la bel on the machine for when to perform maintenance.

SAFETY

5

1.

1. 1.

1. Cable Ends:

Cable Ends : Cable Ends:

Cable Ends: Inspect end fittin gs daily for wear. Replace cables at the f irst sign of wear or

on an annual basis. If the cable tension has been adjusted, be certain that the cable nut

is tight. On pivoting cable-ends, lubricate the ca ble pivot screw by spraying a small

amount of Tri-Flow

TM

between the cable-end and the screw.

2.

2. 2.

2. Nuts, Bolts, and Fasteners:

Nuts, Bolts, and Fasteners: Nuts, Bolts, and Fasteners:

Nuts, Bolts, and Fasteners: Check tightness weekl y. If any hardware has become loose,

retighten and/or use Loct ite

TM

brand Threadlocker 242.

3. Frames:

Frames:Frames:

Frames: Wipe all machin es do wn with a damp clo th and dry comple t ely each da y. This

includes painted parts, chrome parts and upholstered pads.

4. Painted and chrome plated parts:

Painted and chrome plated parts:Painted and chrome plated parts:

Painted and chrome plated parts: Use Simple Green or similar cleaner for light dirt and

grime. Use Turtle Wax Polishing Compound or a good car polish to rem ove heavier dirt

and grease as well as for polishing. DO NOT

DO NOTDO NOT

DO NOT use solvents, lacquer thinner, a cetone or

finger nail polish remover. For scuffs and marks that are not removed by the above

methods use a soft scrub cleanser. Make sure all parts are dry upon completion.

5. Upholstery:

Upholstery:Upholstery:

Upholstery: Use cloth towels and warm water daily to remove surface dirt and

perspiration. Use a lanolin based hand cleaner or a suitable vinyl upholstery cle aner to

condition and deep clean on a weekly basis.

DO NOT

DO NOT DO NOT

DO NOT use Windex, Simple Green, 409, or similar products to clean the upholstery.

6. Weight stack enclosures (shrouds):

Weight stack enclosures (shrouds):Weight stack enclosures (shrouds):

Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

7. Exercise instruction labels:

Exercise instruction l abels:Exercise instruction l abels:

Exercise instruction labels: Clean with soap and water as ne eded.

8. Guide rods:

Guide rods:Guide rods:

Guide rods: Wipe all dirt and dust from the guide rods before applying a light application

of Tri-Flow

TM

or other teflon spray lubricant . Spray the Tri-FlowTM on a rag and then wipe

the guide rods with the rag. DO NOT

DO NOTDO NOT

DO NOT use oil lubr icants s uch as WD-40 . Caution: T ri-Flow

TM

will sta in carpet and clothing.

9. Bronze bushings:

Bronze bushings:Bronze bushings:

Bronze bushings: Check monthly for signs of wear and replace as needed. Lubricate

monthly with Tri-Flow

TM

.

10. Seat adjustments:

Seat adjustments:Seat adjustments:

Seat adjustments: Clea n the chrom e seat adju stme nt tu be on a w eek ly b asis using a

rag sprayed with Tri-Flow

TM

. Keep a light layer of Tri-FlowTM on these tubes at all times.

To maintain your Paramount products, order the Paramount Performance Kit (part number:

KIT-01). This wil l ins ure that the proper mainten anc e mat erials required will be used. Please

refer to the General Maint enance Ma nual (pa rt number: AM- GMM) f or ot her important sa fet y

and maintenance information.

GENERAL CARE AND MAINTENANCE

6

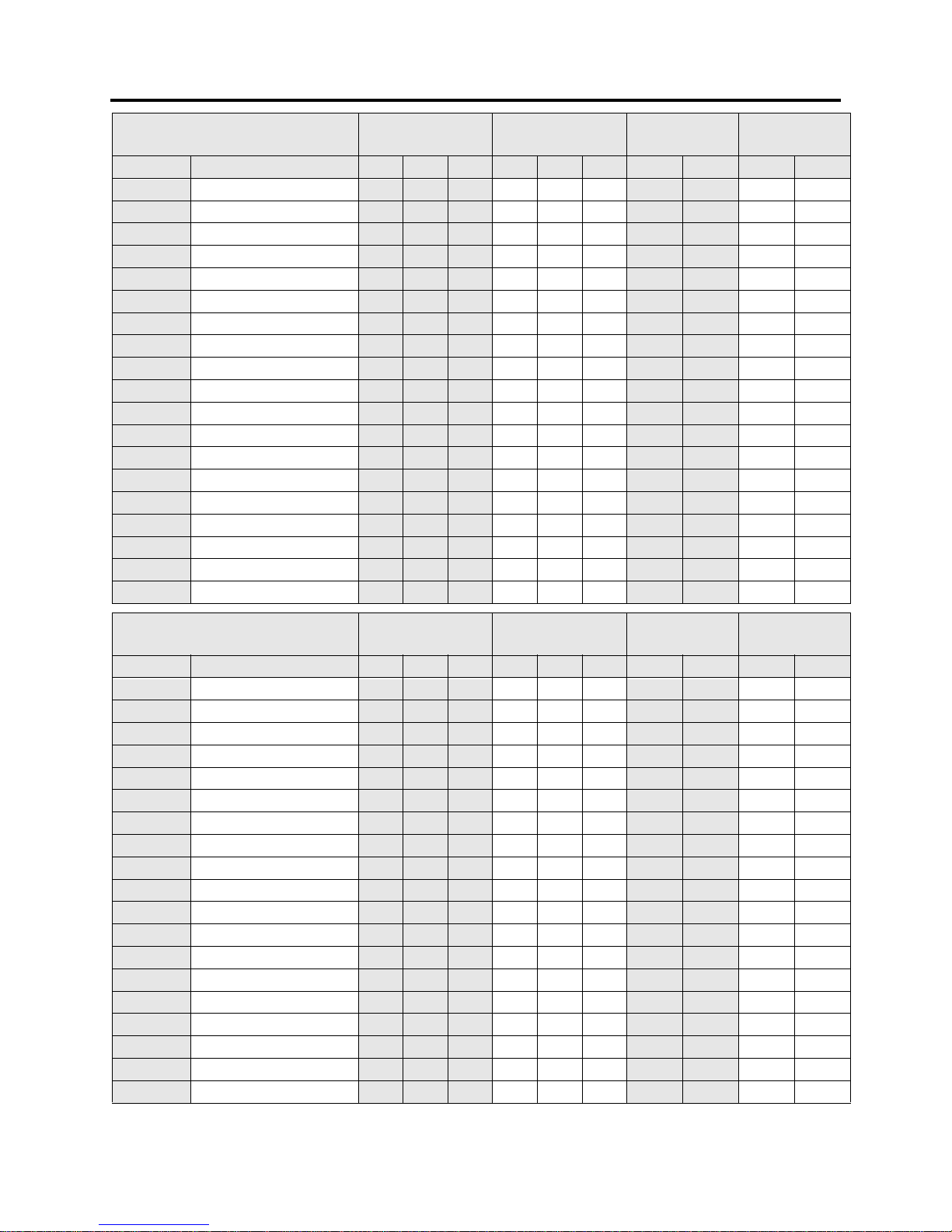

The width measurement (W) is in the direction across the chest of the user as positioned in the machine performing the exercise.

EEEENNNNGGGGLLLLIIIISSSSH

HH

H

U

UUUNNNNIIIITTTTSSS

S

AAAAT

TT

T R

R R

RE

EEESSSSTTT

T

((((

IIIINNNN.)

.).)

.)

DDDDU

UUURRRRIIIINNNNGGG

G E

E E

EX

XXXEEEERRRRCCCCIIIISSSSEEE

E

((((

IIIINNNN.)

.).)

.)

MMMMA

AAACCCCHHHHIIIINNNNEEE

E

WWWW

EEEEIIIIGGGGHHHHTTTT (

( (

(L

LLLBBB

B.)

.).)

.)

FFFFL

LLLOOOOOOOORRR

R L

L L

LO

OOOAAAADDD

D

((((

LLLLBBBB./

././

./S

SSSQQQ

Q.

..

.F

FFFTTT

T.)

.).)

.)

MMMMO

OOODDDDEEEELLL

L D

DD

DE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N L

LL

L WWWW HHHH LLLL WWWW HHHH RRRRE

EEEGGG

G.

..

. OOOOP

PPPTTT

T.

..

. RRRRE

EEEGGG

G.

..

. OOOOP

PPPTTT

T

XL0100 Leg Extension 57 45 57 7 4 45 57 399 479 76 91

XL0200 Seated Leg Curl 68 47 57 73 47 57 424 504 71 84

XL0300 Leg Press 75 49 66 75 49 66 617 717 37 43

XL0400 Inner/Outer Thigh 67 29 57 67 74 57 464 544 44 51

XL0500 Triceps Extension 38 50 57 49 50 57 337 397 45 53

XL0600 Biceps Curl 38 50 57 46 50 57 368 428 55 64

XL0700 Shoulder Press 58 56 57 58 56 78 413 493 48 57

XL0800 Lateral Raise 35 48 57 35 54 57 310 370 48 58

XL0900 Seated Chest Press 46 56 57 49 56 57 410 490 63 75

XL1000 Pec F ly/Rear Delt 64 57 74 68 57 74 435 515 44 52

XL1100 L at Pu lldown 56 50 93 56 50 93 429 509 46 54

XL1200 Seated Row 55 49 57 55 49 57 406 486 39 46

XL1300 Lower Back 42 47 57 47 47 57 413 493 56 67

XL1400 Abdominal 38 46 57 38 46 57 325 385 42 50

XL1500 Triceps Pushdown 52 46 57 52 46 57 382 462 51 62

XL1600 Inc line Chest Press 75 60 57 75 60 57 445 525 36 42

XL1700 Rotary Torso 35 49 57 39 54 57 356 416 49 57

XL1800 Horizontal Leg Curl 62 43 57 63 43 57 366 446 60 73

XL1900 Low Cable Row 78 41 74 78 41 74 422 502 33 40

MMMMEEEETTTTRRRRIIIIC

CC

C

U

UUUNNNNIIIITTTTSSS

S

AAAAT

TT

T R

R R

RE

EEESSSSTTT

T

((((

CCCCMMMM.)

.).)

.)

DDDDU

UUURRRRIIIINNNNGGG

G E

E E

EX

XXXEEEERRRRCCCCIIIISSSSEEE

E

((((

CCCCMMMM.)

.).)

.)

MMMMA

AAACCCCHHHHIIIINNNNEEE

E

WWWW

EEEEIIIIGGGGHHHHTTTT (

( (

(K

KKKGGG

G.)

.).)

.)

FFFFL

LLLOOOOOOOORRR

R L

L L

LO

OOOAAAADDD

D

((((

KKKKGGGG./

././

./S

SSSQQQ

Q.

..

.M

MM

M.)

.).)

.)

MMMMO

OOODDDDEEEELLL

L D

DD

DE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N L

LL

L WWWW HHHH LLLL WWWW HHHH RRRRE

EEEGGG

G.

..

. OOOOP

PPPTTT

T.

..

. RRRRE

EEEGGG

G.

..

. OOOOP

PPPTTT

T

XL0100 Leg Extension 145 114 145 188 114 145 181 217 370 444

XL0200 Seated Leg Curl 173 119 145 185 119 145 192 229 347 413

XL0300 Leg Press 191 124 168191124168 280 326 180 209

XL0400 Inner/Outer Thigh 170 74 145 170 188 145 211 247 214 251

XL0500 Triceps Extension 97 127 145124127145 153 180 221 260

XL0600 Biceps Curl 97 127 145 117 127 145 167 194 267 311

XL0700 Shoulder Press 147 142 145 147 142 198 188 224 235 280

XL0800 Lateral Raise 89 122 145 89 137 145 141 168 236 282

XL0900 Seated Chest Press 117 142 145 124 142 145 186 222 308 368

XL1000 Pec F ly/Rear Delt 163 145 188 173 145 188 197 234 216 256

XL1100 L at Pu lldown 142 127 236 142 127 236 195 231 223 264

XL1200 Seated Row 140 124 145140124145 184 221 189 226

XL1300 Lower Back 107 119 145 119 119 145 188 224 276 329

XL1400 Abdominal 97 117 145 97 117 145 148 175 207 245

XL1500 Triceps Pushdown 132 117 145 132 117 145 173 210 250 303

XL1600 Inc line Chest Press 191 152 145 191 152 145 202 238 176 207

XL1700 Rotary Torso 89 124 145 99 137 145 162 189 239 279

XL1800 Horizontal Leg Curl 157 109 145 160 109 145 166 202 292 356

XL1900 Low Cable Row 198 104 188 198 104 188 192 228 163 194

LAYOUT AND SPACING - MACHINE DIMENSIONS & WEIGHTS

7

It is recommended to leave a space of 24 inches (61 cm.) around the machine at its

maximum exercise dimensions. The spacing may be less if the machine is positioned next to

a wall, or upright-to-upright with another machine so as to prevent a user from passing

through the area. If the spacing is t o be less than the recommended 2 4 inches (6 1 cm.), then

it should be less than 12 inches (31 cm.) so as to prevent users from passing through the

area.

DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion

caused by installation in these locations can lead to premature failure of components.

!

WALL

12” (31 cm.) or less

WALL

24” (61 cm.) or more OR

12” (31 cm.) or less

24” (61 cm.) or more

24” (61 cm.) or more

24”

or

more

(61 cm.)

LAYOUT AND SPACING

8

RRRRE

EEEQQQQUUUUIIIIRRRREEEEDDD

D T

T T

TO

OOOOOOOLLLLSSS

S

UUUUN

NNNPPPPAAAACCCCKKK

K

T

TTTHHHHEEE

E H

H H

HA

AAARRRRDDDDWWWWAAAARRRREEE

E B

B B

BA

AAAGGG

G

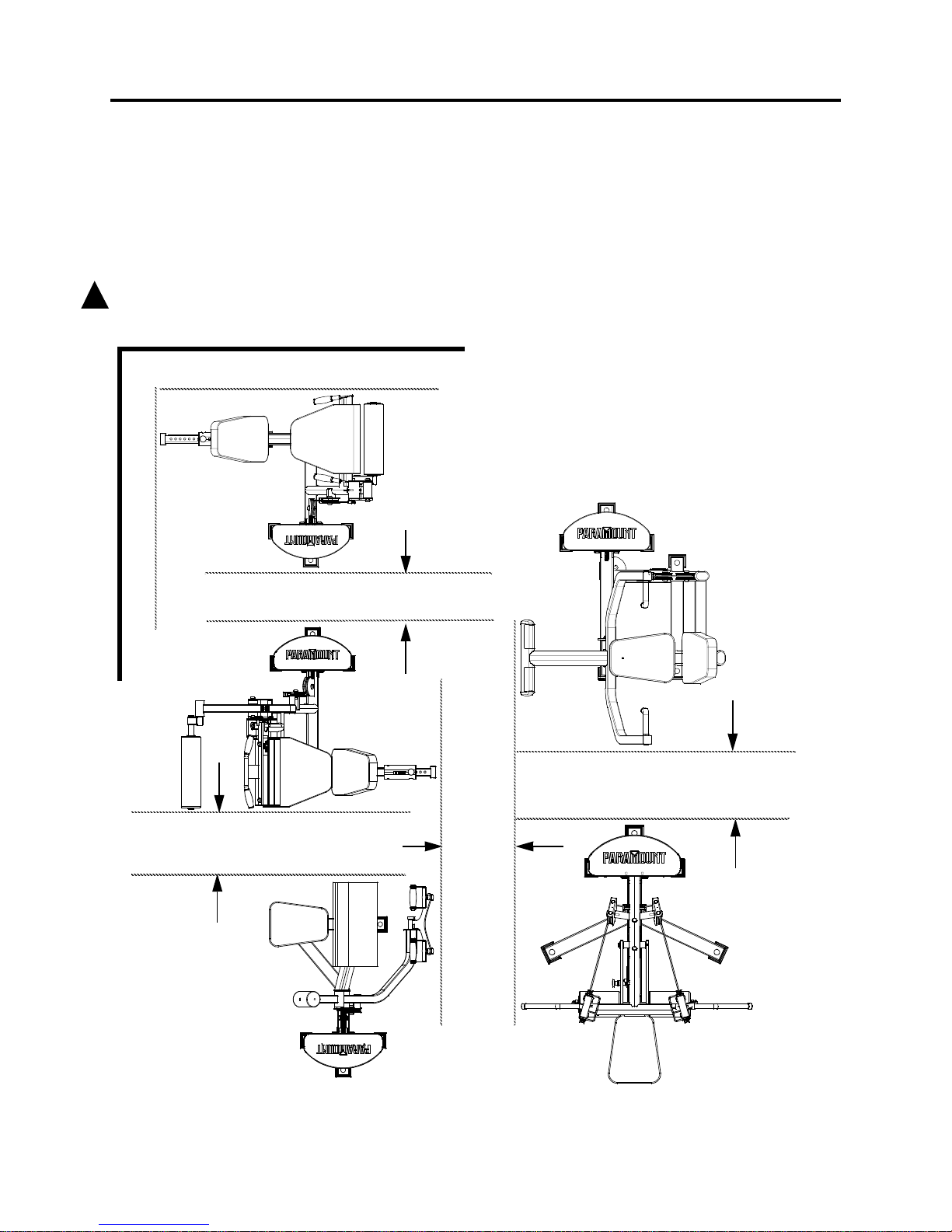

FOR SAFETY REASONS, THE FOLLOWING STEPS REQUIRE THE ASSISTANCE OF MORE THAN ONE

FOR SAFETY REASONS, THE FOLLOWING STEPS REQUIRE THE ASSISTANCE OF MORE THAN ONE FOR SAFETY REASONS, THE FOLLOWING STEPS REQUIRE THE ASSISTANCE OF MORE THAN ONE

FOR SAFETY REASONS, THE FOLLOWING STEPS REQUIRE THE ASSISTANCE OF MORE THAN ONE

PERSON.

PERSON.PERSON.

PERSON.

After the machine is in position on a level surface, unpack the hardware bag attached to the

machine. In this bag you will find:

7/32” allen wrench. Used for guide rod bracket.

Wrenches (9/16”, 7/8” and 15/16” or an adjustable

crescent wrench). Used for guide rod bracket, cable bolt, and

cable nut.

Rubber mallet, used for end caps.

PPPPA

AAARRRRTTT

T #

# #

# DDDDE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N

B751 Non-slip molded feet.

B1216 1” hole plugs.

B470 Weight stack selector pin with

lanyard.

!

INSTALLATION AND ASSEMBLY

9

INSTALLATION AND ASSEMBLY

FFFFO

OOOOOOOTTT

T I

I I

IN

NNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNN

N

1. To install the feet, ti lt the machine

to one side by pushing on the

upright or frame.

2. Place one of the feet onto the

lower f rame t ube as s how n. Ma ke

sure that the end caps are seated

in the frame tube before installing

the foot.

3. Lower the machine then ti lt the

machine towards another s ide.

4. Install another foot. Repeat until

all of the feet have been ins talled.

WWWWE

EEEIIIIGGGGHHHHTTT

T S

S S

ST

TTTAAAACCCCKKK

K I

I I

IN

NNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNN

N

1. Weight plates are packaged (4) per box and are marked with the quantity and weight of

the plates. The various configurations are shown below.

MOLDED FOOT

Make sure END

CAP is installed

Standard

170 LB.

(16) x 10lb. plates

4 boxes of B1602

Optional

250 LB.

(16) x 15lb. plates

4 boxes of B1603

Optional

310 LB.

(20) x 15lb. plates

5 boxes of B1603

Standard

210 LB.

(20) x 10lb. plates

5 boxes of B1602

Standard

130 LB.

(12) x 10lb. plates

3 boxes of B1602

Optional

190 LB.

(12) x 15lb. plates

3 boxes of B1603

10 LB. Weight Plate Box

Part Number: B1602

Comprised of

(4) x 10 lb. Weight Plates

15 LB. Weight Plate Box

Part Number: B1603

Comprised of

(4) x 15 lb. Weight Plates

Weight Stack Configurations

10

2. Review the equipment order to determine the correct w eight stack conf iguration of each

machine. Us e the following table to assist you in noting your configuration.

3. Disconnect the cable from the cap plate/select or bar, remove the bolts holding the guide

rod bracket and tilt the guide rods forward as shown on the following page.

4. Slide the guide rod bracke t an d th e cap plat e/selec t or bar upw ard and off t he gu ide rods.

On the XL0200, XL0500, XL1400, XL1500 and XL1800, remove the hardware from the

first hole in the selector bar (directly under the cap plate). Set the hardware aside.

5. Slide each weight plate onto the guide rods.

6. After installing all of the weights, slide the cap

plate/selector bar back onto the guide rods.

Ensure that the label is faci ng you.

7 . On the XL0200, XL0500, XL1400, X L1500

and XL1800, re-assemble the hardware

removed in Step 4. according to the diagram

shown. Slide the sleeve into the first hole in

the selector bar. Attach the first weight to the

selector bar.

MMMM

AAAACCCCHHHHIIIINNNNEEEE D

DD

DE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N S

SS

ST

TTTAAAANNNNDDDDAAAARRRRDDD

D O

OO

OP

PPPTTTTIIIIOOOONNNNAAAALLL

L

XL0100 Leg Extension 170 lb. (77 kg.) 250 lb. (114 kg.)

XL0200 Seated Leg Curl 170 lb. (77 kg.) 250 lb. (114 kg.)

XL0300 Leg Press 210 lb. (95 kg.) 310 lb. (141 kg.)

XL0400 Inner/Outer Thigh 170 lb. (77 kg.) 250 lb. (114 kg.)

XL0500 Triceps Extension 130 lb. (59 kg.) 190 lb. (86 kg.)

XL0600 Biceps Curl 130 lb. (59 kg.) 190 lb. (86 kg.)

XL0700 Shoulder Press 170 lb. (77 kg.) 250 lb. (114 kg.)

XL0800 Lateral Raise 130 lb. (59 kg.) 190 lb. (86 kg.)

XL0900 Seated Chest Press 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1000 Pec Fly/Rear Delt 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1100 Lat Pulldown 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1200 Seated Row 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1300 Lower Back 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1400 Abdominal 130 lb. (59 kg.) 190 lb. (86 kg.)

XL1500 Triceps Pushdown 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1600 Incline Chest Press 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1700 Rotary Torso 130 lb. (59 kg.) 190 lb. (86 kg.)

XL1800 Horizontal Leg Curl 170 lb. (77 kg.) 250 lb. (114 kg.)

XL1900 Low Cable Row 170 lb. (77 kg.) 250 lb. (114 kg.)

INSTALLATION AND ASSEMBLY

Sleeve

Cap plate

Step 7.

11

INSTALLATION AND ASSEMBLY

Cap Plate/

Guide Rod

Cable

TILT

Bracket

Selector Bar

Adder

Weight

Adder

Weight

Bracket

STEP #9.

OPTIONAL

Adder Weight

Bushing

Long side

of

Pull Pin

FORWARD

12

INSTALLATION AND ASSEMBLY

8. If you DID NOT order the Adder Weight Option, proceed to Step #10.

9. INSTALLATION OF TH E OPTIONAL ADDER WEIGHT SYSTEM:

•Slide the adder weight onto the guide rods as shown in the “OPTIONAL ADDER

WEIGHT” diagram on the previous page. Make sure that the long end of the bushing

faces down and that the pull pin faces the user. Insert the cable through the hole in

the adder weight.

• Assemble the adder weight bracket and guide rod bracket as shown.

10. Tilt the guide rods back to vertical and re-attach the gu ide rod bracket to the u pright.

IF

IFIF

IF the opti onal adder weight w as in stalled , secure i t in pl ace on t he adder weight brack et.

Make sure that the pull pin on the adder weight lines up with and freely passes through

the retaining hole in the adder weight bracket. You may need to reposition the adder

weight bracket slightly to ensure this.

11. Check the cable to ensure that it is

tracking in all of the pulleys and that the

cap plate/selector bar is sitting flush on the

top weight. Before re-attaching the cable to

the cap plate/selector bar assembly, insert

the selector pin lanyard ring between the

cable bolt head and the cable nut as shown.

12. Re-attach the cable to the cap

plate/selector bar and adjust the cable

tension so that th e cap/plate ba rely lifts o ff

of the first weight plate. Cycle the machine

with a light we ight to ensure that the

movement is smooth. Verify that the

selector pin can be inserted into the bottom

weight of the weight stack. If the selector

pin does not insert freely, loosen the cable

tension slightly.

13. Be sure that the dimension from under the

bolt head to the bottom of the cable nut

DOES NOT exceed 1-3/8” (35 MM.) as

shown. With the cable tension properly

adjusted, tighten the cable nut.

Lanyard Ring

Cable Bolt

Cable Nut

Selector

Pin Holder

Selector pin

with lanyard

WARNING

1. MAKE S U RE selecto r pin is

inserted completely. Use only

the Paramount pin shown.

2. Bolt height must not exceed

1-3/8”. Check regu larly. MAKE

SURE locking nut is tight.

ASTM F1749 P/N B2442

STORE

STORESTORE

STORE

SELECTOR PIN

SELECTOR PINSELECTOR PIN

SELECTOR PIN

HERE

HEREHERE

HERE

MAXIMUM

MAXIMUMMAXIMUM

MAXIMUM

Height

Under Nut to

Bolt Head

MAX

1-3/8” (35mm)

4

-

1

/

4

”

(

1

0

8

m

m)

Paramount Pin B 470

!!!!

1-3/8” (35mm)

MAX!

Cable Bolt

Cable Nut

13

WWWWE

EEEIIIIGGGGHHHHTTT

T S

S S

ST

TTTAAAACCCCKKK

K L

L L

LA

AAABBBBEEEELLL

L I

I I

IN

NNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNN

N

Locate the weight stack labels packed with your machine order. For your reference, a list of

weight stack labels and their correspo nding part numbers is shown below:

* Kilogram (KG.) labels are available upon request.

Note that the 130 lb. and 190 lb. weight stacks (wh ich have 12 weight plates each) use

the same labels as the 170 lb. and 250 lb. weight stacks (w hich have 16 weight plates

each). When installing labels on the 130 lb. and 190 lb. weight stacks, discard the last

4

numbers from the label.

To install the weight stack labels:

1. Verify tha t the co rrect weight stack is

properly installed on the machine.

2. With a clean, dry cloth, wipe the front

surface of the weight s with rubbin g

alcohol and allow the weights to dry

completely. Make sure that there is no

lint on the su rface.

3. Remove the backing from the label.

Align the top edge of the label with the

top edge of the weights and the side

of the label with the outside edge of

the selector pin holes.

4. Verify that the label strip is straight and

remove the liner. As the line r comes

off the label, press and rub each label

into place.

5. IMPORTANT!

IMPORTANT!IMPORTANT!

IMPORTANT! DO NOT attempt to “test”

the integrity of t he labels after they

have been installed. The adhesive on

the labels requires 72 hours to cure.

Weight St ack

Weight St ackWeight St ack

Weight St ack 130 lb.

130 lb.130 lb.

130 lb.

(12) x 10 lb.

190 lb.

190 lb.190 lb.

190 lb.

(12) x 15 lb.

170 lb

170 lb170 lb

170 lb.

(16) x 10 lb.

250 lb.

250 lb.250 lb.

250 lb.

(16) x 15 lb.

210 lb.

210 lb.210 lb.

210 lb.

(20) x 10 lb.

310 lb.

310 lb.310 lb.

310 lb.

(20) x 15 lb.

Label Part #

Label Part #Label Part #

Label Part # B2170 B2172 B2170 B2172 B2071 B2073

WARNING

1. MAKE SUR E selector pin is

inserted completely. Use only

the Paramount pin shown.

2. Bolt height must not exceed

1-3/8”. Check regular ly. MAKE

SURE locking nut is tight.

ASTM F1749

P/N B2442

STORE

STORESTORE

STORE

SELECTOR PIN

SELECTOR PINSELEC TOR PIN

SELECTOR PIN

HERE

HEREHERE

HERE

MAXIMUM

MAXIMUMMAXIMUM

MAXIMUM

Height

Under Nut to

Bolt Head

MAX

1-3/8” (35mm)

4

-

1

/

4

”

(

1

0

8

m

m)

Paramount Pin B 470

!!!!

Individual

Labels

Liner

Align with

outside

edge of

pin holes

INSTALLATION AND ASSEMBLY

14

OPTIONAL F

OPTIONAL FOPTIONAL F

OPTIONAL FR

RRROOOONNNNTTT

T P

P P

PA

AAANNNNEEEELLL

L K

K K

KI

IIITTT

T

If you have purchased the optional front panel kit for the upright, it should be installed now.

Each machine requires (1) front panel option (depending upon the machine model). The

components included with the kit are s hown below:

FFFFR

RRROOOONNNNTTT

T P

P P

PA

AAANNNNEEEELLL

L O

O O

OP

PPPTTTTIIIIOOOONNNNSSS

S KIT #

KIT #KIT #

KIT #

Fro nt Panel, for sta nd ar d up ri ght (used

on all machines except those li sted

below)

Single panel part number: S518

FPK

Front Panel for:

XL0300 (Leg Press)

XL1000 (Pec Fly/Rear Delt)

Single panel part number: S518A

FPK-LP

Front Panel for:

XL1100 (Lat pull).

Single panel part number: S518B

FPK-LAT

Each of the above listed Front Panel Kits contains a hardware pack (part number

HW-FPK). The following components are included in the pack.

BBBBR

RRRAAAACCCCKKKKEEEETTTTSSS

S & H

& H & H

& HA

AAARRRRDDDDWWWWAAAARRRREEE

E P

PP

PA

AAARRRRTTT

T #

# #

#

Long Bracket (qty. 4) 9004951

Short Bracket (qty. 2) 9004949

Rubber Insert (qty. 8) C 775

10-32 X 1” Phillips Head Screw (qty. 8) C 904

48”

57”

65”

INSTALLATION AND ASSEMBLY

15

1. Remove the hardware

holding the c urved rear

cover in place. DO NOT

remove the cover.

Assemble the brackets

and hardware as shown.

TIP: When assembli ng

the screw (C904) , press

on the bracket firmly to

prevent the rubber

insert (C 775) from

turning. Fully

tighten the

screws.

2. Assemble the front

panel as shown.

TIP: When assembli ng

the screw (C904) press

on the panel (S518) to

prevent the rubber

insert (C 775) from

turning. Fully

tighten the

screws.

9004951

C775

C740

(Reuse nut from

rear cover)

Typical for bottom bracket.

C905

(Reuse screw fr om

rear cover)

C775

9004949

C904

C775

C-904

(S 518A for XL-300 &

XL-1000)

S 518 for standard up right

(S 518B for XL1100)

INSTALLATION AND ASSEMBLY

16

OPTIONAL F

OPTIONAL FOPTIONAL F

OPTIONAL FO

OOORRRREEEEIIIIGGGGNNN

N L

L L

LA

AAANNNNGGGGUUUUAAAAGGGGEEE

E L

L L

LA

AAABBBBEEEELLLLSSS

S

If you have purchased optional foreign language label kits, they can be installed now. Each

machine requires (1) set of labels. The kits include all of the warning and procedure labels

and are available in either French, German, or Spanish. Also available are Kilogram (KG.)

weight stack labels.

Place the warning labels in close proximity to the English versions of the labels.

The procedure label can be installed on the inside surface of the weight stack shroud or on

the face of the front panel if the Optional Front Panel Kit was installed.

To install the KG. weight labels, follow the same instructions shown on page -13.

AAAAN

NNNCCCCHHHHOOOORRRRIIIINNNNGGG

G

T

TTTHHHHEEE

E M

M M

MA

AAACCCCHHHHIIIINNNNEEEESSS

S

T

TTTOOO

O

T

TTTHHHHEEE

E F

F F

FL

LLLOOOOOOOORRR

R

If desired, the machines in the Performance XL line can be anchored into position. Holes in

the base frame have been provided for bolts to be used to fasten the machines to the floor

(see below).

Due to the wide variation of flooring on which the machines can be installed, contact a

qualified contractor to determine the appropriate fastening method.

FFFFI

IIINNNNAAAALLL

L A

A A

AS

SSSSSSSEEEEMMMMBBBBLLLLYYY

Y

1. Insert the plugs provided in the hardware bag into the holes in the base frame as shown.

2. Lubricate the guide rods with a teflon spray lubricant such as Tri-Flow

TM

.

3. Inspect the machine. Check and tighten ALL fasteners and cable fittings as required.

4. Make sure that the machine functions cor r ectly and smoothly.

Provision for

anchor bolt

(typical)

1” Diameter

Hole Plug

B 1216

Drill through molded foot

INSTALLATION AND ASSEMBLY

17

RRRRE

EEEPPPPLLLLAAAACCCCEEEEMMMMEEEENNNNTTT

T P

P P

PA

AAARRRRTTTTSSS

S: C

: C: C

: CA

AAABBBBLLLLEEEESSS

S

A

AAANNNNDDD

D U

U U

UP

PPPHHHHOOOOLLLLSSSSTTTTEEEERRRREEEEDDD

D P

P P

PA

AAADDDDSSS

S

CCCCA

AAABBBBLLLLEEEESSS

S

Paramount recommends that the cable ends be inspected daily

and that the area that passes over the pulle ys be inspect ed weekly.

Remove the view port plugs and inspect the cable while someone

cycles the machine. Replace the cable at the fi rst sign of wear or on

an annual basis. Refer to the General Maintenance Manual.

Shown to the righ t is the routin g for the cable through the upright. If

a machine must be disassembled, disconnect the cable at the

machine side, leaving the section of cable that is routed through

the upright, in tact.

Remove the view port plugs to assist in routing the cable as well as

verifying that the c able is in the pulley groove. After installation,

make sure that the machine functions smooth ly and that all

pulleys rotate.

MMMMO

OOODDDDEEEELLL

L D

DD

DE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N M

MM

MA

AAAIIIINNN

N C

C C

CA

AAABBBBLLLLEEE

E#

##

# AAAAU

UUUXXX

X. C

. C. C

. CA

AAABBBBLLLLEEE

E #

# #

# SSSSE

EEEAAAATTT

T P

P P

PA

AAADDD

D#

##

# TTTTO

OOORRRRSSSSOOO

O P

P P

PA

AAADDD

D#

##

# AAAAU

UUUXXX

X. P

. P. P

. PA

AAADDD

D #

# #

#

XL0100 Leg Extension LECAB04000 N/A LESPD04000X 9004970X 9002880X

XL0200 Seated Leg Curl LCCAB04000 N/A LESPD04000X 9004970X 9002880X

9000660x

XL0300 Leg Press LPCBL04000 N/A LPPAD04000X LPPAD04010X N/A

XL0400 Inner/Outer Thigh IOCAB04000 N/A IOSPD04000X IOBPD04000X IOTPD04000X (2)

XL0500 Triceps Extension TRCAB04000 N/A 9004990X TRPAD04000X TRPAD04020X

XL0600 Biceps Curl ACCAB04000 N/A 9004990X N/A ACPAD04000X

XL0700 Shoulder Press SPCAB04000 N/A 9004990X 9004970X N/A

XL0800 Lateral Raise DLCAB04000 DLCAB0401 0 9004990X SRCPD04000X SRCPD04000X (2)

XL0900 Che st Press CPCAB04000 N/A 9004990X 9004970X N/A

XL1000 Pec Fly/Rear Delt VBCAB04000 VBCAB04010 9004990X VBBPD04000X N/A

XL1100 L at Pu lldown LATCAB04000 LATCAB04010 9004990X N/A 9092083X (2)

XL1200 Seated Row SRCAB0400 N/A 9004990X N/A SRCPD04000X

XL1300 Lower Back LBCAB04000 N/A LBSPD04000X LBBPD04000X 9002880X

XL1400 Abdominal ABCAB04000 N/A 9004990X IOTPD04000X 9002880X

XL1500 Triceps Pushdown STCAB04000 N/A 9004990X 9004970X N/A

XL1600 Inc line Chest ICCAB04000 N/A 9004990X ICPAD04000X N/A

XL1700 Rotary Torso RTCAB04000 N/A RTSPD04000X 3000BPD000X

QTY. (2)

RTPAD04010X (2)

SRCPD04000X (2)

XL1800 Horizontal Leg Curl HCCAB04000 N/A HCPAD04010X HCPAD04000X 9002880X

XL1900 Low Cable Row RWCAB05000 RWCAB05010 RWSPD05000X N/A N/A

MACHINE MAINTENANCE

View Port Plug

18

XL0300 L

XL0300 LXL0300 L

XL0300 LE

EEEGGG

G P

P P

PR

RRREEEESSSSSSS

S R

R R

RO

OOOLLLLLLLLEEEERRR

R A

A A

AD

DDDJJJJUUUUSSSSTTTTMMMMEEEENNNNTTT

T

The XL-300 Leg Press is provided with an adjustable roller feature that ensures smooth

operation. This adjustment is preset at the factory. However, if you need to disassemble the

machine and remove the seat assembly, the rollers must be re-adjusted.

Tools Required:

(2) - 5/16” allen wrenches

1-1/4” wrench (or large adjustable crescent wrench)

The adjustment is made using the roller clearance adjusters which are located on both the

left and right s ides of t he trolley. To make the adjustment, start by loosening the button head

cap screws in the center of the adjusters. Then use a wrench to rotate the adjuster so that

there is only a small gap of about 1/32” (1 mm) between one of the rollers and the rail.

Look down the length of the rail from the rear of the machine at the position of the upper

and lower rollers relative to the rail. Adjust both the left and right roller. Once the correct

position is set, hold the wrench in place and use the allen wrenches to tighten the button

head screws.

Roller Clearance Adjuster

Leave a small gap,

between either the

and the rail.

Wrench

Trolley

Upper

Roller

Lower

Roller

View looking

down the rail

from the rear

Rail

1/32” (1 MM.),

top or bottom roller

MACHINE MAINTENANCE

19

LLLLA

AAABBBBEEEELLLLSSS

S

The following are the Warning and Procedure labels required for each machine. If any of

these labels are missing or become damaged, Paramount will replace them free of charge.

WARNING

!

SERIOUS INJURY CAN OCCUR ON

THIS EQUIPMENT. FOLLOW THESE

PRECAUTIONS TO HELP AVOID INJURY.

1. BEFORE USING: Read all of the

warnings and obtain instruction on the

use of this machine. Use only for the

intended exercise. DO NOT modify the

machine.

2. Get a medical exam before beginning an exercise program.

3. Keep body and clothing clear of all

moving parts. DO NOT wear anything

loose or dangling.

4. Inspect the machine before use.

DO NOT use if it appears damaged.

DO NOT try to fix any machine. Notify

staff immediately .

5. INSPECT MACHINE DAILY for

loose, worn or damaged parts. Tighten

and adjust all loose parts. Replace

any part or label at first signs of wear.

Inspect all cables and their connections closely . If you are in doubt about

any part, DO NOT use the machine

until the part is replaced.

6. Inspect cables and connections

before using the machine. DO NOT

use this machine if any part appears

worn or damaged.

7. Be certain that weight pin B460 is

completely inserted. Use only the pin

provided by the manufacturer. If

unsure, seek assistance.

8. NEVER pin the weights or top plate

into an elevated position. DO NOT

use the machine if found in this condition. DO NOT try to fix. Seek assistance.

9. Use only the incremental weights

supplied by the manufacturer. DO NOT

use dumbbells or other means to add

resistance to the machine.

10. NEVER allow children near this

machine. Supervise teenagers.

11. DO NOT REMOVE THIS LABEL.

REPLACE IF DAMAGED.

P/N B2060

ASTM F1749

B2060

MAINTENANCE

SCHEDULE

Check the integrity and function

of the following items. Replace

all worn components immediately.

D

A

I

L

Y

W

E

E

K

L

Y

Cables - Check tension end

fittings, and coating

Check tightness of

weight stack locking nut.

REPLACE CABLES ANNUALLY

Upholstery - Wipe down and dry.

Clean and condition.

Frame - Wipe with water dampened

cloth and dry completely.

DO NOT leave parts moist.

Polish/Wax

Chrome - Wipe with water dampened

cloth and dry co m p le tely.

DO NOT leave parts moist.

Polish/Wax

Nuts/Bolts/Fasteners - Tighten

and/or adjust as needed.

Guide Rods - Lubricate and clean

Linear Rods - Lubricate and clean

Seat Sleeves - Lubricate and clean

Adjustments/ Locking Pins/

Tightening Knobs

Weight Stack Pin

Warning/Instruction Labels

Springs

Anti-Skid

Hand Grips

Order Paramount Service Kit P/N KIT-01

for recommended maintenance products

PARAMOUNT CUST OMER SERVICE

1-800-721-2121

P/N B2315

B2315

WARNING LABELS

20

WARNING LABELS

WARNING

!

SERIOUS INJURY CAN OCCUR

ASTM F1749

P/N B2051

ON THIS EQUIPMENT IF THE

CABLES AND THEIR ATTACHMENT COMPONENTS ARE NOT

INSPECTED OFTEN. REPLACE

AT FIRST SIGNS OF WEAR.

B2051

WARNING

SERIOUS INJU RY CAN OCCUR ON THIS EQU IP M E N T IF

ASTM F1749

P/N B2065

THE PIN IS NOT COMPLETELY INSERTED BEFORE USE.

!

B2065

P/N B1299

B1299

USE THIS LAT BAR ON PARAMOUNT LAT STATIONS

WITH 310 POUNDS OR LESS.

INSPECT CABLE FITTING AND CONNECTIONS PRIOR

TO USE. BE CERTA IN THAT THE CONNECTIONS ARE SECURE.

FAILURE TO FOLLOW THESE PR O C EDURES MAY RESULT

IN SERIOUS INJURY.

ASTM F1749

WARNING

!

WARNING

1. MAKE SURE selector pin is

inserted com pletely. Use only

the Paramount pin shown.

2. Bolt height must not exceed

1-3/8”. Check regularly. MAKE

SURE locking nut is tight.

ASTM F1749

P/N B2442

STORE

STORESTORE

STORE

SELECTOR PIN

SELECTOR PINSELECTOR PIN

SELECTOR PIN

HERE

HEREHERE

HERE

MAXIMUM

MAXIMUMMAXIMUM

MAXIMUM

Height

Under Nut to

Bolt Head

MAX

1-3/8” (35mm)

!!!!

Paramount Pin B 470

4

-

1

/

4

”

(

1

0

8

mm

)

B2442

WARNING

!

MOVING PARTS

ASTM F1749

P/N B2064

STAY CLEAR!

B2064

WARNING

!

ASTM F1749

P/N B2083

B2083

SUPPORT WEIGHT

OF SEAT BY

GRASPING HANDLE

BEFORE ADJUSTING

SEAT POSITION

CAUTION

Move handle to

P/N B2445

!

B2445

the left a nd hold

it there when you

adjust the pad

21

HHHHO

OOOWWW

W

T

TTTOOO

O O

O O

OB

BBBTTTTAAAAIIIINNN

N S

S S

SE

EEERRRRVVVVIIIICCCCEEE

E

For warranty service, contact an Authorized Paramount Dealer or Paramount Customer

Service at 1-800-721-2121. Before you call, please have the following information ready:

•••• Model Number

Model NumberModel Number

Model Number

•••• Seria l Number

Serial NumberSerial Number

Serial Number

•••• Date of installation

Date of instal lationDate of instal lation

Date of instal lation

•••• A brief description of the problem

A brief descriptio n of the problemA brief descriptio n of the problem

A brief descriptio n of the problem

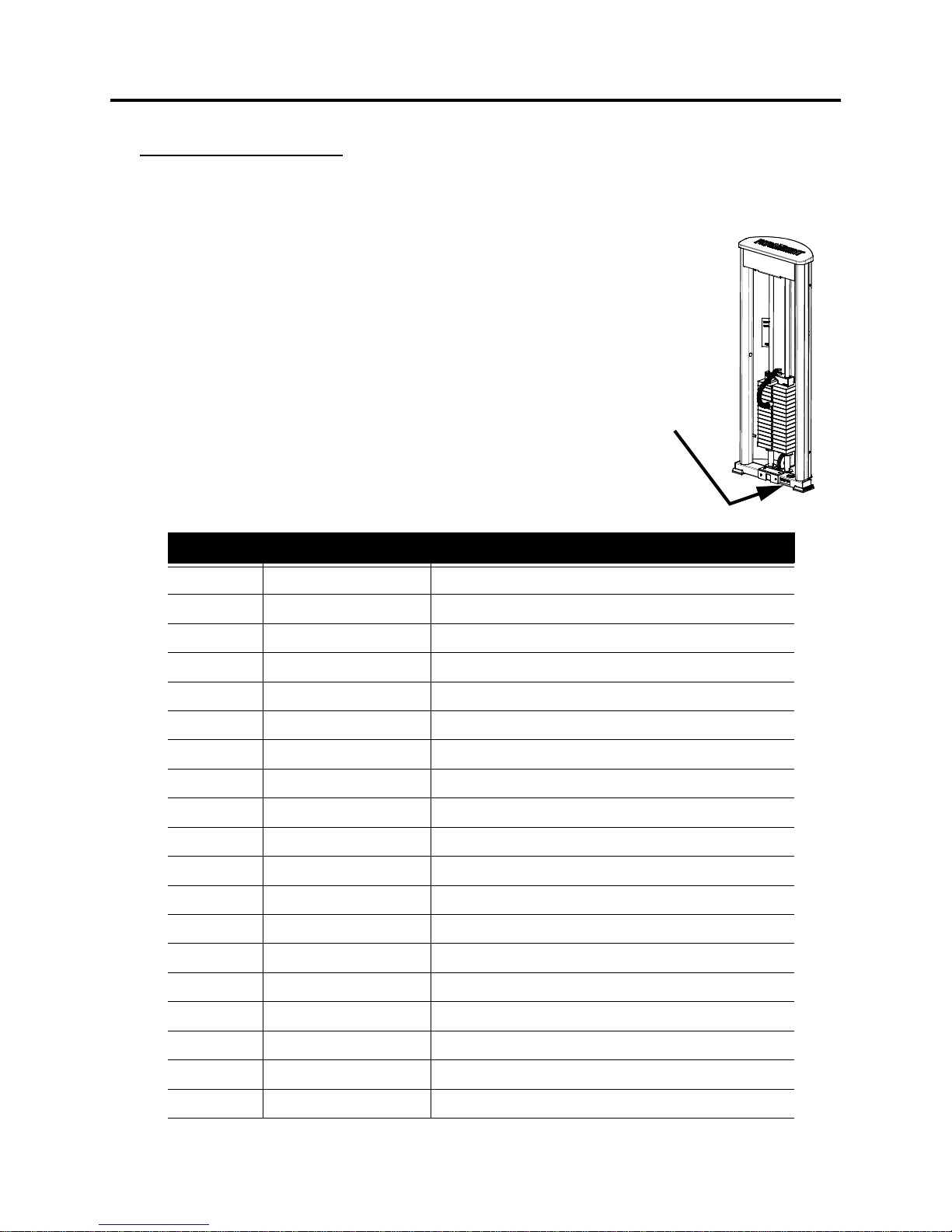

The space below is provided for you to record the model

and serial numbers of the equipment that you

purchased. Serial numbers are located near the bottom

of the upright.

Installation Date _____________________

MMMMA

AAACCCCHHHHIIIINNNNEEE

E D

DD

DE

EEESSSSCCCCRRRRIIIIPPPPTTTTIIIIOOOONNN

N R

RR

RE

EEECCCCOOOORRRRDDD

D S

S S

SE

EEERRRRIIIIAAAALLL

L N

N N

NU

UUUMMMMBBBBEEEERRRRSSS

S H

H H

HE

EEERRRREEE

E

XL0100 Leg Extension

XL0200 Seated Leg Curl

XL0300 Leg Press

XL0400 Inne r/Outer Thigh

XL0500 Triceps Extension

XL0600 Biceps Curl

XL0700 Shoulder Press

XL0800 Lateral Raise

XL0900 Seated Chest Press

XL1000 Pec Fly/Rear Delt

XL1100 Lat Pulldown

XL1200 Seated Row

XL1300 Lower Back

XL1400 Abdominal

XL1500 Triceps Pushdown

XL1600 Incline Chest Press

XL1700 Rotary Torso

XL1800 Horizontal Leg Curl

XL1900 Low Cable Row

Serial Number

SERVICE

22

NOTES

23

Paramount warrants to the original purchaser from a Paramount authorized dealer that

Paramount equipment or equipment from a Paramount authorized m anufacturing contractor will be

free from defects in material and workmanship under normal use and service for the following periods

and in the following respects:

LIFETIME WARRANTY

LIFETIME WARRANTYLIFETIME WARRANTY

LIFETIME WARRANTY - Welds, Weight Plates and Guide Rods

FIVE YEAR WARRANTY

FIVE YEAR WARRANTYFIVE YEAR WARRANTY

FIVE YEAR WARRANTY - Bronze Bushings, Sealed Rotat ing Beari ngs and Pulley Whee ls

ONE YEAR WARRANTY

ONE YEAR WARRANTYONE YEAR WARRANTY

ONE YEAR WARRANTY - Cables, Linear Bearings, Linear Shafts and all other components not

mentioned elsewhere in this warranty

NINETY DAY WARRANTY

NINETY DAY WARRANTYNINETY DAY WARRANTY

NINETY DAY WARRANTY - Upholstery and Grips

This limited warranty DOES NOT

DOES NOTDOES NOT

DOES NOT cover and no warranty is given with respect to:

• Products not manufactured by Paramount

• Products which are altered w i thout the express written consen t of Paramount

• Products purchased other than directly from Paramount or through a Paramount

Authorized Dealer.

All warranty periods begin to run from the da te of delivery to the original purchaser. The

obligation of Paramount unde r this warranty is limited to repairing or replacing warranted de fective

parts, as Paramount may elect, at Paramount's plant in Los An geles, California, without charge to

purchaser for either parts or labor. Purchaser is responsible for all transportation and insurance costs

on returned or replaced equipment to and from Paramount's plant in Los Angeles.

ANY IMPLIED WARRANTY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE AND THE IMPLIED WARRANTY OF MERCHANTABILITY, IS

LIMITED TO ONE YEAR DURATION FROM THE DATE OF DELIVERY TO THE ORIGINAL PURCHASER.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. THE REMEDY OF REPAIR AND REPLACEMENT IS THE

EXCLUSIVE AND SOLE REMEDY OF THE PURCHASER. PARAMOUNT SHALL NOT BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL DAMAGES OF ANY KIND, INCLUDING, BUT

NOT LIMITED TO, DAMAGE OF LOSS OF OTHER PROPERTY OR EQUIPMENT AND LOST PROFITS OR

REVENUE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

No action for breach of this written limited warranty or an implied warranty shall be

commenced more than one year after the accrual of the cause of action. This written limited warranty

is the complete, final and exclusive agreement of the parties with respect to the quality or

performance of the goods and any and all warranties and representations. No modifications of this

limited warranty or waiver of its terms shall be binding on either party unless approved in writing by an

authorized corporate officer of Paramount. This limited warranty gives you specific legal rights, and

you may also have other rights which may vary from state to state. Contact Paramount Fitness Corp.,

6450 E. Bandini Blvd., Los Angeles, California 90040-3185, for a list of authorized dealers or before

returning any defective equipment. Paramount Fitness Co rp. © 2004

PARAMOUNT FITNESS CORPORATION

PARAMOUNT FITNESS CORPORATIONPARAMOUNT FITNESS CORPORATION

PARAMOUNT FITNESS CORPORATION

6450 E. BANDINI BLVD., LOS ANGELES, CA 90040-3185 USA

6450 E. BANDINI BLVD., LOS ANGELES, CA 90040-3185 USA6450 E. BANDINI BLVD., LOS ANGELES, CA 90040-3185 USA

6450 E. BANDINI BLVD., LOS ANGELES, CA 90040-3185 USA

PARAMOUNT LIMITED WARRANTY

Paramount Fitness Corporation

6450 E. Bandini Blvd.

Los Angeles, CA 90040-3185

Phone: 1-323-721-2121 Fax: 323-724-2000

1-800-721-2121

www.paramountfitness.com

AM-XL.fm

REV:10/20/05

Loading...

Loading...