SELECT FITNESS CIRCUIT

CHEST PRESS / VERTICAL BUTTERFLY

SF-1500

ASSEMBLY MANUAL

AM-SF-1500

Rev 10/02

S

AFETY

1. Review and understand all of the warning labels affixed to the machines and t he

facility safety sign. Replace any warning label at first sign of wear. Labels and the Facility

Safety Sign may be obtained from Paramount free of charge.

2. Be certain that machine operation is understood before machine is used . Refe r to

the instruction label provided with th e machine.

3. Keep children away from this equipment.

4. DO NOT high-pin or double-pin the weight stack. DO NOT allow the machi ne to be

used if the top plate or weight stack is pinned in a raised position. Use an assistant and

carefully return the machine to the proper position with the cap plate resting on the top

weight. Inspect the cable to ensure that it is seated in all of the pulleys.

5. Use ONLY Paramount weight selector pins. Other manufacturer’s pins may work

free of the weight stack causing possible injury. Be certain the pin is completely

inserted prior to use.

6. Cables: Inspect the entire cable and the en d fi ttin gs d ai l y. Pay close attention t o th e

area going over pulleys a nd t o th e en d co nnections. When adjustin g cab l es at thr ea de d

inserts make sure all connections are tight. Adjust tension on cables as needed.

Replace all cables at first signs of wear . Use only Paramount supplied replacement

cables. Ensure that the dimension from under the bolt head to the top surface of the

selector bar is no greater than 1-3/8 inches (see installation). Ensure that the cable tension bolt & nut are tight.

7. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become

™

loose, retighten and/or use Loctite

8. Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any

component at first signs of wear.

Threadlocker 242.

9. DO NOT attempt to free any jammed assemb lie s by yourse lf as this m ay cause inj ury.

10. Use ONLY Paramount adder weights or adder weight systems for incremental

resistance adjustment. NEVER use dumbbells or other means to do this.

11. Instruct Users not to wear loose or dangling clothes or have headphone wire hanging when using this equipment.

12. Recommend that users receive a medical exam before commencing an exercise

program. User should stop exercising if they feel faint or dizzy.

13. Check regularly the functionality of your machine by verifying the fol lowing:

• cables and end fittings are intact and tensioned properly,

• all adjustments are possible and carried out with ease,

• the proper selector pin is in the weight stack,

• the exercise is performed smoothly, free of noise and/or binding,

• and the guide rods and linea r bearings are properly lubricated.

14. Follow the installation guidelines provided with the products.

15. Retain these instructions for future reference.

If you have any questions, do not hesitate to contact your Paramount dealer or Para-

mount Fitness Corp. at (800)721-2121 or www.paramountfitness.com.

Refer to Maintenance Schedule label on machine for when to schedule maintenance.

1

MAINTENANCE

1. Frames: Wipe all machines down with a damp cloth and dry completely each day. This includes painted,

chrome parts and upholstered pads.

2. Painted/chrom e parts: Use Simple Green or similar cleaner for light dirt and grime. Use TurtleWax®

Polishing Compound or a good car polish to remove heavier dirt and grease as well as for polishing. DO

NOT use solvents, lacquer thinner, acetone or finger nail polish remover. For scuffs and marks that are not

removed by the above methods use a soft scrub cleanser.

3. Upholstery: Use cloth towels and warm water daily to remove surface dirt and perspiration. Use a lanolin based hand cleaner or Naugahyde® brand upholstery cleaner to condition and deep clean on a weekly

basis. DO NOT use Windex, Simple Green, 409, or similar products to clean the upholstery.

4. Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

5. Exercise instruction labels: Clean with soap and water as needed.

6. Linear bearing shafts: Wipe down linear rails using a light application of Magnalube® lubricant or a

similar teflon grease on a weekly basis to remove dust, hair, and dirt. Polish the shaft using fine sandpaper

or steel wool if light rust is present.

7. Guide rods: Wipe all dirt and dust off the guide rods before applying a light application of Tri-Flow

TM

other silicone spray lubricant, spraying the Tri-Flow

DO NOT use oil base lubricants such as WD-40. Caution: Tri-Flow

on a rag and then wiping the guide rods with the rag.

TM

will stain carpet and clothing.

8. Bronze bushings: Check monthly for signs of wear and replace as needed. Lubricate monthly with Tri-

TM

Flow

.

9. Seat adjustments: Clean the chrome seat adjustment tube on a weekly basis using a rag sprayed with

Tri-Flow

TM

. Keep a light layer of Tri-FlowTM on these tubes at all times.

TM

or

We recommend that you purchase the Paramount Performance Kit (P/N KIT-01) to maintain your Paramount products. This will insure that the proper maintenance materials required will be used. Please refer

to the General Maintenance Manual (p/n AM-GMM) for other important safety and maintenance information.

ASSEMBLY NOTES

1) It is recommended that two (2) people be used to assemble this machine.

2) Assemble this machine on a solid level surface. Read the assembly instructions completely before

beginning to assemble the machine. This will help you to become familiar with the machine and prevent mistakes requiring unnecessary disassembly and reassembly.

3) Hardware placement is indicated as , etc. Refer to the hardware page for corresponding size and

configuration. You will have some remaining hardware as extra pieces are always included in one of

the bags.

4) Install all plastic end caps on assemblies where necessary before assembling the machine.

5) Initially tighten all hardware by hand, as this will assist in the alignment of the machine. When the

framework of the machine is complete, tighten all nuts, bolts and setscrews. Be sure all hardware is

tight before using the machine. Recheck all hardware upon completion of the assembly process.

6) Hex- and Sockethead bolt length is measured from the bottom of the head to the end of the bolt.

Length of Flathead bolts is measured as the total overall length.

A

7) Bolts should point inward on the machine wherever possible, leaving the bolt heads facing out.

8) Route cables prior to installing pulley wheels. Verify that the cables are seated in the pulleys prior to

using the equipment.

9) Read and understand all machine warning and instruction labels before using the machine.

2

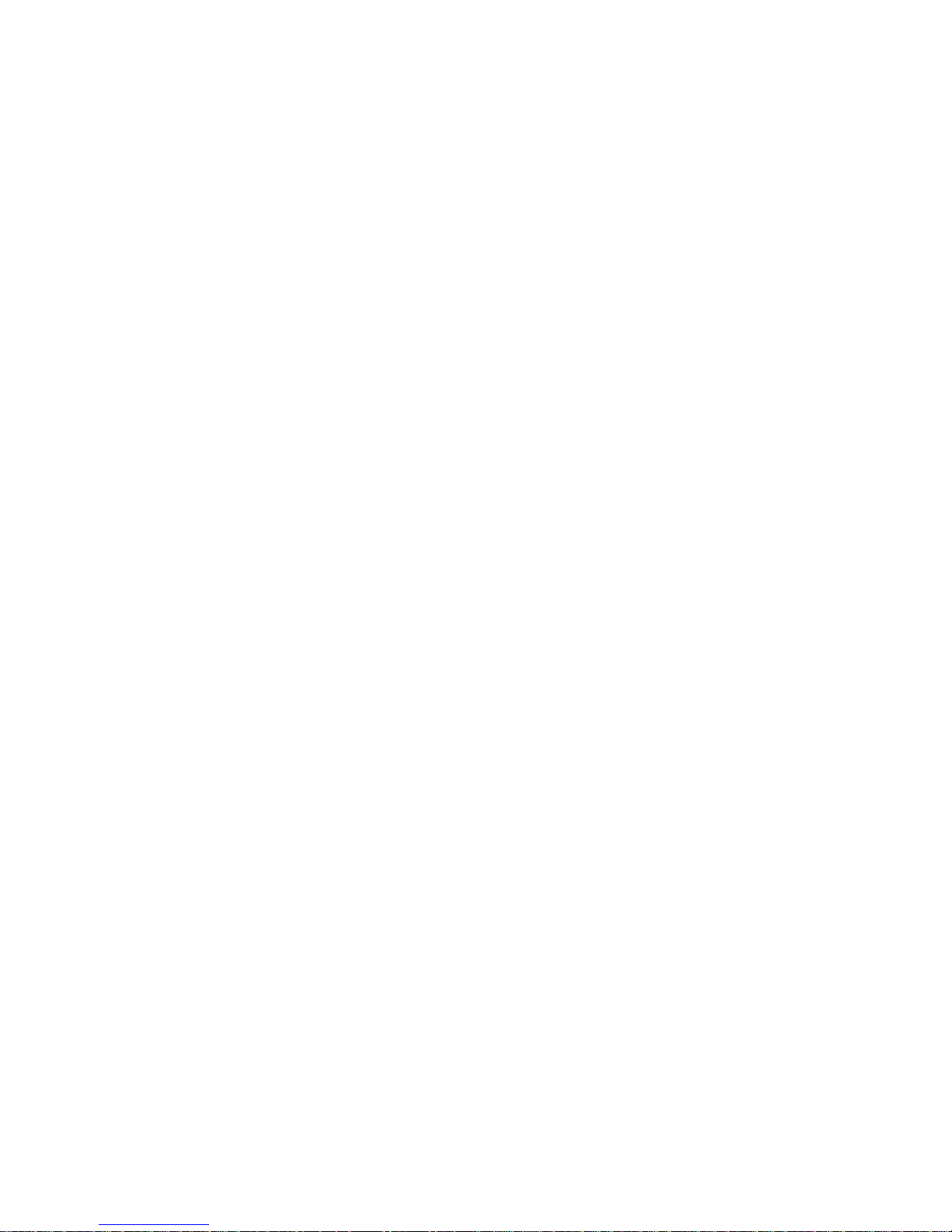

TOOLS REQUIRED:

RUBBER

MALLET

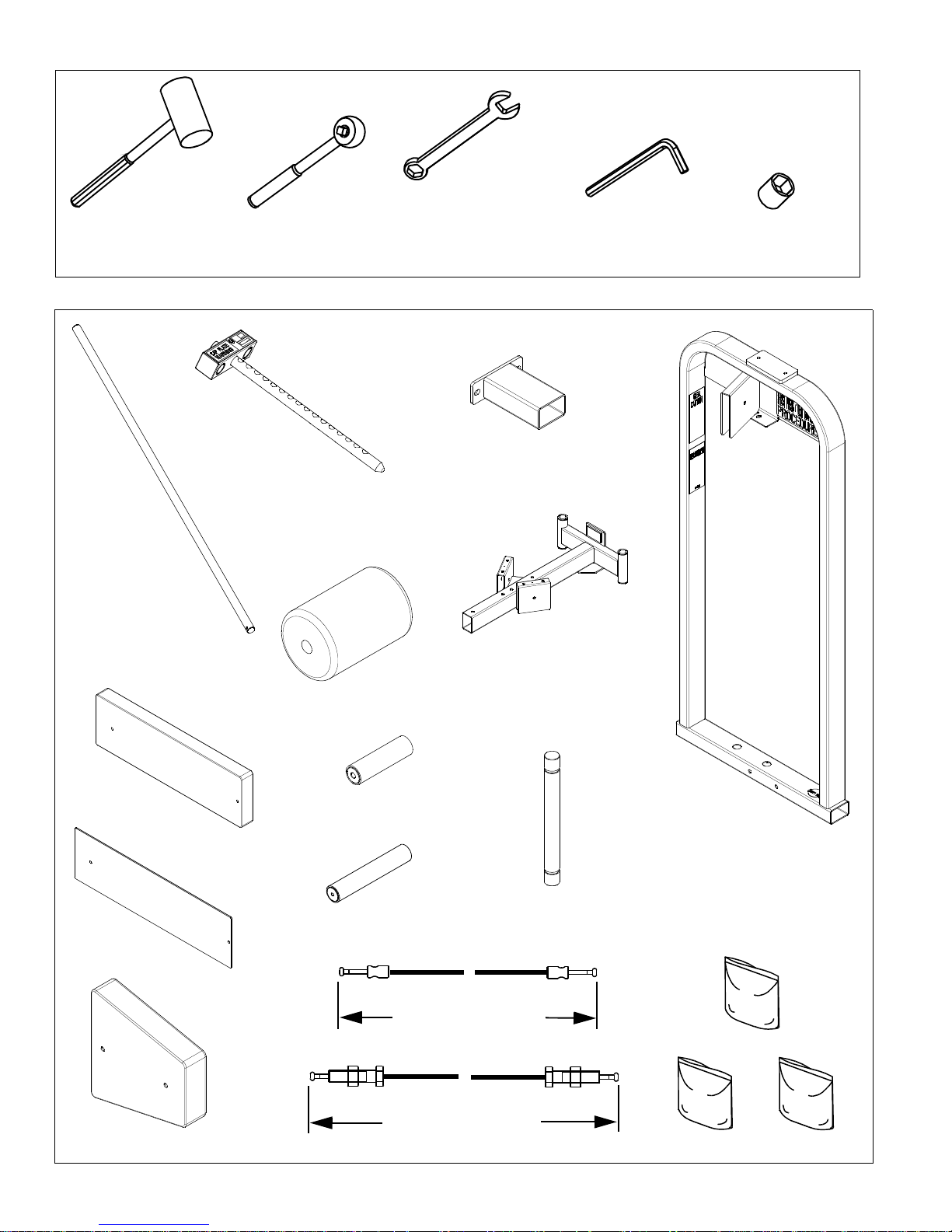

SF-1500CTN1:

SOCKET

WRENCH

9099780X

WRENCH

7/16” (11mm)

9/16” (14mm)

7/8” (22mm)

15/16” (24mm)

8093040

ALLEN WRENCH

5/32” (4mm)

7/32” (6mm)

SOCKET

7/16” (11mm)

9/16” (14mm)

9000801X (2)

8001540X

8001539

8001120X (2)

1501597X

1501596X

1501505X

1501595

144 3/4” (368cm)

1501610

1501515X

HW-1501-1

8001520X

217 3/8” (552cm)

1501615

HW-1501-2

HW-1501-3

3

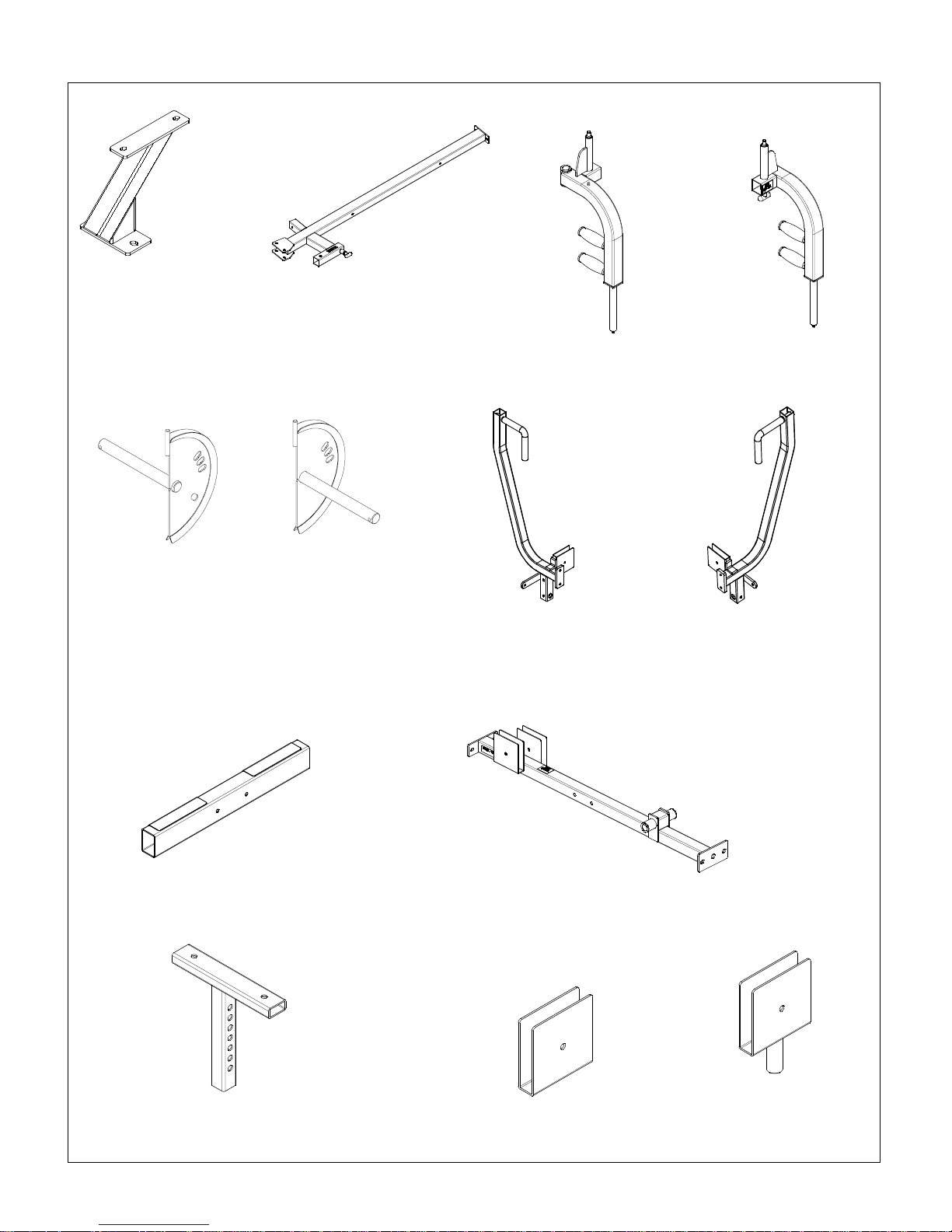

SF-1500CTN2:

1501500

1501525

1501510X

1501530

1501550X

1501555X

1501570X 1501575X

8093006X

8001525

1501520X

9098831A

4000PLY000

4

HARDWARE BAG 1501-2:

B 582 (2)

B 921 (6)

B 1182 (2)

B1117 (8)

B 682 (8)

B1136

D 829B (2)

B1015

B 447

8001594 (2)

B 900 (8)

B 898

HARDWARE BAG 1501-1:

B

3/8-16 x 1 BHCS

3/8 Black Washer

3/8-16 Locknut

3/8 Metal Base

Plastic Cover for 3/8

L

DG

3/8-16 x 2 3/4 HHCS

3/8 Black Washer (2)

3/8-16 Locknut

3/8 Metal Base (2)

Plastic Cover for 3/8 (2)

N

3/8-16 x 1 3/4 HHCS

3/8-16 Locknut

3/8 Black Washer (2)

3/8 Metal Base (2)

Plastic Cover for 3/8(2)

3/8-16 x 2 HHCS

3/8 Metal Base

3/8 Split Lockwasher

3/8 Washer

Plastic Cover for 3/8

B 1295

E

3/8-16 x 3/4 BHCS

3/8 Lock Washer

3/8 Washer

S

3/8-16 x 4 HHCS

3/8 Metal Base

3/8 Split Lockwasher

3/8 Black Washer

Plastic Cover for 3/8

8001593 (2)

F

3/8-16 x 3 HHCS

3/8-16 Thin Locknut

3/8 Metal Base (2)

3/8 Black Washer (2)

Plastic Cover for 3/8 (2)

C 754B

3/8” Black

Washer (6)

3/8-16 X 3 3/4 HHCS

3/8-16 Locknut

3/8 Black Washer (2)

3/8 Metal Base (2)

Plastic Cover for 3/8 (2)

C 757

1” USS Flat

Washer (2)

B 460

H

3/8-16 x 4 HHCS

3/8 Black Washer (2)

3/8-16 Locknut

Plastic Cover for 3/8 (2)

3/8 Metal Base (2)

C 766A

3/8-16

Locknut (4)

C 446

3/8-16 x 1 1/4

HHCS (2)

C 641

1/2-13 x 1 1/4

SHCS (2)

C 628

3/8-16 x 2 1/4

SHCS (2)

C 612

1/4-20 x 1 3/4

SHCS (2)

C 675A

1/4-20 x 5/8

BHCS (2)

C 955

Plastic Co ver for

3/8 & 1/2” (4)

C 749

3/8” Split

Lockwasher (4)

C 955A

3/8” Metal

Base (4)

C 750

1/2” Split

Lockwasher (2)

C 747

1/4” Split

Lockwasher (2)

C 740

1/4-20 Insert

Locknut (2)

5

MINIMUM FLOOR AREA REQUIRED:

59”

(150cm)

MACHINE WEIGHT (NOT INCLUDING

WEIGHT OF USER):

W/ 170LB STACK 471 LBS

W/ 250LB STACK 551 LBS

SHROUD OPTION +30LB

95”

(241cm)

IN USE

39” (99cm)

75” (191cm)

IN USE

HEIGHT= 75” (191 cm)

NOTE: THIS MACHINE IS DESIGNED FOR

USERS WEIGHING 300LB OR LESS

HARDWARE MEASUREMENT GUIDE:

BHCS - BUTTON HEAD CAP SCREW

SHCS - SOCKET HEAD CAP SCREW

MEASURE BOLT

FROM HERE

FHCS - FLAT HEAD CAP SCREW

HHCS - HEX HEAD CAP SCREW

12345

6

1

8093040

H (2)

2

G (4)

1501500

E (2)

1501515X

NOTE: ST ABILIZER FOOT MUST BE

ATTACHED TO THE MACHINE!

8093006X

1501520X

D (2)

TOP VIEW

PULLEY HOUSING

1501515X

1501505X

NOTE: WHEN INSTALLING HARDWARE,

TIGHTEN BY HAND ONLY UNTIL ALL

COMPONENTS ARE ASSEMBLED. BOLT

HEADS SHOULD FACE TO OUTSIDE OF

MACHINE WHERE POSSIBLE. BE SURE

ALL HARDWARE IS TIGHT BEFORE

1501510X

F (2)

7

3

5

C 641

C 750

1501595

1501570X

150157

1501596X

C 675A

C 747

C 955 (2)

C 446 (2)

C 749 (2)

C 955A (2)

C 754B (2)

4

1501555X

1501525

1501530

1501550X

C 612

C 740

D 829B

8

5

8001594 (2)

6

8001593

C 955

C 955A

C 766A

C 754B

8001120X (2)

8001540X

8001539

S (2)

B1295 (2)

8001520X

8001525

N (2)

9

WEIGHT STACK INSTALLATION

Review the equipment order to determine

the weight stack configuration. The

boxes are marked with the quantity and

weight of the plates.

P/N: B1602

Comprised of

(4) EACH 10lb MACHINED WEIGHT PLATES

or

P/N: B1603

Comprised of

(4) EACH 15lb MACHINED WEIGHT PLATES

170lb

16 x 10lb plates

Qty (4) Box B1602

7

250lb

16 x 15lb plates

Qty (4) Box B1603

NOTE: TIGHTEN

HARDWARE BY HAND

ONLY AT THIS POINT.

FRONT VIEW

B (2)

B 447

9000801X (2)

9099780X

WEIGHT

PLATES

C 757 (2)

B 582 (2)

NOTE: IF INSTALLING THE WEIGHT SHROUD

OPTION REFER TO THE INSTALLATION

INSTRUCTIONS PROVIDED WITH THE OPTION.

10

8

9099780X

NOTE: MOVE CAP PLATE 9099780X UP TO PULLEY HOUSING

TO SET THE CORRECT GUIDE ROD AND BRACKET SPACING.

NOW COMPLETELY TIGHTEN HARDWARE. CAP PLATE

SHOULD MOVE SMOO TH LY ALONG GUIDE RODS. IF NOT,

LOOSEN HARDWARE AND RESET SPACING.

9

L (2)

1501610

C 766A (2)

B 900 (3)

4000PLY000

L

11

10

B 898

L

1501615

MAX!

1 3/8” (35mm)

1501615

MAKE SURE

LOCKING NUT

IS SECURE!

11

9098831A

G

B 460

NOTE: PARAMOUNT SELECTOR PIN B 460 IS

THE ONLY PIN THAT SHOULD BE USED WITH

THIS MACHINE. UNDER NO CIRCUMST ANCES

SHOULD THE CAP PLATE OR WEIGHT STACK

BE PINNED IN AN ELEVATED POSITION.

1501597X

B 900 (5)

L (2)

1501615

C 628 (2)

C 749 (2)

C 754B (2)

12

SELECT FITNESS

W

EIGHT STACK LABEL INSTALLATION

Hardware Bag 1501-3 is packed with a weight stack number label set. Follow th e i nstructions printed on the label. Be low is a list of weight stacks an d t he corresp ond ing lab el se t

part numbers:

To install weight stack labels:

1. Verify weights are installed properly.

2. Wipe front surface of the weights with rubbing alcohol and a llow to dry completely.

3. Remove the backing from the labels. Align the top edge of the label with the top

edge of the weights and the side of the label with the outside edge of the pin hole in

the weights.

F

ITNESS LINE

WEIGHT ST ACK LABELS

WEIGHT ST ACK LABELS

Wt. Stack 170lb 250lb

Part No. B2170 B2172

4. Verify that the label strip is straight and then remove the liner. As the liner comes off

the labels, press and rub each la be l in to place.

5. The adhesive requires 48 hours to cure so DO NOT attempt to “test” the integrity of

the labels after they have been installed.

Take the time during inst allatio n to align the la bel with th e edge of the pin ho le and the top

surface of the weights to get all of the individual labels straight.

Liner

Individual

labels

Align with outside

edge of pin holes

13

W ARNING LABELS

The following warning labels are affixed to the SF-1500. Be certain that you and the

facility staff are aware of the meaning and importance of each label. If the labels become

damaged, replacements can be or dered free of charge from Paramou nt.

!

WARNING

SERIOUS INJURY CAN OCCUR. KEEP YOUR HANDS

CLEAR OF THIS AREA DURING USE OF THE MACHINE.

P/N B2316 6/96

ASTM Fxxx

B2316

!

WARNING

SERIOUS INJURY CAN OCCUR ON THIS EQUIPMENT IF

THE PIN IS NOT COMPLETELY INSERTED BEFORE USE.

P/N B2065 11/96

ASTM Fxxx

B2065

!

WARNING

STABILIZING FOOT MUST BE ATTACHED HERE.

P/N B2017

ASTM Fxxx

B2017

!

WARNING

SERIOUS INJURY CAN OCCUR

ON THIS EQUIPMENT IF THE

CABLES AND THEIR ATTACHMENT COMPONENTS ARE NOT

INSPECTED OFTEN. REPLACE

AT FIRST SIGNS OF WEAR.

P/N B2051 6/96

ASTM Fxxx

B2051

!

WARNING

1. MAKE SURE selector pin is inserted

completely. Use only the Paramount pin shown

2. Bolt height must not exceed 1 3/8”. Check

regularly. Make sure locking nut is tight.

ASTM F1749

MAINTENANCE

SCHEDULE

Check the integrity and function

of the following items. Replace

all worn components immediately.

Cables - Check tension, end

Upholstery - Wipe down and dry

Frame - Wipe down and dry

Chrome - Wipe down and dry

Nuts/Bolts/Fasteners - Tighten

Guide Rods - Lubricate and clean

Linear Rods - Lubricate and clean

Seat Sleeves- Lubricate and clean

Adjustments/Locking Pins/

Weight Stack Pin

Warning/Instruction Labels

Springs

Anti-Skid

Hand Grips

Order Paramount Serv ice Kit P/N KIT-01

for recommended maintenance products

PARAMOUNT CUST OMER SERVICE

P/N B2141

fittings, and coating

Check weight stack

locking nut

Clean and condition

Polish/Wax

Polish/Wax

and/or adjust as needed

Tightening Knobs

1-800-721-2121

PIN

B2315

MAXIMUM Heig ht

under Nut to

Bolt head

e

H

”

5

Paramount Pin P/n B 460

P/N B2315 5/98

o

t

d

a

MAX

1 3/8”

B

W

D

E

A

E

I

K

L

L

Y

Y

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

l

l

a

!

WARNING

SERIOUS INJURY CAN OCCUR ON

THIS EQUIPMENT. FOLLOW THESE

PRECAUTIONS TO HELP AVOID INJURY.

1. BEFORE USING: Read all of the

warnings and obtain instruction on

the use of this machine. Use only for

the intended exercise. DO NOT

modify the machine.

2. Get a medical exam before

beginning an exercise program.

3. Keep body and clothing clear of all

moving parts. DO NOT wear anything

loose or dangling.

4. Inspect the machine before use.

DO NOT use it if it appears damaged.

DO NOT try to fix any machine.

Notify staff immediately.

5. INSPECT MACHINE DAILY for

loose, worn or damaged parts.

Tighten and adjust all loose parts.

Replace any part or label at first

signs of wear. Inspect all cables and

their connections closely. If you are

in doubt about any part, DO NOT

use the machine until the part is

replaced.

6. Inspect cables and connections

before using the machine. DO NOT

use this machine if any part appears

worn or damaged.

7. Be certain that weight pin B1003 is

completely inserted. Use only the pin

provided by the manufacturer. If

unsure, seek assistance.

8. NEVER pin the weights or top plate

into an elevated position. DO NOT

use the machine if found in this

condition. DO NOT try to fix. Se e k

assistance.

9. Use only the incremental weights

supplied by the manufacturer. DO

NOT use dumbbells or other means

to add resistance to the machine.

10. NEVER allow children near this

machine. Supervise teenagers.

11. DO NOT REMOVE THIS LABEL.

REPLACE IF DAMAGED.

P/N B2060 1/98

ASTM F1749

B2060

B2141

14

PARAMOUNT’s Limited Warranty

Paramount warran ts t o th e orig ina l purch aser from a Par amount au thorize d dea ler that P aramount equipment will be free from defects in material and workmanship under normal use and

service for the following periods and in the following respects:

LIFETIME WARRANTY Welds, Weight Plates, and Guide Rods

FIVE YEAR WARRANTY Bronze Bushings, Sealed Rotating Bearings and Pulley Wheels

ONE YEAR WARRANTY Cables, Linear Bearings, Linear Shafts and all other components

not mentioned elsewhere in this warranty

90-DAY WARRANTY Upholstery and Grips

This limited warranty DOES NOT cover and no warranty is given with respect to:

‚ Products not manufac tured by Paramount

‚ Products which are altered without the express written consent of Paramount

‚ Products purchased other than directly from Paramount or through a Paramount autho-

rized dealer.

All warranty periods begin to run from the date of delivery to the original purchaser. The

obligation of Paramount under this warranty is limited to repairing or replacing warranted defective parts, as Paramount may elect, at Paramount’s plant in Los Angeles, California, without

charge to purchaser for either parts or labor. Purchaser is responsible for all transportation and

insurance costs of retur ned or replace d equipmen t to and from Para mount’ s plant i n Los Angeles.

ANY IMPLIED WARRANTY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND THE IMPLIED WARRANTY OF

MERCHANTABILITY, IS LIMITED TO THE ONE YEAR DURATION FROM THE DATE OF

DELIVERY TO THE ORIGINAL PURCHASER. SOME ST ATES DO NOT ALLOW LIMITATIONS

ON HOW LONG AN IMPLIED WA RRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU. THE REMEDY OF REPAIR AND REPLACEMENT IS THE EXCLUSIVE AND

SOLE REMEDY OF THE PUCHASER. PARAMOUNT SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL DAMAGES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, DAMAGE OR LOSS OF OTHER PROPERTY OR EQUIPMENT AND LOST PROFITS OR REVENUE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

No action for breach of this written limited warranty or any implied warranty shall be commenced more than one year after the accrual of the cause of action. This written limited warranty

is the complete, final and exclusive agreement of the parties with respect to the quality or performance of the goods and any and all warranties and representations. No modification of this limited warranty or waiver of its terms shall be bin ding on either party unless approved in writing by

an authorized corporate officer of Paramount. This limited warranty g ives you specific legal

rights, and you may also have other righ ts which vary from st ate to stat e. Cont act Pa ramou nt Fitness Corp., 6450 E. Bandini Blvd., Los Angeles, California 90040-3185, before returning any

defective equipment. Paramount Fitness Corp. © 1999.

Paramount Fitness Corp. © 1993, 1995, 1997

For More Information On Other Paramount Products:

6450 E. Bandini Blvd., Los Angeles, CA 90040-3185 USA

Advanced Performance Products

Select Fitness Circuit

Performance Free Weight Benches

Multi-Station Machines

Call (323) 721- 2121 • (800) 721- 2121

PARAM OUNT FITNESS CORP.

Loading...

Loading...