Paramount Fitness MS-1000, MS-1050 Assembly Manual

ASSEMBLY MANUAL

OPTIONAL STATION

MS-1000/1050

ADJUSTABLE CABLE COLUMN

MS-1000 Right Side

MS-1050 Left Side

AM-MS1000.fm

Rev 04-02

SAFETY REQUIREMENTS

1. Review and understand all of the warning labels affixed to the machines and the facility

safety sign. Replace any warning l abel at the first sign of wear. Labels and the Facility Safety

Sign may be obtained from Paramount free of charge.

2. Be certain that machine operation is understood before machine is used. Refer to the

instruction label provided with the machine.

3. Keep children away from this equipment.

4. DO NOT high-pin or double-pin the weight stack. DO NOT allow the mac hin e to be used if the

top plate or weight stack is pinned i n a raised position. Use an assistant and carefully return

the machine to the proper position with the cap plate resting on the top weight. Inspect the

cable to ensure that it is seated in all of the pulleys.

5. Use ONLY Paramount weight selector pins. Other manufacturer’s pins way work free of the

weight stack causing possible injury . Be certain the pin is completely inserted prior to use.

6. Cables: Inspect the entire cable and the end fittings daily. Pay close attenti on to the area

going over the pulleys and to the end connections. When adjusting cables at the threaded

inserts make sure all connections are tight. Adjust tension on cables as needed. Replace all

cables at first signs of wear. Use only Paramount supplied replacement cables. Ensure

that the dimension from under the bol t head to t he t op surface of the sel ector b ar i s no great er

than 1-3/8 inches (see installation). Ensure that the cable tension bolt & nut are tight.

7. Adjustment Pins: check the function of select or pins on adjustable pulley housings. Make

sure that the selector pin inserts completely into each position without binding.

8. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose,

retighten and/or use Loctite

TM

Threadlocker 242.

9. Frames and Lifting Ar ms: Inspect weekly for integrity and function. Replace any component

at first signs of wear.

10. DO NOT attempt to free any jammed assemblies by yourself as this may result in injury.

11. Instruct Users not to wear loose or dangling clothes or have headphone wires hanging when

using this equipment.

12. Recommend that users receive a medical exam before commencing an exercise program.

User should stop exercising if they feel faint or dizzy.

13. Regularly Check the function of your machine by verifying the following:

•Cables and end fittings are intact and tensioned properly.

•All adjustments are possible and carried out with ease.

•The proper selector pin is in the weight stack.

•The exercise is performed smoothly, free of noise and/or binding.

•The guide rods are properly lubricated.

14. Follow the installation guidelines provided with the products.

15. Retain these instr uctions for future reference.

If you have any questions, do not hesit ate to cont act your Paramoun t Dealer of Paramount Fi tness

Corp. at (800) 721-2121 or www.paramountfitness.com.

Refer to Maintenance Schedule label located on the machine for maintenance intervals.

2 MS Assembly Instructions PT1.fm

MAINTENANCE REQUIREMENTS

• Frames: Wipe all machines down with a damp cloth and dry completely each da y. This

includes painted and chrome parts and upholstered pads.

• Painted/chrome parts: Use Simple Green or similar cleaner for light di rt and gri me. Use TurtleWax® Polishing Compound or a good car polish to remove heavier dirt and grease as well

as for polishing. DO NOT use sol vents, l acquer thinner, acetone or finger nail polis h remover .

For scuffs and marks that are not removed by the above methods use a soft scrub cleanser.

• Upholstery: Use cloth towels and warm water daily to remove surface dirt and perspiration.

Use a lanolin based hand cleaner or Naugahyde® brand upholstery cleaner to condition and

deep clean on a weekly basis. DO NOT use Windex, Simple Green, 409, or similar products

to clean the upholstery.

• Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

• Exercise instruction labels: Clean with soap and water as needed.

• Guide rods: Wipe all dirt and dust off the guide r ods befo re applyi ng a light applicat ion of Tri-

TM

Flow

guide rods with the rag. DO NOT use light oil base lubricants such as WD-40. Caution: Tri-

Flow

• Bronze bushings: Check monthly for signs of wear and replace as needed. Lubricate

monthly with Tri-Flow

We recommend that you purchase the Paramount Performance Kit (P/N KIT-01) to maintain your Paramount products. This will insure that the proper maintenance materials

required will be used. Please refer to the General Maintenance Manual (p/n AM-GMM)

for other important safety and maintenance information.

or other silicone spray l ubricant, spr aying the T ri-FlowTM on a rag and then wiping the

TM

will stain carpet and clothing.

TM

.

ASSEMBLY NOTES

• It is recommended that at least two (2) people be used to assemble this machine.

• Read the assembly instructions completely before beginning to assemble the

machine. This will help you to become familia r with the machine and prevent mistakes requiring unnecessary disassembly and reassembly.

• Hardware placement is indicated with a balloon. Refer to the hardware page for co rresponding size and configuration. You may have some remaining hardware as extra

pieces are alw ays included in on e of the bags.

• Install all plastic end caps on assemblies where necessary before assembling the

machine.

• Initially tighten all hardware by hand, as this will assist in the alignment of the

machine. When the framewo rk of the ma chin e is complete , tigh ten all nuts, bolts and

setscrews. Be sure all hardware is tight before using the machine.

• Bolts should point inward on the machine wherever possible, leaving the bolt heads

facing out.

• Route cables prior to installing pulley whee ls.

• Read and understand all machine warning and instruction labels before using the

machine.

3 MS Assembly Instructions PT1.fm

HARDWARE MEASUREMENT GUIDE

As shown below, Button Head, Socket Head and Hex Head screw length is measured

from the bottom of the head to the end of the screw. The length of Flat Head screws is

measured as the total overall length.

BHCS - BUTTON HEAD CAP SCREW

SHCS - SOCKET HEAD CAP SCREW

FHCS - FLAT HEAD CAP SCREW

HHCS - HEX HEAD CAP SCREW

MEASURE BOLT

FROM HERE

TOOLS REQUIRED

STEP LADDER

1

SOCKET

WRENCH

2

SOCKET

9/16”

3/4”

3

WRENCH

9/16”

3/4”

7/8”

15/16”

45

ALLEN WRENCH

5/32”

7/32”

5/16”

4 MS Assembly Instructions PT1.fm

MS-1000/1050 ASSEMBLY INSTRUCTIONS

1. Your MS-1000 (ri ght side ha ndl e ) or MS-10 50 (l e ft side handle) adjustabl e cabl e column stations require minimal assembly to comp lete. These assembly instructions

may vary slightly depending upon the method of shipment.

2. To complete the installation, you will need an available side “A” on a 4-sided modular

frame. Each station will add an additi onal 10-3/4” to the overall size of the unit (see

diagram below). The minimum ceiling height requirement is 93”.

Total weight per station with 170 lb. stack = 270 lbs. (123 kg.)

Total weight per station with 250 lb. stack = 350 lbs. (159 kg.)

MS-1000

RIGHT SIDE HANDLE

MS-1050

LEFT SIDE HANDLE

5 MS-1000 PT1.fm

PLACEMENT OF OPTIONAL STAT IONS

Optional stat ions are d esigned to fi t a parti cular side of your MS M odular Frame. Use the

diagram below to determine the correct side of the modular frame that the optional stations should be attached. Note that the optional stations are referred to as either Side

“A” or Side “B” Stations.

MS-4000

Optional Stations = 4

- (2) Side “A” St a tio ns .

- (2) Side “B” Stations.

MS-5000

Optional Stations = 3

- (1) Side “A” Station.

- (2) Side “B” Stations.

MS-6000

Optional Stations = 2

- (2) Side “B” Stations.

MS-8000

Optional Stations = 6

- (2) Side “A” Stations.

- (4) Side “B” Stations.

A

A

A

B

B

B

B

B

B

A

B

B

B

A

B

MS-12000

Optional Stations = 8

- (2) Side “A” Stations.

- (6) Side “B” Stations.

A

IMPORTANT!

IF YOU DID NOT ORDER AN OPTIONAL SIDE “A” STATION FOR ANY OF THE

ABOVE CONFIGURATIONS, A HALF-BLANK STATION (MS-0005) MUST BE

INSTALLED IN PLACE OF EACH SIDE “A” STATION.

B

B

B

B

A

B

6 MS-1000 PT1.fm

B

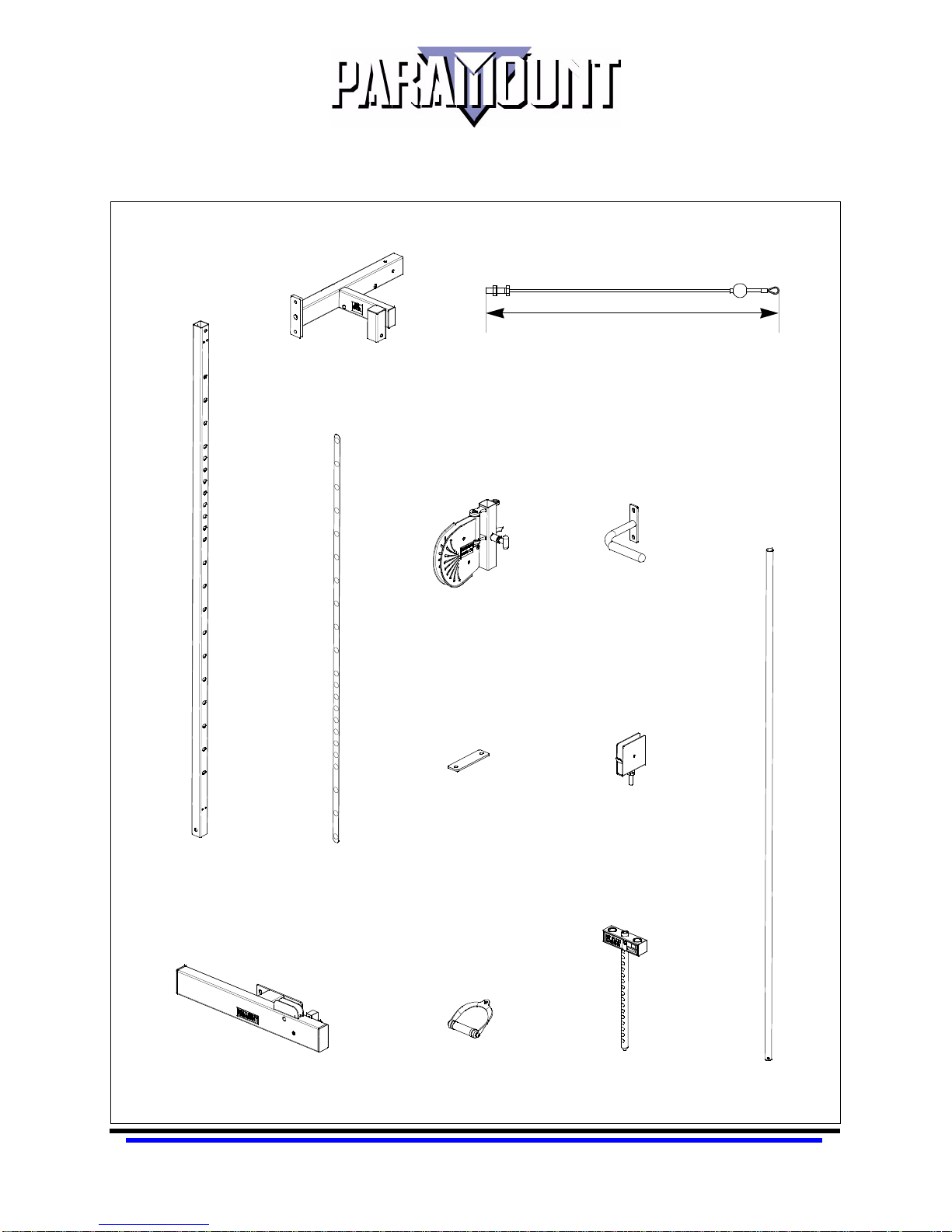

MS-1000 COMPONENTS

RIGHT SIDE

(see following page for left side)

Note: Depending upon the method of shipment, some

of the items that appear may already be assembled

to your machine.

MS1002000X

TOP PULLEY

HOUSING (RIGHT)

MS1002035X

ADJUSTABLE PULLEY

(RIGHT)

351-1/2 in. (893 cm)

MS1002090

CABLE

MS1002050X

HANDLE

MS1002061

ADJUSTMENT

COLUMN

MS1002010X

BOTTOM PULLEY

HOUSING (RIGHT)

B5000

ADJUSTMENT

LABEL

MS8002002

BEAM CONNECTOR

B1100

HANDLE

7 MS-1000 PT1.fm

MS1002020X

CAP PLATE PULLEY

9099780X

SELECTOR BAR

MS8002009X

GUIDE ROD (2)

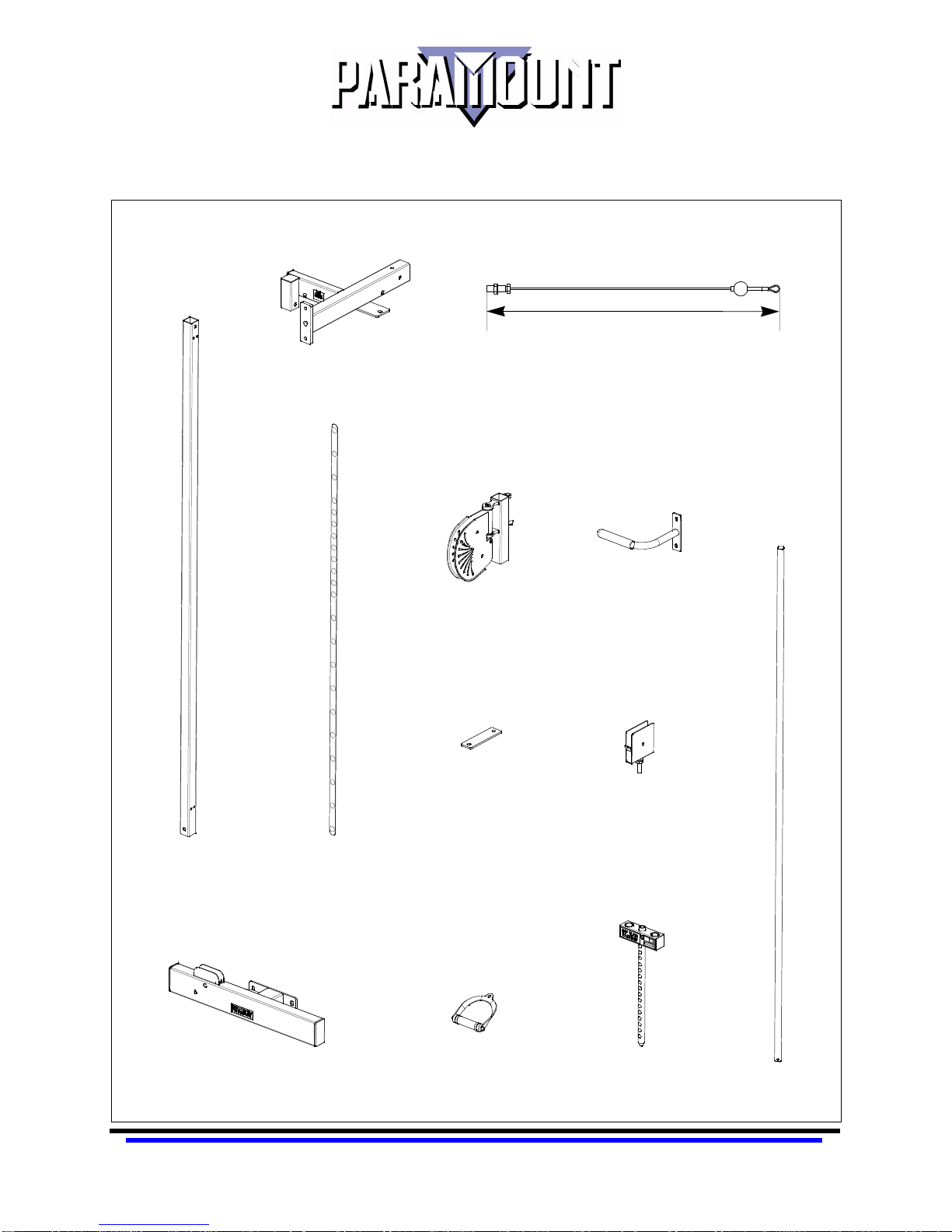

MS-1050 COMPONENTS

LEFT SIDE

(see previous page for right side)

Note: Depending upon the method of shipment, some

of the items that appear may already be assembled

to your machine.

MS1002005X

TOP PULLEY

HOUSING (LEFT)

MS1002030X

ADJUSTABLE PULLEY

(LEFT)

351-1/2 in. (893 cm)

MS1002090

CABLE

MS1002050X

HANDLE

MS1002061

ADJUSTMENT

COLUMN

MS1002015X

BOTTOM PULLEY

HOUSING (LEFT)

B5000

ADJUSTMENT

LABEL

MS8002002

BEAM CONNECTOR

B1100

HANDLE

8 MS-1000 PT1.fm

MS1002020X

CAP PLATE PULLEY

9099780X

SELECTOR BAR

MS8002009X

GUIDE ROD (2)

Loading...

Loading...