MP 3.5 - MP 4.0 LEG PRESS

ASSEMBLY MANUAL

I NNOVATIVE S TRENGTH S YSTEMS

AM-MP-3-4

A MESSAGE TO OUR CUSTOMERS

Thank you for purchasing the Paramount MP Strength Training System. Because of the many

unique features included in this product, this manual was created to provide you with information

on how to properly assemble and maintain your equipment. Proper maintenance will ensure that

your new equipment will last for years.

For your convenience, product questions can be answered by an Authorized Paramount Dealer or

by contacting a Paramount Customer Service Representative at:

1-800-721-2121 or 1-323-721-2121 or nasales@paramountfitness.com

Office hours are M-F 7:30 am - 4:30 pm PST

Paramount Fitness Corporation

6450 East Bandini Blvd.

Los Angeles, CA 90040

IMPORTANT

!

REVIEW THE GENERAL MAINTENANCE MANUAL FOR IMPORTANT SAFETY AND

MAINTENANCE TIPS. THE MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER

AND CAN ALSO BE DOWNLOADED FROM OUR WEBSITE AT:

http://www.paramountfitness.com

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

2

TABLE OF CONTENTS

SAFETY................................................................................................... 4

G

ENERAL CARE AND MAINTENANCE......................................................... 5

REPARATION......................................................................................... 6

P

L

EG PRESS CARTON CONTENTS............................................................... 7

I

NSTALLATION & ASSEMBLY

LP STEP 1: INSTALL THE LEG PRESS CABLE.................................... 9

LP S

TEP 2: ASSEMBLE BASE CONNECTION PIECE............................ 11

LP S

TEP 3: ASSEMBLE LP TO UPRIGHT.......................................... 12

LP S

TEP 4: ASSEMBLE THE LEG PRESS CABLE................................ 13

LP S

TEP 5: ASSEMBLE FOOT PLATE.............................................. 14

LP S

TEP 6: ASSEMBLE THE HANDLES............................................ 15

LP S

TEP 7: ASSEMBLE THE SEAT PADS.......................................... 16

LP S

TEP 8: INSTALL THE LEG EXT/CURL CABLE.............................. 17

P

ROCEDURE LABEL................................................................................. 19

W

ARNING LABELS................................................................................... 20

S

ERVICE................................................................................................. 21

P

ARAMOUNT LIMITED WARRANTY............................................................. 22

3

SAFETY

1. Review and understand all of the warning labels affixed to this machine and on the facility safety

2. Be certain that the machine operation is understood before it is used. Refer to the instruction label

3. Keep children away from this equipment. Supervise use by teenagers.

4. DO NOT high-pin or double-pin the weight stack. DO NOT allow the machine to be used if the top

5. Use ONLY Paramount weight selector pins. Other manufacturer’s pins may work free of the weight

6. Cables: Inspect the entire cable weekly and the end fittings daily. Pay close attention to the area

7. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose, retighten

8. Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any component at first

9. Adjustment Pins: check the function of the position selector pins on the adjustable arms. Make

10. DO NOT attempt to free any jammed assemblies by yourself as this may cause injury.

11. DO NOT use adder weights or adder weight systems on this machine.

12. Instruct Users NOT to make arm position adjustments during exercise or when pulling on the

13. Instruct Users to return the handgrips and bars to their rest position before releasing. Sudden

14. Instruct users NOT to attach two cables to single bars or handles. Use one handle or exercise bar

15. Instruct Users not to wear loose or dangling clothes or have headphone wire hanging when using

16. It is recommended that users receive a thorough medical exam before commencing an exercise

17. Check the function of your machine regularly by verifying the following:

sign. Replace any warning label at first sign of wear. Labels and the Facility Safety Sign may be

obtained from Paramount free of charge.

provided with the machine.

plate or weight stack is pinned in a raised position. Use an assistant and carefully return the

machine to the proper position with the cap plate resting on the top weight. Inspect the cable to

ensure that it is seated in all of the pulleys.

stack causing possible injury. Be certain the pin is completely inserted prior to use.

going over pulleys and to the end connections. Replace all cables at first signs of wear or on an

annual basis. Use only Paramount supplied replacement cables.

and/or use Loctite

signs of wear.

sure that the selector pin inserts completely into each position without binding.

cable end. Always support the arms when making position adjustments.

release of the handgrips and bars may cause serious injury to users or bystanders.

for each weight stack at a time.

this equipment.

program. All medical issues should be reviewed to ensure that weight training will not aggravate

pre-existing medical conditions.

• Cables and end fittings are intact.

• All adjustments are possible and carried out with ease.

™

Threadlocker 242.

• The proper selector pin is in the weight stack.

• The exercise is performed smoothly, free of noise and/or binding.

18. Follow the installation guidelines provided with the products.

19. Retain these instructions for future reference.

20. If you have any questions, do not hesitate to contact your Paramount dealer or Paramount

Fitness Corp. at (800)721-2121 or www.paramountfitness.com.

21. Refer to Maintenance Schedule label on the machine and this manual for when to perform

maintenance.

4

GENERAL CARE AND MAINTENANCE

1. Cable Ends: Inspect end fittings daily for wear. Replace cables at the first sign of wear or

on an annual basis. If the cable tension has been adjusted, be certain that the cable nut

is tight.

2. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose,

retighten and/or use Loctite

3. Frames: Wipe all machines down with a damp cloth and dry completely each day. This

includes painted parts, chrome parts and upholstered pads.

4. Painted and chrome plated parts: Use Simple Green or similar cleaner for light dirt and

grime. Use Turtle Wax Polishing Compound or a good car polish to remove heavier dirt

and grease as well as for polishing. DO NOT use solvents, lacquer thinner, acetone or

finger nail polish remover. For scuffs and marks that are not removed by the above

methods use a soft scrub cleanser. Make sure all parts are dry upon completion.

5. Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

6. Exercise instruction labels: Clean with soap and water as needed.

7. Guide rods: Wipe all dirt and dust from the guide rods before applying a light application

of Tri-Flow

the guide rods with the rag. DO NOT use oil lubricants such as WD-40. Caution: Tri-Flow

will stain carpet and clothing.

TM

or other teflon spray lubricant. Spray the Tri-FlowTM on a rag and then wipe

TM

brand Threadlocker 242.

TM

8. Bronze bushings: Check monthly for signs of wear and replace as needed. Lubricate

monthly with Tri-Flow

9. Please refer to the General Maintenance Manual (part number: AM-GMM) for other

important safety and maintenance information.

10. Hardware and components are indicated with a balloon. Refer to the hardware tables

that accompany each step for corresponding size and type.

11. Be sure all hardware is tight before using the machine.

!

DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion

caused by installation in these locations can lead to premature failure of components.

TM

.

After you have unpacked and inventoried all of the components, read through the

!

remainder of the assembly instructions to familiarize yourself with the assembly

procedure!

Each step will require the components shown in the table associated with the step.

Read the instructions for each step before assembling.

5

PREPARATION

REQUIRED TOOLS

Ratchet Wrench and Sockets:

1/2” , 9/16”, 6” ratchet extension

Wrenches: 1/2” , 9/16” , 7/8” and 15/16”

(or an adjustable crescent wrench).

Rubber mallet.

Hardware Measurement Guide:

12345

MEASURE BOLT

FROM HERE

Allen wrenches:

3 mm, 5 mm, 6 mm, 8 mm,

(included with the machine)

BHCS - BUTTON HEAD CAP SCREW

SHCS - SOCKET HEAD CAP SCREW

FHCS - FLAT HEAD CAP SCREW

HHCS - HEX HEAD CAP SCREW

Before you Begin

!

Hardware and components are indicated with a balloon. Refer to the hardware tables that

accompany each step for corresponding size and type.

Be sure all hardware is tight before using the machine.

6

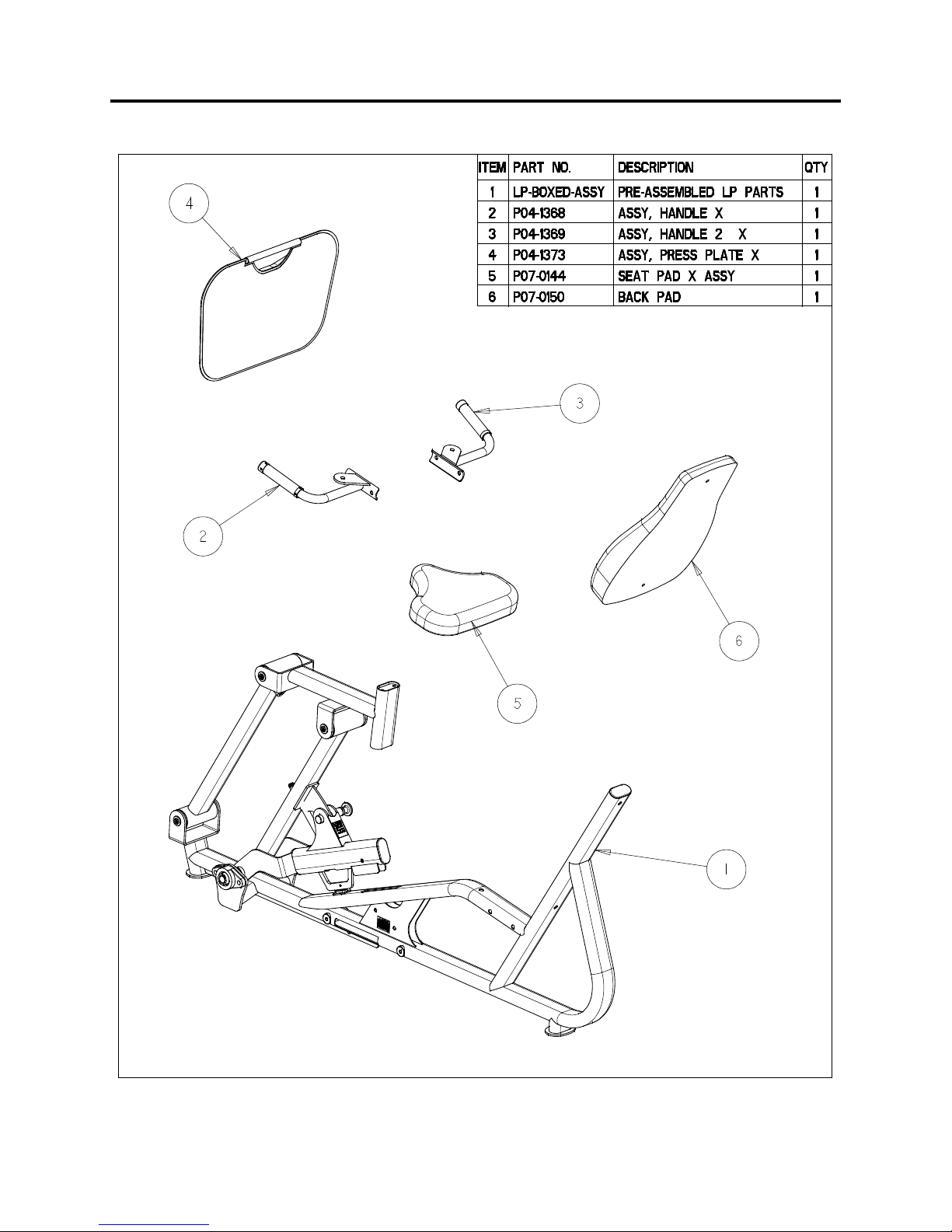

LEG PRESS CARTON CONTENTS

(Carton: MPLPCTN)

7

MP3/4 LEG PRESS KIT CARTON CONTENTS

Tag ged fo r use on ly

on MP3.5 or MP4.0

weight stack.

(Carton: MPLPKIT)

Included in this box:

-All Hardware for MP3.5 and MP4.0 Leg Press.

-Assembly Manual for MP3.5 and MP4.0 Leg Press.

-Weight Stack Labels

8

STOP!

This manual is for the installation of the Leg Press

station on the MP3.5 or MP4.0 only.

Once you have finished this Leg Press installation,

please resume assembly in the MP3.0-MP3.5MP4.0 Assembly Manual on page 46.

Note: Be sure to check which weight stack is

!

assigned to each station. Each weight stack

consists of either (Qty. 16) - 10 lb. weight plates

(Qty. 16) - 15 lb. weight plates.

OR

9

LP STEP 1: INSTALL THE LEG PRESS CABLE

1. Shown on this page is the general

routing of the Leg press cable

(P13-0216). The following pages

show sections in greater detail.

2. This cable routing is identical for

both configurations of the MP3.5.

10

LP STEP 1: INSTALL THE LEG PRESS CABLE

11

LP STEP 2: ASSEMBLE BASE CONNECTION PIECE

1. Route the Leg Press cable through

the Base Connection Assy as shown.

2. Loosely assemble ALL hardware

shown in this step.

3. After aligning all component edges

and surfaces, tighten the hardware.

Be Sure to Tighten

This Bolt.

12

LP STEP 3: ASSEMBLE LP TO UPRIGHT

1. The leg press can be mounted to

two different locations on the

mainframe when the cable column

is not used. See pictures below.

2. Route the Leg Press cable through

the opening in the Upright frame as

shown

3. Loosely assemble ALL hardware

shown in this step.

4. After aligning all component edges

and surfaces, tighten the hardware.

13

IMPORTANT!

The leg press can be mounted

to two different locations.

However, if the cable column

is used, the leg press must be

mounted as in Fig.2.

Fig.2

Fig.1

LP STEP 4: ASSEMBLE THE LEG PRESS CABLE

1. Assemble the Pulleys, Hardware, and

Cable as shown.

2. Install the pulleys and associated

hardware as you go along.

3. Be sure the cable and pulleys can move

freely after installation.

Top of Upright

Frame

Bottom of

Upright Frame

To Weight

Stack

Leg Press

14

LP STEP 5: ASSEMBLE THE FOOT PLATE

1. Assemble the foot plate as shown.

2. Loosely assemble ALL hardware

shown in this step.

3. After aligning all component edges

and surfaces, tighten the hardware.

15

LP STEP 6: ASSEMBLE THE HANDLES

1. Loosely assemble All hardware

shown in this step.

2. Do not tighten the hardware until

the next step.

IMPORTANT !

Do Not Tighten

Hardware Until

Next Step.

16

LP STEP 7: ASSEMBLE THE SEAT PADS

1. Loosely assemble ALL hardware

shown in this step.

2. After aligning all the components,

tighten ALL the hardware. Make

sure to also tighten ALL the

hardware from the previous step.

IMPORTANT !

Make sure to t ighten A L L

the hardware, including

the hardware from the

previous step.

17

LP STEP 8: INSTALL THE WEIGHT STACK

1. Be sure to assemble the shroud

holders, washers and bumpers before

adding weights.

MAX

1” (25mm)

Be sure to assemble

the shroud holders

before the weight

plates.

Make sure sleeve is inserted in the

first hole of the selector bar before

pinning weight plate.

Pin (1) weight plate to

be used as a counter

weight.

18

This is the Procedure

Label required for the

MP 2.0 and MP 2.5. If

this label is missing

or becomes

damaged,

Paramount will

replace it free of

charge.

PROCEDURE LABEL

19

WARNING LABELS

Warning Labels

The following are the Warning labels required for the MP 3.5 and MP 4.0. If any of

these labels are missing or become damaged, Paramount will replace them free of

charge.

Note: these labels are not to scale.

!

WA RN IN G

SERIOUS INJURY CAN OCCUR

ON THIS EQUIPMENT IF THE

CABLES AND THEIR ATTACHMENT COMPONENTS ARE NOT

MG000055

!

WA RNI NG

SERIOUS INJURY CAN OCCUR ON THIS EQUIPMENT IF

THE PIN IS NOT COMPLETELY INSERTED BEFORE USE.

P/N B2065

ASTM F1749

INSPECTED OFTEN. REPLACE

AT FIRST SIGNS OF WEAR.

P/N B2051

MG000057

ASTM F1749

MG000058

If this machine is to be installed in a

public use facility, ASTM F1749

requirements specify that the facility

sign shown to the right is to be

installed in plain view.

If you did not receive the facility sign

with your order, you can obtain one

free of charge from Paramount by

calling 1-800-721-2121.

MD000180

MG000056

BE ALERT!

THE FITNESS EQUIPMENT IN THIS FACILITY

PRESENTS HAZARDS WHICH, IF NOT AVOIDED,

COULD CAUSE SERIOUS INJURY OR DEATH.

PRIOR TO USING THE EQUIPMENT, READ THE WARNING LABELS

AND INSTRUCTION PLACARDS AFFIXED TO EACH MACHINE.

IF YOU ARE UNSURE ON HOW TO USE A MACHINE, SEEK THE

ASSISTANCE OF OUR FLOOR PERSONNEL. WE WILL BE HAPPY

TO INSTRUCT YOU ON HOW TO USE THE EQUIPMENT PROPERLY.

IMMEDIATELY REPORT ANY PIECE OF EQUIPMENT THAT IS NOT

FUCTIONING PROPERLY TO OUR FLOOR PERSONNEL SO THAT

IT MAY BE EVALUATED AND SERVICED PROMPTLY.

DO NOT ATTEMPT TO USE OR FIX ANY PIECE OF EQUIPMENT

THAT IS NOT FUNCTIONING PROPERLY

ASTM F1749-96

20

SERVICE

HOW TO OBTAIN SERVICE

For warranty service, contact an Authorized Paramount Dealer or a Paramount Customer

Service representative at 1-800-721-2121 or 1-323-721-2121. Or by E-mail at

nasales@paramountfitness.com. Before you call, please have the following information

ready.

• Model Number: MP Leg Press

• Serial Number: ________________________

• Date of Installation: ____________________

• A brief description of the problem

The serial number tag is located under the seat on

the Leg Press main frame as shown.

Serial Number

FINAL CHECK

1. If you haven’t already done so, lubricate the guide rods with a teflon spray lubricant.

Paramount recommends using TriFlow

2. Adjust the foot plate through each position. Verify that the adjustment pin inserts freely

into each position and is fully engaged.

TM

brand.

3. Place the selector pin into the holder on the cap plate. Push the foot plate out slowly

until the assembly cannot move any further. Verify that the cable moves freely, without any

binding.

4. Verify that the selector pin can be inserted into each weight plate.

5. Perform the exercises on each station to verify the cable routes smoothly and the

machine operates correctly.

21

PARAMOUNT LIMITED WARRANTY

Paramount warrants to the original purchaser from a Paramount authorized dealer that

Paramount equipment or equipment from a Paramount authorized manufacturing contractor will be

free from defects in material and workmanship under normal use and service for the following periods

and in the following respects:

LIFETIME WARRANTY - Welds, Weight Plates and Guide Rods

FIVE YEAR WARRANTY - Bronze Bushings, Sealed Rotating Bearings and Pulley Wheels

ONE YEAR WARRANTY - Cables, Linear Bearings, Linear Shafts and all other components not

mentioned elsewhere in this warranty

NINETY DAY WARRANTY - Upholstery and Grips

This limited warranty DOES NOT cover and no warranty is given with respect to:

• Products not manufactured by Paramount

• Products which are altered without the express written consent of Paramount

• Products purchased other than directly from Paramount or through a Paramount

Authorized Dealer.

All warranty periods begin to run from the date of delivery to the original purchaser. The

obligation of Paramount under this warranty is limited to repairing or replacing warranted defective

parts, as Paramount may elect, at Paramount's plant in Los Angeles, California, without charge to

purchaser for either parts or labor. Purchaser is responsible for all transportation and insurance costs

on returned or replaced equipment to and from Paramount's plant in Los Angeles.

ANY IMPLIED WARRANTY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE AND THE IMPLIED WARRANTY OF MERCHANTABILITY, IS

LIMITED TO ONE YEAR DURATION FROM THE DATE OF DELIVERY TO THE ORIGINAL PURCHASER.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU. THE REMEDY OF REPAIR AND REPLACEMENT IS THE

EXCLUSIVE AND SOLE REMEDY OF THE PURCHASER. PARAMOUNT SHALL NOT BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL DAMAGES OF ANY KIND, INCLUDING, BUT

NOT LIMITED TO, DAMAGE OF LOSS OF OTHER PROPERTY OR EQUIPMENT AND LOST PROFITS OR

REVENUE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

No action for breach of this written limited warranty or an implied warranty shall be

commenced more than one year after the accrual of the cause of action. This written limited warranty

is the complete, final and exclusive agreement of the parties with respect to the quality or

performance of the goods and any and all warranties and representations. No modifications of this

limited warranty or waiver of its terms shall be binding on either party unless approved in writing by an

authorized corporate officer of Paramount. This limited warranty gives you specific legal rights, and

you may also have other rights which may vary from state to state. Contact Paramount Fitness Corp.,

6450 E. Bandini Blvd., Los Angeles, California 90040-3185, for a list of authorized dealers or before

returning any defective equipment. Paramount Fitness Corp. © 2005

6450 E. BANDINI BLVD., LOS ANGELES, CA 90040-3185 USA

PARAMOUNT FITNESS CORPORATION

22

NOTES

23

Phone: 1-323-721-2121 Fax: 323-724-2000

Paramount Fitness Corporation

6450 E. Bandini Blvd.

Los Angeles, CA 90040-3185

1-800-721-2121

www.paramountfitness.com

AM-LP-3-4.fm

REV:11/3/06

Loading...

Loading...