The Paramount Robotic Telescope System

User Guide

Paramount ME II, MYT, MX, and MX+ models

Revision 1.94 August, 2015

Copyright 2015 Software Bisque, Inc. All rights reserved.

Paramount User Guide

Information in this document is subject to change without notice and does not represent a commitment

on the part of Software Bisque. The software products described in this document are furnished under a

license agreement or nondisclosure agreement. They may be used or copied only in accordance with the

terms of the agreement. It is against the law to copy the software on any medium except as specifically

allowed in the license or nondisclosure agreement. The purchaser may make one copy of the software

for backup purposes.

No part of this manual and/or databases may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including (but not limited to) photocopying, recording, or information storage

and retrieval systems, for any purpose other than the purchaser's personal use, without the express

written permission of Software Bisque, Inc.

Software Bisque

862 Brickyard Circle

Golden, CO 80403-8058

USA

Web Site: http://www.bisque.com

The Paramount ME, Paramount ME II, Paramount MX, Paramount MX+, Paramount MYT, Bisque TCS, MKS

4000, MKS 5000, and TheSkyX Professional Edition Astronomy Software are trademarks of Software

Bisque, Inc.

All other product names are trademarks of their respective owners and are used solely for identification.

2 | P a g e

Paramount User Guide

Table of Contents

Telescope Operation Disclaimer ................................................................................................................... 8

Sun Warning .................................................................................................................................................. 8

The Paramount Robotic Telescope System .................................................................................................. 9

Paramount Model Comparison ............................................................................................................... 12

Optional Accessories ............................................................................................................................... 14

Getting Help ................................................................................................................................................ 15

What You Need to Know ............................................................................................................................. 15

Coordinate Systems ................................................................................................................................ 16

The Horizon Coordinate System ......................................................................................................... 16

The Equatorial Coordinate System ..................................................................................................... 17

Hour Angle .......................................................................................................................................... 18

Local Sidereal Time ................................................................................................................................. 19

Atmospheric Refraction .......................................................................................................................... 19

Polar Alignment Basics ............................................................................................................................ 20

Homing .................................................................................................................................................... 22

Labeling the Home Position on the Sky Chart ..................................................................................... 23

Physically Marking the Home Position ................................................................................................ 24

Synchronization ...................................................................................................................................... 25

Best Synchronization Practices ........................................................................................................... 26

Step by Step Synchronization ............................................................................................................. 26

Session to Session Pointing Repeatability ........................................................................................... 27

Making Sure Synchronization Is Correct ............................................................................................. 28

The Local Celestial Meridian ............................................................................................................... 29

Maintaining Accurate Time ................................................................................................................. 30

Parking the Paramount ........................................................................................................................... 31

Parking from TheSkyX Professional Edition ........................................................................................ 31

Defining the Park Position ................................................................................................................... 32

Park Position Rules .............................................................................................................................. 32

Audible Control System Feedback ...................................................................................................... 32

Visual Control System Feedback ......................................................................................................... 35

3 | P a g e

Paramount User Guide

Through the Mount Cabling ................................................................................................................ 35

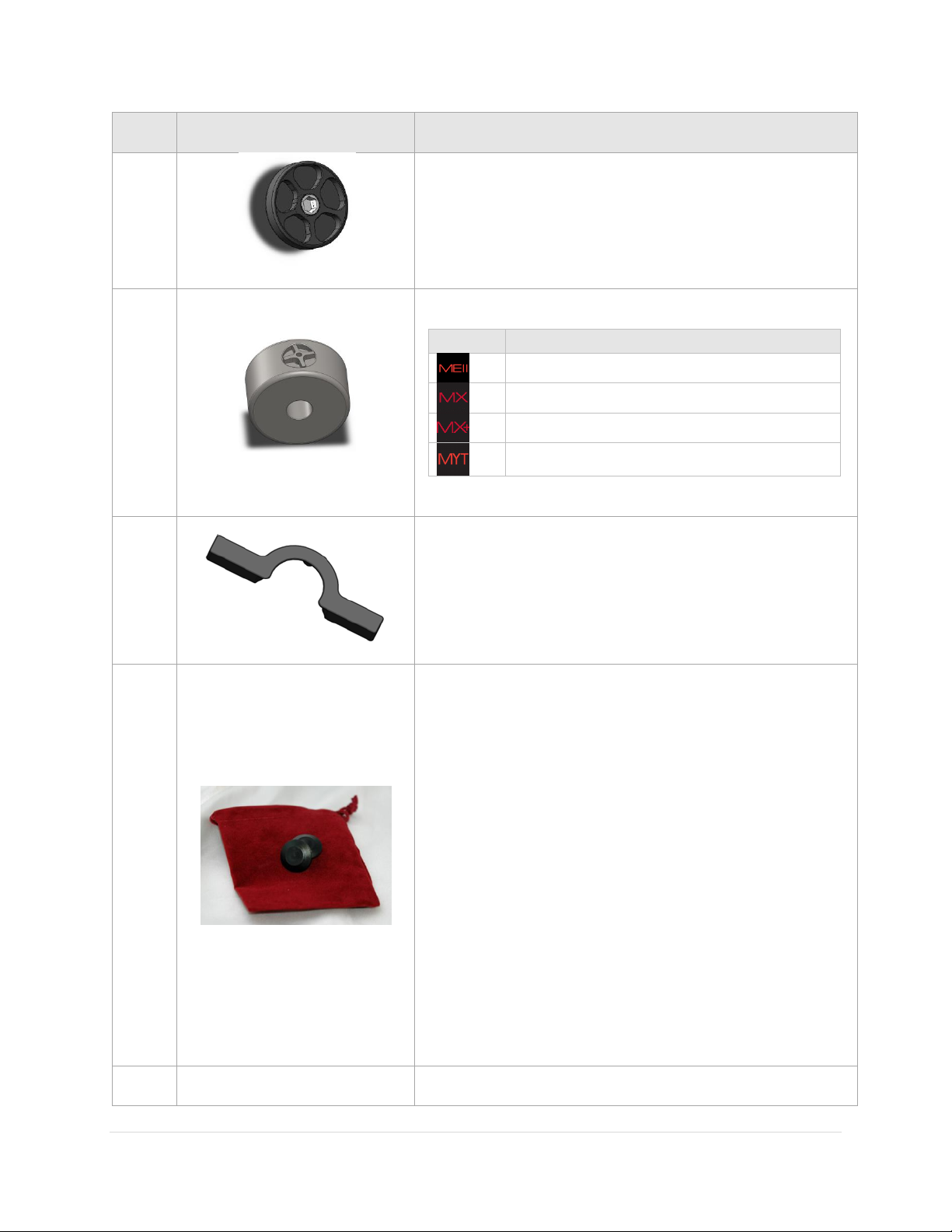

Packing List .................................................................................................................................................. 41

Box 1 Contents ........................................................................................................................................ 41

Important Packing Material Notes ...................................................................................................... 43

Box 2 Contents (Accessories Box) ........................................................................................................... 44

Locating Your Serial Numbers ............................................................................................................. 47

Paramount and Software Serial Number Registration ........................................................................... 48

Unpacking the Paramount .......................................................................................................................... 48

Your Safety is Paramount ........................................................................................................................ 48

Paramount ME II Unpacking Insert ..................................................................................................... 49

Paramount MX Unpacking Insert ........................................................................................................ 50

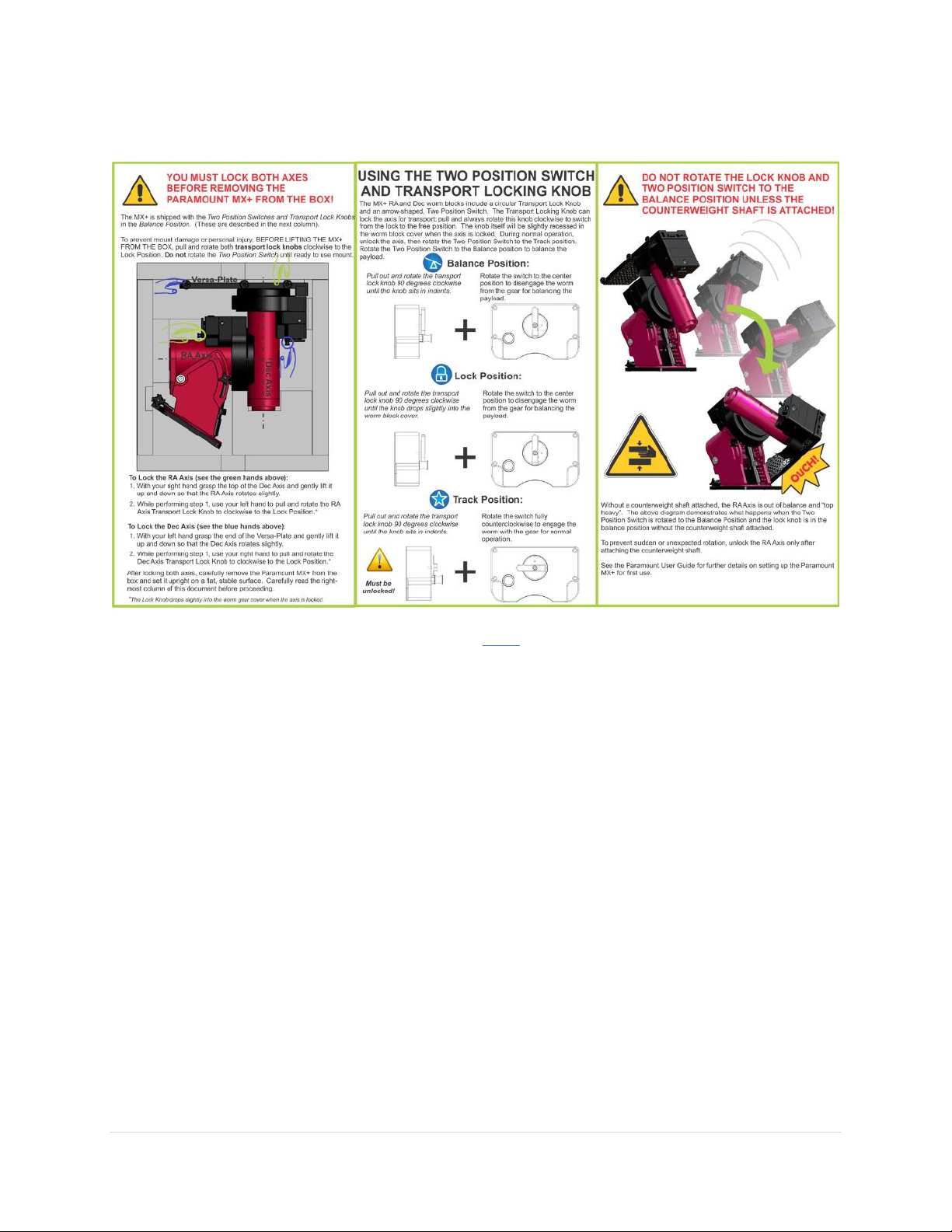

Paramount MX+ Unpacking Insert ...................................................................................................... 51

Paramount MYT Unpacking Insert ...................................................................................................... 52

Packing the Paramount for Transport .................................................................................................... 54

Paramount Components ............................................................................................................................. 55

Paramount ME II Front View ................................................................................................................... 56

Paramount MX Front View ..................................................................................................................... 57

Paramount MX+ Front View ................................................................................................................... 58

Paramount MYT Front View .................................................................................................................... 59

RA Worm Block Cover ......................................................................................................................... 59

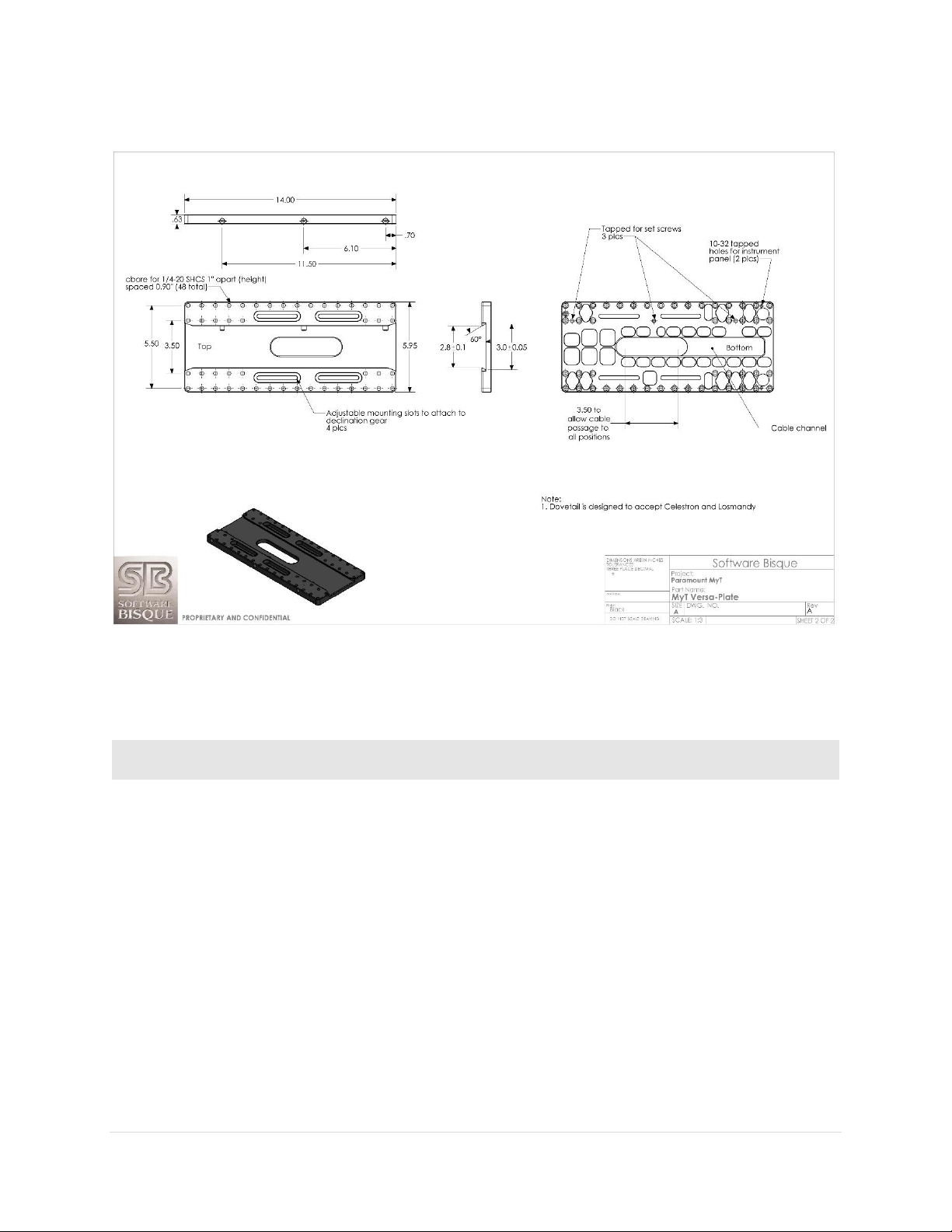

Payload Mounting Plate (Versa-Plate) ................................................................................................ 60

Paramount Versa-Plate Knobs ............................................................................................................ 63

Large Dovetail Accessory Rail (Paramount ME II only, Optional) ....................................................... 68

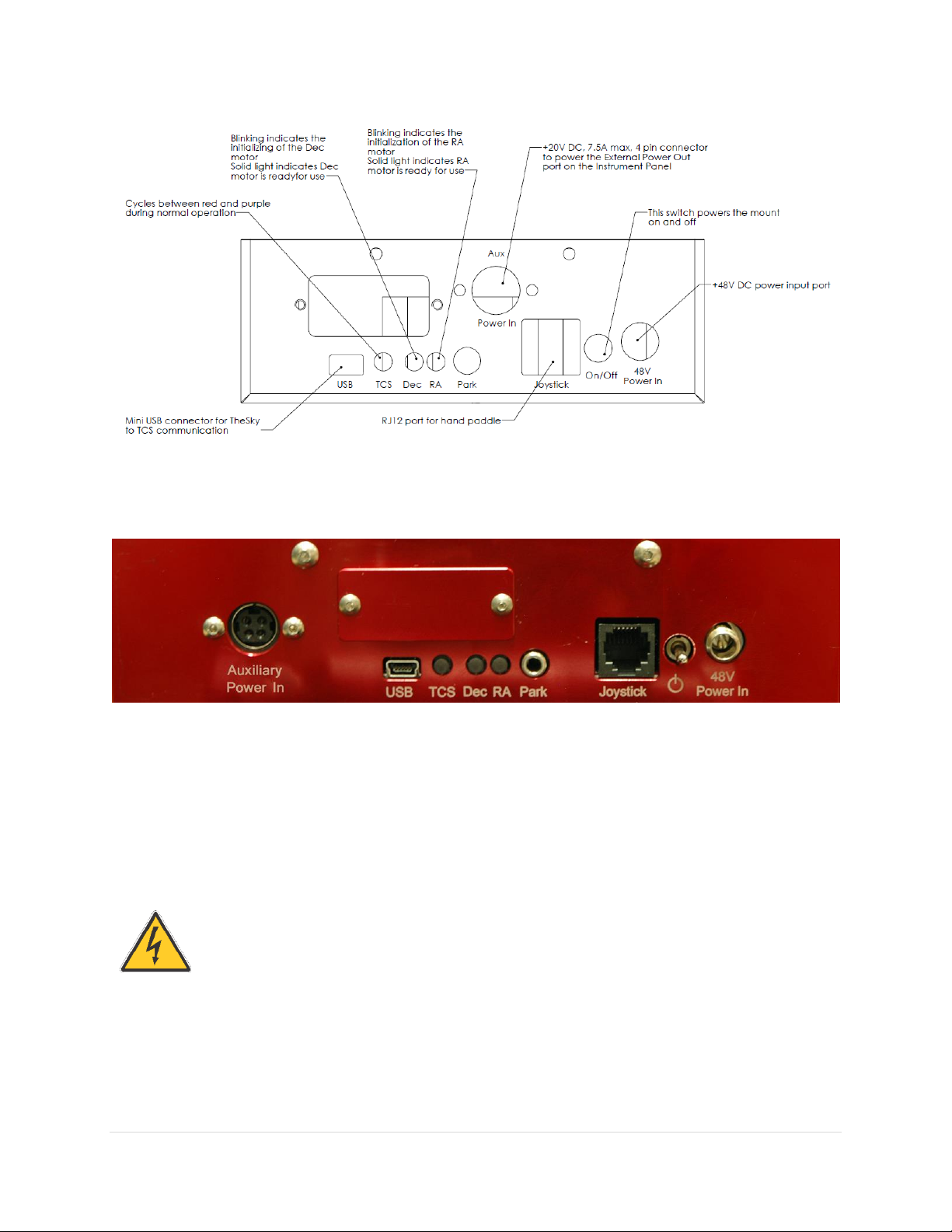

Instrument Panel ................................................................................................................................. 68

RA Worm Block Cover ......................................................................................................................... 72

RA Cable Conduit ................................................................................................................................ 72

RA Gear Cover (ME II Only) ................................................................................................................. 72

Dec Cable Conduit ............................................................................................................................... 72

Right Ascension Carrying Handle ........................................................................................................ 72

RA Worm Block Switch ........................................................................................................................ 73

RA Spring Plunger and Cam Stop Access Hole (Paramount ME II and MX+ Only) .............................. 77

RA Encoder Cover (Paramount ME II Only) ......................................................................................... 77

4 | P a g e

Paramount User Guide

RA Assembly ........................................................................................................................................ 77

Electronics Box .................................................................................................................................... 77

Polar Axis Adjustments ....................................................................................................................... 81

Azimuth Adjuster Knobs ......................................................................................................................... 82

Base Thrust Mounting Knobs .............................................................................................................. 84

Base Plate ............................................................................................................................................ 84

Paramount ME II Rear View .................................................................................................................... 85

Paramount MX Rear View ....................................................................................................................... 86

Paramount MX+ Rear View ..................................................................................................................... 87

Declination Carrying Handle (Paramount MX Only) ........................................................................... 88

Declination Axis Three Position Switch (Paramount MX Dec Three Position Switch) ........................ 88

Cable Conduit Access Hole and Cover ................................................................................................ 88

Right Ascension Axis Locking Hole (Paramount ME II Only) ............................................................... 89

Configurable Hard Stop Positions (Paramount ME II Only) ................................................................ 90

Declination Axis Assembly (Dec Assembly) ......................................................................................... 90

Paramount Serial Number (Serial Number) ........................................................................................ 91

Altitude Scale ...................................................................................................................................... 91

Altitude Adjuster ................................................................................................................................. 93

Counterweight Shaft ........................................................................................................................... 98

Counterweight Shaft Extension Bar (Optional) ................................................................................... 99

Counterweights ................................................................................................................................... 99

Payload Imbalance Cause and Effect ................................................................................................ 101

Balancing the Payload ....................................................................................................................... 101

Counterweight Safety Knob .............................................................................................................. 102

Paramount ME II Side View ................................................................................................................... 103

Paramount MX Side View ..................................................................................................................... 104

Paramount MX+ Side View ................................................................................................................... 105

Altitude Adjuster Thrust Knobs ......................................................................................................... 106

Wedge ............................................................................................................................................... 106

Bubble Level ...................................................................................................................................... 107

Declination Axis Locking Hole (Paramount ME II Only) .................................................................... 108

Micro Levelers (Paramount ME II Only) ............................................................................................ 108

5 | P a g e

Paramount User Guide

Hand Controller ................................................................................................................................. 110

Other Paramount Accessories .............................................................................................................. 111

USB 2.0 Cable .................................................................................................................................... 111

Hex Wrenches ................................................................................................................................... 112

Power Supply Unit (PSU) ................................................................................................................... 112

Altitude Adjuster Wrench (Paramount ME II Only) .......................................................................... 112

How To Polar Align .................................................................................................................................... 112

Rough Polar Alignment Method ........................................................................................................... 113

Step-By-Step Rough Polar Alignment ............................................................................................... 113

Accurate Polar Alignment ..................................................................................................................... 114

Using TheSkyX Pro for Precise Polar Alignment ................................................................................ 114

Using the Polar Alignment Scope ...................................................................................................... 115

The Paramount and TheSkyX Professional Edition ................................................................................... 116

Paramount Minimum System Requirements ....................................................................................... 116

First Time Paramount Setup ................................................................................................................. 117

Paramount USB Driver Installation ....................................................................................................... 117

Mac OS X ........................................................................................................................................... 118

Windows ........................................................................................................................................... 118

Controlling the Paramount with TheSkyX Professional Edition ............................................................ 118

Getting Started with TheSkyX Professional Edition .............................................................................. 119

The Bisque TCS Window ....................................................................................................................... 120

Status Messages (Status Text) .......................................................................................................... 121

Firmware Version and Mount Identifier ........................................................................................... 121

Parameters Tab ..................................................................................................................................... 121

Advanced Parameters ....................................................................................................................... 124

Commands Pop-up Menu ................................................................................................................. 131

Show Status Tab .................................................................................................................................... 135

Periodic Error Correction Tab ............................................................................................................... 137

Bisque TCS PEC Table Tab ................................................................................................................. 138

Compute PEC Curve Tab ................................................................................................................... 140

Collecting and Using Periodic Error Tracking Data ............................................................................... 142

Utilities Tab ....................................................................................................................................... 148

6 | P a g e

Paramount User Guide

Logging Tab ....................................................................................................................................... 164

Using ProTrack™ ....................................................................................................................................... 164

ProTrack Minimum Requirements .................................................................................................... 164

Getting Started with ProTrack .......................................................................................................... 165

Troubleshooting Mount Operation........................................................................................................... 166

USB Hubs and USB Extenders ............................................................................................................... 167

Controlling Multiple USB Devices with USB Hubs ............................................................................. 167

Windows and USB Port Power Settings ............................................................................................ 168

Appendix A: Installing the MKS 5000 USB Windows Driver ..................................................................... 170

Windows USB Driver Installation and Use ............................................................................................ 170

Accessing Windows Device Manager ................................................................................................ 171

Uninstalling the MKS 5000 Driver ..................................................................................................... 172

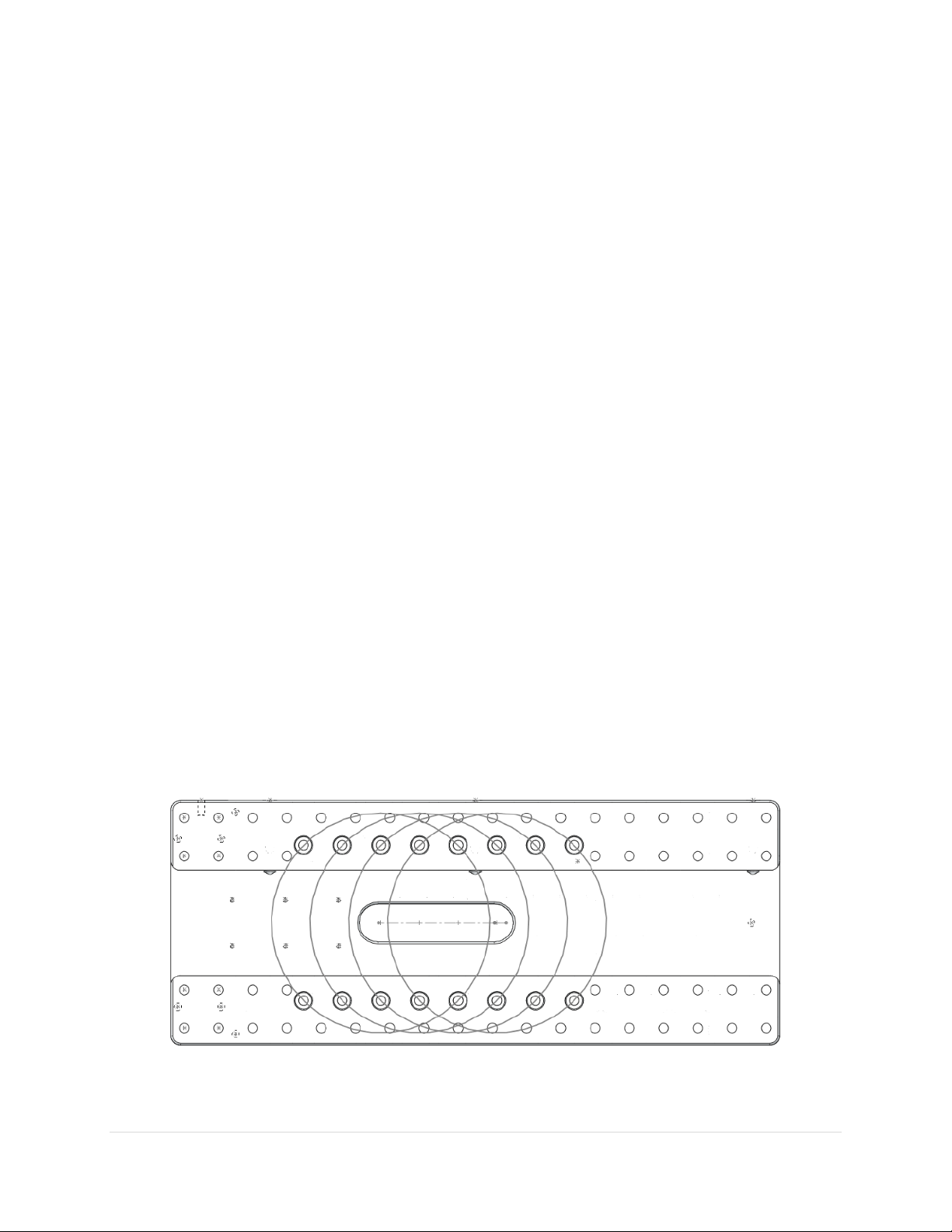

Appendix B: Paramount Technical Drawings ............................................................................................ 174

Computing Dome Offset Distance ........................................................................................................ 175

Appendix C: External Power Cable Sets .................................................................................................... 178

Apogee/QSI/SBIG ST-402/STF-8300 Model Camera External Power Cable Set Specifications ............ 178

SBIG ST-7 Series (5-Pin) External Power Cable Set Specifications ........................................................ 181

SBIG ST-L Series (6-Pin) External Power Cable Specs ............................................................................ 182

Finger Lakes Instruments External Cable Specs .................................................................................... 184

Generic External Power Cable Specs .................................................................................................... 185

Appendix D: Paramount Warranty ........................................................................................................... 187

MKS 5000 Warranty Replacement Procedure and Policy ..................................................................... 187

MKS 5000 Non-Warranty Replacement Procedure and Policy ............................................................. 188

Shipping Address ................................................................................................................................... 188

Appendix E: Revision History .................................................................................................................... 189

Index.......................................................................................................................................................... 192

7 | P a g e

Paramount User Guide

NEVER attempt to observe the Sun through your telescope! Without

a specially designed solar filter, viewing the Sun – for even a fraction of

a second – will cause instant, irreversible eye damage. When observing

during the day, do not point the telescope near the Sun. Do not use

TheSkyX Professional Edition’s automatic slew feature to find objects

during the day.

Telescope Operation Disclaimer

Robotic telescope mounts do not have an unlimited range of movement. The telescope’s shape, the way

it is mounted, or the addition of accessories can prevent it from pointing at particular parts of the sky. If

the telescope is forced past these points, the telescope, its mounting, or accessories might be damaged.

TheSkyX Professional Edition includes telescope limit features that let you define these inaccessible

positions; TheSkyX Professional Edition, or the mount’s control system, will try to prevent the telescope

from entering or crossing them. This feature is provided as a convenience, not as a panacea. Since any

telescope can run into its mechanical limits through accident, carelessness, or component failure,

Software Bisque cannot be responsible for any damage to your telescope that occurs when using TheSkyX

Professional Edition to control it.

Furthermore, Software Bisque cannot be held responsible for damage caused by plugging cables into

electronic devices. We strongly recommend turning off all electronic devices (computers, mobile devices,

telescopes, focusers, dew heaters, CCD cameras, etc.) before attaching any cabling or power supplies.

Sun Warning

8 | P a g e

Paramount User Guide

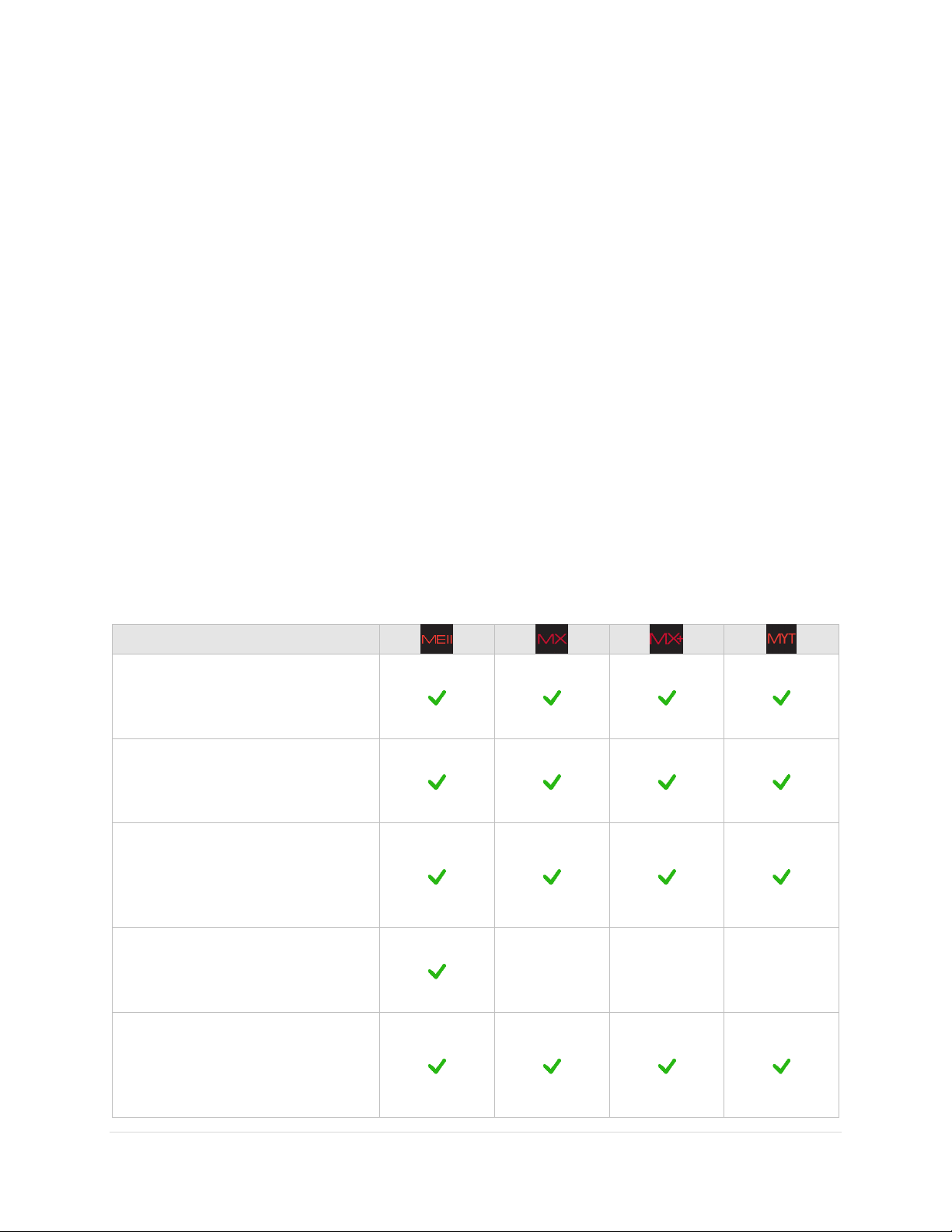

Feature

Software Bisque’s fourth

generation dual axis control system

(MKS 5000™) provides precision,

reliable performance.

Integration with TheSkyX

Professional Edition for Mac or

Windows control.

Camera Add On™ software provides

single software telescope, camera,

focuser, filter wheel, SBIG AO and

rotator control.

Dome Add On™ keeps the

motorized dome aligned with

telescope.

- - -

TPoint Add On™ with Super

Model™ and ProTrack™ provides

the same telescope pointing

correction software that is used on

most professional telescopes.

The Paramount Robotic Telescope System

Thank you for purchasing the Paramount Robotic Telescope System. The Paramount mount is an ultraprecision German equatorial mount (GEM) that is designed to deliver unmatched pointing, tracking and

stability for amateur or professional astronomers in portable or permanent installations. These precision

mechanics, when commanded TheSkyX Professional Edition, create a formidable imaging system that can

help you achieve your most lofty observing goals.

This user guide covers the basic setup and use of the Paramount ME II, Paramount MX, Paramount MX+,

and Paramount MYT model mounts, as well as how to control your mount using TheSkyX Professional

Edition.

This document assumes you are familiar with many fundamental concepts in astronomy and are

somewhat experienced using a telescope and or CCD camera in conjunction with a personal computer.

If a concept presented here is new to you, consider searching the Internet to find out more information

about it. Unfortunately, there is simply no way that all the different facets of setting up and controlling a

robotic telescope mount can be covered in a single document.

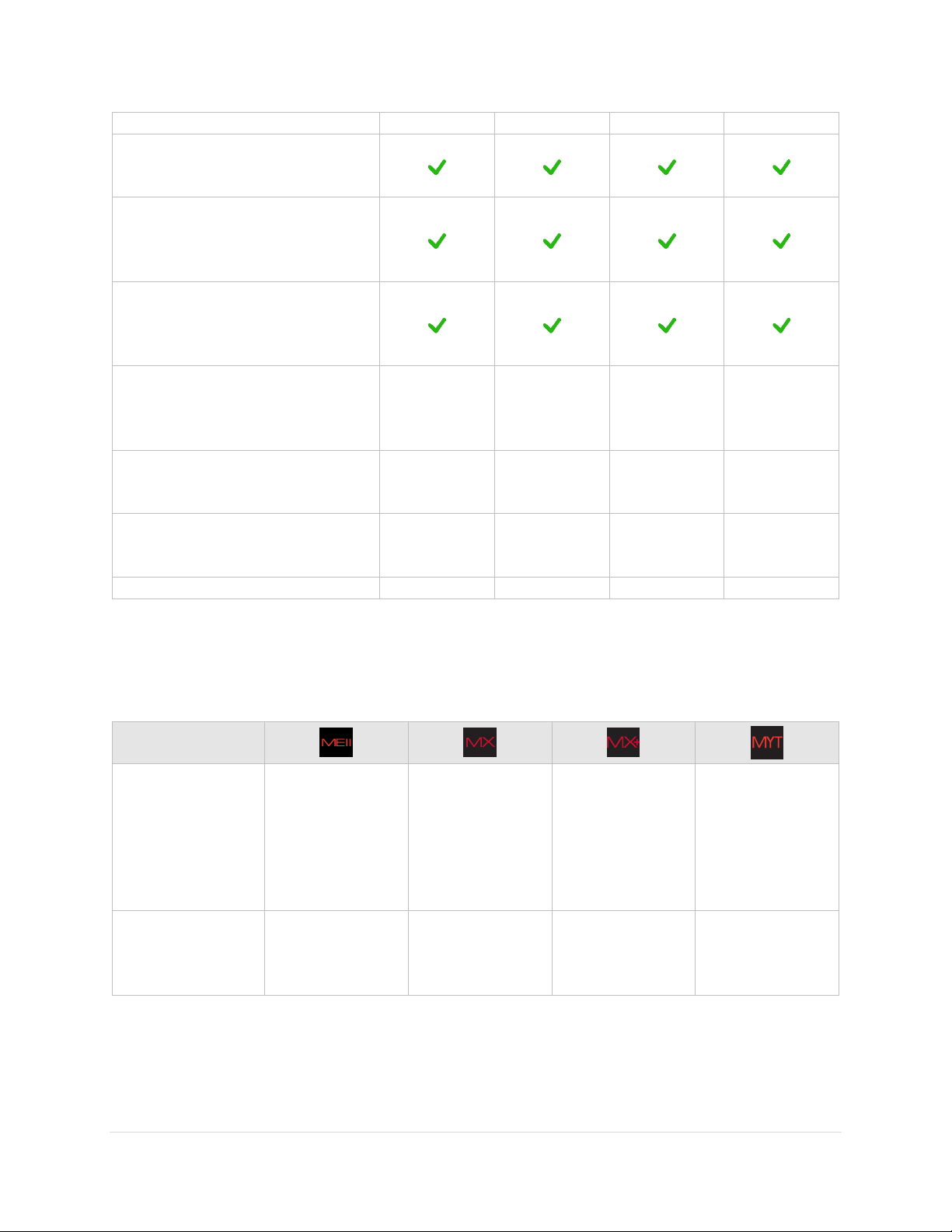

The table below lists the significant Paramount hardware, electronics and software features that are

designed to help foster memorable and productive observing experiences.

9 | P a g e

Paramount User Guide

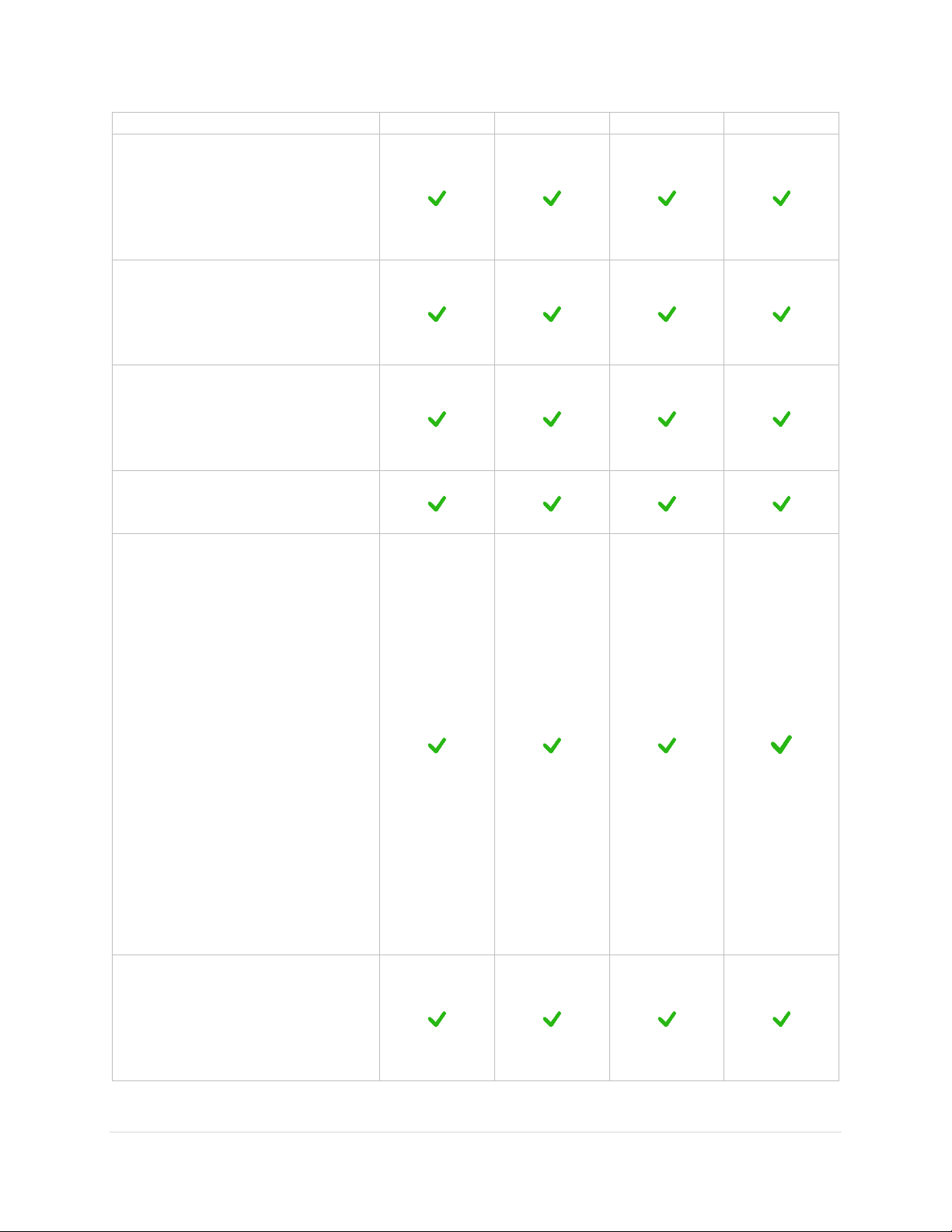

The Multi-OS and Six License Add

On lets you install TheSkyX

Professional Edition and related

Add Ons on up to six (6) different

Mac and Windows computers.

Research-grade right ascension

gears with seven (7) arcsecond or

less peak to peak periodic error

before training PEC.

Optimal periodic error correction

curve fitting that can produce

“seeing indifferent” periodic error

curves.

Direct Guide™ allows optimal

guiding without a guider cable.

Both the right ascension and

declination axes include mechanical

switches to change quickly switch

between balancing the payload and

tracking.

The Paramount ME II’s axes

may be locked in place by

installing locking bolts

(page 89).

The Paramount MX

includes a three position

mechanical switch (page

50).

Each axis of the Paramount

MX+ and Paramount MYT

has two separate

mechanical switches (page

52).

Clutch-free worm block design

preserves the mount’s physical

orientation for accurate and

repeatable TPoint modeled

pointing and tracking.

10 | P a g e

Paramount User Guide

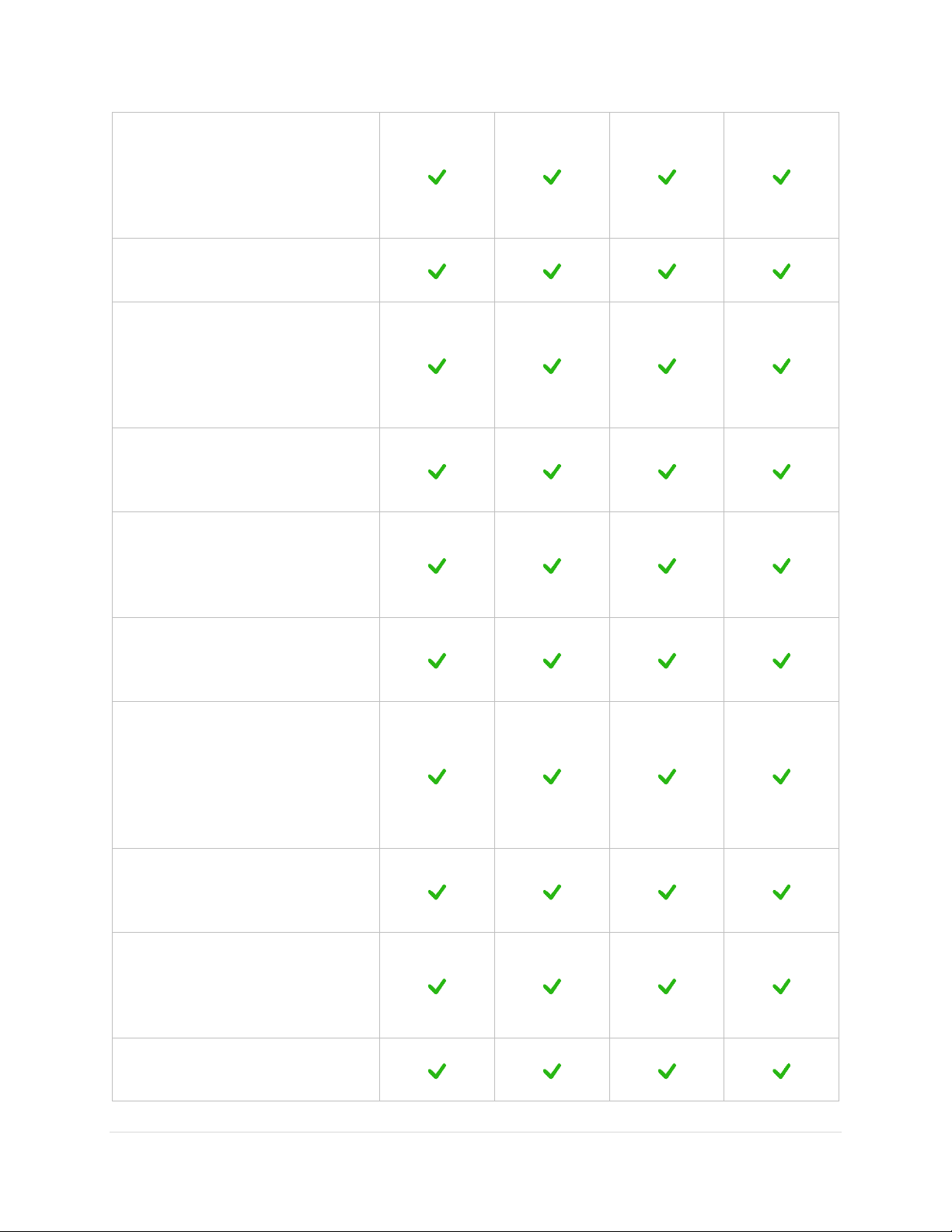

The control system supports a wide

dynamic range for slewing and

tracking rates. Virtually any slew

speed is available between zero

and several degrees per second.

Configurable acceleration and

deceleration rates during slews.

Integrated homing sensors that

allow rapid mount initialization to

produce precision and reliable

repeatability from night to night, or

if power is lost.

Super-stable physical design that

rapidly dampens external

vibrations.

Configurable software slewing

limits prevent damage to the

mount and telescope by slowly

decelerating to limit regions.

Clutch-free design ensures

consistent pointing and tracking

from night to night.

Fifty individual through the mount

cabling conductors that help

minimize the tedium of having CCD

power, CCD signal, focus, video,

dew heater, and other accessory

cables routed to the telescope.

Integrated Cable Conduit™ allows

adding custom cables, wires

through the mount.

Integrated rotating base allows

calibrated azimuth adjustments to

be made without affecting the

mount’s altitude.

Integrated altitude scale to provide

an accurate altitude starting point

for polar alignment.

11 | P a g e

Paramount User Guide

Feature or

Specification

Maximum payload

capacity (total

instrument

capacity not

including

counterweights)

109 kg/240 lb.

41 kg/90 lb.

45 kg/100 lb.

23 kg/50 lb.

Physical

dimensions

See technical

drawing

references on

page 174.

See technical

drawing

references on

page 174.

See technical

drawing

references on

page 174.

See technical

drawing

references on

page 174.

Structural design is extremely rigid,

even at maximum payload capacity.

Landing lights under the mount can

be turned on to illuminate dark

working areas during setup.

Two counterweights and one

counterweight shaft included

standard.

Oversized right ascension and

declination bearings provide

maximum stability.

20.3 cm

(8 in.)

15.2 cm

(6 in.)

15.2 cm

(6 in.)

11 cm

(4.3 in.)

Integrated equatorial wedge for

polar axis altitude adjustment.

14° – 68°

10° – 65°

10° – 65°

0° – 64°

High total instrument capacity to

mount weight ratio.

109 kg/38 kg

(240 lb./84

lb.)

41 kg/23 kg

(90 lb./50 lb.)

45 kg/23 kg

(100 lb./50

lb.)

23 kg/15.4 kg

(50 lb./34 lb.)

Power supply included with mount.

200W max

80W max

80W max

80W max

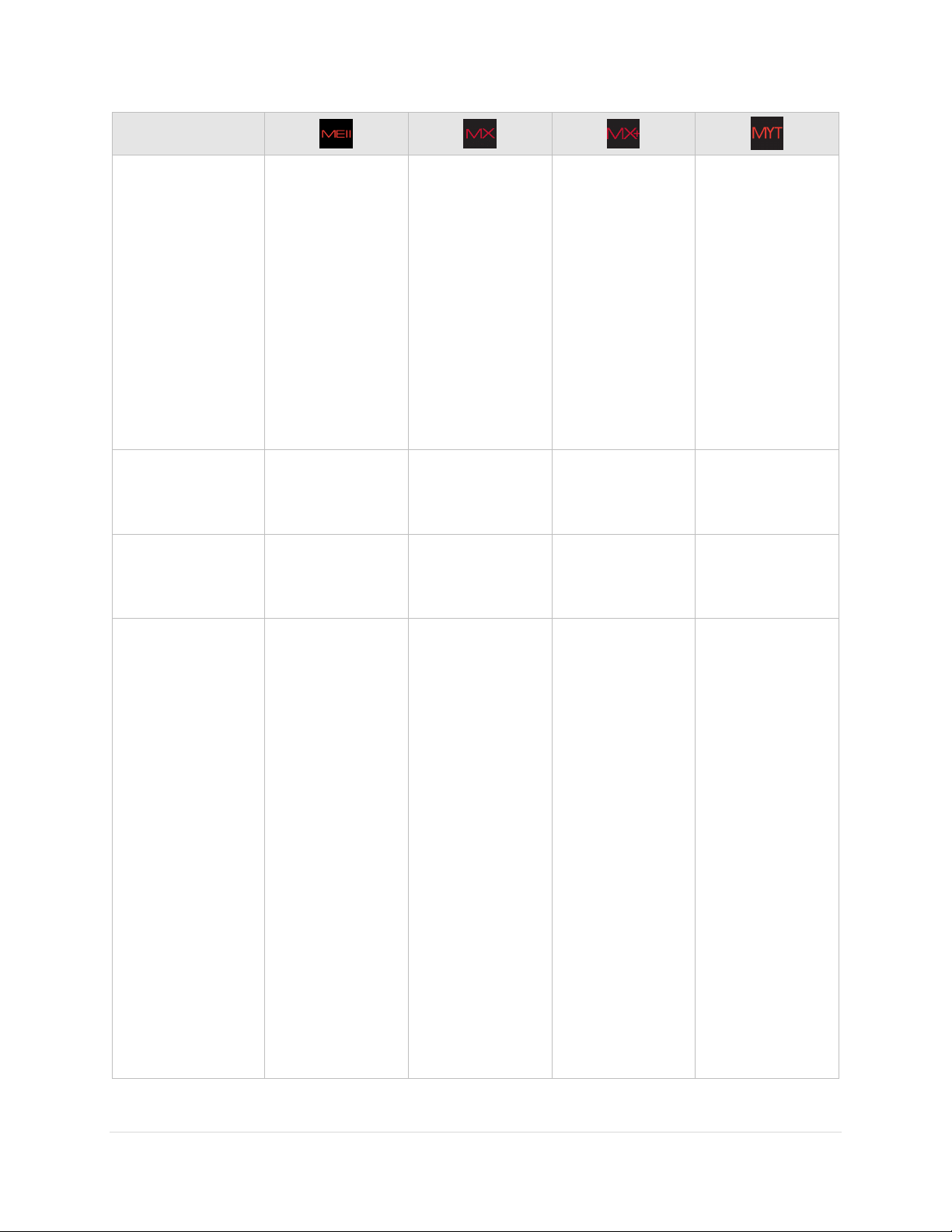

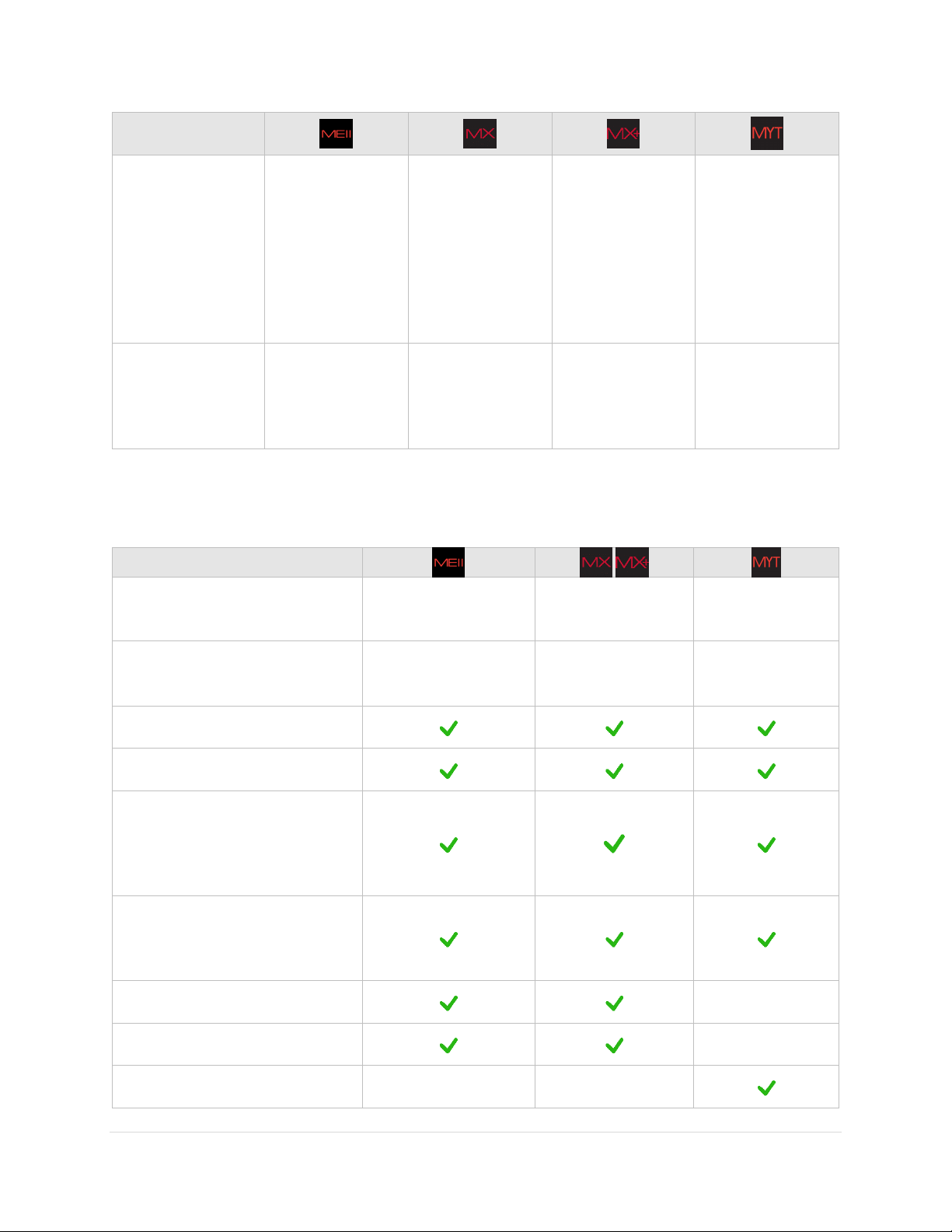

Paramount Model Comparison

The Paramount ME II, Paramount MX and Paramount MX+ are very similar in function and design. The

table below lists the “significant” differences between these models.

12 | P a g e

Paramount User Guide

Feature or

Specification

Versa-Plate

dimensions and

optional mounting

accessories (page

60)

25 cm x 51 cm x

2.5 cm

(9.9-in. x 20-in. x

1.0-in)

Four dovetail

mounting

knobs.

Optional

mounting

rails for

attaching

large OTAs.

16 cm x 41 cm x

1.8 cm

(6.4-in. x 16-in x

0.72 in.)

Three

dovetail

mounting

knobs.

16 cm x 41 cm x

1.8 cm

(6.4-in. x 16-in x

0.72 in.)

Three

dovetail

mounting

knobs.

15 cm x 35.6 cm x

1.6 cm

(5.95-in. x 14-in x

0.63 in.)

Three

dovetail

mounting

knobs.

Number of Altitude

Adjuster Thrust

Knobs (page 106)

Four (4)

Two (2)

Two (2)

Two (2)

Routing custom

cabling through

the mount

See “Through the

Mount Cabling”

on page 35 for

details.

See “Through the

Mount Cabling”

on page 35 for

details.

See “Through the

Mount Cabling”

on page 35 for

details.

See “Through the

Mount Cabling”

on page 35 for

details.

Mechanical switch

on right ascension

and declination

axes (page 73)

The Two Position

Switch engages

the worm with

the gear, or

permits payload

balance by

separating the

worm from the

gear.

The right

ascension and

declination axes

can be locked in

place for

transport, or

when adding

payload, by

installing two

locking bolts on

each axis.

The Three

Position Switch

engages the

worm with the

gear, permits

payload balance

by separating the

worm from the

gear, or locks the

gears to prevent

axis rotation

during shipment

or transport.

The Two Position

Switch engages

the worm with

the gear, or

permits payload

balance by

separating the

worm from the

gear.

The

Transportation

Lock Knob can be

placed in a lock or

balance position

for transportation

or adding payload

by pulling and

rotating a

mechanical

switch 90 degrees

for each axis.

The Two Position

Switch engages

the worm with

the gear, or

permits payload

balance by

separating the

worm from the

gear.

The

Transportation

Lock Knob can be

placed in a lock or

balance position

for transportation

or adding payload

by pulling and

rotating a

mechanical

switch 90 degrees

for each axis.

13 | P a g e

Paramount User Guide

Feature or

Specification

Physical hard stops

that permit

tracking past the

meridian without

the optical tube

assembly flipping

sides

Configurable.

Five different

positions, located

at a minimum of

seven minutes to

up to two (2)

hours past the

meridian.

Fixed, nonconfigurable hard

stop position that

allows a

maximum of two

(2) hours tracking

past the

meridian.

Fixed, nonconfigurable hard

stop position that

allows a

maximum of two

(2) hours tracking

past the

meridian.

Fixed, nonconfigurable hard

stop position that

allows a

maximum of two

(2) hours tracking

past the

meridian.

Base Plate Micro

Levelers

See “Micro

Levelers

(Paramount ME II

Only)” on page

108.

Not available.

Not available.

Not available.

Optional Accessory

Counterweight Shaft Extension

Bar

8-in. long, 1.875-in.

wide

8-in. long, 1.5-in.

wide

Not available.

Counterweights

14 kg/30 lb.

18 kg/40 lb.

1.875-in. bore

9 kg/20 lb.

4.5 kg/10 lb.

1.5-in. bore

9 kg/20 lb.

4.5 kg/10 lb.

1.5-in. bore

Software Bisque Permanent Pier

48V 5AH Portable Power Supply

Power supply cables to use in

conjunction with the mount’s

built-in through the mount

power cabling (page 177)

Base to Pier Adaptor Plate for

mounting the Paramount to an

existing pier

Polar alignment scope, mounting

hardware, and cover

Not available.

Pyramid™ Portable Pier

Not available.

Paramount Mighty Tripod

Not available.

Not available.

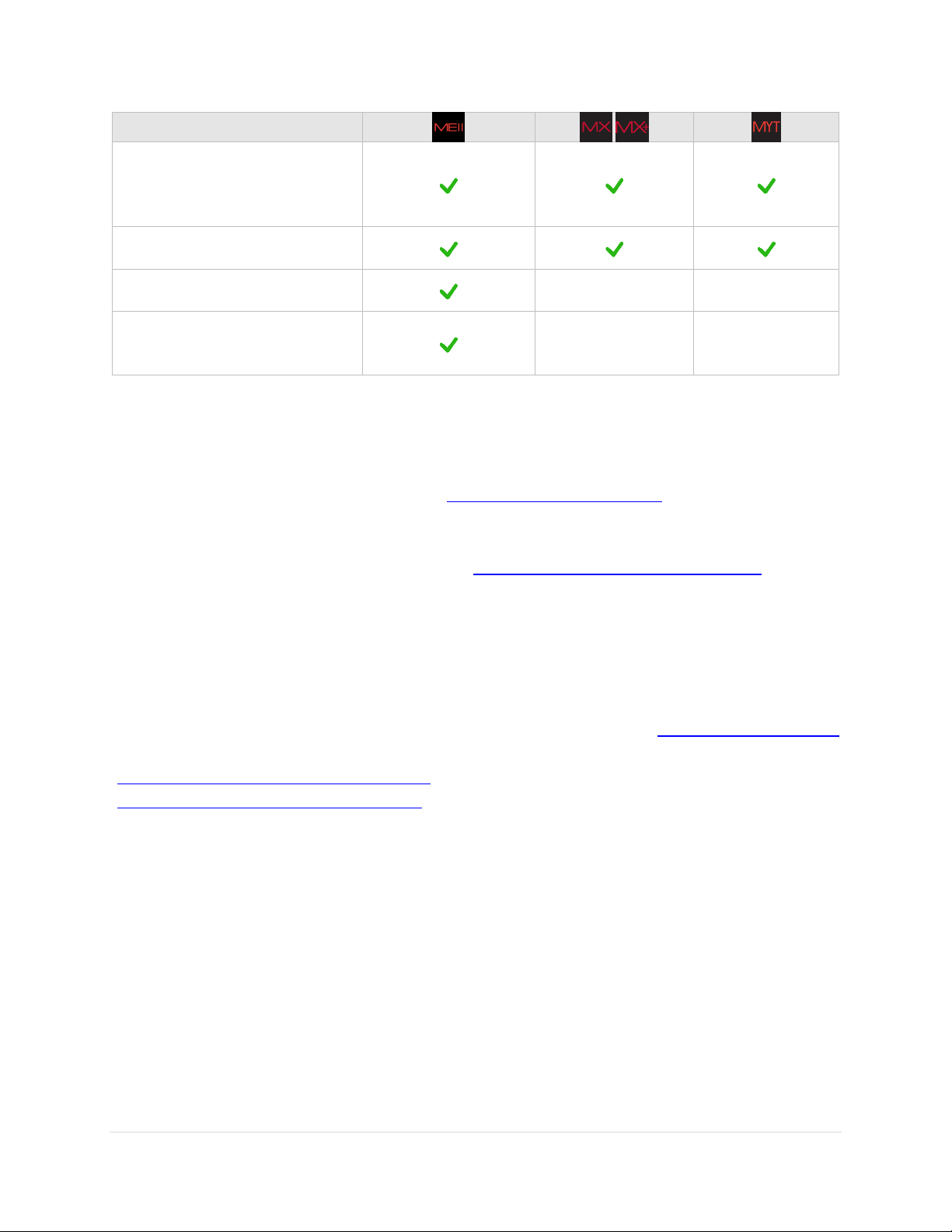

Optional Accessories

The table below lists optional accessories for each model.

14 | P a g e

Paramount User Guide

Optional Accessory

Latitude Adjustment Wedge for

use below 10 degrees and above

about 64 degrees latitude

WiSky Wi-Fi Control

Absolute Encoders

Not available.

Not available.

Versa-Plate Spacers

Not available.

Not available.

Optional Software Add Ons and Databases

TheSkyX Professional Edition offers additional software Add Ons and astronomical databases.

For imaging system’s housed inside an automated astronomical dome, consider the optional

TheSkyX Professional Edition Dome Add On (http://www.bisque.com/dome) to automatically keep

the dome aligned to, and track with the mount. (The Dome Add On is included with all Paramount

ME IIs shipped after January 2015.)

TheSkyX Professional Edition Database Add On (http://www.bisque.com/DatabaseAddOn) offers

over 200 GB of astronomical catalogs.

Getting Help

If you have questions about your Paramount, please first carefully review the information in this

document. If you still cannot find an answer, please join the Software Bisque at www.bisque.com/support

and click the Write a New Post link on the Paramount ME II Support Forum

(http://www.bisque.com/sc/forums/114.aspx), the Paramount MX/MX+ Support Forum

(http://www.bisque.com/sc/forums/96.aspx), or the Paramount MYT Support Forum to ask your

question. The Software Bisque monitors this forum between 9 a.m. to 4 p.m. Mountain Time MondayFriday and tries to respond to questions within 5 business days (usually faster). Other knowledgeable

community members are there to help outside regular office hours.

What You Need to Know

Successful operation of a Paramount requires a solid understanding of many basic astronomy concepts, a

familiarity with operating a GEM, as well as an understanding TheSkyX Professional Edition.

If you are new to the Paramount, operating a GEM, or just getting into astronomy, please peruse the

following section. Based on years of support feedback, even experienced observers often do not

understand fundamental concepts as they relate to operating a Paramount.

15 | P a g e

Paramount User Guide

What are the differences between right ascension, azimuth and hour angle?

Why does the meridian matter when operating a GEM?

What exactly is synchronization?

What is homing and what does it actually do?

What is mount parking?

How does atmospheric refraction affect mount performance?

Why is polar alignment so important?

In addition to these basic questions, if you have never controlled a robotic GEM with TheSkyX Professional

Edition, please carefully read the following sections and then use TheSkyX Professional Edition’s Telescope

Simulator feature before setting up, connecting to, and operating the Paramount.

Coordinate Systems

The three most common coordinate systems used when working with equatorial mountings are described

below. Making sure you understand the differences between each system now will really help

troubleshooting issues in the future.

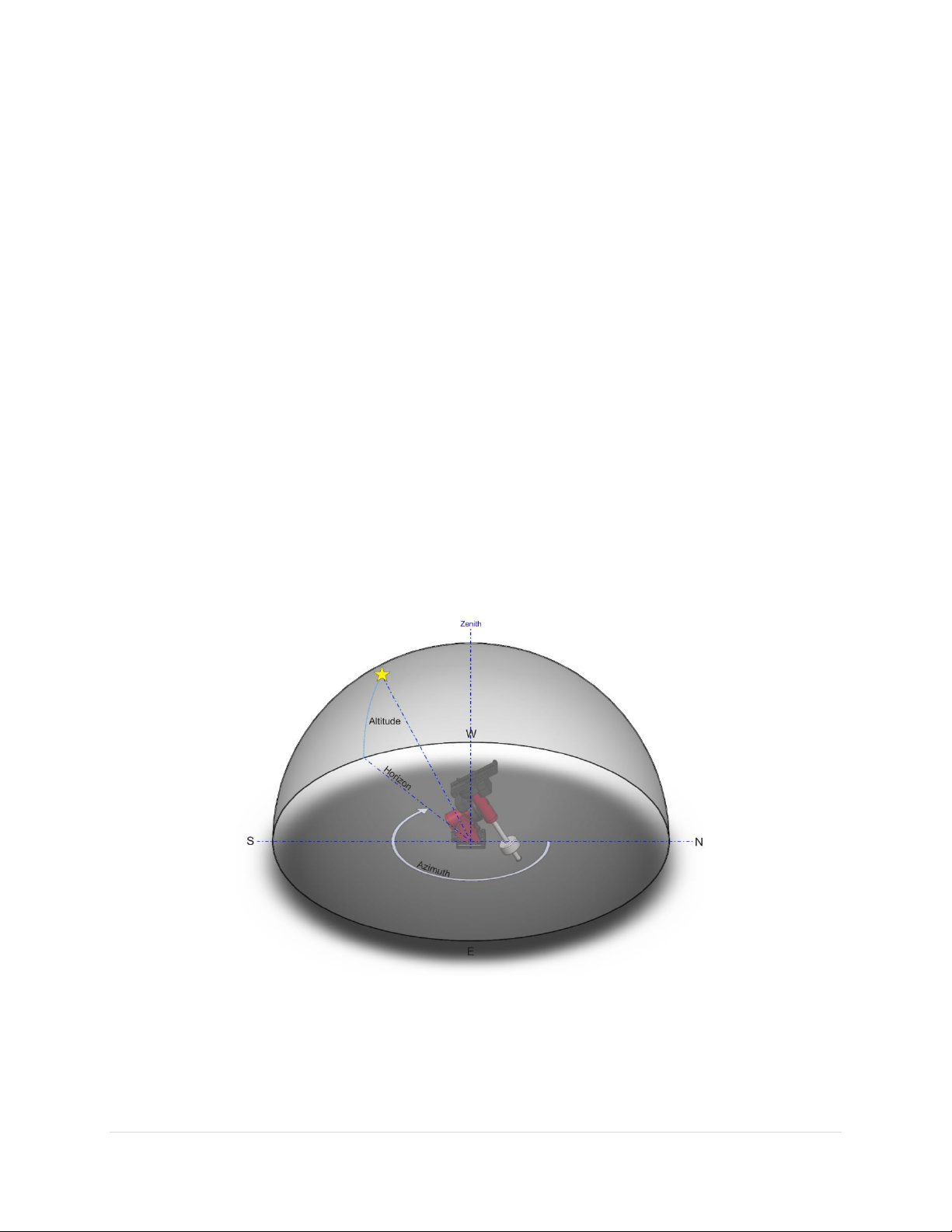

The Horizon Coordinate System

The horizon or “horizontal” coordinate system is used to specify the position of celestial objects relative

to the local horizon.

Figure 1: The horizon-based altitude and azimuth coordinate system.

Altitude

The altitude (alt) of an object is expressed as the number of degrees from the horizon (the ground at a

far distance) to the object, and is always between minus 90 and plus 90 degrees. Objects that have a

16 | P a g e

Paramount User Guide

negative altitude are below the horizon. For example, the Sun just after sunrise is close to the horizon so

it has an altitude of a couple of degrees, and just after sunset its altitude is minus one or two degrees.

Azimuth

The azimuth (az) of an object is generally reckoned from North, increasing in the clockwise direction, and

ranges from 0 to 359 degrees. North is 0 degrees, east is 90 degrees, south is 180 degrees and west is 270

degrees.

When the Paramount is controlled by TheSkyX Professional Edition, attempting to slew the mount below

the local horizon is not permitted and will result in an error message.

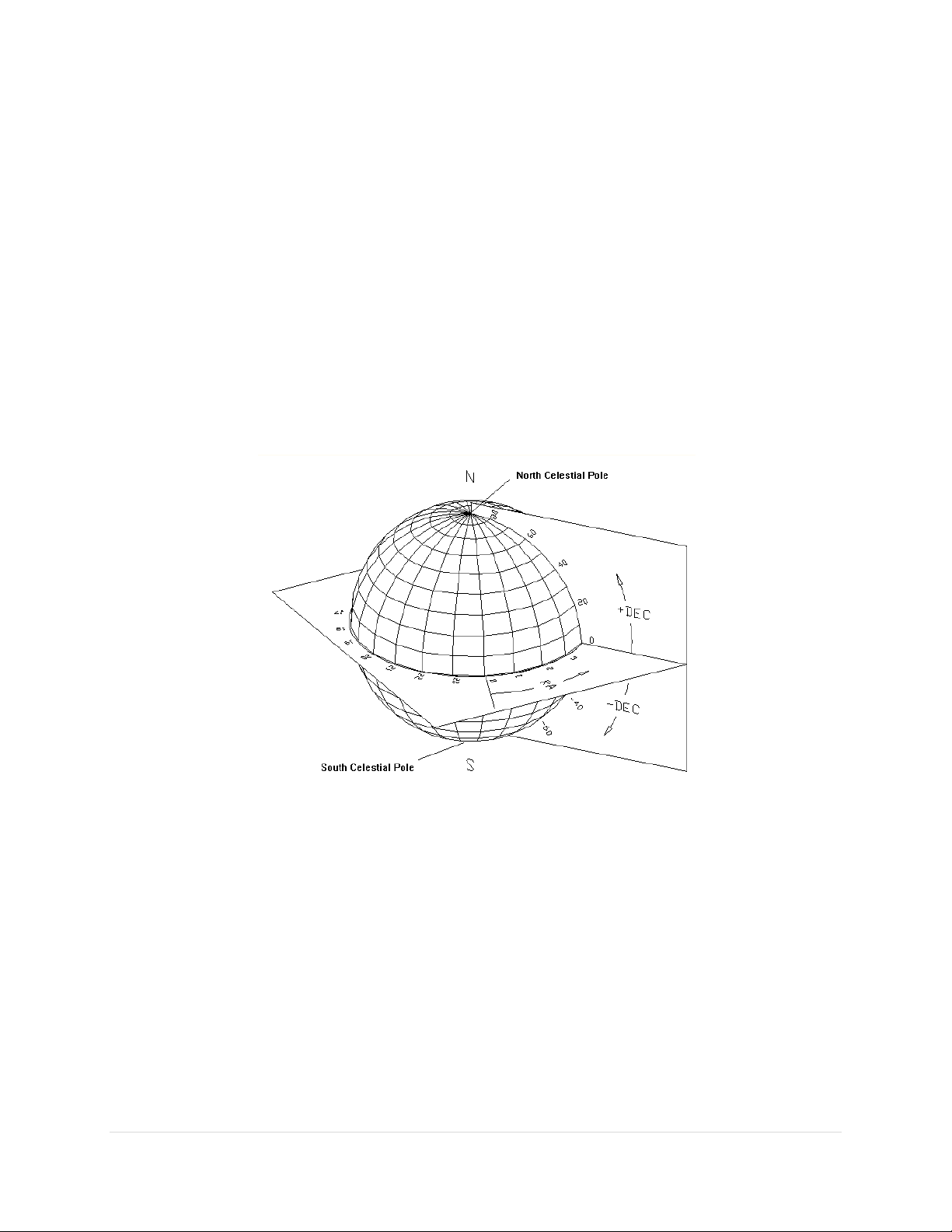

The Equatorial Coordinate System

The horizon coordinate system is not convenient for specifying the location of celestial objects because

the horizon coordinates of stars and other objects are continuously changing with time (due to the

rotation of the Earth).

The exception occurs with objects near the north and south celestial poles. These positions are unique

since they are near to the axis of rotation of the Earth and therefore move only in small circular paths.

Polaris, the North Star, for example, remains at a nearly constant altitude and azimuth. In the equatorial

coordinate system, the coordinates of all celestial objects remain fixed* from hour-to-hour, day-to-day

and so on.

An object's equatorial coordinates remain the same regardless of from where on Earth the object is

viewed. This allows astronomers to create star maps that apply to any place on Earth, or publish the

anticipated position of an upcoming comet so that astronomers everywhere know where it is located

among the stars.

The equatorial coordinate system used to specify the positions of celestial objects is directly analogous to

the latitude-longitude coordinate system used on Earth. In fact, if you were to expand the latitude and

longitude grid of the Earth so that it is out beyond all stars, you would have a sphere with identical

geometry to the celestial sphere.

We suppose that all stars and deep-sky objects are located on a very large sphere (out beyond all stars).

We call this the celestial sphere. For purposes of describing the positions of celestial objects, we consider

all stars and deep sky objects to be on the celestial sphere, when actually they are all positioned at varying

distances from the Earth.

* Equatorial coordinates change over long periods of time due to precession (wobbling of the Earth).

TheSkyX computes this change in stars’ position for the current date. Precession, however, does not

change the relative positions of objects with respect to one another.

17 | P a g e

Paramount User Guide

Right Ascension

The geometry of the right ascension (RA) lines on the celestial sphere is the same as the longitude lines

on Earth. Longitude lines divide the Earth into 360 degrees. Right ascension lines divide the celestial

sphere into 24 hours, based on one revolution of Earth. Therefore one hour of right ascension equals 15

degrees (360 divided by 24). See the definition of Local Sidereal Time for additional information on why

24 hours are used for right ascension instead of 360 degrees.

Zero degrees longitude passes through Greenwich, England and is the designated reference line for

longitude. What, then, is the reference line for zero hour’s right ascension? Astronomers use the vernal

equinox, the location where the Sun crosses the celestial equator during its apparent annual motion

against the background stars, as a "starting point" for right ascension.

The term "right ascension" comes from the fact that when viewed from the equator, all stars rise (or

ascend) at right angles to the horizon, so their times of rising are called their times of right ascension.

Figure 2: Right ascension and declination relative to the celestial sphere.

Declination

The declination (dec) lines on the celestial sphere are similar to latitude lines on Earth, ranging from –90

degrees to +90 degrees. The “declination” of an object is the angle measured from the celestial equator

(0 degrees declination) along a meridian line through the object. Polaris, the North Star has a declination

of just over 89 degrees so it is very close to the north celestial pole.

Hour Angle

Hour angle (HA) is measured from the meridian westward, along the celestial equator and uses the same

units as right ascension (hours, minutes, and seconds). A celestial object on the meridian is located at

hour angle 0. Six hours of time later, the object is located at hour angle +6. Twelve hours later, when the

object rises, its hour angle is –6 h.

18 | P a g e

Paramount User Guide

Hour angle can be used to describe a telescope’s mechanical orientation with respect to a horizon-based

hemisphere. For Paramount mounts with AutoHoming™, when the mount finds home, the home position

is a fixed, mechanical mount orientation. In the northern hemisphere, when homing is successful, the

mount always points to hour angle 2 and declination 0.

Smaller hour angles equate to positions of optimal observing, so your telescope will probably spend a

great deal of the time pointing to and tracking objects near hour angle zero (or, near the meridian).

Note that TheSkyX Professional Edition can be used to configure the Paramount’s “flip hour angle” (page

122) in order to maximize the length of time an object can be tracked past the meridian.

Local Sidereal Time

Local sidereal time (LST) is always equal to the instantaneous right ascension of the local meridian. When

you know the LST, you can look at star maps and determine which objects are near the meridian (those

with a right ascension close to the LST). For example, if the LST is 6:10:00, this means that stars with a

right ascension of about 6 hours are visible along the meridian.

If everyone reckoned time based on the Sun crossing the meridian, then each longitude on earth would

have a different time of day. That means noon, or the time the Sun crosses the meridian, would come a

few minutes earlier for someone living 60 miles to the east. Only those people living at the same longitude

would share a common time.

In the late 1800’s time zones were established to minimize the problem of having different time in

populous regions. The time within these zones is called zone time. Zone time places all locations on Earth

into various time zones. By definition, time zone zero is at zero degrees longitude, and the time zone

increases by one hour every 15 degrees longitude moving east, or decreases by one hour moving west.

The Paramount relies on TheSkyX Professional Edition having the correct time zone for your observing

site. When TheSkyX Professional Edition’s time zone is not correct, the position of the telescope cross

hairs will be offset by the time zone hour error when viewing horizon-based Sky Charts.

Atmospheric Refraction

The effects of atmospheric refraction on the position of celestial objects, as well as its effect on the

sidereal tracking rate, are often overlooked or even ignored by many amateur astronomers.

The refraction nuisance (and other system errors like tube flexure) means the “sidereal tracking rate” is

simply not good enough to precisely track objects. Refraction also displaces the position of the celestial

pole and makes precise polar alignment more difficult.

Some other interesting and significant facts about how refraction affects an object’s apparent position

include:

For a sea-level site, the refraction at 45 degrees zenith distance (ZD) is about 60 arcseconds (one

arcminute).

19 | P a g e

Paramount User Guide

For optimal performance, the equatorial axis of a GEM must be aligned to the refracted pole

to within 100 arcseconds.

If the mount’s equatorial axis is not “closely” aligned with the celestial pole…

Stars will drift in of the field of view, mostly in declination; quickly when polar

alignment is particularly poor.

When you tell TheSkyX Professional Edition where the mount is pointing, through a

process called “synchronization” (page 25), the synchronization results will be

incorrect, or “skewed” by the amount of the polar alignment error. For example, if

the polar axis is ten degrees “low” in altitude, then the resulting synchronization

positions computed by TheSkyX Professional Edition will be off by this same amount

in declination. The result is that the mount will not point with any accuracy or

repeatability.

Except low down in the sky, the refraction goes roughly as the tangent to ZD, so at ZD = 70 degrees,

or, at 20 degrees above the horizon, it is up to 165 arcseconds. (It reaches a 1800 arcseconds, or

0.5 degrees at the horizon.)

Refraction is proportional to pressure, so at high-altitude sites the refraction comes down

significantly. For example at Mauna Kea, 4,205 meters above sea level, the refraction is about 60

percent of the sea level amount.

Refraction is roughly inversely proportional to absolute temperature, so at –5C the refraction is

about 10 percent more than at 20C.

Humidity has little effect in the optical, though it matters a lot at radio wavelengths.

The color of the observed object matters, blue being refracted a few arcseconds more than red

at ZD 70.

When you use your Paramount to take long, unguided exposures at modest or longer focal lengths,

refraction becomes an important source of tracking error that is not taken into account in the standard

sidereal tracking rate.

TPoint can be employed to take care of the atmospheric refraction details for you.

TPoint’s Super Model feature and Polar Alignment Report automatically determines the position

of the refracted pole and give recommendations on how to proceed, including how much to rotate

the altitude and azimuth knobs when adjustment is necessary.

It accounts for and applies refraction when acquiring telescope calibration data as well as corrects

the telescope’s position when the mount is slewed.

TPoint’s ProTrack™ feature can be used to apply tracking corrections to the mount based on the

point calibration data.

Polar Alignment Basics

20 | P a g e

Paramount User Guide

The mount’s “TPoint unassisted pointing accuracy” will be disappointing, especially

when the OTA switches sides of the pier.

These symptoms may make you frustrated with the performance of your Paramount and

leave you wondering, “What am I doing wrong?” Mastering the polar alignment techniques

described below (or using your trusted method) is critical.

Step 1

Use the “Rough Polar Alignment Method” (page 113) to align the mount’s polar axis to

within five arcminutes of the pole, even during daylight.

Step 2

If the pole is visible, and you have a polar alignment scope (page 115), use it to roughly

align the mount to the celestial pole.

-Or-

Use the TPoint Add On to quantify the mount’s polar alignment error. The TPoint Add On’s

Polar Alignment Report indicates exactly how much the altitude adjuster (page 93) and

azimuth adjuster knobs (page 93) need to be rotated so that both axes are aligned to the

refracted pole.

Figure 3: Paramount aligned with the refracted celestial pole in the northern hemisphere.

Software Bisque recommends the following polar alignment methods to ensure efficient and optimal

polar alignment.

See “How To Polar Align” on page 112 for the best ways to achieve optimal polar alignment.

21 | P a g e

Paramount User Guide

Mount synchronization is one of the least understood and most confusing processes for new

Paramount users; understanding exactly what homing a Paramount does is a very close

second. Please carefully read the following to avoid falling into the “my mount is not homing

to the correct position” trap.

The home position is located at hour angle 2 and 0 degrees declination. The

home position is a fixed, mechanical orientation and cannot change; it is

defined by the physical position of the gears relative to fixed internal

homing sensors. See “Physically Marking the Home Position” on page 24

for a simple procedure to demonstrate the mount’s absolute home

position.

If the mount is not physically pointing to approximately hour angle 2 and 0

degrees declination after finding home, then either the Versa-Plate is

mounted incorrectly, the mount’s polar axis is not oriented north-south.

If, after homing is complete, the coordinates of the telescope cross hairs

displayed by TheSkyX Professional Edition indicate that the mount is pointing

anywhere other than the home position, then either TheSkyX Professional

Edition’s location, date, time or time zone is not correct, or the mount has been

synchronized incorrectly. See “Synchronization” on page 25 for more

information.

The Paramount cannot slew and will not track at the

sidereal rate until after the mount is successfully homed.

Homing

Finding the home position, or “homing” the Paramount is an automated initialization process. When the

Paramount control system receives the “find home position command”, the mount’s right ascension and

declination axes are slewed to an absolute, mechanically fixed orientation.

Homing must be performed every time the Paramount is powered on so that the control system can

establish the mount’s position and restore the synchronization information, when possible.

Once the mount is homed, and the previous session’s synchronization information is applied by TheSkyX

Professional Edition, the telescope will know its orientation and have the same pointing accuracy as the

last observing session.

When a Find Home command is issued from the hand controller (by double-tapping the button on the

end of the joystick handle, see page 108 for details) or TheSkyX Professional Edition (page 119), the mount

slews to the home position and zeros the control system’s “position registers”. When the mount is

subsequently synchronized on a star, the computed hour angle and declination of the home indices are

stored in the internal flash of the Paramount’s control system.

22 | P a g e

Paramount User Guide

Subsequent observing sessions use TheSkyX Professional Edition’s local sidereal time to determine the

mount’s equatorial coordinates. Make sure the computer’s clock is accurate (page 29).

Homing provides the following benefits.

Once a mount is aligned with the celestial pole and homed, repeatable and accurate pointing from

night to night can be achieved using TheSkyX Professional Edition and the TPoint Add On.

After homing, the mount “knows” its orientation and therefore cannot be slewed into the pier

(see “Software Slew Limits” on page 159).

The control system’s periodic error correction (PEC) uses this information to calibrate the control

system’s internal PEC table with the orientation of the worm gear.

The mount’s orientation can be restored after power outages or other communication

malfunctions.

The home position can be used to align the polar axis to the celestial pole (see “Rough Polar

Alignment Method” on page 113).

Labeling the Home Position on the Sky Chart

Synchronizing the mount (page 25) on the wrong star or configuring TheSkyX Professional Edition to use

the wrong location, date, time or time zone for your location means the Paramount will be “lost in space”.

The telescope cross hairs will appear in the “wrong” place on the Sky Chart and the mount will apparently

not slew to the correct coordinates when commanded to do so. If the coordinates of the telescope cross

hairs do not match the actual physical orientation of the Paramount, or it does not slew to the correct

coordinates, you will be scratching your head wondering what is wrong. The next step is to post a support

question asking, “Why is my mount pointing to the wrong coordinates?”

For this reason, Software Bisque strongly recommends creating a label that shows the location of the

mount’s absolute home position (page 149) directly on the Sky Chart to provide a constant visual reminder

of where the telescope cross hairs must be after finding home.

If, after homing the mount, the telescope cross hairs do not end up very near hour angle 2 and declination

0 (or hour angle –2.0, declination 0 in the southern hemisphere), either TheSkyX Professional Edition’s site

information is wrong or the mount has been synchronized on the wrong star.

Remember, the absolute home position of the Paramount cannot change. So, if the mount’s relative home

position is wrong (or the telescope cross hairs do not appear in the correct location on the Sky Chart),

please double check the synchronization (page 25) and TheSkyX Professional Edition’s location, date and

time settings for your location before submitting a support request.

To Label the Home Position in Software

The following procedure assumes this is a first time mount synchronization.

1. From TheSkyX Professional Edition, choose the Location command from the Input menu and make

sure the settings on the Custom tab match your observing site.

2. Choose the Verify TheSkyX Time command from the Tools menu to make sure you computer’s

time matches an independent time source.

23 | P a g e

Paramount User Guide

3. Choose the Connect command from the Telescope menu. The mount Status text will show Not

Homed.

4. Choose the Find Home command from the Start Up pop-up menu on the Telescope window. The

mount will slew to the home position. The mount Status text will show Not Synced.

5. Choose the Turn Tracking Off command from the Tools pop-up menu on the Telescope window.

Turn tracking off to pin the mount to this position.

6. Choose the TPoint Add On command from the Telescope menu.

7. Then turn off the Apply Pointing Corrections checkbox on the Setup tab and click Close. TPoint

will change the position of the telescope cross hairs based on the current model and we want the

label to show the “unmodeled” cross hair position.

8. Click on the center of the telescope cross hair and note the exact altitude and azimuth of this

position. This is the horizon-based coordinate of the home position.

9. Choose the My Chart Elements command from the Input menu.

10. Click the Add Object button (the upper-left most button on the Manage tab), then click the Add

and Edit button to add an object to the Sky Chart.

11. On the Add/Edit Chart Element window, turn on the Horizon radio button, then enter the azimuth

(Azm) and altitude (Alt) of the telescope cross hair. In the Label text box, enter the text Absolute

Home Position and then click OK.

The Sky Chart now shows a label at the absolute home position of the mount. To double-check the

accuracy of this position, choose the Find Home command. Note that, when compared to the absolute

home position, the position of the telescope cross hairs on the Sky Chart will also be affected by the

following:

Synchronizing the mount on a star introduces small pointing errors.

A TPoint pointing model will change the position of the telescope cross hairs based on the pointing

calibration data.

The above two items necessarily introduce a small offset between the mount’s absolute home position

and the position of the telescope cross hairs after finding home (once the mount has been synchronized

and a TPoint model is established).

Physically Marking the Home Position

If, after finding the home position, the cross hairs that are displayed on the Sky Chart are at the wrong

coordinates, one or more of the following is probably true:

The mount is not aligned to the celestial pole. (Believe it or not, Software Bisque has had several

support cases claiming that the mount could not point the telescope correctly, only to discover

the Paramount’s polar axis was mounted in the wrong direction; for example, the polar axis was

pointing south in the northern hemisphere, in other words, 180 degrees off.)

The optical tube assembly is mounted “backwards” on the Versa-Plate.

In TheSkyX Professional Edition’s location, date, time, time zone or Daylight Saving Time settings

are wrong for your observing site.

24 | P a g e

Paramount User Guide

The wrong star was centered in the eyepiece when the mount was synchronized. Improper

synchronization results in the telescope cross hairs to be displayed at the wrong spot on the Sky

Chart. And this error is particularly apparent after the mount is homed.

Many come to the incorrect conclusion when the telescope cross hairs on the Sky Chart are wrong, there

must be something wrong with the homing process. Homing is generally very reliable and rarely fails. The

procedure below demonstrates that, after homing, the Paramount is always in the same mechanical

position.

1. Home the mount.

2. On each axis, place a piece of masking tape over the rotating portion and cut the tape between

the rotating parts of the mount. The “vertical” edges of the tape mark the home position in that

axis.

3. Use the joystick (or TheSkyX Professional Edition) to slew the mount to any orientation.

4. Double-tap the joystick to find home again.

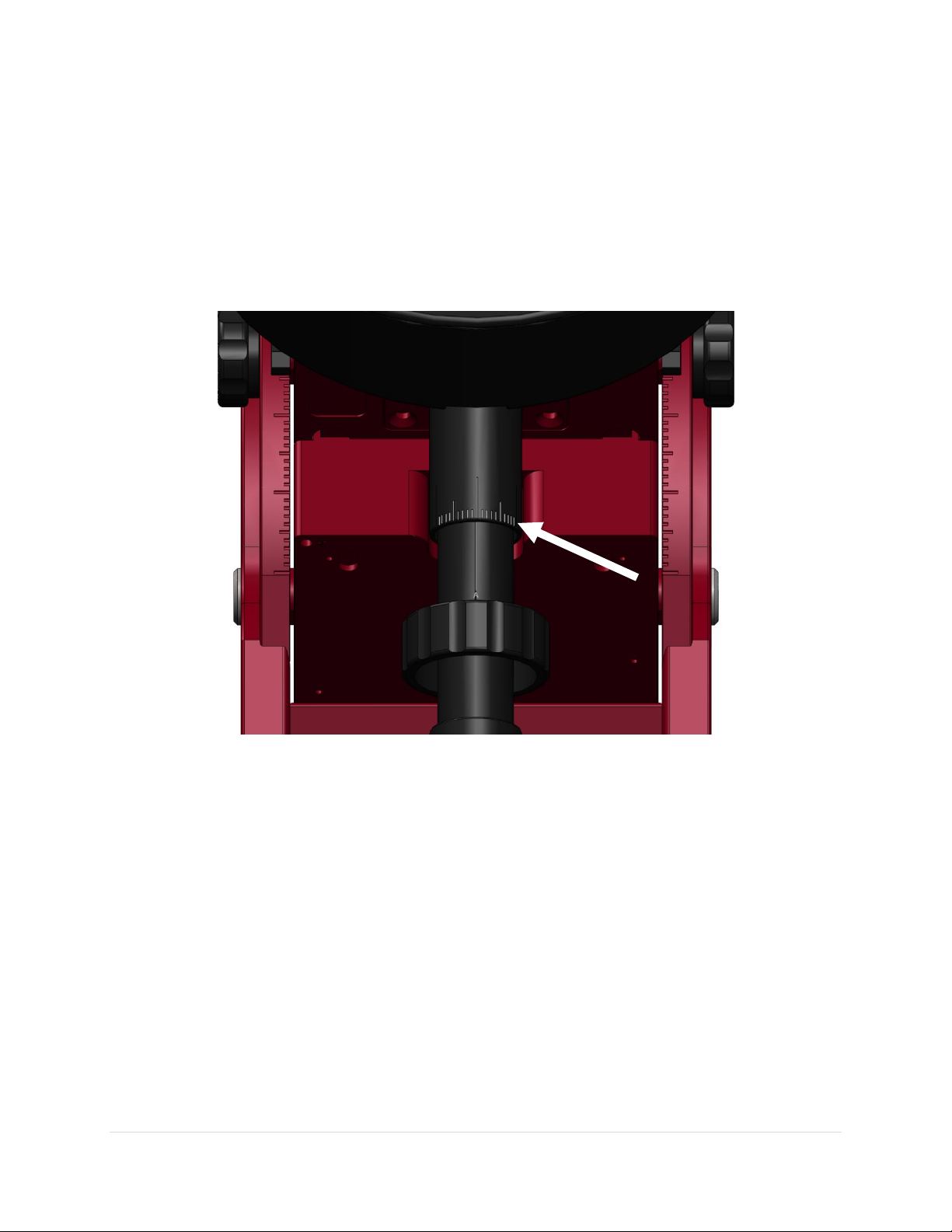

Figure 4: Marking the Paramount’s home position.

The Paramount will dutifully return to the identical position in each axis.

This “homing repeatability test” will hopefully provide confidence that, after finding home, the mount is

always pointing to hour angle 2 and declination 0 (in the northern hemisphere), and will help narrow down

the actual causes of pointing errors (most commonly, an invalid synchronization, incorrect settings in

TheSkyX Professional Edition, or poor polar alignment).

Synchronization

Synchronizing (or “syncing”) the Paramount initializes the control system to a specific equatorial

coordinate. In short, you tell the mount, “You are here!” Synchronization involves centering a known star

25 | P a g e

Paramount User Guide

Consider using a GPS to also obtain your site’s latitude and longitude. Make sure

the time zone and daylight saving options are correct for your location (a GPS does

not supply this information).

in the eyepiece, identifying this star in TheSkyX Professional Edition then choosing the Synchronize

command from the Start Up pop-up menu on the Telescope window.

Once the Paramount has been synchronized on a star, TheSkyX Professional Edition uses the equatorial

coordinates of the star to determine the mount’s mechanical orientation and software slew limits.

TheSkyX Professional Edition stores this synchronization position so that the mount’s orientation can be

restored in subsequent observing sessions.

In theory, after a permanently mounted Paramount is aligned with the celestial pole (page 20), it need be

synchronized only once. In practice, the mount will have to be synchronized:

Each time the mount is setup for portable use.

When the mount’s polar alignment is changed.

When the optical tube assembly (OTA) is changed.

Synchronization is an essential first step to “normal” mount operation. If the mount is not synchronized

correctly, the actual orientation the telescope will not match the simulated telescope’s position on the

Sky Chart. And, when commanded to slew from TheSkyX Professional Edition, the telescope will end up

pointing at the wrong place in the sky.

Best Synchronization Practices

Do not synchronize on stars near the celestial pole – The celestial pole represents a point of

“singularity” on the celestial sphere. As a best practice, do not synchronize on Polaris (in the

northern hemisphere) and avoid stars above 60 degrees declination or so.

Use brighter, easily identifiable stars – Fainter stars can be hard to identify, making

synchronization more difficult.

Step by Step Synchronization

Carefully follow the procedure below to ensure that synchronization is performed correctly. If you make

a mistake and point the telescope at the wrong star, for example, see “Starting Synchronization Over” on

page 29 to restore the default settings and try again.

1. Set the computer’s clock accurately. Accurate time is crucial for consistent, accurate pointing and

synchronization. Consider using an Internet time server or a GPS-based clock to regularly update

your computer’s clock and keep it accurate. See “The Local Celestial Meridian” on page 29 for

more information.

2. Choose the Location command from the Input menu to set the observing site’s latitude, longitude,

time zone and Daylight Saving option if necessary.

26 | P a g e

Paramount User Guide

Errors in latitude “appear” to TPoint as a vertical misalignment in the polar axis,

and will pollute synchronization (and the TPoint model, if one is in place).

If your time zone is off by one hour or more, then pointing will be off by the

same amount.

If the wrong Daylight Saving Option is selected, then time will be off by an hour

(or more) and the mount will not slew to the correct position.

3. Choose the Connect command from the Telescope menu.

4. Choose the Find Home command from the Start Up pop-up menu on the Telescope window.

5. Locate an easily identifiable, bright star to use for synchronization.

Partial clouds or twilight can make this task more difficult than it might seem. The Paramount can

be synchronized to virtually any position on the celestial sphere on the east or west side of the

meridian (See “Best Synchronization Practice” on page 26).

6. Center the bright star in the eyepiece, photo or video display using the joystick on the hand

controller or TheSkyX Professional Edition’s Motion Controls on the Telescope window.

7. From TheSkyX Professional Edition, enter the name of the bright star in the Search For text box

and click the Find button on the Telescope window to identify the star. Or, click on the star if it is

visible on the Sky Chart.

8. Choose the Synchronize command on the Start Up pop-up menu in Telescope tab. When the

Telescope Synchronization window appears, click the Sync button.

The mount is now synchronized on the bright star.

Session to Session Pointing Repeatability

In subsequent observing sessions, TheSkyX Professional Edition computes the current equatorial and

horizon coordinates of the telescope using the stored hour angle and declination of the mount and the

local sidereal time. In fact, the Paramount’s pointing accuracy should be virtually identical from session

to session.

Please verify the repeatability of the Paramount pointing before proceeding (this test assumes that the

mount’s polar axis is aligned with the celestial pole):

1. Turn the mount off.

2. Turn the mount on (this terminates communication between TheSkyX Professional Edition and

the Paramount).

3. Home the mount.

4. From TheSkyX Professional Edition, choose the Connect command from the Telescope menu. The

telescope cross hairs appear at the relative home position (see page 149 for an explanation of the

difference between the absolute and relative home position).

5. Slew the mount to the star you just synced on. The mount should slew back to this star; that is, it

should return to the same position in the eyepiece, video or CCD detector. In practice, there may

be small pointing errors that are introduced by mirror flop, or slight differences in time, so the

star may not be in exactly the same position, but it should be very close.

27 | P a g e

Paramount User Guide

Note that during the process of polar alignment, you will be required to synchronize the mount several

times (each time the mount is adjusted to a new altitude and/or azimuth). For permanent installations,

once the mount is sufficiently aligned with the celestial pole, it should not have to be synchronized again

unless the optical tube assembly or the telescope’s physical mounting changes.

Portable setups must synchronize the mount each session, or, if a TPoint pointing model will be used, a

Portable Recalibration, as described in the TPoint Add On User Guide, must be performed first.

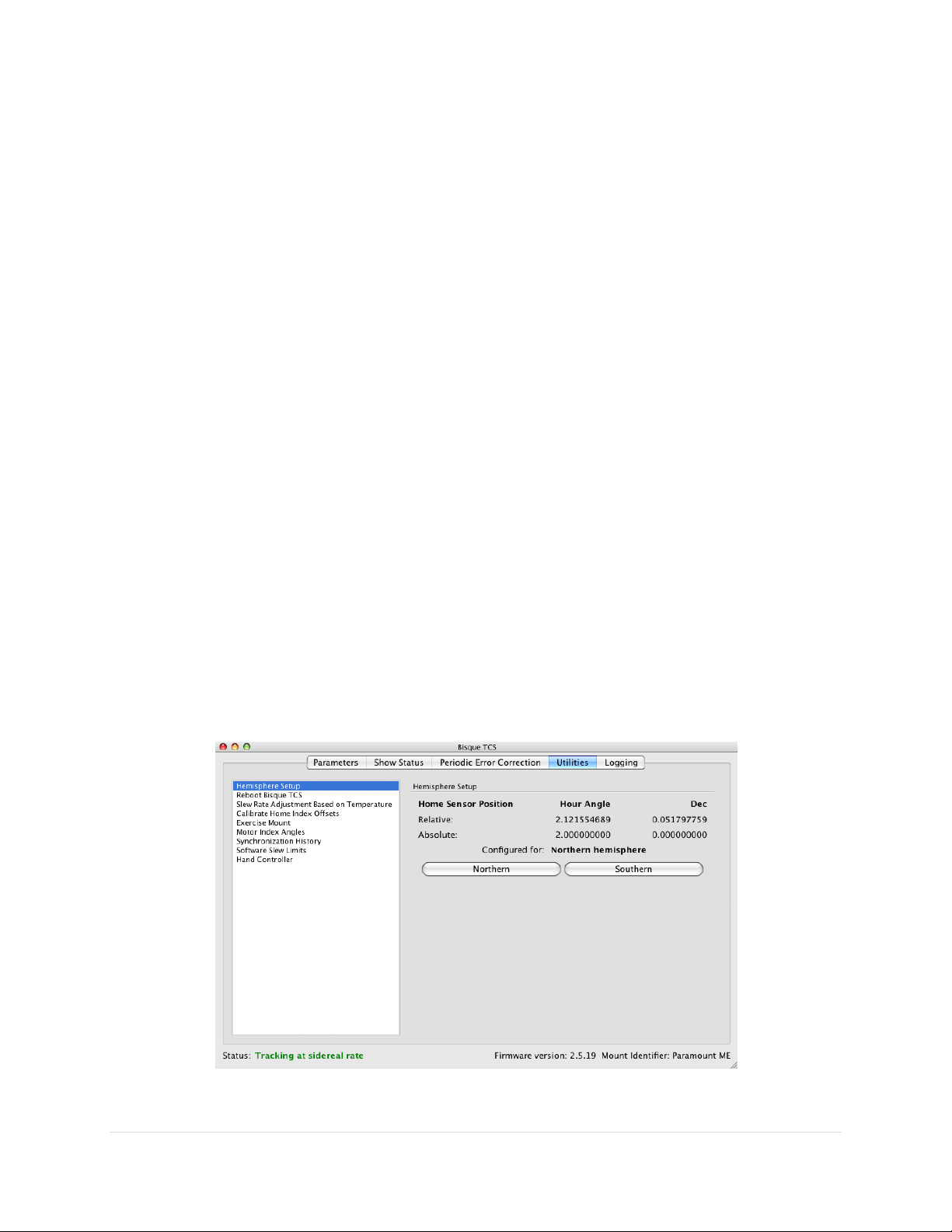

Making Sure Synchronization Is Correct

The first step to ensure the Paramount is properly synchronized is to look at the hour angle and the

declination of the homing sensors reported by TheSkyX Professional Edition.

When the mount has been properly synchronized, TheSkyX Professional Edition’s relative position of the

home sensors should approximately match the absolute position of the home sensors. Remember, the

mount’s absolute home position cannot change, so TheSkyX Professional Edition’s reported home position

must be near hour angle 2 and declination 0 in the northern hemisphere. If TheSkyX Professional Edition

reports a relative home position that is significantly different from hour angle 2 and declination 0, then

the mount’s synchronization is wrong. A small difference is okay, it just means that your

telescope/eyepiece/camera is not perfectly aligned with the mount’s axes.

See “Starting Synchronization Over” on page 29 to restore the default settings and resynchronize the

mount.

Note that the above description assumes the Paramount is located in the northern hemisphere and the

Versa-Plate is mounted in the standard orientation (page 65). When the Versa-Plate is mounted in the

wide orientation, then reported home position will be 90 degrees from hour angle 2.

28 | P a g e

Figure 5: The absolute and relative homing sensor positions.

Paramount User Guide

The Sky Chart provides graphical feedback to help verify the mount is synchronized correctly and identifies

the regions near the meridian that have unique behavior when tracking or slewing. While TheSkyX

Professional Edition is connected to the Paramount, two regions are drawn near the meridian. If the

regions are centered on the meridian, then the synchronization is most likely correct.

Purple Region

When the optical tube assembly is on the east side of the mount (pointing to the west), the purple region

(that is, the region on the east side of the meridian) indicates the area where the mount can be slewed

beyond the meridian without flipping sides. If the OTA is on the east side, and you attempt to slew beyond

this region, the mount automatically flips sides.

Red Region

When the optical tube assembly is on the west side of the mount, the red region indicates how far past

the meridian the mount can track before encountering a software or hardware limit. If the OTA remains

on the west side and the mount tracks to the tracking limit, then tracking is turned off. Note that the

Paramount will not automatically flip sides of the meridian and continue tracking in this situation. The

red region also indicates the area where, when the OTA is on west side, the mount can be slewed past the

meridian without flipping sides.

Synchronization Checklist

Make sure that the computer’s time is accurate, and that TheSkyX Professional Edition is

configured to use the computer’s clock.

Verify that synchronization is performed using the star listed in TheSkyX Professional Edition’s

Object Information Report. When clicking the Sky Chart to identify an object, the Object

Information Report can list other objects that are “near” the mouse click position.

In general, avoid synchronizing on a star that is located near the meridian.

Avoid synchronizing on stars above 60 degrees declination.

Starting Synchronization Over

If you are ever unsure about synchronization, you can start over by:

1. Choose the Connect command from the Telescope menu.

2. Choose the Bisque TCS command from the Tools pop-up on the Telescope window.

3. On the Bisque TCS window, click the Utilities.

4. Select Synchronization History on the left side of the window.

5. Click the Clear button to clear the existing synchronization.

The Local Celestial Meridian

The local celestial meridian is a great circle on the celestial sphere that runs from the zenith directly

overhead to a point due South on the horizon, continuing around to the nadir (directly below) and back

up to the zenith. This line divides the celestial sphere into east and west hemispheres.

29 | P a g e

Paramount User Guide

From TheSkyX Professional Edition, expand Reference Lines and Photos in the Chart Elements window

and turn on the Meridian checkbox.

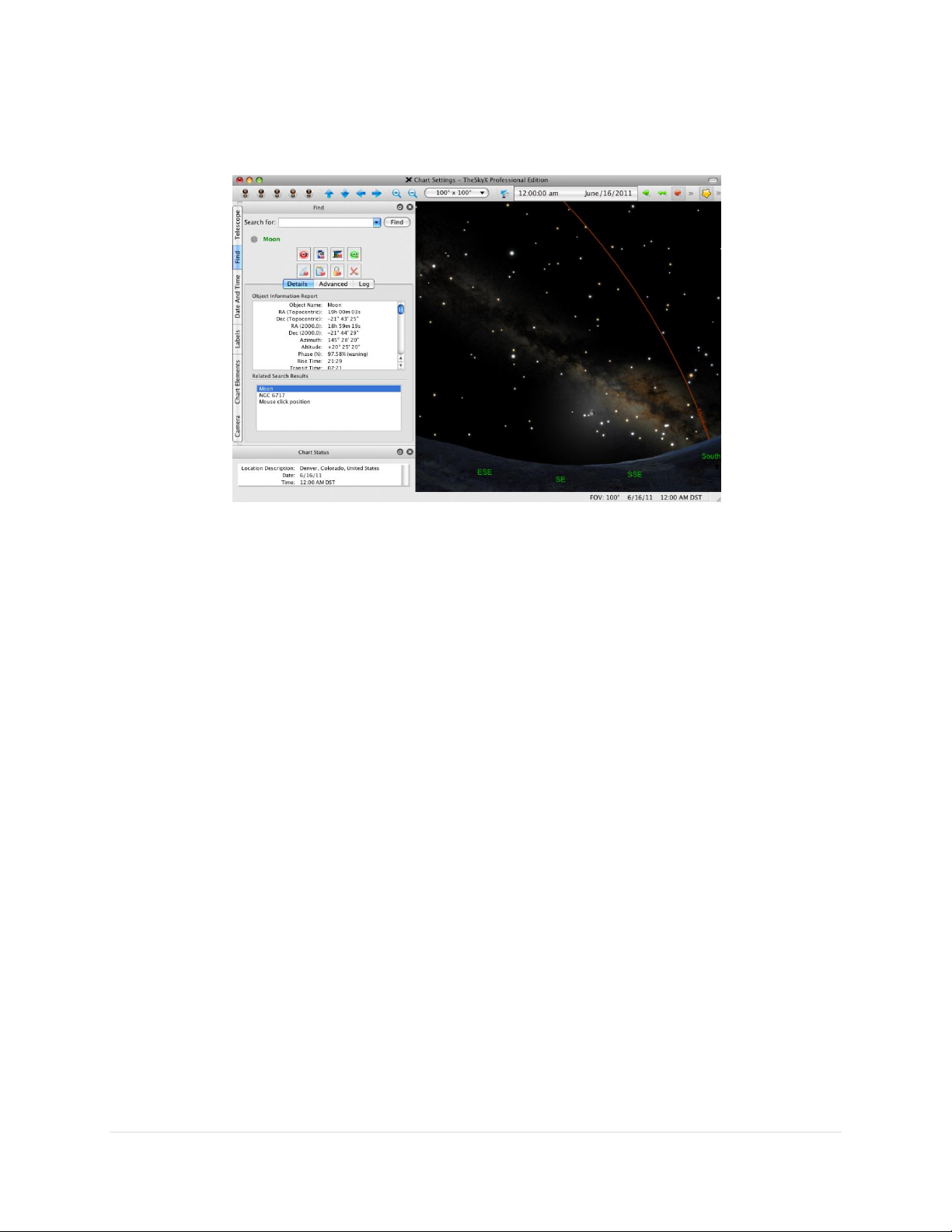

Figure 6: TheSkyX Professional Edition with the meridian reference line turned on.

The arcing line in Figure 6 represents the local celestial meridian. When the Paramount is at the home

position, the telescope must be pointing to the west side of the meridian, near hour angle 2 and

declination 0 in the northern hemisphere. (Or, hour angle –2.0 and declination 0 in the southern

hemisphere).

If the optical tube assembly is not pointing to the home position, or if the telescope cross hairs in the

TheSkyX Professional Edition indicate that the home position is anywhere else (by more than a few

arcminutes or so), then one or more is the case:

TheSkyX Professional Edition is not configured correctly for your location.

The Versa-Plate is mounted in the wide configuration (page 65).

The Versa-Plate is mounted 180 degrees off.

Before continuing, make sure that TheSkyX Professional Edition’s location, date, time, time zone, and

Daylight Saving Option are correct. Also make sure the Versa-Plate is mounted in the correct orientation

before proceeding.

Maintaining Accurate Time

The Paramount can provide very accurate all sky pointing during a single session without an accurate time

base (that is, if the computer’s clock is accurate to one or two minutes or so). However, TheSkyX

Professional Edition must make decisions on how to slew to various positions in the sky based on the local

time. For example, an object that is on the east of the meridian may require the telescope be slewed to

west side of the pier and vice versa. So, maintaining accurate time is important.

30 | P a g e

Paramount User Guide

Always perform “reality check” by comparing the coordinates of objects in TheSkyX

Professional Edition to objects in the night sky. If TheSkyX Professional Edition’s

location or time is not accurate, the two will not match!

Choose the Verify TheSkyX Time command on the Tools menu to compare the

computer’s date, time and time zone settings with a web-based time source.

Initializing the Paramount requires a very accurate time base. TheSkyX Professional Edition uses the

computer’s clock to compute the local sidereal time (LST). When a connection is established between

TheSkyX Professional Edition and the “homed” Paramount, the LST is used to re-establish the

synchronization between the Paramount’s “electronic setting circles” and the celestial sphere to within a

few arcseconds. If the computer’s time is accurate, you can just power-up the mount, home, and then

start imaging each night.

Setting the Computer’s Clock

The best method to accurately set your computer’s clock is with “time server” software. Remember, each

second of error in time translates to fifteen arcseconds error in angular distance near the celestial equator.

So, telescope pointing will degrade if time is not accurately maintained from night to night.

Inaccurate time causes the mount to slew to objects ahead or behind objects in right ascension by a

consistent offset. Software that periodically resets your computer’s clock using an accurate time base

solves this problem.

Many applications maintain accurate time and most operating systems can be configured to update the

computer’s clock automatically. Windows users might consider Dimension 4 from Thinking Man Software.

Search the web for “time server software” to locate alternatives.

Parking the Paramount

Parking is a command that can be issued to the Paramount from TheSkyX Professional Edition and

performs the following operations:

1. After confirmation by the user, the mount is automatically slewed to a user-defined altitude and

azimuth coordinate, called the park position.

2. Once the park position is reached, the Paramount’s tracking is immediately turned off.

3. Communication between TheSkyX Professional Edition and the mount is terminated.

Note that the park position is not used to initialize the mount.

Parking from TheSkyX Professional Edition