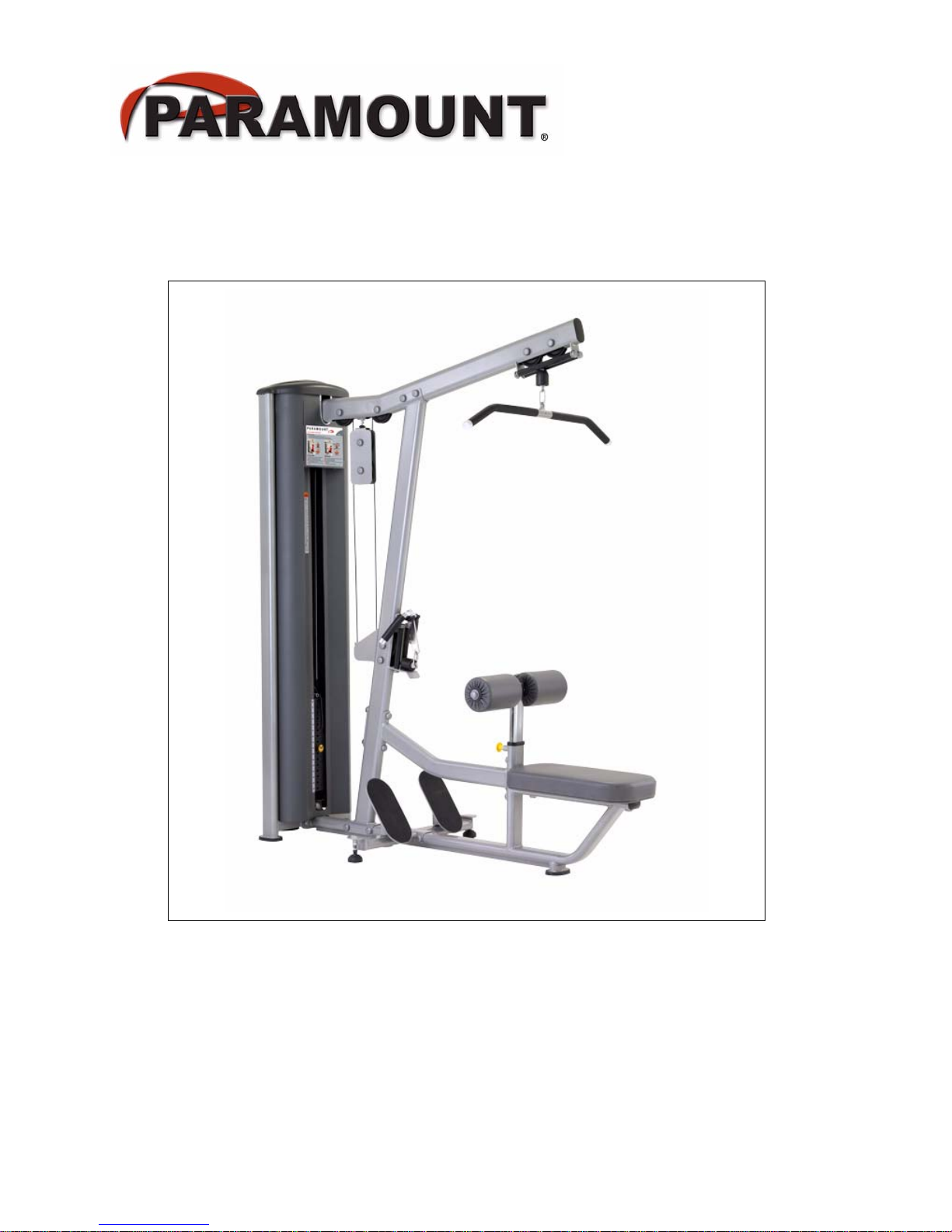

FS-53

L

AT

A

/R

OW

SSEMBLY

M

ANUAL

AM-FS53

112014

A M

ESSAGE TO OUR CUSTOMERS

Thank you for purchasing products from the Paramount FS line. Because of the many unique

features included in these machines, this manual was created to provide you with information on

how to properly install and maintain your equipment. Proper maintenance will ensure that your

new equipment will last for years.

For your convenience, product questions can be answered by an Authorized Paramount Dealer or

by contacting a Paramount Customer Service Representative at:

1-800-721-2121 or 1-323-721-2121

Office hours are Monday-Friday, 7:30 am - 4:30 pm PST

Or email us at nasales@paramountfitness.com

Thank You for your patronage.

Paramount Fitness Corporation

6450 East Bandini Blvd.

Los Angeles, CA 90040

IMPORTANT

!

SERIOUS INJURIES TO USERS, BYSTANDERS OR INSTALLERS CAN OCCUR IF THE

INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL ARE NOT FOLLOWED. TO

MINIMIZE THIS RISK, READ THE MANUAL BEFORE BEGINNING THE INSTALLATION TO

FAMILIARIZE YOURSELF WITH ITS CONTENTS AND THEN BE CERTAIN TO FOLLOW EACH

OF THE STEPS AND PRACTICES DESCRIBED. IN ADDITION, REVIEW THE GENERAL

MAINTENANCE MANUAL, FACILITY SAFETY SIGN AND OTHER DOCUMENTS THAT MAY

ACCOMPANY EACH MACHINE, FOR IMPORTANT SAFETY AND MAINTENANCE TIPS. THE

MANUAL HAS BEEN INCLUDED WITH YOUR MACHINE ORDER AND CAN ALSO BE

DOWNLOADED FROM OUR WEBSITE AT: http://www.paramountfitness.com

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

2

S

AFETY

...................................................................................................................... 4

G

ENERAL CARE AND MAINTENANCE

T

ABLE OF CONTENTS

........................................................................... 7

IMENSIONS AND WEIGHT

D

REPARATION

P

B

OX

1 C

OX

2 C

B

NSTALLATION

I

S

S

S

S

S

S

S

ACHINE LABELS

M

ERVICE

S

B

OLTING THE MACHINE TO THE FLOOR

............................................................................................................. 9

ARTON CONTENTS

ARTON CONTENTS

& A

SSEMBLY

TEP

1: A

SSEMBLE THE MAIN FRAME

TEP

2: A

SSEMBLE WEIGHT STACK

TEP

3:A

SSEMBLE FRONT SHROUD,ROW TUBE

TEP

4: A

SSEMBLE ROW CABLE

TEP

5: I

NSTALL LAT BAR

TEP

6: I

NSTALL REAR SHROUD

TEP

7 I

NSTALL THE WEIGHT STACK LABEL

........................................................................................................ 25

..................................................................................................................... 26

........................................................................................... 8

............................................................................................ 10

............................................................................................ 11

...................................................................... 12

& LAT

& ROW T

& ROW H

TUBE

UBE SUPPORT

ANDLE

............................................................. 21

...................................................... 14

, F

OOT FRAME

.................................. 16

......................................... 19

& TOP CAP............................................................ 22

............................................................. 24

............................................................................ 27

ARRANTY

W

................................................................................................................. 28

3

S

AFETY

F

ACILITY AND USER SAFETY PRECAUTIONS

1. Review and understand all of the warning labels affixed to this machine and on the facility

safety sign.

2. Be certain that the machine operation is understood before it is used. Refer to the

instructional Procedure Label affixed to the machine.

3. Make sure all users are properly trained on how to use this equipment. If this machine is

being used in a commercial setting, end users may not have access to this Owners Manual. It

is the responsibility of the facility to instruct users as to the proper usage of the equipment as

well as making them aware of potential hazards. Maximum user weight is 300 lbs (136 kg).

4. Use each machine only for the intended exercise. Do not allow anyone to invent exercises not

included on the Instructional Procedure Label or the Intended Use Label.

5. Do not modify the machine.

6. This equipment meets industry safety standards for stability when used for the intended

exercise. Do not allow straps, resistance bands or other means to be attached to the

framework of this machine to perform stretching or body weight exercises. This can result in

machine instability and lead to serious crushing injuries.

7. Keep children away from this equipment. Adults should closely supervise use by teenagers.

8. It is recommended that users receive a thorough medical exam before commencing an

exercise program. All medical issues should be reviewed to ensure that weight training will

not aggravate pre-existing medical conditions.

9. If the machine appears damaged or inoperable, contact a facility staff member to place an

“OUT OF ORDER, DO NOT USE” sign on the machine until it is repaired. Only use Paramount

supplied replacement components to service this machine.

10. Instruct users not to wear loose or dangling clothes or have headphone wires hanging when

using this equipment.

11. Do not attempt to free any jammed assemblies by yourself as this may cause injury.

12. On Plate Loaded and Free Weight machines:

12a. Use of spotter(s). Instruct users to seek the advice of the facility staff as to the

appropriate use of spotters when lifting. More then one spotter may be required

depending upon the amount of weight being lifted.

12b. Instruct users to load weight plates evenly and carefully (one side and then the other)

to avoid tipping equipment and crushing injuries.

12c. If the machine is equipped with safety stops or catches, inspect them and verify their

proper operation before use and make sure they are securely in place before using or

exiting the machine. Be certain members are instructed on how to operate and adjust

all safety mechanisms.

4

12d. This equipment is designed for standard olympic size weight plates with a 50mm bore

(1.9”).

12e. Do not exceed the maximum weight capacity of the machine. Maximum plate size is

45 lbs. (25 kg.).

13. On Selectorized and Cable equipped machines:

13a. Do not allow users to perform any exercise by holding the end of the cable and/or the

cable end fitting. Use only appropriate handles or attachments properly connected to

the cable end.

13b. Do not high-pin or double-pin the weight stack. Do not allow the machine to be used if

the top plate or weight stack is pinned in a raised position. Use an assistant and

carefully return the machine to the proper position with the cap plate resting on the top

weight. Inspect the entire length of the cable to ensure that it is properly seated in all

of the pulley grooves.

13c. Do not allow the use of weight plates or dumbbells to be used as a means to add

additional weight to the weight stacks. Use only the Paramount adder weight system

specifically designed for the machine.

I

NSTALLATION SAFETY PRECAUTIONS

S

AFETY

1. Read this Installation Manual entirely before assembling this equipment.

2. Verify that there is adequate space surrounding this piece of equipment for safe access and

operation. Installation must meet ADA requirements for accessibility.

3. Install this piece of equipment on a solid level surface that does not deviate more then 1/8”

over a 10’ distance (or as defined and required by local building and architectural codes.

4. Paramount strongly recommends that all equipment be anchored to the floor to prevent

movement and increase stability.

• Due to the wide variation of flooring on which the unit can be installed, contact a

qualified contractor to determine an appropriate fastening system for your floor.

• Use 3/8” diameter hardware (10 mm) to anchor the machine. Anchors should have a

minimum pull out force of 220 lbs (110 kgs) for each position.

• When attaching the machine to the floor, if there is a gap between the machine foot

and the floor, do not use the anchor to remove the gap as this can cause the

machine frame to deform. Instead, place a shim between the bottom of the foot and

the floor, then tighten the anchor.

• Anchoring holes are provided on the feet of the frame. All anchoring locations must

be used when anchoring the equipment to the floor.

5. DO NOT install any fitness equipment near a pool, hot tub or other damp locations. Corrosion

caused by installation in these locations can lead to premature failure of components.

6. Be sure all hardware is tight before using this machine.

5

S

AFETY

M

AINTENANCE SAFETY PRECAUTIONS

1. Refer to Maintenance Schedule label on the machine as well as this manual for when to

perform maintenance.

2. Check the function of your machine DAILY by verifying the following:

• Inspect cables and end fittings for any signs of wear. Replace if worn, frayed or

damaged with original Paramount replacement components.

• Verify that all adjustments are possible and carried out with ease. Make sure that

each adjustment pin inserts completely into each position without binding.

• Verify that safety catches and stops are in proper working order and engaged.

• Verify that the exercise is performed smoothly, free of noise and/or binding.

• If equipped with a weight stack, verify that the proper weight selector pin is in place.

3. Check the function of your machine WEEKLY by verifying the following:

• Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become

loose, retighten and/or use Loctite

• Frames and Lifting Arms: Inspect weekly for integrity and function. Replace any

component at first signs of wear. Use only Paramount supplied components.

4. Replace any warning label at first sign of wear. Labels and the Facility Safety Sign may be

obtained from Paramount free of charge.

B

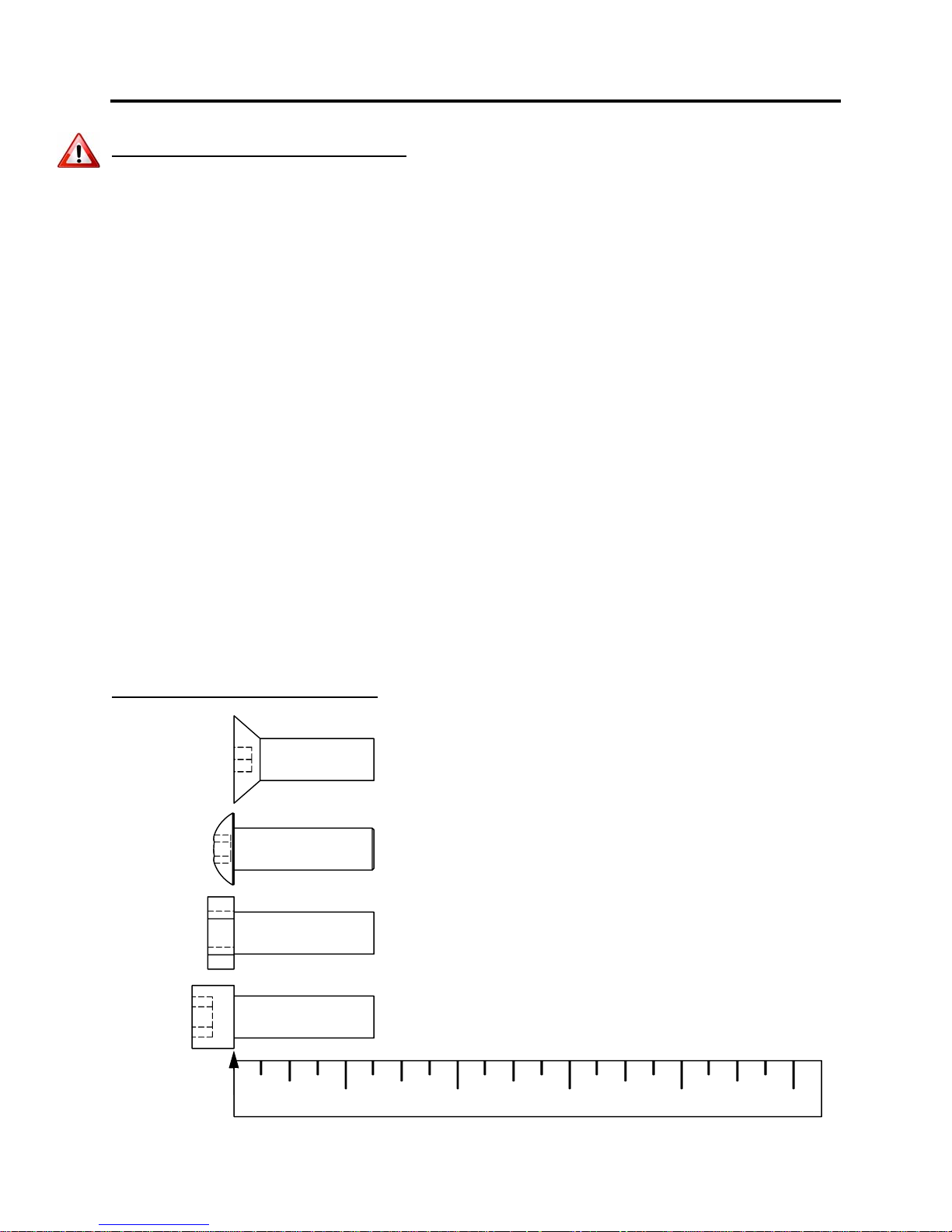

OLT LENGTH MEASURING GUIDE

FLAT HEAD SCREW

BUTTON HEAD SCREW

HEX HEAD SCREW

™

Threadlocker 242.

SOCKET HEAD SCREW

1

23

6

4

5

G

ENERAL CARE AND

M

AINTENANCE

IMPORTANT

Preventative maintenance is crucial to maintaining the function and safety of this equipment. Your

facility must establish written guidelines for preventative maintenance and keep written or online

records of the maintenance performed on these products. As a minimum, the items presented in

the SAFETY section of this document and the items that follow here, should be included in your

maintenance program.

1. Cables: Inspect end fittings daily for wear. Inspect the entire length of the cable weekly.

Replace cables at the first sign of wear and on an annual basis. If the cable tension has

been adjusted, be certain that the cable nut is tight.

2. Nuts, Bolts, and Fasteners: Check tightness weekly. If any hardware has become loose,

retighten and/or use Loctite

before using the machine.

3. Safety Catches: Inspect catches, stop rods and their associated fasteners weekly. Tighten

any loose hardware and replace any components at first signs of wear.

4. Frames: Sweat, disinfecting sprays and spills can lead to corrosion which may lead to

premature failure of components. Wipe all machines down with a damp cloth and dry

completely each day. This includes painted parts, chrome parts and upholstered pads.

5. Painted and chrome plated parts: Use Simple Green or similar cleaner for light dirt and

grime. Use Turtle Wax Polishing Compound or a good car polish to remove heavier dirt

and grease as well as for polishing. DO NOT use solvents, lacquer thinner, acetone or

finger nail polish remover. For scuffs and marks that are not removed by the above

methods use a soft scrub cleanser. Make sure all parts are dry upon completion.

6. Weight stack enclosures (shrouds): Wipe down with a damp cloth as needed.

7. Exercise instruction labels: Clean with soap and water as needed.

8. Guide rods: Wipe all dirt and dust from the guide rods before applying a light application

of Tri-Flow

the guide rods with the rag. DO NOT use oil lubricants such as WD-40. Caution: Tri-Flow

will stain carpet and clothing.

9. Bronze bushings: Check monthly for signs of wear and replace as needed.

10. Linear Bearing Shafts: Wipe any accumulation of dust or other contaminants from the

shafts on a weekly basis. Apply a thin layer of a Teflon

Paramount recommends Magnalube

11. When replacing any component, use only Paramount supplied parts.

TM

or other teflon spray lubricant. Spray the Tri-FlowTM on a rag and then wipe

TM

brand Threadlocker 242. Be sure all hardware is tight

®

(PTFE) grease on a weekly basis.

®

brand.

TM

12. Please refer to the General Maintenance Manual (part number: AM-GMM) for other

important safety and maintenance information.

13. Be sure all hardware is tight before using the machine.

Retain these instructions for future reference.

If you have any questions, do not hesitate to contact your Paramount dealer or Paramount Fitness

Corp. at (800)721-2121 or nasales@paramountfitness.com.

7

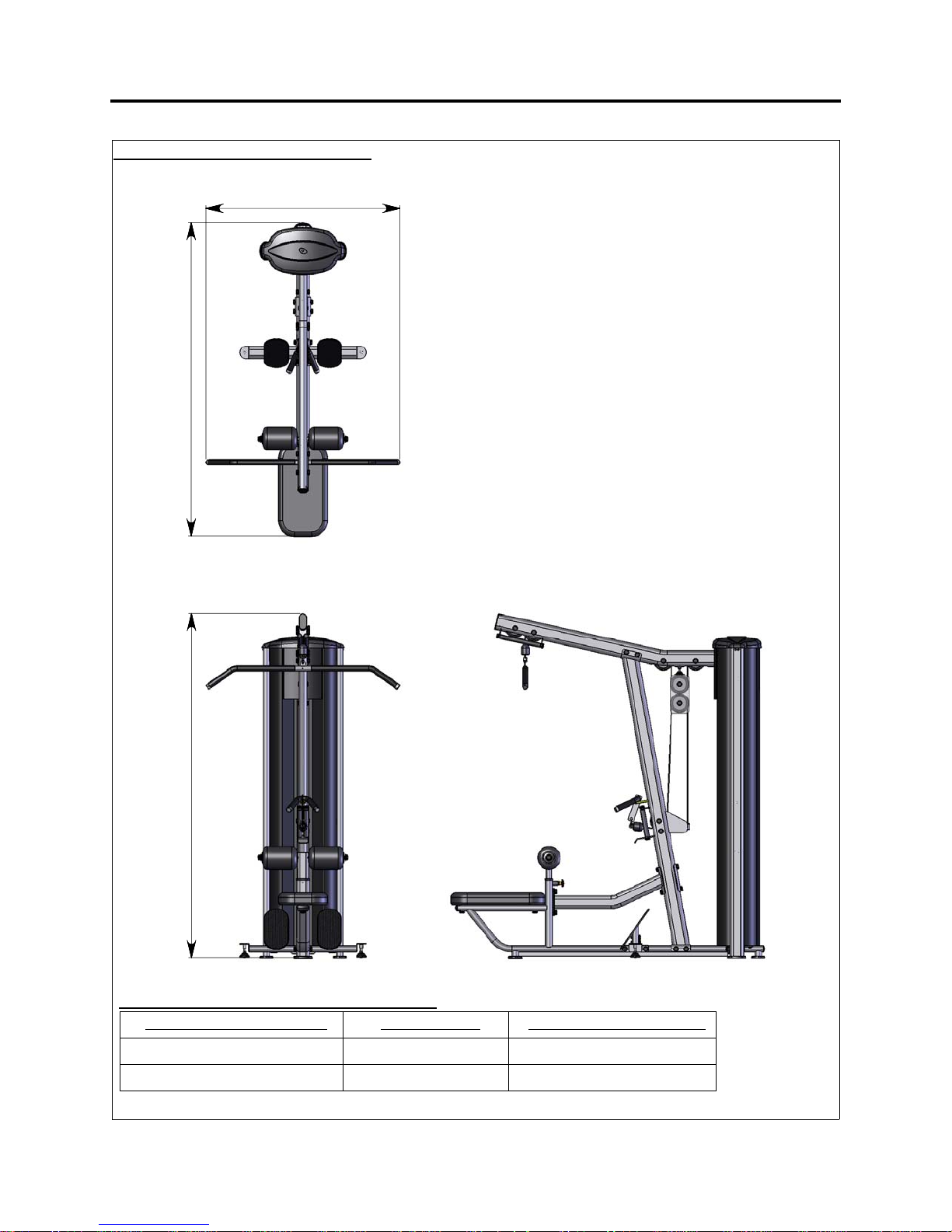

D

IMENSIONS AND

W

EIGHT

“IN USE” M

[1936]

76-1/4”

ACHINE DIMENSIONS

[1199]

47-1/4 ”

[2126]

83-3/4”

M

ACHINE WEIGHT AND FLOOR LOADING

W

EIGHT STACK CONFIGURATION

170 lbs. 454 LBS [206 KG] 53 LBS/FT2 [257 KG/M2]

250 lbs. 534 LBS [242 KG] 62 LBS/FT

M

AXIMUM USER WEIGHT

300LBS (136KG)

M

ACHINE WEIGHT

A

PPROXIMATE FLOOR LOADING

2

[303 KG/M2]

8

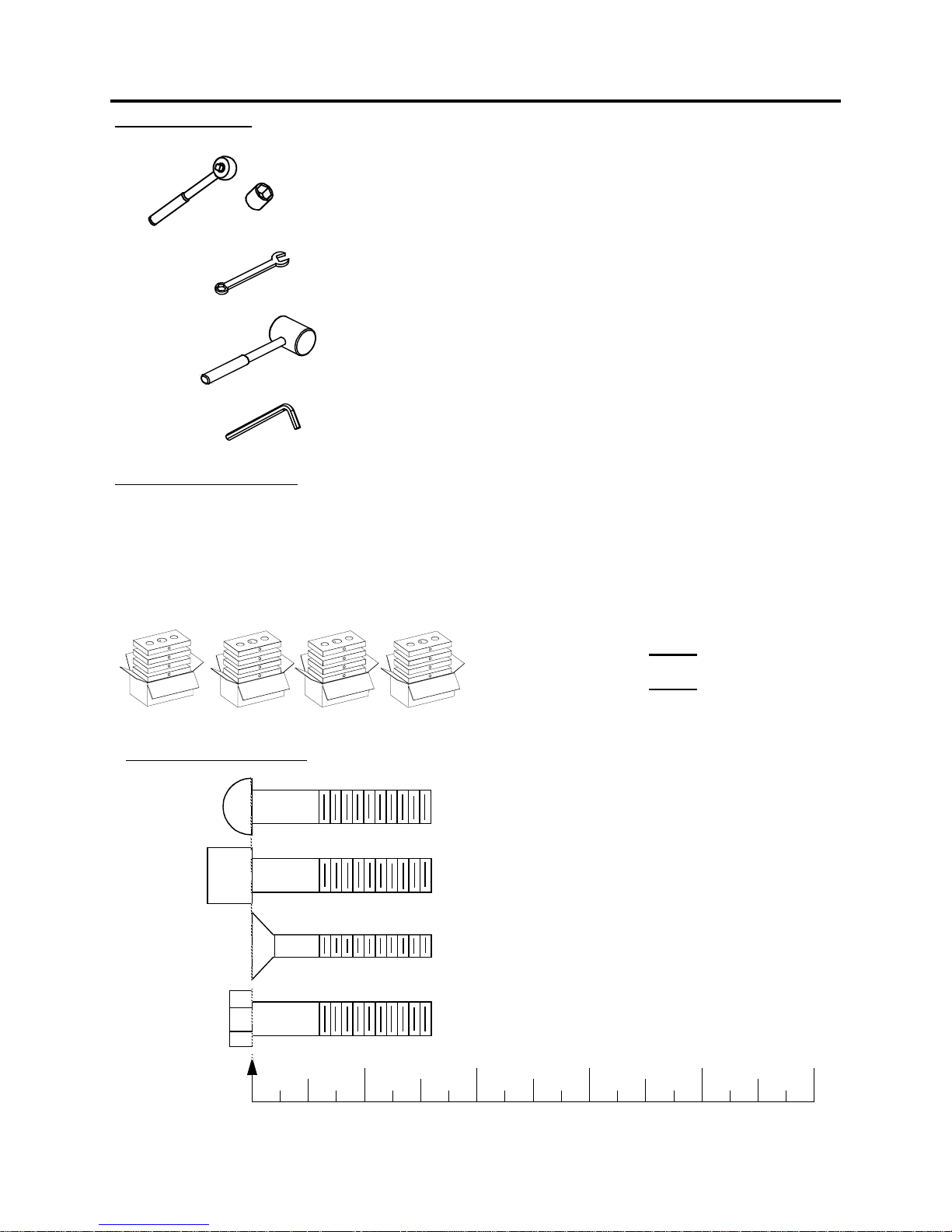

R

EQUIRED TOOLS

Ratchet Wrench and Socket:

9/16”

Wrenches: 9/16”

(or an adjustable crescent wrench).

Rubber mallet.

P

REPARATION

Weight Plate Cartons

Depending upon your order, this machine can be assembled with either a 170 lb. or 250

lb. weight stack. For a 170 lb. weight stack, (4) cartons of 10 lb. plates are required. For a

250 lb. weight stack, (4) cartons of 15 lb. plates are required.

See below for weight stack options/requirements:

Measurement Guide:

Allen wrenches:

(included with the machine)

10 LB. Weight Plate Box

Part Number: B1602

Comprised of

(4) x 10 lb. Weight Plates

OR

15 LB. Weight Plate Box

Part Number: B1603

Comprised of

(4) x 15lb. Weight Plates

Use this table to measure bolts and set collar spacing.

BHCS - BUTTON HEAD CAP SCREW

MEASURE BOLT

FROM HERE

SHCS - SOCKET HEAD CAP SCREW

FHCS - FLAT HEAD CAP SCREW

HHCS - HEX HEAD CAP SCREW

12345

9

B

OX

1 C

ARTON

C

ONTENTS

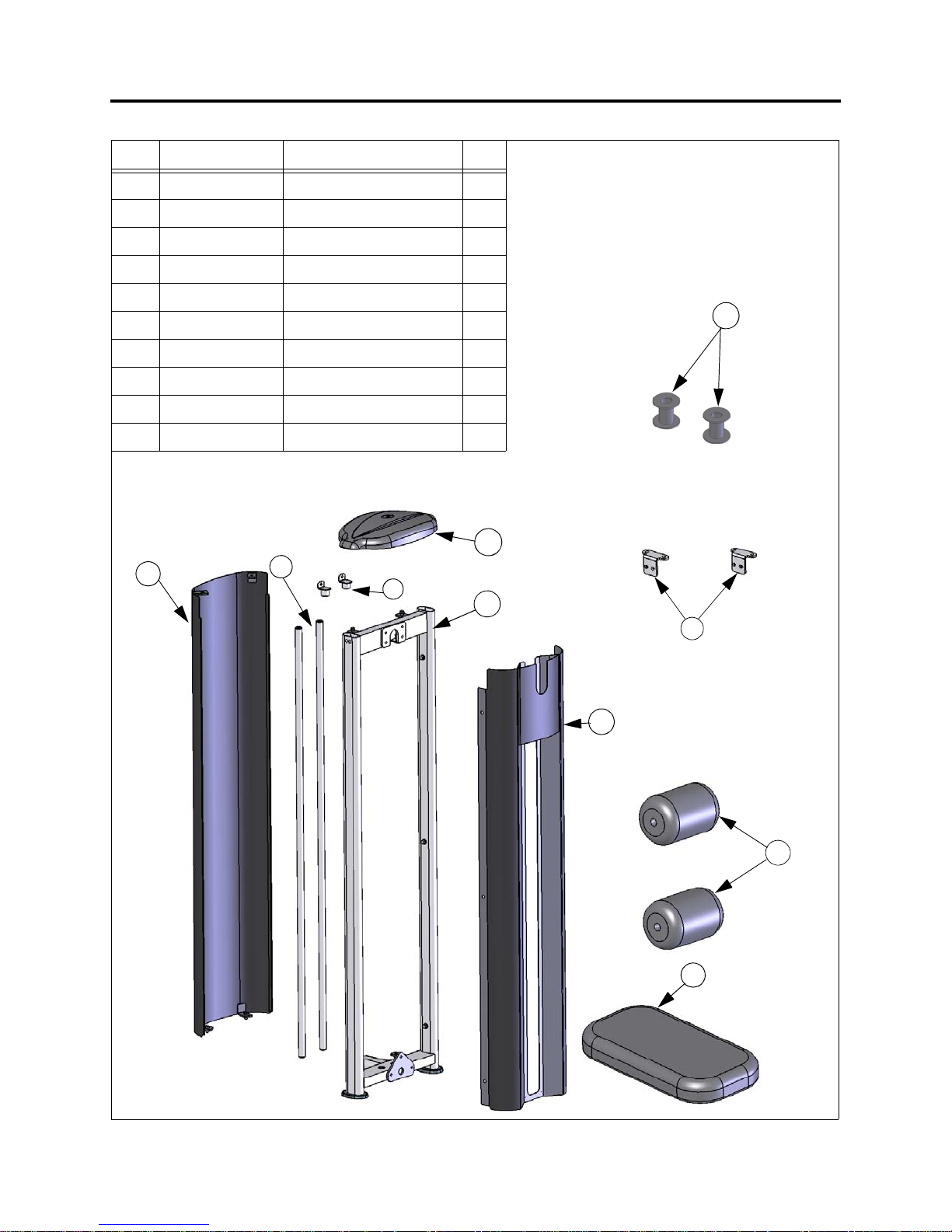

ITEMPART NUMBER

1 FS-CAP-000X TOP CAP 1

2 FS53-SHD-300X FRONT SHROUD 1

3 FS-SHD-350X REAR SHROUD 1

4 FS53-UPR-000X UPRIGHT 1

5 FS53-GRD-300X GUIDE ROD 2

6 FS53-PAD-100X SEAT PAD 1

7 FS-BKT-000 GUIDE ROD BRACKET 2

8 FS-PAD-400X ROLL ER PAD, SHORT 2

9 FS-BKT-001 TOP CAP BRACKET 2

10 FS-WSB-000 WEIGHT STACK BASE 2

3

D

ESCRIPTION

5

7

Q

TY

10

1

4

9

10

2

8

6

B

OX

2 C

ARTON

C

ONTENTS

ITEMPART NUMBER

1 FS53-MFR-100X LAT TUBE 1

2 FS53-MFR-200X ROW TUBE 1

3 FS53-MFR-300X ROW TUBE SUPPORT 1

4 FS53-MFR-400X FLOATING PULLEY SET 1

5 FS53-SFR-100X FOOT FRAME 1

6 FS53-SFR-200X FOOT PLATE 2

7 FS53-SFR-300X SEAT FRAME 1

8 FS53-SFR-400X THIGH FRAME 1

9 FS-BAR-100X LAT BAR 1

10 FS-BAR-200X ROW HANDLE 1

11 FS53-CBL-100X LAT CABLE 1

12 FS53-CBL-200X ROW CABLE 1

13 FS-SBR-000X SELECTOR BAR 1

14 FS53-HWR-000X HARDWARE BOX 1

15 FS53-FPL-002 FOOT PLATE BRACE 1

D

ESCRIPTION

Q

TY

14

HARDWARE BOX

1

12

11

9

13

10

4

2

3

8

15

6

5

7

11

S

TEP

1: A

SSEMBLE THE

M

AIN FRAME

1. Assemble frame components as shown.

2. Loosely assemble ALL hardware shown

in this step.

3. After aligning all component edges and

surfaces, tighten the hardware.

4. Install the rubber feet

ITEMPART NUMBER

1 FS53-UPR-000X UPRIGHT FRAME 1

2 FS53-SFR-300X SEAT FRAME 1

3 FS53-SFR-400X THIGH FRME 1

4 FS53-PAD-100X SEAT PAD 1

5 FS-PAD-400X THIGH ROLLER PAD 2

6 S 550 FOOT, MOLDED 4

7 C-965 WASHER, FENDER, 3/8 2

8 FS53-SFR-001 ROLLER COVER, PLASTIC 4

9 C 955A COVER, BASE 7

10 C 955S COVER, SILVER PLASTIC 7

11 C 754C WASHER, FLAT, 3/8 5

12 C 749 WASHER, LOCK, 3/8 7

13 C 444 SCREW, HH, 3/8 X 3/4 2

14 C 445 SCREW, HH, 3/8 X 1 3

15 C 451 SCREW, HH, 3/8 X 2-3/4 2

D

ESCRIPTION

Q

TY

10,13,12,9,7,8,5,8

X 2

5

3

12

S

TEP

1: A

SSEMBLE THE

M

AIN FRAME

DETAIL B

DETAIL A

10,14,12,9,11

10,15,9,12,11

X 3

X 2

1

4

A

2

13

B

S

TEP

2: A

SSEMBLE

W

EIGHT STACK

& LAT

TUBE

1. Assemble the Weight Stack,

Bumper, Weight Stack Support,

Top Plate/Selector Bar, Guide

Rods, Weight Stack 1” Washer,

and Collars as shown below.

2. Lock the guide rods as shown in

view DETAIL C.

3. Install the Lat Tube as shown in

view DETAIL D.

4. Align all component and tighten

all hardware.

C

X 2

6

ITEMPART NUMBER

1 FS-GRD-300X GUIDE ROD 2

2 FS-SBR-000X TOP PLATE/SELECTOR BAR 1

3 C 757A WASHER, WEIGHT STACK 1” 2

4 FS-BMP-001 BUMPER, WEIGHT STACK 2

5 FS-WSB-000 WEIGHT STACK SUPPORT 2

6 FS-BKT-000 GUIDE ROD BRACKET 2

7 FS53-MFR-100X LAT TUBE 1

8C 749 WASHER, LOCK 3/8 6

9 C 754C WASHER, FLAT, 3/8 6

10 C 445 SCREW, HH, 3/8 X 1 6

11 D 840 Collar, Clamping, 1” I.D. 2

12 FS-SPN-000X SELECTOR PIN 1

D

ESCRIPTION

Q

TY

1

X 2

2

DETAIL C

3

X 2

4

X 2

X 2

5

10,8,9 X 2

The Selector Pin should

be installed as shown.

14

S

TEP

2: A

SSEMBLE

W

EIGHT STACK

& LAT

TUBE

D

DETAIL D

Set the distance between

the Collars and the tube as shown

Use tape measure

1” distance from the bottom of the bolt to the

top of the bar as shown. Lock the nut after the

distance is set.

10,8,9

X 4

2 1/2”

1”

15

S

TEP

3:A

SSEMBLE FRONT SHROUD,ROW TUBE

, F

OOT FRAME

1. Install the front Shroud first. Slide

the top portion of the shroud up to

the Lat Tube from the side, and

push the lower portion of the

shroud into the Upright.

2. Install the Row Tube between the

Lat Tube and the Seat Frame. The

end of the Lat Tube might have to

be lifted to insert th e Row Tube and

align all bolt holes.

3. Install the Foot Frame as shown in

View DETAIL H.

3. DO NOT TIGHTEN THE HARDWARE

SHOW ON VIEW DETAIL F AND

DETAIL G.

10,8,7 X 6

ITEMPART NUMBER

1 FS53-SHD-300X FRONT SHROUD 1

2 FS53-MFR-200X ROW TUBE 1

3 FS53-SFR-100X FOOT FRAME 1

4 FS53-SFR-200X FOOT PLATE 2

5 C 955A COVER 3/8, BASE 16

6 C 955S COVER, SILVER 16

7 C 745C WASHER, FLAT, 3/8 18

8C 749 WASHER, LOCK, 3/8 14

9 C 766A NUT, JAM, 3/8 6

10 C 445 SCREW, HH, 3/8 X 1” 6

11 C 449 SCREW, HH, 3/8 X 2-1/4” 4

12 C 451 SCREW, HH, 3/8 X 2-3/4” 2

13 C 455 SCREW, HH, 3/8 X 4” 4

14 FS53-FPL-002 FOOT PLATE BRACE 1

D

ESCRIPTION

Q

TY

DETAIL E

'(7$,/(

E

(

1

There are six sets of bolt and washers to hold down

the Front Shroud. Three sets on the left side, and

three sets on the right side.

16

S

TEP

3:C

ONTINUED

...

F

)

6,12,5,7 X 2

DETAIL F

'(7$,/)

7,5,9,6 X 2

2

*

G

6,13,8,5,7

X 2

7,5,9,6

DETAIL G

'(7$,/*

X 2

17

S

TEP

3 C

ONTINUED

...

'(7$,/+

DETAIL H

7,5,9,6

6,13,8,5,7

X 2

X 2

14

6,11,8,5

X 4

H

+

Slide Foot Plate on to the Foot Frame

and tighten all hardware.

18

S

TEP

4:A

SSEMBLE ROW CABLE

& R

OW TUBE SUPPORT

1. Install the Row Tube Support

below, then tighten all hardware in

previous steps.

2. Install the Row Cable as shown

next page.

ITEMPART NUMBER

1 FS53-MFR-300X ROW TUBE SUPPORT 1

2 FS53-ROL-001A ROW TUBE A, PVC 2

3 FS53-ROL-002A ROLL SHAFT A 2

4 B 900 PULLEY, 4.5” 2

5 FS-BSH-101 PULLEY BUSHING, 3/8 2

6C 749 WASHER, LOCK 3/8 6

7 C 745C WASHER, FLAT, 3/8 12

8 C 955A COVER, BASE 16

9 C 955S COVER, SILVER 16

10 C 443 SCREW, HH, 3/8 x 5/8 2

11 C 460 SCREW, HH, 3/8 x 5” 2

12 C 445 SCREW, HH, 3/8 x 1” 4

13 C 448 SCREW, HH, 3/8 x 1-3/4” 1

14 C 451 SCREW, HH, 3/8 x 2-3/4” 1

15 C 450 SCREW, HH, 3/8 x 2-1/2” 1

D

ESCRIPTION

Q

TY

J

-

16 C 766A NUT, NYLOCK, JAM, 3/8 5

17 FS53-MFR-400X FLOATING PULLEY SET 1

18 FS53-CBL-200X ROW CABLE 1

9,16,8,7

9,11,8,7 X 2

DETAIL J

'(7$,/-

9,10,6,8,7

1

K

.

X 2

DETAIL K

'(7$,/.

X 2

19

S

TEP

4:A

SSEMBLE ROW CABLE

& R

OW TUBE SUPPORT

Adjust stop to remove

cable slack.

M

$

18

9,16,8,7

1”

17

DETAIL M

'(7$,/$

9,12,8,6

9,13,8,7

4

X 2

9,16,8,7,5

9,16,8,7

2

X 2

9,14,8,7,5

9,15,8,7

N

%

'(7$,/%

DETAIL N

4

9,12,8,6

X 2

3

X 2

20

S

TEP

5: I

NSTALL LAT BAR

& R

OW HANDLE

1. Install the Lat Bar and Row Handle

as shown below.

ITEMPART NUMBER

1 FS-BAR-100X LAT BAR 1

2 FS-BAR-200X ROW HANDLE 1

3 B 1004 1/4 QUICK LINK 2

D

ESCRIPTION

3

1

Q

TY

2

3

21

S

TEP

6: I

NSTALL REAR SHROUD

& T

OP CAP

1. Install the Rear Shroud, put the

bottom of the shroud in first and push

the shroud into the upright.

2. Install the Top Cap on the upright as

shown in view DETAIL AF.

2

ITEMPART NUMBER

1 FS-SHD-350X REAR SHROUD 1

2 FS-CAP-000X TOP CAP 1

3 C 754C WASHER, FLAT 3/8 4

4 C 444 SCREW, HH, 3/8 - 3/4” 2

5 C 766A NUT, JAM 3/8 2

6 C 675D SCREW, BH, 1/4 - 1/2” 8

7 FS-BKT-001 TOP CAP BRACKET 2

1

D

ESCRIPTION

Q

TY

$&

'(7$,/$&

6

7

$'

'(7$,/$'

22

S

TEP

6: I

NSTALL REAR SHROUD

4,3

5,3

& T

OP CAP

$(

'(7$,/$(

$)

'(7$,/$)

6

23

S

TEP

7: I

NSTALL THE

W

EIGHT STACK LABEL

1. Select the appropriate weight stack label(s) according to your order. You can install pound

labels, kilogram labels, or both.

2. If you ordered a 170 lb weight stack, use labels:

LBL-WSE-01170 (for pounds)

LBL-WSM-01170 (for kilograms).

3. If you ordered a 250 lb weight stack, use labels:

LBL-WSE-01250 (for pounds)

LBL-WSM-01250 (for kilograms).

4. Remove the backing from the label to expose the adhesive. Carefully locate the label on the

shroud so that it is centered between the edge and the bend. Line up the numbers with their

corresponding weight plate. Once the correct position is attained and the label is a uniform

distance from the edge, press firmly along the entire length of the label.

5. NOTE: Adhesive takes 24 hours to fully set.

100

110

120

130

140

150

160

170

INSTALL LABEL HERE

OR HERE

20

30

40

50

60

70

80

90

24

M

ACHINE LABELS

LBL-WSE-01170 (170 LB)

LBL-WSE-01250 (250 LB)

LBL-WSM-01170 (77 KG)

LBL-WSM-01250 (114 KG)

LBL-WRN-0002

WARNING

!

SERIOUS INJURY CAN OCCUR ON

THIS EQUIPMENT IF THE PIN IS NOT

COMPLETELY INSERTED BEFORE USE.

ASTM F1749

P/N B2065

WARNING

!

MAXIMUM

Height Under Nut

to Bolt Head.

MAKE SURE

locking nut is tight.

B2141C

B2141C

MAX

1”

!

W ARNING

SERIOUS INJURY CAN OCCUR

ON THIS EQUIPMENT IF THE

CABLES AND THEIR ATTACH-

MENT COMPONENTS ARE NOT

INSPECTED OFTEN. REPLACE

AT FIRST SIGNS OF WEAR.

B2051

LBL-PR-FS53

P/N B2051

B2065

WARNING

!

USE THIS LAT BAR ON PARAMOUNT LAT STATIONS WITH 250 LBS

OR LESS. INSPECT CABLE FITTING AND CONNECTIONS PRIOR TO

USE. BE CERTAIN THAT THE CONNECTIONS ARE SECURE. FAILURE

TO FOLLOW THESE PROCEDURES MAY RESULT IN SERIOUS

INJURY.

LBL-WRN-0003

LBL-WRN-0003

If this machine is to be installed in a

public use facility, ASTM F1749

requirements specify that the facility

sign shown to the right is to be

installed in plain view.

If you did not receive the facility sign

with your order, you can obtain one

free of charge from Paramount by

calling 1-800-721-2121.

BE ALERT!

THE FITNESS EQUIPMENT IN THIS FACILITY

PRESENTS HAZARDS WHICH, IF NOT AVOIDED,

COULD CAUSE SERIOUS INJURY OR DEATH.

PRIOR TO USING THE EQUIPMENT, READ THE WARNING LABELS

AND INSTRUCTION PLACARDS AFFIXED TO EACH MACHINE.

IF YOU ARE UNSURE ON HOW TO USE A MACHINE, SEEK THE

ASSISTANCE OF OUR FLOOR PERSONNEL. WE WILL BE HAPPY

TO INSTRUCT YOU ON HOW TO USE THE EQUIPMENT PROPERLY.

IMMEDIATELY REPORT ANY PIECE OF EQUIPMENT THAT IS NOT

FUNCTIONING PROPERLY TO OUR FLOOR PERSONNEL SO THAT

IT MAY BE EVALUATED AND SERVICED PROMPTLY.

DO NOT ATTEMPT TO USE OR FIX ANY PIECE OF EQUIPMENT

THAT IS NOT FUNCTIONING PROPERLY

ASTM F1749-96

25

S

ERVICE

H

OW TO OBTAIN SERVICE

For warranty service, contact an Authorized Paramount Dealer or a Paramount Customer

Service representative at 1-800-721-2121 or 1-323-721-2121. You can also email us at

nasales@paramountfitness.com.

Before you call, please have the following information ready:

• Model Number: FS-53

• Serial Number: ________________________

• Date of Installation: ____________________

• A brief description of the problem

The serial number is located on the rear of the upright

frame at the bottom as shown.

F

INAL CHECK

1. If you haven’t already done so, lubricate the guide rods and seat adjustment tubes with

a teflon spray lubricant. Paramount recommends using TriFlow

2. Adjust the thigh pad through each position. Verify that the adjustment pin insert freely

into each position and is fully engaged.

3. Place the selector pin into the holder on the cap plate. Pull the Lat cable out slowly until

the cap plate tops out against the top upright frame. Verify that the cable moves freely,

without any binding. Repeat this procedure with the row cable.

4. Verify that the selector pin can be inserted into each weight plate.

5. Perform the exercise on each station to verify the cable routes smoothly and the

machine operates correctly.

26

Serial Number

TM

brand.

FS B

The machines in this product line were designed and tested to meet the ASTM (American) and EN

(European) safety standards for stability (without floor anchors) when the machine is used for it’s

intended purpose as designated by the manufacturer.

However, Paramount strongly recommends that all equipment be anchored to the floor to prevent

movement and increase stability.

OLT DOWN INSTRUCTIONS

• You will need to order an anchoring kit for each machine. This kit will include brackets and

instructions for securing the brackets to the machines. Note: the kit does not include the

floor anchor bolts. Order part number: FS-BLTDN-000X, 1 kit per FS machine.

• Due to the wide variation of flooring on which the unit can be installed, contact a qualified

contractor to determine an appropriate fastening system for your floor.

• Use 3/8” diameter hardware (10 mm) to anchor the machine. Anchors should have a

minimum pull out force of 220 lbs (110 kgs) for each position.

• When attaching the machine to the floor, if there is a gap between the machine foot (or

bracket) and the floor, do not use the anchor to remove the gap as this can cause the

machine frame to deform. Instead, place a shim between the bottom of the foot and the

floor, then tighten the anchor.

Floor Anchor Point

Upright hold down brackets with hardware

(included in kit, qty 2)

Floor Anchor Point

Main frame hold down bracket

(included in kit, qty 1)

Re-uses existing machine

hardware. Refer to kit instructions

for details.

1

P

ARAMOUNT LIMITED

READ PARAMOUNT’S WARRANTY SET FORTH BELOW PRIOR TO USING PARAMOUNT PRODUCTS. BY INITIAL USE OF PARAMOUNT

PRODUCT YOU ARE CONSENTING TO BE BOUND BY THE FOLLOWING WARRANTY TERMS AND CONDITIONS. THE WARRANTY

PERIODS COMMENCE ON THE INVOICE DATE OF THE ORIGINAL PURCHASE. LABOR COVERED DURING WARRANTY PERIODS

REQUIRES PRIOR AUTHORIZATION OF PARAMOUNT. PARAMOUNT WARRANTS TO THE ORIGINAL BUYER OF ALL NEW EQUIPMENT

PURCHASED FROM A PARAMOUNT AUTHORIZED DEALER OR FROM A PARAMOUNT AUTHORIZED MANUFACTURING CONTRACTOR

THAT THESE PRODUCTS WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USE AND SERVICE FOR

THE FOLLOWING PERIODS AND IN THE FOLLOWING RESPECTS:

STRENGTH PRODUCTS

• TEN YEAR WARRANTY COMMERCIAL PRODUCTS – Frame Components and Welds excluding coatings

• FIVE YEAR WARRANTY - Bronze Bushings, Sealed Rotating Bearings, Pulleys, Weight plates and Guide Rods excluding coatings

• ONE YEAR WARRANTY - Cables, Linear Bearings and Shafts and all other components not mentioned elsewhere in this warranty

• 90-DAY WARRANTY - Normal wear parts including but not limited to labels, upholstered pads and grips

• ONE YEAR WARRANTY – Labor

THE SHIPPING MODE OF PARTS REPLACED UNDER WARRANTY TO BE DETERMINED BY PARAMOUNT. PARTS REPLACED UNDER

WARRANTY CARRY THE REMAINING ORIGINAL WARRANTY PERIOD OR 90 DAYS, WHICHEVER IS LONGER.

THIS LIMITED WARRANTY DOES NOT COVER AND NO WARRANTY IS GIVEN WITH RESPECT TO:

• Products not manufactured by Paramount or by an Authorized Paramount Manufacturing Contractor.

• Products which are altered without the express written consent of Paramount.

• Products purchased other than directly from Paramount or through a Paramount Authorized Dealer.

• Defective paint, chrome and other coatings caused by environmental conditions including but not limited to climate conditions,

cleaning materials and moisture or humidity coming from HVAC systems.

• All parts including but not limited to frames with cosmetic damage. Such damage includes but is not limited to scratches and

dents caused after the initial installation.

• Products not maintained in compliance with Paramount’s specifications as shown in the owners’ manual and on product labels.

• Products with a missing, unreadable or altered serial tag.

• Labor for components beyond their warranty coverage.

• On site service calls to solve installation errors or to provide technical training on the proper use and servicing of the equipment.

W

ARRANTY

THIS WARRANTY APPLIES UNDER THE FOLLOWING CONDITIONS.

• These products have not been subjected to misuse, abuse, modifications not authorized by Paramount or any damage caused

by improper handling, natural disasters, acts of God or servicing by non-Authorized Dealers. This includes but is not limited to

the relocation of the product and the application of cleaning materials or lubricants not specified by Paramount.

• These products remain in possession of the original purchaser.

• Warranty claims are made within the warranty periods previously shown and that such claims occur within 30-days after the

date of discovery.

• Labor coverage applies only within the United States and Canada.

• Warranties for parts and labor may vary outside the United States. Contact the Paramount Dealer within your geographic area

for warranty terms.

• Maximum load capacities as specified by Paramount are not exceeded.

THE OBLIGATION OF PARAMOUNT UNDER THIS WARRANTY IS LIMITED TO REPAIRING OR REPLACING WARRANTED DEFECTIVE

PARTS, AS PARAMOUNT MAY ELECT, AT PARAMOUNT'S PLANT IN LOS ANGELES, CALIFORNIA. PURCHASER IS RESPONSIBLE FOR

ALL TRANSPORTATION AND INSURANCE COSTS ON RETURNED OR REPLACED EQUIPMENT TO AND FROM PARAMOUNT'S PLANT IN

LOS ANGELES. ANY IMPLIED WARRANTY, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE AND THE IMPLIED WARRANTY OF MERCHANTABILITY, IS LIMITED TO ONE-YEAR DURATION FROM THE DATE

OF DELIVERY TO THE ORIGINAL PURCHASER. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. THE REMEDY OF REPAIR AND REPLACEMENT IS THE EXCLUSIVE AND

SOLE REMEDY OF THE PURCHASER.

PARAMOUNT SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONTINGENT OR CONSEQUENTIAL DAMAGES OF ANY KIND,

INCLUDING, BUT NOT LIMITED TO, DAMAGE OF LOSS OF PROPERTY OR EQUIPMENT AND LOST PROFITS AND REVENUE. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU. NO ACTION FOR BREACH OF THIS WRITTEN LIMITED WARRANTY OR AN IMPLIED

WARRANTY SHALL BE COMMENCED MORE THAN ONE YEAR AFTER THE ACCRUAL OF THE CAUSE OF ACTION. THIS WRITTEN LIMITED

WARRANTY IS THE COMPLETE, FINAL AND EXCLUSIVE AGREEMENT OF THE PARTIES WITH RESPECT TO THE QUALITY OR

PERFORMANCE OF THE GOODS AND ANY AND ALL WARRANTIES AND REPRESENTATIONS. NO MODIFICATIONS OF THIS LIMITED

WARRANTY OR WAIVER OF ITS TERMS SHALL BE BINDING ON EITHER PARTY UNLESS APPROVED IN WRITING BY AN AUTHORIZED

CORPORATE OFFICER OF PARAMOUNT. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE

OTHER RIGHTS, WHICH MAY VARY, FROM STATE TO STATE. CONTACT PARAMOUNT FITNESS CORP., 6450 E. BANDINI BLVD., LOS

ANGELES, CALIFORNIA 90040-3185, FOR A LIST OF AUTHORIZED DEALERS OR BEFORE RETURNING ANY DEFECTIVE EQUIPMENT.

PARAMOUNT FITNESS CORP. ©JANUARY 1, 2014.

1

N

OTES

N

OTES

Phone: 1-323-721-2121 Fax: 323-724-2000

Paramount Fitness Corporation

6450 E. Bandini Blvd.

Los Angeles, CA 90040-3185

1-800-721-2121

www.paramountfitness.com

Loading...

Loading...