1

BM30 Planetary Mixer

INSTALLATION / OPERATION

MANUAL

F26292-6

2

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in

writing by the manufacturer.

In line with policy to continually develop and improve its products, Moffat Ltd. reserves the right to change the specifications and

design without prior notice.

© Copyright Moffat Ltd. July 2010.

INTERNATIONAL CONTACTS

AUSTRALIA

Moffat Pty Limited

E.Mail: vsales@moffat.com.au

Main Office: (tel) (03) 9518 3888

(fax) (03 9518 3833

Service: (tel): 1800 622 216

Spares: (tel): 1800 337 963

Customer Service: (tel): 1800 335 315

(fax): 1800 350 281

CANADA

Serve Canada

Web: www.servecanada.com

E.Mail: info@servecanada.com

Sales: (tel): 800 551 8795 (Toll Free)

Service: (tel): 800 263 1455 (Toll Free)

NEW ZEALAND

Moffat Limited

Web: www.moffat.co.nz

E.Mail: sales@moffat.co.nz

Main Office: (tel): 0800 663328

UNITED KINGDOM

Blue Seal

Web: www.blue-seal.co.uk

E.Mail: sales@blue-seal.co.uk

Sales: (tel): 0121 327 5575

(fax): 0121 327 9711

Spares: (tel): 0121 322 6640

(fax): 0121 327 9201

Service: (tel): 0121 322 6644

(fax): 0121 327 6257

UNITED STATES

Moffat

Web: www.moffat.com

Sales: (tel): 800 551 8795 (Toll Free)

(tel): 336 661 1556

(fax): 336 661 9546

Service: (tel): 800 858 4477 (Toll Free)

(tel): 366 661 1556

(fax): 336 661 1660

REST OF WORLD

Moffat Limited

Web: www.moffat.co.nz

E.Mail: export@moffat.co.nz

1

Introduction............................................................................................ 2

Specifications.......................................................................................... 3

Installation ............................................................................................. 4

Operation ................................................................................................ 5

Cleaning and Maintenance ..................................................................... 8

Competency Checklists ........................................................................... 9

Operations Competency Checklist

Daily Cleaning Competency Checklist

Risk Assessment ...................................................................................12

Replacement Parts List ......................................................................... 13

Wiring Diagrams ................................................................................... 14

Date Purchased .......................................................... Serial No.....................................................

Dealer.............................................................................................................................................

Service Agent ..................................................................................................................................

Contents

2

Introduction

We are confident that you will be delighted with your PARAMOUNT MIXER, and it will become a most

valued appliance in your commercial kitchen.

A new mixer can seem very complex and confusing at first glance. To ensure you receive the utmost

benefit from your new Paramount, there are two important things you can do.

Firstly

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly

If you are unsure of any aspect of the installation, instructions or performance of your oven, contact your

Paramount dealer promptly. In many cases a phone call could answer your question.

The Paramount BM30 is a dependable mixer for kneading and mixing all kinds of dough, egg, cream,

cookies, mayonnaise etc. The mixer works smoothly and reliably. The mixer has 3 speed selections and

an electronic timer. The mixer comes with various style attachments which can be used to obtain the

best results. These are made of alloy aluminum or are made of a food hygiene standard material.

This model Mixer is equipped with a powerful 1HP motor and strong belt & gear drive design. The gears

are made of hardened alloy steel and a hardened steel worm wheel. A stainless steel safety guard and

electronic timer are available on all models.

With proper operation and maintenance this mixer will give you years of service, and obtain the best

results.

Introduction

Safety Precautions

• Keep hands and clothing away from the bowl and hob attachments when in operation.

• Keep rigid objects away from the bowl and hub attachments when in operation.

• Do not use this machine for any applications other than food processing.

• Use the machine only with the electrical supply specified on the rating plate.

• Disconnect the machine from its power source before carrying out any maintenance.

• Do not disable or remove any of the safety mechanisms included with this machine.

• Do not leave the machine in operation unattended.

• Observe all maintenance and safety inspection schedules.

• Ensure the machine and any accessories / attachments are in stable, upright position before

operating.

• Ensure all safety features of the machine are fitted and operate correctly within the safety

requirements and procedures before operating the machine.

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment. Failure to do so may result in serious injury or

damage.

3

Specifications

Motor

1 HP (0.75kW) powerful, ball bearing, ventilated within mixer enclosure.

Electrical Supply

230-240 Volts AC, 50Hz, 1P+N+E

or 400-415 Volts AC, 50Hz, 3P+E

Transmission

The gears are a constant mesh gear in a special lubricant assuring long life; transmission gears are

of heat treated alloy steel, of high accuracy construction. All bearings are ball bearings. Positive

timing belt drive eliminates slip and speed variation.

Electronic Timer

The timer will stop the mixer when the desired time has elapsed.

Emergency ‘Stop’ Button

Located on the Control Panel on the right hand side of the machine. Pressing this button will stop

all movement of the machine.

The Emergency Stop Button should only be used in cases of emergency and SHOULD NOT be

used as the standard OPERATING method of stopping the mixer.

Safety Guard

Stainless steel safety guard smoothly rotates open. Fitted with a limit switch to shut off power

immediately to protect the operator.

Hub

The hub is only for the BM30HAT models.

Dimensions

Model

BM30AT BM30HAT

Description

30 litre

Mixer

30 litre

Mixer

(with Hub)

Motor

Power

1.0 HP (0.75 kW)

Net Weight

(approx.)

150 Kg

Agitator

Speed

(RPM)

Low 100

Med 182

High 381

4

Before installing the mixer, check that the available electrical supply match that

of the mixer as stated on the mixer’s rating plate.

Installation

Unpacking

Immediately after unpacking the mixer, check it for possible shipping damage. If this machine is

found to be damaged after unpacking, save the packaging material and contact the carrier within

one day of delivery.

Location

Place the mixer in its operating location - this should be a sturdy level surface. There should be

adequate space around the mixer for the user to operate the control and install and remove bowls.

Holes are provided in the base to permanently secure the mixer, although this not necessary in

normal installations.

Floor models must be leveled front-back and side-to-side by sliding shims under the legs as

required.

Electrical Connection

The supply cord on this machine is provided with a three-pin 13A fused and earthed plug. It is

imperative that the outlet to which this plug is connected be properly earthed (grounded).

Prior to installation, test the electrical service to assure it agrees with the specifications on the

machine data plate located on the back side of the pedestal.

Permissible voltage fluctuation is ± 10% of nominal voltage.

Components having adjustments protected (e.g. paint sealed) by the manufacturer, are

only allowed to be adjusted by an authorised service agent.

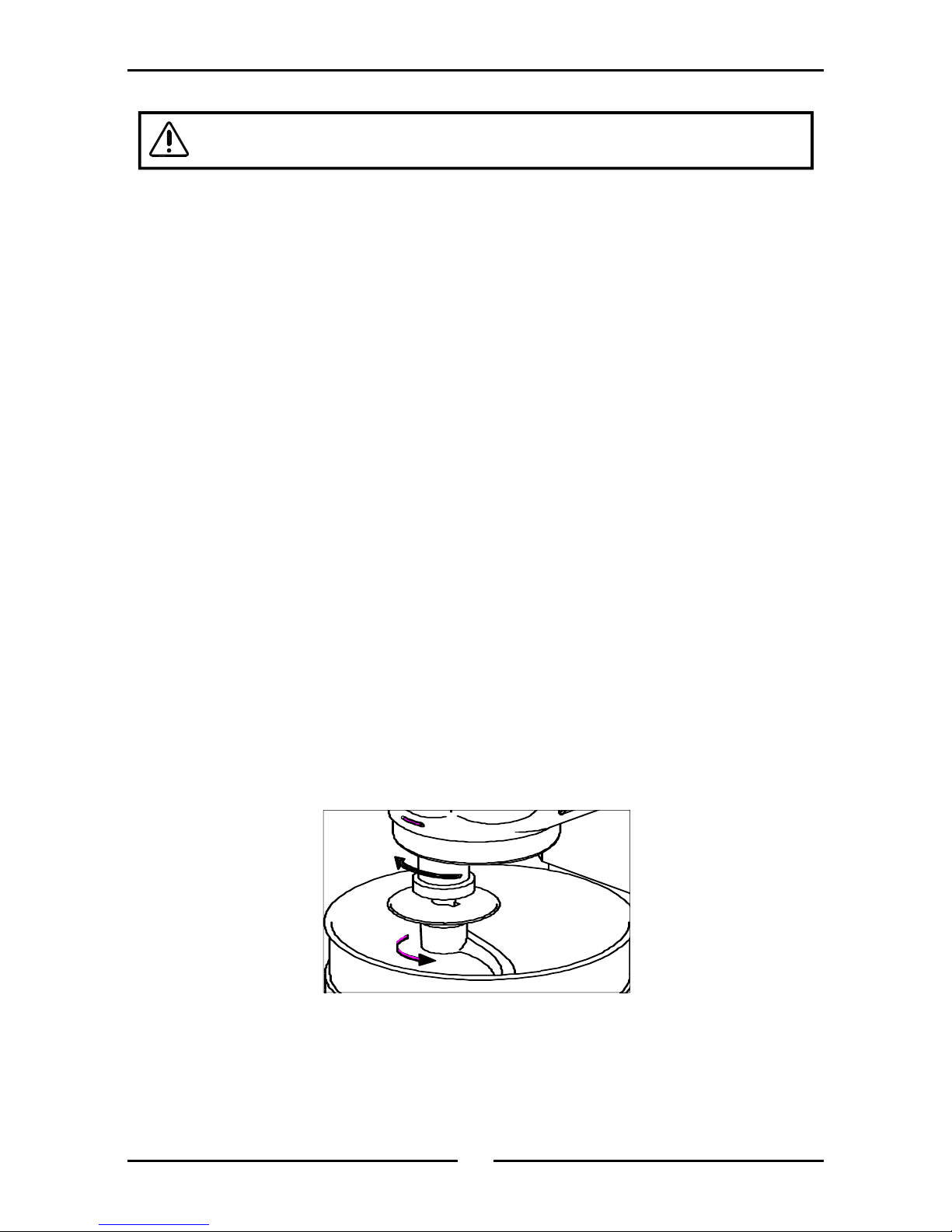

Rotation

To start the motor, push the 'ON' button. The speed selector handle must be at one of the

numbers indicating a speed and not located between the numbers.

Figure 1

5

Operation

Keep hands, clothing and utensils out of the bowl whilst the machine is in operation.

Failure to follow the operation instructions or improper use of the mixer may result in

damage to the mixer, or cause injury to the operator.

Controls

All models are fitted with an 'ON' / 'OFF' switch and an emergency stop button which controls power to

the mixer.

The Electronic Timer is used in conjunction with the 'ON' / 'OFF' switch for timed mixing operations and

will stop the mixer when the desired timed has elapsed.

The Gear Shift Lever is used to change speeds. Always stop the mixer before changing speeds. To

change speeds, turn the switch 'OFF', move the gear shift lever to the desired speed, and turn the switch

back 'ON'.

Speed 1 (Low) - This speed is for heavy mixtures such as bread dough, heavy batters, and potatoes.

Speed 2 (Medium) - This speed is for light dough which must rise quickly, heavy batters, and some

whipping operations.

Speed 3 (High) - This speed is fast speed for light work such as whipping cream, beating eggs, and

mixing thin batters.

Important:

Great care must be taken to minimise dust emission when handling dry ingredients such as flour. Bags

should opened in the lower part of the bowl and poured from as close to the base of the bowl as possible.

It is recommended that ingredients suppliers’ hazard data sheets are consulted prior to use. The use of

respiratory protective equipment may be required during loading of the bowl.

Figure 2

Bowl Lift Slides

Bowl Lift Handle

Bowl

Guard

Drip Cup

Gear Shift Lever

Electronic Timer

‘Emergency ‘Stop’ Button

‘On’ / ‘Off’ Power Switch

6

Emergency ‘Stop’ Button

The Emergency Stop Button should only be used in cases of emergency and SHOULD NOT be

used as the standard OPERATING method of stopping the mixer.

Located on the right hand side of the machine, on the Control Panel. Pressing this button will stop all

movement of the machine. ONLY ATTEMPT TO RE-START AFTER THE FAULT IS CORRECTED.

The machine cannot be re-started until:- The Emergency Stop Button is pulled up to release.

Mixing Bowl / Agitators

New mixers bowls and agitators (beaters, whip, and dough arms) should be thoroughly washed with hot

water and mild soap solution, rinsed with either a mild soda or vinegar solution, and thoroughly rinsed

with clean water BEFORE being put into service. This cleaning procedure should also be followed for

bowls and agitators before whipping egg whites or whole eggs.

Fitting the Bowl

The bowl must be installed before the agitator. To install the bowl, fully lower the bowl support (Fig. 2).

Position the bowl so the alignment bracket on the back of the bowl is in the bowl retainer and the

alignment pins on the front of the bowl support fit in the holes on the sides of the bowl.

Fitting the Agitators

To install an agitator, the bowl must be installed and fully lowered. Place the agitator in the bowl, push it

up on the agitator shaft, and turn it clockwise to seat the shaft pin in the slot of the agitator shank.

Dough Arm (Fig 3)

It is frequently used for heavy bread dough, and preferably

used at low speed.

The moisture content of heavy dough is a critical when

selecting proper mixing speed. The 2

nd

speed should never

be used when mixing heavy dough with an Absorption Ratio

(AR) of 50% or less.

Beater (Fig 4)

It is commonly used for thin batters, cake and mashing

potatoes, like stuffing and preferably used at middle speed.

Whip (Fig 5)

It is best for whipping cream and beating eggs and

preferably used at high speed.

Operation

M

ODEL NO.

M

ODEL NO.

M

ODEL NO.

Fig 3

Fig 4

Fig 5

7

Operation

* 1st speed only.

** 1

st

speed & 2nd speed only.

†

If high gluten flour is used, reduce above dough batch size by 10 %.

Attachments - Optional

To install an attachment, loosen the thumb screw on the attachment hub and remove the plug. Insert

the attachment into the attachment hub making certain that the square shank of the attachment is in the

square driver of the mixer. Secure the attachment by tightening the thumb screw.

Move the gear shift lever to the desired speed and start the mixer to operate the attachment.

The meat and food chopper attachment should be operated in second or third speed. If material in the

cylinder stalls the mixer, stop the mixer at once. DO NOT attempt to restart the mixer in a lower speed remove the adjusting ring, knife, plate, and worm and clear the obstruction.

Mixing Heavy Dough

The moisture content of heavy dough is a critical factor when selecting proper mixing speed. Do NOT use

2

nd

speed when mixing heavy dough with an Absorption Ratio (AR) of 60% or less. To determine the

Absorption Ratio (AR) of a product, the water weight divide by the flour weight.

Example: Calculate the Absorption Ratio of a mixture containing 2 kg of water and 4 kg of flour.

AR = 2 ÷ 4 = 0.50 = 50 %.

Product Agitator BM30

Egg Whites Whip 1 - 1½ ltrs

Mashed Potatoes Beater 9 kg

Mayonnaise (Litres Oil) Beater 11 ltrs

Meringue (Litres Water) Whip 1 ltr

Waffle/Pan cake Batter Beater 11 ltrs

Whipped Cream Whip 5.5 ltrs

Sheet Cake Batter Beater 9 kg

Cup Cake Beater 30 doz

Layer Cake Beater 13.5 kg

Pound Cake Beater 10 kg

Sugar Cookie Beater 50 doz

Raised Donut Dough (65% AR) Hook * 7 kg

Whole Wheat Dough ( 70% AR) Hook ** 18 kg

Egg & Sugar for Sponge Cake Beater * 5.5 kg

Bread or Roll Dough (Light / Medium, 60% AR)† Hook * 18 kg

Bread or Roll Dough (Heavy, 55% AR)† Hook * 11 kg

Pie Dough Beater 11 kg

Thin Pizza Dough (40% AR†, 5 minutes maximum mix time) Hook * 6.5 kg

Medium Pizza Dough (50% AR)† Hook * 9 kg

Thick Pizza Dough (60% AR)† Hook * 18 kg

8

Cleaning / Maintenance

C

AUTION

:

ALWAYS TURN OFF THE POWER SUPPLY BEFORE CLEANING OR MAINTENANCE

THIS UNIT IS NOT WATER PROOF.

DO NOT USE WATER JET SPRAY TO CLEAN INTERIOR OR EXTERIOR OF THIS UNIT.

Cleaning Guidelines

The mixer should be thoroughly cleaned daily with a clean damp cloth and plastic scraper (metallic

implements are not recommended.

Never use a metal or stiff brush to clean the mixer. Never clean the mixer with a water hose or any

fluid pressure.

Bowls and agitators should be removed from the mixer and cleaned in a sink. The bowl guard should

be removed periodically and wiped clean.

Maintenance Guidelines

The Transmission Case and Planetary Mechanism should be inspected weekly for leaks, damage,

etc. Should it become necessary to repack the ball bearings, an authorized service technician or the

manufacturer should be contacted. Use of unproved grease or lubricants may lead to damage and

void the unit’s warranty.

The Bowl Lift Slides (Figure 2) should be lubricated every six months, or more often under heavy

usage.

Disconnect the unit from the power supply before removing the top housing or apron.

The Drip Cup (Figure 2) should be inspected periodically for moisture or lubricant dripping. Remove

the cup and wipe it with a soft cloth.

Any parts found to be damaged, defective or worn out should be replaced immediately.

Fault Finding

Fault Possible Cause Remedy

The mixer does not operate. The mains isolating switch on the

wall, circuit breaker or fuses are

'Off' at the power board.

The mixer electronic timer is set

to ’0’.

Turn 'On'.

Set time setting, or set electronic

timer to '0' to allow manual

operation.

Mixer stops during operation. Mixer overload tripped.

(Ensure that mixer is not being

overloaded - refer to table on

previous page for capacity guide).

Single phase models:

Press reset button at rear of

mixer.

Three phase models:

Call service

9

Competency Checklists

Guide Sheets for Staff Training

The pages in the following section of this manual should be copied and used when training staff to

operate the Paramount mixers. It is suggested that the competency assessment checklists be completed,

signed, and a copy kept in the personnel files for future reference.

Supervisors to Ensure

• Competency check lists are copied and completed as part of the training of staff.

• Correct training of staff to the required competency expectations.

• The verification section of the competency check list is signed off.

• A copy of the completed and signed competency check list is placed in personnel records as

evidence of operator competence.

10

Paramount Planetary Mixer

Element:

Implement safe work procedures

Assessment Criteria

“Can the operator”

Identify the purpose and use of:

• Equipment guards.

• Warning signs.

• Safety features.

Related to this equipment?

Identify:

• Machine-related health and safety risks of this equipment?

• Emergency procedures to be used with this equipment?

Operate this equipment correctly in normal and emergency situations?

Identify:

• OH&S reporting procedures related to hazard reporting for this machine?

Comments:

To gain competency in the use of the PARAMOUNT PLANETARY MIXER, the assessor must be

satisfied that the operator has consistently applied the knowledge and skills in all of the above elements.

This form should be signed off only when the assessor is satisfied that the

employee/trainee is competent to carry out all of the tasks described above.

Applicant’s signature:

Date: / /

Assessor’s signature:

Date: / /

Operations Competency Checklist

SUGGESTION

— Use this form to train staff, and place a copy in personnel files.

11

SUGGESTION

— Use this form to train staff, and place a copy in personnel files.

Daily Cleaning Competency Checklist

Assessment Criteria

“Can the operator”

Maintain sound personal hygiene at all times when working with the PARAMOUNT MIXER?

Use appropriate protective and work clothing while working with the PARAMOUNT MIXER?

Identify:

• Product handling requirements during production process?

• Critical points in the process where contamination can be introduced?

• Why it is important to monitor hygiene and sanitation performance?

• The effect of poorly maintained equipment on the control of contamination and spoilage?

• Company policies and procedures regarding hygiene and sanitation?

• Actual and potential contamination and spoilage hazards?

• Solutions to rectify contamination and spoilage problems?

Use work practices and methods that reduce the risk of product contamination?

Remove contamination where appropriate in accordance with:

• Workplace hygiene and sanitation procedures?

• Procedures specific to the PARAMOUNT MIXER?

Paramount Planetary Mixer

Element:

Implement essential hygiene and sanitation procedures

This form should be signed off only when the assessor is satisfied that the

employee/trainee is competent to carry out all of the tasks described above.

Applicant’s signature:

Date: / /

Assessor’s signature:

Date: / /

Comments:

To gain competency in the use of the PARAMOUNT PLANETARY MIXER, the assessor must be

satisfied that the operator has consistently applied the knowledge and skills in all of the above elements.

12

Risk Assessment

The following risk assessment covers the reasonably foreseeable hazards to health and safety arising from

the mixer and from systems of work associated with this machine.

Risk Rating Extreme Risk Immediate action required.

High Risk Senior management attention required.

Moderate Risk Management responsibility must be specified.

Low Risk Manage by routine procedures.

Based on AS4360 1999 Risk Management.

Hazard Identified Existing Controls Consequences Likelihood Risk Rating

Cleaning the machine with buckets of

water or hoses is extremely dangerous

and may lead to electrocution. The

machine must be cleaned with a damp

cloth only.

Safe work cleaning practices

included in training manual

local workplace rules and

management.

Catastrophic Rare High

Microswitch on safety guard should never

be removed nor tampered with otherwise

machine could continue working with

moving parts exposed.

Safe work guidelines

reinforce non-authorised

tampering with the machine.

Access to microswitches

service item only.

Major injuries Rare Moderate

Electrical isolation switch should be fully

accessible to the operator. Recommend

no more than 1.5 metres above the floor

and within easy access by the operator.

Dependent on bakery

electrical policy.

Major injuries Rare High

Safety guard should not be removed. Microswitch interlocked with

machine - controls will not

operate.

Major injuries Unlikely Moderate

Service panels should not be removed

whilst the machine is in operation nor still

connected to the power supply. The

machine must not be operated with any

service access panel removed.

Machine designed to be

accessed by authorised

service technicians only.

Warning signs clearly

evident.

Major injuries Unlikely Moderate

Hands or arms should not be placed

behind bowl whilst the machine is in

operation.

Safe operating procedure

reinforces this not to be

done.

Warnings in place.

Minor injuries Unlikely Low

Hands should never be placed near dough

hook whilst in motion.

Bowl guarded during

operation. Safe operating

procedures highlight safe

work.

Major injuries Unlikely Moderate

Cleaning of the machine should not take

place whilst it is in operation nor still

connected to the power supply.

Correct cleaning procedure

detailed in training

procedure.

Major injuries Unlikely Moderate

The machine should never be connected

to alternate power source other than that

which it has been designed for and

specified within this manual.

External plug designed to

Australian / New Zealand

standards for the appropriate

power supply.

Warnings in manual.

Major injuries Rare Moderate

Owners and Operators of Paramount Equipment Please Note:

The risk ratings and control measures as outlined in this manual must be incorporated into your safety

management systems and procedures. Ensure effective risk control by reinforcing these procedures with

staff. For example: Never clean any electrical equipment with buckets of water or pressurised hoses.

13

Replacement Parts List

Replacement Parts List

When ordering replacement parts, please quote the part number and the description as listed below. If

the part required is not listed below, request the part by description and quote model number and

serial number which is shown on the Rating Plate located on the front lower corner of the right hand side

panel.

Part No. Description

BM30AT-12-001 Stainless Steel Bowl.

BM30AT-12-003 Aluminium Hook.

BM30AT-12-004 Stainless Steel Wire Whip.

BM30AT-12-002 Batter Beater.

BM30AT-06-003 HUB Attachment Drive.

HL-GL12SH Mincer.

HL-VS12A Slicer / Shredder.

BM30ATM 20 litre Reduction Kit (includes Bowl, Hook & Beater).

T.B.D. Electronic Timer.

IMPORTANT:

Only genuine authorized replacement parts should be used for the servicing and

repair of this appliance. The instructions supplied with the parts should be followed

when replacing components.

For further information and servicing instructions, contact your nearest authorized

service branch (contact details are as shown on the reverse of the front cover of this

manual).

14

Wiring Diagrams

Single Phase Models

Three Phase Models

15

Loading...

Loading...