Page 1

Parameter Generation and Control, Inc.

Black Mountain, North Carolina

(828) 669-8717

500-1000 CFM Air Handler

460V, 60 Hz

Model #9354-4250

Installation and Operation Manual

Customer

Serial #

Ship Date

Parameter Generation and Control, Inc.

P. O. Box 129 1054 Old US 70 West Black Mountain, NC 28711

(800) 438-5494 (828) 669-6928 FAX

.

.

.

Page 2

PGC Inc. Horizontal 500-1000 CFM June 2006

Parameter Generation and Control, Inc.

2

Page 3

PGC Inc. Horizontal 500-1000 CFM June 2006

Inspection........................................................................................................................ 4

Installation....................................................................................................................... 4

Plumbing..................................................................................................................... 4

Electrical Connections................................................................................................7

Electrical Connections................................................................................................8

Operation......................................................................................................................... 9

Turning the Chamber Off and On............................................................................... 9

Process Variable Display.......................................................................................... 10

Adjusting Set Points.................................................................................................. 10

Operation After Loss of Power................................................................................. 10

Fault Displays ........................................................................................................... 11

Control Modes .......................................................................................................... 12

Specifications, 500-1000 CFM..................................................................................... 13

Replacement Parts, 500-1000 CFM.............................................................................. 14

Appendices

Appendix A – Technical Information

Appendix B – SmartPad™ Operation Manual

Appendix C – Diagrams

Appendix D - Manuals for Accessory Equipment

Parameter Generation and Control, Inc.

3

Page 4

PGC Inc. Horizontal 500-1000 CFM June 2006

Inspection

If the equipment is damaged upon receipt, immediately request the delivering carrier to

perform an inspection and prepare a report. All claims for damage must be made against

the delivering carrier. Report the nature and extent of the damage to PGC, 828-669-8717,

and include instrument serial and catalog numbers to facilitate repair or replacement.

Installation

The 500-1000 CFM Conditioner was designed to be located adjacent to or on top of the

chamber to be conditioned. Allow at least 36 inches on the right side and front of the unit

for service. The location must be convenient to an adequate process water supply, drains

and electrical power. The conditioner must be reasonably level for proper water level

control.

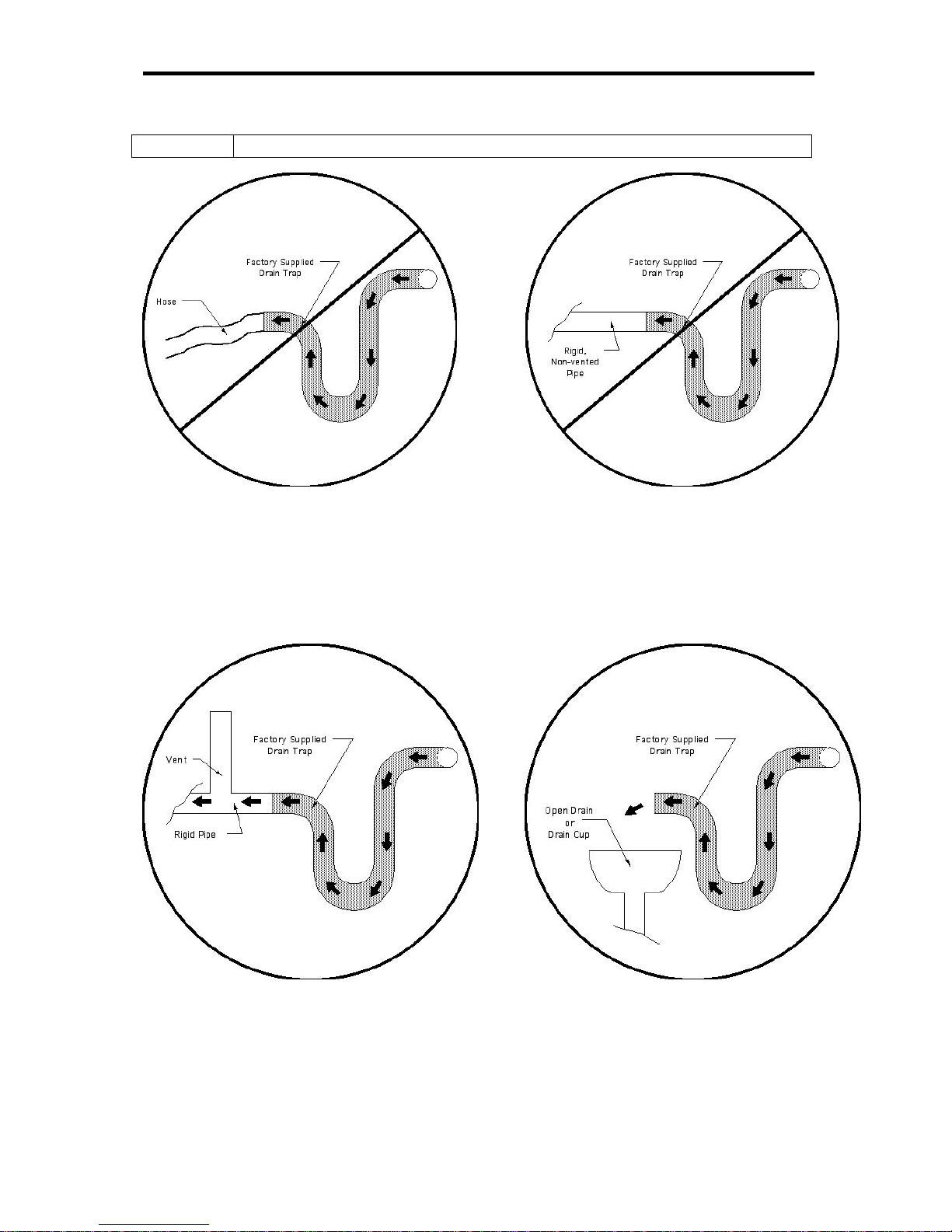

Electrical power and water must be connected to this unit prior to operation. The required

voltage and current are listed on the nameplate located on the unit. The sump drain may

be connected directly to a facility drain, but the condensate drain must be connected to an

open (vented) trapped drain (see Figure 3) to ensure that backpressure on the facilities’

drain does not prevent proper drainage.

Note

The condensate drain has been supplied with a copper trap.

Plumbing

To prevent damage to the water pump and water heater, the unit must not

CAUTION

be operated until water is supplied to the unit and the sump has filled to the

proper level.

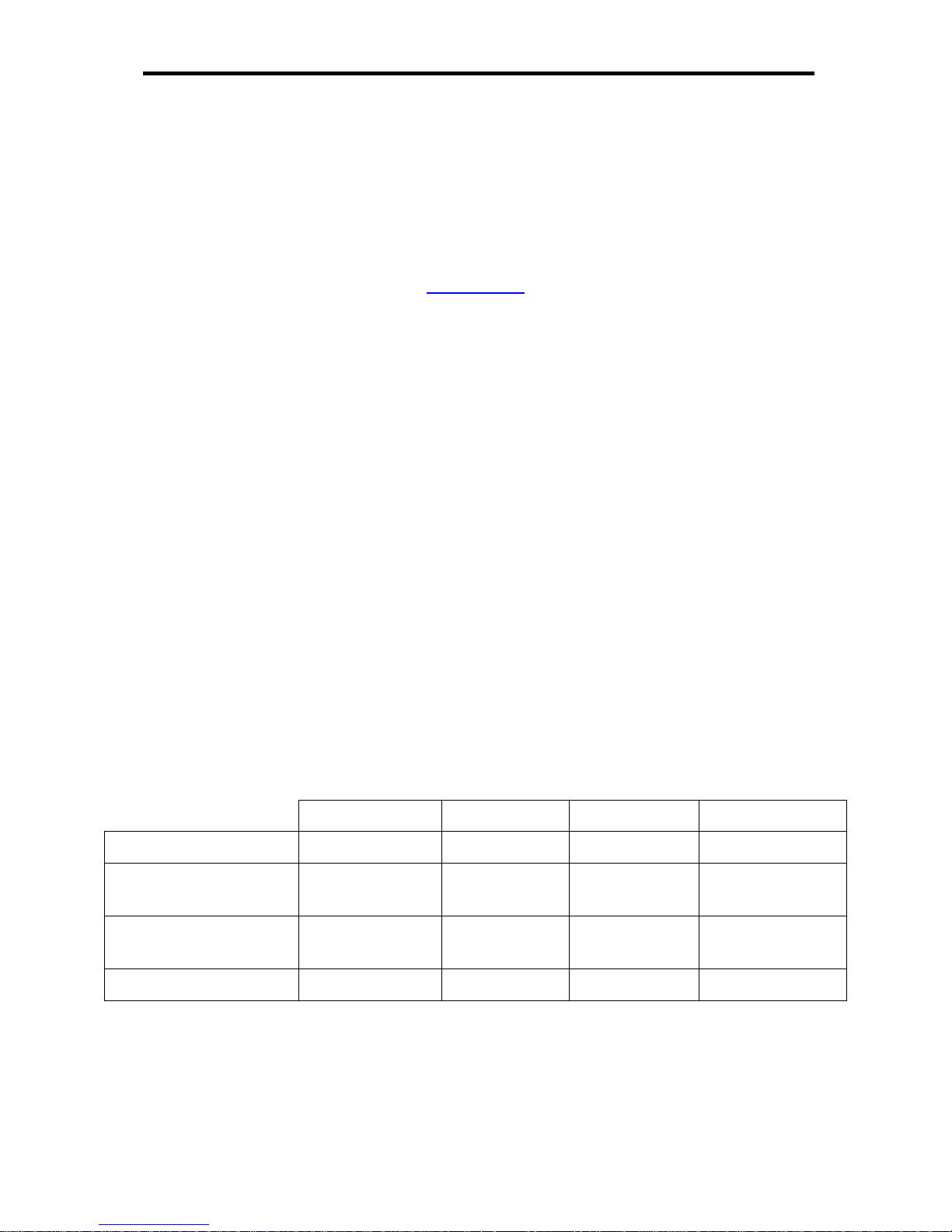

Process Water Supply Specifications

Units Maximum Typical Minimum

Process Water Pressure PSIG (Bar)

Process Water Daily

Gallons (Liters)

125 (8.6) N/A 5 (0.35)

5.0 (19) 1.5 (5.7) 0 (0)

Consumption

Condensate Production

Gallons (Liters)

5.0 (19) 1.5 (5.7) 0 (0)

per Day

Sump Water Volume Gallons (Liters)

15 (57) 15 (57) 6.6 (25)

Process Water Inlet

Connect a clean water supply line through an external customer-supplied hand valve to

the Process Water Inlet connection on the rear of the conditioner; this is a ½” male NPT

connection.

Parameter Generation and Control, Inc.

4

Page 5

PGC Inc. Horizontal 500-1000 CFM June 2006

Condensate Drain

Connect the condensate drain to an open (vented) trapped external drain. This drain is a

¾” female copper sweat connection on the rear of the conditioner.

Sump Drain

Connect the sump drain to a facilities

drain. This drain does not require a trap.

This drain connection is made to the ¾” ¼

turn ball valve, supplied on the rear of the

Coolant Water

Outlet

conditioner.

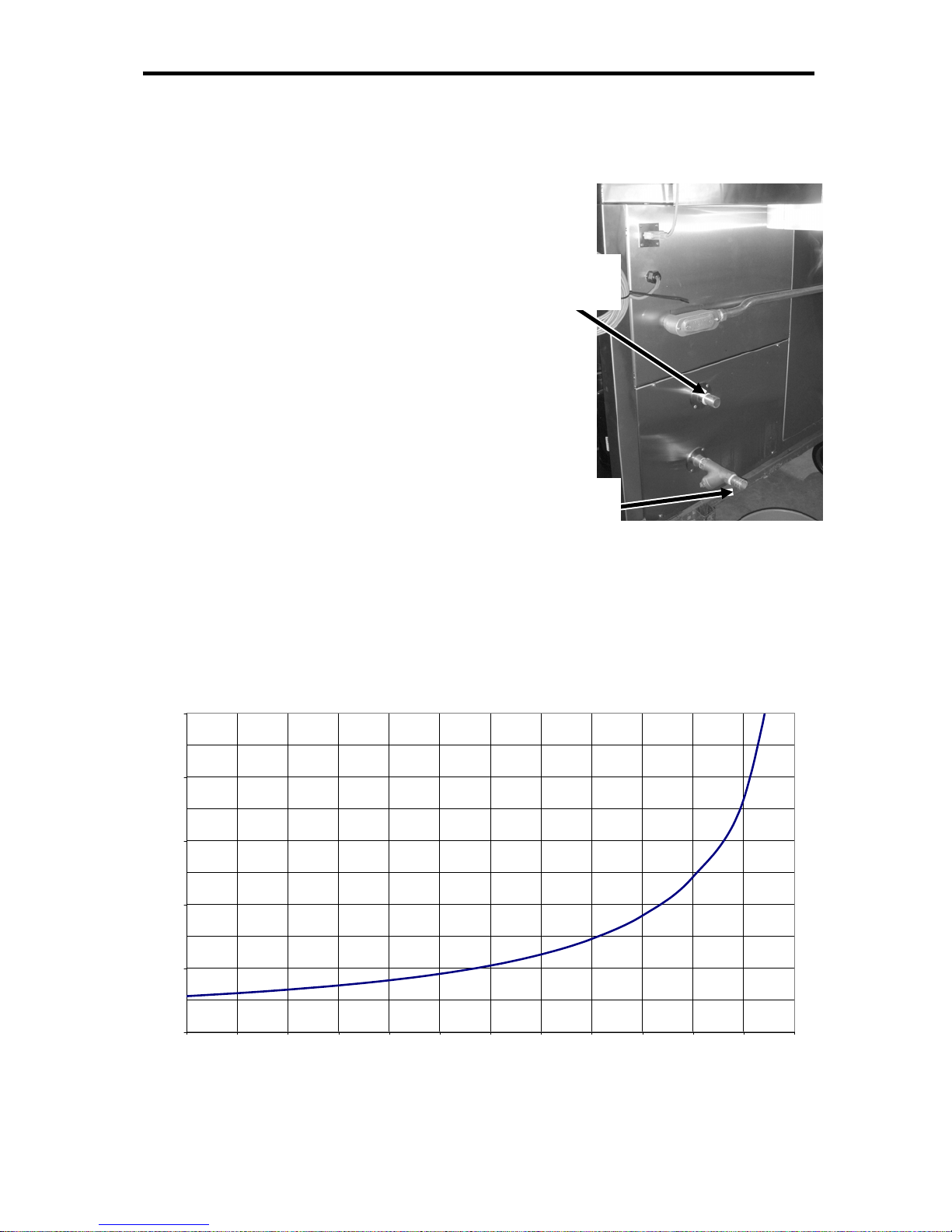

Coolant Water Supply and Return

If the refrigeration system is equipped

with a water-cooled condenser. Connect

coolant water to the condenser inlet

connection on the rear of the chamber

cabinet. Connect the coolant water return

line to the coolant water outlet connection.

Coolant Water

Inlet

Coolant flow requirements will vary based

on the operating conditions of condensing

units, as the temperature of the coolant fluid.

The following graph indicates the maximum

Coolant Water Connections

500-1000 CFM

coolant flow requirements for the condenser.

Maximum Condensor Water Flow Requirements

5.00

4.00

3.00

2.00

Gallons Per Minute

1.00

0.00

45 50 55 60 65 70 75 80 85 90 95 100 105

500-1000 CFM

Entering Water Temperature (Degrees F)

Parameter Generation and Control, Inc.

5

Page 6

PGC Inc. Horizontal 500-1000 CFM June 2006

Filling the sump

To fill the conditioner with water, ensure

that the sump drain valve is closed and open

the customer-supplied external water inlet

valve. When the sump is filled to the proper

Process Water

Inlet

level, a mechanical float valve will

automatically shut off the flow and maintain

the proper water level during operation. The

float valve is preset at the factory to

maintain the proper level (1/2” above the

evaporator tubing); to change the water

Condensate

Drain

level, adjust the angle of the float arm

slightly.

A low-water safety switch is located in the

front, left corner of the sump. This switch

will open when the water level is too low for

safe operation of the pump and water heater.

When the water level is correct, the float

Plumbing Connections

Service

Drain

switch will close and allow the controller to

resume operation of the unit.

The water fill valve float may be padded to prevent damage during

CAUTION

shipping. Remove the padding before connecting the water supply to the

inlet.

NOTE

The conditioner will not operate until the low water level safety is satisfied.

Parameter Generation and Control, Inc.

6

Page 7

PGC Inc. Horizontal 500-1000 CFM June 2006

CAUTION

Do not connect the drain connection to an un-vented drain.

NOR

Ensure that the drain connection is vented, as shown below.

OR

“Open” (Vented) Drain Connections

Parameter Generation and Control, Inc.

7

Page 8

PGC Inc. Horizontal 500-1000 CFM June 2006

Electrical Connections

Turn all electrical switches, circuit breakers, and motor starter protectors

CAUTION

(MSPs) off to prevent accidental starting of equipment when power is

connected.

Determine voltage and current requirements of equipment before making

NOTE

electrical connections. This information is on a data plate attached to the

machine.

Connect the air handler in accordance with all applicable codes, using a customersupplied disconnect device.

The SmartPad™ user interface and the optional circular chart recorder can be located

remote from the air handler. Typically, the controller is located on the front of the

chamber to be controlled. These components are usually disconnected for shipment and

must be re-connected prior to operation. Refer to the attached wiring diagrams for reconnection information.

The SmartPad™ user interface interconnect cable has a maximum voltage

NOTE

of 24VDC. Refer to local codes to determine the proper conduit

requirements for the control cable.

The optional circular chart recorder can be powered by 24VDC or

120/230VAC. Refer to the wiring diagrams or the data plate on the

recorder for more information.

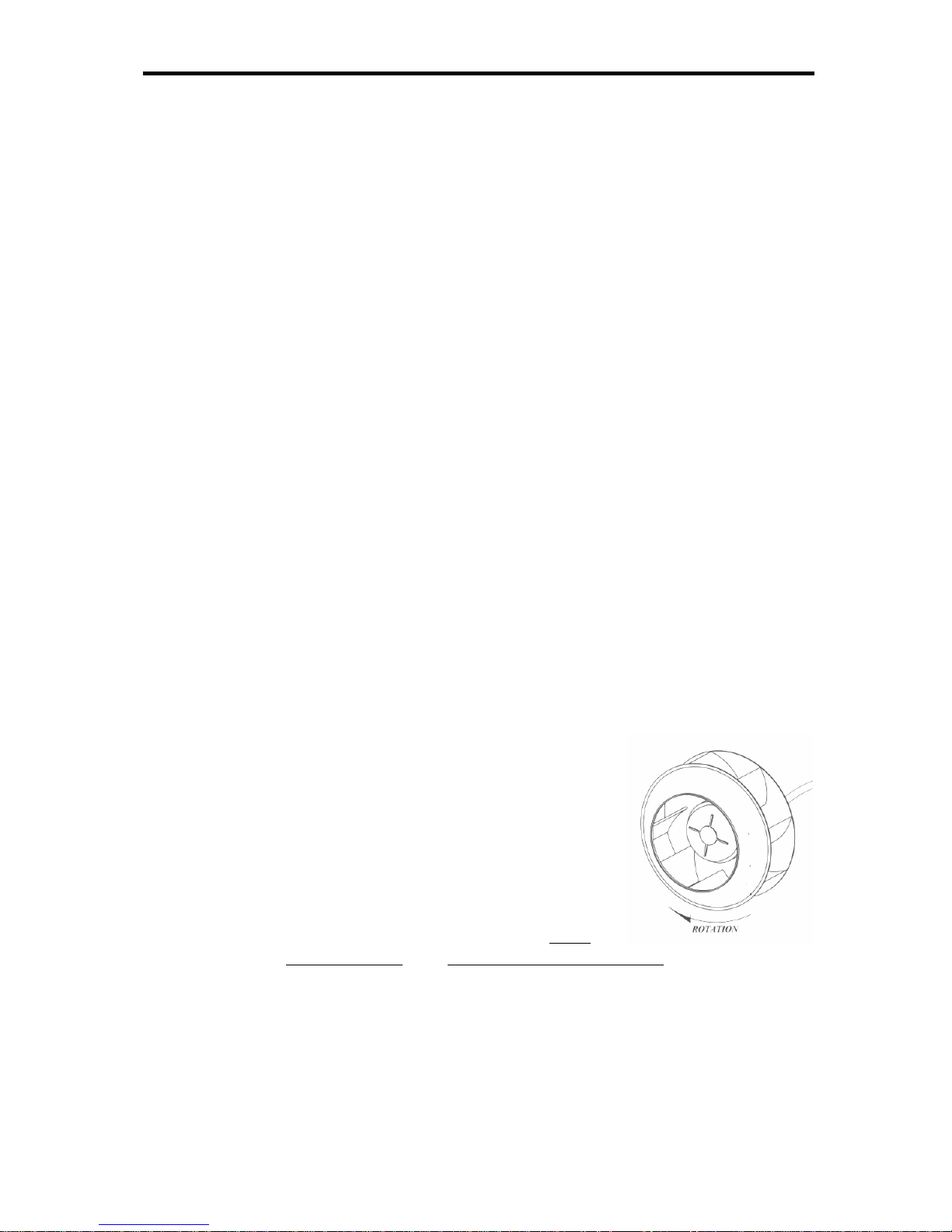

CAUTION

The compressor and blower will not

operate properly and may be damaged if

permitted to run backward. After the

Conditioner has filled with water and is

operating, observe the rotation of the

blower through the air bypass damper.

Ensure that the blower is turning as

indicated in the diagram below. If

necessary, turn off the wall disconnect and

interchanging any two phase wires at the

wall disconnect or of the line connection terminals. Exchanging

phases at this point will reverse the rotation of all 3-phase motors.

Parameter Generation and Control, Inc.

8

Page 9

PGC Inc. Horizontal 500-1000 CFM June 2006

Operation

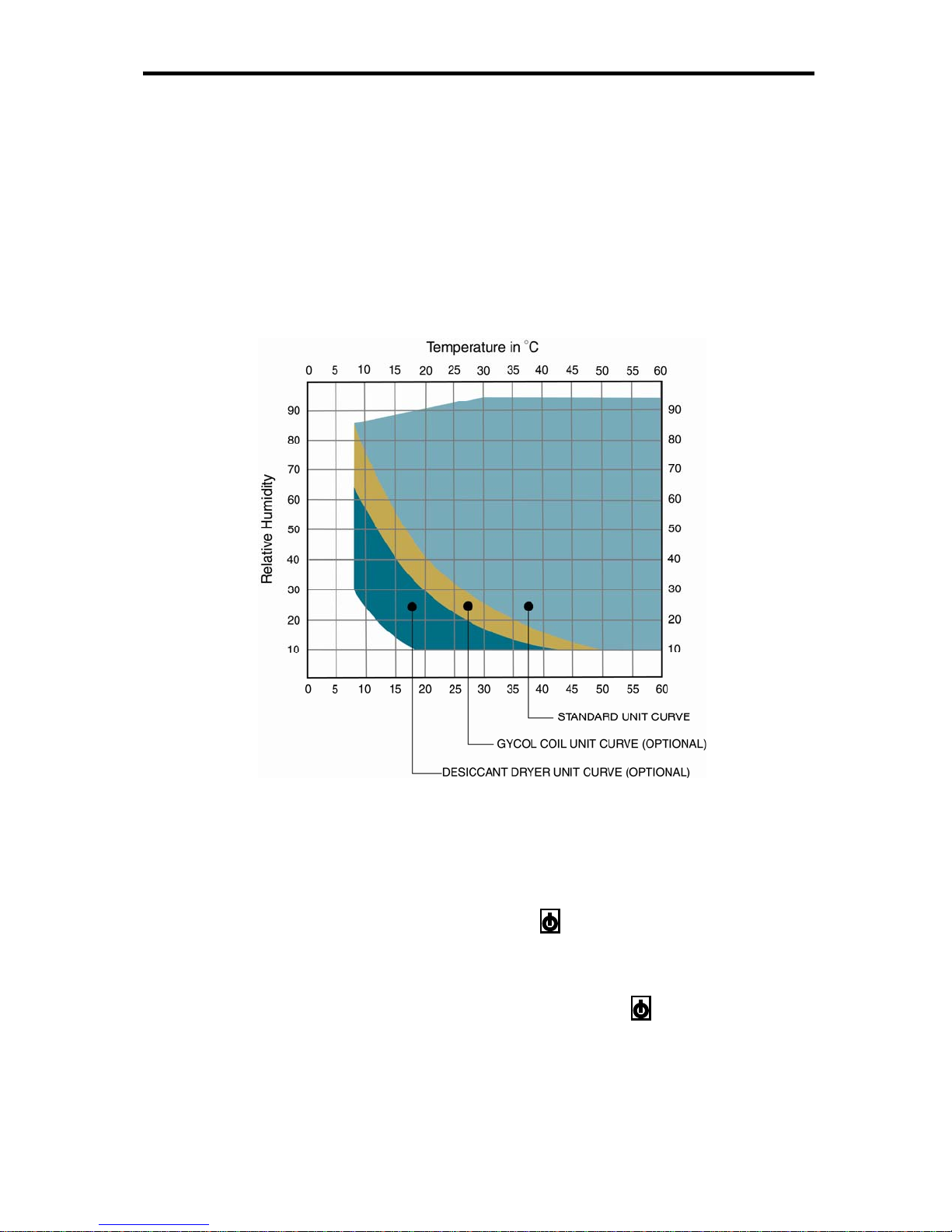

The 500-1000 CFM Conditioner is a self-contained conditioner designed to control drybulb temperatures over a range of 7°C - 60°C (44.6ºF - 140ºF), dependent upon the size

and construction of the test chamber. The dry-bulb temperature is held to ± 0.2°C and

relative humidity constancy to ± 0.5% with dew points above 5°C (41°F).

The SmartPad™ may be remotely mounted; refer to the PGC SmartPad™ section at the

rear of this manual for instructions.

Operating Range

Turning the Chamber Off and On

When the chamber is energized and the Standby key has been pressed, the system

should begin to operate and control the temperature and humidity in the chamber at the

set points entered into the SmartPad™ user interface.

The SmartPad™ user interface is configured with a Standby key located in the lower

right corner of the keypad. Pressing this key will disable the system and place the

controller in a Standby mode. The SmartPad™ display will indicate:

Parameter Generation and Control, Inc.

9

Page 10

PGC Inc. Horizontal 500-1000 CFM June 2006

STANDBY MODE

Press the ON/OFF key

to energize the system

When the system is in Standby mode, it can be energized by pressing the Standby key

Process Variable Display

The Process Variable screen is the first screen that will be displayed when the conditioner

is energized. This screen will display the measured process variables and will allow

access to the other screens in the SmartPad™.

The bottom line of the SmartPad™ display is a label for the four function keys on the key

pad. This label will vary from screen to screen to reflect the action of each of the function

keys.

Refer to the SmartPad™ manual in the appendix for a complete listing and discussion of

available screens.

Adjusting Set Points

In the Process Variable screen, pressing the SP function key will access the Set Point

screen. The Set Point screen will allow the user to enter the desired air temperature and

relative humidity set points for the chamber.

The SmartPad™ has no ENTER key. In order to enter a value in any field

NOTE

all digits must be entered. For example, to enter 25.0°C air set point you

must press “2”, “5” and “0”. When the field has been filled and the data has

been entered, the cursor will jump back to the beginning of the field.

Operation After Loss of Power

If power is removed from the conditioner, the controller will resume operation in the

same mode when power is regained. For instance, if the SmartPad™ was in Standby

mode when power was lost, it will be in Standby mode when power is restored. If the

SmartPad™ was operating and controlling the chamber, it will return to that mode of

operation.

Parameter Generation and Control, Inc.

10

Page 11

PGC Inc. Horizontal 500-1000 CFM June 2006

The SmartPad™ is not equipped with a battery backup.

NOTE

All set points, tuning values and ramping profiles are stored in non-volatile

memory and will be permanently stored in the SmartPad™.

If power is removed from the controller it will resume operation when

power is restored.

In Steady State set point mode the controller will resume operation at the

previous steady state set points.

In Programmable set point mode the controller will resume operation at

exactly the same segment and time remaining in that segment if the

duration of the power loss is less than approximately 20 minutes. If the

duration of the power loss exceeds approximately 30 minutes the

controller will re-initiate the program according to the loop parameters

defined in the INIT screen.

Fault Displays

If the system encounters a temperature, low-water, remote on/off switch, or refrigerant

pressure fault, the system will shut down and the SmartPad™ will indicate the fault that

has occurred. The SmartPad™ will continue to indicate that the fault exists, and will

indicate if/when the fault has cleared.

If the fault has been cleared, the system can be re-energized by pressing the Standby key

. If the fault has not cleared, the source of the fault must be determined and corrected

before the system can be re-energized.

Some faults will clear automatically and others will require user

NOTE

intervention.

Regardless of the fault clearing mechanism, the user must press the Standby

key in order for the conditioner to resume operation.

Parameter Generation and Control, Inc.

11

Page 12

PGC Inc. Horizontal 500-1000 CFM June 2006

Control Modes

The PGC conditioning system offers four modes of temperature and humidity control.

1. Cascade Temperature Mode

This is the most commonly used mode because the user specifies only the desired

air temperature and relative humidity (Rh) level in the chamber. The temperature

of the water spray controls the dew point of the discharge air and the water

temperature is adjusted in order to achieve desired humidity level. The air is then

re-heated to the desired temperature before returning to the test chamber. This

allows the system to respond to load variations while retaining the basic stability

of a spray system.

2. Two-Temperature Mode

In this mode, the user establishes the desired air and water temperatures that are

required to produce the desired relative humidity level, as determined by a

psychometric chart. The Two-Temperature mode can be used when operating the

very edges of the system capabilities.

3. Slow Damper Mode

This mode is similar to Cascade mode with the difference being that the air

bypass damper control loop and the air heater control loop have been separated.

In this mode the damper is moved slowly and its final position is when the desired

percentage of air heat output is achieved. The desired percentage of air heat is

determined by the user in the tuning parameters (Manual Adjust) section of the

controller. In some situations, slow damper mode can be applied to improve

energy efficiency or extend the operating range of the system. Typically, slow

damper mode is most effective when the system is operated at a single condition

as it will often require manual tuning adjustments for proper operation at multiple

set points.

4. Dry Mode

This mode is required to control dew points below 4°C. In this mode, all water is

removed from the spray chamber and an optional desiccant dryer is used to

control humidity. Although this mode is accessible in SmartPad, it is nonfunctional unless the system is equipped with a desiccant dryer.

Parameter Generation and Control, Inc.

12

Page 13

PGC Inc. Horizontal 500-1000 CFM June 2006

Specifications, 500-1000 CFM

Voltage-------------------------------------------------------------------------------- 460V~

Frequency----------------------------------------------------------------------3ph, 60 hertz

Current------------------------------------------------------------------------------ 8.8 FLA

Circuit Capacity (Max / Min)--------------------------------------------------30A / 12A

Heater, Water ------------------------------------------------------------------- 1800 watts

Heater, Air (Two, 1500 watt) ------------------------------------------------- 3000 watts

Refrigerant-------------------------------------------------------------R-404a, 96 Ounces.

Process Water Pressure, (Max/Min) ------------------------------------------125/5 psig

Weight Net --------------------------------------------------------------------------1000 lb.

Weight Shipping--------------------------------------------------------------------1400 lb.

Temperature Range -------------------------------------------------------------7° to 60°C

Relative Humidity Range----------------------------------------------------10% to 95%

1

Temperature Constancy (control) ------------------------------------------------ ± 0.2°C

Rh Constancy (control) ----------------------------------------------------------± 0.5%

1

Minimum Rh is limited by a minimum dew point of 5°C (41°F) for standard Spray

Mode. For example:

Air

Max. Rh Min. Rh

Temperature

10°C (50°F) 88% 70%

25°C (77°F) 93% 32%

40°C (104°F) 95% 17%

> 50°C

95% 10%

(122°F)

Parameter Generation and Control, Inc.

13

Page 14

PGC Inc. Horizontal 500-1000 CFM June 2006

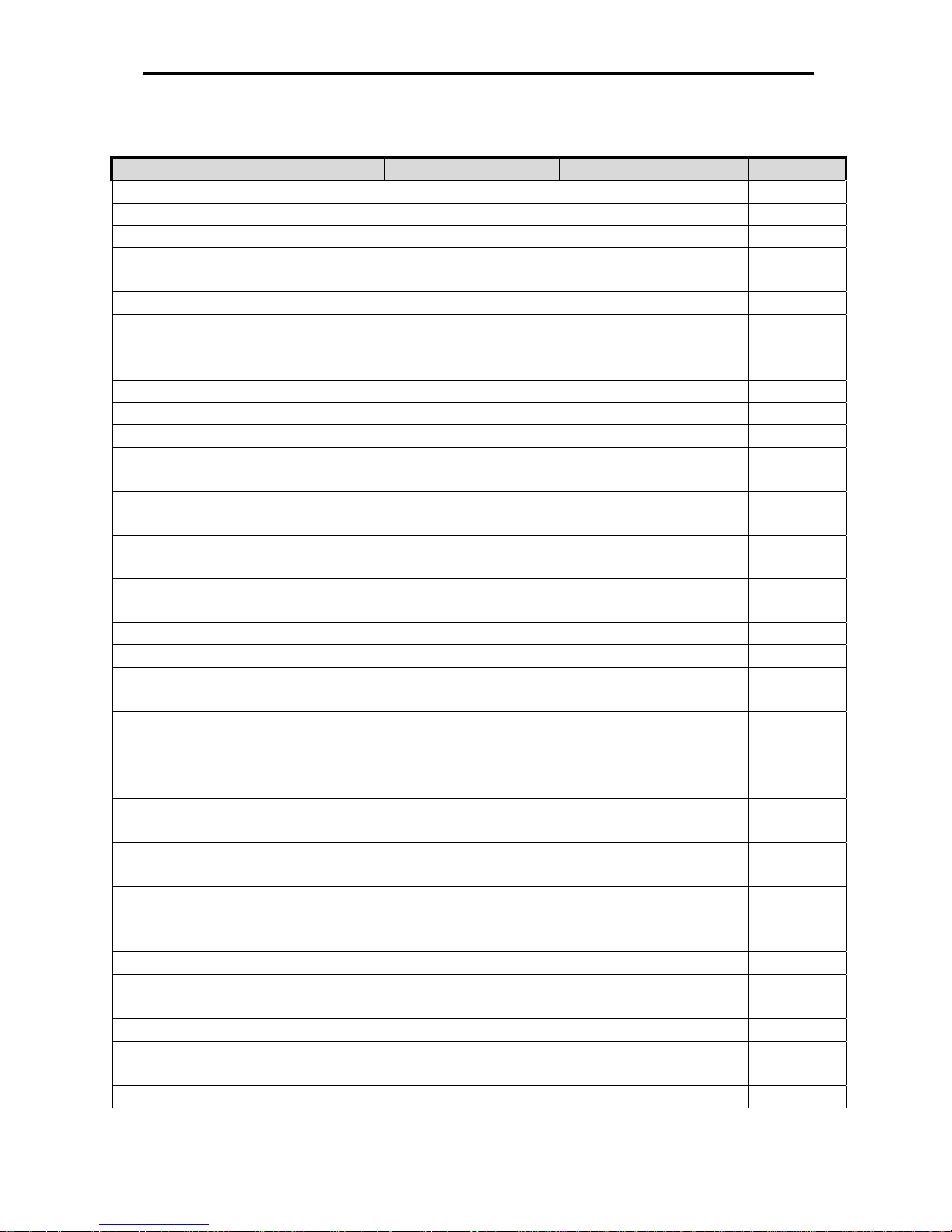

Replacement Parts, 500-1000 CFM

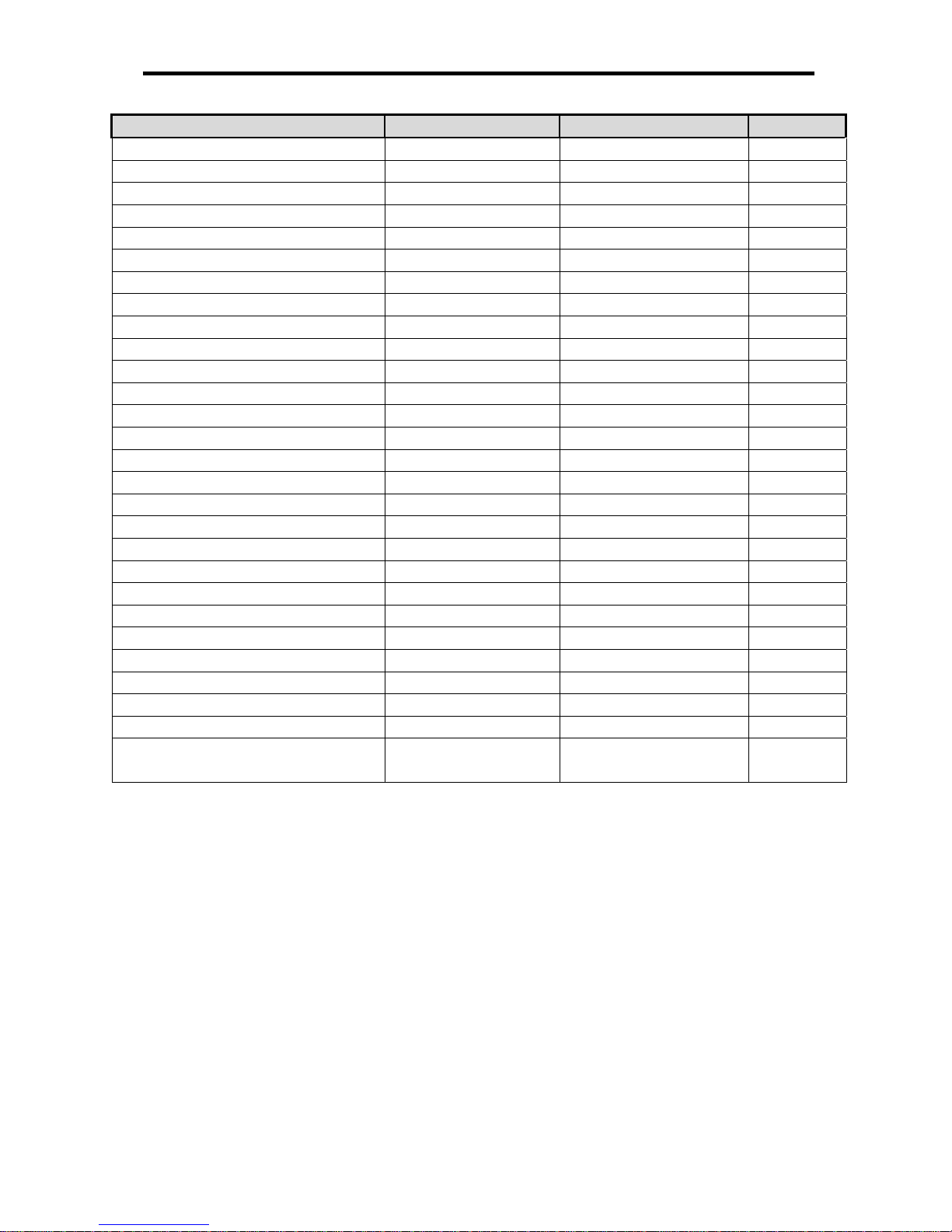

Description Mfg. / Supplier Mfg./Supplier # PGC #

ACE Master Micro Controller PGC ACE 503g N/A

ACE4 Controller Assy. PGC OEM 6000-1559

ACE4 Power Supply Meanwell PS45-24 1607-0024

Circuit Breaker,1 Pole, 2AMP Siemens 5SX2102-8 0426-1020

Circuit Breaker,2 Pole, 2AMP Siemens 5SX2202-8 0426-2020

Compressor Copeland CS14K6E-TFD-230 1510-0298

Contactor Siemens 3RT1025-1BB40 0419-0948

Damper Drive Motor Actuator Belimo

OEM

1608-

0916A

Door, Spray Chamber, Inner PGC N/A 6000-0303

Door, Spray Chamber, Outer PGC N/A 6000-0392

Evaporator Coil, 5/8 OD x .032 wall Super Radiator Co. OEM 1244-0066

Filter Bag,5 Micron, Polyester McMaster-Carr 9316T22 0215-1800

Fuse, Door Heat 5A Bussman FNM5 0409-0123

Gasket, Return Duct Transition

Refrig. Hardware 47-131 1604-0101

Box, 140”

Gasket, Spray Chamber Inner

Refrig. Hardware 47-131 1604-0101

Door, 95”

Gasket, Spray Chamber Outer

Refrig. Hardware 47-131 1604-0101

Door, 95”

Gasket, Supply Duct Transition Box Refrig. Hardware 47-131 1604-0101

Heater, Air Vulcan OEM 0416-0508

Heater, Water Watlow OEM 0416-0599

Hour meter, UV Durant E42DIR48230 0215-2821

HygroClip Connector and Cable,

5 meters, amplified analog, 0ºC to

PGC MOK-05-XX-005V-1-

DIO

1636-0159

100ºC

HygroClip Micro Controller PGC Hygro 503 N/A

HygroClip T/Rh Transmitter,

PGC OEM

1608-0865b

Full-Range Calibration

HygroClip T/Rh Transmitter,

PGC OEM

1608-0865a

Single-Point Calibration

HygroClip T/Rh Transmitter, Un-

Rotronic HygroClip S 1608-0865

calibrated

HygroPalm Calibration Cable PGC AC1620-modified 1609-0866

HygroPalm Calibrator Rotronic HygroPalm 2 1609-0865

Latches, Access Panel Southco 62-43-251-3 1008-0080

Latches, Inner Doors Southco OEM 1001-0082

Latches, Outer Doors McMaster-Carr 5481K19 1009-1017

Mist Eliminator PGC N/A 5000-0135

Motor Protector Siemens 3RV1021-1KA10 0427-1250

Motor Protector Siemens 3RV1021-0GA10 0427-0063

Parameter Generation and Control, Inc.

14

Page 15

PGC Inc. Horizontal 500-1000 CFM June 2006

Description Mfg. / Supplier Mfg./Supplier # PGC #

Motor Protector Siemens 3RV1021-1BA10 0427-0200

Motor, Blower Continental Fan RO-TMK280-2-34 1602-0199

Pump March TE5.5CMD 1619-0091

Refrigeration Dryer, Filter Sporlan CW-165S 0215-0887

Relay , Solid State, Door Heat Omron G3NE-210T-US 0416-0414

Relay, Solid State, 4-28 VDC Continental RVDC/6V25 0416-0403

Sensor , Door Jamb Temperature JMS Southeast OEM 1607-0652

Sensor ,Water Temperature JMS Southeast 3ESCK6BZZ3120JYTA1619-0862

SmartPad™ controller PGC OEM 1607-1100

SmartPad™ Micro Controller PGC Spad 503D N/A

Spray Nozzle Spraying System NO. 1/4A-SS5-15. 1612-0201

Stepper Micro Controller PGC Step 503 (SDR3) N/A

Strainer, Bronze “Y” McMaster-Carr 43935K24 0215-0904

Supply Duct Transition, 10” Round PGC N/A 5000-1389

Surge Suppressor Siemens 3RT1936-1TR00 0419-0891

Switch, Float Gems LS1750-192-908 0421-0060

Switch, Hi-Lo Refrig Pressure Copeland 085-CP2M-7K 0423-0683

Thermostat, Safety Thermtrol TS-120SR 30F-240F 1636-0223

Timer, Chamber Light Intermatic FF60MC 0419-0355

Transformer Micron B100MBT713XK 0419-0326

UV Lamp Severn Trent Water 5340UD 0215-2825

UV Lamp Power Supply Severn Trent Water 20697UD 0215-2831

UV Lamp Quartz jacket Severn Trent Water 2450UD 0215-2824

UV Plastic Support PGC OEM 0215-2826

Valve, Expansion, Body Danfoss 068U2287 0215-0872

Valve, Expansion, Cartridge Danfoss 068U1037 0215-0777

Valve, Hot Gas Temp Control Sporlan SDR-3-20-S 0215-0873

Valve, Sump Float Hawkeye Steel

UFV600 0209-0050

Products

Parameter Generation and Control, Inc.

15

Page 16

Parameter Generation and Control, Inc

Precise Humidity Control

Notes:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

www.humiditycontrol.com

sales@humiditycontrol.com

(800) 438-5494

Fax (828) 669-6928 (828) 669-8717

Black Mountain, North Carolina

Page 17

PGC, Inc 500-1000 CFM Air Handler May 2006

Appendix A

System Construction ................................................................................................................... 2

Theory of Operation.................................................................................................................... 3

Description of Operation............................................................................................................. 4

Measurement of Test Chamber Conditions ............................................................................ 4

Air Flow.................................................................................................................................. 4

Water Flow ............................................................................................................................. 5

Temperature Controls ............................................................................................................. 5

Description of Circuitry .............................................................................................................. 7

Safety Devices............................................................................................................................. 9

Troubleshooting ........................................................................................................................ 12

Operating Range of the System. ........................................................................................... 12

Water Temperature ...............................................................................................................12

Air Temperature.................................................................................................................... 13

Water Level .......................................................................................................................... 13

Rh Control ............................................................................................................................ 14

Maintenance .............................................................................................................................. 15

Preventive Maintenance Schedule........................................................................................ 15

Automatic Damper Motor Adjustments ............................................................................... 18

Calibration ............................................................................................................................ 18

Calibration ............................................................................................................................ 19

Calibration, Air/Rh ............................................................................................................... 19

Water Temperature Calibration ............................................................................................ 22

Appendix A A-1

Page 18

PGC, Inc 500-1000 CFM Air Handler May 2006

SYSTEM CONSTRUCTION

The 500-1000 CFM Conditioner consists of four main sections:

1. Conditioning Compartment: spray bypass damper, blower, spray eliminators, spray

jets, water sump, low water level safety float switch, process water float valve, stirring

jet, evaporator coil, and particulate filter

2. Mechanical Compartment (side access panels): refrigeration condenser, compressor,

receiver, , high- and low-pressure safety switches, filter/dryer, hot gas bypass valve,

water pump, water heater, water RTD, Programmable Logic Controller (PLC), and power

panel with terminal strips, circuit breakers, motor starter, and contactors

3. Conditioner Exterior: sump drain valve, air bypass damper actuator, UV filter, and air

temperature safety thermostat.

4. Control Enclosure: SmartPad™ user interface and optional chart recorder.

The unit is sturdily constructed, with a stainless steel interior and exterior, and insulated door

with heavy refrigerator-type latches and vapor-resistant seals. Double walls separated by

insulation are used around the conditioning chamber. All internal seams are welded to preclude

saturation of the insulation.

The spray tree is a 3” stainless steel tube (spray header) with spray nozzles attached along the

sides, and a clamp on each end for sealing the tube. The clamp on the right end secures a blank

plate against an O-ring gasket. A UV lamp is inserted from the electrical compartment, through

the plate on the left end.

Appendix A A-2

Page 19

PGC, Inc 500-1000 CFM Air Handler May 2006

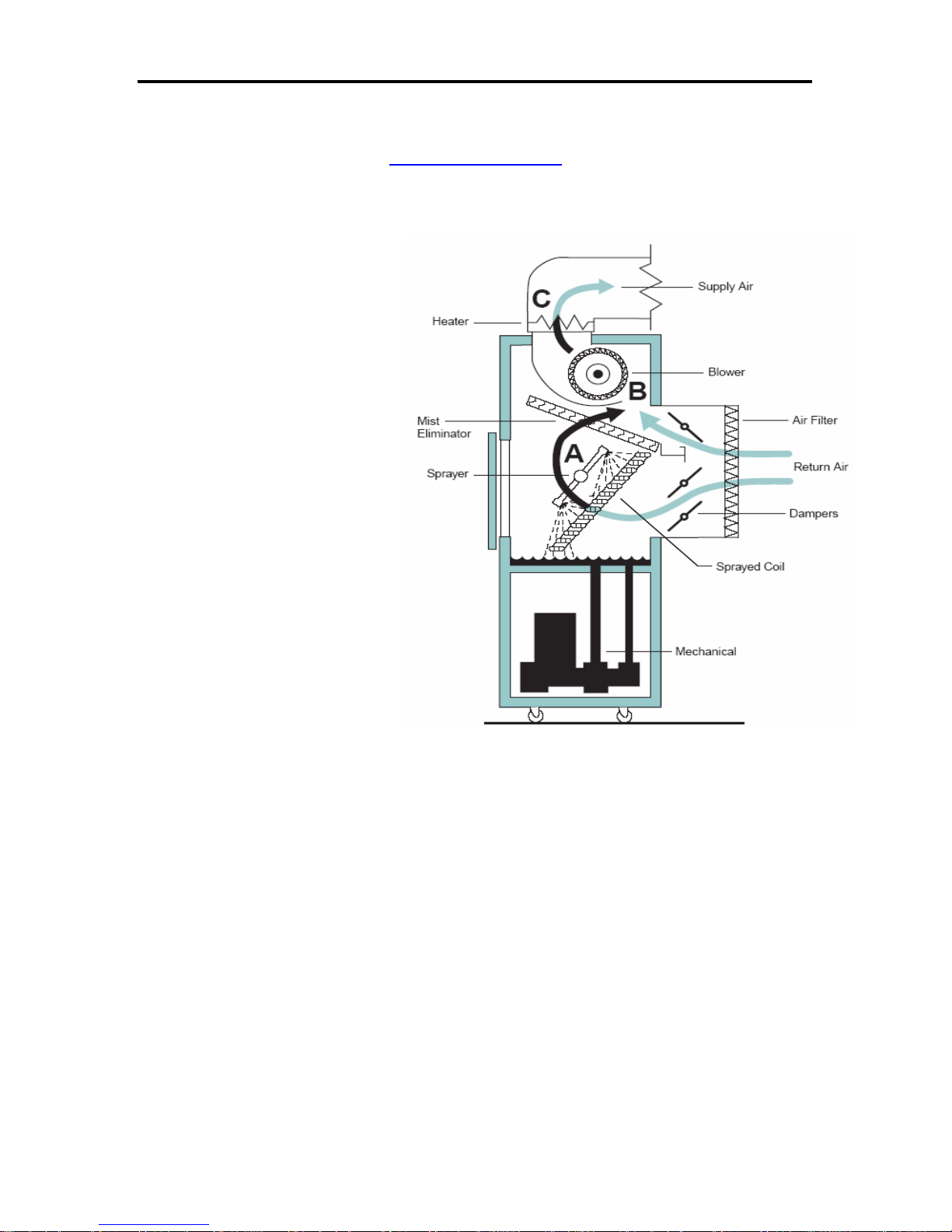

THEORY OF OPERATION

PGC’s method of control is the

same for both reach-in

chambers and conditioning

systems. The environment to be

conditioned is controlled at a

Supply Air

targeted dew point temperature,

and then reheated to the desired

air temperature. This

methodology follows a proven

technique that maintaining a

constant dew point and air

temperature will produce a very

constant relative humidity. The

desired air temperature and

relative humidity or water

Blower

Air Filter

Return Air

Dampers

temperature are set via the

SmartPad™. If equipped with

Sprayed Coil

an optional recorder, it can be

wired to record the actual air

temperature and relative

humidity or water temperature.

Mechanical

The air is cooled by means of a

water spray which constantly

sprays water across the air

stream, saturating the air. A

submerged refrigeration

evaporator coil operates 1°C2ºC (1.8°F-3.6°F) below the

desired dew point and cools the

Figure A-1 - Generic Conditioning Unit

water that is sprayed across the

air stream. The air is then reheated before it is returned to

the test chamber.

NOTE

Dew point is the temperature at which the air can contain no more moisture and

some moisture begins to condense.

A portion of the air can be diverted around the water spray saturator by a bypass damper. If the

air does not pass through the water spray, it will not be cooled; if the air is not cooled, it will not

require as much (if any) air heat to be applied before it is returned to the test chamber. The

amount of air that passes through the saturator, or bypasses the saturator, is determined by the air

temperature control loop.

Appendix A A-3

Page 20

PGC, Inc 500-1000 CFM Air Handler May 2006

DESCRIPTION OF OPERATION

The 500-1000 CFM Conditioner is a self-contained conditioner designed to control dry-bulb

temperatures over a range of 7°C – 60°C (44.6ºF - 140ºF), dependent upon the size and

construction of the test chamber. The dry-bulb temperature is held to ± 0.2°C and relative

humidity constancy to ± 0.5% with dew points above 5°C (41°F).

The temperature of the water spray saturator controls the dew point of the discharge air. When in

Rh Cascade or Slow Damper mode, the water temperature in the saturator is varied slowly in

response to a humidity control system. This allows the system to respond to wide load variations

while retaining the basic stability of a spray system. When in Two-Temperature mode, the user

establishes the air and water temperatures.

M

EASUREMENT OF TEST CHAMBER CONDITIONS

Precise control of temperature and humidity within the test chamber is obtained by accurately

measuring the dry-bulb temperature and the dew point temperature of the air in the test chamber

or the duct. The temperature of the water in the spray chamber controls the dew point

temperature, and is measured prior to the spray nozzles.

When operating in one of the spray modes, the dew point of the air exceeds the water temperature

by approximately 1°C for each 10°C difference between the air and water temperatures. During

the ramp portion of program cycling, the dynamic heat exchange process that takes place makes it

difficult to establish any exact relationship. When operating in the Two-Temperature mode, refer

to the air/Rh/water spray graph provided with the unit for air and water temperatures necessary

for the desired relative humidity.

A

IR FLOW

As the air enters the conditioner through the round, flexible duct connection in the removable top

cover. The process blower, located beneath this cover, will force the air into the conditioning

section. Entering the conditioning section, the air first encounters the by-pass damper; the

damper determines the volume of air that enters the saturator, and the volume that is bypassed

around the saturator. When the damper is fully closed, all of the air is forced through the water

spray. As the air passes through the water spray, it is saturated and cooled, nearly to the water

temperature. This method provides a stable dew point for the air as it leaves the saturator section.

The chilled and saturated air then passes through the water droplet eliminator to remove any free

moisture that may be present. The air then continues over the dry-bulb heaters, where it is heated

to the desired chamber air temperature (without affecting the dew point) and is returned to the

chamber through the round, flexible duct connection on the left end of the conditioner.

When the damper is fully open, most of the air bypasses the water spray and travels directly to the

air heaters. The bypassed air is then mixed with any air that traveled through the saturator section

and then returns to the test chamber. The spray bypass damper will be automatically positioned

by the actuator operating on a control signal derived from the duty cycle of the air heater. The

position of the damper can range from 0% to 100% open.

The dew point of the air stream is controlled even when most of the air is bypassed around the

water spray saturator. The air bypass damper is not 100% efficient, allowing some air to enter the

water spray saturator even when closed.

Appendix A A-4

Page 21

PGC, Inc 500-1000 CFM Air Handler May 2006

In Slow Damper mode, the position of the damper is load dependent; the damper

will change slowly to achieve the desired conditions. The damper will also change

NOTE

position in order to compensate for droop or overshoot in the air temperature

control loop.

W

ATER FLOW

The water pump is located in the right section of the cabinet (accessible through the front or side

access doors). The water is picked up by the pump and heated, and then forced across the water

temperature sensor (100Ω platinum RTD) and into the spray header in the spray chamber. The

spray header is situated to spray water across air stream. The remainder of the water passes

through the particulate filter to remove debris.

T

EMPERATURE CONTROLS

The water temperature is sensed immediately prior to entering the spray headers, and the air &

humidity are measured by the HygroClip™ T/Rh transmitter that is located in the air stream.

The air heaters are positioned in the air-stream path between the chamber and the saturator. The

amount of heat applied is controlled by the dry-bulb control system with the sensing element in

the air stream. The duty cycle (the percentage of heat applied) for the air heater can be accessed

from the SmartPad™.

The water in the sump is cooled by the refrigeration evaporator, and is then sprayed across the air

stream to cool and saturate the air. Since the refrigeration system has a greater capacity than is

needed for most conditions, a hot gas bypass valve is provided to modulate the refrigeration

capacity as required. This valve is automatically adjusted by an actuator operating on a control

signal derived from the duty cycle of the water temperature control loop; the more the hot gas

valve opens, the more the refrigeration capacity is reduced. The relative position of the hot gas

bypass valve is represented by the water heater output percentage: Zero (0%) out is full

refrigeration capacity (hot gas bypass valve closed); one hundred percent (100%) out is minimum

refrigeration capacity (hot gas bypass valve open).

There are four factors that limit or control Water Set Point:

1. Humidity Control Band

Water Set Point will change in order to control Rh. If the measured Rh value is less

than the Rh set point, the Water Set Point will increase in order to increase the Rh by

increasing the dew point. The maximum rate at which the Water Set Point will

change is adjustable; the most common Water Set Point Rate of Change is

0.25ºC/minute (the maximum value). The Water Set Point Rate of Change is

proportional to the deviation from Rh Set Point. For example, if the Rh control band

is +/- 10% and the measured Rh is 10% below Set Point (at 100% of the control

bandwidth), the water Set Point will change at the rate of 0.25°C/minute (the

maximum Rate of Change X 100%). If the measured Rh is 5% below the Rh Set

Point (at 50% of the control bandwidth), the water Set Point will change at the rate of

0.125ºC/minute (the maximum rate of change X 50%).

Appendix A A-5

Page 22

PGC, Inc 500-1000 CFM Air Handler May 2006

2. Water Temperature Set Point Limits

Minimum and maximum Water Set Point limits are factory pre-set in order to prevent

freezing or overheating the pump.

3. Dew Point

Humidity is a function of air temperature and dew point, and the water temperature is

directly related to dew point The controller limits the Water Set Point to 1ºC < Air

Set Point to prevent a runaway temperature control. Without this limit, a runaway

condition could be experienced when operating the unit with a high humidity set

point. Such a setting could cause the water temperature to keep increasing in order to

achieve the humidity set point, which would have the side effect of increasing the air

temperature; this increase in air temperature would increase the capacity of the air to

hold moisture, such that the system would never reach the humidity set point.

4. Measured Water Temp

If the Rh Set Point is set above or below the current Rh control band, the Water Set

Point Rate of Change will automatically maximize to change the water temperature

as quickly as possible. Many variables affect how fast the water temperature will

change, such as the efficiency of the pump, how much water is in the sump, how

often the test chamber is opened, etc. These are beyond the capability of the control

system to measure; however, the controller measures how quickly the water

temperature is actually changing, regardless of the uncontrollable variables. When

the measured Rh is outside of the control band, the Water Set Point is changed

automatically:

Water Set Point = Measured Water Temp + Control Bandwidth

For example, assume that the unit is operating with a Water Set Point of 25ºC and the

water control bandwidth is 5ºC, with the humidity controlling at 50% with the control

bandwidth at 10%. If the Humidity Set Point is set above the upper level of the

control band (>60%), then:

Measured Water Temperature + the Water Control Band = new Water Set Point

In this example, the new water Set Point would be (25ºC + 5ºC=) 30ºC. This will

cause 100% water heater output, and the Water Set Point will continue to increase at

a value equal to the rate that the water temperature is changing. As soon as the

measured humidity value is back within the control band (in this example, when the

measured Rh is 65.01%), the Water Set Point will resume changing at the normal

rate.

Appendix A A-6

Page 23

PGC, Inc 500-1000 CFM Air Handler May 2006

DESCRIPTION OF CIRCUITRY

Although this conditioner utilizes 24 volts DC for the control circuits, some

CAUTION

components require 120 or 460VAC; these voltages can be present even when the

conditioner is not operating.

CAUTION

Power to the unit should be removed at the wall disconnect prior to opening any of

the access panels.

Line voltage is applied to the 24 VDC power supply. The 24VDC power supply provides power

to the Programmable Logic Controller (PLC), the HygroClip T/Rh transmitter, the air bypass

damper actuator, safety devices, and the line contactor.

The PLC has an on-board DC-DC converter that will produce +5VDC for the board-level logic

components. A second DC-DC converter produces +15VDC for use by the SmartPad user

interface, stepper motor, and the RTD amplifiers.

When power is applied to the conditioner, and control circuit breaker(s) are closed, the SmartPad

user interface will be energized. If all of the safety devices are satisfied (pressure switches,

thermostats, float switches, etc.), then the conditioner can be energized by pressing the Standby

key on the SmartPad™ user interface. This will instruct the PLC to energize the line contactor

(1CON).

When 1CON is closed, power is applied to the motor starter protectors (MSPs) and the heater

circuit breaker. If the MSPs are closed, then the compressor, blower, and pump will be energized.

If the heater circuit breakers are closed, then the air and water heaters will be enabled. The

operation of the air heaters and water heater is controlled by the PLC; the PLC determines the

duty cycle (On time verses Off time) for each of the heaters, based on the requirements of each

temperature control loop. The PLC will open and close digital outputs that will control the input

signals to solid-state relays, which will apply power to the respective heater based on the

respective control loop. An LED on each relay will indicate the On or Off status of that particular

heater control loop.

The UV filter will also be enabled by the control circuit breaker(s). Any time power is applied to

the conditioner, the control circuit breakers are closed, and the unit is operational (i.e. 1CON is

closed), the UV filter should be energized.

On initial power up, the PLC will determine the hot gas bypass valve position by driving the

stepper motor to fully close (0% output) the hot gas bypass valve in order to “zero” the valve.

This involves driving the motor past the full closed position; the valve will be seated against the

full closed stop but is not damaged by this over driving maneuver. Bumping the valve against the

full-closed stop can correct for any “lost steps” or accumulated errors that could occur over time

due to the constant reversal of the stepper motor.

During normal operation, the position of the hot gas valve is based on the output percentage of

the water temperature control loop. This output percentage is translated into a percentage of

“open” value for the stepper motor. The PLC converts this percentage open value into a step

count that will position the valve accordingly. When the valve is adjusted to the desired position,

the PLC will cease to step the motor, and the motor will maintain its current position.

Appendix A A-7

Page 24

PGC, Inc 500-1000 CFM Air Handler May 2006

The position of the air bypass damper is determined by the PLC based on the air output

percentage. The input to the damper actuator is a frequency modulated (FM) square-wave signal.

The damper will be positioned based on the frequency of the FM signal. A yellow LED on the

PLC indicates the duty cycle. Zero percent (0%) air heat output will produce a 0.59 second On

time pulse, which instructs the damper to move to the full spray position. One hundred percent

(100%) air heat output will produce a 2.93 second On time pulse, which instructs the damper to

move to the full bypass position. An On time between 0.59 seconds and 2.93 seconds will

produce a proportional response in the damper position.

The water temperature is measured using a positive-coefficient 100Ω Platinum RTD temperature

sensor. This sensor consists of a very thin Platinum wire that is wound around a ceramic core. As

the temperature of this wire increases, the resistance of the Platinum element increases linearly.

This resistance is placed in a bridge network to produce a linear voltage proportional to the

change in temperature. This voltage is then converted to a digital value that can be used by the

PLC by and the A/D converter.

The air temperature is also measured using a 100Ω RTD located in the HygroClip T/Rh

transmitter. A circuit in the HygroClip converts this RTD input to a digital signal that is

transmitted to the PLC using a single-wire serial interface. The PLC receives this digital signal

and converts it to a digital value that the PLC can use in its calculations.

The HygroClip also converts the RTD input into a 0-1VDC analog signal that is scaled so that

0.1VDC = 1°C. This analog signal is applied to an amplifier built into the HygroClip connection

cable, which converts the 0-1VDC signal into a 0-5VDC signal (0-5VDC is required if the analog

signal is transmitted more than 10 feet). The 0-5VDC amplifier can be used to scale the analog

output for different ranges; the most common range is (0-5VDC) = (0°C to 100°C). However,

amplifiers are available for (-30°C to +70°C) and (-40°C to +60°C). This 0-5VDC analog

amplifier is not used by the chamber controller, and is only required when an analog device (such

as a chart recorder) is connected to the system. This analog output is available on the chart

recorder connector of the PLC.

The relative humidity is measured using a thin-film polymer capacitive element that changes

capacitance as moisture is absorbed or given off. The HygroClip T/Rh transmitter will convert

this change in capacitance into a digital value. This digital value is transmitted to the PLC in the

same single-line serial interface as the air temperature measurement. The PLC will decode the

digital value and convert it to a digital value that can be used by the PLC. The HygroClip T/Rh

transmitter will also convert the measured Rh to a 0-1VDC analog output. The same analog

amplifier that is used in the analog air temperature output will convert the 0-1VDC signal to a 05VDC signal. In all instances, the Rh output will be scaled so that 0-5VDC will equal 0-100%

Rh. This analog output is also available at the chart recorder connection on the PLC.

A separate voltage to current converter is installed in the air handler electrical compartment for

both the air temperature and relative humidity. This device will convert the 0-5VDC analog

signal from the HygroClip to 4-20mA. The output will be scaled so that 4-20mA corresponds to

the same temperature or Rh range as the analog signal from the HygroClip (typically this will be

4-20mA = 0-100°C or 0-100% Rh). The 4-20mA signal is provided as an interface to a customer

supplied monitoring device. This converter is equipped with a zero and span calibration

potentiometer that can be field adjusted in order to match the 4-20mA output with the NIST

traceable temperature and Rh output from the HygroClip.

Appendix A A-8

Page 25

PGC, Inc 500-1000 CFM Air Handler May 2006

SAFETY DEVICES

The unit is equipped with several safety devices to guard against serious trouble due to failure of

any components.

Alarm contacts are available on the PLC, which will switch when either of the process variables

is in an alarm condition. The process variables are Air and Water in Two-Temperature mode, or

Air and Rh in any other mode. The alarm type, set points, and time delay are all programmable

from the SmartPad™; and the alarm can be disabled from the SmartPad™; refer to the

SmartPad™ manual for further information. The alarm contact is a single-pole double-throw

(SPDT), Normally Open / Normally Closed, dry contact relay rated at 6 Amps @ 250VAC.

Compressor Internal Overload: The refrigeration compressor is equipped with an internal

thermal protector. If the compressor draws excessive current, the motor windings will overheat. If

the windings overheat, the internal thermal protector will open and the compressor will not

operate. The rest of the chamber will continue to function, although it is not possible to control air

or water temperature unless the compressor is operating. As soon as the internal temperature of

the compressor motor drops to a safe operating level, the compressor will resume operation. This

reset process will normally require about 45 minutes.

Several potential causes of a compressor internal overload include the loss of coolant water flow,

excessive coolant water temperature, clogged coolant water inlet filter, high ambient temperature,

or excessive refrigerant charge, low line voltage, or unusually high ambient temperature.

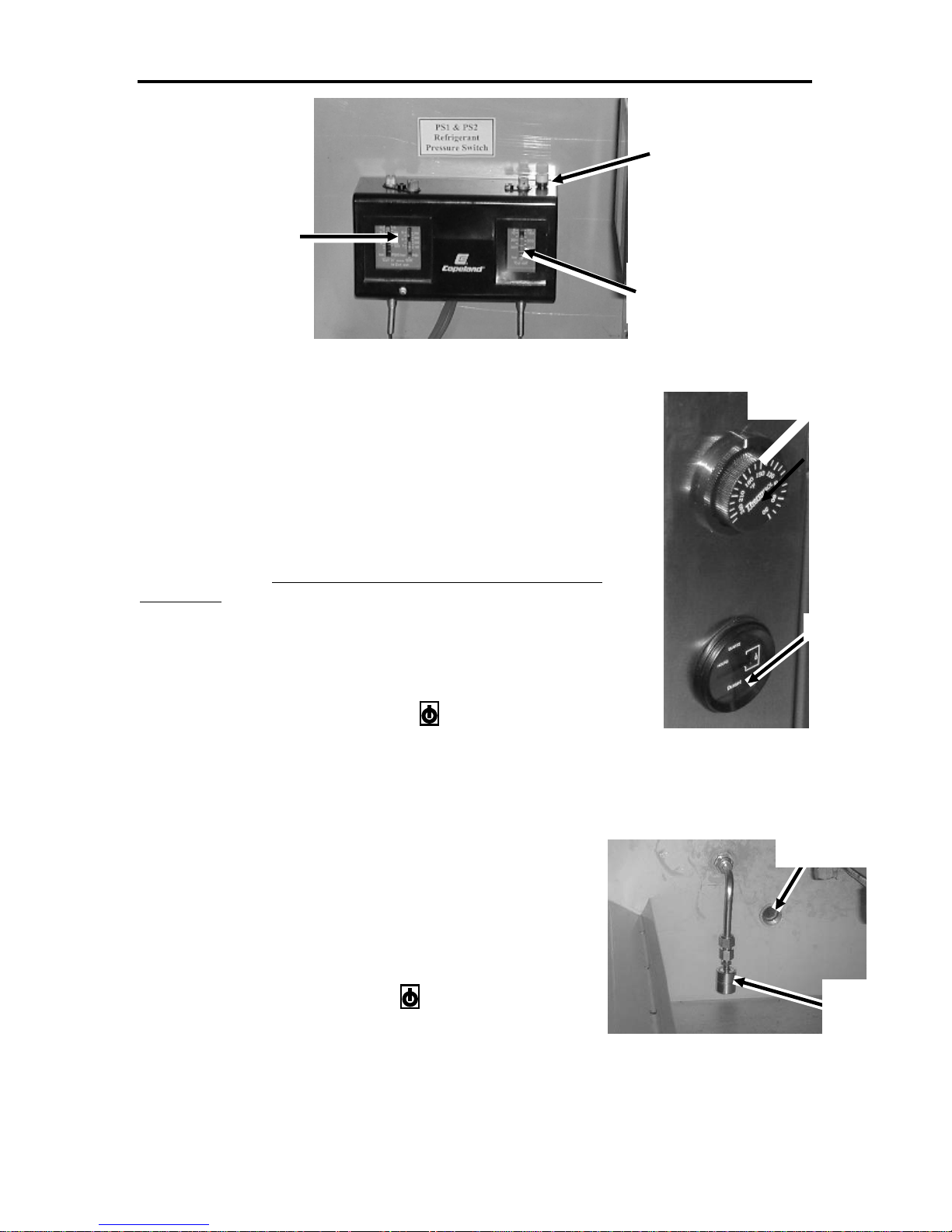

Refrigeration High Pressure Fault: A pressure switch monitors the discharge pressure in the

refrigeration system. This switch is located beside the compressor. If the pressure is allowed to

operate at an excessive level, the compressor will be damaged. If the high-pressure switch opens,

the SmartPad™ will pad indicate “HIGH PRESSURE FAULT SET” and the system will shut

down. The high-pressure switch will automatically reset after the refrigeration discharge pressure

falls below the pressure trip point. When the switch is reset, the SmartPad™ display will indicate

“HIGH PRESSURE FAULT CLEAR”, and the system may be restarted by pressing the Standby

key on the SmartPad™ key

Several potential causes of a compressor internal overload include obstructed or dirty air cooled

condenser, excessive refrigerant charge, low line voltage, or unusually high ambient temperature.

Refrigeration Low Pressure Fault A pressure switch monitors the suction pressure in the

refrigeration system. If this pressure is allowed to operate below a safe level, the compressor may

be damaged. If the low-pressure switch opens, the SmartPad™ will indicate “LOW PRESSURE

FAULT SET” and the system will shut down. The low-pressure fault will automatically reset

when the refrigeration suction pressure rises above the pressure trip point; when this occurs, the

SmartPad™ display will indicate “LOW PRESSURE FAULT CLEAR”, and the system may be

restarted by pressing the Standby key on the SmartPad™ key pad.

Some potential causes of a low-pressure fault include, but are not limited to, low refrigerant

charge, frozen evaporator, or a poor spray pattern.

Appendix A A-9

Page 26

PGC, Inc 500-1000 CFM Air Handler May 2006

r

High Pressure

Reset

Low Pressure

Switch

High Pressure

Switch

Figure A-2 - Pressure Switches

Air Temperature

Safety Thermostat

Over Temperature Thermostat An air over-temperature safety

thermostat has been incorporated into the chamber. The temperature

adjustment for this device is located at the rear of the unit, on the side of

the heater housing. This safety thermostat is designed to protect the

contents of the test chamber from excessive temperature rise in the event

of a system failure. The operator may set this manually to protect the

product under test, normally 2-3°C (5°F) degrees above highest test

temperature. If this thermostat opens due to excessive temperature, the

chamber will shut down and the SmartPad™ user interface will indicate

“TEMPERATURE FAULT SET”. The thermostat will automatically

reset when the temperature inside the chamber drops below the cut-out

temperature. After the thermostat has reset, the SmartPad™ user interface

will indicate “TEMPERATURE FAULT CLEAR”, and the system may

UV Time

be restarted by pressing the Standby key on the SmartPad™ key pad.

Low-Water Safety Switch A low-water level safety float

switch is located in the front left corner of the sump, near the

floor of the sump; this switch will shut down the air handler if the

Figure A-3 – Low Water

Safety Float Switch

Condensate

water level in the sump falls below a safe operating level. If this

float switch opens, the air handler will shut down. The

SmartPad™ user interface will indicate “LOW WATER FAULT

SET”. The float switch will automatically reset when the water

level in the sump returns to a safe operating level. After the

switch has reset, the SmartPad™ user interface will indicate

“LOW WATER FAULT CLEAR”, and the system may be

restarted by pressing the Standby key on the SmartPad™ key

pad.

Blower Motor Thermal Contact The blower motor is

equipped with a contact that will open if the blower motor

Figure A-4 – Low Water

Safety Float Switch

temperature exceeds a safe operating level. If this contact

Appendix A A-10

Drain

Low Water

Safety Float

Page 27

PGC, Inc 500-1000 CFM Air Handler May 2006

opens, the air handler will shut down. The SmartPad™ user interface will indicate “FAN TEMP

FAULT SET”. The thermostat will automatically reset when the blower motor tempeature returns

to a safe operating level. After the thermostat has reset, the SmartPad™ user interface will

indicate “FAN TEMP FAULT CLEAR”, and the system may be restarted by pressing the

Standby key on the SmartPad™ key pad.

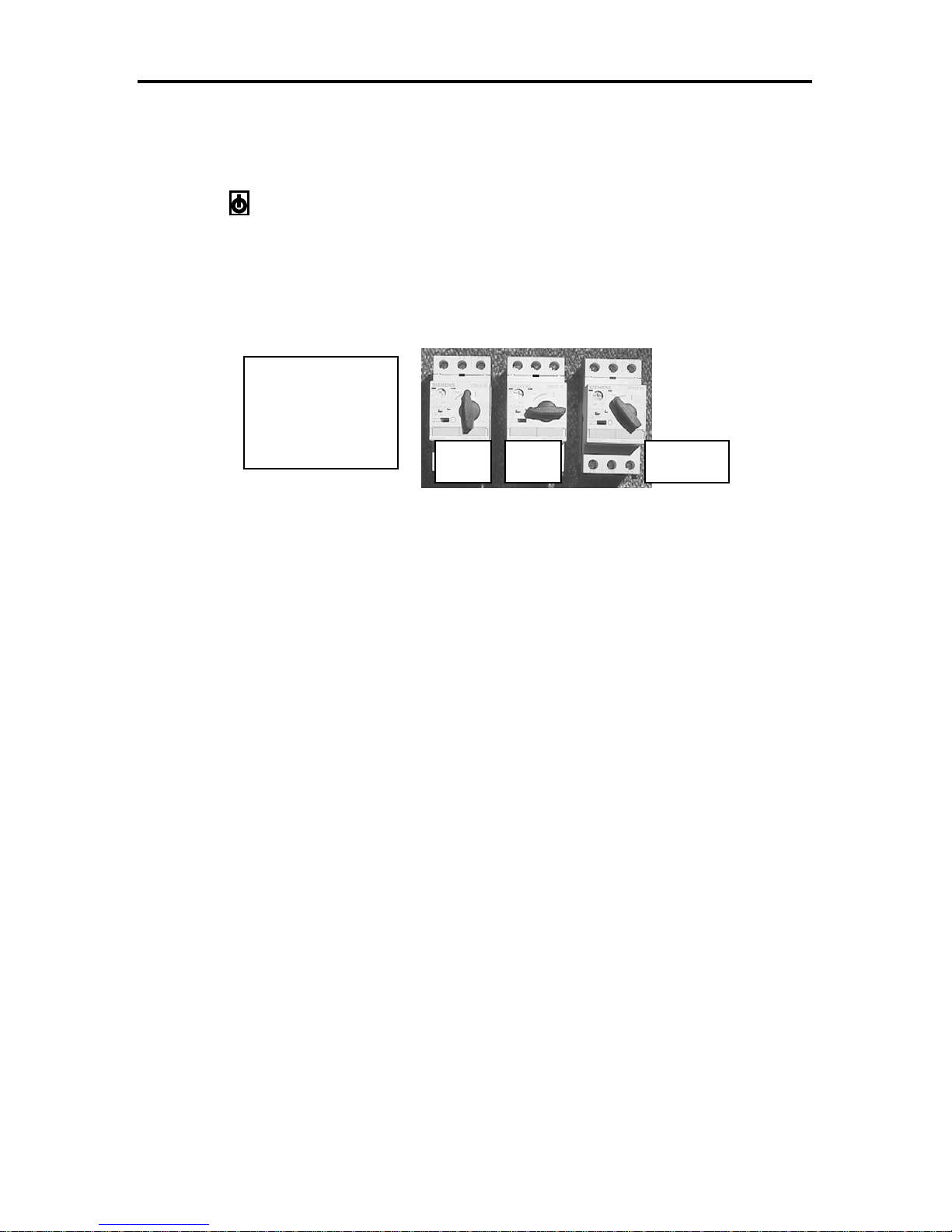

Motor Starter Protector If a motor starter protector (MSP) trips, that component will not

operate. The starter must be reset by turning it to the Off position and then to the On position.

MSPs are used by the process blower, pump, and compressor.

Manual motor

starters in on,

off and tripped

positions

On Off Tripped

Figure A-5 – Motor Starter Protector (MSP)

Appendix A A-11

Page 28

PGC, Inc 500-1000 CFM Air Handler May 2006

TROUBLESHOOTING

CAUTION If the unit has a sight glass / moisture indicator, the hot gas bypass valve may cause

a false indication of low refrigerant charge if the valve is not closed at the time it is

being observed.

PERATING RANGE OF THE SYSTEM.

O

When the system will not control properly there are many potential causes. A basic understanding

of the operation of the system will assist in determining the cause of the problem.

1.) The air temperature will always be greater than the water temperature. Heat is

removed from the air only when the air passes through the water spray.

2.) The water temperature can approach freezing, but it must not be allowed to freeze;

the minimum water temperature is approximately 2.5°C (34.5°F). Since the dew

point is determined by the temperature of the water spray, the minimum dew point

will always be greater than the water temperature, thereby limiting the minimum

achievable dew point.

3.) All blowers, pumps and compressors operate at all times. If any of these items are not

operating, check for motor overload or failure or loose connections.

4.) Ambient conditions will limit operation of the unit. If the room temperature

surrounding the conditioner is too warm or humid, heat cannot be properly rejected

by the air cooled-condenser, affecting the chamber temperature and humidity.

The system will not operate if the low-water level safety switch has opened due to

NOTE

low water level in the sump.

W

ATER TEMPERATURE

1.) The refrigeration system controls the water temperature.

2.) If the water temperature is too high:

a. Check for proper condenser operation.

i. Is the condenser fan(s) operating?

ii. Is the condenser coil clean? During normal operation lint, dirt and debris

will deposit on the entering side of the condenser coil. This will reduce

the cooling capacity of the condenser which will reduce the refrigeration

capacity.

iii. Is the air flow path for the condenser clear? Obstructions such as boxes,

panels are walls can reduce the air flow across the condenser to the point

that it will reduce refrigeration capacity.

iv. Are all of the spray nozzles working? (All of the nozzles should have a

similar spray pattern. If the patterns vary, remove the nozzles and clean

the debris from the orifice)

v. Is the (optional) finned evaporator clean and free of debris?

b. Verify the operation of the refrigeration system

i. When the hot gas valve is fully closed (i.e., water set point is much less

than measured water temperature), the refrigeration sight glass should be

clear. Any bubbles in the sight glass will indicate a low refrigerant

charge.

Appendix A A-12

Page 29

PGC, Inc 500-1000 CFM Air Handler May 2006

ii. Is ice present on the fins of the evaporator (or on the surface of the

submerged tube evaporator)? It is not unusual for the supply lines to the

finned evaporator to be covered in ice; however, it is important that no

ice form on the surface of the coil. Ice on the surface of the coil could

indicate poor water flow or a low refrigerant charge.

iii. Is the refrigeration discharge pressure too high?

1. The air-cooled condenser could be dirty

2. The ambient temperature could be above 95°F

3. The condenser fan(s) may not be working

c. Does the heat load in the chamber exceed the capacity of the system? Since the

heat from the air stream is removed by the evaporator and the water spray, if the

heat load in the chamber is too great, the refrigeration system will become

overloaded if the heat load in the chamber is too great. The first indication of this

will be water temperature, and therefore Rh, that is higher than requested.

A

IR TEMPERATURE

1.) The refrigeration system must have enough capacity to control the water temperature.

If the water temperature is out of control, it is usually not possible to control the air

temperature.

2.) Is the air damper operating properly? Press the clutch release on each actuator two

times to initialize the motor. Observe that the damper moves full travel in both

directions; this may take up to three minutes to complete. If the motor cannot reach

the stops (the Phillips screws at each end of rotation), determine cause of the fault.

3.) Are the air heaters operating properly? Measure the air heater current when the

SmartPad™ indicates 100% air heat output.

4.) Is the airflow restricted or the ductwork leaking? Ordinary A/C ductwork is not

sufficiently vapor tight for an environmental chamber. The duct work must be

capable of holding water for proper vapor barrier.

5.) Is the blower operating efficiently? Inspect the blower wheel for sediment that can

accumulate over time, which decreases the efficiency of the wheel. If this build-up

cannot be removed safely, the wheel must be replaced.

6.) Is the chamber properly sealed?

a. Check the seals around any doors and windows.

b. Are all covers properly installed?

7.) Has the load in the chamber increased?

8.) Check the line voltage. Low line voltage will drastically reduce the wattage of the air

heaters and efficiency of the compressor.

W

ATER LEVEL

1.) The overflow drain must be connected to an open drain; the drain will not work

properly if any backpressure is present.

2.) The overflow drain must functional. If the water level is above the overflow drain

standpipe, the drain is not working properly and the refrigeration system may become

overloaded.

3.) The float valve must maintain the proper water level. The proper water level is high

enough to prevent the pump from cavitating (drawing air into the pump inlet), but

should not be high enough to cause excessive, constant overflow (too much overflow

will overload the refrigeration system)

Appendix A A-13

Page 30

PGC, Inc 500-1000 CFM Air Handler May 2006

H CONTROL

R

1.) The humidity cannot be controlled if the water temperature or air temperature is out

of control; refer to the respective troubleshooting section.

2.) Verify that the air flow through the mist eliminator is unrestricted; restrictions could

permit water droplets to bypass the mist eliminator. If droplets contact the heater, the

droplets will flash into steam and adversely affect the humidity control.

3.) Common Sense. Refer to the air/water/Rh graph supplied. Verify that the measured

air and water temperatures will yield the Rh that is measured. Any gross errors may

help to indicate the source of the problem.

a. Verify the chamber air temperature and/or relative humidity using an

independent sensor. This can be a rough verification just to make sure the air

temperature and Rh measurements are close.

b. Verify the water spray temperature using an independent sensor placed in the

water sump. This can be a rough verification just to make sure the water

temperature measurement is close.

c. If the water spray temperature is considerably colder than should be required:

i. If the ambient dew point is greater than the dew point in the conditioned

space; check for excessive chamber or duct work leakage.

d. If the water spray temperature is considerably warmer than should be required:

i. If the ambient dew point is less than the dew point in the conditioned

space; check for excessive chamber or duct work leakage.

Appendix A A-14

Page 31

PGC, Inc 500-1000 CFM Air Handler May 2006

MAINTENANCE

PGC chambers are designed to be reliable and require minimal maintenance. If the Conditioner is

to be out of service for an extended period, it is advisable to clean the spray chamber interior to

remove contaminants that collected; refer to “Spray Chamber” in the Preventive Maintenance

Schedule table.

P

REVENTIVE MAINTENANCE SCHEDULE

Component What to Check Periodicity

Blower Wheel The blower wheel should be checked periodically for

cleanliness. A dirty blower wheel may reduce airflow

drastically. If the wheel cannot be cleaned, the blower should

be replaced.

Condenser,

Air-Cooled

Inspect and clean the outside coils. Typical A/C condensers

require less frequent cleaning than PGC air cooled

condensers because they only operate part of the time.

Heaters Check resistance to ground; less than 50KΩ indicates a

possible heater failure.

Spray Chamber Drain and flush out the interior (including evaporator coil,

spray eliminator, walls and sump) to remove deposits.

Spray Nozzles The spray nozzles should be checked periodically to make

sure they are free of foreign particles that might impair their

operation. The spray pattern may be observed by opening the

front access door. All spray jets should be working and

spraying uniformly.

UV Lamp and

Quartz Jacket

Particulate

Filter

The UV filter lamp and quartz jacket should be replaced

every 9,000 hours of operation.

Inspect and/or replace particulate filter as needed. Different

applications will generate varying quantities of airborne

particulates. Different water sources will also supply varying

amounts of particulates. Due to this the service frequency for

the particulate filter can vary widely. Visually inspect the

filter frequently at first until an appropriate schedule can be

developed.

Annually

Quarterly

Annually

Quarterly or as

needed

Quarterly or as

needed

Annually

Monthly (at

first) then as

needed.

Water RTD

Calibration

Air

RTD was calibrated at the factory. Re-calibration should not

be necessary.

HygroClip™ must be re-calibrated. Annually, or

Temperature/Rh

Calibration

Spray nozzles

It is important to change the water periodically. All water contains some impurities, and the spray

water picks up anything in the air. During normal conditioner operation, some water vapor is lost

Appendix A A-15

As needed

as needed

Page 32

PGC, Inc 500-1000 CFM Air Handler May 2006

r

and the water is replaced by the supply. Over time, the concentration of all these impurities

increases and deposit out on the coils and other parts of the chamber. Periodic draining and

flushing with clear water will significantly reduce such accumulations.

Air Heaters Spray Nozzles

Finned

Evaporator

Spray Heade

Particulate Filter

Connection

Figure A-2 – Spray Chamber

The spray nozzles should be checked periodically to ensure they are free of foreign particles that

might impair their operation. The spray pattern may be observed by opening the access door. All

spray jets should be working and spraying uniformly.

Particulate Filter

Proper filtration by the UV lamp requires that the water be free of

particulates that block the UV light from passing through the water.

The particulate bag filter is located in the sump and will trap

particulates that are 5 microns and larger. This filter bag must be

replaced periodically; the frequency of replacing this bag filter

depends mostly upon the process in the test chamber and upon the

environment in which the air handler is used. When starting a new

process, inspect the filter frequently in order to determine the

replacement frequency.

Replacement Instructions.

Figure A-7 – Particulate Filter

1. Turn the air handler off.

Appendix A A-16

Page 33

PGC, Inc 500-1000 CFM Air Handler May 2006

2. Remove the filter carrier by un-screwing it from the base..

3. Remove the used filter using an “un-screwing” motion.

4. Install the new filter. Typically, the filter can simply be “pressed” into the housing.

5. Replace the filter carrier.

UV Filter

CAUTION

fail prematurely. Wear gloves or wipe down these parts with alcohol before

installing them in the system.

The UV filter lamp and quartz jacket should be replaced every 9,000 hours of operation

(annually); an hour meter on the power panel keeps a cumulative time of operation. The UV lamp

may continue to operate after 9000 hours of use, but the wavelength of the light produced will no

longer provide an adequate kill rate. The lamp is accessed from the left access door of the unit. To

replace the lamp, shut down the unit by pressing the SmartPad™ Standby key , disconnect

power from the unit, pull out the lamp using the harness cap as a handle until the lamp is

extended far enough to unplug the harness, and withdraw the lamp from the unit.

UV Filter Removal Instructions.

1. Turn the air handler off. The quartz tube will be under discharge pressure from the water

spray pump.

2. Gently pull the UV lamp harness to remove the UV lamp from the quartz tube

3. Disconnect the lamp from the harness.

4. Remove the lamp from the quartz tube.

5. Remove the solid cap from the other end of the spray header. This will provide access to

the quartz tube support bracket, located inside of the spray header.

6. Remove the quartz tube support bracket.

7. Remove the blue, aluminum gland nut and S/S retaining washer from the UV mounting

flange.

Oily fingerprints on the lamp or quartz tube will cause the lamp or quartz tube to

Figure A-4 – Remove the lamp Figure A-3 – Disconnect the wiring harness

8. Remove, and loosely install the new quartz tube. Clean the new tube and lamp surface

with alcohol to remove fingerprints, or use un-powered latex gloves to prevent oil on the

glass surface of usable components.

9. Carefully install the quartz tube support bracket inside the spray tree.

10. Re-install the solid spray header cap.

Appendix A A-17

Page 34

PGC, Inc 500-1000 CFM Air Handler May 2006

11. Install the quartz tube o-ring, S/S retaining washer and the blue, aluminum gland nut. Do

not over tighten the gland nut or the quartz tube will crack.

12. Install the new UV lamp and connect the wiring harness. The rubber boot on the wiring

harness will secure the lamp in the quartz tube.

Figure A-6 – Remove the gland nut Figure A-5 – Spray header with solid cap removed.

A

UTOMATIC DAMPER MOTOR ADJUSTMENTS

(quartz tube support bracket exposed)

The damper actuator is designed to rotate a full 90°C, which may be more than necessary for the

air bypass damper on this unit. To accommodate for the limited movement of the damper, the

mechanical stops (Philips screws) on the actuator shaft are adjusted to reduce the operation range

of the motor.

After the stops are adjusted the actuator must be acclimated. This is an initialization procedure

that informs the actuator where the physical stops are located. To perform the acclimation

process remove the control input signal from PLC1 to the damper actuator. Then, while the

input signal is disconnected, press the clutch on the actuator two times. The motor will then cycle

to both stops. After the cycle is complete, re-connect the input signal.

Appendix A A-18

Figure A-12 – Air Bypass Damper Actuator

Page 35

PGC, Inc 500-1000 CFM Air Handler May 2006

CALIBRATION

C

ALIBRATION, AIR/RH

The air temperature and Rh are measured by a self-contained and calibrated Rotronics

HygroClip™ T/Rh transmitter. The Rotronics HygroClip™ T/Rh transmitter should be

recalibrated annually. The three different options for calibration are Exchange, Calibration in an

Independent Chamber, and Calibration In Place

Exchange

Both PGC and Rotronics© (the sensor manufacturer) have a sensor exchange program. Contact

Rotronics© for details regarding their plan and calibration schedule. For a nominal calibration

fee, PGC will provide a calibrated temperature and Rh transmitter as often as you desire. The

replacement sensor will be shipped complete with calibration data that can be used for validation.

The returned sensor will be re-calibrated and used as an exchange sensor in the future. The “as

found” data from the returned sensor can be forwarded to the customer to be used for validation.

Contact PGC for current pricing for this service.

The customer can also purchase a second calibrated transmitter, which can be interchanged with

the original sensor. The original sensor can then be returned to Rotronics©, PGC, or a calibration

laboratory for re-certification. This process can then be repeated on a schedule determined by the

customer’s specific requirements.

Calibration in an independent chamber

The HygroClip can also be calibrated through the serial port of a Windows based PC. An

interface cable, available from Rotronics, allows the PC to communicate directly to the

HygroClip. The HygroClip is then positioned in a stable chamber, compared to a reference

standard, and adjustments made to the calibration constants from the PC. Contact Rotronics or

PGC for more details regarding PC based HygroClip calibration.

Calibration in place

Rotronics© produces a hand-held device, called a HygroPalm™, that can be used to calibrate the

HygroClip™ transmitter, without removing the transmitter from the air handler. A special cable,

available from PGC, is connected from the HygroPalm to the communication line in the conditioning

unit. The HygroPalm then interrupts the communications from the HygroClip™ to the PLC in order to

modify the calibration constants that are stored in the HygroClip™. The HygroPalm can be equipped

with a second, calibrated HygroClip™ that is used as a reference probe, or an independent reference,

supplied by the customer or the calibration technician, can be used as the reference.

The actual location of the connection for the HygroPalm™ depends on where the HygroClip™ is located.

If the HygroClip™ is located within 5 meters of the PLC in the electrical compartment on the air handler,

it does not require external amplification of the digital signal. In this case, the HygroClip™ can be

connected directly to the PLC. To calibrate a HygroClip™ connected directly to the PLC, the

HygroPalm™ interface cable should be connected to the DIO and common connections on the PLC pc

board. This connection can be “piggy-backed” onto the existing wires in these terminals, or a special

cable, available from PGC can be used to connect to a calibration header on the circuit board.

Appendix A A-19

Page 36

PGC, Inc 500-1000 CFM Air Handler May 2006

“Piggy-back”

HygroPalm™

Connection

Calibration header

HygroPalm™

Connection

Figure A-13 – ACE4 PCB,

HygroPalm™ Connection

If the HygroClip™ is located more than 5 meters from the air handler, it will require an amplifier on the

digital signal. The HygroPalm™ cannot calibrate “through” the amplifier. This means that the

HygroPalm™ must be connected to the DIO and common on the sensor-side of the amplifier. The DIO

amplifier is located in a plastic box near the HygroClip™. Two terminals are provided for the DIO and

common connections from the HygroPalm™.

Connect

HygroPalm™

Here

Figure A-15 – DIO Amplifier,

HygroPalm™ Connection

Appendix A A-20

Page 37

PGC, Inc 500-1000 CFM Air Handler May 2006

HygroPalm© Single-Point Temperature Calibration Procedure

1.) Install a temperature reference as close as possible to the HygroClip© sensor.

2.) Using a special cable from PGC (Part Number 1609-866), connect the HygroPalm©

to ACE pc board at the two-pin connector in the upper left-hand corner, labeled DIO.

It is important to note that as long as the HygroPalm© is connected to the ACE pc

board, the chamber controller cannot communicate with the HygroClip©; therefore,

it is important make the calibration adjustment as quickly as possible.

3.) Press the HygroPalm© down arrow key until the display indicates “PROBE 2”. The

display should indicate the temperature and Rh measured by the HygroClip© in the

air handler/chamber. If the display does not indicate the measured temperature and

Rh, check the cable connection

4.) Press the MENU key. The display will indicate “CALCULATE”

5.) Press the down arrow ↓key until the display indicates “ADJUST 1 PT.”

6.) Press ENTER. The display will indicate “RHS”.

7.) Press the down arrow key until the display indicates “Temperature”.

8.) Press ENTER. The display will indicate the current measured temperature. Press the

UP or DOWN ARROW keys until the measured temperature matches the

temperature measured by the reference standard.

9.) Press ENTER. The display will respond “sure?”. Press ENTER again to enter the

calibration offset.

10.) The display will respond “wait” until the data written to the HygroClip©.

11.) When “wait” disappears, you can press ENTER to return to the measured value

display screen.

HygroPalm Single-Point Rh Calibration Procedure

1.) Install an Rh reference as close as possible to the HygroClip© sensor.

2.) Using a special cable from PGC, connect the HygroPalm© to the ACE pc board at

the two-pin connector in the upper left-hand corner. It is important to note that as

long as the HygroPalm© is connected to the ACE pc board, the chamber controller

cannot communicate with the HygroClip©; therefore, it is important make the

calibration adjustment as quickly as possible.

3.) Press the HygroPalm© down arrow key until the display indicates “PROBE 2”. The

display should indicate the temperature and Rh measured by the HygroClip©. If the

display does not indicate the measured temperature and Rh, check the cable

connection

4.) Press the MENU key. The display will indicate “CALCULATE”

5.)

Press the down arrow key until the display indicates “ADJUST 1 PT.”

6.) Press ENTER. The display will indicate “RHS”.

7.) Press the down arrow key until the display indicates “Humidity”.

8.) Press ENTER. The display will indicate the current measured relative humidity.

9.) Press the UP or DOWN ARROW keys until the measured Rh matches the Rh

measured by the reference standard.

10.) Press ENTER. The display will respond “sure?”. Press ENTER again to enter the