Page 1

Beadmaking, Glassblowing,

Fusing and Glass Kiln

Manual

Sundance

Glass

1

Page 2

Introduction

Contents

Thank you for choosing this kiln! We have designed it to

give you many years of reliable service.

Please read this manual. It will help you gain the maximum

enjoyment from your kiln. It will show you how to avoid damag

ing the kiln and will answer many questions. Your instruction

packet also includes a separate digital controller manual. Please

save both manuals.

Inspect the kiln. When you receive your kiln, check the carton

for damage (crushed, holes, etc.). Check the kiln for both inte

rior and exterior damage. If the kiln is damaged, you can refuse

the shipment and have it returned, or accept the shipment after

having the driver note the damage on the Bill of Lading.

Check the Bill of Lading to insure that you received the correct

number of packages. Note any shortages on the Bill of Lading,

and have the driver sign the copy.

If there were no signs of visible kiln damage and you discover it

after the driver has left, notify the shipper immediately.

Save the shipping carton. It was carefully designed to provide maximum protection during shipping. Use the carton to

take the kiln to seminars or on vacation, or to return the kiln to

the factory for repairs.

Needless worries. Tremendous stresses are generated

within the kiln. The ceramic fiber firing chamber actually expands and contracts with each firing. Do not be concerned if

small cracks appear in the fiber. This is normal. These are sur

face cracks that close tightly when the heated fiber expands. You

may find a small pin hole in the center of the firing chamber. It

is from the manufacturing process and will not affect the kiln’s

performance.

The paint around the door will eventually discolor from heat.

This, again, will not affect the kiln’s performance.

Safety 3

Setting Up the Kiln 4

Electrical Installation. . . . . . . . . . . . . . . . . . 4

Where to Locate the Kiln . . . . . . . . . . . . . . 4

Transporting the Kiln . . . . . . . . . . . . . . . . . 4

Basic Operation 5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Guidelines . . . . . . . . . . . . . . . . . 5

Loading the Kiln . . . . . . . . . . . . . . . . . . . . . 7

Venting the Kiln . . . . . . . . . . . . . . . . . . . . . 8

Silver & Gold Clay 8

Drying Time . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading the Kiln . . . . . . . . . . . . . . . . . . . . . 8

Venting the Kiln . . . . . . . . . . . . . . . . . . . . . 9

Rate, Temperature and Hold . . . . . . . . . . . 9

Cooling Time . . . . . . . . . . . . . . . . . . . . . . . 9

Combining Silver Clay

With Other Materials. . . . . . . . . . . . . . . . . . 9

Glass Fusing & Slumping 10

How to Cut Glass . . . . . . . . . . . . . . . . . . . 10

Fusing Compatibility of Glass . . . . . . . . . . 10

The Annealing Range . . . . . . . . . . . . . . . . 10

Cleaning and Gluing the Glass . . . . . . . . . 11

Loading the Kiln . . . . . . . . . . . . . . . . . . . . 11

Firing the Glass . . . . . . . . . . . . . . . . . . . . . 11

Enameling on Metal 12

Preparing the Copper . . . . . . . . . . . . . . . . 12

Decorating the Copper . . . . . . . . . . . . . . . 12

Firing Enamel . . . . . . . . . . . . . . . . . . . . . . 13

Ceramic Overglaze 13

Pyrometric Cones . . . . . . . . . . . . . . . . . . . 13

Loading and Firing Overglaze. . . . . . . . . . 13

Lost Wax Burnout 14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 14

A Sample Program . . . . . . . . . . . . . . . . . . 14

Burnout Instructions . . . . . . . . . . . . . . . . . 15

Firing Mistakes 15

Silver Clay . . . . . . . . . . . . . . . . . . . . . . . . . 15

Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ceramic Overglaze . . . . . . . . . . . . . . . . . . 16

During firing, you will hear an intermittent, distinct clicking.

This is the sound of the relay(s) sending power to the heating

elements. Do not be concerned with this sound.

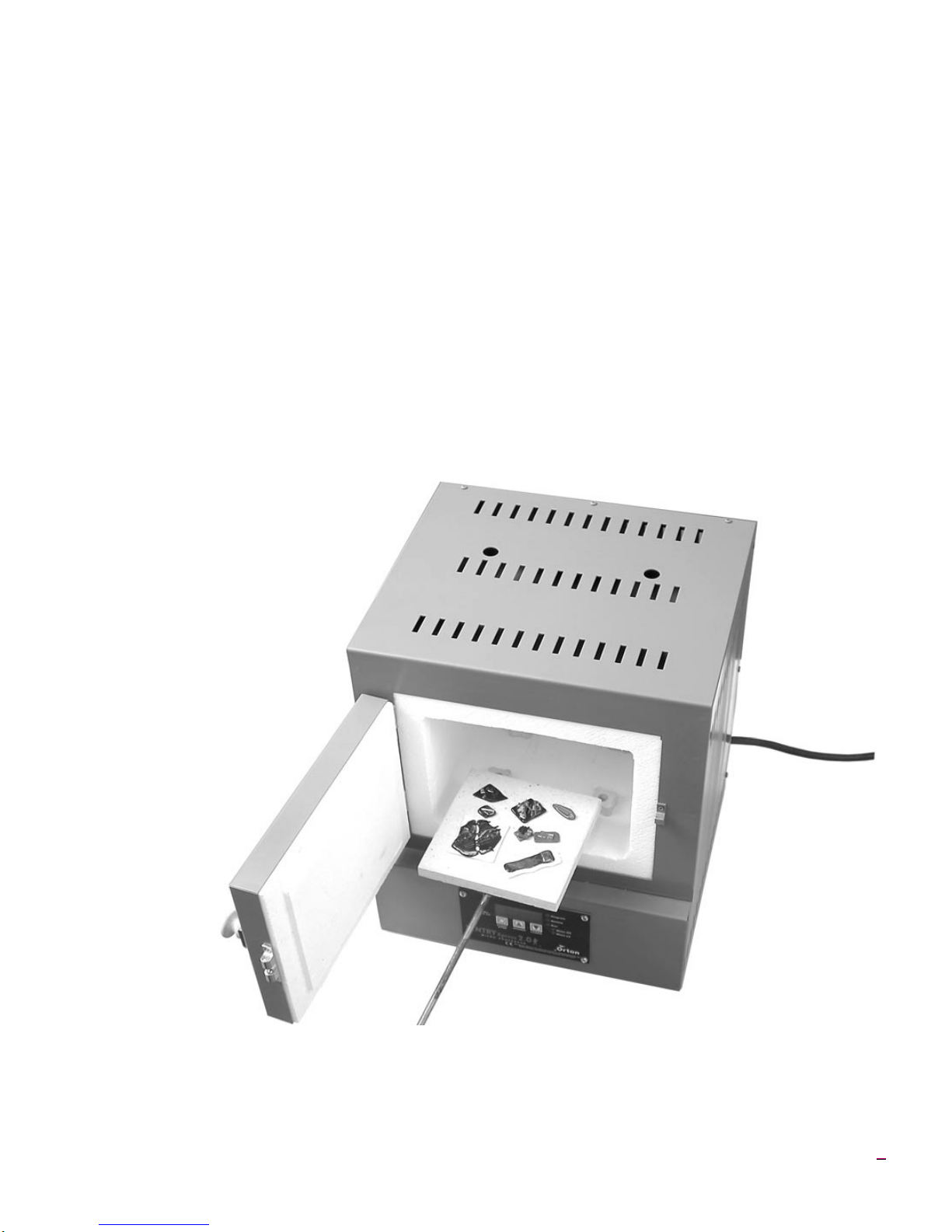

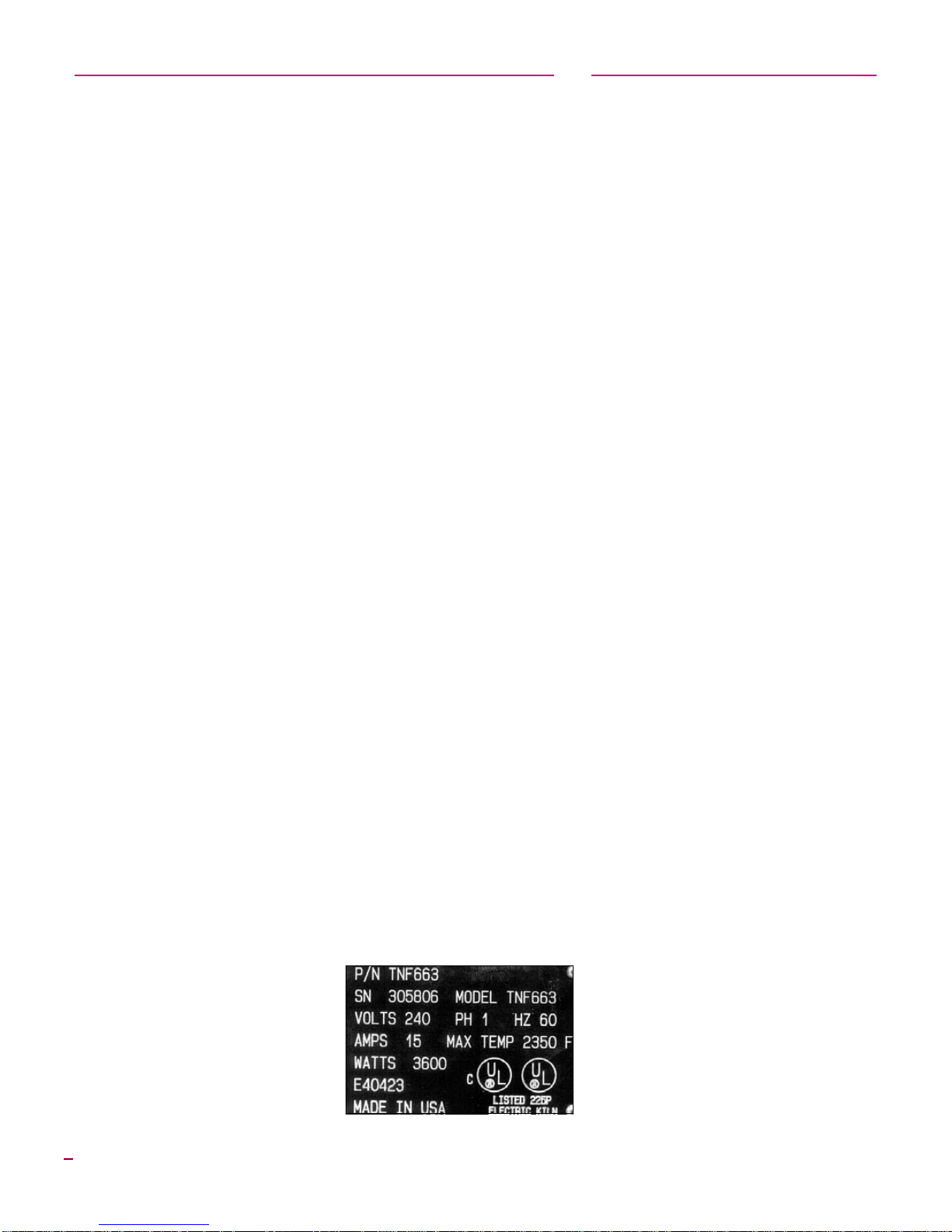

The Electrical data plate. Im

portant information about your

kiln is recorded on its electrical

data plate. Please include this in

formation when ordering parts or

calling your dealer or the factory

about your kiln.

©2001, IM-164/1-02

2

Kiln Maintenance 17

Trouble-Shooter . . . . . . . . . . . . . . . . . . . . 17

Door Latch Adjustment . . . . . . . . . . . . . . . 17

Ceramic Fiber Repair . . . . . . . . . . . . . . . . 17

Cleaning or Replacing Glass View Port . . 17

-

Replacing the Thermocouple . . . . . . . . . . 18

Replacing a Relay or Transformer . . . . . . 18

Replacing the Temperature Controller . . . 19

Replacing the Firing Chamber

(testing the element) . . . . . . . . . . . . . . . . . 19

Page 3

Safety

Overfiring

The warranty on your kiln does

not cover damage from overfiring,

regardlessofthecircumstances.Itisthe

operator’s responsibility to make sure

the kiln turns off at the proper time.

The Ceramic Fiber

Avoid touching the firing chamber

surface with sharp or pointed objects.

They can damage the fiber surface.

Touching the embedded heating

element with sharp or pointed objects is

a shock hazard.

Read the Manual!

Read each page of this manual in detail

before operating your kiln. Warranty

does not cover damage caused by

failure to follow instructions.

Food or Drink Surfaces

Some decorative materials may be

unsafe and toxic when used for surfaces

that will be in contact with food or drink.

When you make food or drink

containers, select a glaze or glass that

has been formulated, tested and labeled

as approved for surfaces that will be in

contact with food or drink. Follow the

glaze or glass manufacturer’s

instructions exactly, without any

variations.

Important Safety Rules

An electric kiln is extremely safe to operate provided you

follow these basic safety rules:

G

Unplug kiln when not in use.

G

Do not touch hot sides.

G

Keep unsupervised children away.

G

Place kiln on a non-combustible surface.

G

Do not installcloser than 12” from any wall

or combustible surface.

G

Fire only in a well ventilated, covered and

protected area.

G

Keep cordset away from hot sides of kiln.

G

DANGEROUS VOLTAGE: Do not touch

heating elements with anything.

G

Disconnect kiln before servicing.

G

Do not leave kiln unattended while firing.

G

Wear safety glasses when cutting glass.

G

Wearfiringsafety glasses when looking into

a hot kiln.

G

Keep food away from your work area.

G

Never fire tempered glass inside a kiln. It

could explode.

G

Avoid firing toxic materials inside the kiln,

suchas styrofoam (used as a coreforhollow

beads).

G

Kilnswiththeglassviewport:do notfirethe

kilnhotterthan1700°F/926°C.Firinghotter

will damage the glass.

3

Page 4

Setting Up the Kiln

Electrical Installation

Youmustplugyourkilnintoacircuitthatnootherappli

anceuses whilethekiln isfiring.Turnoffthecircuitbreaker

or unscrew the fuse for the circuit that your kiln will be

pluggedinto.Checktosee

ifotherappliancesshutoff

too. If that circuit powers

appliances that must re

main on while the kiln is

firing,plugyour kiln intoa

different circuit.

Note: 120 volt kilns:

avoidextensioncords

if possible. If you

must use one, never

use one smaller than

12 gauge and longer

than 20 feet. Never

plug it into a ceiling

outlet!

-

2 Remove gasoline, paint, and other flammable

materials from the kiln room.

3 Providea minimum of 12 inchesclearancebetween

kiln and the closest wall.

4 Never allow the room temperature of your firing

-

roomtoexceed100-110°F.Measurethe tempera

tureabout3feet fromthekiln.Ifnecessary,usefans

to lower room temperature.

-

Voltage fluctuation can vary firing time from as little as

halftomore than twice the average time. If the voltage is too

low, the kiln may never reach full temperature.

The receptacle must have a separate safety grounding

wire. This protects you from serious electrical shock.

Changing the cord plug will void your warranty!

Where to Locate the Kiln

1 Place your kilninawellventilated, covered andpro

tected area such as the garage, basement, utility or

hobby room.

Note: Somepeople keeptheir kilnoutsideon acov

eredpatio. Thisisokaysolongasthekiln isnotsub

jected to excessive humidity. We recommend good

ventilation.However,somematerials,suchas silver

clay, may not need special ventilation.

-

-

-

Place the kiln on a fire-proof surface, such as a large ceramic kiln shelf.

5 Keepthekilnawayfromcurtainsorothercombusti-

ble materials.

6 Position kiln on a level, fire-proof surface. We rec-

ommendan18” x 18”pieceofsheet metaloralarge

ceramic kiln shelf.

Note: Ifyou are with the kiln at all times during fir

ing, you can place it directly onto a workbench or

kitchen table. A fire-proof surface is ideal, though,

becauseitprovidesa safe placetolayhotshelves re

moved from the kiln.

7 Keep unsupervised children away.

8 Keepthepowersupplycordawayfromthekilncase.

There is little danger of serious burn from accidental

contact if you exercise the same caution you would use with

an electric iron.

-

-

Transporting the Kiln

Some people take their kilns to seminars or on vacation.

The easiest way to transport the kiln is to use the original

packing materials.

Ifyounolongerhavethepackingmaterials,transportthe

kilnonits back with the door facing up. Place a thin sheetof

foamcushioning betweenthedoor andthefiringchamberto

prevent rubbing. Avoid subjecting the kiln to excessive vi

bration during travel.

-

4

Page 5

Basic Operation

Accessories

Ceramic Fiber Shelves

The soft ceramic fi

ber shelf, which comes

standard with the kiln,

cradles gold and silver

clay pieces. These

shelves are not suitable

for firing glass or ce

ramics.

Ceramic Fireclay Shelves & Posts

Ceramic fireclay

shelves, available from

Sundance are hard ce

ramic surfaces on

which to fire ceramics

and glass. Firing glass,

enameling,and ceramic

glazes directly on the

firing chamber bottom

would ruin the bottom.

Shelves can be stacked

using posts.

Glass Separator & Kiln Wash

Glass separator and

kilnwash are mixtures of

finely ground minerals

that will not melt and

fuse together at high

temperatures. They pre

vent glass and ceramic

glaze from sticking to

fireclay shelves. The

main difference between

glass separator and kiln

wash is that the separator is ground more finely to leave a

smooth back to glass pieces laid on the shelf.

Aspowders,glass separatorandkilnwash haveanunlim

ited shelf life. Do not breathe the powder when mixing.

Caution: If glass separator or kiln wash contact a

heating element, that element will burn out in the

next firing. NEVER apply glass separator or kiln

wash to the ceramic fiber firing chamber.

Haik Brush

The haik brush is used to apply

glass separator to the kiln shelf in a

smooth, thin layer. The smoother

the glass separator, the smoother

the underside of the glass.

-

-

-

-

Alumina Hydrate

Delicatesilveror goldclayshapesmay needextrasupport

duringfiringtopreventwarping.Placetheseshapesinathin

layerofaluminahydrateinsideasmallceramicbisquebowl.

Do not breathe alumina hydrate.

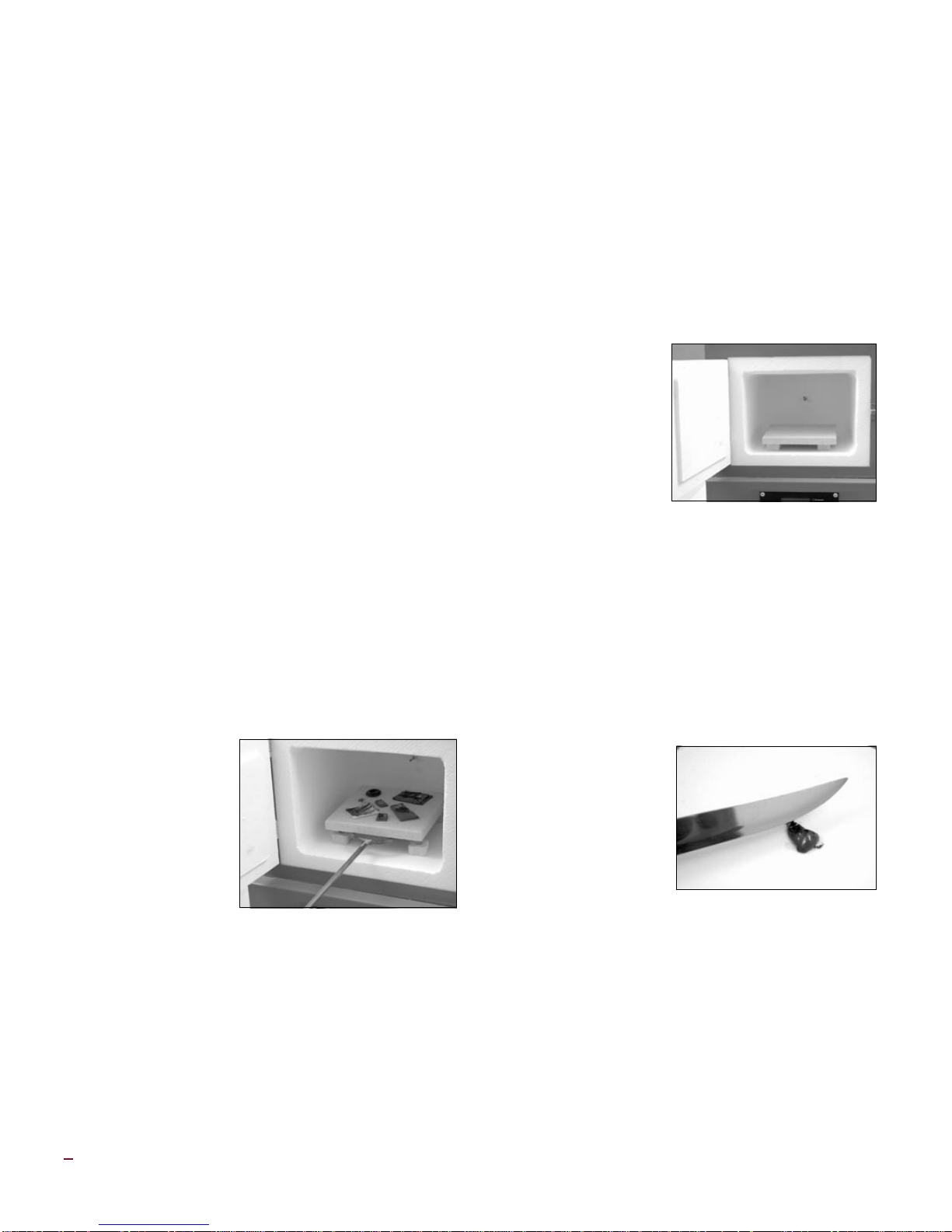

Stilts

Stiltsarepoints embedded in a ceramic base. The points

separate enameling and glazed ceramics from the shelf.

The wire mesh above is referred to as an enameling rack. An enameling

fork lifts therack out of thekiln. A stiltseparates the piece fromthe rack.

Enameling Racks

Enamelingistheartoffiringglassontometal.The metal

shapes are loaded onto a high temperature wire rack. The

enameled pieces and wire rack are loaded into a hot kiln,

fired for just a few minutes, and removed red hot. To load

and unload the racks safely, use an enameling fork.

The heating element under power is dangerous. Do not

touch the element with anything! Turn the kiln switch off

beforeinsertinganenamelingforkintothefiringchamber.

Fiber Repair Filler

Thisisa permanent,hightemperature refractorycement

used to repair holes or cracks in the ceramic fiber firing

chamber.

Safety Glasses

Wear clear safety glasses

when cutting or chipping glass.

Wear firing safety glasses when

-

looking into a hot kiln, such as

when checking the progress of

glass.

Caution: Always wear fir

ing glasses when viewing

the interior through the optional glass view port.

-

5

Page 6

Important Guidelines

The Embedded Heating Element

Theheatingelementsofyourkilnareembeddedintothe

ceramicfiberfiringchamber.Thefiringchambersurface is

hardenedtoadepthof¼”.Thismakesthefibermoredura

ble. It is important that you do not touch the firing chamber

with sharp objects. These can penetrate the fiber surface

and contact the heating element, which is a shock hazard.

Note: Theheatingelementunderpoweris danger

ous.Do not touch the element with anything! Turn

the kiln switch off before inserting an enameling

fork into the firing chamber to remove a shelf.

The Clicking Noise

Do not be concerned if your kiln makes a clicking sound

during firing. Your kiln contains a relay, which sends power

to the element. The relay clicks as it cycles on and off to

maintain the correct temperature.

Check Thermocouple

You will find a small rod, called the thermocouple, ex

tending into the firing chamber. The digital controller

senses temperature by reading a voltage from the thermocouple. If this rod is pushed out of the firing chamber, the

kilnwillassumethat the firingchamberiscold.This will result in an over-fire. Be sure the rod extends into the firing

chamber by ½” - ¾” before firing the kiln.

Vacuum the Kiln

Clean the kiln before firing glass, enameling, or ceramic

glaze. (Cleaning is not necessary when firing silver or gold

clay).Usea softbrushnozzleon avacuumcleanerto remove

dust from inside the kiln.

Removing Hot Ware

To remove hot ware

from the kiln, turn off

the kiln. Carefully slide

an enameling fork un

der the shelf. Place the

hot shelf on a large ce

ramickilnshelfin front

of the kiln. Wear thick

work gloves.

-

-

Firing Log Book

Record the following information in a firing log book:

I

Date

I

Firing temperature, speed and hold; or Ramp/Hold pro

gram

I

Starting time

I

Total firing time

I

Type of pieces

I

Firing results

-

Asyou gain experience, you will finda wealth of informa

tion in your firing logs.

Low Temperature Holds

A low temperature hold (i.e. 200° - 300°F) is more diffi

cult to maintain than higher temperature holds (1400° -

-

1700°F). At low temperatures, turning on the heating ele

ment affects firing temperature to a larger degree than at

high temperatures.

When holding at a low temperature, heat the kiln slowly.

Otherwisethetemperaturemayovershoottheholdtemper

ature before the element turns off.

Avoid Contaminating the Heating Element

Contact with silica or

silica bearing com

pounds, such as kiln

wash, glass separator,

alumina hydrate, glass,

enameling powder, and

ceramic glaze, will ruin

the heating element.

-

Neverfireglazed ceramic

ware, glass, or enameling

directly on the firing chamber bottom. Use a ceramic shelf

on short posts to protect the bottom from glaze drips, glass

and enameling powder.

Caution: Some kilns contain a heating element

embeddedinthe bottomofthefiring chamber.Materials such as glass and glaze, if absorbed into the

fiber firing chamber, can ruin the element. This

type of damage is not covered by warranty. Prevent

glass separator, kiln wash, and alumina hydrate

from falling from a shelf onto the firing chamber.

These materials can destroy the element.

Note: If a contami

nantsuchasdripping

glassorglaze embeds

into the firing cham

ber, unplug the kiln.

Gently scrape off the

contaminant with a

knife, being careful

not to damage the

heatingelement.Vac

uum the kiln.

-

-

-

-

The Effect of Silver Residue on Glass

Firing silver clay leaves traces of silver in the poresof the

firingchamber.Sometimesthere is enough silverresiduein

the kiln to affect colors of glass. For instance, green might

turn yellow.

Note: Before firing an important glass piece in a

kiln used for silver clay, perform color tests. Fire

small samples of each glass color on a base sheet of

clearglass.Placethe glassonafireclayshelf(notthe

soft fiber shelf).

-

-

-

-

6

Page 7

The Optional

Glass View Port

Caution: Wear fir

ing safety glasses

whenever looking

into the optional

view port.

Maximum tempera

ture for a kiln with view

port is 1700°F/926°C.

Firinghotterwilldamagetheglass.Seepage17forglassport

maintenance instructions.

-

-

Loading the Kiln

Place Ware on a Protective Shelf

Alwaysprotectthefiringchamberby firingyourpieceson

a shelf or in a bowl. Do not place the pieces directly on the

bottom of the firing chamber.

Types of shelves and containers:

Fiber Shelf

Place the standard fi

ber shelf directly onto the

kiln bottom. This shelf is

used to support silver and

gold clay.

Note: Fireonlysilver

or gold clay on the fiber shelf—never ceramics, enameling or glass. Do not coat the fiber

shelf with glass separator or kiln wash.

Fireclay Shelf

Ceramic fireclay

shelves, available from

Sundance protect the fir

ing chamber bottom and

provide a smooth surface.

Use a ceramic shelf in

yourjewelry kilntofirece

ramics, glass, and enameling.

Insulating Firebrick

Piece

Insulating firebricks

are porous, light-weight,

and canbe shapedtosup

port delicate silver clay

designs. Carve the fire

brickwithaknifeorhack

saw.

Ceramic Bowl

You can purchase an unglazed, small ceramic bisque

bowlfroma ceramic supplystore.Thebowl willlastthrough

many firings. Use it to hold alumina hydrate. You can also

shape hot glass by slumping it into the bowl.

-

-

-

-

-

-

Note: Ceramic shelves and bowls and insulating

firebricks may slow the firing. They absorb more

heat than the ceramic fiber shelf. They also cool

more slowly than the fiber shelf.

Applying Glass Separator or Kiln Wash

Glass and ceramics are fired on a fireclay kiln shelf and

notdirectly onthekilnbottom.Youcanalsoslumpglassover

amold, suchasabowl.The kilnshelfandsaggingmold must

becoatedwithglassseparatortokeepglass or ceramic glaze

from sticking to them.

A coat of glass separator or

kiln wash will usually last

through several firings. When

the shelf coating begins to

crack or chip, apply a fresh

coat.

Whenrecoatingashelf,re

move most of the old coating

with grit cloth (available from

sundance). This is an abra

sive-coated mesh that allows

residueto pass through. Removing the old coatinggivesyou

a smooth surface to start with. Then recoat the shelf using

thefollowingdirections. (Both glassseparatorandkilnwash

will be referred to as “separator.”)

Caution: Donotapply glass separator or kiln wash

totheceramic fiber firingchamberorto the bottom

of the shelf! Contact with glass separator or kiln

wash can ruin the embedded heating element.

Note: Do not coat the soft ceramic fiber shelf with

separator. If you are firing only silver or gold clay,

you do not need separator. When firing silver clay

withglass, however, fire the piece on ahard fireclay

shelf coated with separator.

1 Mix the separator with water followingthedirections

on the bag. Stir.

2 Useahaik brush or a soft

paint brush to apply the

separator to the shelf.

(The haik brush is easier

to use because it lays

down a more even coat

ing.) Each time you dip

your brush into the sepa

rator mixture, swirl the

brush around the bottom

of the container. This is

because the separator settles quickly. Use two or

three thin coats changing the direction of the brush

stroke 90° with each coat.

3 Drytheshelf beforefiring.Tospeeddrying,placethe

shelf on three ½” posts inside the kiln. Heat at full

rate to 300°F/148°C and hold for five minutes. Then

turn off the kiln and leave the shelf inside.

-

Separator lasts through several

glass firings. Apply new separator

when the oldcoat begins to flake.

-

-

-

7

Page 8

4 Afterthe separator has dried and your shelf is cool,

youcansmoothen the separator further by rubbing

your hand lightly over the shelf. The smoother the

separator,thesmootherthe backsideoftheglass.

A coat of glass separator will usually last several firings.

The lower the fusing temperature, the more firings you can

get from one application of separator.

Using Ceramic Fireclay Posts

Ceramic posts support ceramic fireclay shelves inside a

kiln.

I

Donotuse postsundertheceramic fibersoftshelf.Place

the fiber shelf directly onto the bottom of the firing

chamber.

I

Place three ½” posts under the ceramic hard fireclay

shelf. This aids air circulation, preventing heat built-up

under the shelf.

I

Youcan firetwoormoreceramicfireclayshelvesinaPar

agon jewelry kiln. Support the bottom shelf on three ½”

posts. Separate the shelves with taller posts. The length

of the posts and the number of shelves you can fire de

pends on the size of the kiln. When you load multiple

shelves,fireataslowerrate.Thisaidsheatdistribution.

Silver & Gold Clay

Withsilverclay, it ispossibletoshape intricate,free-form

silver jewelry in minutes—even as a beginner. (The clay is

alsoavailablein gold;forsimplicitywe willrefertoboth met

als as “silver clay.”) At the time of printing, the silver clay

brands available were Art Clay Silver and Precious Metals

Clay.

Silver clay looks and feels like modeling clay. It is formed

withsimpletoolssuchas a tooth pick, small knife, and razor

blade. Its surface is pliable and accepts impressions from

objectssuchasleaves,coins,andcoarsefabrics.Afterthesil

ver clay is formed, it is fired in a kiln. The recommended

temperature and hold time is included with the silver clay.

Formingandfiringsilverclayissimple.Thereisnothing

mysterious about making silver clay jewelry. The silver clay

is made of micron-size silver (or gold) particles held in an

organic binder. During firing, the binder burns away. The

silver particles then fuse together forming real silver. Since

thebinder disappears,thereisacertainamountofshrinkage

duringfiring. Shrinkage varies depending onthe type of sil

ver clay you use.

-

-

-

Venting the Kiln

Some types of ware, such as glass and ceramics, contain

impurities that burn off during firing. These impurities

mustbe releasedfromthekiln.Otherwise theycanaffectthe

quality of the ware.

Silver and gold clay need no venting unless you are firing

themwith amaterialthatburnsout forahollowshape,or you

are combining them with another material such as glass.

Ifthekiln hasavent hole,openthevent. Ifitdoes nothave

a vent hole, open the door about ½”. Venting will be ex

plained in greater detail in sections on glass and ceramics.

Drying Time

Small, thin silver clay pieces can be placed into the kiln

whilestill moist, and fired. Thicker pieces need time to dry.

Otherwise they may warp during firing.

Tobeon thesafeside,givethe silverclayplentyof time to

dry. As you gain experience, you will know just how much

drying time each type of piece needs. You can speed drying

with a hair dryer.

Loading the Kiln

Silverclaypiecesthathaveaflatsidecanbeplaced inside

the kiln directly onto a shelf. Use the soft ceramicfiber type

shelf. It cushions the clay silver.

I

Silverclaypiecescanbeclose together,butthey mustnot

touch.

I

The soft ceramic fiber shelf can be placed directly onto

thefiringchamberbottom. It is not necessary to support

the fiber shelf with posts, since the heat transfers easily

through the fiber shelf.

I

-

Donotcoatthe ceramic

fiber shelf with kiln

washorglassseparator.

I

You can also place the

silver clay on a piece of

ceramic fiber batting.

Alumina Hydrate

Rounded, hollow, or

other delicate shapes may

needsupport to prevent collapsing. You can lay these pieces

onto a mound of alumina hydrate.

8

Page 9

If the piece needs only shallow support of ¼” depth or

less, pour the alumina hydrate onto a ceramic fireclay shelf.

Support the fireclay shelf on three ½” posts to aid heat flow

under the shelf.

If the silver clay shape needs deeper support, pour the

alumina hydrate into an unglazed ceramic bisque bowl.

These are available at ceramic supply stores.

I

Place the ceramic bowl directly onto the kiln bottom.

I

NEVERusea glazed bowl to hold the alumina hydrate. If

the glaze runs, it can embed into the firing chamber.

Caution: Avoid breathing alumina hydrate dust.

Caution: Alumina hydrate can destroy the heating

elementoncontact.Ifitspillsontothefiringcham

ber, remove with a vacuum cleaner.

-

combination, eliminating the need to visually check the

glass.

Venting the Kiln

Silver clay by itself needs no venting. Load the kiln, close

thedoor,andleaveitclosed untiltheclay silverisready tore

move.

The kiln needs venting if you fire ceramics or glass with

the clay silver, or if you make hollow objects that contain a

core of organic materials.

Paper maché and paper clay are good core materials. Do

not use wax or styrofoam as a core. They emit harmful

fumes.

Rate, Temperature, Hold

Each brand of silver clay fires to a specific temperature

andholdtime.Thisinformationisavailablefromyoursilver

clay supplier.

Note: Hold time is the length of time that the rec

ommended temperature is maintained in the kiln.

Do not fire longer than the recommended hold, or

the silver will begin to overfire.

Besides selecting a temperature and hold time on your

kiln’s digital controller, you will also need a firing rate. (See

the separate digital controller instruction booklet.) Select a

Full Power rate if you are firing silver clay alone. If you fire

glassorceramics withthesilverclay, selectaratebest suited

for the glass or ceramics.

Note: Do not place silver clay into a kiln that is al

readyhotunlesstheclayiscompletely dry. The kiln

should be no hotter than 500°F/260°C when insert

ing the silver clay.

After the kiln begins firing, leave the door closed. Do not

open the door until it is time to remove the clay. Visual in

spection of the clay is unnecessary.

If you are firing glass with the silver clay, on the other

hand,youmayneedto check the fusing progress oftheglass

by opening the door ½” and looking inside. Look for just a

second or two. As you gain experience, you will be able to

programthecorrect temperature forthesilverclay andglass

-

-

-

Cooling Time

-

Aftertheclaysilver has fired to completion,youcancrack

the door an inch to speed cooling. If you are firing stones,

glass,orothermaterialswiththesilverclay,itissafertoallow

the kiln to cool slowly with door closed. Remove the piece

when the kiln reaches room temperature.

Silver clay pieces that contain no other materials can be

removed from the kiln at 1100°F/593°C. You can remove

them with tongs and drop them into water.

Caution: Turn the kiln off before inserting tongs

into the firing chamber. Wear protective gloves.

Combining Silver Clay

With Other Materials

Thereare two ways to fire silver claywith other materials

such as glass:

I

Fire the silver clay first by itself. After you have cleaned

andpolished the silver clay, fire it a secondtimewith the

other material.

I

Fire the silver clay and other materials, such as a stone,

together in a single firing.

Enamelingpowderiseasiertofirewiththe silver clay in a

secondfiring.See page12.Glassis oftenfiredwiththesilver

clay in a single firing. Many types of glass will melt to the

point of overfire at silver clay temperatures. So before

combiningglassandsilverclay in a single firing, test a small

sample of the glass. To do this, fire the glass during a silver

clay firing, keeping the glass separate from the silver clay

piece. (This way you won’t ruin the silver clay piece.) Place

theglasspiecesonaceramicfireclayshelf. Youmustcoatthe

shelfwith glassseparator,orotherwisetheglasssamplewith

embed into the shelf.

If the glass sample survives the firing, you can fire that

typeofglasswithsilverclayin a single firing. Note, however,

that different types of glass fire to different temperatures.

Every time you fire a different type of glass, be sure to test.

9

Page 10

Glass Fusing &

2 Hold the straight edge firmly and score the glass

withtheglass cutter.Pressjusthard enoughsothat

the scoring noise sounds steady and unbroken.

Slumping

You will probably fire mostly stained glass, but you can

also fire standard float (window) glass. Some types of float

glass devitrify (form a dull, frosty surface) when fired.

Caution: Never fire tempered glass. It could ex

plode if heated inside a kiln.

Basic Glass Tools

Reservoir Glass Cutter uses a reservoir of oil to lu

bricate the cutter wheel.

Running Pliers are for cutting large pieces of glass.

Breaking Pliers are for cutting small strips.

Grozing Pliers shape the glass by chipping away the

edges.They areoftenusedwhenthescoreline doesn’tbreak

cleanly. Note that rough edges will become smooth when

fired to fusing temperature.

How to Cut Glass

Note: IMPORTANT! Wear safety glasses when

cutting or chipping glass.

1 Lay the glass on a clean surface. Mark off the cut

withagreasepencilor felt-tip pen. A smallmarkon

each end of the glass will do. Lay a wooden straight

edgeoverthe glassandlineit upwiththemarks you

just made.

-

3 Place the straight edge under the glass so that an

edge is lined up with the score line you just made.

Press down on the glass. It will break cleanly.

Fusing Compatibility

of Glass

When glass changes temperature, it expands and con

tracts.Therateatwhich glasschangessize iscalledthecoef

-

ficient of thermal expansion. If you fuse two glass pieces to

gether and one changes size faster or slower than the other,

the fused piece may crack—even several months after fus

ing.

Whendifferentglasses have a close enough coefficient of

expansiontofusesuccessfully,they’recalled fusing compati

ble. Buy glass labeled fusing compatible. Or fuse glass that

has been cut from the same sheet, which guarantees com

patibility.

Fusing Compatibility Test

1 Totestglassforcompatibility,fusesmall½”square

samplepiecesof differentglassesontoa largerbase

piece of clear transparent. It should extend beyond

thesmall samplepiecesbyhalfaninchon eachside.

One of the sample pieces should be cut from the

base piece.

2 Heat the glass to a temperature that completely

rounds the edges of the small sample pieces.

-

-

-

-

-

-

3 After the glass cools, place a polarizing filter under

the glass and another filter over the glass. Look at

theglasswith lightshiningthroughit (hold itovera

lamp).Turn one of the filters until the filters areat

their darkest.

Results of the Test

Ifyou see a halo around the edges ofthe small glass sam

ples,thisusuallymeanstheglassisnot compatible.Ifyousee

no halo, the glass is fusing compatible.

Why did we include a sample square cut from the base

transparent glass? It tests for annealing. A halo around that

piece means the glass was not annealed properly. Perform

thetestagain,thistimecoolingmoreslowlythroughthean

nealing range.

The Annealing Range

Each type of glass has a temperature range that it must

passthroughslowlywhenitcools.Thisiscalledtheanneal

ing range. This slow cooling gives hot glass time to release

thestressofcooling.Ifyoucooltheglass toofastthrough the

annealing range, it will break.

The larger and thicker the glass, the slower it must pass

through its annealing range. You cannot over-anneal, so err

-

-

-

10

Page 11

on the side of caution if you aren’t sure how long to anneal.

Smallprojectssuchasearringsrarelyneedannealingtimeas

they cool.

Cleaning and

Gluing the Glass

Grease, dirt, and

fingerprints etch per

manently into the

glass during firing.

Clean the glass with

glasscleaner(thetype

without silicones),

rubbing alcohol, or

even plain water just

before assembling

the pieces on the kiln

shelf.

Use white glue,

such as Elmer’s

diluted1:1with water,

to hold the glass

pieces together after

you place them on the

kiln shelf. Use the

gluesparingly.Glueis

especially important

whenfusing wire into the glass. The glue prevents the glass

or wire from moving out of place before they fuse. The glue

disappears during firing.

Avoid using glue on the coated side of dichroic glass. If

youlaydichroicglasscarefully onto the piece, glueisunnecessary,soavoiditaltogether if you do notknowwhichsideof

the dichroic is coated.

-

Loading the Kiln

Air should circulate

between the shelf and

the bottom of the kiln,

so place three or four

1/2” posts in the kiln.

Lay the shelf over the

posts.

Firing the Glass

1 Vent kiln by openingthedoor½”and leaving thevent

hole (if your kiln has one) open. Venting allows the

gasesreleasedto escape. Whenthekilnreaches500 800° F / 260 - 426°C, close the door.

2 The first time you fire a particular brand or type of

glass, program the controller for a higher tempera

-

Looking at the glass during firing. Open the door about ½”. Always

wear firing safety glasses when looking at the hot glass.

ture than the estimated fusing temperature. Watch

the glass by opening the door ½” for several seconds

at a time. Shut the kiln off when the glass fuses the

way you want. Make a note of the shut-off tempera

ture. For future firings, program the kiln for that

temperature and rate.

Note: With everyfiring,besureyou arenearthekiln

before the expected shut-off time.

3 After you shut the kiln off, vent the kiln for five min-

utes by opening the door 1”. Then close the door.

Note: Someglass artists flash cool the glass after it

fuses. They vent the kiln until the temperature

drops to 1000° F. Then they close the door again.

This speeds up cooling.

4 The annealing range for most glasses is between

950°/510°C and 700°F/371°C. Cool slowly through

this annealing range. Leaving the door closed will

slow the cooling enough for most projects. If you

need even slower cooling, program a separate seg

ment for cooling. See the kiln’s digital controller

manual.

Note: For safest cooling, leave the ware inside the

kilnuntilthe kiln reaches room temperature. If you

remove the ware too soon, the sudden temperature

change can crack the piece.

To remove small

pieces, such as glass

jewelry, before they

have cooled com

pletely, remove the

shelf also. Leave the

pieces on the shelf

untilthey reachroom

temperature. The

heat in the shelf will

help prevent them

from cooling too quickly.

Caution: Beforeremoving a shelf,turnoffpowerto

the kiln.

-

-

-

11

Page 12

Enameling

on Metal

Preparing the Copper

Enamels come in transparent or opaque. They can be

purchased directly from Thompson Enamel, P.O. Box 310,

Newport, Kentucky 41072. Their Lead Free Enamels come

readytouse. Noenamelwashingisrequiredforthese enam

els.

Startwithoneof themanypre-shapedcopperformsavail

able, or shape and trim the copper to your own design.

1 Heat the copper on an enameling rack to about

1400°F/760°C to burn off oil or grease. Heat the

copper to just until smoke from oil or grease stops

coming off the metal and its color has changed to a

purple-red-pale green iridescence that moves

across the copper. This indicates that the grease

hasvaporized.Do not fire the copper any longer than

this point. Otherwise excess fire scale will form,

making the next cleaning step difficult.

2 After the copper cools, brush any loose scale from

the copper. Use a brush or paper towel, being sure

thatyoudonotput anygreaseor oilontothe copper,

Decorating the Copper

Counter Enameling

Most enameled pieces should be counter enameled on

the back side. This gives the piece a much more finished

look, it eliminates a great deal of fire-scale cleaning, and it

controls the chipping and cracking that can result from the

different rates of expansion and contraction in copper and

enamel after the enamel has been fired.

-

-

Counter or backing enamel, a mixture that gives a mot

tled effect, can be used for counter enameling. Or you can

useregularenamel.Counter enamelisappliedbythe sifting

method described below.

When firing counter enamel, underfire it so that the fire

scale on the front of the piece isn’t too difficult to remove.

Youcanpurchaseamaskingpreparationfromyoursupplier

tohelp prevent fire scale. You must place thepiece on a stilt

whenfiringtheother(front)sideofthepiece.Thestiltprevents the back of the counter enameled piece from sticking

to the enameling rack.

-

such as fingerprints. Clean the copper with a 3M

Scotch-Brite® pad. This pad does such a good job

that in most cases no further cleaning will be re

quired. Additional copper cleaning products are

availableintheThompsonEnamel Catalog,includ

ing Sparex No. 2.

Itisbesttocleanthe copper just before you decorate it.If

youwaittoo longtodecorateafter cleaning,thecoppercould

get dirty again.

-

-

Applying Enamels

Apply enamel over a clean sheet of paper so you can pour

theexcessbackintothebottle forreuse.Transparentenam

els should be applied in several thin coats. Transparent

enamels can be mixed with fairly good results. If opaque

enamelsaremixed,however, agrainyeffectresults.The two

basic methods of applying enamels are sifting and spatula.

Sifting Enamel

SprayorbrushThompsonholdingagentontothecopper.

Thensifta1/32”layerof enamel onto the copper. Usea#60

meshsifter.Ifthecoatis too thin, you can easily addanother

coat after firing. But a coat that is too thick will bubble and

crack. The enamel must dry completely before firing.

Spatula or Inlaid Method

You can use this method to decorate a small area with

manydifferentcolors.UsingadilutedsolutionofThompson

holding agent, dampen the enamels just to the saturation

point, and maintain this moisture while working with the

enamels. Apply the enamels onto the copper with a small

spatula, and spread them out with a spreader to a coat of

about 1/32” thick. Lines of contact can be formed by the

spatula blade. Then spray the enamels with the holding

-

12

Page 13

agenttokeepthegrainsof enamelinplace. Allowtheenamel

to dry completely before firing.

Ceramic Overglaze

Firing Enamel

1 Heat the kiln to 1450°F/787°C for most enameling.

Use a Single Segment. (Please see your digital con

troller instruction manual.)

Rate Temp.

Segment °F/°C °F/°C Hold

1 1799/999 1450/787 01.00

Note: Hold time should be the length of time you

will be inserting enameling into the kiln. In the

above example, hold time is for a one hour.

2 Lay the copper shape on an enameling rack. If the

part that touches the rack is enameled, place a stilt

under the copper. Some bowls or other shapes have

enameled sides that might run during firing. These

shouldbefiredwitha stiltevenif thepiecehas aplain

bottom.Use anenamelingforkor,iftherackis small,

a 6” putty knife, to place the rack into the kiln on top

of ½” ceramic posts.

Note: Firing the piece at enameling temperature

shouldtakeabout threeminutesandrequires undivided attention!

3 Look at your pieceevery15secondsbycrackingopen

thedoor.Removethe rack whenthecopperpieceap

pears a rosy red and the enamel is smooth. Place the

rackonasteelpadorlargeceramickilnshelfandletit

cool completely.

4 After counter enameling, you will need to clean the

fire scale off the front of the piece. A 3M Scotch

Brite® pad works well for this. Then clean it with

Thompson Sparex No. 2.

Pyrometric Cones

-

-

Pyrometric cones are small pyramids of clay and mineral

oxide that soften and bend

whenexposedtoheat.They

indicatewhenceramic ware

has fired to maturity.

Pyrometric cones come

in 1 1/8" and 2 ½" lengths.

Use the 2½” cones. Cones

mounted on the kiln shelf

mustbeslanted8° fromver

tical.Theywillnotbendac

curately if they are slanted

to the wrong angle.

Self-supporting large

coneshave thecorrectslant

built into the base. Stan

dard cones must be

mounted in a clay or wire

plaque.

The chart on page 14

shows the temperatures of

pyrometriccones.Program

your controller to the cone

recommended for the ceramic ware that you are

firing.

For small ceramic

pieces, such as figurines,

program a rate of

400°F/222°C. Fire to the

temperature shown in the

108°F column of the Tem

perature Equivalents chart

for the cone number you

are firing.

Before deciding on the

firingspeedofimportantpieces,testfiresampleclaypieces.

Note: Do not fire beyond your kiln’s maximum

temperature. Firing hotter will void your warranty.

Kilns with glass view port: do not fire hotter than

1700°F/926°C.

-

-

A self-supporting cone fired to matu

rity. Do not be concerned if the tip is

slightly higher or lower than shown.

-

A “puddled” over-fired cone.

-

Under-fired cone.

-

Loading and Firing

Overglaze

Overglaze is decoration applied over fired glaze or pol

ished porcelain bisque. Overglazes include china paints,

gold, and luster, which fire from cone 022 to 014.

Load overglazed ware the same way you would load ce

ramic glaze. Use stilts and make sure ware is not touching

other ware. Ware must be completely dry before firing.

13

-

-

Page 14

China paints will

crack or peel if ap

plied heavily. Apply

several light coats in

stead, firing between

each,untilyougetthe

shade you want. Not

all china paint colors

reach maximum

colorsaturation atthe

same temperature

even when fired on

thesameware.Soyou

mustknowwhichcol

ors you should fire

first at higher tem

peratures to prevent burning out the original colors in later

firings. For example, reds mature at a lower temperature

than other colors and are fired after the other colors have

beenfired.Reds and yellowsshouldnotbe fired sidebyside.

Colorsalsomatureatalower temperatureonceramic pieces

thanonporcelainorhardchina.Checktheoverglazemanu

facturer’s literature for information on which cone to use

with each color and type of ware.

Vent the door during the first hour of firing. If your kiln

has a vent hole, leave it open during the entire firing. Allow

kiln to cool to room temperature before opening the door.

-

-

Open the door ½” to vent the kiln if your kiln

-

does not have vent holes.

-

Temperature Equivalents For Orton

Self-Supporting Pyrometric Cones

Cone

Cone Self-Supporting Cones Pre-Fire

Number Color

Heated at: 27° F 108° F 270° F

Per Hour* Per Hour* Per Hour*

022 — 1087 1094 Green

021 — 1112 1143 Fuschia

020 — 1159 1180 Orange

019 1213 1252 1283 Yellow

018 1267 1319 1353 White

017 1301 1360 1405 Pink

016 1368 1422 1465 Light Blue

015 1382 1456 1504 Violet

014 1395 1485 1540 Gray

013 1485 1539 1582 Green

012 1549 1582 1620 Fuschia

*Rate of temperature increase during last 90 - 120

minutes of firing. Tables by courtesy of the Edward

Orton, Jr. Ceramic Foundation.

Lost Wax Burnout

Caution: Only kilns with vent holes are designed

for lost wax burnout. However, you can use a kiln

without the vent hole provided that you open the

door ½” during venting.

Caution: Always use a wax tray.

Caution: If your kiln’s heating element is embed

ded in the floor of the firing chamber, place the

metal wax tray on 3 or4-½”posts inside the kiln.

This prevents the element from possibly shorting

out against the tray.

Note: Theseinstructionsapply toinjectionwaxthat

melts at 200°F, not pattern waxes and plastics that

meltathighertemperatures.Ifsmokeappearsdur

ing wax elimination, turn off the kiln. Smoking wax

means the kiln fired hotter than 300°/148°C.

-

Overview

Lostwaxcastingistheprocessofcarvingashapeinwax,

andthencasting that shape in metal. After the wax has been

carved,amold is madeofthewax shape. Themoldisa negativeimageofthewax.Thewaxislatermeltedoutofthemold

through hollow channels called sprues.

Lost wax burnout is the process of preparing a casting

mold for the melted metal that will be poured into it. The

steps in lost wax burnout:

1 Melt the wax from the mold.

2 Remove wax from the kiln before raising the tem-

perature higher than 300°F/148°C.

3 Harden the mold at high temperature.

4 Maintain the mold at the casting temperature rec

ommendedforthetypeofmetalthatwillbepoured

into the mold.

Caution: Prevent wax or carbon from contacting

the kiln’s walls and elements. Carbon build-up in

sideakilnruins the interior.Carbonconductselec

tricityand causeselementstoshortcircuit. Damage

to elements from contact with foreign materials is

not covered by warranty.

A Sample Program

See your digital controller instruction manual to enter

this program:

Rate Temp.

Segment °F/°C °F/°C Hold

1 500/277 300/148 01.00

2 500/277 1350/732 01.00

3 450/250 800/426 02.00

-

-

-

-

-

14

Page 15

Segment 1 heats the wax to 300°F/148°C and holds it for

one hour, allowing it to drip from the mold.

Segment 2 hardens the mold.

Segment 3 lowers temperature to 800°F/426°C, the typi

calcastingtemperatureforsilver.(Most types of gold cast at

900°F/482°C.)

Note: Casting temperature depends on the size of

themold.Thetemperaturesaboveareonlyaguide.

See your jewelry supply dealer for temperature

recommendations.

Burnout Instructions

1 Place a metal tray inside the kiln on three ½” posts.

Place the mold on a wire mesh screen on top of the

tray.Themold’ssprueholeshouldbedown.Thetray

willcatchmeltingwaxasitdripsfromthespruehole.

2 Keep the kiln’s vent hole(s), if any, open during wax

elimination. If the kiln has no vent hole, leave the

door open ½”. This allows fumes to escape from the

kiln. Heat the kiln to 300°F/148°C and hold it at that

temperature for at least one hour.

Note: Do NOT heat the wax above 300°F/148°C.

Hold at 300°F/148°C for at least one hour. During

this hour, the wax will melt from the mold and drip

into the tray. If the kiln gets hotter than

300°F/148°C, the wax may smoke and deposit carbon inside your kiln, causing expensive damage.

3 Afteronehourat300°F/148°C,openthe kiln.Remove

themoldandwaxtray.Pourthewaxfromthetray and

leavethetrayoutofthe kilnuntilyour nextwaxelimination. (Do not leave the tray in the kiln!)

4 Heat the mold to the temperature recommended by

yourjewelers’supplyhousewhereyoupurchasedthe

moldmaterial.Thisisusuallyaround1350°F/732°C.

5 Lower the temperature tothecastingtemperatureof

the metal. Hold at that temperature until you are

ready to begin casting. Remove the mold with tongs.

Wear protective gloves and safety glasses.

Saving a Carbon-Damaged Kiln

Ifyoufollow theabovedirections,yourkiln shouldbesafe

from wax damage. In some cases, a small amount of carbon

mayformonthewallsoveraperiodoftime.Thisisduetothe

burningof waxresiduethatwasleft inthemold.Forthis rea

son we recommend that you periodically fire the kiln to

1500°F/815°C as follows:

1 Open the vent cover(s) or leave the door ajar ½”.

2 Fire the kiln empty to 1500°F/815°C at a rate of

300°F/166°C with a one hour hold (01.00).

Firing Mistakes

-

Silver Clay

Cracks

Cracks that appear in fired silver clay may be due to too

much water in the silver clay before it was fired. Another

cause is careless handling of a dried, unfired piece. To re

pair, fill the crack with silver clay and fire again.

Brittle

Silver clay will not reach full strength if underfired. You

may be able to save the piece by firing again to the correct

temperature and hold.

Too Much Shrinkage

When silver clay is overfired, it shrinks too much and

loses detail. If the kiln is firing hotter than the temperature

programmed, check the position of the thermocouple (see

page17,bottom left column).Replacethethermocouple if it

is old.

Glass

Glass Cracking

Probable Causes:

I

Heating the Kiln Too Fast

I

Cooling the Kiln Too Fast

I

Fusing Incompatible Glass

I

Not Enough Glass Separator on Shelf

Mostproblemsin fusing arecausedbyrushing the firing.

Theglass must change temperature slowly during the criti

cal temperature range of 100° - 500° F / 37° - 260°C. This

critical range applies to both heating and cooling.

The second critical temperature range is annealing,

whichis thecoolingrangeof950°-700°F/510°-371°Caver

age. Cool the glass slowly during this range so the stress in

the glass will have time to dissipate.

If you become im

patient after the glass

has fused and you

crack open the door of

the kiln for a few sec

onds to peek inside,

-

you may hear a “ping,”

which is the sound of

glass cracking. Avoid

the temptation to open

thedoor.Waituntilthe

kilnhascooled toroom

temperature. Some

artists schedule their

fusingsothatitiscom

pletedbefore theygoto

bed. That way they will

-

-

Flaking glass separator can cause the

-

glass to crack. This is because the glass

sticks to the shelf.

-

-

-

15

Page 16

beasleep while the glass cools andthey won’t be tempted to

open the door.

After each firing, examine the shelf. Recoat if the kiln

washischipped.Whenglassstickstoabaresectionofshelf,

the glass cracks.

Glass Bubbles

Probable Causes:

I

Heating the Kiln Too Fast

I

Air Trapped Between Layers of Glass

I

Grease or Dirt Between Layers of Glass

I

Uneven Glass Volume

I

Moisture or trapped Air Between the Glass and Shelf

Makesuretheshelfiscompletelydrybeforefiring.If you

have applied fresh glass separator, leave the shelf in the kiln

at 300°F/148°C for 20 minutes before placing glass on it.

One way to eliminate bubbles is to hold the temperature

at 100°F/55°C below fusing temperature for 15 minutes.

This gives the shelf time to heat up to match the tempera

ture of the glass.

Glass Devitrification (Frosty Surface)

Probable Causes:

I

Impurities in Glass

I

Kiln Not Vented Long Enough During Initial Heating

Devitrification is a frosty surface on the glass caused by

impurities. With some glasses, it is unavoidable. To lessen

devitrification, some artists vent the door of the kiln slightly

afterfusingiscompleted.Theyclosethedoorwhentheglass

reaches 1000°F/537°C.

Glass Separator Sticks To Glass

Probable Causes:

I

Firing Too Hot

I

Overglaze On the Back of the Piece

Instead of firing to a full fuse temperature, try firing

50°F/28°Ccoolerand holding atthattemperatureforseveral

minutes.

Ceramic Overglaze

Breaking in Overglaze Firing

Canbecaused bypoorlyfired bisque.Aslowbisque fireis

always better for ware that is to be china painted. The

greenware should be completely dry before being placed in

the kiln.

Purple Spots in Gold

Usuallydueto athinapplicationof goldortoo muchthin

ner.Ifgoldis applied accidentally to anareaitwillshowpur

ple after being fired unless cleaned with a good gold re

mover.

Broken Lines in Gold

Can be caused by overfiring or too heavy an application.

However, this can be very attractive when gold is crackled

over a dark color of fired glaze.

Peeling China Paint

-

Can be caused by the paint being applied too heavily.

Loss of Color in China Paints

Usually a result of overfiring or thinning your paint with

too much medium when applying.

Faded Colors in Overglaze Decals

This is the result of either underfiring or overfiring. If

pinks and reds are drab, refire to a hotter cone. When used

withachinapaintbackground,apply andfirethe decalsfirst,

thenchina paintandfireagain.Checktherecommendations

ofdecal supplier.Ifdecalwasunderfired,refiretoproperfiringcone.Ifdecalwasoverfired,the design may be repainted

in china paints and refired.

Weakening of Luster Colors

This can be caused by overfiring.

White Spots in Lusters or Metals

Can be caused by moisture on the ware before it was

placedinthekilnorfrom having been fired at the sametime

as other overglazes.

Note: Apply lusters only on a dry day.

-

-

-

16

Powdering of Luster Colors

This can be caused by too heavy an application.

Page 17

Kiln Maintenance

Trouble-Shooter

Kiln Does Not Turn On, Display is Blank

I

Make sure the circuit

breaker is in the “on” po

sition.

I

Ifthecircuitbreakerison,

check the kiln’s fuse. Re

move by pressing on the

fuse holder and turning

counter-clockwise half a

turn. Check the fuse by

placing the probes of an

ohmmeter on the ends of

the fuse. If the ohmeter

reads less than one ohm

(digital meter) or reads 0

ohms (analog meter), the

fuse is bad. Replacement

fuse:

AGC ½ A 250V AC

Note: If you do not have an ohmmeter, visually inspect the fuse. You will see a thin strand of unbroken wire in a good fuse. The wire usually appears

broken in a burned fuse.

-

-

Kiln Repairs

Door Latch

Adjustment

Adjustthetwoscrews

on the door latch to

change the spring ten

sion.

Note: Do not

loosen the screws

too far, or they

could fall out.

Ceramic Fiber Repair

If glass, ceramic glaze, or other materials drip onto the

firing chamber, repair before the next firing. Otherwise the

glaze will remelt and embed deeper into the fiber.

1 Unplug the kiln.

2 Cutorscrape the ceramic

fiber to remove the con

taminant.Removeaslittle

fiberaspossible. If aheating element is located

where you are scraping,

avoid touching the element.

-

-

Circuit Breaker Trips

I

If the circuit breaker trips after the kiln has fired for

awhile, make sure no other appliances are operating on

the same circuit as the kiln.

I

If the circuit

breaker trips im

mediately after the

kiln is turned on,

the kiln may have a

short circuit. Un

plug the kiln. Re

move the bottom

cover and look for a

loosewiretouching

the case.

-

-

-

Temperature is

Inaccurate

I

Make sure the ther

mocouple is pushed

½”- ¾” intothefiring

chamber.

I

Ifthe thermocouple is

pushed into the firing

chamber, and the

temperature is inac

curate, replace the thermocouple.

-

Thermocouple

-

Cleaning or Replacing the

Glass Viewing Port

Never fire a kiln equipped with the glass view port hotter

than 1700°F/926°C. Firing hotter will damage the glass.

To remove the window:

1 Remove the four

screws holding the

glass cover.

2 Remove the glass.

Clean with glass

cleaner. To remove

scratches, take the

glassto an eye glass

polisher.

17

Page 18

Replacing the Thermocouple

1 Unplug the kiln.

2 Remove the four screws holding the controller to

the front of the kiln. Carefully remove the control

ler.

5 The thermocouple is located in the back of the fir

ingchamber,held inplacebya metalband.Remove

the thermocouple from the kiln.

-

6 Bend the new thermocouple between porcelain in

sulators. The thermocouple end should be two in

-

sulators long after bending.

3 Removethe two thermocouple wires from the back

ofthe controller.Theyareheldinplacebybutton or

lever type connectors. To remove the wires, lift the

levers (or press down on the connector buttons)

and pull the wires out.

7 Push the newther

mocouple into the

hole in the firing

chamber. The

twisted end must

extendintothefir

ingchamberby ½”

- ¾”. Make sure

the band holds the

thermocouple.

Otherwise, the

thermocouple can

be pushed out, re

The band must secure the thermocou

ple. Otherwise the kiln could overfire.

sulting in an overfire.

8 Thread the thermocouple wires down to the con

troller opening at the front of the kiln. Keep the

thermocouple wires away from electrical components and other wires.

9 Strip½” of insulation from theendsofthethermo-

couple wires.

10 Attach the wires to the back of the controller. One

wire is yellow, the other red. Make sure the wires

connect to the correct terminals, which are color

coded.

-

-

4 Remove the back cover of the kiln.

Removing the thermocouple.

11 Install the controller and back cover of the kiln.

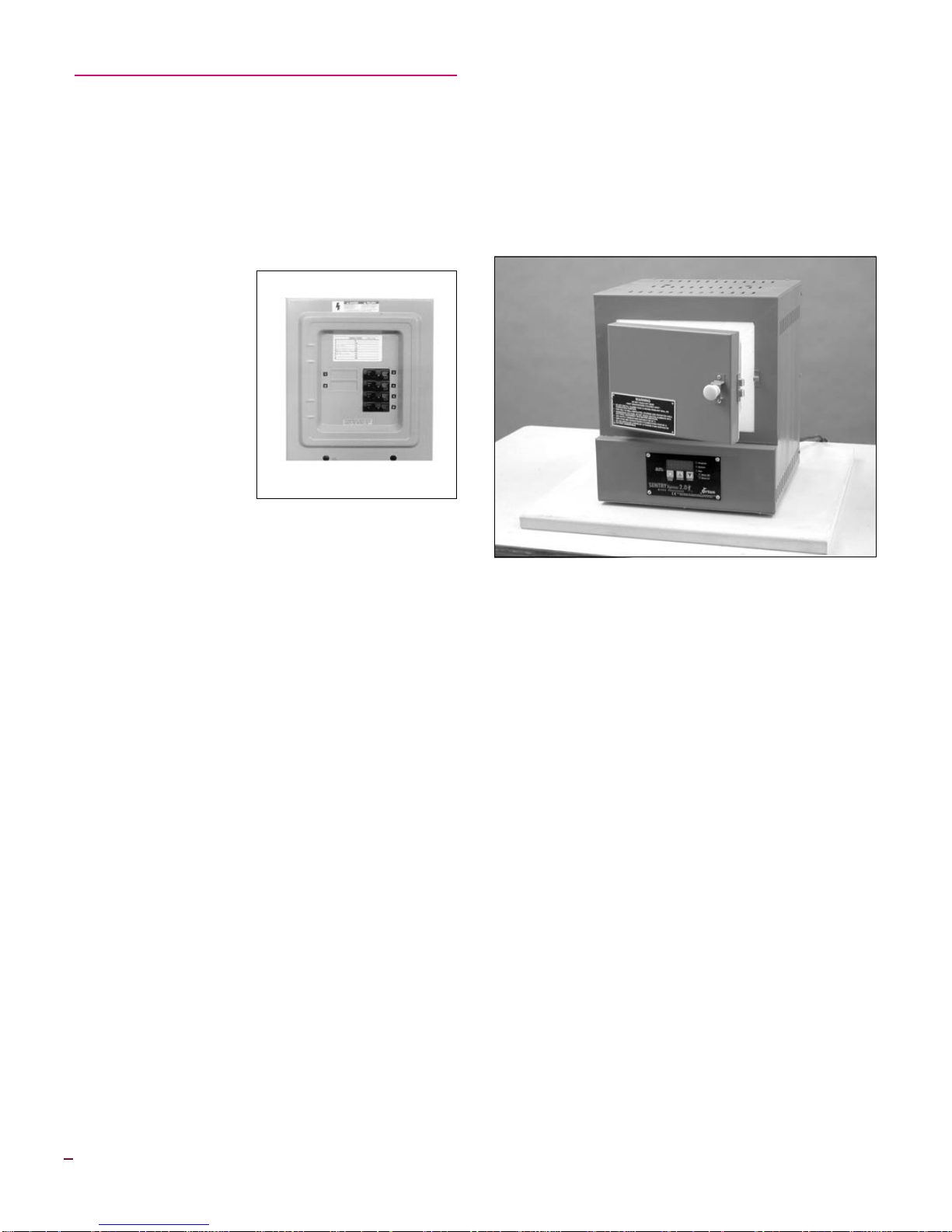

Replacing a Relay or Transformer

1 Unplug the kiln.

2 Place the kiln on its back.

3 Removethescrewsholdingthesheet metal bottom

tothekiln. Tiltthebottomforward togainaccessto

the transformer and relay.

18

Page 19

Replacing the Temperature Controller

1 Unplug kiln.

2 Remove the 4 corner screws holding the control

ler faceplateto the switchbox.Carefullylift outface

plate.

3 Disconnect the wires

from the back of the

board. You will find

twoplugsandtwosin

-

gle wires.

4 Connect the wires to

the new board. Reinstall faceplate.

-

-

Place the new part next to the old one, aligned in the same direction. Remove and replace one wire at a time. In the photo, the relay is being replaced. The transformer is the part in the foreground.

4 Hold the new part next to the one you are replacing,

aligned in the same direction. Remove and transfer

one wire at a time from the old part to the new one.

Make sure each connection is tight.

5 Replace push-on

connectors and

wires damaged by

heat from a burned

terminal. If wire

connectorsdo not fit

snugly on terminals,

gently squeeze the

end of the terminal

with pliers.

6 Asyou move the sheet metal bottom back into place,

make sure the thermocouple wire attached to the

back of the board is away from the other wires.

7 Install the screws holding the bottom to the kiln.

Replacing the Firing Chamber

When the element burns out, the ceramic fiber firing

chamber must be replaced.

To test for a burned out element, you will need an ohm-

meter:

1 Unplug the kiln.

2 Remove the back of the kiln (page 18, left column).

3 Place ohmmeter leads against the element connec

tors. A no-needle-movement reading on an analog

meter, or OPEN on a digital meter, indicates a

burned out element.

-

Replacing the firing chamber is a factory repair.

19

Loading...

Loading...