Page 1

GranDSLAM® 4200

IP DSLAM

Installation Guide

Document No. 4200-A2-GN21-30

June 2004

Page 2

Copyright © 2004 Paradyne Corporation.

All rights reserved.

Printed in U.S.A.

Notice

This publication is protected by federal copyright law. No part of this publication may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or

by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties without the express

written permission of Paradyne Corporation, 8545 126th Ave. N., Largo, FL 33773.

Paradyne Corporation makes no representation or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for a particular purpose. Further, Paradyne Corporation

reserves the right to revise this publication and to make changes from time to time in the contents hereof without

obligation of Paradyne Corporation to notify any person of such revision or changes.

Changes and enhancements to the product and to the information herein will be documented and issued as a new

release to this manual.

Warranty, Sales, Service, and Training Information

Contact your local sales representative, service representative, or distributor directly for any help needed. For additional

information concerning warranty, sales, service, repair, installation, documentation, training, distributor locations, or

Paradyne worldwide office locations, use one of the following methods:

Internet: Visit the Paradyne World Wide Web site at www.paradyne.com. (Be sure to register your warranty at

www.paradyne.com/warranty.)

Telephone: Call our automated system to receive current information by fax or to speak with a company

representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

Document Feedback

We welcome your comments and suggestions about this document. Please mail them to Technical Publications,

Paradyne Corporation, 8545 126th Ave. N., Largo, FL 33773, or send e-mail to userdoc@paradyne.com. Include the

number and title of this document in your correspondence. Please include your name and phone number if you are

willing to provide additional clarification.

Tradem ark s

ACCULINK, COMSPHERE, FrameSaver, Hotwire, MVL, NextEDGE, OpenLane, Performance Wizard are registered

trademarks of Paradyne Corporation. BitStorm, EtherLoop, GranDSLAM, GrandVIEW, iMarc, ReachDSL,

StormTracker, and TruePut are trademarks of Paradyne Corporation. All other products and services mentioned herein

are the trademarks, service marks, registered trademarks, or registered service marks of their respective owners.

A June 2004 4200-A2-GN21-30

Page 3

!

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or included in the manual.

2. This product is to be connected to a nominal –48 or –60 VDC supply source that is electrically isolated from the AC

source. The positive terminal of the DC source is to be reliably connected to earth. Connect a green/yellow

earthing (grounding) wire to the protective earthing (grounding) screw, identified by the protective earth symbol on

the front of the chassis.

3. FUSE WARNING: An energy hazard (a potential equal to or greater than 240VA) may exist at the fuse holder.

When installing or replacing either of the alarm-indicating fuses, do not contact metal parts of the fuse spring arm,

which may be energized, even after the fuse has tripped. Never remove the plastic fuse cap from the fuse; it is

there to protect against inadvertent contact with the spring arm. Refer all fuse installation/replacement to qualified

service personnel who have been trained on this equipment.

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH THE SAME

TYPE AND RATING OF FUSE. Use a fuse that is rated for a minimum 60 VDC, maximum 4A.

ATTENTION: Pour ne pas compromettre la protection contre les risques d’incendie, remplacer par un fusible de

même type et de mêmes caractéristiques nominales.

4. This product may only be used in a Restricted Access Location in accordance with the requirements of the

National Electric Code, ANSI/NFPA 70, or in accordance with the standards and regulatory requirements of the

country in which it is installed. A Restricted Access Location is a secure area (dedicated equipment rooms,

equipment closets, or the like) for equipment where access can only be gained by service personnel or by users

who have been instructed about the reasons for the restrictions applied to the location and about any precautions

that must be taken. In addition, access into this designated secured area is possible only through the use of a tool

or lock and key, or other means of security, and is controlled by the authority responsible for the location.

5. A readily accessible disconnect device as part of the building installation shall be incorporated in fixed wiring. The

DC disconnect device must be rated at a minimum 48 VDC, minimum 2A. The disconnect device shall be readily

accessible to the operator. The disconnect device must be included with an adequately rated fuse or circuit breaker

in the ungrounded conductor. Use a minimum 18 AWG (0.75 mm²) fixed power source wires with strain retention.

6. Input power to the ALARM relay interface (located on the front panel of the enclosure) must not exceed 30 V rms

or 60 VDC.

7. Do not allow anything to rest on the power cord and do not locate the product where persons will walk on the power

cord.

8. Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to

protect it from overheating, these slots and openings must not be blocked or covered.

9. Do not attempt to service this product yourself, as it will void the warranty. Opening or removing covers may expose

you to dangerous high voltage points or other risks. Refer all servicing to qualified service personnel.

10. A rare phenomenon can create a voltage potential between the earth grounds of two or more buildings. If products

installed in separate buildings are interconnected, the voltage potential may cause a hazardous condition. Consult

a qualified electrical consultant to determine whether or not this phenomenon exists and, if necessary, implement

corrective action prior to interconnecting the products.

11. CLASS 1 LASER PRODUCT: This product has provisions for the customer to install a Class 1 laser transceiver,

which provides optical coupling to the telecommunication network. Once a Class 1 laser product is installed, the

equipment is to be considered to be a Class 1 Laser Product (Appareil à Laser de Classe 1). The customer is

responsible for selecting and installing the laser transceiver and for insuring that the Class 1 AEL (Allowable

Emission Limit) per EN/IEC 60825 is not exceeded after the laser transponders have been installed. Do not install

laser products whose class rating is greater than 1. Refer to all important safety instructions that accompanied the

transceiver prior to installation. Only laser Class 1 devices certified for use in the country of installation by the

cognizant agency are to be utilized in this product. Also, laser warnings are to be provided in accordance with

IEC 60825-1 and its Amendments 1 and 2, as well as 21 CFR 1010 and 1040.10(g).

12. General purpose cables are described for use with this product. Special cables, which may be required by the

regulatory inspection authority for the installation site, are the responsibility of the customer. To reduce the risk of

fire, use a UL Listed or CSA Certified, minimum No. 26 AWG (0.128 mm

comparable cables certified for use in the country of installation.

2

) telecommunication cable, or

4200-A2-GN21-30 June 2004 B

Page 4

13. The equipment is intended for installation in a maximum 149° F (65° C) ambient temperature, in an environment

that is free of dust and dirt.

14. Do not physically stack more than eight (8) 42xx units high. Physical stability has not been evaluated for stacking

higher than eight units, and any configuration greater than eight may result in an unstable (tip-over) condition.

Ensure that the four (4) rubber feet supplied with the product have been installed on the bottom of each unit prior to

stacking any 42xx units on top of one another.

15. In addition, if the equipment is to be used with telecommunications circuits, take the following precautions:

— Never install telephone wiring during a lightning storm.

— Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

— Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the

network interface.

— Use caution when installing or modifying telephone lines.

— Avoid using a telephone (other than a cordless type) during an electrical storm. There may be a remote risk of

electric shock from lightning.

— Do not use the telephone to report a gas leak in the vicinity of the leak.

16. If the equipment has an internal POTS splitter, then to be compliant with the Bellcore NEBS requirements

GR-1089-CORE, sections 4.2.2 (Current Limiting Protectors) and 4.5.11 (Current Limiting Protector Tests), current

limiting protectors shall be used on the DSL lines entering the facility. Also, to comply with GR-1089-CORE

radiated emissions criteria, ferrite chokes must be installed as described in the installation instructions.

17. When installed in the final configuration, the product must comply with the applicable Safety Standards and

regulatory requirements of the country in which it is installed. If necessary, consult with the appropriate regulatory

agencies and inspection authorities to ensure compliance.

C June 2004 4200-A2-GN21-30

Page 5

EMI Notices

!

UNITED STATES – EMI NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

The authority to operate this equipment is conditioned by the requirements that no modifications will be

made to the equipment unless the changes or modifications are expressly approved by Paradyne

Corporation.

If the equipment includes a ferrite choke or chokes, they must be installed per the installation instructions.

!

CANADA – EMI NOTICE:

This Class A digital apparatus meets all requirements of the Canadian interference-causing equipment

regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du réglement sur le matérial

brouilleur du Canada.

Notices to Users of the Canadian Telephone Network

NOTICE: This equipment meets the applicable Industry Canada Terminal Equipment Technical Specifications. This is

confirmed by the registration number. The abbreviation IC before the registration number signifies that registration was

performed based on a Declaration of Conformity indicating that Industry Canada technical specifications were met. It

does not imply that Industry Canada approved the equipment.

NOTICE: The Ringer Equivalence Number (REN) for this terminal equipment is labeled on the equipment and includes

the effect of the POTS splitter. The REN assigned to each terminal equipment provides an indication of the maximum

number of terminals allowed to be connected to a telephone interface. The termination on an interface may consist of

any combination of devices subject only to the requirement that the sum of the Ringer Equivalence Numbers of all the

devices does not exceed five.

CE Marking

When the product is marked with the CE mark on the equipment label, a supporting Declaration of Conformity may be

downloaded from the Paradyne World Wide Web site at www.paradyne.com. Select Library → Technical Manuals →

CE Declarations of Conformity.

4200-A2-GN21-30 June 2004 D

Page 6

Japan

Class A ITE

This is a Class A product based on the standard of the Voluntary Control Council for interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise. When

such trouble occurs, the user may be required to take corrective actions.

E June 2004 4200-A2-GN21-30

Page 7

Contents

About This Guide

1 Installation

Document Purpose and Intended Audience . . . . . . . . . . . . . . . . . . . . v

Document Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Product Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cables Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Unpacking the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Mounting Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Installing the Brackets for Rack Mounting . . . . . . . . . . . . . . . . . . . . . . 1-6

Installing the GranDSLAM 4200 Into a Rack . . . . . . . . . . . . . . . . . . . . 1-8

Installing the GranDSLAM 4200 on a Wall. . . . . . . . . . . . . . . . . . . . . . 1-10

Installing the GranDSLAM 4200 on a Shelf or Desktop . . . . . . . . . . . . 1-12

2 Cabling

Cabling Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DSL Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

GigE Uplink (Port 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

10/100BaseT Uplink (Port 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chaining GrandDSLAM 4200s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Management Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Ethernet Ferrite Choke Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Connecting a Terminal or PC to the Console Port. . . . . . . . . . . . . 2-8

Connecting a Modem to the Console Port . . . . . . . . . . . . . . . . . . . 2-9

Alarm Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

4200-A2-GN21-30 June 2004 i

Page 8

Contents

Connecting to Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3 LEDs

LED Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LED Meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the CLI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

GranDSLAM 4200 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Startup Procedure for Inband Management . . . . . . . . . . . . . . . . . . . . . 4-5

Startup Procedure for Out-of-Band Management . . . . . . . . . . . . . . . . 4-5

Using the Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

System / Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Configuration / Management / SNMP . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Using a Single DC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Using Two DC Power Sources for Power Redundancy. . . . . . . . . 2-13

Conventions Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configure Management Default Gateway Address . . . . . . . . . . . . 4-2

Configure Management Inband Address . . . . . . . . . . . . . . . . . . . . 4-3

Configure Management Out-of-Band Address . . . . . . . . . . . . . . . 4-3

Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Management Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

A Connectors and Pin Assignments

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

DSL Ports and POTS Splitter Connectors . . . . . . . . . . . . . . . . . . . . . . A-2

Port 1 and Port 2 10/100BaseT Connectors . . . . . . . . . . . . . . . . . . . . A-3

Port 3 1000BaseT Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Port 3 GigE SFP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Console Port Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

ALARM Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

ii June 2004 4200-A2-GN21-30

Page 9

B Equipment List

C Technical Specifications

Index

Contents

4200-A2-GN21-30 June 2004

iii

Page 10

Contents

iv June 2004 4200-A2-GN21-30

Page 11

About This Guide

Document Purpose and Intended Audience

This document is written for technicians who install the GranDSLAM®4200 IP

DSLAM.

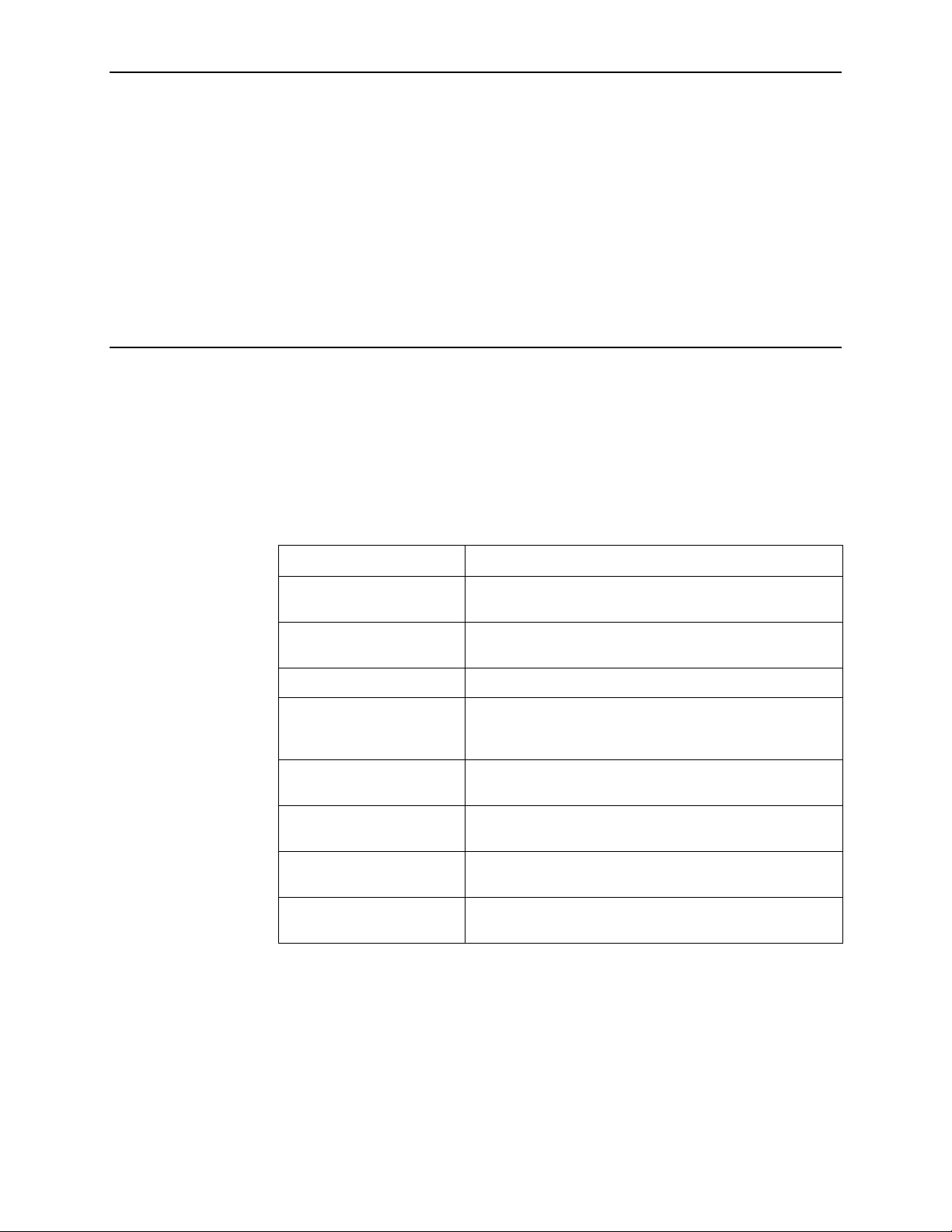

Document Summary

Section Description

Chapter 1, Installation Describes the physical installation of the GranDSLAM 4200

into a rack.

Chapter 2, Cabling Describes how to install all cables for the

GranDSLAM 4200.

Chapter 3, LEDs Explains the meaning and usage of the front panel LEDs.

Chapter 4, Configuration Describes the minimal configuration steps required to

prepare the GranDSLAM 4200 for remote access, using

the command line interface and web interface.

Appendix A, Connectors

and Pin Assignments

Appendix B, Equipment List Provides part numbers for the GranDSLAM 4200 and

Appendix C, Tec hn ic al

Specifications

Index Lists key terms, acronyms, concepts, and sections in

A master glossary of terms and acronyms used in Paradyne documents is

available on the World Wide Web at www.paradyne.com. Select Support →

Technical Manuals → Technical Glossary.

Provides pinouts for all connectors on the

GranDSLAM 4200.

related products.

Lists the technical characteristics of the GranDSLAM 4200.

alphabetical order.

4200-A2-GN21-30 June 2004 v

Page 12

About This Guide

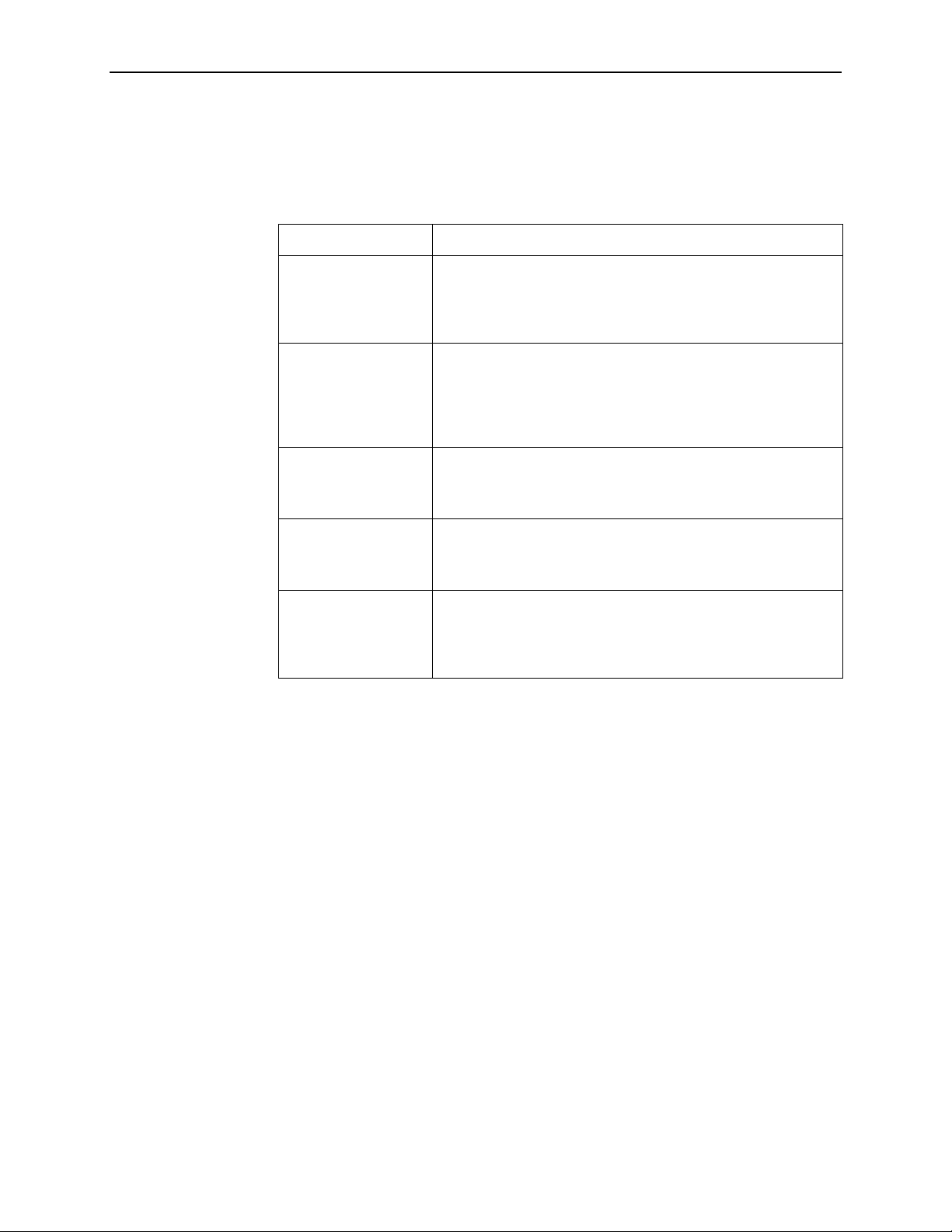

Related Product Documents

Documentation for the GranDSLAM 4200 IP DSLAM is available on the World

Wide Web at www.paradyne.com. Select Support → Technical Manuals.

Document Number Document Title

2600-A2-GB21 BitStorm 2600 and GranDSLAM 4200 IP DSLAM Command

2600-A2-GB22 BitStorm 2600 and GranDSLAM 4200 IP DSLAM SNMP

2600-A2-GT20 BitStorm 2600 and GranDSLAM 4200 Training Guide

Line Interface Reference

Describes the Command Line Interface (CLI) used to configure

and monitor the GranDSLAM 4200 IP DSLAM.

Reference

Contains the information necessary to use Simple Network

Management Protocol (SNMP) to configure and monitor the

GranDSLAM 4200 IP DSLAM.

Describes how to configure the GranDSLAM 4200 IP DSLAM for

triple play (video, voice, and data).

6210-A2-GB20 Hotwire 6210-A2, 6211-A2, and 6381-A2 User’s Guide

Describes the installation and operation of the 6210 ADSL

bridge, 6211 ADSL router, and 6381 ADSL/R router.

7890-A2-GB22 GrandVIEW EMS User’s Guide

Contains instructions for maintaining network services and

resources using the GrandVIEW Element Management System

(EMS).

To order a paper copy of a Paradyne document, or to talk to a sales representative,

please call 727-530-2000.

vi June 2004 4200-A2-GN21-30

Page 13

Installation

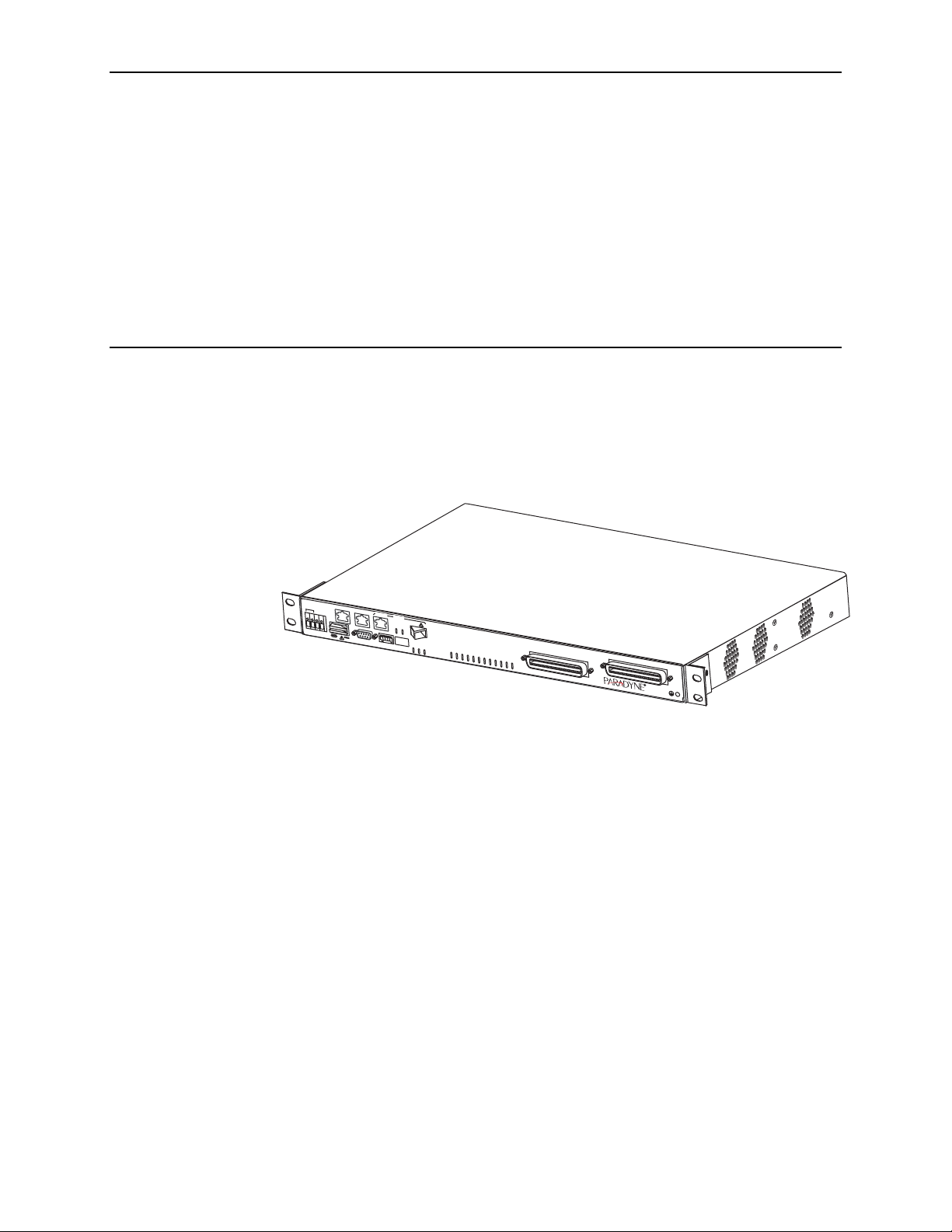

Overview

1

The GranDSLAM® 4200 is a family of stackable IP DSLAMs designed for

installation in the Central Office (CO) environment. The GranDSLAM 4200 is

available with or without internal POTS splitters.

PORT1-10/100BT

RTN

PORT2-10/100BT

A

B

-48/-60 VDC

1000BT

PORT3

GigE

LINK

A

B

4A

60V

ACT

CONSOLE

ALARM

STATUS

ALARM

TEST

1

3

5

7

9

2

1

1

4

1

3

6

1

5

8

1

7

1

0

19

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

DSL PORTS 1-24

POTS 1-24

4200

03-17442

®

The ReachDSL™ Model 4219 is interoperable with the Hotwire

6381 ADSL/R

modem, as well as with all other Customer Premises Equipment (CPE) containing

Asymmetric Digital Subscriber Line/ReachDSL (ADSL/R™) chipsets.

The ADSL Model 4229 is interoperable with the Hotwire 6381 ADSL/R modem, as

well as any standard ADSL CPE. It supports ADSL, ADSL2, and ADSL2+.

The SHDSL Model 4279 is interoperable with any standard SHDSL CPE. It

supports SHDSL (G.991.2).

A Command Line Interface (CLI) and a web browser interface are provided. The

unit also may be managed using a network manager such as the Paradyne

GrandVIEW™ Element Management System (EMS).

Up to eight GranDSLAM 4200 units can be logically stacked, with aggregation for

up to 192 ports of DSL traffic. ReachDSL, ADSL, and SHDSL units can be

included in the same stack.

4200-A2-GN21-30 June 2004 1-1

Page 14

1. Installation

Preparation

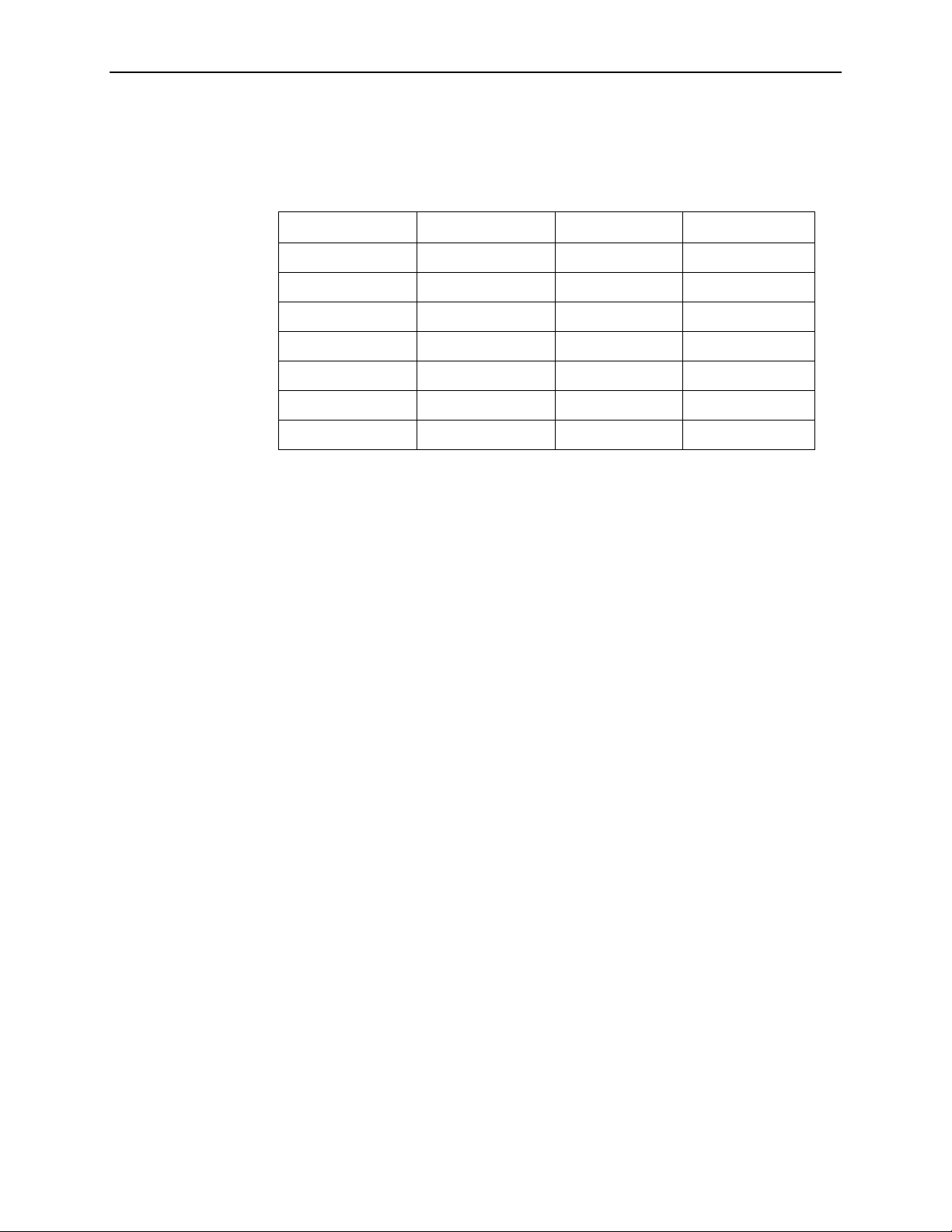

GranDSLAM 4200 IP DSLAM models and features are listed in Table 1-1,

GranDSLAM 4200 Models and Features.

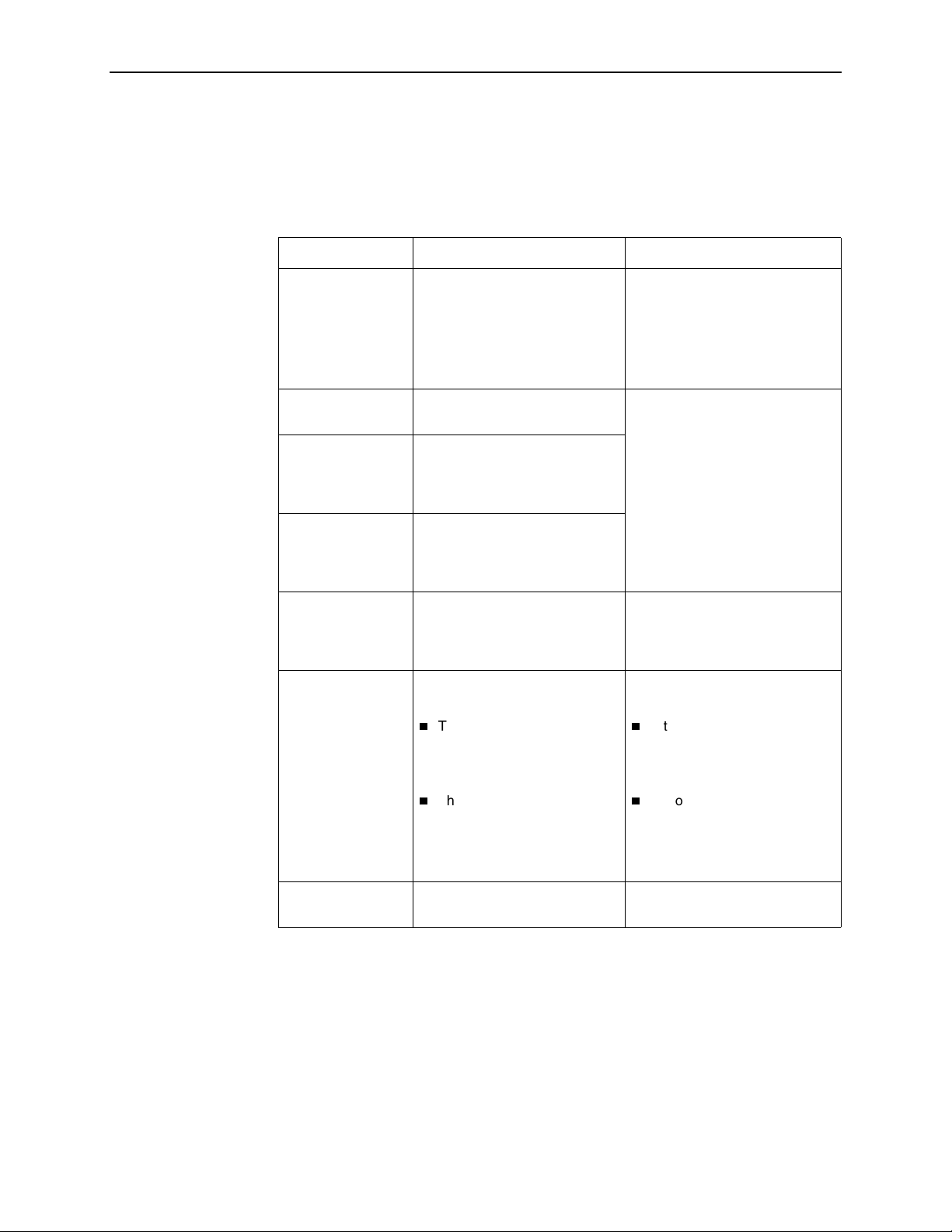

Table 1-1. GranDSLAM 4200 Models and Features

Model Number Type Number of Ports POTS Splitters

4219-A1-520 ReachDSL 24 No

4219-A1-530 ReachDSL 24 900-Ohm

4219-A1-531 ReachDSL 24 600-Ohm

4229-A2-520 ADSL 24 No

4229-A2-530 ADSL 24 900-Ohm

4229-A2-531 ADSL 24 600-Ohm

4279-A1-520 SHDSL 24 No

Consider the following before installing the GranDSLAM 4200 IP DSLAM:

Installation Site

Your installation site should be well ventilated, clean, and free of

environmental extremes.

Installation Options

The GranDSLAM 4200 may be:

— Mounted with the included mounting brackets in a standard 19-inch

(483 mm) or 23 -inch (584 mm) rack (including both Bay Networks and

Nortel 23-inch racks), or, with separately purchased mounting brackets, in

a 21-inch (535 mm) ETSI rack. ETSI brackets are available from

Paradyne. See Appendix B, Equipment List.

As many GranDSLAM 4200 units may be mounted in a standard rack as

there are 1.75-inch (44.45 mm) spaces in the rack, so long as adequate

cooling is provided.

— Mounted vertically against a wall.

The standard mounting brackets provided can be fastened to the base of

the unit for wall mounting.

— Set on a shelf or desktop.

Up to five GranDSLAM 4200 units may be stacked on a shelf or desktop.

Different models can be mixed in a stack.

Power

The GranDSLAM 4200 operates from a – 48 or –60 VDC power supply to

allow for standard power connections available in a CO. For AC voltage

environments, an external AC-to-DC power converter is required.

Other Cabling

No cables are provided with the GranDSLAM 4200. See Table 1-2, Cable

Descriptions, to determine what cables you need to procure before

installation.

1-2 June 2004 4200-A2-GN21-30

Page 15

Cables Required

1. Installation

Ta bl e 1 -2 shows all the cables that may be required for your installation.

Table 1-2. Cable Descriptions

Connector Name Connector and Cable For Connecting . . .

DSL PORTS 1–24

POTS 1–24

Port 3

GigE

Port 3

1000BT

Port 2 10/100BT 8-position modular plug and

Port 1 10/100BT 8-position modular plug and

CONSOLE DB9 plug connector and

50-pin RJ21X Telco-type

straight connector and 50-wire

cable. Two cables required, one

for DSL and one for POTS (if

used).

SFP Transceiver An upstream GranDSLAM 4200

8-position modular plug and

8-wire Category 5 or better

unshielded twisted pair (UTP)

cable.

8-wire Category 5 or better

unshielded twisted pair (UTP)

cable.

8-wire Category 5 or better

unshielded twisted pair (UTP)

cable.

shielded cable.

The other connector

depends on the serial port on

your terminal or PC, but

normally is a DB9 socket.

The other connector

depends on the serial port on

your modem, but normally is

a DB25 plug. A null modem

(crossover) cable is required.

Up to 24 DSL ports to Main

Distribution Frame, punchdown

block, or splitters.

Up to 24 POTS splitter ports to

Main Distribution Frame or

punchdown block.

to a downstream

GranDSLAM 4200, or a

downstream GranDSLAM 4200

to an upstream

GranDSLAM 4200 or network.

A Network Management System

(NMS) over a Local Area

Network (LAN) employing

10BaseT or 100BaseT.

The GranDSLAM 4200 to one of

the following:

A terminal or a PC with a

terminal emulation program,

or

A modem.

ALARM 5-position terminal block and

shielded, twisted-pair cable.

4200-A2-GN21-30 June 2004

The GranDSLAM 4200 to an

alarm system.

1-3

Page 16

1. Installation

Unpacking the Hardware

HANDLING PRECAUTIONS FOR

!

STATIC-SENSITIVE DEVICES

This product is designed to protect sensitive components from damage

due to electrostatic discharge (ESD) during normal operation. When

performing installation procedures, however, take proper static control

precautions to prevent damage to equipment. If you are not sure of the

proper static control precautions, contact your nearest sales or service

representative.

The GranDSLAM 4200 is shipped in a cardboard shipping container. Carefully

remove the unit from its shipping container and check for physical damage. If the

unit shows signs of shipping damage, notify your sales representative.

Package Contents

In addition to this installation guide, the GranDSLAM 4200 shipping carton should

contain:

GranDSLAM 4200

Two sets of mounting brackets, one set suitable for a 19-inch (483 mm) rack

and one set suitable for a 23-inch (584 mm) rack (including Bay Networks and

Nortel)

Hardware kit (see Table 1-3, Contents of Hardware Kit Shipped with the

GranDSLAM 4200)

If anything is missing, notify your sales representative.

Before installing the GranDSLAM 4200, read the Important Safety Instructions in

the beginning of this document.

Be sure to register your warranty at www.paradyne.com/warranty.

1-4 June 2004 4200-A2-GN21-30

Page 17

1. Installation

02-17326

02-17256

02-17257

02-17258

02-17325

02-17261

02-17262

02-17327

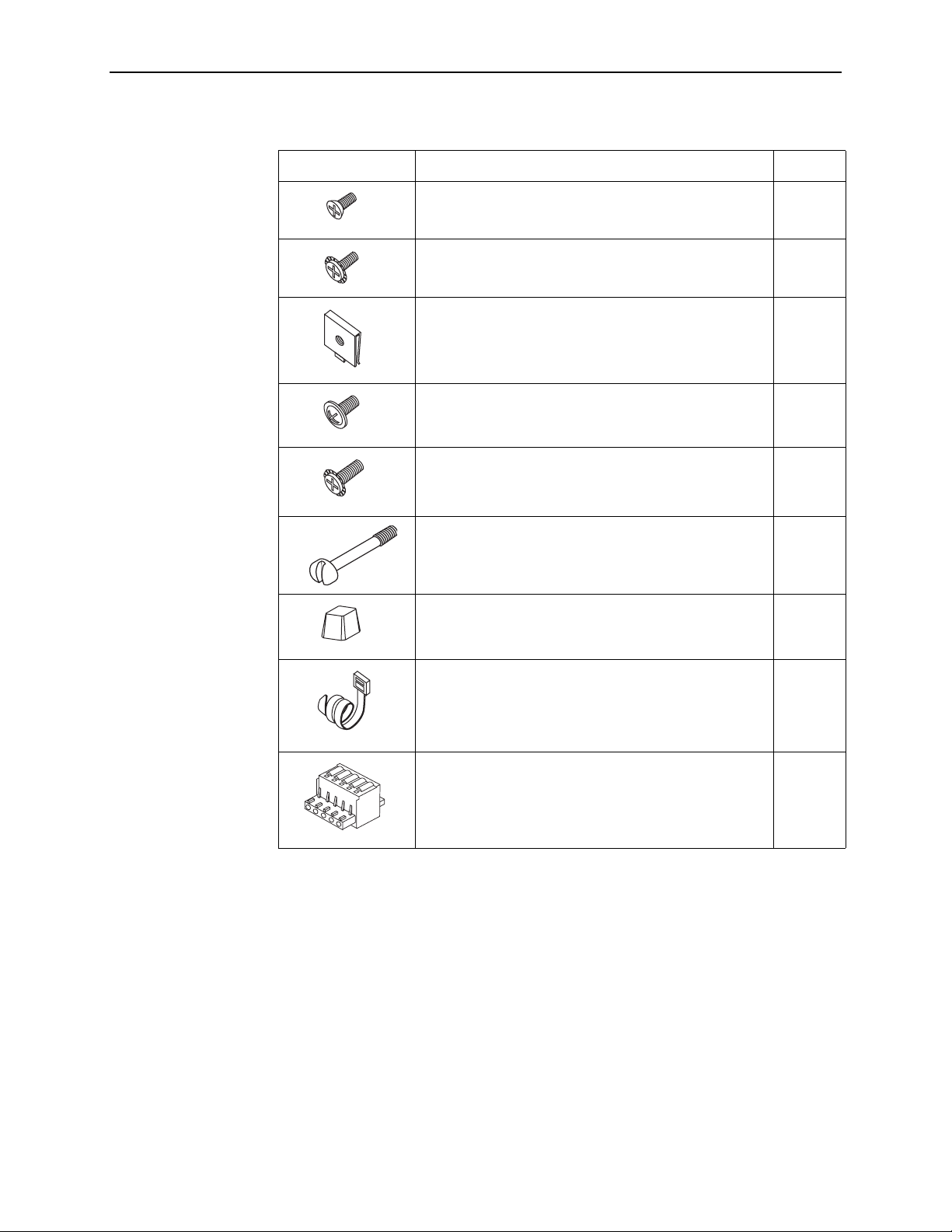

Table 1-3. Contents of Hardware Kit Shipped with the GranDSLAM 4200

Appearance Description Quantity

02-17259

Flat-head screw for attaching 19" mounting brackets to

unit

Machine screw with captive starwasher (6-32 x 1/4″) for

attaching 23" mounting brackets to unit

Self-retaining nut for racks without threaded holes 4

Dress screw (12-24 x 1/2″) for use with self-retaining

nuts

Machine screw with captive starwasher (10-32 x 1/2″)

for use with racks with threaded holes

Captive pan-head screw for replacing long Telco screw 2

Rubber foot for desk-mount and stacking of units 4

6

6

4

4

Cable tie (8″) for strain relief and cable management 2

5-position plug for ALARM connection 1

4200-A2-GN21-30 June 2004

1-5

Page 18

1. Installation

Mounting Configurations

Three basic installation configurations are available:

Rack mount – see Installing the Brackets for Rack Mounting on page 1-6 and

Installing the GranDSLAM 4200 Into a Rack on page 1-8.

Wall mount – see Installing the GranDSLAM 4200 on a Wall on page 1-10.

Shelf or desktop – see Installing the GranDSLAM 4200 on a Shelf or Desktop

on page 1-12.

Mounting Brackets

Your GranDSLAM 4200 can be installed in a rack or on the wall using mounting

brackets. Two brackets suitable for a 19-inch (483 mm ) rack (marked EIA-19) and

two brackets suitable for a 23-inch (584 mm) Bay Networks or Nortel rack (marked

with Paradyne Part Number 868-6282-0020) are shipped with the unit. Two

brackets suitable for a 21-inch (535 mm) rack (marked ETSI) are available from

Paradyne as a separate feature (see Appendix B, Equipment List ).

Rack-mounting brackets may also be used to attach the unit to a wall.

NOTE:

In this guide, the term rack refers to any rack, cabinet, frame, or bay suitable

for mounting telecommunications equipment.

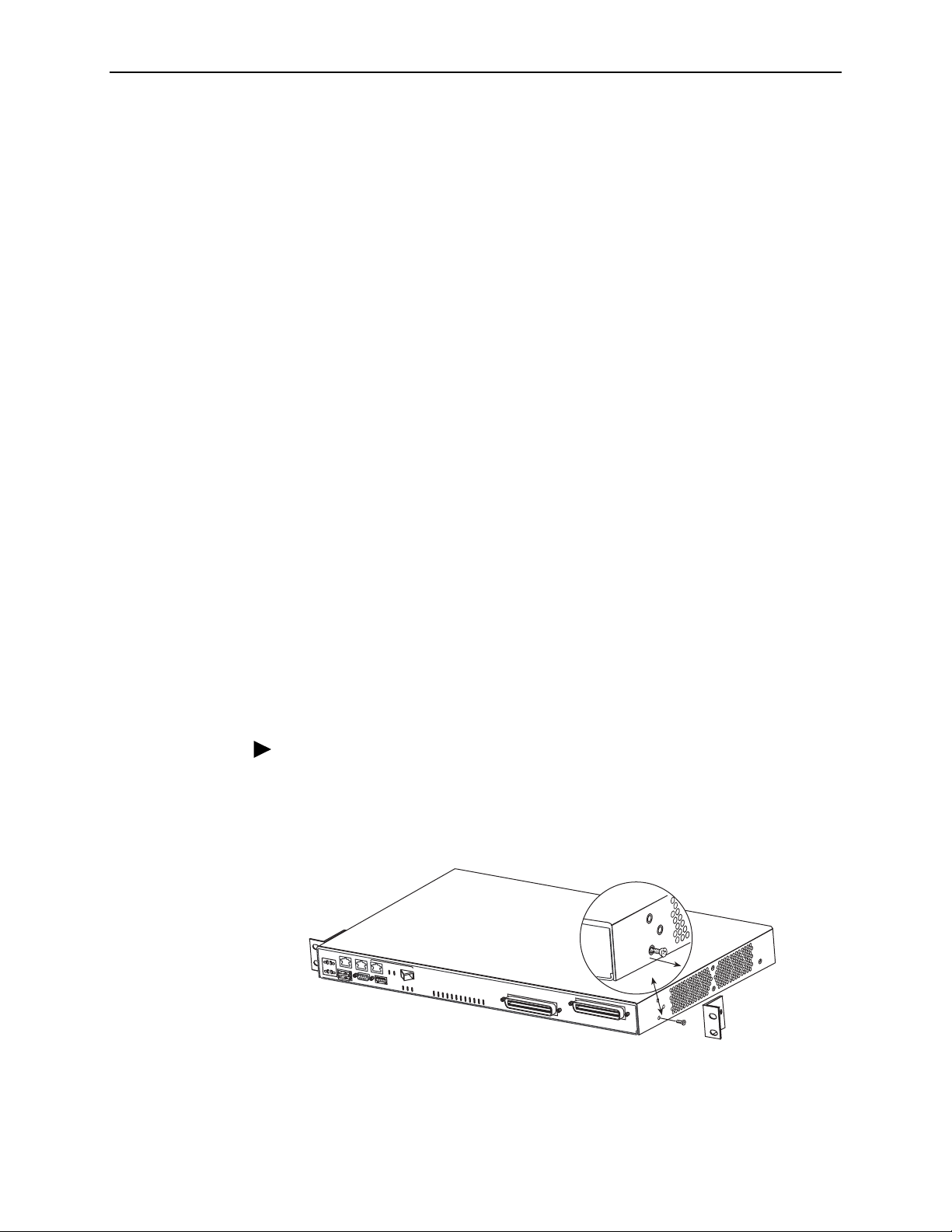

Installing the Brackets for Rack Mounting

Procedure

To install the mounting brackets for rack mounting:

1. Locate the black screw nearest the front panel on each side of the unit as

shown.

1

3

5

7

9

2

1

1

4

1

3

6

1

5

8

1

7

1

0

1

9

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

D

S

L

P

O

R

T

S

1

-

2

4

P

O

T

S

1

2

4

03-17445

2. Remove these two black screws (one from each side) before attempting to

install the mounting brackets.

1-6 June 2004 4200-A2-GN21-30

Page 19

1. Installation

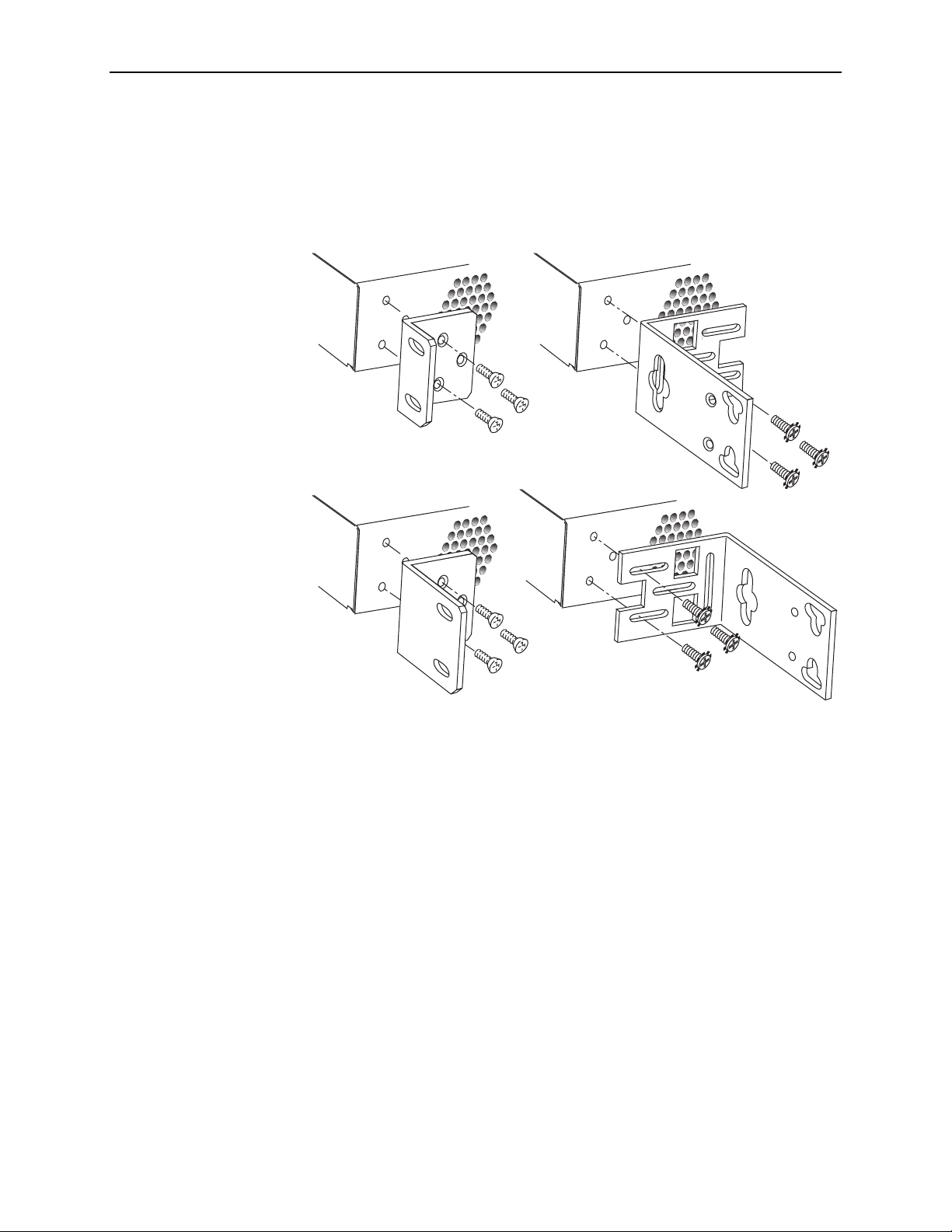

3. Identify six flat-head screws (for 19-inch racks) or six machine screws (for

23-inch racks) provided with the mounting brackets in the hardware kit.

4. Attach the brackets appropriate to your rack size. Tighten all screws firmly.

19-inch (483 mm) Rack Mount

23-inch (584 mm) EIA and Bay Networks

Rack Mount

21.1-inch (535 mm) Rack Mount

23-inch (584 mm) Nortel

Rack Mount

02-17324

4200-A2-GN21-30 June 2004

1-7

Page 20

1. Installation

Installing the GranDSLAM 4200 Into a Rack

Two types of mounting screws are provided. Use:

#10-32 mounting screws for rails with threaded screw holes

#12-24 mounting screws and self-retaining nuts for rails with unthreaded

screw holes

Procedure

To install the GranDSLAM 4200 into a rack:

1. Determine where in the rack you will mount the GranDSLAM 4200. If your rack

does not have threaded screw holes, slip self-retaining nuts onto the rails

where the GranDSLAM 4200 will be fastened.

02-17070

2. Place the unit so that the brackets rest against the front of the rails. Insert

screws in the bottom screw positions and hand-tighten them.

1-8 June 2004 4200-A2-GN21-30

Page 21

1. Installation

3. Insert and tighten the screws in the top screw positions, then tighten the

bottom screws.

P

O

R

T

1

-10

/10

0B

T

P

O

R

T2

-10

/1

0

0

B

T

100

0

B

T

PO

R

T

3

K

T

G

ig

E

IN

C

L

A

S

U

C

O

N

S

O

LE

M

T

R

T

A

T

S

A

LA

LA

R

S

M

E

A

T

1

3

5

7

9

2

1

1

4

13

6

15

8

17

10

19

12

21

14

23

16

18

20

22

24

D

S

L

P

O

R

T

S

1

-2

4

P

O

T

S

1

-2

4

03-17436

P

O

R

T

1

1

0

/

1

0

0

B

T

P

O

R

T

2

1

0

/

1

0

0

B

T

1

0

0

0

B

T

P

O

R

T

3

K

T

G

i

g

E

IN

C

L

A

S

M

U

T

R

T

A

A

S

T

L

P

E

O

T

C

S

S

O

1

N

-

2

S

A

4

O

L

E

T

A

L

A

R

M

1

3

5

7

9

1

1

1

3

1

5

2

1

7

4

1

9

6

2

1

8

2

3

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

D

S

L

P

O

R

T

S

1

2

4

4200-A2-GN21-30 June 2004

1-9

Page 22

1. Installation

Installing the GranDSLAM 4200 on a Wall

Wall mounting requires two wood screws suitable for the weight of the fully cabled

unit. These are not included. Use at a minimum 1/4-inch (6 mm) diameter screws

in 3/4-inch (19 mm ) plywood (not drywall).

Procedure

To install the GranDSLAM 4200 on a wall:

1. Identify the flat-head screws provided in the hardware kit and the brackets

suitable for a 23-inch rack. Two screws are required for each bracket.

2. Orient the unit so that the bottom is facing you and the faceplate is at the top.

3. Locate the supplied Right Side mounting bracket and fasten it to the right side

of the unit.

04-17522

4. Locate the supplied Left Side mounting bracket and fasten it to the left side of

the unit.

5. Tighten all screws firmly.

1-10 June 2004 4200-A2-GN21-30

Page 23

1. Installation

6. Install two wood screws (not provided) at the same height above the floor and

18.75 inches (476.25 mm) apart. Do not completely tighten the screws. Leave

them so their heads are about 1/4 inch (6 mm) from the wall.

17.85 in (453 mm)

03-17437

7. Hang the unit from the wood screws to verify that the screws are properly

placed. The screws should freely slide into the top of the key slots in the

brackets.

Do not fasten the unit to the wall until after it is completely cabled and tested.

4200-A2-GN21-30 June 2004

1-11

Page 24

1. Installation

Installing the GranDSLAM 4200 on a Shelf or Desktop

If the GranDSLAM 4200 will be placed on a shelf or desktop, install the provided

rubber feet before putting the unit in position.

Procedure

To install the GranDSLAM 4200 on a shelf or desktop, as a standalone unit or in a

stack:

1. Locate the rubber feet in the hardware kit provided with the unit.

2. Turn the unit upside down on a work surface. Squares stamped into the

bottom of the unit show the proper positions for the feet.

3. Remove the protective sheet from the bottom of each foot, then press the foot

onto a corner of the bottom of the unit.

4. Turn the unit right side up and place it in position on a shelf or desktop.

If the installation includes more than one unit, one can be stacked atop

another. Up to five units can be stacked together.

03-17439

1-12 June 2004 4200-A2-GN21-30

Page 25

Cabling

Cabling Overview

The GranDSLAM 4200 has a large variety of possible cabling configurations. This

chapter describes all possible connections, not all of which are required:

DSL Ports on page 2-2

GigE Uplink (Port 3) on page 2-3

10/100BaseT Uplink (Port 2) on page 2-4

Chaining GrandDSLAM 4200s on page 2-5

2

Management Port on page 2-6

Ethernet Ferrite Choke Installation on page 2-7

Console Port on page 2-8

Alarm Interface on page 2-10

Ground on page 2-11

Connecting to Power on page 2-12

4200-A2-GN21-30 June 2004 2-1

Page 26

2. Cabling

DSL Ports

The GranDSLAM 4200 DSL connector supports the tip and ring connections of up

to 24 DSL ports over a 50-position cable. A POTS (plain old telephone service)

splitter connector is also provided. If your model does not contain an integrated

POTS splitter, you must connect the unit to a separate POTS splitter.

Procedure

To cable the DSL Ports:

1. Insert a cable tie (provided) through the top of the anchor mount next to the

DSL PORTS 1–24 connector.

2. If the connector for your cable has a short captive screw, attach the cable to

the DSL PORTS 1–24 connector and fasten it to the jack screw with its short

captive screw.

#4-40

Jack Screw

Short

Screw

50-Pin

Connector

Anchor

Mount

02-17083

3. If the connector for your cable has a long captive screw, remove the provided

jack screw from the threaded hole next to the DSL PORTS 1–24 connector.

Attach the DSL PORTS 1–24 connector to the unit using the long, captive

pan-head screw (provided).

Anchor

Mount

Long

Screw

50-Pin

Connector

02-17346

4. Tighten the cable tie around the connector and trim the excess.

02-17084

5. If using an integrated POTS splitter, the POTS 1–24 connector is used.

Repeat Step 1 through Step 4, substituting POTS 1–24 for DSL PORTS 1–24.

6. Secure the cables as required for strain relief.

2-2 June 2004 4200-A2-GN21-30

Page 27

GigE Uplink (Port 3)

Port 3 comprises two interfaces, only one of which may be used at a time:

An 8-position modular jack providing support for 1000BaseT

A Small Form-Factor Pluggable (SFP) socket providing, with the appropriate

transceiver installed, support for 1000BaseX. A single-mode 1000BaseLX

transceiver is available from Paradyne. See Appendix B, Equipment List.

Either interface can be used as the uplink for a single GranDSLAM 4200, or for the

terminating unit in a stack of GranDSLAM 4200s.

Procedure

To use Port 3 as the uplink:

1. Connect the uplink cable to the GranDSLAM 4200:

— For a wire connection, plug the 8-position modular plug of your uplink

2. Cabling

cable into the Port 3 1000BT modular jack. A straight-through cable can

be used regardless of the destination interface, since the port

automatically distinguishes between a Medium-Dependent Interface (MDI)

and an MDI Crossover (MDIX).

— For a fiber connection, plug your transceiver into the Port 3 GigE SFP

socket. Plug the LC connector of your fiber optic uplink cable into the cable

socket of the transceiver. Observing the minimum bend radius for your

cable, fasten it with cable ties in such a way that it will not be kinked or

snagged in the course of other cabling. If you do not know the

specifications for your cable, maintain a radius of at least ten times the

cable diameter.

PORT1-10/100BT

PORT2-10/100BT PORT3

CONSOLE

1000BT

LINK

ALARM

GigE

ACT

STATUS

SFP

Transceiver

ALARM

TEST

LC

Connector

03-17441

2. Connect the other end of the uplink cable to the uplink interface, such as an

Ethernet switch.

4200-A2-GN21-30 June 2004

2-3

Page 28

2. Cabling

3. Port 3 (eth3) is the default uplink. If you have changed the default, use the

configure uplink CLI command or the Configuration / Uplink screen of the

web interface to specify eth3 as the uplink port.

4. For a wire connection, install a ferrite choke if one is included with your

GranDSLAM 4200. See Ethernet Ferrite Choke Installation on page 2-7.

10/100BaseT Uplink (Port 2)

Port 2 can be configured as the uplink for a single GranDSLAM 4200, or for the

terminating unit in a stack of GranDSLAM 4200s. A straight-through cable can be

used regardless of the destination interface, since the port automatically

distinguishes between an MDI and an MDIX.

Procedure

To use Port 2 as the uplink:

1. Connect an 8-position modular cable to Port 2.

2. Connect the other end of the cable to the uplink interface, such as an Ethernet

switch.

3. Using the configure uplink CLI command or the Configuration / Uplink screen

of the web interface, specify eth2 as the uplink port.

Install a ferrite choke if one is included with your GranDSLAM 4200. See Ethernet

Ferrite Choke Installation on page 2-7.

2-4 June 2004 4200-A2-GN21-30

Page 29

Chaining GrandDSLAM 4200s

Up to eight GranDSLAM 4200s can be chained together to use a single uplink.

The same port (eth2 or eth3) used as the uplink for one unit must be used as the

downlink for the next. For example, in this illustration:

The top unit has Port 3 (eth3) defined as its uplink and is connected to Port 3

of the next unit in the chain using a straight-through 8-position modular cable.

The middle unit has Port 2 (eth2) defined as its uplink and is connected to

Port 2 of the next unit.

The bottom unit has Port 3 (eth3) defined as its uplink, which is the uplink for

the stack. That unit is using the fiber interface.

2. Cabling

P

O

R

T

1

-10

/1

0

0B

T

P

O

R

T

2-1

0/10

0B

T

1

0

00

B

T

P

O

R

T

3

K

G

ig

E

T

IN

C

L

A

S

U

C

O

N

S

O

L

E

P

O

R

T1

-1

0/10

0B

T

P

O

R

T

2-1

0/1

0

0

B

T

C

O

N

S

O

L

E

P

O

R

T

1-10

/1

00

B

T

P

O

R

T

2

-10

/10

0B

T

C

O

N

S

O

L

E

M

R

T

AT

A

T

S

A

L

LA

R

S

M

E

A

T

1

3

5

7

9

2

11

1

00

0B

T

P

O

R

T

3

K

T

IN

C

L

A

A

LA

R

M

1

00

0B

T

P

O

R

T3

K

T

IN

C

L

A

A

L

A

R

M

4

13

6

15

8

17

10

19

12

21

14

23

16

18

20

G

igE

S

U

M

R

T

AT

A

T

S

L

S

E

A

T

1

3

2

4

G

igE

S

U

M

R

T

AT

T

S

LA

S

E

A

T

1

3

2

4

22

24

D

S

L

P

O

R

T

S

1-2

4

5

7

9

1

1

13

6

15

8

17

10

19

12

21

14

23

16

18

20

22

24

D

S

L P

O

R

TS

1-2

4

5

7

9

11

13

6

15

8

17

1

0

19

12

21

14

23

16

18

20

22

24

D

S

L

P

O

R

T

S

1

-2

4

P

O

T

S

1

-2

4

P

O

T

S

1

-24

P

O

T

S

1

-24

03-17440

Copper cables connecting:

Port 2 to Port 2 must be at least 3 feet (0.9 m) long

Port 3 to Port 3 must be at least 6 feet (1.8 m) long

A shorter cable may cause data errors.

Install a ferrite choke if one is included with your GranDSLAM 4200. See Ethernet

Ferrite Choke Installation on page 2-7.

4200-A2-GN21-30 June 2004

2-5

Page 30

2. Cabling

Management Port

Port 1 can be used to connect the GranDSLAM 4200 to a network management

system using a 10BaseT or 100BaseT LAN. A straight-through cable can be used

regardless of the destination interface, since the port automatically distinguishes

between an MDI and an MDIX.

Procedure

To use Port 1 as the out-of-band management port:

1. Connect an 8-position modular cable to Port 1.

2. If the GranDSLAM 4200 is in a rack, fasten the cable to a rail with a cable tie.

3. Connect the other end of the cable to your Ethernet hub or to a network

interface card in a PC.

Hub Device

PORT1-10/100BT

PORT2-10/100BT PORT3

1000BT

K

T

GigE

IN

C

L

A

S

U

M

T

CONSOLE

Port 1

ALARM

R

T

TA

S

LA

S

A

TE

1

3

5

7

9

2

1

1

4

1

3

6

1

5

8

1

7

1

0

1

9

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

DSL PORTS 1-24

03-17446

Install a ferrite choke if one is included with your GranDSLAM 4200. See Ethernet

Ferrite Choke Installation on page 2-7.

2-6 June 2004 4200-A2-GN21-30

Page 31

Ethernet Ferrite Choke Installation

If NEBS compliance is required, install the ferrite chokes included in the NEBS

Compliance Upgrade, Feature Number 4200-F4-000. The smaller of the two ferrite

chokes must be installed on the alarm cable, if used. (See Alarm Interface on

page 2-10.) The larger of the two ferrite chokes must be installed on any Ethernet

cables used:

Procedure

1. Open the ferrite choke. Lay any cable connected to the 10/100BaseT ports or

1000BaseT port in the ferrite choke.

2. Snap the ferrite choke shut around the cables and slide it as close as possible

to the chassis.

3. Secure the ferrite choke in place with a cable tie.

2. Cabling

P

O

RT1-10/100BT

Cable Tie

PO

RT2-10/100B

C

O

N

S

O

Ferrite

Choke

T

1000B

T

P

O

R

T3

G

igE

LINK

ACT

LE

A

LA

R

M

STATUS

ALARM

TEST

1

3

5

7

9

2

11

4

13

6

15

8

17

10

19

12

21

14

23

16

18

20

22

24

03-17458

4200-A2-GN21-30 June 2004

2-7

Page 32

2. Cabling

Console Port

The CONSOLE port normally serves as the primary user interface with the

GranDSLAM 4200 during installation. You can connect a terminal or PC directly to

the CONSOLE port using a DTE cable (see procedure below). You can also use

the CONSOLE port to attach a modem to the GranDSLAM 4200 for remote dial-in

management of the unit using a DCE cable (see Connecting a Modem to the

Console Port on page 2-9).

Connecting a Terminal or PC to the Console Port

Procedure

To connect a terminal or PC to the CONSOLE port:

1. Configure the terminal or terminal emulation program to use the following

parameters:

— Maximum speed: 9600 bps

— Data bits: 8

— Parity: None

— Flow Control: None

— Stop bits: 1

2. Determine and procure the proper Data Terminal Equipment (DTE) cable type.

The CONSOLE port requires a DB9 plug connector. The other connector

depends on the serial port on your terminal or PC.

3. Connect the DB9 plug connector to the CONSOLE port socket. The

CONSOLE port is ordinarily used only during installation, so do not fasten the

connector.

4. Connect the other end of the cable to the serial port of your terminal or PC.

Serial

Por t

PORT1-10/100BT

PORT2-10/100BT PORT3

1000BT

K

T

GigE

IN

C

L

A

S

U

M

T

CONSOLE

R

T

A

A

T

ALARM

S

L

S

E

A

T

1

3

5

7

9

2

1

1

4

1

3

6

1

5

8

1

7

1

0

1

9

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

DSL PORTS 1-24

03-17447

2-8 June 2004 4200-A2-GN21-30

Page 33

Connecting a Modem to the Console Port

Procedure

To connect a modem to the CONSOLE port:

1. Determine and procure the proper DCE cable type for your modem. The

CONSOLE port requires a DB9 plug connector. The other connector depends

on the serial port on your modem, but normally a DB25 plug is required. The

cable must be an EIA-232E crossover (null modem) cable.

2. Connect the DB9 plug connector to the CONSOLE port socket.

3. If the modem will be permanently connected, fasten the connector to the

Management Module with its captive screws. If the GranDSLAM 4200 is in a

rack, dress the cable to the left and attach it to the rail with a cable tie.

4. Connect the other end of the cable to the serial port of your modem.

2. Cabling

PORT1-10/100BT

PORT2-10/100BT PORT3

1000BT

CONSOLE

ALARM

CONSOLE

Por t

Serial Port

W

R

A

LMP

T

S

T

LIN

E

ET

H

ER

NE

T

GigE

LINK

ACT

STATUS

ALARM

TEST

1

3

5

7

9

2

11

4

13

6

15

8

10

12

14

16

Modem

17

19

21

23

18

20

22

24

DSL PORTS 1-24

03-17448

4200-A2-GN21-30 June 2004

2-9

Page 34

2. Cabling

Alarm Interface

The ALARM interface consists of five contacts. Three of the contacts provide

access to alarm relays that that can be used to set off Major and Minor physical

alarms. The other two contacts provide access to a sense circuit that can be used

to detect the open or closed condition of an external alarm relay.

A 5-position plug provided in the hardware kit is used to connect 20–28 AWG wire

to the ALARM terminal block (see Table 1-3, Contents of Hardware Kit Shipped

with the GranDSLAM 4200, in Chapter 1, Installation).

The contacts are closed during normal operation. They open in response to loss of

power, hardware failure, or other alarm conditions. See ALARM Connector in

Appendix A, Connectors and Pin Assignments for more information.

CAUTION:

The ALARM Sense + and Sense – contacts are intended to be connected

to an external alarm relay. Do not apply power to these contacts; doing so

will result in damage to the unit.

Procedure

To connect the ALARM interface:

1. Strip the tips of the alarm source wires about 1/2 inch (13 mm).

2. Use a screwdriver to press the orange spring tab in while inserting the wire

into the hole below it. The insulation should be fully within the plug and no

bare wire should be exposed outside of the plug.

Spring

Ta b

02-17328

3. Insert the plug into the ALARM interface on the front panel of the

GranDSLAM 4200.

4. If the GranDSLAM 4200 is in a rack, dress the cable to the left and secure it to

the rail with a cable tie.

5. Connect the other end of the cable to your alarm monitoring system.

2-10 June 2004 4200-A2-GN21-30

Page 35

Ground

2. Cabling

6. If NEBS compliance is required, install the ferrite chokes included in the NEBS

Compliance Upgrade, Feature Number 4200-F4-000. The larger of the two

ferrite chokes must be installed on any Ethernet cables used. (See Ethernet

Ferrite Choke Installation on page 2-7.) The smaller of the two ferrite chokes

must be installed on the alarm cable. Open the ferrite choke then snap it shut

around the alarm cable as close as possible to the ALARM jack. Secure it with

a cable tie.

Procedure

To connect the unit to a ground:

1. Crimp a ring terminal onto the stripped end of 14 AWG or heavier copper

ground wire.

2. Remove the screw marked by the ground symbol ( ) at the right side of the

front panel.

3. Fasten the ring terminal to the front panel using the same screw.

4. Attach the ground wire to an earth ground.

POTS 1-24

4200

To Earth Ground

03-17449

4200-A2-GN21-30 June 2004

2-11

Page 36

2. Cabling

Connecting to Power

The GranDSLAM 4200 is powered by a nominal –48 or –60 VDC source

providing – 40 to – 72 VDC. Dual power feeds are provided for redundancy. The

terminal block accepts 18 to 14 AWG wire.

The 4200 GranDSLAM contains two external fuses, each with a visual spring

indicator and an alarm circuit indicator in case the fuse is blown.

Using a Single DC Power Source

Procedure

✔ Make sure that the DC power source wires are not powered (that is, the circuit

breakers or fuses are open at the source).

✔ The ends of the power source wires (18–14 AWG or 0.75–2.5 mm

stranded wire) must be stripped of insulation. If the wires are not stripped, strip

the tip of each wire about 1/2 inch (13 mm) before inserting the wire into the

appropriate terminal on the – 48/–60V input terminal block.

2

solid or

To supply –48/60 VDC power to the GranDSLAM 4200 from a single power

source:

1. Insert the following wires into Terminal A and securely fasten each wire by

tightening the screw above it. The insulation should be fully within the terminal

block and no bare wire should be exposed outside of the block.

2. Clearly label these power source wires as – 48V (or –60V) and RTN.

Insert the . . . Into the . . .

Negative wire from the power source –48/–60V A input terminal.

Positive wire from the power source Left RTN (return) terminal.

RTN

AB

1

3

5

7

9

2

1

1

4

1

3

6

1

5

8

1

7

1

0

1

9

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

D

S

L

P

O

R

T

S

1

-2

4

-48/-60 VDC

P

O

T

S

1

2

4

03-17450

3. Turn on power to the GranDSLAM 4200.

4. Make sure the STATUS LED on the front panel is ON (green). See Chapter 3,

LEDs.

2-12 June 2004 4200-A2-GN21-30

Page 37

Using Two DC Power Sources for Power Redundancy

Procedure

✔ Make sure that the DC power source wires are not powered (that is, the circuit

breakers are open).

✔ The ends of the power source wires (18–14 AWG or 0.75–2.5 mm

stranded wire) must be stripped of insulation to about 1/2 inch (13 mm) in

length before inserting the wires into the appropriate terminal on the – 48/–60V

input terminal block.

To supply two DC power sources to the GranDSLAM 4200 for power redundancy:

1. Insert the following wires in the appropriate terminal and securely fasten each

wire by tightening the screw directly above it. The insulation should be fully

within the terminal block and no bare wire should be exposed outside of the

block.

2. Clearly label these four power source wires as –48V A (or –60V A), RTN A,

–48V B (or –60V B), and RTN B.

2. Cabling

2

solid or

Insert Power Source . . . Into the . . .

Negative side of the first power source

(Power Source A)

(Optional) Negative side of the second

power source (Power Source B)

Positive side of the first power source

(Power Source A)

(Optional) Positive side of the second

power source (Power Source B)

–48/–60V A input terminal.

–48/–60V B input terminal.

Left RTN (return) terminal.

Right RTN (return) terminal.

3. If the unit is in a rack, dress the power cables to the left and fasten them to the

rail with a cable tie.

4. Turn on power to the GranDSLAM 4200.

5. Make sure the STATUS LED on the front panel is ON (green). See Chapter 3,

LEDs.

4200-A2-GN21-30 June 2004

2-13

Page 38

2. Cabling

2-14 June 2004 4200-A2-GN21-30

Page 39

LEDs

LED Locations

3

The locations of the System and DSL Port LEDs on the front panel of the

GranDSLAM 4200 are shown in Figure 3-1, Front Panel LEDs.

Link LEDs Activity LEDs DSL Ports LEDs

PORT1-10/100BT

PORT2-10/100BT PORT3

1000BT

LINK

A

B

CONSOLE

60V

4A

ALARM

P

O

R

R

T

1

T

-

N

1

0

/

1

0

0

B

T

P

O

R

T

2

1

0

A

/

1

0

0

B

B

T

1

0

0

0

B

T

P

O

R

T

3

K

G

T

N

i

g

E

I

C

L

A

A

4

8

/

6

0

V

D

C

B

4

A

S

6

0

V

U

C

M

O

N

S

O

T

L

E

R

A

T

A

T

A

S

L

A

L

R

M

S

E

A

T

1

3

5

2

4

Figure 3-1. Front Panel LEDs

GigE

ACT

TEST

ALARM

STATUS

1

2

10

8

6

4

16

14

12

15

13

11

9

7

5

3

21

19

17

18

23

22

20

24

03-17451

7

9

1

1

1

3

6

1

5

8

1

7

1

0

1

9

1

2

2

1

1

4

2

3

1

6

1

8

2

0

2

2

2

4

P

O

T

S

1

2

D

4

S

L

P

O

R

T

S

1

2

4

4

2

0

0

4200-A2-GN21-30 June 2004 3-1

Page 40

3. LEDs

LED Meanings

When power is first applied to the unit, it performs a power-on self-test. When this

test is successfully completed, the Status LED blinks. The meaning of all the LEDs

is shown in Table 3-1, Front Panel LEDs.

Table 3-1. Front Panel LEDs

LED Color State Meaning

Link*

Activity* Green Off

STATUS Green Off

ALARM Amber Off

TEST Amber Off

DSL Ports

(LEDs

numbered 1–24

correspond to

DSL ports 1–24)

* The three RJ45-type connectors for Port 1, Port 2, and Port 3 bear two LEDs: the left

one is the Link LED and the right one is the Activity LED. The SFP socket for Port 3

has two adjacent LEDs marked LINK and ACT.

Green Off

On

Flashing

On

On

On

On

Green Off

On

No Ethernet link present.

Ethernet Link present.

Ethernet link is present, but port is

administratively disabled.

No data is being transferred.

Data is being transferred.

No power, or the unit has not completed

initialization.

Unit has power and has completed initialization.

No Alarms.

Unit failed self-test, or the unit has exceeded a

safe temperature, or a fan has failed.

Normal operating mode.

At least one port is in test mode.

The port is disabled or no signal is detected on

the line.

Port has successfully trained with the remote

and is active.

3-2 June 2004 4200-A2-GN21-30

Page 41

Configuration

Overview

The GranDSLAM 4200 is designed to require minimal configuration before it can

be accessed by a Network Operations Center (NOC). When the

GranDSLAM 4200 is first powered up it is a fully functional bridge, and all DSL

ports are set to their maximum speed.

Initial configuration is performed using the Command Line Interface (CLI). The CLI

is available from a terminal or PC connected to the CONSOLE port.

Additional configuration may be necessary, depending on the mode used to

manage the GranDSLAM 4200:

4

Conventions Used

Inband

Out of band through Port 1

This can be performed using the CLI, SNMP, or the web interface.

For more configuration information, see the BitStorm 2600 and GranDSLAM 4200

IP DSLAM Command Line Interface Reference (for the CLI) and the online Help

(for the web interface).

In this book, the Enter key means whatever key you use to submit data to your

terminal or PC. It may be called the Return key on older devices.

Characters displayed on your screen, including those you type, are shown in the

Courier font in this book.

4200-A2-GN21-30 June 2004 4-1

Page 42

4. Configuration

Using the CLI

A command line interface (CLI) can be used to configure and monitor the unit. The

CLI is available from a PC or terminal connected to the Console port, or from a

Telnet session with the device.

The following commands are available:

Table 4-1. CLI Commands

Command Function

clear Clear the system log.

configure Enter Configuration mode.

copy Copy from one file to another.

date Set the time zone and date format.

end If user is in Administrator mode, shifts to User mode; if user is in

User mode, positions interface at top of menu tree.

exit Terminate current session.

firmware Download or apply new firmware.

paging Enable or disable paging (more prompt) for this session.

privilege Enable administrator mode.

restart Restart a unit.

show Display configuration, statistics, and status.

technical-support Display information for contacting technical support.

test Test the system.

Descriptions of some essential configuration commands follow.

Configure Management Default Gateway Address

The configure management default gateway command specifies the IP address

of the next hop router for the management traffic.

configure management default-gateway {ip_address}

Minimum Access Level: Administrator

ip_address – Specifies the IP address of the default gateway for the management ports.

Example:

PDYN# configure management default-gateway 137.90.127.1

4-2 June 2004 4200-A2-GN21-30

Page 43

Configure Management Inband Address

The configure management inband address command specifies the IP address

of the unit.

configure management inband address {ip_address} { subnet_mask}

Minimum Access Level: Administrator

ip_address – Specifies the management IP address. Default is 0.0.0.0 (disabled). Do

not configure inband and out-of-band management on the same subnet.

subnet_mask – Specifies the subnet mask to be applied to the IP address. The default

mask is 255.255.255.0.

Example:

PDYN# configure management inband address 137.90.127.3

255.255.255.0

4. Configuration

Configure Management Out-of-Band Address

The configure management out-of-band address command specifies the IP

address of the unit that will accept management traffic on the out-of-band

management port.

configure management out-of-band address {bootp | {{ip_address} {

subnet_mask} }

Minimum Access Level: Administrator

bootp – Specifies that a BOOTP server will determine the management IP address.

ip_address – Specifies the management IP address. The default address is

10.10.10.10. Do not configure inband and out-of-band management on the same

subnet.

subnet_mask – Specifies the subnet mask to be applied to the IP address. The default

mask is 255.255.255.0.

Example:

PDYN# configure management out-of-band address bootp

PDYN# configure management out-of-band address 137.90.80.3

255.255.255.0

4200-A2-GN21-30 June 2004

4-3

Page 44

4. Configuration

GranDSLAM 4200 Startup Procedure

You can initialize your GranDSLAM 4200 via a PC or terminal connected to the

unit’s CONSOLE port. Then, using a series of CLI commands, GrandVIEW EMS

or another Element Management System, or the web interface, you can configure

the unit according to your requirements.

Login

Procedure

To log in to the GranDSLAM 4200:

1. Connect a PC or terminal to the CONSOLE port. (See Console Port in

Chapter 2, Cabling.)

2. At the login> prompt, type admin and press Enter.

3. At the password> prompt, press Enter. The default login password is blank.

Management Modes

4. At the PDYN> prompt, type privilege and press Enter.

5. At the password# prompt, press Enter. The default privileged password is

blank.

You are now logged on and in privileged mode, which allows you to configure the

unit.

The startup procedure for the GranDSLAM 4200 system differs depending on the

type of management used:

Inband Management – Operates over the uplink.

Out-of-Band Management – Operates over Port 1.

4-4 June 2004 4200-A2-GN21-30

Page 45

Startup Procedure for Inband Management

With inband management, the GranDSLAM 4200 is managed using the uplink

port.

Procedure

To start up the GranDSLAM 4200 using inband management:

1. Specify the uplink port using the configure uplink command. It must be either

eth2 (Port 2) or eth3 (Port 3). For example:

PDYN# configure uplink eth3

2. Assign an IP address, netmask, and next-hop router using the configure

management command. For example:

PDYN# configure management inband address 137.90.127.3

255.255.255.0

PDYN# configure management default-gateway

137.90.127.1

4. Configuration

Do not configure inband and out-of-band management on the same subnet.

Startup Procedure for Out-of-Band Management

In out-of-band management, you manage the unit through Port 1.

Procedure

To start up the GranDSLAM 4200 using out-of-band management:

1. Assign an IP address, netmask, and next-hop router using the configure

management command. For example:

PDYN# configure management out-of-band address

137.90.80.3 255.255.255.0

PDYN# configure management default-gateway 137.90.80.1

You can now access the web interface by typing into the Location field of your

web browser the IP address assigned to the Port 1. See Using the Web

Interface on page 4-6.

Do not configure inband and out-of-band management on the same subnet.

2. Configure routers as necessary to route data from the NOC to the

GranDSLAM 4200.

4200-A2-GN21-30 June 2004

4-5

Page 46

4. Configuration

Using the Web Interface

To access the web interface:

Procedure

1. Open your web browser. (Internet Explorer Version 6 or above is

recommended.)

2. Type http:// and the IP address of the GranDSLAM 4200 into the Address field

of your browser window. For example:

3. A login window appears. Enter the default User ID (admin) and leave

Password blank. Click on OK. The web interface screen appears.

4. Click on the menu tab appropriate to what you would like to do:

— Configuration – To configure the system and interfaces

— Status – To display statistics, status, and contents of memory

— System – To display system information, download firmware, back up

configurations, and modify users

— Diagnostics – To start and stop tests

4-6 June 2004 4200-A2-GN21-30

Page 47

System / Users

4. Configuration

For security reasons, it is a good idea to change the default password the first time

you use the system.

Procedure

To change the default password for user admin:

1. Click on the System menu tab, then click on Users. The folllowing screen

appears.

2. In the Configured Users box, select admin by clicking in the circle next to it.

3. Click on Modify Selected. The System / Users / admin screen appears.

4. Type in a new Login Password and a new Privilege Password, then click on

Apply. Keep a record of the new password.

4200-A2-GN21-30 June 2004

4-7

Page 48

4. Configuration

Configuration / Management / SNMP

SNMP access to the unit is enabled by default. The read-only community string is

public, and the read-write string is private. Community strings, network

management system addresses, and trap manager addresses can be set using

the System/Management/SNMP screen.

Procedure

To set SNMP parameters:

1. Click on the Configuration menu tab, then click on SNMP. The

System/Management/SNMP screen appears.

2. Enter new SNMP parameters as desired. Click on Apply.

4-8 June 2004 4200-A2-GN21-30

Page 49

Connectors and Pin Assignments

Overview

The following sections provide pin assignments for:

DSL Ports and POTS Splitter Connectors on page A-2

Port 1 and Port 2 10/100BaseT Connectors on page A-3

Port 3 1000BaseT Connector on page A-3

Port 3 GigE SFP Connector on page A-4

Console Port Connector on page A-5

A

RTN

-48/-60 VDC

AB

PORT1-10/100BT

4A

A

B

60V

ALARM Connector on page A-6

1000BT

PORT2-10/100BT PORT3

ALARM

CONSOLE

Figure A-1. GranDSLAM 4200 IP Front Panel

GigE

ACT

LINK

TEST

ALARM

STATUS

1

2

11

9

7

5

3

12

10

8

6

4

21

19

17

23

15

13

22

20

18

16

14

24

DSL PORTS 1-24

POTS 1-24

4200

03-17452

4200-A2-GN21-30 June 2004 A-1

Page 50

A. Connectors and Pin Assignments

DSL Ports and POTS Splitter Connectors

The 50-pin RJ21X Telco connector labeled DSL Ports 1–24 provides the 2-wire

loop interface from each DSL port to the demarcation point. (The Canadian

designation for this connector is CA21A.) The 50-pin RJ21X Telco connector

labeled POTS 1–24 provides the interface with the internal POTS splitters, if

installed.

Ta bl e A -1 lists the pin assignments for each of these interfaces. Note that Pins 25

and 50 are not used.

Table A-1. DSL Connector Pinouts

Connector Pins

DSL Port

11, 26

22, 27

(Ring, Tip)

1

25

33, 28

44, 29

55, 30

66, 31

77, 32

88, 33

99, 34

10 10, 35

11 11, 36

12 12, 37

13 13, 38

14 14, 39

15 15, 40

16 16, 41

17 17, 42

18 18, 43

19 19, 44

50

26

02-17151

20 20, 45

21 21, 46

22 22, 47

23 23, 48

24 24, 49

A-2 June 2004 4200-A2-GN21-30

Page 51

Port 1 and Port 2 10/100BaseT Connectors

Port 1 and Port 2 are 8-pin unkeyed modular jacks for a 10/100Base interface.

Table A-2. Port 1 and Port 2 Pinouts

Signal Pin

Transmitted Data + 1

Transmitted Data – 2

Received Data + 3

Unused 4

Unused 5

Received Data – 6

Unused 7

Unused 8

A. Connectors and Pin Assignments

Pin 1

Pin 8

97-15449

Port 3 1000BaseT Connector

Port 3’s 1000BaseT interface is an 8-pin unkeyed modular jack.

Table A-3. Port 3 1000BaseT Connector

Signal Pin

Tip 1 1

Ring 1 2

Tip 2 3

Ring 3 4

Tip 3 5

Ring 2 6

Tip 4 7

Ring 4 8

Pin 1

Pin 8

97-15449

4200-A2-GN21-30 June 2004

A-3

Page 52

A. Connectors and Pin Assignments

Port 3 GigE SFP Connector

Port 3’s GigE interface is a standard SFP socket.

Table A-4. Port 3 GigE Connector

Signal Pin

VeeT 1

TXFault 2

TXDisable 3

MOD-DEF(2) – I2C_DATA 4

MOD-DEF(1) – I2C_CLK 5

MOD-DEF(0) – SFP_PRESENT_L 6

Rate Select 7

LOS 8

VeeR 9

VeeR 10

VeeR 11

RD- 12

RD+ 13

VeeR 14

VccR 15

VccT 16

VeeT 17

TD+ 18

TD- 19

VeeT 20

A-4 June 2004 4200-A2-GN21-30

Page 53

Console Port Connector

The CONSOLE port connector is a DB9 socket connector that supports an

EIA-232-E circuit as shown in Ta b le A - 5.

Table A-5. Console Port Connector

RS-232 Signal Direction Pin

Data Carrier Detect Out 1

Receive Data Out 2

Send Data In 3

Data Terminal Ready In 4

Ground — 5

Data Set Ready Out 6

Request to Send In 7

Clear to Send In 8

A. Connectors and Pin Assignments

Ring Indicator — 9

4200-A2-GN21-30 June 2004

A-5

Page 54

A. Connectors and Pin Assignments

ALARM Connector

The alarm relay reports major alarms through the ALARM connector.

Table A-6. ALARM Connections

Signal Direction Contact

5 4 3 2 1

Major Alarm Out 1

Common Out 2

Minor Alarm Out 3

Alarm Sense + In 4

Alarm Sense – In 5

ALARM

03-17453

The alarm contacts are closed during normal operation. They open in response to

loss of power, hardware failure, or other alarm conditions. The maximum rated

load for the alarm relays is:

30 VDC: 1.0 Amp

60 VDC: 0.6 Amp

60 VAC: 0.6 Amp

A-6 June 2004 4200-A2-GN21-30

Page 55