Page 1

Jetstream® CPX-1000

Voice Services Platform

Installation and Operation

Release 2.5

Document No. 1000-A2-GN22-00

February 2003

Page 2

1000-A2-GN22-00

Copyright © 2003 Paradyne Corporation.

All rights reserved.

Printed in U.S.A.

Notice

This publication is protected by federal copyright law. No part of this publication may be copied or distributed,

transmitted, transcribed, stored in a retrieval system, or translated into any human or computer language in any form or

by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties without the express

written permission of Paradyne Corporation, 8545 126th Ave. N., Largo, FL 33773.

Paradyne Corporation makes no representation or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of merchantability or fitness for a particular purpose. Further, Paradyne Corporation

reserves the right to revise this publication and to make changes from time to time in the contents hereof without

obligation of Paradyne Corporation to notify any person of such revision or changes.

Changes and enhancements to the product and to the information herein will be documented and issued as a new

release to this manual.

Warranty, Sales, Service, and Training Information

Contact your local sales representative, service representative, or distributor directly for any help needed. For

additional information concerning warranty, sales, service, repair, installation, documentation, training, distributor

locations, or Paradyne worldwide office locations, use one of the following methods:

Internet: Visit the Paradyne World Wide Web site at www.paradyne.com. (Be sure to register your warranty at

www.paradyne.com/warranty.)

Telephone: Call our automated system to receive current information by fax or to speak with a company

representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

Document Feedback

We welcome your comments and suggestions about this document. Please mail them to Technical Publications,

Paradyne Corporation, 8545 126th Ave. N., Largo, FL 33773, or send e-mail to userdoc@paradyne.com. Include the

number and title of this document in your correspondence. Please include your name and phone number if you are

willing to provide additional clarification.

Tradem ark s

Jetstream is a registered trademark of Paradyne Corporation. All other products and services mentioned herein are the

trademarks, service marks, registered trademarks, or registered service marks of their respective owners.

A February 2003

Page 3

1000-A2-GN22-00

!

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or included in the manual.

2. Slots and openings in the cabinet are provided for ventilation. To ensure reliable operation of the product and to

protect it from overheating, these slots and openings must not be blocked or covered.

3. Do not attempt to service this product yourself, as opening or removing covers may expose you to dangerous high

voltage points or other risks. Refer all servicing to qualified service personnel.

4. The power supply cord for countries other than North America is to be a minimum H05 V V-F type, min. 0.75 mm

2-conductor. Do not allow anything to rest on the power cord and do not locate the product where persons will walk

on the power cord. When powering the equipment, do not exceed the electrical ratings stated on the product

nameplate.

5. This product may only be used in a Restricted Access Location in accordance with articles 110-16, 110-16, 110-17,

and 110-18 of the National Electric Code, ANSI/NFPA 70. A Restricted Access Location is a secure area

(dedicated equipment rooms, equipment closets, or the like) for equipment where access can only be gained by

service personnel or by users who have been instructed about the reasons for the restrictions applied to the

location and about any precautions that must be taken. In addition, access into this designated secured area is

possible only through the use of a tool or lock and key, or other means of security, and is controlled by the authority

responsible for the location.

6. General purpose cables are described for use with this product. Special cables, which may be required by the

regulatory inspection authority for the installation site, are the responsibility of the customer. To reduce the risk of

fire, use only UL Listed or CSA Certified (or comparable cables which are certified for use in the country of

installation) cable(s) that are suitably rated for the application.

7. A rare phenomenon can create a voltage potential between the earth grounds of two or more buildings. If products

installed in separate buildings are interconnected, the voltage potential may cause a hazardous condition.

Consult a qualified electrical consultant to determine whether or not this phenomenon exists and, if necessary,

implement corrective action prior to interconnecting the products.

8. The equipment is intended for installation in a max. 25° C ambient temperature, in an environment that is free of

dust and dirt.

9. When installed in the final configuration, the product must comply with the applicable Safety Standards and

regulatory requirements of the country in which it is installed. If necessary, consult with the appropriate regulatory

agencies and inspection authorities to ensure compliance.

2

,

EMI Notices

!

UNITED STATES – EMI NOTICE:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

The authority to operate this equipment is conditioned by the requirements that no modifications will be

made to the equipment unless the changes or modifications are expressly approved by Paradyne

Corporation.

In order to maintain compliance with Part 15 limits, the supplied RJ21X cable must be used. Refer to the

installation instructions.

February 2003 B

Page 4

1000-A2-GN22-00

!

CANADA – EMI NOTICE:

This Class A digital apparatus meets all requirements of the Canadian interference-causing equipment

regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du réglement sur le matérial

brouilleur du Canada.

CE Marking

When the product is marked with the CE mark on the equipment label, a supporting Declaration of Conformity may be

downloaded from the Paradyne World Wide Web site at www.paradyne.com. Select

CE Declarations of Conformity.

Library → Technical Manuals →

Japan

Class A ITE

This is a Class A product based on the standard of the Voluntary Control Council for interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective actions.

C February 2003

Page 5

Table of Contents

Preface

Audience ...................................................................................vii

Organization .............................................................................vii

Related Documents................................................................ viii

Conventions............................................................................ viii

Chapter 1 Voice-over-Broadband Networking

Local Access Network Architecture..................................... 1-1

CPX-1000 Voice Services Platform........................................ 1-3

Packet Network Configuration.............................................1-4

Call Origination and Completion.........................................1-6

CPX-1000 Calling Features .................................................... 1-8

CPX-1000 Management Tools and APIs ..............................1-9

Chapter 2 CPX-1000 Voice Services Platform Description

Equipment Operational Features..........................................2-2

Traffic Capacity........................................................................2-2

CPX-1000 Operation ...............................................................2-3

Management Processing .................................................. 2-6

Call Processing ..................................................................2-6

PSTN Interface................................................................... 2-6

Packet Interface .................................................................2-7

Physical Description ...............................................................2-8

February 2003 i

Page 6

Table of Contents 1000-A2-GN22-00

CPX-1000 Shelf ................................................................2-10

System Alarm Panel .......................................................2-10

Line Modules with T1 ....................................................2-12

Line Modules with STS-1............................................... 2-12

Call Processor Modules..................................................2-13

Management Processor Module ...................................2-17

PSTN Modules.......................................................................2-20

T1 Load Sharing .............................................................. 2-20

Octal T1 Module..............................................................2-21

12-Port T1 ECAC Module ..............................................2-23

STS-1 Module...................................................................2-25

STS-1 ECAC Card ...........................................................2-28

Splitter Assembly for STS-1........................................... 2-30

ATM OC-3 Module .........................................................2-32

Echo Cancellation Module............................................. 2-35

Echo Cancellation and Compression Module (ECAC)2-36

DC Power Supply Fan and Fan Modules.................... 2-37

DC Power Distribution Panel........................................ 2-39

Chapter 3 Installing the CPX-1000

Installation Checklist ..............................................................3-2

Turn-up Checklist ...................................................................3-4

Installation Requirements......................................................3-5

Safety Requirements.........................................................3-5

General Safety Precautions .............................................3-5

Ground the Equipment .............................................. 3-5

Do Not Service Internal Assemblies.........................3-7

Do Not Work Alone ....................................................3-7

Do Not Modify or Substitute Parts/Equipment ....3-7

Aisle Requirements........................................................... 3-7

Environmental Requirements ......................................... 3-7

Power Requirements ........................................................3-8

ii February 2003

Page 7

1000-A2-GN22-00 Table of Contents

Rack Requirements ...........................................................3-8

Tools and Supplies ...................................................... 3-9

Facility Connections and Cabling............................. 3-9

Unpack and Inspect the CPX-1000 ..................................... 3-10

Inventory CPX Components ...............................................3-11

Attach the Mounting Flanges..............................................3-12

Rack Mount the CPX ............................................................3-13

Mount the Splitter Assembly ..............................................3-16

Connect Plant Battery and Frame Ground........................3-16

Install Modules in CPX ........................................................3-19

Installing Additional Cards...........................................3-22

Verify Hardware Installation............................................... 3-23

Attach OC-3 ATM Cables ....................................................3-24

Attach Ethernet Cables......................................................... 3-25

Attach MP Card to CP Cards ........................................ 3-25

Connect the CPX to the LAN ........................................3-25

Attach CP Redundancy Cable............................................. 3-25

Attach the T-1/DS-1 Cables.................................................3-26

Attaching Cables to Octal T1 Modules ........................3-26

Attaching Cables to 12-Port T1 Modules.....................3-28

Attach the STS-1 Cables .......................................................3-30

Verify Cabling........................................................................3-32

Apply Power..........................................................................3-32

Check Plug-in Module Indicators.......................................3-33

Alarm Panel Indicators ..................................................3-34

Check the Fans.......................................................................3-34

Verify Remote Interface........................................................3-34

Connect JetCraft PC to CPX-1000 .................................3-34

Change CPX Default IP Address..................................3-34

Verify CPX LAN Connection......................................... 3-35

Provision the CPX-1000........................................................ 3-35

February 2003 iii

Page 8

Table of Contents 1000-A2-GN22-00

Chapter 4 Troubleshooting

General Troubleshooting Guidelines ...................................4-2

System Trouble Shooting .......................................................4-3

Using the JetCraft Alarm Window .......................................4-3

Troubleshooting the CPX Shelf ............................................. 4-3

Alarm Panel Indicators ....................................................4-3

Module Troubleshooting.................................................. 4-6

Power System Troubleshooting ....................................4-12

Loopbacks ........................................................................4-14

Chapter 5 Repair Procedures

Recommended Power Off......................................................5-1

Emergency Power-Off ............................................................5-1

Power Supply/Fan Module Removal.................................. 5-2

Replacing Inoperative Fans ...................................................5-2

Install Power Supply/Fan Module ................................5-3

Alarm Panel .............................................................................5-4

Removing the Alarm Panel .............................................5-4

Installing the Alarm Panel...............................................5-5

Power Distribution Panel.......................................................5-5

Removing Power Distribution Panel .............................5-5

Installing Power Distribution Panel............................... 5-6

Module Removal and Installation ........................................5-7

Removing and Replacing Cards .....................................5-9

Hot Swapping........................................................................ 5-10

Hot Swapping an MP Card ...........................................5-10

Hot Swapping CP and HSC Cards............................... 5-11

Hot Swapping Line Cards ............................................. 5-11

Planned Hot Swap .................................................... 5-12

Unplanned Hot Swap...............................................5-12

Hot Growth............................................................................5-13

iv February 2003

Page 9

1000-A2-GN22-00 Table of Contents

Appendix A Using the Console

Logging In.........................................................................A-1

Console Commands.........................................................A-4

?.....................................................................................A-5

clocking........................................................................A-5

crv.................................................................................A-6

exit ................................................................................A-6

help...............................................................................A-6

setpassword ................................................................A-6

showadminstate .........................................................A-6

showclock....................................................................A-6

showecac .....................................................................A-7

showport .....................................................................A-7

showportgroups.........................................................A-7

showpps ......................................................................A-7

showpstnpg.................................................................A-7

stats ..............................................................................A-7

status ............................................................................A-7

sub ................................................................................A-8

Admin Console Commands ...........................................A-8

clearstats ......................................................................A-8

fan.................................................................................A-8

portloop .......................................................................A-9

reboot ...........................................................................A-9

restartsub.....................................................................A-9

setactiveport................................................................A-9

setcdv ...........................................................................A-9

setechocancel ..............................................................A-9

setlinelen....................................................................A-10

tap...............................................................................A-10

vpath ..........................................................................A-10

February 2003 v

Page 10

Table of Contents 1000-A2-GN22-00

Appendix B Pin Assignments and Indicators

System Alarm Connection Requirements .......................... B-7

Appendix C Replacement Parts

Appendix D Specifications

Index

vi February 2003

Page 11

Preface

Audience This manual is for technicians and engineers who install and put

into service (turn-up) the CPX-1000 Voice Services Platform or who

perform routine diagnostic testing, troubleshooting, and repair of

the equipment.

Note

Throughout this document, the terms CPX-1000 and

CPX refer to the CPX-1000 Voice Services Platform

equipment.

Organization The CPX-1000 Voice Service Platform Installation and Operation is

organized as follows:

Chapter 1, Voice-over-Broadband Networking, describes

Voice-over-Broadband (VoBB) local access network

architecture and the role of the CPX-1000 Voice Services

Platform in implementing voice over DSL, T1, and wireless

broadband networks.

Chapter 2, CPX-1000 Voice Services Platform Description,

describes the features, components, and specifications of the

CPX-1000.

Chapter 3, Installing the CPX-1000, provides procedures to

unpack, install, power up, and turn up the CPX-1000.

Chapter 4, Trou bl es hoo ti ng , describes CPX-1000 operational

and hardware problem isolation and correction.

Chapter 5, Repair Procedures, describes how to remove and

replace CPX-1000 modules and components.

February 2003 vii

Page 12

Preface 1000-A2-GN22-00

Appendix A, Using the Console, describes how to use the

console, and lists user and admin console commands.

Appendix B, Pin Assignments and Indicators, describes port

and plug specifications, and indicators on each module.

Appendix C, Replacement Parts, lists CPX-1000 field

replaceable parts.

Appendix D, Specifications, lists requirements for NEBS

and CPX-1000 specifications for physical, environmental,

electrical, electronic, and operational parameters.

Related Documents

Complete documentation for this product is available online at

www.paradyne.com. Select Support

Jetstream Media Gateway Systems.

JetCraft User’s Guide

Describes how to install Paradyne Jetstream craft interface

terminal software, and provides instructions to configure a

CPX-1000 Voice Services platform using JetCraft.

JetVision Installation

Provides instructions for installing JetVision software on

Windows or Solaris computers.

JetVision User’s Guide

Describes the top level management of multiple CPX-1000

equipment.

CPX-1000 Voice Services Platform TL 1 Reference

Lists all commands and messages supported by the

Jetstream TL 1 agent.

To order a paper copy of a Paradyne document or to talk to a sales

representative, please call 727-530-2000.

→

Tec hn ic a l M an ua l s →

Conventions This document uses the following symbols to identify important

notes, and hazardous or dangerous tasks.

Tip

Provides useful information to help you install the CPX.

viii February 2003

Page 13

1000-A2-GN22-00 Preface

Note

The pointing finger highlights important information.

Be sure to read this information before continuing.

Warning

Alerts you to an action or inaction that could lead to an

injury to yourself or damage to the CPX-1000.

CAUTION

CLASS 1 LASER

Alerts you to a laser hazard—never look directly into the

source of a laser beam, which may be invisible.

Voice/Data Interruption

Alerts you to an action that, if done incorrectly, will interrupt

voice or data traffic.

Electro-Static Caution

Reminds you to take precautions to prevent electrostatic

damage to static-sensitive assemblies and circuits.

Danger: Shock Hazard

Alerts you to an electrical hazard that may cause fatal injury.

Caution

Alerts you to a lifting hazard that may cause physical injury.

February 2003 ix

Page 14

Preface 1000-A2-GN22-00

x February 2003

Page 15

C H A P T E R

Voice-over-Broadband

Networking

This chapter describes the Paradyne Jetstream Voice-overBroadband (VoBB) product solution, including the following

topics:

Local access network architecture (page 1-1)

CPX-1000 Voice Services Platform (page 1-3)

Packet network configuration (page 1-4)

Call origination and completion (page 1-6)

1

Local Access Network Architecture

CPX-1000 calling features (page 1-8)

CPX management tools and APIs (page 1-9)

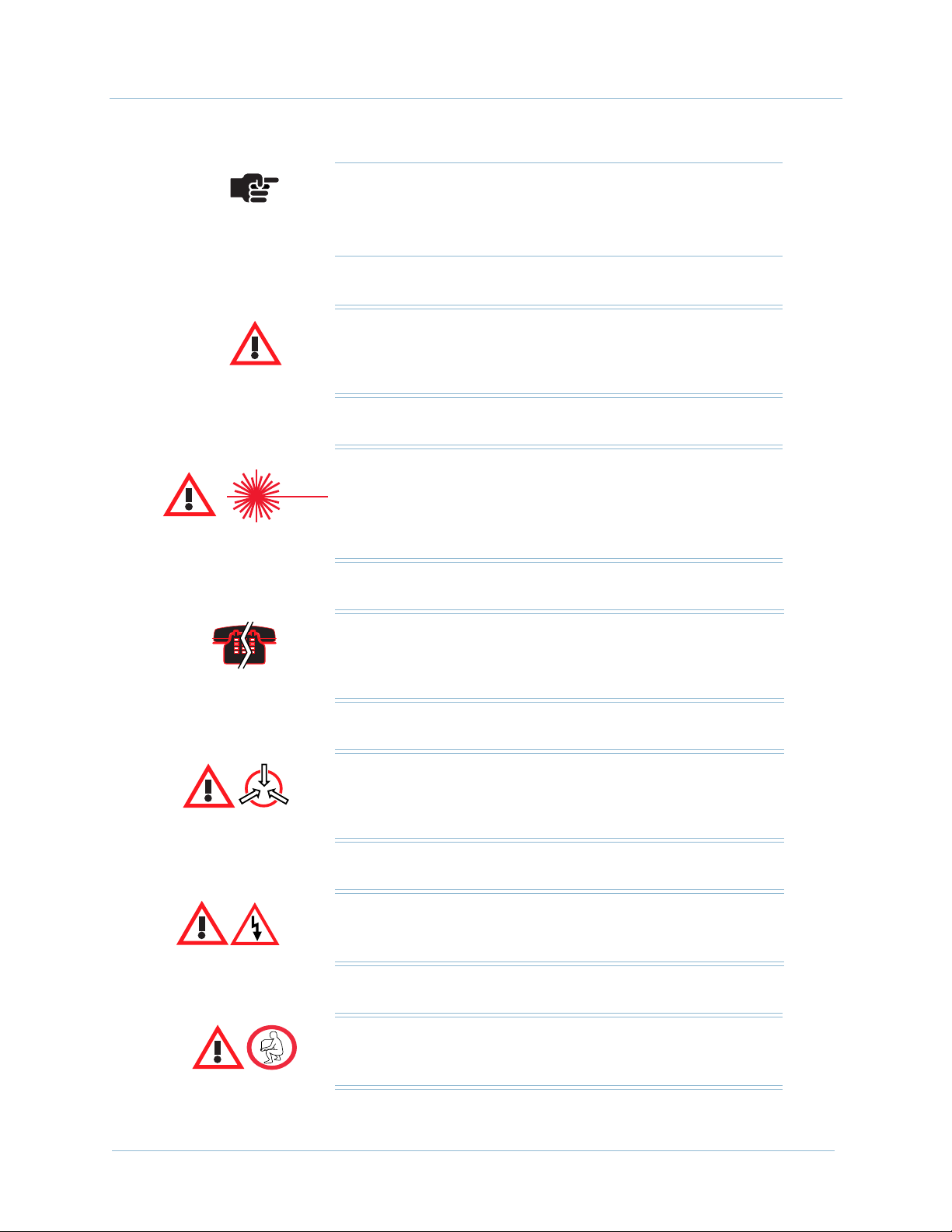

The modern packet-based local access network enables Integrated

Communication Providers (ICPs) to deliver a combination of voice

and data services to their subscribers over the local loop.

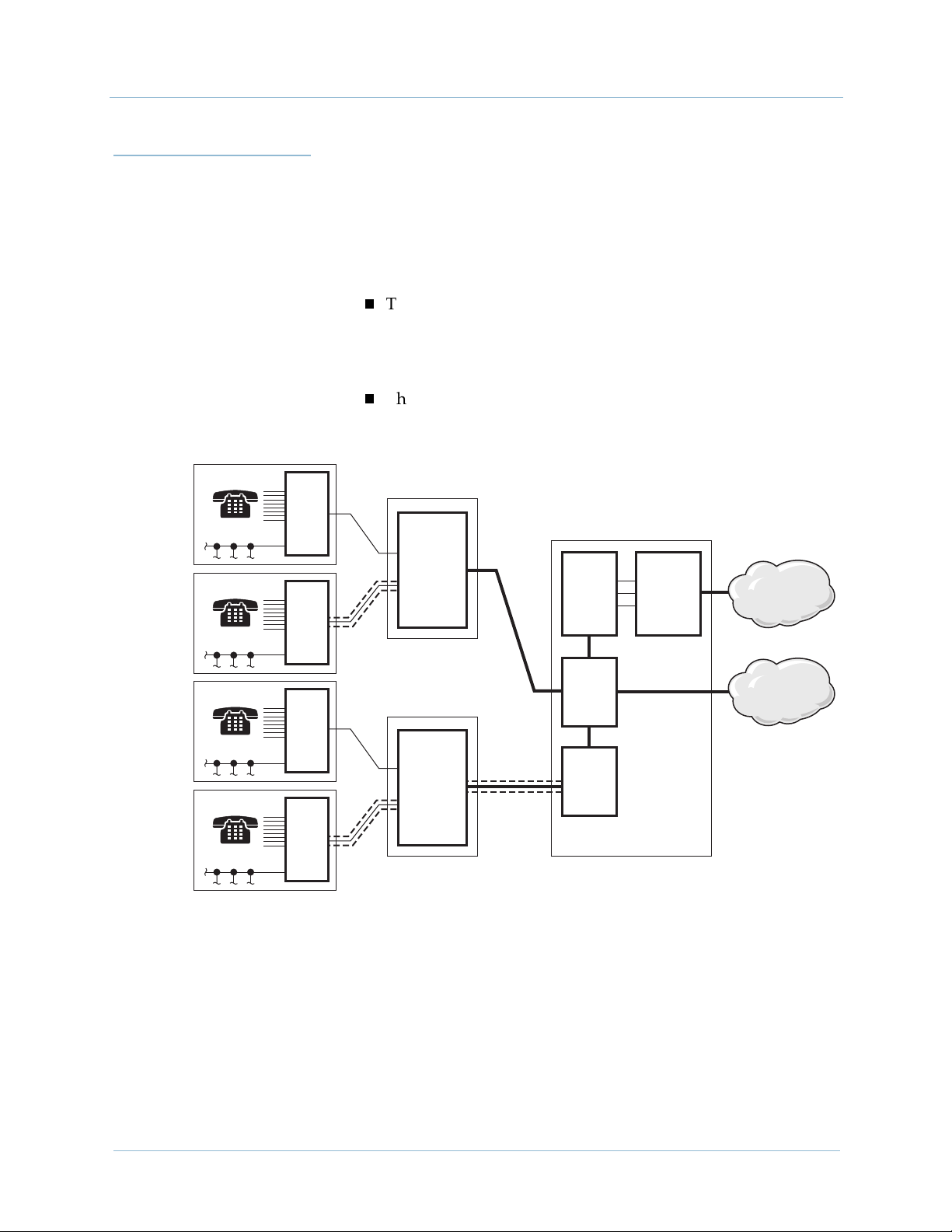

Our Voice-over-Broadband (VoBB) local access network

alternatives (Figure 1–1) include:

Voice over DSL (VoDSL)—enables the delivery of

integrated high-speed voice and data services over a single

DSL circuit; that is, over a single copper pair.

Voice over T1 (VoT1)—offers access at greater distances

(i.e., hundreds of miles when repeaters are used) and

provides guaranteed bandwidth. It also uses existing T1

aggregation resources at the ILEC central office.

Voice over Wireless (VoWLL)—eliminates the need for

land line copper loops by using ATM over MMDS or U-NII

wireless broadband access networks.

February 2003 1-1

Page 16

1. Voice-over-Broadband Networking 1000-A2-GN22-00

Regional

Switching

()

()

*+$*

Wiring

Centers

()

#

()

*+$*

Center

!"

$&'

()

+$'*'*

'

$

$ % #

Customer

Premises

Phone Sys

LAN

Phone Sys

LAN

Subscribers

Figure 1–1. VoBB Local Access Networks

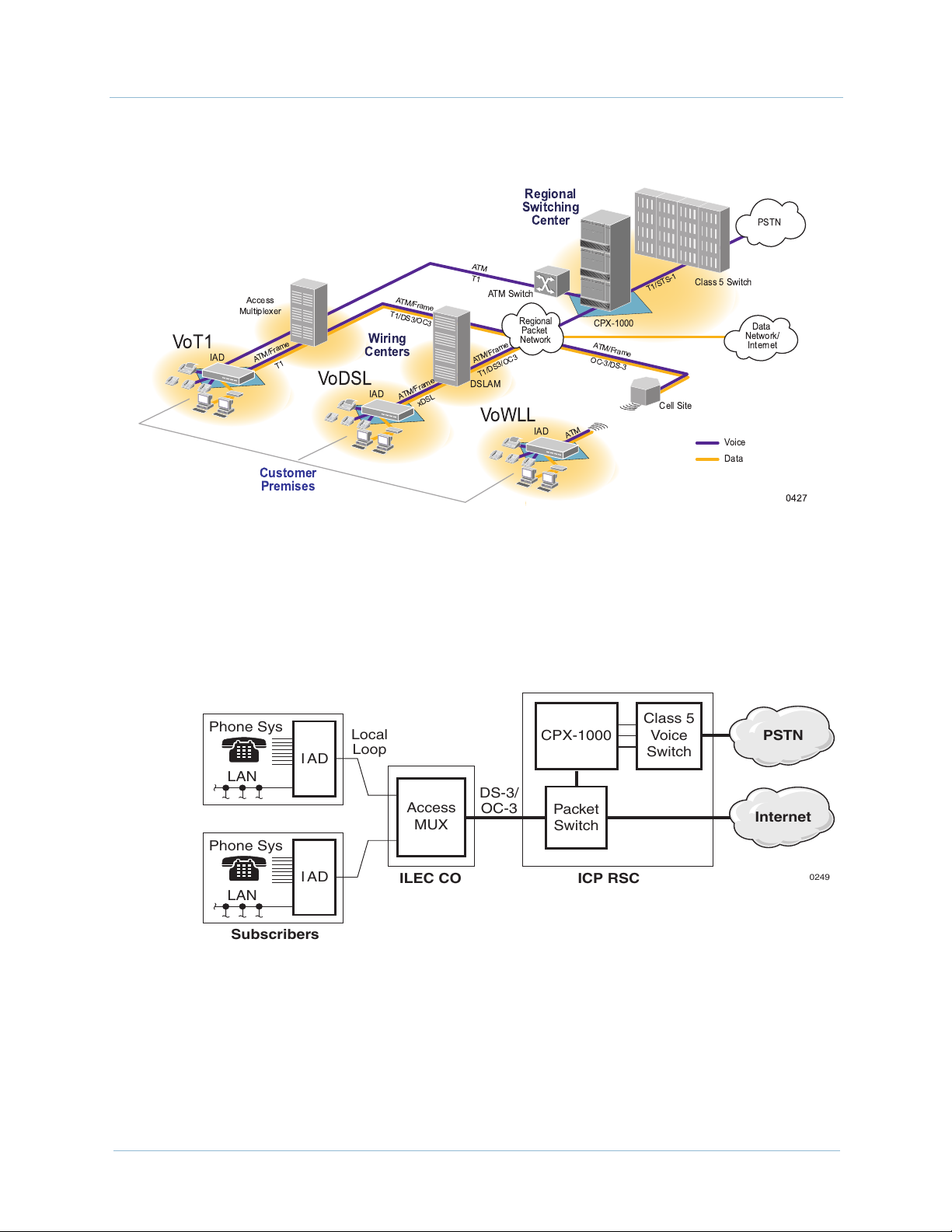

The CPX-1000 Voice Services Platform is a large-scale voice

platform that resides in an ICP's Regional Switching Center (RSC).

It serves as the gateway between an ICP’s existing Class 5 voice

switch and a packet-based local access network (Figure 1–2).

Class 5

IAD

Local

Loop

CPX-1000

Voice

Switch

DS-3/

IAD

Access

MUX

ILEC CO

OC-3

Packet

Switch

ICP RSC

Internet

Figure 1–2. VoBB Network Architecture

The CPX-1000 Voice Services Platform architecture provides

seamless integration of voice and data networks. These networks

comprise standard ATM switches and local access multiplexers

available from multiple equipment manufacturers.

PSTN

0249

1-2 February 2003

Page 17

1000-A2-GN22-00 1. Voice-over-Broadband Networking

The heart of our VoBB solution is the CPX-1000. IADs, supplied by

other manufacturers, reside at subscriber premises. Each IAD

provides dial tone to standard (POTS) local telephones and data

service, using a single transmission link.

The network architecture provided by the CPX-1000 enables ICPs

to extend local dial tone services from an existing Class 5 switch

over a packet-based access network. From this perspective, as a

loop extender, voice-over-broadband is functionally similar to

traditional Digital Loop Carrier (DLC) equipment, where the Class

5 switch provides the actual dial tone, as well as Custom Local

Area Signaling Services (CLASS) and calling features.

However, unlike traditional DLCs, which supply the physical

subscriber line interface at the central office, the packet architecture

places that interface at the subscriber premises.

The benefits of this architecture are:

better voice quality, by performing analog-to-digital

conversion near the phone

CPX-1000 Voice Services Platform

more efficient use of copper connections between the

subscriber premises and the Class 5 switch

The CPX-1000 supports any broadband access network technology,

including voice-over-T1, voice-over-DSL, and voice-over-wireless

local loop (Figure 1–1 on page 1-2).

The CPX-1000 is a carrier-class, rack-mounted shelf with

redundant components.

The CPX-1000 incorporates a scalable architecture within a single

shelf, or by using multiple CPX shelves.

A single shelf can support additional subscribers by adding

more network modules or using the spare capacity of

existing network modules.

Multi-shelf equipment is comprised of more than one CPX

when the capacity of a single shelf is exceeded.

Most shelf components are modules comprised of a line card and a

transition card. The line card installs in the front of the CPX and

the transition card installs in the rear. A passive midplane within

the CPX shelf connects the line modules and transition modules.

February 2003 1-3

Page 18

1. Voice-over-Broadband Networking 1000-A2-GN22-00

Packet Network Configuration

Phone Sys

LAN

Phone Sys

LAN

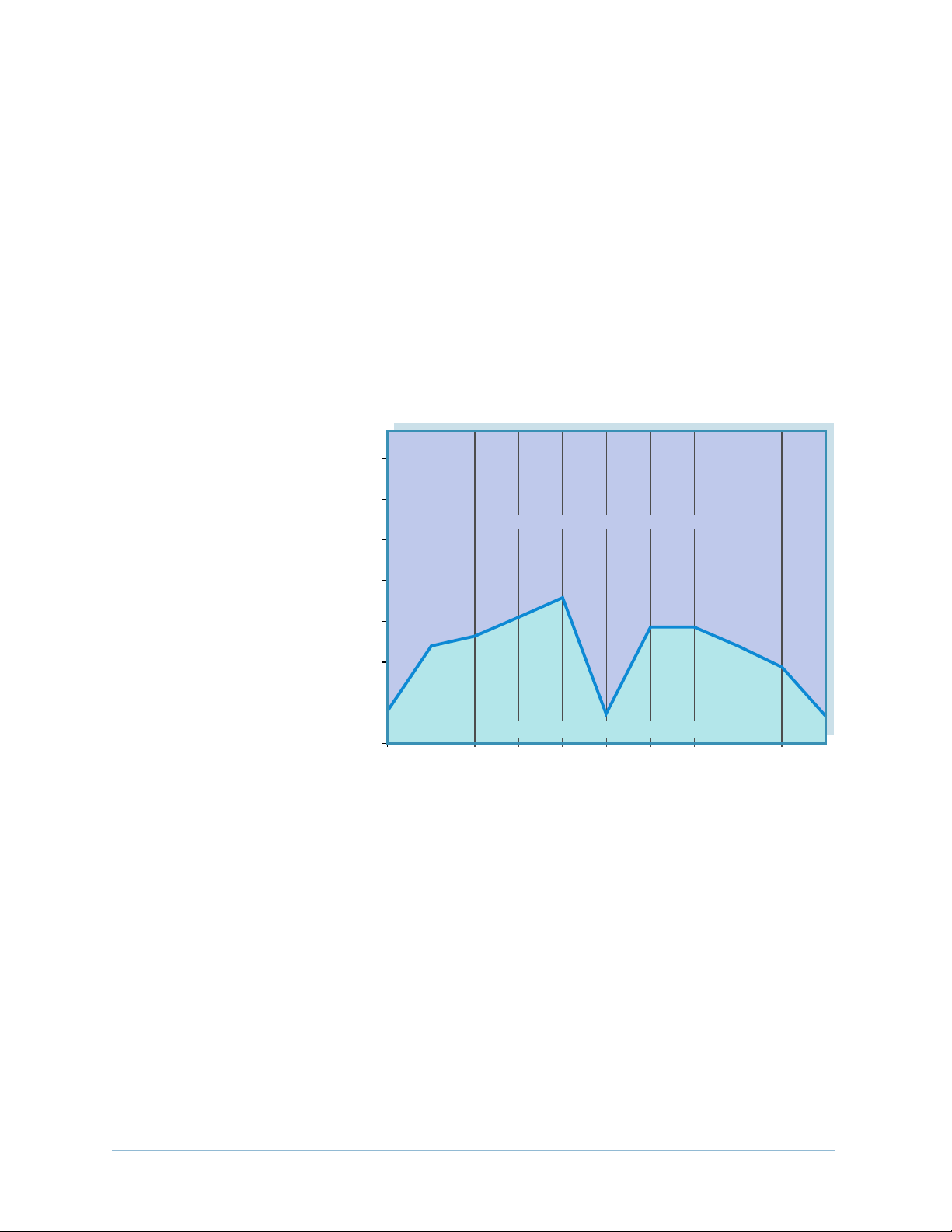

The CPX-1000 transports voice traffic via an ATM network. When

Frame Relay is used, the frames are encapsulated in ATM cells.

In the packet network (Figure 1–3), voice-over-broadband requires

a minimum of two Permanent Virtual Circuits (PVCs) across the

network for each IAD (in both ATM and Frame Relay networks).

The first PVC transports the voice and management traffic

associated with all of the subscriber's telephone lines. The

voice PVC is configured as a variable bit rate-real time

(VBR-rt) PVC, and has priority over the data PVC.

The second PVC transports the data traffic. The data PVC is

typically set up as an unspecified bit rate (UBR) PVC.

Local

IAD

IAD

Loop

AT M

Access

MUX

ILEC CO

Voice PVC

Data PVC

CPX-

1000

Class 5

Voice

Switch

PSTN

Phone Sys

LAN

Phone Sys

LAN

Subscribers

Packet

Switch

IAD

Frame

Relay

Access

MUX

IAD

ILEC CO

Voice

DLCI

Data

DLCI

FRF8

IWF

ICP RSC

Figure 1–3. VoBB Network Configuration

Internet

0250

1-4 February 2003

Page 19

1000-A2-GN22-00 1. Voice-over-Broadband Networking

Voice is more sensitive to network latency than data, so this

configuration ensures that voice traffic always has priority over

data. However, this configuration also enables voice traffic to

consume bandwidth when a call is in progress. Typically, few

subscriber's telephone lines are simultaneously in use, so the

majority of the bandwidth is usually available for data service.

For example, over a single 768 kbps symmetric DSL connection, an

ICP supports up to eight simultaneous telephone calls using 2:1

compression serving a KTS with 32 extensions at a P.01 grade of

service and still delivers data service at an average speed of

550 kbps (Figure 1–4).

700

600

Average bandwidth available for data

500

400

300

Bandwidth (K)

200

100

0

7am

8am

Average bandwidth used by telephony

9am 10am 11am 12pm 1pm 2pm 3pm 4pm 5pm

0202

Figure 1–4. Bandwidth Usage—768 kbps SDSL Circuit

However, many network operators have Frame Relay-based local

access networks interconnected with ATM networks. The CPX can

interface with the Frame Relay network through an Interworking

Function (IWF) between the Frame Relay and ATM (Figure 1–3).

The IWF is an industry-standard function that either the access

mux or a Frame Relay/ATM switch can execute.

In a Frame Relay network, each PVC uses an identifying Data Link

Connection Identifier (DLCI). ATM PVCs, however, use a Virtual

Path Identifier/Virtual Channel Identifier (VPI/VCI). The IWF

maps each Frame Relay DLCI to a corresponding ATM VPI/VCI.

This association between the Frame Relay DLCI and ATM VPI/

VCI is made when provisioning PVCs.

February 2003 1-5

Page 20

1. Voice-over-Broadband Networking 1000-A2-GN22-00

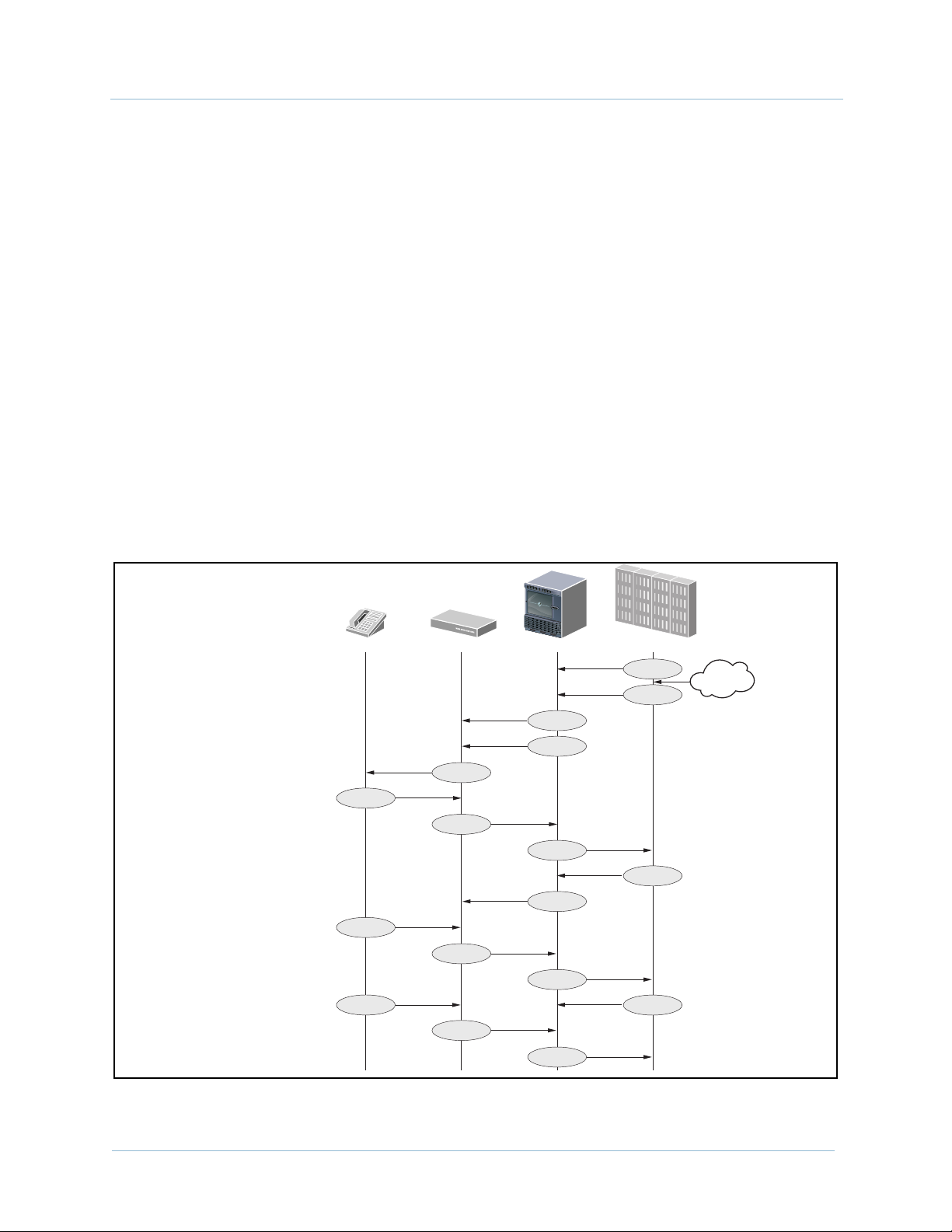

Call Origination and Completion

These steps describe the network interaction that occurs when a

subscriber initiates a call (Figure 1–5):

1. A subscriber initiates the call by taking the telephone off-hook.

2. The IAD notifies the CPX through the Common Channel

Signaling (CCS) channel in the voice PVC.

3. The CPX sends an outgoing call request message to the Class 5

switch through the PSTN (GR-303 protocol) Time Management

Channel (TMC).

4. The Class 5 switch selects the available time slot in a PSTN

interface group and directs the CPX to connect the IAD port to

the specified time-slot on the switch.

5. The host Class 5 switch provides dial tone.

6. The CPX cuts the calling station through to the switch.

7. The subscriber dials the destination number and the Class 5

switch collects DTMF digits.

8. The Class 5 switch routes the call, returns the call progress, and

generates a call data record.

9. The CPX notifies the Class 5 switch when the station hangs up.

Telephone IAD CPX-1000 Class 5 Switch

1

2

3

4

5

5

5

6

7

7

7

8

9

Figure 1–5. Subscriber Initiates a Call

PSTN

0352

1-6 February 2003

Page 21

1000-A2-GN22-00 1. Voice-over-Broadband Networking

These steps describe the network interaction that occurs when a

subscriber receives a call (Figure 1–6):

1. The Class 5 switch sends an incoming call request message to

the CPX through the PSTN (GR-303) TMC.

2. The Class 5 switch assigns a time slot.

3. The CPX sends a setup message to the IAD, verifying both

bandwidth and port availability.

4. The CPX connects the specified time slot to an IAD port.

5. The IAD initiates ringing.

6. The IAD notifies the switch via the CPX when the first ring is

complete and connects the station through to the host.

7. The Class 5 switch sends a caller ID to the IAD via the CPX.

8. When the station answers, the CPX sends a call connected

message to the Class 5 switch.

9. The Class 5 switch notifies the CPX when the call is cleared.

10. The CPX notifies the switch when the station hangs up.

Telephone IAD CPX-1000 Class 5 Switch

10

1

2

3

4

5

6

6

6

7

7

8

8

8

9

10

PSTN

10

0353

Figure 1–6. Subscriber Receives a Call

February 2003 1-7

Page 22

1. Voice-over-Broadband Networking 1000-A2-GN22-00

CPX-1000 Calling Features

The CPX transparently passes all Class 5 switch standard POTS

features to subscribers. These include:

On-hook message delivery, with power ringing (caller ID)

On-hook message delivery, without power ringing

— Visual Message Waiting Indication (VMWI)

— other messaging services, such as stock quotes

Off-hook message delivery

— caller ID

— call waiting

Flash features

— call waiting

— 3-way calling

— call hold

— call transfer

In-band calling features

— stutter dial tone for message waiting

— code-activated features

— call forwarding

— call return

Distinctive ringing

Loop battery control

— answer supervision

—toll alerting

— calling-party control

411 directory assistance

911 emergency assistance

Anonymous call rejection

Automatic call back

Call blocking

Call forward busy

Call forward no answer

Operator barge in

Privacy support—number blocking

Selective call forwarding

Speed calling

1-8 February 2003

Page 23

1000-A2-GN22-00 1. Voice-over-Broadband Networking

CPX-1000 Management Tools and APIs

We provide several management tools and APIs for use in other

network management systems.

JetCraft

We provide a Windows-based voice service management tool with

a graphic user interface, called JetCraft. JetCraft manages one CPX

at a time. See the JetCraft User’s Guide for more information.

JetVision

We also provide a second, more extensive element management

system, called JetVision. JetVision can manage up to 50 CPX

shelves at a time. JetVision is used in a standalone configuration to

support flow-through management from a higher level Network

Management System (NMS) via the JetWay API. See the JetVision

User’s Guide for more information.

Jetway

JetWay is an API (Application Program Interface) for JetVision that

enables northbound network management systems to integrate

functionality into managerial capabilities provided by JetVision.

TL1 Agent

The TL1 Agent is an application that allows TL1 (Transaction

Language 1) messages to be sent to the CPX. TL1 is a standard

command-line interface protocol designed for element

management. The messages supported allow for alarm

management and retrieval of CPX configuration information. See

the CPX-1000 Voice Services Platform TL 1 Reference for more

information.

JetSNMP

We also provide JetSNMP, a CPX native interface that allows

SNMP Managers (e.g., HP Open View) to discover and monitor the

CPX-1000 equipment. When the CPX-1000 is purchased, we can

provide the standard Jetstream SNMP MIB file.

February 2003 1-9

Page 24

1. Voice-over-Broadband Networking 1000-A2-GN22-00

1-10 February 2003

Page 25

C H A P T E R

2

CPX-1000 Voice Services

Platform Description

This chapter describes the features, components, and overall

specifications of the CPX-1000, including the following topics:

Equipment operational features (page 2-2)

Capacity (page 2-2)

CPX-1000 operation (page 2-3)

Physical description (page 2-8)

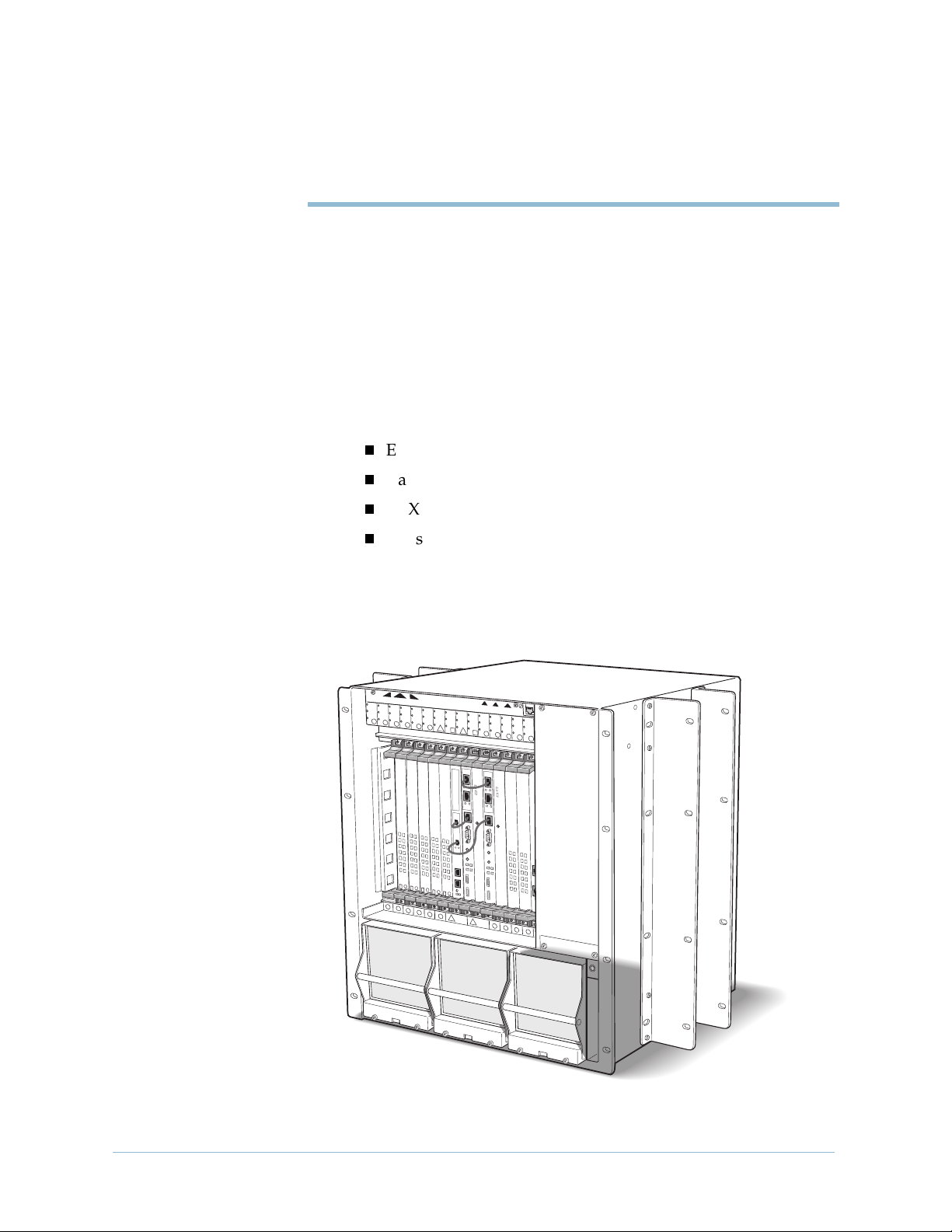

The CPX-1000 (Figure 2–1) is a carrier-class, rack-mounted shelf

that resides in an Integrated Service Provider’s (ICP's) Regional

Service Center (RSC).

A

L

E

R

T

A

A

L

E

R

T

B

A

L

E

R

T

D

IS

U

N

A

C

C

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

L

O

C

K

E

D

U

N

L

O

T

A

C

T

1

D

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

A

C

T

A

C

T

A

2

C

T

A

C

T

3

4

5

6

1

2

3

4

5

M

IN

O

RM

A

J

O

R

C

R

IT

IC

A

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

A

C

T

A

C

T

A

C

T

7

8

9

6

7

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

L

E

D

D

IS

A

B

K

E

D

U

N

L

O

C

K

E

D

U

N

A

C

T

A

C

10

9

L

E

L

O

T

D

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

U

N

L

O

C

K

E

D

A

C

T

A

C

T

A

C

T

11

A

C

T

12

13

14

15

11

12 13

14

Figure 2–1. CPX-1000 (Front View)

0484

February 2003 2-1

Page 26

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

A CPX installation is scalable: first by populating an individual

shelf, then by adding additional shelves. Each CPX shelf occupies

12 RU (21 inches high) and is 17 inches deep.

Using optional mounting brackets, the shelf can be installed in

19-inch EIA310, Bell Wide, Bell Narrow, and NEBS2000 racks.

Reversible mounting brackets allow installation in 23-inch racks.

Equipment Operational Features

A single CPX-1000 can manage than 18,800 subscriber telephone

lines (at 9:1 concentration ratios) on a voice-over-broadband

network, including:

Circuit-to-packet conversion—converts DS0s from the

Class 5 switch into cell-based ATM format.

Routing—routes cells to and from IADs at subscriber

locations.

Call administration—manages call-control signaling to

both the Class 5 switch and the IADs.

Traffic management—monitors the connection over the

access network to each end user.

Concentration management—supports line

concentration levels up to 40:1.

System and Service Administration—acts as the

administrative platform for managing voice-over-packet

services.

Traffic Capacity

2-2 February 2003

The CPX supports up to 4,000 IADs, and supports two types of T1

modules, which may be used interchangeably: The Octal T1

module provides 8 T1 ports, and up to 6 modules may be placed in

the CPX. Echo cancellation or echo cancellation and compression is

provided on separate cards. The 12-port T1 ECAC module

provides 12 T1 ports, and up to 7 modules may be placed in the

CPX. Also, echo cancellation and compression is provided directly

onboard, eliminating the need for separate EC or ECAC cards.

The CPX also supports two types of STS-1 cards, which may be

used interchangeably. Up to 6 STS-1 cards may be installed in each

CPX. The STS-1 module does not provide onboard echo

cancellation or compression—you must use separate modules. The

STS-1 ECAC module includes onboard echo cancellation and

compression, eliminating the need for separate EC or ECAC cards.

Page 27

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

The capacity of the CPX shelf configured with either T1 modules

depends on the shelf configuration and the concentration and

redundancy options selected.

A CPX shelf using either STS-1 or 12-port T1 card with ATM OC-3

can support over 2,000 simultaneous calls and 16,000 subscriber

lines (8:1 concentration).

Carriers can upgrade the CPX network by adding additional

CPX-1000s, all of which can be managed by a single JetVision

workstation.

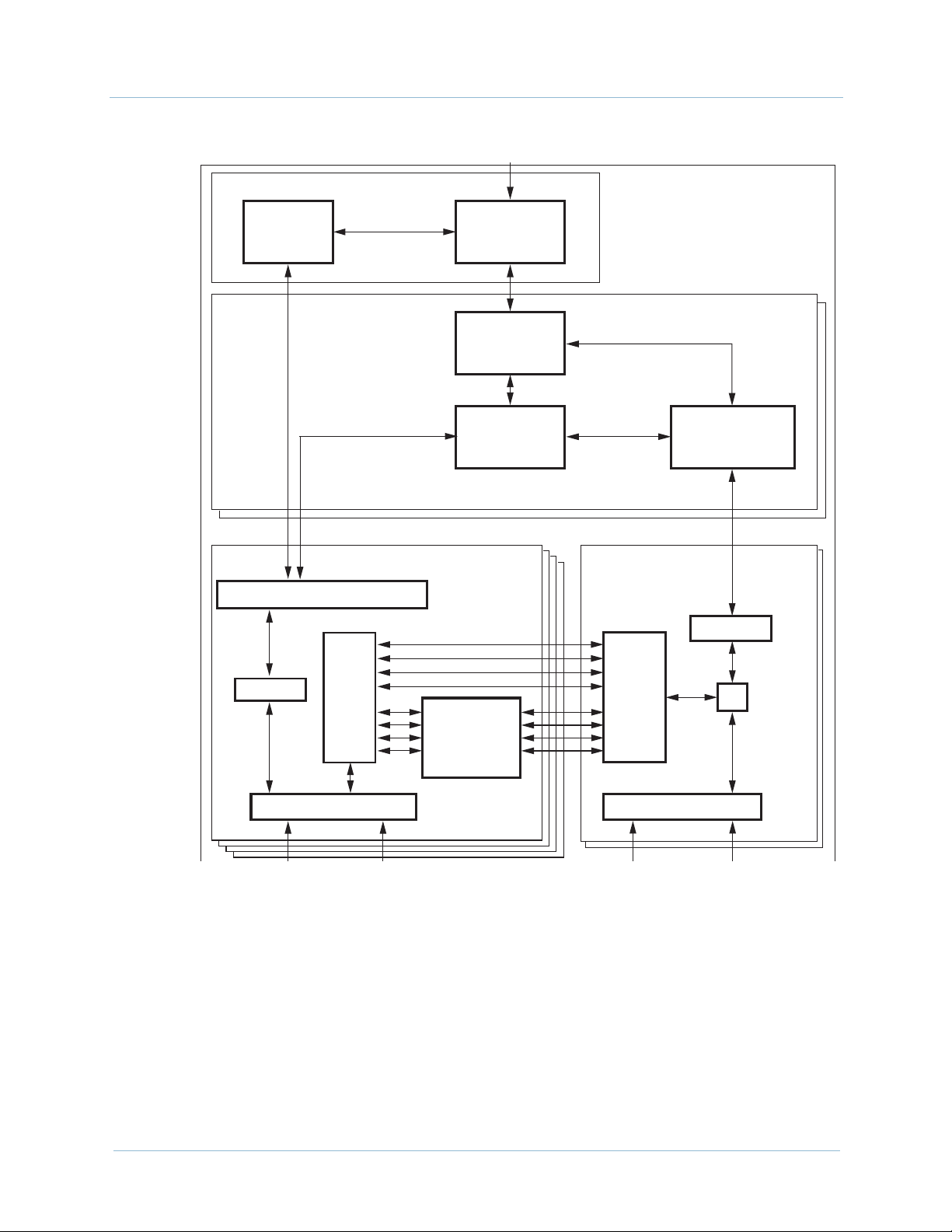

CPX-1000 Operation

Call control, circuit-packet switching, network interfaces,

provisioning, and management, are divided into four basic

functional blocks:

Management processing (MP)

Call Processing (CP)

PSTN interface (T1 or STS-1)

Packet interface

Figure 2–2 illustrates this functionality when providing access to

the PSTN via T1, using the 12-port T1 ECAC module.

February 2003 2-3

Page 28

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

MP Module

EOC

Process

CP

Modules

PSTN Interface

T1 Modules

Q.931 (LAPD) Link Layer

Management

Process

Call

Processing

Engine

TMC

Processing

Voice Bus

CPX-1000

Shelf

IAD

Signalling and

Connectivity

Packet Interface

ATM Modules

Control

Control

Voice Voice

T1 Interface Controller

Figure 2–2. CPX Functional Diagram (T1 Interface)

Echo

Cancellation

and

Compression

Voice/

Control

Splitter

OC3 Port

0481

2-4 February 2003

Page 29

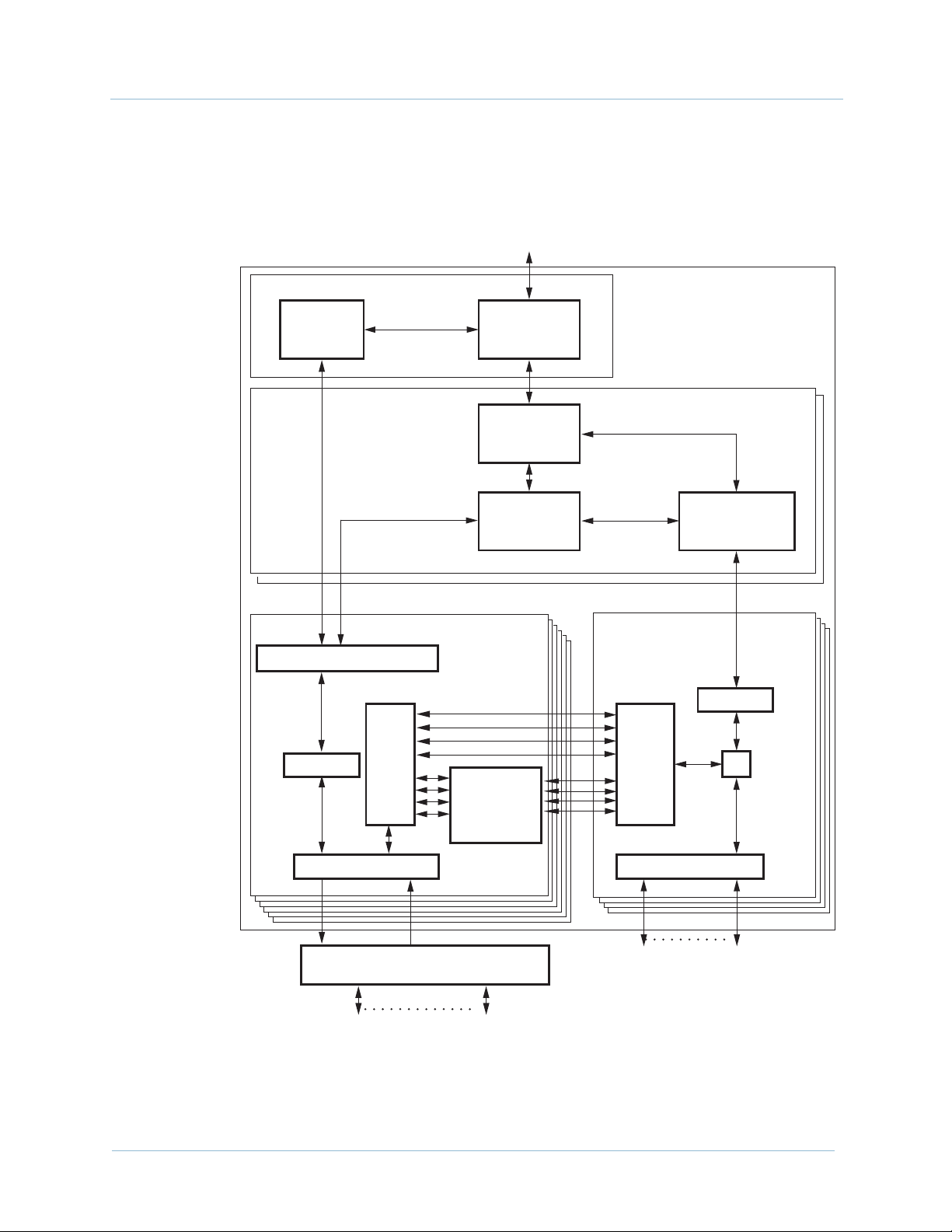

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Figure 2–3 illustrates this same functionality when providing

access to the PSTN via STS-1, using the STS-1 ECAC module.

LAN Connection To/From

Network Management System

MP Module

EOC

Process

CP

Modules

Q.931 (LAPD) Link Layer

Management

Process

Call

Processing

Engine

TMC

Processing

PSTN Interface

STS1 Modules

Voice Bus

CPX-1000

Shelf

IAD

Signalling and

Connectivity

Packet Interface

ATM Modules

Control

Control

STS-1 Interface

Voice Voice

PSTN Lines To/From

Class 5 Switch

Figure 2–3. CPX

Splitter

Echo

Cancellation

and

Compression

OC3 Port

ATM Lines To/From

Packet Switch

Functional Diagram (STS-1 Interface)

Voice/

Control

Splitter

0420

February 2003 2-5

Page 30

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

Management Processing

The Management Processor (MP) module is the administrative

CPU for the CPX shelf. It acts as a database for the shelf and as an

administrative interface for JetCraft, JetVision, and other

management interfaces. The MP supports:

Configuration, fault, and security management for the CPX

Configuration management, fault management, and remote

software upgrade of the IADs

High-performance, memory-resident database for persistent

configuration

Real-time performance and error statics

The Embedded Operations Channel (EOC) process on the MP

module handles the interface between the CPX shelf and the GR303 interface on the Class 5 switch. The EOC supports the

following set of management services to the switch using the T1

model and GR-303 protocol stack:

1. The EOC process receives the management requests over the

EOC connection to the switch.

2. It then interacts with the management process to complete

these requests.

3. The management process notifies the EOC process about

changes in the operating status of the CPX-managed objects.

4. The EOC process sends this information to the Class 5 switch.

Call Processing The Call Processor Engine manages the connections between the

CPX shelf and the IADs at subscriber premises.

The Call Processor Engine resides on the redundant Call Processor

(CP) modules that handle call processing, call-control signaling,

call setup, and call tear-down.

The Timeslot Management Channel (TMC) process on the CP

modules receive all call control signaling from both the Class 5

switch and the CP using the Q.921 (LAPD) data link protocol.

The IAD Signaling and Connectivity function manages

communication between the CPX and the IADs. The information

passed between the CPX and each IAD includes common channel

signaling, alarms and events, and software downloads.

PSTN Interface The PSTN interface connects the CPX to the Class 5 switch via T1

or STS-1 lines. The Port Controller inserts framing and supervision

signals into the TDM data stream. The PSTN interface then directs

2-6 February 2003

Page 31

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

all signaling to both the TMC process and the CP. The PSTN

interface controls all time slot mapping and CP functions.

The PSTN routes all voice timeslots over the voice bus to the

packet interface.

The Voice Processing function switches individual timeslots

between the TDM (T1/STS-1) ports and the voice bus. The Voice

Processing function maps all incoming and outgoing voice data

streams.

Packet Interface The packet interface physically connects the CPX shelf to the

packet network. The interface provides TDM data transport

services over ATM using standard ITU and ATM Forum-compliant

communications protocols.

This interface converts the information on the Bearer Bus to

standard ATM cells and transmits these cells on the packet

network. It also converts packet cells to voice timeslots. The

Voice/Control Splitter directs the ATM cells (which contain call

control and signaling) through the IAD Signaling and Connectivity

function to the Call Processor Engine.

The CPX supports up to 4,096 unique PVCs (each representing one

IAD). Each PVC (i.e., IAD) has a unique VPI and VCI assigned to

it. The CPX supports 256 VPIs in the range of 0 to 255. IADs can be

provisioned on any of these VPIs. The permissible range of VCIs

per VPI is 0 to 1023. The maximum number of VCIs per VPI can be

configured as one of five possible settings when the equipment is

initially configured. The possible settings are:

1,024 (default)

512

256

128

64

Selection of the maximum of VCIs is determined by the network

planner for what best fits the network topology.

In order to afford the maximum number of PVCs available from

the CPX, IADs can be organized into IAD Groups. Groups are

logical entities where IADs meet these criteria:

provisioned with differing VPIs but the same VCI

February 2003 2-7

Page 32

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

the remainder of the formula is the same for all IADs:

VPI

(1024/VCIs per VPI)

For example, consider three IADs with the VPI/VCI pairs and

where the maximum number of VCIs configured for the

equipment is 256:

A. 32, 100

B. 36, 100

C. 38, 100

1. All three have the same VCI.

2. The maximum number of VCIs possible (1,024) divided by

the number of VCIs configured (256) equals 4.

3. Pairs A and B yield a result with no remainder when their

VPIs (32 and 36, respectively) are divided by the resultant of

1024 divided by 256: 32/4 = 8 with a remainder of 0 and

36/4=9 with a remainder of 0. (Pair C yields a different

remainder: 38/4=9, remainder 2. Therefore, it is not in the

same group with A and B.)

Physical Description

A maximum 4,096 IADs can be assigned. However, only 63

simultaneously active calls through IAD unlocked ports are

allowed in any one IAD Group.

Note

IAD ports can be over-provisioned; however, only 63

can obtain dial tone at one time.

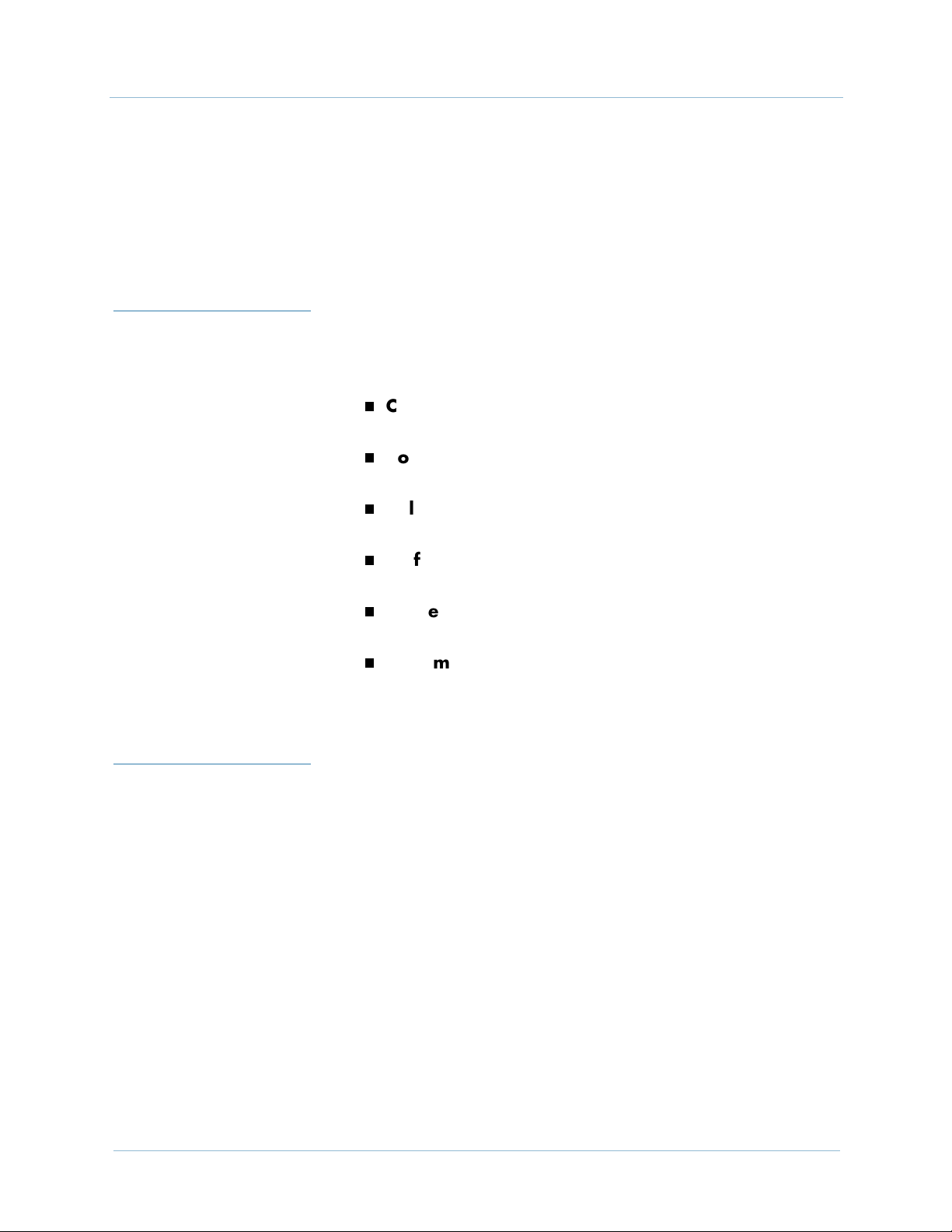

The CPX hardware consists of these items (Figure 2–4):

CPX shelf (Figure 2–4)

Summary alarm panel (detail, page 2-10)

Line modules—line cards and transition cards for T1 or

STS-1 (beginning on page 2-19)

STS-1 Splitter Assembly (when STS-1 equipped)

DC Power Supply Fan and Fan modules (page 2-37)

DC power distribution panel (page 2-39)

2-8 February 2003

Page 33

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Front

ALERT A

ALERT B

Summary Alarm Panel

ALERT C

D

IS

ABL

ED

D

ISA

B

LED

D

ISAB

LED

DIS

ABLED

D

ISA

B

LED

D

U

N

LO

CKE

D

UN

LOC

KE

D

U

NLO

C

KE

D

UN

LO

CK

ED

U

N

LO

CK

ED

UNL

ACT

AC

T

AC

T

1

A

CT

AC

2

T

3

4

5

M

IN

O

R

MA

JO

R

C

R

ITICA

IS

AB

L

ED

DISAB

LE

D

D

IS

AB

L

ED

O

CK

E

D

UN

LOC

KE

D

UNL

O

CK

A

CT

A

CT

AC

T

6

7

8

L

D

IS

AB

LED

DIS

AB

LED

DISA

B

LED

D

IS

AB

LE

D

D

IS

ABLED

DISA

BL

ED

U

N

LO

AC

T

ED

D

ISA

CK

ED

U

NLO

AC

9

BLE

D

C

KED

UN

LO

C

KE

D

U

NL

OC

KE

D

U

NLO

CK

ED

U

NL

O

CKE

D

U

N

LO

C

KE

T

10

D

A

CT

A

CT

A

C

T

A

CT

11

A

C

T

12

13

14

15

Module Cage

1

2

3

4

56

7

9

1

1

12

13

14

Power Supply/Fan

Assemblies

Rear

Module Cage Rear View

Power Distribution

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Plant Battery Terminals

Grounding Phillips Screws

Figure 2–4. CPX-1000 Front and Rear Views

0485

February 2003 2-9

Page 34

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

CPX-1000 Shelf Each CPX shelf is 12 RU (21 inches) high and 17 inches deep. The

shelf can mount in either a 19-inch Electronic Industries

Association (EIA) rack or a 23-inch rack.

The CPX shelf is a forced-air cooled Network Equipment Building

Standard (NEBS) Level 3-compliant platform with:

16-slot midplane

DC power input panel

Alarm panel

Three hot-swappable power supplies

The midplane is the interconnect for all 16 slots, power

distribution, and alarm signal distribution. The CPX midplane

accepts line cards, processing modules, and rear mounted

transition modules.

The power supplies (including integral fan assemblies) are located

below the card cage (accessible from the front of the shelf).

System Alarm Panel

Alarm

Panel

The CPX alarm panel is located on the top front of the shelf.

Indicators display the current operating status of the shelf and an

alarm connector outputs to remote Telco alarm equipment

(Figure 2–5). The CPX includes three types of indicators:

Slot Status indicators for all 16 slots

System Status indicator for system status

Telc o ala rms

Table 2–1 lists the description and status of each group.

System Status Indicators Telco Alarm Indicators

SYSTEM ALERTS TELCO

ALERT A ALERT B MINOR

DISABLED

DISABLED

UNLOCKED

ACT

1

DISABLED

UNLOCKED

UNLOCKED

ACT

ACT

23456

DISABLED

UNLOCKED

ACT

ALERT C

DISABLED

UNLOCKED

ACT

DISABLED

UNLOCKED

ACT

DISABLED

UNLOCKED

ACT

7

DISABLED

UNLOCKED

ACT

8

DISABLED

UNLOCKED

ACT

9

DISABLED

DISABLED

UNLOCKED

UNLOCKED

ACT

ACT

11 12 13 14

10

MAJOR CRITICAL

DISABLED

UNLOCKED

ACT

DISABLED

UNLOCKED

ACT

DISABLED

UNLOCKED

ACT

ALARM

DISABLED

UNLOCKED

ACT

15

Slot Status Indicators

Figure 2–5. System Alarm Panel

DISABLED

UNLOCKED

ACT

16

0233-01

2-10 February 2003

Page 35

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Table 2–1. Alarm Indicator Status and Description

Alarm Indicator Status Description

Slot Status Act

Unlocked

Disabled

System Status Alert A

Alert B

Alert C

Tel co Sta tu s Mi no r

Major

Critical

The three Telco alarms and a rack alarm are also routed through a

dry contact relay to the RJ-45 remote alarm connector.

The standard Telco alarm signals and rack alarm are available as an

output to remote alarm equipment (Table 2–2).

Table 2–2. Remote Alarm Connector

Module is in Active state (not Standby)

Module administrative state is Unlocked

Module operational state is Disabled

Not used

Not used

Not used

CPX minor alarm

CPX major alarm

CPX critical alarm

Pin Signal

1Critical Alarm

2 Critical Alarm Return

3Major Alarm

4Major Alarm Return

5Minor Alarm

6Minor Alarm Return

7 Rack Alarm (not used)

8 Rack Alarm Return (not used)

February 2003 2-11

Page 36

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

Line Modules with T1

Line Modules with STS-1

When configured with T1, the CPX may contain the following

module types:

Call Processor (CP) module (page 2-13)

Management Processor (MP) module (page 2-17)

Octal T1 module (page 2-19)

12-port T1 ECAC module (page 2-23)

ATM OC- 3 modul e ( page 2-32)

Echo Cancellation (EC) module (page 2-35)

– or –

Echo Cancellation and Compression module (ECAC)

(page 2-36)

The EC and ECAC modules are used only with the Octal T1

module. The 12-port T1 ECAC module provides onboard echo

cancellation and compression. See Chapter 3, Installing the CPX-

1000 for more information.

When configured with STS-1, the CPX contains the following

module types:

Call Processor module (page 2-13)

Management Processor module (page 2-17)

STS-1 module with Echo Cancellation (page 2-25)

STS-1 ECAC module with Echo Cancellation and

Compression (page 2-28)

ATM OC- 3 modul e ( page 2-32)

Echo Cancellation and Compression module (page 2-36)

The ECAC module is used only with the STS-1 module. The STS-1

ECAC module provides onboard echo cancellation and

compression. See Chapter 3, Installing the CPX-1000 for more

information.

2-12 February 2003

Page 37

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Call Processor Modules

The CPX shelf supports two CP modules in an active/standby

configuration, made up of two cards (Figure 2–6):

Call Processing card—contains a processor, plus volatile

and non-volatile RAM.

Hot Swap Controller (HSC) card—maintains each

module’s status, controls power and each module’s reset,

monitors and controls peripherals, including power/fan

modules, board and system indicators/alarms.

CP2

RJ-45

Ethernet Port

Receive

Link

Status

LEDs

Control

Processor

Card

PCI MEZZANINE CARD

LNK1ACT

2

LNK

ACT

10/100

ETHERNET

Hot Swap

Controller

Card

PWR

ERROR

Transmit

RST

ABT

BFL

CP Status LEDs

CPCI

USB 1COM 110/100 BASE T USB 0

CPU

PCI

Figure 2–6. Call Processor Module

0483

February 2003 2-13

Page 38

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

Table 2–3 lists the function of each control, port, and indicators.

Table 2–3. CP Module Controls, Indicators, and Ports

Card Controls, Indicators, and Ports Function

Call Processor (CP)

T64 1 ETHERNET

Connects to CP A module’s Ethernet

port

Link (green)

ACT (Amber)

T64 2 ETHERNET

Link is established

Ethernet circuit is in use

Connects to CP B module’s Ethernet

port

LINK (green)

ACT (Amber)

10/100 BASE T Connects to MP card

COM 1 Not used

RST Resets the CP module and may reset

Link is established

Ethernet circuit is in use

the shelf—DO NOT USE

ABT Not used

BFL Lights yellow when board fails

CPU Lights green when there is CPU

activity

CPCI Lights green when there is cPCI bus

activity

PCI Lights green when there is PCI bus

activity

USB 1 Not used

USB 2 Not used

Hot Swap Controller

PWR CP and HSC cards are powered

(HSC)

ERROR Lights when there is an HSC error

2-14 February 2003

Page 39

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

The CPX supports redundant CP modules (Figure 2–7).

LAN

MP

T1 EC ATM

T1

LAN

MP

CPX-1000

CP-BCP-A

AT M

CPX-1000

CP-BCP-A

Before

Switchover

(CP-A is Active,

CP-B is Standby)

After

Switchover

(CP-A is Standby,

CP-B is Active)

T1 EC ATM

T1

AT M

0242

Figure 2–7. Call Processor Redundancy

On power up, the primary CP (in the lower numbered slot

— slot 7) is the active CP and the secondary CP (in the

higher numbered slot — slot 9) is the standby CP.

The active CP module handles all call processing activity,

maintains all signaling, manages all IADs, captures statistics

and alarms, and monitors all hardware in the system. It

passes all this information to the management system.

The standby CP module mirrors the state information of

the active CP module (i.e., all of the activity on the active CP

module) and can take over at any time.

February 2003 2-15

Page 40

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

This architecture enables two types of CP module switchovers:

Automatic switchover—the system detects a problem

with the active CP module and performs a forced

switchover to the standby CP module. Mechanisms used to

detect problems with a CP module include:

— Loss of a CP-to-MP (Management Processor) module

heartbeat

— Loss of a CP-to-CP module heartbeat

— Failure of a CP to respond to an “are you alive” ping

request from the High Availability software

— Failure of the High Availability software to detect a ping

request from the ping component on a CP module

Administrative switchover—the network administrator

initiates a CP switchover using JetCraft or JetVision. A

forced switchover always goes through regardless of voice

traffic and active cells remain up.

Voice/Data Interruptionœ – possible

Calls that are in setup process are lost during a forced

switchover. Calls that are already established and carrying

voice traffic continue during a switchover.

Upon initiating a switchover, the previously active CP’s calls are

assumed by the new active CP. After the switchover, the old active

CP assumes the standby role (if all is well). CP switchovers do not

automatically revert back.

2-16 February 2003

Page 41

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Management Processor Module

The Management Processor (MP) module contains a processor,

volatile and non-volatile RAM, and an Ethernet interface for

administration.

The MP module is the administrative engine of a CPX shelf. It acts

as a database for the shelf and as the administrative interface for

JetCraft, JetVision and other management interfaces.

The MP module consists of two individual cards (Figure 2–8):

Management Processing card—processor and

interface connections for monitoring redundant CP

modules.

MP Transition card—I/O ports for connecting to the local

area network and other peripheral devices.

The MP module hosts the CPX Management Entity, which features

and supports:

Configuration, fault, and security management for the CPX

Configuration management, fault management, and remote

software upgrade of the IADs

High-performance, memory-resident database for

configurations persistence

Real-time performance and error statics

Two Ethernet ports are provided on the MP Card. Each port

provides one connection to the CP A and B modules, configured to

run at 100BaseTX Full Duplex. Each Ethernet port supports

10BaseT, 10BaseT Full Duplex, 100BaseTX, and 100BaseTX Full

Duplex media types. It can detect the network media type to which

it is connected, when the AutoDetect mode is selected

(recommended in most cases).

On the MP Transition card, there are also 2 Ethernet connections, 1

and 2. Ethernet 1 is enabled and Ethernet 2 is disabled. On the front

of the MP, there is also a third Ethernet connection marked

“Ethernet”, which is the same as Ethernet 1 on the back. The back

port is active, but the front Ethernet port is not active (unless there

is no MP Transition card present).

Table 2–4 lists the function of each control, port, and indicators.

February 2003 2-17

Page 42

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

Transmit

Link

Status

LEDs

Receive

Management

Processor

(Shelf Front)

ETHERNET

LNK1ACT

2

LNK

ACT

10/100

ETHERNET

ETHERNET

COM 1

V

I

P

M

C

2

P

M

C

1

D

E

O

C

O

M

2

ETHERNET 2

ETHERNET 1

P

I

M

1

Management

Processor

Transition

Card

(Shelf Rear)

RESET

PWR

EXT

0449

Figure 2–8. Management Processor Module

2-18 February 2003

Page 43

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Table 2–4. MP Module Controls, Indicators, and Ports

Card Controls, Indicators, and Ports Function

Management

Processor Card

(Front)

T64 1 ETHERNET

Link (green)

ACT (Amber)

T64 2 ETHERNET

LINK (green)

ACT (Amber)

ETHERNET

COM1

RESET

Connects to CP A module’s Ethernet

port

Link is established

Ethernet circuit is in use

Connects to CP B module’s Ethernet

port

Link is established

Ethernet circuit is in use

Connects to LAN or PC for access to

network management systems. Port

is only in service when no MP

transition card is present.

Connects to PC via serial cable for

network management via

HyperTerminal.

Press to restart processor

MP Transition Card

EXT

PWR

Keyboard/Mouse Port

Hot swap

MP and MP transition cards powered

Not used

(Rear)

VIDEO

COM 2 Connects to a modem for Paradyne

Not used

support only

ETHERNET 2

ETHERNET 1

Not used

Connects to LAN or PC for access to

network management systems.

February 2003 2-19

Page 44

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

PSTN Modules The CPX provides complete support of the GR-303 protocol,

including full GR-303 line concentration, all CLASS and calling

features, full EOC, TMC, and path protection switching.

The CPX supports eight T1 interface groups (IGs). Each T1 port is

independently assigned to an interface group, and each interface

group supports up to 28 T1 ports. The CPX also supports path

protection switching for the control channels in the GR-303

interface group.

T1 Load Sharing T1 load sharing is implemented by designing in excess capacity.

Overcapacity protection means the capacity of the T1 interface is

maintained when one of the following failures occurs even at the

busy hour call volume:

T1 module failure—oversize the capacity of the T1

interface for a fully operational system (Figure 2–9A) so that

the interface can still handle the busy hour call volume even

when one of the T1 modules has failed (Figure 2–9B).

T1 port failure—interface groups comprise T1 ports and

are arranged across T1 modules so that IGs are shared

among T1 modules (Figure 2–10). The shared arrangement

provides a backup T1 port to each T1 module should one of

the IG groups fail.

The illustrations below show how to implement primary and

secondary module pairs, and group the T1 ports in Interface

Groups across the cards, using Octal T1 cards for clarity.

When implementing PSTN using 12-port T1 ECAC modules, you

attach the RJ-21X cable from each 12-port T1 card to a patch panel

to split out each T1 port separately for connection as usual. T1

modules are paired as primary and secondary modules, and group

the T1 ports into Interface Groups across cards in the same manner.

Caution

Do not put primary and secondary DS1 links on the same T1

module. Doing so prevents new calls from being made if

one T1 module fails.

2-20 February 2003

Page 45

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

T1 Modules

(all operational)

A. Full Capacity

(all TDM modules operational)

Primary

Secondary

IG #1

IG #2

T1 Modules

(single failure)

B. Diminished Capacity

(one TDM module failed -

TDM interface must still be able

to handle busy hour call volume)

Primary

Secondary

IG #1

IG #2

0228

Figure 2–9. T1 Module Path Protection Switching

T1 Modules

IG #1

IG #2

0271

Figure 2–10. T1 Port Failure Protection

Octal T1 Module The Octal T1 module supports eight T1 interfaces to the Class 5

switch.

The T1 module consists of two separate cards (Figure 2–11):

February 2003 2-21

Page 46

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

T1 Processing card—processor that controls T1

processing.

T1 Transition card—provides eight T1 interfaces via RJ48C jacks (1 through 8), plus a Line Interface Unit (LIU) to

insert framing and supervision signals into the T1 data

stream.

Table 2–5 describes the controls, indicators, and ports of the Octal

T1 module ports and indicators.

FAILRUN

15

26

37

48

PORTS

Ethernet

DIAG

LINKACT

0161

Octal T1

T1 Transition Card

Figure 2–11. Octal T1 and Transition Cards

2-22 February 2003

Page 47

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Table 2–5. Octal T1 Module Controls, Indicators, and Ports

Cards Controls, Indicators, and Ports Function

Octal T1 RUN Lights green when processor is active

FAIL Lights if module fails

T1 Port Indicators (8) Lights if carrier fails or no carrier is

present on the indicated port

ACT Not used

LINK Not used

Ethernet Not used

DIAG Reserved for factory use only

T1 Transition

12-Port T1 ECAC Module

Power Both cards are powered

8 RJ-48C jacks For T1/DS1 cables to Class 5 switch

The 12-port T1 Echo Cancellation And Compression (ECAC)

module supports twelve T1 connections to the Class 5 switch via

an RJ-21X port, plus onboard echo cancellation and compression.

The 12-port T1 ECAC module consists of two separate cards

(Figure 2–11):

12-port T1 ECAC Processing card—performs T1

processing, plus onboard echo cancellation and

compression.

T1 Transition card—provides twelve T1 interfaces via the

RJ-21X port (attached to a patch panel), plus a Line Interface

Unit (LIU) that inserts framing and supervision signals into

the T1 data stream.

Table 2–6 describes the controls, indicators, and ports of the

12-port T1 ECAC module ports and indicators.

February 2003 2-23

Page 48

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

TDM-12E1/T1

12 PORT T1

RJ-21X

Port

12-port T1

ECAC Card

12-port

T1 ECAC

10 BT ETH

S

A

T

C

A

T

T

2

1

4

3

6

5

8

7

910

11 12

BITS

PCM TEST

RS-232

HOT

SWAP

0478

0479

Figure 2–12. 12-port T1 ECAC and T1 Transition Cards

2-24 February 2003

Page 49

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

Table 2–6. 12-port T1 ECAC Module Controls, Indicators, and Ports

Cards Controls, Indicators, and Ports Function

12-port T1 ECAC STAT Lights green when processor is active

ACT Lights green if module is in active

group

T1 Port Indicators (12) Lights red if carrier fails, or no carrier

is present on the indicated port

Hot Swap

12-port T1 Transition

RJ-21X PORT for 12 T1s

10 BT ETH RJ-48C port Unused

BITS RJ-48C port For onsite BITS clocking source

PCM TEST RJ-48C port Unused

RS-232

For T1 cable to Class 5 switch

Unused

STS-1 Module The STS-1 module consists of two cards (Figure 2–14) that supports

one STS-1 interface containing 672 DS0s (28 DS1s) in a single

physical interface. This interface may be connected directly to the

Class 5 Switch, or it may be routed through an external STS-1 mux

before being connected to the switch.

STS-1 Processing Card—processor that controls the 28

DS1s within an STS-1 circuit.

STS-1 Transition Card—provides the STS-1 interface via

Tx and Rx coaxial connections, plus a BITS timing interface.

The STS-1 card features on-board echo cancellation. If compression

is required, an Echo Cancellation and Compression card may be

added. Debug interfaces are also provided.

The STS-1 module increases the traffic capacity of the CPX over

what can otherwise be obtained by using T1 modules. When

configured for redundancy (1 + 1), these modules occupy shelf

slots 11-16 in pairs.

February 2003 2-25

Page 50

2. CPX-1000 Voice Services Platform Description 1000-A2-GN22-00

STS-1 Card STS-1 Transition Card

P

C

M

Status

TX

T

E

S

T

B

T

S

O

S

A

T

C

A

T

T

T

R

X

X

Activity

RX

RS-232

PROT

SWITCH

PCM Test Port

I

BITS Port

I

B

T

10BaseT

E

T

H

Ethernet Port

RS-232C Port

Protection

Switching Port

Hot Swap

Indicator

STS-1 Ports

TX

Hot

Swap

RX

0421

Figure 2–13. STS-1 Module

As with a T1-based configuration, the STS-1 configuration

provides complete support for the GR-303 protocol including full

GR-303 line concentration, CLASS and calling features, full EOC,

TMC and path protection switching.

2-26 February 2003

Page 51

1000-A2-GN22-00 2. CPX-1000 Voice Services Platform Description

A single CPX shelf supports eight interface groups (IGs) with each

port independently assigned to an interface group. Each interface

group supports up to 28 DS1 ports. The CPX also supports path

protection switching for the control channels in the GR-303

Interface group.

Table 2–7 describes the controls, indicators and ports of the STS-1

module ports and indicators.

Table 2–7. STS-1 Module Controls, Indicators, and Ports

Cards Controls, Indicators, and Ports Function

STS-1 STATus Lit solid green when fully initialized.

Flashing red indicates board error

ACTivity Lit green when card is active. Unlit

when card is in standby mode.

STS-1 Transition

TX

RX

Hot Swap

PCM Test Port

BITS

10BaseT Ethernet

RS-232C

Protection Switching

Lights solid green when transmitting

data. Lights flashing red when

SONET Far End Section receive

failure is indicated. Unlit when STS-1

port is not enabled.

Lights solid green when receiving