Page 1

COMSPHERE

3000 SERIES CARRIER

INSTALLATION MANUAL

Document No. 3000-A2-GA31-D0

July 1999

Page 2

COMSPHERE 3000 Series Carrier

COMSPHERE

3000 Series Carrier

Installation Manual

3000-A2-GA31-D0

14th Edition (July 1999)

Changes and enhancements to the product and to the information herein will be documented and issued as a new release.

Warranty, Sales, Service, and Training Information

Contact your local sales representative, service representative, or distributor directly for any help needed. For additional information

concerning warranty, sales, service, repair, installation, documentation, training, distributor locations, or Paradyne worldwide office

locations, use one of the following methods:

• Internet: Visit the Paradyne World Wide Web site at www.paradyne.com. (Be sure to register your warranty there. Select

Technical Support → Warranty Registration.)

• Telephone: Call our automated system to receive current information by fax or to speak with a company representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

Document Feedback

We welcome your comments and suggestions about this document. Please mail them to Technical Publications, Paradyne Corporation,

8545 126th Ave. N., Largo, FL 33773, or send e-mail to userdoc@paradyne.com. Include the number and title of this document in

your correspondence. Please include your name and phone number if you are willing to provide additional clarification.

Trademarks

All products and services mentioned herein are the trademarks, service marks, registered trademarks or registered service marks of their

respective owners.

Printed on recycled paper

COPYRIGHT 1999 Paradyne Corporation. All rights reserved.

This publication is protected by federal copyright law. No part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system,

or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties

without the express written permission of Paradyne Corporation, 8545 126th Avenue North, P.O. Box 2826, Largo, Florida 33779-2826.

Paradyne Corporation makes no representation or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability

or fitness for a particular purpose. Further, Paradyne Corporation reserves the right to revise this publication and to make changes from time to time in the contents

hereof without obligation of Paradyne Corporation to notify any person of such revision or changes.

A July 1999 3000-A2-GA31-D0

Page 3

!

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or included in the

manual.

2. This product is intended to be used with a 3-wire grounding type plug – a plug which has a

grounding pin. This is a safety feature. Equipment grounding is vital to ensure safe operation.

Do not defeat the purpose of the grounding type plug by modifying the plug or using an

adapter.

Prior to installation, use an outlet tester or a voltmeter to check the ac receptacle for the

presence of earth ground. If the receptacle is not properly grounded, the installation must not

continue until a qualified electrician has corrected the problem.

If a 3-wire grounding type power source is not available, consult a qualified electrician to

determine another method of grounding the equipment.

The dc configuration of this product is to be grounded by connecting an external wire

between the building ground and the equipment ground screw on the rear of the power supply

assembly. Consult a qualified electrician to ensure that the ground connections are connected.

3. Slots and openings in the cabinet are provided for ventilation. T o ensure reliable operation of

the product and to protect it from overheating, these slots and openings must not be blocked

or covered.

Important Information

4. Do not allow anything to rest on the power cord and do not locate the product where persons

will walk on the power cord.

5. Do not attempt to service this product yourself, as opening or removing covers may expose

you to dangerous high voltage points or other risks. Refer all servicing to qualified service

personnel.

6. General purpose cables are provided with this product. Special cables, which may be required

by the regulatory inspection authority for the installation site, are the responsibility of the

customer.

7. Install carriers while still empty. Start at the bottom of the cabinet and work up.

8. When installed in the final configuration, the product must comply with the applicable Safety

Standards and regulatory requirements of the country in which it is installed. If necessary,

consult with the appropriate regulatory agencies and inspection authorities to ensure

compliance.

9. A rare phenomenon can create a voltage potential between the earth grounds of two or more

buildings. If products installed in separate buildings are interconnected, the voltage potential

may cause a hazardous condition. Consult a qualified electrical consultant to determine

whether or not this phenomenon exists and, if necessary, implement corrective action prior to

interconnecting the products.

10. In addition, if the equipment is to be used with telecommunications circuits, take the

following precautions:

– Never install telephone wiring during a lightning storm.

– Never install telephone jacks in wet locations unless the jack is specifically designed for

wet locations.

– Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

– Use caution when installing or modifying telephone lines.

– Avoid using a telephone (other than a cordless type) during an electrical storm. There may

be a remote risk of electric shock from lightning.

– Do not use the telephone to report a gas leak in the vicinity of the leak.

B3000-A2-GA31-D0 July 1999

Page 4

COMSPHERE 3000 Series Carrier

Notices Regarding Telecommunications Equipment

THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPL Y WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE,

PURSUANT TO PART 15 OF THE FCC RULES. THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE

PROTECTION AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL

ENVIRONMENT. THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF

NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL

INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS

LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE

INTERFERENCE AT HIS OWN EXPENSE.

THE AUTHORITY TO OPERATE THIS EQUIPMENT IS CONDITIONED BY THE REQUIREMENTS THAT NO

MODIFICATIONS WILL BE MADE T O THE EQUIPMENT UNLESS THE CHANGES OR MODIFICA TIONS ARE EXPRESSL Y

APPROVED BY PARADYNE.

Canada

Notice to Users of the Canadian Public Switched Telephone Network

The Canadian Department of Communications label identifies certified equipment. This

certification means that the equipment meets certain telecommunications network protective,

operational and safety requirements. The Department does not guarantee the equipment will

operate to the user’s satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. In some cases, the company’s inside wiring associated with a

single line individual service may be extended by means of a certified connector assembly

(telephone extension cord). The customer should be aware that compliance with the above

conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility

designated by the supplier. Any repairs or alterations made by the user to this equipment, or

equipment malfunctions, may give the telecommunications company cause to request the user to

disconnect the equipment.

C July 1999 3000-A2-GA31-D0

Page 5

United Kingdom

Important Information

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone line and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

CAUTION

Users should not attempt to make such connections

themselves, but should contact the appropriate electric

inspection authority, or electrician, as appropriate.

The Load Number for this equipment is listed on a label on the device. The Load Number (LN)

assigned to each terminal device denotes the percentage of the total load to be connected to a

telephone loop which is used by the device to prevent overloading. The termination on a loop may

consist of any combination of devices subject only to the requirement that the total of the Load

Numbers of all devices does not exceed 100.

Ringer Equivalence Number

The Ringer Equivalence Number (REN) is a customer guide indicating approximately the

maximum number of items of apparatus that should be connected simultaneously to the telephone

line. The sum of the RENs should not exceed four. This value includes any BT-provided

instrument which may be assumed to have a REN of 1 unless marked otherwise. The REN of this

apparatus is 1.

Connection to Leased Lines

If any other apparatus, including cable or wiring, is connected between the apparatus and the point

of connection to any speechband circuit, then all that other apparatus shall comply with the

following:

1. The overall transmission characteristics of all that other apparatus shall be such as to

2. All that other apparatus shall comprise only:

introduce no material effect upon the electrical conditions presented to one another by the

apparatus and the speechband circuit; and

(i) apparatus approved for the purpose of connection between the apparatus and a

speechband circuit; and

(ii) cable or wiring complying with a code of practice for the installation of equipment

covered by this part of BS 6328 or such other requirements as may be applicable.

No d.c. interaction is intended between the apparatus and the telephone network.

D3000-A2-GA31-D0 July 1999

Page 6

COMSPHERE 3000 Series Carrier

All European Countries

Safety Notice

Interconnection circuits between a modem and any other equipment should be such that the

equipment continues to comply with the requirements of EN41003 for TNV (T elephone Network

Voltage) circuits and EN60950 for SELV (Safety Extra Low Voltage) circuits after making

connection between circuits.

Japan

Notices

This equipment is classified in the 1st Class category. When used in a residential

area or in an adjacent area thereto, radio interference may be caused to radios and

TV receivers, etc. VCCI-1*

Restrictions

Due to JATE (Japan Approvals Institute for Telecommunications Equipment) regulations, only

3 attempts to dial a number are permitted in a 3-minute period. If a fourth attempt is made to dial

the same number, the modem returns the ERROR return code. This restriction applies to the

number dialed from the command line or from a directory. An occurrence of the restriction is

canceled when a different number is dialed, or when 3 minutes have elapsed.

Equipment W arranty and Support

If you experience trouble with this equipment, please contact your sales or service representative

(as appropriate) for repair or warranty information. If the product needs to be returned to the

company service center for repair, contact them directly for return instructions using one of the

following methods:

• Internet: V isit the Paradyne World Wide Web site at www.paradyne.com.

• Telephone: Call our automated call system to receive current information via fax or to speak

with a company representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

If the trouble is causing harm to the telephone network, the telephone company may request that

you remove the equipment from the network until the problem is resolved.

E July 1999 3000-A2-GA31-D0

Page 7

Table of Contents

Preface

About This Document v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Document Contents v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Document Ordering Information v. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Introduction

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Components 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Cabinet Unpacking and Setup

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presetup Inspection 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Cabinet 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Setup 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Installing the Carrier and Assembly Components

Overview 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Carrier Equipment 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Carrier Equipment 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preinstallation Inspection 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Considerations 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Mounting Brackets 3-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Installation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDCP Installation 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Transformer Unit Installation 3-8. . . . . . . . . . . . . . . . . . . . . . . . .

Fan Module Installation 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SDCP 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speaker Panel Installation 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SGRD/FGRD Connection 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Output Connection 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Modem Control Interface 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDU Installation 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NMS Connection 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i3000-A2-GA31-D0 July 1999

Page 8

COMSPHERE 3000 Series Carrier

4. T1 Auxiliary Backplane

5. Connecting to the Network

T1 Auxiliary Backplane Installation 4-1. . . . . . . . . . . . . . . . . . . . . . . . .

T1 CSU and T1 DSU/CSU Network Interface 4-5. . . . . . . . . . . . . . . . .

T1 CSU DTE Port 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T1 DSU/CSU DTE Ports 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP LAN Adapter Connectivity 4-5. . . . . . . . . . . . . . . . . . . . . . . . . .

T1 COM Port Connection to an External PC 4-6. . . . . . . . . . . . . . . . . . .

Overview 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Arrangements in the Carrier 5-1. . . . . . . . . . . . . . . . . . . . . . . . .

Interface Connectors 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Interface Module (NIM) Connectors 5-4. . . . . . . . . . . . . . . . .

NIM Installation 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Circuit Card Installation

Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preinstallation Inspection 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modular Circuit Card Interface Connectors 6-2. . . . . . . . . . . . . . . . . . .

Modular Circuit Card Installation 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Filler Panel Installation 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ferrite Choke Installation 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Pin Assignments

Overview A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital/Lease Network Connections A-1. . . . . . . . . . . . . . . . . . . . . . . . .

NIM Interface Connections A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NMS Interface Connections A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50-Pin Modular Plugs A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Backplane Connectors A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-Lead Control Interface A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii July 1999 3000-A2-GA31-D0

Page 9

B. T1 CSU and T1 DSU/CSU Interface Connectors

Overview B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T1 Auxiliary Backplane Connectors B-1. . . . . . . . . . . . . . . . . . . . . . . . .

T1 Network Interface Connector B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSX-1 Port DTE Interface B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COM Port Interface B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Port Interfaces B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Channel Extension Cable B-10. . . . . . . . . . . . . . . . . . . . . . . . .

External Clock Connector B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Technical Specifications

D. Equipment List

Document Ordering Information D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment List D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Glossary

Index

iii3000-A2-GA31-D0 July 1999

Page 10

COMSPHERE 3000 Series Carrier

This page intentionally left blank.

iv July 1999 3000-A2-GA31-D0

Page 11

Preface

About This Document

This document contains installation information for the

COMSPHERE 3000 Series Carrier and is designed to be

used with:

• Data Service Units (DSUs): Models 3511, 3551,

3611, and 3616

• Data Backup Modules (DBMs): Model 3611

• Dial/lease modems: Models 3811, 381 1Plus (3981),

3821Plus, 3911, and 3921Plus

• T1 Channel Service Units (CSUs): Model 3151

• T1 DSU/CSUs: Model 3161

Refer to the appropriate device manual for specific unit

installation and operation information. It is assumed that

you are familiar with the functional operation of data

equipment, digital network services, DSUs, and dial/lease

modems.

Document Contents

Chapter 1 provides descriptive information about the

COMSPHERE 3000 Series Carrier and optional features.

Chapter 2 lists the steps for cabinet unpacking, setup,

and installation.

Chapter 3 provides descriptive information and

procedures for installing the:

• Shared Diagnostic Control Panel (SDCP)

• Power supply

• Fan module

• Speaker panel

• Network Interface Module (NIM)

• Shared Diagnostic Unit (SDU)

• DSU

• Dial/lease modem

• Ferrite chokes.

Chapter 4 includes T1 CSU and T1 DSU/CSU

auxiliary backplane installation procedures.

Chapter 5 presents details regarding connecting to the

network.

Chapter 6 provides circuit card installation procedures.

Appendix A provides pin assignments.

Appendix B includes T1 CSU and T1 DSU/CSU

interface connections.

Appendix C presents technical specifications.

Appendix D includes related documents and an

equipment list.

The Glossary provides definitions for acronyms and

product-specific terms used in this manual.

Document Ordering

Information

For a list of related documents, see T able D-1 in

Appendix D, Equipment List.

v3000-A2-GA31-D0 July 1999

Page 12

COMSPHERE 3000 Series Carrier

vi July 1999 3000-A2-GA31-D0

Page 13

Introduction

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Components 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Overview

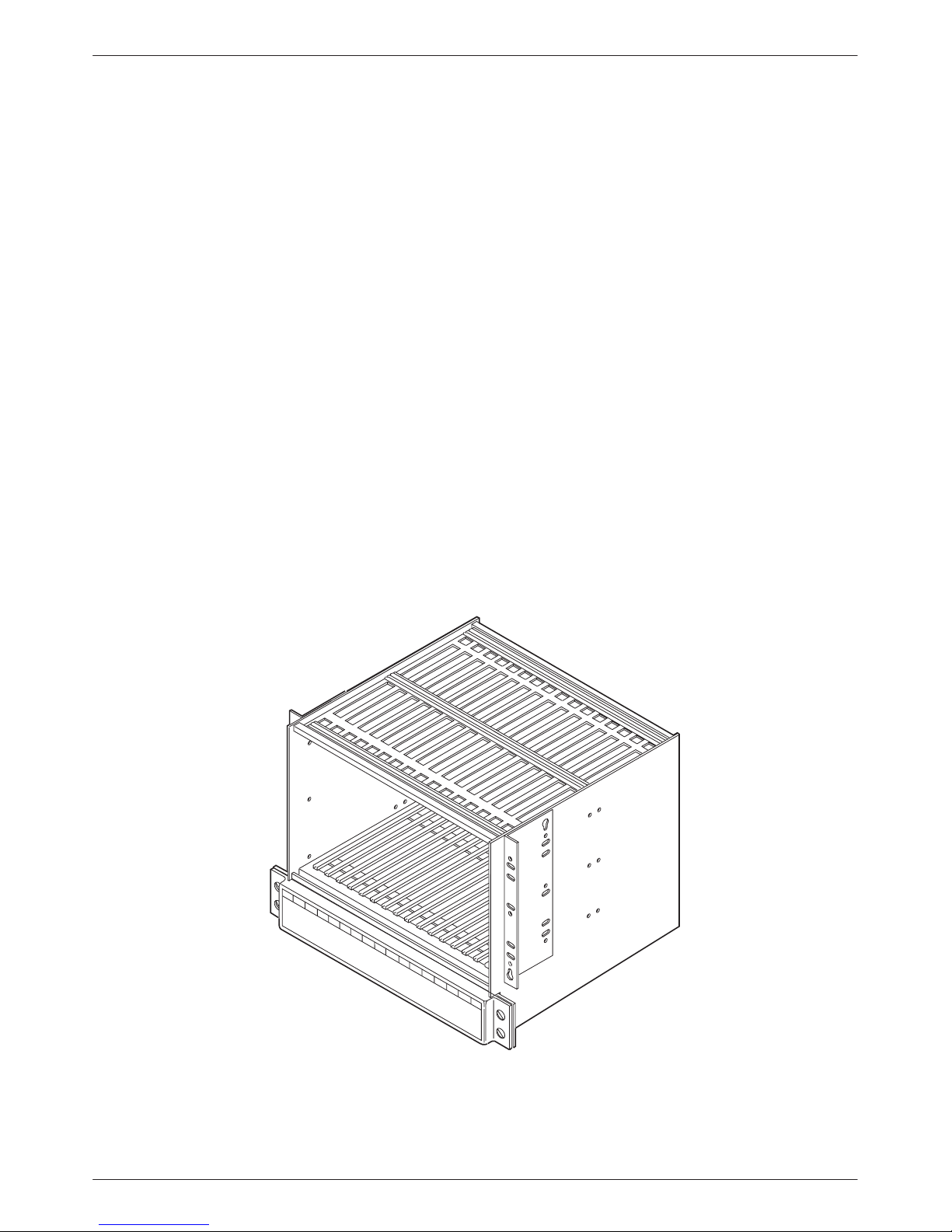

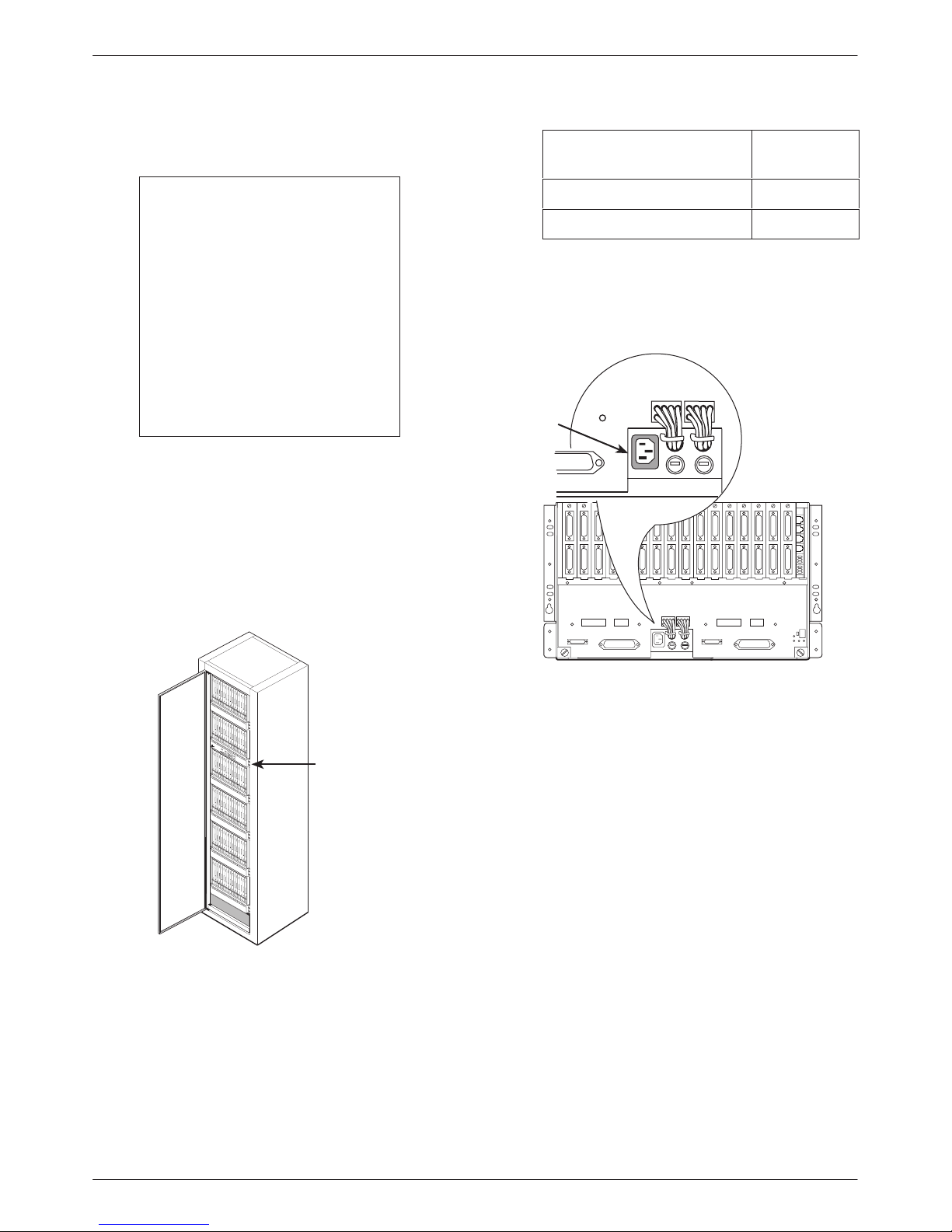

The COMSPHERE 3000 Series Carrier assembly,

Figure 1-1, supports high-density mounting of the

following Paradyne products in a central-site

environment:

• Channel Service Units (T1 CSUs)

• Data Service Units/Channel Service Units

(T1 DSU/CSUs)

• Data Service Units (DSUs)

• Dial Backup Modules (DBMs)

• Time Division Multiplexer (TDM)

• Multichannel Multipoint Multiplexer (MCMP)

• Dial/Lease Modems

Figure 1-1. COMSPHERE 3000 Series Carrier

496-12291-04

1-13000-A2-GA31-D0 July 1999

Page 14

COMSPHERE 3000 Series Carrier

Carrier Components

The carrier assembly is shipped with a power

transformer unit. Refer to Equipment List (T able D-2) in

Appendix D for details. Other carrier components are

ordered separately:

• Power transformer unit. Provides low voltage

ac power to the carrier’s internal power distribution

bus.

• –48 Vdc Central Office (CO) Power Unit. For

carriers designed to operate from a –48 Vdc power

unit. Consists of a single dc power module with a

fan and operates in Basic mode. An optional second

power module is available for the CO Power Unit.

• Fan module. Provides forced air cooling to

dissipate heat generated within the carrier. It is

recommended that fully configured carriers and

cabinets have fan modules installed to extend the

life of the equipment.

• Shared Diagnostic Control Panel (SDCP).

Required for initial installation and testing of the

devices and their options. In conjunction with the

SDU, allows up to eight carriers to be managed

from one control panel.

• Network Interface Modules (NIMs). Provides the

dial, ISDN, or switched 56 kbps digital service

interface for DSUs, DBMs, and dial/lease modems.

• Shared Diagnostic Unit (SDU). Provides the

required interface that daisy chains carriers together

for network management system (NMS) and/or

SDCP control. In a cabinet configuration,

connectivity between the units in the individual

slots allows control of compatible units in the

carrier. The control can be a single NMS interface,

a single SDCP, or both.

• T1 auxiliary backplane(s). Provides an interface

between a T1 digital network and customer

provided equipment (CPE).

• Rear connector plate(s). Provides the interface

between DSUs, DBMs, and dial/lease modems and

the DTEs.

• Connector module(s). Provides the interface

between DSU/TDMs or DSU/MCMPs and the

DTEs.

• Filler panel(s). Prevents accidental contact with

backplane connectors. Required for unfilled slots in

the carrier.

• Speaker panel. Provides audio monitoring of

dial/lease modems. Allows the user to hear audio

signals (ringing, busy signal) during normal

operation.

1-2 July 1999 3000-A2-GA31-D0

Page 15

Cabinet Unpacking and Setup

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presetup Inspection 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Cabinet 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Setup 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leveling the Cabinet 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reversing the Cabinet Doors 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Overview

Paradyne provides a COMSPHERE 72-inch high

cabinet for mounting the COMSPHERE 3000 Series

Carriers. Up to six carriers can be mounted into a single

cabinet. Alternatively, you can mount carriers into other

commercial EIA standard 19-inch and 23-inch wide

cabinets.

When shipped:

• Cabinets are packed in cardboard shipping

containers secured to wooden pallets.

• The shipping containers are bound with plastic

straps.

• Inside the shipping container, the cabinet itself is

strapped to the wooden pallet with plastic straps.

There is minimal clearance between the cabinet and the

shipping container, and the cabinet frame is not wrapped

in packing material.

Presetup Inspection

Before opening the shipping container, inspect it for

signs of damage. Specific signs to check for are:

• Major tears or puncture holes on the sides of the

container

• Splits in the seams

• Corner damage or any additional signs of the

container having been dropped

Unpacking the Cabinet

" Procedure

1. Use a utility knife to cut all plastic straps

surrounding the shipping container.

2. Cut around the base of the container to unpack the

cabinet. Do not cut along the container’s seams.

Doing so may damage the cabinet because of the

lack of clearance. Lift the container off the

cabinet.

NOTE

If your ceilings do not provide

enough clearance to lift the

container, tip the container and

cabinet sideways. You will need

another person to help you tip

the container and cabinet, and

pull the container off.

3. Once the container is off, cut the plastic straps

holding the cabinet frame to the pallet.

4. Remove the packing material at the base of the

cabinet and use a large dolly to lift and move the

cabinet to its desired location.

If the shipping container does show signs of damage,

report this immediately to your shipping representative

and also to your service representative.

2-13000-A2-GA31-D0 July 1999

Page 16

COMSPHERE 3000 Series Carrier

Cabinet Setup

The cabinet is shipped with the following:

• Doors (two)

• Mounting rails

• T wo factory-installed ac power strips

Cabinet setup requirements consist of:

• Leveling the cabinet once it is in place at your site

and, if needed

• Reversing the cabinet doors

Leveling the Cabinet

There are four adjustable leveling feet at the bottom of

the cabinet; these screw up or down, enabling you to

adjust the cabinet to a level position on the floor.

The required tools are a level and an adjustable

crescent wrench.

" Procedure

Reversing the Cabinet Doors

The cabinet’s front and back hinged doors are installed

on the cabinet frame at the factory to open left-to-right. T o

reverse the doors, use the pre-drilled holes on the opposite

side of the frame.

" Procedure

1. Supporting the door, use a flat-blade screwdriver

to remove the screws from the bottom hinge,

detaching the hinge from the cabinet frame.

2. Supporting the door, remove the screws from the

top hinge, detaching the hinge and the door from

the cabinet frame.

3. Flip the door end-over-end.

4. Holding the door in position on the opposite side,

align the hinge holes with the predrilled holes on

the cabinet frame provided for this purpose. Then,

use the same screws to reattach the door by its

hinges to the cabinet.

1. Place the level against the front door and adjust

the leveling feet until the cabinet stands level

vertically from front to rear.

2. Place the level against one cabinet side and adjust

the leveling feet until the cabinet stands level

vertically from side to side.

496-14890

2-2 July 1999 3000-A2-GA31-D0

Page 17

Installing the Carrier and

Assembly Components

Overview 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Carrier Equipment 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Carrier Equipment 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preinstallation Inspection 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Considerations 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning the Mounting Brackets 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Installation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a Carrier With Threaded Screw Holes 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a Carrier Without Threaded Screw Holes 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDCP Installation 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SDCP Ribbon Cable 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Transformer Unit Installation 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Module Installation 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SDCP 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the SDCP 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speaker Panel Installation 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Speaker Panel 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SGRD/FGRD Connection 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Output Connection 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Modem Control Interface 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDU Installation 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDU Modular Jacks and DIP Switches 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDU CC/DC Operation 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SDU 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDU Front Panel Connection 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the SDU 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NMS Connection 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the NMS 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3-13000-A2-GA31-D0 July 1999

Page 18

COMSPHERE 3000 Series Carrier

Overview

The COMSPHERE 3000 Series Carrier is a metal

enclosure that has seventeen slots for installing circuit

cards. The Shared Diagnostic Unit (SDU) uses Slot 0; the

other sixteen slots are for devices. This number is reduced

by one slot for:

• Dial/lease multiport modems, which occupy two

slots.

• DSU with MUX card. The MUX card for TDM or

MCMP is physically attached to a DSU, and the

two cards occupy two slots.

• Digital bridge applications, where each DBM-X

also occupies a separate slot.

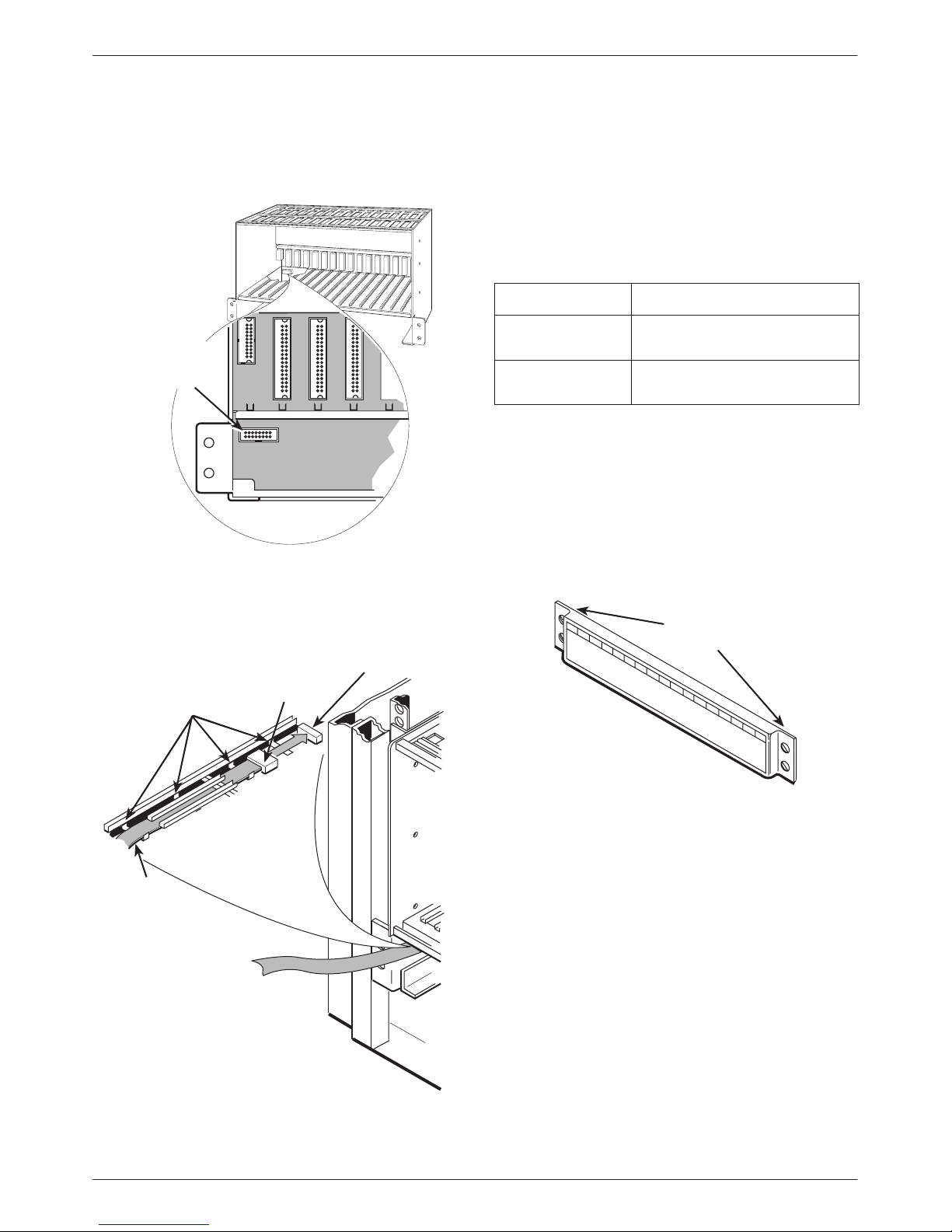

Standard Carrier Equipment

Each carrier is shipped with the items listed below

bundled in a plastic bag:

• Six cable ties

• T wo fuses (spares)

• Four #10-32 mounting screws

• Four cabinet #12-24 mounting screws and four

speed nuts for use with other cabinets

• One jumper wire for the frame ground/signal

ground

In addition, the carrier is shipped with a power cord

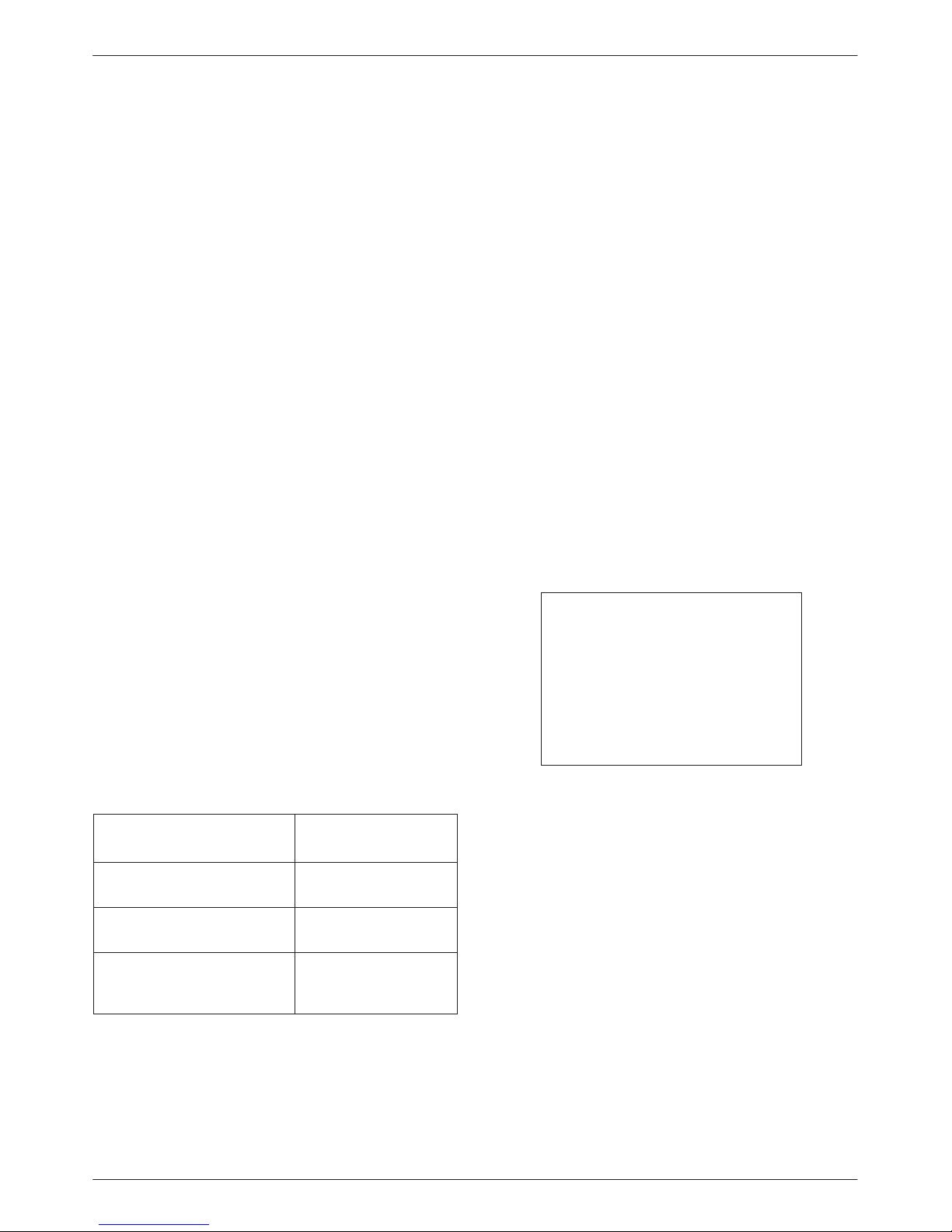

and power transformer unit. Figure 3-1 shows a fully

loaded carrier.

3000 Series

Carrier

Slot Numbers

SDU 1

Shared Diagnostic

21516

3000

Control Panel

(SDCP)

SDU

Slot 0

Circuit

Card

Captive

Screws

Brackets Set for

19-Inch Cabinet

AC Power

Transformer

Unit

Fan Module

(optional)

496-13596-05

Figure 3-1. 3000 Series Carrier and Components

3-2 July 1999 3000-A2-GA31-D0

Page 19

Installing the Carrier and Assembly Components

Other Carrier Equipment

You are responsible for ordering/supplying the

following equipment:

• COMSPHERE 72-inch high cabinet, or other EIA

standard 19- or 23-inch wide cabinet

• Fan module(s), if needed

• Shared Diagnostic Control Panel (SDCP)

• Shared Diagnostic Unit (SDU), if needed

• DTE interface assembly, if needed

• Alarm buzzer or light

• One or two Network Interface Modules (NIMs), if

needed

• Connector modules

• Speaker panel, if needed

• One network interface cable for each of the DSUs

or modems

• TDM, MCMP, and/or digital bridge interface

cables, if needed

• Connecting cables and cords

• Rear connector plates for optional pre-mounting;

modular devices are packaged with rear connector

plates. You can also order rear connector plates

separately

• Power transformer unit. Ensure that the unit has

not been damaged, possibly causing a short circuit

of internal components. Tighten any screws that

may have worked loose.

• Shared Diagnostic Control Panel (SDCP).

Inspect the SDCP and its cable.

• Shared Diagnostic Unit (SDU). Check the SDU

for physical damage. Ensure that the circuit card

and faceplate are not damaged.

• Speaker panel. Check the speaker, speaker jack,

and panel for physical damage.

If any of your equipment shows signs of shipping

damage, report this immediately to your shipping and

service representatives.

Installation Considerations

Before installing your carrier, make sure:

• Your installation site is well-ventilated, clean, and

free of environmental extremes.

• You have 2 to 3 feet clearance at the front and rear

of the cabinet for installing the following:

— DTE cables

— Fan module

— Network interface connectors

• Filler panels for empty slots

• T1 auxiliary backplane(s), if needed

• Devices, including DSUs and CSUs

• Applicable manuals. Appendix D contains a related

documents list and equipment list.

Preinstallation Inspection

When your equipment arrives, perform an inspection:

• Carrier. Remove the carrier from its shipping

container and check for physical damage (refer to

Chapter 2).

• Fan module. Check for physical damage, such as

broken blades. Spin fan blades manually to test for

damage.

— Rear connector plates or connector modules

— SDCP (optional)

You will need the following tools:

• A large Phillips screwdriver to install a:

— Carrier in the cabinet

— Power transformer unit under the carrier

• A small, flat-blade screwdriver for:

— Removing and replacing the cover plate or

SDCP

— Installing the 50-pin cable connectors

3-33000-A2-GA31-D0 July 1999

Page 20

COMSPHERE 3000 Series Carrier

Positioning the Mounting

Brackets

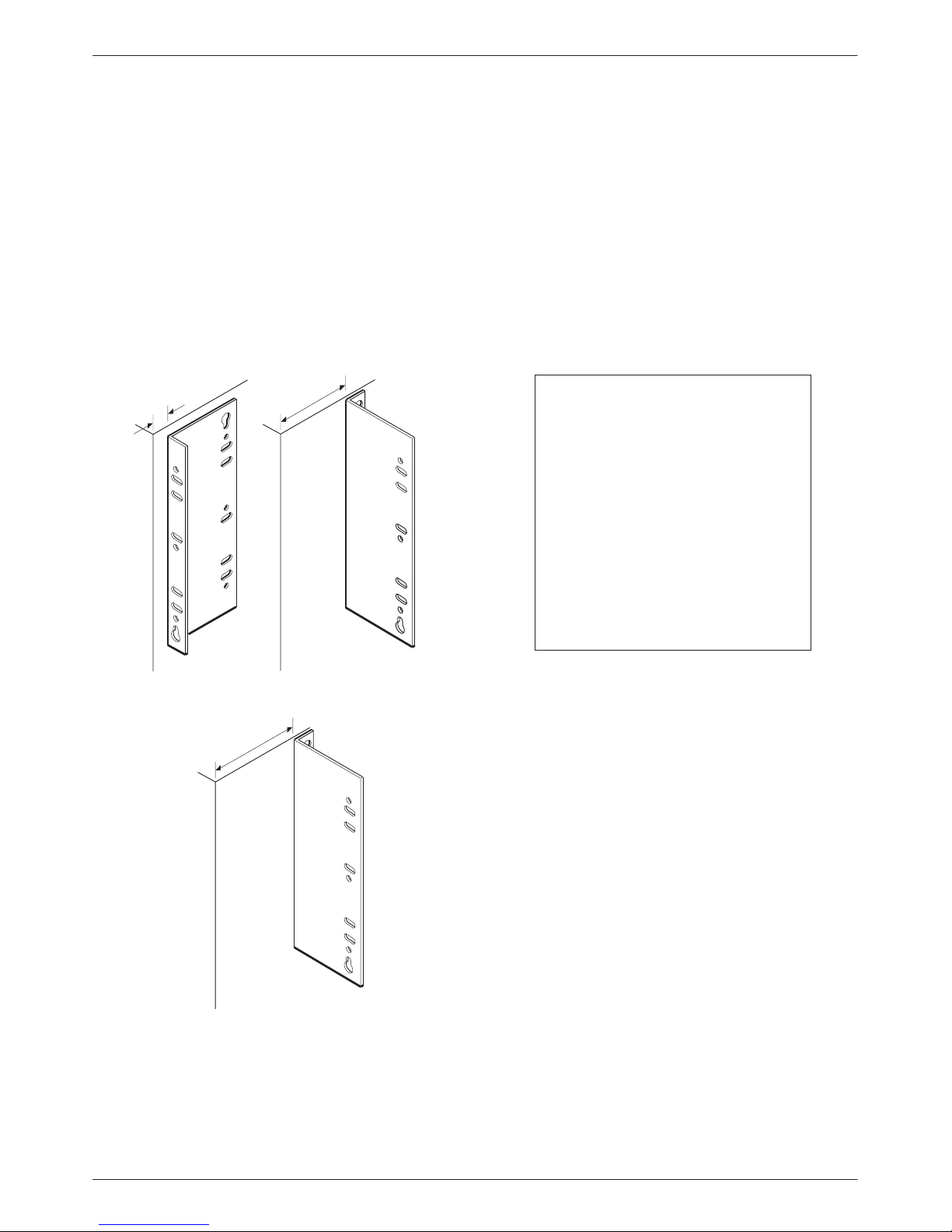

The carrier has reversible mounting brackets, which

allow installation in cabinets that are either 19 inches or

23 inches wide. The brackets:

• Are initially positioned for installation into a

19-inch cabinet.

• Must be reversed on the carrier for installation into

an EIA standard 23-inch wide cabinet.

.67"

6.00"

T o reverse the mounting brackets:

" Procedure

1. Remove the screws that attach them to the sides of

the carrier.

2. Reverse the brackets and replace the screws.

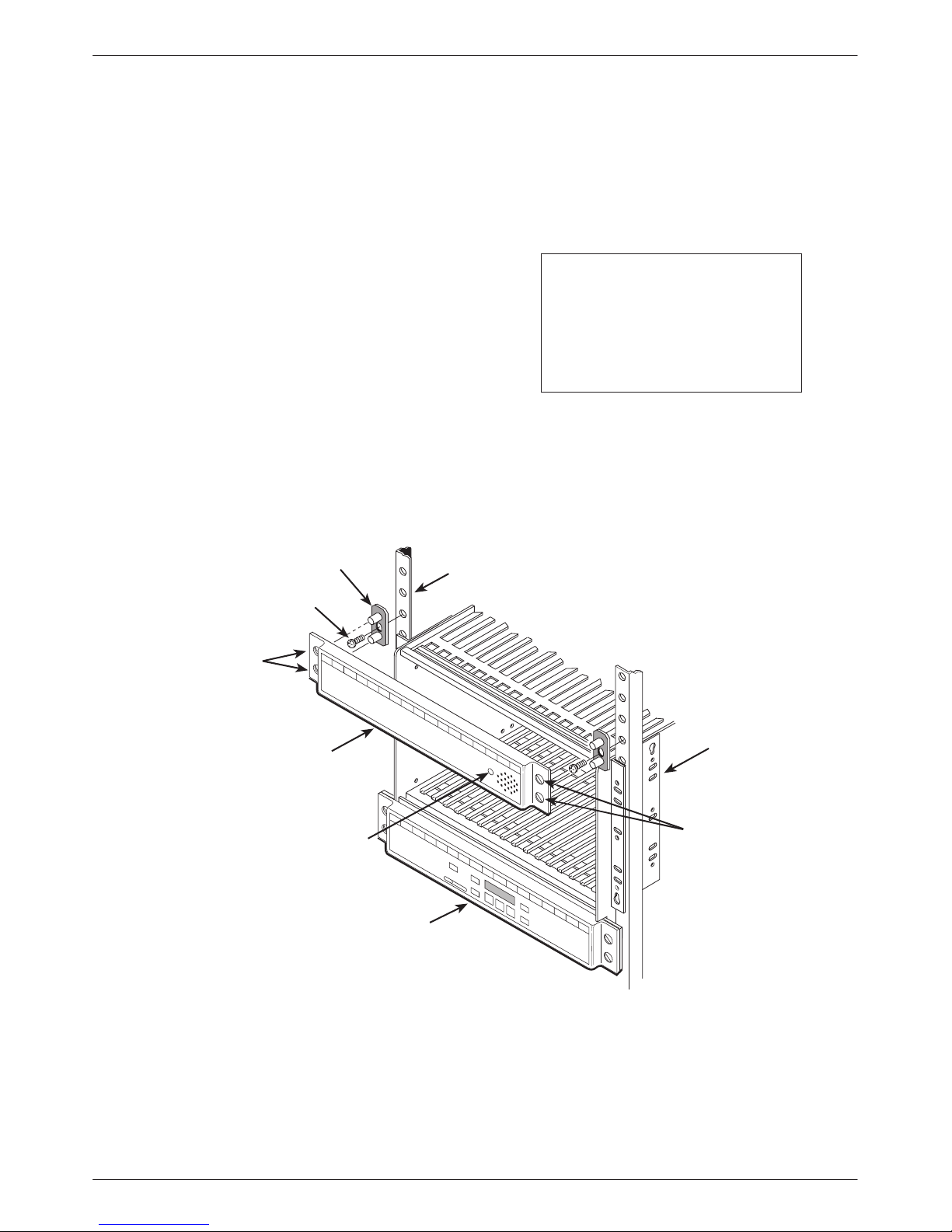

Carrier Installation

HANDLING PRECAUTIONS

FOR

ST ATIC-SENSITIVE DEVICES

This product is designed to protect

sensitive components from damage

due to electrostatic discharge (ESD)

during normal operation. When

performing installation procedures,

however, take proper static control

precautions to prevent damage to

equipment. If you are not sure of the

proper static control precautions,

contact your nearest sales or service

representative.

19-Inch Cabinet 23-Inch Cabinet A

6.52"

23-Inch Cabinet B

496-12293-04

One COMSPHERE 72-inch cabinet can hold up to six

carriers; however, a cabinet does not need to be fully

populated. Follow these rules during installation.

• Install carriers from the bottom of the cabinet and

work up. This provides the following:

— Proper alignment for subsequent carriers.

— Easier installation since the carriers can be

lowered onto the mounting screws from above.

— Convenient connection of the DTE interface.

— Proper cabinet balance. Bottom-up installation

keeps the cabinet from becoming top heavy.

• Install empty carriers in the cabinet.

3-4 July 1999 3000-A2-GA31-D0

Page 21

Installing the Carrier and Assembly Components

Installing a Carrier With

Threaded Screw Holes

" Procedure

1. Place the carrier against the front rails at the

bottom of the cabinet to determine where the two

lower machine screws should be installed. Then,

set the carrier aside.

496-14763-01

The carrier cabinet may or may not have threaded

screw holes.

If the cabinet . . .

Has threaded

screw holes

Does not have

threaded screw

holes

Use the short Phillips-head screws

included in the hardware package

and follow the procedure in

Installing a Carrier With Threaded

Screw Holes

Use the self-retaining nuts and the

longer Phillips-head screws

included in the hardware package

and follow the procedure in

Installing a Carrier Without

Threaded Screw Holes

.

3-6

Then . . .

in the next section

Install

First

on page

Front Rail

7th Hole

Front of 19-inch Carrier Cabinet

.

2. Use a screwdriver to install the two screws loosely

enough to allow the bracket keyholes to drop

Mounting

Bracket

Keyhole

496-12294-02

under the screw heads during installation.

3. Place the carrier against the front rails of the

cabinet again, allowing the installed machine

screws to pass through the keyholes.

4. Lower the carrier into place, allowing the

keyholes to slide under the screw heads.

NOTE

Installing the carrier may be a

two-person task. One person

holds the carrier in proper

alignment, and one person

installs the screws.

This positions the carrier correctly for installation

of the two remaining machine screws and helps

support its weight during installation of these

screws.

5. Install the two remaining machine screws at the

top corners of the carrier and tighten all four.

6. Install the next carrier in the same manner (from

the bottom up) using Steps 1 through 5.

3-53000-A2-GA31-D0 July 1999

Page 22

COMSPHERE 3000 Series Carrier

Installing a Carrier Without

Threaded Screw Holes

" Procedure

1. Position the carrier in the cabinet and determine

the front rail holes to be used.

2. Slip a self-retaining nut (Speed Nut) onto each rail

hole selected and align the hole of the nut with the

hole in the rail.

3. Line the carrier mounting bracket up with the

self-retaining nut, and turn the screw into the

carrier mounting bracket and the nut. Start all four

screws, then tighten all four until each screw head

is flush with the carrier and the carrier is securely

mounted in the cabinet.

Front Rail

7th Hole

Mounting

Bracket

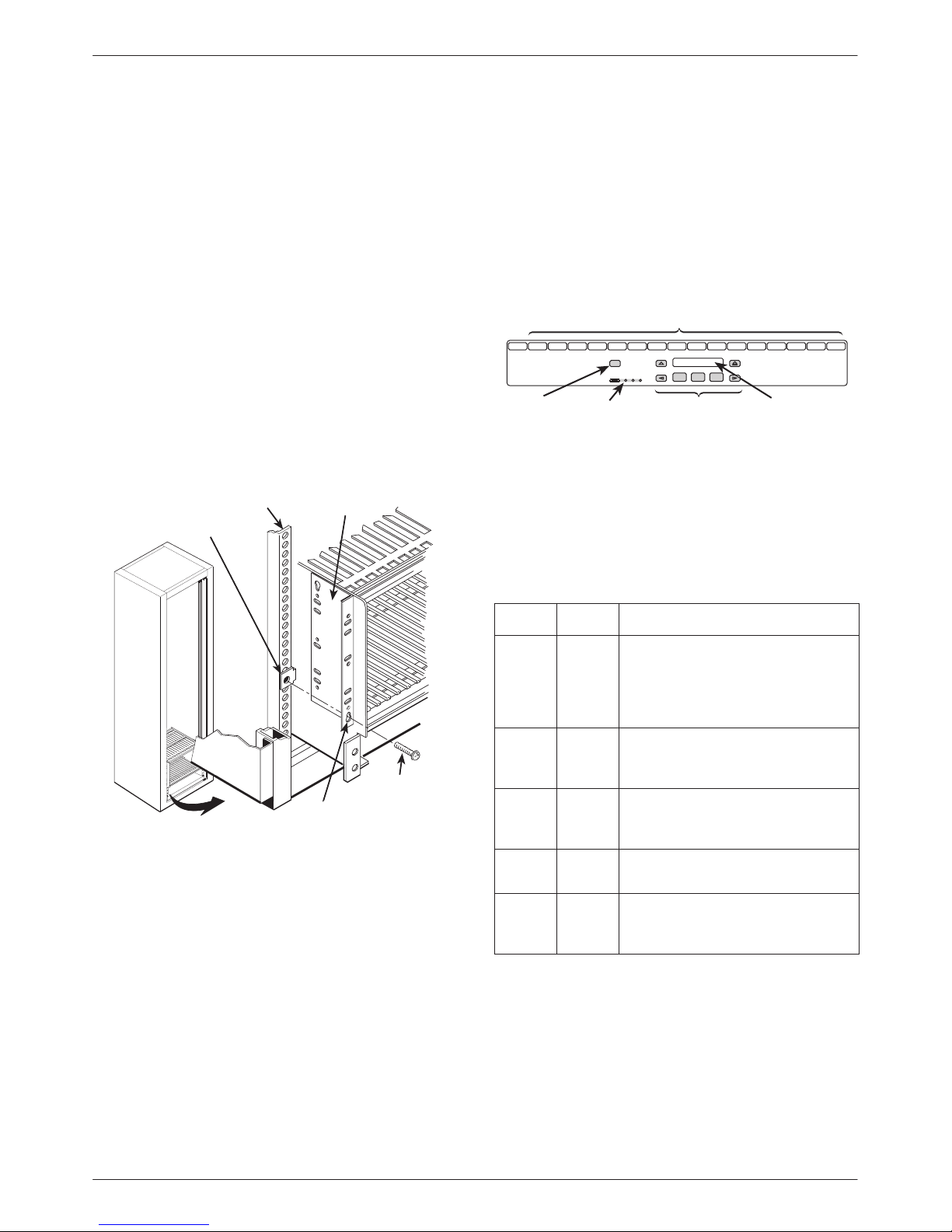

SDCP Installation

An SDCP can control up to eight carriers containing:

• Up to 128 compatible T1 CSUs, T1 DSU/CSUs,

DSUs, or dial/lease modems, or

• A reduced number when TDMs, MCMPs, DBMs,

or dial/lease multiport modems are also installed.

Carrier Slots 1–16

SDU12345678910111213141516

Select

OK Alarm BckUpTest EC

Select

Key

Status

Indicators

If your configuration has two or more carriers, an SDU

is also required in each carrier to connect the SDCP

interface from carrier to carrier. Refer to the SDU

Installation section, page 3-16.

The following table defines the SDCP status indicators.

F1 F2 F3

Keypad

COMSPHERE 3000

LCD

Display

496-12348a-03

Speed Nut

Screw

Keyhole

Front of 19-inch Carrier Cabinet

496-12294a-02

4. Install the next carrier in the same manner (from

the bottom up) using Steps 1 through 3.

Label

Color Description

OK green Health and status indicator for the

selected device. Mirrors the OK

indicator on the faceplate, except for

dial/lease modems, where OK

replaces the power indicator.

Alarm red Health and status indicator for the

selected device. Mirrors the Alrm

indicator.

BckUp yellow Mirrors the Dial indicator on the

selected device. Not used for

T1 CSUs and T1 DSU/CSUs.

Test yellow Mirrors the Test indicator on the

selected device.

EC green Error Correction indicator for dial/

lease modems. Not applicable for

other devices.

3-6 July 1999 3000-A2-GA31-D0

Page 23

Installing the Carrier and Assembly Components

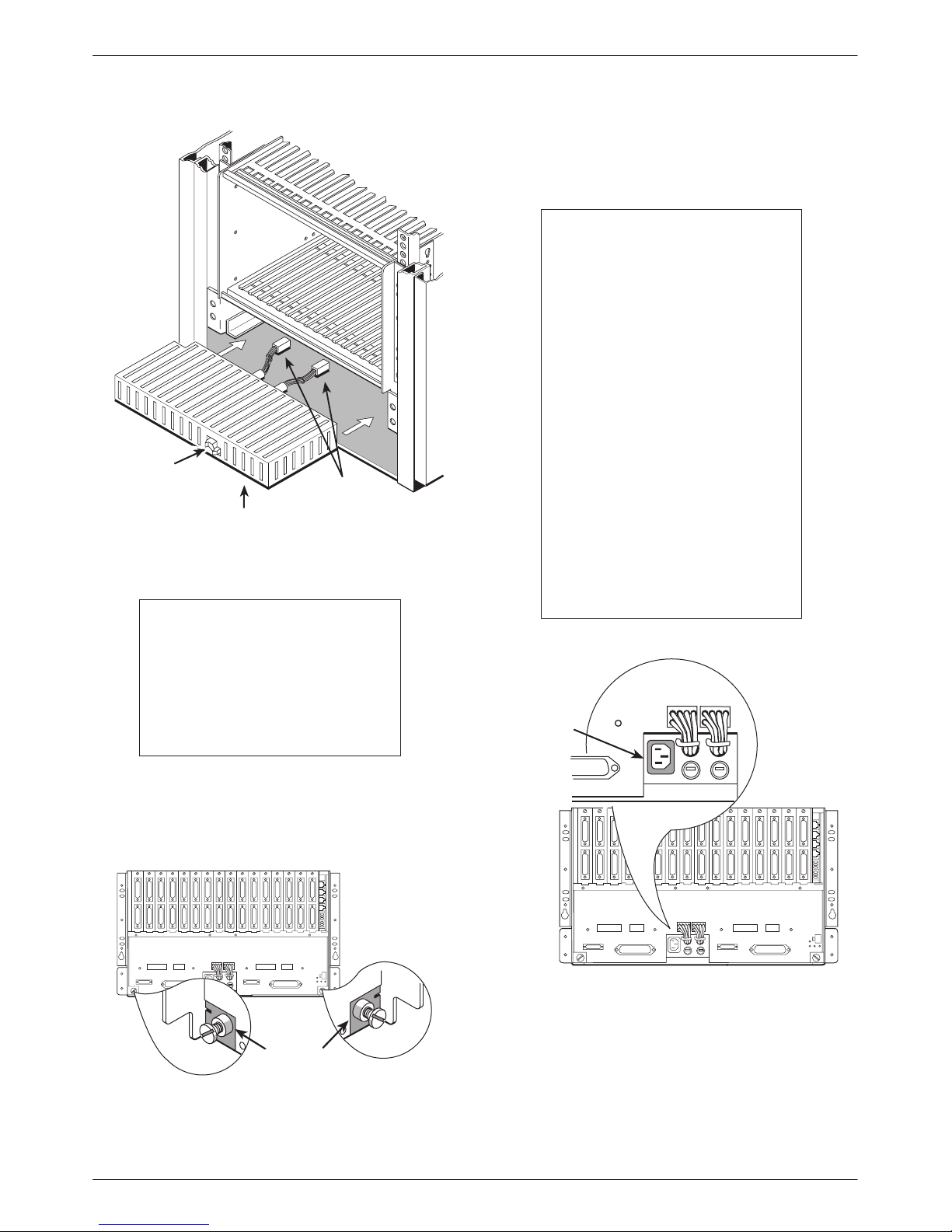

Installing the SDCP Ribbon Cable

NOTE

The SDCP ribbon cable must be

connected to the carrier

backplane before the power

transformer unit and optional fan

module are installed.

Removing power causes loss of

service to all circuit card slots in

the carrier. It is recommended

that you do not perform this

procedure during peak operating

hours.

" Procedure

1. Select the carrier on which to install the SDCP.

The SDCP can be installed on any carrier in a

cabinet. The most convenient height for the SDCP

is at eye level (the second or third carrier from the

top of the cabinet).

If the ac power

transformer unit is . . .

Then go

to . . .

Installed Step 3

Not installed Step 6

3. At the rear of the carrier, disconnect the ac power

cord from the carrier. Unscrew the two captive

screws securing the power transformer unit.

AC

Receptacle

P26 P25 P24 P23

J2 P22 J1 P21

P20 P19

P20 P19

P

a

r

a

d

y

n

e

SDCP

Installed at

Eye Level

496-14892

2. Remove the carrier’s cover plate by unscrewing

the four captive screws.

496-14804-01

4. Disconnect the two power connectors (P19 and

P20) by pressing the catch on the bottom of each

and pull it free of its mating connector.

5. At the front of the carrier, slide the power

transformer unit straight out and set aside. You

may need another person standing at the rear to

feed the transformer output wires through the

opening in the backplane.

3-73000-A2-GA31-D0 July 1999

Page 24

COMSPHERE 3000 Series Carrier

6. Attach either end of the 16-pin ribbon cable

(delivered with the SDCP) to the P18 ribbon cable

connector.

P18-SDCP

Ribbon Cable

Connector

P17

P18

496-14921

7. Feed the ribbon cable through the four built-in

retainer clips provided in the carrier.

Backplane

Connector

Built-in

Retainer

Clips

SDCP

Ribbon

Cable

Connector

Install the power transformer unit. Refer to the next

section, Power Transformer Unit Installation.

Power Transformer Unit

Installation

If you are . . . Then . . .

Installing an SDCP

in the carrier

Not installing an

SDCP

The carrier obtains low voltage ac power from the

power transformer unit mounted at the bottom of the

carrier.

" Procedure

1. At the front of the carrier, remove the cover plate

by unscrewing the four captive screws.

Go to the

section, page 3-6.

Continue with the following

procedure.

SDCP Installation

Captive

Screws

Cover Plate

496-14889-01

2. Place the power transformer unit on the flanges at

the bottom of the carrier. Slide the power

SDCP

Ribbon Cable

transformer unit into place against the rear rail of

the enclosure, guiding the transformer output

wires through the opening in the backplane.

495-14810

3-8 July 1999 3000-A2-GA31-D0

Page 25

Fan Module

Power

Connector

Power

Transformer

Unit

NOTE

Transformer

Output

Wires and

Connectors

495-14803

Installing the Carrier and Assembly Components

4. Plug the power transformer output connectors into

the P19 and P20 connectors on the backplane and

latch them.

CAUTION

The power cord contains a

3-wire grounding-type plug

which has a grounding pin.

This is a safety feature.

Grounding of the carrier is

vital to ensure safe operation.

Do not defeat the purpose of

the grounding plug by

modifying it or by using an

adapter.

Prior to installation, use an

outlet tester or voltmeter to

check the ac receptacle for

earth ground. If the power

source does not provide a

ground connection, consult an

electrician to determine

another method of grounding

the carrier before proceeding

with the installation.

The power transformer unit

output wires are terminated with

plastic connectors. The power

transformer unit must be installed

with the output wires protruding

through the backplane carrier.

3. At the rear of the carrier, use the larger

screwdriver to tighten the two captive screws that

fasten the power transformer unit to the carrier.

P26 P25 P24 P23

J2 P22 J1 P21

P20 P19

Captive

Screws

496-14894

AC

Receptacle

P26 P25 P24 P23

J2 P22 J1 P21

P20 P19

P20 P19

496-14804-01

5. Plug the appropriate end of the power cord into

the ac receptacle on the carrier.

6. Attach the ferrite choke on the ac power

transformer cord as close as possible to the

connector.

3-93000-A2-GA31-D0 July 1999

Page 26

COMSPHERE 3000 Series Carrier

7. Plug the other end of the power cord into one of

the convenience outlets inside the cabinet, or to an

external ac outlet.

If you are not installing a fan module or SDCP, return

to the front of the carrier and replace the cover plate. Use

the smaller screwdriver to tighten the four captive screws.

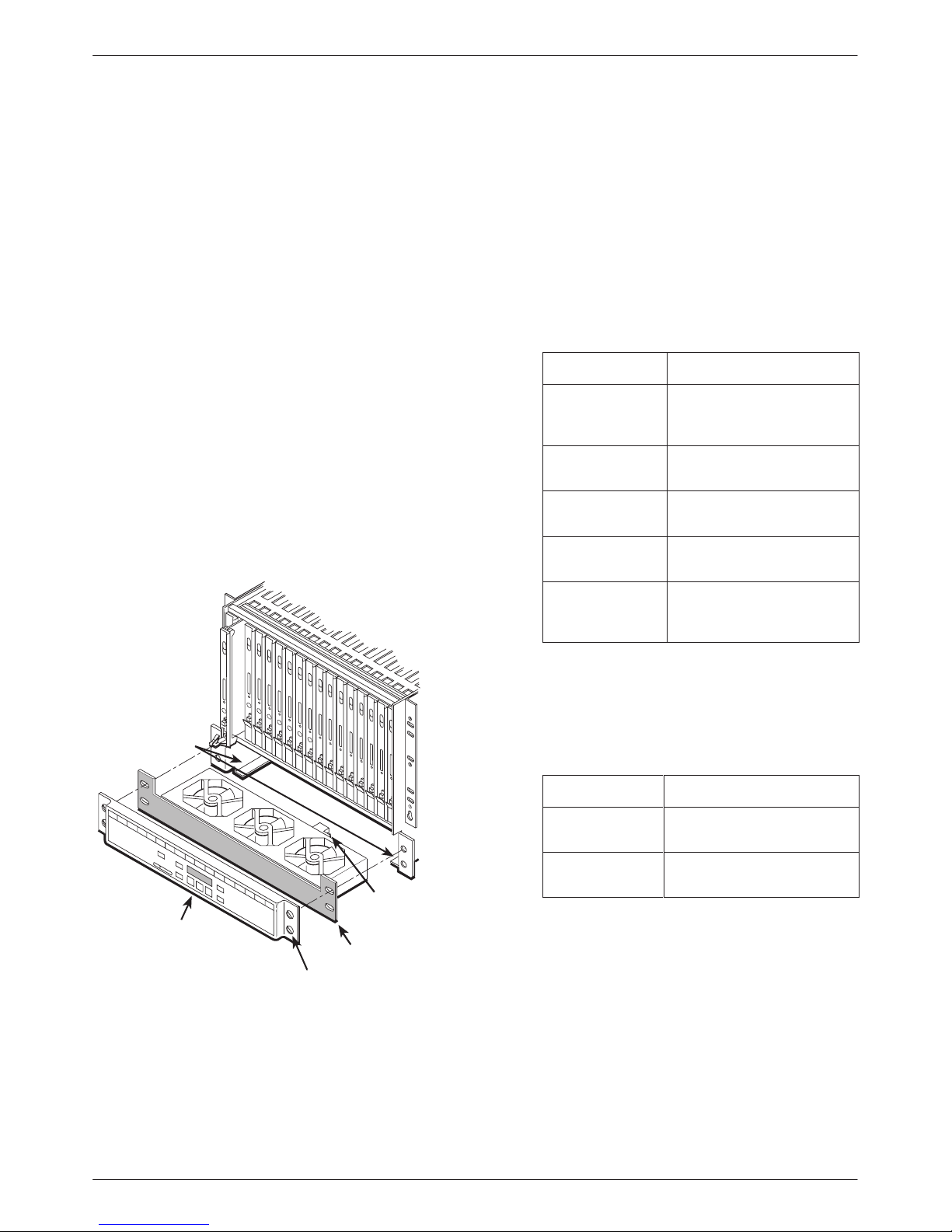

Fan Module Installation

Install a fan module for installations where the ambient

temperature is likely to be near the upper limit of the

acceptable range (see T able 3-1) to provide forced air

cooling.

The power transformer unit must be installed before

the fan module.

" Procedure

1. If the carrier has been installed, remove the cover

plate by loosening the four captive screws. Set the

cover plate aside.

2. Place the fan module on the flanges at the bottom

of the carrier with the power connector facing the

mating power connector on the installed power

transformer unit.

3. Slide the fan module into the carrier until the

power connectors engage firmly.

4. Once the carrier is connected to ac power, the fans

in the fan module will begin blowing. If they do

not, check potential reasons in the following table.

If the . . .

Fan module does

not operate

Fuses are blown Replace and determine the

Fuses are okay Install the fan module in

Fan module still

does not work

Check the fuses on the back

of the power transformer

unit.

cause of the overload.

another powered carrier.

Replace the fan module.

Then . . .

Flanges

Cover Plate

(SDCP Shown)

Captive

Screws

Power

Connector

Fan

Module

496-14809-02

Fan module

works in a

different carrier

Replace the power

transformer unit of the first

carrier.

5. If you are not installing an SDCP or a speaker

panel, reposition the cover plate over the installed

fan module. Use a small screwdriver to engage

and tighten the four captive screws.

To install . . .

An SDCP

A speaker panel

Go to the . . .

SDCP Installation

page 3-6.

Speaker Panel Installation

section on page 3-12.

section on

3-10 July 1999 3000-A2-GA31-D0

Page 27

Installing the Carrier and Assembly Components

Circuit Card

1 fan module er carrier

Table 3-1

Fan Module Cooling Requirements

Ambient

T emperature

Range

39_ – 86_F

(4_ – 30_C)

Circuit Card

Configuration

DSUs without

DBMs and CSUs

Dial/lease

modems and

DSUs with DBM

1

1–2 3 4 5–6

No fan modules

No fan

modules

2

1 fan module

(place in middle

carrier)

Number of Carriers

2 fan modules (place in

bottom carrier and

second from top)

T1 DSU/CSUs 21 fan module per carrier or 1 fan module per two carriers

(placed in upper carrier)

86_– 122_F

T1 DSU/CSUs

(30_– 50_C)

1

Installing the TDM or MCMP option has no effect on this table.

2

Use the strictest cooling requirements when there is a mixture of units installed.

3

Allow 1.75″ (IU) spacing between carriers if more than 3 carriers are required.

Installing the SDCP

After the SDCP ribbon cable, power transformer unit,

2

1 fan module per carrier (Limit of 3 carriers in a cabinet at temperatures above 40_C

or 104_F)

3

2. Secure the panel to the front of the carrier with its

four captive screws, using the same screw holes

that held the blank cover plate.

and optional fan module are installed:

The display on the SDCP should light up immediately.

" Procedure

Continue with the following section, Testing the SDCP. If

the SDCP does not light up:

1. Attach the connector on the free end of the ribbon

cable to the back of the SDCP.

• Check the ac power connections at the rear of the

carrier and the two fuses at the rear of the power

transformer unit.

1 fan module (place in

second carrier from top)

1 fan module per carrier

SDCP

Ribbon

Cable

P

a

r

a

dyn

e

Shared Diagnostic

Control Panel

(SDCP)

• Verify that both ends of the SDCP ribbon cable are

seated securely in their connectors.

• If the SDCP still does not light up, call your service

representative.

495-14811

3-113000-A2-GA31-D0 July 1999

Page 28

COMSPHERE 3000 Series Carrier

Testing the SDCP

Once devices have been installed (see Chapters 5

and 6), use the following procedure to test the SDCP by

entering device addresses.

" Procedure

1. From the front panel, press Select.

2. Enter a valid carrier and slot address. Refer to the

SDU Installation section, page 3-16, for

information on carrier addresses.

— For T1 CSUs and T1 DSU/CSUs, the green

OK indicator flashes and should be the only

OK indicator flashing in the cabinet.

— For all devices except T1 CSUs and

T1 DSU/CSUs, the yellow Front Panel

indicator on the selected device should light

and should be the only Front Panel indicator

lit in the cabinet.

3. Press Select again. The SDCP display should

show the:

T o install the speaker panel to the carrier:

" Procedure

1. Remove the cover plate.

2. Secure the speaker panel to the front of the carrier

using its four captive screws.

3. Use the same screw holes that held the cover plate

in place. Go to the Testing the Speaker Panel

section, page 3-13.

T o install the speaker panel to the cabinet’s front

mounting rails:

" Procedure

1. Determine if you want to mount the speaker panel

above or below the carrier. See Figure 3-2.

2. Fasten one of the speaker panel mounting brackets

to a front mounting rail with a #10 Phillips

screwdriver (supplied).

— Last menu displayed.

— Top-level menu on the selected device, in the

case of a new installation.

Speaker Panel Installation

You can install an optional speaker panel to provide

audio monitoring of any dial/lease modem installed in a

cabinet containing COMSPHERE 3000 Series Carriers.

If there is . . .

Only one carrier in the cabinet

and no SDCP installed

More than one carrier in the

cabinet

Only one carrier in the cabinet

and an SDCP is mounted on

the carrier

Mount the speaker

panel . . .

Directly to the carrier in

place of the cover plate.

On a carrier that does

not contain the SDCP.

To the front rail.

NOTE

If your cabinet has unthreaded

rails, first attach a speed nut to

the rail hole you intend to use.

Then, fasten a bracket to the

mounting rail using a supplied

#12 screw (the longer

Phillips-head screw).

3. Verify the position by holding the panel against

the bracket and aligning the panel’s captive screws

with the bracket’s screw post. For appearance, you

can adjust the bracket’s position to eliminate space

between the speaker panel and carrier.

4. Fasten the second speaker panel bracket to the

other mounting rail to match the first bracket’s

position.

5. Once the brackets are installed, use a small

flathead screwdriver to tighten the speaker panel’s

four captive screws to the mounting brackets.

3-12 July 1999 3000-A2-GA31-D0

Page 29

Installing the Carrier and Assembly Components

Testing the Speaker Panel

Once the speaker panel is installed, verify that the

speaker is working.

" Procedure

1. Connect one end of the supplied coiled cable into

the speaker panel’s jack labeled Spkr and the

other end into any dial/lease modem’s speaker

jack labeled Spkr.

2. If the cabinet has an SDCP, press Select and enter

a valid carrier and slot address for the modem

used in Step 1. The Front Panel status indicator

on the dial/lease modem’s faceplate lights,

indicating that it is connected to the SDCP.

3. Using the SDCP, scroll the menu until the Control

branch appears on the LCD.

Speaker Panel

Mounting

Bracket

#10

Phillips-head

Screw

4. Access the Control branch and select the Speaker

function.

5. Select a speaker setting of Low, Medium, or High

and place a call to listen to the dialing sequence.

NOTE

This is only a temporary setting.

Upon a reset, the modem returns

to its default setting of Medium.

To change the default setting,

refer to the device’s manual.

If you do not have an SDCP installed and are using

AT commands, use the ATM command to turn the speaker

ON and the ATL command to adjust the speaker volume.

Front Rail

Captive

Screws

Modem Speaker

Panel

Speaker Jack

Carrier

Mounting

Bracket

Captive

Screws

SDCP

496-13184-05

Figure 3-2. Speaker Panel for Dial/Lease Modems

3-133000-A2-GA31-D0 July 1999

Page 30

COMSPHERE 3000 Series Carrier

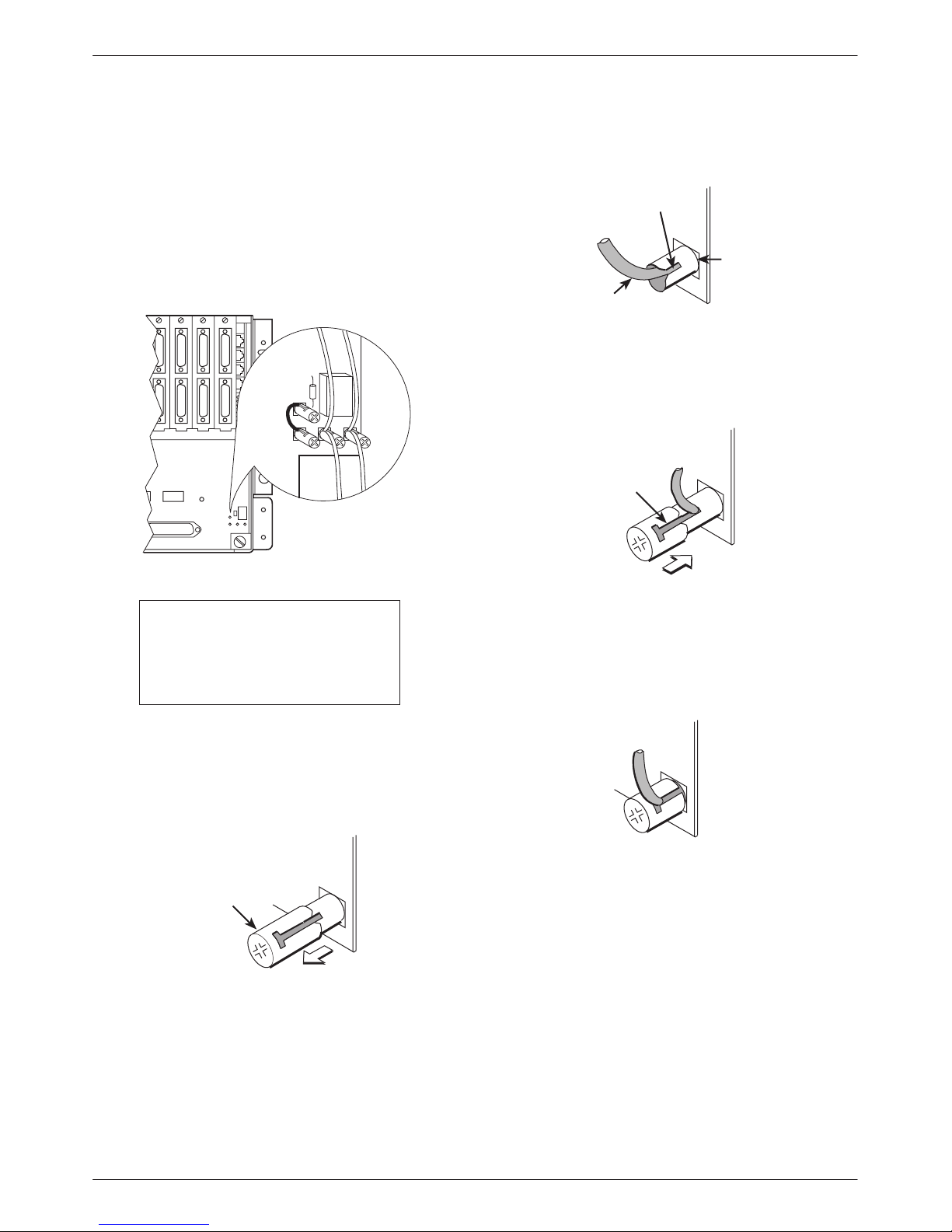

SGRD/FGRD Connection

Grounding reduces interference. To connect frame

ground (FGRD) to signal ground (SGRD) for all DSUs

and modems in the carrier, install the provided wire strap

between the SGRD and FGRD terminals at the rear of the

carrier. The terminals are an insulation displacement type,

with a slot designed to cut through the insulation on the

wire.

SGRD

E4

FGRD

P23

P21

ALARM

E3 E1 E2

496-14805-01

2. Insert one end of the strap into the SGRD

terminal. It is not necessary to strip the wire.

Tube Slot

Hollow Tube

E2

Wire End

496-14656b-01

3. Fit the strap into the slot in the terminal. Replace

the plastic cap on the terminal, fitting the strap

into the matching slot cut lengthwise in the cap.

Cover Slot

E2

496-14656c-01

NOTE

SGRD must not be connected to

FGRD when leased modems

are installed in the carrier.

" Procedure

1. Use pliers to pull the plastic covers off the

SGRD (E4) and FGRD (E3) terminals.

Plastic Cover

E2

496-14656a-01

4. Use a Phillips screwdriver to push the cap firmly

onto the terminal. As you seat the cap, the

terminal cuts through the insulation on the strap

and makes contact.

495-14656d-01

5. Insert the other end of the strap into the FGRD

terminal and repeat Steps 3 and 4.

3-14 July 1999 3000-A2-GA31-D0

Page 31

Installing the Carrier and Assembly Components

Alarm Output Connection

T o connect the alarm output to an external light or

buzzer:

• Install the alarm light or buzzer and voltage source

as described in the instructions received with the

light/buzzer and voltage source.

• Use the two ALARM terminals labeled E1 and E2

at the rear of the carrier to install two external

device leads.

Customer

Supplied

Voltage

Source

Rear of Cabinet

Carrier 6

Carrier 5

Customer

Supplied

Alarm Light

or Buzzer

" Procedure

1. Use pliers to pull the plastic covers off the E1 and

E2 terminals.

Plastic Cover

E2

496-14656a-01

2. Insert the end of the wire coming from the voltage

source and the end of a wire to be connected to the

next carrier into the E1 terminal. It is not

necessary to strip the wires.

Tube Slot

Hollow Tube

Wire Ends

Carrier 4

Carrier 3

Carrier 2

Carrier 1

SGRD

E4

FGRD

ALARM

E3 E1 E2

496-14919b

3. Fit the wires into the slot in the terminal. Replace

the plastic cap on the terminal, fitting the wires

into the matching slot cut lengthwise in the cap.

NOTE

The last carrier to be connected

has one incoming lead for each

terminal.

Cover Slot

To Next

Cabinet

495-12261-02

496-14919c

3-153000-A2-GA31-D0 July 1999

Page 32

COMSPHERE 3000 Series Carrier

4. Insert the other end of the wire to the next carrier’s

E1 terminal, if any. Repeat Steps 2, 3, and 4 until

all the carriers are linked together.

5. Use a Phillips screwdriver to push the cap firmly

onto the terminal. As you seat the cap, the

terminal cuts through the insulation on the wires

and makes contact.

496-14919d

6. Insert the end of the wire coming from the alarm

and the end of a wire to be connected to the next

carrier into the E2 terminal, as described in Step 2.

7. Repeat Steps 3 through 5, connecting the E2

terminals instead, until all the carriers are linked

together.

SDU Installation

An SDU is a circuit card designed for installation in the

slot at the extreme left end of the carrier (Slot 0). The

SDU is required for either or both of the following

conditions:

• The devices in the carrier are to be controlled by an

NMS.

• Multiple carriers in a cabinet configuration are to

be controlled from a single SDCP.

The SDU is not required for a single carrier:

• Without an NMS interface or

• With an SDCP installed.

SDU

Status

Ok

Alrm

Diag

In

Diag

Out

Dial Modem Control Interface

Connectors J1 and J2 are defined in Table A-12 in

Appendix A and provide an interface that can be used for:

• D-lead control signaling. Directly supported.

Associates a signal lead with each modem.

Momentary connection of this lead to a common

ground activates the signal.

• MI/MIC signaling. Supported by connecting all

MIC leads together and wiring them to Pin 25

(Signal Ground) on the corresponding J1 or J2

connector. Each MI lead can then be treated as a

D-lead connection. Provides two leads:

— Mode Indicate (MI)

— Mode Indicate Common (MIC) – usually via

Pins 3 and 6 of an 8-position modular VF

connector

Activation of the signal is by momentary connection of

these two leads. These two control signal methods are

identical in function. Activation causes the associated dial

modem to go off-hook in the Originate mode.

Spkr

SDU

496-12350-03

3-16 July 1999 3000-A2-GA31-D0

Page 33

Installing the Carrier and Assembly Components

The following table describes the SDU’s status

indicators.

Label

OK green Normal operation.

Alrm red Fault in SDU.

Diag In yellow Incoming message from the NMS to

Diag Out yellow Outgoing message to the NMS from

Color Description

a DSU, DBM, or dial/lease modem.

a DSU, DBM, or dial/lease modem.

SDU Modular Jacks and DIP Switches

At the rear of the SDU are four modular jacks:

• CC IN/DC OUT – 6-pin

• CC OUT/DC IN – 6-pin

• FP IN – 8-pin

• FP OUT – 8-pin

Below the four modular jacks are two sets of DIP (dual

in-line package) switches labeled S2 and S1.

• S2: Each device in a cabinet configuration must

have a unique identity. For Model 3611 with

software version 3.nn and earlier, use the top DIP

switch to set the carrier address.

• S1: Use the bottom DIP switch for CC or

DC operation of the NMS channel.

T o set the carrier addresses:

If the device is . . . Then . . .

Not Model 361 1 Enter the address manually

from the front panel.

Model 3611 with software

nn

version of 4.

Model 3611 with software

version of 3.nn or lower

or higher

Enter the address manually

from the front panel.

Use the following procedure

to set the S2 DIP switch for

the carrier address.

" Procedure

SDU Circuit

Card

CC IN/DC OUT

CC OUT/DC IN

FP IN

FP OUT

S2

S1

S2

S1

ON OFF

Carrier

S2 –

Address

S1 –

4

3

2

1

4

3

2

1

Protocol

Strap

495-14812

1. Set the carrier address S2-1, S2-2, and S2-3 DIP

switches on the rear of the card, as specified in

T able 3-2. Note that each carrier in a cabinet must

have a unique address. Use T able 3-3 to determine

the new carrier’s address.

For a . . .

Single carrier Leave the S2 switch address

set for Carrier 1 (factory

default).

New cabinet

with an NMS

control channel

Carrier added

to an existing

control channel

Use the address Carrier 1 for

the first carrier, Carrier 2 for

the next, and go up to the

Carrier 7 and 8 addresses for

carriers in the second cabinet

in a single installation.

For the next installation, the

carrier address is numbered 1,

but is on a different control

channel.

Use Table 3-3 to determine the

new carrier’s address.

Then . . .

3-173000-A2-GA31-D0 July 1999

Page 34

COMSPHERE 3000 Series Carrier

S2 DIP

C

2. Write the carrier number on the slot label located

under each slot on the SDCP or cover plate.

Table 3-2

Carrier Address SDU S2 DIP Switches

S2 DIP

Switch

S2-4 — — — — — — — —

S2-3 Off Off Off Off On On On On

S2-2 Off Off On On Off Off On On

S2-1 Off On Off On Off On Off On

1* 2 3 4 5 6 7 8

Carrier Number

* Factory default setting.

On is to the left as you face the rear of the carrier.

Off is to the right.

Table 3-3

Carrier Address Assignment

Highest Existing Network Address

First New

arrier

DA TAPHONE II ADp

Address

SDU CC/DC Operation

Set the SDU S1 DIP switch on the rear of the circuit

card (T able 3-4).

If connecting to . . . Then set the . . .

Network control channel CC IN/CC OUT option

Diagnostic channel of an

upstream device

Table 3-4

SDU S1 DIP Switch

S1 DIP

Switch

S1-4 — —

S1-3 — —

S1-2 Off On

S1-1 Off Off

CC IN/CC OUT* DC OUT/DC IN

* Factory default setting.

On is to the left from the rear of the carrier.

Off is to the right.

DC OUT/DC IN option

1 1 – 48 01 – 32 2

51 – 88 33 – 64 3

91 – 128 65 – 96 4

131 – 168 97 – 128 5

171 – 208 129 – 160 6

21 1 – 248 161 – 192 7

251 – 288 193 – 224 8

291 – 328 225 – 256

*

* Start a new control channel when the carrier address

reaches this limit.

3-18 July 1999 3000-A2-GA31-D0

Page 35

Installing the Carrier and Assembly Components

Installing the SDU

" Procedure

1. Using a Phillips screwdriver, loosen the screw

holding the circuit pack lock. Rotate the lock to

the open position.

Circuit

Pack

Lock

Closed

(Locked)

Open

(Unlocked)

Circuit

Card

Guides

2. With the latch in the open position, insert the

circuit card into the top and bottom card guides of

the slot labeled SDU.

3. Slide the SDU circuit card into the slot until the

SDU backplane connector is seated firmly in P17.

P17-SDU

Backplane

Connector

P17

P18

496-14920

Latch

495-14813

4. Press the latch to secure the SDU in the carrier.

Rotate the circuit pack lock back into the closed

position, and tighten the screw.

3-193000-A2-GA31-D0 July 1999

Page 36

COMSPHERE 3000 Series Carrier

SDU Front Panel Connection

For a cabinet configuration with multiple carriers,

connect all the SDUs in a daisy chain.

" Procedure

1. Use an 8-pin modular cable to connect the FP

OUT jack at the rear of the SDU in one carrier to

the FP IN jack of the SDU in the next carrier

above or below the first connection.

2. Use another modular cable to connect the second

SDU’s FP OUT jack to the next SDU’s FP IN

jack. Continue to the last carrier in the cabinet.

In the accompanying illustration, Carrier 5 is

chained in this way to Carrier 4, 4 to 3, 3 to 2,

2 to 1, and 1 to 6. The 8-pin modular cables are

shown as solid black lines.

NOTE

If more than one SDCP is

connected in the daisy chain, the

first front panel will display data

and be operational. The

remaining front panels will

display Slave on the SDCP.

After installing at least one device in the carrier, check

that the SDU is functioning properly by polling selected

devices for health and status.

• If there is an NMS connection, poll for health and

status. Refer to the NMS Connection section.

• If the SDCP is already installed, select each device

in turn and request its health and status. Refer to the

Testing the SDCP section on page 3-12.

To Next

Cabinet

Rear of Cabinet

CC IN

Carrier 6

Carrier 5

SDCP

Installed at

Eye Level

Carrier 4

16

16

16

CC OUT

FP IN

FP OUT

SDU

CC IN

CC OUT

FP IN

FP OUT

SDU

CC IN

CC OUT

FP IN

FP OUT

SDU

Testing the SDU

When . . . Then . . .

The carrier’s power

transformer unit is

operating

The test completes All indicators go off except the

There is an NMS

connection and the

devices in the

carrier are on the

NMS or poll list

All indicators on the SDU’s

faceplate light briefly as the SDU

performs a self-test routine.

green OK indicator.

The yellow Diag In and Diag Out

indicators also flash periodically

as the NMS polls the devices in

the carrier.

Carrier 3

Carrier 2

Carrier 1

CC IN

CC OUT

FP IN

FP OUT

16

16 SDU

16 SDU

SDU

CC IN

CC OUT

FP IN

FP OUT

CC IN

CC OUT

FP IN

FP OUT

From

NMS

496-12281-04

3-20 July 1999 3000-A2-GA31-D0

Page 37

Installing the Carrier and Assembly Components

NMS Connection

A COMSPHERE 3000 Series Carrier can be connected

to a variety of Network Management Systems:

• 6800 Series NMS

• 6700 Series NMS

• DATAPHONE II Diagnostic Controller (DC)

The control channel CC IN interface, a 6-pin modular

jack on the SDU, connects the NMS to the carrier. Each

type of NMS requires a specific adapter to convert the

control channel interface to the 6-pin modular jack

required for the SDU.

This connection is via the control channel interface on

the SDU, but all 16 slots in the carrier can only be

controlled by one NMS. One control channel can manage

up to eight carriers by daisy chaining from the CC IN to

the CC OUT interfaces on the SDU in each carrier. Some

protocols result in DC OUT and DC IN. Refer to the

SDU CC/DC Operation section, page 3-18.

NOTE

You cannot use an NMS

connected through the SDU

with either T1 CSUs or

T1 DSU/CSUs.

Connecting the NMS

4. For a cabinet configuration with multiple carriers,

connect all of the SDUs in a daisy chain, starting

with the SDU connected to the NMS.

— Use a 6-pin modular telephone cord to connect

the CC OUT jack at the rear of this SDU to

the CC IN jack of the SDU in the next carrier

above or below it.

— Use another cord to connect the second SDU’s

CC OUT jack to the next SDU’s CC IN.

Continue the connections until the last carrier in

the cabinet is connected.

To Next

Cabinet

Rear of Cabinet

CC IN

Carrier 6

Carrier 5

SDCP

Installed at

Eye Level

Carrier 4

16

16

16

CC OUT

FP IN

FP OUT

SDU

CC IN

CC OUT

FP IN

FP OUT

SDU

CC IN

CC OUT

FP IN

FP OUT

SDU

" Procedure

1. Obtain the correct adapter. Refer to Table 3-5,

page 3-22. Connect the adapter to the network

management port on the NMS device (on the

COMSPHERE and DATAPHONE II systems, the

port is labeled DC OUT or DC IN).

2. Use a 6-pin modular telephone cord to connect the

modular side of the adapter to the CC IN jack on

the rear of the SDU in the carrier. In the

accompanying illustration, 6-pin modular

telephone cords are shown as dashed lines.

3. After at least one device has been installed in the

carrier, check that the SDU is functioning properly

by polling the device for health and status.

Carrier 3

Carrier 2

Carrier 1

CC IN

CC OUT

FP IN

FP OUT

16

16 SDU

16 SDU

SDU

CC IN

CC OUT

FP IN

FP OUT

CC IN

CC OUT

FP IN

FP OUT

From

NMS

496-12281-04

3-213000-A2-GA31-D0 July 1999

Page 38

COMSPHERE 3000 Series Carrier

Table 3-5

NMS Carrier Connections

SDU Jack

CC IN/

DC OUT

CC IN/

DC OUT

CC IN/

DC OUT

CC IN/

DC OUT

CC IN/

DC OUT

CC IN/

DC OUT

CC IN/

DC OUT

CC OUT/

DC IN

CC OUT/

DC IN

Connecting To Using Adapter and Cable Connections*

COMSPHERE 6800 Series NMS Central Site: Feature 6821-F1-513 includes 4400-F1-594 Adapter and

4400-F1-512 Cable

Remote Site: Feature 6821-F1-518 Adapter

COMSPHERE 6700 Series NMS Cable provided with software package

COMSPHERE Model 3610 DSU Features 3600-F3-300 Hubbing Device and 4400-F1-51x Cable

Remote NMS connecting via DSU to carrier: NMS adapter cable

Feature 3000-F2-510

COMSPHERE Models 38xx and

39xx Modems

Primary Channel Device Feature 6821-F1-518 Cable

DATAPHONE II Device –

CC OUT Connector

DATAPHONE II Device –

DC OUT Connector

COMSPHERE Model 3610 DSU Features 3600-F3-300 Hubbing Device and 4400-F1-51x Cable

Primary Channel CC Extension Features 4400-F1-592 Adapter & 4400-F1-51x Cable