Page 1

ACCULINK

336x E1 NETWORK

TERMINATION UNIT

OPERATOR’S GUIDE

Document No. 3360-A2-GB20-20

December 1996

Page 2

ACCULINK 336x E1 NTU

ACCULINK

336x E1 Network Termination Unit

Operator’s Guide

3360-A2-GB20-20

3rd Edition (December 1996)

Changes and enhancements to the product and to the information herein will be documented and issued as a new release.

Warranty, Sales, and Service Information

Contact your sales or service representative directly for any help needed. For additional information concerning warranty ,

sales, service, repair, installation, documentation, or training, use one of the following methods:

• Via the Internet: Visit the Paradyne World Wide Web site at http://www.paradyne.com

• Via Telephone: Call our automated call system to receive current information via fax or to speak with a company

representative.

— Within the U.S.A., call 1-800-870-2221

— International, call 727-530-2340

Trademarks

All products and services mentioned herein are the trademarks, service marks, registered trademarks or registered service

marks of their respective owners.

Printed on recycled paper

COPYRIGHT 1996 Paradyne Corporation. All rights reserved.

This publication is protected by federal copyright law. No part of this publication may be copied or distributed, transmitted, transcribed, stored in a retrieval system,

or translated into any human or computer language in any form or by any means, electronic, mechanical, magnetic, manual or otherwise, or disclosed to third parties

without the express written permission of Paradyne Corporation, 8545 126th Avenue North, P.O. Box 2826, Largo, Florida 33779-2826.

Paradyne Corporation makes no representation or warranties with respect to the contents hereof and specifically disclaims any implied warranties of merchantability

or fitness for a particular purpose. Further, Paradyne Corporation reserves the right to revise this publication and to make changes from time to time in the contents

hereof without obligation of Paradyne Corporation to notify any person of such revision or changes.

A December 1996 3360-A2-GB20-20

Page 3

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or included in the

manual.

2. When an AC power source is used, this product is intended to be used with a three-wire

grounding type plug – a plug which has a grounding pin. This is a safety feature. Equipment

grounding is vital to ensure safe operation. Do not defeat the purpose of the grounding type

plug by modifying the plug or using an adapter.

Prior to installation, use an outlet tester or a voltmeter to check the ac receptacle for the

presence of earth ground. If the receptacle is not properly grounded, the installation must not

continue until a qualified electrician has corrected the problem.

If a three-wire grounding type power source is not available, consult a qualified electrician to

determine another method of grounding the equipment.

3. Slots and openings in the cabinet are provided for ventilation. T o ensure reliable operation of

the product and to protect it from overheating, these slots and openings must not be blocked

or covered.

4. Do not allow anything to rest on the power cord and do not locate the product where persons

will walk on the power cord.

Important Instructions

5. Do not attempt to service this product yourself, as opening or removing covers may expose

you to dangerous high voltage points or other risks. Refer all servicing to qualified service

personnel.

6. General purpose cables may be provided with this product. Special cables, which may be

required by the regulatory inspection authority for the installation site, are the responsibility

of the customer. Use a Listed, minimum No. 26 AWG line cord for connection to the High

bit-rate Digital Subscriber Line (HDSL) network.

7. When installed in the final configuration, the product must comply with the applicable Safety

Standards and regulatory requirements of the country in which it is installed. If necessary,

consult with the appropriate regulatory agencies and inspection authorities to ensure

compliance.

8. A rare phenomenon can create a voltage potential between the earth grounds of two or more

buildings. If products installed in separate buildings are interconnected, the voltage potential

may cause a hazardous condition. Consult a qualified electrical consultant to determine

whether or not this phenomenon exists and, if necessary, implement corrective action prior to

interconnecting the products.

9. Input power to the AC voltage configuration of this product must be provided by one of the

following: (1) a UL Listed/CSA certified power source with a Class 2 or Limited Power

Source (LPS) output for use in North America, or (2) a certified power source with a Safety

Extra Low Voltage (SELV) output for use in the country of installation.

Input power to the DC voltage configurations of this product must be provided by one of the

following: (1) a National Electric Code (NEC)/Canadian Electric Code (CEC) Class 2 circuit

for use in North America, or (2) a certified Safety Extra Low Voltage (SELV) circuit input for

use in the country of installation.

10. This product contains a coin cell lithium battery that is only to be replaced at the factory.

Caution: There is a danger of explosion if the battery is incorrectly replaced. Replace only

with the same type. Dispose of used batteries according to the battery manufacturer’s

instructions. Attention: Il y a danger d’explosion s’il y a remplacement incorrect de la

batterie. Remplacer uniquement avec une batterie du même type. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

B3360-A2-GB20-20 December 1996

Page 4

ACCULINK 336x E1 NTU

Notices

In addition, if the equipment is to be used with telecommunications circuits, take the following

precautions:

– Never install telephone wiring during a lightning storm.

– Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

– Never touch uninsulated telephone wires or terminals unless the telephone line has been

disconnected at the network interface.

– Use caution when installing or modifying telephone lines.

– Avoid using a telephone (other than a cordless type) during an electrical storm.

There may be a remote risk of electric shock from lightning.

– Do not use the telephone to report a gas leak in the vicinity of the leak.

THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPL Y WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE,

PURSUANT TO PART 15 OF THE FCC RULES. THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE

PROTECTION AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL

ENVIRONMENT. THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF

NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL

INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS

LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE

INTERFERENCE AT HIS OWN EXPENSE.

THE AUTHORITY TO OPERATE THIS EQUIPMENT IS CONDITIONED BY THE REQUIREMENTS THAT NO

MODIFICATIONS WILL BE MADE T O THE EQUIPMENT UNLESS THE CHANGES OR MODIFICATIONS ARE EXPRESSLY

APPROVED BY PARADYNE.

TO USERS OF DIGITAL APPARATUS IN CANADA:

THIS CLASS A DIGITAL APPARATUS MEETS ALL REQUIREMENTS OF THE CANADIAN INTERFERENCE-CAUSING

EQUIPMENT REGULATIONS.

CET APPAREIL NUMÉRIQUE DE LA CLASSE A RESPECTE TOUTES LES EXIGENCES DU RÉGLEMENT SUR LE

MATÉRIEL BROUILLEUR DU CANADA.

C December 1996 3360-A2-GB20-20

Page 5

Table of Contents

Preface

Objectives and Reader Assumptions iii. . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Documents iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Introduction

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Installation

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Examples 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Connection Examples 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Instructions 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Power Sources 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Examples 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up Self-Test 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Operation

Overview 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Front Panel 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Unit Identity 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying LED Conditions 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the G.703 DTE or Data Port for LED Display 3-11. . . . . . . . . .

Changing Configuration Options 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the E1 NTU for SNMP Management 3-14. . . . . . . . . . . . . .

Configuring SNMP Traps 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DS0 Channels 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Timing Source 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring/Releasing the User Interface 3-35. . . . . . . . . . . . . . . . . . . . . . .

Resetting the E1 NTU 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Operations 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i3360-A2-GB20-20 December 1996

Page 6

ACCULINK 336x E1 NTU

4. Maintenance

Overview 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test Health 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Health and Status 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HDSL Loop Performance 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Reports 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Traps 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Jacks 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Commands 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Loopback T ests 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Loopback T ests 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Patterns 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lamp Test 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying E1 NTU T est Status 4-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

Glossary

Index

A. %"!' ! !( *

B. ! #'"!& *

C. "!(%'"! #'"!& *

D. ! &&! !'& *

E. '& *

F. ')"% %&&! !%" *

G. %"!' ! ('"! *

H. $(# !' &' *

ii December 1996 3360-A2-GB20-20

Page 7

Preface

Objectives and Reader

Assumptions

This operator’s guide contains installation, operation,

and maintenance information for the ACCULINK 336x

E1 Network T ermination Unit (NTU).

It is assumed that you are familiar with the operation of

digital data communication equipment and NTUs in

particular. You should also be familiar with Simple

Network Management Protocol (SNMP) if you want your

E1 NTU to be managed by an SNMP manager.

Related Document

7800-A2-GB20 ACCULINK 3100 Series Open

Management Application for

HP OpenView User’s Guide

Reference Documents

• CSA-22.2 No. 950-M89

• CSA 108-M1983

• FCC Part 15

• UL 1950

• Management Information Base for Network

Management of TCP/IP-Based Internets: MIBII.

RFC 1213, March 1991

• Definitions of Managed Objects for the DS1 and E1

Interface T ypes . RFC 1406, January 1993

• Definitions of Managed Objects for RS-232-like

Hardware Devices. RFC 1317, April 1992

• Extensions to the Generic-Interface MIB.

RFC 1229, May 1991

iii3360-A2-GB20-20 December 1996

Page 8

Introduction

Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.703 DTE Interface 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Message Capability 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Emulation 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Management Support 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Overview

The E1 NTU acts as an interface between a High

bit-rate Digital Subscriber Line (HDSL) network and the

customer’s Data Terminal Equipment (DTE), converting

signals received from the DTE into the two binary, one

quaternary (2B1Q) signal format for transmission over the

HDSL network.

The E1 NTU’s G.703 DTE interface supports

2.048 Mbps (E1) data that is compatible with the signal

format of ITU Recommendation G.703 and the frame

structure of ITU Recommendation G.704.

In addition to the G.703 DTE interface, the 336x E1

NTUs have one to four EIA 530A synchronous data ports

that may be configured for rates of 64 kbps to 1984 kbps.

The 336x Series consists of a Model 3360 NTU

(2-port), a Model 3364 NTU (4-port), and a Model 3365

NTU (1-port). Differences between these models are

discussed where applicable throughout this guide.

Features

The E1 NTU optimizes network performance with a

wide range of features such as the following:

• Software configuration menu displayed via a liquid

crystal display (LCD) to permit quick and easy

operation, and elimination of complicated hardware

strapping.

• Local or remote configuration and operation

flexibility.

• Several loopback capabilities and test pattern

generators.

• G.703 DTE capability.

• Alarm message display/print capability.

• Front panel emulation via Windows-based Front

Panel Emulation software.

• Network management provided through

industry-standard Simple Network Management

Protocol (SNMP).

1-13360-A2-GB20-20 December 1996

Page 9

ACCULINK 336x E1 NTU

G.703 DTE Interface

The G.703 DTE interface is compatible with the signal

format of ITU Recommendation G.703 and the frame

structure of ITU Recommendation G.704. This interface

allows DTEs/PBXs to share the network with other

high-speed equipment.

Alarm Message Capability

The E1 NTU can be attached, either locally or

remotely , to an ASCII terminal or printer to display or

print alarm messages. The communications (COM) port

can be used as the destination for Alarm Set and Alarm

Clear messages. This enables an ASCII terminal or printer

to monitor the E1 NTU for alarm conditions. Alarms can

also be displayed on a PC that is using a terminal

emulation package.

Front Panel Emulation

The E1 NTU offers functionality through Front Panel

Emulation software that is similar to that provided by the

E1 NTU front panel. The E1 NTU can either be locally or

remotely attached to a 386 or higher personal computer

(PC) that has at least four megabytes (MB) of

random-access memory (RAM). (An external modem is

required for remote attachment.) A copy of the E1 NTU

front panel appears on the PC. The functionality of the

front panel is available by clicking on the function keys

with the mouse rather than by pressing keys from the

actual front panel. For more information, refer to

Appendix G, Front Panel Emulation.

SNMP Management Support

SNMP is a network management protocol that is used

to monitor network performance and status, and to report

alarms (i.e., traps). T o function, SNMP requires a manager

consisting of a software program housed within a

workstation or PC; an agent consisting of a software

program housed within a device (e.g., the E1 NTU); and a

Management Information Base (MIB) consisting of a

database of managed objects.

Users of the external SNMP manager can issue “Get”

and “Set” commands to an object in the SNMP database

maintained by the E1 NTU.

The E1 NTU can be managed by any industry-standard

SNMP manager. Paradyne provides an SNMP application

that runs on a Hewlett-Packard HP OpenView network

management platform. For more information, refer to the

ACCULINK 3100 Series Open Management Application

for HP OpenView User’s Guide.

The E1 NTU supports the following MIBs:

• MIB II – Defines the general objects for use in

Transmission Control Protocol/Internet Protocol

(TCP/IP) internets and provides general

information about the E1 NTU. MIB II is

backward-compatible with MIB I.

• DS1/E1 MIB – Defines objects for managing E1

interfaces and supports the network and G.703 DTE

interfaces on the E1 NTU.

• RS-232-like MIB – Defines objects for managing

RS-232-type interfaces (e.g., RS-422, RS-423, etc.)

and supports synchronous data ports (PORTs 1– 4)

and management communication ports (AUX and

COM ports) on the E1 NTU.

• Generic-Interface Extension MIB – An extension to

MIB II that defines additional objects for control of

generic interfaces in MIB II. It supports control of

tests on the G.703 DTE and synchronous data

interfaces that are not supported by other MIBs.

• Enterprise MIB – Defines objects that are unique to

Paradyne devices.

Two link layer protocols, Point-to-Point Protocol (PPP)

and Serial Line Internet Protocol (SLIP), are supported for

connection to an external SNMP manager or network

device (e.g., a router).

The SNMP manager or network device can be directly

connected to the communications (COM) port. An

external LAN Adapter can be connected to either the

COM port or the auxiliary (AUX) port to provide Ethernet

connectivity. Also, the E1 NTU can be daisy chained

together by connecting the COM port of one device to the

AUX port of the other, providing SNMP connectivity.

The SNMP management system can communicate to

the E1 NTU remotely through the Facility Data Link

(FDL) or (for 2-port and 4-port E1 NTUs) the

synchronous data port’s Embedded Data Link (EDL).

FDL provides an in-band channel for performance and

control signals on the network interface. It uses the spare

in time-slot zero as defined in ITU

bit S

a4

Recommendation G.704. EDL provides the ability to

detect and synchronize on a framing pattern, provides

cyclic redundancy checking (CRC), and maintains

near-end and far-end performance statistics.

1-2 December 1996 3360-A2-GB20-20

Page 10

Introduction

1

Physical Description

The 336x Series consists of a Model 3360 NTU

(2-port), a Model 3364 NTU (4-port), and a Model 3365

NTU (1-port).

Front Panel

The E1 NTU front panel (Figure 1-1) contains,

• One 2-line, 16-alphanumeric-character-per-line

liquid crystal display (LCD)

• One 7-button keypad (three Function and four

directional keys)

• Twelve light-emitting diodes (LEDs)

• Six test jacks

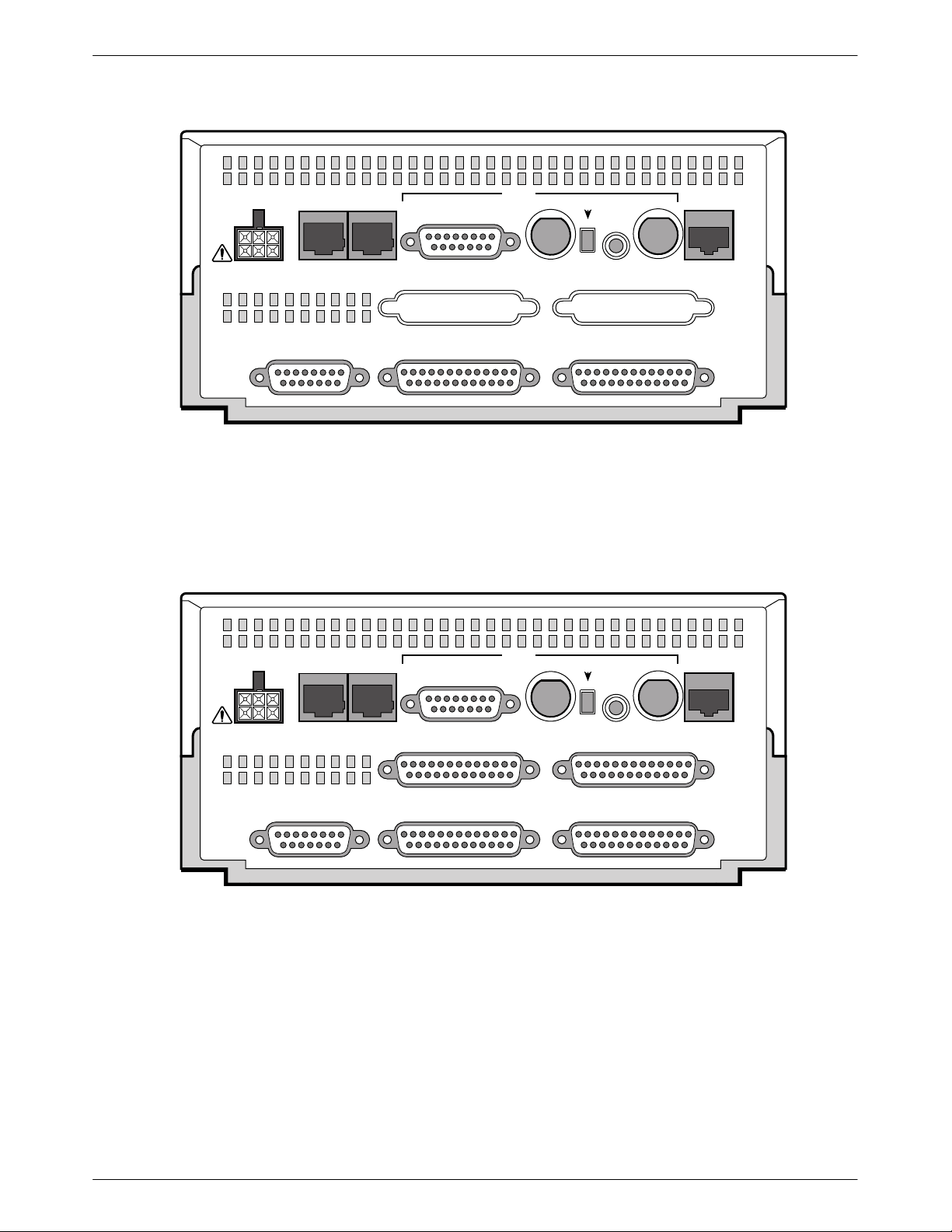

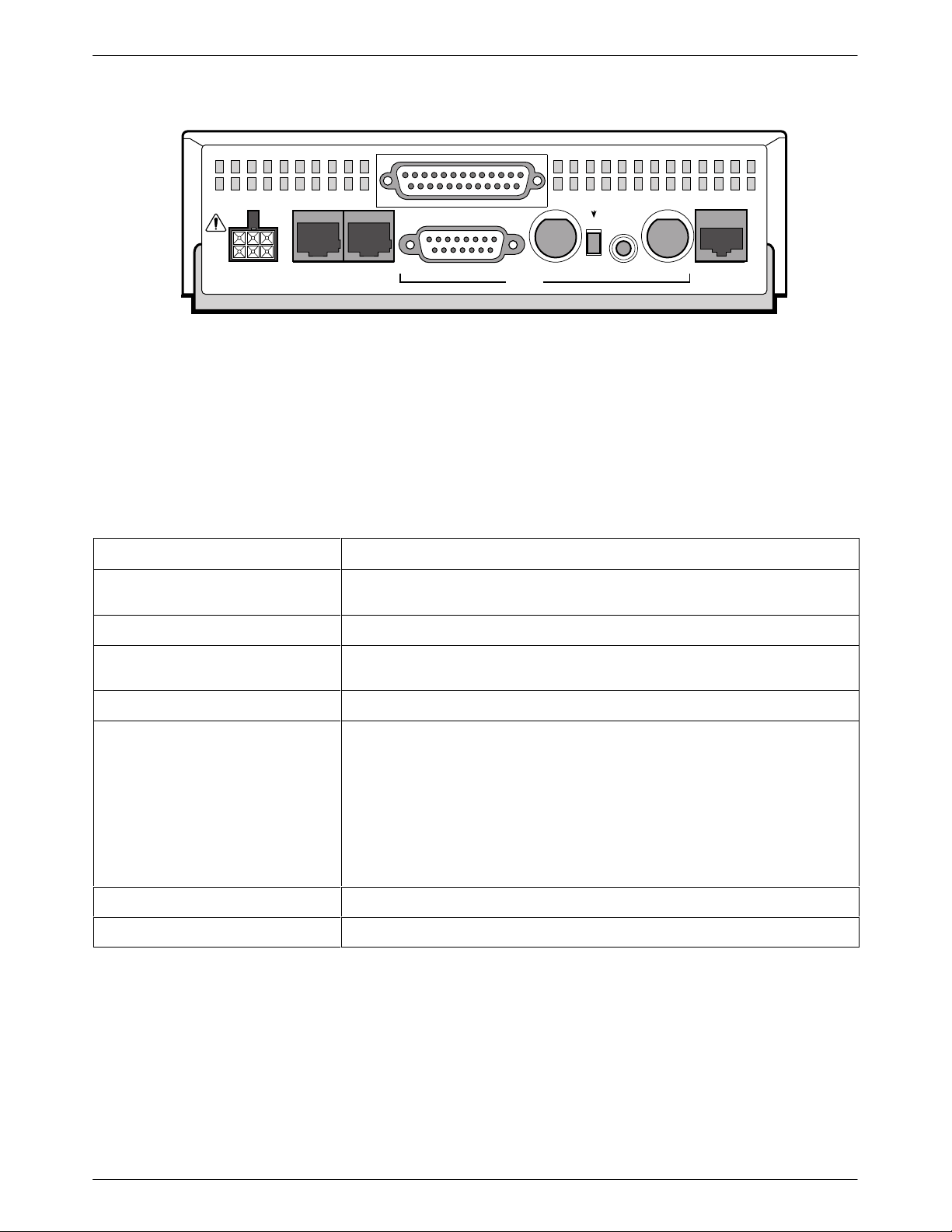

Rear Panel

The E1 NTU rear panel contains the connectors and

switches required for the operation of the E1 NTU

(Figures 1-2, 1-3, and 1-4). The connectors and switches

are described in Table 1-1.

LCD

KEYPAD

F1 F2 F3

E1

HDSL

LINEE1MON

LINE

Lp1

Lp2InOutInOut

TEST JACKS LEDs

OK

FAIL TEST SIG1 OOF ALRM

Figure 1-1. Front Panel

SIG2 SIG ALRM PDVOOF BPV

NETWORK RXD

DTR TXD CTS RTS

496-14728-0

1-33360-A2-GB20-20 December 1996

Page 11

ACCULINK 336x E1 NTU

3

4

AUX

POWER

CAUTION: AUX PORT OR COM PORT MUST

NOT BE CONNECTED TO HDSL NETWORK

PORT

COM

PORT

Figure 1-2. Model 3360 Rear Panel

G.703

TX RX

75

RX SHIELD

Ω

OPEN

EARTH

120

IN

OUT

75

Ω

Ω

120

Ω

PORT 3 PORT 4

PORT 2PORT 1CLOCK IN

75

Ω

HDSL

NETWORK

495-1473

AUX

POWER

CAUTION: AUX PORT OR COM PORT MUST

NOT BE CONNECTED TO HDSL NETWORK

PORT

COM

PORT

Figure 1-3. Model 3364 Rear Panel

G.703

TX RX

75

RX SHIELD

Ω

OPEN

EARTH

120

IN

OUT

75

Ω

Ω

120

Ω

PORT 3 PORT 4

PORT 2PORT 1CLOCK IN

75

Ω

HDSL

NETWORK

495-1473

1-4 December 1996 3360-A2-GB20-20

Page 12

2

POWER

PORT 1

AUX

PORT

COM

PORT

120

Ω

Figure 1-4. Model 3365 Rear Panel

TX RX

RX SHIELD

OPEN

EARTH

75

Ω

G.703

120

IN

OUT

75

Introduction

Ω

Ω

HDSL

NETWORK

495-1473

75

Ω

Table 1-1

Rear Panel Connectors and Switches

Name

POWER Supplies power to the E1 NTU by providing an attachment for the ac power

module or the optional dc power cable (+24 or –48 Vdc).

AUX PORT Supports SNMP LAN Adapter or daisy-chain connections.

COM PORT Provides access to a locally connected PC, an ASCII terminal or printer, or an

SNMP management link.

HDSL NETWORK Provides access to the HDSL network.

G.703—120Ω

G.703—120Ω/75Ω (switch)

G.703—75Ω TX/RX

G.703—RX SHIELD (switch) Selects either an “open” or “earth” shield connection for the 75 ohm RX interface.

CLOCK IN (Models 3360/3364) Used to attach an external clock to the E1 NTU.

PORTs 1–4 Used to connect the customer’s synchronous data DTE to the E1 NTU.

Provides a 120 ohm balanced G.703 interface.

Selects either a 120 ohm balanced G.703 interface (the switch is IN) or a 75 ohm

unbalanced G.703 interface (the switch is OUT).

Provides two BNC connectors (Transmit and Receive) for a 75 ohm unbalanced

G.703 interface.

(This switch must be set to “open” when using the 120 ohm interface.)

Function

1-53360-A2-GB20-20 December 1996

Page 13

Installation

1

Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Examples 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP Connection Examples 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Instructions 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Power Sources 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the +24 Vdc Power Supply 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Single –48 Vdc Power Supply 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Redundant –48 Vdc Power Supply 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Examples 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up Self-Test 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Overview

This chapter contains information for installing your

E1 NTU. It includes application examples, cabling, and

power-up information.

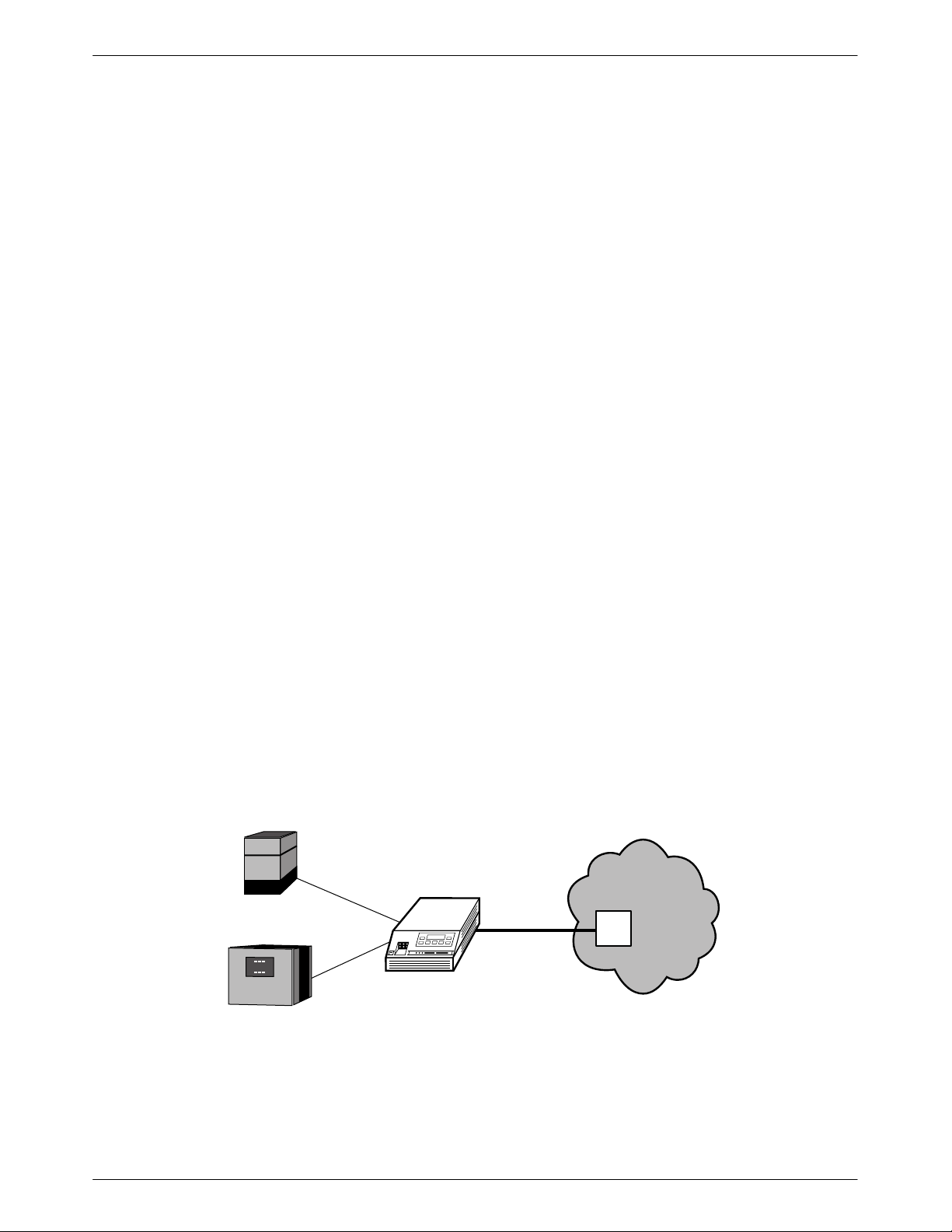

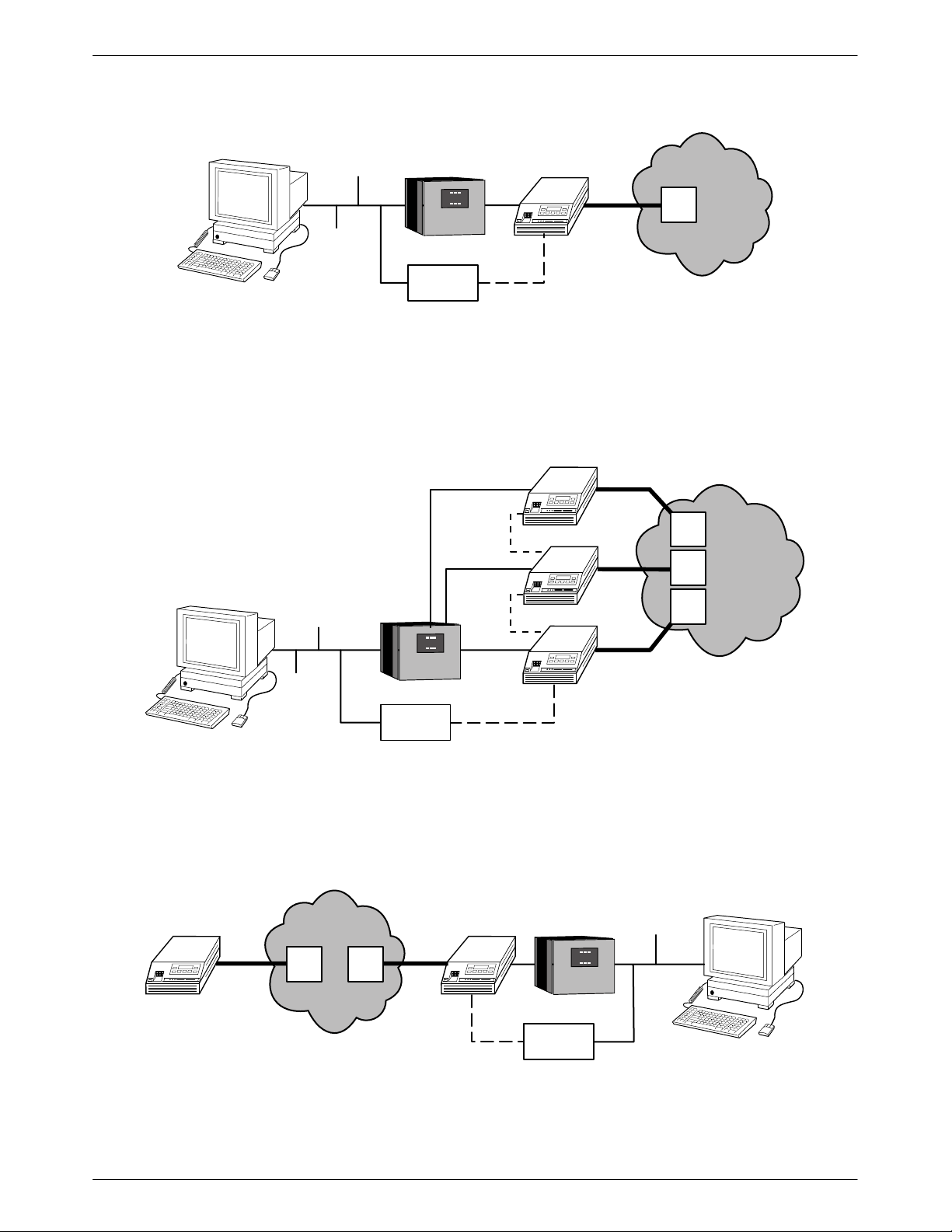

Application Examples

The E1 NTU acts as an interface between a High

bit-rate Digital Subscriber Line (HDSL) network and the

customer’s equipment.

PBX

The E1 NTU is connected to the customer’s equipment

through one of the synchronous data ports (PORTs 1– 4)

or the G.703 DTE port. It is connected to the network

through the HDSL Network interface.

The E1 NTU normally operates in conjunction with a

Line T ermination Unit (LTU) that is installed in an

ACCULINK Access Controller (AAC).

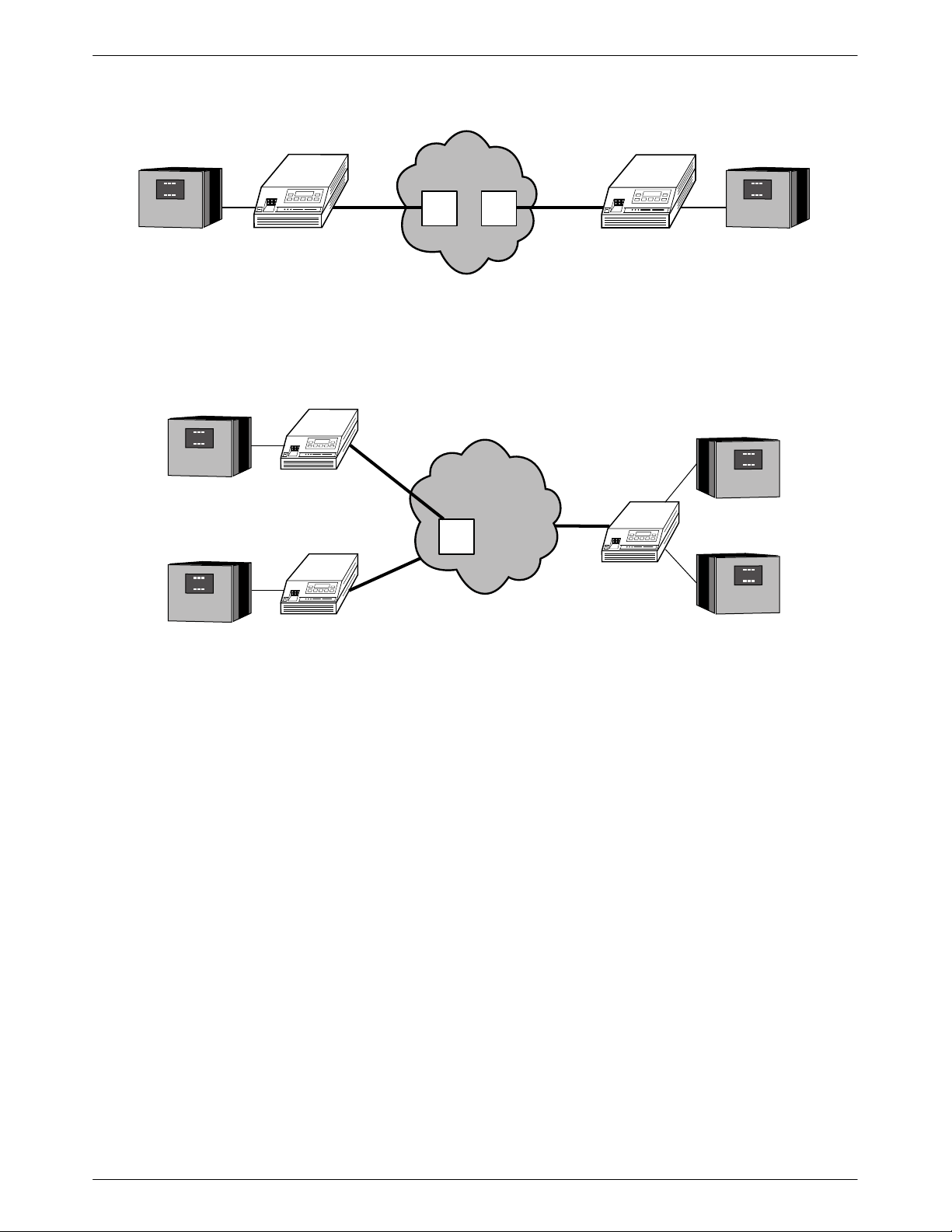

Some common applications for the E1 NTU are:

• Shared access to network-based services

(Figure 2-1).

• Point-to-Point LAN interconnection (Figure 2-2).

• Fractional E1 network applications (Figure 2-3).

NETWORK

SERVICES

HDSL

AAC

LTU

LAN

ROUTER

NTU

496-14736-0

Figure 2-1. Shared Access Application Example

2-13360-A2-GB20-20 December 1996

Page 14

ACCULINK 336x E1 NTU

1

1

NETWORK

HDSL HDSL

AAC

LTU

AAC

LTU

LAN

ROUTER

ROUTER

ROUTER

LAN

LAN

NTU

Figure 2-2. Point-to-Point Application Example

HDSL

NTU

FRACTIONAL

NETWORK

AAC

LTU

E1

DSU/CSU

E1

NTU

DSU/CSU

LAN

ROUTER

496-14735-0

LAN

ROUTER

LAN

ROUTER

496-14737-0

Figure 2-3. Fractional E1 Application Example

2-2 December 1996 3360-A2-GB20-20

Page 15

Installation

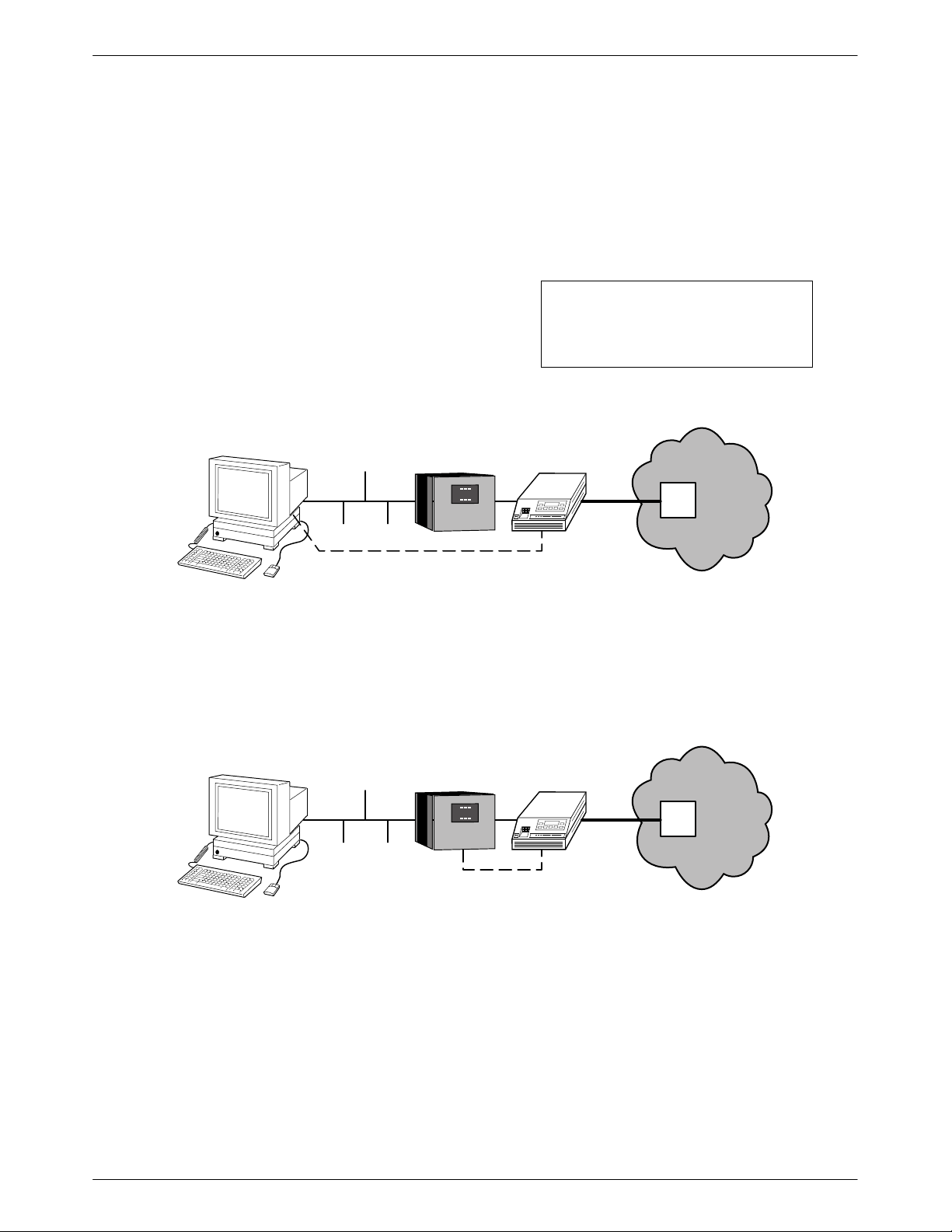

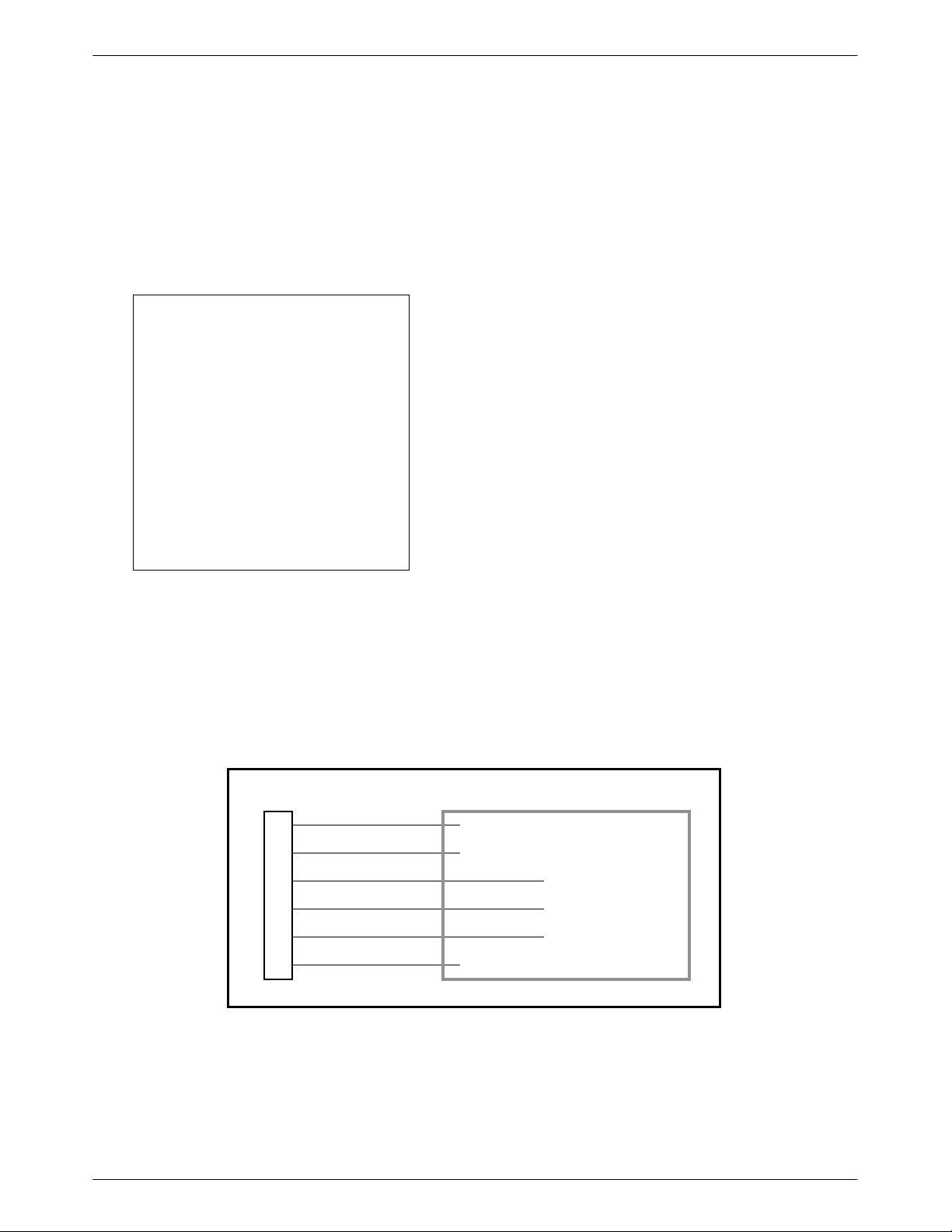

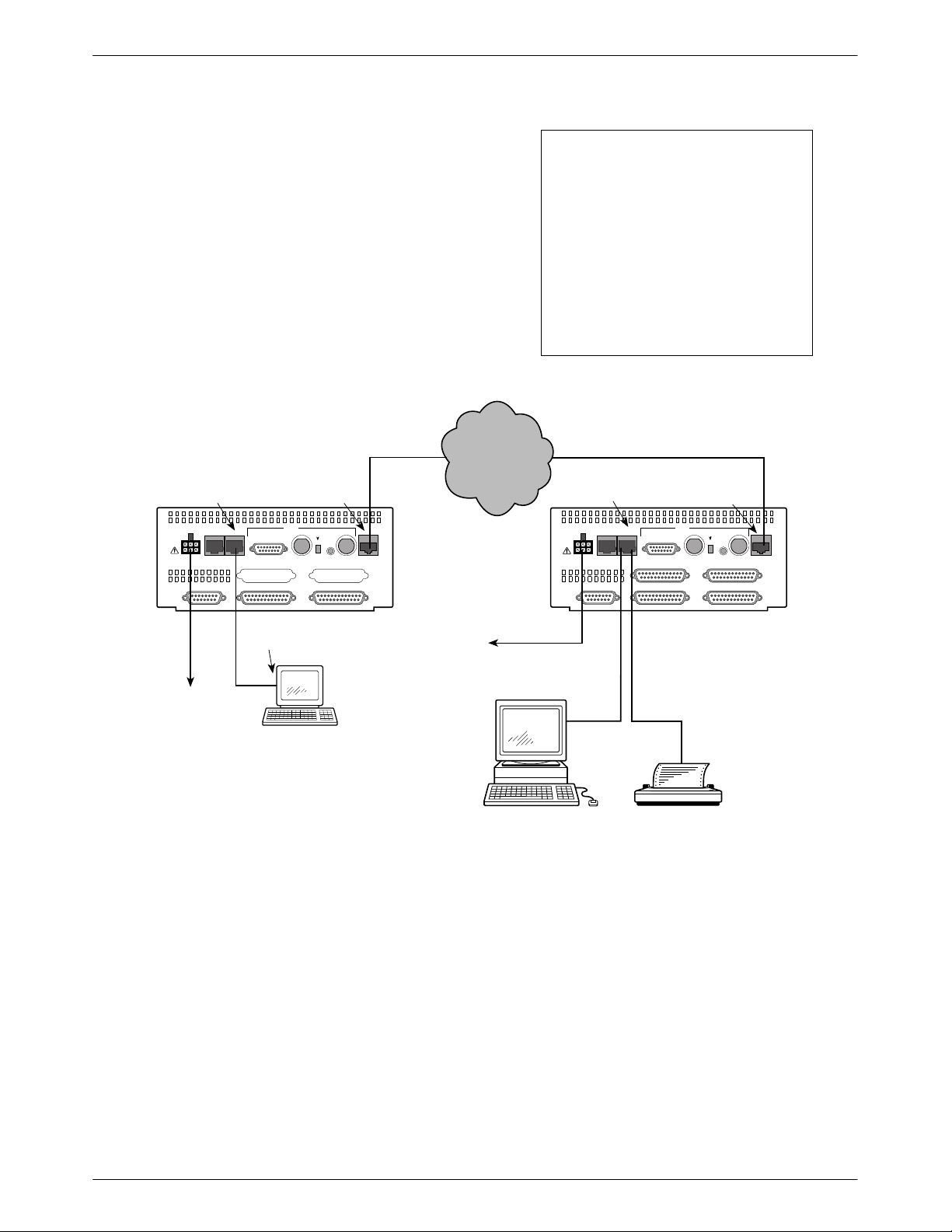

SNMP Connection Examples

The E1 NTU can be connected to an SNMP

management system in a number of ways. Some examples

include:

• Directly connecting the COM port to the SNMP

manager (Figure 2-4).

• Connecting the COM port to a network device (e.g.,

a router) for SNMP management (Figure 2-5).

• Connecting the COM port or the AUX port to an

external LAN Adapter for Ethernet SNMP

connectivity (Figure 2-6).

SNMP

ETHERNET

LAN

ROUTER

SNMP

PPP/SLIP

• Daisy chaining the COM port of one device to the

AUX port of the other to provide SNMP

connectivity (Figure 2-7).

• Remotely managing the E1 NTU through the

Facility Data Link (FDL) or the synchronous data

port’s Embedded Data Link (EDL) ( Figure 2-8 ).

NOTE

EDL is only available on 2-port

and 4-port E1 NTUs.

NTU

HDSL

NETWORK

AAC

LTU

496-14738-01

Figure 2-4. Direct Connection to an SNMP Manager

SNMP

ETHERNET

LAN

ROUTER

NTU

SNMP

PPP/SLIP

Figure 2-5. Connection through a Router to SNMP

HDSL

NETWORK

AAC

LTU

496-14739-01

2-33360-A2-GB20-20 December 1996

Page 16

ACCULINK 336x E1 NTU

1

SNMP

NMS

ETHERNET

LAN

ROUTER

LAN

ADAPTER

NTU

HDSL

SNMP

PPP

Figure 2-6. Connection through a LAN Adapter to SNMP

NTU

HDSL

NETWORK

AAC

LTU

496-14740-01

NTU

SNMP

NMS

ETHERNET

LAN

ROUTER

LAN

ADAPTER

SNMP

PPP

SNMP

PPP

SNMP

PPP

NTU

HDSL

NTU

HDSL

Figure 2-7. LAN Adapter and Daisy Chaining for SNMP Support

LAN

ROUTER

LAN

ADAPTER

ETHERNET

HDSL

SNMP

FDL/EDL

NETWORK

AAC

LTU

AAC

NTU

HDSL

LTU

SNMP

PPP

AAC

LTU

AAC

LTU

AAC

LTU

NETWORK

496-14741-01

496-14742-0

Figure 2-8. Remote SNMP Management through FDL/EDL

2-4 December 1996 3360-A2-GB20-20

Page 17

Installation

3

Important Instructions

Read and follow all warning notices and instructions

marked on the E1 NTU or included in this guide.

For a complete listing of the safety instructions, see the

Important Safety Instructions section at the beginning of

this guide.

HANDLING PRECAUTIONS

FOR

ST ATIC-SENSITIVE DEVICES

This product is designed to protect

sensitive components from damage

due to electrostatic discharge (ESD)

during normal operation. When

performing installation procedures,

however, take proper static control

precautions to prevent damage to

equipment. If you are not sure of the

proper static control precautions,

contact your nearest sales or service

representative.

Using the optional dc power cable, the E1 NTU is

capable of operating on either a +24 Vdc power source,

–48 Vdc single source battery, or –48 Vdc redundant

source batteries (for power backup). T o select the power,

choose one of the following power supply types.

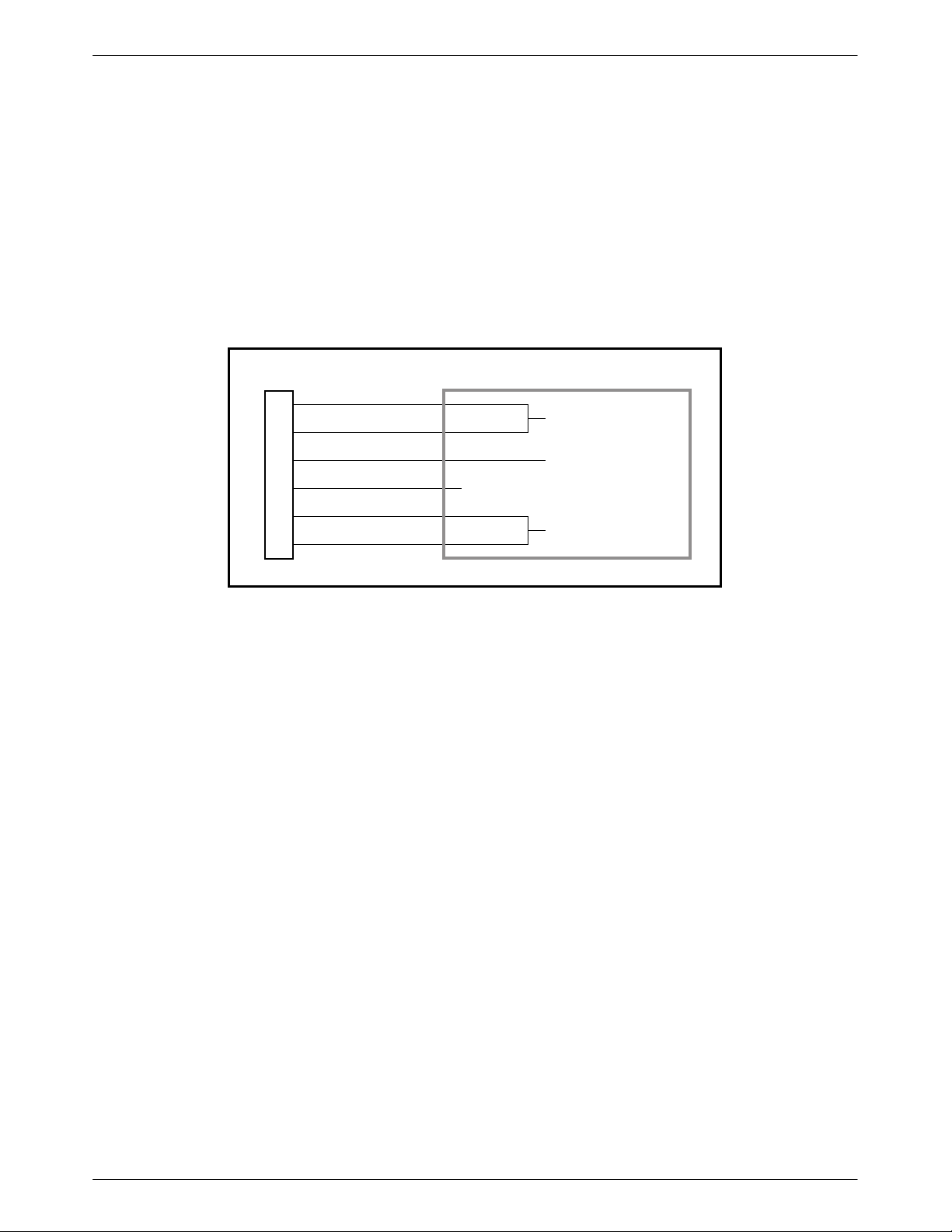

Installing the +24 Vdc Power Supply

To install the E1 NTU using a +24 Vdc power supply,

refer to Figure 2-9 and use the following procedure.

To install the +24 Vdc power supply,

1. Connect the green wire to a suitable earth ground.

2. Connect the white wire to the +24 Vdc return.

3. Connect the orange wire to the +24 Vdc source.

4. Cut the black, red and blue wires off at the outer

insulation.

5. Plug the power connector into the E1 NTU.

Optional Power Sources

The E1 NTU is typically powered by the ac power

module. Use the following procedures only if you want

to use an optional dc power source.

NTU POWER

PLUG

1

2

3

4

5

6

BLACK

RED

GREEN

WHITE

ORANGE

BLUE

CABLE NUMBER 3100-F1-520

Figure 2-9. +24 Vdc Power Supply Pinouts

TO CUSTOMER-SUPPLIED BATTERY

X

X

EARTH GROUND

+24 VDC RETURN

+24 VDC SOURCE

X

495-1474

2-53360-A2-GB20-20 December 1996

Page 18

ACCULINK 336x E1 NTU

4

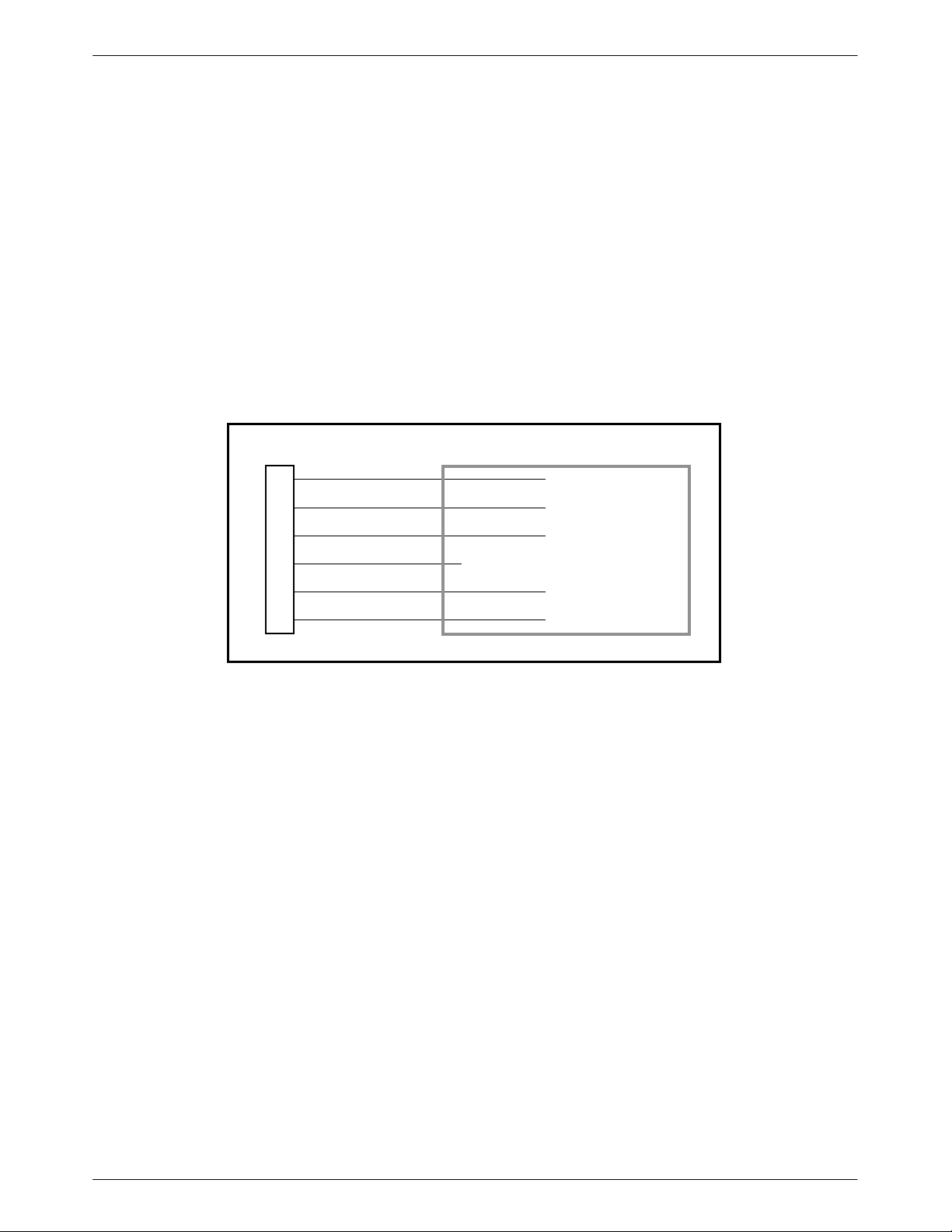

Installing the Single –48 Vdc Power Supply

To install the E1 NTU using a single source –48 Vdc

power supply, refer to Figure 2-10 and use the following

procedure.

To install the –48 Vdc single source power supply,

1. Connect the black and red wires to the –48 Vdc

return source.

NTU POWER

PLUG

1

2

3

4

5

6

BLACK

RED

GREEN

WHITE

ORANGE

BLUE

CABLE NUMBER 3100-F1-520

2. Connect the green wire to a suitable earth ground.

3. Connect the orange and blue wires to the –48 Vdc

input source.

4. Cut the white wire off at the outer insulation.

5. Plug the power connector into the E1 NTU.

TO CUSTOMER-SUPPLIED BATTERY

–48 VDC RETURN

EARTH GROUND

X

–48 VDC INPUT

495-1474

Figure 2-10. – 48 Vdc Single Source Power Supply Pinouts

2-6 December 1996 3360-A2-GB20-20

Page 19

Installation

5

Installing the Redundant –48 Vdc Power

Supply

To install the E1 NTU using a redundant –48 Vdc

power supply, refer to Figure 2-11 and use the following

procedure.

To install the redundant –48 Vdc power supply,

1. Connect the black wire to the –48 Vdc return

source B.

2. Connect the red wire to the –48 Vdc return

source A.

NTU POWER

PLUG

1

2

3

4

5

6

BLACK

RED

GREEN

WHITE

ORANGE

BLUE

3. Connect the green wire to a suitable earth ground.

4. Connect the orange wire to the –48 Vdc input

source B.

5. Connect the blue wire to the –48 Vdc input

source A.

6. Cut the white wire off at the outer insulation.

7. Plug the power connector into the E1 NTU.

TO CUSTOMER-SUPPLIED BATTERY

–48 VDC RETURN B

–48 VDC RETURN A

EARTH GROUND

X

–48 VDC INPUT B

–48 VDC INPUT A

CABLE NUMBER 3100-F1-520

495-1474

Figure 2-11. –48 Vdc Redundant Source Power Supply Pinouts

2-73360-A2-GB20-20 December 1996

Page 20

ACCULINK 336x E1 NTU

6

Cabling Examples

The E1 NTU is supplied with an ac power module.

Optional cables that you can order from the company

are described in Appendix D, Pin Assignments.

Figure 2-12 illustrates some cabling examples.

COM PORT

COM

AUX

POWER

CAUTION: AUX PORT OR COM PORT MUST

NOT BE CONNECTED TO HDSL NETWORK

PORT

PORT

120Ω

PORT 3 PORT 4

PORT 1 PORT 2CLOCK IN

HDSL

NETWORK

G.703

TX RX

RX SHIELD

OPEN

EARTH

75Ω

HDSL

NETWORK

120Ω

IN

OUT

75Ω

75Ω

The 120Ω/75Ω switch selects

either the 120 ohm balanced

G.703 interface or the 75 ohm

unbalanced G.703 interface. The

RX SHIELD switch selects either

an “open” or “earth” shield

connection for the 75 ohm RX

interface. (This switch must be set

to “open” when using the 120 ohm

interface.)

HDSL HDSL

NTU

NETWORK

NTU

COM PORT

COM

AUX

POWER

CAUTION: AUX PORT OR COM PORT MUST

NOT BE CONNECTED TO HDSL NETWORK

PORT

PORT

NOTE

HDSL

NETWORK

G.703

TX RX

RX SHIELD

120Ω

PORT 3 PORT 4

PORT 1 PORT 2CLOCK IN

120Ω

OPEN

IN

EARTH

OUT

75Ω

75Ω

HDSL

NETWORK

75Ω

TO AC

POWER

MODULE

SERIAL

PORT

3100-F1-550

NOTE:

3100 SERIES

FRONT PANEL

EMULATION

SOFTWARE,

3100-C1-010

TO DC

POWER

(OPTIONAL)

3100-F1-520

SNMP

MANAGER

Figure 2-12. Cabling Examples

3100-F1-540

OR

495-1474

2-8 December 1996 3360-A2-GB20-20

Page 21

Installation

7

8

7

9

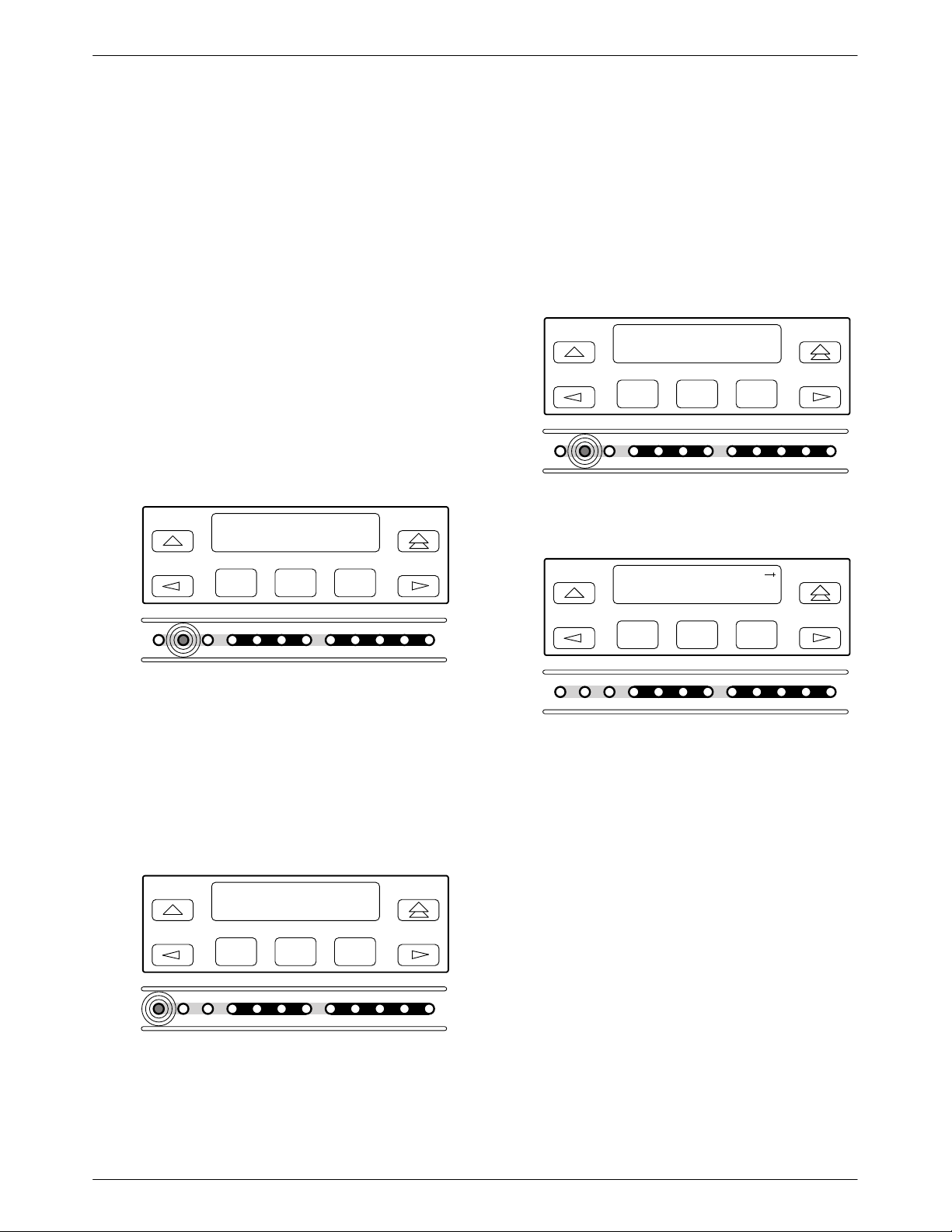

Power-Up Self-Test

After you connect the E1 NTU to a power source, the

unit performs the power-up self-test to ensure that it is in

good working order. The E1 NTU performs this test on

itself upon power-up or after a device reset, unless it has

been disabled by the Self-T est configuration option (see

Appendix C, Configuration Options).

The self-test includes a basic processor test, a limited

memory test, a code checksum test, and basic verification

tests of the internal components. The front panel LCD

displays the progress and pass/fail status of these

power-up tests.

The power-up self-test consists of the following steps:

1. Once the E1 NTU is plugged in, the In Progress

screen appears and the Fail LED blinks ON and

Off continuously.

Self-Test:

In Progress

F1

F2

F3

If the self-test fails, the Failed screen appears for

five seconds. The Fail LED lights, and an

eight-digit failure code (xxxxxxxx) is displayed for

use by service personnel to determine the cause of

the self-test failure. The E1 NTU continues to try

to operate. If you are in doubt about the results of

the self-test, use the Self-T est Health command to

display the status of this test (see the Self-Test

Health section in Chapter 4, Maintenance).

Self-Test:

xxxxxxxx

F1

F2

ALRM SIG ALRM PDVOOF BPV

NETWORK RXD

F3

OK

FAIL

Failed

TEST SIG1 SIG2 OOF

4. The top-level menu screen appears.

E1 HDSL NTU

Stat Test Cnfig

CTS RTSTXDDTR

495-1474

OK

FAIL

TEST SIG1 SIG2 OOF

ALRM SIG ALRM PDVOOF BPV

NETWORK RXD

CTS RTSTXDDTR

495-1474

2. All the LEDs then start to flash simultaneously in

the pattern twice ON, then Off. Then, the LCD

begins to flash characters and numbers in the same

pattern, alternating with the flashing LEDs.

3. If the self-test is successful, the Passed screen

appears for one second, the Fail LED turns Off

and the OK LED lights.

Self-Test:

Passed

F3

DTR TXD CTS RTS

495-1474

OK

FAIL

F1

TEST SIG1 SIG2 OOF

NETWORK RXD

F2

ALRM SIG ALRM PDVOOF BPV

OK

FAIL

F1

TEST SIG1 SIG2 OOF

NETWORK RXD

F2

ALRM SIG ALRM PDVOOF BPV

F3

DTR TXD CTS RTS

495-1474

2-93360-A2-GB20-20 December 1996

Page 22

Operation

Overview 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Front Panel 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad. 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Jacks. 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEDs 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Unit Identity 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying LED Conditions 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the G.703 DTE or Data Port for LED Display 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Configuration Options 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying/Editing Configuration Options 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Edit Changes 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting/Copying to a Specific Port 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the E1 NTU for SNMP Management 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Port 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the IP Address 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Link Layer Protocol 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying the Community Name(s) and Access Type(s) 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring SNMP Traps 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling SNMP Trap Messages 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Number of Trap Managers 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Destination for SNMP Traps 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring DS0 Channels 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying DS0 Channel Assignments 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Allocating Data Ports 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Channel Assignment Method 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Channel Assignment Method 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Allocating DS0 Channels from the G.703 DTE Interface to the Network Interface 3-30. . . . . . . . . . . . . .

Clearing DS0 Channel Allocation 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Timing Source 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring for Network Timing 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring for External Timing 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring/Releasing the User Interface 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring the Active User Interface 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Releasing the Active User Interface 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the E1 NTU 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Operations 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3-13360-A2-GB20-20 December 1996

Page 23

ACCULINK 336x E1 NTU

1

Overview

This chapter contains information for operating your

E1 NTU. It includes a description of the front panel and

sample procedures for configuring the E1 NTU.

Using the Front Panel

The E1 NTU front panel (Figure 3-1) consists of an

LCD, a keypad, test jacks, and 12 LEDs.

NOTE

You can display a graphical

representation of the E1 NTU

front panel on an attached PC

(see Appendix G,

Emulation

LCD

F1 F2 F3

).

KEYPAD

Front Panel

E1

HDSL

LINEE1MON

LINE

Lp1

Lp2InOutInOut

TEST JACKS LEDs

OK

FAIL TEST SIG1 OOF ALRM

Figure 3-1. E1 NTU Front Panel

SIG2 SIG ALRM PDVOOF BPV

NETWORK RXD

DTR TXD CTS RTS

496-14728-0

3-2 December 1996 3360-A2-GB20-20

Page 24

Operation

LCD

The LCD (Figure 3-2) displays two types of data:

• Messages such as alarms, command/test

completion, and action in progress

• Front panel menu tree information (see

Appendix A, Front Panel Menu)

F1 F2

Figure 3-2. LCD

The LCD displays status messages as requested via the

Device Health and Status branch of the front panel menu

(see the Device Health and Status section in Chapter 4,

Maintenance). In addition, the highest level status

message appears on the front panel automatically if no

front panel action has occurred at the E1 NTU for the past

five minutes.

The LCD also lists commands, configuration options,

and test results. In most cases, the top line shows the

command or option name and default value, while the

second line displays options and responses. When a

response is required, select from the options displayed

directly above the Function keys (F1, F2, F3); make your

choice by pressing the corresponding Function key.

F3

Keypad

The 7-button keypad (Figure 3-3) enables you to

navigate through the menu tree and select choices

presented on the second line of the LCD.

F1 F2

Figure 3-3. Keypad

Use the

key to move up the menu.

F1 F2

Use the key to exit any part of the menu in which

you may be operating. You immediately return to the

top-level menu screen shown on the front panel menu (see

Appendix A, Front Panel Menu).

F3

F3

F1 F2

F3

Use the Function (F1, F2, F3) keys to make selections

from the choices presented on the second line of the LCD.

When this line presents choices, it is generally divided

into three sections, each displayed directly above one of

the Function keys. When your choice appears above one

of the Function keys, press that key to select that choice.

F1 F2

F3

3-33360-A2-GB20-20 December 1996

Page 25

ACCULINK 336x E1 NTU

3

9

The scroll keys ( and ) serve one of two functions,

depending on whether a menu screen or a data entry

screen appears on the front panel.

For data entry screens, the

character to the left while the

key scrolls one

key scrolls one

character to the right.

For menu screens, the

menu choice while the

key scrolls to the previous

key scrolls to the next menu

choice.

If a choice is available to the left of the screen, the

character ← appears on the top line. If a choice is

available to the right of the screen, the → character

appears on the top line. If choices are available to both the

right and the left of the screen, two arrows appear (

).

The arrows indicate that you must use the scroll keys to

bring the additional options onto the screen.

F1 F2

F3

LEDs

There are twelve LEDs on the E1 NTU front panel.

The five LEDs on the right (Figure 3-5) are shared

between the G.703 DTE port and the data ports. Refer to

the Selecting the G.703 DTE or Data Port for LED

Display section later in this chapter to choose which port’s

status the LEDs display.

OK

FAIL

TEST SIG1 SIG2 OOF

Figure 3-5. E1 NTU LEDs

A green LED indicates normal operation. A yellow

LED indicates a warning (for the G.703 DTE port) or

activity (for the data ports). Conditions are sampled every

tenth of a second.

The twelve front panel LEDs are grouped into four

sections to indicate the status of the:

• System (T able 3-1 )

ALRM SIG ALRM PDVOOF BPV

NETWORK RXD

DTR TXD CTS RTS

495-1474

Test Jacks

Six test jacks are located on the front panel

(Figure 3-4). These are described in the Test Jacks section

in Chapter 4, Maintenance.

HDSL

NETE1LINEE1MON

Lp1

Lp2InOutInOut

495-1475

Figure 3-4. Test Jacks

• Network interface (T able 3-2 )

• G.703 DTE Port (Table 3-3)

• Data Ports (T able 3-4 )

3-4 December 1996 3360-A2-GB20-20

Page 26

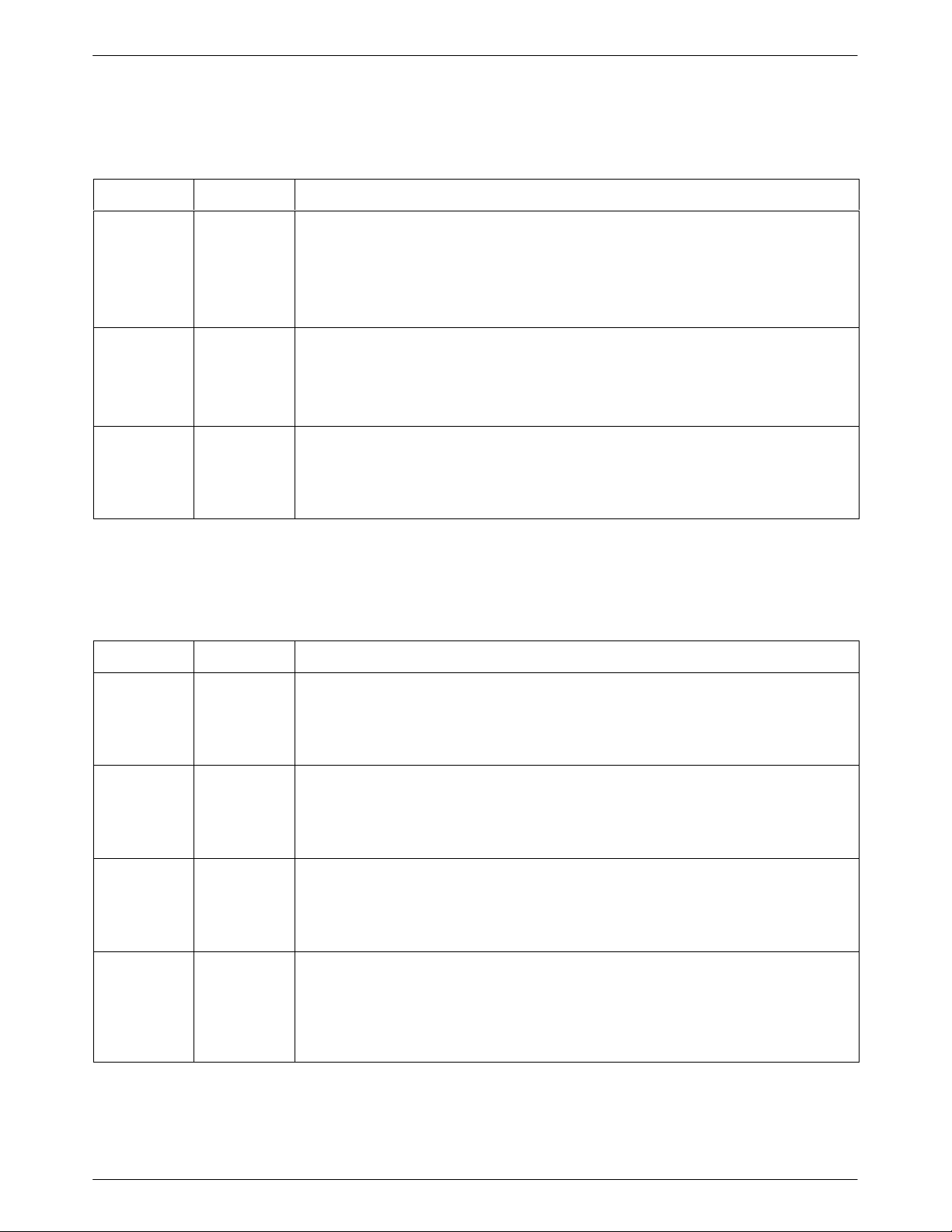

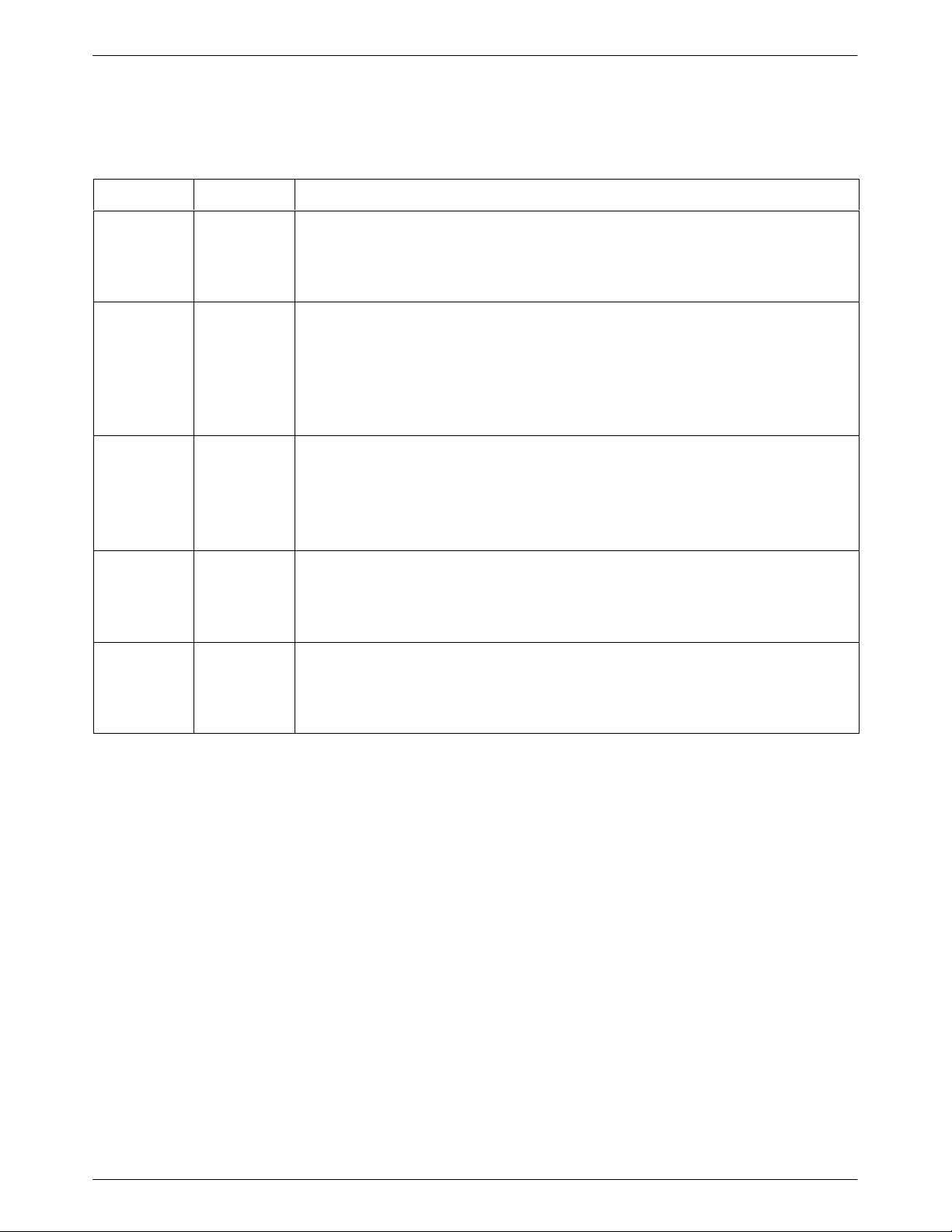

Table 3-1

System LEDs

Operation

Name

OK Green Indicates the current operational state of the E1 NTU.

FAIL Yellow Indicates a system failure or a self-test.

TEST Yellow A system test is in progress.

Color Meaning

ON:

OFF:

BLINKING:

ON:

OFF:

BLINKING

ON:

OFF:

The E1 NTU is operational and has power.

The E1 NTU is performing a power-up self-test or a system failure

has occurred.

A software download is in progress.

A device error/fault is detected or a reset has just occurred.

No system failures are detected.

: A self-test is in progress.

A loopback or pattern test has been initiated either locally , by the

network, or externally.

No tests are active.

Table 3-2

Network Interface LEDs

Name

SIG1 Green Monitors the signal being received from the network.

SIG2 Green Monitors the signal being received from the network.

OOF Yellow Monitors Out Of Frame (OOF) conditions on the received network signal.

ALRM Yellow Indicates whether an alarm condition exists on the received network signal.

Color Meaning

ON:

OFF:

ON:

OFF:

ON

: At least one OOF was detected on the signal during the sampling

OFF:

ON:

OFF:

A recoverable signal is being received from the network on loop 1.

The signal cannot be recovered from the network on loop 1 (a Loss

of Signal condition exists).

A recoverable signal is being received from the network on loop 2.

The signal cannot be recovered from the network on loop 2 (a Loss

of Signal condition exists).

period.

No OOFs were detected on the signal during the sampling period.

An alarm condition (LOS, LOF, EER, RAI, AIS, RMA, MFA) exists on

the received network signal. Use the Device Health and Status

command to determine the alarm type.

No alarm condition exists on the network interface signal.

3-53360-A2-GB20-20 December 1996

Page 27

ACCULINK 336x E1 NTU

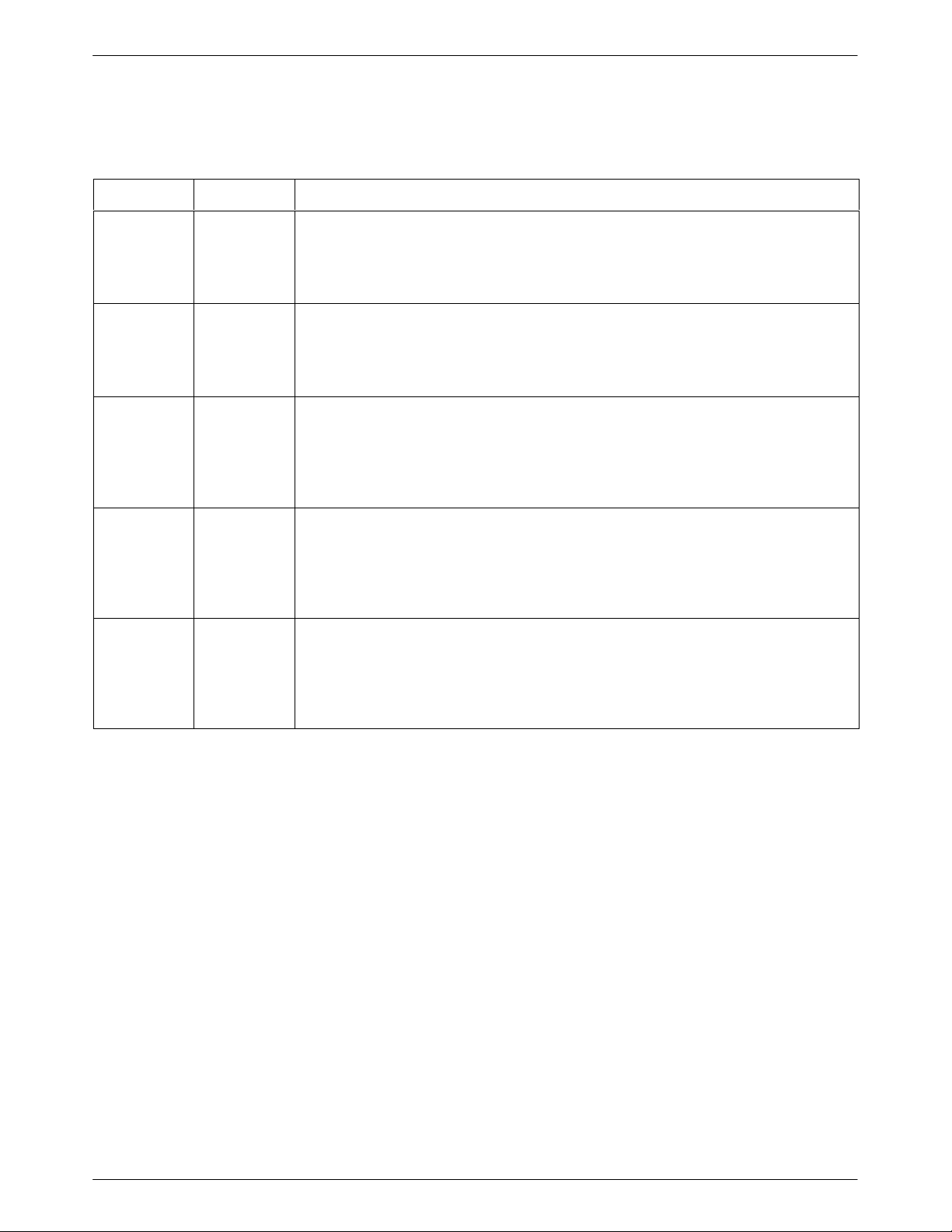

Table 3-3

G.703 DTE Port LEDs

Name

SIG Green Monitors the signal being received from the G.703 DTE port.

OOF Yellow Monitors Out Of Frame (OOF) conditions on the received G.703 DTE signal.

ALRM Yellow Indicates whether an alarm condition exists on the received G.703 DTE signal.

PDV Yellow Monitors Pulse Density Violations (PDV) on the received G.703 DTE signal.

BPV Yellow Monitors Bipolar Violations (BPV) on the received G.703 DTE signal.

Color Meaning

ON:

OFF:

ON:

OFF:

ON:

OFF:

ON

: At least one PDV was detected (and corrected) on the received

OFF:

ON:

OFF:

A recoverable signal is being received from the G.703 DTE port.

The signal cannot be recovered from the G.703 DTE port (a Loss of

Signal condition exists).

At least one OOF was detected on the signal during the sampling

period.

No OOFs were detected on the signal during the sampling period.

An alarm condition (LOS, LOF, EER, RAI, AIS, RMA, MFA) exists on

the received G.703 DTE signal. Use the Device Health and Status

command to determine the alarm type.

No alarm condition exists on the G.703 DTE Interface signal.

G.703 DTE signal during the sampling period.

No PDVs were detected on the received G.703 DTE signal during

the sampling period.

At least one BPV was detected (and corrected) on the received

G.703 DTE signal during the sampling period.

No BPVs were detected on the received G.703 DTE signal during

the sampling period.

3-6 December 1996 3360-A2-GB20-20

Page 28

Table 3-4

Data Port LEDs

Operation

Name

DTR Green Monitors the state of interchange circuit CD (CCITT 108/1, /2) – Data Terminal Ready

TXD Yellow Monitors activity on interchange circuit BA (CCITT 103) – Transmitted Data. This is the

RXD Yellow Monitors activity on interchange circuit BB (CCITT 104) – Received Data. This is data

CTS Yellow Monitors the state of interchange circuit CB (CCITT 106) – Clear-to-Send sent to the

Color Meaning

received from the synchronous data DTE.

ON:

OFF:

data sent from the synchronous data DTE to the data port on the E1 NTU.

ON:

OFF:

CYCLING:

sent to the synchronous data DTE from the data port on the E1 NTU.

ON:

OFF:

CYCLING:

synchronous data DTE.

ON:

OFF:

DTR is being asserted by the synchronous data DTE.

DTR is not being asserted.

Ones are being received from the synchronous data DTE.

Zeros are being received from the synchronous data DTE.

Both ones and zeros are being received from the synchronous

data DTE.

Ones are being sent to the synchronous data DTE.

Zeros are being sent to the synchronous data DTE.

Both ones and zeros are being sent to the synchronous data DTE.

CTS is being asserted by the E1 NTU.

CTS is not being asserted.

RTS Yellow Monitors the state of interchange circuit CA (CCITT 105) – Request-to-Send received

from the synchronous data DTE.

ON:

OFF:

RTS is being asserted by the synchronous data DTE.

RTS is not being asserted.

3-73360-A2-GB20-20 December 1996

Page 29

ACCULINK 336x E1 NTU

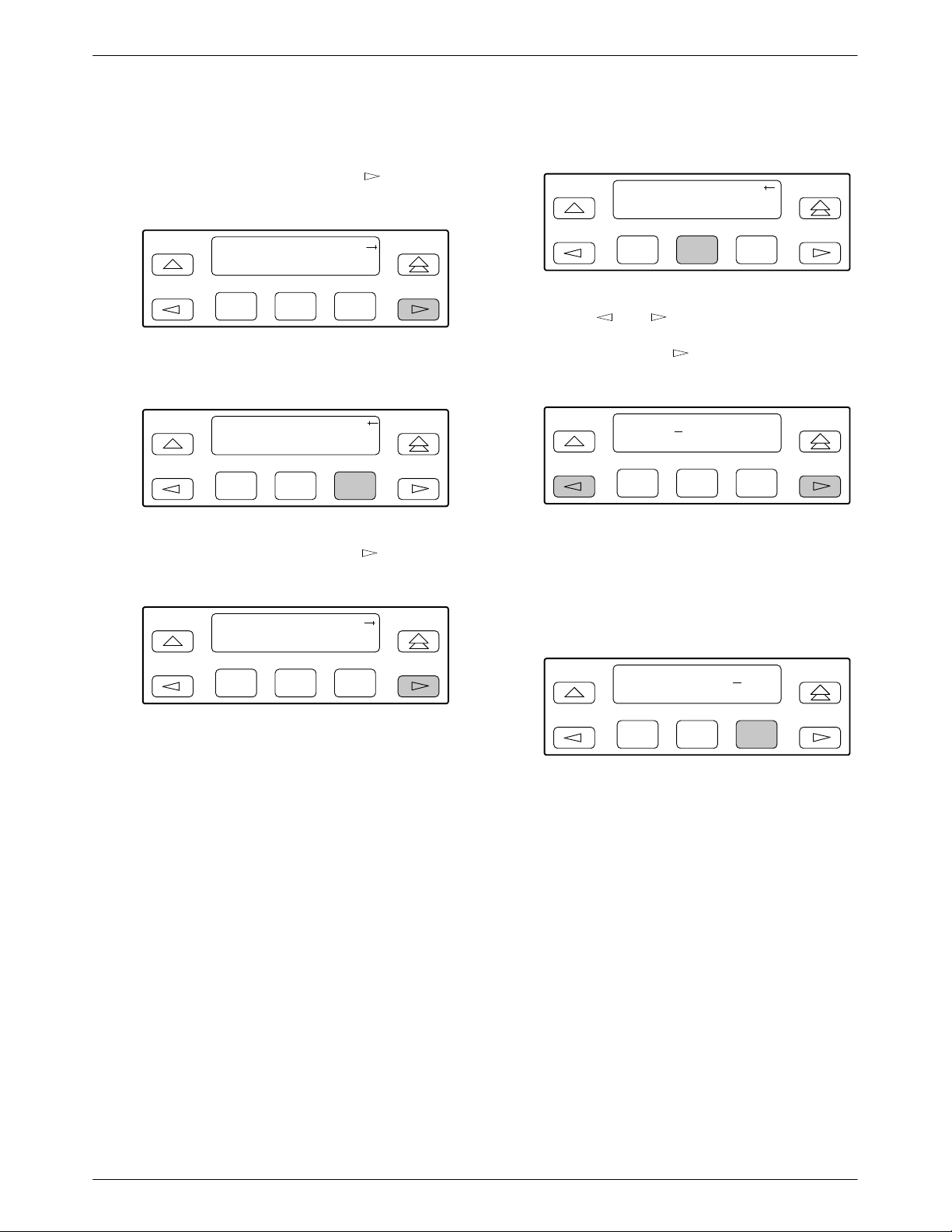

Displaying Unit Identity

The identity of the E1 NTU (serial number, model

number, software revision level, hardware revision level,

and customer identification) is available through the

Status branch of the front panel menu (see Appendix A,

Front Panel Menu).

The customer identification is the only identity number

you can change.

To display the E1 NTU’s identity (ID),

1. From the top-level menu screen, select Stat.

E1 HDSL NTU

Stat Test Cnfig

F1

F2

2. From the Status screen, press the key until the

ID selection appears on the screen.

F3

4. The following screens appear in the order listed

each time you press the

key.

Identity:

xxxxxxx

Ser=

F1

F2

F3

Identity:

xxxx-xx-xxx

Mod=

F1

F2

F3

Identity:

Cust ID=

F1

xxxxxxxx

F2

F3

3. Select ID.

Status:

HDSL DevHS STest

F1

F2

F3

Status:

TStat LED ID

F1

F2

F3

Identity:

SRev=

F1

Identity:

CCA1=

F1

Identity:

CCA2=

F1

Identity:

CCA3=

xx.xx.xx

F2

xxxx-xxx

F2

xxxx-xxx

F2

xxxx-xxx

F3

F3

F3

F1

3-8 December 1996 3360-A2-GB20-20

F2

F3

Page 30

Operation

To change the customer identification (CID),

1. From the top-level menu, press the

key until

the Ctrl selection appears on the screen.

E1 HDSL NTU

Stat Test Cnfig

F1

F2

F3

2. Select Ctrl.

E1 HDSL NTU

Test Cnfig Ctrl

F1

F2

F3

3. From the Control screen, press the key until

the CID selection appears on the screen.

Control:

Rel LED ClrReg

4. Select CID.

Control:

Reset CID DL

F1

F2

F3

5. Use the and keys to position the cursor

under the desired character. You must enter a

character before the

moves the cursor to the

next space to the right.

CustID:

xxxxxxxx

Up Down Save

F1

F2

F3

6. Enter the desired ID. Press F1 (Up) and F2

(Down) to scroll up and down through the valid

characters/numbers for the customer ID. Valid

characters are 0 through 9, #, -, ., /, A to Z, and

blank space. Press F3 (Save) to save the ID.

F1

F2

F3

CustID:

xxxxxxxx

Up Down Save

F1

F2

F3

3-93360-A2-GB20-20 December 1996

Page 31

ACCULINK 336x E1 NTU

Displaying LED Conditions

The same conditions monitored by the front panel

LEDs can also be monitored by the LED command. This

command is most useful when the E1 NTU is being

accessed remotely (see Appendix G, Front Panel

Emulation). When using Front Panel Emulation, no LEDs

are shown on the PC’s screen; you must use the Stat

command procedure described below to get LED

information.

NOTE

The following procedure is an

example only. Screen displays

may vary depending on the

model of the E1 NTU.

To display LED conditions on the front panel screen,

1. From the top-level menu screen, select Stat.

4. From the Select LEDs screen, press the Function

key that corresponds to E1 or the port for which

you want to display LEDs. Use the scroll keys, if

necessary.

Select LEDs:

E1 Prt1 Prt2

F1

F2

F3

If you chose E1, the LED Display screen lists the

LED signals, two at a time, on the second line. A

vertical bar at the left of the LED name indicates

the condition is ON, while an underscore indicates

the condition is Off.

LED Display:

_Test _NetSig1

F1

F2

F3

E1 HDSL NTU

Stat Test Cnfig

F1

F2

F3

2. From the Status screen, press the key until the

LED selection appears on the screen.

Status:

HDSL DevHS STest

F1

F2

F3

3. From the Status screen, select LED.

Status:

Perf TStat LED

F1

F2

F3

If you chose a port, the Port n LEDs screen lists

the LED signals, two at a time, on the second line.

A vertical bar at the left of the LED name

indicates the condition is ON, while an underscore

indicates the condition is Off.

Port n LEDs:

_DTR _TXD

F1

F2

F3

5. Use the and keys to scroll LED names

onto the screen.

3-10 December 1996 3360-A2-GB20-20

Page 32

Operation

Selecting the G.703 DTE or

Data Port for LED Display

Use the LED command on the Control branch to select

which port’s (G.703 DTE or data port) status appears on

the five shared LEDs on the front panel.

NOTE

The following procedure is an

example only. Screen displays

may vary depending on the

model and configuration of the

E1 NTU.

To select a port for LED display,

1. From the top-level menu screen, press the

until the Ctrl selection appears on the screen.

E1 HDSL NTU

Stat Test Cnfig

F1

F2

F3

key

The currently selected port name appears on the

top line of the LCD. DTE indicates the G.703

DTE port.

LED Dsply: DTE

DTE Prt1 Prt2

F1

F2

F3

4. From the LED Dsply screen, press the Function

key that corresponds to the G.703 DTE or data

port for which you want the LEDs to display. Use

the scroll keys, if necessary.

Select DTE to monitor the G.703 DTE port’s SIG,

OOF, ALRM, PDV, and BPV status signals on the

shared LEDs.

Select a particular data port to monitor the data

port’s DTR, TXD, RXD, CTS, and RTS control

signals on the shared LEDs.

Changing Configuration

Options

2. Select Ctrl.

E1 HDSL NTU

Test Cnfig Ctrl

F1

F2

F3

3. From the Control screen, select LED.

Control:

Rel LED ClrReg

F1

F2

F3

The E1 NTU is an intelligent device that displays only

valid options for the current configuration. Therefore, you

are only presented with menu choices that are consistent

with the current configuration and operational state of the

E1 NTU; invalid combinations of configuration options

do not appear. For example, menus displayed for the

Model 3360 (2 ports) and the Model 3364 (4 ports) differ

due to the number of ports available. Also, if the G.703

DTE interface selection is disabled, many of the menu

choices do not appear. Be aware that although all options

are shown in this guide, what you see on your E1 NTU

varies with your configuration.

The E1 NTU offers four sets of configuration options

located in the following memory areas:

• Active (Activ). The configuration option set active

for the E1 NTU is stored here. Before a

configuration option set becomes active for the E1

NTU, you must save the set to the Active area.

When the E1 NTU is shipped from the factory, the

Active configuration option set is identical to the

Factory set. This area can be written to and controls

the current operation of the device.

3-113360-A2-GB20-20 December 1996

Page 33

ACCULINK 336x E1 NTU

• Customer 1 (Cust1). The first of two sets of

customer-defined configuration options. This area

can be written to.

• Customer 2 (Cust2). The second of two sets of

customer-defined configuration options. This area

can be written to.

• Factory (Fact). This is a set of configuration

options preset at the company. This set is

determined by what is considered to be the most

common configuration used in the E1 NTU market.

Factory options are read-only.

The configuration options are divided into functional

groups. Appendix C contains a list of the configuration

options and defaults. These groups are:

• DTE (G.703) Interface

• Port

• Network Interface

• Channel

• General

• User Interface

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

Load from:

Activ Cust1

F1

F2

F3

3. Select Edit.

Choose Funct:

Edit Save

F1

F2

F3

4. From the Edit screen, select the functional group

you want to edit by pressing the appropriate

Function key. Use the scroll keys, if necessary.

(The NET selection is shown as an example only.)

• Alarm

• General SNMP

• SNMP Trap

Use the Configuration (Cnfig) branch of the front panel

menu tree to display or change E1 NTU configuration

options (see Appendix A, Front Panel Menu).

Displaying/Editing Configuration Options

To display/edit configuration options,

1. From the top-level menu screen, select Cnfig.

E1 HDSL NTU

Stat Test Cnfig

F1

F2

F3

Edit:

DTE Port NET

F1

F2

F3

The configuration options for the selected

functional group appear on the front panel one

option at a time. The option name appears on

Line 1 with the current value next to it. T o reach

other options, use the Next and Previous selections

to scroll forward and backward through the group

of options.

HDSL Mode:NTU

Next NTU LTU

F1

F2

F3

5. Press the appropriate Function key to choose

another value. Use the scroll keys, if necessary.

6. Use the Save procedure to save your changes to

the Active or Customer area.

3-12 December 1996 3360-A2-GB20-20

Page 34

Operation

Saving Edit Changes

Save edit changes to the Active area when you want

those changes to take effect immediately. Save edit

changes to the Customer area when you want to overwrite

the existing Customer configuration options and store

these changes for future use.

NOTE

If you attempt to exit the Edit

function after making changes

without performing a Save, the E1

NTU prompts you with Save

Options? Choose Yes or No.

To save edit changes,

1. From the Choose Function screen (one level above

the Edit screen, two levels below the top-level

menu screen), select Save.

Choose Funct:

Edit Save

F1

F2

F3

Selecting/Copying to a Specific Port

For the E1 NTU, you have the capability of selecting a

specific port to configure, and then (for 2-port and 4-port

E1 NTUs) copying the configuration options from that

port to another port (or to all ports).

NOTE

The following procedure is an

example only. Screen displays

may vary depending on the

model and configuration of the

E1 NTU.

To select a specific port to configure,

1. From the top-level menu screen, select Cnfig.

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

3. Select Edit.

4. From the Edit screen, select Port.

2. Choose whether you want to save to the Active,

Customer 1, or Customer 2 area. Use the scroll

keys, if necessary.

Save Edit to:

Activ Cust1

F1

F2

F3

Edit:

DTE Port NET

F1

F2

F3

5. From the Port Select screen, press the Function

key that corresponds to the port you want to

configure. Use the

key to scroll addition ports

onto the screen, if necessary. Configure the port

(see Appendix C, Configuration Options).

Port Select:

Copy Prt1 Prt2

F1

F2

F3

3-133360-A2-GB20-20 December 1996

Page 35

ACCULINK 336x E1 NTU

To copy the configuration options to one or all ports,

6. From the Port Select screen, select Copy.

Port Select:

Copy Prt1 Prt2

F1

F2

F3

7. Select the port from which you want to copy the

configuration options using the corresponding

Function key.

Copy From:

Prt1 Prt2 Prt3

F1

F2

F3

8. Select the port to which you want to copy the

configuration options using the corresponding

Function key . Or, press F1 (All) to choose to copy

to all ports.

• Specify the two community names that are allowed

to access the device’s Management Information

Base (MIB).

• Configure the device to send traps to the SNMP

manager, if desired.

Selecting the Port

The SNMP manager or network device (e.g., a router)

can be directly connected to the communications (COM)

port. An external LAN Adapter can be connected to either

the COM port or the auxiliary (AUX) port to provide

Ethernet or T oken Ring connectivity. Also, the E1 NTU

can be daisy chained together by connecting the COM

port of one device to the AUX port of the other, providing

SNMP connectivity.

The COM port can support either synchronous or

asynchronous PPP, or asynchronous SLIP at data rates of

up to 38,400 bps. The AUX port can support data rates up

to 38,400 bps.

The example shown below assumes that the COM port

is being used as the link to the SNMP manager.

To select the COM port as the management link,

1. From the top-level menu screen, select Cnfig.

Copy To:

All Prt1 Prt2

F1

F2

F3

Configuring the E1 NTU for

SNMP Management

To configure the E1 NTU for management by an

SNMP management system you must,

• Select and configure the port that provides the link

to the SNMP management system.

• Set the Internet Protocol (IP) address and subnet

mask needed to access the device (see Appendix F,

IP Network Addressing Scenario).

• Select the link layer protocol (PPP or SLIP) for the

port.

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

3. Select Edit.

4. From the Edit screen, press the

key until the

User selection appears on the screen.

5. Select User.

Edit:

Chan Gen User

F1

F2

F3

6. Press F1 (Next) until the Com Use configuration

option appears.

3-14 December 1996 3360-A2-GB20-20

Page 36

Operation

7. Select SNMP to configure the COM port as the

management link to an external SNMP manager.

Com Use:

Next SNMP ASCII

F1

F2

F3

Setting the IP Address

The IP address is the address used by the SNMP

manager to access the device. For devices using PPP, the

IP address can be negotiated if the network device (e.g.,

router or SNMP manager) supports such negotiation. The

IP address is composed of four fields with three digits per

field (xxx.xxx.xxx.xxx).

The IP address is set for the COM port or the AUX

port (with LAN Adapter or daisy chain), depending on

which one has been chosen as the SNMP communications

link. The example below assumes that an IP address of

010.155.111.222 is being set for the COM port. You can

use the same principles to assign any value (between 000

and 255 for each digit field) to either port.

To assign an IP address to the COM port,

6. From the SNMP Config screen, select Gen.

SNMP Config:

Gen Trap

F1

F2

F3

7. Press F1 (Next) until the Com IP Adr

configuration option appears.

NOTE

Steps 8 and 9 describe the

process for entering the Com IP

address. This process applies to

any IP address.

8. Press F2 (Edit) to edit the IP address. You have the

option of using F3 (Clear) to reset the IP address

to the factory default 000.000.000.000.

Com IP Adr:

Next Edit Clear

1. From the top-level menu screen, select Cnfig.

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

3. Select Edit.

4. From the Edit screen, press the

key until the

SNMP selection appears on the screen.

5. Select SNMP.

Edit:

User Alarm SNMP

F1

F2

F3

F1

F2

F3

9. Use the and keys to position the cursor

under the digit you want to change. Press F1 (Up)

to increment the digit or F2 (Down) to decrement

the digit. In this example, you would press

once to place the cursor under the middle digit in

the first digit field, then press F1 (Up) once to

change the 0 to a 1. Continue in this manner to

change the other digits.

000.000.000.000

Up Down Save

F1

F2

F3

3-153360-A2-GB20-20 December 1996

Page 37

ACCULINK 336x E1 NTU

10. When you are through changing the IP address,

you must press F3 (Save) to save the value.

Otherwise, the original value will be retained.

010.155.111.222

Up Down Save

F1

F2

F3

Selecting the Link Layer Protocol

Two link layer protocols, Point-to-Point Protocol (PPP)

and Serial Line Internet Protocol (SLIP), are supported for

connection to an external SNMP manager or network

device (e.g., a router). PPP can be used for synchronous or

asynchronous operation. SLIP can be used for

asynchronous operation only.

The E1 NTU implementation of PPP supports the

following:

• Full negotiation of PPP’s Link Control Protocol

(LCP).

To select the link layer protocol,

1. From the top-level menu screen, select Cnfig.

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

3. Select Edit.

4. From the Edit screen, press the

key until the

SNMP selection appears on the screen.

5. Select SNMP.

Edit:

User Alarm SNMP

F1

F2

F3

6. From the SNMP Config screen, select Gen.

• Active negotiation of LCP when the connection is

established.

• Maximum Request Unit (MRU) sizes up to

1500 bytes, but the E1 NTU will attempt to

negotiate down to 500 bytes.

• The E1 NTU provides a unique LCP magic number

derived from the unit serial number and the elapsed

time.

• Full negotiation of escape characters.

The E1 NTU implementation of PPP does not support

Link Quality Reports (LQR), compression, encryption,

Password Authentication Protocol (PAP) or Challenge

Authentication Protocol (CHAP).

The E1 NTU implementation of SLIP supports a fixed

MRU size of 1006 bytes.

Before selecting the protocol, you must first select the

port to be used as the communications link. Refer to the

Selecting the Port section on page 3-14. This example

assumes that the COM port is being used as the

communications link.

SNMP Config:

Gen Trap

F1

F2

F3

7. Press F1 (Next) until the Com Link configuration

option appears.

8. Press F2 (PPP) or F3 (SLIP).

Com Link:

Next PPP SLIP

F1

F2

F3

3-16 December 1996 3360-A2-GB20-20

Page 38

Operation

Specifying the Community Name(s) and

Access Type(s)

You have the capability of specifying up to two

community names (community name 1 and community

name 2) to be used by external SNMP managers when

trying to access objects in the E1 NTU’s MIB. Once you

specify the community name(s), you must then specify the

type of access to the MIB that SNMP managers in the

community are permitted to have.

To specify the community name 1 and its access type,

1. From the top-level menu screen, select Cnfig.

2. Select the configuration option set to be copied

into the Edit area by using the appropriate

Function key. Use the scroll keys, if necessary.

3. Select Edit.

4. From the Edit screen, press the

SNMP selection appears on the screen.

5. Select SNMP.

key until the

8. Press F2 (Edit) to edit the community name. The

factory default community name is public.

CommunityName1:

Next Edit Clear

F1

F2

F3

NOTE

Steps 9 and 10 describe the

process for entering text strings

for SNMP configuration options.

This process applies to entering

any text strings into SNMP

configuration options.

9. Use the and keys to position the cursor

under the character you want to change. Press

F1 (Up) or F2 (Down) to scroll through the valid

numbers/characters for the text string.

Edit:

User Alarm SNMP

F1

F2

F3

6. From the SNMP Config screen, select Gen.

SNMP Config:

Gen Trap

F1

F2

F3

7. Press F1 (Next) until the CommunityName1

configuration option appears.

public

Up Down Save

F1

F2

F3

The F1 (Up) key scrolls through the ASCII

character set in the following order: numbers

(0–9), lowercase letters (a–z), uppercase letters

(A–Z), space character, ASCII symbols (ascending

order, based on ASCII code), and the End of Line

symbol (←). The ← erases all characters to the

right of the cursor.

10. When you are through changing the community

name, you must press F3 (Save) to save the value.

Otherwise, the original value will be retained.

3-173360-A2-GB20-20 December 1996

Page 39