Operating Manual

Preparation Range

Preparation Range

BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Product Range Also Includes:

Induction Hobs / Combination Ovens / Pizza Ovens / Mixers

Salamander Grills / Contact Grills / Pie Warmers / Fryers

Heated Displays / Veg Prep Machines / Bains Marie / Mincers and more

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

BS1 – Band Saw

(Pictured Bottom Left)

MM12, MM22, MM32 – Meat Mincer

(Pictured Lower Right)

MS250, MS300, MS350 – Meat Slicer 10”, 12”, 14”

(Pictured Upper Right)

VPM –Vegetable Preparation Machine

(Pictured Top Right)

Featured Devices

Convection Collection

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Introduction………………………………………………………………………………………………………………………..………

Warnings and Precautions…………………………………………………………………………………………..………………

Technical Data Specifications………………………………………………………………………………………………………

Band Saw…………………………………………………………………………………………………………………….

Meat Mincers………………………………………………………………………………………………………………

Meat Slicers……………………………………………………………………………………………………………......

Vegetable Preparation Machine…………………………………………………………………………………..

Accessories………………………………………………………………………………………………………………………………….

Meat Mincers………………………………………………………………………………………………………………

Meat Slicers……………………………………………………………………………………………………………......

Vegetable Preparation Machine…………………………………………………………………………………..

Installation………………………………………………………………………………………………………………………………....

General………………………………………………………………………………………………………………………..

Band Saw…………………………………………………………………………………………………………………….

Vegetable Preparation Machine…………………………………………………………………………………..

The cutting Blades and Graters…………………………………………………………………….

Operating Instructions…………………………………………………………………………………………………………………

Band Saw…………………………………………………………………………………………………………………….

Meat Mincers………………………………………………………………………………………………………………

Meat Slicers……………………………………………………………………………………………………………......

Vegetable Preparation Machine…………………………………………………………………………………..

Maintenance……………………………………………………………………………………………………………………………….

Band Saw…………………………………………………………………………………………………………………….

Replacing the Saw Blade………………………………………………………………………………

Adjusting the Saw Blade……………………………………………………………………………….

To adjust the Slope……………………………………………………………………………………….

Cleaning……………………………………...……………………………………………………………….

Meat Mincers………………………………………………………………………………………………………………

Cleaning……………………………………...……………………………………………………………….

Meat Slicers……………………………………………………………………………………………………………......

General Maintenance…………………………………………………………………………………..

Lubrication……………………………………………………………………………………………………

Guide Lubrication……………….…………………………………………………………

Pusher Axle Lubrication……………………………………….………………………..

Sharpener Lubrication…………………………………………...........................

Localising Head Lubrication…………………………………………………………..

Blade Sharpening…………………………………………………………………………………………

Vegetable Preparation Machine……………………………….………………………………………………….

Cleaning……………………………….……...………………………………………………………………

Troubleshooting………………………………………………………………………………………………………………………….

Vegetable Preparation Machine……………………………….………………………………………………….

Table of Contents

1

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

5

6

6

7

7

7

8

8

8

9

9

8

9

10

10

10

10

10

10

10

10

11

11

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Introduction

Thank you for purchasing a Pantheon Catering Equipment product. In this booklet you will find

instructions for the safe operation of the product so please read carefully and retain for future

reference.

Warnings and Precautions

The following warnings and precautions are important and must be adhered to:

Ensure the voltage and frequency power requirements for the Mincer match that of the

supply.

The machine must be earthed when used. There is a danger of electric shock if it is not

earthed. You must check the links frequently ensure a safe use of the machine.

In case of emergency, please turn off the power switch and unplug the machine.

If the electric wire becomes damaged, a qualified engineer or the manufacturer must

replace it.

Pantheon Catering Equipment is not responsible for any accidents or faults caused by amendments

made to the machine or improper use by the user.

Technical Data Specifications:

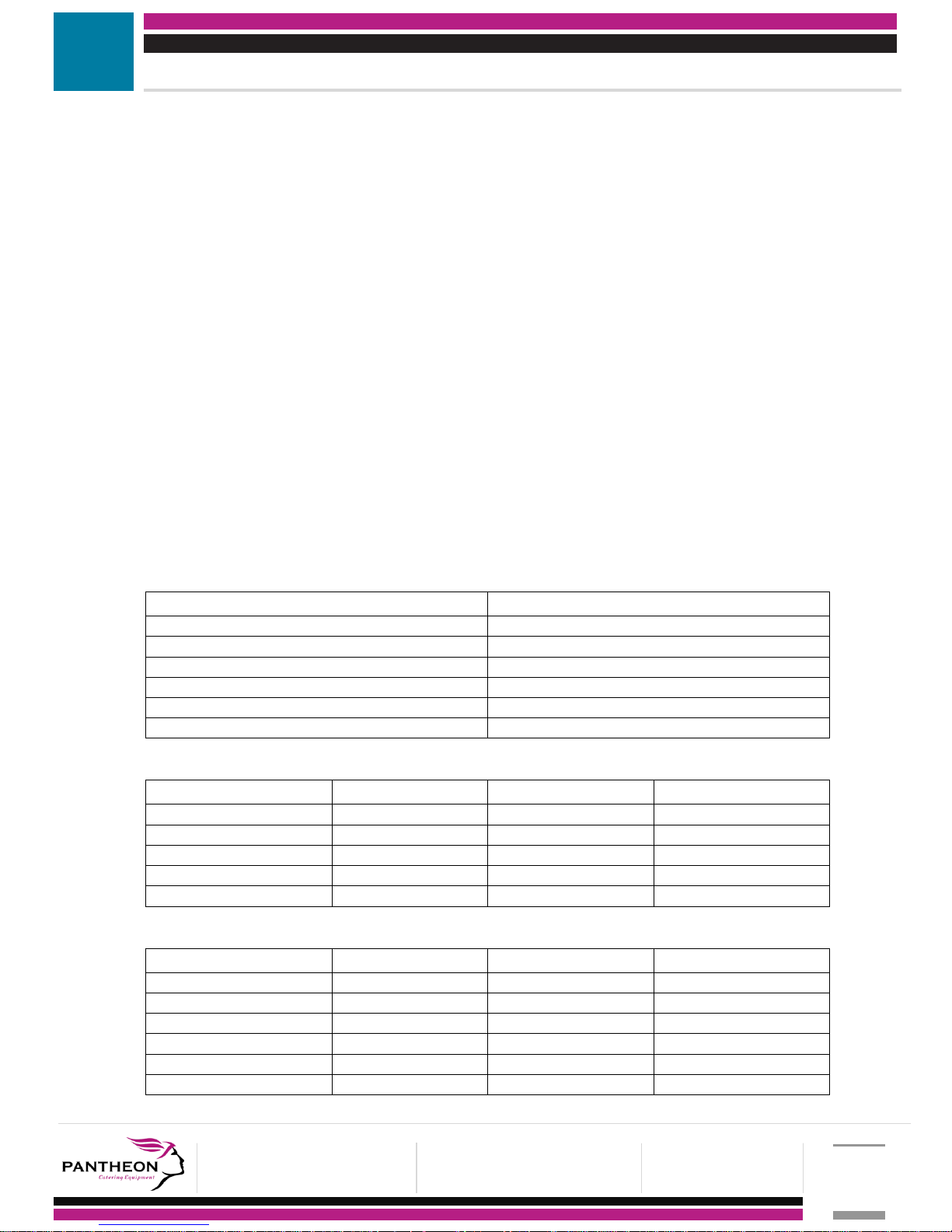

Band Saw

Model

BS1

Voltage (V)

220-240V 50Hz

Power (w)

750

Saw Blade Size (mm)

1650

Max Weight (kg)

1000-2000

Weight (Kg)

52

Dimensions (mm)

530w x 515d x 955h

Meat Mincers

Model

MM12

MM22

MM32

Voltage (V)

220 - 240V 50Hz

220 - 240V 50Hz

220 - 240V 50Hz

Power (w)

1100

1600

1600

Capacity (kg/hr)

120

150

260

Weight (Kg)

20

26

31

Dimensions (mm)

430w x 210d x 460h

670w x 250d x 480h

645w x 305d x 500h

Meat Slicers

Model

MS250

MS300

MS350

Voltage (V)

220-240V 50Hz

220-240V 50Hz

220-240V

Power (w)

1800

1800

2000

Blade Diameter (mm)

250

300

350

Max Slicing Width (mm)

180

220

260

Weight (Kg)

20

26

49

Dimensions (mm)

500w x 385d x 360h

500w x 590d x 450h

787w x 610d x 495h

1

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

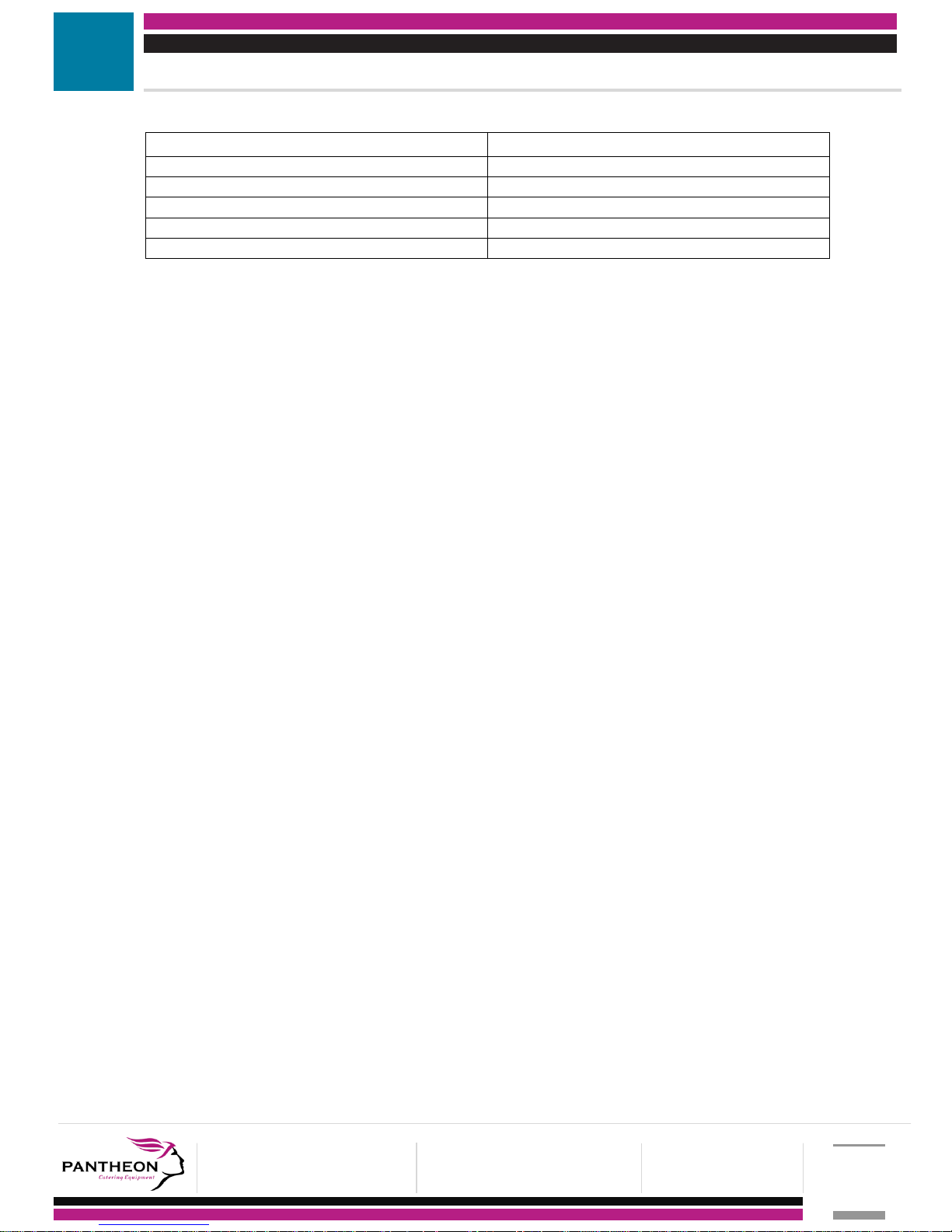

Vegetable Preparation Machine

Model

VPM

Voltage (V)

220-240V 50Hz

Power (w)

500

Disc Speed (rpm)

270

Weight (Kg)

23

Dimensions (mm)

235w x 490d x 480h

Specifications are subject to change. Please check the rating label on the back of the machine.

Accessories

Meat Mincer

The stated device comes with the following accessories as standard:

1x Sausage Encaser and Filler

1x 4 ½mm Mincing Disc

1x 10mm Mincing Disc

All Meat Mincers come equipped with this as standard

You can also purchase the following items as extra:

3mm Mincing Disc

6mm Mincing Disc

8mm Mincing Disc

These can be bought as optional extras off of the internet.

Meat Slicer

All meat slicers come with the following accessories as standard:

1 x Blade removal tool

Vegetable Preparation Machine

The VPM comes with the following blades as standard:

1 x 2mm Blade

1 x 4mm Blade

3 x Graters

The VPM also has other optional extra accessories that can be purchased online

2

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Installation

General

The installation of the unit must be only performed by a qualified technician.

Place the device on top of a solid, even, safe and stable surface that tolerates the weight of

the unit.

Ensure no flammable products are placed near the unit, as it may get hot.

Position the device appropriately so that the plug is always accessible. Also ensure the unit

isn’t placed close to any water.

Please Note: These instructions apply to all the devices covered in this manual

Band Saw

Once Un-boxed and placed following the warnings above inspect the saw belt length on the

top and bottom block to confirm that it is parallel with the edge on the block

Ensure the machine works once plugged in by pressing the green switch, if it works you can

turn the machine off by pressing the red switch, if it doesn’t work press the red switch

unplug the machine and contact the manufacturer.

The machine should operate in a clockwise fashion if this is not the case please cease use of

the machine and contact the manufacturer

To adjust the tension on the saw belt take the handle on the top of the machine and turn it

clockwise until the machine makes a slicing sound this means that the saw belt has the

correct amount of tension.

Vegetable Preparation Machine

The Cutting Blades and Graters

Follow the instructions below and use Figures 2-4 to ensure the blades and graters are correctly

installed.

Open the unit by rotating the knurled locking handle and swinging open the top cover

(See fig.2)

Fit the ejector disc, ensuring it engages on the driver shaft via the two pegs

locate the dicing grid if required

Dicing grids will only fit one way

(See fig.4)

Locate the slots on the cutting disc in the pes on the driver shaft and turn 90 degrees to

secure.

(See fig.3)

The cutting disc is correctly fitted when its centre boss is flush with the head of the drive

shaft

Return the cover to its operating position and relock into position using the knurled locking

handle.

3

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Warning: The cutting Discs must be located/ removed by handling the plastic disc and not by

handling the cutting blade.

Operating Instructions

Band Saw

Please follow the following instructions and use ‘figure 1’ to ensure that the machine is operated

correctly

Ensure the machine is plugged in at the mains

Switch the machine on using the green switch

Place the required meat in-between the sawblade and push device

Using the push device with your left hand Push the meat into the saw blade in order to slice

it

The Sliced meat can then be collected from behind the saw blade with your right hand once

the meat has fully passed through the blade

If the meat requires additional slicing repeat the process above.

Once the slicing process is complete and no additional slicing is required turn the unit off

using the red switch and switch the machine off at the mains.

Note: ALWAYS use the ‘Push Device’ to feed the meat into the mincing machine; do NOT use

your hands. Also, never overload the Band Saw, as it may begin to function incorrectly.

4

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Note: ALWAYS wear protective gear when using the band saw Especially when slicing smaller

meats also ALWAYS pay attention as even if protective wear is worn the blade can still cause

harm particularly the fingers

’Figure 1’

Meat Mincers

To operate the mincer correctly please follow the instructions below and use ‘figure 1’ to help

familiarise yourself with the parts on the unit.

Ensure the mincer is plugged in and turned on at the mains.

Place the required quantity of meat that is required to mince on the tray.

Now turn the unit on using the power switch on the side of the mincer.

Then using the white plastic ‘pusher’, feed the meat into the mincing unit.

Apply constant pressure to ensure the meat is minced uniformly.

The minced meat will emerge from the side of the mincer.

Once the mincing process has been completed turn the unit off and switch it off at the

mains.

Be sure to follow the cleaning process regularly in the ‘maintenance’ section of this manual,

to ensure the mincer continues to operate correctly.

Note: ALWAYS use the ‘white plastic pusher’ to feed the meat into the mincing machine; do NOT use

your hands. Also, never overload the mincer, as it may begin to function incorrectly.

5

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Meat Slicers

Please use figure 1 and follow the instructions below to correctly operate the slicer:

Turn the switch on and let the machine run for about 2-3 minutes check if the machine is

working well before attempting to slice any products.

During operation the blade rotates anti-clockwise.

Adjust the slice thickness by turning the slice thickness regulator anticlockwise. Turn the

support knob anticlockwise ensuring the head is in contact with the size controlling board.

Push the product carriage forward and back over the blade with a continuous motion, using

the product pusher handle and the pusher knob.

After slicing the desired amount turn the Slice thickness regulator knob to Zero and turn the

machine off.

You can now remove the slices and the product.

1. Sharpener

2. Blade protection

3. Blade cover Active pusher

4. Product pusher handle

5. Carriage

6. Size controlling board

7. Switch

8. Slicer thickness regulator

“Figure 1”

6

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Vegetable Preparation Machine

Please follow the instructions below to correctly operate the VPM:

Select the correct feed hope (large half-moon or small circular)

insert chosen vegetable

Use the feed arm or feed stick to apply gentle, constant pressure on the required food

The VPM works rapidly therefore once a vegetable has placed in the hopper it is imperative

to maintain constant pressure to achieve uniform cuts/slices. This is particularly important

when using the chipper

When using smaller vegetables a more uniform slice is achieved utilizing the small hopper

Warning: Under NO circumstances attempt to push vegetables into the machine by hand, as it could

lead to an injury.

Maintenance

Band Saw

Replacing the Saw Blade

When replacing the saw blade follow these instructions to ensure that it is completed correctly:

Loosen the setting b rotating it anticlockwise

When installing a new saw blade pay attention to its direction as the blade could break off

from the machine

Make sure the blade and the slicer are positioned between the top wheel, bottom wheel

and middle plate. Furthermore ensure that the blade passes through the guide groove.

Once changed tighten the setting to ensure the blade is sufficiently positioned and adjust

the tension on the saw belt to ensure the machine is in its optimal state.

Different Saw Blades are used to cut Different foods follow the image below as a guide to this

7

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Adjusting the Saw blade

When adjusting the saw blade follow these instructions to ensure that it is completed

correctly:

In order to ensure the machine is working in its optimal state the saw blade can be adjusted.

Make sure the saw belt is around the wheel and the blades edge is in line with the round

wheel

If the blade isn’t kept in line it can either be replaced or the slope of the blade can be

adjusted

To adjust the slope

Loosen the nut in order to loosen the slope knob

When adjusting the slope knob turn it by hand

When you tighten the knob the blade will move forward and when loosened the blade will

move backwards.

The machine must not be operated when adjusting the knob as it will ensure that the blades

adjustment will incur minimum errors and the blade can’t fall off.

Once the saw blade has been adjusted check that the machine operates normally before

using it in its normal capacity.

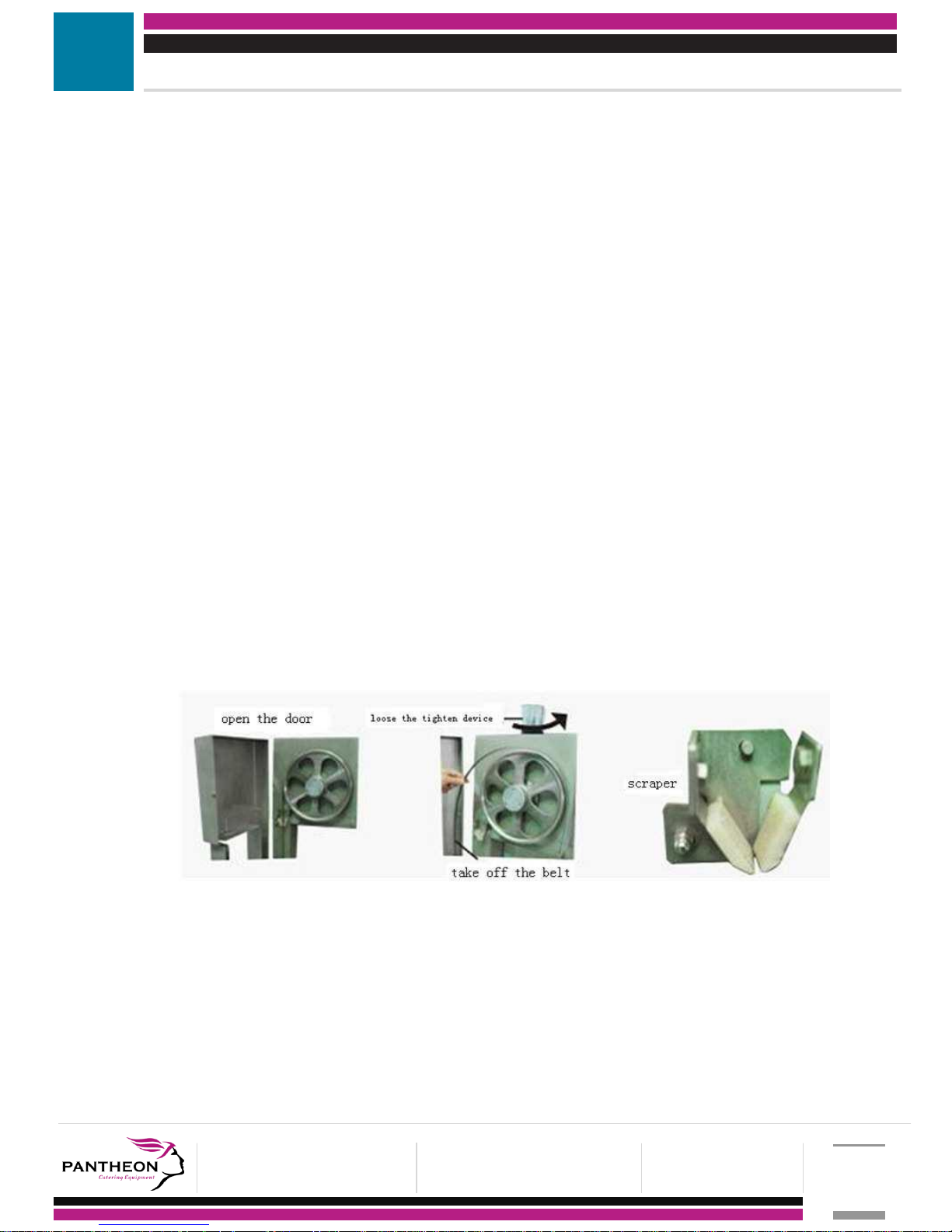

Cleaning

When cleaning the band saw please follow these instructions

Open the door of the machine and loosen the press setting, then take of the saw blade.

Loosen the scraper protection knob and take of the scraper

The machine should be cleaned with hot water and a hard brush

The main parts, belt and protective device can be washed with hot water and a hard brush

In order to clean the dead angle, wheel and wheel chain and bottom parts of the machine

the bolt must be taken out of the wheel by loosening it in a clockwise fashion

8

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Take care to avoid water getting into contact with the electrical parts

Once the machine has been washed ensure that it is thoroughly dried off by using a dry

cloth.

Meat Mincer

Cleaning

Please ensure the unit is turned off and unplugged prior to cleaning. Also ensure that the unit has

sufficiently cooled down if cleaning shortly after use.

To clean the mincer, use the following procedure:

Unscrew the large nut to take out the circular knife and the grinding cage.

Unscrew the lock screw to take out the grinding tank.

Use hot water and detergent to clean both of these parts.

After cleaning, assemble them in order. Be careful not to screw the nut too tight or too loose which

may damage the machine or affect the meat grinding process.

To clean the outside and front stainless steel parts of the unit simply use a damp cloth to wipe all

grease and food from the unit. Regularly cleaning the unit will help prolong its life.

Caution: When cleaning the mincer, ensure that no water is allowed near the motor.

Meat Slicers

General Maintenance:

To avoid the blade rusting:

Dry the blade with a dry cloth after use

Spread cooking oil on the edge of the blade with dry cloth

Sharpen the blade every day to prevent rust.

9

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Lubrication:

Ensuring the slicer is well lubricated can prolong its life. Following this lubrication guide will ensure

your product remains in good working order:

Guide Lubrication:

Push the carriage to one side, and clean any grease or dirt on the blade guide with a dry cloth

Smear the guide surface with grease by hand, spreading evenly to lubricate effectively

It is necessary to lubricate the guide every week.

Pusher axle lubrication:

To lubricate the pusher axle, firstly clean the pusher axle with a dry cloth

Then put cooking oil on both of the axles and pull the pusher up and down to make the oil

spread well

It is necessary to lubricate the axle every day.

Sharpener lubrication:

To lubricate the sharpener, foremost ensure the sharpener axle is clean.

Put cooking oil on both axles

Turn around and slide the axle until the axles work well.

Localising Head lubrication:

Turn the fixing position anti-clockwise to the maximum length

Clean the localising head, then put cooking oil on it

Turn the fixing position back to the original position

It is necessary to lubricate it every week but ensure to spread the oil evenly and not to apply too

much.

Blade Sharpening:

Follow the guide below when the slice thickness becomes uneven or the slices break into pieces:

Always turn off and unplug the machine before cleaning, and make sure to turn the slice thickness

regulator to the zero position.

Clean the edge of blade before sharpening.

Pull the sharpener out and lubricate the sharpener axles until they work well.

Pull the sharpener out and turn 180º.

Make sure the surface of stone is resting closely to the surface of the blade edge. If that is

not the case adjust it.

Turn the power on and press both sides of the stone down using the finger buttons making

contact with the blade for approximately 10 to 15 seconds.

Stop the machine and look to see if the blade has sharpened well, if not, continue.

Return the sharpener back to the original position after work.

Note: Always keep the stones clean so they work well. Avoid looking directly at the stone during

rotation to avoid injury from a piece of the stone. Ideally use safety glasses.

10

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Vegetable Preparation Machine

Cleaning

When cleaning the slicer you should always follow the following conditions:

Always turn off and unplug the machine before cleaning.

Never use any chemical or abrasive products.

Do not use a brush or any other type of abrasive instrument, which could damage the

machine.

Use a damp cloth with a mild detergent to clean the body of the machine and inside the top

cover. Before operation ensure it has been dried thoroughly.

Make sure to clean the machine thoroughly every day after use.

All removable parts:

o Ejector Disc

o Cutting Blades

o Dicing Grids

o Feed Stick

Are Dishwasher safe, or alternatively could be washed in warm soapy water. However prior

to placing them in the machine ensure the have been rinsed and dried thoroughly.

Warning: Never immerse the body of the machine in water or spray directly with a jet of water

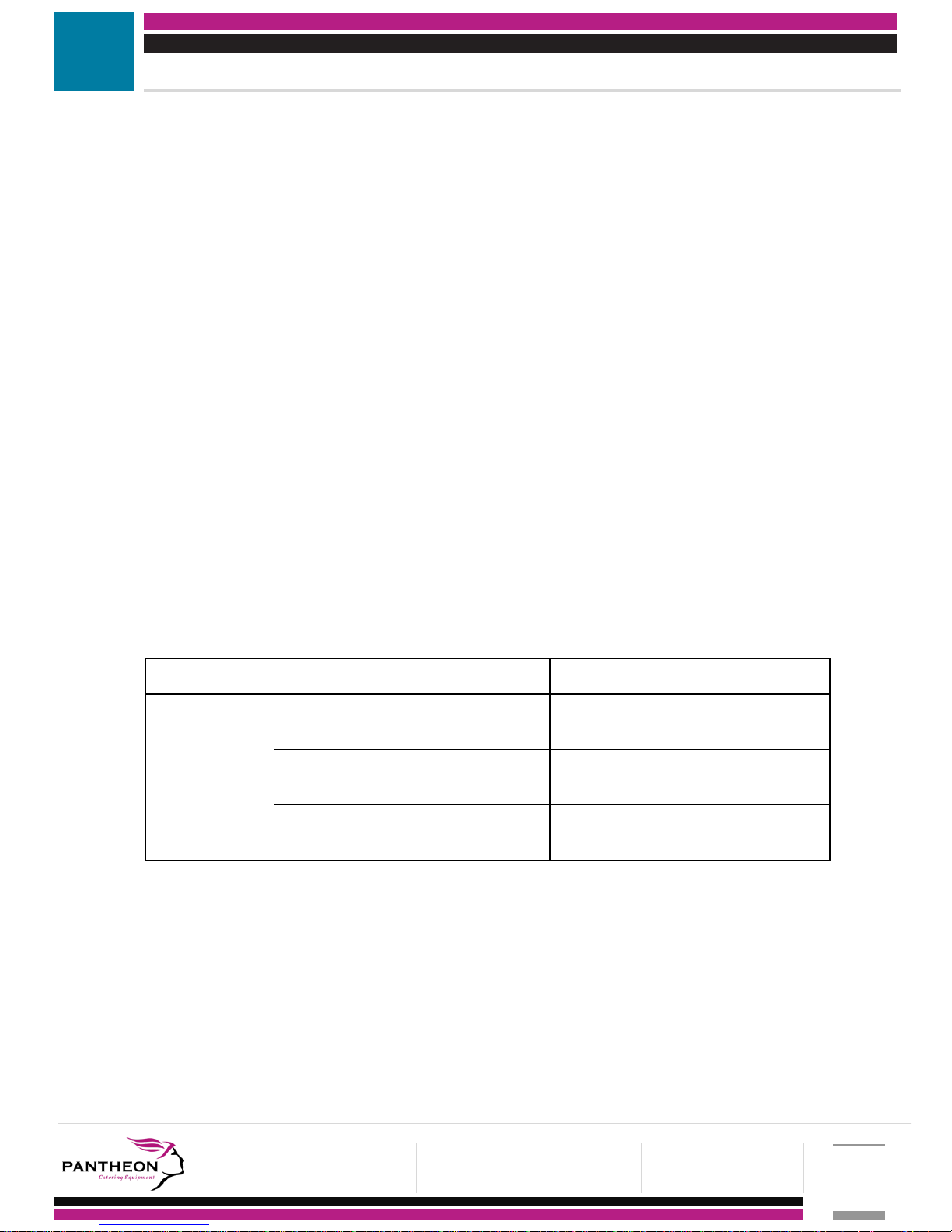

Troubleshooting

Vegetable Preparation Machine

Problem

Possible Cause

Solution

The VPM doesn’t

operate

The fuse isn’t of the correct rating /

type or has blown

Supply the correct rating/ type of fuse

or replace the fuse.

The Top cover or fed arm could be

incorrectly positioned

Position them correctly.

Reset the Machine, Switching it OFF and

ON again.

Note: If none of the above resolves the issue, please cease use of the device immediately and please

contact the manufacturer.

11

Preparation Range Operating Manual – BS1, MM12, MM22, MM32, MS250, MS300, MS350, VPM

Tel: 0800 0461570

Fax: 0800 0461571

Web: www.pantheonce.co.uk

Email: Info@pantheonce.co.uk

Pantheon Catering Equipment

Vulcan Works, Dixon Street,

Bolton, BL6 7PH

Product Range:

Induction Hobs / Combination Ovens / Pizza Ovens / Mixers

Salamander Grills / Contact Grills / Pie Warmers / Fryers

Heated Displays / Veg Prep Machines / Bains Marie / Mincers and more

Loading...

Loading...