PANJIT GS1G, GS1K, GS1M, GS1J, GS1A Datasheet

...

DATA SHEET

GS1A~GS1M

SURFACE MOUNT RECTIFIER

VOLTAGE- 50 to 1000 Volts CURRENT - 1.0 Ampere

FEA TURES

• For surface mounted applications

• Low profile package

• Built-in strain relief

• Easy pick and place

• Plastic package has Underwriters Laboratory Flammability

Classification 94V-O

• Glass passivated chip junction

• High temperature soldering : 260°C /10 seconds at terminals

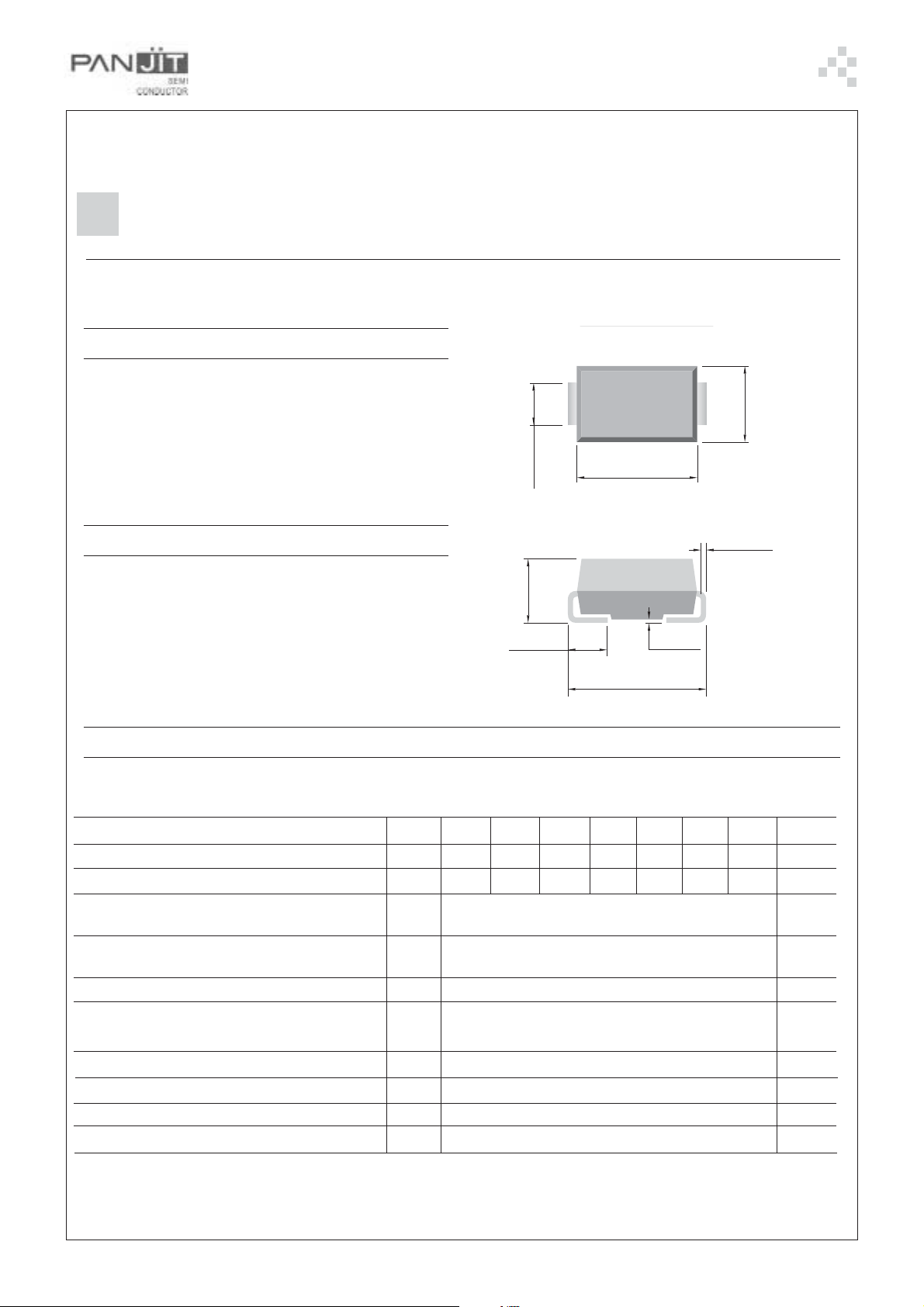

.062 (1.60)

SMA / DO-214AC

.055 (1.40)

.181 (4.60)

.157 (4.00)

Unit: inch ( mm )

.114 (2.90)

.098 (2.50)

MECHANICAL DA TA

Case: JEDEC DO-214AC molded plastic

.012 (.305)

.006 (.152)

Terminals: Solder plated, solderable per MIL-STD-750,

Method 2026

Polarity: Indicated by cathode band

Standard packaging: 12mm tape (EIA-481)

Weight: 0.002 ounce, 0.064 gram

.096 (2.30)

.078 (2.00)

.060 (1.52)

.030 (0.76)

.208 (5.28)

.188 (4.80)

.008(.203

.002(.051)

)

MAXIMUM RA TINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified. Single phase, half wave, 60 Hz, resistive or inductive load.

For capacitive load, derate current by 20%.

Maximum Recurrent Peak Reverse Voltage

Maximum RMS Voltage

Maximum DC Blocking Voltage

Maximum Average Forward Rectified Current,

at T

=75°C

L

Peak Forward Surge Current 8.3ms single half sine-wave

superimposed on rated load (JEDEC method)

Maximum Instantaneous Forward Voltage at 1.0A

Maximum DC Reverse Current T

at Rated DC Blocking Voltage T

Maximum Reverse Recovery Time(Note 1) T

Typical Junction Capacitance (Note 2)

Maximum Thermal Resistance(Note 3) RθJA

Operating and Storage Temperature Range

=25°C

A

=125°C

A

=25°C

J

SYMBOLS

V

RRM

V

RMS

V

DC

I(AV)

I

FSM

V

F

I

R

T

RR

C

J

RθJA

T

J,TSTG

GS1A

50

35

50

GS1B GS1D GS1G GS1J GS1K GS1M

100

100

70

200

140

200

400

280

400

1.0

30.0

1.10

5.0

50.0

2.5

12

30.0

-55 to +150

600

420

600

800

560

800

1000

700

100

UNIT

V

V

V

A

A

V

µA

µA

µs

pF

°C/ W

°C

NOTES:1. Reverse Recovery Test Conditions: I

2. Measured at 1 MHz and applied V

3. 8.0 mm

2

( .013mm thick ) land areas.

r

=0.5A, IR=1.0A, Irr=0.25A

F

= 4.0 volts.

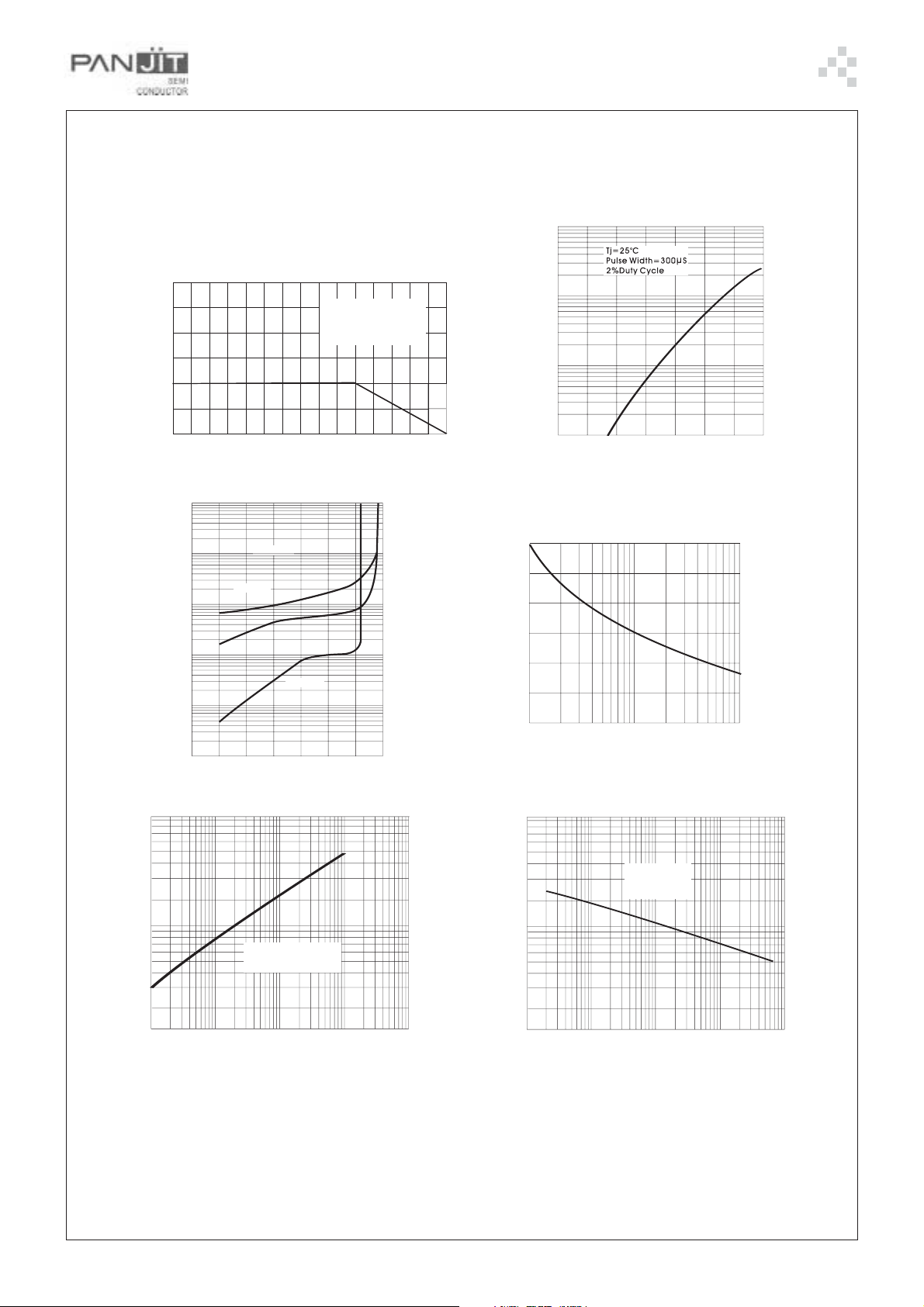

AVERAGE FORWARD CURRENT

AMPERES

TEMPERATURE C

O

Fig. 1- DERATING CURVE FOR OUTPUT RECTIFIED CURRENT

RATING AND CHARACTERISTIC CURVES

INSTANTANEOUS FORWARD VOLTAGE, VOLTS

Fig. 2- TYPICAL INSTANTANEOUS FORWARD

CHARACTERISITCS PER ELEMENT

INSTANTANEOUS FORWARD CURRENT, AMPERES

PERCENT OF PEAK REVERSE VOLTAGE

Fig. 3- TYPICAL REAK REVERSE CHARACTERISTICS

FPRWARD SURGE CURRENT, AMPERES pk

(HALF SINE-WAVE)

NO. OF CYCLES AT 62Hz

Fig. 4- MAXIMUM NON-REPETITEVE PEAK

FORWARD SURGE CURRENT

3.0

2.0

1.0

0

0 50 100 150

100

40

20

10

4.0

2.0

1.0

0.4

0.2

0.1

0.6

0.8

1.0

1.2

1.4

1.6

1.8

25

20

15

10

5

0

1

2

6

10 20 40 60 100

0.4

SINGLE PHASE HALF WAVE 60Hz

RESISTIVE OR INDUCTIVE LOAD

P.C.B MOUNTED

ON 0.315 X 0.315" ( 8.0 X 8.0mm )

COPPER PAD AREAS

0.5

1.5

2.5

CAPACITANCE, pF

REVERSE VOLTAGE, VOLTS

Fig. 6- TYPICL JUNCTION CAPACITANCE PER ELEMENT

10

0.1 1.0

100

1000

Tj=25 C

f=1.0MHz

Vsig=50mVp-p

O

1

2

5

10

20

50

100

HEATING TIME(SEC)

Fig. 5- TRANSIENT THERMAL IMPEDANCE

10

0.1

1.0

100

1

2

5

10

20

50

100

THERMAL IMPEDANCE(

O

C/W)

Units Mounted On 20in (5.4mm )

+0.5mil inches(0.013mm)

Thick Copper Land Areas

22

0.01

100

1.0

0.01

20 40 60 80 100 120

T =75 C

J

O

T =25 C

J

O

T =100 C

J

O

140

0.001

0.1

0

10

30

Loading...

Loading...