PANJIT GBU4D, GBU4B, GBU4K, GBU4J, GBU4G Datasheet

...

DATA SHEET

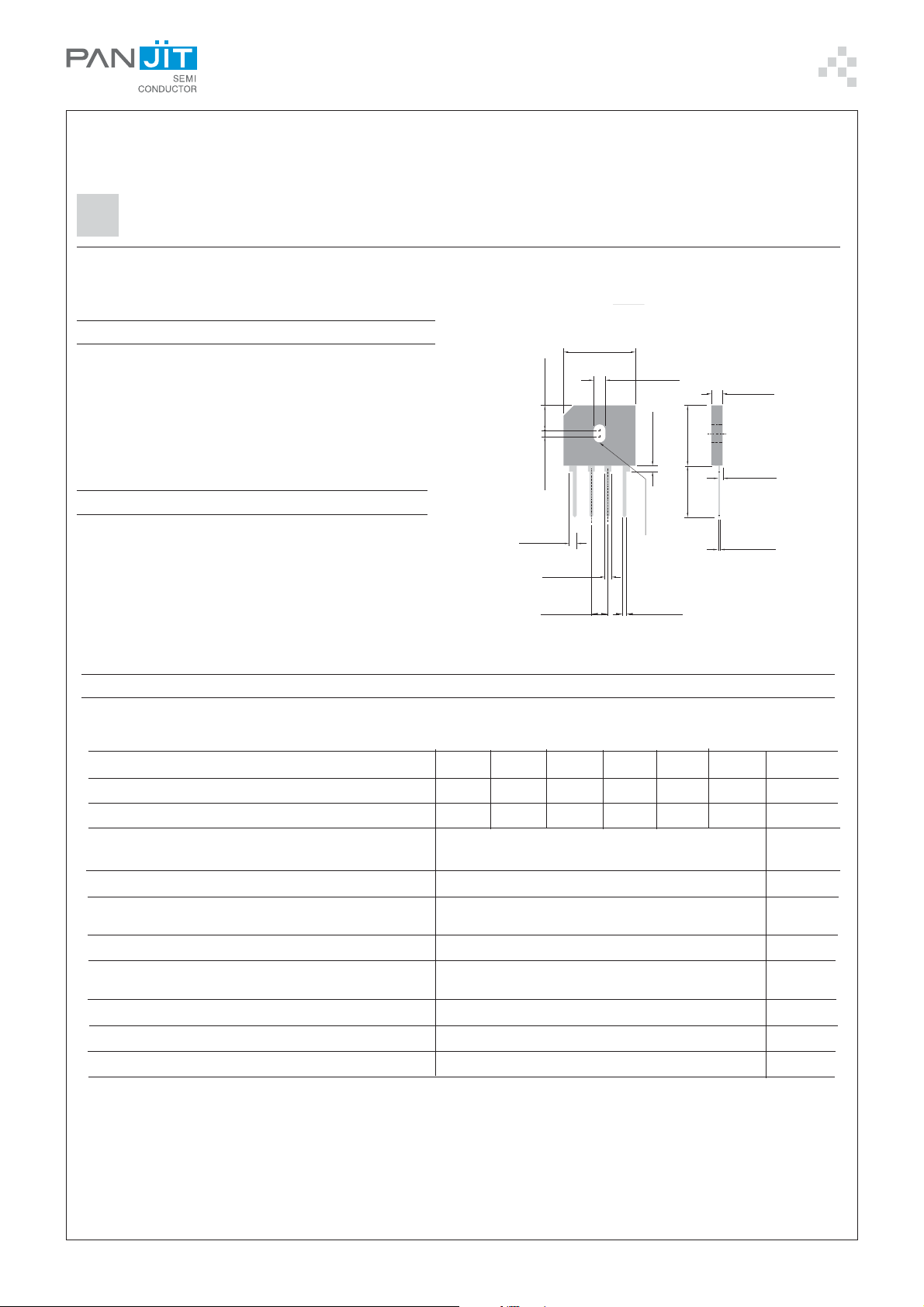

GBU4A~GBU4K

GLASS PASSIVATED SINGLE-PHASE BRIDGE RECTIFIER

VOLTAGE 50 to 800 Volts CURRENT - 4.0 Amperes

FEA TURES

• Plastic material has Underwriters Laboratory

Flammability Classification 94V-O

• Ideal for printed circuit board

• Reliable low cost construction utilizing molded plastic technique

• Surge overload rating: 150 Amperes peak

• High temperature soldering guaranteed:

260°C/10 seconds/.375"(9.5mm) lead length at 5 lbs. (2.3kg) tension

MECHANICAL DATA

Case: Reliable low cost construction utilizing

molded plastic technique

T erminals: Leads solderable per MIL-STD-202,

Method 208

Mounting position: Any

Mounting torque: 5 in. lb. Max.

Weight: 0.15 ounce, 4.0 grams

MAXIMUM RA TINGS AND ELECTRICAL CHARACTERISTICS

Rating at 25°Cambient temperature unless otherwise specified. Resistive or inductive load, 60Hz.

For Capacitive load derate current by 20%.

Maximum Recurrent Peak Reverse Voltage

Maximum RMS Input Voltage

Maximum DC Blocking Voltage

Maximum Average Forward T

Rectified Output Current atT

=100°C

C

=40°C

A

I2t Rating for fusing ( t<8.3ms)

Peak Forward Surge Current single sine-wave superimposed on

rated load(JEDEC method)

Maximum Instantaneous Forward Voltage Drop per element at 2.0A

Maximum Reverse Leakage at rated T

CDc Blocking Voltage per element T

=25°

A

=100°C

C

Typical Thermal Resistance per leg(Note 2) RθJA

Typical Thermal Resistance per leg(Note 3) RθJA

Operating and Storage T emperature Range, T

,TSTG

J

GBU4A

50

35

50

.100(2.54

.085(2.16)

GBU4B

100

70

100

)

)

7.40

7.90

(

(

.290

.310

)

)

1.65

2.16

(

(

.065

.085

)

.080(2.03

.065(1.65

.190(4.83

.210(5.33

GBU4D

200

140

200

.880(22.3

.860(21.8

)

)

)

)

GBU

)

)

GBU4G

4.0

3.0

93

150

1.0

5

500

19

4

-55+150

400

280

400

.160(4.1

.140(3.5

)

)

2.03

1.52

(

(

.080

.060

R

)

1.90

(

.075

.050(1.27

.040(1.02

)

)

)

18.8

(

.740

)

18.0

(

.710

)

)

GBU4J

600

420

600

Unit: inch ( mm )

)

18.3

(

.720

)

17.5

(

.690

GBU4K

800

560

800

.140(3.56

.130(3.30

.040(1.02

.030(0.76

.022(0.56

.018(0.46

)

)

)

)

)

)

°C / W

°C / W

UNIT

2

A

Apk

Vpk

µA

µA

V

V

V

A

sec

°C

NOTES:

1. Recommended mounting position is to bolt down on heatsink with silicone thermal compound for maximum heat transfer with #6 screw.

2. Units Mounted in free air, no heatsink, P.C.B at 0.375"(9.5mm) lead length with 0.5 x 0.5"(12 x 12mm)copper pads.

3. Units Mounted on a 2.0 x 1.6" x 0.3" thick (5 x 4 x 0.8cm) AL plate.

DATE : SEP.12.2002

PAGE . 1

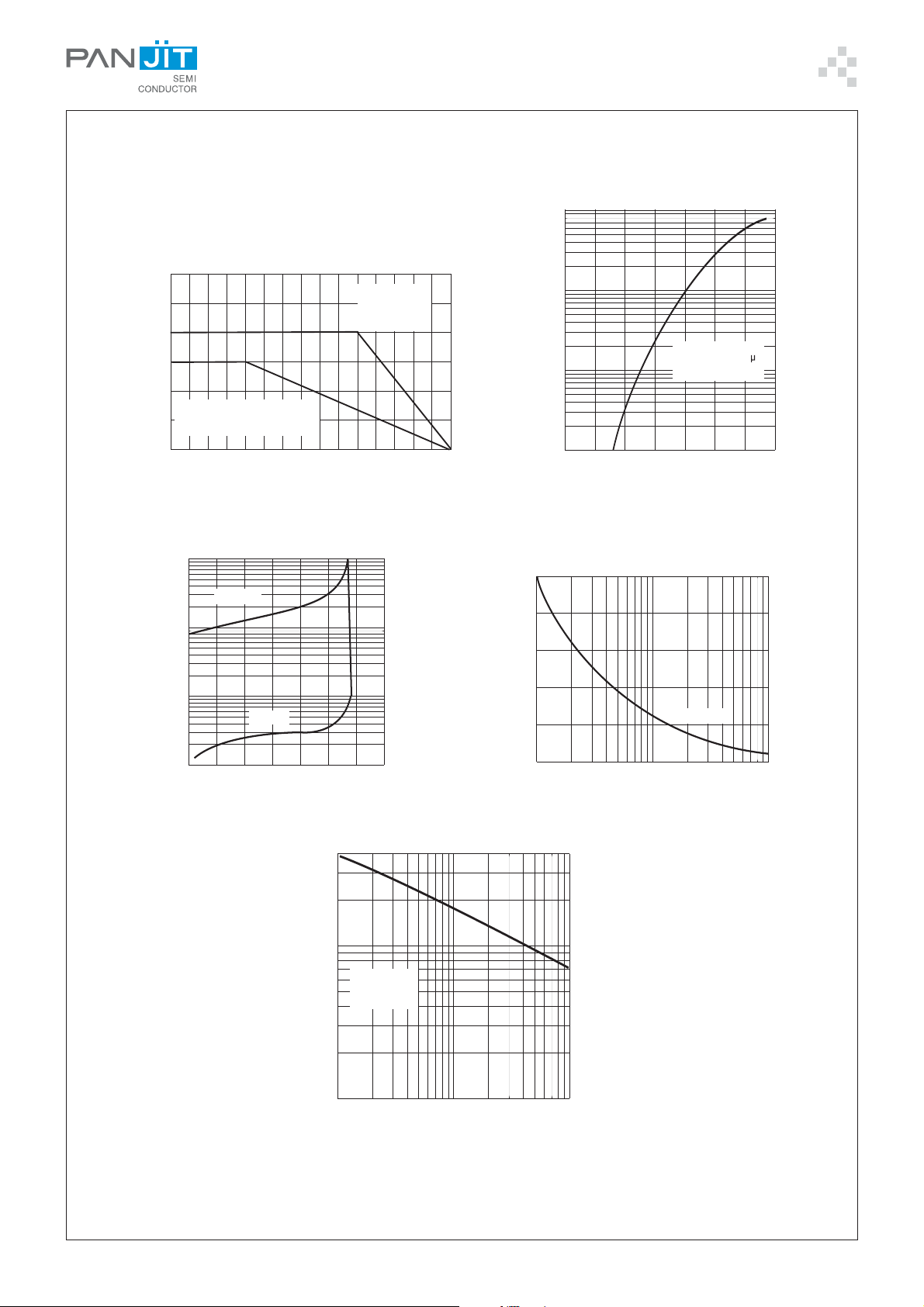

RATING AND C HARAC TERI STIC C URVES

6.0

4.0

2.0

AMPERES

MOUNTEDONPCBOARD.

TA 0.5"(12.7mm) LEAD LENGTH

60 Hz RESISTIVE OR INDUCTIVE LOAD

0

AVERAG E FO RWARD C URREN T

0 50 100 150

TEM PERATURE C

HEAT-SINK

MOUNTING ,TC

(4*4*0.15)INCH

COPPERPLATE

O

Fi g . 1 - DERATING C URVE FO R OUTPUT REC TIFIED C URREN T

,

10

O

T=100 C

C

1.0

EVERSE CURREN T

0.1

MICROAMPERES

O

T=25 C

A

100

40

,AMPERES

20

10

4.0

RD C URREN T

2.0

ORWA

1.0

0.4

0.2

0.1

0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4

INSTANTANEOUS F

TJ = 2 5 O C

Pu l se W i d t h = 3 0 0 S

1% DULY Cycle

INSTANTANEOUS FORWARD VOLTAGE,VOLTS

Fig . 2- TYPICAL INSTANTANEOUS FORWARD

CHARACTERISITCS PER ELEMENT

150

120

,AMPERESpk

90

INE-WAVE)

60

O

T=105 C

(HALF S

30

A

INSTANTANEOUS R

0.01

Fi g . 3 - TYP

0 20 40 60 80 100 120 140

PERC EN T OF PEAK REVERSE VO LT AG E

IC A L REA K REVERSE CHA RAC TERISTIC S

400

100

O

ANCE, p F

CAPACIT

Fig.5- TYPICL JUNCTION CAPACITANCE PERELEMENT

Tj = 2 5 C

f= 1.0MHz

50

Vsig = 5 0m Vp- p

10

1

5

REVERSE VOLTAGE, VOLTS

FPRWA RD SURG E CURREN T

0

12

6

10 20 40 60 100

NO.OFCYCLESAT62Hz

Fi g . 4 - M A XIM UM N O N - REPETI TEV E P EA K

FO RWA RD S URG E CURREN T

10

50

100

DATE : SEP.12.2002

PAGE . 2

Loading...

Loading...