DATA SHEET

B1S~B10S

MINI SURFACE MOUNT GLASS PASSIV ATED BRIDGE RECTIFIER

VOL TAGE - 100 to 1000 Volts CURRENT - 0.5 Amperes

FEA TURES

• Plastic material used carries Underwriters

• Laboratory recognition 94V-O

• Low leakage

• Surge overload rating-- 30 amperes peak

• Ideal for printed circuit board

• Exceeds environmental standards of MIL-S-19500

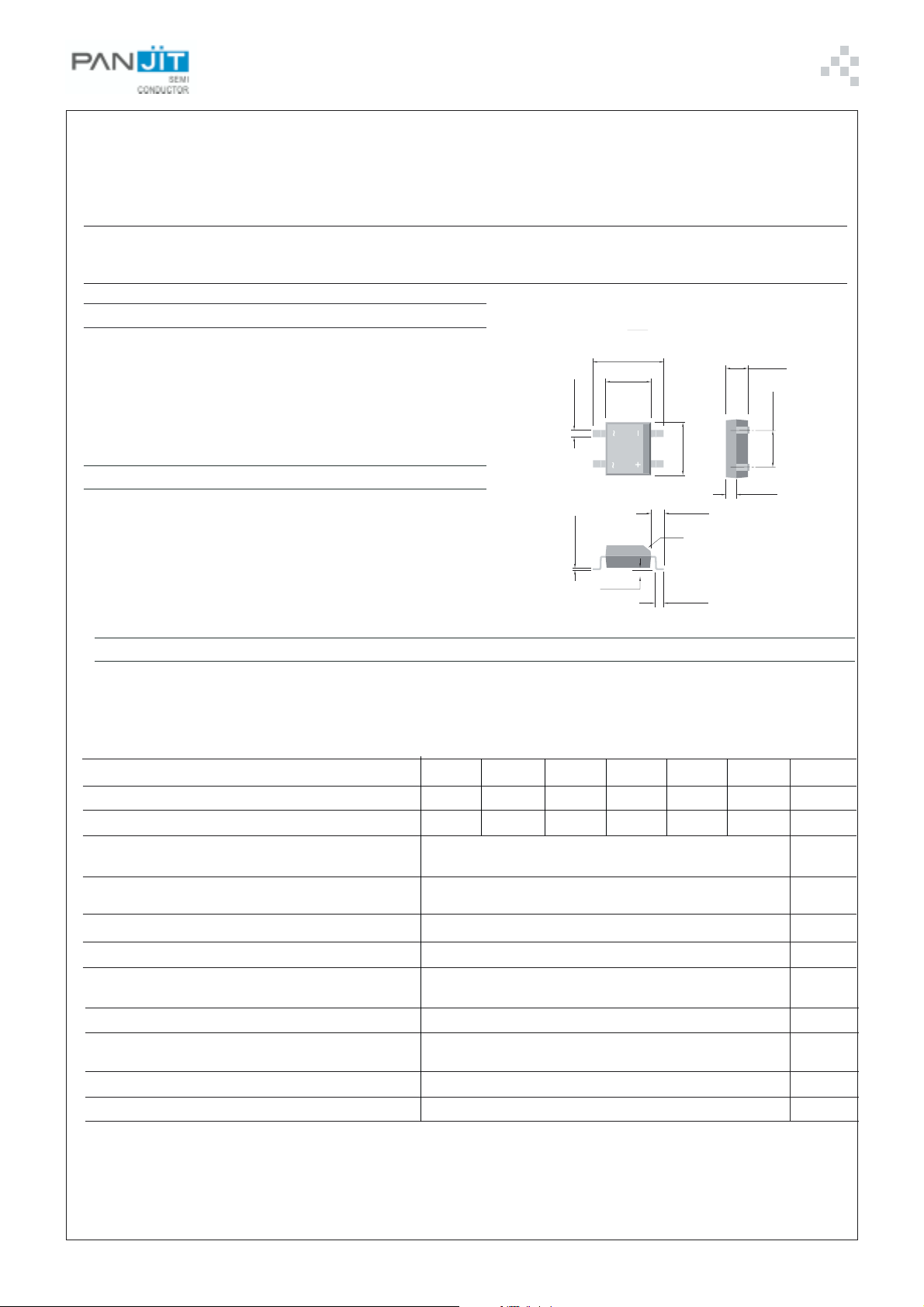

.0310 (0.8)

.0191 (0.5)

MDI

.275 (7) MAX

.165 (4.2)

.150 (3.8)

.193 (4.9)

.177 (4.5)

MECHANICAL DAT A

Case: Reliable low cost construction utilizing molded plastic technique results in

inexpensive product

Terminals: Lead solderable per MIL-STD-202, Method 208.

Polarity: Polarity symbols molded or marking on body.

Mounting Position: Any.

Weight: 0.008 ounce, 0.22 gram.

.014 (0.35)

.006 (0.15)

.008 (.20)

.067 (1.7)

.057 (1.3)

C .02(5)

.043 (1.1)

.027 (0.7)

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified.

Single phase, half wave, 60Hz, Resistive or inductive load.

For capacitive load, derate current by 20%

B1S

Maximum Recurrent Peak Reverse Voltage

Maximum RMS Bridge input Voltage

Maximum DC Blocking Voltage

Maximum Average Forward on glass-epoxy P.C.B (Note 1)

Current T

Peak Forward Surge Current, 8.3ms singlehalf sine-wave

superimposed on rated load

2

I

t Rating for fusing ( t < 8.35 ms)

Maximum Forward Voltage Drop per Bridge Element at 0.5A

Maximum Reverse Current at Rated T

DC Blocking Voltage per element T

Typical Junction capacitance per leg (Note 1) CJ

Typical Thermal resistance per leg (Note 2) RθJA

Typical Thermal resistance per leg (Note 2) RθJA

Operating T emperature Range T

Storage T emperature Range T

=30°C on aluminum substrate (Note 3)

A

= 25°C

J

=125°C

J

J

A

NOTES:

1. Measured at 1.0 MHz and applied reverse voltage of 4.0 Volts

2. Thermal resistance from junction to ambient and from junction to lead mounted on P.C.B. with 0.05 X 0.05"(13 x 13mm) copper pads.

3. On alum: substrate P.C.B with an rea of 0.8 x 0.8 x 0.25” ( 20 x 20 x 6.4mm ) mounte on 0.05 x 0.05 “( 13 x 13 mm ) solder pad.

100

70

100

B2S

200

140

200

B4S

400

280

400

B6S B8S

600

420

600

0.5

0.8

30.0

5.0

1.00

5.0

25.0

85.0

-55 to 150

-55 to 150

800

560

800

Unit: inch ( mm )

.106 (2.7)

.090 (2.3)

.106 (2.7)

.090 (2.3)

.051 (1.3)

.035 (0.9)

B10S

1000

700

1000

UNIT

V

V

V

A

A

A2t

V

µA

mA

pF

°C/W

°C

°C

PAGE . 1

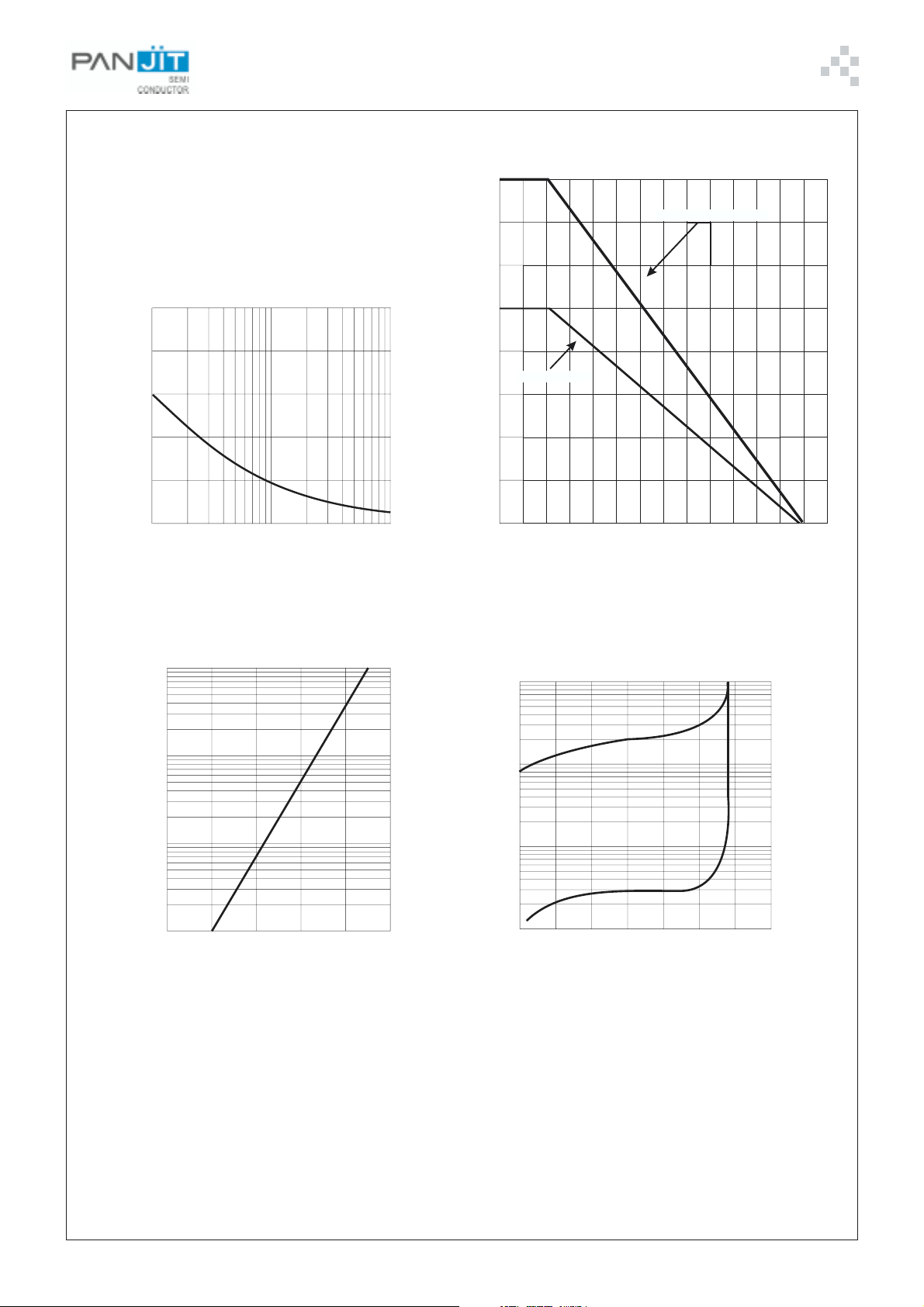

RATING AND CHARACTERISTIC CURVES

50

0.8

On aluminunsubsttrate

0.6

FORWARD SURGE CURRENT, AMPERES pk

40

30

20

(HALF-SINE WAVE)

10

1

2

8

4

6

10

NUMBER OF CYCLES AT 60Hz

Fig.1-MAXIMUM NON-REPETITIVE

SURGE CURRENT

10

1.0

0.4

On GlassP.C.B

CURRENT, AMPERES

AVERAGE FORWARD OUTPUT

0.2

60

100

80

40

20

0

20 40 60 80 100 120 140

160

AMBIENT TEMPERATURE, OC

Fig.2-DERATING CURVE FOR

OUTPUT RECTIFIED CURRENT

10

1.0

0.1

0.01

INSTANTANEOUS FORWARK CURRENT, AMPERES

0.4 0.6 0.8

1.0

INSTANTANEOUS FORWARD VOLTAGE, VOLTS

Fig.3-TPICAL FORWARD

CHARACTERISTICS

1.2

1.4

MICROAMPERES

INSTANTANEOUS REVERSE CURRENT,

0.1

0.01

0 20 40 60 80 100 120 140

PERCENT OF PEAK REVERSE VOLTAGE

Fig.4-TYPICAL REVERSE

CHARACTERISTICS

PAGE . 2

Loading...

Loading...