Page 1

VeriSafe Access

Control Kit

1003190

© Panduit Corp. 2019

Original Instructions

The VeriSafe Access Control Kit, inst alled with the VeriSafe Abse nce of Volta ge Te ster, provide s an added layer

to the equipment.

VS-ACK-CPWR

VS-ACK-EXT

VS-ACK-BATTERY

VS-ACK-KEY

Instruction Manual

Models: VS-ACK-CPWR, VS-ACK-EXT, VS-ACK-KEY & VS-ACK-BATTERY

Rev: 01; 1-2020

of protection by preventing enclo sure doors from being opened until absence o f voltage is confirmed. Before

entering the electrical cabinet, personnel will use the VeriSafe Absence of Volt ag e T este r to test for absence of

voltage. The VeriSafe Access Control Kit will receive a signal from the VeriSafe Absence of Voltage Tester when

the absence of voltage is confirmed. The rotary latch will unlock, releasing the enclosure door and allow access

TO REDUCE THE RISK OF INJURY, USER

MUST READ INSTRUCTION MANUAL

NOTE: In the interest of higher quality and value, Panduit products are

continually being improved and updated. Consequently, pictures may vary

from the enclosed product.

North America Tech Support:

techsupport@panduit.com

Tel: 1-866-405-6654

EU Tech Support :

emeatoolservicecenter

@panduit.com

Tel: +31-546-580-452

Fax: +31-546-580-441

NOTE: Updates to this Instruction Manual may be available. Check

www.panduit.com for the latest version of this manual.

Asia Pacific Tech Support:

TechSupportAP@ panduit.com

Telephone:

Korea: 02-21827300

www.panduit.com

Singapore: 1-800-Panduit (7263848)

Australia: 1-800-Panduit (7263848)

Page 2

© Panduit Corp. 2019

Warning: Do not use this product outside of the specified performance and environmental limits.

Failure to comply with these specifications could result in product failure, personal injury, or death.

Standards

Applications

Degree of Protection*

For Flat Surface Mounting in a TYPE (UL, NEMA and CSA) 1, 12, 4, IP65 Enclosure

Environment

Operating Temperature

-25°C to 60°C (-13°F to 140°F)

Storage Temperature

-45°C to 85°C (-50°F to 185°F)

Humidity

5 to 90% non-condensing; Rated 80% at 40°C, decreasing linearly to 50% at 60°C

VS-ACK-BATTERY

Type

Industrial 9V Metal Lithium (qty: 2)

INSTRUCTION MANUAL VeriSafe ACK

Safety Information

This manual contains information and warnings which must be follow ed to ensure safe operation of the Access Control Kit. If the

Access Control Kit is not used as described in this manual, the safety features of the Access Control Kit might be imp aire d. The

Access Control Kit is designed for use with the VeriSafe AVT. Reference the VeriSafe AVT instruction manual for critical safety

information, installation and operating instructions. Failure to comply with the warnings and information in this manual

could result in product failure, electrical shock, severe injury or death.

Warning:

•

Always de-energize power before accessing an electrical enclosure.

•

Always follow safety and lockout/tagout procedures when working on or near electrical systems and equipment.

•

Use of the Access Control Kit does not replace lockout/tagout procedures. The Access Contr ol Kit is intended to be used in

conjuncti on with the VeriSafe AVT and the lockout/tagout processes.

•

Use proper personal protective equipment (PPE) when working around sources of hazardous electrical energy.

•

Do not use this product outside of the specified performance and environmental lim its. Failure to comply with these

specifications could result in product failure, personal injury or death.

•

This product must be installed by a qualified electrical worker familiar with local and national electrical codes.

•

Always comply with local installation codes and standards.

•

The VS-ACK-BATTERY product uses a lithi um battery that is a fire, explosion and s evere bur n hazard. Do not crush, rechar ge,

disassemble or heat above 85° C, incinerate, or expose contents to water.

•

Use only the included Wire Harness or approved replacement harness to connect the Rotary Latch and VeriSafe AVT.

Technical Specifications

RoHS Restriction of hazardous substances

Electrical System For use in 1 and 3-phase AC or DC systems

*Degree of protection specified is related to the Latch Cam only. To meet the TYPE (UL, NEMA and CSA) 1, 12, 4, IP65 requirements, mount on

a flat surface of an enclosure meeting the appropriate TYPE rating. Verify that the Sealing Washer is clean and properly seated onto the Latch

Cam to ensure proper sealing.

Classification Non-Rechargeable

Designation ANSI-1604LC

Operating Temperature -20°C to 60°C (-4°F to 140°F)

Mounting Type DIN Rail or Surface Mount

Estimated Capacity 1 cycle per week for 10 years

1003190 R00 Page: 1 of 7 10-2019

Page 3

© Panduit Corp. 2019

INSTRUCTION MANUAL VeriSafe ACK

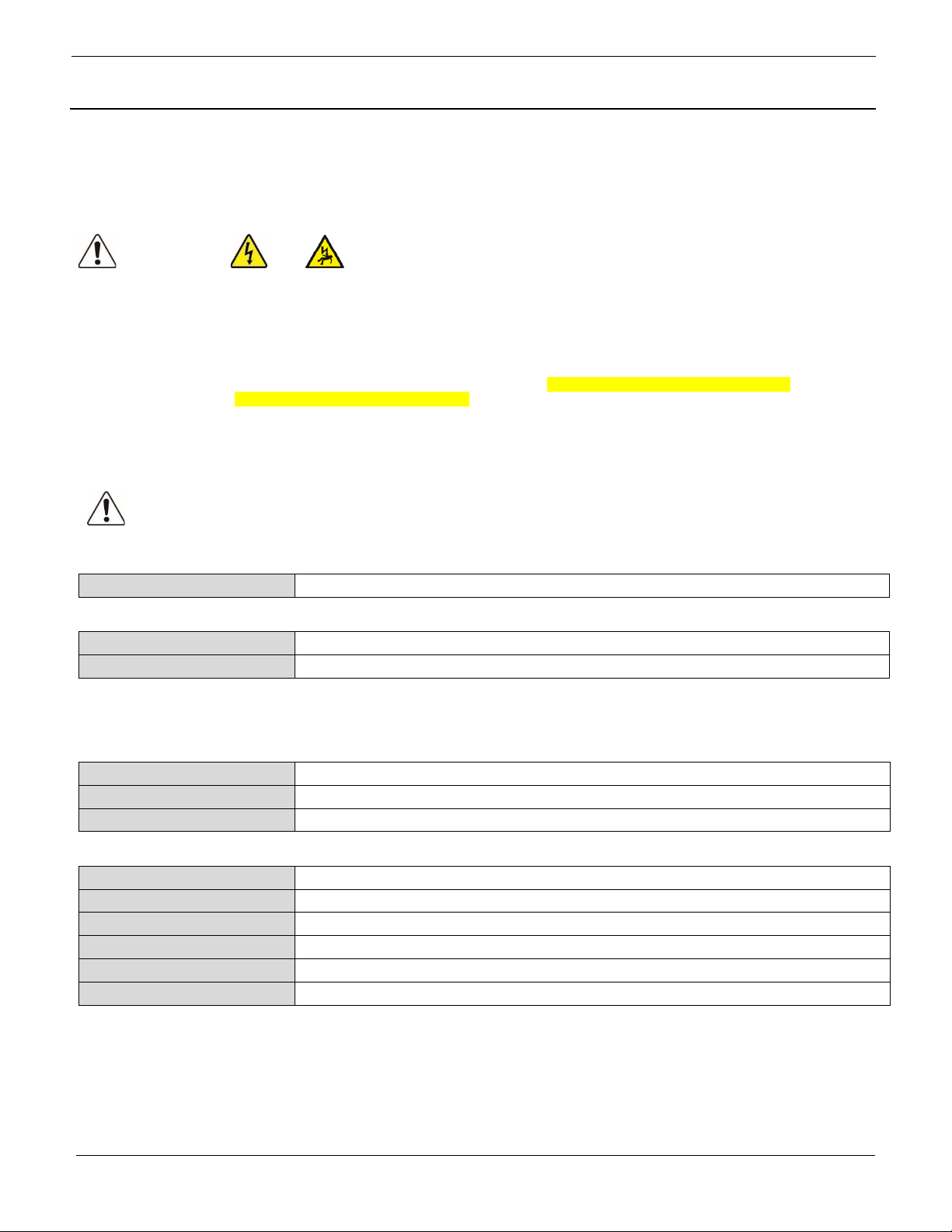

VS-ACK-CPWR Install Instructions

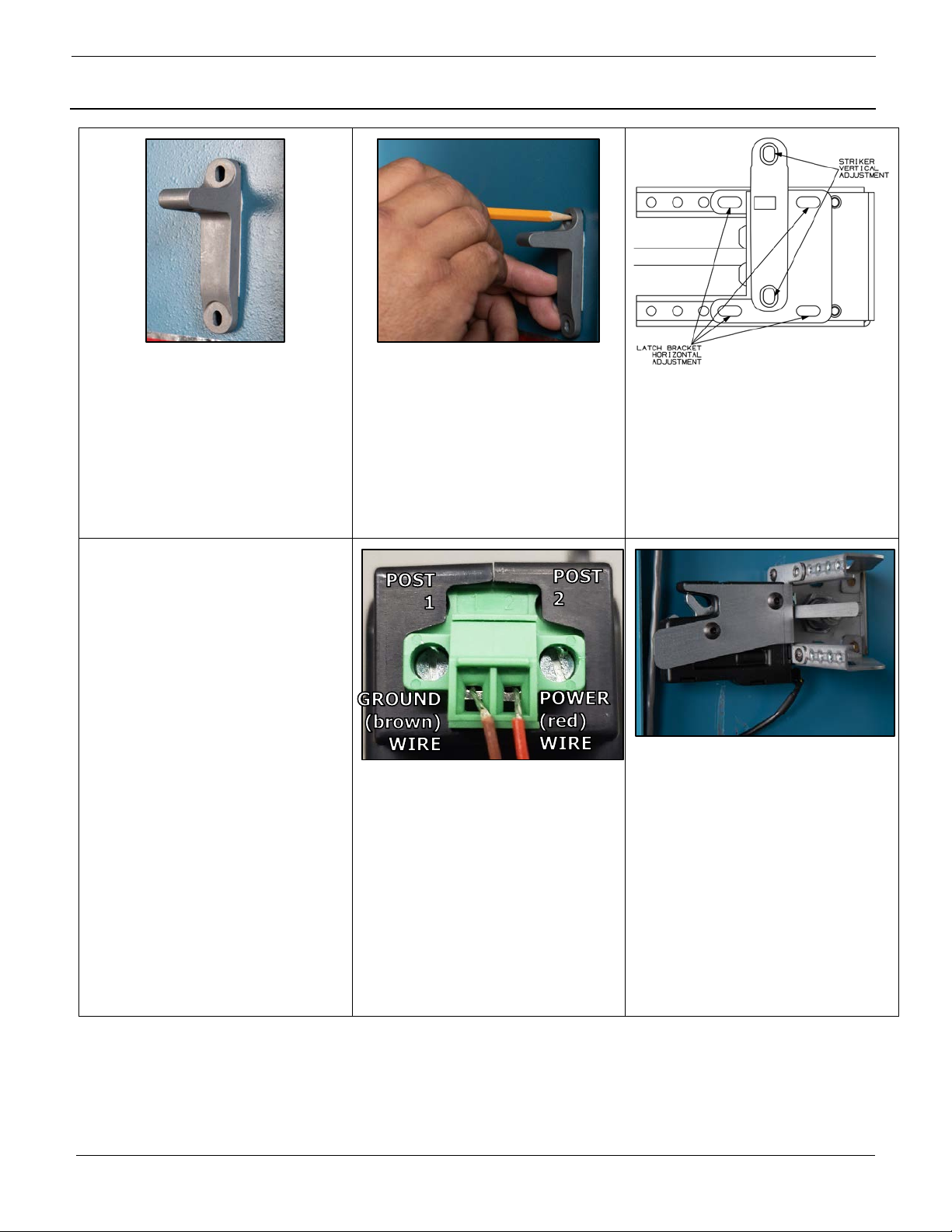

Figure 1 - Componen ts of the VeriSaf e A cces s C ontr ol Kit – Control Power (VS-ACK-CPWR)

Figure 2 – Quick Assembly Guide 1 – Contr ol Powe r (VS-ACK-CPWR)

1003190 R00 Page: 2 of 7 10-2019

Page 4

© Panduit Corp. 2019

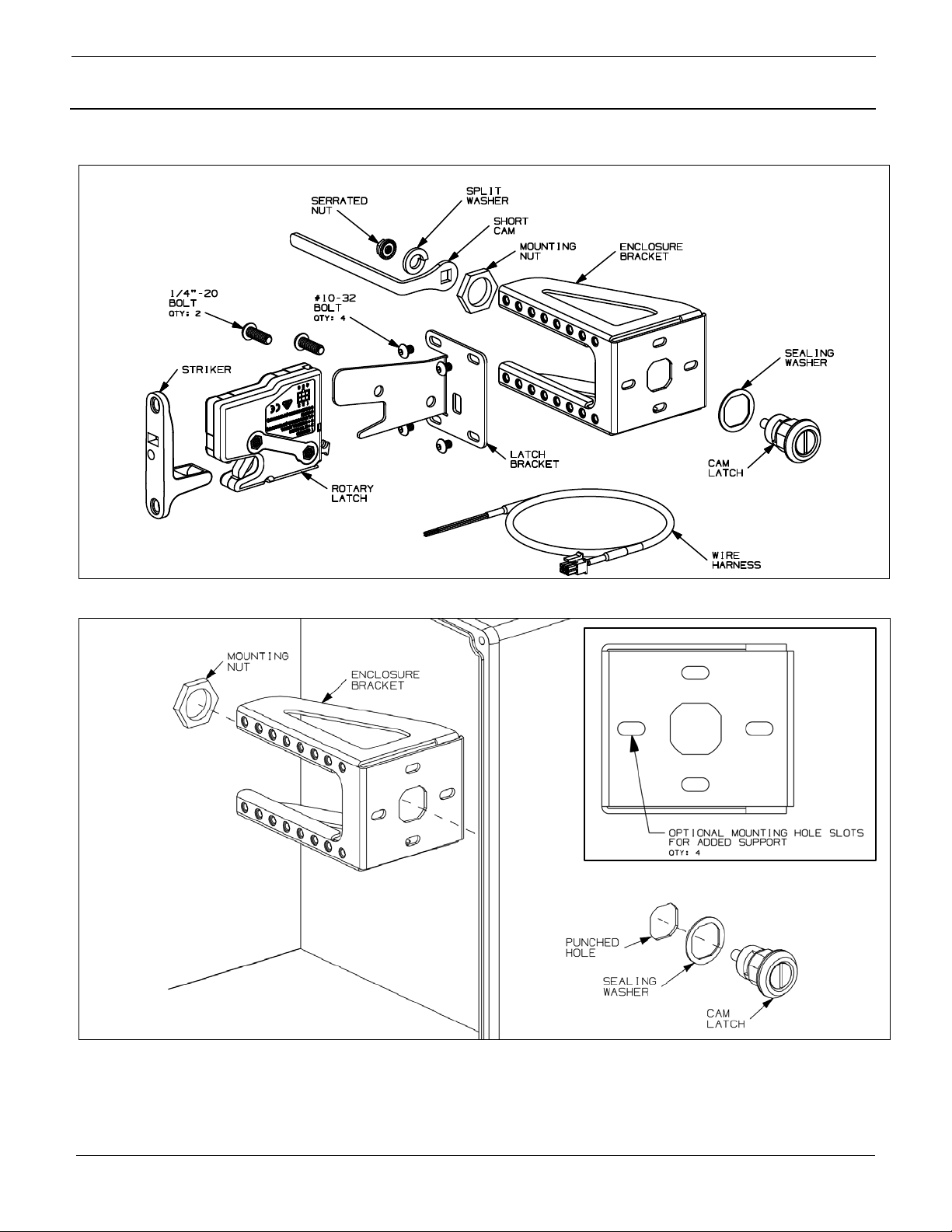

The Enclosure Bracket and Cam Latch are designed for

INSTRUCTION MANUAL VeriSafe ACK

Figure 3 – Quick Assembly Guide 2 – Contr ol Powe r (VS-ACK-CPWR)

use with a standard Double “D” punch.

Greenlee Punch Number: 61095

Figure 4 – Punch Knockout

1003190 R00 Page: 3 of 7 10-2019

Figure 5 – Wiring Schematic

Page 5

© Panduit Corp. 2019

Left Side Mount

Right Side Mount

•

The ACK must be installed correctly and grounded as described in this Instructio n Manual to oper ate prope rl y.

Always de-energize power before accessing an electrical enclosure.

Use proper personal protective equipment (PPE) when working around sources of hazardous electrical energy.

Always follow safety and lockout/tagout procedures when working on or near electrical systems and equipment.

Do not use this product outside of the specified performance and environmental limits.

Always comply with local installation codes and standards.

1. Locate position for the knockout hole by

be vertical (see figure 4 ).

2. Insert the Cam Latch into the knockout

3. Install the Enclosure Bracket onto the Cam

4. Install Cam onto Cam Latch with

5. Install the Rotary Latch to the Latch

6. Place supplied Two-Sided tape onto the

Installation Instructions

Warning:

•

•

•

•

•

INSTRUCTION MANUAL VeriSafe ACK

measuring 5-1/8 inches from the surface

where the cabinet door seats to the

desired mounting location on the side of

the cabinet (when installing the VS-ACKEXT kit refer to VS-ACK-EXT install

instructions for proper hole distanc e). Use

Double “D” knockout (not included) to

punch hole. Ensure that the punch is

positioned properly. The punch flats shall

supplied Split Washer and Serrated Nut

(see figure 3).

1003190 R00 Page: 4 of 7 10-2019

hole. Ensure that the Sealing Washer is

properly seated between the panel wall

and the Cam Latch (see figure 2).

Latch and hand tighten the Mounting Nut.

Check that the bracket is level and finish

tightening the Mounting Nut to 88 IN*LB

(10 N*m) max (see figure 2).

Bracket with supplied ¼”-20 Bolts (2) and

secure to Enclosure Bracket with supplied

#10-32 Bolts (4). Ensure that the Rotary

Latch is installed so the Cam rotates and

engages the Override Latch (left side

mount shown) (see figure 3).

back side of the Striker and install Striker

onto the Rotary Latch.

Page 6

© Panduit Corp. 2019

7. Close the cabinet door and lock into

8. Mark the mounting locations for the

9. Close the cabinet door and ensure that

INSTRUCTION MANUAL VeriSafe ACK

position. Engage the mechanical override

on the ACK and open the cabinet door.

The Striker will be positioned onto the

inside of the cabinet door.

10. IF USING CONTROL POWER

OPTION:

Connect the wires of the Wire Harnes s to

the VeriSafe Absense of Voltage Tester

(AVT) and the desired power source per

the wiring schematic.

POWER SOURCE REQUIREMENTS

• 12-24 VDC

• Operating current to be less than

500mA at 12 VDC

Striker as it is positioned on the cabinet

door. Remove Striker from door and

remove all the Two-Sided tape from the

door and Striker. Mount Striker to the

cabinet door using the proper NEMA rated

mounting hardware (not included).

11. VS-ACK-BATTERY POWER

OPTION:

Connect the wires of the Wire Harnes s to

the VeriSafe Absense of Voltage Tester

(AVT) and the VS-ACK-BATTERY kit.

• Ground (brown) wire to post 1

• Power (red) wire to post 2

the ACK is working properly. If needed

adjust the Striker or Latch Bracket to

eliminate any interference. The

mounting holes for both the Striker and

Latch Bracket are slotted for adjustment.

12. Install the Wire Harness to the Rotary

Latch.

1003190 R00 Page: 5 of 7 10-2019

Page 7

© Panduit Corp. 2019

INSTRUCTION MANUAL VeriSafe ACK

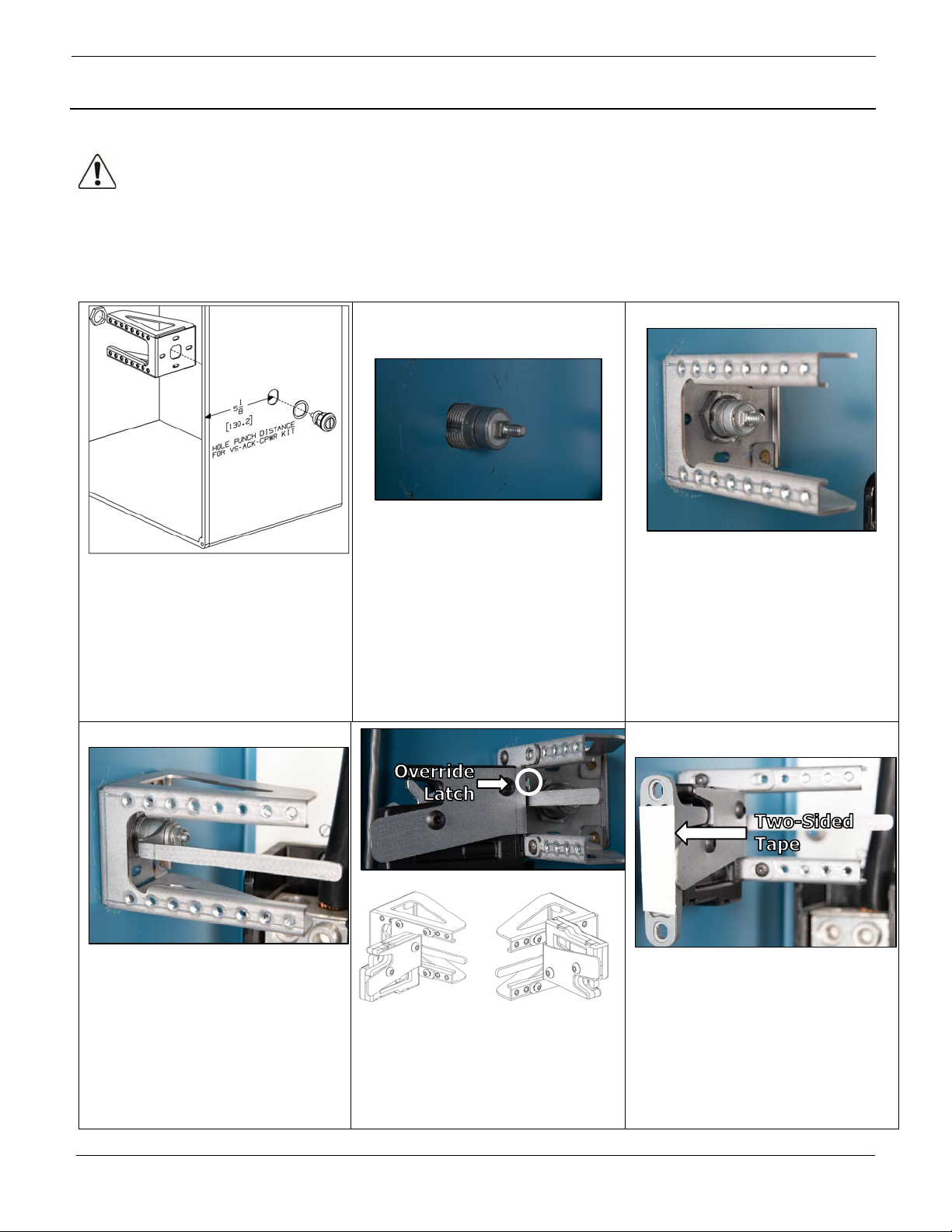

VS-ACK-EXT Install Instructions

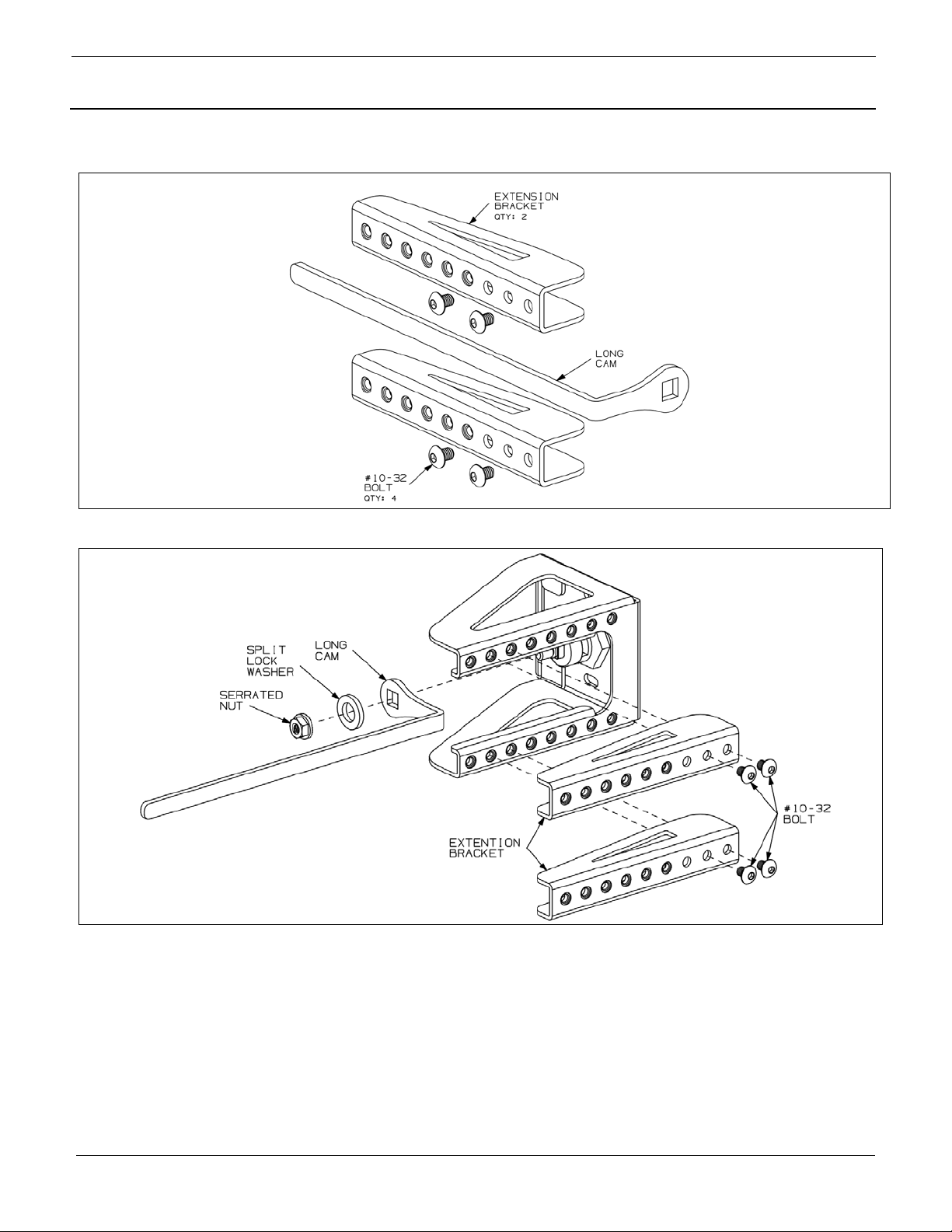

Figure 6 - Components of the VeriSafe Access Control Kit – Extension Kit (VS-ACK-EXT)

Figure 7 – Quick Assembly Guide – Extension Kit (VS-ACK-EXT)

Installation Instructions

In the case of the cabinet having a door lip greater that 5-1/8 inches the VS-ACK-EXT kit will need to be installed onto the VS-ACK-CPWR kit.

• Locate position for the knockout hole by measuring 5-13/64 inches from the surface where the cabinet door seats to the desired

mounting location on the side of the cabinet.

• Replace Short Cam (supplied in VS-ACK-CPWR kit) with the Long Cam (supplied in VS-ACK-EXT kit).

• Install the Extention Brackets onto the Enclosure Bracket with supplied #10-32 Bolts (4). See figure 7.

1003190 R00 Page: 6 of 7 10-2019

Page 8

© Panduit Corp. 2019

Commissioning Checklist

INSTRUCTION MANUAL VeriSafe ACK

□ Visually inspect the ACK:

• Mechanical Overrid e : Ver ify that t h e C am engages the overri de latch on the Rot ary Latch.

• Striker: Verify that the S t r iker is properly aligned with th e Ro t ary Latch.

• Enclosure Bracket: Ensure that the Mounting Nut is tightened to 88 IN*LB (10 N*m) max and that the

Enclosure Bracket does not rota t e. If rot ation occurs, there are four (4) #10-3 2 clearance slots w h ere

additional bolts can be added to the Enclosure bracket.

• Wire Harness: Verify that the cable is locked into place on the Rotary Latch. Also verify that the wire leads

are securely t er m i n ated to the AVT a n d t h e power source by g ently pulling on each wire lead.

□ Record changes to panel documentation.

□ Verify that the mechanical override is properly working before closing the panel door.

□ Close panel door and secure.

Warning

electric shock, use proper personal protective equipment when working on or near electrical hazards.

: Always follow your company’s safety procedures when energizing equipment. To avoid

□ Energize the system.

□ Verify that the red Voltage Presence Indicators are illuminated.

□ Verify that entry into t he cabinet is prohibited by the Access Control Kit.

□ De-energize the system.

□ Press the Test Button on the AVT Indicator Module to begin the absence of voltage test. Look for the

yellow Caution Indicator to flash and then the green Absence of Voltage Indicator should illuminate.

□ Verify that entry is allowed into the cabinet.

Maintenance

Visual Inspection

• Periodically inspect the Access Control Kit an d re place any damaged parts, cables or terminations.

• Inspect the Access Control Kit Wire Harness to ensure it is locked into place on the Rotary Latch and does

not show signs of damage.

• The Procedure described in the Commissioning Checklist can be performed at any time.

1003190 R00 Page: 7 of 7 10-2019

Loading...

Loading...