Page 1

Custom Color Insulation Sleeves

Applications:

Equipment manufacturers that prefer a non-standard color

scheme to:

1. Comply to performance requirements

(Example: military camouage)

2. Improve item identication during assembly

and maintenance

3. Strengthen brand identity

Customer Concern:

A manufacturer of amusement rides required insulated terminal

products that had very little appearance in low light areas. The

appearance of the wiring would reduce the impact of the

entertainment experience.

Panduit Solution:

Custom Color Insulated Terminal Products.

Modied colorant was added to the vinyl insulation material.

Samples were checked with the customer to verify a color

match. The colorant did not alter the electrical or mechanical

performance of the vinyl insulated terminal products. The part

dimensions were maintained, which prevented any required

change of crimp tools, dies, or UL certication.

APPLICATION NOTE

PV14-10R with Standard Blue Color Insulation

Application Considerations:

Consult factory to match specic color for your application.

The ability to identify wire range from industry standard

[Red (18 – 22 AWG); Blue (14 – 16 AWG);Yellow (10 – 12 AWG)]

is lost when non-standard colors are used, as it is difcult to

differentiate barrel sizes when insulation housings are all the

same color.

PV14-10R with Custom Color Black Insulation

PV14-10R with Custom Color Green Insulation

www.panduit.com

Page 2

Custom Color Insulation Sleeves

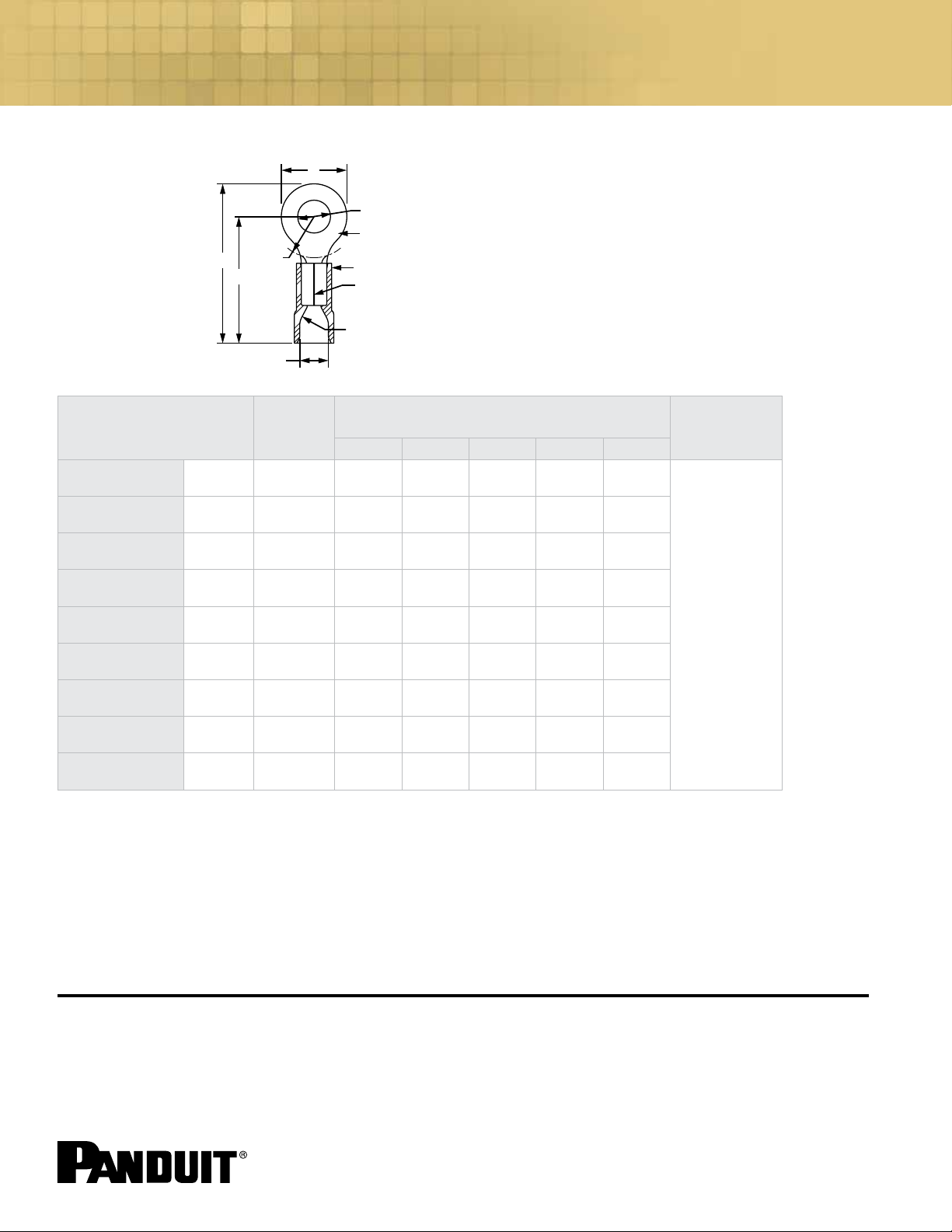

Loose Piece

A

M

.170 (4.3)

Max. Wire

Insul. Dia.

C Rad.

W

Funneled

Stud

Part Number

PV14-4R -C

Size

#4 .84

-M

PV14-6RN -C

#6 .84

-M

PV14-6R -C

#6 .92

-M

PV14-8R -C

#8 .92

-M

PV14-10R -C

#10 .92

-M

PV14-14R -C

1/4" 1.12

-M

PV14-56R -C

5/16" 1.12

-M

PV14-38R -L

3/8" 1.21

-M

PV14-12R -L 1/2" 1.42

H Dia.

Terminal

Housing

Brazed

Seam

Entry

±0.03

(21.3)

(21.3)

(23.4)

(23.4)

(23.4)

(28.5)

(28.5)

(30.7)

(36.1)

±0.01

W

.25

(6.4)

.25

(6.4)

.31

(7.9)

.31

(7.9)

.31

(7.9)

.46

(11.7)

.46

(11.7)

.53

(13.5)

.72

(18.3)

Dimensions

In. (mm)

±0.02

C

.19

(4.8)

.19

(4.8)

.25

(6.4)

.25

(6.4)

.25

(6.4)

.38

(9.7)

.38

(9.7)

.43

(10.9)

.53

(13.5)

M±

.71

(18.0)

.71

(18.0)

.76

(19.3)

.76

(19.3)

.76

(19.3)

.89

(22.6)

.89

(22.6)

.94

(23.9)

1.06

(26.9)

0.03

0.01

H±

.12

(3.1)

.15

(3.8)

.15

(3.8)

.17

(4.3)

.20

(5.1)

.27

(6.9)

.34

(8.6)

.40

(10.2)

.52

(13.2)

Crimp ToolA

CT-100A,

CT-1550,

CT-1551

Notes:

1. UL Listed and CSA Certied for:

a. 600 V maximum voltage rating (1000 V maximum in signs, xtures,

and luminaries)

b. 18 – 14 AWG solid or stranded copper wire and 221°F (105°C)

maximum temperature rating, with the CT-1550 and CT-1551

installation tools

c. 16 – 14 AWG solid or stranded copper wire and 167°F (75°C)

maximum temperature rating, with the CT-100A installation tools

2. RoHS compliant

WORLDWIDE SUBSIDIARIES AND SALES OFFICES

PANDUIT CANADA

Markham, Ontario

cs-cdn@panduit.com

Phone: 800.777.3300

PANDUIT EUROPE LTD.

London, UK

cs-emea@panduit.com

Phone: 44.20.8601.7200

PANDUIT SINGAPORE PTE. LTD.

Republic of Singapore

cs-ap@panduit.com

Phone: 65.6305.7575

For a copy of Panduit product warranties, log on to www.panduit.com/warranty

For more information

Visit us at www.panduit.com

Contact Customer Service by email: cs@panduit.com

or by phone: 800.777.3300

3. Material:

a. Stamping – .032 (.8) thick tin-plated copper

b. Housing – Vinyl, Custom Specied Color

4. Strip length: 5/16+1/32" / -0

5. Dimensions in brackets are in millimeters

6. Package qty.:

a. (Std. pkg. qty.) – L = 50 pcs.

b. (Std. pkg. qty.) – C = 100 pcs.

c. (Bulk pkg. qty.) – M = 1000 pcs.

PANDUIT JAPAN

Tokyo, Japan

cs-japan@panduit.com

Phone: 81.3.6863.6000

PANDUIT LATIN AMERICA

Guadalajara, Mexico

cs-la@panduit.com

Phone: 52.33.3777.6000

PANDUIT AUSTRALIA PTY. LTD.

Victoria, Australia

cs-aus@panduit.com

Phone: 61.3.9794.9020

©2015 Panduit Corp.

ALL RIGHTS RESERVED.

TMAN17--WW-ENG

replaces WW-TMAN06

12/2015

Loading...

Loading...