Page 1

PTR3E

Thermal Transfer Printer

Operator and Technical

Reference Manual

Page 2

Panduit Corp.

Identification Products Division

1819 Atlanta Hwy.

Cumming, GA 30040-1069

Phone: 888-506-5400

Fax: 770-889-9264

Copyright © Panduit Corp. 2001. All Rights Reserved

Panduit PTR3E

Page 3

This manual will guide you step by step in the set-up, operation, and

troubleshooting of the PTR3E Printer. If you have problems not covered

call Technical Support at 1-888-506-5400, ext. 7470.

SAFETY PRACTICES

The following general safety practices supplement the specific warnings

and cautions elsewhere in this manual. They are recommended

precautions that must be understood and applied during the operation

and maintenance of the equipment covered herein.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the product in the presence of flammable gases or fumes.

Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

DO NOT OPERATE IN WET OR DAMP AREAS

Do not operate the product in wet or damp areas. Operation of any

electrical equipment in such an environment constitutes a definite safety

hazard.

DO NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT

Because of the danger of introducing additional hazards, do not install

substitute parts or perform an unauthorized modification to the

equipment. The proper components for service and repair may be

obtained from Panduit Corp., Labeling Systems Department,

1-888-506-5400, ext. 7470. The product may also be returned for service

and repair by calling the above number and requesting a Tracking

Number. Please provide your company name, contact name, address,

telephone number and serial number of the printer (and P.O. Number if

out of warranty) when requesting the Tracking Number. After Tracking

Number is received the printer should be returned to :

Panduit Corp.

1819 Atlanta Highway

Cumming, GA 30040-1069

Attention: Labeling Systems Repair Department

WARNING

When the printer has been in use for a long time, the print head may

become hot. DO NOT touch the print head with bare hands.

Page 4

INFORMATION TO USER

NOTE: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part 15 of

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause interference in which case the user will be

required to correct the interference at his own expense.

WARRANTY INFORMATION

Our products are warranted to be free from defects in material and

workmanship at the time of sale but our obligation under this warranty is

limited to the replacement of any product proved to be defective within 6

months (for product) or 90 days (for printers) from the date of delivery.

Please remember to fill out the enclosed warranty card and return it to

Panduit. Printer warranty is void if Panduit printers are modified,

altered, or misused in any way. Use of Panduit printers with any product

other than the specified Panduit products for which the printer was

designed, constitutes misuse. Before using, user shall determine the

suitability of the product for his intended use and user assumes all risk

and liability whatsoever in connection therewith.

This warranty is made in lieu of and excludes all other warranties,

expressed or implied. THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR USE ARE

SPECIFICALLY EXCLUDED. Neither seller nor manufacturer shall be

liable for any injury, loss or damage, whether direct or consequential,

arising out of the use of, or the inability to use the product.

The information contained in this literature is based on our experience to

date and is believed to be reliable. It is intended as a guide for use by

persons having technical skill at their own discretion and risk. We do not

guarantee favorable results or assume any liability in connection with its

use. Dimensions contained herein are for reference purposes only. For

specific dimensional requirements consult the factory. This publication

is not taken as a license to operate under, or a recommendation to

infringe upon any existing patents. This supersedes and voids all

previous literature, etc.

Page 5

PTR3E OPERATOR MANUAL

The PTR3E Operator Manual contains basic information about the printer such

as setup, installation, cleaning and maintenance. It also contains complete

instructions on how to use the operator panel to configure the printer. The

following is a brief description of each section in this manual.

SECTION 1. PRINTER OVERVIEW

This section contains a discussion of the printer specifications and

optional features.

SECTION 2. INSTALLATION

This section contains instructions on how to unpack and set up the

printer, load the labels and ribbon.

SECTION 3. CONFIGURATION

This section contains instructions on how to configure the printer using

the DIP switches and the LCD / Menu / Control Panel.

PREFACE

SECTION 4. CLEANING AND MAINTENANCE

This section contains instructions on how to clean and maintain the

printer.

SECTION 5. INTERFACE SPECIFICATIONS

This section contains the printer’s interface specifications.

SECTION 6. TROUBLESHOOTING

This section contains troubleshooting procedures to follow in the event

you have printer problems.

i

Page 6

Preface

TABLE OF CONTENTS

SECTION 1. PRINTER OVERVIEW

Introduction ..............................1

General Printer Specifications ....................2-3

Character Fonts ............................4

BarCodes...............................5

Physical ................................6

SECTION 2. INSTALLATION

Introduction ..............................7

Unpacking and Parts Identification .................8-9

Setting Up the Printer ........................9-10

LoadingLabels............................11-13

LoadingtheRibbon..........................14-15

Operator Panel ............................16-17

Rear Panel...............................18

Switches and Sensors .........................19

Label Sensor Adjustment .......................20

SECTION 3. CONFIGURATION

Printer DIP Switch Configuration ..................21-25

PrinterAdjustments .........................26-35

Potentiometer Adjustments .....................35-36

DisplayCounterValues........................37

SECTION 4. CLEANING AND MAINTENANCE

Introduction ..............................39

Procedures...............................39-45

Adjusting the Print Quality ...................39-40

Darkness............................39

PrintSpeed ..........................40

Cleaning the Print Head, Platen and Rollers ..........41-42

Cleaning the Sensors .......................42

ReplacingthePrintHead.....................43-44

ReplacingtheFuse........................45

ii

Page 7

SECTION 5. INTERFACE SPECIFICATIONS

IEEE1284 Parallel Interface .....................47

RS232C Serial Interface .......................48

SECTION 6. TROUBLESHOOTING

Initial Checklist ............................49

Using the IEEE1284 (Parallel) Interface ..............49-50

Using the RS232C (Serial) Interface .................50

Error Signals .............................51

Preface

iii

Page 8

Page 9

INTRODUCTION

The Panduit PTR3E Thermal Transfer Printer is a complete, high-performance

on-site labeling system. All printer parameters are user programmable using the

front panel controls and the DIP switches. All popular bar codes and 14

human-readable fonts, including a vector font and two raster fonts, reside in

memory providing literally thousands of type styles and sizes.

The Operator Manual will help you understand the basic operations of the

printer such as setup, installation, configuration, cleaning and maintenance.

The PTR3E has a resolution of 203 dpi and can print labels up to four inches

wide.

The following general information is presented in this section:

SECTION 1.

PRINTER OVERVIEW

• General Printer Specifications

• Character Fonts

• Bar Codes

• Physical Specifications

1

Page 10

Section 1. Printer Overview

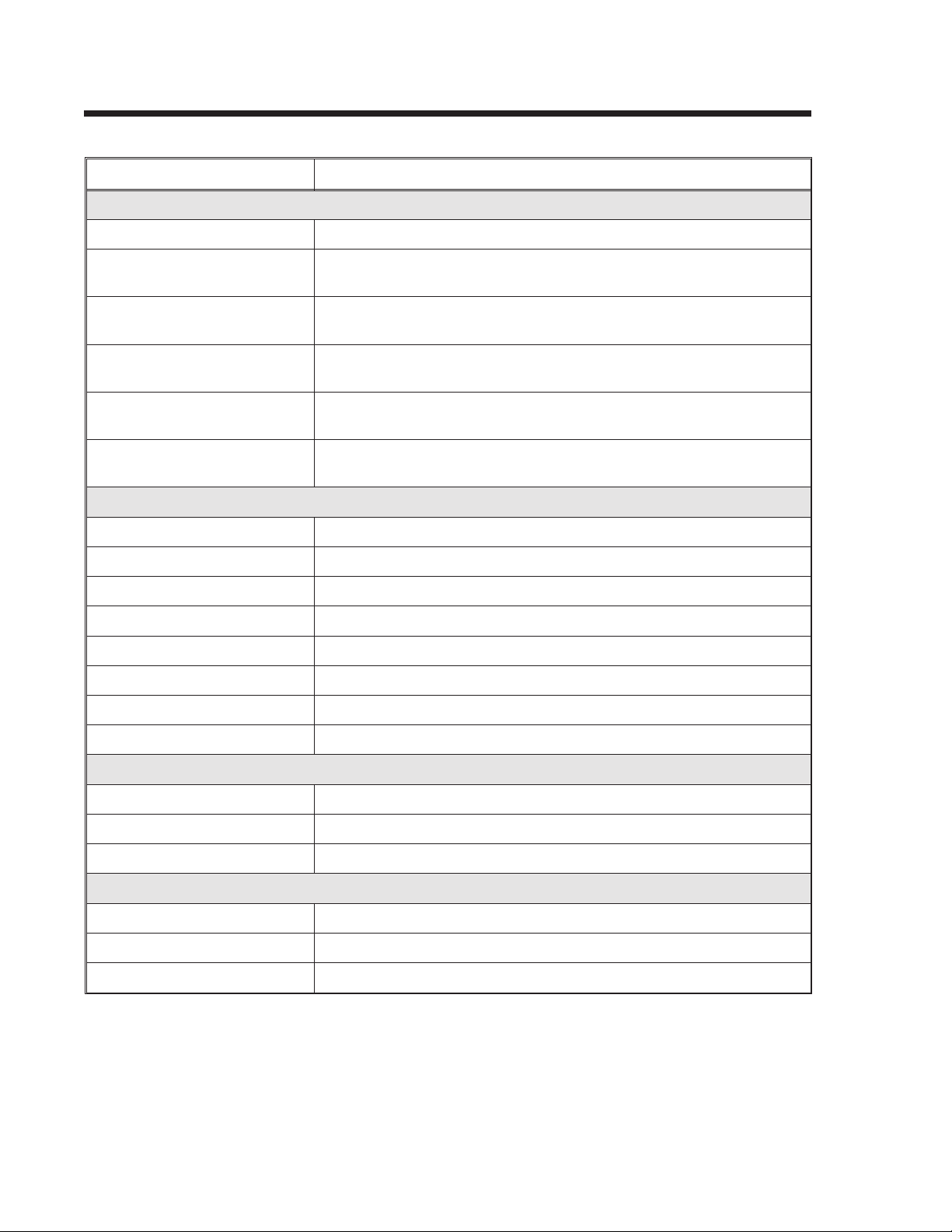

GENERAL PRINTER SPECIFICATIONS

SPECIFICATION PTR3E

PRINT

Method Direct or Thermal Transfer

Speed (User Selectable) 2 to 10 ips

50 to 250 mm/s

Print Module (Dot Size) .0049 in.

.125 mm

Resolution 203 dpi

8 dpmm

Maximum Print Width 4.1 in.

104 mm

Maximum Print Length 49.2 in.

1249 mm

MEDIA

Minimum Width .87 in. (22 mm)

Minimum Length .63 in. (16 mm)

Maximum Width 5.0 in. (128 mm)

Type Die Cut Labels, Fan-Fold or Continuous

Maximum Caliper .010 in. (.25 mm)

Roll OD (max) 8.6 in. (218 mm), Face-Out Wind

Core ID (min) 1.5 in. (38 mm)

Core ID (Recommended) 3 in. (76 mm)

SENSING

See-Thru for labels Movable

Reflective Eye-Mark Movable

Continuous Form Sensor not used

RIBBON

Maximum Width 4.4 in. (111 mm)

Maximum Length 1475 ft. (450 m)

Thickness 4.5 micron, Ink-In Wind

All specifications subject to change without notice.

2

Page 11

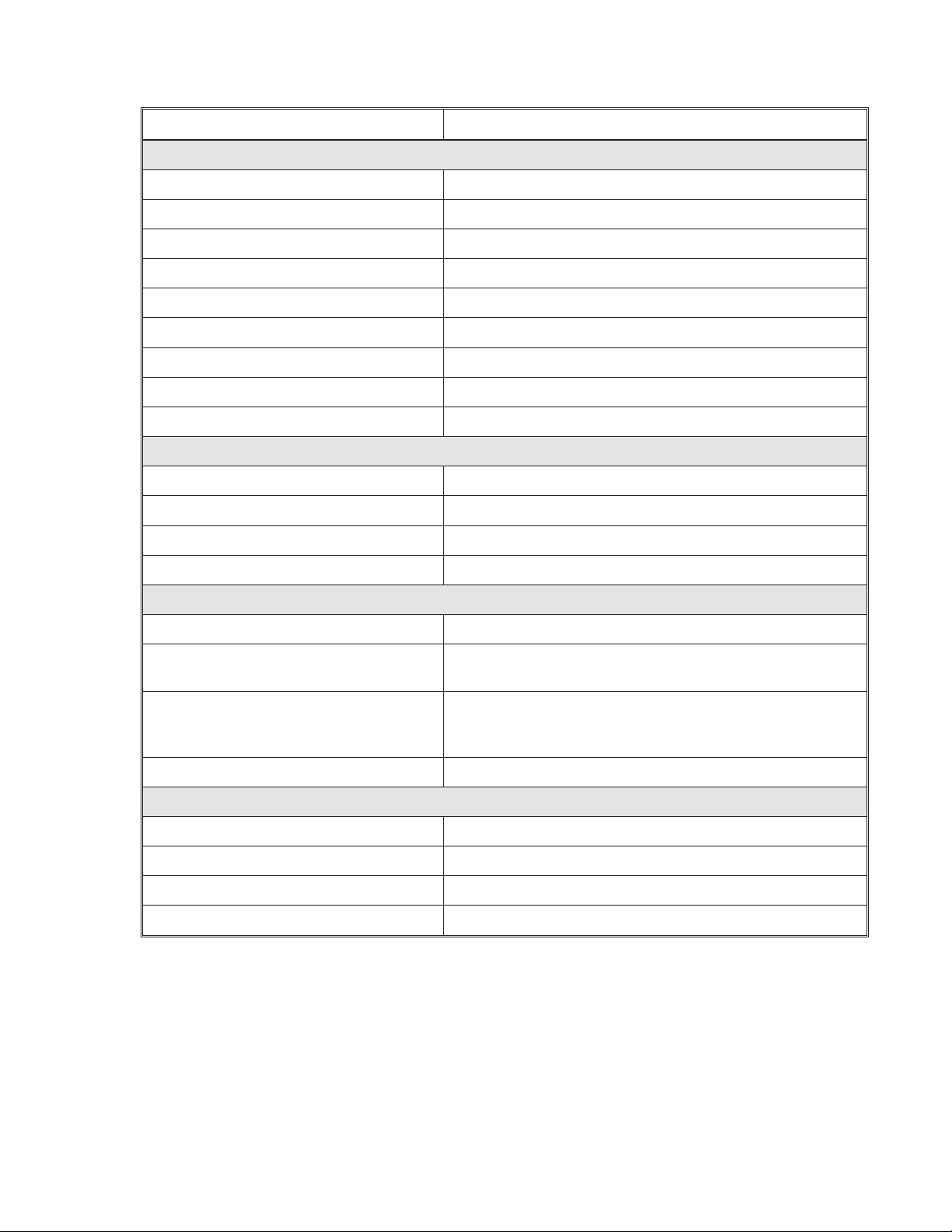

Section 1. Printer Overview

SPECIFICATION PTR3E

CONTROLS AND SIGNALS

On-Line Green LED

Power Green LED

Label Red LED

Ribbon Red LED

Error Red LED

LCD Panel 2 Line x 16 Character

On/Off-Line Switch Front Panel

Label Feed Switch Front Panel

Power On/Off Switch Front Panel

POTENTIOMETER ADJUSTMENTS

Print Darkness Front Panel

Pitch Front Panel

Offset Front Panel

Display Front Panel

INTERFACE CONNECTIONS

Parallel* IEEE1284 Compatible Standard

Serial RS232C (9600 to 57600 bps) Standard

RS422/485 (9600 to 57600 bps) Optional

Serial Protocol Hardware Flow Control (Ready/Busy)

Software Flow Control (X-On/X-Off)

Bi-directional Status

Data Transmission ASCII Format

PROCESSING

CPU 32 Bit RISC

Flash ROM 2 MB

SDRAM 16 MB

Receive Buffer 2.95 MB

All specifications subject to change without notice.

* PTR3E comes standard with parallel port. Contact factory if serial port is required.

3

Page 12

Section 1. Printer Overview

CHARACTER FONTS

SPECIFICATION PTR3E

MATRIX FONTS

U Font (5 dots W x 9 dots H)

S Font (8 dots W x 15 dots H)

M Font (13 dots W x 20 dots H)

XU Font (5 dots W x 9 dots H) Helvetica

XS Font (17 dots W x 17 dots H) Univers Condensed Bold

XM Font (24 dots W x 24 dots H) Univers Condensed Bold

OA Font (15 dots W x 22 dots H) OCR-A

OB Font (20 dots W x 24 dots H) OCR-B

AUTO SMOOTHING FONTS

WB WB Font (18 dots W x 30 dots H)

WL WL Font (28 dot W x 52 dots H)

XB XB Font (48 dots W x 48 dots H) Univers Condensed Bold

XL XL Font (48 dot W x 48 dots H) Sans Serif

VECTOR FONT

Proportional or Fixed Spacing

Font Size 50 x 50 dots to 999 x 999 dots

Helvetica, 10 Font Variations

AGFARASTER FONTS

Font A CG Times, 8 to 72 pt

Font B CG Triumvirate, 8 to 72 pt

DOWNLOADABLE FONTS

Bit Mapped TrueTypeFonts with Utility Program

CHARACTER CONTROL

Expansion up to 12X in either the X or Y coordinates

Character Pitch control

Line Space control

Journal Print facility

0°, 90°, 180° and 270° Rotation

All specifications subject to change without notice.

4

Page 13

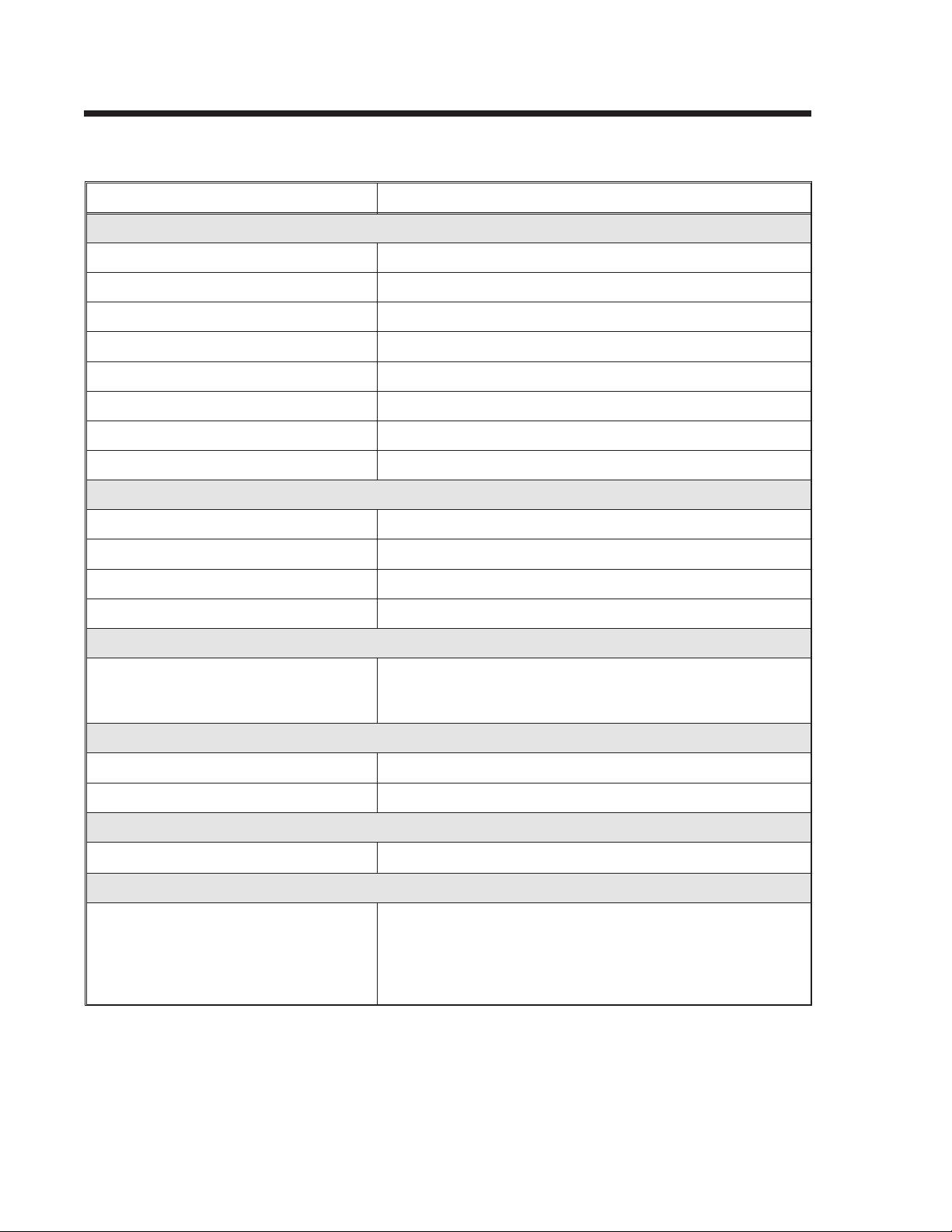

Section 1. Printer Overview

BAR CODES

SPECIFICATION PTR3E

SYMBOLOGIES

Bookland (UPC/EAN Supplemental)

EAN-8, EAN-13

CODABAR

Code 39

Code 93

Code 128

Interleaved 2 of 5

Industrial 2 of 5

Matrix 2 of 5

MSI

POSTNET

UCC/EAN-128

UPC-A and UPC-E

Data Matrix

Maxicode

PDF417

Micro PDF

Truncated PDF

QR Code

Ratios 1:2, 1:3, 2:5 User definable bar widths

Bar Height 4 to 600 dots, User programmable

Rotation 0°, 90°, 180° and 270°

OTHER FEATURES

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Graphics Full dot addressable graphics, .BMP or .PCX formats

Form Overlay Form overlay for high-speed editing of complex formats.

All specifications subject to change without notice.

5

Page 14

Section 1. Printer Overview

PHYSICAL

SPECIFICATION PTR3E

DIMENSIONS

Wide 10.4 in. (265 mm)

Deep 17.1 in. (435 mm)

High 13.4 in. (341 mm)

WEIGHT 39.6 lbs (18 Kg)

POWER REQUIREMENTS

Voltage

Power Consumption 50W Idle

ENVIRONMENTAL

Operating Temperature 41° to 104°F (5° to 40°C)

Storage Temperature -0° to 104°F (-20° to 40°C)

Operating Humidity 15-85 % RH, non-condensing

Storage Humidity Max 90% RH, non-condensing

Electrostatic Discharge 8KV

REGULATORY APPROVALS

Safety UL, CSA, TUV, CE

RFI/EMI FCC Class A

All specifications subject to change without notice.

100 - 115 V , ±10 % (Default Setting)

220V , ±10 %

50/60 Hz, ±1%

130W Operating

6

Page 15

INTRODUCTION

This section will assist you in taking the PTR3E from the shipping container to

the application environment.

The following information is provided in this section:

SECTION 2.

INSTALLATION

Unpacking and Parts Identification

•

Setting Up the Printer

•

Loading Labels

•

Loading the Ribbon

•

• Operator Panel

• Rear Panel

• Switches and Sensors

• Label Sensor Adjustment

7

Page 16

Section 2. Installation

UNPACKING AND PARTS IDENTIFICATION

Consider the following when unpacking the printer:

The box should stay right-side up.

•

Lift the printer out of the box carefully.

•

Remove the plastic covering from the printer.

•

Remove the accessory items from their protective containers.

•

If the printer has been stored in a cold environment, allow it to reach

•

room temperature before powering it on.

Set the printer on a solid, flat surface. Inspect the shipping container

•

and printer for any signs of damage that may have occurred during

shipping.

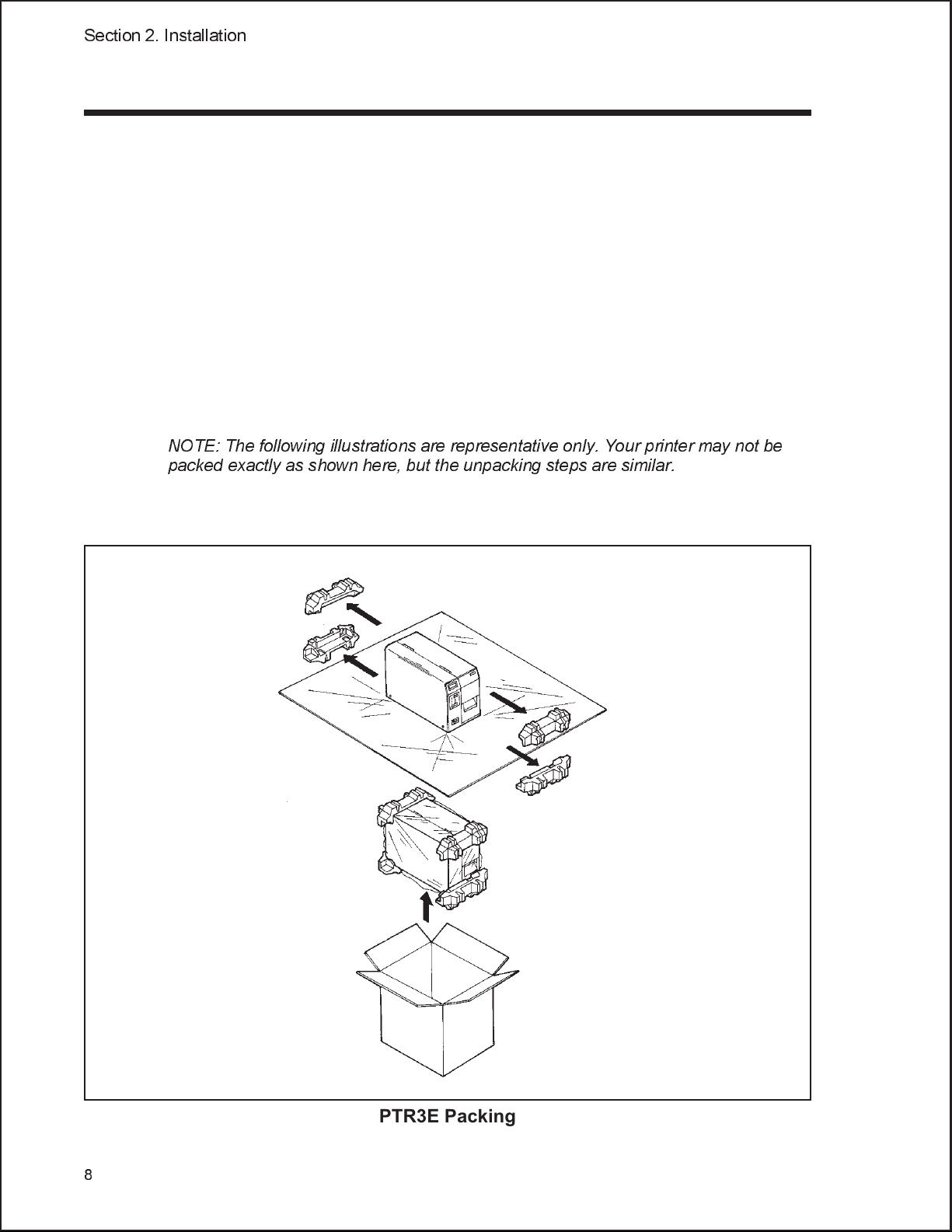

NOTE: The following illustrations are representative only. Your printer may not be

packed exactly as shown here, but the unpacking steps are similar.

PTR3E Packing

8

Page 17

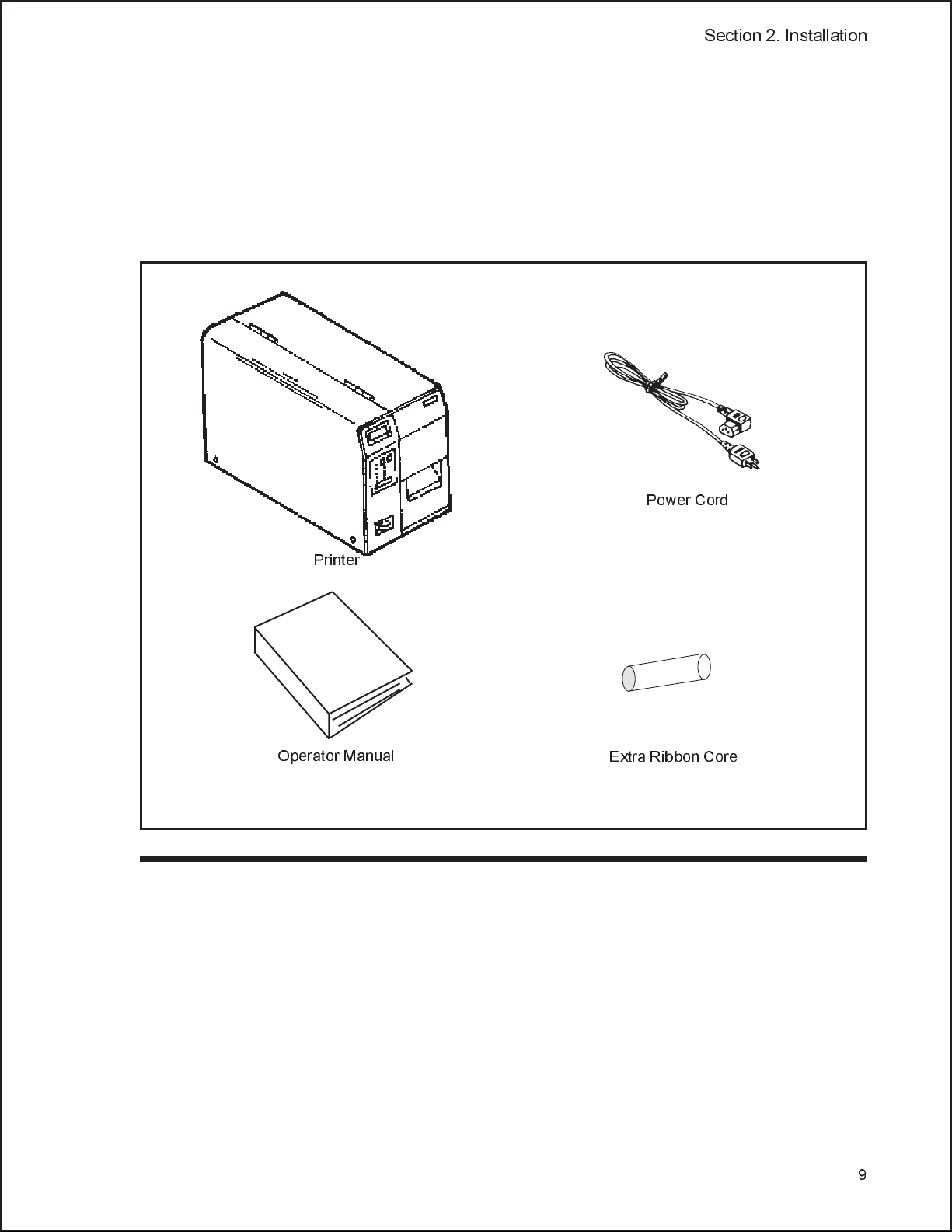

Verify that you have the following materials when unpacking:

Printer

•

Power Cord

•

Extra Ribbon Core

•

Operator and Technical Reference Manual

•

Section 2. Installation

Printer

Operator Manual

SETTING UP THE PRINTER

Consider the following when setting up the printer:

•

Locate a solid flat surface with adequate room to set the printer. Make

sure there is enough room at the top and right-hand (facing the printer)

side to provide clearance for the label access door to swing open.

Power Cord

Extra Ribbon Core

•

The location should be near the host computer or terminal. The maximum

distance for RS232 cables is 35 feet and six feet for IEEE1284 Parallel

cables. Cables can be purchased locally, and their configuration will

depend upon the host system being used. An IEEE1284 compliant cable

must be used to realize the full throughput potential of the printer.

9

Page 18

Section 2. Installation

Top Access

Door

LCD

Display

DIP Switch

Cover

Power Switch

Ribbon Rewind

Spindle

Ribbon Supply

Spindle

Side Access

Door

Label Roll Retainer

Label Supply Spindle

Label Guide

Print Head

Head Latch

Platen

10

Page 19

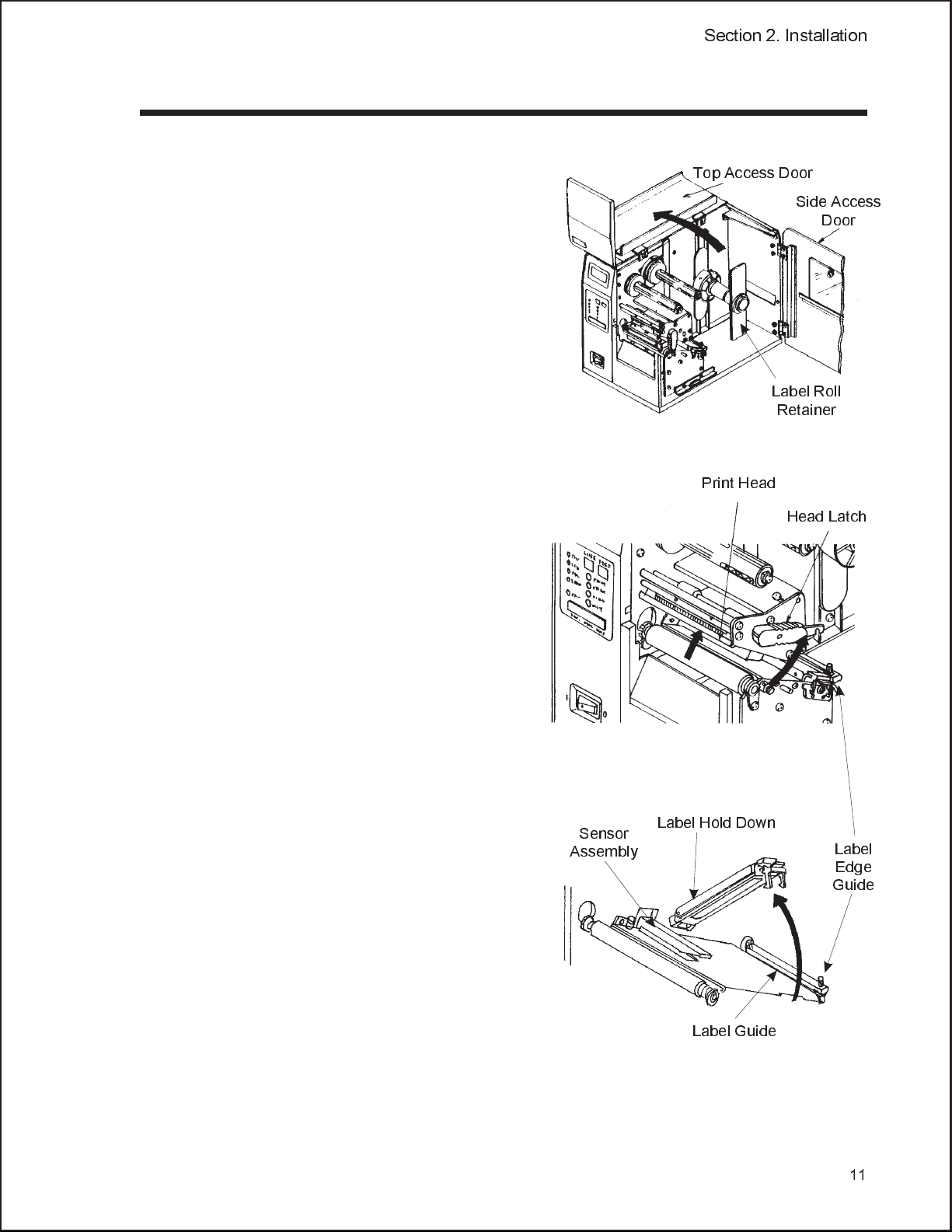

LOADING LABELS

Follow these steps to properly load labels into

the PTR3E:

Section 2. Installation

Top Access Door

1. Open the Top Access Door by

swinging it up and to the left. Open

the Side Access Door by

swinging it to the rear of the

printer.

2. Open the Print Head Assembly

by pushing the Head Latch

toward the rear of the printer. The

Print Head Assembly is

spring-loaded and will

automatically open as soon as the

Head Latch is disengaged.

Side Access

Door

Label Roll

Retainer

Print Head

Head Latch

3. Loosen the Label Edge Guide

and push it to the outside of the

printer to give the maximum label

width.

4. Remove the Label Roll

Retainer.

Sensor

Assembly

Label Hold Down

Label

Edge

Guide

Label Guide

11

Page 20

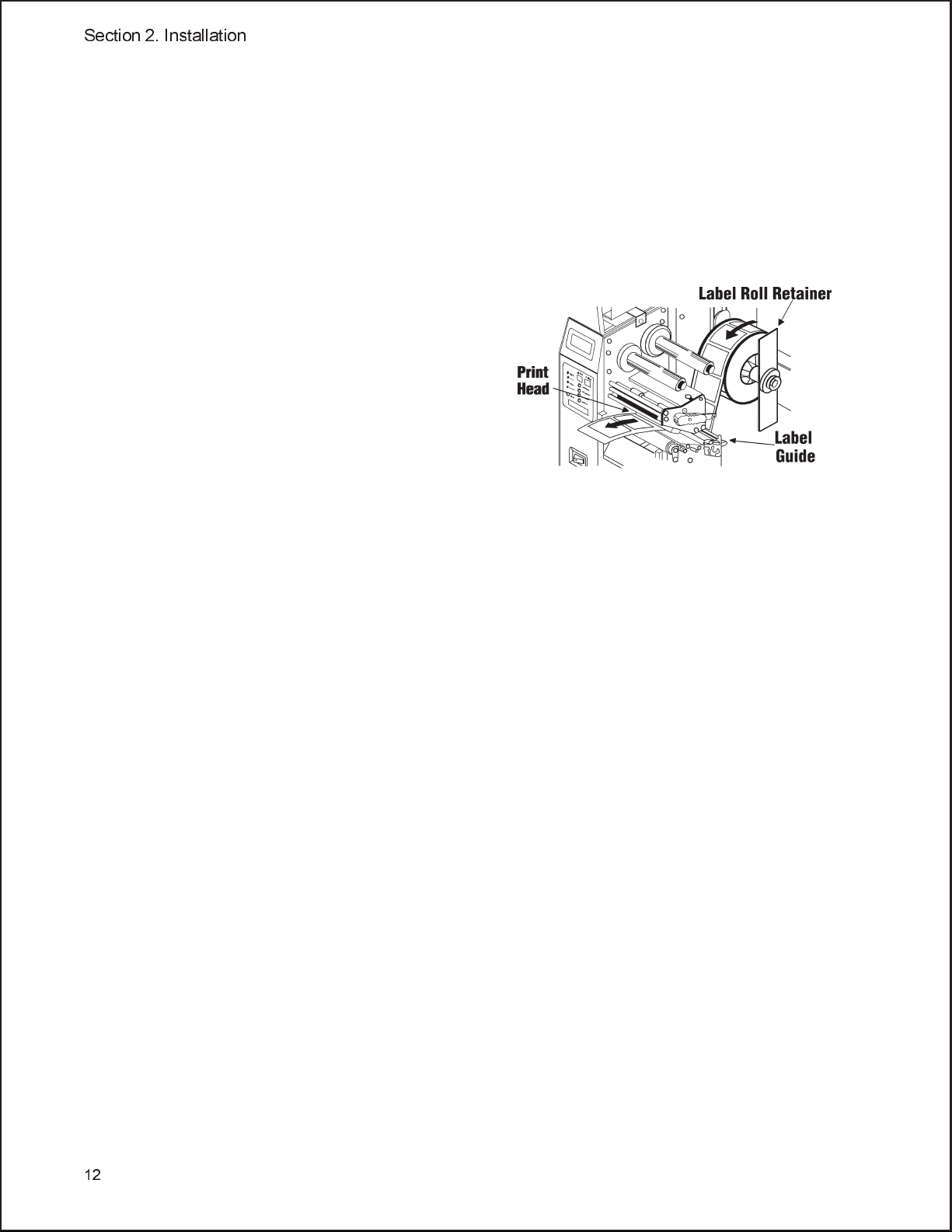

Section 2. Installation

5. If using roll labels (or tags), load the roll onto the Label Supply Spindle so that

the printing side of the labels faces upwards as it unwinds from the roll. Push

the roll all the way to the inside of the printer and push the Label Roll

Retainer snugly against the outside of the label roll.

6. If using fanfold labels set them on a flat surface behind the printer. Pass the

labels (printing side up) through the slot in the rear of the printer.

7. Make sure the labels are routed

under the Label Guide and

through the Sensor Assembly.

8. Open the Label Hold-Down by

squeezing the green tab and the

release tab together. The Label

Hold Down is spring loaded and

will open automatically when the

latch is disengaged. Feed the labels

under the Label Guide, under the

Label Hold Down, through the

Sensor Assembly and out the front

of the printer.

9. Inspect the label routing and verify that the path matches that illustrated in the

Label Loading diagram. Set the Adjustable Label Guide to keep the labels

against the inside of the printer.

10. Close the Label Hold-Down by pushing downward on the green tab until it

latches closed.

12

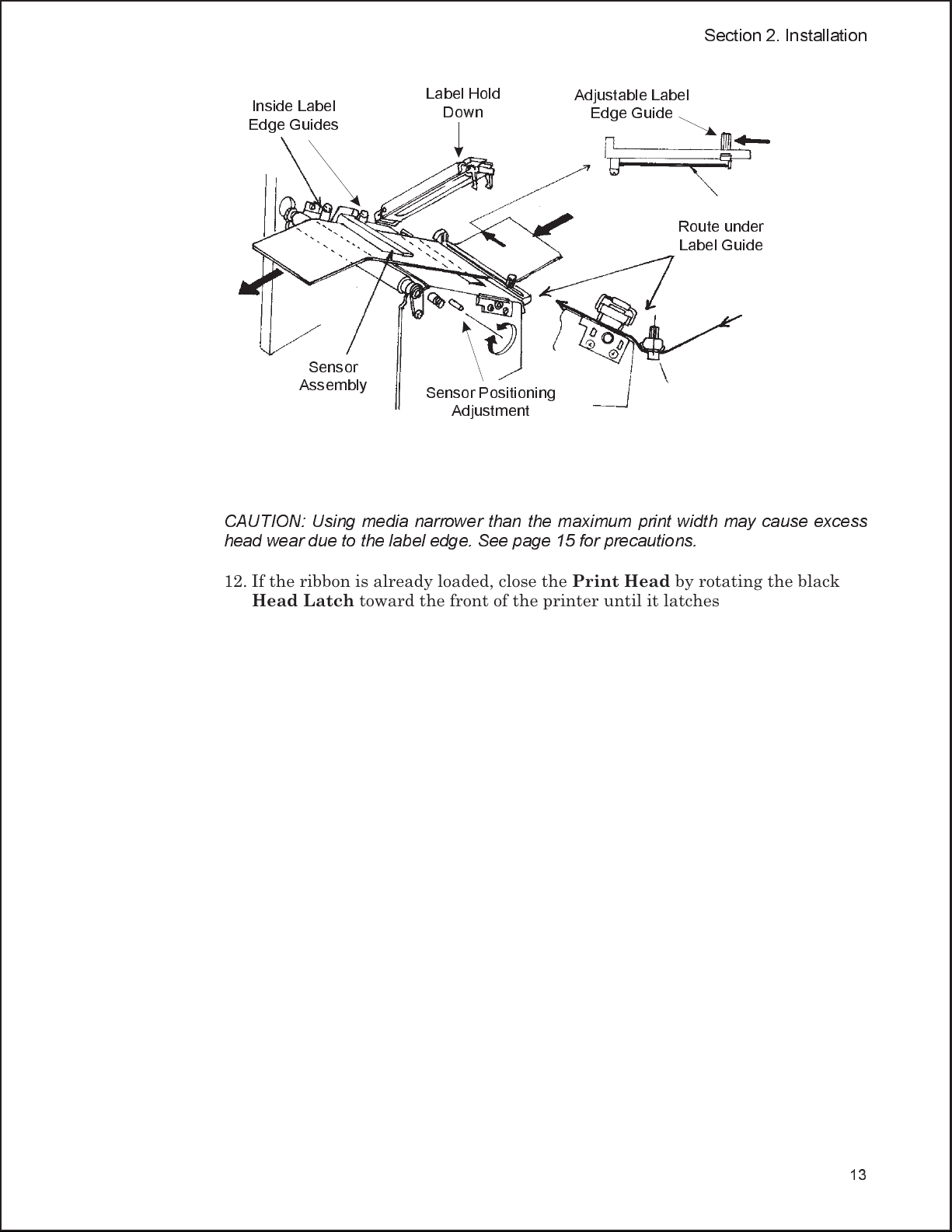

Page 21

Section 2. Installation

Inside Label

Edge Guides

Sensor

Assembly

Label Hold

Down

Sensor Positioning

Adjustment

Adjustable Label

Edge Guide

Route under

Label Guide

11. Adjust the outside Label Edge Guide until it touches the outside edge of the

label and tighten the thumb screw. Make sure the labels are also touching the

inside edge guides.

CAUTION: Using media narrower than the maximum print width may cause excess

head wear due to the label edge. See page 15 for precautions.

12. If the ribbon is already loaded, close the Print Head by rotating the black

Head Latch toward the front of the printer until it latches closed.

13. If the ribbon is not loaded, see the following description for loading

instructions.

14. Close both Access Doors.

13

Page 22

Section 2. Installation

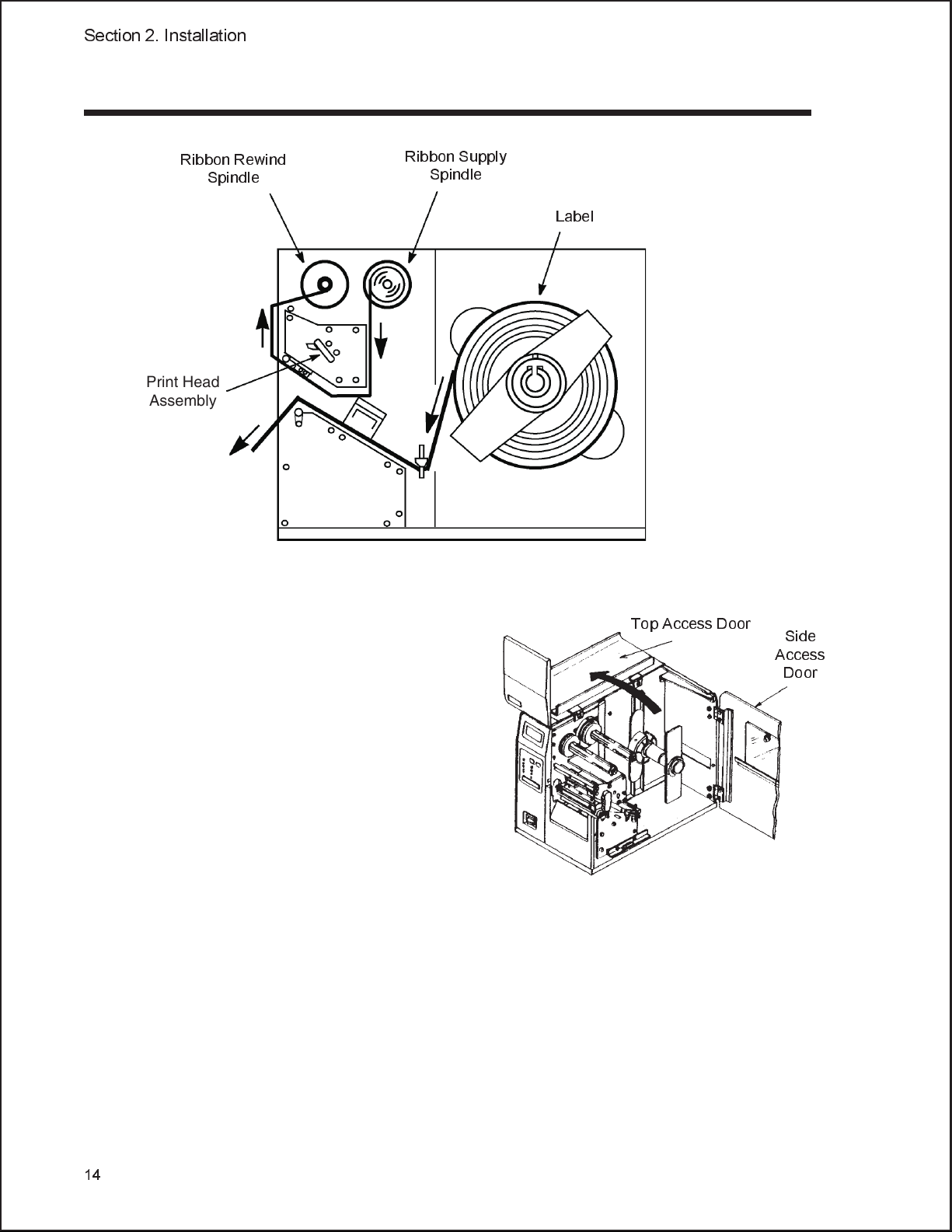

LOADING THE RIBBON

Ribbon Rewind

Print Head

Assembly

Spindle

Ribbon Supply

Spindle

Label

1. Open the Top Access Door by

swinging it up and to the left and

the Side Access Door by

swinging it toward the rear of the

Top Access Door

Side

Access

Door

printer.

2. Open the Print Head by rotating

the Head Latch toward the rear

of the printer. The Print Head is

spring-loaded and will

automatically open as soon as the

Head Latch is disengaged.

3. Locate the Extra Ribbon Core

supplied with the printer. Place

the core on the Ribbon Rewind Spindle, pushing it all the way to the inside of

the spindle. Note that the new empty core of each subsequent roll becomes the next

rewind core.

4. Load the ribbon onto the Ribbon Supply Spindle, also pushing it all the way

to the inside of the spindle. The dull side of the ribbon should be facing down as it

travels through the Print Head Assembly.

14

5. Feed the leader portion of the ribbon through the Print Head Assembly and

up to the Ribbon Rewind Spindle following the routing shown in the

diagram.

Page 23

Section 2. Installation

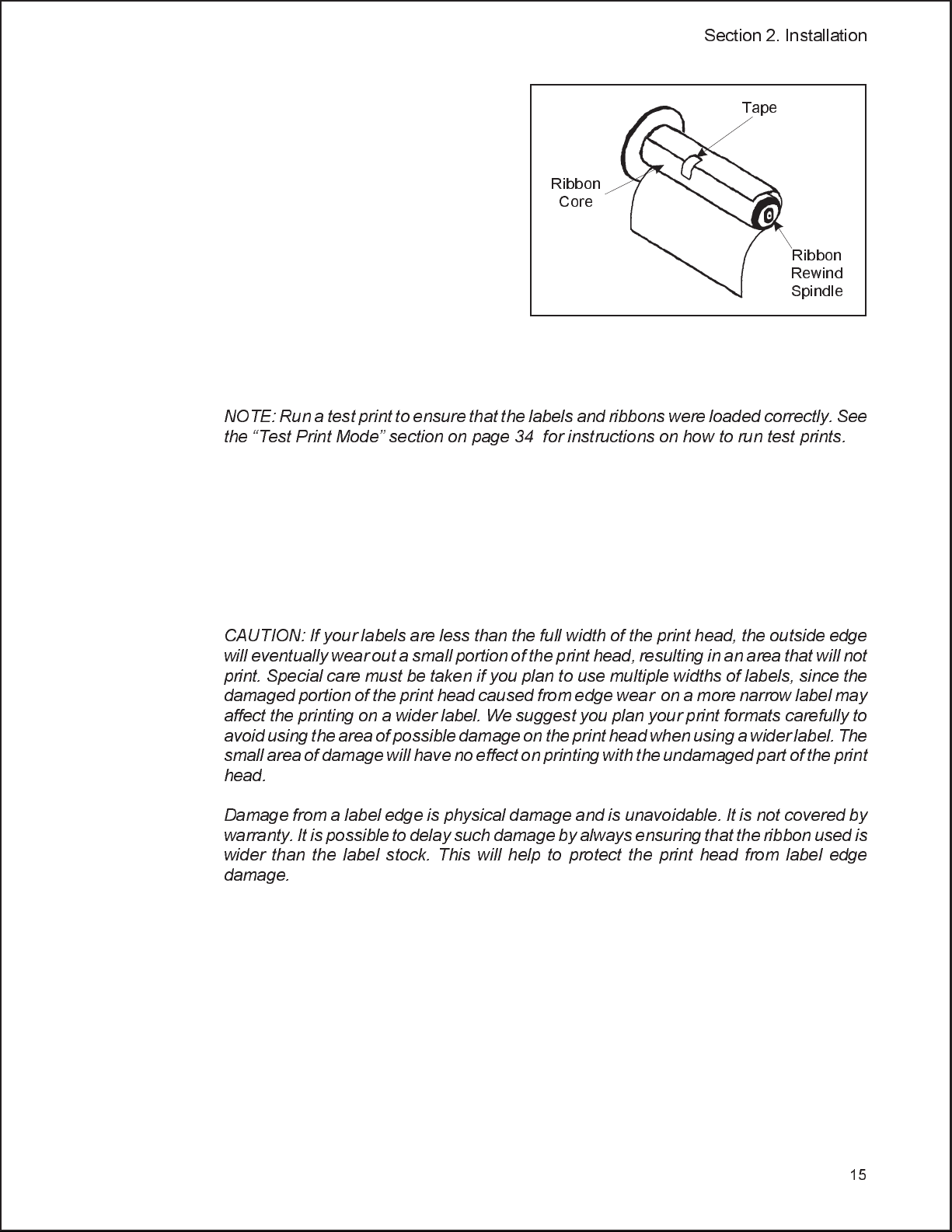

6. Load the ribbon behind and over

the top of the Ribbon Rewind

Tape

Spindle and tape it to the Extra

Ribbon Core. Make sure it

matches the ribbon path shown in

the diagram.

Ribbon

Core

7. Manually turn the Rewind

Spindle to wrap the ribbon onto

the core one to two turns to secure

it.

Ribbon

Rewind

Spindle

8. If the labels are already loaded,

close the Print Head Assembly by pushing downward on the green tab until it

latches closed.

NOTE: Run a test print to ensure that the labels and ribbons were loaded correctly. See

the Test Print Mode section on page 34 for instructions on how to run test prints.

CAUTION: If your labels are less than the full width of the print head, the outside edge

will eventually wear out a small portion of the print head, resulting in an area that will not

print. Special care must be taken if you plan to use multiple widths of labels, since the

damaged portion of the print head caused from edge wear on a more narrow label may

affect the printing on a wider label. We suggest you plan your print formats carefully to

avoid using the area of possible damage on the print head when using a wider label. The

small area of damage will have no effect on printing with the undamaged part of the print

head.

Damage from a label edge is physical damage and is unavoidable. It is not covered by

warranty. It is possible to delay such damage by always ensuring that the ribbon used is

wider than the label stock. This will help to protect the print head from label edge

damage.

15

Page 24

Section 2. Installation

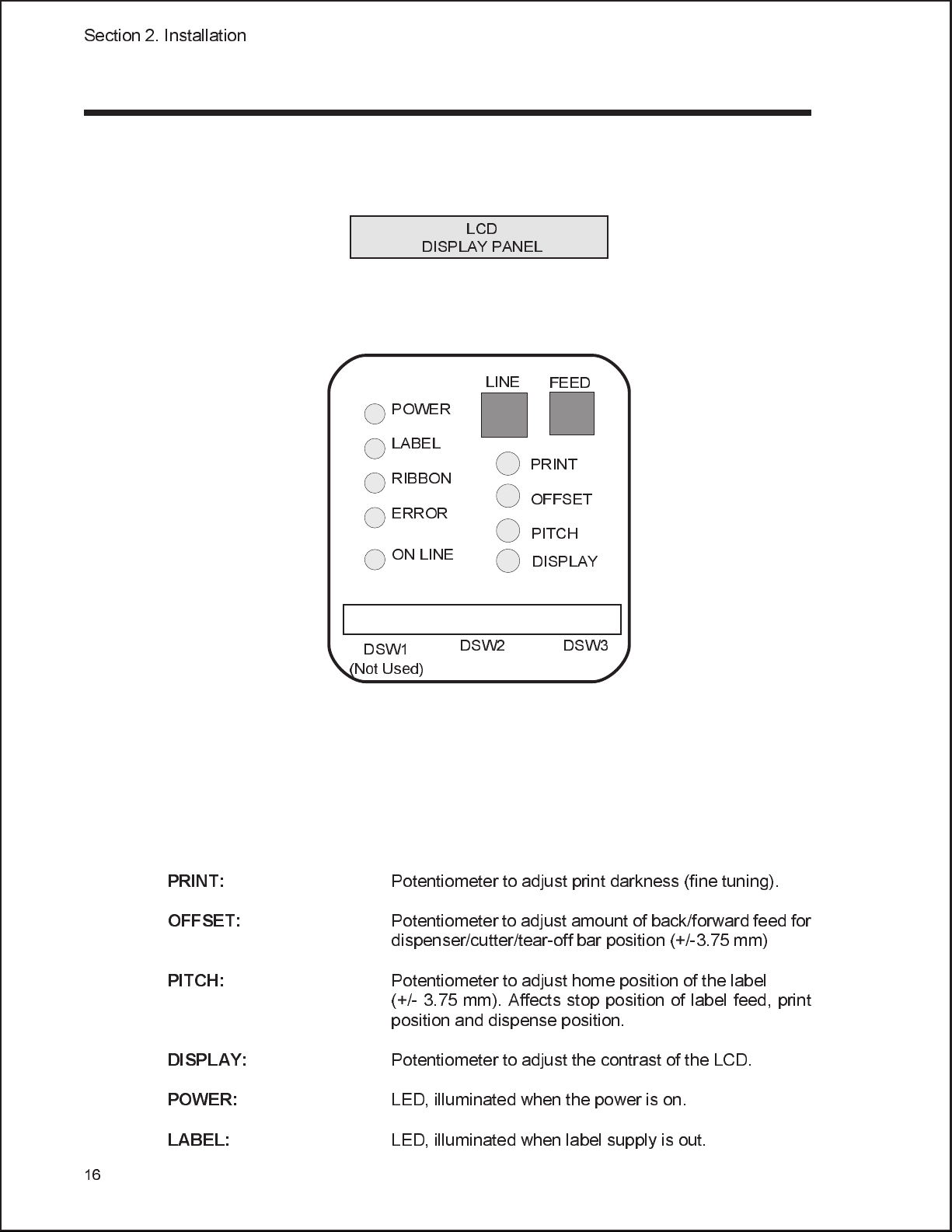

OPERATOR PANEL

LCD

DISPLAY PANEL

POWER

LABEL

RIBBON

ERROR

ON LINE

DSW1

(Not Used)

LINE

DSW2

FEED

PRINT

OFFSET

PITCH

DISPLAY

DSW3

The PTR3E Operator Panel consists of five LED indicators, two momentary

contact switches, two DIP switches, four adjustment potentiometers and one LCD

Display. All of these are accessible from the front of the printer. They are used to set

the printer operating parameters and to indicate the status of the printer to the

operator. After you power on the printer, familiarize yourself with the keys and

indicators as it will help you understand the configuration process.

16

PRINT:

OFFSET:

PITCH:

DISPLAY:

POWER:

LABEL:

Potentiometer to adjust print darkness (fine tuning).

Potentiometer to adjust amount of back/forward feed for

dispenser/cutter/tear-off bar position (+/-3.75 mm)

Potentiometer to adjust home position of the label

(+/- 3.75 mm). Affects stop position of label feed, print

position and dispense position.

Potentiometer to adjust the contrast of the LCD.

LED, illuminated when the power is on.

LED, illuminated when label supply is out.

Page 25

Section 2. Installation

RIBBON:

ERROR:

ON LINE:

LINE:

FEED:

DSW:

LED, illuminated when ribbon motion sensor does not

detect any ribbon motion (ribbon out).

LED, illuminated when there is a system fault such as

an open print head.

LED, illuminated when printer is ready to receive data.

It is turned on and off by toggling the LINE key.

Momentary switch. Pressing this key toggles the printer

between the on-line and off-line mode. When the printer

is on-line, it is ready to receive data from the host. This

key acts as a pause during a print job by taking the printer

off-line. It can also be used as a

Pause

function key to

stop the printer during the printing process.

Momentary switch. Pressing this key feeds one blank

label through the printer when it is off-line. When the

printer is on-line, another copy of the last label will be

printed.

DIP switch array to set operational parameters of the

printer.

LCD:

2 Line x 16 Character LCD display. Used for setting

operationalparameters of the printerand displayingerror

conditions.

17

Page 26

Section 2. Installation

REAR PANEL

AC Input:

AC Fuse:

Interface Slot:

Memory Card Slot:

EXT:

DC 5V:

Input 115V 50/60 Hz connector. Use the cable

provided.

Input power protection. Type 3A/250V.

Connector for Plug-In Interface Module

Connectors for optional PCMCIA Memory Cards.

(Inside Side Cover)

External signal connector, AMP 57-60140.

Power for accessory items.

Fan Fold

Access Panel

Memory Card

Option

AC Power In

Parallel Port

Connector

EXT Port

Connector

Fuse

18

Page 27

SWITCHES AND SENSORS

Section 2. Installation

Ribbon End Sensor:

Head Open Switch:

Label Sensor Unit:

This sensor is a motion detector that signals the printer

when the ribbon supply is turning.

When the print head is opened, this switch is activated

and the printer will stop printing.

This sensor unit contains two types of sensors, one for

label gap and one for Eye-Mark sensing. The sensors

are adjustable over a limited range.

19

Page 28

Section 2. Installation

LABEL SENSOR ADJUSTMENT

The Label Sensor Assembly can be positioned to match the location of the label

registration hole/gap/edge. The diagram below illustrates the relative position of

each sensor along the Label Sensor Unit and its range of movement. To position the

sensors, use the adjustment knob located outside and below the print head

assembly.

Reflective Sensor

Label Gap Sensor

Eye-Mark

on bottom

of liner

14mm

min

Reflective

7mm to 54 mm

Label Gap

The range of sensor adjustment can be

increased to allow the Gap sensor to be

positioned as close as 3mm from the inside label

edge. Contact Panduit for information on how to

make this modification.

20

Label Sensor

Adjustment Knob

Page 29

SECTION 3.

CONFIGURATION

PRINTER DIP SWITCH CONFIGURATION

DIP Switch Panels

There are two DIP switches (DSW2 and DSW3) located underneath a snap-on cover

on the front panel. These switches can be used to set:

Thermal transfer or direct thermal mode

•

Label sensor enable/disable

•

Head check mode

•

Hex dump mode

•

• Single job or multi-job buffer

• Operation mode

In addition, a third DIP switch is located on the RS232C Serial Adapter card and is

used to set the RS232C transmit/receive parameters. (NOTE: Notfactory standard)

Each switch is an eight section “toggle” switch. The ON position is always to the top.

To set the switches, first power the unit OFF, then position the DIP switches.

Finally, after placing the switches in the desired positions, power the printer back

on. The switch settings are read by the printer electronics during the power up

sequence. They will not become effective until the power is cycled.

Printer Set Up

Print Mode Selection (DSW2-1). Selects between direct thermal printing on

thermally sensitive paper and thermal transfer printing using a ribbon.

DSW2-1 SETTING

OFF Therm Xfr

ON Direct Therm

Sensor Type Selection (DSW2-2). Selects between the use of a label gap or a

reflective Eye-Mark detector. See page 20 for the location of these sensors.

ON

OFF

12345678

DSW2

DSW2-2 SETTING

OFF Gap

ON Eye-Mark

DSW2

ON

OFF

12345678

21

Page 30

Section 3. Configuration

Head Check Selection (DSW2-3). When selected, the printer will check for head

elements that are electrically malfunctioning.

DSW2

DSW2-3 SETTING

OFF Disabled

ON Enabled

ON

OFF

12345678

Hex Dump Selection (DSW2-4). Selects Hex Dump mode (see page 37).

DSW2-4 SETTING

OFF Disabled

ON Enabled

ON

OFF

12345678

DSW2

Receive Buffer Selection (DSW2-5). Selects the operating mode of the receive

buffer. See Section 5: Interface Specifications for more information.

DSW2-5 SETTING

OFF Single Job

ON Multi Job

ON

OFF

DSW2

22

12345678

Firmware Download (DSW2-6). Places the printer in the Firmware Download

mode for downloading new firmware into flash ROM.

DSW2-6 SETTING

OFF Disabled

ON Enabled

ON

OFF

12345678

DSW2

Protocol Code Selection (DSW2-7). Selects the command codes used for protocol

control.

DSW2-7 SETTING

OFF Standard

ON Non-Std

ON

OFF

18

DSW2

23 567

4

Page 31

Section 3. Configuration

Print Speed Adjustment (DSW2-8). See page 27.

Mode Selection (DSW3-1 and DSW3-2). Selects the operating mode of the printer.

Batch/Continuous disables the label taken (dispense option) sensor.

DSW3-1 DSW3-2 SETTING

OFF OFF Continuous

OFF ON Tear Off

ON OFF Cutter

ON ON Dispenser

ON

OFF

12345678

DSW3

Label Sensor Selection (DSW3-3). Enables or disables the Label Pitch Sensor. If

the Sensor is enabled, it will detect the edge of the label and position it

automatically. If it is disabled, the positioning must be under software control using

Line Feed commands for continuous media printing.

DSW3

DSW3-3 SETTING

OFF Sensor Used

ON Not Used

ON

OFF

12345678

Back-Feed Selection (DSW3-4). When Back-Feed is enabled, the printer will

position the label for dispensing/cutting and retract it before printing the next

label. See page 38 for information on setting the amount of offset.

DSW3

DSW3-4 SETTING

OFF Enabled

ON Disabled

ON

OFF

12345678

EXT Print Start Signal Selection (DSW3-5). Allows an external device to initiate

a label print.

DSW3-5 SETTING

OFF Disabled

ON

OFF

ON Enabled

12345678

DSW3

Note: This switch must be in the ON position if an external device is used to control

the printer via the EXT connector.

23

Page 32

Section 3. Configuration

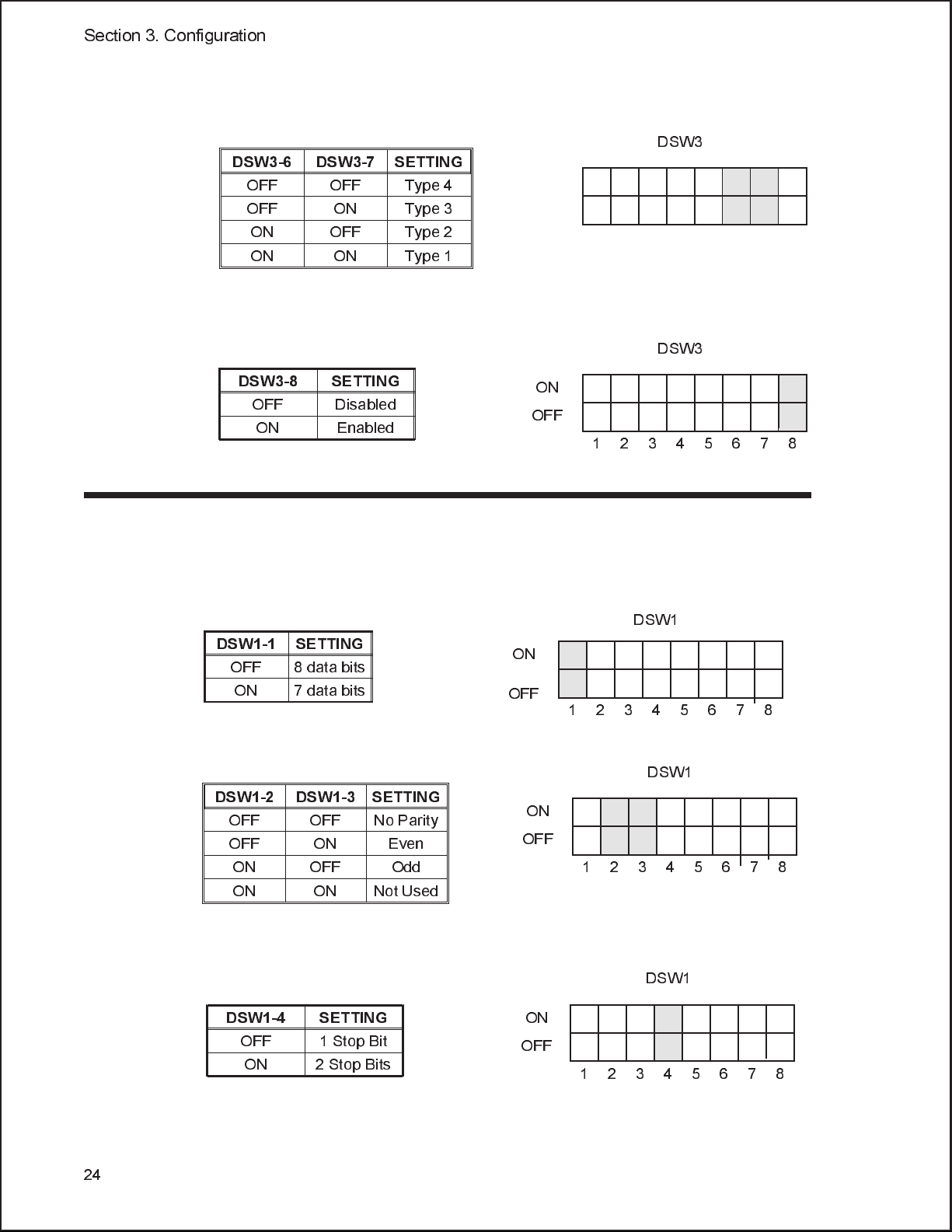

External Signal Type Selection (DSW3-6, DSW3-7). Selects the type of output

signal.

DSW3-6 DSW3-7 SETTING

OFF OFF Type 4

OFF ON Type 3

ON OFF Type 2

ON ON Type 1

Repeat Print via External Signal (DSW3-8). Allows an external device to control

the reprint of the label in the print buffer.

DSW3

DSW3

DSW3-8 SETTING

OFF Disabled

ON Enabled

ON

OFF

12345678

RS232 Transmit/Receive Setting (located on RS232C I/F Module)

The PTR3E comes standard with a parallel port only. Contact Product

Management if serial port is required.

Data Bit Selection (DSW1-1). This switch sets the printer to receive either 7 or

8 bit data bits for each byte transmitted.

DSW1-1 SETTING

OFF 8 data bits

ON 7 data bits

ON

OFF

1

Parity Selection (DSW1-2, DSW1-3). These switches select the type of parity used

for error detection.

DSW1-2 DSW1-3 SETTING

OFF OFF No Parity

OFF ON Even

ON OFF Odd

ON ON Not Used

ON

OFF

12345678

DSW1

2345678

DSW1

24

Stop Bit Selection (DSW1-4). Selects the number of stop bits to end each byte

transmission.

DSW1

DSW1-4 SETTING

OFF 1 Stop Bit

ON 2 Stop Bits

ON

OFF

12345678

Page 33

Section 3. Configuration

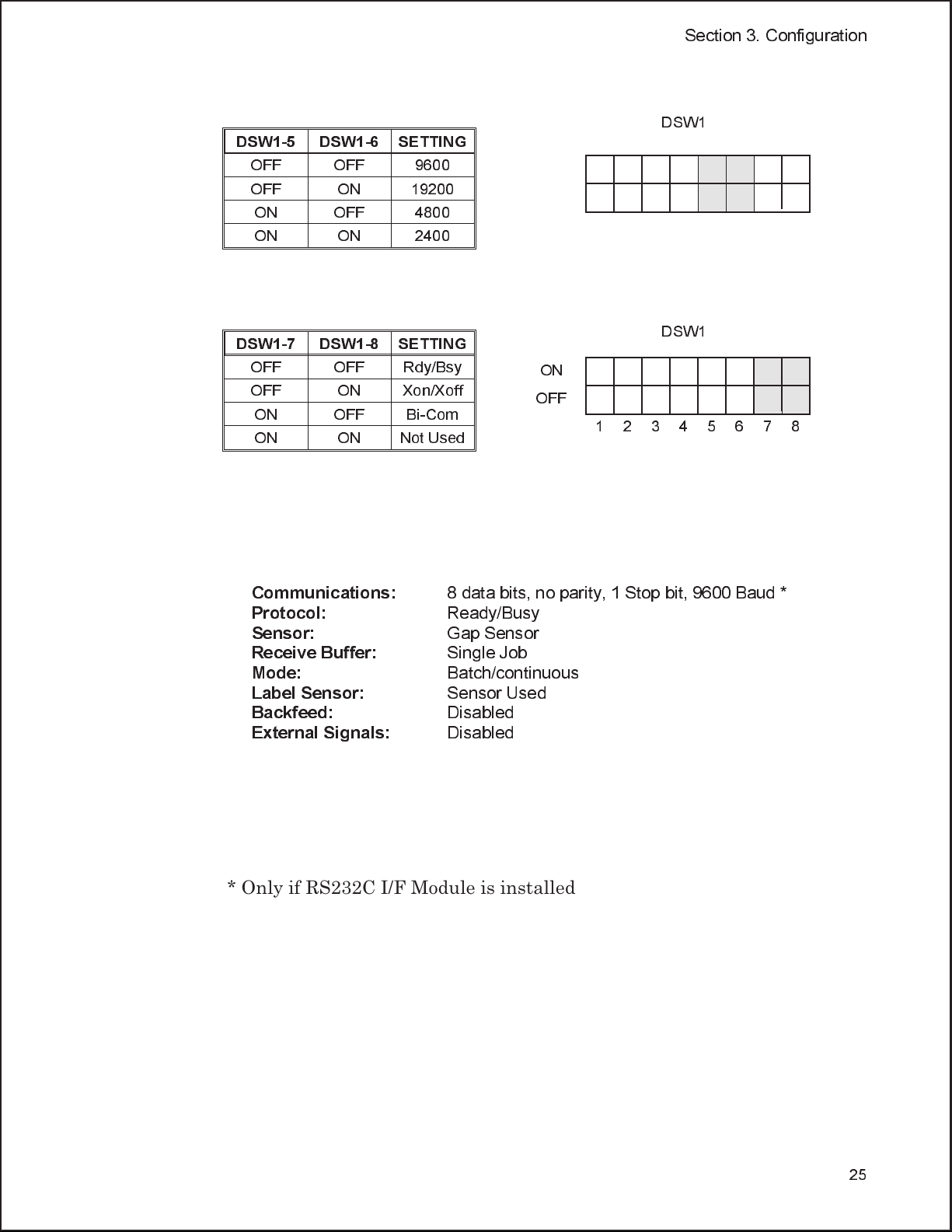

Baud Rate Selection (DSW1-5, DSW1-6). Selects the data rate (bps) for the

RS232 port.

DSW1-5 DSW1-6 SETTING

OFF OFF 9600

OFF ON 19200

ON OFF 4800

ON ON 2400

DSW1

Protocol Selection (DSW1-7, DSW1-8). Selects the flow control and status

reporting protocols. See Section 4: Interface Specifications for more information.

DSW1-7 DSW1-8 SETTING

OFF OFF Rdy/Bsy

OFF ON Xon/Xoff

ON OFF Bi-Com

ON ON Not Used

ON

OFF

12345678

DSW1

Default Settings

Switch Selections - All switches are placed in the OFF position (default) for

shipping. This will result in the following operating configuration:

Communications:

Protocol:

Sensor:

Receive Buffer:

Mode:

Label Sensor:

Backfeed:

External Signals:

8 data bits, no parity, 1 Stop bit, 9600 Baud *

Ready/Busy

Gap Sensor

Single Job

Batch/continuous

Sensor Used

Disabled

Disabled

* Only if RS232C I/F Module is installed

25

Page 34

PRINTER ADJUSTMENTS

The LCD Panel on the PTR3E is used in conjunction with the LINE and FEED

switches by the operator to manually enter printer configuration settings. Many of

the settings can also be controlled via software commands and in the case of conflict

between software and control panel settings, the printer will always use the last

valid setting. If you load a label job that includes software settings and then enter a

new setting via the LCD Panel, the manually set values will be used by the printer.

If you set the values manually and then download a job with software settings, the

software settings will be used.

MODE KEY SEQUENCE INITIAL DISPLAY PAGE

Section 3. Configuration

Normal POWER ONLINE

QTY: 000000

Advanced LINE + POWER ADVANCED MODE 29

Test Print FEED + POWER TEST PRINT MODE

CONFIGURATION

Default Setting LINE + FEED + POWER DEFAULT SETTING

YES NO

Clear Non-Standard Protocol DSW2-7 ON + LINE + FEED +

POWER

Protocol Code Download DSW2-7 ON + POWER + LINE USER DOWNLOAD

Hex Dump DSW2-4 ON + POWER ONLINE

ALT. PROTOCOL

COMPLETE

PRESS THE LINE KEY

QTY: 000000

27

33

34

34

34

35

26

Page 35

Section 3. Configuration

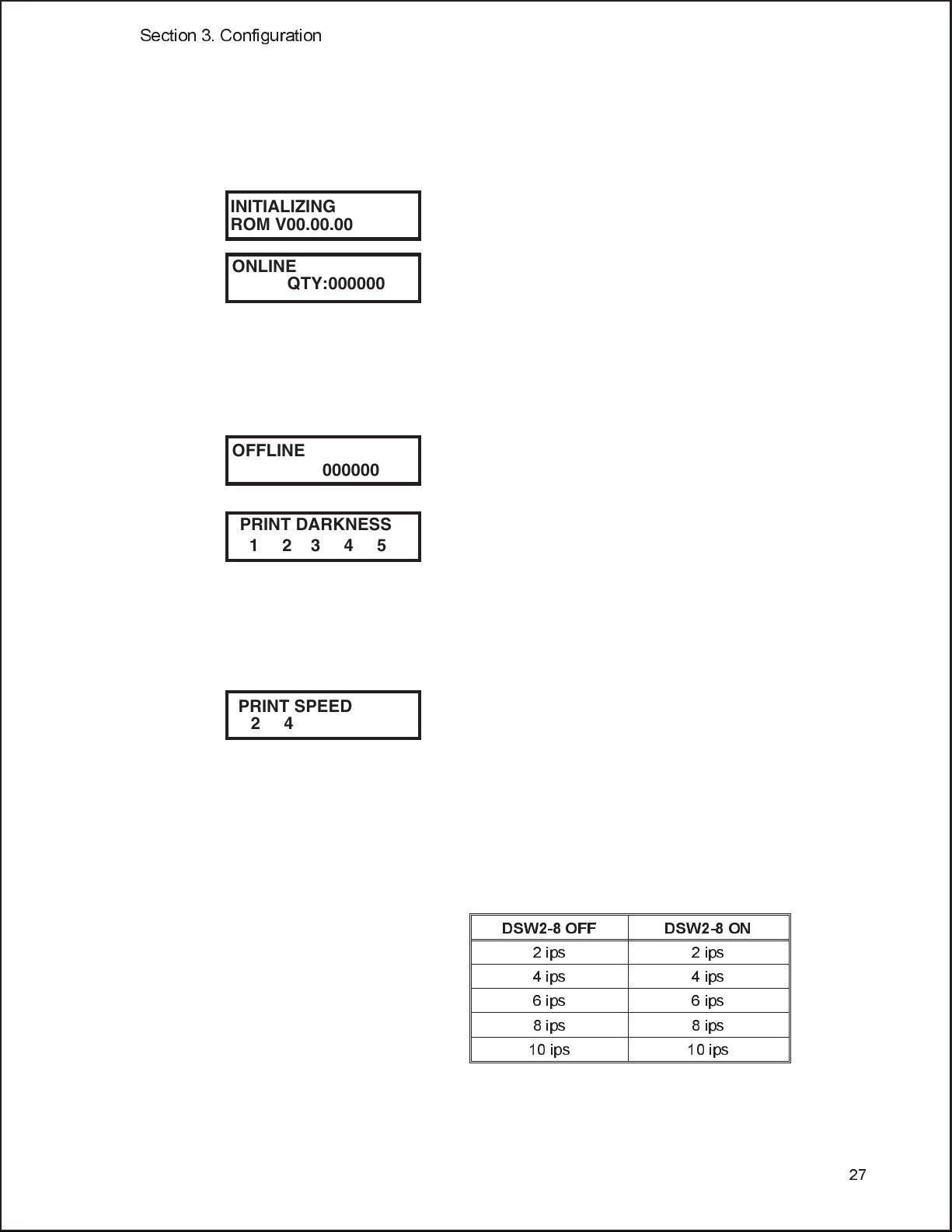

Normal Mode

The printer initially powers on in the ONLINE mode. The user can access the User

Settings using the following procedures:

INITIALIZING

ROM V00.00.00

ONLINE

QTY:000000

OFFLINE

000000

PRINT DARKNESS

12345

Display lists the current ROM version of the printer

during the initialization process.

The LCD will display the ONLINE status on the top

line and the bottom line will contain the label quantity

(QTY) status. The message will be changed to OFFLINE

whenever the printer is switched offlineby pressing the

LINE key. As soon as a print job is received, the quantity

line will indicated the number of labels to be printed. As

the label job begins to print, the display will indicate the

number of labels in the print job that remains to be

printed.

Press the LINE key once. When the display changes to

OFFLINE, press the FEED and LINE keys

simultaneously for more than one second.

The LCD now displays the Print Darkness selections.

The current setting is indicated by an underline cursor

under one of the range settings.

1. Press the LINE key to step the cursor to the desired

setting.

2. Once the correct setting is underlined, press the

FEED key to accept the selection and stepthe

display to the next adjustment.

PRINT SPEED

246810

The print speed selections are dependent upon the

printer setting of DSW2-8. The current setting is

indicated by the underlined cursor.

1. Press the LINE key to step the cursor to the

desired setting.

2. Once the correct setting is underlined, press the

FEED key to accept the selection and step the

display to the next adjustment.

DSW2-8 OFF DSW2-8 ON

2 ips 2 ips

4 ips 4 ips

6 ips 6 ips

8 ips 8 ips

10 ips 10 ips

27

Page 36

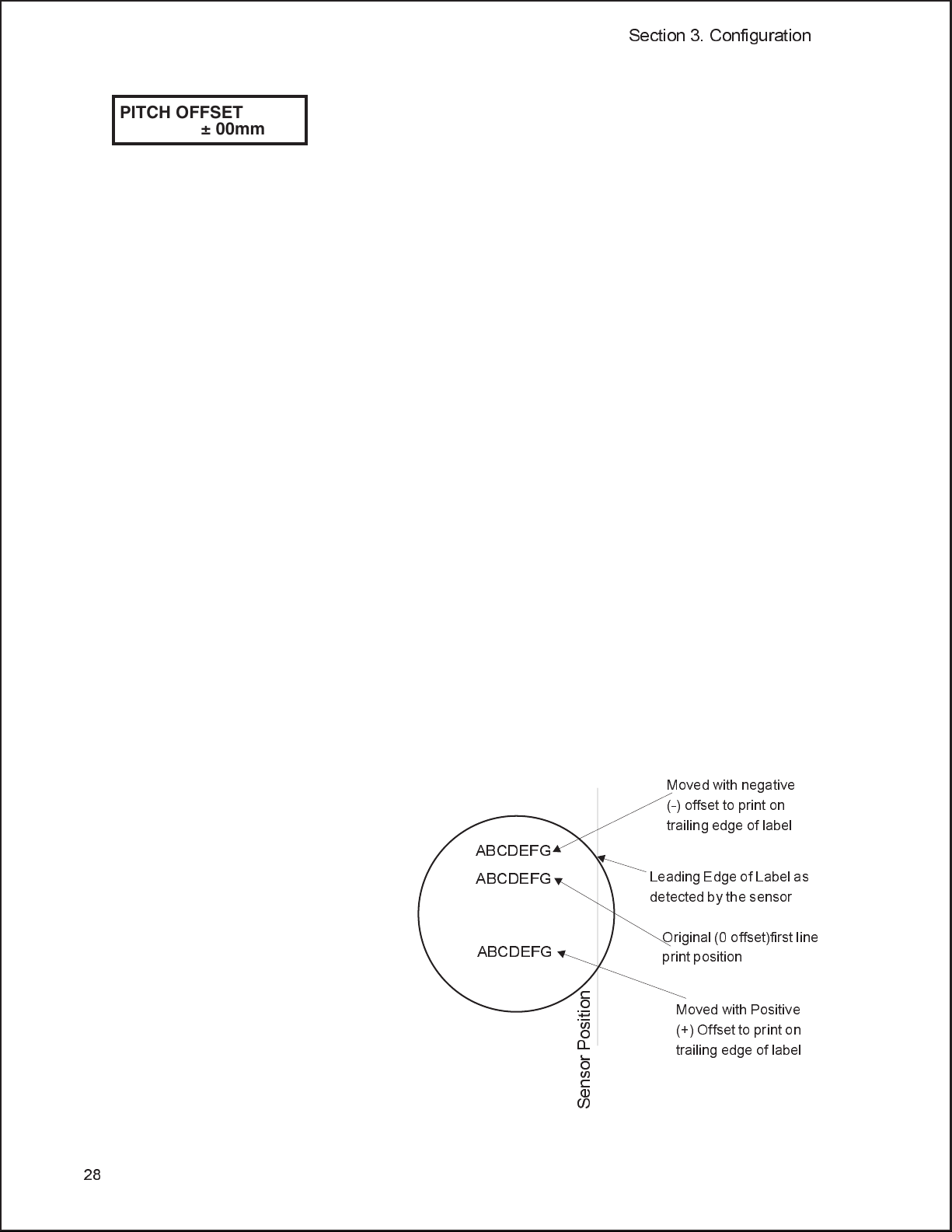

PITCH OFFSET

± 00mm

Section 3. Configuration

The label Pitch distance from the leading edge (the

edge that comes out ofthe printer first) of a label and

the leading edge of the next label. The leading edge

position of the label can be adjusted relative to the

print head +/- 49 mm in increments of 1mm. Once the

position is set, it can be fine adjusted +/- 3.75mm using

the PITCH potentiometer on the Adjustment Panel.

1. The underline cursor will initially be positioned

underneath the Pitch Direction setting. Pressing

the LINE key will step the setting to the positive (+)

or negative (-) selection. A positive selection moves

the leading edge of the label forward (away from the

print head) while a negative selection moves the

leading edge of the label back the mechanism.

2. Once the correct direction is selected, pressing the

FEED key will accept the setting and advance the

cursor to the Offset selection.

3. Use the LINE key to step the first digit of the

counter to the desired setting. The display will

increment one step each time the LINE key is

pressed. The reading will advance to a setting of

4 after which it will automatically wrap and start

at 0 again.

4. Press the FEED key to accept the setting and

advance the cursor to the second digit. Again use

the LINE key to step the desired setting. Once it

is correct, pressing the FEED key will step to the

next adjustment. You may wish to print a test

label after completing the adjustments to ensure

they are correct.

Moved with negative

(-) offset to print on

trailing edge of label

ABCDEFG

ABCDEFG

ABCDEFG

Leading Edge of Label as

detected by the sensor

Original (0 offset)first line

print position

Moved with Positive

(+) Offset to print on

trailing edge of label

28

Sensor Position

Page 37

Section 3. Configuration

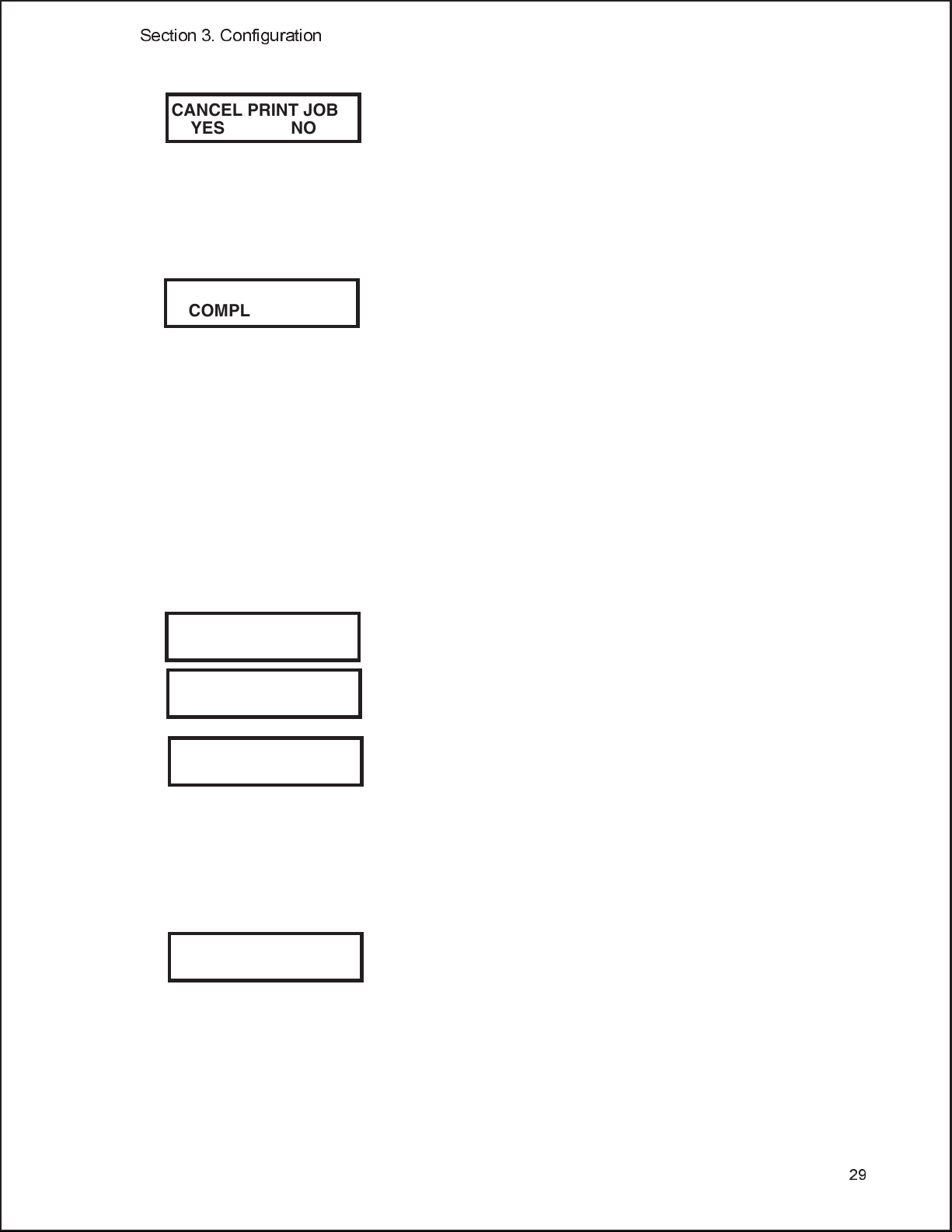

CANCEL PRINT JOB

YES NO

CANCEL PRINT JOB

COMPLETED

ADVANCED MODE

An Advanced Mode is provided to make adjustments that require only occasional

changes. Since they affect the basic operation of the printer, the procedure for

entering this mode is designed to prevent someone from accidentally changing

the settings.

If the printer has print job(s) in memory, selecting

YES will cause the job(s) to be cleared. The default

selection is number Be sure you want to cancel the

print job(s) before selecting yes as the job(s) cannot

be recovered and will have to be retransmitted to

the printer.

1. Use the LINE key to step the underline

cursor to either the YES or NO selection.

2. Once the correct setting is underlined,

pressing the FEED key will accept the

setting.

3. After the print job(s) have been cleared from

memory, the printer will display a

COMPLETED message for 3 seconds and

then return to the initial ONLINE Normal

Mode.

4. If you wish to change any of the settings, you

must enter the User Settings mode again by

taking the printer OFFLINE and pressing

the LINE and FEED keys.

INITIALIZING

ROM V00.00.00.00

ADVANCED MODE

ZERO SLASH

YES NO

AUTO ONLINE

YES NO

The Advanced Mode is entered by pressing the LINE

key while simultaneously turning power on. The

printer will emit one long beep after which the LINE

key is released. Pressing the FEED key will step the

display to the first selection.

This setting determines if a zero is printed with a

slash or without a slash. This setting can also be

controlled via software commands. When YES is

selected, the printer internal fonts will have a slash

through the center of the zero character.

1. Use the LINE keyto step the underline cursor to

either the YES or NO selection.

2. Once thecorrect settingis underlined, pressing

the FEED key will accept thesetting and

advance the display to the Auto Online display.

This setting determines the mode inwhich the printer

powers up. If the YES selection is made, the printer

powers up in the ON LINE mode andis ready to print.

If NO is selected, the printerpowers upin theOFF LINE

mode and must be manually placedin the ON LINE

mode by pressing the LINE key before it is ready to print.

1. Use the LINE key to step the underline to either

the YES or NO selection.

29

Page 38

Section 3. Configuration

2. Once the correct setting is underlined, pressing

the FEED key will accept the setting and

advance the display to the Print Offset display.

PRINT OFFSET

V:+0000 H:+000

Vertical Offset is the distance down from theleading edge

(the edge of the label that comes outof the printer first) to

the first vertical print position. A positive setting moves

the first print position down the length ofthe label.

Horizontal Offset is distance that the label image is

shifted to the right or left on thelabel. The image is

shifted to the left (towards the inside edgeof the label for a

right-hand printer) for a positive settingand itis shifted

to the right (towards the outside edge ofthe label) for a

negative setting. The setting changes the base reference

point for all subsequent label jobs. It’s effect is identical to

the <ESC>A3 BaseReference point command. Since the

printer moves the label in discretesteps equalto the size

of the print dot, the units of measurefor Vertical and

Horizontal Offset distance is dots. The maximum values

that can be set for each is +/-800.

1. Use the LINE key to step the first digit of the

counter to the desired setting. The display will

increment one step each time theLINE keyis

pressed.

2. Press the FEED key to accept the setting and

advance the cursor to the second digit. Again use

the LINE key to step to the desiredsetting.

Once it is correct, pressing the FEED keywill

step to the next adjustment.

3. Once the setting is correct, pressing the FEED

key will accept the setting and advance tothe

next display.

You may wish to print a test labelafter completing the

adjustments to ensure they are correct.

Note: This settingcan be overridden by the Base

Reference Point Command

30

IGNORE CR/LF

YES NO

This selection tells the printer to strip out all carriage

return/line feed repairs (CRLF) from the data stream,

including graphics and 2D bar codes.

1. Use the LINE key to step the underline cursor to

either the YES or NO selection.

2. Once the correct setting is underlined, pressing

the FEED key will accept the setting and

advance the display to the Character Pitch

display.

Page 39

Section 3. Configuration

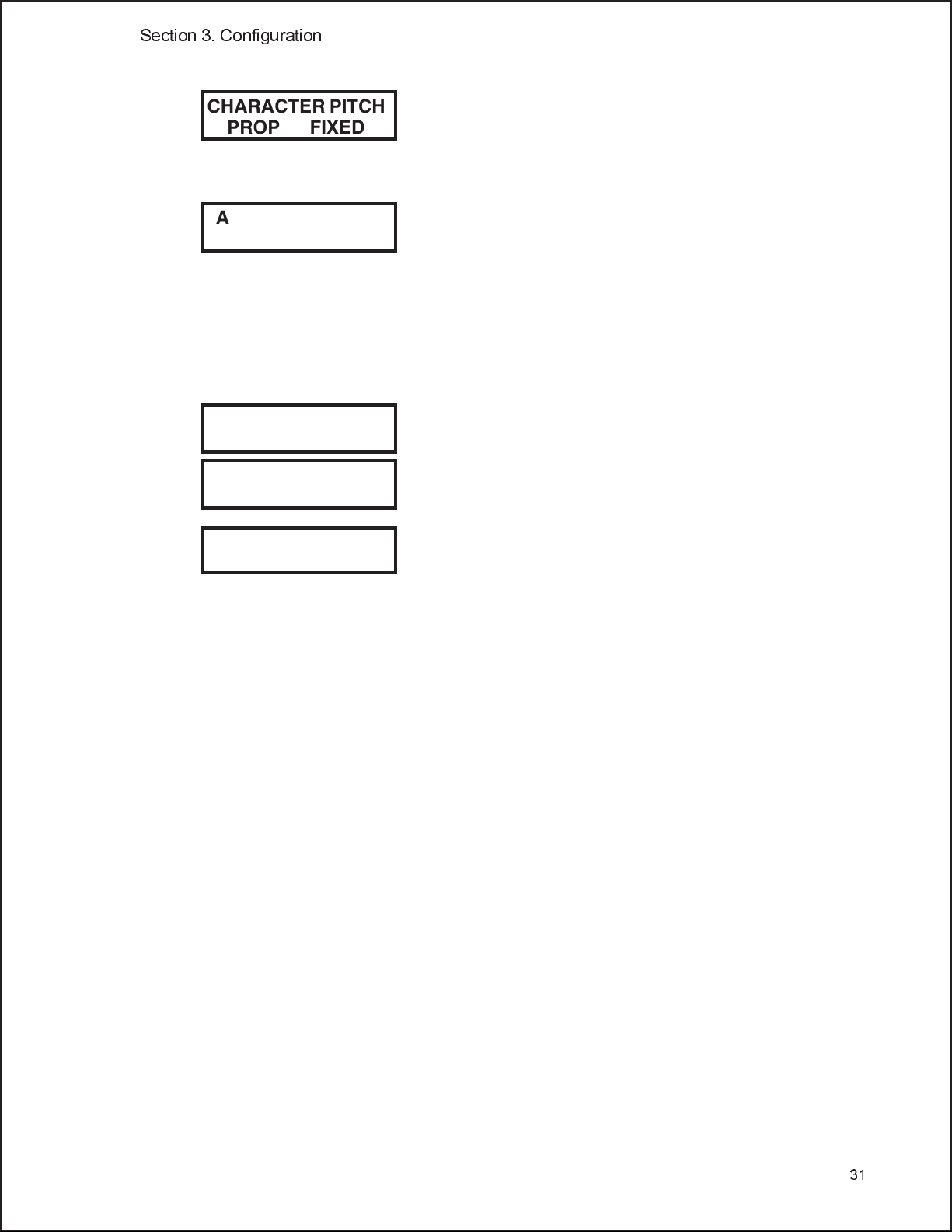

CHARACTER PITCH

PROP FIXED

ADVANCED MODE

This selection allows you to setthe defaultcharacter

pitch to either fixed character spacing or proportional

character spacing.

1. Use the LINE key to step the underline cursor to

the desired setting.

2. Once the correct setting is underlined, pressing

the FEED key will accept the setting and

advance the display. Note: This command can be

overridden by the <ESC>PR or <ESC>PS

Character Pitch Commands. To exit the

Advanced mode, power the printer off and then

back on.

SERVICE MODE

The Service Mode allows the operator to set up the basic operation parameters of the

printer.

ADVANCED MODE

SERVICE MODE

GAP [X.XV]

INPUT [X.XV]

The service Mode is entered from the Advanced Mode

display by pressing the LINE key twice.

The Service Mode display indicates that the printer is in

the Card Mode. To advance to the first selection, press

the FEED key.

The PTR3E printer determines the locationof theleading

edge of thelabel by measuring the differencebetween light

levels when it sees either a label edgeor a black “EYE”

mark. The adjustmentallows you to manually set the

threshold voltage level, between the maximumand

minimum light levels. DIP switchDSW2-2 selects the

sensor type. If DSW2-2 is in the OFF position,the setting

will be for a See-Thru (or Gap) sensorand the LCD will

display “GAP” on the top line along withthe current

setting. If DSW2-2is in the ON position, the LCD will

display “EYE” on the top line with its currentsetting. If

the value entered for the bottom line settingis “0.0V”,

then the printer will automatically calculate the setting

when the first label is fed after the printer ispowered on or

the head is closed. There are some instances wherethe

automatically calculated value must be adjusted to ensure

reliable label feeding, such as whenthe backingopacity or

the reflectance of the EYE mark varies significantly

within a roll of labels or between label rolls. In these

instances the value should be setusing thefollowing

procedures.

31

Page 40

Section 3. Configuration

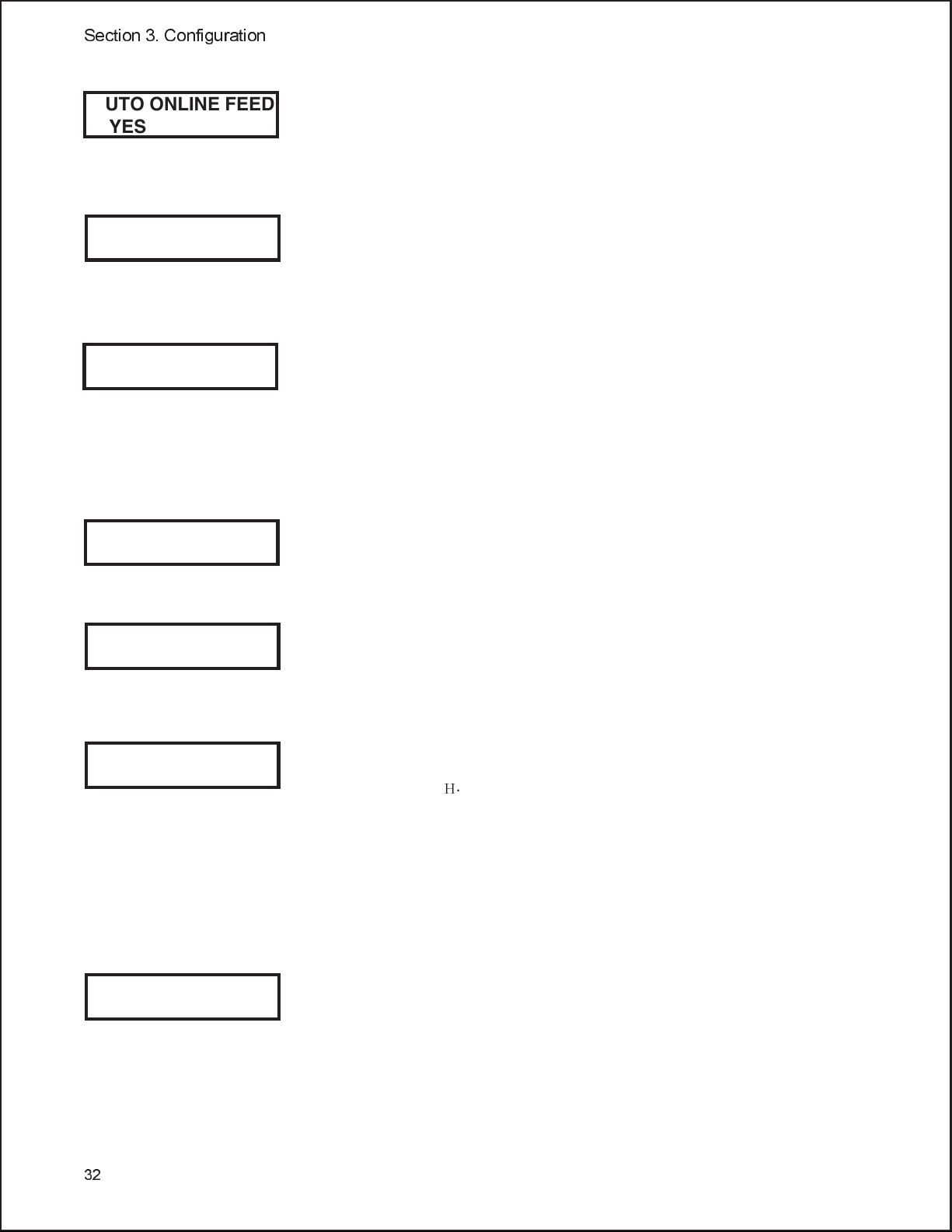

AUTO ONLINE FEED

YES NO

FEED ON ERROR

YES NO

REPRINT W/FEED

YES NO

FORWARD/BACKFEED

DISTANCE DEFAULT

FORWARD/BACKFEED

DISTANCE XXXmm

EURO CODE

D5

SELECT LANGUAGE

ENGLISH

This selection specifies whether or not the printer will automatically

feed a blank label when it is placed in the Online mode.

1. Use the LINE key to step the cursor to desired setting. If

Yes is selected, the printer will feed a blank label anytime

it enters the Online mode. If No is selected, the display

will advance to the mode display.

This selection specifieswhether or not the printer will feed a

blank label automatically when an error condition is cleared...

1. Use the LINE key to step the cursor to desired setting. If

Yes is selected, the printer will feed a blank label anytime

an error condition is cleared. If No is selected, the display

will advance to the mode display.

This selection specifieswhether or not the printer will print the

last printed label stored in memory when the FEED key is

pressed in the Normal Online mode.

1. Use the LINE key to step the cursor to desired setting. If Yes

is selected, the printer will reprint the last label when the

FEED key is pressed when the printer is Online. If the

printer is Offline, pressing the FEED key will feed a blank

label. If No is selected, the display will advance to the mode

display.

This display will only appear when the Backfeed is enabled

(DSW3-4 = OFF).The maximum backfeed distance is 255mm.

1. Use the LINE key to select either the Default or the

Distance selection. If Default is selected, the display steps

to the Web acceleration selection.

2. If Manual setting is selected, use the LINE key to advance

the distance to the desired setting. Each time the LINE key

is pressed, the Distance will advance 1 mm. The maximum

distance is 255mm.

3. Once the desired distance is set, press the FEED key

to accept the setting and step to the next display.

This selection allows the user to specify the hexidecimal code

for the character which is replaced with the Euro Character.

The default is D5

1. The underline cursor should be positioned underneath

the first digit selection. Use the LINE key to step to the

desired setting.

2. Press the FEED key to advance the underline cursor to

the second digit of the desired hexidecimal code.

3. Press the LINE key to step to the desired setting.

4. When the setting is correct, press the FEED key to

accept the setting and step to the next display.

This selection allows the user to select the character set used by the

printer. The selections are English, French, German, Spanish

Italian and Portuguese. The default is English.

1. Press the LINE key to advance to the desired language

setting.

2. When the setting is correct, press the FEED key to accept

the setting and step to the next display.

.

H

32

Page 41

Section 3. Configuration

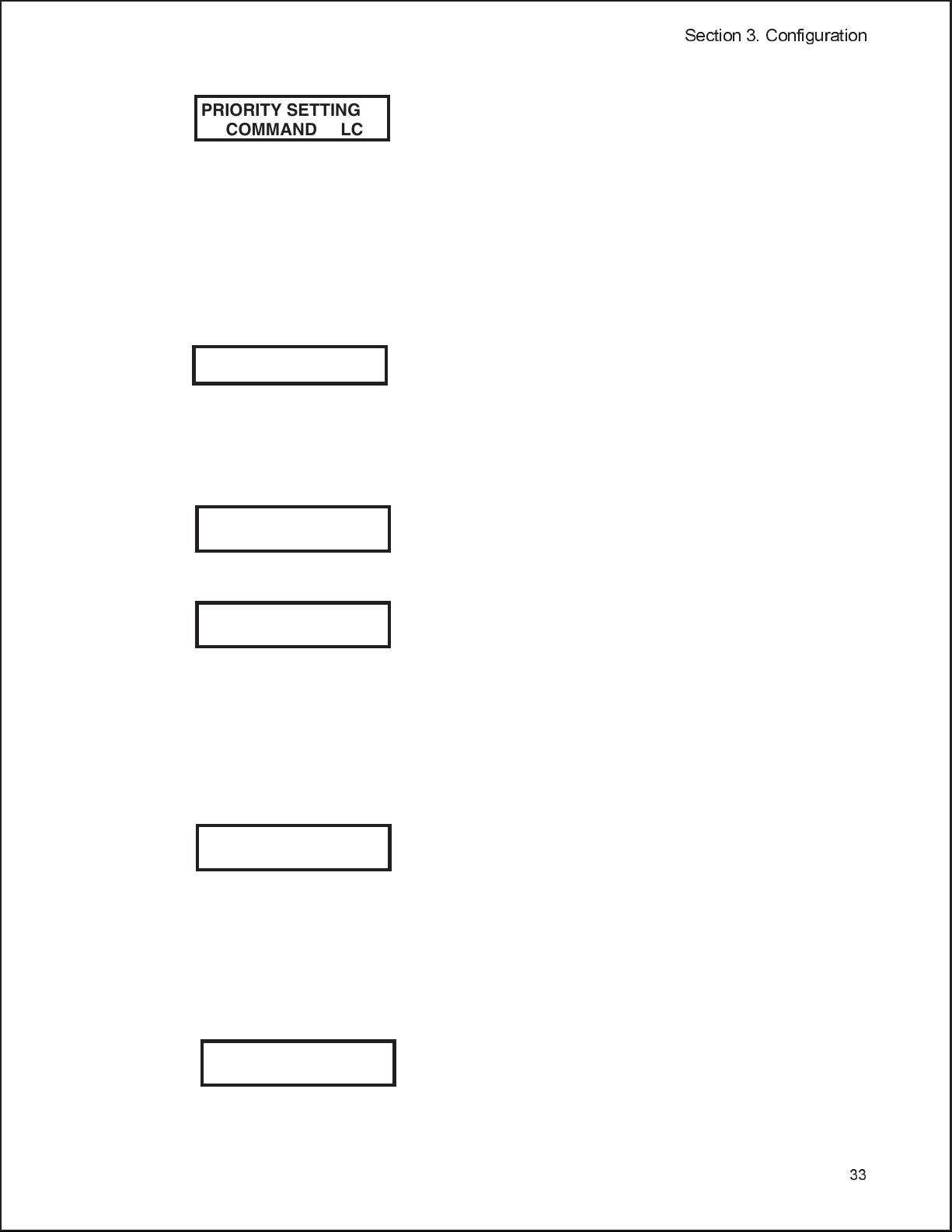

PRIORITY SETTING

COMMAND LCD

SERVICE MODE

This selection allows the user to assign a priority for Print

Darkness, Print Speed and Print Offset.

1. Use the LINE key to step to the desired priority. If

LCD is selected, the setting established via the LCD

display/menu system will be used for an incoming

label job, regardless of any different command

settings. If Command is selected, any commands in

the label job will take precedence and be used for

printing the job and the LCD Display will reflect the

new setting.

2. Once the desired setting is selected, press the FEED

key to accept the setting and step to the next display.

The Service mode is exited by powering the printer off

and then back on.

TEST PRINT MODE

The Test Print Mode offers five different printer status labels for troubleshooting.

If DSW3-5 is On, the Test Print cycle must be initiated with a Print Start command.

This option allows you to print a test label. It is

recommended that you print a testlabel afterhave

INITIALIZING

ROM V00.00.00.00

TEST PRINT MODE

CONFIGURATION

TEST PRINT SIZE

10 CM

Note: This display

does not appear when

a Memory Test Print is

chosen. Only a small

Memory Test Print

label can be printed.

PRESS FEED KEY

TO STOP PRINTING

changed any of the settings in the Advanced Mode.

The test label allows you to verify thatyou indeed

did make the desired changes. To enter the User

Test Print Mode, power the printer on while

pressing the FEED key. The printerwill beep.

Release the FEED key and the printer willdisplay

the Test Print Mode message on the LCD panel:

1. Use the LINE key to step the underline cursor to

the type of test labels you wish to print. The

choices are:

Configuration

Bar Code

Head Check

Memory

Factory

Once you have selected the type of test label to be

printed, use the FEED key to accept the selection and

the display advances to the Test Print Size display.

This display allows you to select the label width.

1. Use the LINE key to select the label width. Each

time the LINE key is pressed, the label size

advances 1 cm until it reaches a maximum width

of 10 cm, at which point it will wrap to the

smallest size of 4 cm.

2. Pressing the LINE key accepts the selection

3. Press the FEED key to start printing test labels

continuously.

4. Press the FEED key to stop the printer.

5. To exit the Test Print Mode, power the printer off

and then back on.

33

Page 42

Section 3. Configuration

DEFAULT SETTING MODE

Occasionally it is desirable to reset all printer configuration settings to their original default

conditions. This allows the operator to start reconfiguration of the printer starting from a

known set of conditions.

INITIALIZING

ROM V00.00.00.00

DEFAULT SETTING

YES NO

DEFAULT SETTING

COMPLETED

You enter the Default Setting Mode by pressing the LINE and

FEED keys while simultaneously powering the printer on. The

printer will emit one long beep after which the FEED and

LINE keys should be released.

1. Use LINE key to select either the YES or number

2. Once the desired setting is selected, pressing the FEED

key will accept the selection and the printer will reset to

the original default conditions.

3. When the printer has completed the reset process, the

Default Setting Completed display will appear. At this

time the printer is in the default configuration.

4. To exit the Default Setting Mode, power the printer off

and then back on.

CLEAR NON-STANDARD PROTOCOL

The standard protocol codes used by the printer can be modified to accommodate the

requirements of different host systems. However, if the printer is to be used with a system that

does not use the custom protocol codes, they can be cleared and the default protocol codes

H

reactivated. The default values are: STX = 7B

H

,CAN=21H, and OFFLINE = 5DH.

7E

INITIALIZING

ROM V00.00.00.00

ALT. PROTOCOL

DEFAULT COMPLETE

To Clear Non-Standard protocol codes, DSW2-7 is placed in the

OFF position and the printer powered on while simultaneously

pressing the LINE and FEED keys. The printer will emit one

long beep at which time the LINE and FEED keys should be

released.

1. When the keys are released, the printer will replace the

Alternate protocol codes with the default values.

2. After the default setting is complete, the printer will

emit two short beeps indicating the process is complete.

3. To exit the mode, power the printer off and then back

on.

, ETX = 7DH, ESC = 5EH, ENQ = 40H, NULL =

DOWNLOAD USER DEFINED PROTOCOL CODES

The user can define a set of custom protocols codes and download them to the printer using

the <ESC>LD command.

INITIALIZING

ROM V00.00.00.00

USER DOWNLOAD

PRESS THE LINE KEY

USER DOWNLOAD

WAITING

To enter the User Download mode, DSW2-7 is placed in the

OFF position and the printer is powered on while

simultaneously pressing the LINE key. The printer will emit

one long beep after which the LINE key should be released.

1. Press the LINE key. The printer is now waiting for the

datatobesent.

2. Transmit the download data command stream to the

printer.

3. After the data has been received, the printer will beep

and print a status label. If it does not beep and print a

status label, the printer did not accept the data.

34

Page 43

Section 3. Configuration

4. If the printer did not beep and print a status label, turn

the printer off and check your data stream for errors

and start the download process over.

5. If the custom codes are correct, press the FEED key to

accept them and terminate the download process. If

they are incorrect, turn the printer off without pressing

the FEED key and begin the process again.

HEX DUMP MODE

In addition to the User Test PrintLabels, theprinter canprint thecontents ofthe receivebuffer

in a hexadecimal format to allow the data stream to be examined for errors and

troubleshooting.

INITIALIZING

ROM V00.00.00.00

ONLINE

QTY:000000

The Hex Dump Mode is entered by placing DSW2-4 in the ON

position and powering the printer on.

1. The printer is now ready to receive data.

2. Send the data stream to the printer.

3. The received data will be printed in a hexadecimal

format

4. To return the printer to normal operation, place

DSW2-4 in the OFF position and power the printer off

andthenbackon.

POTENTIOMETER ADJUSTMENTS

PITCH

After the pitch has been set with the LCD Control Panel, it is sometimes desirable to

make minor adjustments. This can be done using the PITCH potentiometer on the

front panel. This potentiometer is set at the factory so that it has a range of +/-3.75

mm. The midpoint setting should have no effect on the pitch. Turning the

potentiometer all the way clockwise should move the print position 3.75 mm up

towards the top edge of the label. Turning it all the way counter clockwise should

move the print position down 3.75 mm.

1. While depressing the FEED key on the front panel, power the printer on.

2. When you hear one beep from the printer, release the FEED key and the

printer will display on the LCD panel a message asking what type of Test

Label you want to print.

3. Use the LINE key to step to the Configuration selection and press the FEED

key to accept the selection.

4. Use the LINE key to select the Test Label size. After the size is selected,

press the FEED key to accept the selection and the printer will begin to print

test labels continuously.

5. Adjust the PITCH potentiometer on the front panel until the first print

position is at the desired location on the label. If the potentiometer does not

35

Page 44

Section 3. Configuration

have enough range, then you will have to change the pitch setting using the

LCD front panel display.

6. Press the FEED key to stop the printer.

7. To exit the Test Label mode, power the printer off and then back on.

Adjusting the PITCH potentiometer will affect the stop position of the label.

BACKFEED OFFSET

When a label is printed it must be correctly positioned for dispensing and

application. The Backfeed adjustment is used to position the label so that it is fully

dispensed and ready for application. It may then be necessary to reposition the next

label before printing. The Backfeed (repositioning of the label) operation is enabled

if DSW3-4 is in the Off position. If backfeed is enabled, placing DSW3-1 in the Off

position will cause the backfeed operationto be performed immediately before each

label is printed. If DSW3-1 is in the On position, the backfeed operation is

performed as soon as the dispensed label has been printed and taken from the

printer.

The amount of backfeed is controlled by the OFFSET potentiometer on the DIP

Switch Panel inside the cover. When turned all the way counterclockwise, the

amount of backfeed is +3.75 mm, and -3.75 mm when turned all the way

counterclockwise.

1. Turn the printer on.

2. Press the LINE key to place the printer in the Off Line status.

3. Press the FEED key to feed out a blank label.

4. Adjust the position using the OFFSET potentiometer on the front control

panel and feed another label by depressing the FEED key. Repeat this

procedure until the label is fully released from the liner.

DISPLAY

This potentiometer is used to adjust the contrast of the LCD display for optimum

viewing under various lighting conditions.

PRINT

The PRINT potentiometer is used to adjust the amount of heat (i.e., power) applied

to the head for printing. It provides a continuous range of adjustment. Maximum

print darkness is obtained by turning the potentiometer all the way clockwise and a

maximum counterclockwise setting will give the lightest print.

36

NOTE: The PRINT potentiometer adjustment will affect the darkness in all of the

commend code speed and darkness ranges.

Page 45

DISPLAY COUNTER VALUES

The internal counters are used to track the number of kilometers of media that has been

processed through the printer, the number of labels cut and/or the number of label

dispensed. These values can be used to track component life for service and

maintenance functions. The current counter settings are displayed on the

Factory/Service mode Test Label. To print the Factroy/Service Test Label, the

following procedure must be used:

1. Turn the printer OFF and place DSW2-4 in the ON position.

2. Open the print head by releasing the Head Latch.

3. While simultaneously pressing the LINE and FEED keys, turn the printer

ON.

4. Close and latch the print head.

Section 3. Configuration

5. The LCD panel should read:

MAINTENANCE MODE

DIPSW2-4 ON->OFF

6. Place DSW2-4 in the OFF position.

7. The LCD panel should indicate that the printer is in the FACTORY MODE.

FACTORY MODE

8. Press the FEED key and the display will advance to the COUNTER CLEAR

message screen. Make sure that the NONE selection is displayed on the

bottom line. If it is not, press the LINE key once until ALL is displayed.

COUNTER CLEAR

NONE

9. Press the FEED key to initiate the Test Label print mode. Then press the

LINE key to begin printing Test Labels. The printer will print Test Labels

continuously until the FEED key is pressed again, which pauses the printer.

Test Labels will again start printing as soon as the FEED key is pressed

again.

WARNING: The Test Label is designed to print on a full width label. If smaller

labels are used, the print head may be damaged if more than one label is printed.

10. The counter readings and ROM version are printed on the label along with

other pertinent information.

11. Turn the unit OFF and reset the DIP switches to the proper operating

positions before powering the printer back ON.

37

Page 46

Section 3. Configuration

38

Page 47

CLEANING AND MAINTENANCE

INTRODUCTION

This section provides information on user maintenance for the PTR3E. This

section contains the following information.

Adjusting the Print Quality

•

Cleaning the Print Head, Platen and Rollers

•

Cleaning the Sensors

•

Replacing the Print Head

•

Replacing the Fuse

•

PROCEDURES

ADJUSTING THE PRINT QUALITY

SECTION 4.

The PTR3E printer has two different means of adjusting the quality of the print:

print darkness and speed. When adjusting the printer for optimum print quality, a

bar code verifier system should be used. The human eye is a poor judge of the

relative widths of the bars in a symbol, a characteristic that is extremely important

for good bar code quality.

Darkness (Print)

This adjustment allows the user to control (within a specified range) the amount of

power that is used to activate the individual print head heat elements. It is

important to find a proper print darkness level based on your particular label and

ribbon combination. The printed images should not be too light nor should the ink

from the ribbon “bleed.” The edgesof eachimage should be crisp and well defined.

The Print Darkness range can be set using the front panel LCD panel (see page 26)

or by downloading the setting using the Print Darkness software command. There

are five ranges, with 1 being the lowest and 5 being the highest. Once the range has

been selected, the PRINT Potentiometer on the front panel can be used to make

finer adjustments.

39

Page 48

Section 4: Cleaning and Maintenance

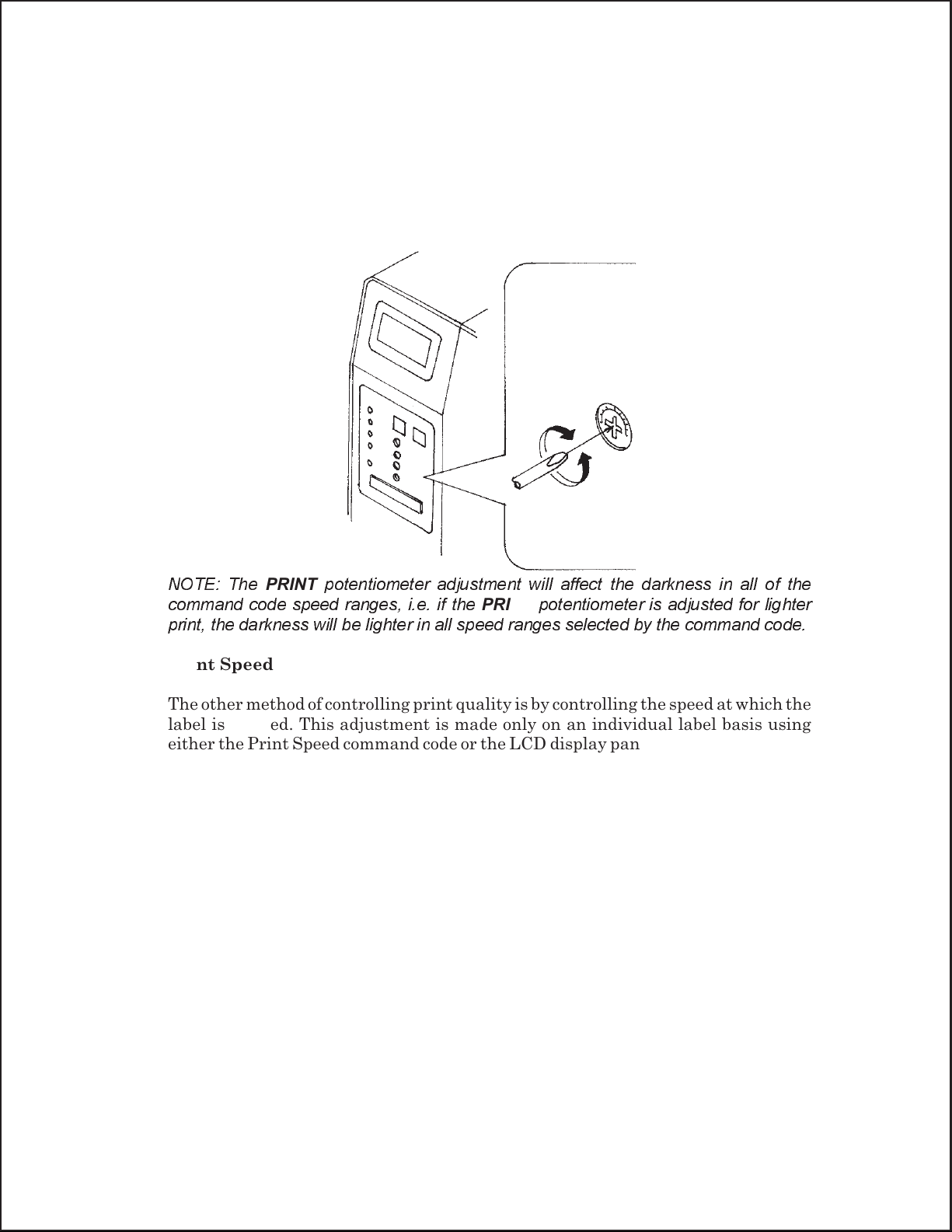

Print Potentiometer

The fine adjustment for Print Darkness is the PRINT potentiometer on the

operator panel. It provides a continuous range of adjustment, allowing you to make

precise changes. Use a small cross-point screwdriver, turning clockwise for darker

print and counterclockwise for lighter print.

NOTE: The

command code speed ranges, i.e. if the

PRINT

potentiometer adjustment will affect the darkness in all of the

PRINT

potentiometer is adjusted for lighter

print, the darkness will be lighter in all speed ranges selected by the command code.

Print Speed

The other method of controlling print quality is by controlling the speed at which the

label is printed. This adjustment is made only on an individual label basis using

either the Print Speed command code or the LCD display panel. Changing the print

speed allows the user tocontrol the amount of time allowed for print element cooling

before the media is stepped to the next print position. It is especially critical when

printing “ladder” bar codes (bar codes printed with the bars parallel to the print

line). When printing a “ladder” bar code, it is important to allow the head to cool

sufficiently before stepping to the next position. If it does not have sufficient time to

cool, the bar will be “smeared” on the trailing edge.

The Print Speed can be set to 2, 4, 6, 8 or 9 inches per second (with DSW2-8 OFF) or

2, 4, 6, 8 or 10 inches per second (DSW2-8 ON) using the LCD panel (see page 26) or

using software. The software command will override the any setting entered using

the LCD panel.

40

Page 49

Section 4: Cleaning and Maintenance

CLEANING THE PRINT HEAD, PLATEN AND ROLLERS

Supplies Needed: PTR-CLN printer cleaning kit

Includes: 4 oz. (116 ml) bottle cleaning solution with MSDS,

cleaning pens, 100 swabs, 12 alcohol wipes and instructions

Cleaning the Print Head and Platen

1. Turn the printer OFF and remove the power cable.

2. Open the Top Access and Side Access doors.

3. Open the Print Head by pushing the Head

Latch toward the rear of the printer. The

Print Head is spring-loaded and will

automatically open as soon as the Head

Latch is disengaged. Remove the ribbon.

4. Apply isopropyl alcohol to a cotton swab.

5. The Print Head faces downward along the

front edge of the assembly. Pass the end of

Print Head

the dampened swab along the entire width

of the Print Head (you may need to move

the ribbon out of the way to do this).

Platen

Head Latch

6. Check for any black coloring or adhesive

on the swab after cleaning.

7. Repeat if necessary until the swab is clean after it is passed over the head.

8. The head should be cleaned at least every time the ribbon is changed and

more often in harsh environments.

9. Apply isopropyl alcohol to one of the cotton swabs.

10. The Platen is the rubber roller directly below the Print Head.Itshouldbe

cleaned of any ribbon or label residue.

41

Page 50

Section 4: Cleaning and Maintenance

Cleaning the Rollers and Guides

1. The Label Load Drive is located

underneath the Label Hold-Down.It

should be cleaned of any label residue or

foreign material. The Label Hold Down

Roller is located on the underneath side of

the Label Hold Down. It should also be

cleaned of any residue or foreign material.

2. There are two Label Edge Guides used in

guiding the labels through the printer.

They should be cleaned of any residue or

foreign material.

3. Repeat when necessary. The rollers and

guides should be cleaned whenever foreign matter such as dust or adhesive is

present.

CLEANING THE SENSORS

There are two sensors that are used to control the positioning of the label. One is a

transmissive see-thru sensor that detects the edge of the label by looking through

the liner which is translucent and detecting the presence of the opaque label. The

other is a reflective sensor that detects the light reflected from the bottom of the

label liner. When a printed black Eye-Mark passes through the beam, the light is no

longer reflected back to the sensor detector, indicating to the printer that it should

use this position as the start of a new label. When dust, dirt or other foreign matter

interferes with the light path of either of these sensors, the results is erratic label

positioning. These sensors should be cleaned regularly, at least every two rolls of

labels. They are both located on an adjustable assembly in the throat of the printer

between the Label Hold Down and the Print Head.

Label Edge

Guides

Label Hold

Down Roller

Label Drive

Roller

Sensor

Assembly

42

1. Turn the printer OFF and remove the power cable.

2. Open the Top Access and Side Access doors.

3. Open the Print Head by pushing the Head Latch toward the rear of the

printer. The Print Head is spring-loaded and will automatically open as soon

as the Head Latch is disengaged. Remove the ribbon.

4. Apply isopropyl alcohol to a cotton swab.

5. Carefully insert the swab between the top and bottom portions of the Sensor

Assembly. The location of the sensors is identified by two marks on the front

of the assembly.

6. Move the swab back and forth to clean any residue from the sensors (see page

20 for location of sensors).

Page 51

REPLACING THE PRINT HEAD

The print head on the PTR3E printer is a user-replaceable item. If it becomes

damaged for any reason, it can be easily removed and replaced. Contact Technical

Support for information on obtaining a new print head.

Section 4: Cleaning and Maintenance

Supplies needed:

No. 2 Phillips screwdriver (a magnetic tip is

helpful), Replacement Print Head (available

through Panduit Printer Repair Department)

1. Turn the printer OFF and remove the power cable.

2. Open the Top and Side Access doors.

3. Open the Print Head by pushing the Head Latch toward the rear of the

printer. The Print Head is spring-loaded and will automatically open as soon

as the Head Latch is disengaged.

4. Remove the ribbon from the Ribbon Rewind Spindle if necessary.

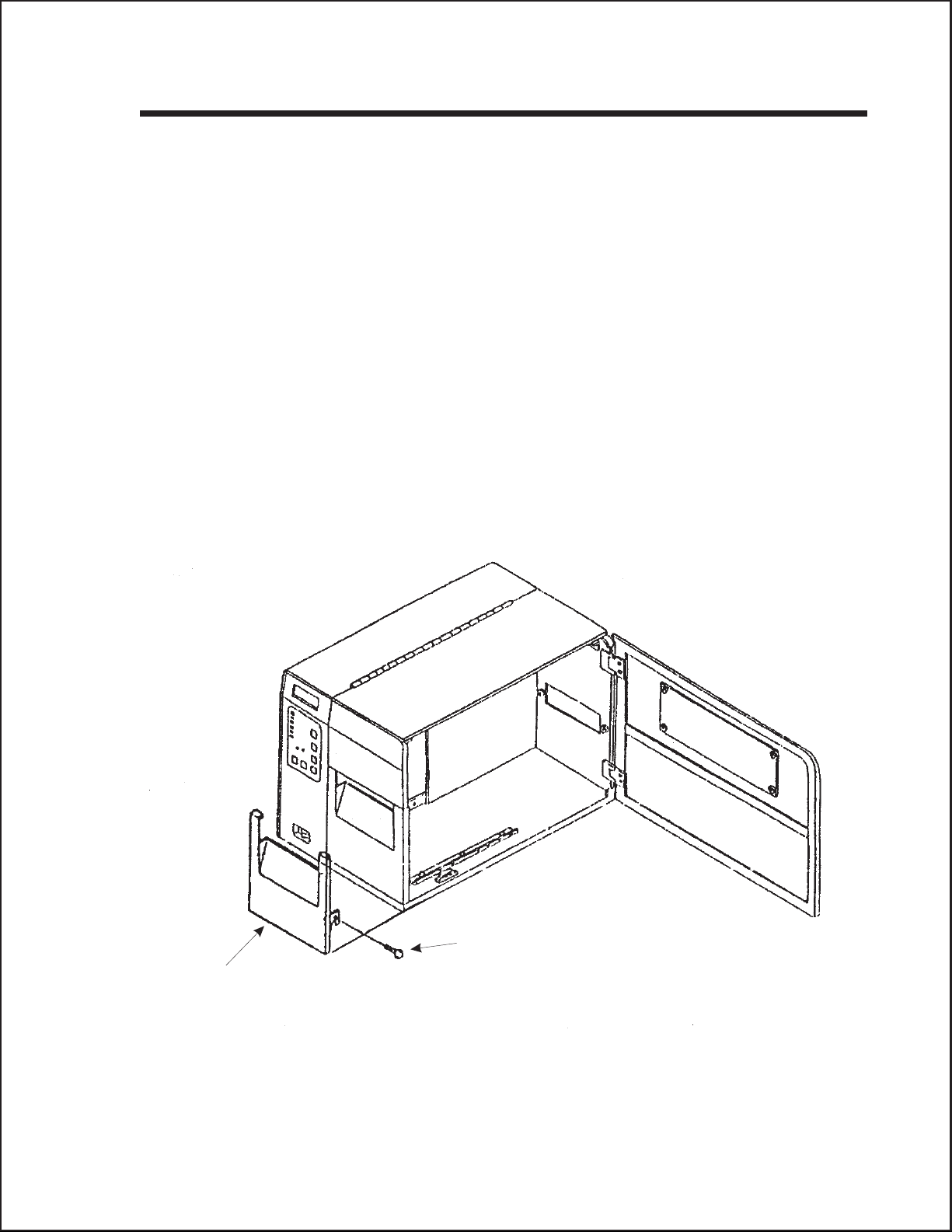

5. Remove the Label Cover Assembly by removing the securing screw from

the assembly.

Label Cover

Label Cover securing

screw

43

Page 52

Section 4: Cleaning and Maintenance

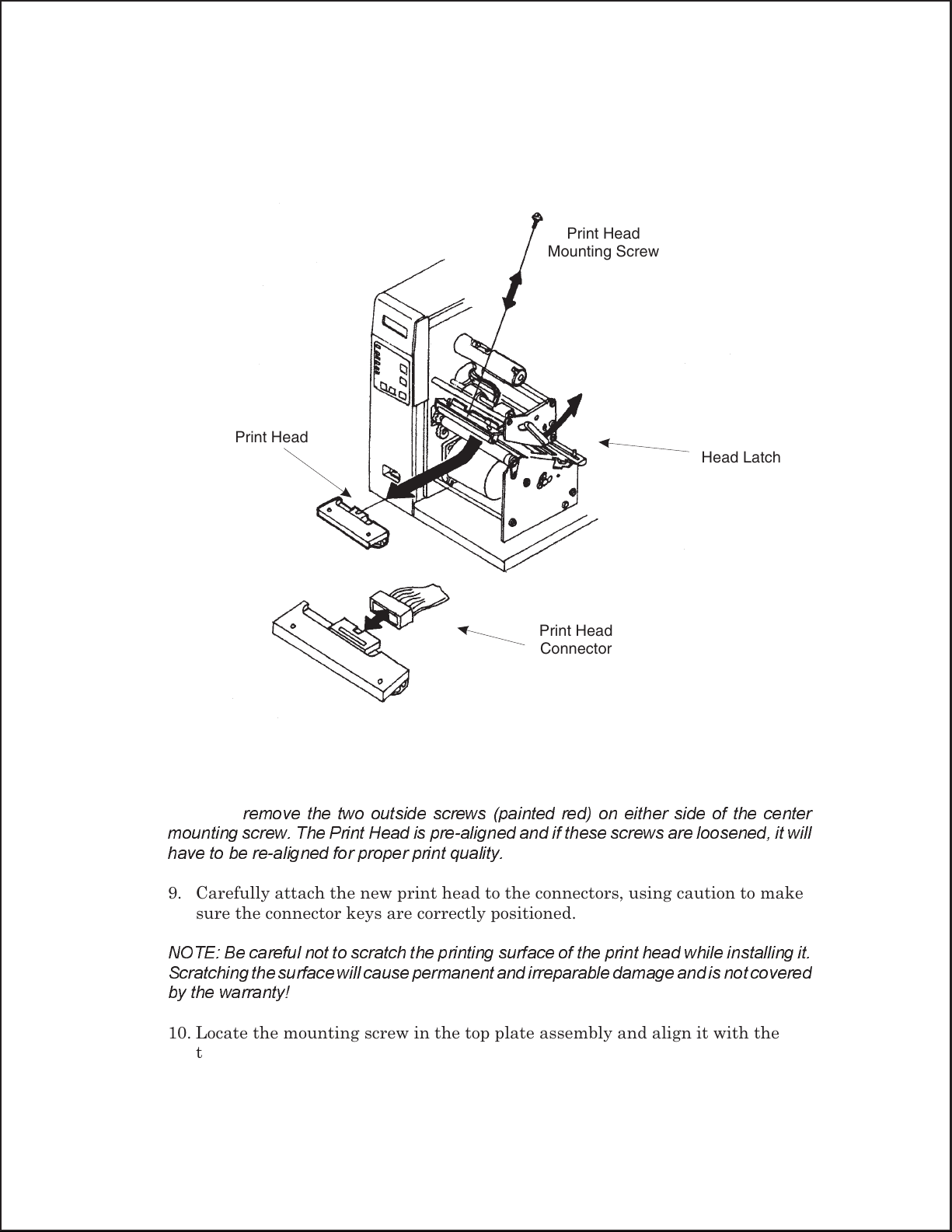

6. View the Print Head from the front of the printer. Locate the center mounting

screw on the top of the assembly. Unscrew this screw and set it aside.

7. The Print Head should now be loosened from the top of the assembly by

grasping either side and carefully pulling it down.

Print Head

Print Head

Mounting Screw

Head Latch

Print Head

Connector

8. Disconnect the signal and power cables from the print head connectors and

set the Print Head aside.

DO NOT

remove the two outside screws (painted red) on either side of the center

mounting screw. The Print Head is pre-aligned and if these screws are loosened, it will

have to be re-aligned for proper print quality.

9. Carefully attach the new print head to the connectors, using caution to make

sure the connector keys are correctly positioned.

NOTE: Be careful not to scratch the printing surface of the print head while installing it.

Scratchingthe surface willcause permanent andirreparable damage and is not covered

by the warranty!

10. Locate the mounting screw in the top plate assembly and align it with the

tapped hole in the new print head.

44

11. Re-secure the print head by tightening the screw.

Page 53

REPLACING THE FUSE

Supplies needed: 250V 3A Fuse

1. Turn the printer power OFF and remove the power cable.

2. On the back of the printer, locate the Fuse Cap on the right-hand side of the

AC connector.

3. Unscrew the cap and remove the defective fuse.

4. Replace with a new 250V 3A fuse.

5. Screw the cap back onto the printer and replace the power cord.

Section 4: Cleaning and Maintenance

45

Page 54

Section 4: Cleaning and Maintenance

46

Page 55

INTERFACE TYPES

The parallel interface for the PTR3E printer is a high speed, bi-directional interface

that conforms to the IEEE1284 specification (ECP mode on some computers). The

interface is also compatible with the older Centronics parallel interface standard. If it

does not detect the correct IEEE1284 signals I the interface connection, it will

automatically operate in the standard Centronics mode which is much slower. To use

the IEEE1284 parallel interface to its fullest capability requires that the host also have

an IEEE1284 compatible interface and that the two be connected with a cable that

meets the IEEE1284 specification. If either of these two are not present, the data rate

is severely compromised.

In order to provide flexibility in communicating with a variety of host computer

systems all “e” printers use a Plug-In Interface Module. The IEEE1284 Interface

module is shipped with the printer unless another interface type is specified at the time

of the order. A serial interface at a high speed to 57.6k bps is also available.

The Parallel interface will probably be the most useful in communicating with IBM

purchase and compatibles. The RS232C Serial interface allows connectivity to a

number of other hosts.

SECTION 5.

INTERFACE SPECIFICATIONS

WARNING: Never connect or disconnect interface cables (or use a switch box) with

power applied to either the host or the printer. This may cause damage to the

interface circuitry in the printer/host and is not covered by warranty.

IEEE1284 PARALLEL INTERFACE

The parallel interface for the PTR3E printer is a Plug-In Interface Module that can be

installed by the user. It conforms to the IEEE1284 specification. It will automatically

detect the IEEE1284 signals and operate in the high speed mode. If it does not detect the

IEEE1284 signals, it will operate in the standard Centronics mode, which is significantly

slower. For this reason, an interface cable and host interface conforming to the IEEE1284

specification must be present to fully utilize the speed capabilities. This interface also

operates bi-directionally and can report the status of the printer back to the host.

ELECTRICAL SPECIFICATIONS

Printer Connector AMP 57-40360 (DDK) or equivalent

Cable Connector AMP 57-30360 (DDK) or equivalent

Cable IEEE1284 Parallel, 10 ft. (3 m) or less

Signal Level High = +2.4V to +5.0V

Low = 0V to -0.4V

47

Page 56

Section 5. Interface Specifications

RS232C SERIAL INTERFACE

The High Speed Serial Interface is a Plug-In Interface Module. The PTR3E comes standard

with parallel interface.

GENERAL SPECIFICATIONS

Asynchronous ASCII

Half-duplex communication

Ready/Busy Hardware Flow Control

Pin 20, DTR Control

Pin 4, RTS Error Condition

X-On/X-Off Software Flow Control

Bi-Directional Communication (ENQ/Response)

Data Transmission Rate

Character Format

2400, 4800, 9600 and 19200 bps

1 Start Bit (fixed)

7 or 8 data bits (selectable)

Odd, Even or No Parity (selectable)

1 or 2 Stop bits (selectable)

ELECTRICAL SPECIFICATIONS

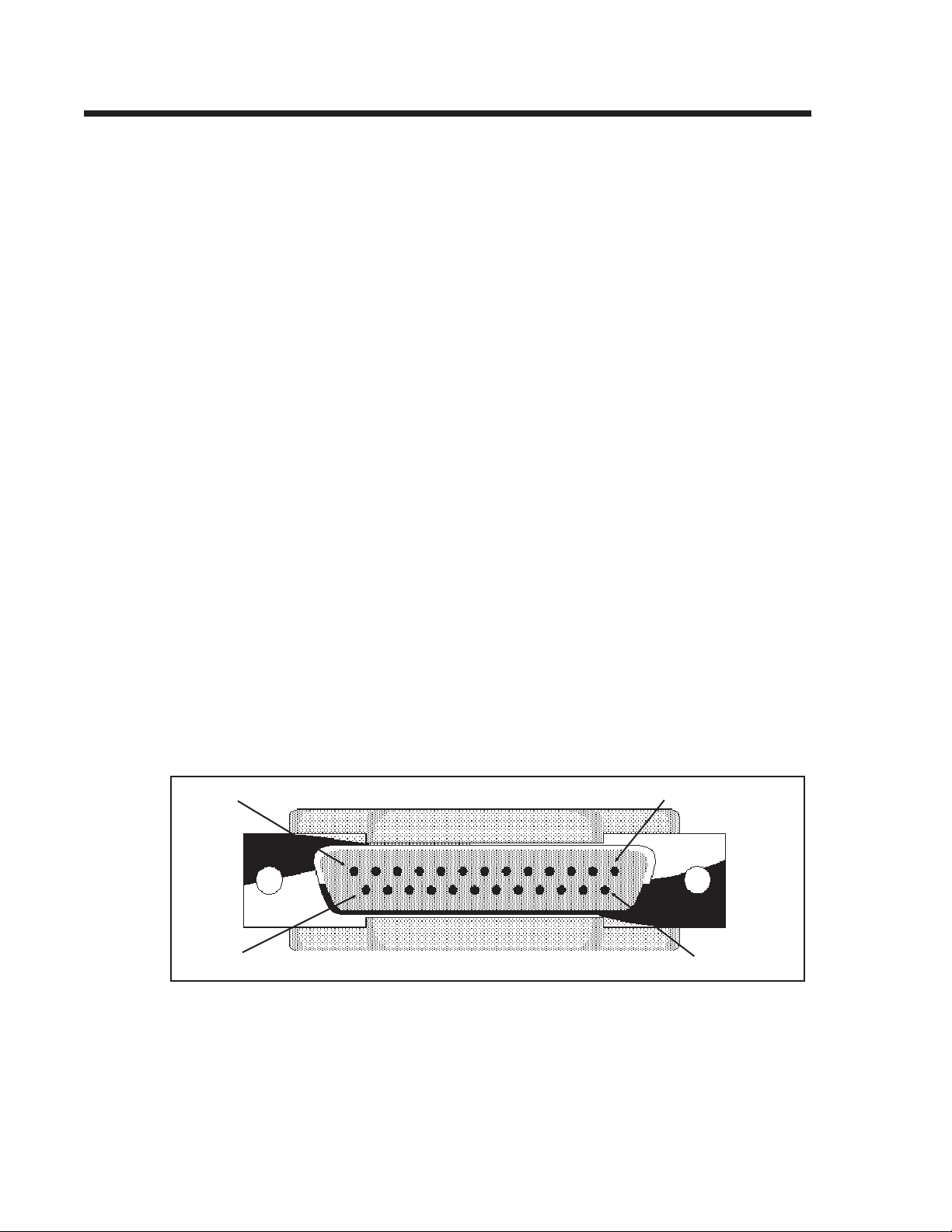

Connector DB-25S (Female)

Cable

DB-25P (Male), 50 ft. maximum length. For cable

configuration, refer to Cable Requirements

appropriate to the RS232C protocol chosen.

48

Pin 13

Pin 25

Signal Levels

Pin 1

Pin 14

High = +5V to +12V

Low = -5V to -12V

Page 57

This section has been compiled to help you produce output on the PTR3E. Use this

section to make sure the basics have been checked before deciding you are unable to

proceed any further. The section is divided into four parts:

Initial Checklist

•

IEEE1284 Parallel Interface

•

RS232C Serial Interface

•

Error Signals

•

INITIAL CHECKLIST

1. Is the printer powered up and On-Line?

2. Is the ERROR light on the front panel off? If this light is on, it may

SECTION 6.

TROUBLESHOOTING

mean the Print Head Assembly or the Label Hold-Down is not closed

and latched in position.