Page 1

Page 2

DD ii ss cc oo vv ee rr

N

ET

F

RAME

™

Rack System

Page 3

Changes to your patch fields instantly triggered an alert message?

•

Any changes were instantly recorded into your patch field database, ensuring

100% accuracy day or night?

•

Network assets could be automatically identified by type and physical

location — Giving you the ability to see what is connected and where?

•

You could graphically look at the whole link — end to end, to eliminate any

uncertainty about any connection?

•

You could electronically plan, prioritize and assign all moves, adds and changes,

document the status of each, guide the technician through the changes using LEDs

on patch panels, record the time needed to complete the task, and automatically

update the database to reflect the new configuration?

•

You could do all this on-site at your management station?

Now you can.

Wouldn't it be great if...

310

Page 4

Introducing the PANVIEW

™

Physical Layer

Management System

Structured Cabling is the foundation of your

network and patch fields are the heart of

your structured cabling system. A single

patch cord disconnection can bring critical

segments of the network down, provide an

unimpeded source for a breach in network

security or decrease the efficiency of the

network exponentially. Without an on-line

physical layer management system, those

same patch fields are virtually invisible in your

network management system.

The

PANVIEW

system, through its innovative use

of scanners, enabled patch panels, reliable

patch cords and software, provides real-time

monitoring of physical layer connectivity. This

system provides networks with greater

reliability, improved security, better efficiency

and greater savings. From financial firms to

logistic and manufacturing firms, network

reliability is essential. This system with its

capabilities of monitoring and protecting

these connections 24 hours a day, 7 days a

week, 365 days a year, is a must. The

PANVIEW

system not only meets these criteria, it takes

network management to the next level by

providing the accurate, real-time information

necessary to manage the physical layer in

today's world.

Real-Time and Real-

Network Reliability, Security and

Efficiency.

Network Reliability, Security and

Efficiency.

Page 5

PHYSICAL LAYER MANAGEMENT SYSTEM

The

PAN

VIEW

™

system, through its continuous scanning

process, provides the user with real-time end-to-end

documentation of their physical layer. Movement of a

patch cord instantaneously triggers an alert message

at the management station. However, the

P

ANVIEW

system takes reliability a step further by ensuring that

your patch field database is 100% accurate day or

night. The continuous scanning process in the

PANVIEW

system allows the management software to

continually verify the accuracy of the database,

providing the user with a real-time picture of the patch

field.

Today’s networks handle millions of bytes of sensitive

information everyday. Whether it is information

pertaining to a large financial transaction a company

is making or an individual customer placing an order,

confidentiality and security is imperative. Using the

PANVIEW

system helps improve your network security.

The most powerful way to improve network security is

through the

P

ANMAP

™

module, which uses leading

edge technology to identify and track asset

movement throughout the network. It then shows

these assets in the appropriate locations within the

database — giving the user the ability to see what is

connected and where.

Reliability Security

58

Page 6

The Link Module allows the administrator to graphically

view the entire link from the management station. It

also allows for changes to be made to any link in the

system with just a few clicks of the mouse button.

With the Work Order Module, the Network

Administrator can plan, prioritize, and assign all of the

moves, adds, and changes in the system. The system

then documents the status of the work order, guides

the technician through the changes using LEDs on the

patch panels, records the time needed to complete

the task, and automatically updates the database to

reflect the new configuration.

Efficiency

Link Module

Link Module

Work Order Module

Work Order Module

Responding quickly and efficiently to user requests for service changes is often a

challenge. Network Administrators and Technicians spend significant amounts of

time planning and executing the process. Even then, mistakes happen. The wrong

patch cord is accidentally disconnected or the right cord ends up in the wrong port

causing even greater confusion. The

PANVIEW

™

system eliminates this problem with two

software modules, the Link Module and the Work Order Module.

Page 7

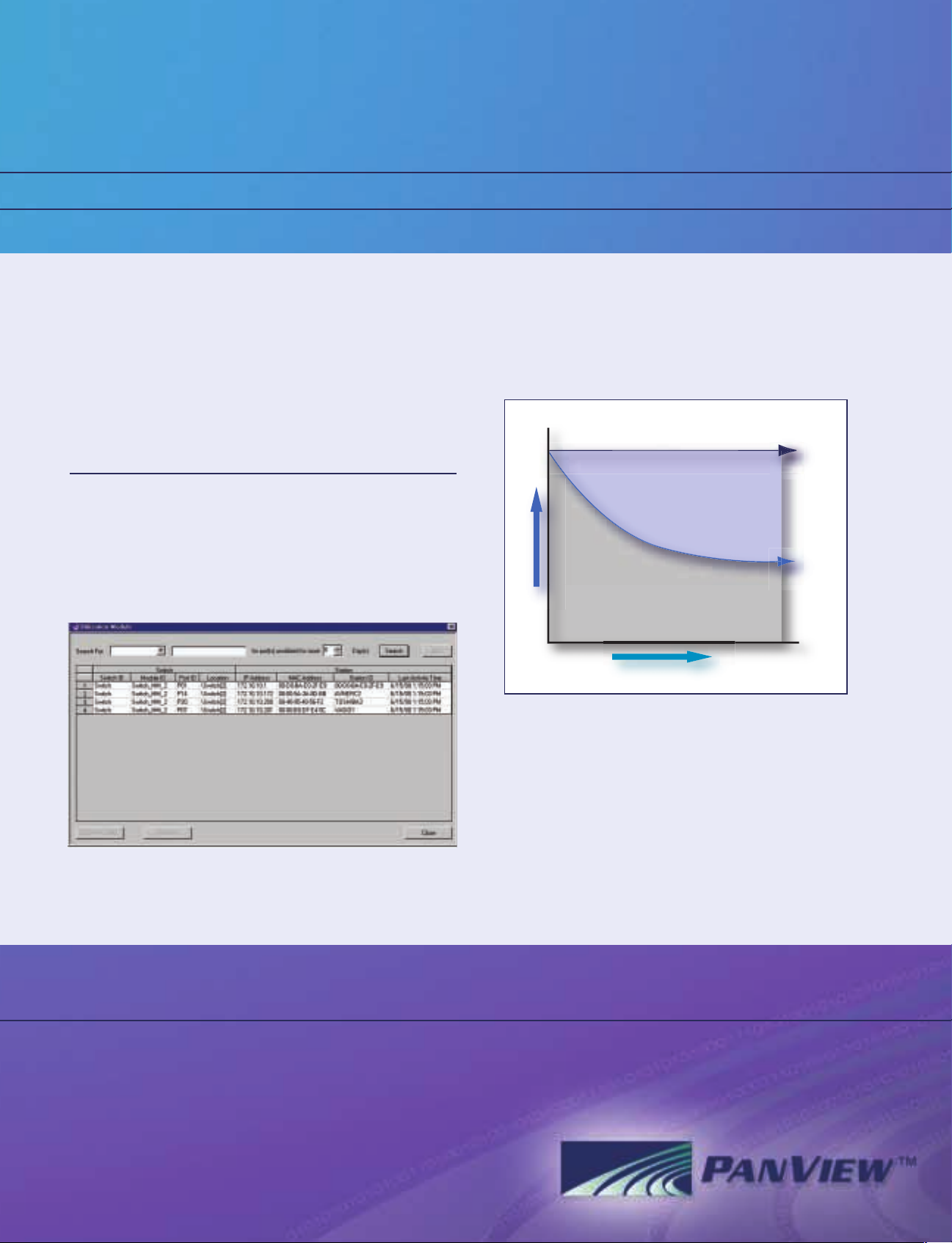

Network assets, from switches and patch panels to

computers and software, are expensive. Making sure

that your system optimizes the use of these assets can

be a formidable task. Quite often it is easier to

purchase a new piece of equipment than it is to

reclaim an existing one.

The

PANVIEW

™

system solves this by keeping a database

of switch port usage. The system makes reclaiming

network capacity as simple as the click of a few

buttons. And if your system approaches a capacity

limitation,

PAN

VIEW

's Utilization Report provides

complete details.

The

PAN

VIEW

system provides invaluable benefits for

customer networks in the form of greater reliability,

improved security and better efficiency. A customer

specific return on investment (ROI) model provides

step-by-step guidance to answering these questions.

Savings Value

PHYSICAL LAYER MANAGEMENT SYSTEM

Utilization Module

Utilization Module

Normal Network Asset Utilization

over time

Network

Operations

with

PANVIEW

100%

Network

Operations

without

PANVIEW

Life of the Network (years)

Network Asset Savings

generated by

PANVIEW

Network Equipment

Network Asset Utilization

For feasibility study assistance contact

PANDUIT

®

at 866-405-6654.

76

Page 8

The

PANVIEW

software is based on client/server

architecture, and provides valuable information in an

easy to use format. The software ensures the

information is 100% accurate by automatically

updating the database whenever there is a

connectivity change. It has several different modules

that allow single user changes or complete

department moves with just a few clicks. In addition,

the software provides seamless integration into select

network management programs, documents asset

utilization, and tracks the movement of network assets

using the

PANMAP

™

module.

P

ANVIEW

electronic scanners are the connectivity data

collectors of the

PANVIEW

system. The scanners monitor

on-site patch panel connectivity, and provide realtime information on the status of all network

connections monitored by the system. The

PANVIEW

system includes both Master and Satellite Scanners.

Scanners are mounted in racks in the

telecommunication room at various sites adjacent to

enabled patch panels.

PANVIEW

Enabled Patch Panels perfor m two functions

in the telecommunications room. Their primary

facilitates data transfer throughout the network.

However, by adding a circuit board and an additional

connectivity point to the panel design; they become

an integral component of the

PANVIEW

physical layer

management system.

Each patch panel is connected to the scanner through

an attachment cord. This cord allows the scanner to

transmit and monitor the status of the connectivity. An

additional contact in the

PANVIEW

patch cord plug

provides the connection to close the loop between

connected ports making a complete circuit for the

scanners to monitor. The scanners then collect all the

connectivity information and report it over the LAN to

the network management station running the

PANVIEW

software. There are LEDs above each patch panel port

that guide the technician through patch cord

changes. A blinking LED indicates that the patch cord

should be disconnected, while a solid LED indicates

that the patch cord should be connected.

The Accessory Controller enables the

PANVIEW

Management Station to monitor the status of various

sensors and activate remote-controlled devices. A

change in status to any of the connected sensors (e.g.

temperature) is immediately noted and sent to the

PANVIEW

Management Station through the Accessory

Controller. The control pad is a portable handheld

device that is connected to the first scanner in each

room. It allows the person performing the MAC to

begin the process under the guidance of the LEDs

above each port.

II. PANVIEW Scanners

II. P

ANVIEW Scanners

System Components

••

Software • Scanners • Enabled Patch Panels

I. Software

I. Software

III. Enabled Patch Panels,

P

ANVIEW Patch Cords

and Accessories

III. Enabled Patch Panels,

P

ANVIEW Patch Cords

and Accessories

Page 9

PHYSICAL LAYER MANAGEMENT SYSTEM

I. Software

Switch

Work Station

II. ScannersIII. Enabled Patch Panels and

PANVIEW

™

Patch Cords

94

Page 10

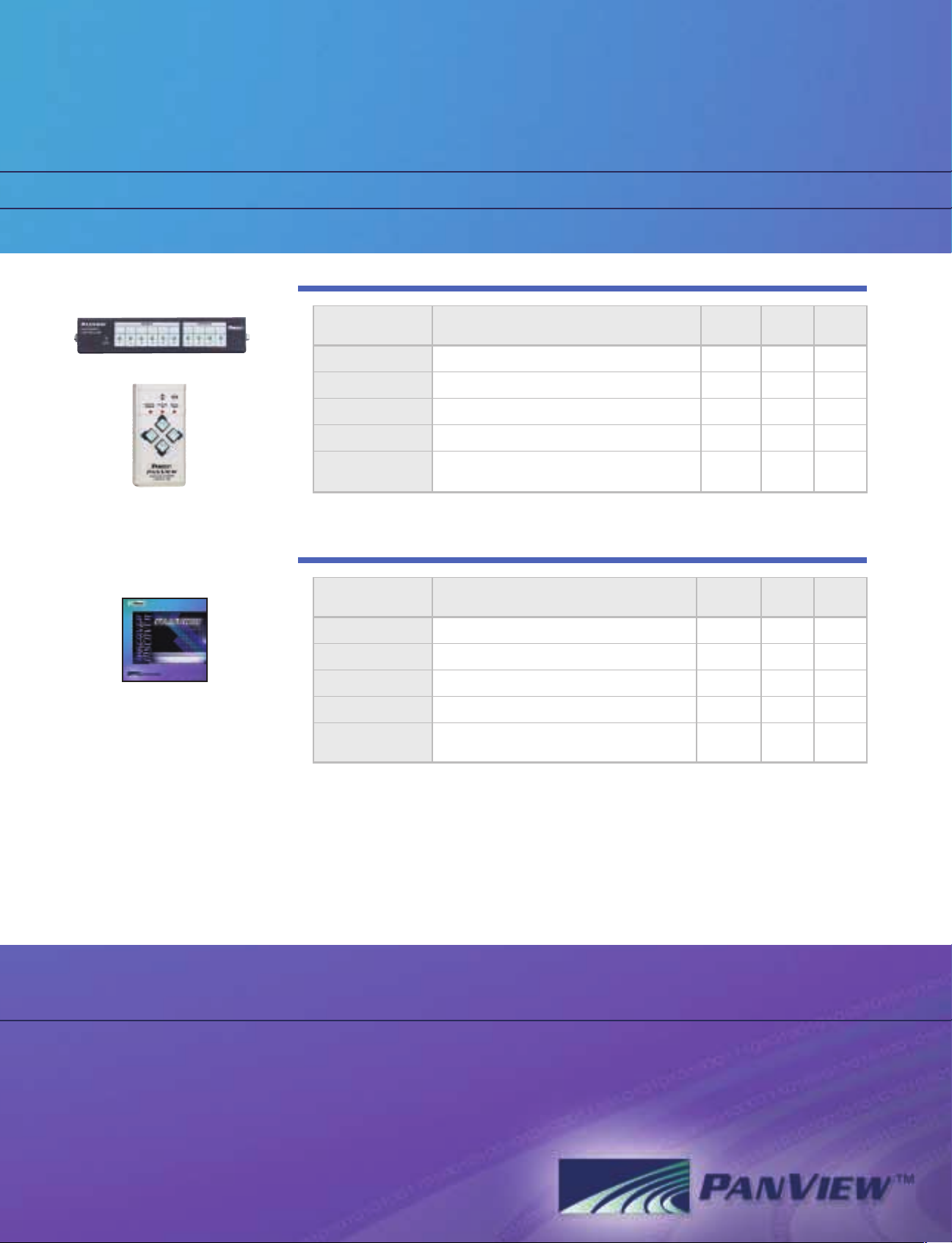

PAN

VIEW

™

Scanners

PANVIEW Patch Panels

PVMSO

PVSSO

PVEDP246B

PART NUMBER DESCRIPTION

STD.

PKG.

QTY.

NO. OF

RACK

SPACES^

STD.

CTN.

QTY.

PVMSO Master Scanner 2 1 1

PVMSEO Master Scanner with extended memory 2 1 1

PVSSO Satellite Scanner 1 1 1

PVSSEO Satellite Scanner with extended memory 1 1 1

P

ANVIEW Patch Cords

PART NUMBER DESCRIPTION

STD.

PKG.

QTY.

COLORLENGTH

STD.

CTN.

QTY.

PVUTPCTG3BBU Cat 6 UTP patch cord 3 ft. Blue 1 10

PVUTPCTG5BBU 5 ft. Blue 1 10

PVUTPCTG7BBU 7 ft. Blue 1 10

PVUTPCTG9BBU 9 ft. Blue 1 10

PVUTPCTG14BBU 14 ft. Blue 1 10

PVUTPCTG20BBU 20 f t. Blue 1 10

PART NUMBER DESCRIPTION

STD.

PKG.

QTY.

NO. OF

RACK

SPACES^

STD.

CTN.

QTY.

^ One rack space = 1.75" (44.45mm)

^ One rack space = 1.75" (44.45mm)

PVUTPCTG7BBU

PVEDP246B Cat 6 24 port UTP patch panel 1 1 1

Page 11

Software Version

1.0

PVCP

PVSCP

PVACSC

P

ANVIEW

™

Accessories

PART NUMBER DESCRIPTION

STD.

PKG.

QTY.

NO. OF

RACK

SPACES^

STD.

CTN.

QTY.

PVACSC Rack Mount Accessory Controller 1 1 1

PVCP Control Pad — 1 1

PVFACB1.5M 1.5 meter Attachment Cord — 1 10

PVFACB2.5M 2.5 meter Attachment Cord — 1 10

CORD-S* US Power Cord — 1 1

(one required per scanner)

^ One rack space = 1.75" (44.45mm)

* International power cords are also available.

PANVIEW Software

PART NUMBER DESCRIPTION

STD.

PKG.

QTY.

FORMAT

STD.

CTN.

QTY.

PVSCP

P

ANVIEW

Core Software CD ROM 1 1

PVSAMM

PANVIEW

Asset Management Software CD ROM 1 1

PVSWOM

PANVIEW

Work Order Module CD ROM 1 1

PVSAUC

PANVIEW

Core Software Additional User CD ROM 1 1

PVSAUWOM

PANVIEW

Work Order Module Additional CD ROM 1 1

User

For installation design and technical assistance contact

PANDUIT

®

at 866-405-6654

or your authorized

PANVIEW

Systems Integrator.

PHYSICAL LAYER MANAGEMENT SYSTEM

112

Page 12

Copyright © 2002

PANDUIT

Corp. All rights reserved. Printed in the U.S.A.

SA-NC07BR01A

™

NETWORK CONNECTIVITY GROUP

PANDUIT

NETWORK CONNECTIVITY GROUP. The information contained in this literature is based on our experience to date and is believed to be reliable. It

is intended as a guide for use by persons having technical skill at their own discretion and risk. We do not guarantee favorable results or assume any liability in

connection with its use. Dimensions contained herein are for reference purposes only. For specific dimensional requirements consult the factory. This publication

is not to be taken as a license to operate under, or a recommendation to infringe any existing patents. This supersedes and voids all previous literature, etc.

PANDUIT

®

Corp.

(Worldwide HQ)

17301 Ridgeland Avenue

Tinley Park, Illinois 60477-3091, USA

Telephone +1 708 532 1800

Fax +1 708 532 1811

PANDUIT

Corp.

(Network Connectivity Group HQ)

10500 West 167th Street

Orland Park, Illinois 60467, USA

Telephone +1 708 460 1800

Fax +1 708 460 9211

PANDUIT

Europe Ltd

(EMEA HQ)

West World, Westgate

London W5 1XP, United Kingdom

Telephone +44 (0) 208 601 7200

Fax +44 (0) 208 601 7319

PANDUIT

Australia

(National Office)

30-36 Kitchen Road, Dandenong

Victoria 3175, Australia

Telephone +61 (0) 3 9794 9020

Fax +61 3 9794 7101

PANDUIT

Corp.

(Japan Branch)

31-5, Omori-Kita, 6-Chome Ota-Ku

Tokyo, Japan 143-0016

Telephone +81 3 3767 7011

Fax +81 3 3767 7033

PANDUIT

Mexico

(Guadalajara Corp. Offices)

Ave. Lazaro Cardenas 2785

Col. Alamo Industrial, Tlaquepaque

Jal 44490, Mexico

Telephone +52 3 666 2501

Fax +52 3 666 2510

PANDUIT

Asia Pacific Pte Ltd

60 Tuas Avenue 11, Singapore

Republic of Singapore 639106

Telephone +65 379 6700

Fax +65 379 6759

PANDUIT

Canada

140 Amber Street, Markham

Ontario, Canada L3R 3J8

Telephone +1 905 475 6922

Fax +1 905 475 6998

Loading...

Loading...