Page 1

© Panduit Corp. 2006

PA24578A01

Rev. 04 7-2006

METAL EMBOSSING HAND TOOL

OPERATION INSTRUCTIONS

For Technical Support:

888-506-5400, ext. 3255

Fax: 630-759-7532

Website: www.panduit.com

E-mail: cs@panduit.com

MEHT

Page 2

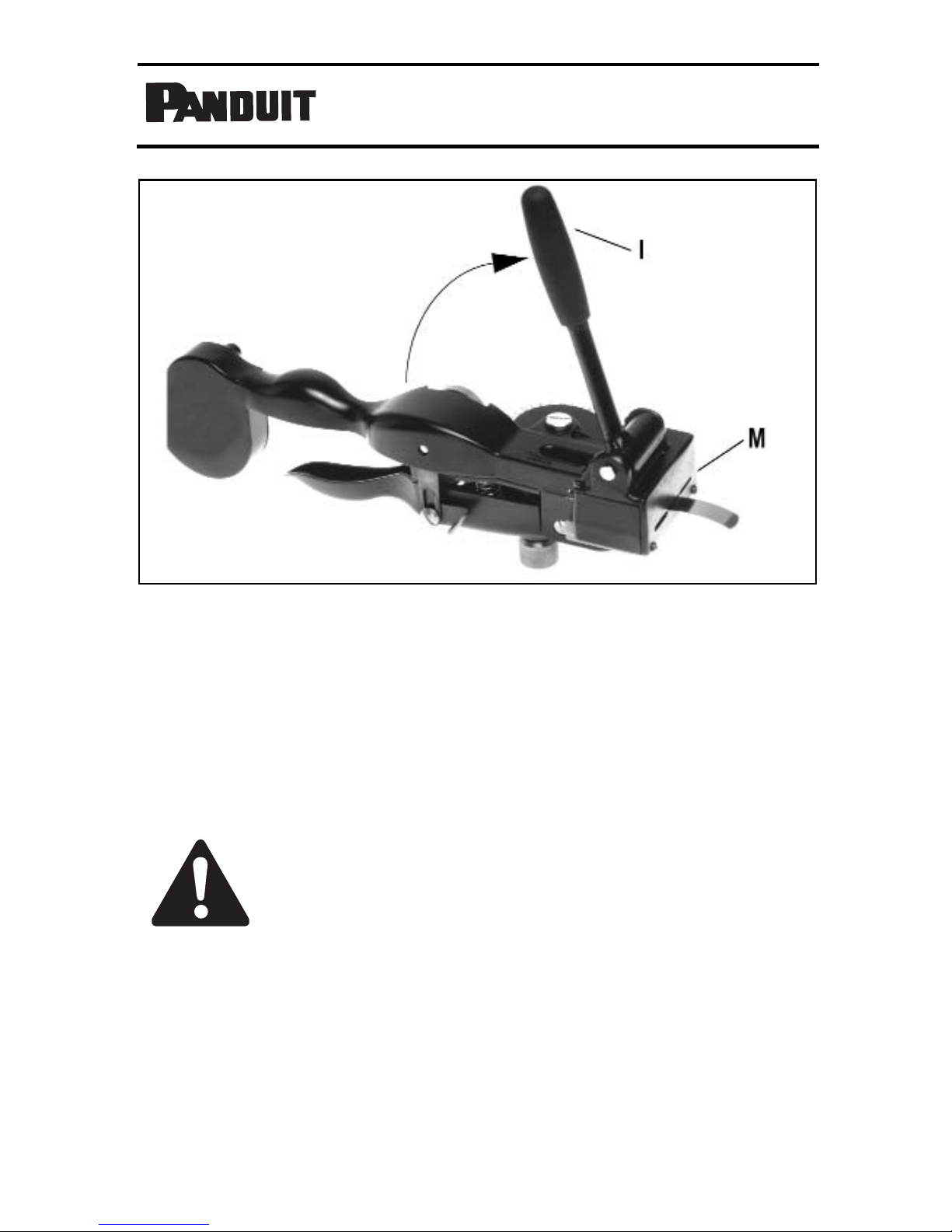

A. Tape cassette door

B. Tape rollers

C. Tape advance knob

D. Start line

E. Tape pawl

F. Embossing handle

G. Embossing wheel

H. Character selection window

I. Cutting handle

J. Embossing adjustment screw

K. Cable tie slot entrance

L. Tape exit/Cutting assembly

M. Trailer length guide

MEHT

OPERATION INSTRUCTIONS

Page: 1 of 14

Page 3

MEHT

OPERATION INSTRUCTIONS

Page: 2 of 14

About Your New Labelmaker

With your new

PANDUIT

MEHT labelmaker,

you can create a wide variety of aluminum and

stainless steel labels. The labelmaker uses

1/2" (12 mm) label tape. Aluminum and

stainless steel tapes are available as follows:

• META-X: 1/2" x 16 ft. (12.6mm x 4.9m)

aluminum tape

• METS4-X: 1/2" x 21 ft. (12.6mm x 6.4m)

304 grade stainless steel tape

• METS3-X: 1/2" x 21 ft. (12.6mm x 6.4m)

316 grade stainless steel tape

You can also use a Reverse Image Wheel with

the

PANDUIT

MEHT labelmaker. This wheel

allows you to print mirror script labels that

meet special requirements in the industry.

Mirror labels are used on moulds or casts for

metal or rubber injection, silicon casting, fiber

glass applications, and so on.

Visit www.panduit.com for information on

obtaining tapes and accessories for your labelmaker.

Page 4

MEHT

OPERATION INSTRUCTIONS

Page: 3 of 14

Loading the Label Tape

The

PANDUIT

MEHT is set to emboss non-

adhesive aluminum or stainless steel tape.

To load the tape roll

1. Hold the labelmaker in your left hand.

2. Open tape door (A).

3. Insert roll of tape allowing the end to

extend about 2" (5 cm) through the tape

slot.

4. Close the tape door.

5. Feed the tape between the two rollers (B).

6. Squeeze the embossing handle (F) half-

way (one click) several times to ensure

the tape is inserted all the way.

F

A

B

Page 5

Cutting the Tape

To cut the tape

1. Squeeze the embossing handle half-way,

several times until the tape extends from

the front of the cutting assembly (M) by at

least 1" (2.5cm).

Note: Before cutting the tape, make

sure the end of the tape extends

beyond the edge of the cutting

assembly so you can easily pull the

label out. Otherwise, a tape jam may

occur.

2. Lift the cutting handle (I) gently until it is

vertical to cut the tape.

Page: 4 of 14

MEHT

OPERATION INSTRUCTIONS

Page 6

MEHT

OPERATION INSTRUCTIONS

Page: 5 of 14

Embossing the Label

Avoid turning the embossing wheel at

the same time you are squeezing the

embossing handle. This can damage

the character wheel.

To emboss a label

1. Turn the character selection wheel (G)

until the desired letter is centered in the

window (H).

2. Squeeze the embossing handle (F) firmly.

3. Release the embossing handle fully

before selecting the next character.

To add space between words

• Squeeze embossing handle (F) half-way

(one click) or turn the tape advance knob

clockwise (one click per space).

Page 7

MEHT

OPERATION INSTRUCTIONS

Page: 6 of 14

Embossing on Stainless Steel Tape

You may need to adjust the labelmaker to

emboss properly when using stainless steel

tape.

To adjust for stainless steel tape

1. Turn the adjustment screw (J) clockwise

1/2 to 3/4 turn.

2. Emboss the text as described in

"Embossing the Label" on page 5. When

you return to using aluminum tape, you

may need to reverse this adjustment.

Page 8

Retracting the Tape

You may want to retract the tape, for example,

if the tape advanced too far or to center the

text on the label.

To retract the tape

1. Pull back the pawl (E).

2. Turn the tape advance knob (C) counterclockwise.

MEHT

OPERATION INSTRUCTIONS

Page: 7 of 14

Page 9

Removing the Tape

To remove the tape

1. Retract the tape as described in

"Retracting the Tape" on page 7.

2. Open the tape cassette door (A) and

remove the tape.

Use caution when removing stainless

steel tape that may have sharp

edges.

3. Reload the tape as described in "Loading

the Label Tape" on page 3.

Page: 8 of 14

MEHT

OPERATION INSTRUCTIONS

A

Page 10

Centering the Text on the Label

The leader/trailer length guide (M) has

positioning marks for a short (S) or long label

(L). Use the marks on the guide to center the

text on your label.

To center the text on a long label

1. After cutting the previous label, emboss

the text on a new label.

2. Pull the leader/trailer length guide (M) to

the forward position.

3. Advance the tape until the last embossed

letter is opposite the L on the guide. The

label has a leader/trailer of approximately

2" (5 cm) and the text is centered.

4. Lift the cutting handle (I) to the vertical

position to cut the tape.

MEHT

OPERATION INSTRUCTIONS

Page: 9 of 14

M

Page 11

MEHT

OPERATION INSTRUCTIONS

Page: 10 of 14

To center the text on a short label

1. Retract the tape until the tape edge is at

start line (D).

2. Emboss the text on your label.

3. Advance the tape until the last embossed

letter is opposite the S on the guide. The

label has a leader/trailer of approximately

1.5" (3 cm) and the text is centered.

4. Lift the cutting handle (I) to the vertical

position to cut the tape.

Page 12

Page: 11 of 14

MEHT

OPERATION INSTRUCTIONS

Punching Cable Tie Slot in Labels

You can punch a cable tie slot in one or both

ends of the label, then label can be attached

using ties. Cable tie slot accommodates

PANDUIT

stainless steel ties:

•

MLT-S: .18" width (4.6mm)

•

MLT-LH: .25" width (6.4mm)

• MLT-H: .31" width (7.9mm)

1. Insert one end of the cut label into the

cable tie slot (K) with the letters facing

down. The letters must face down to

ensure the bridge of the slot is on the

same side of the label as the characters.

I

K

Page 13

Make sure to allow enough room for

the tie-buckle before and/or after the

letters. A cable tie slot positioned on

top of the characters or a punched

hole may cause the tape to jam.

2. Lift the cutting handle (I) to the vertical

position to punch the slot.

MEHT

OPERATION INSTRUCTIONS

Page: 12 of 14

Page 14

Page: 13 of 14

MEHT

OPERATION INSTRUCTIONS

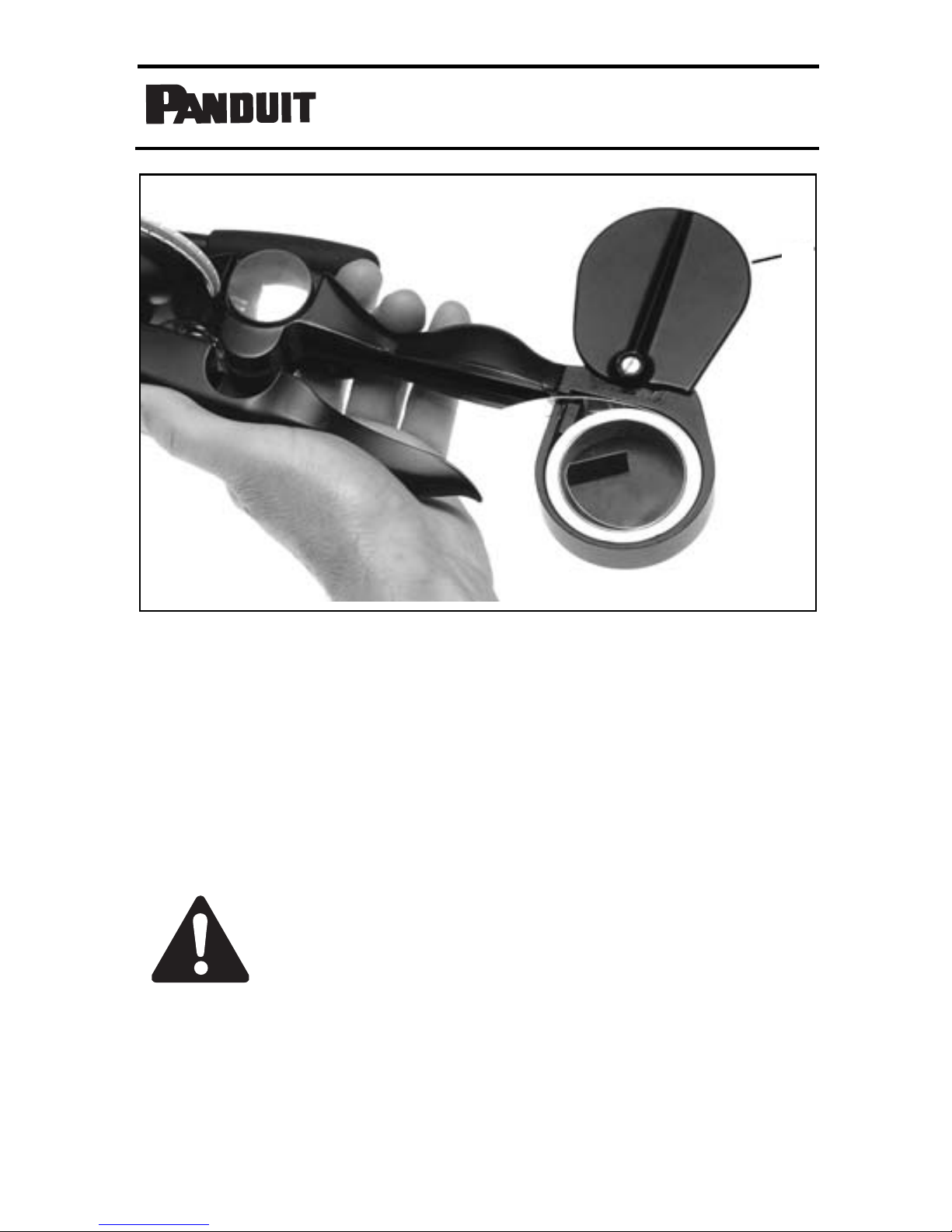

Changing the Wheel

You can replace the character wheel with a

Reverse Image Wheel.

To change the wheel

1. Remove the label tape.

2. Unscrew the screw in the center of the

embossing wheel (G) and remove the

wheel.

3. Position the new wheel.

4. Insert the screw in the center and tighten.

Do not tighten the screw too tightly.

G

Page 15

MEHT

OPERATION INSTRUCTIONS

Page: 14 of 14

Hints for Trouble Free Operation

Keep the following in mind when using the

labelmaker:

• Letters appear where you want spaces -

You are probably squeezing the

embossing handle too hard.

• Letters overlap - The tape is slipping. This

can happen when dirt or grease gets on

the rollers. Clean the rollers by using a

soft cloth and alcohol, while turning the

tape advance knob back and forth several

times.

•

Avoid turning the embossing wheel at the

same time you are squeezing the

embossing handle. This can damage the

character blades.

• When punching a cable tie slot, make

sure the label is well inserted and abutted

against the end of the slot. If the label is

not inserted to the end, tape jam may

occur.

Loading...

Loading...