Page 1

© Panduit Corp. 2007

Website: www.panduit.com

E-mail: cs@panduit.com

Technical Support:

888-506-5400, ext. 3255

Fax: 630-759-7532

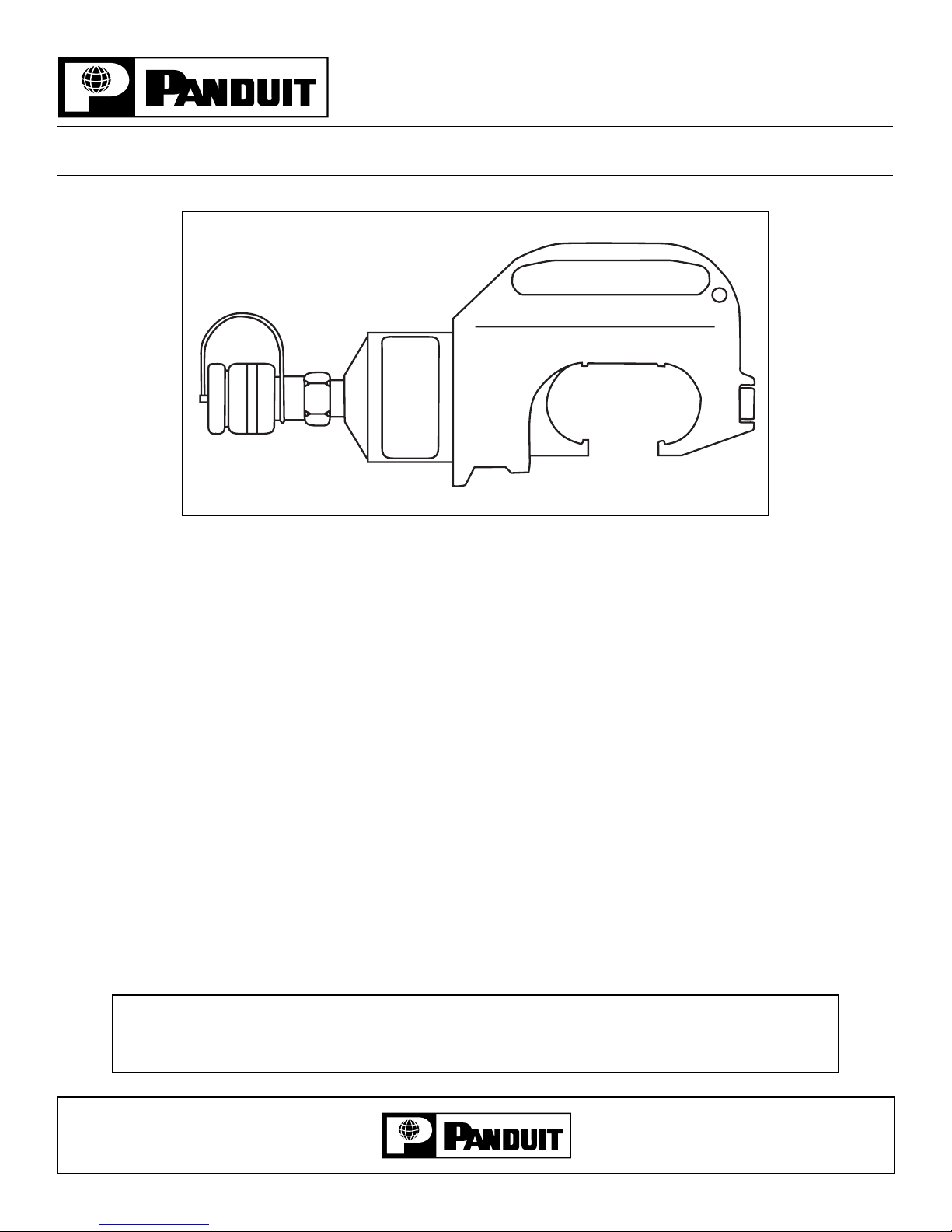

CT-930CH, CT-930LPCH

and CT-940CH

PA22141A01

Rev: 02 9-2007

REMOTE HYDRAULIC CRIMPING TOOLS

OPERATING INSTRUCTIONS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SYSTEM SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRECAUTIONS AND GENERAL GUIDELINES

FOR MAINTENANCE OF TOOLS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DIE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Die Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DIE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TOOL OPERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MAINTENANCE

Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Inspection of Compression Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CT-930CH

Panduit Corp., Tinley Park, IL

NOTE: In the interest of higher quality and value, PANDUIT is constantly

improving and updating our products. Consequently, pictures herein

may vary from the actual product.

Page 2

Page: 1 of 6

INTRODUCTION

The CT-930CH and CT-940CH Remote Hydraulic Crimping Tools are used in conjunction with a compatible hydraulic

pump system capable of sustaining 10,000 PSI (700 kg/cm2).

PANDUIT

recommends using their CT-901HP Hydraulic

Pump and CT-900HPH 10 foot Hydraulic Hose.

• The CT-930CH and CT-901HP Hydraulic Pump System can crimp #8 AWG thru 750 kcmil

PANDUIT

Copper

Compression Connectors and #6 AWG thru 600 kcmil

PANDUIT

Aluminum Compression Connectors.

PANDUIT'

s

CT-930CH Tool develops up to 14 tons (12.7 metric tons) of compressive force.

• The CT-930LPCH Remote Hydraulic Crimping Tool is used in conjunction with a compatible hydraulic pump system

capable of sustaining 7,500 PSI (525 kg/cm

2

).

PANDUIT

recommends using their CT-8250HP Hydraulic Pump and

CT-900LPHPH 10-foot Hydraulic Hose. The CT-930LPCH and CT-8250HP Hydraulic Pump system can crimp #8 AWG

thru 250 kcmil

PANDUIT

Copper Compression Connectors for use with stranded copper code cable. The CT-930LPCH

Tool develops up to 10 tons (9 metric tons) of compressive force.

• The CT-940CH and CT-901HP Hydraulic Pump System can crimp #8 AWG thru 1500 kcmil

PANDUIT

Copper

Compression Connectors and #6 AWG thru 1000 kcmil

PANDUIT

Aluminum Compression Connectors. The CT-940CH

Tool develops up to 15.0 tons (13.6 metric tons) of compressive force.

This manual will guide you step-by-step in the operation and maintenance of your

Remote Hydraulic Crimping Tool. If you have problems not covered, call:

1-888-506-5400, ext. 3255

Ask for one of our Tool Service Technicians

The information contained in this literature is based on our experience to date and is believed to be reliable. It

is intended as a guide for use by persons having technical skill at their own discretion and risk. We do not

guarantee favorable results or assume any liability in connection with its use. Dimensions contained herein are

for reference purposes only. For specific dimensional requirements consult the factory. This publication is not

to be taken as a license to operate under, or a recommendation to infringe any existing patents. This supersedes and voids all previous literature, etc.

CT-930CH

Hydraulic Crimping Tool

Output: 14 Tons / (12.7 metric tons)

Input:

10,000 PSI / (700-kg/cm2)hydraulic pressure provided

by a separate hydraulic pump system (

PANDUIT'

s

CT-901HP Hydraulic Pump and CT-900HPH 10-foot

Hydraulic Hose).

Applicable Range: #8 AWG to 750 kcmil copper and #6 to 600 kcmil alu-

minum

PANDUIT

compression connectors.

Dimensions: 12-3/4” L x 5” H x 3” W

324 L x 124 H x 76 W (mm)

Weight: 11 lbs. / (5 kg)

Hydraulic Fittings: Parker-Hannifin 3/8" Female Quick Coupler

Carrying Case Included with CT-930CH Tool

SYSTEM SPECIFICA

TIONS

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Page 3

Page: 2 of 6

CT-930LPCH

Hydraulic Crimping Tool

Output: 10 Tons / 9.0 metric tons

Input:

7,500 PSI / (700-kg/cm2)hydraulic pressure provided

by a separate hydraulic pump system (

PANDUIT'

s

CT-8250HP Hydraulic Pump and CT-900LPHPH 10foot Hydraulic Hose).

Applicable Range: #8 AWG to 250 kcmil copper compression connectors

for use with stranded copper code cable.

Dimensions: 12-3/4” L x 5” H x 3" W

324 L x 124 H x 76 W (mm)

Weight: 11 lbs. / (5 kg)

Hydraulic Fittings: Parker-Hannifin 3/8" Male Quick Coupler

Carrying Case Included with CT-930LPCH Tool

CT-940CH

Hydraulic Crimping Tool

Output: 15.0 tons / (13.6 metric tons)

Input:

10,000 PSI / (700 kg/cm2)hydraulic pressure provided

by a separate hydraulic pump system (

PANDUIT'

s

CT-901HP Hydraulic Pump and CT-900HPH 10 foot

Hydraulic Hose).

Applicable Range: #8 AWG to 1500 kcmil copper and #6 AWG to 1000 kcmil

aluminum

PANDUIT

compression connectors.

Dimensions: 14.5” L x 4.1” H x 2.5” W

386 L x 104 H x 64 W (mm)

Weight: 10.5 lbs. / (4.8 kg)

Hydraulic Fittings: Parker-Hannifin 3/8" Female Quick Coupler

Carrying Case Included with CT-940CH Tool

Compression Dies CT-930CH, CT-930LPCH Refer to

PANDUIT

catalog or Sales Office for part numbers and specific

or CD-940CH: die application information.

CD-940-DA Die Adapter: To be used with CD-920 and CD-930 series dies

CG-920 Compression Gauge: Verifies the compression force of the CT-930CH and CT-930LPCH tools.

CG-940 Compression Gauge: Verifies the compression force of the CT-940CH tool.

CT-900HPH or Electrically non-conductive 10 ft. hose. Supplied pre-filled with hydraulic

CT-900LPHPH: fluid for fast start up.

Hydraulic Pump System CT-901HP Hydraulic Pump System is factory preset at 10,000-PSI ± 200 PSI.

for the CT-930CH and Pump shuts off when cycle is complete. Will not release until the down switch is

CT-940CH: activated.

Hydraulic Pump System CT-8250HP Hydraulic Pump System is factory preset at 7,500-PSI ± 200 PSI.

for the CT-930LPCH: Pump shuts off when cycle is complete. Will not release until the down switch is

activated.

SYSTEM SPECIFICATIONS (continued)

OPTIONAL ACCESSORIES

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Page 4

Page: 3 of 6

1. Safety glasses must be worn at all times when using the tool.

2. Be sure to select appropriate dies to suit the connector to be crimped. Improper combinations result in inferior connections of conductors.

NOTE: DIES ARE DESIGNED TO PRODUCE THE HIGHEST QUALITY CONNECTIONS WITH

PANDUIT

CONNECTORS. CONNECTIONS WITH

PANDUIT

CONNECTORS UTILIZING THIS TOOL ARE

U.L. LISTED AND C.S.A. CERTIFIED ONLY WHEN USING

PANDUIT

COPPER AND ALUMINUM COMPRESSION CONNECTORS. USE OF ANY OTHER BRAND OF COMPRESSION CONNECTORS IS NOT

RECOMMENDED.

3. Always keep fingers out of die set area in crimp head.

4. Always verify the proper size connector for the conductor, by checking the color code and the printing on

the connector.

5. If the tool is kept in cold temperatures below 23°F/-5°C for any extended time, it is advisable to return the

tool to room temperature for 1 hour before using.

6. Keep the tool head portion clean and free from debris. Excessive dirt and grit can contribute to the premature wear of

the tool's internal parts. Always replace the dust cap on the connector fitting, and store the tool in its clean, dry carrying case when not in use. When using the tool, regularly check that no foreign matter or debris exists in the open areas

between the ram and tool head. Solvent can be used on the tool head to remove any foreign matter or debris. A tool

that is dirty with excessive foreign matter may jam and become damaged during operation.

7. To ensure a quality connection, the CT-930CH and CT-940CH Tools must be used with a hydraulic pump capable of

developing and sustaining 10,000 PSI pressure. These tools are matched with

PANDUIT

's CT-901HP Hydraulic Pump

and CT-900HPH Hydraulic Hose system.

The CT-930LPCH Tool must be used with a hydraulic pump capable of developing and sustaining 7,500 PSI pressure.

This tool is matched with

PANDUIT

's CT-8250HP Hydraulic Pump and CT-900LPHPH Hydraulic Hose system.

Consult

PANDUIT

Sales for Hydraulic Pump and Hose specifications.

8. Avoid dropping the tool. Extreme shock may damage the hydraulic circuit or tool head, and result in malfunction of the

tool.

9. As long as the daily maintenance procedures are adequately carried out, the tool will provide quality service for years.

However, if problems are experienced, please contact

PANDUIT'

s Tool Service Department at 1-888-506-5400, ext.

3255.

DIE SELECTION

Match index number and color on die (see figures on Page 5) to index number and color band on connector.

NOTE: Consult your

PANDUIT

catalog or Sales Office for wire size, crimp designations, U.L. listing and C.S.A. certifica-

tion (where applicable) of connections using the CT-930CH, CT-930LPCH and CT-940CH Tool.

WARNING: Keep fingers clear of dies and ram during tool operation.

Do not operate tool without dies and connector in place.

DO NOT USE THIS TOOL ON LIVE ELECTRICAL CIRCUITS

PRECAUTIONS AND GENERAL GUIDELINES FOR MAINTENANCE OF TOOLS

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Page 5

Page: 4 of 6

DIE IDENTIFICATION FOR USE WITH MATCHED CONNECTOR

1. Always verify correct die set by die part number.

2. Color coding dot for verification may be found near die crimp pocket.

CD-920 SERIES DIES

CD-940 SERIES DIES

RED P21

CD920-8

PANDUIT

P21

DIE COLOR CODE AND DIE

INDEX NUMBER FOR COPPER

AND ALUMINUM COMPRESSION

DIES.

DIE COLOR DOT

PANDUIT

PART

NUMBER

P106

PANDUIT

CD-940-750

P106

PANDUIT

PART

NUMBER

DIE COLOR DOT

DIE COLOR CODE AND

DIE INDEX NUMBER FOR

COPPER AND ALUMINUM

COMPRESSION DIES.

CAUTION: DO NOT operate tool without dies installed.

1. Select the appropriate dies to match the connector to be crimped.

2. Align one of the die halves in the die cavity contour in the tool head or ram. While depressing the die release buttons,

slide the die half so it is seated in the die cavity. Release the die release buttons and check to ensure the die is locked

into place. Repeat procedure with second die half.

DIE INSTALLATION

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Page 6

Page: 5 of 6

CT-930LPCH

Panduit Corp., Tinley Park, IL

DUST

CAP

RAM

SNAP

COUPLING

WARNING

DO NOT USE ON LIVE

ELECTRICAL CIRCUITS

DIE RELEASE BUTTON

(FAR SIDE)

DIE RELEASE

BUTTON

TOOL HEAD

CHAIN

DUST

CAP

COUPLING

RAM

TOOL

HEAD

DIE CAVITY

DIE RELEASE BUTTONS

CT -940CH

HYDRAULIC COMPRESSION TOOL

T

OOL OPERATION

(See figures above)

1. The CT-930CH and CT-940CH Tool Heads must be operated with a compatible hydraulic pump system, capable of

developing and sustaining 10,000 PSI (700 kg/cm2).

PANDUIT

's CT-901HP Hydraulic Pump and CT-900HPH High

Pressure Hose (electrically non-conductive; 10 foot long) is recommended. This system's fittings are matched to the

tool head fittings.

The CT-930LPCH Tool Head must be operated with a compatible hydraulic pump system, capable of developing and

sustaining 7,500 PSI (525 kg/cm2).

PANDUIT

's CT-8250HP Hydraulic Pump and CT-900LPHPH Low Pressure Hose

(electrically non-conductive; 10 foot long) is recommended. This system's fittings are matched to the tool head fittings.

2. The CT-930CH, CT-930LPCH and CT-940CH Tool Heads have been charged with hydraulic fluid at the factory.

Remove the dust cap from the connector coupling on the tool.

CAUTION: Upon removing the dust cap, be sure to keep the hydraulic fittings on the tool head, hydraulic pump and

hydraulic hose free from contaminates. Failure to do so may lead to malfunction of the tool head and/or

hydraulic pump.

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Page 7

Page: 6 of 6

T

OOL OPERATION

(continued)

3. Connect the coupling of the tool head onto the coupling of the hydraulic hose.

4. Refer to the operation manual provided with your particular hydraulic pump system for the specific set-up operation,

and maintenance of the hydraulic pump. Verify that the open areas between the ram and tool head are free of foreign

matter and debris that could jam or damage the tool during operation. Cycle the tool head 2 or 3 times by activating

the hydraulic pump. Be sure dies are in the tool head prior to cycling the tool.

Check for leaks at all connections.

5. Carefully place the connector between the dies so that the dies will crimp between the color bands on the connector.

Activate the pump to advance the ram until the connector is held by the dies.

CAUTION: DO NOT crimp the connector at this time.

6. Verify that the conductor size and dies properly match the connector size being used. Insert the conductor completely into the connector barrel.

7. Begin crimping by activating the hydraulic system. The

PANDUIT

CT-901HP and CT-8250HP Hydraulic Pumps incor-

porate a by-pass valve which, when activated, shuts off the pump when the crimp is completed.

8. Deactivate the hydraulic system to retract the ram for removal or repositioning of the connector/conductor assembly.

MAINTENANCE

PERIODIC MAINTENANCE

1. Daily maintenance is important to keep the tool in good working condition. Keep the head clean and free of debris.

Excessive dirt and grit can contribute to the premature wear of the tool's mechanical parts. Always replace the dust

cap on the connector fitting, and store the tool in its clean, dry carrying case when not in use.

2. Particular attention should be made in keeping the tool head openings free of foreign matter and debris. When using

the tool regularly, check that no foreign matter or debris exists in the open areas between the ram and tool head.

Thoroughly clean and lubricate the tool head. A tool that is dirty with excessive foreign matter may jam and become

damaged during operation.

3. The hydraulic system has been calibrated and sealed at the factory. Consult our Tool Service Department if hydraulic

problems are experienced.

4. As long as the daily maintenance procedures are adequately carried out, the tool will provide quality service for years.

However, if problems are experienced, please contact our Tool Service Department at (888) 506-5400, ext. 3255.

INSPECTION OF COMPRESSION FORCE

Inspect the compression force of the crimp head monthly, whenever possible damage has occurred, or as often as operating conditions warrant.

CT-930CH, CT-930LPCH and CT-940CH OPERATING INSTRUCTIONS

Loading...

Loading...