Page 1

TO:

作成日 Issue Date:

改订日 Revision Date:

规格书编号

File No.

PN-RD-0023B

2012 年(Y)09 月(M)25 日(D)

2012 年(Y)11 月(M)02 日(D)

《新规 · 变更》

New Revision

产 品 规 格 书

Product Specification

【接收印栏】

产品名

Product

机种名

Model

TFT-LCD OPEN CELL

LC315TU3A

※ 本基准书由封面、附件等全 23 页构成。

如果对该规格书有异议,请在下订单前提出。

※ This Product Specification have 23 pages including the coversheet and Appendices. Please negotiate

the objection point before purchase order.

中电熊猫集团

南京中电熊猫液晶显示科技有限公司

研发中心 设计整合部

CEC PANDA GROUP

NANJING CEC PANDA LCD TECHNOLOGY CO., LTD.

R&D CENTER, DESIGN INTEGRATION SECTION.

Page 2

PANDA

LC315TU3A Specification Version 1.0

-CONTENTS –

RECORDS OF REVISION .............................................................................................................. 3

1. APPLICATION ............................................................................................................................... 4

OVERVIEW ................................................................................................................................... 4

2.

3. MECHANICAL TECHNICAL LITERATURES ............................................................................... 4

4. PIXEL ARRAY AND MEMBER LOCATION .................................................................................. 5

5. INPUT TERMINALS ...................................................................................................................... 5

5.1 TFT PANEL DRIVING............................................................................................................................... ..............5

5.2 INTERFACE BLOCK DIAGRAM.......................................................................................................................... 7

5.3 BLOCK DIAGRAM (OPEN-CELL)....................................................................................................................... 7

6. ELECTRICAL CHARACTERISTICS ............................................................................................. 9

6.1 ABSOLUTE MAXIMUM RATING.......................................................................................................................... 9

6.2 CONTROL CIRCUIT DRIVING..............................................................................................................................9

7. TIMING CHARACTERISTICS OF INPUT SIGNALS .................................................................. 11

7.1 TIMING CHARACTERISTICS.............................................................................................................................11

7.2 LVDS SIGNAL CHARACTERISTICS................................................................................................................. 12

8. INPUT SIGNAL, BASIC DISPLAY COLORS AND GRAY SCALE OF EACH COLOR .............. 14

OPTICAL CHARACTERISTICS .................................................................................................. 15

9.

10. HANDLING PRECAUTIONS OF THE OPEN-CE LL ................................................................... 17

11. PACKING FORM ......................................................................................................................... 17

12. RELIABILITY TEST ITEM ........................................................................................................... 18

13. OTHERS ...................................................................................................................................... 19

14. EPS BOX STORAGE CONDITION ............................................................................................. 20

15. PRECAUTIONS ........................................................................................................................... 20

2

Page 3

PANDA

r

LC315TU3A Specification Version 1.0

RECORDS OF REVISION

DATE NO.

REVISED

MODEL No. : LC315TU3A

PAGE SUMMARY NOTE

No.

2012/09/25 PN-RD-0023B T1.0 23 First Edition

P5. Change the Using connecto

2012/11/02 PN-RD-0023B V1.0

5,6,9,

P6.Add BIST mode function.

P9.Update the date of I

15

P15.Update

optical characteristics.

CC, IRUSH.

type.

Tentative

Final

3

Page 4

PANDA

r

LC315TU3A Specification Version 1.0

1. APPLICATION

This technical literature applies to the color 31.5” Wide XGA TFT-LCD LC315TU3A.

* These specification sheets are proprietary products of Nanjing CEC-Panda LCD Technology Co., LTD

(“CPL”) and include materials protected under copyright of CPL. Do not reproduce or cause any third

party to reproduce them in any form or by any means, electronic or mechanical, for any purpose, in

whole or in part, without the express written permission of CPL.

* This module is not designed to use in dusty environment and to prevent image retention caused by

long-term display of fixed pattern. So please consider items mentioned above before use and design

equipment.

* In case of using the device for applications such as control and safety equipment for transportation

(aircraft, trains, automobiles, etc.), rescue and security equipment and various safety related equipment

which require higher reliability and safety, take into consideration that appropriate measures such as

fail-safe functions and redundant system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace

applications, telecommunication equipment (trunk lines), nuclear power control equipment and medical

or other equipment for life support.

* CPL assumes no responsibility for any damage resulting from the use of the device that does not

comply with the instructions and the precautions specified in these technical literature.

* Contact and consult with a CPL sales representative for any questions about this device.

2. OVERVIEW

This module is color active matrix LCD Open-cell incorporating amorphous silicon TFT (Thin Film

Transistor). It is composed of a color TFT-LCD panel, driver ICs, etc. Graphics and texts can be

displayed on a 1366×RGB×768 dots panel with about 16,777,216 colors(R/G/B 8bit in each color) by

using LVDS(Low Voltage Differential Signaling) to interface, +12V of DC supply voltage.

In order to improve the response time of LCD, this module applies the Over Shoot driving (O/S

driving) technology for the control circuit. In the O/S driving technology, signals are being applied to the

Liquid Crystal according to a pre-fixed process as an image signal of the present frame when a

difference is found between image signal of the previous frame and that of the current frame after

comparing them.

By using the captioned process, the image signals of this LCD module are being set so that image

response can be completed within one frame, as a result, image blur can be improved and clear image

performance can be realized.

3. MECHANICAL TECHNICAL LITERATURES

Paramete

Display size

Active area 697.685(H) x 392.256(V) mm

Pixel Format

Pixel pitch 0.51075(H) x 0.51075 (V) mm

Pixel configuration R, G, B vertical stripe

Display mode Normally black

Outline Dimensions (*1),(*2)

Mass 1.18±0.1 kg

Surface treatment(*2)

Hard coating: 3H(CF Side)/ None(TFT Side )

(*1) Outline dimensions are shown in Fig.3-1, 3-2.

(*2) This specification is without the protection film.

Technical literatures Unit

80.039 (Diagonal) cm

31.5 (Diagonal) inch

1366(H) x 768(V)

(1pixel = R+G+B)

715.7(H) x455.5(V) x 4.0 (D)

(Open cell (with PWB))

715.7(H)×411.2(V)×1.75(D)

( Multi-cell (Without PWB) )

Anti glare

Low haze (15 or less)

4

pixel

mm

mm

Page 5

PANDA

LC315TU3A Specification Version 1.0

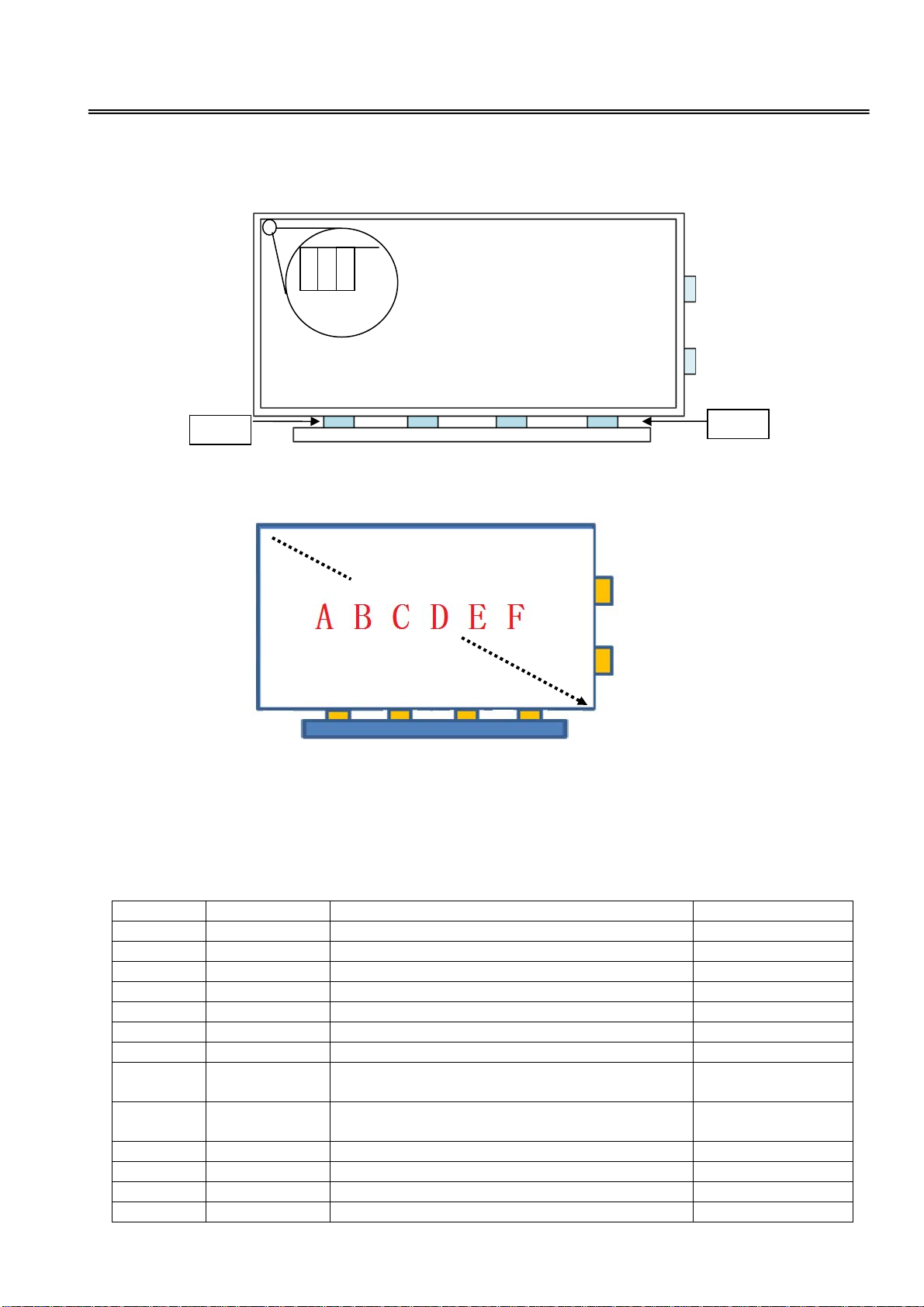

4. PIXEL ARRAY AND MEMBER LOCATION

Pixel array and member located as below.

There are 4 Source Drivers (1026 input terminals S-Dr) on this panel.

R

B

G

(1,1)

(1366,768)

COF 4

Please use this Open Cell like following figure.

Fig.4-1 Pixel array and member location

Scan direction

Fig.4-2 Scan direction

5. INPUT TERMINALS

5.1 TFT PANEL DRIVING

CN1 (Interface signals and +12V DC power supply) shown on the next table.

Using connector:

Matching connector: FI-X30C2L(Japan Aviation Electronics Ind., Ltd) or equivalent device.

Matching LVDS transmitter: THC63LVDM83R (THine) or equivalent device.

Pin No. Symbol Remark

1 VCC +12V Power Supply

2 VCC +12V Power Supply

3 VCC +12V Power Supply

4 VCC +12V Power Supply

5 GND Ground

6 GND Ground

7 GND Ground

8 WP

9 SELLVDS Select LVDS data format[Note1] Default: pull down

10 Reserved Not Available

11 GND Ground

12 RIN0- Negative(-) LVDS differential data input LVDS

13 RIN0+ Positive(+) LVDS differential data input LVDS

FI-X30SSLA-HF-R2500(Japan Aviation Electronics Ind.,Ltd) or equivalent device.

EEPROM Write Protection (for P-Vcom)

(0V~0.7V_Disable,2.7V~3.3V/Open _Enable)

5

COF 1

(L:GND) [Note2]

Page 6

PANDA

LC315TU3A Specification Version 1.0

14 GND Ground

15 RIN1- Negative(-) LVDS differential data input LVDS

16 RIN1+ Positive(+) LVDS differential data input LVDS

17 GND Ground

18 RIN2- Negative(-) LVDS differential data input LVDS

19 RIN2+ Positive(+) LVDS differential data input LVDS

20 GND Ground

21 CLKIN- Clock Signal(-) LVDS

22 CLKIN+ Clock Signal(+) LVDS

23 GND Ground

24 RIN3- Negative(-) LVDS differential data input LVDS

25 RIN3+ Positive(+) LVDS differential data input LVDS

26 GND Ground

27 NC Not connection, this pin should be open. [Note 3]

28 SCL Serial clock input (for P-Vcom)

29 SDA Serial data input (for P-Vcom)

30 GND Ground

[Note 1] SELLVDS

Transmitter SELLVDS

Pin No Data

51 TA0 R0(LSB) R2

52 TA1 R1 R3

54 TA2 R2 R4

55 TA3 R3 R5

56 TA4 R4 R6

3 TA5 R5 R7(MSB)

4 TA6 G0(LSB) G2

6 TB0 G1 G3

7 TB1 G2 G4

11 TB2 G3 G5

12 TB3 G4 G6

14 TB4 G5 G7(MSB)

15 TB5 B0(LSB) B2

19 TB6 B1 B3

20 TC0 B2 B4

22 TC1 B3 B5

23 TC2 B4 B6

24 TC3 B5 B7(MSB)

27 TC4 NA NA

28 TC5 NA NA

30 TC6 DE(*) DE(*)

50 TD0 R6 R0(LSB)

2 TD1 R7(MSB) R1

8 TD2 G6 G0(LSB)

10 TD3 G7(MSB) G1

16 TD4 B6 B0(LSB)

18 TD5 B7(MSB) B1

25 TD6 NA NA

NA: Not Available

(*)The display position is prescribed by the rise of DE (Display Enable) signal, please do not fix DE

signal during operation at "High."

VESA

= L(GND) or Open

6

JEITA

=H(3.3V)

Page 7

PANDA

(15)

(

)

LC315TU3A Specification Version 1.0

[Note 2] The equivalent circuit figure of the terminal

Fig.5-1 The equivalent circuit figure of the terminal

[Note 3] Built-in Self Test (BIST)

*1) PIN27=NC: Disable BIST function.

Available LVDS Signal input : Display LVDS input Pattern.

No LVDS Signal or unavailable LVDS Signal input : Display Black Pattern.

*2) PIN27=High (3.0V~3.6V) : Enable BIST function.

Available LVDS Signal input : Display LVDS input Pattern.

No LVDS Signal or unavailable LVDS Signal input : Display BIST Pattern.

5.2 INTERFACE BLOCK DIAGRAM

Corresponding Transmitter: THC63LVDM83R (THine) or equivalent device.

(TVside)

R0~R7

G0~G7

B0~B7

ENAB

(controller)

8

8

8

CLK

LVDS

TTL

PLL

Rx1IN0+(13)

Rx1IN0-(12)

Rx1IN1+(16)

Rx1IN1Rx1IN2+(19)

Rx1IN2-(18)

Rx1IN3+(25)

Rx1IN3-(24)

Rx1CLKIN+(22)

Rx1CLKIN-(2 1)

TFT - LCD side

8

R0~R7

LVDS

TTL

PLL CLK

8

8

G0~G7

B0~B7

ENAB

Internal circuits

Fig.5-2 Interface block diagram

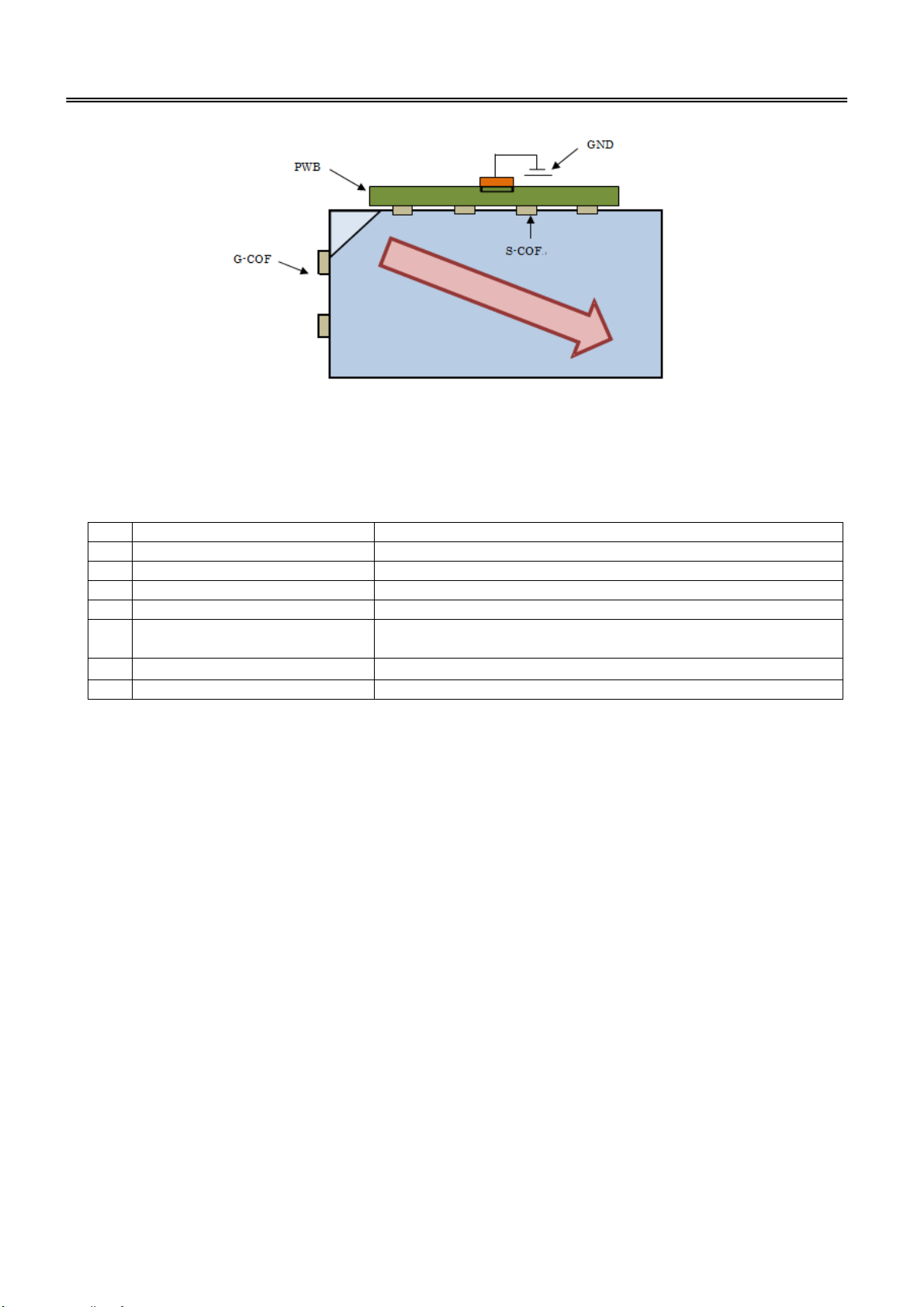

5.3 BLOCK DIAGRAM (OPEN-CELL)

Fig.5-3 block diagram (Open-cell)

7

Page 8

PANDA

LC315TU3A Specification Version 1.0

R0~R7:Pixel R DATA(R7:MSB , R0:LSB)

G0~G7:Pixel G DATA(G7:MSB , G0:LSB)

B0~B7:Pixel B DATA(B7:MSB , B0:LSB)

DE:DATA enable Signal

Fig.5-4 LVDS data map

8

Page 9

PANDA

r

LC315TU3A Specification Version 1.0

6. ELECTRICAL CHARACTERISTICS

6.1 ABSOLUTE MAXIMUM RATING

Paramete

Input voltage VI

+12V supply voltage VCC

Storage temperature T

Operation temperature T

[Note 1] SELLVDS

[Note 2] Max Humidity: 90%RH. (Ta≦40℃)

6.2 CONTROL CIRCUIT DRIVING

+12V supply

voltage

Permissible input ripple

Differential input

threshold

voltage

Input Low voltage VIL 0 0.7 V

Input High voltage

Symbol Condition Ratings Unit Remark

-

stg

-

opa

Wet-bulb temperature should be 39℃Max. (Ta>40℃).

No condensation.

Parameter Symbol Min. Typ. Max. Unit Remark

Supply voltage

Current

dissipation

voltage

High

Low

V

ICC

IRUSH

V

VTH

V

V

Ta= 25℃ -0.3~3.6

Ta= 25℃ 0~+14

-20~+60

0~+50

CC

RP

TL - - -100 mV

IH

+10.8 +12.0 +13.2 V [Note 1]

- 350 600 mA [Note 2]

- - 6 A [Note 5]

- - 100 mVp-p Vcc=+12.0V

100 - - mV

2.7 - 3.3 V

V [Note 1]

V

℃

℃

[Note 2]

[Note 4]

[Note 3]

Input leak current (Low) IIL - - 400 µA VI=0V [Note 3]

Input leak current (High) IIH - - 100 µA VI =3.3V [Note 3]

Terminal resistor RT - 100 - Ω Differential input

Input Differential voltage |VID| 200 400 600 mV [Note 4]

Differential input

common mode voltage

VCM: Common mode voltage of LVDS driver.

[Note 1]

Input voltage sequences

50us ≦ t1 ≦ 20ms a) 9.1V ≦ V

20ms < t2-1 td ≦ 10ms

20ms < t2-2 b) V

0 < t3-1≦1s Dip conditions for supply voltage is

0 < t3-2≦1s based on input voltage sequence.

1s ≦ t4

500ms ≦ t5-1

500ms ≦ t5-2

0 < t6-1

0 < t6-2

VCM |VID|/2 1.2

2.4-|VID|/2

Dip conditions for supply voltage

< 9.1V

CC

V [Note 4]

< 10.8V

CC

9

Page 10

PANDA

LC315TU3A Specification Version 1.0

0.1Vcc

V cc

Data1

Data2

B a ck lig h t:V

0.9Vcc

t1

t2-1

t2-2

INV

t5-1

OFF

t5-2

ON

ON

ON

t6-2

t6-1

t3-1

t3-2

0.9Vcc

0.1Vcc 0.1Vcc

t4

td

OFF

Fig. 6-1 Input voltage sequences Fig. 6-2 Dip conditions for supply voltage

Vcc

10.8V

9.1V

* Data1: CLKIN±,RIN0±,RIN1±, RIN2±, RIN3±

* Data2: SELLVDS

* About the relation between data input and back light lighting, please base on the above-mentioned

input sequence.

When back light is switched on before panel operation or after a panel operation stop, it may not

display normally. But this phenomenon is not based on change of an incoming signal, and does not

give damage to a liquid crystal display.

[Note 2] Typical current situation: 256 gray-bar pattern (VCC = +12.0V).

The explanation of RGB gray scale is seen in section 8.

Fig. 6-3 Typical current situation

[Note 3] SELLVDS

[Note 4] CLKIN+/CLKIN-, RIN0+/RIN0-, RIN1+/RIN1-, RIN2+/RIN2-, RIN3+/RIN3-

*CK-, *IN-

*CK+, *IN+

GND

Fig. 6-4 LVDS input characteristics

V

TH

VTL

|VID|

VCM

10

Page 11

PANDA

0.1 Vcc

500us

LC315TU3A Specification Version 1.0

[Note 5] The Rush current corrugation at the time of power on.

Ton: Vcc(+12V) Rising Time

0.9 Vcc

Vcc=12V

I

RUSH

Current of Vcc 12V

Fig. 6-5 The waveform of rush current

7. TIMING CHARACTERISTICS OF INPUT SIGNALS

7.1 TIMING CHARACTERISTICS

Parameter Symbol Min

Frequency Fclk=1/Tc 72 82 82 85 MHz

Spread Spectrum

Clock

Data

enable

signal

*Timing diagrams of input signal are shown in Fig. 7-1.

* SSCG (Spread spectrum clock generator) is defined as Fig. 7-2.

Modulation range

Spread Spectrum

Modulation frequency

Horizontal period TH

Horizontal period

(High)

Horizontal Blanking

period

Vertical period TV

Vertical period (High) TVd 768 768 768 768 line

Vertical Blanking

period

Fclk_mod Fclk-3%

SSM

F

THd 1366 1366 1366 1366 clock

TH-THd 174 330 330 574 clock

TV-TVd 10 38 199 204 line

30

1540 1696 1696 1940 clock

17.15 20.68 20.68 21.42 µs

778 806 967 972 line

47.7 60 50 62.35 Hz

From 10%Vcc to 90%Vcc

I: Current of Vcc(+12V)

I

RUSH

After Vcc rise.

[HOW TO]

Measure the Vcc(12V) when you turn

the power on. At the same time,

measure the current of Vcc(12V).

The single mode of the oscilloscope is

useful in this case.

NTSC PAL

--

--

: The max current

Typ.

Max. Unit

Fclk+3% MHz

100 KHz

11

Page 12

PANDA

LC315TU3A Specification Version 1.0

Fig.7-1 Timing characteristics of input signals

Fig.7-2 Spread spectrum clock generator

7.2 LVDS SIGNAL CHARACTERISTICS

CLKCLK+

RINxRINx+

tpd0

Vdiff=0V

tpd1

tpd2

tpd3

tpd4

tpd5

tpd6

Fig.7-3 LVDS signal characteristics

t

CLK

12

Page 13

PANDA

Delay time, CLK rising edge

to serial bit position 0

Delay time, CLK rising edge

to serial bit position 1

Delay time, CLK rising edge

to serial bit position 2

Data

position

Delay time, CLK rising edge

to serial bit position 3

Delay time, CLK rising edge

to serial bit position 4

Delay time, CLK rising edge

to serial bit position 5

Delay time, CLK rising edge

to serial bit position 6

LC315TU3A Specification Version 1.0

The item Symbol min. typ. Max. unit

tpd0

tpd1

tpd2

tpd3

tpd4

tpd5

tpd6

-0.40 0 0.40

typ-0.40

typ-0.40

typ-0.40

typ-0.40

typ-0.40

typ-0.40

1*

2*

3*

4*

5*

6*

t

/7

CLK

t

/7

CLK

t

/7

CLK

t

/7

CLK

t

/7

CLK

t

/7

CLK

typ+0.40

typ+0.40

typ+0.40

typ+0.40

typ+0.40

typ+0.40

ns

13

Page 14

PANDA

LC315TU3A Specification Version 1.0

8. INPUT SIGNAL, BASIC DISPLAY COLORS AND GRAY SCALE OF EACH COLOR

0: Low level voltage,

1: High level voltage.

Each basic color can be displayed in 256 gray scales from 8 bit data signals. According to the

combination of total 24 bit data signals, the 16,777,216 colors display can be achieved on the screen.

Fig.8-1 Input Signal

14

Page 15

PANDA

LC315TU3A Specification Version 1.0

9. OPTICAL CHARACTERISTICS

Parameter Symbol Condition Min. Typ. Max. Unit Remark

Viewing

angle range

Contrast ratio CR

Horizontal

Vertical

θ21

θ22

θ11

θ12

CR≥10

Ta= 25 °C

- 88 - Deg.

[Note1,4]

- 88 - Deg.

- 5000 - - [Note2,4]

Response time

Chromaticity of white

Chromaticity of red

Chromaticity of green

Chromaticity of blue

White variation δW - - -

*The measurement shall be executed 60 minutes after lighting at rating.

*These values are measured with CPL LED back light unit.

*The optical characteristics are measured using the following equipment.

Detector(EZ-CONTRAST/ Photodiode)

τ

DRV

x

y 0.290 -

θ

x 0.637 y 0.350 x 0.294 y 0.638 x 0.149 y 0.074 -

=0 deg.

- 7 - ms [Note3,4,5]

0.272

Typ-0.03

500mm

-

Typ+0.03

1.3

Detector(SR-3)

- [Note 6]

[Note 4]

Middle of the screen (

TFT-LCD Module

Fig.9-1 Measurement of Viewing angle range

and Response time.

(Viewing angle range: EZ-CONTRAST,

Response time: Photodiode)

θ

=0°)

Field=2°

Middle of the screen (

TFT-LCD Module

Fig.9-2 Measurement of Contrast, Luminance,

Chromaticity, White variation

θ

=0°)

15

Page 16

PANDA

r

r

r

θ

θ11θ

θ

τ

LC315TU3A Specification Version 1.0

[Note 1] Definitions of viewing angle range:

Normal line

21

12

22

6 o’clock direction

Fig.9-3 Viewing angle

[Note 2] Definition of contrast ratio:

The contrast ratio is defined as the following.

Contrast Ratio =

Luminance (Brightness) with white screen

Luminance (Brightness) with black screen

[Note 3] Definition of response time

The response time (τ

) is defined as the following figure and shall be measured by switching

DRV

the input signal for “any level of gray (0%, 25%, 50%, 75% and 100%) and “any level of gray (0%,

25%, 50%, 75% and 100%).

0% 25% 50% 75% 100%

0%

25%

50%

75%

100%

:25%–0%

τ

d

:50%–0% τd:50%–25%

τ

d

:75%–0% τd:75%–25% τd:75%–50%

τ

d

:100%–0% τd:100%–25% τd:100%–50% τd:100%–75%

τ

d

τ

:0%–25% τr:0%–50% τr:0%–75% τr:0%–100%

τ

:25%–50% τr:25%–75% τr:25%–100%

r

τ

:50%–75% τr:50%–100%

τ

τ*:x-y...response time from level of gray(x) to level of gray(y)

=Σ (τ*:x-y)/20

τ

DRV

Photodetector

Output

(Relative Value)

any level of gray

(bright)

100%

90%

10%

0%

τd:*

any level of gray

(dark)

Fig.9-4 Response time

any level of gray

(bright)

:*

time

[Note 4] This shall be measured at center of the screen.

When black brightness is a max value, the specification of the contrast is satisfied.

[Note 5] This value is valid when O/S driving is used at typical input time value.

[Note 6] Definition of white variation:

White variation is defined as the following with five measurements. (A~E)

:75%–100%

16

Page 17

PANDA

LC315TU3A Specification Version 1.0

Fig.9-5 measurement locations of white variation

10. HANDLING PRECAUTIONS OF THE OPEN-CELL

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) Be sure to design the cabinet so that the module can be installed without any extra stress such as

warp or twist.

c) Since the front polarizer is easily damaged, pay attention not to scratch it.

d) Since long contact with water may cause discoloration or spots, wipe off water drop immediately.

e) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

f) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface.

Handle with care.

g) Since CMOS LSI is used in this module, take care of static electricity and take the human earth

into consideration when handling.

h) The module has a printed circuit boards (PCB) on the back side, take care to keep it from any

stress or pressure when handling or installing the module; otherwise some of electronic parts on

the PCB may be damaged.

i) Observe all other precautionary requirements in handling components.

j) When some pressure is added onto the module from rear side constantly, it causes display

non-uniformity issue, functional defect, etc. So, please avoid such design.

k) When giving a touch to the panel at power on supply, it may cause some kinds of degradation. In

that case, once turn off the power supply, and turn on after several seconds again, and that is

disappear.

l) When handling LCD modules and assembling them into cabinets, please be noted that long-term

storage in the environment of oxidization or deoxidization gas and the use of such materials as

reagent, solvent, adhesive, resin, etc. which generate these gasses, may cause corrosion and

discoloration of the LCD modules.

m) This LCD module is designed to prevent dust from entering into it. However, there would be a

possibility to have a bad effect on display performance in case of having dust inside of LCD

module. Therefore, please ensure to design your TV set to keep dust away around LCD module.

11. P A CKING FORM

(a)Piling number of Pallet : 14 cell boxes/1 pallet

(b)Packing quantity in one EPS BOX : 15 pcs

(c)EPS BOX size : 829(L)×557(W)×141(H) mm

(d)Pallet size : 1140(L)×855(W)×150(H) mm

(e)Pallet size after packing(with 14 boxes) : 1140(L)×855(W)×1117(H) mm

(f) Total mass of one pallet filled with full open-cell : MAX 330 kg

17

Page 18

PANDA

LC315TU3A Specification Version 1.0

Spacer 16pcs

EPS BOX Body

EPS BOX Cover

Panel 15pcs

Cover Sheet

Corner Protector

Stretching film

PP Band 4pcs

PP BAND Protector

PP BAND 2pcs

Pallet

<7 Tiers 2 Rows>

Cell BOX Label

12. RELIABILITY TEST ITEM

No

.

High temperature storage test

1

Low temperature storage test

2

High temperature and high humidity

3

operation test

High temperature operation test

4

Low temperature operation test

5

Thermal shock test

6

7 Package vibration test

8 Package drop test

ESD

9

[Result evaluation criteria]

Under the display quality test condition with normal operation state, there shall be no change, which

may affect practical display function.

Test item Condition

Ta= 60°C 240h

Ta= -2 0°C 240h

Ta= 50°C ; 80%RH 240h

(No condensation)

Ta= 50°C 240h

Ta= 0°C 240h

-20℃/30mins, 60℃/30mins, 100 cycles

Wave form:Random

Vibration level:1.0 Grms

Frequency:5-50 Hz

Duration:X,Y,Z each direction per 10mins

Height:15cm (2 edges, 1 surface)

At the following conditions, it is a thing without

incorrect operation and destruction.

Both under Contact and Non-contact conditions,

apply electric discharge ±300V to the input terminal.

condition:200pF 0Ω under non-operation.

Carton Label

Cover Sheet

18

Page 19

PANDA

13. OTHERS

a) Panel label

a-1) The label of Multi-cell which is stuck on the front side of the panel.

15mm

a-2) The label of Open-cell which is stuck on component side of the PWB.

10mm

b) Packing label

b-1) EPS BOX b-2) Pallet

60mm

c) Adjusting volume has been set optimally before shipment, so do not change any adjusted value.

If adjusted value is changed, the specification may not be satisfied.

LC315TU3A Specification Version 1.0

P A N D A

XXX-XXXXXXXX-XXXX

XXXXXXXXX

PANDA

QUANTITY: 15

20XXXXXXXXXXX

RoHS

(a) Quantity

(b) Model No.

(c) Box ID

(d) Date

DATE: 20XX/XX/XX

MADE IN CHINA

Model No.

80mm

(a)

70mm

XXXXXXXXX

Panel ID

Fig.13-1 Multi-cell label

42mm

XXX-XXXXXXXX-XXXX

Fig.13-2 Open-cell label

XXXXXXXXX

(c)

Fig.13-3 Packing label

(b)

(d)

YYYY/MM/DD

Panel ID

客户名称:

物料代

出货日期:

19

RoHS

XX

Barcode

210mm

南京中电熊猫液晶显示科技有限公司

订单

名 :

品 名:

码

:

数 量:

栈

板号 :

检验

結果

合格

不合格

(e) Customer name

(f) Order No.

(g) Name of products

(h) Pallet No.

31.5”Open cell

LC315TU3A

210Pcs

质检

員

检验

日期

(e)

(f)

(g)

(b)

(a)

(h)

(d)

297mm

Page 20

PANDA

LC315TU3A Specification Version 1.0

d) Disassembling the module can cause permanent damage and should be strictly avoided.

e) Please be careful since image retention may occur when a fixed pattern is displayed for a long time.

f) The chemical compound, which causes the destruction of ozone layer, is not being used.

g) When any question or issue occurs, it shall be solved by mutual discussion.

Regulation to utilize an ozone depletion chemical substance.

h)

Restricted substance : CFCs, halon, carbon, tertrachloide, and 1,1,1-trichloroethane

This product don't include the above matter.

Production process of this product and parts don't include above matter.

14. EPS BOX STORAG E CONDITION

Temperature: 0°C to 40°C

Humidity: 80%RH or less

Reference condition: 20°C to 35°C, 80%RH or less (summer)

5°C to 15°C, 80%RH or less (winter)

The total storage time (40°C, 80%RH): 240h or less

Sunlight: Be sure to shelter a product from the direct sunlight.

Atmosphere: Harmful gas, such as acid and alkali which bites electronic components and/or wires

must not be detected.

Be sure to put cartons on palette or base, don’t put it on floor, and store them with removing from wall.

Please take care of ventilation in storehouse and around cartons, and control changing temperature is

within limits of natural environment.

Storage life 1 year

15. PRECAUTIONS

a) Because the Open-Cell is too weak to destroy by static electricity, please don’t touch the terminal

with bare hands.

b) Front polarizer can easily be damaged. Pay attention on it.

c) Since long contact with drops of water may cause discoloration or spots, please wipe off them as

soon as possible.

d) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

e) The Panel will be broken or chipped when it is dropped or bumped against a hard substance.

f) Precautions of peeling off the Protection film:

- Be sure to peel off slowly (recommended more than 7 sec.) and constant speed.

- Peeling direction shown in the Fig. 15-1.

- Be sure to ground person with adequate methods such as the anti-static wrist band.

- Be sure to connect PWB to GND while peeling off the protection film.

- Ionized air should be blown to the surface while peeling off the protection film.

- The protection film must not touch drivers and PWB.

- After the protection film has been peeled off, some adhesive may be remained on the polarizer.

Please use isopropyl-alcohol to remove it.

20

Page 21

PANDA

LC315TU3A Specification Version 1.0

Fig.15-1 Direction of peeling off

g) Since the Open-cell consists of TFT and electronic circuits with CMOS-ICs, which are very weak to

electrostatic discharge, persons who are handling an Open-Cell should be grounded though

adequate methods such as an anti-static wrist band. Connector pins should not be touched directly

with bare hands.

Reference: Process control standard of CPL.

item Management standard value and performance standard

1 Anti-static mat(shelf) 1to50[Mega ohm]

2 Anti-static mat(floor, desk) 1to100[Mega ohm]

3 Ionizer Attenuate from ±1000V to ±100V within two seconds.

4 Anti-static wrist band 0.8 to 10 [Mega ohm]

5 Anti-static wrist band entry and

ground resistance

6 Temperature

7 Humidity 60 to 70 [%]

h) Since the Open-cell has a PWB, please take care to keep it off any stress or pressure when

handling or installing the Open-cell, otherwise some of electronic parts on it may be damaged.

i) Be sure to turn off the power supply when inserting or disconnecting the cable.

j) Be sure to design the module and cabinet so that the Open-cell van is installed without any extra

stress such as warp or twist.

k) When handling and assembling Open-Cell into module, please be noted that long-term storage in

the environment of oxidization or deoxidization gas and the use of materials such as reagent,

solvent, adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration

of the Open-Cell.

l) Applying too much force and stress to PWB and drivers may cause a malfunction electrically and

mechanically.

m) The Open-cell has high frequency circuits. Sufficient suppression to EMI should be done by system

manufactures.

n) Please be careful since image retention may occur when a fixed pattern is displayed for a long

time.

o) The chemical compound, which causes the destruction of ozone layer, is not being used.

p) This Open-Cell module is corresponded to RoHS.

q) When any question or issue occurs, it shall be solved by mutual discussion.

Below 1000[ohm]

22 to 26 [℃]

21

Page 22

PANDA

LC315TU3A Specification Version 1.0

Fig.3-1. Front outline drawing

22

Page 23

PANDA

LC315TU3A Specification Version 1.0

Fig.3-2. Back outline drawing

23

Loading...

Loading...