Page 1

ORDER NO. VRD9802005C2

Video Cassette Recorder

Panasonicml

Z-MECHANISMCHASSIS

I

INTRODUCTION

The Z-Mechanism chassis are built in several Panasonic VHS Video Cassette

Recordersfrom NV-SD and NV-HD series in 1998.

WARNING

A

This service information isdesigned for experienced repair technicians only and is not designed for use by the general public. It does not contain

warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

IJroductor

Dt’OdUCtSdealt with in this service information by anyone else could result in serious injury or death.

.

(@1998 Matsushita Electric Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of

law,

Panasonic

Page 2

CONTENTS

1.

OUTLINE OF ZMECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1.

Thetapetransportpath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2.

Cassetteholderunit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3.

1-4.

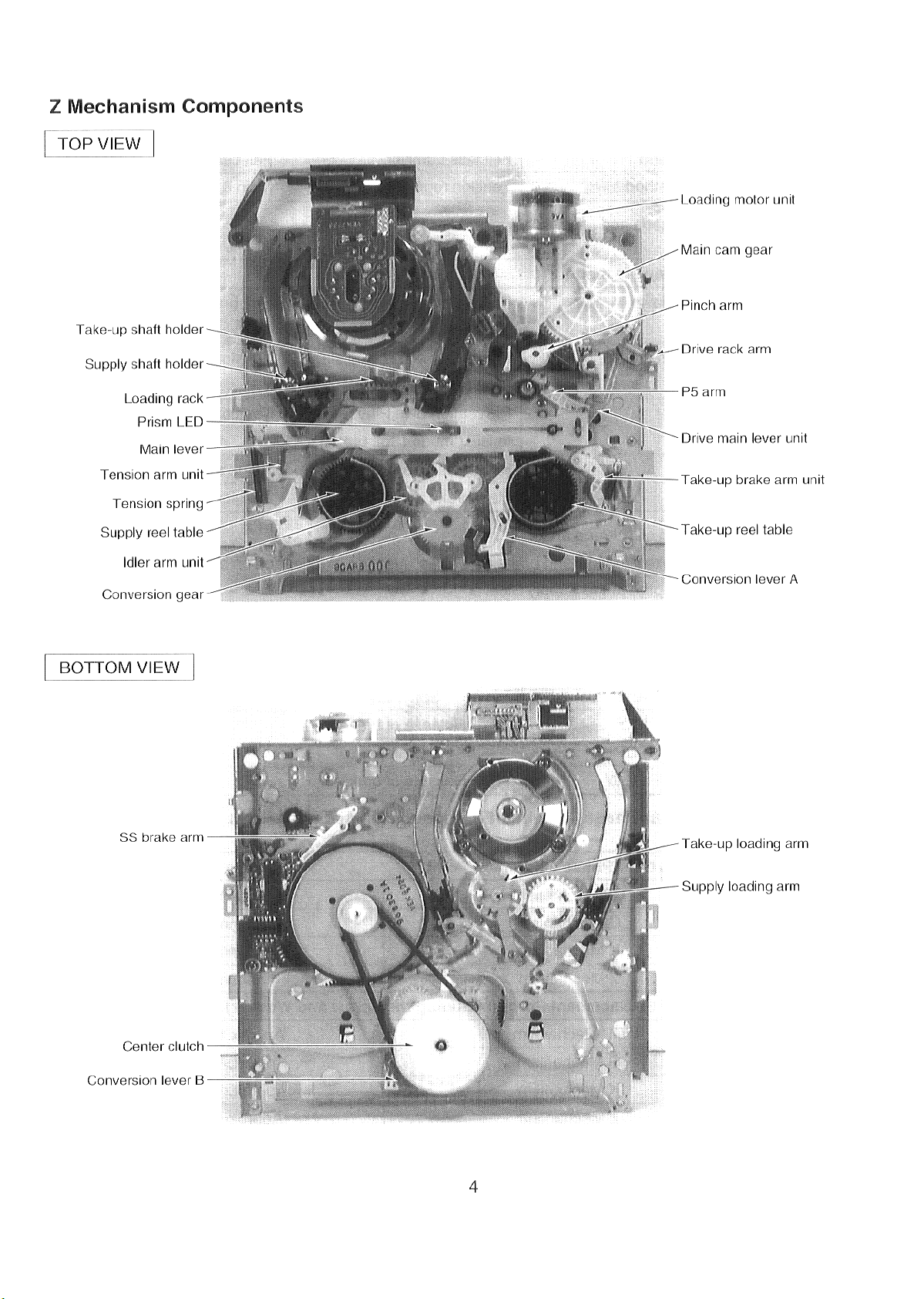

ZMechanismComponents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FLOWCHARTOF LOADING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REMOVALOFCASSEITETAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.

2-1. Removalofcompulsoryloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2. Removalofmanual operation ofMaincam gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

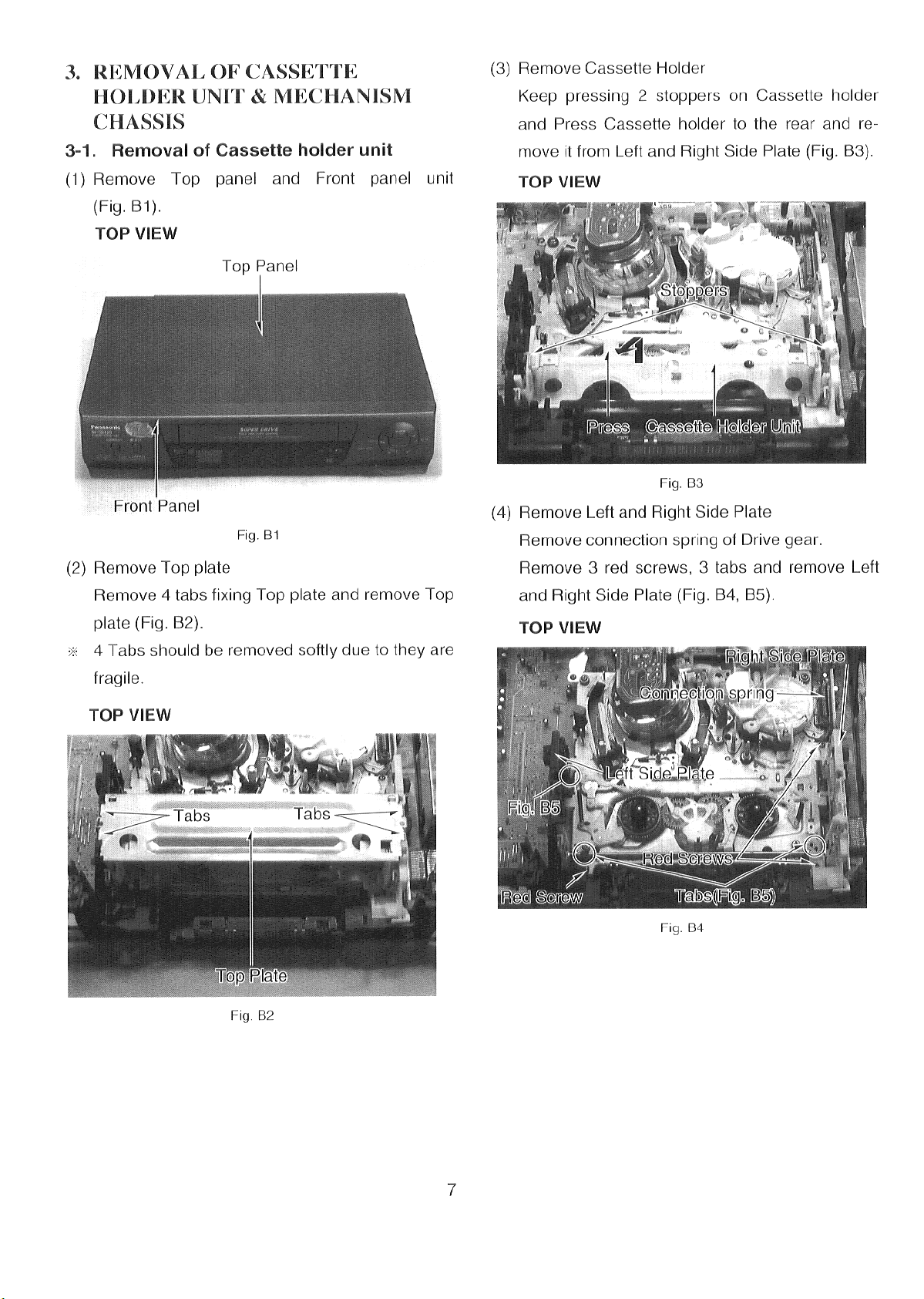

REMOVALOFCASSETTE HOLDER UNIT& MECHANISM Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3,

3-1. Removal ofCassetteholder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-2. RemovalofMechanismchassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DISASSEMBLY/ASSEMBLYMETHOD FORMECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.

4-1. Disassemblyofmechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4-2. Assemblyandphaseadjustment ofmechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4-3. Assemblyofmechanismchassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PartsAccess Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MECHANICALADJUSTMENT PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.

5-1. Tension postposition adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5-2. Backtensionadjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5-3.

5-4. Tapeinterchangeabilityadjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Servicing Fixtures&Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.

SELF-TESTINDICATION DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SERVICE INFORMATION DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.

7-1.

7-2. TurningonService information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7-3.

7-4.

7-5.

7-6. Timingchartfrom ModeSWto Systemcontrol lo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SYSTEM CONTROLCIRCUIT &MECHANISM CONTROLCIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.

8-1. STOP3Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8-2.

8-3. SupplyandTake-upSensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8-4. SafetyTabSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8-5. DewSensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8-6. Settingtimeforeach mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8-7. OperationofshortCUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8-8. Loading/Unloading Mechanism lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8-9. Cassetteloading/unloadinglock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8-10. Reel lockoperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8-11. Cylinderlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8-12. Modetransition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8-13. Poweron reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8-14. Lineartimecounteroperation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8-15. Tapespeed inCUE/REVmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8-16. Automaticfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8-17. CUE/REVlockmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8-18. FR(Forward/Reverse) search mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8-19. FF/REWspeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8-20. FF/REWtime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

EXPLODEDVIEWS &REPLACEMENT PARTS LIST

9.

9-1. MECHANICAL REPLACEMENT PARTS SECTION

Reel brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

NumberofGearPhaseAlignment Pointand Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

P2and P3postsadjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5-4-(I). P2ANDP3 POSTSADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5-4-(2). ADJUSTMENTOFP4 POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5-4-(3). HEIGHTADJUSTMENT OFA/C HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-4-(4). FINE-ADJUSTMENTOF A/CHEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-4-(5). ADJUSTMENTOFX-VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-4-(6). FINE-ADJUSTMENT OFX-VALUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PurposeofService information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

UseofService Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Service Information Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TestMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Stand-byintheSTOP3position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Page 3

1. OUTLINEOFZ MECHANISM

‘2’os’Fv=R’3’osT

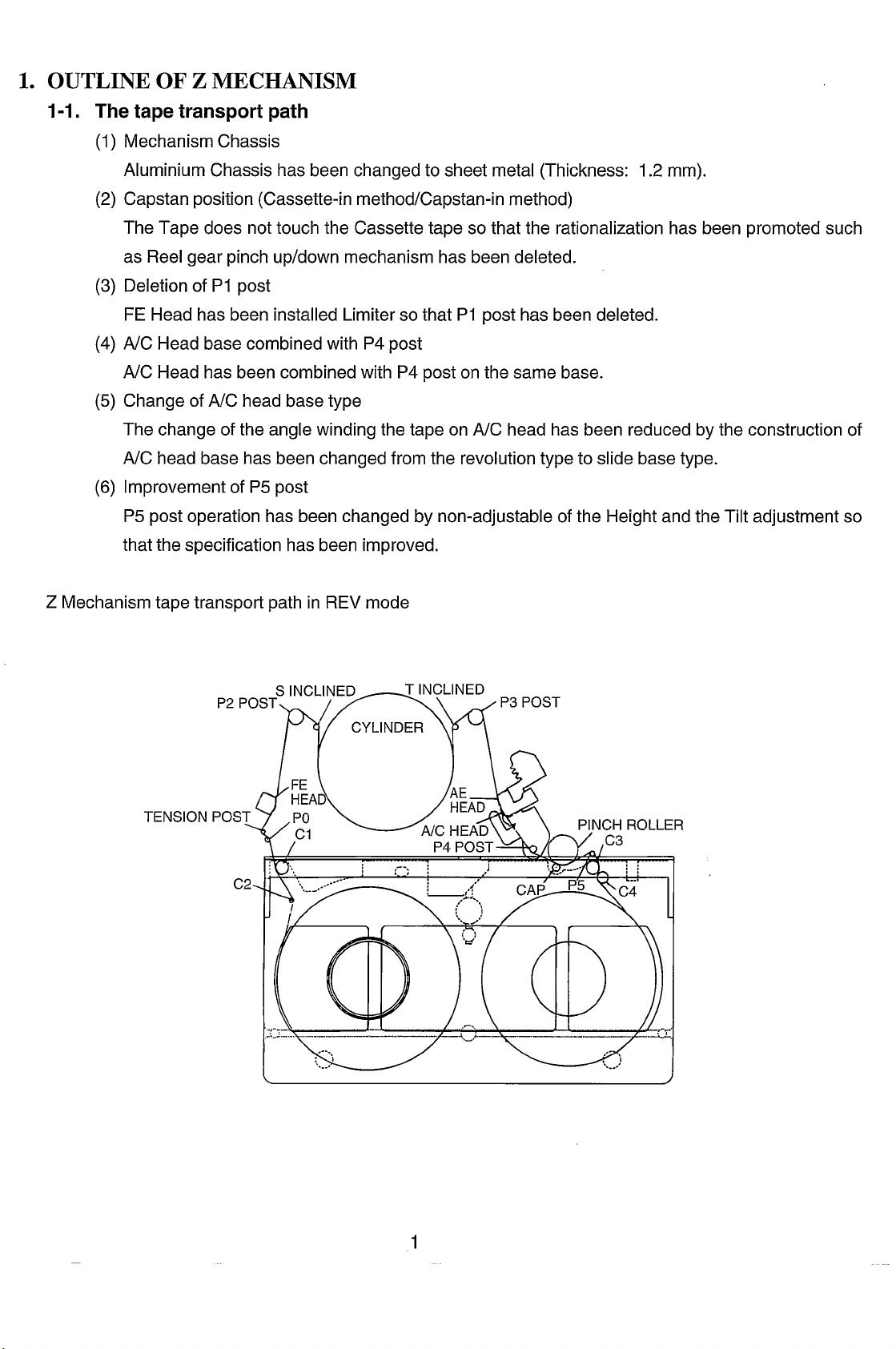

1-1. The tape transport path

(1)

Mechanism Chassis

Aluminium Chassis has been changed to sheet metal (Thickness: 1.2 mm).

(2)

Capstan position (Cassette-in method/Capstan-in method)

The Tape does not touch the Cassette tape so that the rationalization has been promoted such

as Reel gear pinch up/down mechanism has been deleted.

Deletion of PI post

(3)

FE Head has been installed Limiter so that PI post has been deleted.

(4)

A/C Head base combined with P4 post

A/C Head has been combined with P4 post on the same base.

Change of NC head base type

(5)

The change of the angle winding the tape on A/C head has been reduced by the construction of

A/C head base has been changed from the revolution type to slide base type.

Improvement of P5 post

(6)

P5 post operation has been changed by non-adjustable of the Height and the Tilt adjustment so

that the specification has been improved.

Z Mechanism tape transport path in REV mode

TENSION P“

Page 4

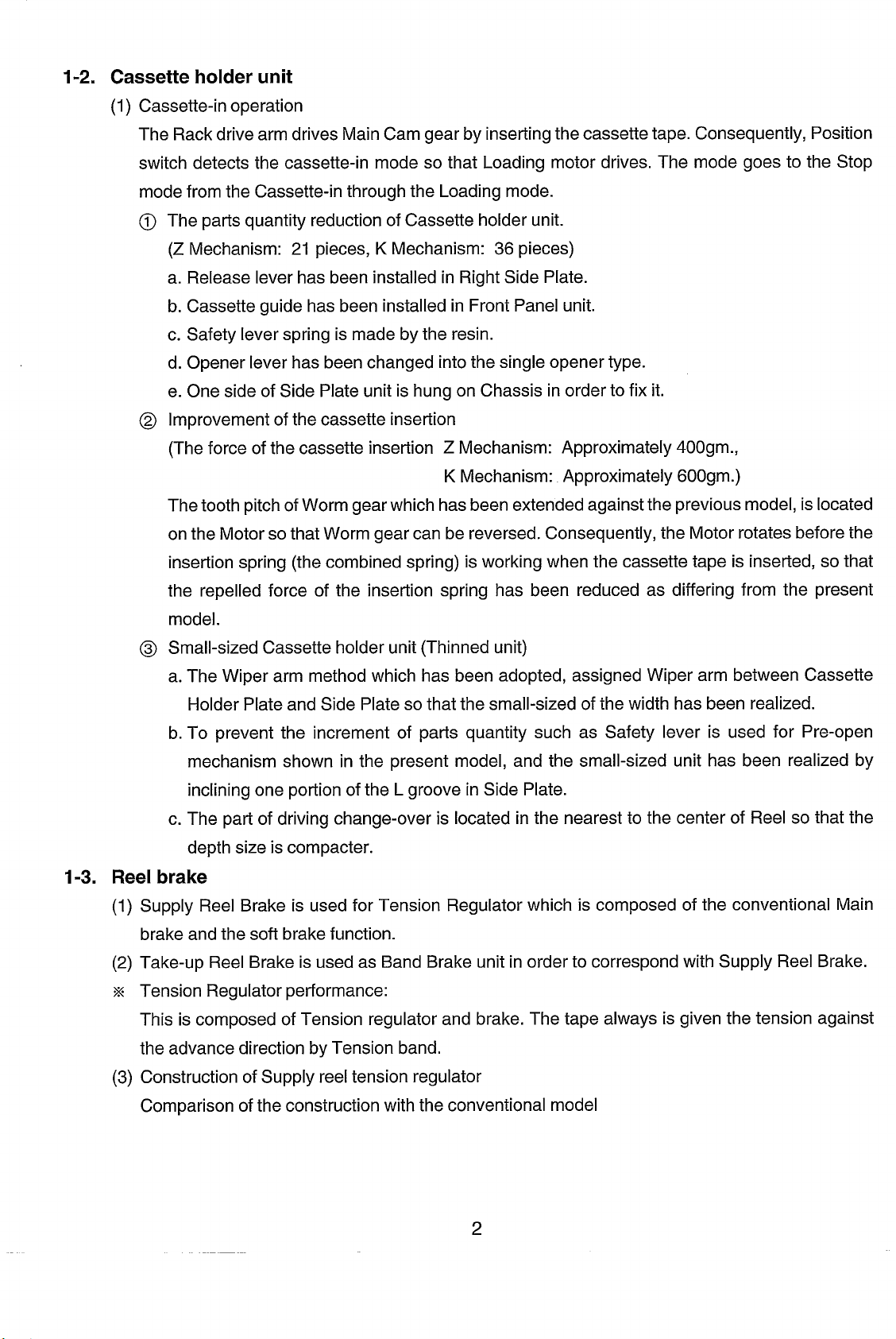

1-2. Cassette holder unit

(1)Cassette-in operation

The Rackdrive arm drives Main Cam gear by inserting the cassette tape. Consequently, Position

switch detects the cassette-in mode so that Loading motor drives. The mode goes to the Stop

mode from the Cassette-in through the Loading mode.

@) The parts quantity reduction of Cassette holder unit.

(Z Mechanism: 21 pieces, K Mechanism: 36 pieces)

a. Release lever has been installed in Right Side Plate.

b. Cassette guide has been installed in Front Panel unit.

c. Safety lever spring is made by the resin.

d. Opener lever has been changed into the single opener type.

e. One side of Side Plate unit is hung on Chassis in order to fix it.

@ Improvement of the cassette insertion

(The force ofthe cassette insertion Z Mechanism: Approximately 400gm.,

The tooth pitchof Worm gearwhich hasbeen extended against the previous model, is located

on the Motor so that Worm gear can be reversed. Consequently, the Motor rotates before the

K Mechanism: Approximately 600gm.)

1-3.

insertion spring (the combined spring) is working when the cassette tape is inserted, so that

the repelled force of the insertion spring has been reduced as differing from the present

model.

@ Small-sized Cassette holder unit (Thinned unit)

a. The Wiper arm method which has been adopted, assigned Wiper arm between Cassette

Holder Plate and Side Plate so that the small-sized of the width has been realized.

b. To prevent the increment of parts quantity such as Safety Iever is used for Pre-open

mechanism shown in the present model, and the small-sized unit has been realized by

inclining one portion of the Lgroove in Side Plate.

c. The part of driving change-over is located in the nearest to the center of Reel so that the

depth size is compacter.

Reel brake

(1)

Supply Reel Brake is used for Tension Regulator which is composed of the conventional Main

brake and the soft brake function.

Take-up Reel Brake is used as Band Brake unit in order to correspond with Supply Reel

(2)

Tension Regulator performance:

x

This is composed of Tension regulator and brake. The tape always is given the tension

Brake.

against

the advance direction by Tension band.

Construction of Supply reel tension regulator

(3)

Comparison ofthe construction with the conventional model

2

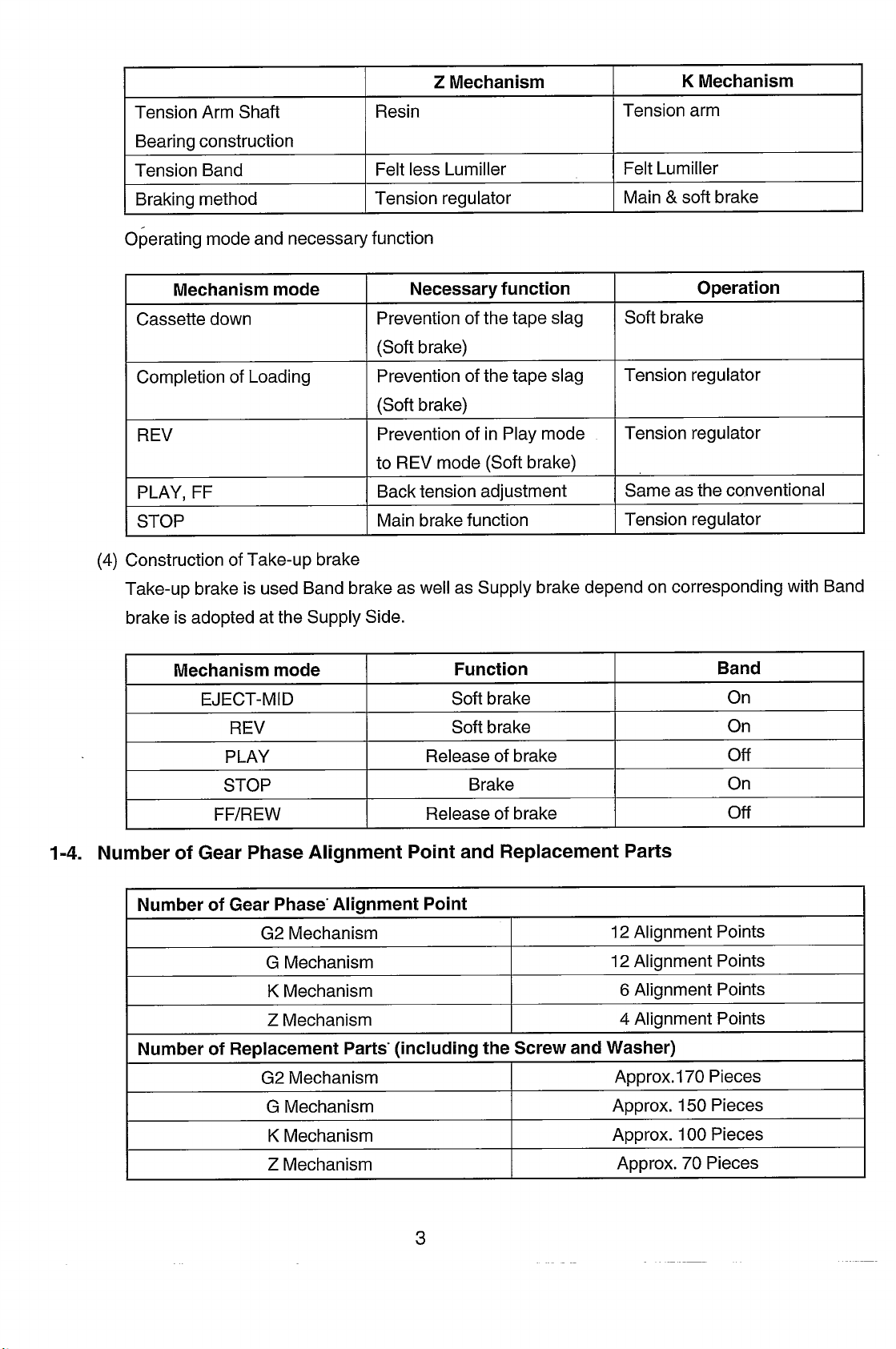

Page 5

I

Z Mechanism

K Mechanism

Tension Arm Shaft

Bearing construction

Tension Band

Braking method

Operating mode and necessary function

Mechanismmode

Cassette down

Completion of Loading

REV

PLAY. FF

STOP

(4)

Construction of Take-up brake

Resin

Felt less Lumiller

Tension regulator

I Necessary function

Prevention of the tape slag

(Soft brake)

Prevention of the tape slag

(Soft brake)

Prevention of in Play mode

to REV mode (Soft brake)

Backtension adjustment

Main brake function

Tension arm

Felt Lumiller

Main & soft brake

Operation

Soft brake

Tension regulator

Tension regulator

Same as the conventional

Tension regulator

Take-up brake is used Band brake as well as Supply brake depend on corresponding with Band

brake is adopted at the Supply Side.

Mechanism mode

EJECT-MID

REV

PLAY

STOP

FF/REW

1-4. Number of Gear Phase Alignment Point and Replacement Parts

Number of Gear Phase-Alignment Point

G2 Mechanism

G Mechanism

K Mechanism

Z Mechanism

Number of Replacement Parts”(including the Screw and Washer)

Function

Soft brake

Soft brake

Release of brake

Brake

Release of brake

12Alignment Points

12Alignment Points

6 Alignment Points

4 Alignment Points

Band

On

On

off

On

off

G2 Mechanism

G Mechanism

K Mechanism

Z Mechanism

I

3

Approx.170 Pieces

Approx. 150 Pieces

Approx. 100 Pieces

Approx. 70 Pieces

Page 6

Page 7

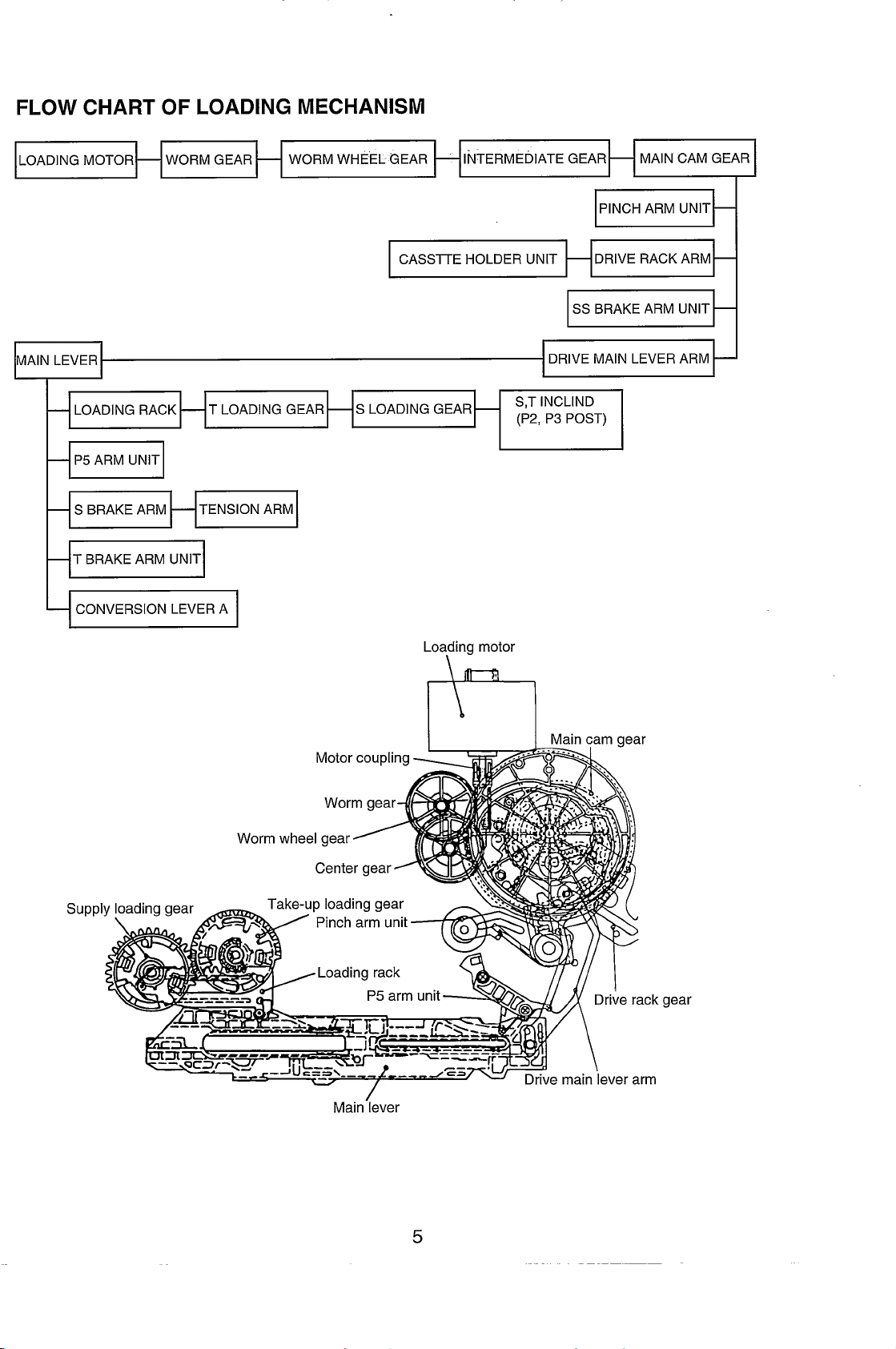

FLOW CHART OF LOADING MECHANISM

LOADING MOTOR

MAIN LEVER

I

l+TBRAKEARM UNITI

+ CONVERSION LEVERA I

T LOADING GEAR

CASSITE HOLDER UNIT

S LOADING GEAR

SS BRAKE ARM UNIT

S,T INCLIND

(P2, P3 POST)

MAIN CAM GEAR

PINCH ARM UNIT

DRIVE RACK ARM

—

—

—

Supplv

Inadinn mmr

Motorcoupling

Wormgear

Wormwheelgear

A

Centergear

Take-uploadinggear

\ Pincharmunit

\

,Loading rack

T

—.

Main-lever

Loafingmotor

Y

P,armunit-n

,.

,, w

..

...

b

...

/

gear

IT

5

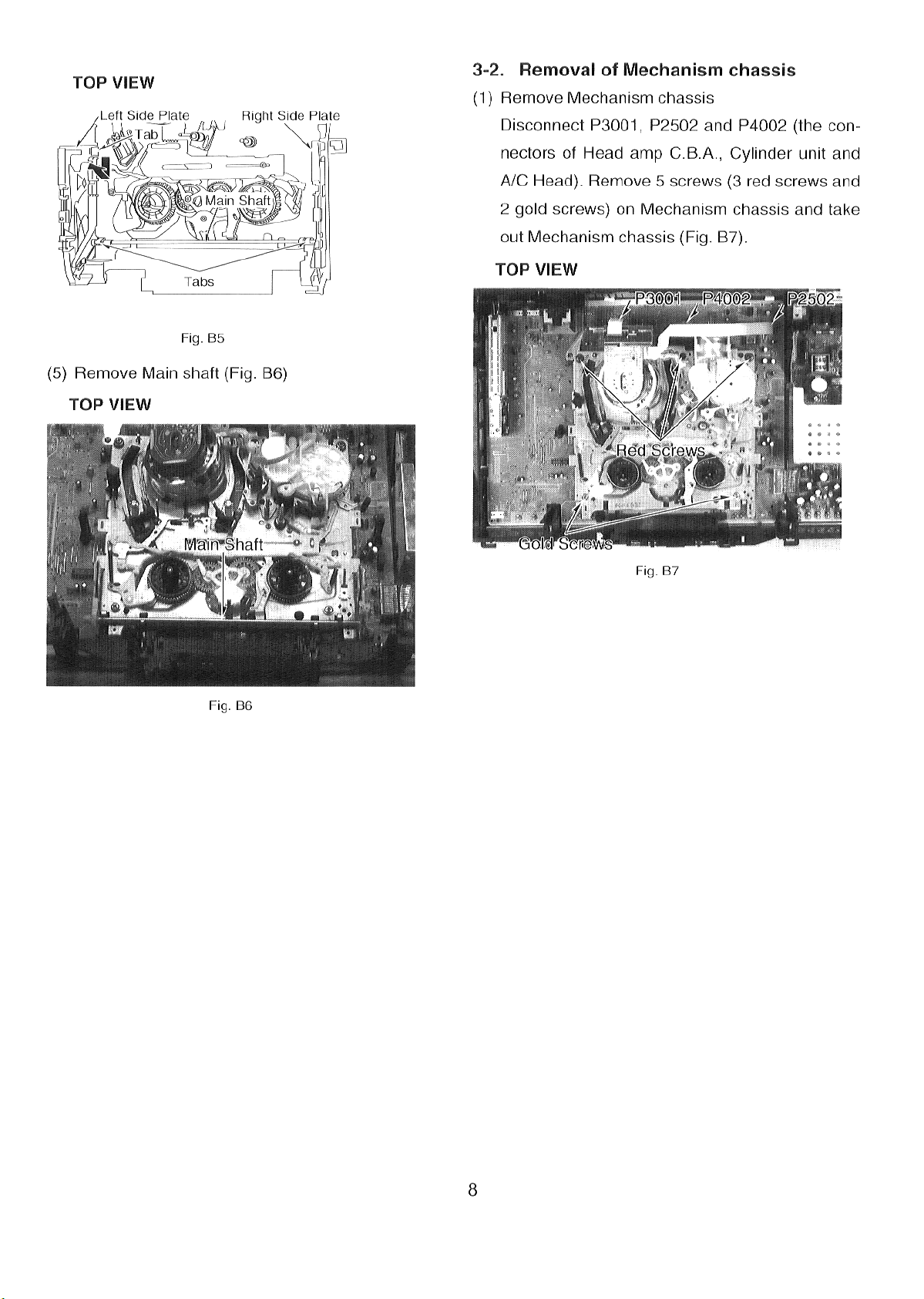

Page 8

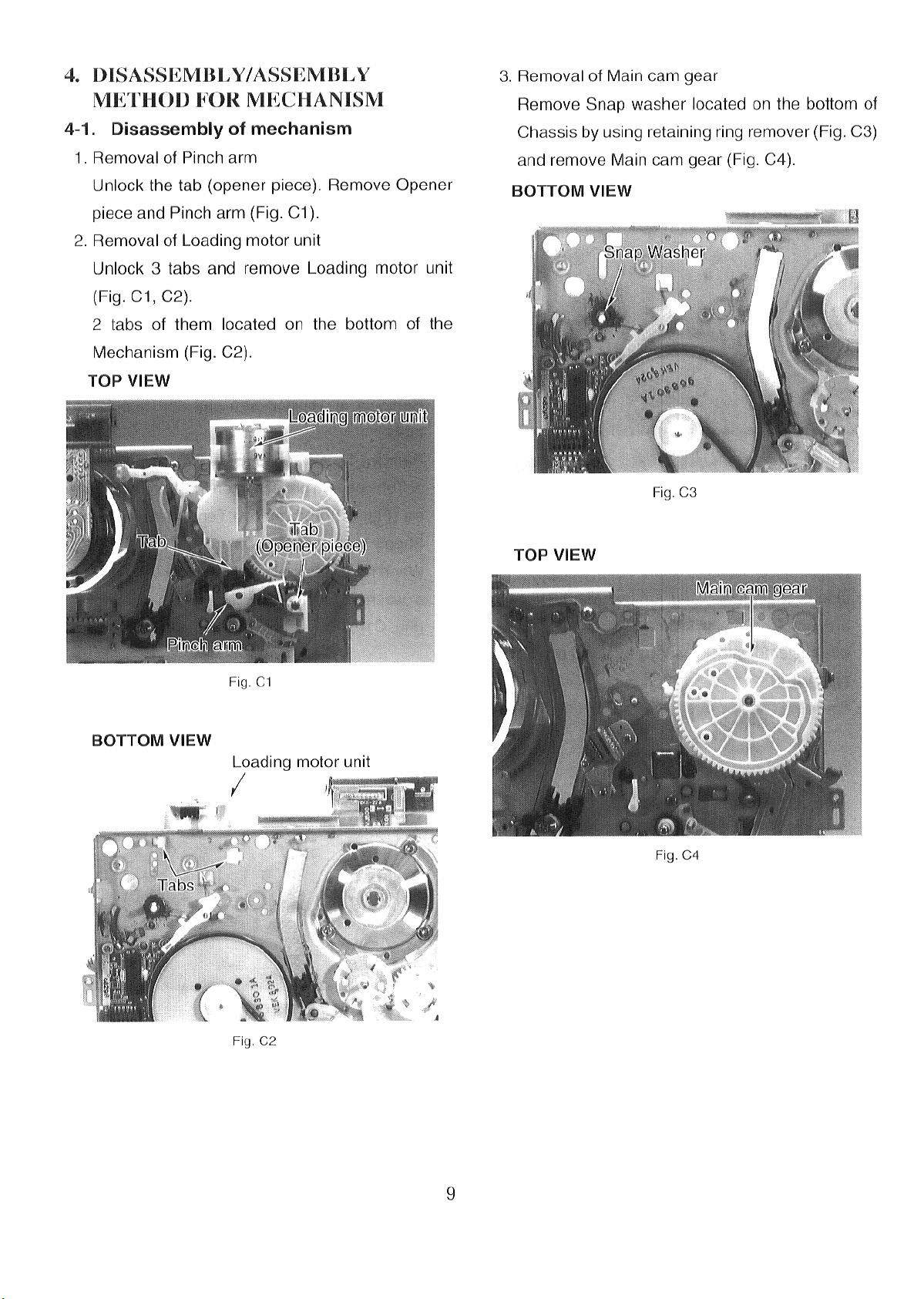

Page 9

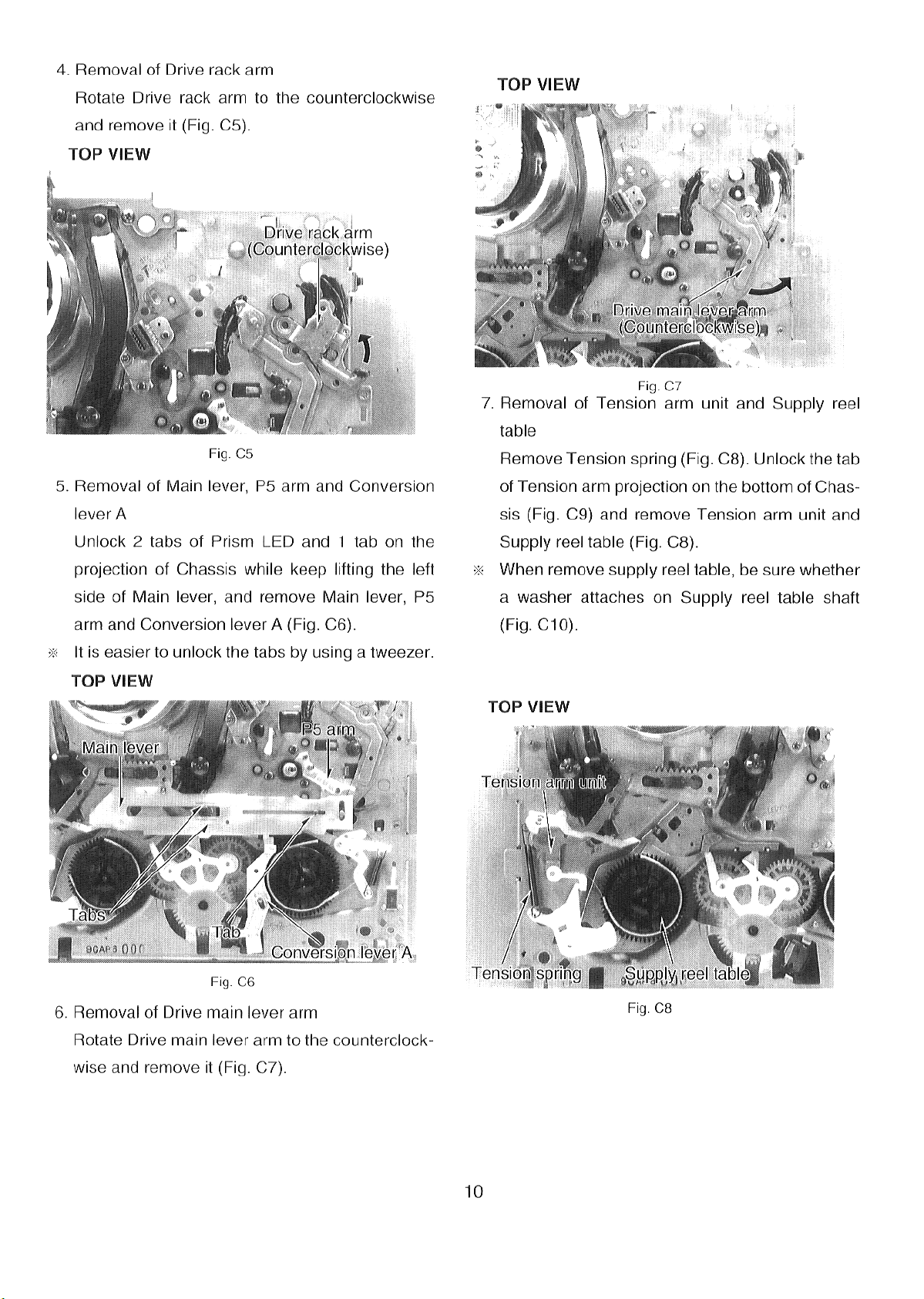

Page 10

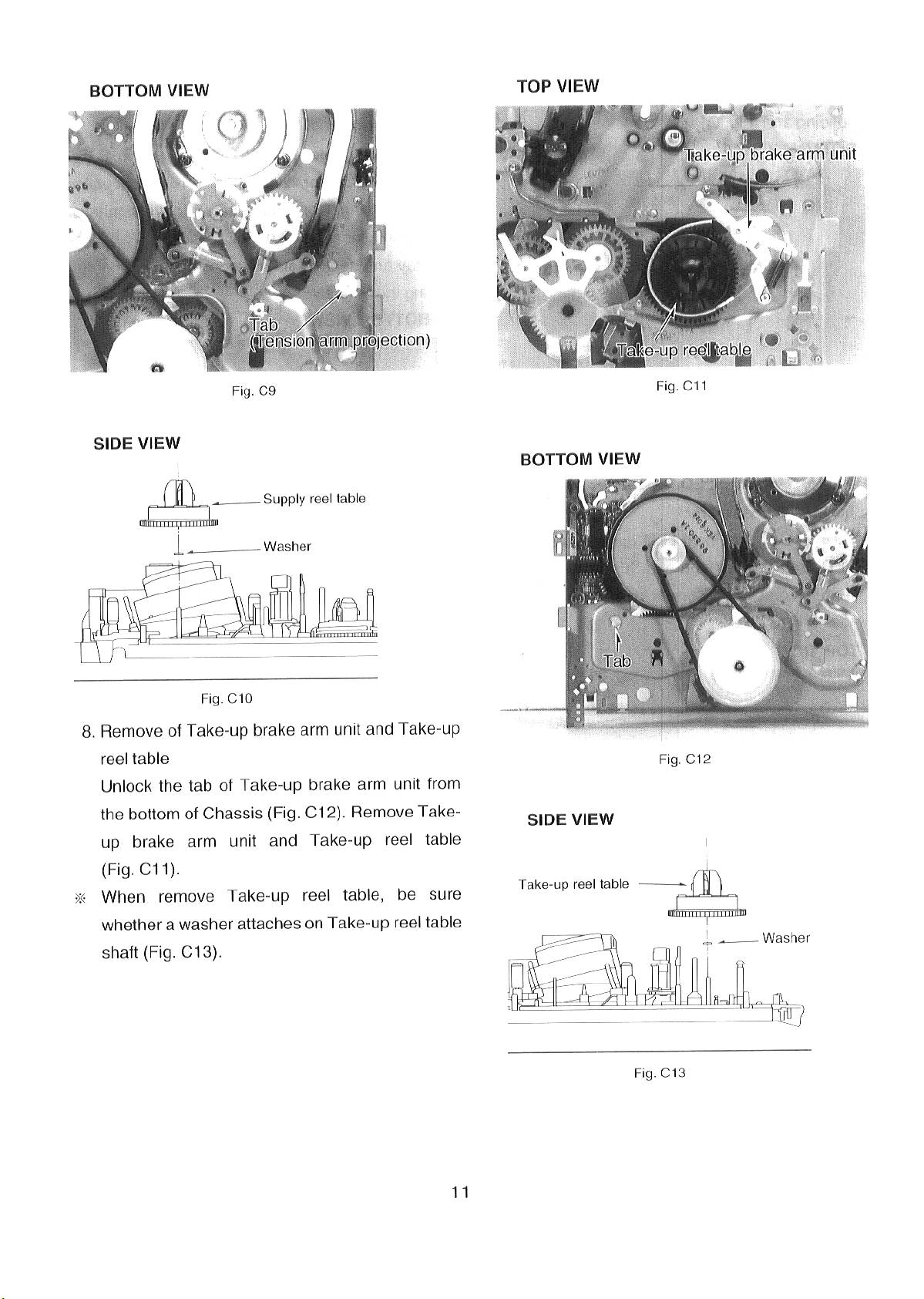

Page 11

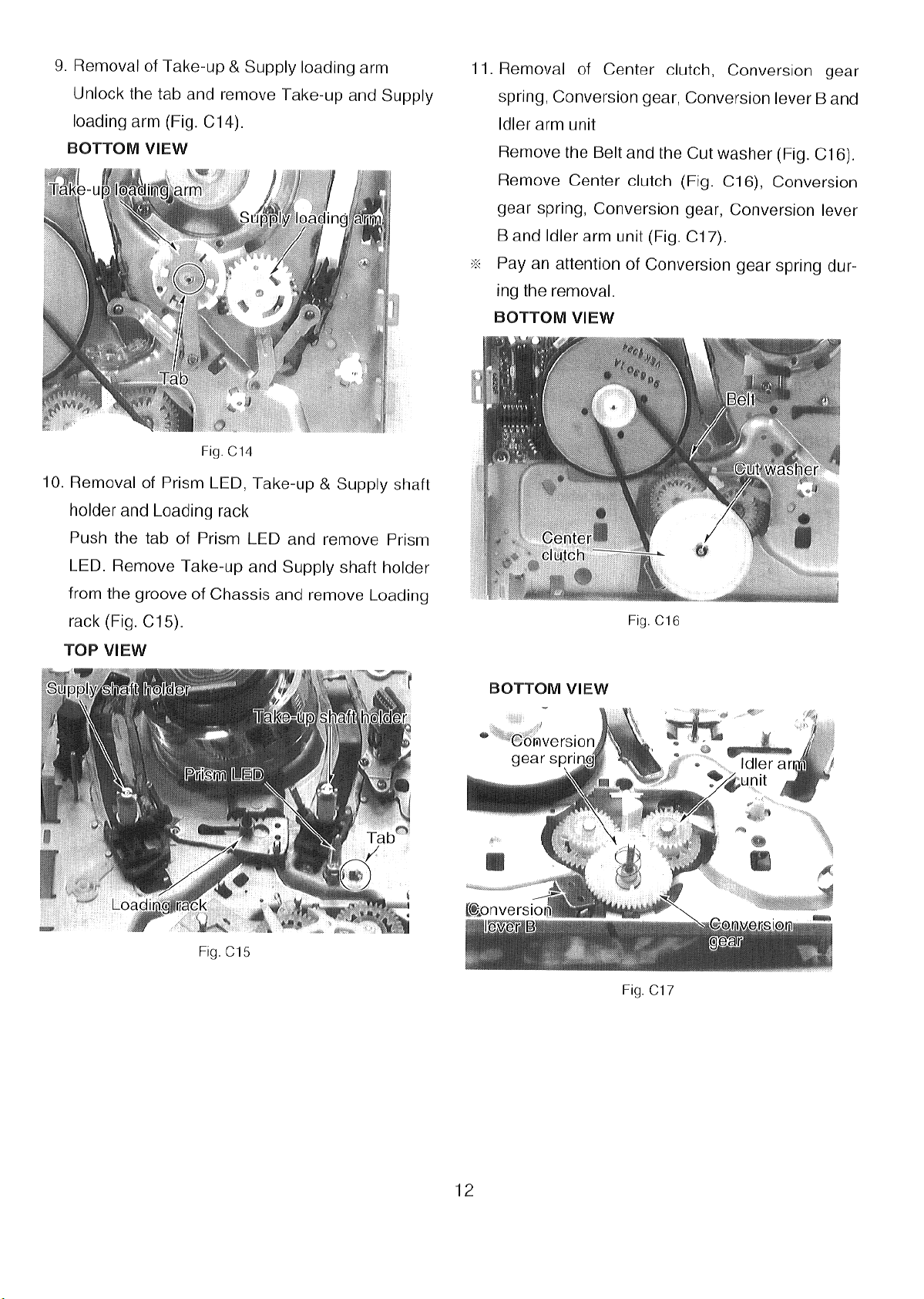

Page 12

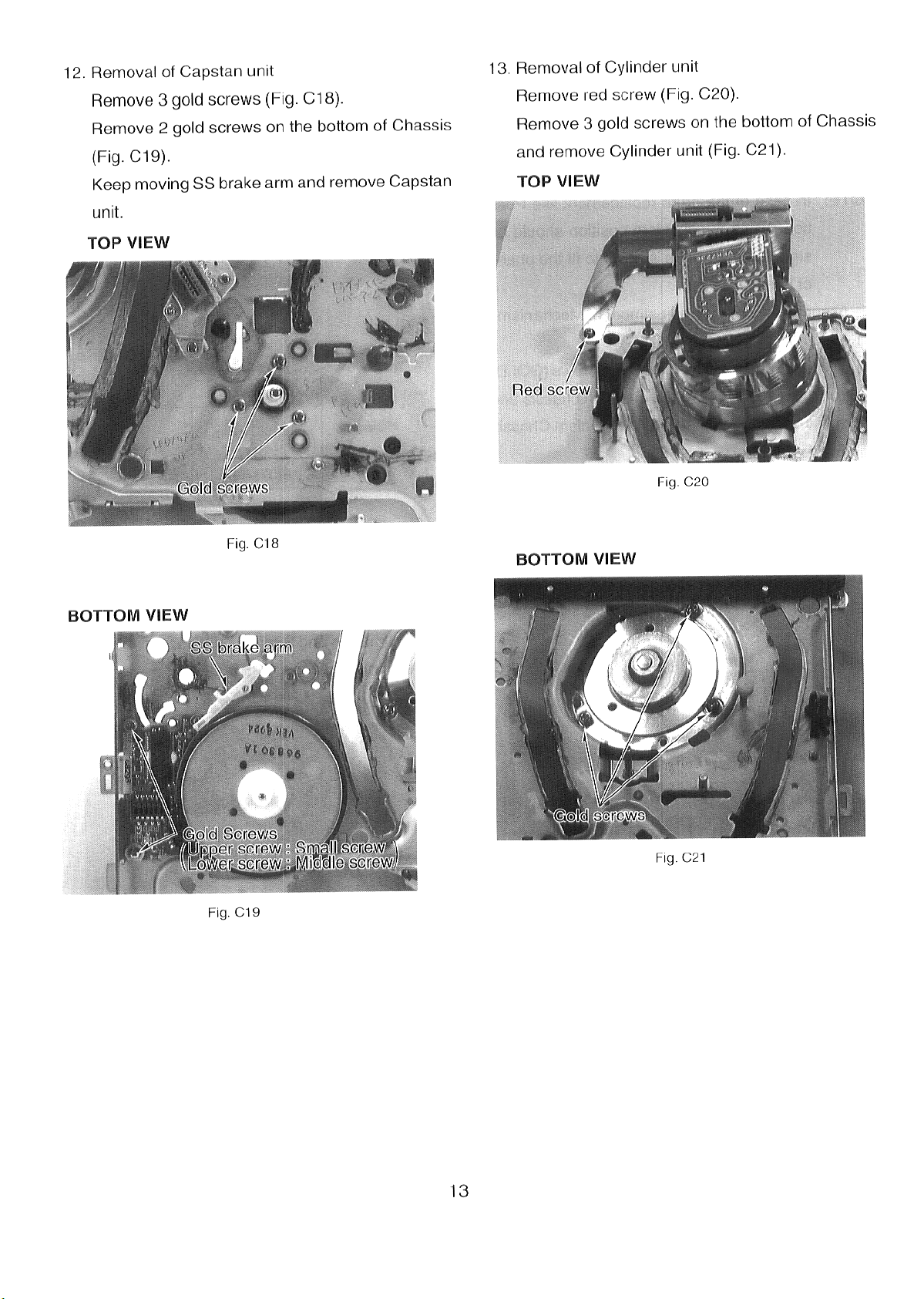

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

1

—

I

U

u

>

u

z

G

2

—

—

—

—

m

@

P

m

cc

w

>

5

m

c1

q

Q

(u

—

23

Page 26

5. MECHANICAL ADJUSTMENT

PROCEDURE

5-1. Tension post position adjustment

Equipment required: Hex. Wrench (VFK0326)

Specification: 50.5* 1.5 mm

(1)

Disconnect the AC plug.

Remove the TOP PLATE.

(2)

Turn the LOADING MOTOR until the loading

(3)

completes.

Adjust the hole of Tension Band Fastener by Hex

(4)

Wrench until the distance between the Tension

Post and the center of Supply reel table is

50.5tl.5 mm as shown in Fig. Ml.

—

Playback the cassette tape from the beginning

(1)

and wait until the tape movement get the stabilization. (for approx. 10–20 seconds)

Insert the Back Tension Meter into the path of a

(2)

tape, and measure the back tension to be within

specification as shown in Fig. M2.

S Inclined post

S2 Post=..+

Probes of

Gauge

Tension

Post

\

<

50.5*1 .5mm

\

Fig. Ml

5-2.

Back tension adjustment

Equipment required:

Back Tension Meter (VFKOI32)

VHS Cassette tape (180 minutes tape: PAL)

table

Fig. M2

(3) If it is out of specification, change the spring

notch as shown in Fig. M3.

Tension spring

, Supply spring arm

“Springnotch

Fig. M3

VHS Cassettetape (120 minutes tape: NTSC)

Specification: 22.5–27.5g

24

Page 27

5-3.

P2 and P3 posts adjustment

(PREADJUSTMENT)

5-4. Tape interchangeability adjustment

Carry out the following procedures for Tape inter-

Equipment Required:

PostAdjustment Screwdriver (VFK0329)

(1) Remove the Top Plate.

(2) Turn the Loading Motor until the unloading com-

pletes.

(3) Rotatethe P2and P3 Posts clockwise to the end.

(Fig. M4)

(4) Rotate the P2 and P3 Posts twice counterclock-

wise. (Fig. M4)

c1

!!

1. Rotate the

POST clockwise

to the end

1

(5) Playback the cassette tape and make sure that

the edges of the tape are not curling at the bottom or top end of the P2, P3, and P4 Posts as

shown in Fig. M5.

2. Rotatethe

POST twice

counterclockwise

Fig. M4

changeability Adjustment to do it correctly and

smoothly.

P2 AND P3 POSTS ADJUSTMENT

(1)

(2)

ADJUSTMENT OF P4 POST

HEIGHT ADJUSTMENT OF WC HEAD

(3)

(4)

FINE-ADJUSTMENT OF A/C HEAD

ADJUSTMENT OF X-VALUE

(5)

(PREADJUSTMENT)

FINE-ADJUSTMENT OF X-VALUE

(6)

Ifthe Tape Interchangeability Adjustment is not per-

fect, repeat the above procedures from (1) to (6).

CAUTIONS: To make an Adjustment ModeforTape

Interchangeability, press the FF and

EJECT buttons simultaneously 3times

to set the Service Mode 2.

Incase of VCR mounted shuttle ring,turn the shuttle

ring to FF and then press EJECT button.

In Loewe model, STOP button is used instead of FF

button

NOTE Cleaning the Tape Transport pathbefore ad-

justing of Tape Interchangeability.The detail

portion is shown below.

POPost, Tension Posts, FE Head, P2 Post,

Supply Inclined Post, Cylinder Unit, Take-up

Inclined Post, P3 Post, A/C Head, P4 Post,

Post P2, P3 Post P4

Curling

/’

-Tape

-Tape

l!!

[No Good]

Fig. M5

(6) If the curling appears, readjusts the P2 and P3

Posts.

[Good]

25

I

Pinch Roller, Capstan Shaft, P5 Post. FE

Head, Cylinder Unit, A/C Head and Capstan

Shaft are more important parts and pay an

attention to clean them.

I

Page 28

5-4-(l). P2 AND P3 POSTS ADJUSTMENT

Equipment required:

Alignment Tape (PALLSECAM: VFJ8125H3F)

(NTSC: VFM8080HQFP)

PostAdjustment Screwdriver (VFK0329)

(2) Playbackthe Alignment Tape.

(3) If the RF envelope appears Iike example “A” or

“B” in Fig. M7, then adjustment of the tape guide

post (P2: Entrance) is necessary. e

(4) Adjust the tape guide post (P2) with the post

adjustment screwdriver so.that the RF envelope

(1) Connect. the oscilloscope to the output of the

Head Amp as shown in Fig. M6.

NOTE: To get a stable waveform of the Head Amp

output (observation point TW3001 and

TW2001 located on Main C.B.A.) on the oscilloscope, use the head switching pulse as

a triggering signal as shown in Fig. M6.

waveform at the entrance portion becomes flat

as shown in Fig. M7 “C”.

1

--------

I

Fig. M7

(5) If the RF envelope appears like “D” or “E” in

Fig. M8, then adjustment of the tape guide post

(P3: Exit) is necessary.

(6) Adjust the tape guide post (P3) in the same man-

Fig. M6 Connect of Oscilloscope

ner as the P2 post so that the exit portion becomes flat as shown in Fig. M8 “F”.

xit Portion

D

0.

E

F

I-

Fig. M8

26

Page 29

(7) Keep pressing the tracking up/down (A or v)

bu~ons on the remote controller unit. The output

envelope should vary nearly parallel with other

condition as shown in Fig. M9.

(8) Set the tracking control into center fix position by

pressing the tracking up/down

(A and v) simul-

taneously and adjust for maximum RF envelope,

whilst being as flat as possible.

Output envelope Mini.

~

+

I_

Output envelope Max.

(Fix position)

Good

Good

5-4-(2). ADJUSTMENT OF P4 POST

Install A/C Head on the Mechanism Chassis by

(1)

one screw.

Playback the Alignment Tape.

(2)

Rotate the screw (A) or (B) until the wrinkle ap-

(3)

pears on the lower edge of tape at P4 Post.

Rotate the screw (A) or (B) until the wrinkle just

(4)

disappears onthe lower edge of tape at P4 Post.

Connect the oscilloscope to audio output termi-

(5)

nal.

Rotate the screw (C) until audio signal is maxi-

(6)

mized.

NOTE: 1. The relation between the rotation direc-

tion of screws (A) and (B) and the condition of wrinkle on the lower edge at P4

Post as shown in Fig. Ml 1.

2. Make sure that there is not the inclined

wrinkle between P4 Post and Pinch

Roller.

Fig. M9

P2

Po

Fig. M1O Loading of Posts

So wrinkle

appears on the

lower edge of tape

So wrinkle

disappears on the

lower edge of tape

, ,

SCREW (A)

COUNTER

CLOCKWISE

CLOCKWISE :~#-&:sE

SCREW (B)

CLOCKWISE

1

I

27

Fig. Ml 1

Page 30

5-4-(3). HEIGHT ADJUSTMENT OF A/C

HEAD

<When moving the A/C Head up>

(1)

Rotate the screw (A) counterclockwise until the

wrinkle appears on the lower edge of tape at P4

Post.

Rotate the screw (B) counterclockwise until the

(2)

wrinkle just disappears onthe lower edge oftape

at P4 post.

Rotate the screw (C) counterclockwise until the

(3)

audio signal is maximized.

~

Q---(l)

5-4-(4). FINE-ADJUSTMENT OF A/C HEAD

Connect the oscilloscope to the output of the

(1)

Head Amp as shown in Fig. M6.

Playback the Alignment Tape.

(2)

Make sure that the condition of the wrinkle at P4

(3)

Post. If the condition of the wrinkle is out of

specification, P4 Post adjustment has to be performed as follows.

Turn the screw (A) counterclockwise until the

wrinkle appears on the lower edge of tape at P4

Post.

Turn the screw (A) clockwise until the wrinkle

disappears on the lower edge of tape at P4 Post.

Turn the screw (C) until the audio signal is maxi-

(4)

(2)- -@

%

c -----(3)

Q

<When moving the A/C Head down>

(1) Rotate the screw (B) clockwise until the wrinkle

appears on the lower edge of tape at P4 Post.

(2) Rotate the screw (A) clockwise until the wrinkle

just disappears on the lower edge of tape at P4

post.

(3) Rotate the screw (C) clockwise until the audio

signal is maximized.

P

Fig. M12

S (@ --(2)

mized.

NOTE: Make sure that the audio output does not

increase when push the upper and lower

I

5-4-(5).

edges of tape around A/C Head.

HeadAmp Output (RF Signal)

l-l

m

Fig. M14

ADJUSTMENT OF X-VALUE

. .

(PREADJUSTMENT)

u

t

Maximum

1

(l)- -@

c

G

G

Fig. M13

#

-----(3)

Equipment required:

Fine Adjustment Gear Drive (VFK0330)

Specification: Less than 15 msec.

(1) Connect the oscilloscope to the audio output and

the video output. Both output signals should be

fixed by the external trigger.

28

Page 31

(2) Playback the Alignment Tape and set the track-

ing control into center fix position.

(3) Adjust A/C Head position by the FineAdjustment

Gear Driver (VFK0330) to meet the signal fault

portion of the audio output and the video output

signals (Lessthan 15 msec.).

(4) After meeting the signal fault portion, adjust A/C

Head position by the Fine Adjustment Gear

Driver (VFK0330) until the video envelope is

maximized.

I

I I

I

I

FineAdjustment Gear

Driver (VFK0330)

\

Fig. M15

(B)

1

1

I

Fig. M16

5-4-(6).

Equipment required:

Fine Adjustment Gear Drive (VFK0330)

(1) Connect the oscilloscope to the audio output and

the video output. Both output signals should be

fixed by the external trigger.

(2) Playbackthe alignment tape and set the tracking

control into center fix position.

(3) Adjust A/C Head position by the Fine adjustment

Gear Driver (VFK0330) until the video envelope

level is maximized at the tracking center fix position.

FINE-ADJUSTMENT OF X-VALUE

29

NOTE: During X-Value Fine Adjustment, in case the

video envelope level became O,Preadjustment of X-value should be adjusted again

due to it is possibility to vary the X-value

adjustment.

Page 32

Servicing Fixtures & Tools

30

Page 33

6. SELF-TESTINDICATIONDISPLAY

This VTR has a self-diagnosis and display function. If the VTR detects trouble during installation or during

use, one of the following fault indication codes will automatically appear inthe VTR display. Fault indication

codes are displayed in the form of a single English letter followed by two numbers, as for example “HOI”.

Note: 1. The indication “U” is displayed on the FIPwhile power remains on.

2. Otherwise, the indication “H” or”F” isdisplayed on the FIP,and the power is automatically turned

off.

When the power isturned on again, the fault indication code will disappear and the unit will retrun

to normal display mode (either clock or counter is displayed).

3. This fault indication code will be stored in the microprocessor even with the AC plug disconnected.

The two-digit number portion of the stored fault indication code can be redisplayed in the FIP’s

“second” display portion (the last2 digits on the light) by placing the unit is Service Mode Number

2 when turning on Service Information Display as for example “01” or “02” etc.

If a second error occurs, only the most recent error will be displayed and stored.

4. To erase the stored fault indication code data, press FF and EJECT buttons for 5 seconds.

31

Page 34

< FIP >

INDICATION CAUSE

u 10

H 01 does not start rotating again even after

H 02

F 03 except Eject mode.

F 04

F 06

F 07 less than the normal condition.

Dew formation.

After cylinder lock is detected, the cylinder

tape unloading.

Cassette tape is not wound up during tape

unloading except Eject mode.

Mechanism locks during mode transition

Mechanism locks during tape unloading.

Mechanism locks after tape unloading in

Eject mode.

During recording mode recording signal is

REMEDYICHECK

Wait until the indication disappears.

Check the cylinder unit and the cylinder

motor drive circuit.

Check the capstan unit and the capstan

motor drive circuit.

1. Check the loading motor drive circuit.

2. Check the mechanism phase alignment.

3. Check the mode switch.

1.Check the loading motor drive circuit.

2. Check the mechanism phase alignment.

1. Check the loading motor drive circuit.

2. Check the mechanism phase alignment

for cassette holder unit.

Protection of the overcurrent flowing in

transistor which produce the power supply

for recording mode.

I

F 08

H 16

H 17

H 18

Recording circuit works except recording

mode.

Cylinder lock detection.

Supply reel mechanism lock detection.

Take-up reel mechanism lock detection.

Fig. T1 Self-Test indication Display

Check the recording circuit.

Check the cylinder unit and the cylinder

motor drive circuit.

Check the supply reel mechanism and the

supply reelcircuit.

Check the take-up reel mechanism and

the take-up reel circuit.

32

Page 35

7. SERVICEINFORMATIONDISPLAY

< FIP >

:1

-

Indicates the circuit

to be checked.

II

En!l

Indicates the condition of

the circuit and/or the

position of the mechanism.

Fig. DI Service Information Display

7-1. Purpose of Service Information Display

This information aids trouble shooting by indicating the source of the malfunction. The service mode

number & service data number are used by the technician during repair while the service information

can be used by consumer to diagnose malfunctions allowing the technician to provide a more

accurate repair cost estimate and reduce repair time.

7-2.

Turning on Service Information Display

Press FF and EJECT buttons simultaneously for more than 3 seconds. In case of VCR mounted

shuttle ring, turn the shuttle ring to FF and then press EJECT button for more than 3 seconds.

-r-- l--

se~ice Information Number

&

Indicates which circuit

malfunction.

senses a

In Loewe model, STOP button is used instead of FF button.

Inthe Service Information Display, there are four digits divided into 3 functions.

The first digit indicates which of the 7 service modes that the unit is currently in.

MODE 1: Checks tape protection circuit.

MODE 2: Checks tape transport mechanism.

MODE 3: Checks mode switching operation.

MODE 4: Checks control buttons.

MODE 5: Checks capstan motor.

MODE 6: Checks cylinder motor.

MODE 7: Checks loading/unloading operation.

The second and third digits are service data which indicate the condition of the circuit or mechanism

being checked.

33

Page 36

The forth digit is the service infromation display. it is to be used by the consumer to help determine

the source of a malfunction. The service information display operates independently of the service

modes and stores the fault indication in memory for as long as AC power is not supplied.

EEE!l

Indicates the circuit

to be checked.

m

Indicates the condition of

the circuit and/or the

position of the mechanism.

Fig. D2 Service Mode Number and Service Data Number on F.I.P.

7-3. Use of Service Modes

(1) Turn on Service information Display.

(2) To change Service Modes, press FF and EJECT buttons simultaneously.

(3) Mode O:

(4) Mode 1:

(5) Mode 2:

(6) Mode 3:

Storing the process number when the fault happened.

Checks that the sensor LED, Supply & Take-up sensor circuits checks the circuits by

blocking the light from the sensor LED to either or both Supply & Take-up Sensors.

When the light is blocked to both sensors, “00” should be indicated on the service data

number.

When the light is blocked to the supply sensor, “01” should be indicated.

Checks the mode switch circuit while indicating mechanism position.

Service Data Numbers indicate the position of the mode switch

mechanism position.

Checks that mode switch circuit operations have been completed.

Service Data Number should indicate “00” after each mechanism

pleted.

and there by the

operation is com-

34

Page 37

(7) Mode 4:

Checks the operation circuit.

Indicates if SYSTEM CONTROL IC receives the operating commands from the mode

buttons and/or remote controller.

(8) Mode 5:

Checks the capstan motor circuit.’ “

Indicates if the SYSTEM CONTROL IC has received the command to rotate the

capstan motor.

(9) Mode 6:

Checks the cylinder motor circuit.

SYSTEM CONTROL [C has received the command to rotatethe cylinder motor.

(10) Mode 7:

Checks the loading/unloading operation.

The loading motor rotates for loading operation when the “PLAY” button is pressed.

The loading motor rotatesfor unloading operation when the “STOP” button is pressed.

This mode can be displayed indefinitely until the OPERATE button is pressed.

<NOTE> Refer to Fig. D5 for details of Service Data Numbers.

Fig. D3 Service Information Number on F.I.P.

1, 7

II SewicelnformationNumber II

Indicates whichcircuitsensesa

malfunction.

35

Page 38

7-4. Service Information Number

Referto Fig. D4 for details of Service Infromation Number.

NOTE: The Service Information Number display is independent of the service mode display. The

Service Information Number will be stored as long as AC power is not supplied. (If can be

displayed in the Service Mode 2.)

Ifa second error occurs, only the most recent error will be displayed.

Service Information Number

00

10 Dewformation

I

01

02

03 Stop at position other than 04 or 06

04 Stop during unloading

06

07

08

16 Cylinder lock

17 Supply reel lock

18

2* PG shifter automatic adjustment error

Fig. D4 Detail Service Information Number

Normal condition (No problem)

] Cylinder stop

Tape reel stop

Stop during Cassette-in/Eject operation

Recording circuit stop in recording mode.

Recording circuit stop except recording mode.

Take-up reel lock

Malfunction

7-5. Test Mode

When the test terminals are shorted during turning off condition, the following operation will be

performed after AC power is applied. Test Mode Information will be displayed on FIP insted of linear

counter. To release Test mode, test Terminals should be opened. @

(1) Power will be turned on automatically when AC power is applied.

(2) The direct operation of buttons are able to be performed.

(Examle) PLAY~

(3) In case the mechanism is in PLAY position, the mechanism goes into PLAY mode when AC

power is applied.

(4) Playback CVC function is turned off.

(5) Tracking is fixed under power off and cassette in. Auto tracking does not perform.

(6) For recording current adjustment.

(7) For reverse slow tracking adjustment.

(8) When the power is turned off, tracking is fixed.

REC, REC+EJECT, REC+FF/REW

36

Page 39

ServiceMode

Number

NoteforcheckingServiceDataNumbers

1

2

Disregardservicedatadisplayeduntilmechanism

3

operationiscompleted.

Thenthedisplayshouldindicate“00”.

4 Displayonlywhentheoperatingbuttonis pressed.

Leftdigitonly,disregardRightdigitdisplay.

Rightdigitonly,disregardleftdigitdispaly.

5

Rightdigitonly,disregardleftdigitdisplay.

Leftdigitonly,disregardRightdigitdisplay.

6

ServiceData

Numbers

00

01

02

03 Light detected at both sensors.

No lightdetectedateithersensor

Tapebeginning

LighttoSupplyphotosensorisblocked.

Tapeend

Light to Take-up photo

00 EJECT

Indication

Tapenotrequired.

sensorisblocked.

Taperequired

Remarks

01 Cassettedown *1.STOP3:PintchrollerisonCapstanmotor

02 REV, REV SLOW

03 Loading/Unloading

04

PLAY,REC,STILL,PAUSE,CUE,FWDSLOW,

STOP3*1

shaft.

STOP:PintchrollerisoffCapstanmotorshaft.

*2.

05 STOP*2

06 FF/REW

07 Intermediateposition

Anydisplayotherthan“00”indicatesa faultinthe

Taperequired.

00 modeswitchcircuitorsystem.

Tapenotrequired.

81

8,9,u,A,—, n,Landnodisplayindicatethatthe

Left Right Capstanmotor“PLAY”commandreceivedby

DigitDigit Systemcontrolmicroprocessor.

87

1,2,3,4, 5,6,7 indicatethattheCapstanmotor

Taperequired.

Ifasymbolotherthanthoselistedis displayed,a

malfunctioninthatcircuitisindicated.

Left Right “CUE,FF,FWDSLOW”commandsreceivedby

DigitDigit systemcontrolmicroprocessor.

8— 8, 9, u,A,—,n,Landnodisplayindicatethatthe

Left Right Capstanmotor“Reverse,REW,ReverseSlow”

DigitDigit commandsreceivedbysystemcontrol

microprocessor.

10 1,3, 5,7, 9,A,nandnodisplayindicatethatthe

Left Right cylindermotor“ON”commandreceivedbysystem

DigitDigit controlmicroprocessor.

Tape required.

[fasymbolotherthanthoselistedis displayed,a

malfunctioninthatcircuitisindicated.

Fig. D5 Service Data Display and Indication

Page 40

7-6. Timing chart from Mode SW to System control IC

System control IC senses the mechanical position through the Mode SW.

Fig. D6 shows the timing for service mode number 2.

<System control IC>

Position SW 1 +

Position SW 2 +

Position SW 3 +

Unloading (H)

Loading (H)

——.—.———

_—_——————————————

<Timing chart>

Position SW 1 : :::.

. . . .

. . .

. . . .

. . .

. . .

.,.

. . . .

. . . .

. . . .

. . .

. . .

———————

<Mechanism>

~

:D h;%:’

———————

.:::

Mode SW

——.———

——————

Position SW 2 ~

Position SW 3

Service Data

Number *3 :

Mode

o ; 7 : 1 :7:3:7: 2 : 7 : 4 : 7 I 5 ~ 7

EJECT[

t ~

CASSETTE : ; : ;

DOWN : :

.;:: :

. .

. . .

. . . .

.-. .

. . .

. . . .

It

:REV ; ; CUE

MID REV SLOW

LOADING

UNLOADING

.~i:;:

t ~ ~ ~

: p~Y/REC ;STOP*2;

STILUPAUSE

FWD SLOW

STOP 3 *1

*1 : Stop 3 ;The Pinch roller is on the Capstan motor shaft.

*2 :Stop ;The Pinch roller is off the Capstan motor shaft.

*3 : ServiceDataNumber;This isfor ServiceMode Number2.

Fig. D6 Timing chart of Mode SW

;

:6

; FF/REW

38

Page 41

8. SYSTEMCONTROLCIRCUIT& MECHANISMCONTROLCIRCUIT

MECHA.

➤

KEY

MATRIX

4

➤

DISPLAY

4

Fig. S1 Overall Block Diagram of System Control Circuit

8-1. STOP3 Specification

(1)

The STOP3 is the playback stand-by mode.

(2)

The unit is put into the STOP3 position after tape loading if the cassette tape does not have a

clear leader tape.

(3)

Ifthe unit is in the STOP3 position when the power is switched off (included the Timer stand-by

TIMER

Ic

4

4

SYSTEM

CONTROL

4

➤

Ic

4

4

CONTROL

SAFETY

DEVICE

OTHERS

mode), the unit goes to the STOP position.

Ifthe cassette is in the unit when the power is turned on, the unit goes to the STOP3 position.

(4)

When the cassette tape has clear leader tape, the unit is in loading mode after winding up the

(5)

clear leader tape by Take-up reel at the cassette down position and the unit goes to STOP3

position.

8-2. Stand-by inthe STOP3 position

(1)

The unit goes to STOP3 position when the Stop mode is selected during the Play or Rec

operations. The unit then loosens the tape tension by performing the Reverse Slow.

The Reverse Slow corresponds to the FG 40 pulses of the capstan (irrespective of SP/LP

modes). The cylinder continues to rotate.

After about 5 minutes in STOP3 mode, the unitshifts to the Stop position and then the unitstops

(2)

the cylinder rotation.

39

Page 42

8-3. Supply and Take-up Sensors

Supply and Take-up photo transistors are used to sense the beginning and end of a tape. The tape

has transparent leaders at the beginning and

When these transparent leaders enter the tape transport path, they allow infrared light from the

end.

sensor LED to reach either one of the tape end sensors(photo-transistor).

IftheTake-upend

sensor detects the light, the microprocessor SYSTEM CONTROL IC places the

VCR inthe Stop mode and then performs a short Cue.

If the Supply end sensor is triggered, the microprocessor activates the Stop mode and the Rewind

mode. The Rewind mode continues until the Take-up end sensor detects the end of the tape. The

tape beginning isdetects by a low signal at SYSTEM CONTROL ICTake-up photo terminal. The tape

end is detected by a low signal at SYSTEM CONTROL ICSupply photo terminal.

Ifthe light is received at both sensors at same time, the cassette is ejected.

<Operation after detecting the beginning and the end of tape>

Mode Detection of the beginning Detection of the end

Power off+on Short CUE

Short REW

Cassette in Short CUE Short REW

Loading Short CUE

Short REW

FF/CUE Auto REW

REW/REV

PLAY, REC Auto REW

I I

Timer REC

Short CUE

Power off

Both ends of tape detection (tape cut, no cassette),

(1) Cassette

in: The cassette tape is ejected

(2) Other mode: The unit goes to Stop mode and it is impossible to operate except EJECT key,

(3) Timer REC:

Power is turned off after short CUE is performed.

8-4. Safety Tab Switch

A recorded video cassette can be protected against accidental erasure by breaking off the tab onthe

cassette. The cassette can now only be used for playback. To be able to record on the cassette,

cover the hole with adhesive tape. Ifthe safety tab on the cassette has been removed, Safety Tab

Switch is off (open) and high signal is supplied to SYSTEM CONTROL IC Safety Tab terminal. The

SYSTEM CONTROL IC will not go into the recording mode and automatically places the VCR in the

playback mode.

40

Page 43

8-5.

Dew Sensor

If excessive moisture or condensation is present inside the machine ( an internal humidity of more

than 98Yo)the unit will stop if running. Until the moisture level decreases only the Eject mode will

operate. To sense the humidity, a dew sensor is used. The sensor is a special variable resistorwhich

change resistance with ambient humidity.

The sensor ranges in resistance from about 5K ohm at 90Y0humidity to about 50K omh at 98Y0

humidity. Normally, the voltage across the sensor is low because of its low resistance.

But if moisture condenses inside the unit, the SYSTEM CONTROL IC voltage of Dew terminal

increases to indicate a Dew condition.

Tape Mode Dew sensor ON

Power

Dew indication Indicate “d” and “UI O“

Cylinder

OUT

IN

“1: When the cylinder locks in dew

Key operation Not possible *2

Cassette in

Power Compulsory Power on

Dew indication Indication “d” and “UI O“

Cylinder

Key operation

Cassettecondition

Compulsory Power on Power off

Rotating*1

immediately a cassette is

ejected after it goes to

cassette down position.

Rotating *1 stop

Not possible *2

A cassette goes to down

position and is in stand-by position.

mode.

mode, it will be released until dew sensor is truned off.

Dew sensor OFF

Normal indication

stop

Possible

Possible

Power off

Normal indication

Possible

Stand-by mode at STOP3

*2: The keys which do not relate to the tape running operation, are able to be used.

Dew sensor on:

Dew sensor off:

During Dew formation is detected and 80 minutes after completion of Dew

detection.

80 minutes later after copmletion of Dew detection.

41

Page 44

Setting time for each mode

8-6.

The time is set on each mode in order to protect tape and capstan driver. When the setting time is

over, the mode is gone to the next mode.

8-7.

8-8.

8-9.

Mode

STILL, PAUSE

CUE/REV lock

SLOW

Approximately 10minutes

Approximately 10minutes

Setting time Switching mode

Approximately 5 minutes

STOP

PLAY

STOP

Operation of short CUE

Short CUE stops when the Take-up photo sensor detects the black portion of the tape.

However its sensor does not detect the black

portion within 4.0+ 1.0 sec., the mode except Power

on/off and Eject modes will be abe to be operated after the unit stops. This is same as the timer over

operation of the reel

lock.

Loading/Unloading Mechanism lock

Loading and unloading times are set, and in case the mechanism locks during loading or unloading

operation within the defined time, the unit detects the mechanism lock and loading motor reverses or

stops.

Loading operation lock:

Cassette tape is unloaded and ejected within 5 seconds.

Unloading operation lock: Power is truned offwithin 5 seconds.

Cassette Ioadinghmloading lock

(1) Mechanism locks during the cassette in operation.

Cassette tape is ejected approximately 2seconds laterwhen the mechanism locks during the

cassette in operation.

Incase mechanism locks during eject operation, cassette tape is inserted and power is turned

off approximately 2 seconds later.

When Mechanism locks during cassette in operation, power is turned off approximately

2

seconds.

Incase the mechanism lock is released on the way and cassette is ejected, the unit continues the

normal operation.

(2) Mechanism locks during the eject operation.

~ Cassette tape goes to cassette down position approximately 2 seconds later and

turned off

when mechanism locks during eject operation.

Q Mechanism locks during cassette down operation, power is turned off.

power is

42

Page 45

8-10. Reel lock operation

When the Suuply or Take-up reel mechanism locks during the tape running, the following operation

is performed in order to protect the tape and the capstan driver.

Incase of Take-up reel mechanism lock,the detecting time is defined depending on the mechanism

position and capstan speed to minimize the tape supplying from supply side.

FF/REW

PLAY/CUE/REV : Unloading till

In play and CUE/REV mode, the reel pulse cycle is started to count after the mechanism mode is

fixed.

Incase the counted pulse cycle exceeds the defined value, the unit goes to

that lock of reel mechanism is detected.

cThe value of reel lock detection time>

NTSC/SP mode

: Unloading and loading. The unit goes to CUE/REV

the cassette down position and loading. The unit goes to STOP3

position.

PAUSP mode

mode.

STOP mode due to judge

-n

In FF/REW mode, the unit goes to CUE/REV mode and continues the tape running in the following

case.

1. (1) Take-up reel pulse can not be detected within 5 seconds after the unit shifted to REW mode.

(2) Supply reel pulse can not be detected within 5 seconds after the unit shifted to FF mode.

2. The reel pulse can not be detected more than 2 seconds sequentially within 5 seconds after

completing the mechanism mode shift.

3. The reel pulse can not be detected more than 800 msec. past 5 seconds after completing the

mechanism mode shift,

8-11. Cylinder lock

<Start rotation>

When the cylinder neither start rotating nor go to the stability rotation within 5 seconds, it is unloading

under keeping the mode. In case the cylinder starts rotating and goes to the stability rotation, the

mechanism loads again and continues the holding mode.

If it is not possible, Power is turned off and cylinder trouble “HOI” is displayed.

<During rotation>

The head switching pulse is supplied to the cylinder when the cylinder starts the stable revolution. In

case the head switching pulse does not come to the cylinder within 0.5 seconds, the cylinder lock is

judged and the following operation is activated.

Timer REC mode: Power off

PLAY, REC mode: STOP (Mechanism shifts to MID. position and the unit goes to stand-by mode.)

43

Page 46

8-12. Mode transition

The relation between the present mode and operation key is shown inthe following table.

PRESET

MODE

P SW EJECT

P-OFF P-ON EJECT

EJECT

STOP

REW P-OFF

P-OFF

—

P-OFF EJECT

EJECT

FF P-OFF EJECT

REV P-OFF EJECT

CUE

PLAY

STILL

REC P-OFF

RECIPS

P-OFF EJECT

P-OFF EJECT

P-OFF EJECT STOP

—

P-OFF

—

OPERATION

STOP REW FF PLAY PAUSE REC

— —

— —

*3

STOP

STOP

REW FF PLAY

REV FF PLAY

REW

STOP —

STOP

STOP

*1 —

*1

*1

STOP —

STOP —

KEY

—

—

CUE

PLAY

—

PLAY

*1 PLAY *2

PLAY *2

*1

—

*1 PLAY PLAY REC PS

—

—

—

—

—

—

—

—

—

*2

REC PS

REC REC

Pressing two keys simultaneously, the key operation is going to be ineffective.

*1:

The unit goes to CUE/REV lock mode by pressing FF/REW key lightly (less than 0.7 seconds)

during Play, still and REV mode. CUE/REV

mode will be returned previous mode when FF/REW

—

—

REC

—

—

—

—

—

—

key is pressed more than 0.7 seconds.

*2:

In case PAUSE key is pressed Iessthan 1 second other than STILL mode, the unit goes to STILL

mode.

If PAUSE key is being held to press, the unit goes to STILL mode and then goes to 1/1OSLOW

mode after 1 second. SLOW mode has not been set in 2 Head LP mode model.

When STOP key is pressed more than 3 seconds while acassette tape is inthe unit,the cassette

*3:

tape is ejected.

8-13.

Power on reset

When the power is turned on, the unit is going to reset and the following datas are cleared.

(1) Position switch data

(2) Operation mode data

(3) Prohibitionflags

Incasethe mechanism is in cassette down position,tape slack is removed as the initial operation and

the unit goes to STOP3 position.

8-14.

Linear time counter operation

The counter value will be gone up/down by counting control pulse.

Play/Rec mode, counter value goes up/down every 30 pulses. As for

As for NTSC system during

PAL system during Play/Rec

mode, counter value goes up/down every 25 pulses.

44

Page 47

8-15. Tape speed in CUE/REV mode

CUE/REV mode Hyper-search mode

MODE NTSC PAL

f SP mode

I EP or LP mode

8-16. Automatic functions

Automatic Power on

(1)

~ Under power off, when a cassette tape is inserted, power is turned on automatically and

cassette tape is loaded.

Q Under power off and a cassette tape has

turned on automatically and goes to PLAY

(2)

Automatic play

When a cassette tape removed safety tab is’ins~.tted,

(3)

Automatic rewind

When tape running is reached to the end of tape, automatically goes to Rew mode and stops

when tape running will be reached to the beginning of tape.

In case of Timer recording, short Flew is performed for 2

tape running is reached to the end of tape.

NTSC PAL

IgtimesI11timesl9times/11times I

timesl 11timesl 29times I 19times I

I 11

been inserted, when PLAY key is pressed, power is

mode.

the mode goes into Play mode.

seconds and power is turned off when

(4)

Power off and Eject

Under power off and a cassette tape has been inserted, when Eject key is pressed, a cassette

tape is ejected and power isturned off.

8-17.

8-18.

8-19.

CUE/REV lock mode

When FF/REW key is pressed lightly (lessthan 0.7 seconds) during Play, STILL and REV mode, unit

goes into CUE/REV mode. To release CUE/REV mode, FF/REW key should be pressed more than

0.7 seconds.

Hyper-search mode

When FF/REW key is pressed during FF/REW mode, unit goes into CUE/REV mode.

This mode is activated while keeping FF/REW key pressed.

When releasing FF/REW key pressed, this mode is released.

FF/REW speed

Maximum tape speed is approximately 4.5 m/s during the stable running.

8-20. FF/REW time

The tape runningfrom the beginning to the end of T-120 type (E-180 type) cassette tape isable to be

completed within 90 seconds.

45

Loading...

Loading...