Panasonic TX-32PS12 Service Manual

SPECIFICATIONS

(Information in brackets [ ] refers to model TX-28PS12)

ORDER No. 03-SM-008

Colour Television

TX-32PS12

TX-28PS12

EURO- 9L Chassis

Power Source: 220-240V a.c., 50Hz

Power Consumption: 114W [105W]

Stand-by Power

Consumption: 0,6W

Aerial Impedance: 75 unbalanced, Coaxial Type

Receiving System: PAL-I

M.NTSC (AV only)

NTSC (AV only)

Receiving Channels: UHF E21-E68

Intermediate Frequency:

Video/Audio

Video39,5MHz

Audio33,5MHz

32,95MHz (NICAM)

Colour35,07MHz

Terminals:

AUDIO MONITOR OUTAudio (RCAx2)500mV rms 1k

AV1 INVideo (21 pin)1V p-p 75

Audio (21 pin)500mV rms 10k

RGB (21 pin)0,7V p-p 75

AV1 OUTVideo (21 pin)1V p-p 75

Audio (21 pin)500mV rms 1k

AV2 INVideo (21 pin) 1V p-p 75

Audio (21 pin) 500mV rms 10k

S-Video INY: 1V p-p 75

(21-pin)C:0,3V p-p 75

AV2 OUTVideo (21 pin) 1V p-p 75

Audio (21 pin)500mV rms 1k

AV3 INS-Video INY: 1V p-p 75

(4-pin)C:0,3V p-p 75

Audio (RCAx2)500mV rms 10k

Video (RCAx1)1V p-p 75

AV4 INVideo (21 pin) 1V p-p 75

Audio (21 pin) 500mV rms 10k

RGB (21 pin)0,7V p-p 75

S-Video INY: 1V p-p 75

(21-pin)C:0,3V p-p 75

AV4 OUTVideo (21 pin) 1V p-p 75

Audio (21 pin)500mV rms 1k

High Voltage: 32kV ± 1kV [30,5kV ± 1kV]

Picture Tube: W76ELE50X7176cm

[W66EKT50X7166cm]

Audio Output: 2x10W RMS, 2x20W MPO,

8 impedance

Headphones: 8 Impedance

Accessories

supplied : Remote Control

2 x R6 (UM3) Batteries

Dimensions:

Height:567mm[510mm]

Width:902mm[805mm]

Depth:551mm[533mm]

Net weight: 55,5kg[43,3kg]

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

PDF created with pdfFactory trial version www.pdffactory.com

Panasonic CS ( U.K. ) Ltd.

WILLOUGHBY ROAD,

BRACKNELL,

BERKS.,

RG12 8FT.

CONTENTS

SAFETY PRECAUTIONS.........................................................................................................................................................2

SERVICEHINTS......................................................................................................................................................................3

SERVICE POSITION................................................................................................................................................................4

ADJUSTMENT PROCEDURE AND SELF-CHECK..................................................................................................................5

WAVEFORM PATTERN TABLE...............................................................................................................................................6

ALIGNMENT SETTINGS..........................................................................................................................................................7

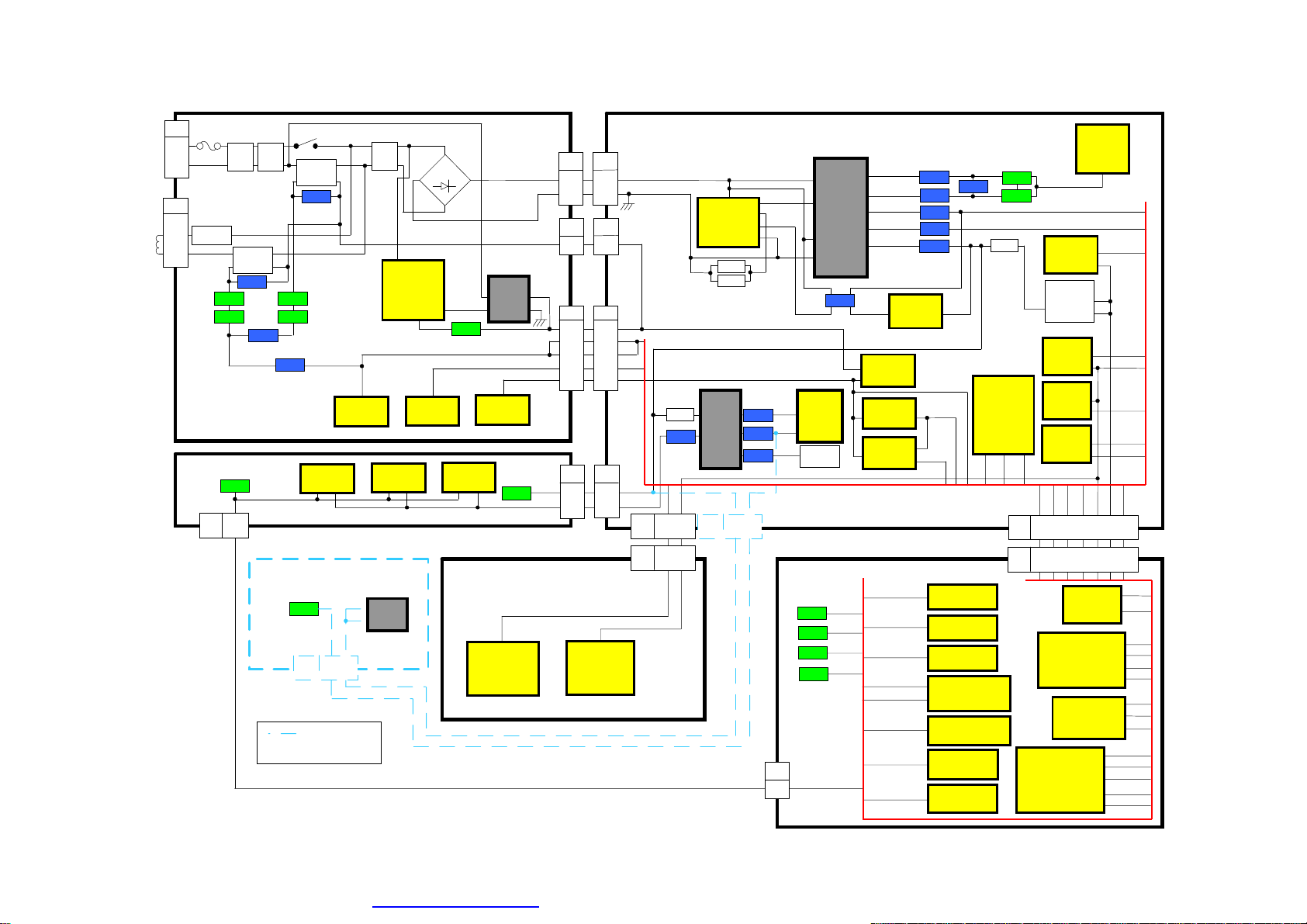

BLOCK DIAGRAMS..................................................................................................................................................................8

PARTS LOCATION.................................................................................................................................................................13

REPLACEMENT PARTS LIST................................................................................................................................................14

SCHEMATIC DIAGRAMS.......................................................................................................................................................27

CONDUCTOR VIEWS............................................................................................................................................................32

SAFETY PRECAUTION

GENERAL GUIDE LINES

1.It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2.When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3.After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4.When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5.Potentials as high as 33kV [31,5kV] are present when

this receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6.After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

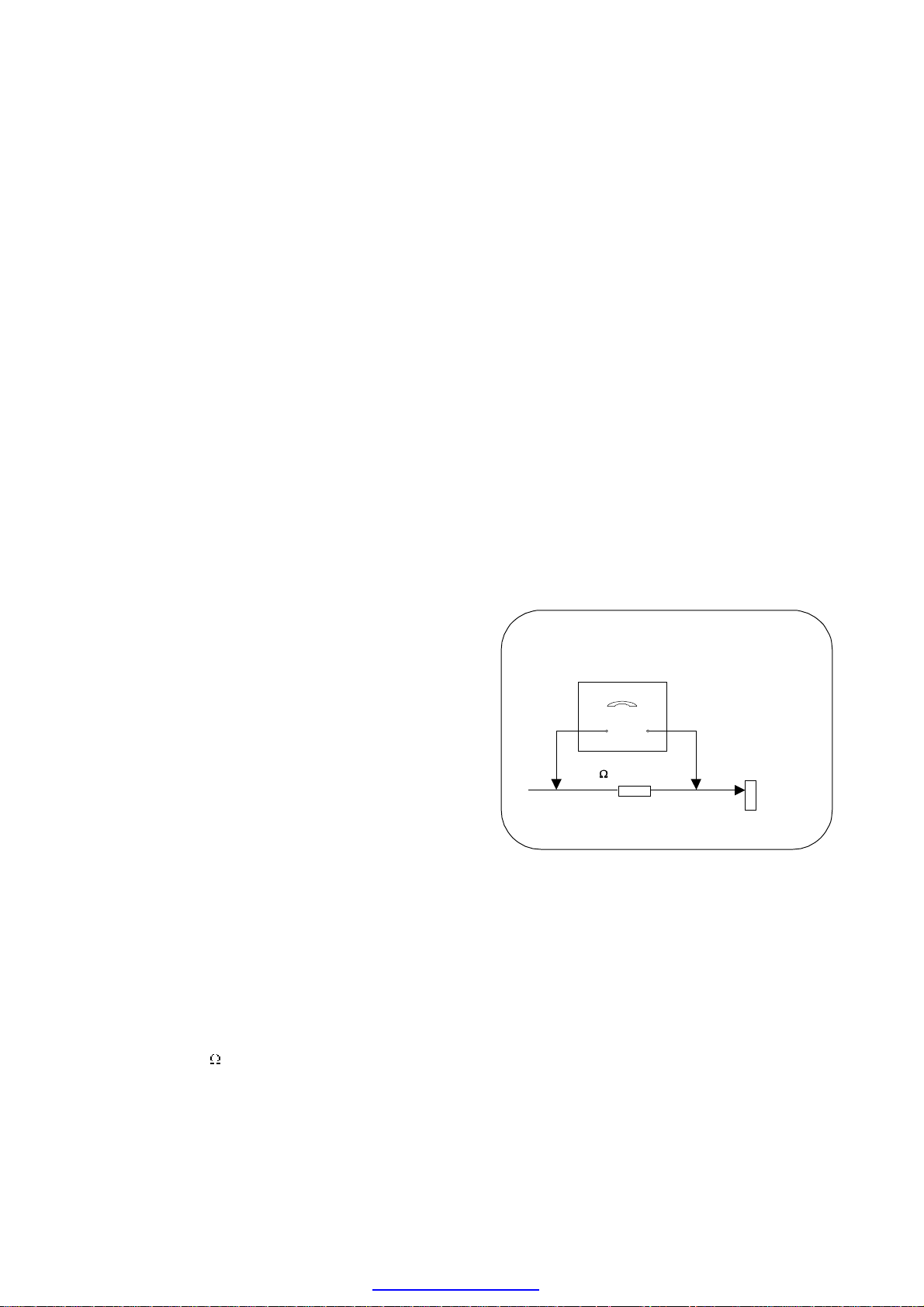

LEAKAGE CURRENT COLD CHECK

1.Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2.Turn on the receiver s power switch.

3.Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1.Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2.Connect a 2k 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3.Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4.Check each exposed metallic part and check the

voltage at each point.

5.Reverse the a.c. plug at the outlet and repeat each of

the previous measurements.

6.The potential at any point should not exceed

1,4 Vrms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

HOT CHECK CIRCUIT

a.c. VOLTMETER

2k 10 Watts

TO INSTRUMENT'S EXPOSED

METALLIC PARTS

Fig. 1.

X-RADIATION WARNING

1.The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2.When using a picture tube test jig for service, ensure

that the jig is capable of handling 33kV [31,5kV]

without causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1.Set the brightness to minimum.

2.Measure the high voltage. The meter should indicate:

32kV ± 1kV [30,5kV ± 1kV].

If the meter indication is out of tolerance, immediate

service and correction is required to prevent the

possibility of premature component failure.

3.To prevent any X-Radiation possibility, it is essential

to use the specified tube.

WATER PIPE

(

EARTH)

2

PDF created with pdfFactory trial version www.pdffactory.com

SERVICE HINTS

How to remove the rear cover

1.Remove the 12 screws as shown in Fig.2.

SCREWS

LOCATION OF CONTROLS

Fig. 2

Focus 1

Focus 2

Screen

FOR TX-32PS12 MODEL:

D-Board

DF-Board

SCREWS

G-Board

L-BoardH-Board A-BoardFocus

Fig. 3

3

PDF created with pdfFactory trial version www.pdffactory.com

FOR TX-28PS12 MODEL:

Screen

D-Board

G-Board

HOW TO MOVE THE CHASSIS INTO SERVICE POSITION

1.Remove the bead clamper from the mains lead.

2.Hold and lift the rear of the chassis and gently pull the chassis towards you, as shown in Fig.4.

3.Release the respective wiring clips and rotate the chassis horizontally through 90° anti-clockwise.

4.Locate the chassis to position Fig .5. :

5.After servicing ensure all wiring is returned to its original position before returning the receiver to the customer.

Fig.4 .

Fig. 5.

4

PDF created with pdfFactory trial version www.pdffactory.com

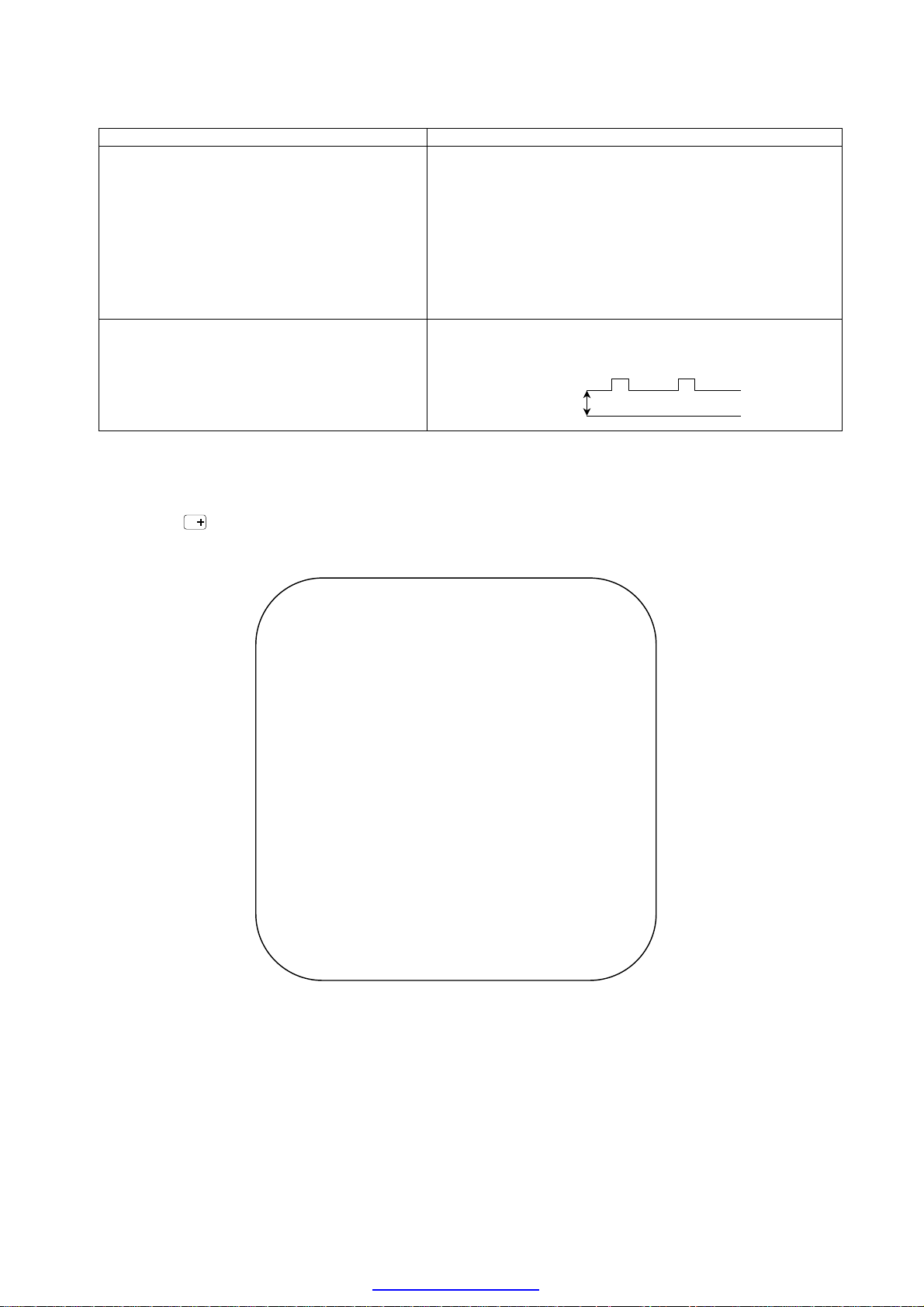

ADJUSTMENT PROCEDURE

A

Item / Preparation Adjustments

+B SET-UP

1.Receive a Window pattern.

2.Set the controls :

BrightnessMinimum

ContrastMinimum

VolumeMinimum

CUT OFF / Ug2 Test

1.Receive a Window pattern.

2.Normalize the TV set.

3.Set brightness: minimum.

Confirm the following voltages:

TPD1 205±10V TPD11 5 ±0,5V

TPD2 137± 2V TPD12 3,3±0,1V

TPD3 42±2V TPD13 2,5±0,1V

TPD5 42± 2V TPD14 3,3 ±0,1V

TPD6 12,5± 1V TPD15 5 ±0,5V

TPD7 -12,5±1V TPD16 5±0,5V

TPD8 30,5± 1V TPG3 7,5±0,5V

TPD9 9± 1V TPG5 300±10V

TPD10 8± 0,5V

To adjust Cutoff connect an oscilloscope to the Blue cathode. Adjust

the screen VR until the black level is 170V +0V/-5V.

Black Level

170V+0V/-5V

GND

SELF CHECK

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set.To enter Self-Check mode, press

the STATUS button on the remote control and at the same time press the down (-/v) button on the customer controls at

the front the TV set. To exit Self Check, switch off the TV set at the power button.

E2O.K.

DDPO.K.

VSPO.K.

VSWO.K.

TUNO.K.

MSPO.K.

DPL--MAS---

OPTION 10D

OPTION 200

OPTION 310

OPTION 410

OPTION 500

OPTION 611

OPTION 70C

OPTION 840

OPTION 900

OPTION 1080

OPTION 1119

OPTION 1208

OPTION 1308

CHECK33

SUM****

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

5

PDF created with pdfFactory trial version www.pdffactory.com

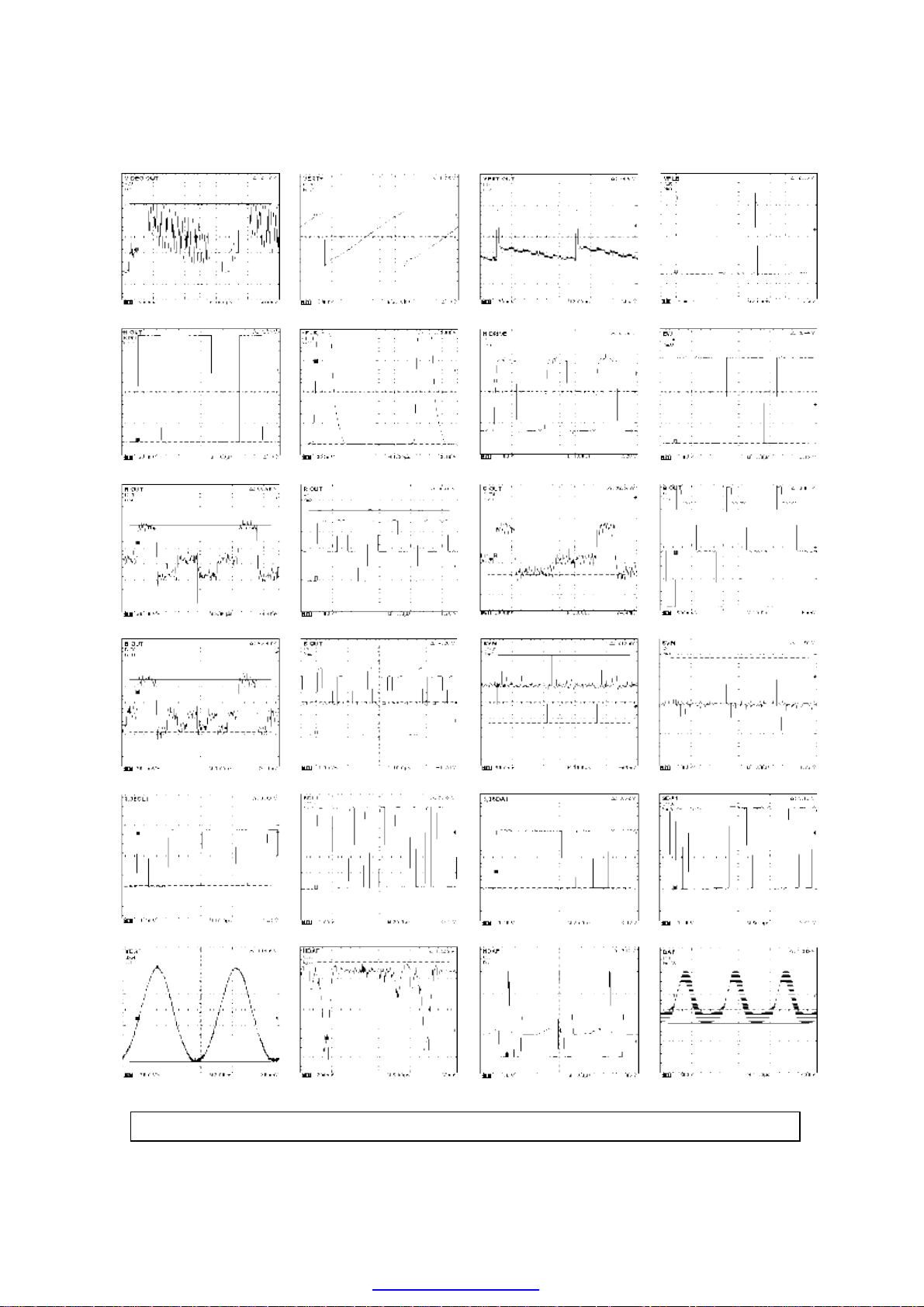

WAVEFORM PATTERN TABLE

CONDITIONS: CONTRAST...MAX, BRIGHTNESS...MID, COLOUR...MID, SHARPNESS...MID

6

PDF created with pdfFactory trial version www.pdffactory.com

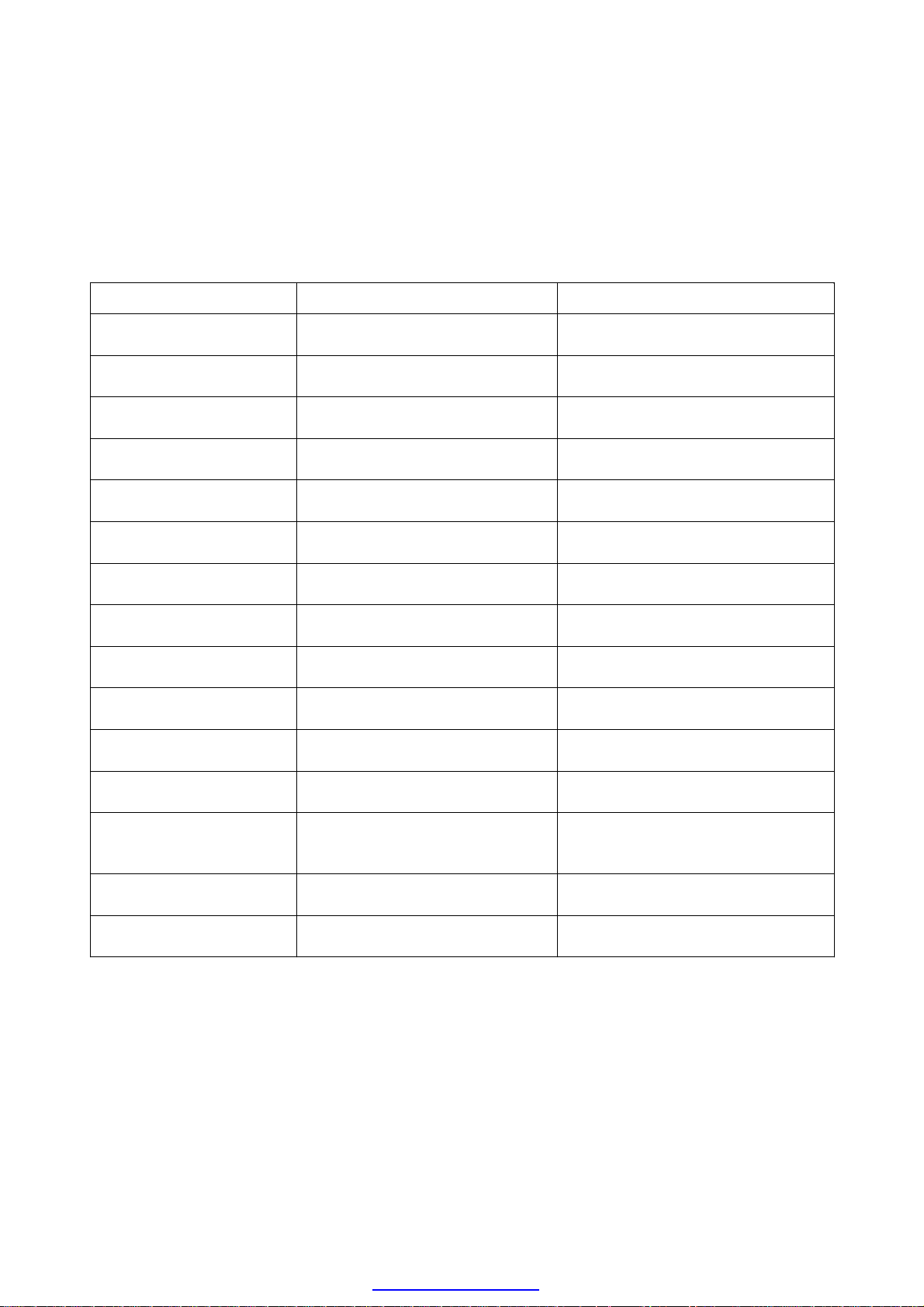

ALIGNMENT SETTINGS

(The figures below are nominal and used for representative purposes only.)

1.Set the Bass to maximum position, set the Treble to minimum position, set the Volume to minimum then press the

down button (-/v) on the customer controls at the front of the TV and at the same time press the INDEX button on the

remote control, this will place the TV into the Service Mode 1.

2.Press the RED/GREEN buttons to step up / down through the functions.

3.Press the YELLOW/BLUE buttons to alter the function values.

4.Press the STR button after each adjustment has been made to store the required values.

5.To exit the Service Mode, press the "N" button.

Alignment Function

Horizontal Position

Vertical Position

Horizontal Amplitude

Vert. Amplitude

EW-amplitude

Lower Corner

Trapezium-comp

Upper Corner

Vertical Symmetry

Vertical Linearity

Note: All setting values are approximate

Setting indication

H-Pos

21

V-Pos

27

H-Amp

41

V-Amp

-66

EW-Amp 1

- 25

Lower Corner

2

Trapez 1

-7

Upper Corner

-2

V-Sym

-4

V-Lin

40

Settings / Special features

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Angle

Bow

DVCO

Highlight

Lowlight

Sub-Brightness

Angle

-2

Bow

0

DVCO

-1

High040303180350

Low007101320160

Sub-Brightness

20

Optimum setting.

Optimum setting.

Receive a PAL Colour Bar Pattern. For

DVCO alignment press "Blue" button, wait

until the colours are changing slowly and

press "STR".

Optimum setting.

Optimum setting.

7

PDF created with pdfFactory trial version www.pdffactory.com

8

V

A

A

Y

A

V

Y

Q109

Y

Q361

Q3

9

9

9

AV1

VIDEO IN 20

VIDEO OUT 19

RED IN 15

GREEN IN 11

BLUE IN 7

AV2

Y/VIDEO IN 20

VIDEO OUT 19

C IN 15

AV4

Y/VIDEO IN 20

VIDEO OUT 19

C/RED IN 15

GREEN IN 11

BLUE IN 7

Q3015

Q3014

TUNER CVBS

15 20 21 22

H1

AV1 VIDEO IN

AV2 Y/ VIDEO IN

AV2 C IN

AV4 Y/ VIDEO IN

AV4 C IN

V3 C

V3

R1

G1

B1

R2

G2

B2

V3 CVBS

2

IC3301

3

TDA8601T/C1

4

6

RGB & FB SW

7

MATRIX

8

24, 22

17, 15

19

10, 8

IC3001

12

CXA2069Q

1

IDEO/AUDIO

3

MATRIX

5

63

12

11

10

AV2 VIDEO OUT

41

56

58

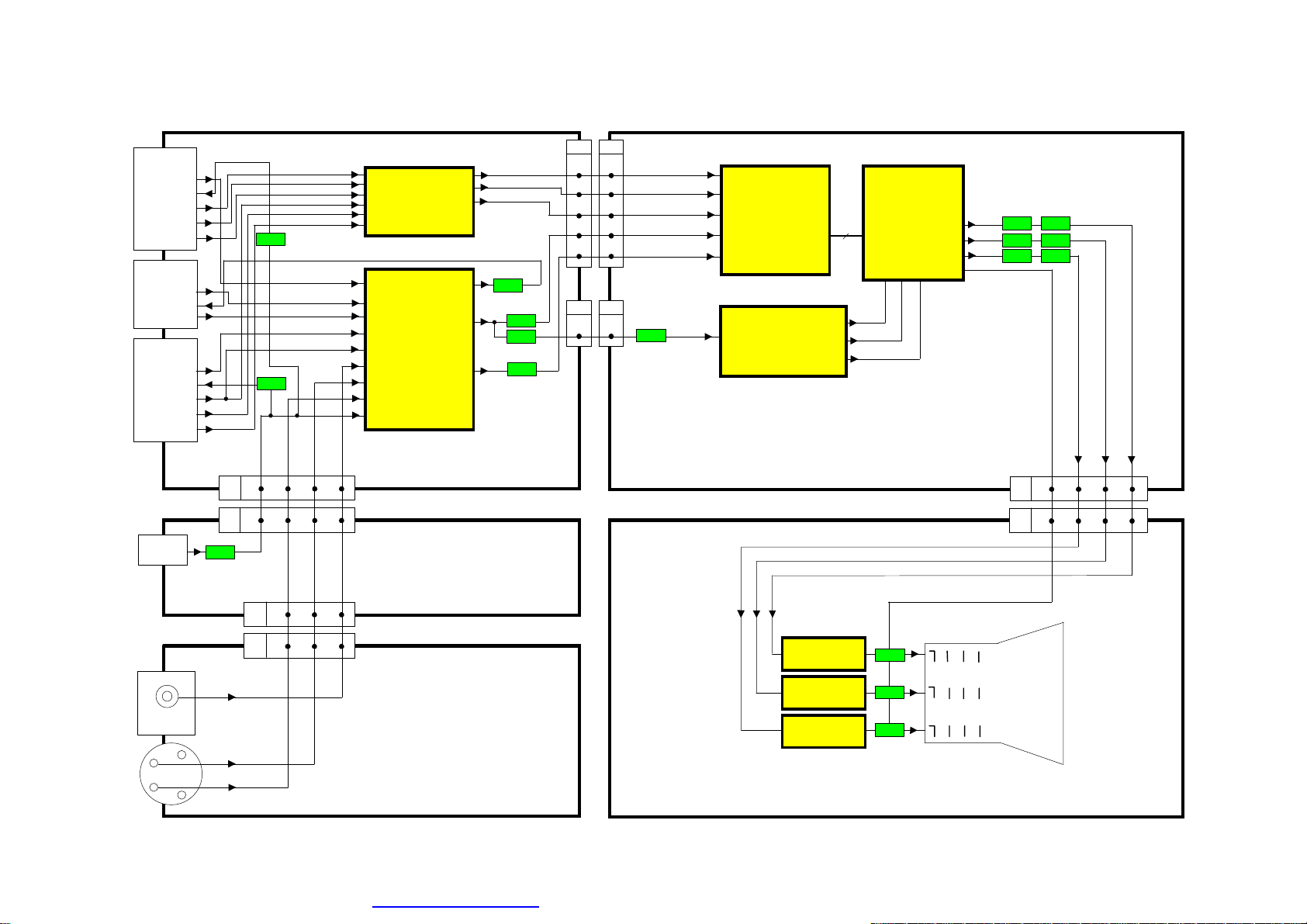

VIDEO BLOCK DIAGRAM

H4

A4

7

R EXT

G EXT

B EXT

Q3013

MAIN Y/CVBS

Q3301

Q3016

MAIN C

Q3011

H - BOARD

8

9

11

12

1H51

7

8

9

11

12

A5

Q1125

A - BOARD

R EXT

G EXT

B EXT

MAIN Y/CVBS

MAIN C

TEXT CVBS

39

40

41

55

56

121

IC1501

VSP9405VKB11

IDEO SIGNAL

PROCESSOR

Y0÷Y7

IC1101

SDA6000-A23

MICRO

PROCESSOR

8bit

112

113

114

IC1701

DDP3315CQAE3

DEFLECTION

PROCESSOR

0÷Y7

515253

R OSD

G OSD

B OSD

R OUT

G OUT

B OUT

SENSE

Q1705 Q1708

Q1704 Q1707

Q1703 Q1706

6 4 3 5

A2

42

43

44

35

15 20 21 22

D1

TUNER

VIDEO

1 2 4

D8

1 2 4

G7

AV3

C

PDF created with pdfFactory trial version www.pdffactory.com

D - BOARD

G - BOARD

L - BOARD

3

3

3

IC351

R OUT

IC361

G OUT

IC371

B OUT

Q351

6 4 3 5

L2

CRT

71

V

A

A

9

AV1

RIGHT IN 2

LEFT IN 6

RIGHT OUT 1

LEFT OUT 3

AV2

RIGHT IN 2

LEFT IN 6

RIGHT OUT 1

LEFT OUT 3

AV4

RIGHT IN 2

LEFT IN 6

RIGHT OUT 1

LEFT OUT 3

AUDIO

MONITOR

OUT

AV1 R IN

AV1 L IN

AV1 R OUT

AV1 L OUT

AV2 R IN

AV2 L IN

AV2 R OUT

AV2 L OUT

AV4 R IN

AV4 L IN

25

23

45

CXA2069Q

43

IDEO/AUDIO

18

16

40

38

11

9

IC3001

MATRIX

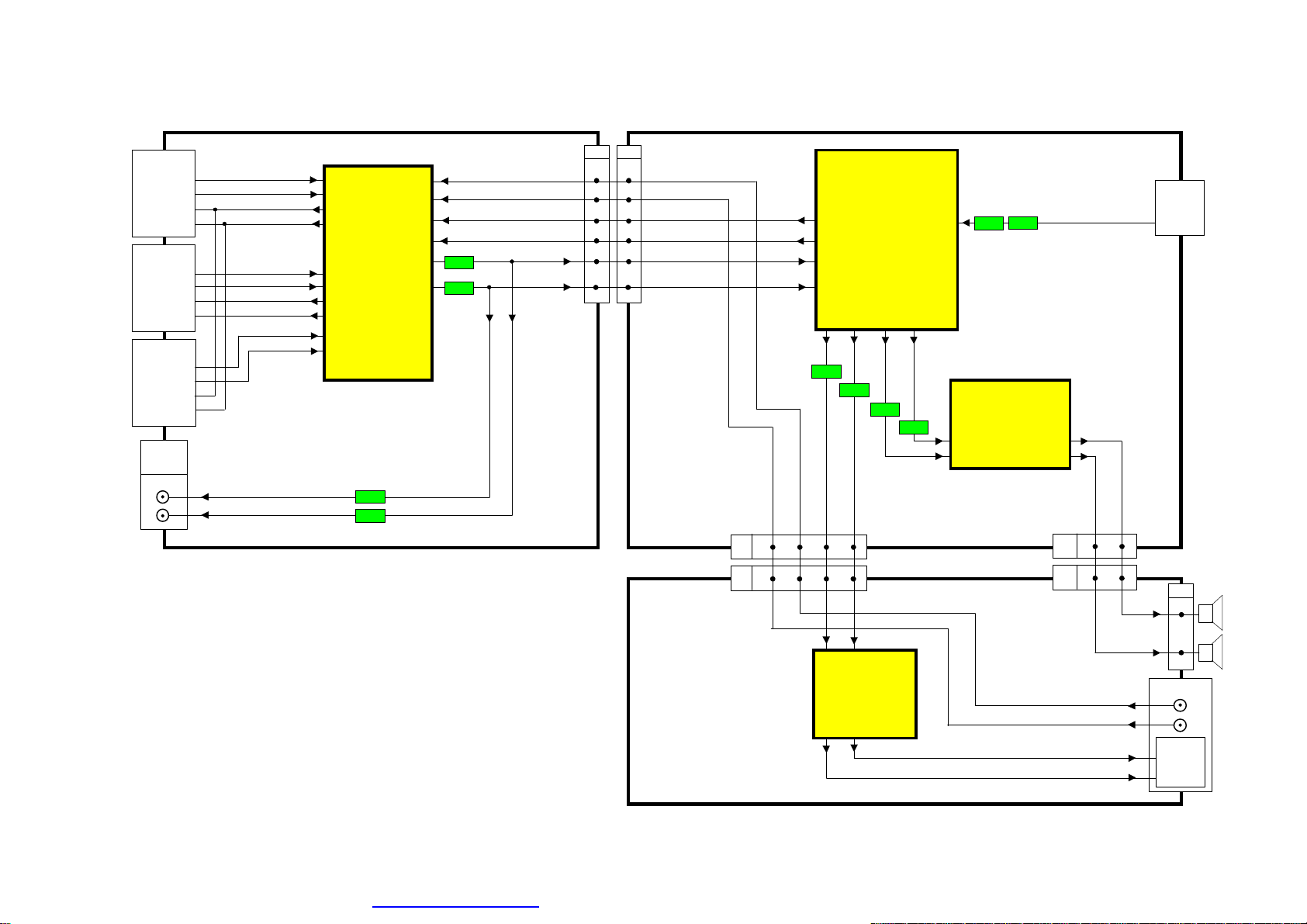

AUDIO BLOCK DIAGRAM

H1

D1

25

24

18

17

9

8 8

25

AV3 R

24

AV3 L

18

TUNER R

17

TUNER L

9

R OUT

L OUT

36

37

57

56

2425

Q2005

AV3 R

4

AV3 L

2

TUNER R

64

TUNER L

62

MAIN R

54

Q3010

MAIN L

52

Q3009

IC2001

MSP3410GAB83

UDIO

PROCESSOR

27

HP R

HP L

SPKR OUT R

Q2004

Q2003

67

28

Q2002

SPKR OUT L

NA IN 1

Q101 Q102

AUDIO OUTPUT

2 L IN

5 R IN

TUNER

MSP

IC251

LA4282

R OUT 7

L OUT 11

L

R

Q3006

Q3005

PDF created with pdfFactory trial version www.pdffactory.com

H - BOARD

D - BOARD

G - BOARD

6 7 16 14

D8

6 7 16 14

G7

4 1

D17

4 1

G16

G14

1

R

5 HP R

3 HP L

NJM4556AD

OP. AM PLIFIER

4

L

IC2351

AV3

2 L

3 R

R

L

HEADPHONE

HP R 7

HP L 1

10

V

A

V

Y

A

A - BOARD

5

SDA16SCL1

IC1104

EAROM

IC1102

FLASH MEMORY

D0÷D15

D0÷D15

IC1106

SDRAM

CE 26

CS 19

IC1101

MICRO

PROCESSOR

46 CSROM

AUDIO MUTE 90

D0÷D15

44 CSSDRAM

AV LINK OUT 7

AV LINK IN 6

SDA1 99

SCL1 98

SDA2 101

SCL2 100

SDA3 75

SCL3 74

ON/OFF 92

PROT1 93

RST IN 73

AFC 125

SERVICE 76

KEYSCAN 124

RC SIG 5

LED SBY 77

VPROT 12

IC1701

DEFLECTION

PROCESSOR

Q1110

Q1109

IC1501

IDEO SIGNAL

PROCESSOR

VPROT 32

PWM1 20

SDA1 (3,3V) 64

SCL1 (3,3V) 63

RESQ 62

VSTBY 24

IC1107

BUS LEVEL

SHIFTER

3,3V=>5V

SDA1 18

2 SDA1

3 SCL1

SCL1 17

SDA2 16

4 SDA2

SCL2 15

5 SCL2

SDA3 14

6 SDA3

SCL3 13

7 SCL3

IC1103

Q1102Q1101

Q1111

Q1108

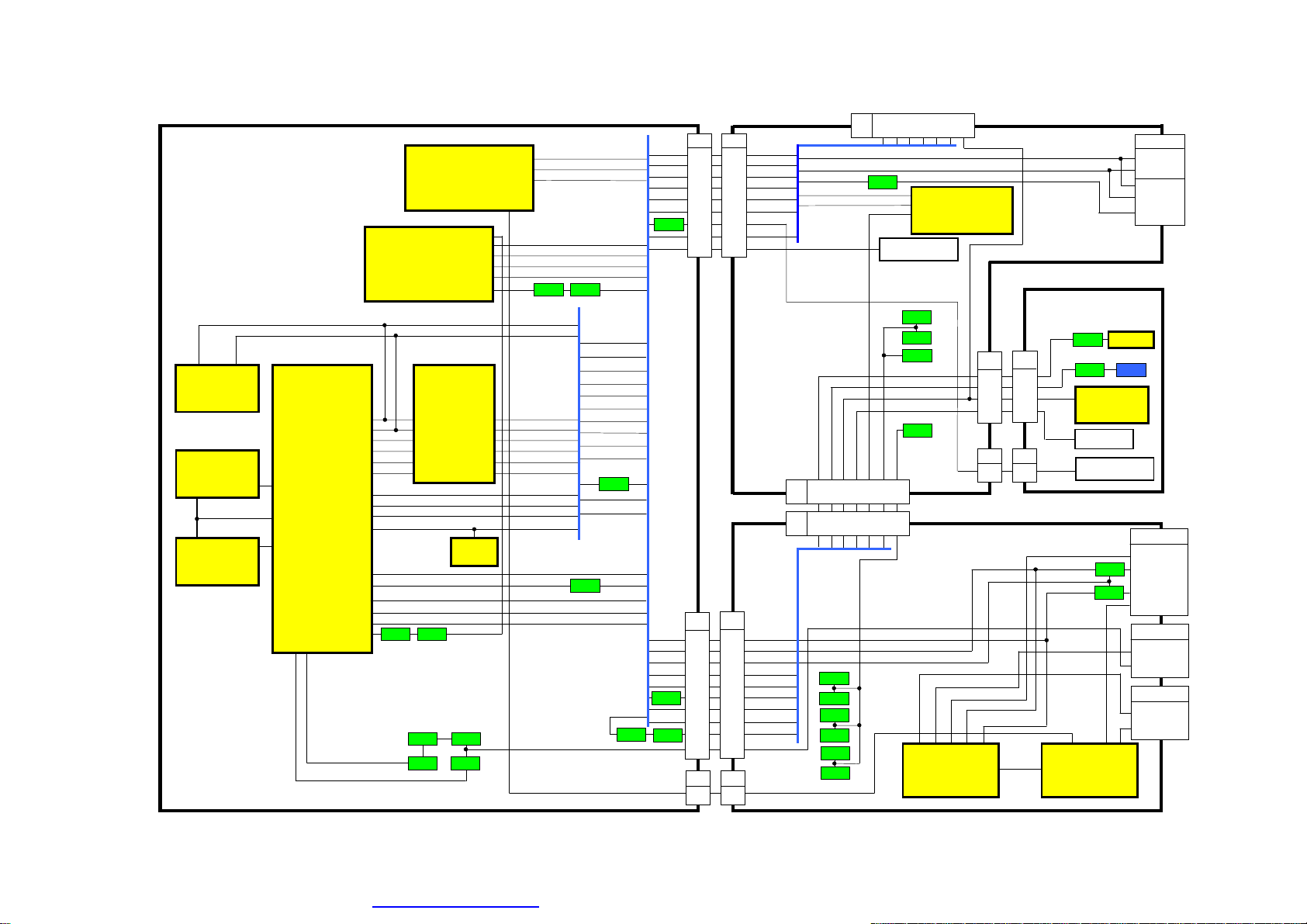

CONTROL BLOCK DIAGRAM

BUS

A1

D2

30

H5

14

15

16

17

18

H4

35

34

33

32

31

28

27

15

5

6

8

9

3

6

SDA3

SCL3

SDA2

SCL2

SDA1

SCL1

ON/OFF

AFC

PROT1

SDA3

SCL3

SERVICE

AUDIO MUTE

KEYSCAN

RC SIG

LED SBY

ROTATION

RST MAIN

AV LINK

SDA1 (3,3V) 6

SCL1 (3,3V) 13

RESET 24

FBL1

37

4

Q1717

SDA1 (3,3V)

SCL1 (3,3V)

SDA1

SCL1

SDA2

SCL2

SDA3

SCL3

ON/OFF

PROT1

AUDIO MUTE

RESET IN

Q1718

BUS

Q1112

SDA1 (3,3V)

SCL1 (3,3V)

RST MAIN

ROTATION

SDA1 (3,3V)

SCL1 (3,3V)

RST MAIN

ON/OFF

PROT1

ON/OFF

SDA1 (3,3V)

SCL1 (3,3V)

SDA1

SCL1

SDA2

SCL2

SDA3

SCL3

AUDIO MUTE

Q1106

LED SBY

RST MAIN

SERVICE

KEYSCAN

RC SIG

LED SBY

Q1115

AFC

Q1104

Q1113

Q1116

AV LINK

FBL1

A5

14

15

16

17

18

A4

35

34

33

32

31

30

28

27

15

5

6

8

9

3

6

D1

H1

SDA2

SCL2

AFC

BUS

BUS

ROTATION

LED SB

123

123

Q3003

Q3004

Q3017

Q3018

Q3007

Q3008

D3

Q103

RST MAIN

KEYSCAN

RC SIG

4

6

462830

SDA2

SCL2

SCL3

234

FBT, HEATER

Q251

Q252

Q2001

Q2006

UDIO MUTE

SMUTE2

28

30

13

SDA1

SCL1

56

3 SDA2

2 SCL2

21 RESET

SLOW4

SLOW2

20

IC3001

IDEO/AUDIO

MATRIX

SDA3

8

IC2001

SLOW1

27

RC SIG

7

PROC.

33

UDIO

D8

9

10

11

12

D28G18

6

H - BOARD

SCL3

SDA3

34

36

G7

10

11

12

CH SEL

9

6

ROTATION

LED SBY

RC SIG

ON/OFF

SERVICE

5

RGB & FB SW

D - BOARD

G - BOARD

Q1901

IC1900

Q1002

RC1001

RC RECEIVER

KEYSCAN

POWER SUPPLY

Q3001

Q3000

131415

IC3301

MATRIX

D1001

TUNER

SDA2

SCL2

SDA2

SCL2

AFC

AV1

8 SLOW1

10 (SCL3)

12 (SDA3)

16 FBIN1

AV2

8 SLOW2

10 AV LINK

AV4

8 SLOW4

16 FBIN2

PDF created with pdfFactory trial version www.pdffactory.com

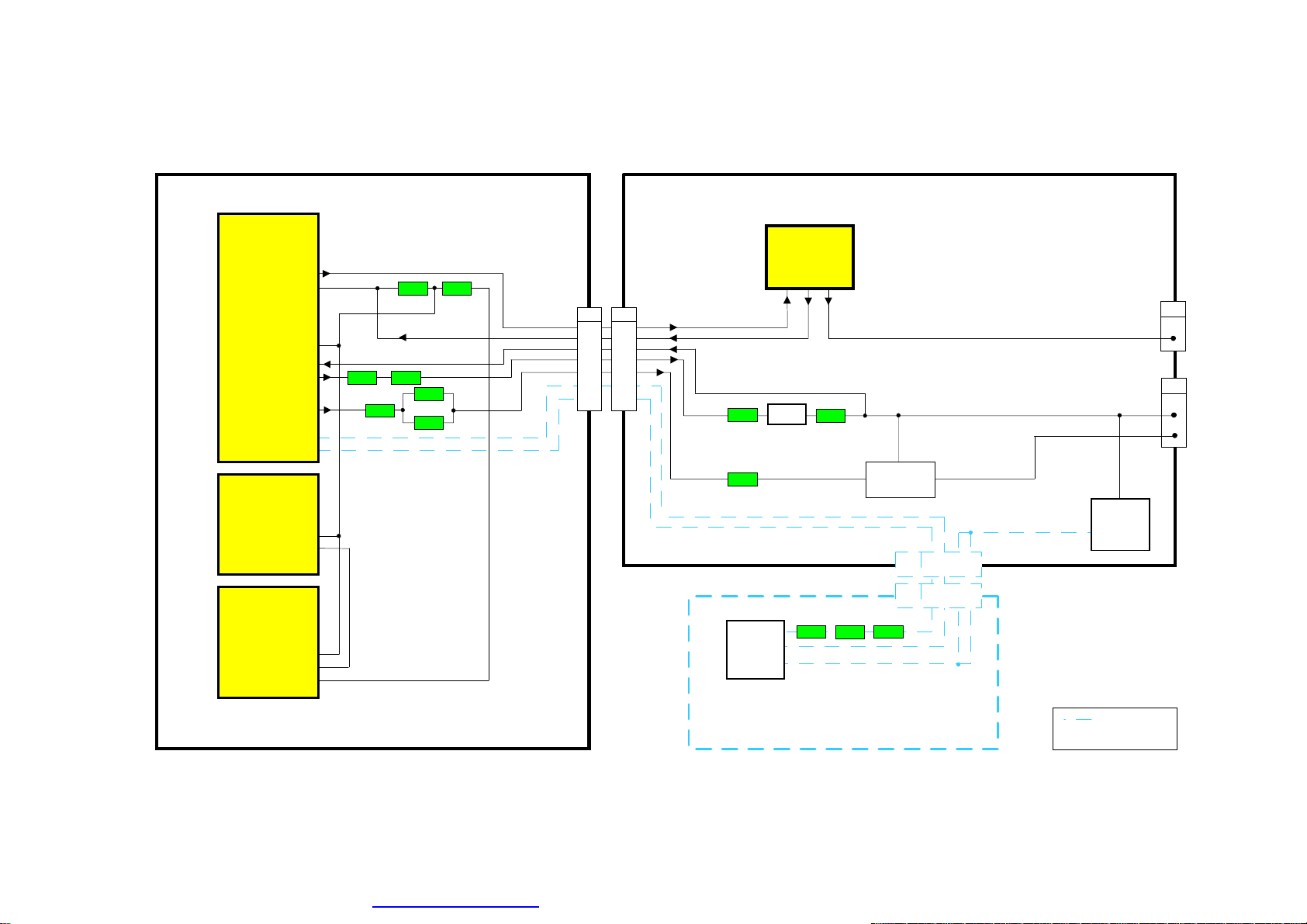

DEFLECTION BLOCK DIAGRAM

V

V

11

IC1701

DDP3315CQAE3

DEFLECTION

PROCESSOR

VERT+ 37

VPROT 32 Q1102 Q1101

VS 10

HFLB 30

HOUT 23

EW 39 Q1715

VDAF 22

HDAF 25

IC1501

VSP9405VKB11

IDEO SIGNAL

PROCESSOR

SDA6000-A23

PROCESSOR

VS 23

H SYNC 8

IC1101

MICRO

V SYNC 102

H SYNC 103

V PROT 12

V SYNC

VFLB

Q1701 Q1702

H DRIVE

Q1713

Q1714

A - BOARD

D - BOARD

IC451

LA7876N

VERTICAL

836

VERT DY

A1

D2

13

12

9

6

4

212

EW

VERT+

13

VFLB

12

HFLB

9

H DRIVE

6

EW

4

VDAF

HDAF

1

T501

Q503

Q703

T701

Q551

DIODE

MODULATOR

10

H-DAF

-DAF

8

127

D14

8

127

DF1

Q522

Q523

Q521

5

8

1

DAF

FBT

D16

3

D15

4

1

HORIZ DY

PDF created with pdfFactory trial version www.pdffactory.com

DF - BOARD

for 32 models

Used only

12

r

r

r

A

V

V

A

V

V

V

V

V

V

V

V

V

V

V

V

V15V

V

POWER SUPPLY BLOCK DIAGRAM

G1

MAINS I N

F801

1

4

Line

Filte

G2

DEGAU SS

COIL

1

D807

2

RL803

D860

Q856

Q855

G - BOARD

L- BOARD

Q906

9V

1

L2

Line

Filte

D861

S801

RL801

D854

Q853

Q854

D862

10

IC1900

IC351

6

2 2

PFC

Filte

2,3,7,8

STBY POWER

IC361

-

IC801

SUPPLY

IC2351

6

~

D801

+

~

400V

0V

G4

1

3

G18

1

T860

SB5V

S1

P2

Q860

IC371

2

P1

VCC

RC1001

6

S2

Q908

147V

200V

G6

15

12

11

L3

3

1

1

3

5

4

8

D11

1

3

D28

1

D9

15

12

11

3

1

D12

1

3

D- BOARD

5V SBY

SB5V HEADER

9V HEADER

9V

SB5V

POWER BU S

D1

R567

D554

8

2734

IC251

UDIO

OUTPUT

T849

4

IC849

POWER

SUPPLY

R843

R842

9VIN

3

2

1

5

5DRAIN

2VCC

1GND

D847

11

13

14

18

28V/AUDIO1

10,5V

6,5V

137V

41V/AUDIO2

10

D897

D896

D870

D871

D895

IC899

21

D884

Q898

Q897

R887

TUNER

IC3801

IC3804

1

3

T551

2

9

D558

7

D557

1

D553

8

147

9

D13

15

82

-15V

15V

27V

IC451

VERT

2

7

T501

IC3806

3

IC3805

2

2

4

1

SB2,5V

SB3,3V

5V STBY

IC2001

UDIO

PROC.

11,1 2,13

65, 66

5

IC3802

IC3803

39

8

5

SB3,3

101720

D2

42V

IC3807

+33V

SB5

3,3

+5V

+5V

2

4

1

3

1

3

5V9

22

10

9V HEADER

5V HEADER

5V HEADER

2

5V

4

9V HEADER

5V HEADER

242526

9V

POWER BUS

8V

8V

SB2,5

5

DF- BOARD

Q522

DF2

T701

147

28

H- BOARD

Used only

for 32 models

PDF created with pdfFactory trial version www.pdffactory.com

1

IC3301

RGB & FB SW

MATRIX

42

IC3001

IDEO/AUDIO

MATRIX

H1

2734

242526

22

101720

SDRAM

A1

VIDEO

IC1101

MICRO

111,116,119,123

IC1502

IC1501

5,28,34,66

35,42,50,64,68

7,12,25,72

IC1701

DEFLECTION

14,32,42

53,61,69

85,106

21,87

1

3

44,59

3,15

73

47

3,3V_STBY

3,3V_STBY

3,3V_STBY

2,5V_STBY

2,5V_STBY

1,8V

1,8V

1,8V

3,3V

3,3V

3,3V

3,3V

5V

5V

9V8

A- BOARD

A2

1

Q1706

Q1707

Q1708

Q1719

9V

9V

9V

9V

POWER BUS

9V

3,3V_STBY

5V

3,3V_STBY

3,3V_STBY

3,3V_STBY

3,3V_STBY

5V_STBY

3,3V_STBY

5

IC1103

2

IC1105

5

IC1108

1,3,9,14

27,43,49

37,47

IC1107

20

BUS L. SHIFT.

IC1104

8

IC1106

IC1102

FLASH MEM

EAROM

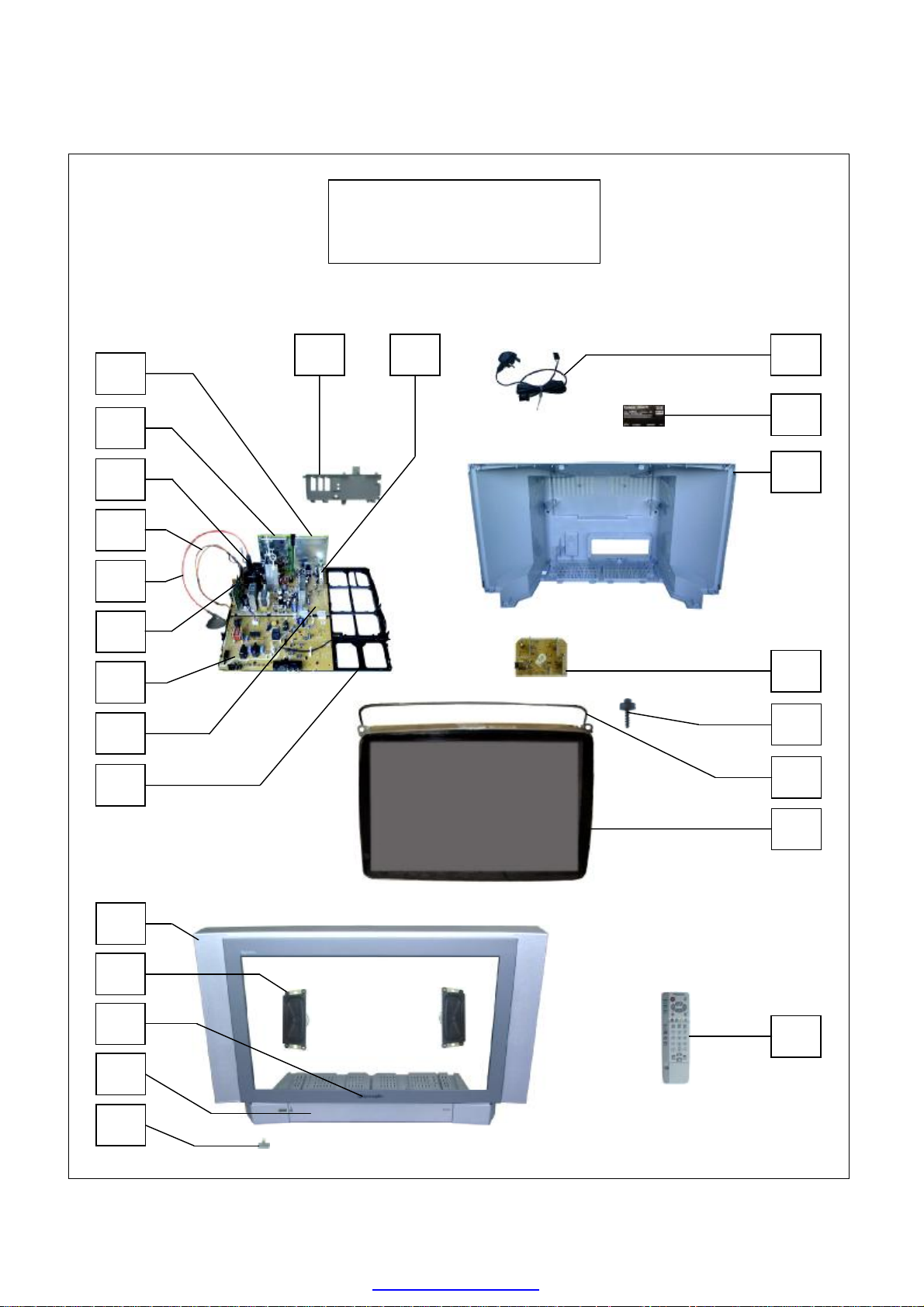

PARTS LOCATION

NOTE:

The numbers on the exploded view below

refer to the exploded view section of the

Replacement Parts List.

9

12

19

20

11

18

8

16

7

6

1

10

22

13

21

4

17

15

24

3

5

23

14

2

13

PDF created with pdfFactory trial version www.pdffactory.com

Loading...

Loading...