Page 1

ORDER No. 03-SM-007

Service Manual

Colour Television

TX-32PS10D, TX-32PS10D/B,

TX-32PS10F, TX-32PS10P,

TX-28PS10D, TX-28PS10F,

TX-28PS10P

EURO- 9L Chassis

SPECIFICATIONS

(Information in brackets [ ] refers to models 28”)

Power Source: 220-240V a.c., 50Hz

Power Consumption: 114W [105W]

Stand-by Power

Consumption: 0,6W

Aerial Impedance: 75Ω unbalanced, Coaxial Type

Receiving System: PAL-I, B/G, D/K, PAL-525/60

SECAM B/G, D/K, L/L’

M.NTSC (AV only)

NTSC (AV only)

Receiving Channels:

VHF E2-E12 VHF H1-H2 (ITALY)

VHF A-H (ITALY) VHF R1-R2

VHF R3-R5 VHF R6-R12

UHF E21-E69 CATV (S01-S05)

CATV S1-S10 (M1-M10) CATV S11-S20 (U1-U10)

CATV S21-S41 (HYPERBAND)

Intermediate Frequency:

Video/Audio

Video 38,9MHz, 33,9MHz

Sound 33,4MHz (B/G), 33,16MHz (A2)

33,05MHz (NICAM B/G,D/K,L)

32,4MHz (D/K),32,66MHz (CZ STEREO)

40,4MHz (L’), 39,75MHz (L’NICAM)

Colour 34,47MHz (PAL)

34,5MHz, 34,65MHz (SECAM)

38,3MHz, 38,15MHz (SECAM L’)

Terminals:

AUDIO MONITOR OUT Audio (RCAx2) 500mV rms 1kΩ

AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

AV1 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV2 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21-pin) C:0,3V p-p 75Ω

AV2 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV3 IN S-Video IN Y: 1V p-p 75Ω

(4-pin) C:0,3V p-p 75Ω

Audio (RCAx2) 500mV rms 10kΩ

Video (RCAx1) 1V p-p 75Ω

AV4 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

S-Video IN Y: 1V p-p 75Ω

(21-pin) C:0,3V p-p 75Ω

AV4 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

High Voltage: 32kV ± 1kV [30,5kV ± 1kV]

Picture Tube: W76ELE50X71 76cm

[W66EKT50X71 66cm]

Audio Output: 2x10W RMS, 2x20W MPO,

8Ω impedance

Headphones: 8Ω Impedance

Accessories

supplied : Remote Control

2 x R6 (UM3) Batteries

Dimensions:

Height: 567mm [510mm]

Width: 902mm [805mm]

Depth: 551mm [533mm]

Net weight: 55,5kg [43,3kg]

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

Page 2

CONTENTS

SAFETY PRECAUTIONS ......................................................................................................................................................... 2

SERVICE HINTS ...................................................................................................................................................................... 3

ADJUSTMENT PROCEDURE AND SELF-CHECK.................................................................................................................. 4

WAVEFORM PATTERN TABLE............................................................................................................................................... 5

ALIGNMENT SETTINGS .......................................................................................................................................................... 6

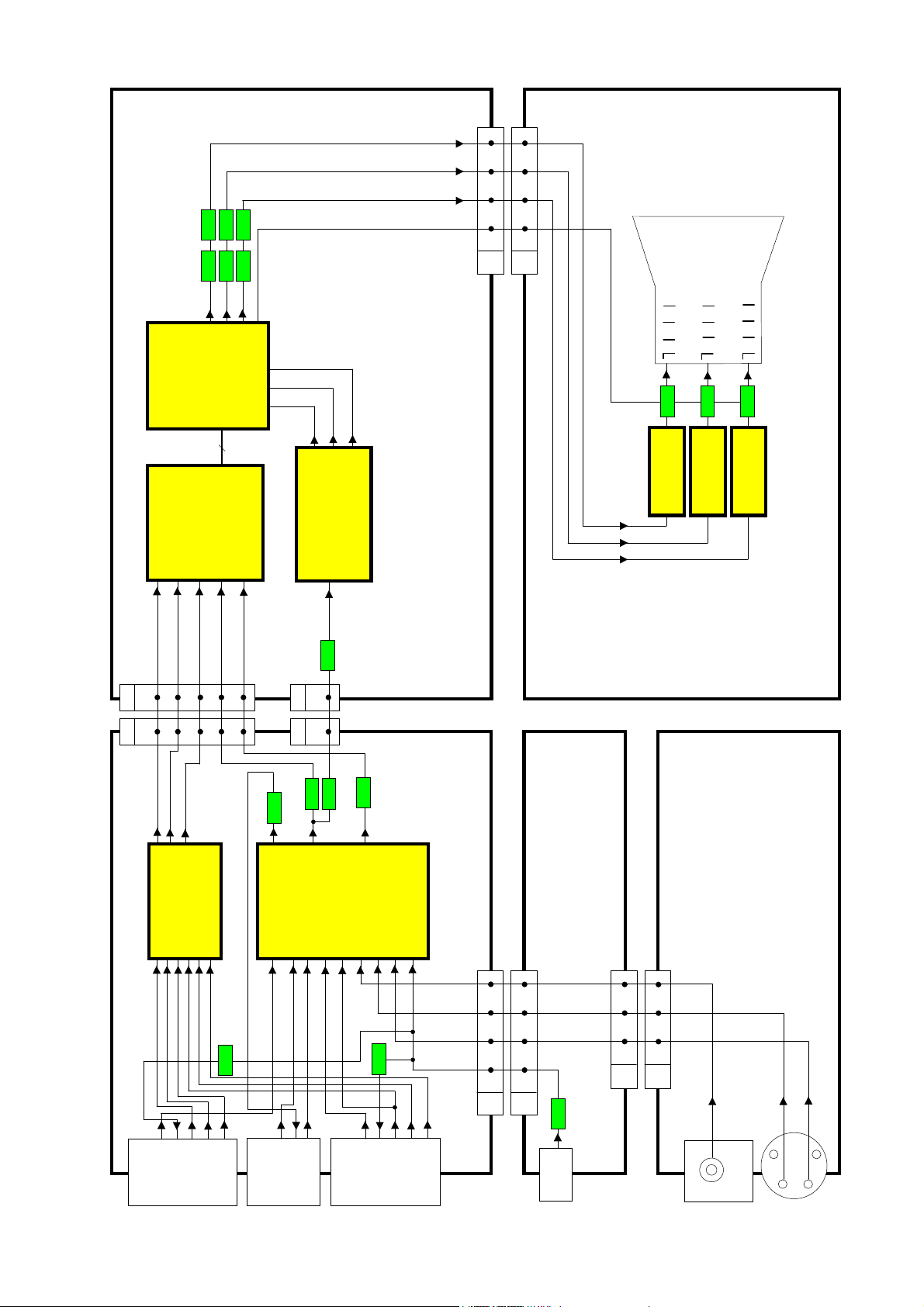

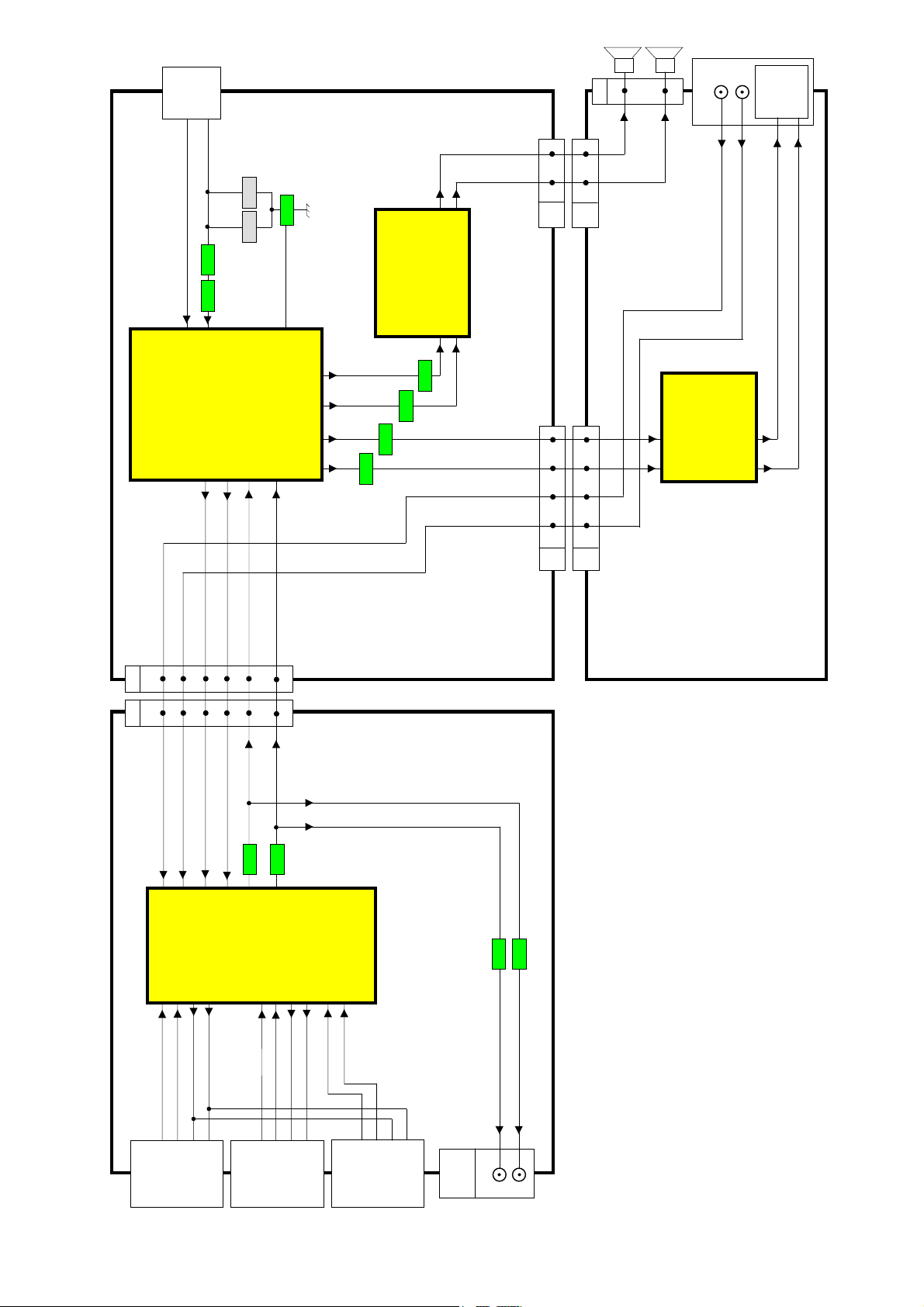

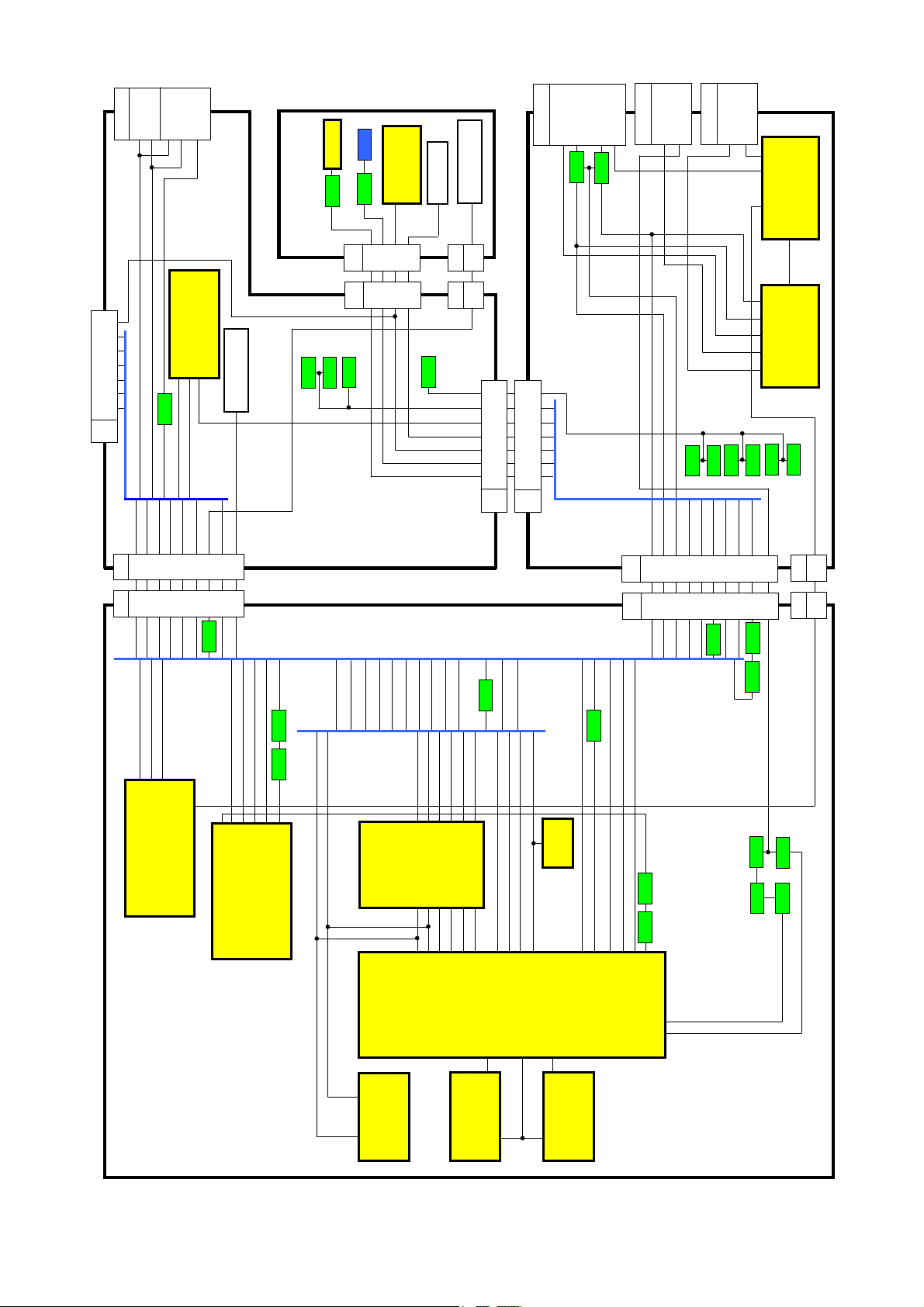

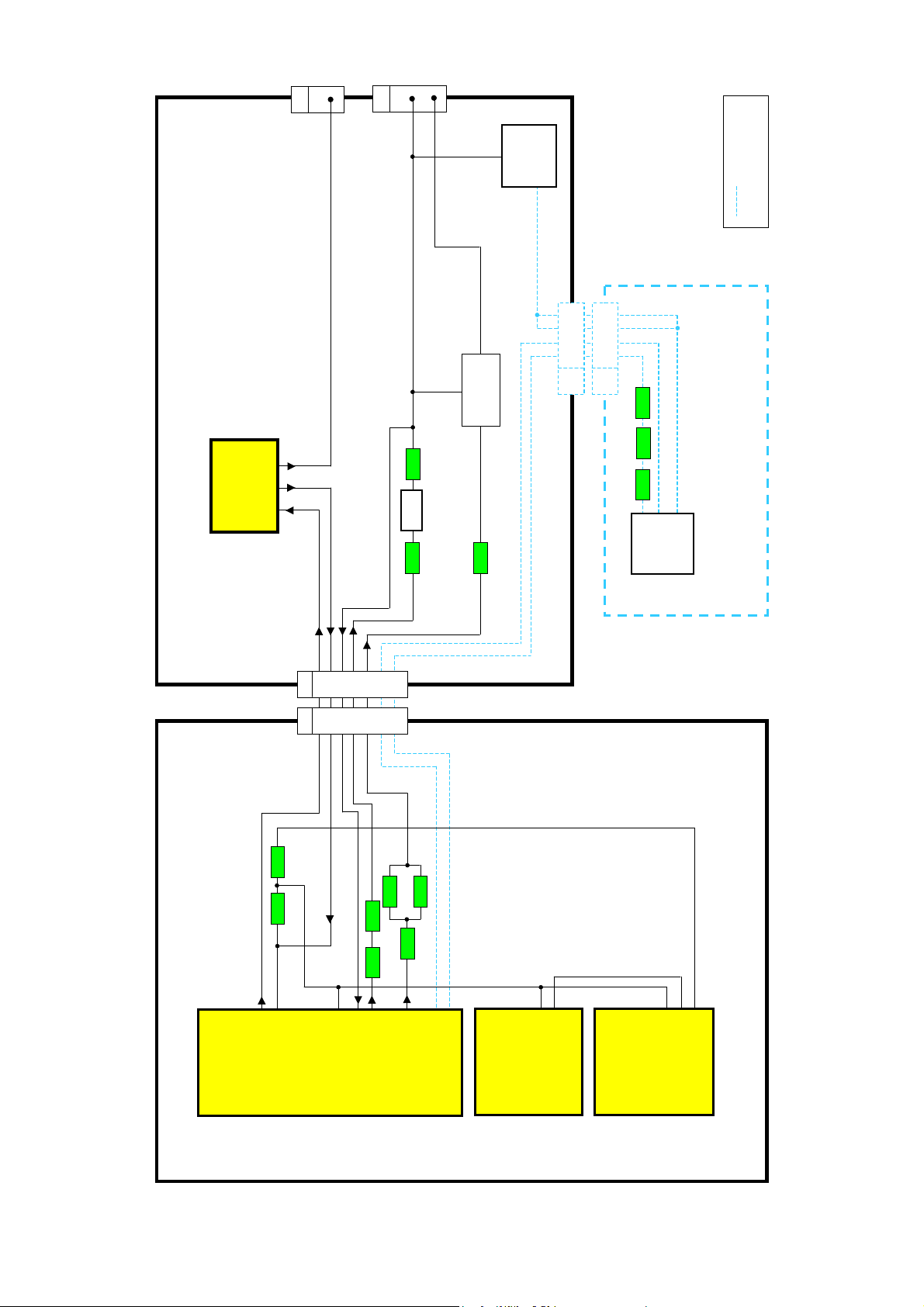

BLOCK DIAGRAMS.................................................................................................................................................................. 7

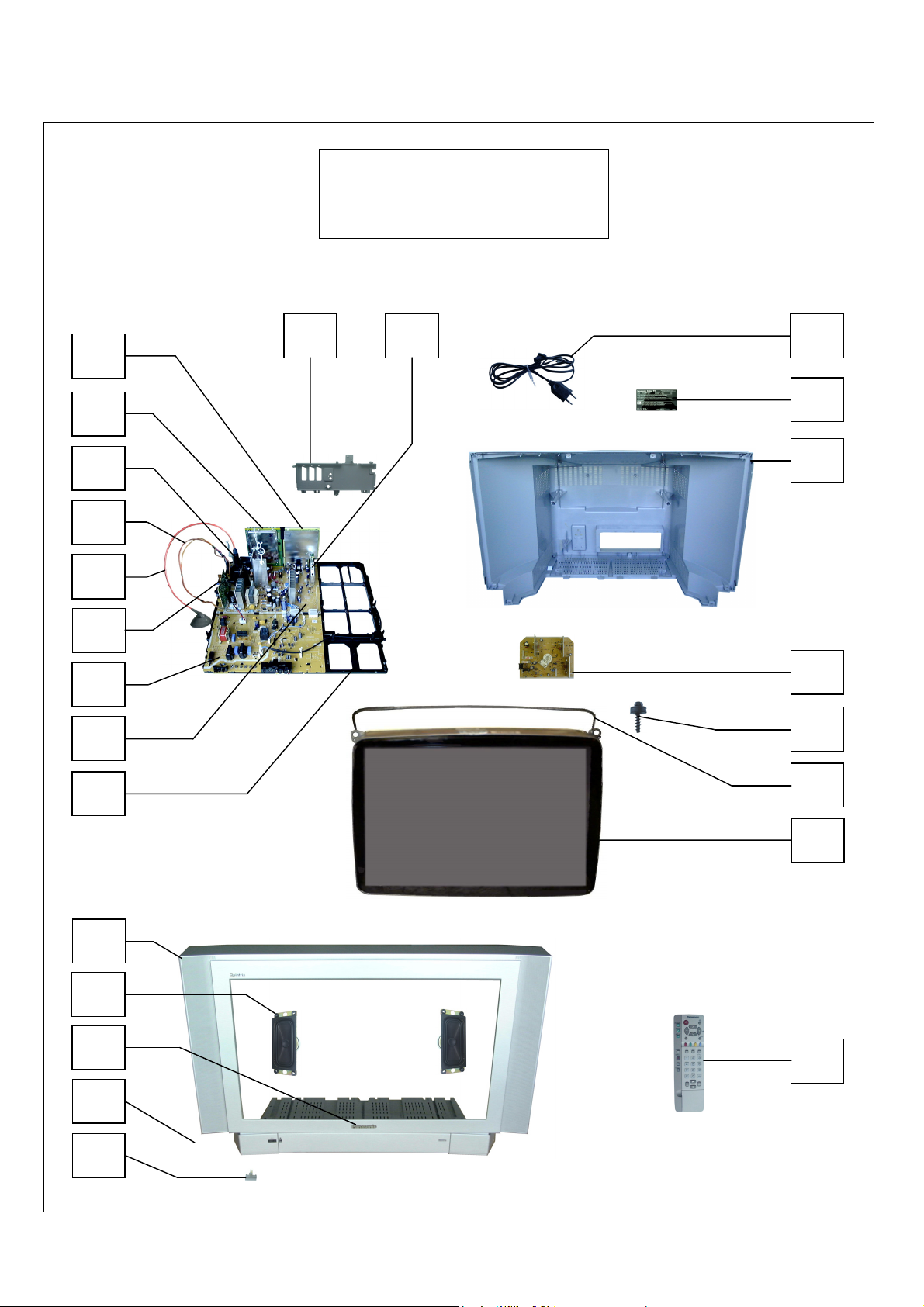

PARTS LOCATION................................................................................................................................................................. 12

REPLACEMENT PARTS LIST................................................................................................................................................ 13

SCHEMATIC DIAGRAMS....................................................................................................................................................... 29

CONDUCTOR VIEWS ............................................................................................................................................................ 34

SAFETY PRECAUTION

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5. Potentials as high as 33kV [31,5kV] are present when

this receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2. Connect a 2kΩ 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the a.c. plug at the outlet and repeat each of

the previous measurements.

6. The potential at any point should not exceed

1,4 Vrms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

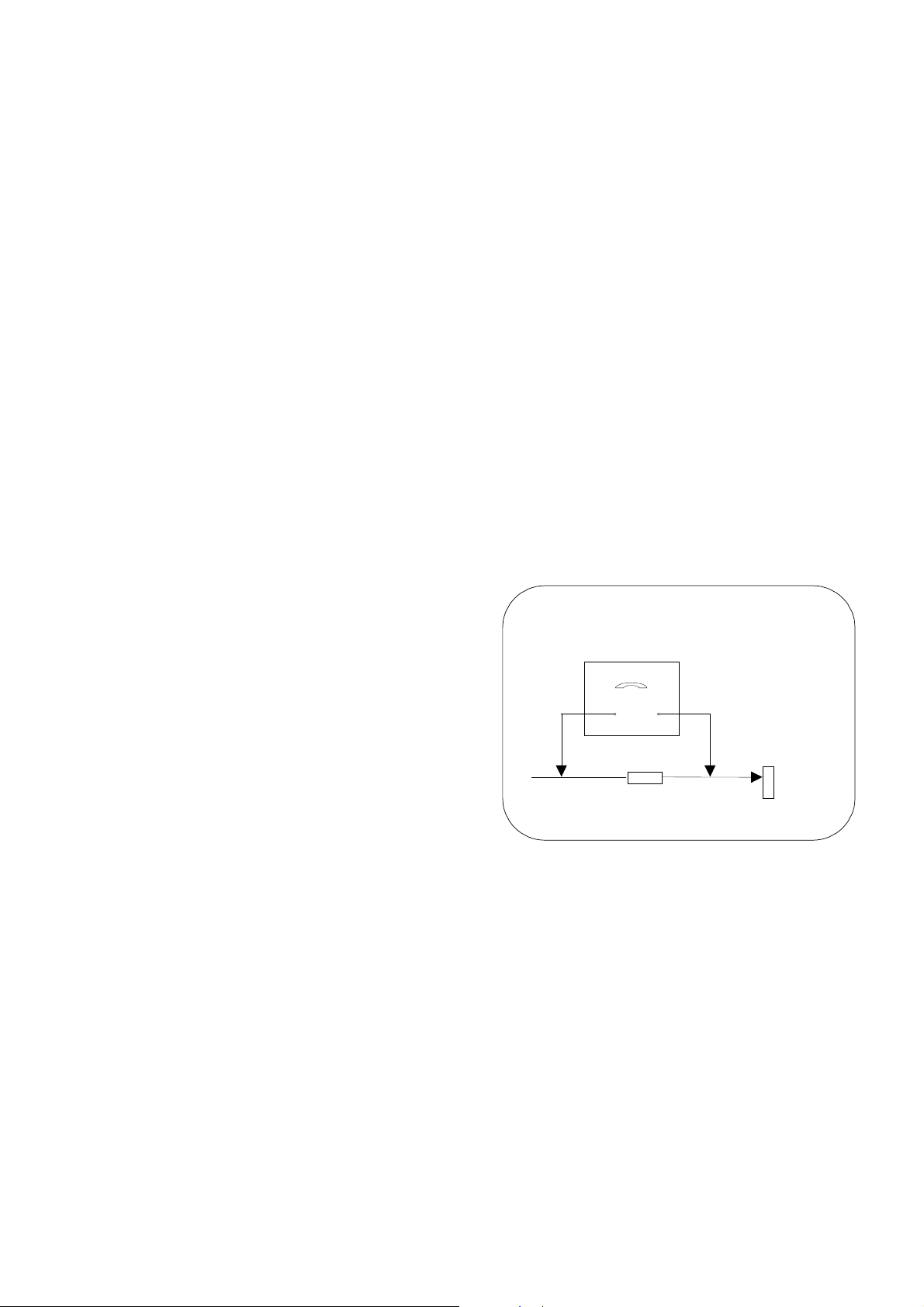

HOT CHECK CIRCUIT

a.c. VOLTMETER

2kΩ 10 Watts

TO INSTRUMENT'S EXPOSED

METALLIC PARTS

Fig. 1.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 33kV [31,5kV]

without causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should indicate:

32kV ± 1kV [30,5kV ± 1kV].

If the meter indication is out of tolerance, immediate

service and correction is required to prevent the

possibility of premature component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

WATER PIPE

(

EARTH)

2

Page 3

SERVICE HINTS

How to remove the rear cover

1. Remove the 12 screws as shown in Fig.2.

SCREWS

LOCATION OF CONTROLS

SCREWS

Fig. 2

FOR 32” MODELS:

Focus 1

Focus 2

Screen

L-BoardH-Board A-Board Focus

Fig. 3

D-Board

Screen

DF-Board

FOR 28” MODELS:

D-Board

G-Board

G-Board

3

Page 4

ADJUSTMENT PROCEDURE

A

Item / Preparation Adjustments

+B SET-UP

1. Receive a Window pattern.

2. Set the controls :

Brightness Minimum

Contrast Minimum

Volume Minimum

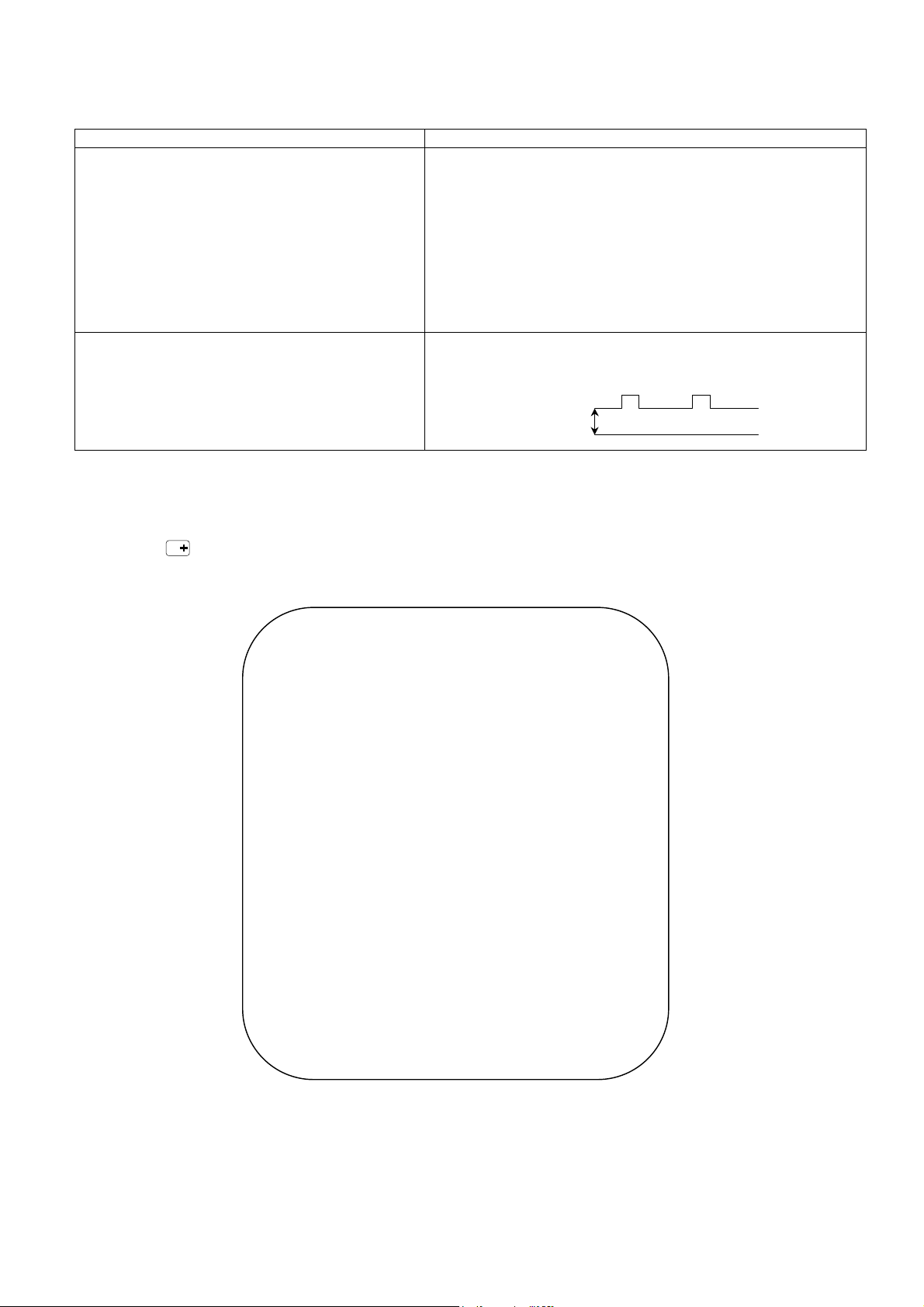

CUT OFF / Ug2 Test

1. Receive a Window pattern.

2. Normalize the TV set.

3. Set brightness: minimum.

Confirm the following voltages:

TPD1 205 ± 10V TPD11 5 ± 0,5V

TPD2 137 ± 2V TPD12 3,3 ± 0,1V

TPD3 42 ± 2V TPD13 2,5 ± 0,1V

TPD5 42 ± 2V TPD14 3,3 ± 0,1V

TPD6 12,5 ± 1V TPD15 5 ±0,5V

TPD7 -12,5 ± 1V TPD16 5 ± 0,5V

TPD8 30,5 ± 1V TPG3 7,5 ± 0,5V

TPD9 9± 1V TPG5 300 ± 10V

TPD10 8 ± 0,5V

To adjust Cutoff connect an oscilloscope to the Blue cathode. Adjust

the screen VR until the black level is 170V +0V/-5V.

Black Level

170V+0V/-5V

GND

SELF CHECK

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set.To enter Self-Check mode, press

the STATUS button on the remote control and at the same time press the down (-/v) button on the customer controls at

the front the TV set. To exit Self Check, switch off the TV set at the power button.

E2 O.K.

DDP O.K.

VSP O.K.

VSW O.K.

TUN O.K.

MSP O.K.

DPL --MAS ---

TX-32PS10D TX-32PS10F

TX-32PS10D/B TX-32PS10P

TX-28PS10D TX-28PS10F

OPTION 1 0F 0F

OPTION 2 00 00

OPTION 3 B0 B0

OPTION 4 11 11

OPTION 5 00 00

OPTION 6 25 25

OPTION 7 7F 7F

OPTION 8 D0 50

OPTION 9 00 00

OPTION 10 80 80

OPTION 11 19 19

OPTION 12 00 00

OPTION 13 08 08

CHECK E5 65

SUM ****

TX-28PS10P

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

4

Page 5

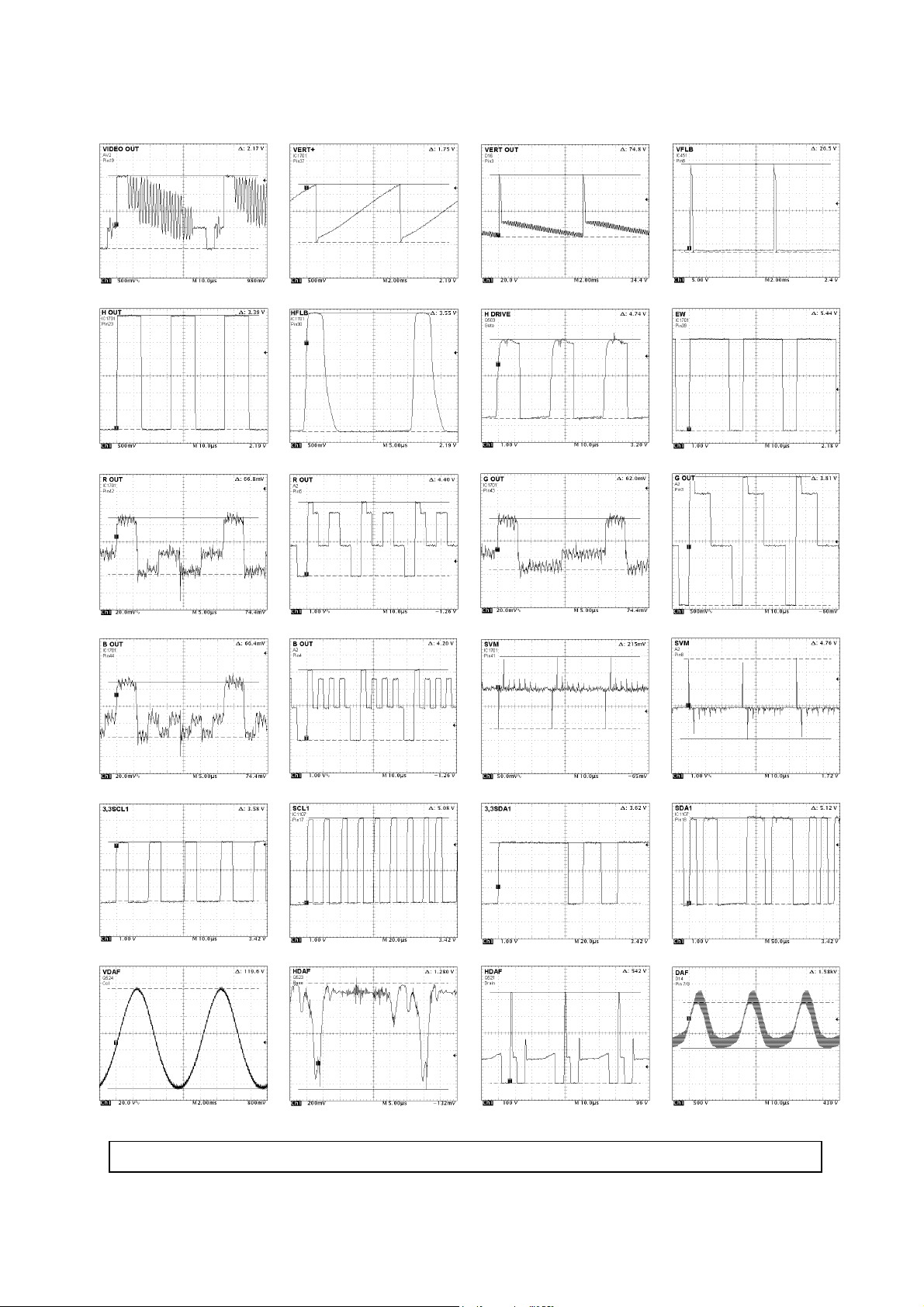

WAVEFORM PATTERN TABLE

CONDITIONS: CONTRAST...MAX, BRIGHTNESS...MID, COLOUR...MID, SHARPNESS...MID

5

Page 6

ALIGNMENT SETTINGS

(The figures below are nominal and used for representative purposes only.)

1. Set the Bass to maximum position, set the Treble to minimum position, set the Volume to minimum then press the

down button (-/v) on the customer controls at the front of the TV and at the same time press the INDEX button on the

remote control, this will place the TV into the Service Mode 1.

2. Press the RED / GREEN buttons to step up / down through the functions.

3. Press the YELLOW / BLUE buttons to alter the function values.

4. Press the STR button after each adjustment has been made to store the required values.

5. To exit the Service Mode, press the "N" button.

Alignment Function

Horizontal Position

Vertical Position

Horizontal Amplitude

Vert. Amplitude

EW-amplitude

Lower Corner

Trapezium-comp

Upper Corner

Vertical Symmetry

Vertical Linearity

Setting indication

Note: All setting values are approximate

H-Pos

21

V-Pos

27

H-Amp

41

V-Amp

-66

EW-Amp 1

- 25

Lower Corner

2

Trapez 1

-7

Upper Corner

-2

V-Sym

-4

V-Lin

40

Settings / Special features

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Angle

Bow

DVCO

Highlight

Lowlight

Sub-Brightness

Angle

-2

Bow

0

DVCO

-1

High 0403 0318 0350

Low 0071 0132 0160

Sub-Brightness

20

Optimum setting.

Optimum setting.

Receive a PAL Colour Bar Pattern. For

DVCO alignment press "Blue" button, wait

until the colours are changing slowly and

press "STR".

Optimum setting.

Optimum setting.

6

Page 7

X

A

A

Y5A

X

Q1705 Q1708

R OUT

42

Q1704 Q1707

G OUT

43

B OUT

Q1703 Q1706

SENSE

44

6 4 3 5

6 4 3 5

L2

A2

35

CRT

0÷Y7

Y0÷Y7

55

56

MAIN C

MAIN Y/CVBS

12

12

52 53

51

AV2 VIDEO OUT

Q3013

41

G OSD

R OSD

112

113

IC1101

SDA6000-A23

121

TEXT CVBS

Q1125

1

A5

1

H5

Q3301

Q3016

MAIN Y/CVBS

56

B OSD

114

MICRO

PROCESSOR

Q3011

MAIN C

58

IC1701

DEFLECTION

PROCESSOR

DDP3315CQAE3

8bit

IC1501

PROCESSOR

VIDEO SIGNAL

VSP9405VKB11

40

39

41

R EXT

B EXT

G EXT

7A48

9

11

7H48

9

11

VIDEO BLOCK DIAGRAM

R EXT

G EXT11B EXT

12

10

A - BOARD

H - BOARD

L - BOARD

D - BOARD

Q351

IC351

IC361

R OUT

3

G - BOARD

G OUT

3

IC371

B OUT

3

IC3001

VIDEO/AUDIO

CXA2069Q

12

1

AV4

Y/VIDEO IN 20

MATRI

3

Q3014

VIDEO OUT 19

C/RED IN 15

63

TUNER CVBS

BLUE IN 7

GREEN IN 11

V3 CVBS

V3

V3 C

15 20 21 22

H1

15 20 21 22

D1

IDEO

TUNER

1 2 4

D8

1 2 4

G7

AV3

C

R1

AV1

IC3301

3

2

G1

VIDEO IN 20

MATRI

RGB & FB SW

TDA8601T/C1

7

6

8

4

R2

B2

B1

G2

Q3015

BLUE IN 7

RED IN 15

GREEN IN 11

VIDEO OUT 19

24, 22

AV1 VIDEO IN

AV2 Y/ VIDEO IN

AV2

Y/VIDEO IN 20

17, 15

AV2 C IN

VIDEO OUT 19

19

C IN 15

10, 8

AV4 C IN

V4 Y/ VIDEO IN

7

Page 8

AM

TUNER

MSP

Q102

Q101

102

101

Q106

IC251

LA4282

R OUT 7

L OUT 11

AUDIO OUTPUT

2 L IN

5 R IN

4 1

D17

4 1

G16

G14

L

R

1

4

AV3

R

HEADPHONE

L

2 L

3 R

IC2001

NA IN 1

67

60 MONO IN

UDIO

PROCESSOR

78 D CTRL

MSP3410GAB83

36

57

AV3 R

25D124

25H124

37

AV3 L

TUNER L

TUNER R

18

17

18

17

R OUT

9

9

56

L OUT

8 8

AUDIO BLOCK DIAGRAM

28

27

24 25

SPKR OUT L

SPKR OUT R

HP L

HP R

Q2005

Q2002

Q2003

Q2004

6 7 16 14

6 7 16 14

D8

G7

D - BOARD

G - BOARD

IC2351

NJM4556AD

OP. AMPLIFIER

3 HP L

5 HP R

HP L 1

HP R 7

H - BOARD

AV1

AV3 R2AV3 L

4

25

AV1 R IN

RIGHT IN 2

23

AV1 L IN

LEFT IN 6

TUNER R

64

IC3001

CXA2069Q

45

43

AV1 L OUT

AV1 R OUT

LEFT OUT 3

RIGHT OUT 1

TUNER L

MAIN R

62

MATRIX

IDEO/AUDIO

Q3010

Q3009

MAIN L

54

52

Q3006

Q3005

18

16

AV2 L IN

AV2 R IN

LEFT IN 6

AV2

RIGHT IN 2

11

40

AV2 R OUT

RIGHT OUT 1

9

38

AV4 L IN

AV4 R IN

AV2 L OUT

AV4

LEFT IN 6

LEFT OUT 3

RIGHT IN 2

LEFT OUT 3

RIGHT OUT 1

OUT

AUDIO

L

MONITOR

R

8

Page 9

X

X

Y

A

RC SIG

Y

SDA3

SDA1

SCL1

SDA2

SCL2

SCL3

7

8

56

234

D3

SCL2

SDA2

TUNER

SCL2

SDA2

SCL3

SDA3

SDA2

353332

34

D2

Q103

AFC

SDA2

SCL2

SCL2

IC2001

3 SDA2

2 SCL2

SDA1

SCL1

31

AFC

PROC.

AUDIO

21 RESET

BUS

ON/OFF

282715

30

D - BOARD

FBT, HEATER

AFC

PROT1

IC1900

G - BOARD

Q1901

LED SBY

ROTATION

Q251

Q252

G7

D8

Q2001

D1001

Q1002

9

9

RC1001

RC SIG

101112

101112

RC RECEIVER

KEYSCAN

Q2006

SMUTE2

UDIO MUTE

RST MAIN

KEYSCAN

RC SIG

LED SB

ROTATION

POWER SUPPLY

ON/OFF

6

6

D28 G18

30

28

6

4

123

D1

AV1

8 SLOW1

H - BOARD

28 30

46

123

BUS

H1

10 (SCL3)

Q3001

SERVICE

12 (SDA3)

Q3000

16 FBIN1

H5

AV2

SDA3

568

8 SLOW2

SCL3

SERVICE

10 AV LINK

SLOW2

SLOW4

Q3003

AUDIO MUTE

KEYSCAN

9

AV4

SCL3

SLOW1

Q3004

RC SIG

LED SBY

141516

8 SLOW4

16 FBIN2

SDA3

Q3017

ROTATION

RST MAIN

17

Q3018

AV LINK

18

14

15

13

CH SEL

34

33

27

20

13

Q3007

3

MATRI

IC3301

RGB & FB SW

5

36

MATRI

IC3001

VIDEO/AUDIO

Q3008

6

H4

35A1343332

BUS

RST MAIN

SCL1 (3,3V)

SDA1 (3,3V)

CONTROL BLOCK DIAGRAM

SDA1 (3,3V) 6

SCL1 (3,3V) 13

IC1501

282715

31

30

Q1104

24

37

FBL1

RESET

PROCESSOR

VIDEO SIGNAL

ROTATION

SDA1 (3,3V)

PWM1 20

VPROT 32

SCL1 (3,3V)

SDA1 (3,3V) 64

RST MAIN

SCL1 (3,3V) 63

IC1701

ON/OFF

BUS

Q1718

Q1717

RESQ 62

VSTBY 24

DEFLECTION

PROCESSOR

PROT1

SCL1 (3,3V)

SDA1 (3,3V)

ON/OFF

SDA1 (3,3V)

SDA1

SCL1 (3,3V)

IC1107

BUS LEVEL

MICRO

IC1101

SCL2

SDA3

SCL1

SDA2

SCL1

SDA1

SDA2

SCL1 17

SDA1 18

SDA2 16

SHIFTER

3,3V=>5V

2 SDA1

3 SCL1

4 SDA2

SCL1 98

SDA1 99

SDA2 101

PROCESSOR

SCL3

SCL2

SCL2 15

5 SCL2

SCL2 100

SDA3

SDA3 14

6 SDA3

SDA3 75

AUDIO MUTE

SCL3

SCL3 13

7 SCL3

SCL3 74

Q1106

LED SBY

ON/OFF

92

ON/OFF

46 CSROM

RST MAIN

PROT1

AUDIO MUTE

93

PROT1

RESET IN

73

RST IN

AUDIO MUTE 90

D0÷D15

4

IC1103

44 CSSDRAM

FC

125

AFC

SERVICE

Q1112

76

SERVICE

A5

RC SIG

LED SB

KEYSCAN

Q1102Q1101

5

124

RC SIG

VPROT 12

LED SBY 77

KEYSCAN

AV LINK IN 6

AV LINK OUT 7

568

9

141516

Q1113

17

18

Q1116

Q1115

Q1111

Q1110

3

AV LINK

Q1108

Q1109

A4

6

FBL1

19

CS

D0÷D15

SDRAM

IC1106

A - BOARD

6

5

SCL1

SDA1

EAROM

IC1104

CE 26

IC1102

D0÷D15

FLASH MEMORY

9

Page 10

VERT DY

V

3

D16

HORIZ DY

1

4

D15

10

DIODE

MODULATOR

FBT

DAF

-DAF

H-DAF

8

127

D14

Used only

for 32” models

8

127

DF1

Q523

IC451

D - BOARD

3

8

VERTICAL

6

LA7876N

D2

VFLB

VERT+

13

13A112

12

HFLB

964

964

H DRIVE

EW

VDAF

2

2

Q551

T501

Q503

HDAF

1

1

A - BOARD

DEFLECTION BLOCK DIAGRAM

V SYNC

Q1102 Q1101

VFLB

H DRIVE

EW

Q1713

Q1714

Q522

Q521

581

T701

Q703

DF - BOARD

Q1701 Q1702

VS 23

H SYNC 8

PROCESSOR

VIDEO SIGNAL

VSP9405VKB11

MICRO

IC1101

PROCESSOR

SDA6000-A23

V SYNC 102

H SYNC 103

V PROT 12

VERT+ 37

IC1701

DEFLECTION

PROCESSOR

DDP3315CQAE3

VS 10

VPROT 32

HFLB 30

EW 39 Q1715

VDAF 22

HOUT 23

HDAF 25

IC1501

10

Page 11

r

r

r

AUDIO

V

V

V

V

V

V

Y

V

V

V

V

V

V

V

V

V

V9V

V8V

V

V

V27V

V

V

V

V

V

Y

Y

Y

Y

Y

V

V9V

V8V

V

V15V

V

IC251

OUTPUT

10

42

Q898

D884

D897

41V/AUDIO2

10

T849

9VIN

9V HEADER

Q897

D896

D870

10,5V

28V/AUDIO1

13

11

5DRAIN

3

2

4

IC849

5V HEADER

5V HEADER

IC3807

R887

D871

D895

6,5V

137V

18

14

2VCC

5

1

POWER

SUPPLY

2

5V

1GND

4

R843

+5

TUNER

D847

R842

+5V

+33

IC899

POWER BUS

9V

9V HEADER

4

2

IC3801

21

IC3804

1

8

5V HEADER

1

IC38023IC3803

39

65,66

PROC.

AUDIO

IC2001

11,12,13

5V STB

SB2,5

2

IC3806

3

3

VERT

IC451

7

2

15

-15

D557

D558

2

7

1

9

T551

D554

R567

8

3

1

8

5

5

SB3,3

1

4

IC3805

2

T501

D553

8

SB2,5

SB5

SB3,3

147

5V

26

24 25

22

10 17 20

D2

26

24 25

22

10 17 20

A1

3,3V_STBY

5

5

3,3

A- BOARD

15

82

1,8V

3

1

IC1502

IC1103

5

9

Q1706

1,8

IC1501

IC1105

2

5V

9V

Q1707

1,8

3,3V

3,3V

5,28,34,66

7,12,25,72

35,42,50,64,68

VIDEO

IC1108

5

3,3V_STBY

9

Q1719

Q1708

3,3V

3,15

44,59

SDRAM

IC1106

1,3,9,14

27,43,49

3,3V_STBY

3,3V_STBY

POWER BUS

5

3,3

73

47

IC1701

DEFLECTION

IC1102

37,47

3,3V_STBY

3,3V_STB

3,3V_STB

14,32,42

FLASH MEM

IC1107

20

5V_STBY

2,5V_STB

2,5V_STB

3,3V_STB

21,87

85,106

53,61,69

111,116,119,123

MICRO

IC1101

EAROM

IC1104

BUS L. SHIFT.

8

3,3V_STBY

9V

1

A2

D13

9

27 34

9

27 34

D- BOARD

1

D11

1G43

0V

400V

+

POWER SUPPLY BLOCK DIAGRAM

~

PFC

D801

-

Filte

5V SBY

3

1

D28

1

G18

~

2,3,7,8

SB5V

S1

S2

T860

P1

P2

5

SUPPLY

IC801

STBY POWER

D9

4

SB5V HEADER

9V HEADER

15

12

15G612

Q860

9V

3

11

3

11

SB5V

1

1

POWER BUS

VCC

RC1001

8

IC2351

10

IC1900

D854

RL801

S801

Q853

Line

Line

F801

1G14

MAINS IN

Filte

Filte

D807

1G22

DEGAUSS

COIL

D860

RL803

Q856

Q854

Q855

D861

D862

G - BOARD

L- BOARD

1

D12

1L33

147

Q908

6

2

IC371

6

2

IC361

6

2

IC351

Q906

3

200V

9

1

D1

L2

H1

H- BOARD

DF- BOARD

T701

Q522

147

42

1

MATRIX

IC3001

VIDEO/AUDIO

MATRIX

IC3301

RGB & FB SW

28

DF2

Used only

for 32” models

11

Page 12

PARTS LOCATION

NOTE:

The numbers on the exploded view below

refer to the exploded view section of the

Replacement Parts List.

9

11

19

20

2

17

8

15

7

6

3

10

22

12

21

5

16

14

24

4

18

23

13

1

12

Page 13

Components Identified by mark have special characteristics important for safety.

* When replacing any of these components, use only manufacturers specified parts.

In case of ordering these spare parts, please always add the complete Model-Type

number to your order.

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COMMON PARTS

EXPLODED VIEW

REMOTE CONTROL 1 EUR511212A

ANODE LEAD 2 KFT7CM446F1

TUNER 3 TADF4-301A

PANASONIC BADGE 4 TBMA060

CRT FIXING SCREW 5 THT1062

AV PANEL 6 TKP8E1497-D

CHASSIS FRAME 7 TMX8E058-1

G P.C.B. 8 TNP8EG005AT

H P.C.B. 9 TNP8EH008AC

AC CORD 10 TXASX01DBYG

MISCELLANEOUS COMPONENTS

BATTERY . R6RC/2P

SET FOOT (FRONT) . TBLG3019

SET FOOT (REAR) . TBLG3020

PRESET LABEL . TBM0E0033

PRESET LABEL . TBM0E0034

LID SWITCH . TEK6935

IR WINDOW . TKP0E10701

ROTATION COIL . TLK8E05177

LED HOLDER . TMW8E050-2

PCB CLIP . TMW8E056-1

SPACER CKN2 TMM8E18027

CRT SUPPORT BRACKET RPPK401 TKK0E9507

CRT SUPPORT BRACKET LPPK402 TKK0E9508

ROPE RK401 TXF5B09W09

I.C.s

AUDIO OUTPUT IC251 LA4282

RGB OUTPUT IC351 TDA6111Q/N4

RGB OUTPUT IC361 TDA6111Q/N4

RGB OUTPUT IC371 TDA6111Q/N4

VERTICAL OUTPUT IC451 LA7876N

STANDBY CONTROL ICIC801 MIP0254SPSCF

POWER SUPPLY IC849 STRF6656LF57

ERROR AMPLIFIER IC899 SE130N

MICRO PROCESSOR IC1101 SDA6000-A23

8MEG FLASH 29LV800BTC7IC1102 EDF1/020/0F

SYSTEM RESET IC1103 PST9128NR

MOS LOGIC IC1105 C0EAH0000067

64M SDRAM IC1106 C3ABPG000102

BUS LEVEL SHIFTERIC1107 TC7MBD3245FK

INVERTER IC1108 74LVC1GU04GW

VIDEO PROCESSOR IC1501 VSP9405VKB11

REGULATOR IC1502 BA18BC0FP

REPLACEMENT PARTS LIST

Important Safety Notice

DEFLECTION PROCESSORIC1701 DDP3315CQAG3

EARTH CORRECTION IC1900 LA6515

AUDIO PROCESSOR IC2001 MSP3410GAB83

HEADPHONE AMPLIFIER IC2351 NJM4556AD

A/V MATRIX SWITCHIC3001 CXA2069Q

RGB, FB MATRIX IC3301 TDA8601T/C1

REGULATOR IC3801 BA09ST-V5

REGULATOR IC3802 BA08T

3.3V REGULATOR IC3803 BA033T

REGULATOR IC3804 BA05T

REGULATOR IC3805 BA033ST-V5

REGULATOR IC3806 LD1117V25C

REGULATOR IC3807 BA05ST-V5

LED RECEIVER RC1001 RPM-6937

FUSES

FUSE HOLDERF801-R EYF52BC

FUSE HOLDERF801-L E YF52BC

FUSE F801 S5055AC

FS LINK R2810 TSF19252

DIODES

DIODE D101 MA3020TX

DIODE D102 MA3020TX

DIODED103 1SS355TE-17

DIODE D251 MA700ATA

DIODE D252 MA700ATA

DIODE D351 ERA15-04V3

DIODE D352 ERA15-04V3

DIODE D361 ERA15-04V3

DIODE D362 ERA15-04V3

DIODE D371 ERA15-04V3

DIODE D372 ERA15-04V3

DIODED376 1SS355TE-17

DIODED377 1SS355TE-17

DIODED378 1SS355TE-17

DIODE D387 MA2160LFS

DIODE D454 EU02V0

DIODE D456 MTZJT-776.8B

DIODE D457 1SS133T-77

DIODE D458 EU02V0

DIODE D501 1SS133T-77

DIODE D502 EU02V0

DIODE D503 1SS133T-77

DIODE D504 1SS133T-77

DIODE D505 MTZJT-7710D

DIODE D553 EU02V0

DIODE D554 EU02V0

DIODE D555 1SS133T-77

DIODE D556 UDZSTE-1722B

DIODE D557 ERB93-02E

DIODE D558 ERB93-02E

DIODE D559 1SS133T-77

13

Page 14

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

DIODE D560 RH3GLF102

DIODE D563 EU02V0

DIODE D565 EU02V0

DIODE D575 MTZJT-775.1C

DIODE D576 EU02V0

DIODE D580 FMV-3GULF730

DIODE D706 EU02V0

DIODE D707 EU02V0

DIODE D710 MTZJT-7716C

DIODE D711 MTZJT-775.1A

DIODE D712 1SS133T-77

DIODE D713 MTZJT-777.5B

DIODE D714 MTZJT-772.7B

DIODE D801 RBV-608LF-B

THERMISTOR D807 59890T60B110

SURGE ABSORBER D808 ERZV10D621CS

DIODE D809 ERC0510E3

DIODE D810 ERC0510E3

DIODE D811 TVSSR2KLV1

DIODE D812 RY24V1

DIODE D814 ERA22-10G1

DIODE D815 MA2082-ALFS

DIODE D841 1SR124-4AT82

DIODE D843 1SR124-4AT82

DIODE D844 1SR124-4AT82

PHOTO COUPLERD847 PC123FY2

DIODE D854 1SS133T-77

DIODE D860 1SS133T-77

DIODE D861 1SS133T-77

DIODE D862 1SS133T-77

DIODE D866 EU02V0

DIODE D867 1SS133T-77

DIODE D868 MA4056HTA

DIODE D870 RK46LF-L1

DIODE D871 RK46LF-L1

DIODE D884 MTZJT-7727A

DIODE D887 BZX79B75A26A

DIODE D888 1SS133T-77

DIODE D889 1SS133T-77

DIODE D890 1SS133T-77

DIODE D891 1SS133T-77

DIODE D892 MA2180TP

DIODE D893 MTZJT-776.2B

DIODE D894 1SS133T-77

DIODE D895 RU4BLF-L1

DIODE D896 FMGG26S

DIODE D897 1SR124-4AT82

DIODE D899 MTZJT-7736A

DIODE D910 R2KNLFA1

L.E.D. D1001 LNH201RFCF6

DIODE D1004 MTZJT-778.2C

DIODED1101 1SS355TE-17

DIODED1104 1SS355TE-17

DIODE D1701 DAN217T146

DIODE D1702 DAN217T146

DIODED1703 1SS355TE-17

DIODE D1901 MTZJT-777.5B

DIODE D1902 1SS133T-77

DIODE D2001 MTZJT-774.7C

DIODE D2002 MA723TA

DIODE D2003 MA723TA

DIODE D2004 MA723TA

DIODE D2005 MA723TA

DIODE D2006 MA723TA

DIODE D2007 MA723TA

DIODE D2008 MA723TA

TRANSISTORS

DIODED2351 1SS355TE-17

DIODED2352 1SS355TE-17

DIODED2353 1SS355TE-17

DIODED2354 1SS355TE-17

DIODED2355 1SS355TE-17

DIODE D3201 MTZJT-778.2C

DIODE D3202 MTZJT-778.2C

DIODE D3204 UDZSTE-1716B

DIODED3351 1SS355TE-17

DIODED3352 1SS355TE-17

DIODED3353 1SS355TE-17

DIODED3354 1SS355TE-17

DIODE D3801 1SS133T-77

DIODE D3802 1SS133T-77

DIODE D3803 MTZJT-775.6B

DIODE D3804 1SS133T-77

DIODE D3805 1SS133T-77

DIODE D3806 1SS133T-77

DIODE D3807 1SS133T-77

DIODE D3808 1SS133T-77

DIODE D3809 1SS133T-77

DIODE D3812 1SR124-4AT82

PHOTO COUPLERQ860 PC123FY2

TRANSISTOR Q101 BC847B

TRANSISTOR Q102 BC847B

TRANSISTOR Q103 BC857B

TRANSISTOR Q106 BC847B

TRANSISTOR Q109 BC847B

TRANSISTOR Q251 2SD1328STX

TRANSISTOR Q252 2SD1328STX

TRANSISTOR Q253 BC847B

TRANSISTOR Q254 BC847B

TRANSISTOR Q351 2SA1767QTA

TRANSISTOR Q361 2SA1767QTA

TRANSISTOR Q371 2SA1767QTA

TRANSISTOR Q503 2SK2231TE16L

TRANSISTOR Q551 2SC5905000RK

TRANSISTOR Q552 2SC1473ATA

TRANSISTOR Q556 BC847B

TRANSISTOR Q701 BC847B

TRANSISTOR Q702 BC847B

TRANSISTOR Q703 2SK2231TE16L

TRANSISTOR Q704 BC847B

TRANSISTOR Q705 BC547B/126

TRANSISTOR Q706 BC847B

TRANSISTOR Q853 BC847B

TRANSISTOR Q854 BC847B

TRANSISTOR Q855 BC847B

TRANSISTOR Q856 BC847B

TRANSISTOR Q893 2SA1018QTA

TRANSISTOR Q894 BC847B

TRANSISTOR Q895 BC847B

TRANSISTOR Q896 BC857B

TRANSISTOR Q897 2SA1534A-RTA

TRANSISTOR Q898 BC557B/126

TRANSISTOR Q906 BC847B

TRANSISTOR Q907 BC857B

TRANSISTOR Q908 2SA1535ARLB

TRANSISTOR Q909 2SC3944ARLB

TRANSISTOR Q1002 BC847B

TRANSISTOR Q1101 BC857B

TRANSISTOR Q1102 BC847B

TRANSISTOR Q1104 BC847B

TRANSISTOR Q1106 BC857B

TRANSISTOR Q1108 BC847B

14

Page 15

TRANSFORMERS

COILS

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

TRANSISTOR Q1109 BC847B

TRANSISTOR Q1110 BC847B

TRANSISTOR Q1111 BC847B

TRANSISTOR Q1112 BC847B

TRANSISTOR Q1113 BC847B

TRANSISTOR Q1115 BC847B

TRANSISTOR Q1116 BC847B

TRANSISTOR Q1125 BC847B

TRANSISTOR Q1701 BC847B

TRANSISTOR Q1702 BC847B

TRANSISTOR Q1703 BC847B

TRANSISTOR Q1704 BC847B

TRANSISTOR Q1705 BC847B

TRANSISTOR Q1706 FMY4AT148

TRANSISTOR Q1707 FMY4AT148

TRANSISTOR Q1708 FMY4AT148

TRANSISTOR Q1710 BC847B

TRANSISTOR Q1712 BC847B

TRANSISTOR Q1713 FDV301N

TRANSISTOR Q1714 FDV302P

TRANSISTOR Q1715 FDV301N

TRANSISTOR Q1717 BC857B

TRANSISTOR Q1718 BC847B

TRANSISTOR Q1719 BC847B

TRANSISTOR Q1901 BC847B

TRANSISTOR Q1902 BC847B

TRANSISTOR Q1903 BC847B

TRANSISTOR Q1904 BC847B

TRANSISTOR Q1905 2SA1534A-RTA

TRANSISTOR Q2001 BC857B

TRANSISTOR Q2002 BC857B

TRANSISTOR Q2003 BC857B

TRANSISTOR Q2004 BC857B

TRANSISTOR Q2005 BC857B

TRANSISTOR Q2006 BC857B

TRANSISTOR Q2351 BC847B

TRANSISTOR Q2352 BC847B

TRANSISTOR Q2353 BC857B

TRANSISTOR Q2354 BC847B

TRANSISTOR Q3000 BC847B

TRANSISTOR Q3001 BC847B

TRANSISTOR Q3003 BC847B

TRANSISTOR Q3004 BC847B

TRANSISTOR Q3005 BC857B

TRANSISTOR Q3006 BC857B

TRANSISTOR Q3007 BC847B

TRANSISTOR Q3008 BC847B

TRANSISTOR Q3009 BC847B

TRANSISTOR Q3010 BC847B

TRANSISTOR Q3011 BC847B

TRANSISTOR Q3013 BC847B

TRANSISTOR Q3014 BC847B

TRANSISTOR Q3015 BC847B

TRANSISTOR Q3016 BC847B

TRANSISTOR Q3017 BC847B

TRANSISTOR Q3018 BC847B

TRANSISTOR Q3301 BC847B

TRANSISTOR Q3352 BC857B

TRANSISTOR Q3802 2SD2396/K

TRANSFORMER T501 ETH19Y187AY

TRANSFORMER T849 10783850

TRANSFORMER T860 ETS19AB1G6AG

COILJ115 EXCELSA35T

COILJ117 EXCELSA35T

FILTERS

COILL103 EXCELSA35T

COILL104 EXCELDR35V

COIL L107 TALV35VB100K

COIL L116 ELESN6R8KA

COILL381 TLT220K991R

COIL L382 ELESN6R8KA

COILL551 EXCELDR35C

COILL557 EXCELDR35C

COILL558 EXCELSA35B

COIL L701 ELC18B221E

COIL L704 ELC18B182F

PFC COIL L804 R39264

COIL L883 TALL08T181KA

COIL L892 ELEIE470KA

COILL893 EXCELSA35T

COILL894 EXCELSA35T

COILL895 EXCELSA35T

COILL896 EXCELSA35T

COILL897 EXCELSA35T

COILL898 EXCELSA35T

COILL899 EXCELSA35T

COIL L1061 TLT 331K991R

COIL L1104 TALC325T4R7M

COIL L1109 TALC325T4R7M

COIL L1115 TALC168T8R2K

COIL L1701 EXC3BB221H

COIL L2001 ELESN4R7KA

COIL L2004 ELESN101KA

COIL L2005 ELESN4R7KA

COIL L2006 ELJFC4R7KF

COIL L2007 ELJFC4R7KF

COILL2351 EXCELDR35V

COILL2352 EXCELDR35V

COIL L3001 ELESN1R5KA

COIL L3003 ELESN1R5KA

COIL L3005 ELESN1R5KA

COIL L3007 ELESN1R5KA

COIL L3009 ELESN1R5KA

COIL L3011 ELESN1R5KA

COILL3015 EXCELDR35V

COILL3016 EXCELDR35V

COIL L3078 ELESN2R2KA

COILL3201 ELEBR6R8KA

COILL3202 ELEBR6R8KA

COILL3203 EXCELSA35T

COILL3204 ELEBR6R8KA

COILL3205 ELEBR6R8KA

COILL3206 EXCELSA35T

COIL L3301 ELESN2R7KA

COIL L3302 ELESN2R7KA

COIL L3303 ELESN2R7KA

COIL L3304 ELESN2R2KA

LINE FILTER L801 ELF20N013A

LINE FILTER L802 ELF20N013A

FILTER LC1107 ELKE103FA

FILTER LC1109 ELKE103FA

FILTER LC1117 ELKE103FA

FILTER LC1120 ELKE103FA

FILTER LC1129 ELKE103FA

FILTER LC1130 ELKE103FA

FILTER LC1131 ELKE103FA

FILTER LC1140 ELKE103FA

FILTER LC1147 ELKE103FA

FILTER LC1151 ELKE103FA

FILTER LC1152 ELKE103FA

15

Page 16

CRYSTALS

RESISTORS

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

FILTER LC1153 ELKE103FA

FILTER LC1154 ELKE103FA

FILTER LC1155 ELKE103FA

FILTER LC1156 ELKE103FA

FILTER LC1157 ELKE103FA

FILTER LC1504 TLK212T256AL

FILTER LC1505 TLK212T256AL

FILTER LC1506 TLK212T256AL

FILTER LC1507 TLK212T256AL

FILTER LC1508 TLK212T256AL

FILTER LC1510 ELKE103FA

FILTER LC1511 ELKE103FA

FILTER LC1512 ELKE103FA

FILTER LC1513 ELKE103FA

FILTER LC1702 TLK212T256AL

FILTER LC1705 ELKE103FA

FILTER LC1706 ELKE103FA

FILTER LC1713 TLK212T256AL

FILTER X101 EFCT6504BN

CERAMIC FILTER X102 EFCT7004BN

CRYSTAL X1101 H0J600400006

CRYSTAL X1501 AI202504E

CRYSTAL X1701 4730007823

CRYSTAL X2001 4730007158

S.M.CARBJA1 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA2 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA3 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA4 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA5 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA6 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA7 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA7 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA8 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA9 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA11 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA12 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA13 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA14 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA15 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA16 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA17 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA20 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA21 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA22 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA23 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJA27 ERJ8GEY0R00V 0.125 0 Ω

S.M.CARBJA32 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSA003 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA004 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA005 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA045 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA046 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA047 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA049 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA050 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA058 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA060 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSA061 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSA062 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSA063 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSA066 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSD010 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSD016 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSD035 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSG017 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSG031 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSH004 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBJSH11 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSH12 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSH13 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSH15 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSL4 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBJSL11 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR111 ERJ6GEYJ393V 0.1W 5% 39K Ω

S.M.CARBR112 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR113 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR114 ERJ6GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR115 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR116 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR117 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR118 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR120 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR121 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR122 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR129 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR130 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR133 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR134 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR135 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR136 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR139 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR140 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR141 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR142 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR250 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR251 ERJ6GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR252 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR253 ERJ6GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR254 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR255 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR256 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR257 ERJ6GEYJ150V 0.125 5% 15 Ω

S.M.CARBR258 ERJ6GEYJ150V 0.125 5% 15 Ω

S.M.CARBR259 ERJ6GEYJ121V 0.1W 5% 120 Ω

S.M.CARBR260 ERJ6GEYJ121V 0.1W 5% 120 Ω

S.M.CARBR261 ERJ6GEYJ152V 0.1W 5% 1K5 Ω

S.M.CARBR262 ERJ6GEYJ152V 0.1W 5% 1K5 Ω

CARBONR263 ERDS2TJ2R2T 0.25W 5% 2R2 Ω

CARBONR264 ERDS2TJ2R2T 0.25W 5% 2R2 Ω

S.M.CARBR265 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR266 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR267 ERJ6GEYJ103V 0.1W 5% 10K Ω

METALR268 ERQ14AJ101P 0.25W 5% 100 Ω

S.M.CARBR269 ERJ6GEY0R00V 0.1W 0 Ω

FUSIBLER350 ERQ12AJ151P 0.5W 5% 150 Ω

S.M.CARBR352 ERJ6GEYJ202V 0.1W 5% 2K Ω

METALR355 ERG1FJ683P 1W 5% 68K Ω

S.M.CARBR356 ERJ6GEYJ181V 0.1W 5% 180 Ω

CARBONR358 ERDS1TJ821V 0.5W 5% 820 Ω

S.M.CARBR361 ERJ6GEYJ183V 0.1W 5% 18K Ω

S.M.CARBR362 ERJ6GEYJ202V 0.1W 5% 2K Ω

METALR365 ERG1FJ683P 1W 5% 68K Ω

S.M.CARBR366 ERJ6GEYJ181V 0.1W 5% 180 Ω

CARBONR368 ERDS1TJ821V 0.5W 5% 820 Ω

METALR370 ERQ1CJPR56S 1W 5% R56 Ω

S.M.CARBR372 ERJ6GEYJ202V 0.1W 5% 2K Ω

METALR375 ERG1FJ683P 1W 5% 68K Ω

S.M.CARBR376 ERJ6GEYJ181V 0.1W 5% 180 Ω

CARBONR378 ERDS1TJ821V 0.5W 5% 820 Ω

S.M.CARBR380 ERJ6GEYJ392V 0.1W 5% 3K9 Ω

16

Page 17

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CARBR381 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR382 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR383 ERJ6GEY0R00V 0.1W 0 Ω

CARBONR391 ERDS2TJ274T 0.25W 5% 270K Ω

S.M.CARBR392 ERJ6GEYJ684V 0.1W 5% 680K Ω

S.M.CARBR394 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR396 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR398 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR451 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR454 ERJ6GEYJ223V 0.1W 5% 22K Ω

CARBONR455 ERDS2TJ223T 0.25W 5% 22K Ω

CARBONR458 ERDS1TJ1R0T 0.5W 5% 1 Ω

METALR460 ERG3SJS271H 3W 5% 270 Ω

METALR461 ERX2SJS1R0H 2W 5% 1 Ω

S.M.CARBR463 ERJ6GEYJ821V 0.1W 5% 820 Ω

S.M.CARBR464 ERJ6GEYJ512V 0.1W 5% 5K1 Ω

S.M.CARBR465 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR467 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR501 ERJ6GEYJ392V 0.1W 5% 3K9 Ω

S.M.CARBR503 ERJ6GEYJ104V 0.1W 5% 100K Ω

METALR507 ERG3FJ820H 3W 5% 82 Ω

METALR509 ERG1SJ222E 0.5W 5% 2K2 Ω

METALR510 ERG1SJ222E 0.5W 5% 2K2 Ω

METALR553 ERX3SJSR68H 3W 5% R68 Ω

S.M.CARBR555 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR556 ERJ6GEYJ563V 0.1W 5% 56K Ω

S.M.CARBR557 ERJ6GEYJ101V 0.1W 5% 100 Ω

CARBONR558 ERDS1TJ124T 0.5W 5% 120K Ω

S.M.CARBR559 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR560 ERJ6GEYJ434V 0.125 5% 430K Ω

S.M.CARBR561 ERJ6GEYJ303V 0.1W 5% 30K Ω

S.M.CARBR562 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR563 ERJ6GEYJ564V 0.1W 5% 560K Ω

S.M.CARBR564 ERJ6GEYJ363V 0.125 5% 36K Ω

S.M.CARBR566 ERJ6GEYJ102V 0.1W 5% 1K Ω

METALR567 343-23R3AY 10W 5% 3R3 Ω

CARBONR568 ERDS1TJ120T 0.5W 5% 12 Ω

S.M.CARBR569 ERJ6GEYJ102V 0.1W 5% 1K Ω

FUSIBLER578 ERQ12HKR39P 0.5W 10% R39 Ω

METALR581 ERG3FJ561H 3W 5% 560 Ω

S.M.CARBR701 ERJ6GEYJ101V 0.1W 5% 100 Ω

METALR702 ERX2SJS1R0H 2W 5% 1 Ω

CARBONR704 ERDS1FJ472V 0.5W 5% 4K7 Ω

METALR705 ERG3FJ151H 3W 5% 150 Ω

METALR706 ERG3FJ151H 3W 5% 150 Ω

S.M.CARBR707 ERJ6GEYJ272V 0.1W 5% 2K7 Ω

S.M.CARBR708 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR709 ERJ6GEYJ473V 0.1W 5% 47K Ω

CARBONR711 ERDS1TJ133T 0.5W 5% 13K Ω

S.M.CARBR712 ERJ6GEYJ203V 0.1W 5% 20K Ω

CARBONR715 ERDS2TJ272T 0.25W 5% 2K7 Ω

METALR716 ERQ12AJ680P 0.5W 5% 68 Ω

S.M.CARBR717 ERJ6GEYJ272V 0.1W 5% 2K7 Ω

S.M.CARBR718 ERJ6GEYJ203V 0.1W 5% 20K Ω

S.M.CARBR720 ERJ6GEYJ302V 0.1W 5% 3K Ω

S.M.CARBR721 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR722 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR723 ERJ6GEYJ473V 0.1W 5% 47K Ω

METALR724 ERG2FJ680H 2W 5% 68 Ω

METALR725 ERG1FJ202P 1W 5% 2K Ω

SOLIDR801 ERC12ZGK105C 0.5W 10% 1M Ω

WOUNDR807 ERF2AJ560P 2W 5% 56 Ω

METALR808 ERG1FJS104D 1W 5% 100K Ω

CARBONR809 ERDS2TJ101T 0.25W 5% 100 Ω

CARBONR836 ERD75TAJ825 1W 5% 8M2 Ω

CARBONR837 ERDS2TJ100T 0.25W 5% 10 Ω

CARBONR838 ERDS2TJ332T 2W 5% 3K2 Ω

CARBONR839 ERDS2TJ202T 0.25W 5% 2K Ω

CARBONR841 ERDS2TJ681T 0.25W 5% 680 Ω

WOUNDR842 D0D2R27KA003 2W 10% R27 Ω

WOUNDR843 D0D2R27KA003 2W 10% R27 Ω

CARBONR853 ERDS1TJ103T 0.5W 5% 10K Ω

CARBONR854 ERDS2TJ473T 0.25W 5% 47K Ω

S.M.CARBR855 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR856 ERJ6GEYJ203V 0.1W 5% 20K Ω

S.M.CARBR859 ERJ6GEYJ123V 0.1W 5% 12K Ω

S.M.CARBR860 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR861 ERJ6GEYJ203V 0.1W 5% 20K Ω

S.M.CARBR862 ERJ6GEYJ153V 0.1W 5% 15K Ω

CARBONR863 ERDS1TJ122T 0.5W 5% 1K2 Ω

CARBONR864 ERDS1TJ102T 0.5W 5% 1K Ω

METALR868 ERG3FJ183H 3W 5% 18K Ω

METALR869 ERG3FJ183H 3W 5% 18K Ω

S.M.CARBR870 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR877 ERJ6GEYJ473V 0.1W 5% 47K Ω

METALR879 ERG1SJ223P 1W 5% 22K Ω

METALR880 ERG1SJ183P 1W 5% 18K Ω

S.M.CARBR881 ERJ6GEYJ153V 0.1W 5% 15K Ω

CARBONR882 ERDS2TJ681T 0.25W 5% 680 Ω

S.M.CARBR883 ERJ6GEYJ752V 0.1W 5% 7K5 Ω

CARBONR884 ERDS1TJ103T 0.5W 5% 10K Ω

S.M.CARBR885 ERJ6GEYJ753V 0.1W 5% 75K Ω

METALR886 ERG3FJ101H 3W 5% 100 Ω

CARBONR887 ERDS1TJ683T 0.5W 5% 68K Ω

METALR888 ERG3FJ101H 3W 5% 100 Ω

S.M.CARBR889 ERJ6GEYJ752V 0.1W 5% 7K5 Ω

CARBONR890 ERDS2TJ202T 0.25W 5% 2K Ω

CARBONR892 ERDS2TJ101T 0.25W 5% 100 Ω

S.M.CARBR893 ERJ6GEYJ752V 0.1W 5% 7K5 Ω

CARBONR894 ERDS1TJ2R2T 0.5W 5% 2R2 Ω

S.M.CARBR895 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR897 ERJ6GEYJ511V 0.1W 5% 510 Ω

S.M.CARBR898 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR914 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR918 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR921 ERJ6GEY0R00V 0.1W 0 Ω

CARBONR922 ERDS2TJ683T 2W 5% 68K Ω

CARBONR923 ERDS2TJ683T 2W 5% 68K Ω

S.M.CARBR925 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR926 ERJ6GEY0R00V 0.1W 0 Ω

CARBONR927 ERDS2TJ681T 0.25W 5% 680 Ω

CARBONR928 ERDS2TJ130T 0.25W 5% 13 Ω

CARBONR929 ERDS1FVJ331T 0.5W 5% 330 Ω

FUSIBLER935 ERQ14AJW3R9E 0.25W 5% 3R9 Ω

FUSIBLER936 ERQ1CJP331S 1W 5% 330 Ω

CARBONR938 ERDS2TJ681T 0.25W 5% 680 Ω

CARBONR941 ERDS1TJ130T 0.5W 5% 13 Ω

S.M.CARBR942 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR943 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR944 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR945 ERJ6GEYJ102V 0.1W 5% 1K Ω

METALR948 ERG5FJ152H 5W 5% 1K5 Ω

S.M.CARBR949 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1005 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR1007 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1017 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1043 ERJ6GEYJ682V 0.1W 5% 6K8 Ω

S.M.CARBR1044 ERJ6GEYJ123V 0.1W 5% 12K Ω

S.M.CARBR1045 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1046 ERJ6GEYJ683V 0.1W 5% 68K Ω

CARBONR1047 ERDS2TJ102T 0.25W 5% 1K Ω

S.M.CARBR1101 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

17

Page 18

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CARBR1102 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR1103 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1104 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1105 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1106 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1107 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1108 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1109 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1110 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1111 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1112 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1113 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1115 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1116 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1117 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1118 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1119 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1120 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1121 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1122 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1123 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1124 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1125 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1126 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1127 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1128 ERJ3GEYJ273V 0.1W 5% 27K Ω

S.M.CARBR1129 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1131 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1132 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR1133 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1134 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR1135 ERJ3GEYJ224V 0.1W 5% 220K Ω

S.M.CARBR1136 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR1137 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR1138 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1139 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR1140 ERJ3GEYJ225V 0.1W 5% 2M2 Ω

S.M.CARBR1141 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1142 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR1144 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1145 ERJ3GEYJ391V 0.1W 5% 390 Ω

S.M.CARBR1146 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1147 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1148 ERJ3GEYJ273V 0.1W 5% 27K Ω

S.M.CARBR1149 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1150 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1151 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1152 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1153 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1154 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR1155 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1157 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1158 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1160 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1161 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1162 ERJ3GEYJ123V 0.1W 5% 12K Ω

S.M.CARBR1164 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1166 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1168 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1169 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1170 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1171 ERJ3GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR1172 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1178 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1180 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1181 ERJ3GEYJ683V 0.1W 5% 68K Ω

S.M.CARBR1182 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1183 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1186 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1187 ERJ3GEYJ683V 0.1W 5% 68K Ω

S.M.CARBR1188 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1189 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1191 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1194 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1195 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.RESR1196 EXB38V680JV 0.063 5% 68 Ω

S.M.CARBR1197 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1199 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1200 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.RESR1202 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1205 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1209 EXB38V680JV 0.063 5% 68 Ω

S.M.CARBR1210 ERJ3GEYJ224V 0.1W 5% 220K Ω

S.M.CARBR1211 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1212 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.RESR1214 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1217 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1221 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1225 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1232 EXB38V390JV 0.063 5% 39 Ω

S.M.RESR1233 EXB38V680JV 0.063 5% 68 Ω

S.M.RESR1236 EXB38V680JV 0.063 5% 68 Ω

S.M.CARBR1251 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1255 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1257 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1258 ERJ3GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR1264 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR1265 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1268 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1269 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1270 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1271 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1272 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1273 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1278 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1280 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1285 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1286 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1287 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1288 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1289 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1292 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1293 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR1501 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1502 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1503 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1504 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1505 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1511 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1512 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1513 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1514 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1515 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1516 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1519 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1521 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1522 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1523 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1524 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1540 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1701 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1704 ERJ3GEY0R00V 0.1W 0 Ω

18

Page 19

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CARBR1705 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR1706 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR1707 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR1708 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR1709 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1710 ERJ3GEYJ563V 0.1W 5% 56K Ω

S.M.CARBR1712 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1713 ERJ3GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR1714 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1716 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1717 ERJ3GEYJ271V 0.1W 5% 270 Ω

S.M.CARBR1719 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1720 ERJ3GEYJ822V 0.1W 5% 8K2 Ω

S.M.CARBR1721 ERJ3GEYJ682V 0.1W 5% 6K8 Ω

S.M.CARBR1723 ERJ3GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR1724 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1725 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1726 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1727 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1728 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1732 ERJ3GEYJ151V 0.1W 5% 150 Ω

S.M.CARBR1733 ERJ3GEYJ151V 0.1W 5% 150 Ω

S.M.CARBR1734 ERJ3GEYJ151V 0.1W 5% 150 Ω

S.M.CARBR1735 ERJ3GEYJ821V 0.1W 5% 820 Ω

S.M.CARBR1736 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1737 ERJ3GEYJ560V 0.1W 5% 56 Ω

S.M.CARBR1738 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR1739 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1740 ERJ3GEYJ560V 0.1W 5% 56 Ω

S.M.CARBR1741 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR1742 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1743 ERJ3GEYJ560V 0.1W 5% 56 Ω

S.M.CARBR1744 ERJ6GEYJ621V 0.125 5% 620 Ω

S.M.CARBR1745 ERJ6GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR1746 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1747 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1748 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1749 ERJ3GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR1750 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1751 ERJ3GEYJ334V 0.1W 5% 330K Ω

S.M.CARBR1752 ERJ6GEYJ560V 0.1W 5% 56 Ω

S.M.CARBR1755 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1758 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1759 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1760 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1761 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1762 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1763 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1766 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1767 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1768 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1769 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1770 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR1771 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1772 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1774 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1775 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1776 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1777 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR1780 ERJ3GEYJ331V 0.1W 5% 330 Ω

S.M.CARBR1781 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR1782 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR1901 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1902 ERJ6GEYJ392V 0.1W 5% 3K9 Ω

S.M.CARBR1903 ERJ6GEYJ103V 0.1W 5% 10K Ω

CARBONR1904 ERDS1TJ2R2T 0.5W 5% 2R2 Ω

S.M.CARBR1905 ERJ6GEYJ273V 0.1W 5% 27K Ω

S.M.CARBR1906 ERJ6GEYJ273V 0.1W 5% 27K Ω

S.M.CARBR1907 ERJ6GEYJ273V 0.1W 5% 27K Ω

S.M.CARBR1908 ERJ6GEY0R00V 0.1W 0 Ω

CARBONR1909 ERDS1TJ2R2T 0.5W 5% 2R2 Ω

CARBONR1912 ERDS2TJ102T 0.25W 5% 1K Ω

S.M.CARBR1913 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR1914 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR1915 ERJ6GEYJ331V 0.1W 5% 330 Ω

S.M.CARBR1916 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1917 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1918 ERJ6GEYJ121V 0.1W 5% 120 Ω

S.M.CARBR1919 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR1920 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1921 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR1923 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR1926 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2011 ERJ6GEYJ183V 0.1W 5% 18K Ω

S.M.CARBR2012 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2013 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2014 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2015 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2016 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2020 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2021 ERJ6GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR2022 ERJ6GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR2023 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR2024 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2025 ERJ6GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR2026 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2027 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2028 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR2029 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2030 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR2031 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2032 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR2033 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2034 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2035 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2036 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2037 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2038 ERJ6GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR2222 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2240 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2351 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR2352 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR2353 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR2354 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR2355 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR2356 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR2357 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR2358 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR2359 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR2360 ERJ6GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR2361 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR2362 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR2363 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR2364 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR2367 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR2368 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR2369 ERJ6GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR2370 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR3001 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3002 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3003 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3004 ERJ6GEYJ750V 0.1W 5% 75 Ω

19

Page 20

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CARBR3005 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3006 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3007 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3008 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3009 ERJ6ENF1802V 0.1W 1% 18K Ω

S.M.CARBR3010 ERJ6ENF9101V 0.1W 1% 9K1 Ω

S.M.CARBR3011 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3012 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3013 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3014 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3015 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3016 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3017 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3018 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3019 ERJ6ENF1802V 0.1W 1% 18K Ω

S.M.CARBR3020 ERJ6ENF9101V 0.1W 1% 9K1 Ω

S.M.CARBR3021 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3022 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3023 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3024 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3025 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3026 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3028 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3029 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR3031 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR3032 ERJ6ENF1802V 0.1W 1% 18K Ω

S.M.CARBR3033 ERJ6ENF9101V 0.1W 1% 9K1 Ω

S.M.CARBR3034 ERJ3GEYJ391V 0.1W 5% 390 Ω

S.M.CARBR3035 ERJ3GEYJ391V 0.1W 5% 390 Ω

S.M.CARBR3036 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3037 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR3038 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3039 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR3040 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR3041 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR3042 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3043 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3044 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3047 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3048 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3051 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3052 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR3053 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3054 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR3055 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3056 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3057 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3059 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3061 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3062 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3064 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3065 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3066 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3067 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3069 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3074 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3075 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3084 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR3085 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR3088 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3089 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3091 ERJ3GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3092 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3093 ERJ3GEYJ331V 0.1W 5% 330 Ω

S.M.CARBR3094 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3095 ERJ3GEYJ391V 0.1W 5% 390 Ω

CAPACITORS

S.M.CARBR3105 ERJ3GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR3106 ERJ3GEYJ682V 0.1W 5% 6K8 Ω

S.M.CARBR3107 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3108 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3109 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3110 ERJ3GEYJ123V 0.1W 5% 12K Ω

S.M.CARBR3111 ERJ3GEYJ682V 0.1W 5% 6K8 Ω

S.M.CARBR3112 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3114 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3115 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3116 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3117 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3118 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3119 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3120 ERJ6GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3121 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3122 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3123 ERJ3GEYJ474V 0.1W 5% 470K Ω

S.M.CARBR3124 ERJ3GEYJ474V 0.1W 5% 470K Ω

S.M.CARBR3125 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3126 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3127 ERJ3GEYJ474V 0.1W 5% 470K Ω

S.M.CARBR3128 ERJ3GEYJ474V 0.1W 5% 470K Ω

S.M.CARBR3201 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR3202 ERJ6GEYJ103V 0.1W 5% 10K Ω

CARBONR3203 ERDS1TJ151T 0.5W 5% 150 Ω

CARBONR3208 ERDS1TJ151T 0.5W 5% 150 Ω

S.M.CARBR3212 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3213 ERJ6GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR3214 ERJ6GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR3215 ERJ6GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR3301 ERJ6GEY0R00V 0.1W 0 Ω

S.M.CARBR3303 ERJ3GEY0R00V 0.1W 0 Ω

S.M.CARBR3304 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR3305 ERJ3GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3306 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3307 ERJ3GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR3308 ERJ3GEYJ750V 0.1W 5% 75 Ω

S.M.CARBR3309 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3311 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3312 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3313 ERJ6ENF82R0V 0.1W 1% 82 Ω

S.M.CARBR3354 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3355 ERJ6GEYJ391V 0.1W 5% 390 Ω

S.M.CARBR3356 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR3357 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR3358 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR3362 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3363 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3364 ERJ6GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR3801 ERJ6GEYJ123V 0.1W 5% 12K Ω

CARBONR3803 ERDS1TJ751V 0.5W 5% 750 Ω

METALR3805 ERG2SJS270H 2W 5% 27 Ω

S.M.CARBR3810 ERJ6GEYJ822V 0.1W 5% 8K2 Ω

S.M.CAPC107 ECJ2VF1H104Z 50V 100nF

S.M.CAPC109 ECJ2VB1H102K 50V 1nF

S.M.CAPC110 ECJ2VB1H103K 50V 10nF

ELECTC111 ECA1HMR33B 50V 330nF

S.M.CAPC117 ECJ2VB1H103K 50V 10nF

S.M.CAPC118 ECJ2VF1H104Z 50V 100nF

ELECTC119 ECA1CM221B 16V 220µF

S.M.CAPC122 ECJ2FB1H104K 50V 100nF

S.M.CAPC130 ECJ2VB1H103K 50V 10nF

S.M.CAPC131 ECJ2VB1C104K 16V 100nF

S.M.CAPC136 ECJ2FB1H104K 50V 100nF

20

Page 21

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CAPC137 ECJ2VC1H100D 50V 10pF

S.M.CAPC138 ECJ2VC1H220J 50V 22pF

S.M.CAPC141 ECJ2VB1H103K 50V 10nF

S.M.CAPC142 ECJ2FB1H104K 50V 100nF

ELECTC251 ECA1HM010B 50V 1µF

ELECTC252 ECA1HM010B 50V 1µF

ELECTC253 ECA1HM4R7B 50V 4.7µF

S.M.CAPC254 ECJ2VB1H103K 50V 10nF

ELECTC255 ECA1HM4R7B 50V 4.7µF

S.M.CAPC256 ECJ2VB1H103K 50V 10nF

FILMC259 ECQV1H684JL3 50V 680nF

FILMC260 ECQV1H684JL3 50V 680nF

ELECTC261 ECA1HM100B 50V 10µF

ELECTC262 ECA1HM100B 50V 10µF

ELECTC263 ECA1HM101B 50V 100µF

FILMC264 ECQV1H154JL3 50V 150nF

FILMC265 ECQV1H154JL3 50V 150nF

S.M.CAPC266 ECJ2FB1H104K 50V 100nF

S.M.CAPC267 ECJ2FB1H104K 50V 100nF

ELECTC269 ECA1HM332E 50V 3300µF

S.M.CAPC350 ECJ2VC1H102J 50V 1nF

S.M.CAPC352 ECJ2VF1H224Z 50V 220nF

S.M.CAPC353 ECJ2YB1H104K 50V 100nF

FILMC354 ECQE2104KF3 250V 100nF

CERAMICC355 ECKR2H102KB5 500V 1nF

S.M.CAPC358 ECJ2VC1H222J 50V 2.2nF

CERAMICC359 CL21C030CBNC 50V 3pF

S.M.CAPC360 ECJ2VC1H102J 50V 1nF

S.M.CAPC362 ECJ2VF1H224Z 50V 220nF

S.M.CAPC363 ECJ2YB1H104K 50V 100nF

FILMC364 ECQE2104KF3 250V 100nF

CERAMICC365 ECKR2H102KB5 500V 1nF

S.M.CAPC368 ECJ2VC1H222J 50V 2.2nF

CERAMICC369 CL21C220JBNC 50V 22pF

S.M.CAPC370 ECJ2VC1H102J 50V 1nF

S.M.CAPC372 ECJ2VF1H224Z 50V 220nF

S.M.CAPC373 ECJ2YB1H104K 50V 100nF

FILMC374 ECQE2104KF3 250V 100nF

CERAMICC375 ECKR2H102KB5 500V 1nF

S.M.CAPC378 ECJ2VC1H222J 50V 2.2nF

ELECTC381 SMG1CV101MT5 16V 100µF

ELECTC382 ECA1CM471B 16V 470µF

S.M.CAPC383 ECJ2VB1H103K 50V 10nF

FILMC384 ECQE2104KFW 250V 100nF

ELECTC385 ECA2EM220B 250V 22µF

CERAMICC386 ECKW 3D152JBR 2KV 1.5nF

ELECTC395 ECA1HMR47B 50V 470nF

S.M.CAPC451 ECJ2VB1H102K 50V 1nF

ELECTC456 KMG1HV221MT5 50V 220µF

FILMC459 ECQB1224KFW 100V 220nF

ELECTC463 ECA1HM221B 50V 220µF

ELECTC501 ECA1EM101B 25V 100µF

FILMC508 ECQB1H103JF3 50V 10nF

ELECTC509 SMG1VV470MT5 35V 47µF

FILMC552 ECWH20102JVY 2kV 1nF

CERAMICC557 ECKR2H471KB5 500V 470pF

ELECTC558 ECA1HHG471B 50V 470µF

S.M.CAPC559 ECJ2FB1H104K 50V 100nF

FILMC560 ECQE2683KFW 250V 68nF

ELECTC561 ECA1EM222E 25V 2200µF

CERAMICC562 ECKR2H101KB5 500V 100pF

ELECTC563 ECA2EM220B 250V 22µF

ELECTC564 ECEA2AU2R2B 100V 2.2µF

FILMC565 ECQB1H273JF3 50V 27nF

CERAMICC566 ECKR2H471KB5 500V 470pF

ELECTC567 ECA1HM102E 50V 1000µF

CERAMICC568 ECKR2H471KB5 500V 470pF

CERAMICC569 ECKR2H102KB5 500V 1nF

CERAMICC573 CL21C221JBNC 50V 220pF

CERAMICC574 CL21C221JBNC 50V 220pF

FILMC588 ECWF4824JBB 400V 820nF

CERAMICC701 ECKR2H152KB5 500V 1.5nF

FILMC702 ECQE1335KFB 100V 3.3µF

S.M.CAPC703 ECJ2VB1H333K 50V 33nF

FILMC704 ECQV1H474JL3 50V 470nF

CERAMICC706 ECKR2H471KB5 500V 470pF

S.M.CAPC707 ECJ2VB1H471K 50V 470pF

S.M.CAPC708 ECJ2VB1H333K 50V 33nF

S.M.CAPC709 ECJ2VB1H333K 50V 33nF

FILMC801 222233820224 275V 220nF

FILMC802 222233820224 275V 220nF

FILMC804 222233820154 275V 150nF

CERAMICC806 ECKW NA101MB 400V 100µF

CERAMICC807 ECKW 2H472PU7 500V 4.7nF

CERAMICC808 ECKW 2H472PU7 500V 4.7nF

CERAMICC809 ECKW 2H472PU7 500V 4.7nF

CERAMICC810 ECKW 2H472PU7 500V 4.7nF

FILMC812 ECQE6823KFB 630V 82nF

CERAMICC813 ECKW AE472ZE 500V 4.7nF

ELECTC814 ECA2WM100E 450V 10µF

CERAMICC815 ECKW 3D392KBP 2kV 3.9nF

FILMC816 ECQV1H104JL3 50V 0.1µF

CERAMICC817 ECKR1H101KB5 50V 100pF

S.M.CAPC838 ECJ2VC1H151J 50V 150pF

CERAMICC839 ECKCW S332MEB 250V 3.3nF

FILMC842 ECQB1H821JF3 50V 820pF

CERAMICC843 ECKR1H471KB5 50V 470pF

CERAMICC844 ECKW 3D152KBP 2KV 1.5nF

ELECTC847 ECA1EM101B 25V 100µF

ELECTC849 43303S9227M5 400V 220µF

S.M.CAPC855 ECJ2VB1H103K 50V 10nF

S.M.CAPC856 ECJ2VB1H103K 50V 10nF

ELECTC865 ECA1HM100B 50V 10µF

ELECTC866 ECA1HM100B 50V 10µF

ELECTC867 ECA1CM222B 16V 2200µF

ELECTC868 ECA1CM471B 16V 470µF

ELECTC870 EEUFC1E102B 25V 1000µF

CERAMICC871 ECKR2H471KB5 500V 470pF

ELECTC873 EEUFC1E102B 25V 1000µF

CERAMICC874 ECKR2H471KB5 500V 470pF

ELECTC891 ECA1HM010B 50V 1µF

ELECTC892 ECA1CM100B 16V 10µF

ELECTC893 ECA2CHG101E 160V 100µF

ELECTC894 EEUEB2D101E 200V 100µF

CERAMICC895 ECKW 3D471KBP 2KV 470pF

ELECTC896 ECA1HHG102E 50V 1nF

ELECTC897 ECA1VHG331B 35V 330pF

CERAMICC899 ECKR2H471KB5 500V 470pF

ELECTC902 ECA1VM101B 35V 100µF

S.M.CAPC904 ECJ2VF1H103Z 50V 10nF

CERAMICC909 ECKR2H472MD5 500V 4.7nF

CERAMICC910 ECKR2H472MD5 500V 4.7nF

ELECTC912 ECA2CM220B 160V 22µF

ELECTC917 ECA1HM100B 50V 10µF

S.M.CAPC918 ECJ2VF1H103Z 50V 10nF

ELECTC1002 SMG1CV101MT5 16V 100µF

S.M.CAPC1003 ECJ2YB1H104K 50V 100nF

S.M.CAPC1004 ECJ2VB1H103K 50V 10nF

ELECTC1005 SMG1CV101MT5 16V 100µF

S.M.CAPC1006 ECJ2YB1H104K 50V 100nF

S.M.CAPC1007 ECJ2VC1H270J 50V 27pF

S.M.CAPC1101 ECJ1VF1E104Z 25V 100nF

21

Page 22

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CAPC1102 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1103 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1104 ECJ1VF1E104Z 25V 100nF

CERAMICC1105 F1J1A1050020 16V 2.2µF

S.M.CAPC1106 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1107 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1108 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1109 ECJ1VF1E104Z 25V 100nF

CERAMICC1110 F1J1A1050020 16V 2.2µF

S.M.CAPC1111 ECJ1VC1H271J 50V 270pF

S.M.CAPC1112 ECJ1VF1E104Z 25V 100nF

ELECTC1113 ECEA1AKA101B 10V 100µF

ELECTC1114 ECEA1CKA100B 16V 10µF

S.M.CAPC1115 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1116 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1117 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1118 ECJ1VB1H472K 50V 4.7nF

S.M.CAPC1119 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1120 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1121 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1122 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1123 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1124 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1125 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1126 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1127 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1128 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1129 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1130 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1131 ECJ1VC1H220J 50V 22pF

S.M.CAPC1132 ECJ1VC1H220J 50V 22pF

S.M.CAPC1133 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1134 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1135 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1136 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1138 ECJ1VC1H221J 50V 220pF

S.M.CAPC1139 ECJ1VC1H221J 50V 220pF

S.M.CAPC1140 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1142 ECJ1VC1H151J 50V 150pF

S.M.CAPC1145 ECJ1VF1E104Z 25V 100nF

ELECTC1146 ECEA1CKA100B 16V 10µF

S.M.CAPC1150 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1151 ECJ1VB1H102K 50V 1nF

S.M.CAPC1155 ECJ1VB1C473K 16V 47nF

S.M.CAPC1156 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1157 ECJ2VF1C105Z 16V 1µF

ELECTC1159 ECEA1CKA100B 16V 10µF

ELECTC1160 ECEA1AKA101B 10V 100µF

ELECTC1161 ECEA1AKA101B 10V 100µF

ELECTC1162 ECEA1AKA101B 10V 100µF

ELECTC1163 ECEA1AKA221Q 10V 220µF

ELECTC1164 ECEA1AKA101B 10V 100µF

S.M.CAPC1165 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1166 ECJ1VF1E104Z 25V 100nF

ELECTC1167 ECEA1AKA101B 10V 100µF

S.M.CAPC1168 ECJ1VF1E104Z 25V 100nF

ELECTC1169 ECEA1AKA101B 10V 100µF

ELECTC1170 ECEA1AKA101B 10V 100µF

CERAMICC1171 F1J1A1050020 16V 2.2µF

S.M.CAPC1177 ECJ1VB1H102K 50V 1nF

S.M.CAPC1178 ECJ1VB1H102K 50V 1nF

S.M.CAPC1179 ECJ1VB1H102K 50V 1nF

S.M.CAPC1180 ECJ1VC1H271J 50V 270pF

S.M.CAPC1181 ECJ1VC1H271J 50V 270pF

S.M.CAPC1182 ECJ1VC1H271J 50V 270pF

S.M.CAPC1183 ECJ1VC1H271J 50V 270pF

S.M.CAPC1184 ECJ1VC1H271J 50V 270pF

S.M.CAPC1185 ECJ1VC1H271J 50V 270pF

S.M.CAPC1188 ECJ1VF1H103Z 50V 10nF

S.M.CAPC1189 ECJ1VF1H103Z 50V 10nF

S.M.CAPC1190 ECJ1VF1H103Z 50V 10nF

S.M.CAPC1191 ECJ1VF1H103Z 50V 10nF

S.M.CAPC1192 ECJ1VF1H103Z 50V 10nF

S.M.CAPC1501 ECJ1VC1H220J 50V 22pF

S.M.CAPC1502 ECJ1VC1H220J 50V 22pF

S.M.CAPC1503 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1504 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1505 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1506 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1507 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1508 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1509 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1510 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1511 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1512 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1513 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1514 ECJ1VF1E104Z 25V 100nF

ELECTC1515 ECEA1CKA100B 16V 10µF

S.M.CAPC1516 ECJ1VB1H103K 50V 10nF

S.M.CAPC1517 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1518 ECJ1VF1E104Z 25V 100nF

ELECTC1519 ECEA1CKA100B 16V 10µF

S.M.CAPC1520 ECJ1VB1H103K 50V 10nF

S.M.CAPC1521 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1522 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1523 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1524 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1525 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1526 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1527 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1528 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1529 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1530 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1531 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1532 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1533 ECJ1VB1H103K 50V 10nF

S.M.CAPC1534 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1535 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1536 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1537 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1538 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1539 ECJ1VF1E104Z 25V 100nF

S.M.CAPC1543 ECJ2YB1H104K 50V 100nF

S.M.CAPC1544 ECJ2YB1H104K 50V 100nF

ELECTC1545 ECEA1AKA101B 10V 100µF

ELECTC1562 ECEA1HKAR33B 50V 0.33µF

ELECTC1563 ECEA1CKA220B 16V 22µF

S.M.CAPC1573 ECJ1VB1C473K 16V 47nF

S.M.CAPC1574 ECJ1VB1C473K 16V 47nF

S.M.CAPC1575 ECJ1VB1C473K 16V 47nF

S.M.CAPC1577 ECJ1VB1H103K 50V 10nF

S.M.CAPC1701 ECJ1VC1H270J 50V 27pF

S.M.CAPC1702 ECJ1VC1H270J 50V 27pF

S.M.CAPC1703 ECJ1VC1H271J 50V 270pF

S.M.CAPC1704 ECJ1VC1H561J 50V 560pF

S.M.CAPC1705 ECJ1VB1H222K 50V 2.2nF

ELECTC1706 ECEA1AKA101B 10V 100µF

S.M.CAPC1707 ECJ1VC1H270J 50V 27pF

S.M.CAPC1709 ECJ2VF1C105Z 16V 1µF

S.M.CAPC1710 ECJ1VB1H153K 50V 15nF

S.M.CAPC1711 ECJ1VB1H682K 50V 6.8nF

ELECTC1713 ECEA1CKA100B 16V 10µF

22

Page 23

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

S.M.CAPC1714 ECJ1VF1E104Z 25V 100nF

ELECTC1715 ECEA1AKA101B 10V 100µF

S.M.CAPC1716 ECJ1VB1H222K 50V 2.2nF

S.M.CAPC1717 ECJ1VC1H561J 50V 560pF

S.M.CAPC1718 ECJ1VC1H271J 50V 270pF

S.M.CAPC1719 ECJ1VB1H103K 50V 10nF

S.M.CAPC1720 ECJ1VB1H103K 50V 10nF

S.M.CAPC1721 ECJ1VB1H103K 50V 10nF

S.M.CAPC1722 ECJ1VB1H103K 50V 10nF

ELECTC1723 ECEA1CKA101B 16V 100µF

S.M.CAPC1724 ECJ1VB1H222K 50V 2.2nF

S.M.CAPC1725 ECJ1VB1H103K 50V 10nF

S.M.CAPC1726 ECJ1VB1H103K 50V 10nF

S.M.CAPC1727 ECJ1VB1H103K 50V 10nF

S.M.CAPC1728 ECJ1VB1H222K 50V 2.2nF

S.M.CAPC1729 ECJ1VC1H561J 50V 560pF